Cosel CHS Series, CHS300-I, CHS400-I, CHS500-I Communications Manual

PMBus communication manual

CHS300/400/500-I

PMBus communication manual

© 2016 COSEL CO.,LTD. ver4.0. 6/15 2016

Applications Manual

1. PMBus interface cable&connection

4. C2 terminal function

5. SMBAlert function

7. Packet error checking

PEC

8. PMBus Hardware specifications

Electrical characters specification on communication terminal

10. PMBus Commands set

CHS300/400/500-I series

1.1

1.2

1.3

1.4

1.5

2. PMBus communication control

2.1

2.2

2.3

2.4

3. Data format

3.1

3.2

4.1

4.2

5.1

5.2

5.3

5.4

6. Explain several functions

6.1

6.2

6.3

6.4

6.5

6.6

6.7

6.8

6.9

6.10

8.1

8.2

9. PMBus software Specifications

9.1

9.2

Terminal function

1.1.1

1.1.2

Terminal function on CHS300-I

Terminal function on CHS400/500-I

How to connect communication

Example of cabling pattern on PMBus communication

PMBus communication pull-up resistor value

Address setting

Overview of control block

RAM (Random Access Memory)

ROM (Random Access Read Only Memory)

Retain the number of abnormal power supply stopping

Data format for output voltage

Data format for another parameter

Power_Good function

Secondary side remote control function

SMBAlert terminal connecting

Checking salve for SMBAlert signal

In case multiple slave devices issue SMB Alert signal

How to do when SMB alert is issued repeatedly

ON/OFF operation

Start-stop voltage

Start-up sequence (start-up delay / rising up)

Setting output voltage

Protective operation for output overvoltage

Protective operation for output undervoltage

Protective operation for overtemperature

Protective operation for undertemperature

Protecting operation for over start-up time

Prohibit re-writing parameter

((((

))))

Ultimate maximum rate on communication terminal

List of PMBus command

PMBus command setting / reading value

Page

2

2

2

3

4

4

5

5

6

6

6

7

7

8

8

8

9

9

9

10

10

10

11

11

12

12

12

13

13

14

14

15

15

17

17

18

19

19

19

20

20

23

25

- 1 -

2.1

Pin configuration

Applications manual

For CHS300/400/500-I series

The PMBus can be used to control and monitor the CHS300/400/500 converter.

For detail, refer to PMBus standard spec manual :

Part I (Revision1.2) and Part II (Revision1.2).

1. PMBus communication cabling and connection

1.1 Terminal function

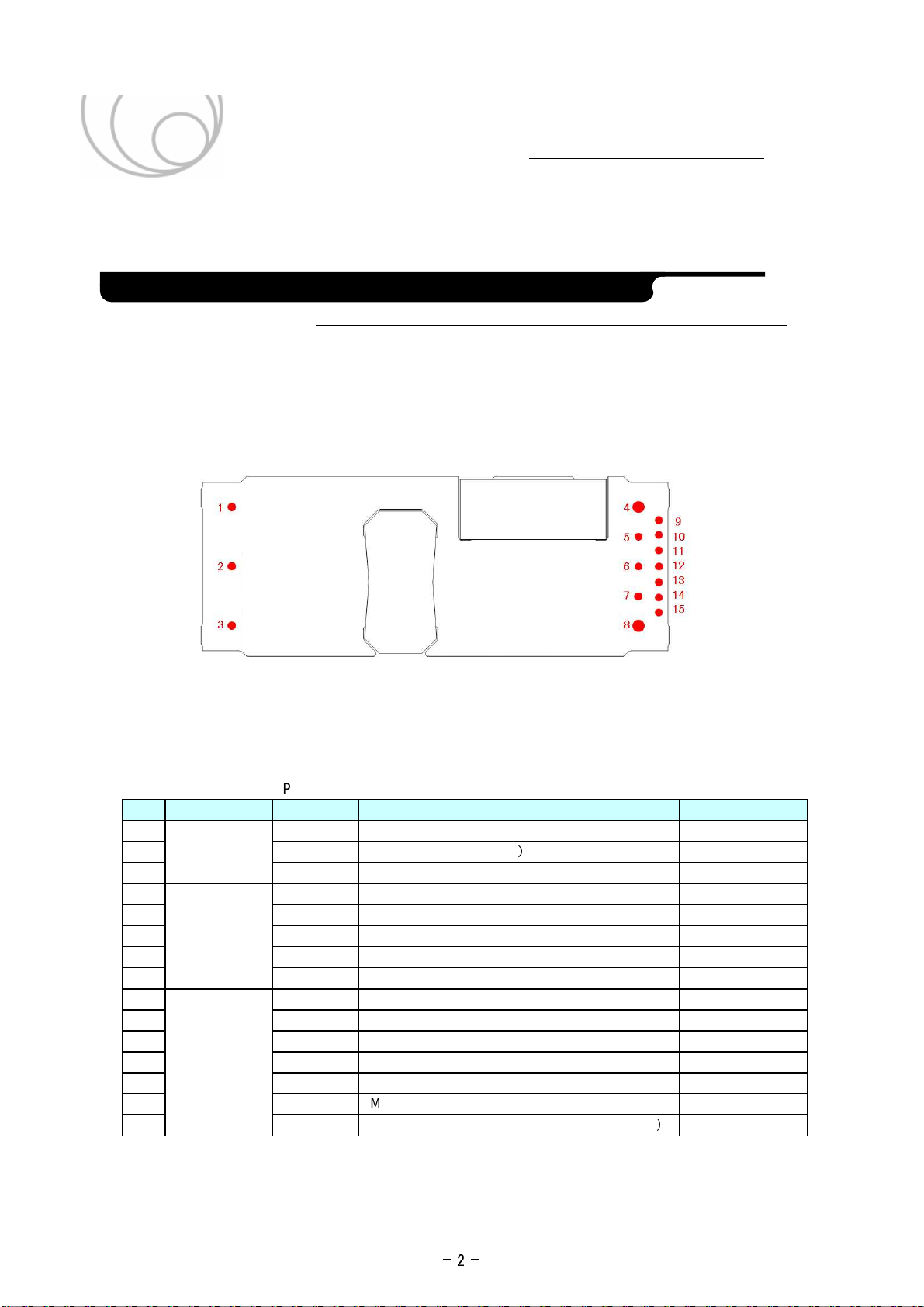

1.1.1 Terminal function on CHS300-I

The figure and the table below show terminal function and name of pins on CHS300-I.

PMBus Power System Management Protocol Specification

#

1

2

3

4

5

6

7

8

9

10

11

12

13

15

Figure 1-1.1. pin assignment in CHS300-I (top view)

Table 1-1.1. Pin Descriptions on CHS300-I

name

Input

terminal

Output

terminal

PMBus

communication

terminal

+VIN

RC

-VIN

+VOUT

+S

TRM

-S

-VOUT

Addr0

NC

Clock

SMBAlert

Data

Sig_GND14

C2

DC input(+)

Remote control (first side

DC input(-)

DC output (+)

Remote sensing (+)

Output voltage adjustment

Remote sensing (-)

DC output (-)

Address setting

Not connected

PMBus communication clock input

Alarm output

PMBus communication data input&output

PMBus communication signal ground

Power_Good or remote control (secondary side

Notefunction

)

)

