CORVUS H-Series, 6, 11, 20 Service Manual

THE

CORVUS

SERVICE

MANUAL

H-Series Drives

*\

CORVUSSYSTEMS

* *

DISCLAIMER OF ALL WARRANTIES & LIABILITIES

Corvus

manualorwith

chantability,orfitness for

licensed lias is:'

Systems, Inc., its distributor,orits retailer.

servicing, repair,orcorrection

Corvus

Corvus

consequential

Every

servicing of

ware

material after

errorsoromissions.

Corvus

ual at

and

This

ment

any

Corvus

Copyright© 1982

Mirror®

Logicalc,T.

Workstation,"" Tap Box,'· Passive Tap

of

Systems, Inc.

Systems, Inc.beliable for direct, indirect,

Systems, Inc.

damages,sothe

effort

has

Corvus

along

with

the

Systems, Inc.

any

time

without

maybepurchasedbywriting to:

Corvus

2029 O'Toole

San

Telephone: (408) 946-7700

TWX 910-338-0226

manual

may

electronic

Corvus

Systems, Inc.

Jose,

CA

is copyrighted

not,inwholeorin

Systems, Inc.

patent

Time

Systems, Inc.

makes

respecttothe

The

entire

has

been

madetoinsure

products.

future

date

reserves

Avenue

95131

medium

by

Corvus

pending,

Travel Editing,T. EdWord,T. Constellation,T. Corvus,T.

no

warranties,

software

any

particular

riskasto its qualityorperformanceiswith

and

any

been

advisedofthe

above

However,

products,

of publication,

notice. Revised

or

Corvus

the

righttomake

and

contains

partbecopied,

machine

Systems, Inc. All rights

The

Corvus

Box,T.

describedinthis manual, its qUality,

incidentalorconsequential

limitation

that

duetothe

nor

manuals

readable

Concept,T. Transporter,T.

FCC WARNING

This

equipment

usedinaccordance

tions. As

limits for Class A

designedtoprovide

mentina residential

expense

willberequired

generates,

temporarily

computing

uses,

with

the

permitted

reasonable

area

is likely to

to take

and

can

instruction

by

regulationithas

devices

pursuanttoSubpart

protection

whatever

cause

either

purpose.

The

this

Systems, Inc.

can

expressedorimplied,

Corvus

buyer

assumes

incidentalorconsequential

possibility of

may

not

manual

accurately

ongoing

cannot

Corvus

NOTICE

changesinthe

and

update

proprietary

photocopied,

Active

radiate

manual,

against

measures

information. All rights reserved. This docu-

form

without

reserved.

Junction

radio

frequency

may

cause

not

such

interferenceinwhich

mayberequired

Systems, Inc.

the

the

entire

damages. Innoevent

such

damages.

applytoyou.

documents

modification

guarantee

Systems, Inc.

product

sheets

willbepublishedasneeded

reproduced,

prior

consent,inwriting,

Corvus

Corvus

Box,T.

Omninet

energy

interferencetoradio

been

tested

J of

Part15of

interference.

case

to correct the interference.

with

respect

performance,

softwareissold

buyer

and

not

Corvus

cost of all

damages,

Some

the

and

updateofthe

the

accuracy of

accept

for

Operation

responsibility

describedinthis

translatedorreduced

OMNINET,T.

Systems,T.

Unif·

andifnot

compliance

FCC

Rules,

the

necessary

statesdonot

operation

printed

Corvus

Personal

are

trademarks

installed

communica-

with

which

of this

userathis

to this

mer-

will

even

and

soft-

for

man-

from

and

the

are

equip-

own

or

if

to

CORVUS DEALER SERVICE

CORVUS SYSTEMS

H-SERIES 5.25-INCH

WINCHESTER DISK DRIVE

SERVICE MANUAL

MODEL

This

document

NOTE,

simplifyaprocedure.

data

or

avoid

PART NO. 7100-04704

PUBLICATION NO. GEN/10.3-01/l.1

PUBLICATION DATE APRIL

CAUTION,

exists,

injury

these.

to

and

the

contains

care

service

three

typesofnotations.

and

WARNING.

The

CAUTION

shouldbetakentoavoid

technician

I,

1983

COVERING

6, MODEL 11, MODEL

The

NOTE

indicates

or

operator

These

indicates

that

this.

exists,

are,inincreasing

some

potential

The

WARNING

and

20

actiontobe

damagetothe

indicates

extreme

care

orderofimportance,

takentospeed

equipmentoruser

that

potential

should

be

harm

taken

or

to

CORVUS DEALER SERVICE

TABLE

OF

CONTENTS

CORVUS

DEALER

SERVICE

ListofFigures

of

List

Assembly

Specifications

CHAPTER

1.1 Scope

1.2

1.3

1.4

1.5

1.6

CHAPTER

2.1 Scope

2.2

2.3

2.4

2.5

1 -

Introduction

PurposeofEquipment.

Model

Corvus

1.5.1

1.5.2

Winchester

2 - INSTALLATION

Introduction

Receiving a

2.3.1

Environmental

Daisy-ChainingofDisk

TABLE

and

Tables v

and

Schematic

Drawings.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...vi

OF

CONTENTS

...'.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

GENERAL

of

Chapter

DESCRIPTION

' . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Identification.

Disk

System

Power

Data

Disk

of

Chapter

Drive.

Diagnostic

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Supply.

Backup.

Drive.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .... . . . . . . . . . . . . .

Test.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Considerations

Drives

..

vii

..

1

1

..

1

..

1

2

..

2

..

2

..

2

..

3

3

..

3

..

3

5

5

CHAPTER

3.1 Scope

3.2

3.3

3.4

3.5

3.6

CHAPTER

4.1 Scope

4.2

4.3

4.4

4.5

4.6

4.7

3 - OPERATION

Introduction

Controls.

3.3.1

3.3.2

Power-On

Environn1ental

3.5.1

3.5.2

3.5.3

Periodic

3.6.1

4 -

Introduction

Drive

4.3.1

4.3.2

General

Disk Sealed

Controller

Data

of

Chapter.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Front

Bezel

LEOs.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Front

Bezel

Switches.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Sequence

Requirements

Static Electricity 8

Line Noise 9

Temperature

Maintenance

DRIVE

of

Chapter

Regular

Checks

DESCRIPTION

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .... . . . . . . . . . . . . . . . . . . . . . . . . . . .

Layout

Power

dc

Supply

Power

Cables

Description

Mechanism

Firmware

Storage

..

7

7

..

7

..

7

..

7

8

8

9

9

9

..

10

10

10

,

10

11

11

12

12

12

CORVUS

DEALER

SERVICE

4.8

4.9

CHAPTER

5.1

5.2

5.3 Plastic Package "

Transportation

TheoryofOperation

4.9.1

4.9.2

4.9.3 Backplane

4.9.4 Paddleboard

4.9.5

4.9.6 Read/Write

4.9.7

5 -

DISASSEMBLY

ScopeofChapter

Introduction

5.2.1 Tools Required

5.3.1 Top

5.3.2

5.3.3 Backplane

5.3.4

5.3.5 Read/Write

5.3.6

5.3.7

5.3.8

Considerations

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...14

Power-

Controller

4.9.2.1

4.9.2.2

Interface

Motor

Controller

Drive

Motor

Power

Front

Up 14

PCA

Controller

Controller

PCA

PCA

PCA

Control

......................................................•....................

