COSDEP STQ14, ST18, MTQ28, MTC28, STQ18 User And Maintenance Manual

...

1

USER’S AND MAINTENANCE HANDBOOK FOR

ECO-PELLET STOVES

STQ14 square covering

ST18 Round covering-STQ18 Square covering-STC18 Fantasy

MT28 Round covering-MTQ28 Square covering-MTC28 Fantasy

SERIAL NUMBER

COSDEP di Vighesso Onorio S.a.s.

Via Copernico, 25, 36034 Malo (VI) ITALY

Tel. (0039) 0445 605255 / 602414 Fax (0039) 0445 602464

Internet: www.cosdep.com e-mail: info@cosdep.com

ST-MT

STQ-MTQ

STC-MTC

2

CONTENTS

1. INTRODUCTION..………………...………………………………………………............. 3

1.1 General precautions

1.2 Compliance with standards

1.3 Rules and instructions

1.4 Declaration of conformity

2. GENERAL DESCRIPTION…………………………………..………………................ 5

2.1 Operating principle

2.2 Pellets and qualities available on the market

2.3 The pellet tank

3. INSTALLATION AND IGNITION ……………………………………………............ 6

3.1 Choosing the correct stove size

3.2 Unpacking and positioning the stove

3.3 The location of the stove and connection to a chimney

3.4 Ignition, starting up

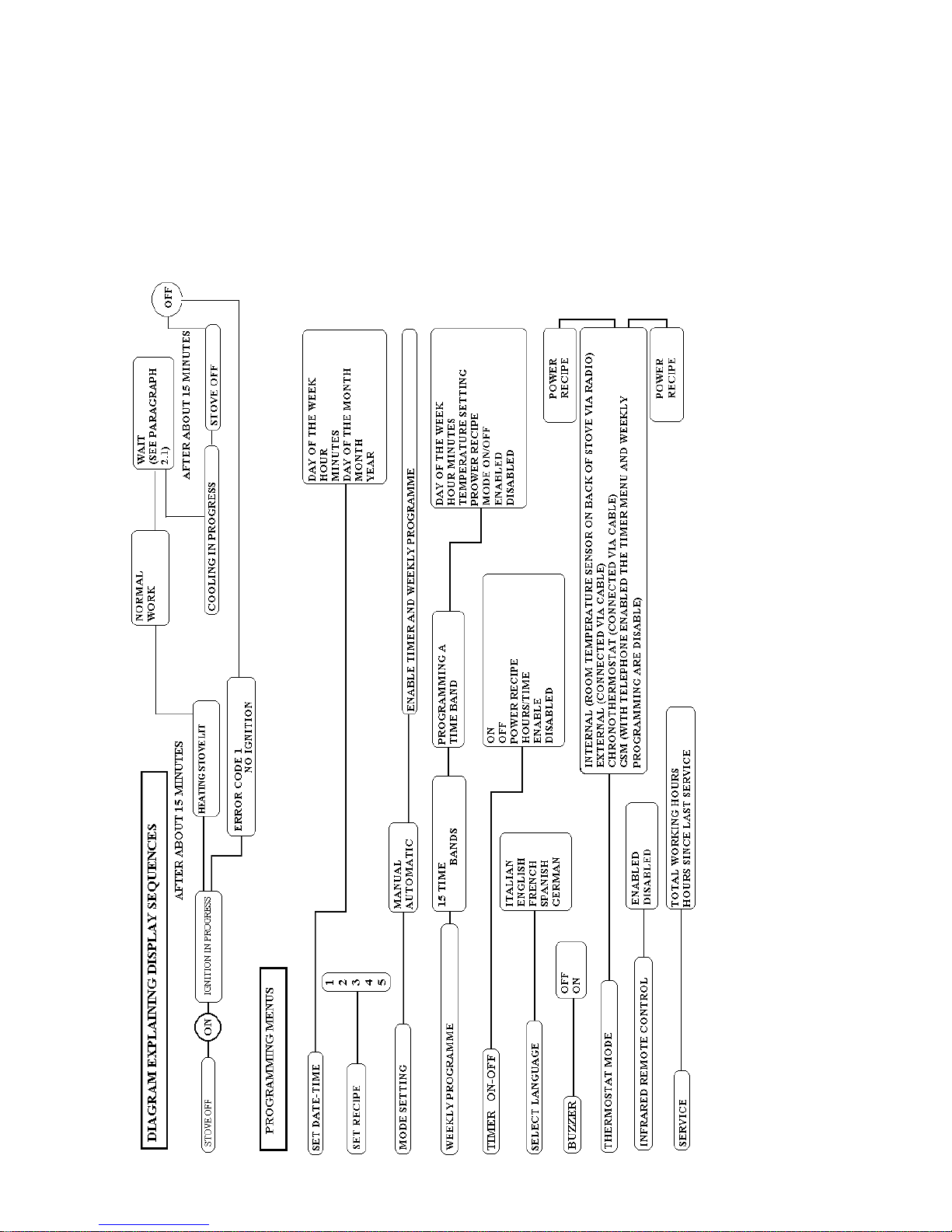

3.5 Diagram explaining display sequences

3.6 Switching off/extinguishing the stove

4. HOW TO PROGRAMME THE STOVE ……..………..……………………............ 10

4.1 Description of control panel

4.2 Selecting function menus

1. The DATE and TIME menu…………………………………………………………………………….. 11

2. The RECIPE SELECTION………………………………………………………………………….……… 12

3. The OPERATING MODE menu……………………………………………………………………….. 13

4. the WEEKLY PROGRAMME menu…………………………………………………………………… 13

5. The TIMER COUNTDOWN menu………………………………………………………………….. . 14

6. The SELECT LANGUAGE menu…………………………………………………………………….. . 15

7. The BUZZER menu………………………………………………………………………………………… 15

8. The THERMOSTAT MODE menu…………………………………………………………………… . 15

9. The IR REMOTE CONTROL (optional) menu…………………………………………………. 16

10. The ASSISTANCE menu………………………………………………………………………………. 16

11. The DEBUG menu………………………………………………………………………………………… 17