- 2 -

Applications manual

For CHS300/400/500-I series

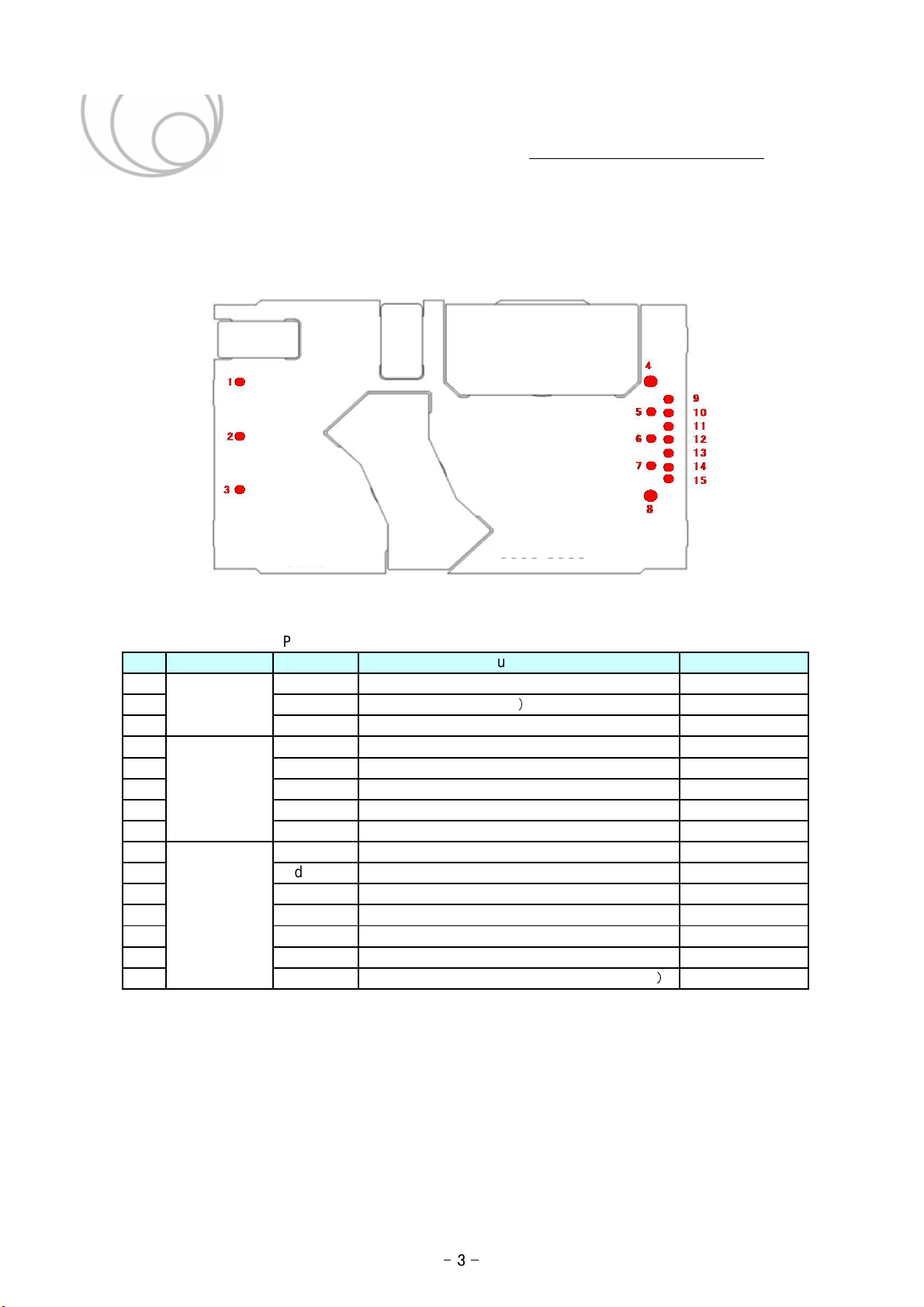

1.1.2 Terminal function on CHS400/500-I

The figure and the table below show terminal function and name of pins on CHS400/500-I.

Figure 1-1.2. pin assignment in CHS400/500-I (top view)

Table 1-1.2. Pin Descriptions on CHS400/500-I

# name

1

2

Input

terminal

3 -VIN

4

5

6 TRM

Output

terminal

7 -S

8

9

10

11

12 SMBAlert

13 Data

PMBus

communication

terminal

14 Sig_GND

15 C2

+VIN

RC

+VOUT

+S

-VOUT

Addr0

Addr1

Clock

*1:

Do not use when adjusting output voltage with PMBus communication.

function

DC input(+)

Remote control (first side

DC input(-)

DC output (+)

Remote sensing (+)

Output voltage adjustment

Remote sensing (-)

DC output (-)

Address setting

Address setting

PMBus communication clock input

Alarm output

PMBus communication data input&output

PMBus communication signal ground

Power_Good or remote control (secondary side

)

Note

*1

)

- 3 -

Applications manual

For CHS300/400/500-I series

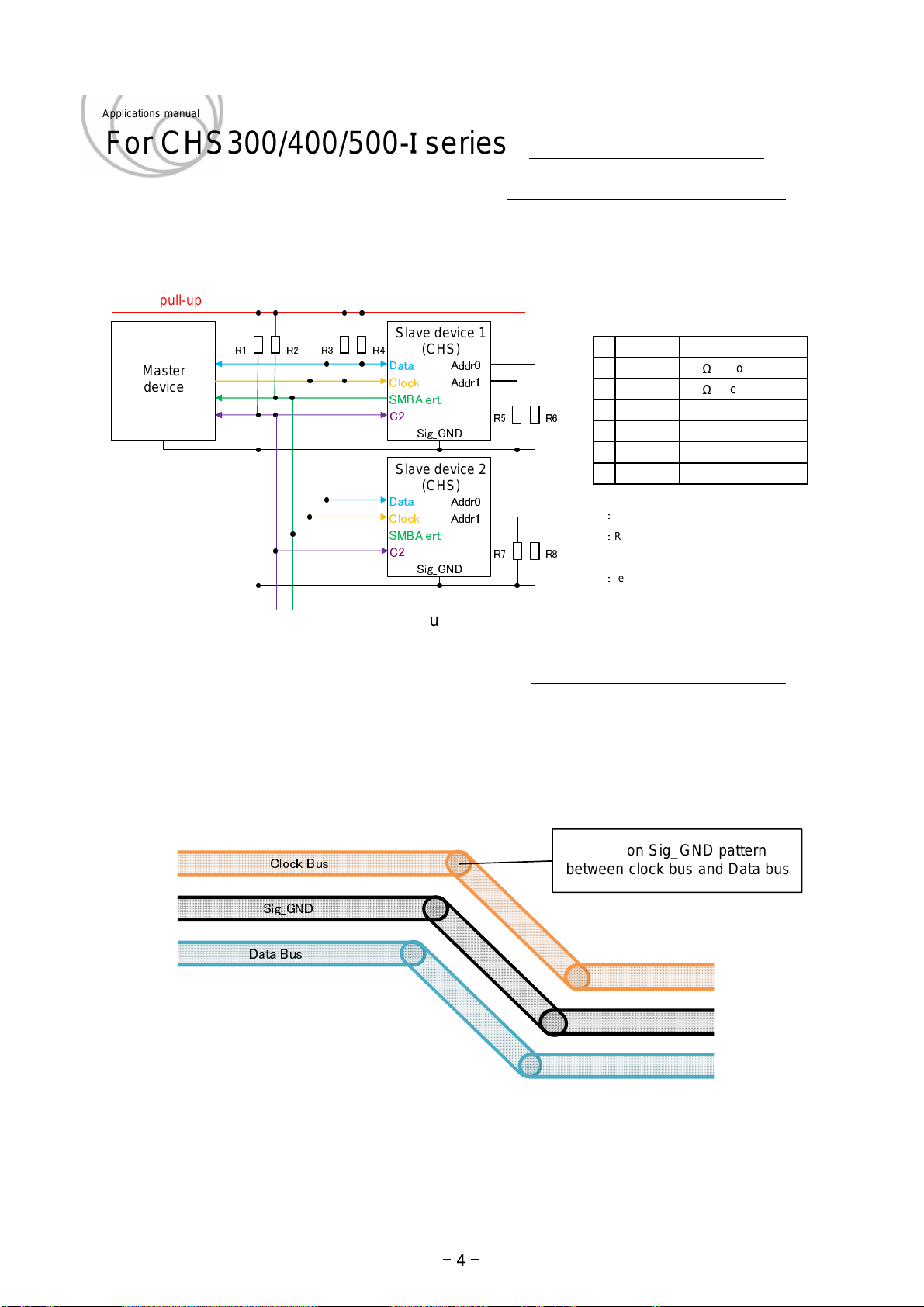

1.2 PMBus Communication connections method

The figure and table below show recommended resistors value for hard wiring PMBus addresses.