Cover

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...20

PCA

Cover

Mechanism

PCA

Control

Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .... . . . . . . ...24

Bezel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...24

PCA

PCA

PCA

During

During

".. . . ...16

Seek 16

Read

and

Write 16

14

18

18

18

19

19

20

20

"20

20

20

21

21

21

21

CHAPTER

6.1 ScopeofChapter

6.2

6.3

6.4

6.5 Index

CHAPTER

7.1

7.2

7.3

6 - ADJUSTMENTS AND MAINTENANCE

Introduction

Power

6.3.1 Voltage

6.3.2 Voltage

Motor

ScopeofChapter

Introduction

Drive

7.3.1

7.3.2 EXR 31

7.3.3

7.3.4

7.3.5

7.3.6

7.3.7

7.3.8 PARK

7.3.9

Supply Voltage

Brake

Adjustment

Sensor

7 -

Diagnostics RevB

Adjustment

DEALER

CRC

UPD

VSN

FMT

PRM

7.3.6.1 MUX 32

7.3.6.2 DRIVE

SET

QUIT

Check

Check

Adjustment

(CP510)

SERVICE

25

".

. . . . .... . . . . . . . . . . . . . . . . . . . . . ...25

and

Adjustment

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...26

25

25

25

28

DIAGNOSTICS

30

30

30

30

31

" 31

32

32

33

33

33

33

ii

CORVUS

DEALER SERVICE

7.4

7.5

7.6

7.7

Controller

7.4.1

7.4.2

7.4.3

Burn-In

7.5.1

7.5.2 L)IST

7.5.3 R)ESTART

7.5.4

Read

Track

7.7.1

7.7.2 L)IST

7.7.3 R)ESTART

7.7.4

Diagnostic

General

Description

Controller

7.4.2.1 A)

7.4.2.2

7.4.2.3 C)

7.4.2.4 D)

7.4.2.5 I) Analyze

7.

4.2.6

7.4.2.7

7.4.2.8

7.4.2.9

7.4.2.10

7.4.2.11 T) Single

7.4.2.12

7.4.2.13

Error

Codes

Program

C)ONT

Q)UIT

Burn-In

Results

Diagnostic

C)ONT

Q)UIT

Diagnostic

Abort

B)

Macro

Change

Download

J)

SingleDoSeek

L)

Full

P)

Print

Q)

Sector

S)

Read Scan

X)

Write Scan

Y)

Rezero

Commands

Diagnostic

Menu

Slot

Servo

Cylinder

Quiet

Quiet

Disk

Cylinder

Heads

Number

Diagnostic

Loopseek

Summary

Program

Seek

Disk

Report

Scan

34

34

34

34

35

35

"

35

36

"

36

36

"

36

"

36

"

37

37

37

37

38

"

38

38

38

38

39

39

39

39

39

40

40

CHAPTER 8 -

8.1 Scope

8.2

8.3

8.4

8.5

Introduction

Tools 41

Error

8.4.1

Troubleshooting

8.5.1

8.5.2

8.5.3

8.5.4

FAULT

of

Chapter

Codes

Interpreting

On-Site

Isolate

Drive

8.5.3.1

8.5.3.2

8.5.3.3

8.5.3.4

8.5.3.5

Link

8.5.4.1

8.5.4.2

8.5.4.3

8.5.4.4

8.5.4.5

8.5.4.6

ISOLATION PROCEDURES

Error

Codes

Procedures

Checks

the

Problem

Not

Ready " "

Interface

Controller

Power

Drive

Drive

Inoperative

Check

Power

CRC

Controller

Servo

Controller

Firmware

Supply

Voltages "

Electronics

Sealed

Mechanism

Link Action ,

Supply

Test

Communication

Action

Firmware

, "

"

,

iii

41

41

" 41

41

45

45

"

45

46

46

46

46

46

47

47

47

47

47

48

48

48

CORVUS DEALER SERVICE

8.6

8.7

8.8

Final

8.6.1

8.b.:? Install

8.6.3

8.6.4

8.6.5

Trouble

Common

Appendix A

Appendix

Appendix

Adjustments

B

C

8.5.4.6

8.5.4.7

8.5.4.8

CRC

CRC

Power

Burn-In

Shooting

Symptoms

Glossary

H-Series

Internal

and

Test

and

Test

Test

Supply

Test

Flowchart

and

Parts

Cabling

Boot

ROM

Interface

Drive

Components

Initialization

Tests

Mirror

Recommended

List

Chart

Solutions

48

48

48

49

~

~

49

49

49

49

49

50

51

56

58

59

iv

CORVUS DEALER SERVICE

LIST

OF

FIGURES

AND

TABLES

CORVUS DEALER SERVICE

Figure 1

Figure 2

Figure

Figure

Figure

Figure

Figure

Figure 8

Figure 9

Figure

Figure

Figure

Figure

Figure

Figure

Table 1

Table 2

Table 3

H-series

Mirror

3

4

5

6

7

10

11

12

13

14

15

Rear

Controller

Front

Data

Drive

Sector

Drive

Stepper

Read/Write

Motor

CPSI0

Bra.ke

Index

Decimal disk

Hexidecimal disk

Signed

LIST

OF

FIGURES

AND

TABLES

Illustrations

drive 1

switches.

bezel.

bezel.

configuration

mechanism

interleaving

mechanism

motor

Control

power

mechanism

sensor

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

address

PCA

switches

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

components

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...14

block

diagram

assembly

removal

PCA

removal

supply

adjustment

adjustment

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...29

Tables

error

codes

error

codes.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...43

decimal disk

error

codes

..

4

..

5

6

..

8

11

13

15

17

22

23

26

27

42

44

v

CORVUS

DEALER SERVICE

LIST OF ASSEMBLY

AND

SCHEMATIC DRAWINGS

CORVUS DEALER SERVICE

LIST

Final Assembly,

Base Assembly,

Cover

Assembly,

Backplane Assembly,

CP5IO

CP

CP5IO

CP5IO

Controller

Controller

Controller

Controller

Controller

Controller

Controller

Motor

Motor

Motor

Motor

Motor

Motor

Read/Write PCA,

Read/Write PCA, PIN 263-0238I-xxx Schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...(2of3)

Read/Write PCA, PIN 263-0238I-xxx Schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

'Read/Write PCA, PIN 263-0238I-xxx

Read/Write PCA, PIN 263-02I57-xxx

Read/Write PCA,

Read/Write PCA, PIN 263-02I57-xxx Schematic

Read/Write PCA,

510

Power

Power

Power

Power

Control

Control

Control

Control

Control

Control

H-Drive

H-IJrive.

H-Drive

Supply

Supply Schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Supply

Supply

PCA, PIN 263-02323-xxx Schematic

PCA, PIN 263-02323-xxx Schematic

PCA, PIN 263-02323-xxx Schematic (3of6)

PCA, PIN 263-02323-xxx Schematic

PCA, PIN 263-02323-xxx Schematic

PCA, PIN 263-02323-xxx Schematic

PCA,

PIN

PCA, PIN 263-024IO-xxx

PCA, PIN 263-024IO-xxx

PCA, PIN 263-024IO-xxx Assembly 77

PCA, PIN 263-0I908-xxx

PCA,

PCA, PIN 263-0I908-xxx

PIN

PIN

PIN

OF

ASSEMBLY

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

H-Drive

Assembly.

Parts

Parts

263-02323-xxx

PIN

263-0238I-xxx Schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...(1of3)

263-02I57-xxx Schematic

263-02I57-xxx

. 63

List

List (2of2)

Assembly.