12. The SERVICE menu……………………………………………………………………………………….. 18

5. FORMULATION PARAMETERS TO THE TYPE OF PELLET..........………….. 19

6. CLEANING, MAINTENANCE AND REPAIRS....................…………………… 20

6.1 Every day

6.2 Once a week

6.3 Once a month or whenever there are ignition problems

6.4 At the end of the winter

6.5 Changing the (optional) remote control battery

6.6 Repairs

7. TECHNICAL SPECS. AND DIAGRAM SHOWING OPERATION..........…… 24

8. ELECTRICAL DIAGRAM………………………………………………………................ 26

9. GENERAL THERMOSTAT WITH MANUAL RESET.............................. 27

10. ELECTRIC BOX…………………………………………………………………............. 27

11. ERROR MESSAGES………………………………………………………….............. 28

12. DISPOSING OF THE STOVE…………………………………………….............. 28

13. GUARANTEE........................................................................... 29

3

1. INTRODUCTION

1.1 GENERAL PRECAUTIONS

This user’s and installation handbook is an

indispensable, integral part of the product;

it should be used and kept with care where

it can be read by all users.

Read all the instructions in the handbook

before starting to install the product.

The apparatus should be utilised only and

exclusively for the purposes for which it

was intended. Any other improper use is to

be considered dangerous for the user and

will invalidate the guarantee.

Do not place any object whatsoever on the

stove.

Do not use inflammable substances to

ignite the stove.

Make sure there are no inflammable

objects, furniture or household linen in the

immediate vicinity of the stove. Respect

the safety distances given in the

handbook.

Keep children away from the stove when it

is in operation.

Do not obstruct the intake and ventilation

grilles of the stove in any way whatsoever.

Installation, maintenance and any

necessary repairs should be carried out by

skilled personnel, using only and

exclusively original spare parts, otherwise

the guarantee will be invalidated.