pull-up

プルアップ電圧

マスター

デバイス

Master

device

●●●

R1 R2 R3 R4

● ●

●

●

●

●

●

●

●

●

●●

スレーブデバイス1

Slave device 1

(CHS)

●

●

(CHS)

Data Addr0

Clock

Addr1

SMBAlert

C2

R5 R6

Sig_GND

●

スレーブデバイス2

Slave device 2

(CHS)

●

Data

Clock

(CHS)

Addr0

Addr1

●

SMBAlert

C2

R7 R8

Sig_GND

●●

component

#

R1

1

R2

2

R3

3

R4

4

R5,R7

5

R6,R8

6

*1: Connecting C2 as Power-Good function

*2: Refer to clause 1.4 PMBus communication

pull-up resistor

*3: refer to clause 1.5 address setting

Setting value

10kΩ (recommend) *1

10kΩ (recommend) *2

*

2

*

2

*

3

*

3

Figure 1-2 PMBus interface cable chart

1.3 PMBus communication cable pattern example

When connecting the PMBus communication cable, please make sure design to minimize

noise from outside and crosstalk by positioning Sig_GND between Data bus and Clock bus

as shown figure 1-3.

Also, do the right setting for pull-up resistor as parasitic capacitance is happened by way of

shielding and length of cabling. (refer to clause 1.4)

Clock Bus

Sig_GND

Data Bus

Position Sig_GND pattern

between clock bus and Data bus

Figure 1-3 Pattern example

- 4 -

Resistors with 1% tolerance are recommended.

*1 *

2

Applications manual

For CHS300/400/500-I series

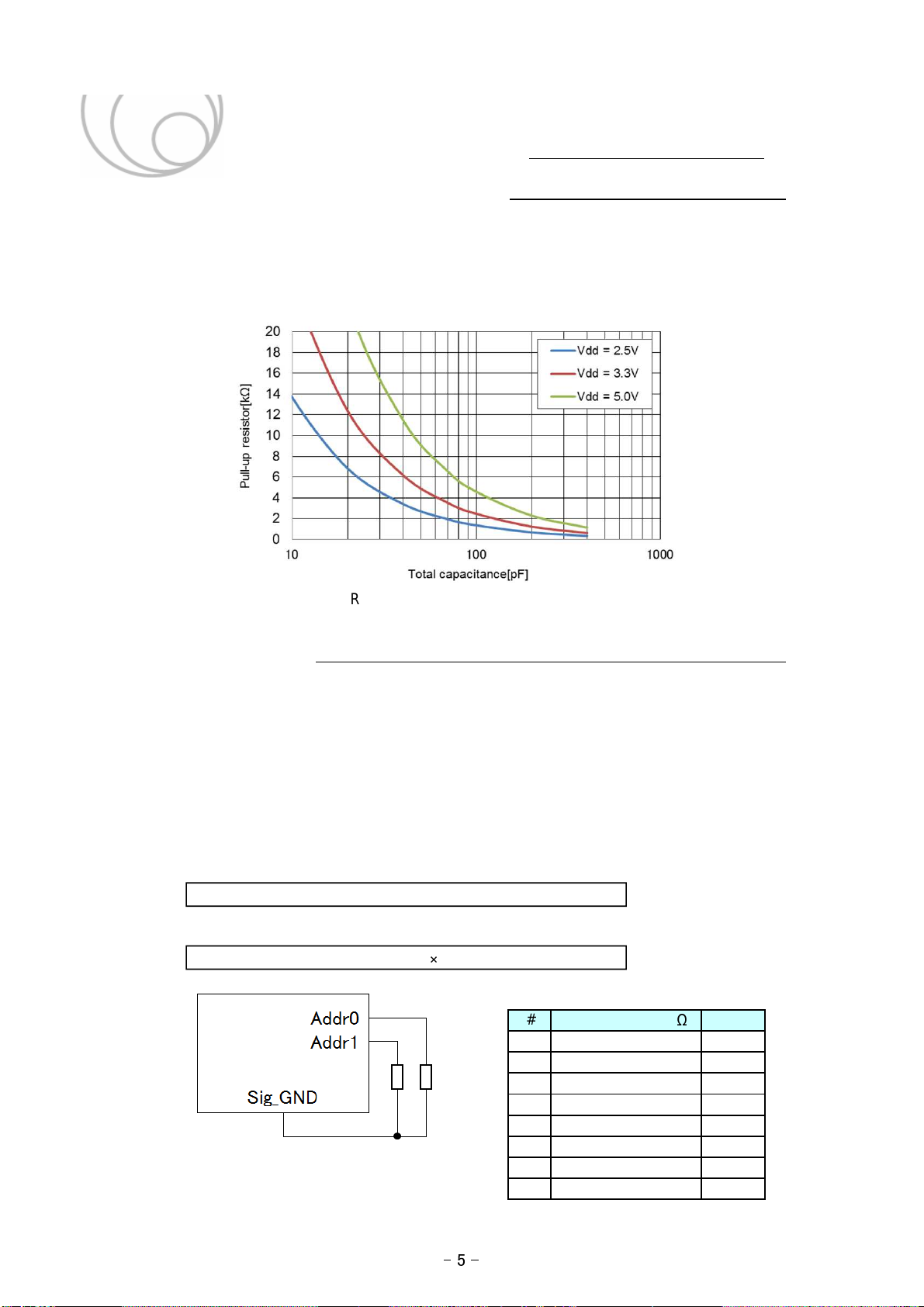

1.4 PMBus communication pull-up resistor value

It is necessary to connect pull-up resistor on Data bus and Clock bus terminal of PMBus .

Recommended value of resistor(maximum value) is shown at figure 1-4.

Note1: Do not exceed the rated output current of converter's terminal (clause 8-1).

Note2: Total of parasitic capacitance and input capacitance should be less 400pF.

Figure 1-4 Recommended value of pull-up resistor

1.5 address setting

The figure and table below show recommended resistors value for hard wiring PMBus addresses.

Take 0-7 on Addr0, Addr1 per value of resistor and address could be assigned 0-63 per

below formula. when calculation result in 0-12,40,44,45,55 setting, address 127 will be return.

*1: Address setting could not be changed after input voltage is applied .

Be sure to make setting before input voltage is applied.

*2: Addr1 is only CHS400/500-I.

