Page 1

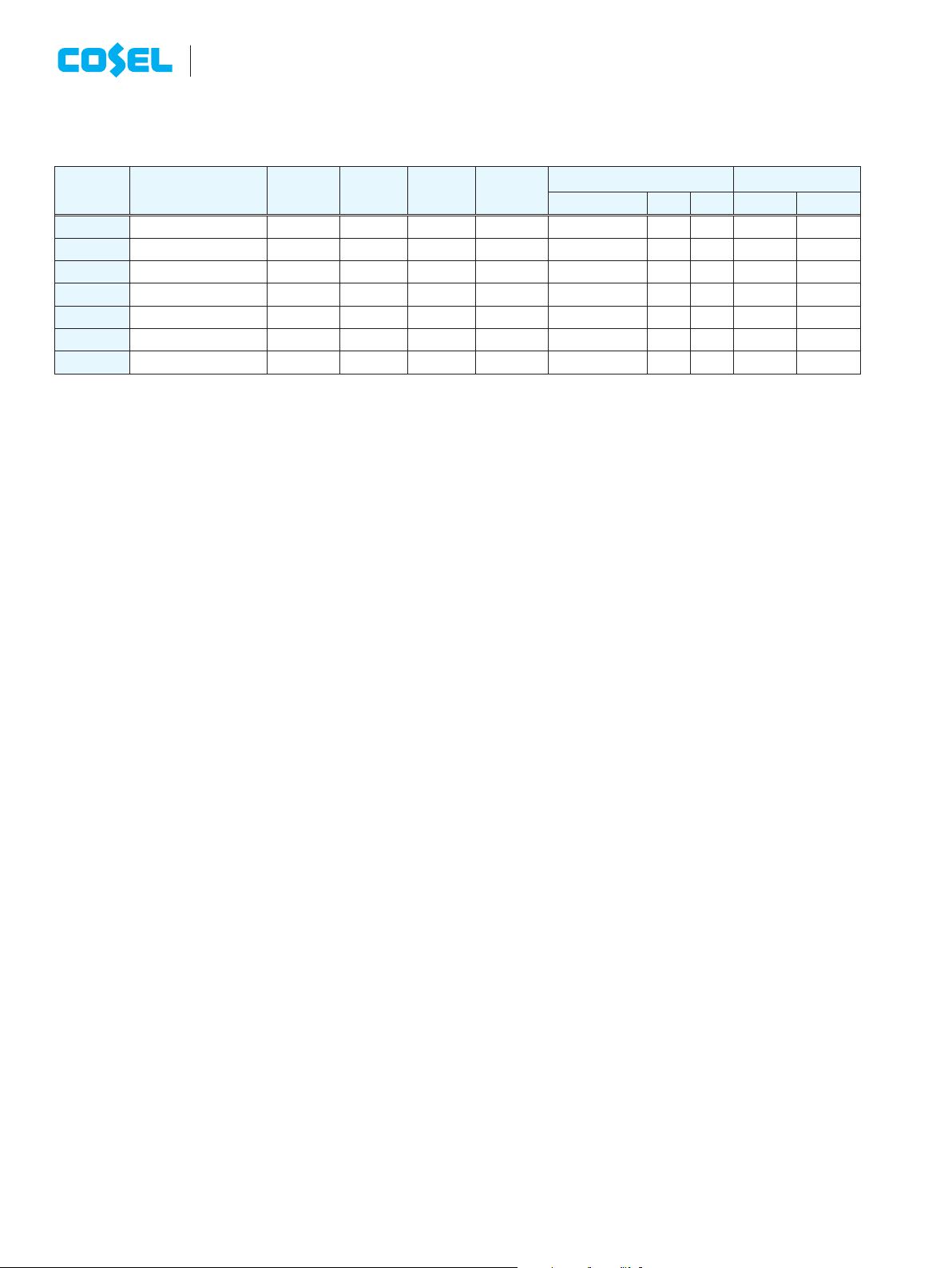

Basic Characteristics Data

Basic Characteristics Data

Switching

Model Circuit method

CHS60 Foward converter 440

CHS80 Half-bridge converter 250

CHS120 Half-bridge converter 200

CHS200 Full-bridge converter 150

CHS300 Full-bridge converter 170

CHS400 Full-bridge converter 150

CHS500 Full-bridge converter 150

*1 Refer to Specification.

Ref

*2

er to Instruction Manual.

frequency

[kHz]