Schematic.

Schematic.

Schematic.

263-0I908-xxx

Schematic.

Assembly.

Assembly.

Schematic.

Assembly.

AND

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...74

. .

. .... . .... . . ....

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...88

SCHEMATIC

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...(1of2)

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .... . . ...(2of2)

. .... . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .... . . ...(1of2)

. . . .... . . . . .... .... . .... . . . . . . . . . . . . . . . . . ...(2of2)

. . . .... . . . . . . . . . .... . . . . . . . . . . . . . . . . .... . . . . . . . . .

.......

. . . .

....

. . . . . . . . . .... . . . . . . . . . . . . .... . . . . . ...84

DRAWINGS

......

. . .... . . . .....

. . .

....

..

(1of2)

(1of6)

(2of6)

(4of6)

(5of6)

(6of6)

(3of3)

(1of3)

(2of3)

(3of3)

60

..

61

62

64

..

65

66

67

68

69

70

71

72

73

75

76

78

79

..

80

81

82

83

85

86

87

vi

CORVUS DEALER SERVICE

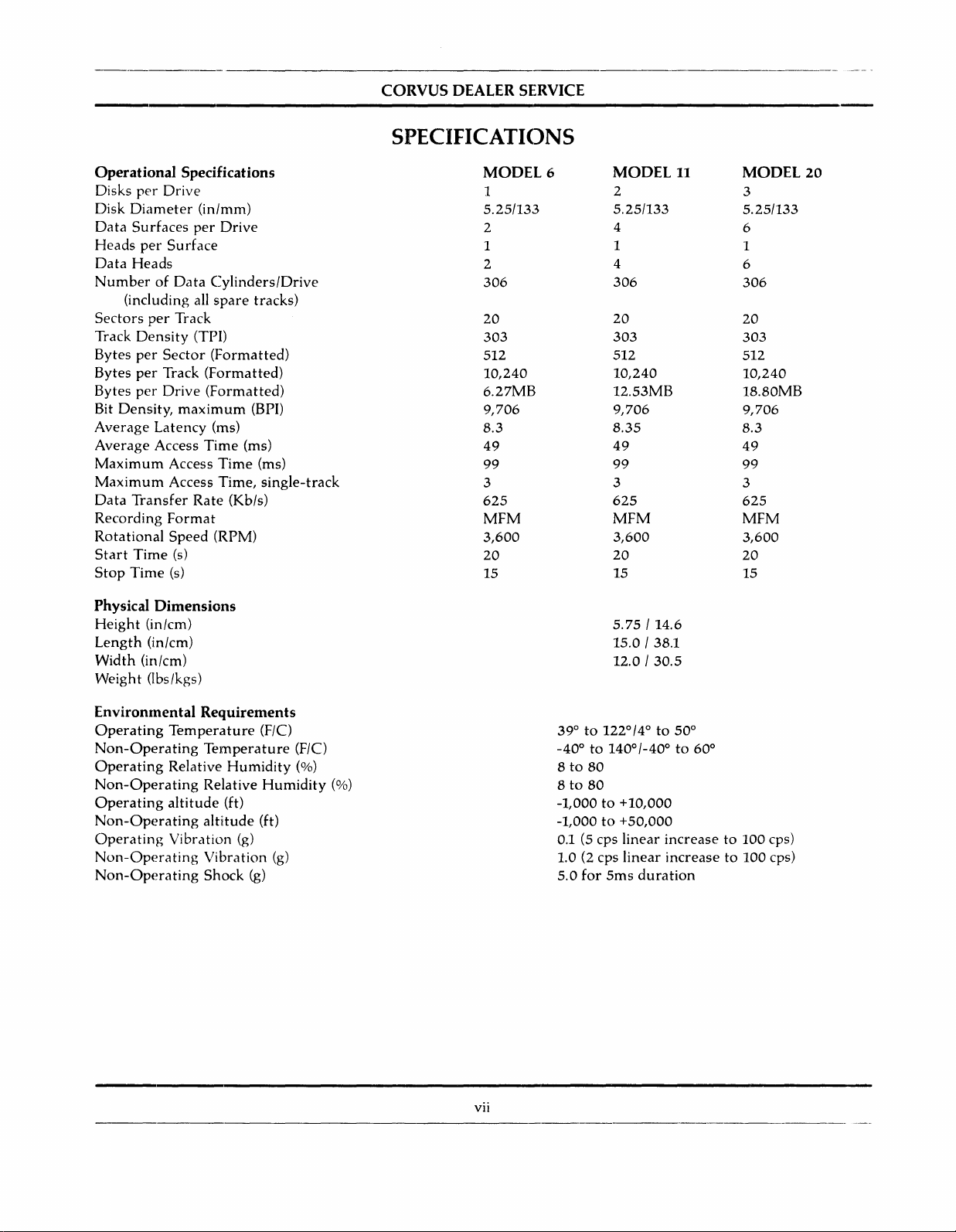

SPECIFICATIONS

CORVUS DEALER SERVICE

SPECIFICATIONS

Operational Specifications

Disks

per

Drive

Disk

Diameter

Data

Surfaces

Heads

per

Data

Heads

NumberofData

(including all

Sectors

Track

Bytes

Bytes

Bytes

Bit

per

Density

per

per

per

Density,

Average

Average

Maximum

Maximum

Data

Transfer

Recording

Rota

tional

Start

Time

Stop

Time

Physical

Height

Length

Width

Weight

(in/cm)

(in/cm)

(in/cm)

Obs/kgs)

(in/mm)

per

Drive

Surface

Cylinders/Drive

spare

Track

(TPI)

Sector

Track

Drive

(Formatted)

(Formatted)

(Formatted)

maximum

Latency

Access

Access

Access

(ms)

Time

Time

Time,

Rate

Format

Speed

(RPM)

(s)

(s)

Dimensions

tracks)

(BPI)

(ms)

(ms)

(Kb/s)

single-track

MODEL

1

5.25/133

2

1

2

306

20

303

512

10,240

6.27MB

9,706

8.3

49

99

3

625

MFM

3,600

20

15

6

MODEL

2

5.25/133

4

1

4

306

20

303

512

10,240

12.53MB

9,706

8.35

49

99

3

625

MFM

3,600

20

15

5.75

15.0/38.1

12.0/30.5

/14.6

11

MODEL

3

5.25/133

6

1

6

306

20

303

512

10,240

18.80MB

9,706

8.3

49

99

3

625

MFM

3,600

20

15

20

Environmental Requirements

Operating

Non-Operating

Operating

Non-Operating

Operating

Non-Operating

Operating

Non-Operating

Non-Operating

Temperature

Temperature

Relative

Humidity

Relative

altitude

(ft)

altitude

Vibration

Vibration

Shock

(F/C)

Humidity

(ft)

(g)

(g)

(g)

(F/C)

(%)

(%)

vii

1220/4

14001-40

0

to

390to

-400to

8to80

8to80

-1,000to+10,000

to

for

+50,000

linear

linear

5ms

duration

-1,000

0.1 (5 cps

1.0 (2 cps

5.0

0

50

0

0

to

60

increaseto100

increaseto100

cps)

cps)

Power Requirements

Line Voltage,

Line Voltage, Foreign (VAC)

Power

Fuse

Line

for

for

Domestic

Consumption

(Amperes)

100V-120V

220V-240V

(VAC)

(Watts)

Reliability

Mean

Time

Maximum

Between

Repair

Failures (MTBF)

Time

CORVUS

DEALER

SERVICE

100-120,

220-240,

125

2.0

1.0

10,000+

requirements

Not

48Hz-62Hz,

48Hz-62Hz,

slow-blow

slow-blow

operational

more

than

0.5

hrs.,

hrs.