The formula for CHS300-I

Address = 16 + Value(Addr0)

The formula for CHS400/500-I

Address = Value(Addr1) ×8 + Value(Addr0)

Table 1-2 Resistor value

ValueResistor value [kΩ]#

10 01

1

2

3

4

5

6

7

Figure 1-5 Address setting

2

3

4

5

6

7

8 220

15

24

36

56

82

130

- 5 -

2.1

Pin configuration

Applications manual

For CHS300/400/500-I series

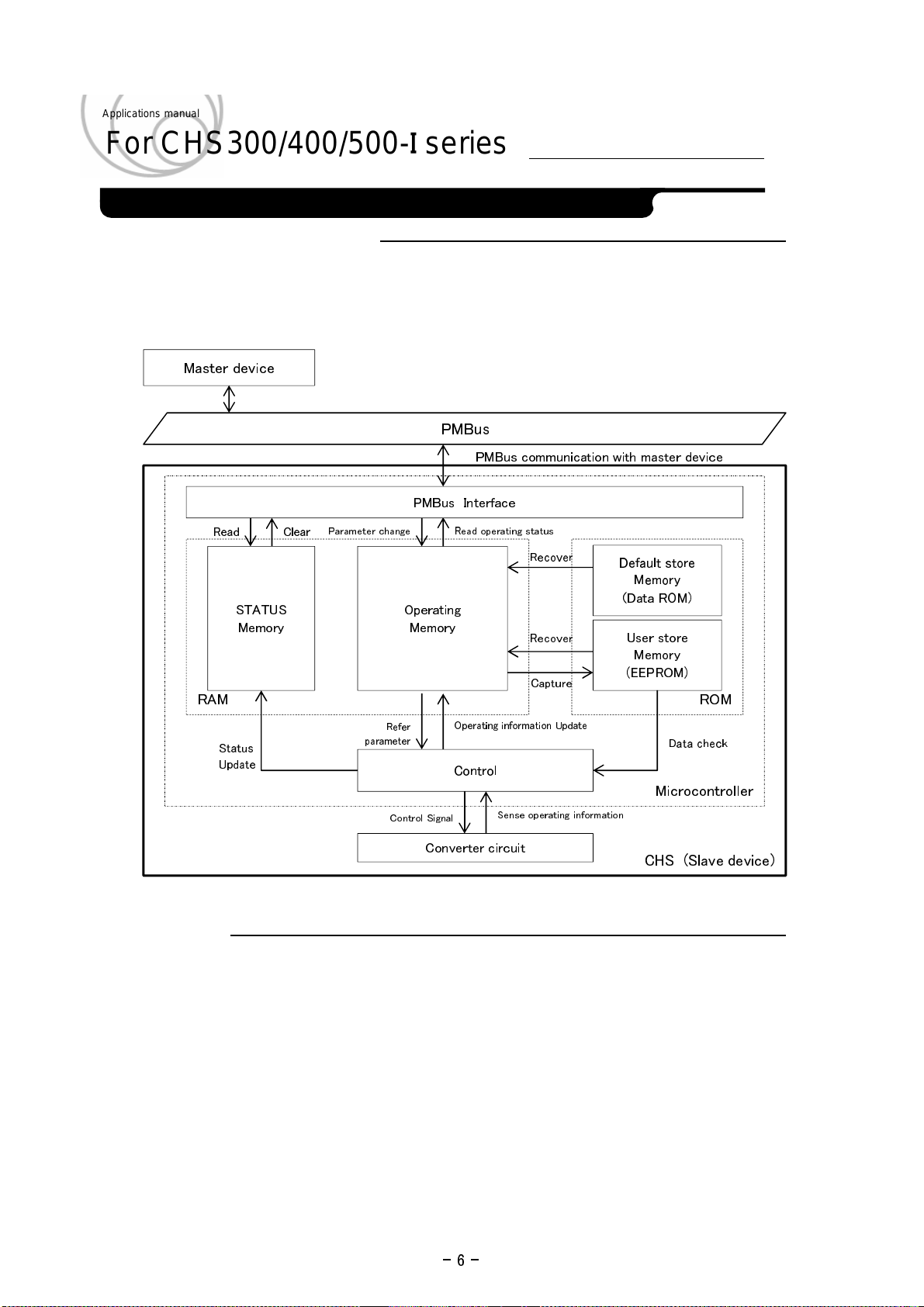

2. PMBus communication control

2.1 Overview for Control block

This product has built-in RAM and ROM.

Based on the memory parameter, controlling power supply and PMBus communication

are implemented. Conceptual diagram shown in figure 2-1.

Master device

PMBus

PMBus communication with master device

PMBus Interface

Memory

Read operating status

Recover

Recover

Capture

Default store

Memory

(Data ROM)

User store

Memory

(EEPROM)

STATUS

Memory

ClearRead

Parameter change

Operating

RAM ROM

Operating information Update

Data check

Control

Status

Update

Refer

parameter

Microcontroller

Control Signal

Converter circuit

Sense operating information

CHS (Slave device)

Figure 2-1 Conceptual diagram of communication control

2.2 RAM

2.2.1 Operating memory

When power supply is being operated, it refers to setting value of operating memory

with RAM and control it. Since setting change by PMBus communication command is

preserved in operating memory, the setting will be lost after a reset unless they are stored

to data flash.

2.2.2 STATUS memory

You can check status of power supply by reading status memory(command [ 78h ]-[ 7Eh ]).

Corresponding bit on Status memory is set to 1 when power supply has something abnormal.

It will be clear by implementing command of CLEAR_FAULTS [ 03h ], blocking input voltage,

stopping ON/OFF operation (refer to clause 6.1).

- 6 -

Please do not insulate input voltage over 3 seconds when command is being implemented.