Input

current

*1

*1

*1

*1

*1

*1

*1

Rated

input fuse

- -

- -

- -

- -

- -

- -

- -

Inrush

current

protection

PCB/Pattern

Material

glass fabric base, epoxy resin

glass fabric base, epoxy resin

glass fabric base, epoxy resin

glass fabric base, epoxy resin

glass fabric base, epoxy resin

glass fabric base, epoxy resin

glass fabric base, epoxy resin

Single

sided

Double

sided

Multilayer

Multilayer

Multilayer

Multilayer

Multilayer

Multilayer

Multilayer

Series/Redundancy

operation availability

Series

operation

Redundancy

Ye s

Ye s

Ye s

Ye s

Ye s

Ye s

Ye s

operation

*2

*2

*2

*2

*2

*2

*2

CHS-20

Page 2

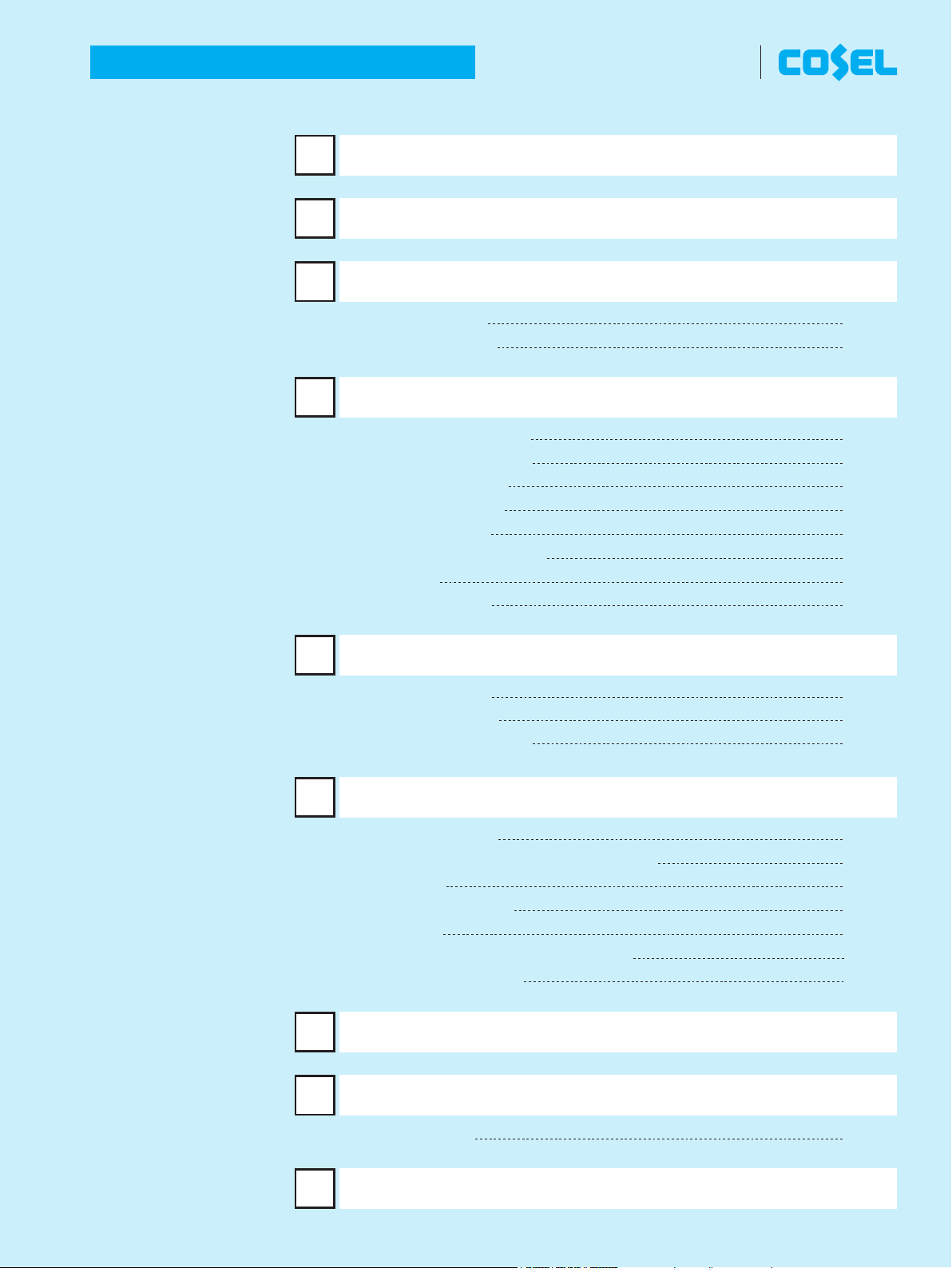

DC-DC Converters Bus Converter

.