The manufacturer declines all liability for

incorrect installation or maintenance that

may cause damage people or objects

When carrying out cleaning and

maintenance make sure that the appliance

is switched off, cool and disconnected from

the power supply.

The product should be situated on

premises with fire-fighting devices and

with adequate air change.

If the appliance is sold to third parties

make sure that the new user is provided

with this handbook.

The manufacturer has the copyright on this handbook. The instructions herein may not be

duplicated or communicated to third parties and may not be used for competitive purposes without

due authorisation.

1.2 COMPLIANCE WITH STANDARDS

The ST16 and MT24 pellet stoves comply with the following standards:

The electronics comply with electromagnetic compatibility directive 89/336/CEE and subsequent

amendments.

List of tests required for Residential, Commercial and Light Industry premises

General Standard CEI EN 50081-1

(Emissions for Residential, Commercial and Light Industry premises)

Tests for standard of reference

RADIATED electromagnetic EMISSIONS EN 55022

CONDUCTED electromagnetic EMISSIONS (30 MHz, 300 MHz) EN 55014

HARMONIC current EMISSIONS EN 61000-3-2

Voltage fluctuation and FLICKER EMISSIONS EN 61000-3-3

CONDUCTED electromagnetic EMISSIONS (150 kHz, 30 MHz) EN 55014

4

General Standard CEI EN 55104

Immunity of Household Appliances, Electric Tools and Similar Apparatus)

Tests for standard of reference

Electrostatic discharge IMMUNITY EN61000-4-2

Radiated, radio frequency electromagnetic field IMMUNITY EN 61000-4-3

Electrical fast transient/ BURST IMMUNITY EN 61000-4-4

SURGE IMMUNITY EN 61000-4-5

Conducted disturbances induced by radio frequency fields IMMUNITY EN 61000-4-6

Voltage dips, short interruptions and voltage variations IMMUNITY EN 61000- 4-1

All electrical and electronic parts comply with the new ROS standards.

1.3 RULES AND INSTRUCTIONS

RECOMMENDATIONS:

In order to use the appliance correctly it is necessary to carefully read the all instructions

contained in this handbook.

Do not use the appliance or carry out any maintenance until you have read this handbook.

Should the appliance be modified or tampered with, the user shall be deemed liable.

IMPORTANT: The appliance must be connected to a (PE) ground installation (low voltage directives

73/23 CEE, 93/98 CEE).

1.4 DECLARATION OF CONFORMITY

DECLARATION OF CONFORMITY

In accordance with Low Voltage Directive 73/23 CEE, Electromagnetic Compatibility Directive

89/336 CEE, Machinery Directive 98/37 CEE, integrated with CE mark according to Directive 93/68

CEE.

Other standards of reference: STANDARD EN 60 335-1:94 + A11:95

+A12:96+A1:96+A13:98+A14:98+A2:00+A15:00+A16:01

DEVIATION PROCEDURES: EN 50165:1997+A1:01

The company COSDEP di Vighesso Onorio sas, registered office Via Copernico No. 25, MALO, Italy

hereby declares that the products

PELLET STOVES mods. STQ14-ST18-STQ18-SCT18 and MT28-MTQ28-MTC28

have been designed and built in conformity with the aforementioned EU Directives and with the

corresponding assimilated Italian laws, in order to apply the CE mark.

Malo, 1st July 2006 COSDEP di Vighesso Onorio sas

Via Copernico,25

36034 MALO – VI- ITALY

Tel. (0039) 0445/605255 – 0445/602414

Fax (0039) 0445/602464

5

2. GENERAL DESCRIPTION

2.1 OPERATING PRINCIPLE

The STQ14-ST18-STQ18-STC18 and MT28-MTQ28-MTC28 stoves have been especially designed to

satisfy requirements for a practical heating appliance. They have a fan to circulate the heat

produced by the burning pellets and are designed for clean, extremely efficient combustion.

Nevertheless, there is a range of pellets on the market and the different qualities may affect

combustion and produce larger quantities of ash.