Applications manual

For CHS300/400/500-I series

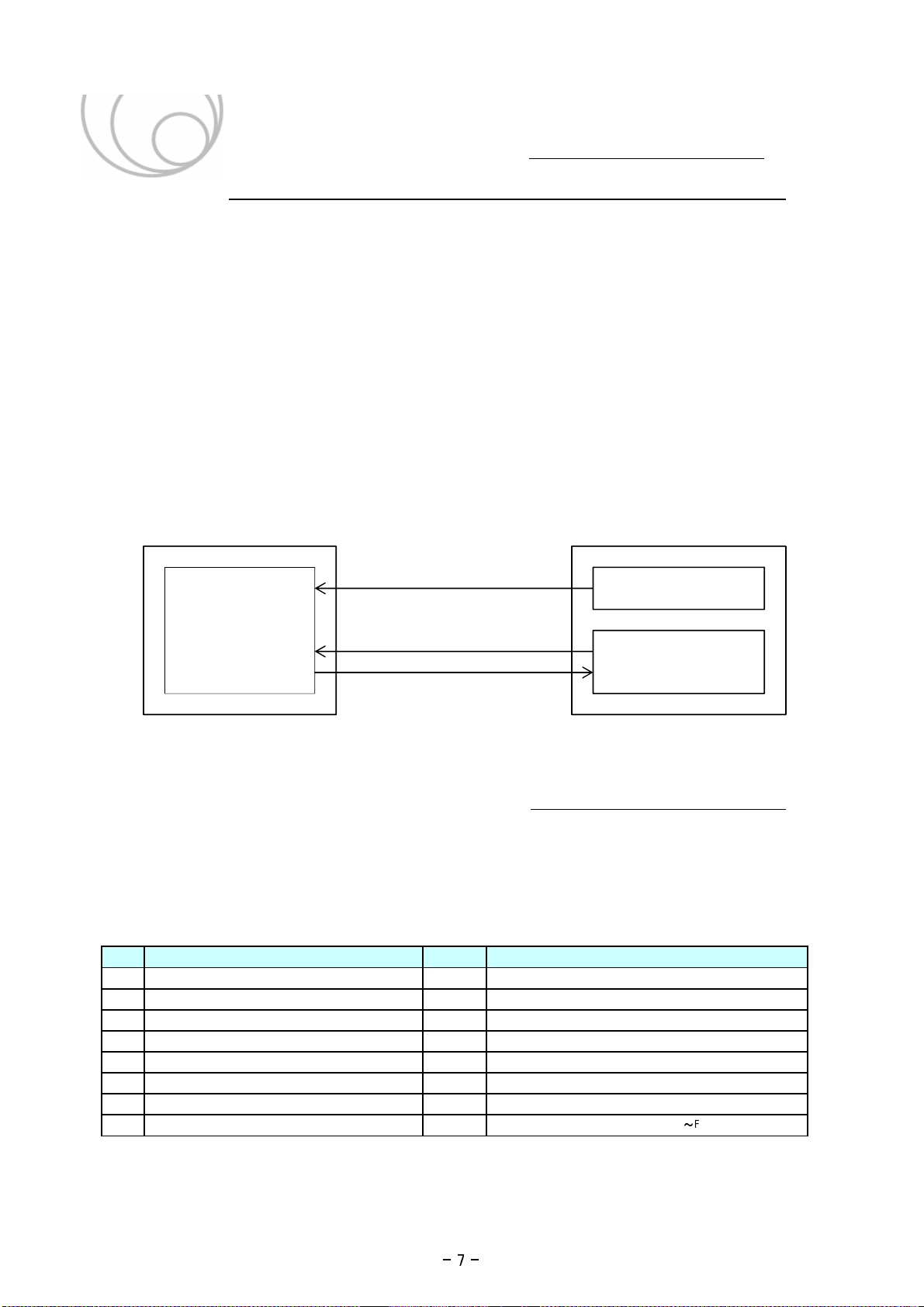

2.3 ROM

2.3.1 DEFAULT STORE MEMORY

Default store memory preserves initial parameter in factory shipment.

Restored information to operating memory is being done by implementing

RESTORE_DEFAULT_ALL [ 12h ] command. *1

2.3.2 USER STORE MEMORY

It is memory to preserve the content of operating memory rewritten by master device after input

voltage after input voltage is insulated. Information is restored by implementing

RESTORE_USER_ALL [ 16h ] command and when power supply is started-up. *1

Information within operating memory is preserved in user store memory by implementing

STORE_USER_ALL [ 15h ] command. *2

*1: Valid only for power supply operation is stopped.

Cannot receive command when power supply is operated. SMBAlert is operated.

*2:

Operating memory

_RAM

Restore

RESTORE_DEFAULT_ALL [12h]

Restore

RESTORE_USER_ALL [16h]

Store

STORE_USER_ALL [15h]

Default store memory

(Data ROM)

User store memory

(EEPROM)

Figure 2-2 Restore and preserving operation for command and parameter

2.4 Retaining the number of protecting operation

When each protective function are operated, the number of information(0-255times) is

preserved in ROM. Command shown in table 2-1 can read the number of protective

operation and delete the number of counts.

Table 2-1 Reading command for the number of stopping abnormal power supply

#

MFR_READ_VOUT_OV_FAULT_COUNT

1

MFR_READ_VOUT_UV_FAULT_COUNT

2

MFR_READ_OT_FAULT_COUNT

3

MFR_READ_UT_FAULT_COUNT

4

MFR_READ_TON_MAX_FAULT_COUNT

5

MFR_READ_VIN_OV_FAULT_COUNT

6

MFR_READ_VIN_UV_FAULT_COUNT

7

MFR_CLEAR_FAULT_CNT

8

Note: In case response of protective operation is auto recovery, it is counted every time

this function is operated after recovery.

Command Code Note

F0h

F1h

F2h

F3h

F4h

F8h

F9h

F5h

Read the number of overvoltage protective operation

Read the number of low output voltage protective operation

Read the number of overheating protective operation

Read the number of low temperature protective operation

Read the number of over star-up time protective operation

Read the number of over input voltage protective operation

Read the number of low input voltage protective operation

Reset the number of operation at F0h~F7h to "00h".

ROM_

- 7 -

3.2 Other

except output voltage

data format

2.1

Pin configuration

N

VALUE = Y ・ 2

Applications manual

For CHS300/400/500-I series

3. Data format

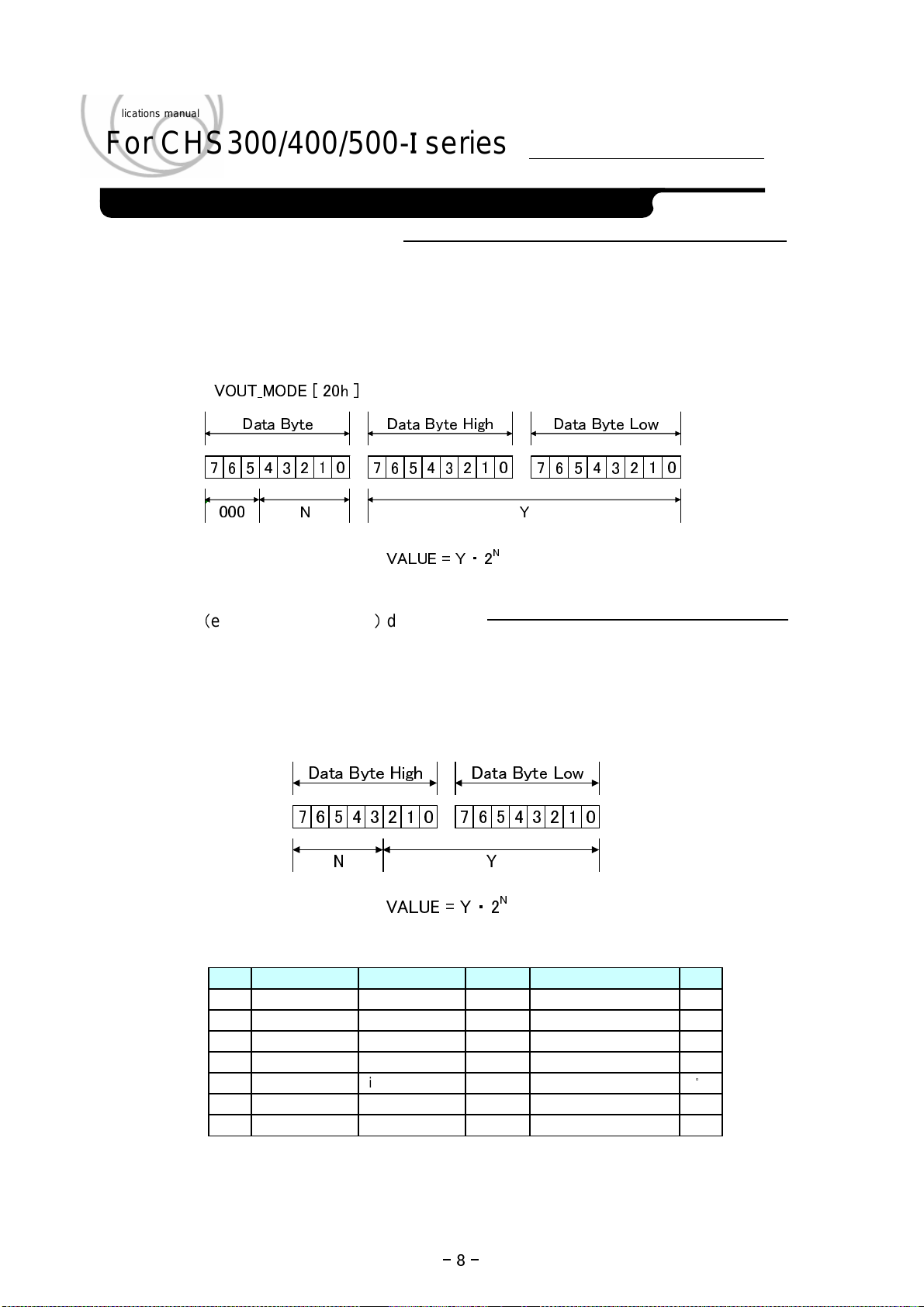

3.1 Data format for output voltage

Please set output voltage and read per shown linear format below.