Power Module Type

Instruction Manual

1 Pin Connection

2 Connection for Standard Use

3 Wiring Input/Output Pin

3.1 Wiring input pin

3.2 Wiring output pin

4 Function

4.1 Overcurrent protection

4.2 Overvoltage protection

4.3 Thermal protection

4.4 Remote ON/OFF

4.5 Remote sensing

4.6 Adjustable voltage range

4.7 Isolation

4.8 PMBus interface

CHS-22

CHS-22

CHS-23

CHS-23

CHS-23

CHS-24

CHS-24

CHS-24

CHS-24

CHS-24

CHS-24

CHS-25

CHS-26

CHS-26

5 Series and Parallel Operation

5.1 Series operation

5.2 Parallel operation

5.3 Redundancy operation

6 Implementation-Mounting Method

6.1 Mounting method

6.2 Automatic Mounting (CHS series:option S)

6.3 Soldering

6.4 Stress onto the pins

6.5 Cleaning

6.6 Storage method (CHS series:option S)

6.7 Stress to the product

7 Safety Considerations

Derating

8

CHS-26

CHS-26

CHS-26

CHS-27

CHS-27

CHS-27

CHS-28

CHS-28

CHS-28

CHS-29

CHS-29

CHS-29

CHS-29

CHS-29

8.1 CHS Derating

9 SMD type(optionS) package information

CHS-29

CHS-34

CHS-21

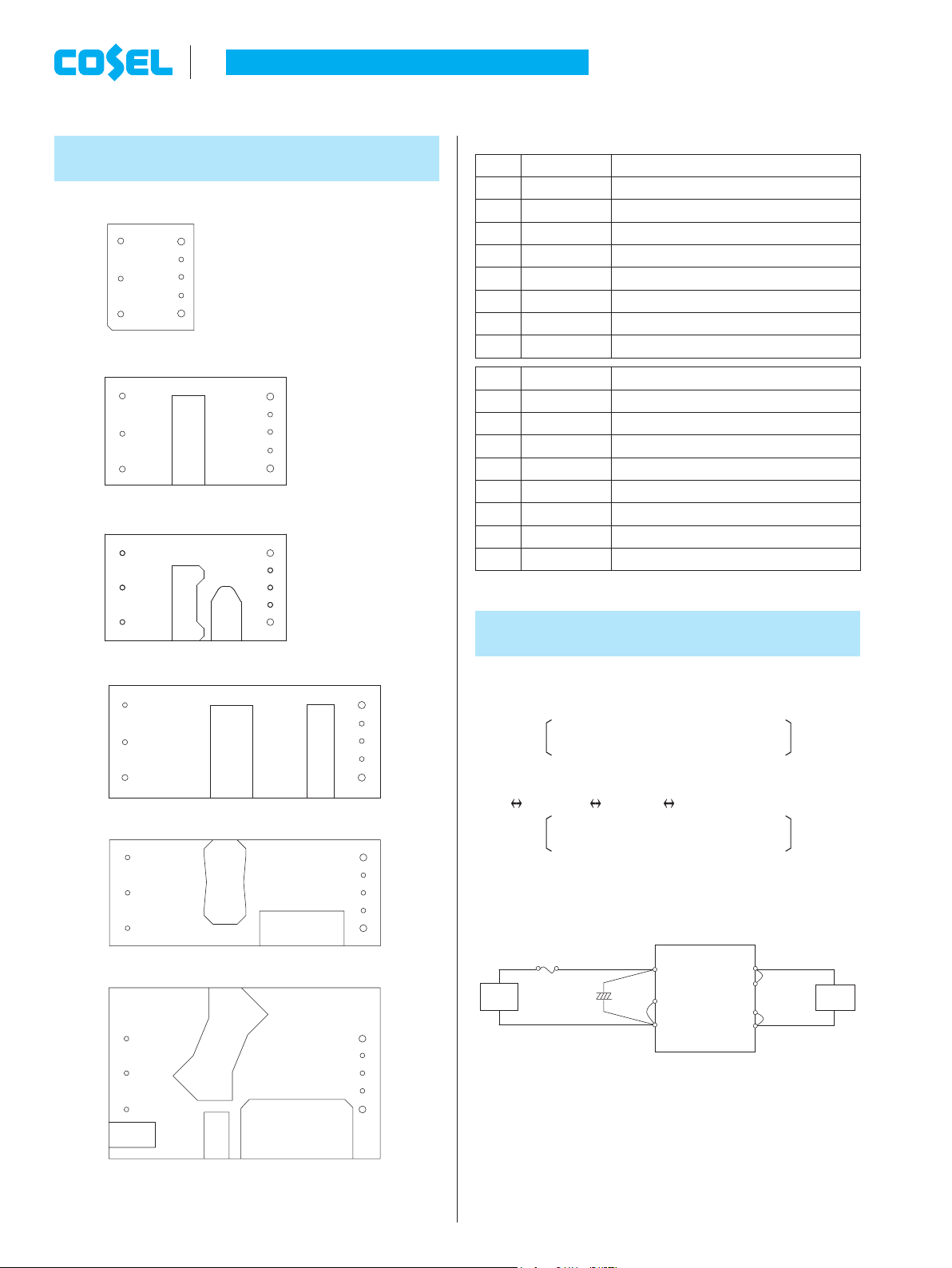

Page 3

+VIN

DC-DC Converters Bus Converter

1 Pin Connection

¿

CHS60

-VIN

3

RC

2

+VIN

1

¿

CHS80

-VIN

3

RC

2

+VIN

1

¿

CHS120

-VIN13

RC

2

¿

CHS200

-VIN

3

RC

2

+VIN

1

¿

CHS300

-VIN

3

RC

2

+VIN

1

8 -VOUT

7 -S

6 TRM

5 +S

4 +VOUT

8 -VOUT

7 -S

6 TRM

5 +S

4 +VOUT

-VOUT

8

-S

7

TRM

6

+S

5

+VOUT

4

8 -VOUT

7 -S

6 TRM

5 +S

4 +VOUT

8 -VOUT

7 -S

6 TRM

5 +S

4 +VOUT

.

Power Module Type

No. Pin Connection Function

1

2

3

4

5

6

7

8

No. Pin Connection Reference

1

2

3

4

5

6

7

8

In order to use the power supply, it is necessary to wire as shown

¡

in Fig.2.1.

Reference : 3 ”Wiring Input/Output Pin”

8 ”Derating”

Short the following pins to turn on the power supply.

¡

-VIN

Reference : 4.4 ”Remote ON/OFF”

4.5 ”Remote sensing”

The CHS series handle only the DC input.

¡

Avoid applying AC input directly.

It will damage the power supply.

+VOUT +DC output

-VOUT -DC output

+VOUT 3.2 ”Wiring output pin ”

-VOUT 3.2 ”Wiring output pin ”

2

Connection for Standard Use

RC, +VOUT +S, -VOUT -S

Instruction Manual

Table 1.1 Pin Connection and function

+VIN +DC input

RC Remote ON/OFF

-VIN -DC input

+S +Remote sensing

TRM Adjustment of output voltage

-S -Remote sensing

+VIN 3.1 ”Wiring input pin ”

RC 4.4 ”Remote ON/OFF ”

-VIN 3.1 ”Wiring input pin ”

+S 4.5 ”Remote sensing ”

TRM 4.6 ”Adjustable voltage range ”

-S 4.5 ”Remote sensing ”

¿

CHS400/CHS500

-VIN

3

RC

2

+VIN

1

Fig.1.1 Pin Connection (bottom view)

CHS-22

8 -VOUT

7 -S

6 TRM

5 +S

4 +VOUT

DC

input

Fuse

Cin

+

Fig.2.1 Connection for standard use

+VIN

RC

-VIN

Cin : External capacitor on the input side

+VOUT

+S

Load

-S

-VOUT

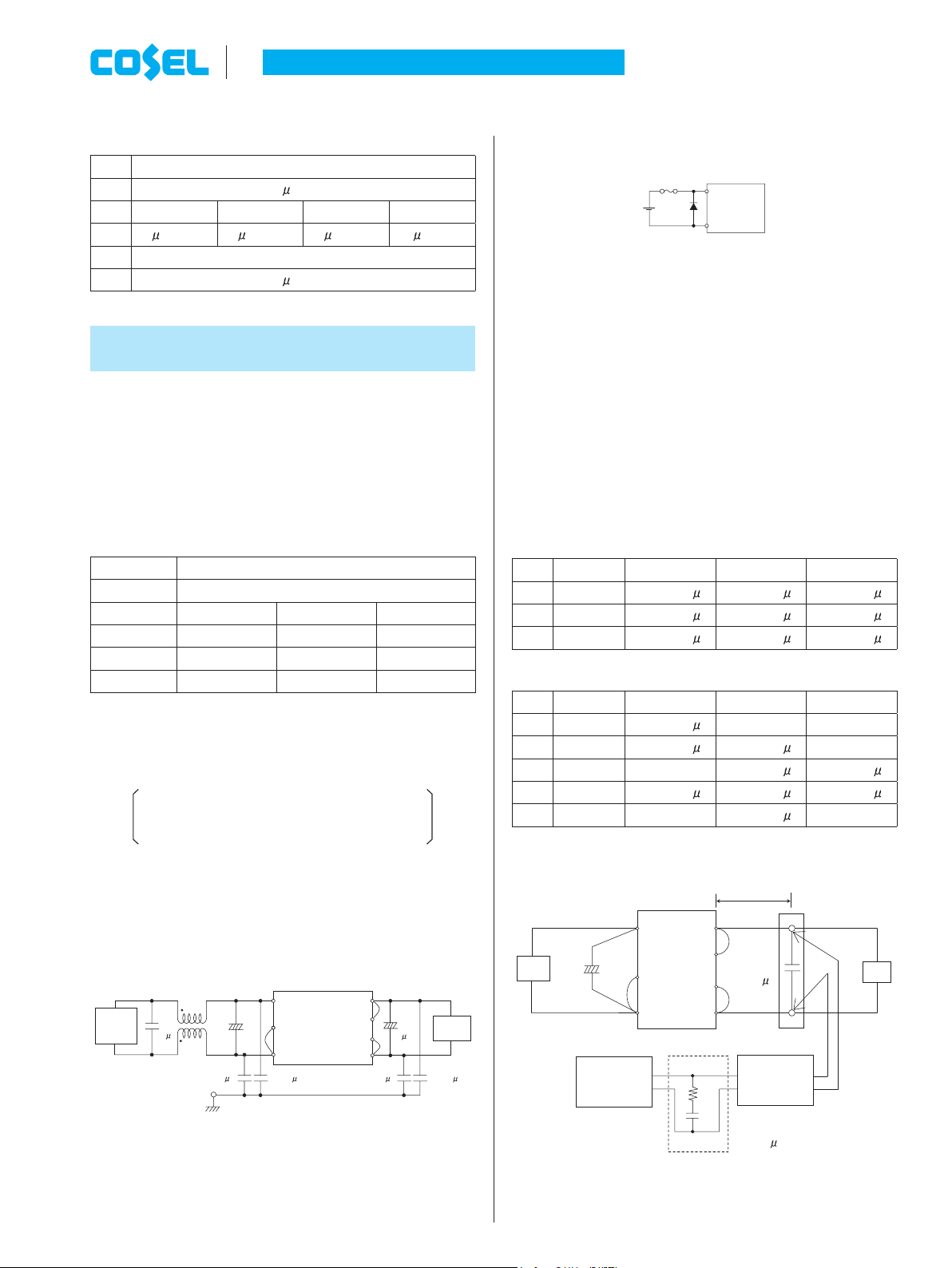

Page 4

+VIN

-VIN

DC-DC Converters Bus Converter

.