Single-Phase

Single-Phase

within

above

viii

CORVUS

DEALER SERVICE

CHAPTER

GENERAL

1

DESCRIPTION

CORVUS

DEALER SERVICE

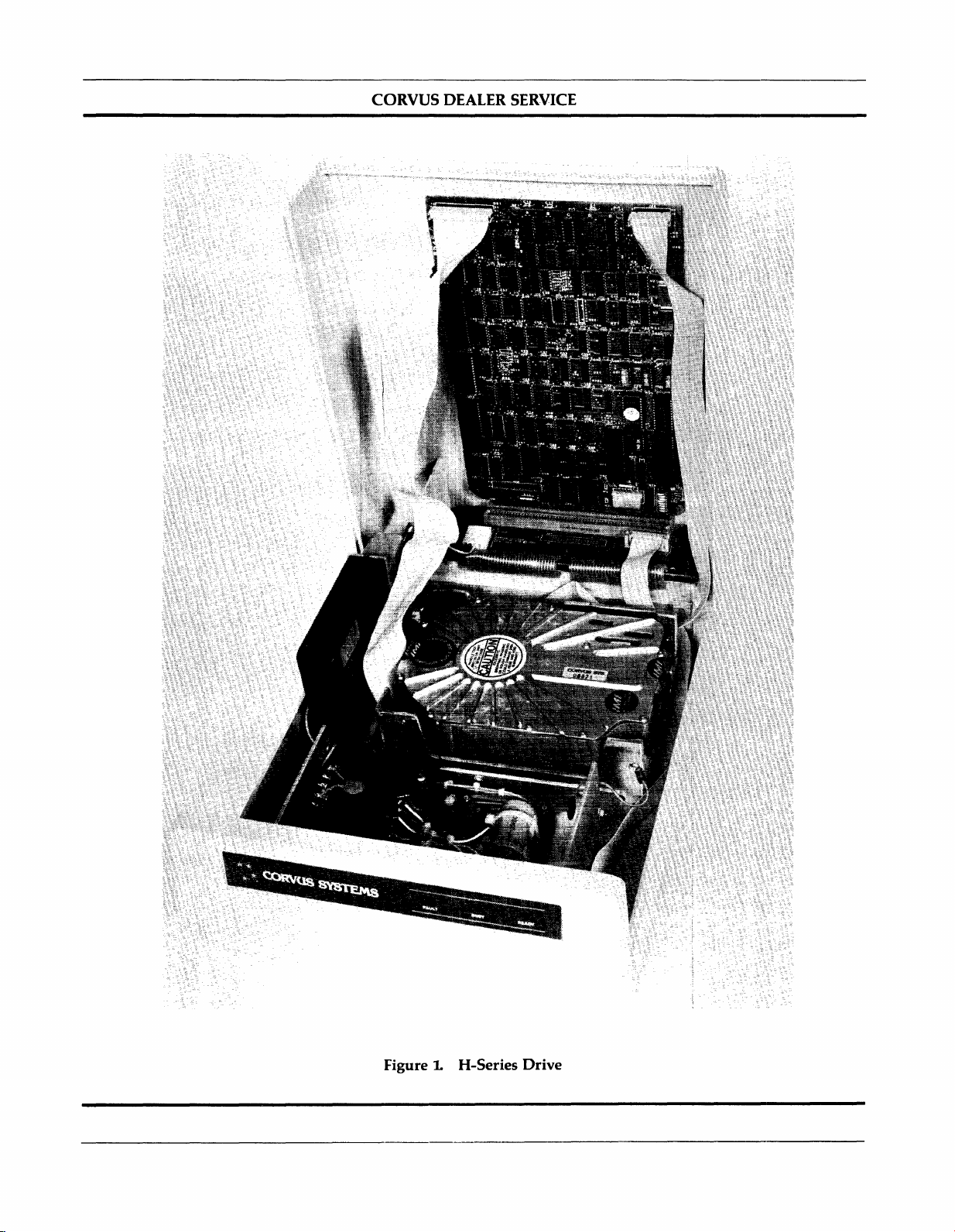

FigureLH-Series

Drive

CORVUS DEALER SERVICE

General

Description

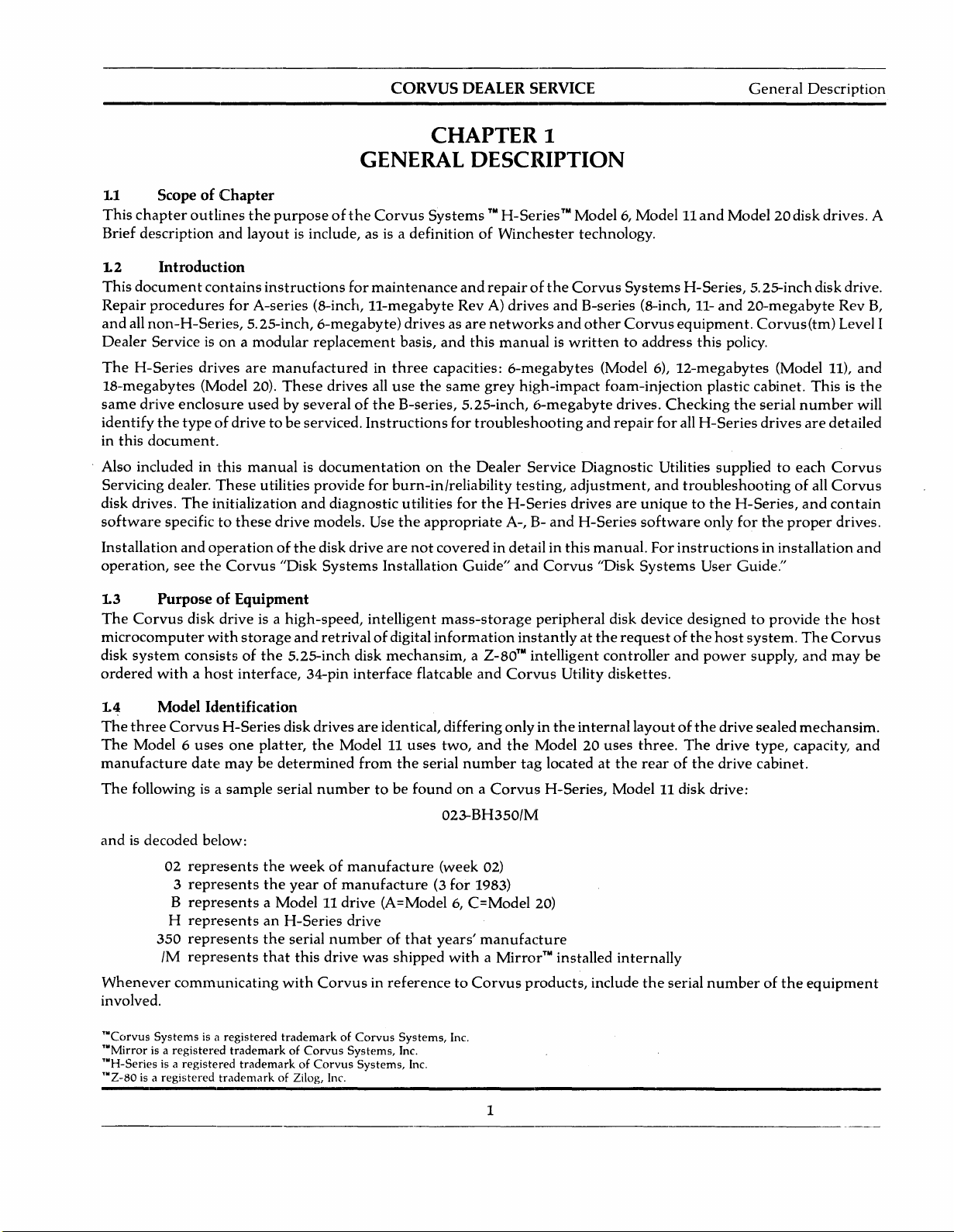

1.1

This

ScopeofChapter

chapter

outlines

Brief description

1..2

This

Repair

and

Dealer

The

Introduction

document

procedures

all

non-H-Series,

Serviceisonamodular

H-Series

drives

18-megabytes

same

drive

enclosure

identify

in this

the

typeofdrivetobe serviced.

document.