Data byte Low 5 bit of VOUT MODE [ 20h ] is complement notation by 2 and represents

index part N with code and is fixed -12.

Mantissa part Y is represented 16 bit data without code.

VOUT_MODE [ 20h ]

Data Byte

7 6

000

N Y

(

In compliance with below linear format, please make setting and reading.

Date dyte High 5 bit is complement notation by 2 and represents index part N with code

and varies with data. Mantissa part Y is complement notation by 2 with code and

represents 11 bit data. *1

Data Byte High

)

10 04 3 2 17 67 6

03 25 45 4 3 2

N

Data Byte Low

51

Data Byte High Data Byte Low

3 2 1 07 6 5 43 2 1 07 6 5 4

N Y

VALUE = Y ・ 2

Table 3-1 Index part N value

# Item

1 Output voltage 10100 -12

2 Input voltage

3 Output current 11101 -3 ALinear(Iout)

5 Input wattage 00000

6 Temperature 11110 -2

Starting-up time 11111

7

8 Count

*1: Index part N value is fixed.

Linear(Temp)

Linear(Time)

N(5bit) Characteristics N (*1)

11101 -3 VLinear(Vin)

0

-1

00000 0Linear(Count)

- 8 -

UnitData format

VLinear(Vo)

WLinear(Pin)

C

ms

times

2.1

Pin configuration

Applications manual

For CHS300/400/500-I series

4. C2 Terminal function

C2 terminal can select Power_Good function and remote control (secondary side)function.

Please select function by MFR_C2_ARA_CONFIG [ E0h ] Initial setting is Power_Good function.

4.1 Power_Good function

Power_Good terminal output is open drain. When you use Power_Good function, please

connect C2 terminal with pull-up resistor. Initial setting of Power_Good signal is negative.

(Please make logic setting by MFR_PGOOD_POLARITY [ E2h ])

If output voltage is beyond setting value of POWER_GOOD_ON [ 5Eh ] , C2 terminal

will be low.

If output voltage is lower than the setting value of POWER_GOOD_OFF [ 5Fh ] ,

C2 terminal will be high.

Also, during 10ms in charging input voltage, voltage level on C2 terminal is unstable.

4.2 Remote control (Secondary side) function

Initial setting of Remote control (secondary side) function is negative and is invalid

when you select function.

Selecting logic and setting for invalid or valid function can be made by MFR_C2_LOGIC [ E1h ].

- 9 -

2.1

Pin configuration

Applications manual

For CHS300/400/500-I series

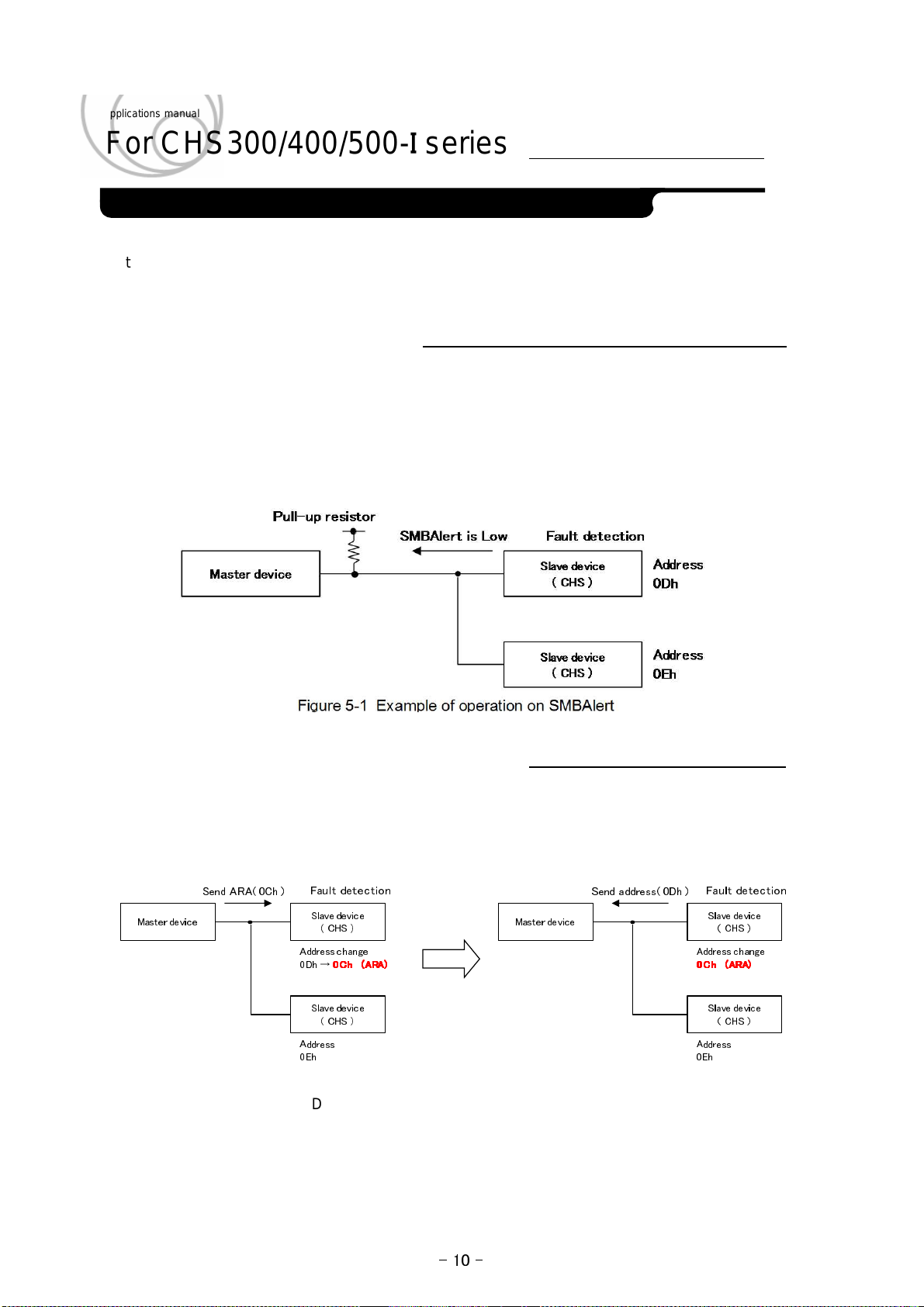

5. Explanation for terminal function of SMBAlert

SMBAlert protocol is also supported by the module. By which the module can alert the PMBus master

that it has an active status or alarm condition.

(Standard manual of SMBus for the details : System Management Bus(SMBus) Specification Ver 2.0)

5.1 Connecting SMBAlert terminal

Output terminal of SMBAlert is open drain. When you use function of SMBAlert,

connect pull-up resistor with SMBAlert terminal.

When something abnormal is happened in slave device, Slave device which detects something

abnormal will make SMBAlert low level.

( URL: http://smbus.org/specs/ )

Figure 5-1 Example of operation on SMBAlert

5.2 Identifying slave device issuing SMBAlert signal

Master-device can identify which slave device has something abnormal.

By receiving READ communication (*1) using ARA from master device, power supply

with something abnormal sends original address.

Send ARA( 0Ch )

Master device

*1:

When receiving READ communication using ARA, SMBAlert will be cancelled .