Power Module Type

Instruction Manual

Table 2.1 Recommended External capacitor on the input side

Model CHS30024

Cin 660

F or more

Model CHS6048 CHS8048 CHS12048 CHS20048

66 F or more 33 F or more 47 F or more 100 F or more

Cin

Model CHS30048/CHS40048/CHS50048

Cin 200

3

Wiring Input/Output Pin

F or more

3.1 Wiring input pin

(1) External fuse

Fuse is not built-in on input side. In order to protect the unit, install

¡

the normal-blow type fuse on input side.

When the input voltage from a front end unit is supplied to multiple

¡

units, install the normal-blow type fuse in each unit.

Table 3.1 Recommended fuse (Normal-blow type)

Model CHS30024

Rated current 20A

Model CHS6048 CHS8048 CHS12048

Rated current 5A 7A 10A

Model

CHS20048/CHS30048

Rated current 15A 20A 30A

(2) External capacitor on the input side

Install an external capacitor Cin, between +VIN and -VIN input

¡

pins for low line-noise and for stable operation of the power sup-

ply.

Capacitance Refer to Table 2.1

Ta = -20 to +85C Electrolytic or Ceramic capacitor

Ta = -40 to +85C Ceramic capacitor

Cin is within 50mm for pins. Make sure that ripple current of Cin

¡

is less than its rating.

(3) Recommendation for noise-lter

Install an external input lter as shown in Fig.3.1 in order to re-

¡

duce conducted noise. Cin is shown in Table 2.1.

1mH

DC

input

F

2. 2

FG

+

Cin

Fig.3.1 Recommended external input lter

(4) Reverse input voltage protection

Avoid the reverse polarity input voltage. It will damage the power

¡

supply.

CHS40048 CHS50048

+VIN

RC

-VIN

0.068 F0.068 F0.033 F0.033 F

+VOUT

+S

-VOUT

+

10 F

-S

Load

It is possible to protect the unit from the reverse input voltage by

installing an external diode as shown in Fig.3.2.

DC IN

Fig.3.2 Reverse input voltage protection

3.2 Wiring output pin

When the CHS series supplies the pulse current for the pulse

¡

load, please install a capacitor Co between +VOUT and -VOUT

pins.

Recommended capacitance of Co is shown in Table 3.2, 3.3.

If output current decreases rapidly, output voltage rises transiently

¡

and the overvoltage protection circuit may operate.

In this case, please install a capacitor Co.

Select a high frequency type capacitor. Output ripple and startup

¡

waveform may be inuenced by ESR-ESL of the capacitor and the

wiring impedance.

Make sure that ripple current of Co is than its rating.

¡

Table 3.2 Recommended capacitance Co (CHS60, CHS80, CHS120)

No.

Output voltage

1 3.3V 0 - 20,000

2 5V 0 - 10,000

3 12V 0 - 2,200

CHS60 CHS80 CHS120

F 0 - 20,000 F 0 - 20,000 F

F 0 - 10,000 F 0 - 10,000 F

F 0 - 1,000 F 0 - 2,200 F

Table 3.3 Recommended capacitance Co (CHS200, CHS300, CHS400, CHS500)

No.

Output voltage

1 3.3V 0 - 40,000 F

2 5V 0 - 20,000 F 0 - 20,000 F

3 10V

4 12V 0 - 2,200

5 15V

Ripple and Ripple Noise are measured, as shown in the Fig.3.3.

¡

CHS200 CHS300

- -

-

0 - 2,200 F 0 - 4,000 F

F 0 - 2,200 F 0 - 4,000 F

-

0 - 2,200 F

CHS400/CHS500

-

-

Cin is shown in Table 2.1.

DC

Input

+

Cin

Oscilloscope

BW:100MHz

+VIN

RC

-VIN

+VOUT

+S

-S

-VOUT

R

C

50mm

22 F

1.5m 50W

Coaxial cable

R=50

C=0.01

Co

W

Measuring

board

Load

F

Fig.3.3 Measuring method of Ripple and Ripple Noise

CHS-23

Page 5

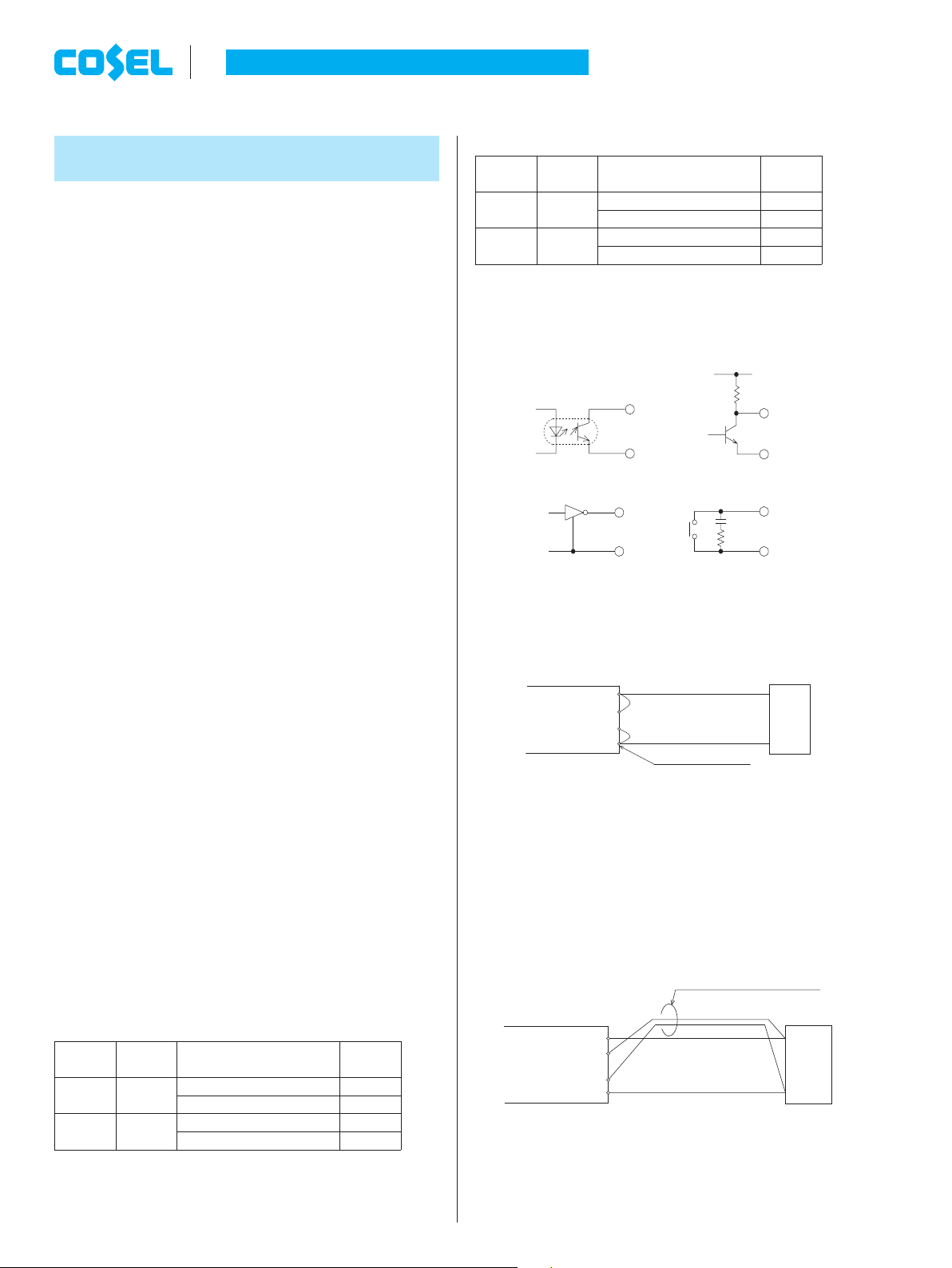

(2.0[Vcc[7.0V)

IC Relay

TransistorPhoto coupler

RC

-VIN

RC

-VIN

RC

-VIN

RC

-VIN

Vcc

DC-DC Converters Bus Converter

4 Function

4.1 Overcurrent protection

Over Current Protection (OCP) is built-in and works at 105% of

¡

the rated current or higher. However, use in an overcurrent situa-

tion must be avoided whenever possible.