Also included in

Servicing dealer.

disk drives.

software

Installation

operation,

The

specifictothese

and

see

the

the

purposeofthe

and

layout

contains

for

A-series

instructions

5.25-inch,

are

manufacturedinthree

(Model 20).

These

usedbyseveralofthe

this

manualisdocumentation

These

utilities

initialization

drive

operationofthe

Corvus

"Disk

CHAPTER

GENERAL

Corvus

Systems™H-Series™Model6,Modellland

DESCRIPTION

1

is include, as is a definitionofWinchester

for

(8-indl,

6-megabyte)

replacement

drives all

provide

and

diagnostic

models. Use

disk

drive

Systems

maintenance

II-megabyte

drives as

basis,

use

B-series, 5.25-inch,

Instructions

for

burn-in/reliability

utilities

the

are

not

Installation

and

Rev A)

are

and

this

capacities:

the

same

for

troubleshooting

on

the

Dealer

for

appropriate

covered

Guide"

repairofthe

drives

and

networks

and

manualiswrittentoaddress

6-megabytes

grey

high-impact

6-megabyte

Service

testing,

the

H-Series

A-, B-

and

in detailin

and

Corvus

technology.

Corvus

Systems

H-Series,5.25-inchdisk drive.

B-series (8-inch, 11-

other

Corvus

equipment.

this

(Model 6),

12-megabytes

foam-injection plastic cabinet.

drives.

and

repair

Diagnostic

adjustment,

drives

are

H-Series

this

manual.

"Disk

Checking

for

all

H-Series

Utilities suppliedtoeach

and

troubleshootingofall

uniquetothe

software

For

Systems

only

instructionsininstallation

User Guide."

Model20disk

and

20-megabyte

Corvus

policy.

(Model

the

serial

drives

H-Series,

for

the

drives. A

(tm) Level I

Thisisthe

number

are

and

proper

Rev

B,

II),

and

will

detailed

Corvus

Corvus

contain

drives.

and

1..3

The

microcomputer

disk

ordered

1.4 Model Identification

The

The

manufacture

The

PurposeofEquipment

Corvus

system

three

Model 6

following is a

disk

drive

with

consistsofthe

withahost

Corvus

uses

date

storage

interface, 34-pin

H-Series

one

maybedetermined

sample

is a

platter,

serial

andisdecoded below:

350

Whenever

represents

02

represents

3

represents

B

H

representsanH-Series

represents

/M

represents

communicating

the

the

a Model 11 drive (A=Model6,C=Model

the

that

with

involved.

"'Corvus

"'Mirrorisa

™H-Series

TI'Z-80

Systemsisa

registered

isaregistered

isaregistered

registered

trademarkofCorvus

trademarkofZilog, Inc.

trademarkofCorvus

trademarkofCorvus

high-speed,

and

ret

5.25-inch disk

disk drives

the

numbertobe

intelligent

rivalofdigital

mechansim,aZ_80™

interface

are

Model 11

from

flatcable

identical, differing

uses

the

serial

foundona

mass-storage

information

two,

023-BH350/M

weekofmanufacture

(week 02)

yearofmanufacture(3for

drive

serial

numberofthat

this

drive

was

years'

shipped

CorvusinreferencetoCorvus

Systems,

Systems,

Inc.

Inc.

Systems,

instantlyatthe

intelligent

and

Corvus

onlyinthe

and

the

Model20uses

number

tag

Corvus

1983)

manufacture

withaMirror™

products,

Inc.

peripheral

disk device

requestofthe

controller

designedtoprovide

host

and

power

Utility diskettes.

internal

locatedatthe

layoutofthe

three.

The

rearofthe

drive type, capacity,

H-Series, Model 11 disk drive:

20)

installed

internally

include

the

serial

numberofthe

system.

supply,

drivesealed

drive cabinet.

the

host

The

Corvus

and

may

be

mechansim.

and

equipment

1

General

Description

CORVUS DEALER SERVICE

1.5 The Corvus

The

Corvus

International

minimal

procedures

appropriate

All

H-Series

single

The

Mirror

software

power

Mass-Storage

Memories,

are

computer

drives

supply,

PCA

backplane, located inside

1.5.1 Power Supply

All

H-Series

single

1.5.2 Data Backup

Data

backupisaccomplished via

format

comes

drives

power

supply.

whichisthen

internaltothe

software-controlled,

repairiscoveredinthe

1.

6 Winchester disk drive

The

Corvus

disk

environment,

surface

and

closely

storage

regular

after

power-down.

recording

media.

relatedtohead-media

capacitiesata

maintenance.

Disk

Inc (lMI).

setup.

coveredinthe

system.

consistofa 5.25-inch

Z-80

(when

installed)

the

operate

These

storedonvideo

drive

remote-control

Corvus

drive

uses

and

low-load,

This

premiumofspace.Anadded

System

Disk

System

utilizes a sealed 5.25-inch

The

drive,

Interfacingtohost

corresponding

drive

Controller

top

from

power

and

cover.

either

supplies

the

PCA,

Z-80

110-120YACor220-240YAC,

Corvus

cassette

when

it is

ordered,oraddedasan

interfacetoa Panasonic™

Mirror

the

IMI

low-mass,

It is

the

resultsinthe

clearance

Service

Winchester

aerodynamically-suspended

contaminant-free

heads

and

with

its

computers

"Disk

System

mechansim

and

cooling

intelligent

are

interchangable

Mirror™.

tape,

using

Manual.

disk

environment

ridingonan

head

mass,

advantageofthe

Winchester

intelligent

controller,isdesigned

is via 34-pin flat-cable

Installation

(with

integral

fan

mounted

Controller

PCA

between

The

Mirror

converts

oneofmany

external

YCR

mechansim.

This

read-write

that

18-micro-inch

disk

drives

utilizing

Winchester

Guide"

and

Read/Write

in a

grey

plastic cabinet.

are

plugged

50Hzor60Hz

all

H-Series

the

commercial

device later. All

model

NY-8200.

new

generationofdisk

heads

allows

for

reduction

air

bearing,orair

Winchester

sealed

disk

mechansim

as a

interface.

"Disk

System

PCA)

into

single-phase

plug-in

and

the

manufactured

device,

Installation

User

Guide"

Motor

two

Control

card

power,

drives.

data

from

digital

formattovideo

YCRs.