In order to enable the SMBAlert signal, it is necessary to send CLEAR_FAULTS [ 03h ].

Fault detection

Slave device

( CHS )

Address change

0Dh →

0000Ch (ARA)

Ch (ARA)

Ch (ARA)Ch (ARA)

Slave device

( CHS )

Address

0Eh

Master device

Diagram 5-2 Identifying Slave using ARA

Send address( 0Dh )

Fault detection

Slave device

( CHS )

Address change

0000Ch (ARA)

Ch (ARA)

Ch (ARA)Ch (ARA)

Slave device

( CHS )

Address

0Eh

- 10 -

Applications manual

For CHS300/400/500-I series

5.3 In case multiple slave devices issue SMBAlert signal

When multiple slave devices issue SMBAlert single at the same time, it is not possible

to make judgment for slave address by ARA. When you restore, please communicate

by ARA and release with SMBAlert.

5.4 How to do when SMBAlert is issued repeatedly.

When abnormal status such as automatic recovery situation keeps going, SMBAlert is

being operated again by READ communication with using ARA regardless returning

original address.

In case setting is made to response only ARA by MFR_C2_ARA_CONFIG [ E0h ] ,

communication other than ARA is not available as address on power supply is set for

only ARA.

When this situation is on going, normal communication is possible by freeing ARA after

stopping power supply with ON/OFF function (refer to 6.1).

- 11 -

2.1

Pin configuration

Applications manual

For CHS300/400/500-I series

6. Explanation of several functions

6.1 ON/OFF operation

Three ON/OFF functions are available with the CHS300/400/500 as shown in table 6-1.

in order to control starting-up and insulating power supply by external signal.

When either setting is "OFF", power supply will be stopped.

Table 6-1 Output ON/OFF function

# ON/OFF function

1

OPERATION [01h] command ON/OFF function

2

Remote control (primary side) function

3

Remote control (secondary side) function

*1: When operating by positive logics, it is optional.

*2: When invalid setting is made by command, it will be status of "ON" compulsory.

logical setting (initial value)

Negative (invalid for change)

Negative (valid for change)

*1

*2

Note

6.2 Start-stop voltage

Power supply is started-up when the input voltage exceeds set value of VIN_ON [ 35h ] (*1)

and is stopped when falling below set value of VIN_OFF [ 36h ] .

When changing a set value with start-up voltage and stop voltage, have an equal to or more

than 2.5 V hysteresis between VIN_ON [ 35h ] and VIN_OFF [ 36h ] to avoid the operation

which repeats a start-up and a stop.

*1: Be sure to set VIN_ON [ 35h ] > VIN_OFF [ 36h ]

- 12 -

6.3 Start-up sequence

starting-up delay / rising up

Applications manual

For CHS300/400/500-I series

(

)

TON_DELAY [ 60h ] can set start-up delay time until output voltage is risen up after input

condition is met. When setting more shortly than the start-up delay-characteristics of

the power, there is not a change in the start-up delay time.

TON_RISE [ 61h ] command can set. rising up time.(only CHS400-I)

But, when setting is more shortly than the start characteristic of the power, there is not

a change in the start time. (For the details of the value setting, refer to clause 10.)

Figure 6-1 Setting for starting-up sequence (example for Vin start-up)

6.4 Output voltage setting (only CHS400/500-I)

You can set output voltage of power supply by command as shown Table 6-2.

Table 6-2 Function of output voltage setting

# Output voltage setting

VOUT_COMMAND [ 21h ]1

2 VOUT_MARGIN_HIGH [ 25h ] *1

3 VOUT_MARGIN_LOW [ 26h ]

4 VOUT_TRIM [ 22h ]

*1: Switching by OPERATION [ 01h ] command. Initial value is VOUT_COMMAND [ 21h ].

Output voltage becomes value shown in below format.

Output voltage of power supply = VOUT_TRIM [ 22h ] value of setting + or VOUT_MARGIN_HIGH [ 25h ] Value of setting

*1

*1

Please use this as slight adjustment for output voltage.

or VOUT_MARGIN_LOW [ 26h ] Value of setting

Note

VOUT_COMMAND [ 21h ] Value of setting

- 13 -

Applications manual

For CHS300/400/500-I series

6.5 Protective operation for output overvoltage

Output overvoltage protection function is operated when the output voltage becomes high.

The operation threshold and the way of the output over voltage protection function can be

changed respectively at VOUT_OV_FAULT_LIMIT [ 40h ] and

VOUT_OV_FAULT_RESPONSE [ 41h ] . In case the way of stopping latch stop,

Power Supply does not restore until restored operation is done by ON/OFF function(clause 6.1)

or re-invert after insulating input.

When the number of automatic recovery is set by 1-6 times, latch stop will be happened

without situation of abnormal power supply is recovered during re-starting up by specific

number of times.

6.6 Protective operation for output undervoltage

Output undervoltage protection function is operated when the output voltage becomes low.

The operation threshold and the way of the output under voltage protection function can be

changed respectively by VOUT_UV_FAULT_LIMIT [ 44h ] and

VOUT_UV_FAULT_RESPONSE [ 45h ]. In case the way of stopping latch stop,

Power Supply does not restore until restored operation is done by ON/OFF function(clause 6.1)

or re-invert after insulating input.

When the number of automatic recovery is set by 1-6 times, latch stop will be happened

without situation of abnormal power supply is recovered during re-starting up by specific

number of times.