The output voltage of the power module will recover automatically

when the fault causing overcurrent is corrected.

When the output voltage drops after OCP works, the power mod-

ule enters a ”hiccup mode” where it repeatedly turns on and off at

a certain frequency.

4.2 Overvoltage protection

The overvoltage protection circuit is built-in. The DC input will be

¡

shut down if overvoltage protection is in operation.

The output voltage of the power module will recover automatically

when the fault causing over voltage is corrected.

.

Power Module Type

Table 4.1.2 Specication of Remote ON/OFF(CHS60,CHS120,CHS300,CHS400,CHS500)

ON/OFF

Standard Negative

Optional -R

When RC is ”Low” level, fan out current is 0.1mA typ. When Vcc is applied,

use 4.0[Vcc[7.0V.

When remote ON/OFF function is not used, please short between RC and

¡

-VIN (-R: open between RC and -VIN).

Positive

Instruction Manual

logic

Between RC and -VIN

L level(0 - 0.8V) or short ON

H level(4.0 - 7.0V) or open OFF

L level(0 - 0.8V) or short OFF

H level(4.0 - 7.0V) or open ON

Output

voltage

Remarks :

Please note that devices inside the power supply might fail when

voltage more than rated output voltage is applied to output pin of

the power supply. This could happen when the customer tests the

overvoltage performance of the unit.

4.3 Thermal protection

When the power supply temperature is kept above 120C, the

¡

thermal protection will be activated and simultaneously shut down

the output.

The output voltage of the power supply will recover automatically

when the unit is cool down.

¿

-U

Option ”-U” means output is shut down when the abovementioned

¡

protection circuit is activated.

If this happens, protection circuit can be inactivated by cycling

the DC input power off for at least 1 second or toggling Remote

ON/OFF signal.

4.4 Remote ON/OFF

Remote ON/OFF circuit is built-in on the input side (RC).

¡

The ground pin of input side remote ON/OFF circuit is ”-VIN” pin.

Fig.4.1 RC connection example

4.5 Remote sensing

(1) When the remote sensing function is not in use

+VOUT

+S

-S

-VOUT

Fig.4.2 Connection when the remote sensing is not in use

When the remote sensing function is not in use, it is necessary to conrm

¡

that pins are shorted between +S & +VOUT and between -S & -VOUT.

Wire between +S & +VOUT and between -S & -VOUT as short as pos-

¡

sible.

Loop wiring should be avoided.

This power supply might become unstable by the noise coming from poor

wiring.

(2)When the remote sensing function is in use

Short at pin root

Wire as close as possible

Load

Table 4.1.1 Specication of Remote ON/OFF(CHS80,CHS200)

ON/OFF

logic

Standard Negative

Optional -R

When RC is ”Low” level, fan out current is 0.1mA typ. When Vcc is applied,

use 2.0[Vcc[7.0V.

CHS-24

Positive

Between RC and -VIN

L level(0 - 0.8V) or short ON

H level(2.0 - 7.0V) or open OFF

L level(0 - 0.8V) or short OFF

H level(2.0 - 7.0V) or open ON

Output

voltage

+VOUT

+S

-S

-VOUT

Fig.4.3 Connection when the remote sensing is in use

Twisted-pair wire or shield wire should be used for sensing wire.

¡

Thick wire should be used for wiring between the power supply

¡

and a load.

Line drop should be less than 0.3V.

Load

Page 6

DC-DC Converters Bus Converter

.

Power Module Type

Instruction Manual

Voltage between +VOUT and -VOUT should remain within the

output voltage adjustment range.

If the sensing patterns are short, heavy-current is drawn and the

¡

pattern may be damaged.

The pattern disconnection can be prevented by installing the pro-

tection parts as close as possible to a load.

Output voltage might become unstable because of impedance of

¡

wiring and load condition when length of wire exceeds 40cm.

4.6 Adjustable voltage range

(1) To adjust output voltage

Output voltage is adjustable by the external potentiometer.

¡

When the output voltage adjustment is used, note that the over

¡

voltage protection circuit operates when the output voltage is set

too high.

If the output voltage drops under the output voltage adjustment

¡

range, the Low voltage protection operates.

By connecting the external potentiometer (VR1) and resistors (R1,

¡

R2), output voltage becomes adjustable, as shown in Fig.4.4.

Recommended external parts are shown in Table 4.2.

The wiring to the potentiometer should be as short as possible.

¡

The temperature coefcient could become worse, depending on

the type of a resistor and potentiometer. Following parts are rec-

ommended for the power supply.

.............

Resistor

Potentiometer

When the output voltage adjustment is not used, open the TRM

¡

pin respectively.

The change speed of the TRM voltage should be less than 0.15V/

¡

ms, when changing output voltage to less than 90% of the rated.

Control Amp.

of rated

voltage

Table 4.2 Recommended value of external potentiometer & resistor

No. VOUT

1 3.3V 2.2kW68k

2 5V 4.7kW68k

3 10V 15kW68k

4 12V 18kW68k

5 15V 22kW68k

Metal lm type, coefcient of less than ±100ppm/

....

Cermet type, coefcient of less than ±300ppm/

+VOUT

+S

RA

5.11kW

+

RC

5.11kW

1.225V

TRM

R2

-S

-VOUT

Fig.4.4 Output voltage control circuit

Output adjustable range

VOUT ±5% VOUT ±10%

R1 R2 VR1 R1 R2 VR1

5k

W

2.2kW33k

5.6kW33k

15kW33k

18kW33k

22kW33k

W

W

W

W

W

C

C

R1

VR1

5kW

W

W

5k

W

W

W

W

(2) To decrease output voltage

By connecting the external resistor (RD), output voltage becomes

¡

adjustable to decrease.

The external resistor (RD) is calculated by the following equation.

5.11

RD= -10.22 [kW]

Δ

VOR-V

Δ=

V

V

OD

V

OR

: Rated output voltage [V]

OR

: Output voltage needed to set up [V]

OD

+VOUT

+S

TRM

RD

-S

-VOUT

Fig.4.5 Connection to decrease output voltage

(3) To increase output voltage

By connecting the external resistor (RU), output voltage becomes

¡

adjustable to increase.