Besides the notice "WAIT" allows to reduce the consumption of pellet because the stove switches off

itself when the temperature environment overcomes of 2 degrees the temperature setting and

automatically the stove switches on again itself when the temperature environment goes down of 1

degree respect the setting one.

P.S. During the notice "WAIT" it is possible to switch OFF the stove pressing the OFF key

2.2 PELLETS AND QUALITIES AVAILABLE ON THE MARKET

Pellets are a by-product of wood "dust”. The resulting sawdust is pressed to form cylinders with a

diameter of 6 mm and a maximum length of 30 mm. They have a maximum moisture content of

10% and a thermal value of 4.9 kW/kg. The best pellets on the market are a blend of beech and

pine dust.

Standards DIN 51731 and ÖNORM M 7135 define pellet quality:

Length: approx. 10 - 30 mm

Diameter: approx. 6 mm

Actual weight: approx. 650 kg/m³

Thermal value: approx. 4.9 kW/Kg

Residual moisture: approx. 6 – 12%

Ash: < 1.5%

Specific weight: > 1.0 kg/dm³

It is also possible to make a visible assessment of pellet quality:

Good quality: shiny, smooth, constant length, very little dust.

Bad quality: horizontal and cross-wise cracks, a lot of dust, varying length.

A simple test for finding a good pellet is to measure its specific weight by putting a few grains into a

glassful of water:

Good quality: the pellet immediately falls to the bottom

Poor quality: the pellet floats

Using other material than that described above as fuel will have an adverse affect on stove

operation and will invalidate the guarantee.

2.3 THE PELLET TANK

The tank holding the reserve of pellets is at the top of the stove. To get at the tank it is necessary

to open the lid on the top. The maximum capacity of the tank depends on the model:

STQ14 - approx. 10 kg

ST18-STQ18-STC18 - approx. 15 kg

MT24-MTQ24-MTC28 - approx. 30 kg

6

3. INSTALLATION AND IGNITION

3.1 CHOOSING THE CORRECT STOVE SIZE

When calculating the stove size it is necessary to consider the volume of the room where it is to be

installed, the hourly requirement of calories to heat the room and the hourly consumption of pellets

(kg).

The following calculations show how to choose the correct stove size:

Volume of room = Length x Width x Height

Kcal/h required for room = 40 approx. (depending on how the building is insulated)

1 kg top quality pellet = 4.9 kW = 4214 kcal/kg

example: room measuring 8m x 5m x 2.7m = 108 m³

108 m³ x 40 Kcal/h = 4320 kcal/h total requirement for the room

Pellet consumption per hour:

STQ14 1,4 kg/h at maximum speed

ST18-STQ18-STC18 1.8 kg/h at maximum speed

MT28-MTQ28-MTC28 2.8 kg/h at maximum speed

1,4 kg/h x 4214 Kcal/kg = 5899 Kcal/h output

1.8 Kg/h x 4214 Kcal/kg = 7585 kcal/h output

2.8 kg/h x 4214 Kcal/kg = 11799 kcal/h output

For the room above, we recommend installing a ST 16 stove.

3.2 UNPACKING AND POSITIONING THE STOVE

The packed stove has already been assembled and is ready for installation. We recommend keeping

it upright when you move it, using appropriate equipment and taking special care with the glass

door. After positioning the stove in the chosen place unpack it, taking care to remove all packing,

which could harm its operation. Align the feet so that the stove is perfectly level and install the

heatproof surface underneath to protect the floor. Using the screws supplied, install the control

panel on top of the stove. To check that the white plastic spar of the sensor is straight.

When disposing of the packing, follow the regulations in the country where the stove is being

installed.

3.3 THE LOCATION OF THE STOVE AND CONNECTION TO A CHIMNEY

The stove should be connected to an 80 mm diameter exhaust flue with a 90° connection.

If the exhaust flue is connected to a chimney, the latter should be inspected and cleaned of all soot

residues and its diameter should be at least 130 mm.

The pipe connectors should be sealed by gaskets or can be sealed with high temperature silicone.

You should make sure that your chimney flue complies with current UNI standards.

7

It is very important to use only and

exclusively material that is suitable for this

type of installation therefore it must be

resistant to high temperatures.