The

Mirrors

Mirror

which

rest

in clearance

cushion.

technology

Corvus

are

Mirror

available

troubleshooting

drive

utilizes a sealed

directlyonthe

between

Sincebit

can

achieve

mechansimisthatitrequires

by

requiring

and

setup

for

the

PCA,

slotsofthe

and

use

option

with

and

disk

head

density

large

no

a

a

is

™Panasonic is a

registered

trademarkofPanasonic,

Inc.

2

CORVUS

DEALER SERVICE

CHAPTER 2

INSTALLATION

CORVUS DEALER SERVICE

CHAPTER 2

INSTALLATION

Installation

2.1 Scope of

This

chapter

proper

Systems

2.2

operation.

Installation

Introduction

Each drive,

contains

2.3 Receiving a Drive

Any

Corvus

these

timeadrive

disk

Chapter

discusses

Installation

Guide"

whenitis

check-out

drive

received,

is received,

shouldbecarefully

installationofthe

and

operation

and

"Corvus

shouldbechecked

procedures

several

as well as

checks

unpacked

maybesymptomaticofdamagetofragile

Any

damage

claims

mustbereportedtothe

Also, if

the

damaged

procedures.Ifthe

Merchandise

The

disk drive

force

This

(one

necessitates

mechanisminthe

gravity)

very

Whenadriveisreceived,

loose

during

1)

Remove

careful

2)

Locate

3) Locate

securely

4)

Replace

5)

Replace drive

shipping

the

two

nottostress

the

Mirror

the

Controller

into

their

Mirror

cover

equipmentisa

damaged

Authorization

equipmentisa

number),

Corvus

willbeamplified

careful

account

screws

handlingofthe

check

that

forapercentageofthe

securing

thedcpower

PCA

(if installed)

PCA

installed

sockets.

PCA.

and

secure

new

and

all chipsinthe

the

cable

with

disk

drive

hardware

procedures

Disk

Systems

for

shipping

those

for

shouldbeperformed

and

checked

mechanisms

within

NOTE:

local

officeofthe

product,

contact

disk

transmittedtothe

plugged

behind

screws.

Corvus

recently

Corvus

systemisan

drive

cabinet

and

flatcables

into

the

Order

serviced

Customer

mechanism

2-80

Controller

failures

covertothe

the

Mirror

as it appliestoenvironmental

for

the

User

Corvus

Guide."

damage,

disk

and

system

tested

installing single drives

before

the

driveisinstalledatthe

for

shipping

the

shippersoan

Processing

product

Service

extremely

heads,

damage.

drive.

inspection

Department

being

returned

Department

sensitive

impacting

maybemade,

them

bothinshipping

PCA

are

seated

upon

reciept.

drive

basepanatthe

connectingtothe

lowerofthe

PCA,

and

two

press

Controller

card

firmlyonall

are

outlinedinthe

for

proper

and

multiple-drive

External

andadamage

mustbecontacted

underanRMA

for

proper

return

device.

onto

and

Subjecting

the

operation.

well in

rear,

PCA

slotsofthe

socketed

requirements,toinsure

"Corvus

function.

This

systems.

customer

site. Each

evidenceofrough

report

filed.

for

proper

return

number

(Return

procedures.

the

drivetoa

platter

their

and

backplane,

with

a 100-g force.

sockets.

remove

and

Chips

the

Backplane PCA.

and

chips,

seating

cover. Be

remove

Disk

chapter

handling

one-g

coming

it.

them

2.3.1 Diagnostic Test

Upon

recieptofa disk drive,

1) Verify

2) Verify

3)

4)

5) Execute

6)

7) Execute EXERCISE Utility

Check

Check

Check

front

bezel

Mirror

Switch

Controller

power

supply

CRe

Test

Parameters

several

switch

positions (on

Firmware

Voltages

(drive

procedures

positions

VERSION

and

MUX)

mustbeexercisedtoverify

rear

bezel)

and

recordonpaper

the

proper

3

functioningofthe

equipment:

Installation

8)

Run

BURN-IN Diagnostic (destructivetodata)

9)

Update

Any

Corvus

plugs

locatedonthe

installedornot).Ifthese

proper

combination.

into

switch

Controller

disk

drive

the

Backplane

rearofthe

configuration).

Firmware

maybeordered

PCA

cabinet,

switches

(drive Diagnostic

alongside

which

are

Drives

CORVUS

withaCorvus

the

Controller

MUSTbesettocorrectly

not

set

properly,

usingaMirror

DEALER SERVICE

option

Mirror

PCA,

the

UPD)

changing

PCA

inside

drive

may

externally

tables

when

prompted

installed. In all S.2S-inch drives,

the

cabinet

reflect

not

should

the

internal

function

use

cover.

properly

the

The

drive

Mirror

(refertothe

"No

has

configuration

Mirror

(answer

the

Mirror

four

DIP

chart

Installed"

"yes")

PCA

switches,

(whether

below

for

switch

MIRROR

Check

the

drive

power

details).

Next,

thoroughly

manual). Execute a

the

Virtual drive

utility

to

reset

themtotheir

A

new

drive

may

be shipped

onanew

Parameters

reference.

the

In

utility

parameters

and

Default

Be

suretocheck

Spare

priortoformatting

drive,

are

first

event

that

shouldbeused

before

therefore

Track

necessitate

parameters

Spare

Track table:

VDO

table:

Interleaving Spec: all H-Series drives

the

table

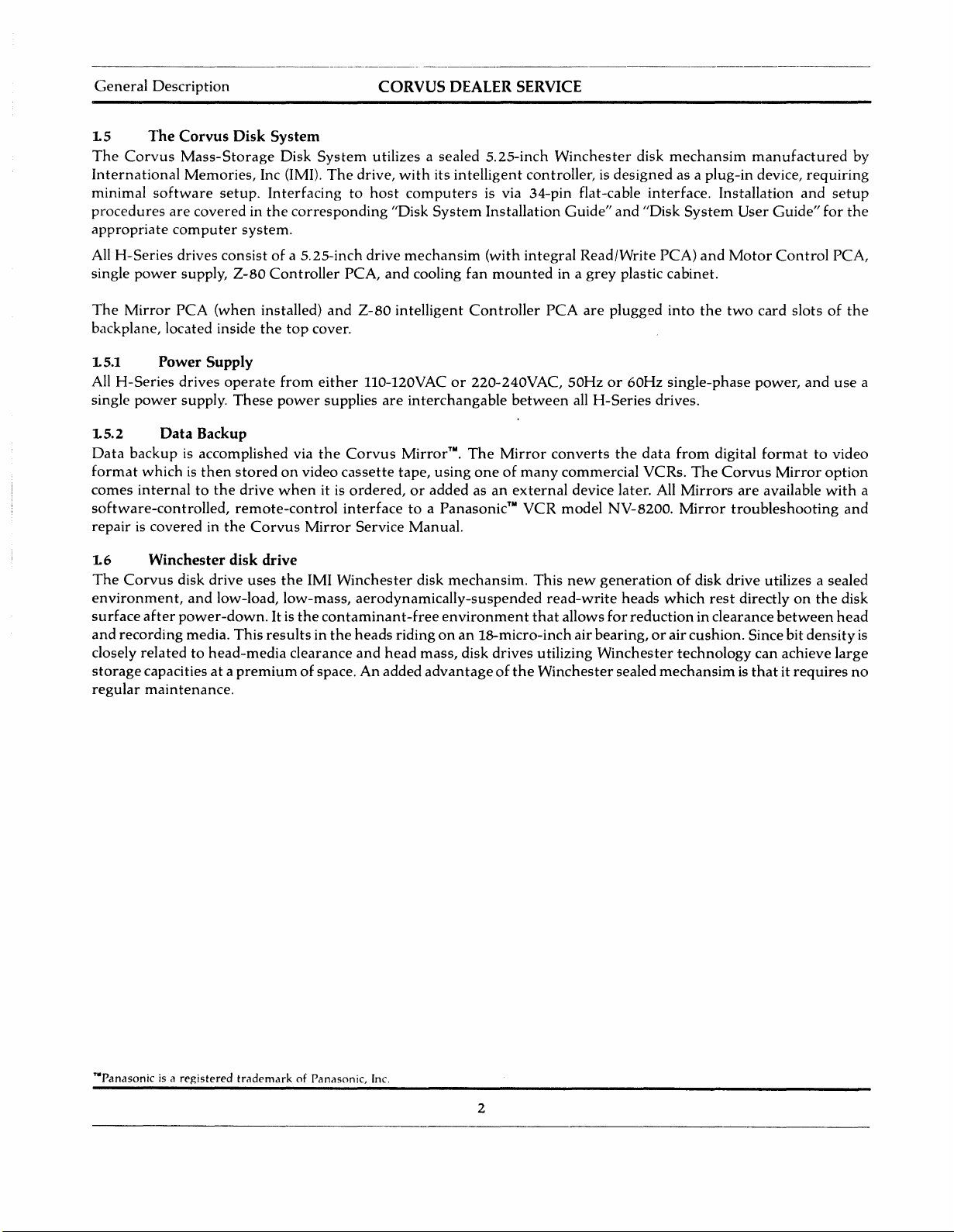

1 2 3 4

Pushed

in

~~~

OPEN

DRIVES WITH NO

OR

EXTERNAL MIRROR:

The shaded area indicates that the switch should be pushed in on that side.

supplyvoltages

test

the

drive,

CRC-Format

Offset

which

the

table). If

appropriate

withupto

leaves a

checked,

drive

only

attempting

are:

Model6

Model 11 drive 1 =0

Model20drive 1 = 0

drive

and

VDO

the

the

formatisdisturbedinshipment,itmaybenecessarytoreformat

as a last

the

re-initializationofthese

no

parameters

table

drive will simplify this

Figure 2.

and

using

the

Check,

eitherofthese

twenty-four

minimumofseven

values

resort.

FORMAT

tracks

spared

drive 1 = 0

(drive 2 = 911

before

may

need

Mirror

adjustifnecessary

Dealer

as well as verify

tables display values

values.

shouldbenoted,

Using

utility.

must

= 9

and

after

reconstructing

procedure.

234

~~

OPEN

DRIVES WITH

PAUSECAM MIRROR:

Configuration Switches

(refertoChapter6,"Adjustments

Service Diagnostics (as

the

drive

tracks

spared.

(and

the

PARAMETERS diagnostic utility,

The

format

parameters

be added

formatting

before

Noteonthe

There

most

likely

recordedona label,

program

with

after

the

the

outlinedinChapter7"Diagnostics"ofthis

Parameters

outofrange,

areatotalofthirty-one

more)

will

restore

the

original values (i.e. previously

FORMAT)

drive.Ifthe

dataisrestored.

label,

any

2 3 4

~~~

OPEN

DRIVES WITH

NTSC MIRROR:

(specifically

use

for

useinthe

and

attachedtothe

drive

future

the

the

PARAMETERS diagnostic

the

first

default

Knowing

parameterstothe

has

ever

tracks spared.

and

Maintenance"

Spare

Track table

spare

tracks available

field.

When

drive

drive.

The

trytorestore

spared

hadatrack

what

tracks

and

the

drive

for

future

FORMAT

the

drive

drive,

tracks).

spared,

are

the

spared

for

4

CORVUS DEALER SERVICE

Installation

2.4

All

the

Environmental Considerations

electronic

drive.

equipment

There

cushionorcarpet;

monitor

on

top

malfunction.

Be

sure

the

proper

Insure

the

stripe)isto

the

interface

PROCESSOR

the

needs

cooling

shouldbesufficient

the

air

intake

slots

of,ornear

line

voltage

the

has

cableisproperly

connectoronthe

right,

when

facing

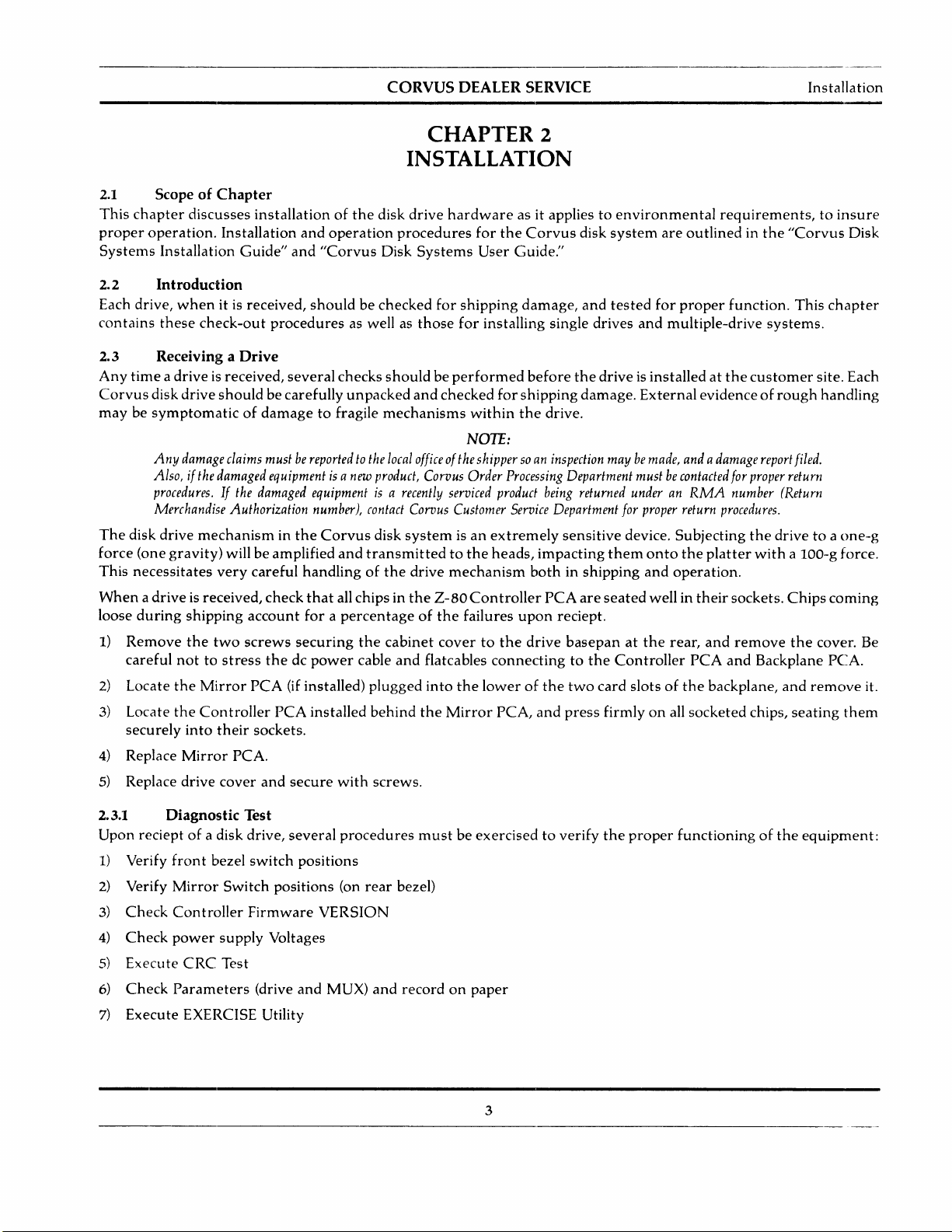

Connects

to

Video

Recorder

and

open

areonthe

Corvus

been

connected

rear

the

rearofthe

Video

0

the

Corvus

area

both

bottomofthe

drive.