The external resistor (RU) is calculated by the following equation.

5.11XV

RU= - - 10.22 [kW]

VOU-V

Δ=

V

OR

X

OR

1.225XΔ

OR

(1+Δ)

5.11

Δ

VOR : Rated output voltage [V]

V

: Output voltage needed to set up [V]

OU

+VOUT

+S

RU

TRM

-S

-VOUT

Fig.4.6 Connection to increase output voltage

CHS-25

Page 7

5V

CHS40048/CHS50048

ADJUSTMENT RANGE [%]ADJUSTMENT RANGE [%]

5V

DC-DC Converters Bus Converter

.

Power Module Type

Instruction Manual

(4) Input voltage derating

When input voltage is 18-21.5V DC or 36-44VDC, the output

¡

voltage adjustment range becomes as shown in Fig.4.7.

120

115

110

105

100

80

0

21.5 360

18

20

INPUT VOLTAGE [V]

CHS30024

120

115

110

105

100

95

90

80

0

43 760

36

INPUT VOLTAGE [V] INPUT VOLTAGE [V]

CHS12048

Fig.4.7 CHS Output Voltage Adjustment Range

4.7 Isolation

For a receiving inspection, such as Hi-Pot test, gradually increase

¡

(decrease) the voltage to start (shut down). Avoid using Hi-Pot

tester with timer because it may generate voltage a few times

higher than the applied voltage at ON/OFF of a timer.

4.8 PMBus interface

¿

-I (CHS300/CHS400)

This option is equipped with a digital PMBus interface.

¡

Please contact us about for details.

5

Series and Parallel Operation

5.1 Series operation

Series operation is available by connecting the outputs of two or

¡

more power supplies, as shown below. Output current in series

connection should be lower than the lowest rated current in each

unit.

(a)(b)

Power

Supply

+

-

Power

Supply

+

LoadLoad

Load

Power

Supply

+

-

12V

15V

3.3V

12V

120

115

110

105

100

95

90

80

ADJUSTMENT RANGE [%]

0

40 760

36

INPUT VOLTAGE [V]

CHS6048

5V

120

115

110

105

100

95

90

80

ADJUSTMENT RANGE [%]

0

40 760

36

3.3V,5V

4812H

44

3.3V

12V

12V

3.3V

10V,12V

5.2 Parallel operation

¿

-P (CHS400/CHS500)

This option is for parallel operation.

5V

¡

Sensing and adjustment of the output voltage are not possible at

¡

the time of the use with this option.

As variance of output current drew from each power supply is

¡

maximum 10%, the total output current must not exceed the value

determined by the following equation.

(Output current in parallel operation)

=(the rated current per unit) x (number of unit) x0.9

Power

Supply

+

-

Fig.5.1 Examples of series operation

When the number of units in parallel operation increases, input

CHS8048/CHS20048/CHS30048/

current increase at the same time. Adequate wiring design for in-

put circuitry is required, such as circuit pattern, wiring and current

capacity for equipment.

Total number of units should be no more than 3 pieces.

¡

Thick wire should be used for wiring between the power supply

¡

and load, and line drop should be less than 0.3V.

Connect each input pin for the lowest possible impedance.

¡

When the number of the units in parallel operation increases,

¡

inputcurrent increases. Adequate wiring design for input circuitry

such as circuit pattern, wiring and current for equipment is re-

quired.

+Vout

DC

INPUT

Fuse

SW

Fuse

+Vin

-Vin

RC

+Vin

-Vin

RC

LOAD

-Vout

+Vout

-Vout

Fig.5.2 Examples of parallel operation

CHS-26

Page 8

I

I

+VIN

26.2

18

T

DC-DC Converters Bus Converter

.

Power Module Type

Instruction Manual

5.3 Redundancy operation

Parallel operation is not possible.

¡

Redundancy operation is available by wiring as shown below.

¡

1

Power

Supply

Power

Supply

Even a slight difference in output voltage can affect the balance

¡

between the values of I

Please make sure that the value of I

current of the power supply.

I

6

Implementation

+

-

I

2

+

-

Fig.5.3 Redundancy operation

and I2.

1

the rated current value

[

3

-

3

Load

does not exceed the rated

3

Mounting Method

6.1 Mounting method

The unit can be mounted in any direction. When two or more pow-

¡

er supplies are used side by side, position them with proper inter-

vals to allow enough air ventilation. The temperature around each

power supply should not exceed the temperature range shown in

derating curve.

Avoid placing the DC input line pattern layout underneath the unit.

¡

It will increase the line conducted noise. Make sure to leave an

ample distance between the line pattern layout and the unit. Also

avoid placing the DC output line pattern underneath the unit be-

cause it may increase the output noise. Lay out the pattern away

from the unit.

Avoid placing the signal line pattern layout underneath the unit be-

¡

cause the power supply might become unstable.

Lay out the pattern away from the unit.

Avoid placing pattern layout in hatched area shown in Fig.6.1 to

¡

insulate between pattern and power supply.

514

+VIN

RC

-VIN

RC

-VIN

524

+VIN

RC

-VIN

1.5

+VIN

RC

-VIN

+VOUT

+S

TRM

-S

-VOUT

(b) CHS80

7

+VOUT

+S

TRM

-S

-VOUT

(C) CHS120

37

(d) CHS200

48

(e) CHS300

4

8

+VOUT

+S

TRM

-S

-VOUT

+VOUT

+S

TRM

-S

-VOUT

57

+VIN

+VIN

RC

-VIN

13

1

102

+VOUT

+S

TRM

-S

-VOUT

(a) CHS60

RC

-VIN

(f) CHS400

Fig.6.1 Prohibition area of pattern layout (top view)

+VOU

+S

TRM

-S

-VOUT

Dimensions in mm

CHS-27

Page 9

DC-DC Converters Bus Converter

.

Power Module Type

Instruction Manual

6.2

Automatic Mounting (CHS series:option S)

To mount CHS series automatically, use the inductor area near the

¡

output pin as an adsorption point. Please see the External View

for details of the adsorption point.

If the bottom dead point of a suction nozzle is too low when

mounting excessive force is applied to the inductor, it could cause

damage. Please mount carefully.

6.3 Soldering

(1)Flow Soldering :260

(2)Soldering Iron :maximum 450C5 seconds or less

(3)Reow Soldering (option “-S”)

Fig.6.2 shows conditions for the reflow soldering for option “-S”

¡

of CHS series. Please make sure that the temperatures of pin

terminals +VIN and -VOUT shown in Fig.6.2 do not exceed the

temperatures shown in Fig.6.3.

If time or temperature of the reflow soldering goes beyond the

¡

conditions, reliability of internal components may be compromised.

Please use the unit under the recommended reow conditions.