Installation should be carried out by

specialised, skilled personnel.

If the floor under the stove is made of inflammable material, you must insert a heat-resistant

surface between the floor and the stove and comply with minimum safety distances.

MINIMUM SAFETY DISTANCES

From non-inflammable

objects:

Behind stove > 100 mm

At side of stove > 100 mm

In front of stove > 400 mm

From inflammable objects:

Behind stove > 200 mm

At side of stove > 200 mm

In front of stove > 800 mm

The exhaust flue must be installed in compliance with a number of standards:

UNI 7129/92 standards.

Among the countless assumptions, it is necessary to bear the following in mind:

use only products that are suitable for a combustive environment, that are resistant to heat and

deterioration and are made using insulating material.

The smoke exhaust flue should follow a vertical path with no interruptions.

The inside diameter of the flue should be slightly greater than that of the stove.

The chimney flue should have the following dimensions:

- height up to 5 m 600 sq. cm

- height from 5 to 7 m 400 sq. cm

- height from 7 to 9 m 300 sq. cm

- height over 9 m 250 sq. cm

Our pellet stoves are made with an exhaust flue with a diameter of 8 cm. Therefore they do not

need a particularly tall chimney flue (minimum 1.5 m).

This gain in length is possible because the smoke is driven into the flue by a fan, so that the

negative pressure created by the chimney flue is actually reproduced artificially by the stove itself.

Ventilating the premises:

For correct combustion, the room where the stove is situated should be permanently ventilated by

an air vent from the outside of the building.

Air intake:

The stove has an air intake on the back to improve combustion. The intake air should be taken from

the room where the stove is situated. If the room where the stove is situated contains other

appliances such as gas boilers, cookers etc., it is important to guarantee air change for all the

appliances.

8

3.4 IGNITION, STARTING UP

Before using the stove make sure all the moving and movable parts are positioned correctly. Also

make sure the ash box is in position; remove any labels and adhesives from the glass, otherwise

they may leave a permanent mark.

Make sure that the voltage of the appliance corresponds with that of the mains power supply.

Then connect the cable supplied with the stove to a 220 V 50Hz power outlet and turn the

switch on the back to “I”= ON (see section 8 page 18). In this position the display will show the

message “Stove OFF” with the various preset functions.

Press the ON button on the manual control panel of the stove for at least 3 seconds or on the

remote control; this will start the ignition cycle. At this point the display will show the message

Ignition No. 1 in progress; the resistance (“ign. torch”) will start to heat up to a high

temperature while pellets are deposited in the burner to start combustion.