- 14 -

Thermal protection

Applications manual

For CHS300/400/500-I series

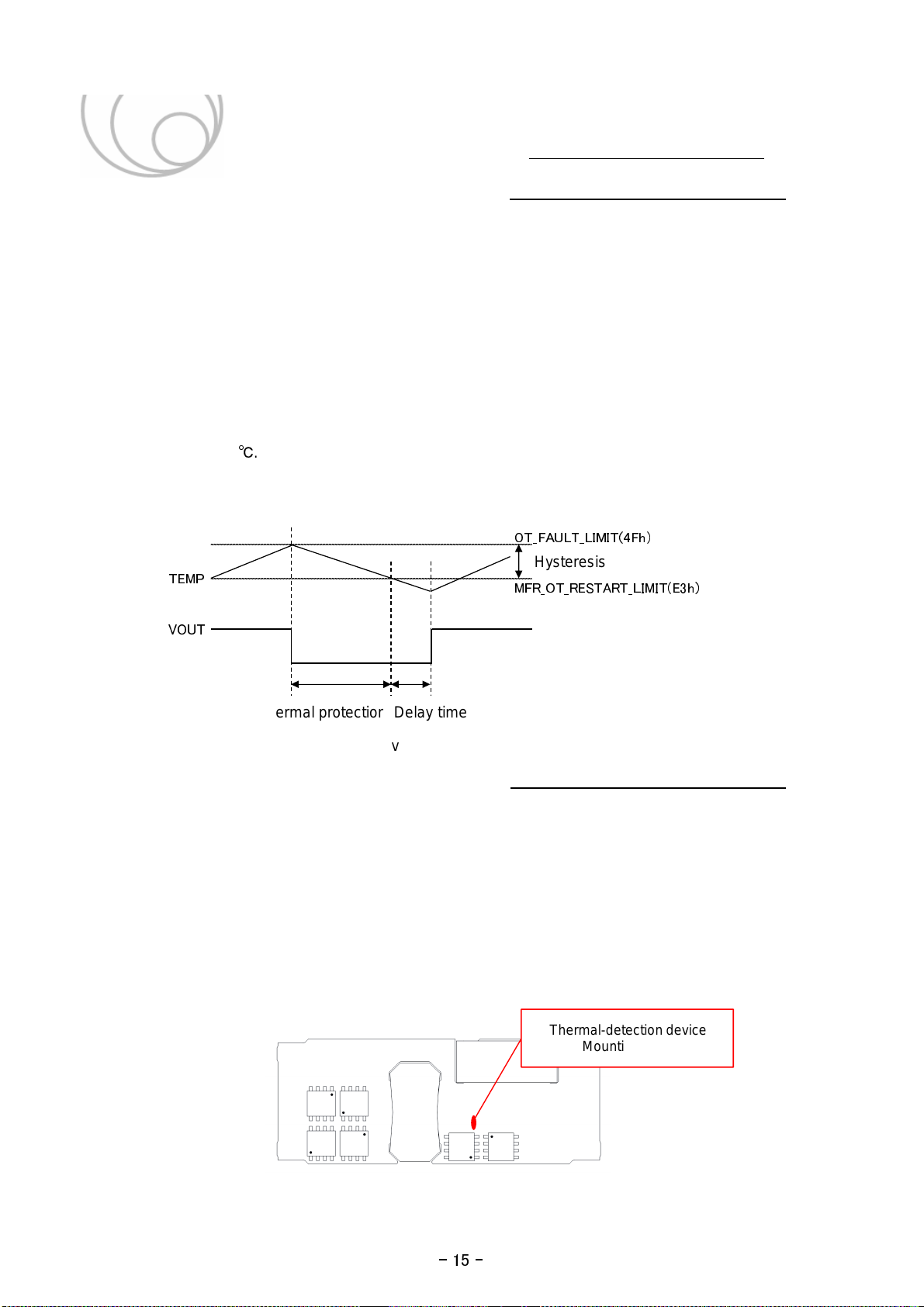

6.7 Protective operation for overtemperature

The overtemperature protection feature works when the temperature detecting-element

temperature which is shown in figure 6-3 becomes high.

In protection operation, power supply will be stopped and re-start via delaying time originally

to be set after abnormal status is cancelled.

The operation threshold and the way of stopping overheating is changed by

OT_FAULT_LIMIT [ 4Fh ] and OT_FAULT_RESPONSE[ 50h ] respectively.

The return temperature of the overheating protection is set to

MFR_OT_RESTART_LIMIT [ E3h ] and status of stopping is canceled by being below

this threshold.

Set temperature difference with operating temperature and return temperature to equal to or

more than 10℃.

In case the way of stopping latch stop, Power Supply does not restore until restored

operation is done by ON/OFF function(clause 6.1) or re-invert after insulating input.

OT_FAULT_LIMIT(4Fh)

ヒステリシス

Hysteresis

TEMP

MFR_OT_RESTART_LIMIT(E3h)

VOUT

過熱保護

遅延時間

Delay time

Figure 6-2. overtemperature protection restart

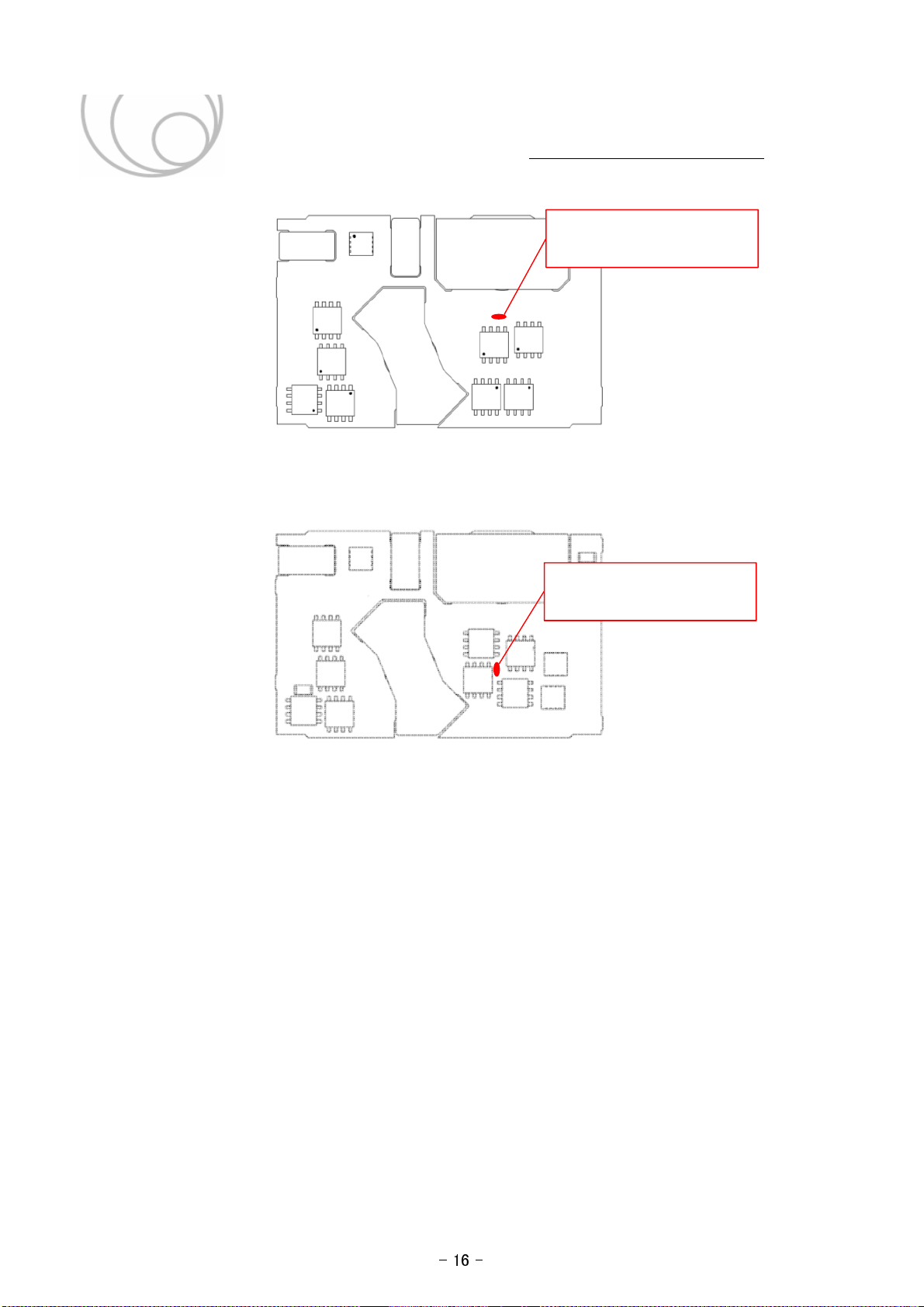

6.8 Protective operation for undertemperature

The undertemperature protection feature works when the temperature of the temperature

detecting-element which is shown in figure 6-3 becomes low.

The operation threshold and the way of stopping low temperature protection are changed

at UT_FAULT_LIMIT [ 53h ] and UT_FAULT_RESPONSE respectively.

The change of going out is possible.

When making a way of stopping a restart, the return temperature of the low temperature

protection is cancelled by exceeding the threshold which was set

in MFR_UT_RESTART_LIMIT [ E4h ] and then does a restart via the delay time which

is set at UT_FAULT_RESPONSE [ 54h ].

Thermal-detection device

Mounting point

Figure 6-3.1 Temperature measuring point for CHS300-I (top view)

- 15 -

Applications manual

For CHS300/400/500-I series

Figure 6-3.2 Temperature measuring point for CHS400-I (top view)

Thermal-detection device

Mounting point

Thermal-detection device

Mounting point

Figure 6-3.3 Temperature measuring point for CHS500-I (top view)

- 16 -

Loading...

Loading...