+VIN

C

15 seconds or less

C

Tp

Tx

Ty2

Ty1

A’A B B' C

A 1.0 - 5.0C/s

A' Ty1:160±10

Ty2:180±10

Ty1 - Ty2:120s max

B 1.0 - 5.0C/s

B' Tp:Max245C 10s max

Tx:220C or more:70s max

C 1.0 - 5.0C/s

Fig.6.3 Recommend Reow Soldering Conditions

C

C

time(s)

(a) CHS60

+VIN

(b) CHS80

+VIN

(c) CHS120

Fig.6.2 Temperature Measuring Points when Setting

Reow Soldering Conditions

-VOUT

-VOUT

-VOUT

¿

Notes to use option “-S”

Solder iron or other similar methods are not recommended solder-

¡

ing method for option “-S” because it may not be able to retain

connection reliability between the PCB and the Pins. Solder reow

is the acceptable mounting system for the option.

Option “-S” is not reusable product after soldered on any applica-

¡

tion PCB.

6.4 Stress to the pins

When too much stress is applied to the pins of the power supply,

¡

the internal connection may be weakened.

As shown in Fig.6.4, avoid applying stress of more than 19.6N

(2kgf) to the pins horizontally and more than 39.2N (4kgf) verti-

cally.

The pins are soldered on PWB internally. Therefore, do not pull or

¡

bend them with strong force.

Fix the unit on PCB (using silicone rubber or xing ttings) to re-

¡

duce the stress to the pins.

Less than

19.6N

Less than

39.2N

Less than

19.6N

Less than

19.6N

Less than

(option S)

Less than

19.6N

39.2N

CHS-28

Fig.6.4 Stress to the pins

Page 10

DC-DC Converters Bus Converter

6.5 Cleaning

When cleaning is necessary, clean under the following conditions.

¡

Method : Varnishing, ultrasonic wave and vapor

Cleaning agents : IPA (Solvent type)

Total time : 2 minutes or less

Do not apply pressure to the lead and name plate with a brush or

¡

scratch it during the cleaning.

After cleaning, dry them enough.

¡

.

Power Module Type

Instruction Manual

8 Derating

It is necessary to note thermal fatigue life by power cycle.

¡

Please reduce the temperature uctuation range as much as pos-

sible when the up and down of temperature are frequently gener-

ated.

6.6 Storage method (CHS series:option S)

To stock unpacked products in your inventory, it is recommended

¡

to keep them under controlled condition, 5-30C, 60%RH and use

them within a year.

24-hour baking is recommended at 125C, if unpacked products

¡

were kept under uncontrolled condition, which is 30C, 60%RH or

higher.

Original trays are not heat-resistant. Please move them to heat-

resistant trays in preparation to bake.

To check moisture condition in the pack. Silica gel packet has

some moisture condition indicator particles.

Indicated blue means good. Pink means alarm to bake it.

Notication. The tray will be deformed and the power supply might

¡

be damaged, if the vacuum pressure is too much to reseal.

6.7 Stress to the product

CHS series transformer core and choke coil core are attached by

¡

glue.

There is a possibility that the core will be removed and power sup-

ply will be damaged when they receive stress by the fall or some

kind of stress.

7 Safety Considerations

To apply for safety standard approval using this power supply, the

¡

following conditions must be met.

This unit must be used as a component of the end-use equipment.

¿

The equipment must contain basic insulation between input and

¿

output. If double or reinforced insulation is required, it has to be

provided by the end-use equipment in accordance with the nal

build-in condition.

Safety approved fuse must be externally installed on input side.

¿

8.1 CHS Derating

Use with the convection cooling or the forced air cooling.

¡

Make sure the temperatures at temperature measurement loca-

tions shown from Fig.8.2.1 to Fig.8.2.10 below are on or under the

derating curve in Fig.8.1.

Ambient temperature must be kept at 85C or under.

100

80

60

40

Load factor[%]

20

0

-40

(a) CHS60, CHS80, CHS200, CHS300, CHS400, CHS500

100

80

60

40

Load factor[%]

20

0

-40

Option “B”

1

Option “BC”

2

Others

3

-20 0 20 40 60 120100

Temperature of measurement location[C]

Option “B” (Vin:36-60V)

1

Option “B” (Vin:60-76V)

2

Others

3

-20 0 20 40 60 12010080

Temperature of measurement location[C]

(b) CHS120

Fig.8.1 Derating curve

2

80

3

1

(95)

1

2

3

(115)(105)

Temperature measurement location

Fig.8.2.1 Temperature measurement location (CHS60)

CHS-29

Page 11

Measurement point

DC-DC Converters Bus Converter

Temperature measurement location

Fig.8.2.2 Temperature measurement location (CHS80)

Temperature measurement location

Fig.8.2.3 Temperature measurement location (CHS120)

.

Power Module Type

Fig.8.2.7 Temperature measurement location (CHS500)

option “B” which is used with the convection cooling, forced

¡For

air cooling or conduction cooling, use the temperature measure-

ment location as shown in Fig.8.2.8 to Fig.8.2.10.

Instruction Manual

Temperature measurement location

Temperature measurement location

Fig.8.2.4 Temperature measurement location (CHS200)

Temperature measurement location

Fig.8.2.5 Temperature measurement location (CHS300)

Temperature measurement location

Fig.8.2.6 Temperature measurement location (CHS400)

Aluminum base plate

Fig.8.2.8 Measurement point (CHS120 option “B”)

Aluminum base plate

Measurement point

Fig.8.2.9 Measurement point (CHS200/CHS300 option “B” and “BC”)

Aluminum base plate

Measurement point

Fig.8.2.10 Measurement point (CHS400/CHS500 option “B”)

Shown the thermal curve with measuring as shown in Fig.8.3.

¡

Verify nal design by actual temperature measurement.

Use the temperature measurement location as shown in Fig.8.2.1

to Fig.8.2.7 at 120C or less.

CHS-30

Page 12

DC-DC Converters Bus Converter

.

Power Module Type

Instruction Manual

CHS

Top

Input side

Output side

Measurement point for

ambient temperature

and airflow

Airflow Airflow

Fig.8.3 Measuring method

PWB

25.4mm

12.7mm

CHS

76mm

20

18

16

14

12

10

1convection cooling(0.2m/s)

8

21m/s

6

Load current[A]

32m/s

4

2

0

-40-30 -20-10 0102030405060708090

Ambient temperature[C]

3

2

1

Fig.8.4 Load current vs. ambient temperature(CHS60483R3 Vin=48V)

14

12

10

8

6

1convection cooling(0.2m/s)

Load current[A]

21m/s

4

32m/s

2

2

3

1

0

-40-30 -20-10 0102030405060708090

Ambient temperature[C]

Fig.8.5 Load current vs. ambient temperature(CHS604805 Vin=48V)

7

6

5

4

3

1convection cooling(0.2m/s)

Load current[A]

21m/s

2

32m/s

1

0

-40-30 -20-10 0102030405060708090

Ambient temperature[C]

3

2

1

Fig.8.6 Load current vs. ambient temperature(CHS604812 Vin=48V)

30

25

20

15

1

3

2

1convection cooling(0.2m/s)

10

Load current[A]

21m/s

32m/s

5

0

-40-30 -20-10 0102030405060708090

Ambient temperature[C]

Fig.8.7 Load current vs. ambient temperature(CHS80483R3 Vin=48V)

CHS-31

Page 13

DC-DC Converters Bus Converter

0

Ambient temperature[C]

35

Load current[A]

0

30

Load current[A]

Ambient temperature[C]

0

12

Load current[A]

Ambient temperature[C]

18

16

14

]

12

10

8

1convection cooling(0.2m/s)

6

Load current[A

21m/s

32m/s

4

2

0

-40-30 -20-10 0102030405060708090

Ambient temperature[C]

1

2

.