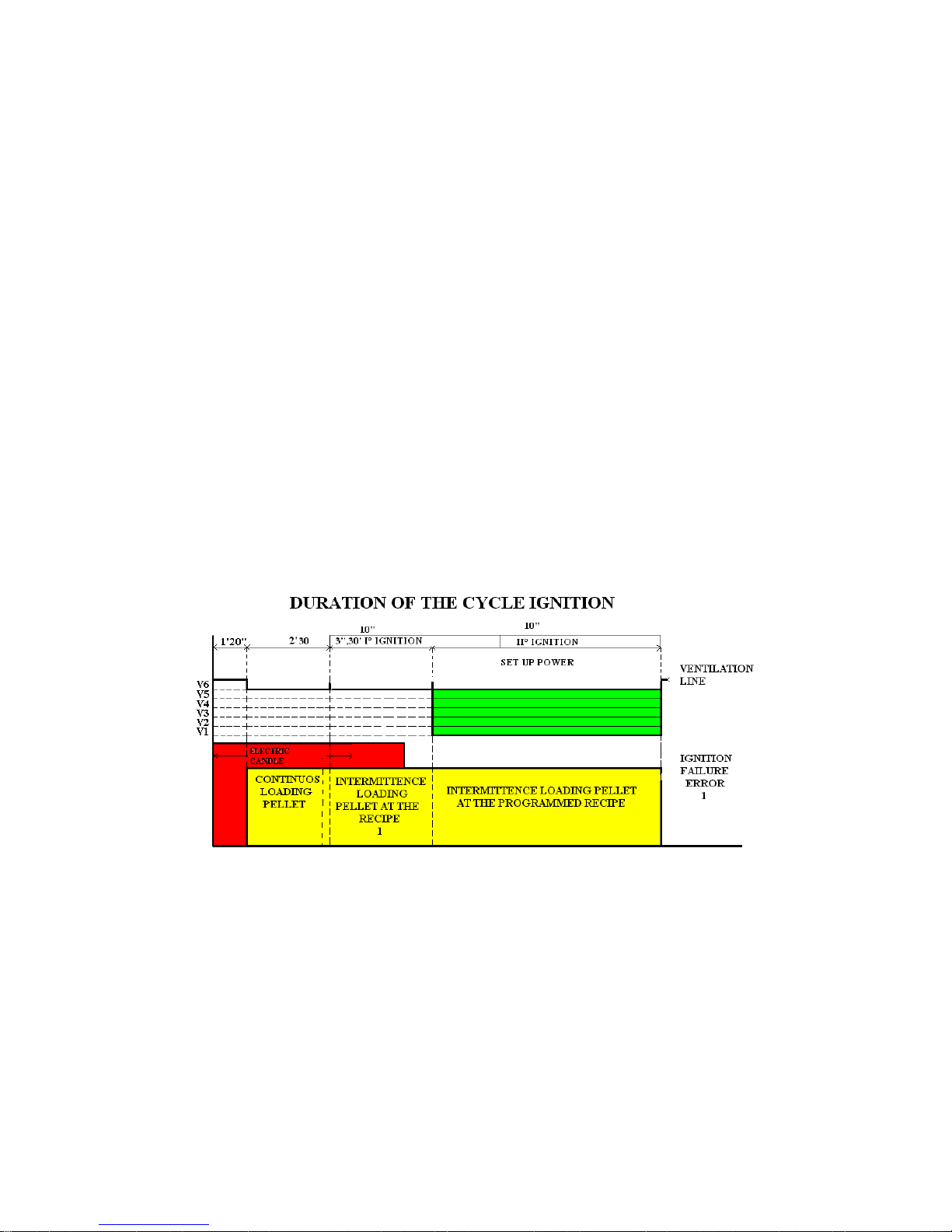

The ignition cycle can be explained as follows:

1. When ON is pressed on the control panel, the ign. torch will start to heat up as the

smoke exhaust fan starts at speed 6, for about 60 seconds.

2. The pellets begin to fall into the burner at a continuous rate for about 160 seconds.

3. The fan starts to work at 5 speed in order to reach the temperature setting for the

smoke temperature sensor.

4. At this point the ign. torch goes off and the fan smokes it works at the most (6

speed) for 3,30 minutes for to turn on the pellet.

5. The stove starts the selected recipe and power.

6. At temperatures below 3 ° C too low for the heating element to glow or temporary

non-functionality of the resistance can be used to ignite the firelighter. Insert a piece

of the crucible firelighter well lit, close the door and press ON / OFF.

IMPORTANT: the startup stage lasts 1 CYCLE of 27 minutes before signalling error 1. After this

stage the display will show the message Stove Lit, Automatic or Manual mode, Date and Time, and

it will be possible to make adjustments to the combustion. The stove is normally lit after 3 minutes.

IMPORTANT: the ROOM circulation fan will start as soon as the temperature of the exhaust smoke

will be 80°C.

If the stove is not lit within 1 cycle the message error1 will appear. The possible causes are:

No pellets

Pellets blocked

Grate obstructed by dirt

Faulty resistance (ign. torch).

9

Lighting the stove for the first time

The first time you light up the stove it will be necessary to wait about 5 minutes for the pellets in

the tank to reach the combustion chamber, because the cylinder containing the feed screw has to

be filled. So if 1 cycle is insufficient, switch off the stove and repeat the operation of lighting.

3.5 DIAGRAM EXPLAINING DISPLAY SEQUENCES

Loading...

Loading...