Power Module Type

3

10

8

6

4

Instruction Manual

1

1convection cooling(0.2m/s)

3

2

21m/s

2

32m/s

0

-40 -30 -20 -10 0 10 20 30 40 50 60 70 80 9

Fig.8.8 Load current vs. ambient temperature(CHS804805 Vin=48V)

8

7

6

]

5

4

1convection cooling(0.2m/s)

3

Load current[A

21m/s

2

32m/s

1

0

-40-30 -20-10 0102030405060708090

1

3

2

Ambient temperature[C]

Fig.8.9 Load current vs. ambient temperature(CHS804812 Vin=48V)

30

25

20

15

1convection cooling(0.2m/s)

21m/s

10

32m/s

5

0

-40 -30 -20 -10 0 10 20 3 0 40 50 6 0 70 80 9

1

3

2

Fig.8.12 Load current vs. ambient temperature(CHS1204812 Vin=48V)

60

50

40

30

1convection cooling(0.2m/s)

20

Load current[A]

21m/s

10

32m/s

0

-40-30 -20-10 0102030405060708090

1

2

3

Ambient temperature[C]

Fig.8.13 Load current vs. ambient temperature(CHS200483R3 Vin=48V)

45

40

35

30

25

20

1convection cooling(0.2m/s)

15

Load current[A]

21m/s

10

32m/s

5

0

-40-30 -20-10 0102030405060708090

1

Ambient temperature[C]

2

3

Fig.8.10 Load current vs. ambient temperature(CHS120483R3 Vin=48V)

25

20

15

10

1convection cooling(0.2m/s)

1

3

2

21m/s

5

32m/s

0

-40 -30 -20 -10 0 10 20 30 40 50 60 70 80 9

Fig.8.11 Load current vs. ambient temperature(CHS1204805 Vin=48V)

CHS-32

Fig.8.14 Load current vs. ambient temperature(CHS2004805 Vin=48V)

18

16

14

12

10

8

1convection cooling(0.2m/s)

6

Load current[A]

21m/s

4

32m/s

2

0

-40-30 -20-10 0102030405060708090

1

3

2

Ambient temperature[C]

Fig.8.15 Load current vs. ambient temperature(CHS2004812 Vin=48V)

Page 14

DC-DC Converters Bus Converter

.

Power Module Type

Instruction Manual

45

40

35

30

25

20

1convection cooling(0.2m/s)

15

Load current[A]

21m/s

10

32m/s

5

0

-40 -30-20 -10010 20 30 40 50 60 70 80 90

1

2

3

Ambient temperature[C]

Fig.8.16 Load current vs. ambient temperature(CHS3002405 Vin=24V)

18

16

14

12

10

8

1convection cooling(0.2m/s)

6

Load current[A]

21m/s

4

32m/s

2

0

-40 -30-20 -10010 20 30 40 50 60 70 80 90

1

2

Ambient temperature[C]

3

28

24

20

16

12

1convection cooling(0.2m/s)

Load current[A]

21m/s

8

32m/s

4

0

-40-30 -20-10 0102030405060708090

1

3

2

Ambient temperature[C]

Fig.8.20 Load current vs. ambient temperature(CHS3004812 Vin=48V)

28

24

20

16

12

1convection cooling(0.2m/s)

Load current[A]

21m/s

8

32m/s

4

0

-40-30 -20-10 0102030405060708090

1

Ambient temperature[C]

3

2

Fig.8.17 Load current vs. ambient temperature(CHS3002412 Vin=24V)

14

12

10

8

6

Load current[A]

4

convection cooling(0.2m/s)

1

21m/s

2

1

)

3

32m/s

2

0

-40 -30-20 -10010 20 30 40 50 60 70 80 90

Ambient temperature[C]

Fig.8.18 Load current vs. ambient temperature(CHS3002415 Vin=24V)

32

28

24

20

16

1convection cooling(0.2m/s)

12

Load current[A]

21m/s

8

32m/s

4

0

-40-30 -20-10 0102030405060708090

1

2

Ambient temperature[C]

3

Fig.8.21 Load current vs. ambient temperature(CHS3004812H Vin=48V)

45

40

35

30

25

20

1convection cooling(0.2m/s)

15

Load current[A]

21m/s

10

32m/s

5

0

-40-30 -20-10 0102030405060708090

1

2

3

Ambient temperature[C]

Fig.8.22 Load current vs. ambient temperature(CHS4004810 Vin=48V)

35

30

25

20

15

1convection cooling(0.2m/s)

Load current[A]

21m/s

10

32m/s

5

0

-40 -30 -20 -100 10 20 30 40 50 60 70 80 90

2

1

Ambient temperature[C]

3

Fig.8.19 Load current vs. ambient temperature(CHS3004810 Vin=48V)

Fig.8.23 Load current vs. ambient temperature(CHS4004812 Vin=48V)

CHS-33

Page 15

DC-DC Converters Bus Converter

.

Power Module Type

Instruction Manual

35

30

25

20

15

1convection cooling(0.2m/s)

Load current[A]

Fig.8.24 Load current vs. ambient temperature(CHS4004812H Vin=48V)

Load current[A]

21m/s

10

32m/s

5

0

-40-30 -20-10 0102030405060708090

Ambient temperature[C]

45

40

35

30

25

20

1convection cooling(0.2m/s)

15

21m/s

10

32m/s

5

0

-40-30 -20-10 0102030405060708090

Ambient temperature[C]

1

1

3

2

3

2

9

SMDtype(optionS)package information

These are packed in a tray (Fig.9.1 to Fig.9.3).

¡

Please order “CHS60

tray type packaging.

Capacity of the tray is 15max.

In case of fractions, the units are stored in numerical order.

46.8

323

59×4=236

-S”, “CHS80□□-S”, “CHS120□□-S” for

□□

136

3724.6 37

23

Fig.8.25 Load current vs. ambient temperature(CHS5004812 Vin=48V)

Dimensions in mm

Material : Conductive PS

Fig.9.1 Delivery package information (CHS60)

CHS-34

Page 16

DC-DC Converters Bus Converter

3833.2 38

323

136

23

37.5

62×4=248

.

Power Module Type

Instruction Manual

323

48.55

62X4=248

136

3834.1 38

136

23

323

33.2 38

37.5

62×4=248

38

23

Dimensions in mm

Material : Conductive PS

Dimensions in mm

Material : Conductive PS

Fig.9.3 Delivery package information (CHS120)Fig.9.2 Delivery package information (CHS80)

CHS-35

Loading...

Loading...