Electromagnetic

selected

between

bezelofthe

Connects

Remote

Control

VIDEO

IN VCR REMOTE

to

OUT~

and

Corvus

drive

disk

driveisno

front

and

cabinet,

proper

fuse

the

connectoronthe

disk

unit.

Connects

to

Interface

Card

•

exception.

rear. Place

and

fields

generated

sizeisinstalled.

drive

cabinet.Besure

Connects

to

Add-on

Drive (If any)

PROCESSOR

,:

Bi

DRIVE

:I

:1

When

installing,donot

the

driveona level,

must

notberestricted.Donot

by

this

interface

Air

the

Flow

cardinthe

"one"

Slots

III

0

hard

device

edge

"pigeon-hole"

surface

may

host

computer,

(edge

without

place a

cause

with

video

drive

and

dark

Check

switches.

ortoa

Locate

bezel

the

after

drive

2.S

A

accomplished

Corvus

additional disk

exceptionofthe

must

™DEC is a

™LSI_ll is a

that

all

four

All

switches

DEC™

the

Light

LSI-11™

power

Emitting

switchonthe

FAULT LED willgoout,

which

the

drive

is

now

ready

Daisy-Chaining of Disk Drives

maximumof80

by

usingacommon

add-on

use

registered

drive

driveinthe

Rev A,

Controller

trademarkofDigital

registered

Mirror

front

panel

switches

shouldbeto

computer.Ifso,

rearofthe

Diodes) will

will

for

communication

set

and

the

come

the

megabytesofon-line

areinthe

the

left,

the

on,

heads

READY

with

unless

appropriate

drive,

and

will

signal,

the

storage

input/output

flat cableisavailable specifically

system.

8-inch

Firmware

trademarkofDigital

All series

11MB disk

version

CF18.3orlater.

Equipment

Equipment

drive

Corporation

Corporation

Dip

Switches

Power

Switch

Figure 3. Rear Bezel

correct

the

and

the

BUSY LEDwill flash regularly.

rezero.

and

host

maybeachievedbydaisy-chaining

interface

and

(Rev A

position.

disk

driveisconnectedtoa

switches

turniton.

Run

your

shouldbeset.

The

drive

LED activitywill briefly

all LED

activity

will cease,

system.

bus,

commonly

for

this

purpose.

One

Versionsofdisk drives

drives

maybedaisy-chained

finger

motor

referredtoas daisy-chaining. A special

maybedaisy-chained

Connects

toAC

Cable

along

Corvus

will

After

alternate

with

add-on

from

righttoleft,

Multiplexer

begintospin,

approximately

between

the

READY

four

Model 20 drives.

drive

cableisrequired

onlytoother

under

Network

and

all LEOs

thirty

READY

LED on.

system,

seconds,

and

BUS~

The

(front

This

for

together

with

Rev A drives). All

the

disk

is

each

the

5

Installation

CORVUS

DEALER SERVICE

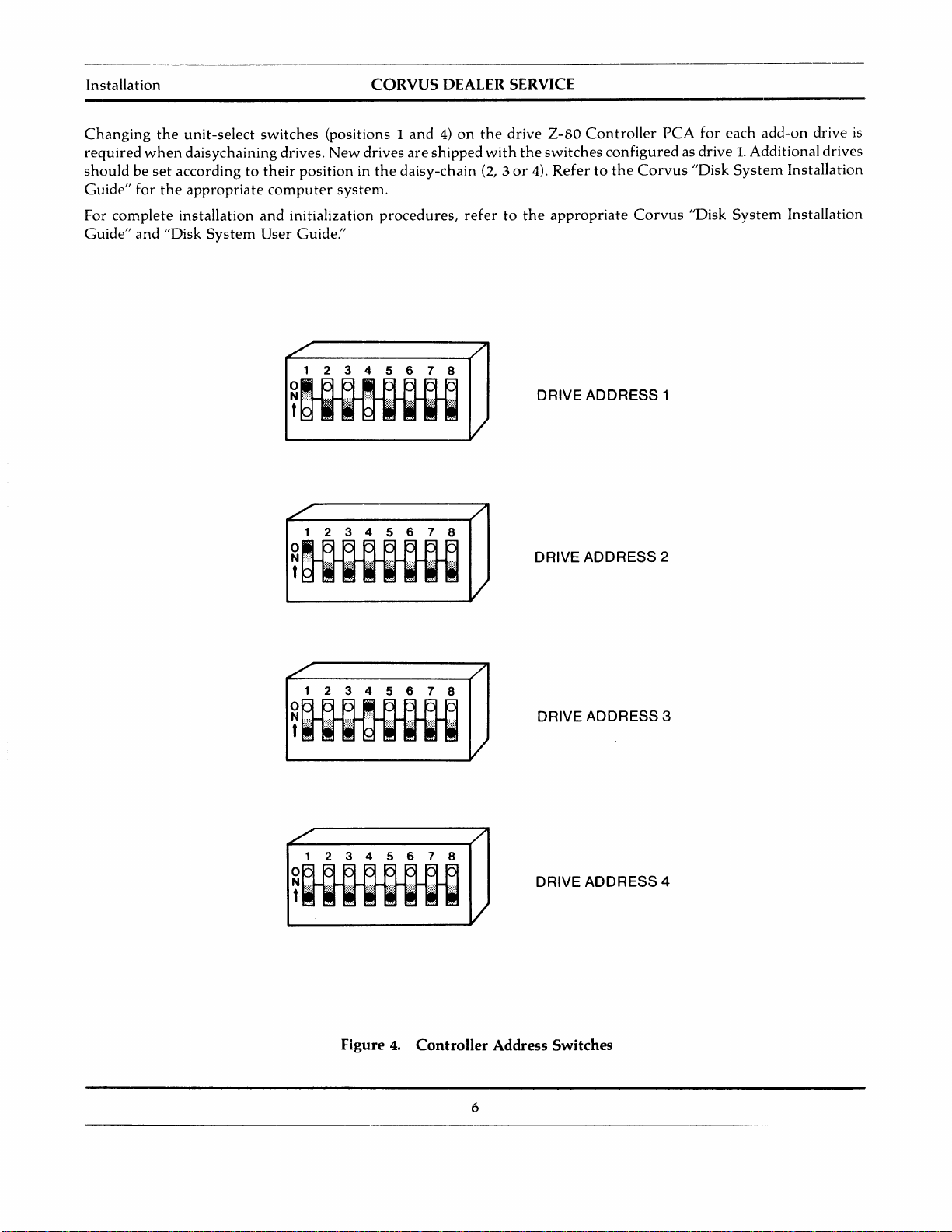

Changing

required

shouldbeset

Guide"

For

Guide"

the

when

for

complete

and

unit-select

daisychaining

accordingtotheir

the

appropriate

installation

"Disk

System

switches

computer

and

User

(positions 1

drives.

New

positioninthe

system.

initialization

Guide."

t'/

12345678

and4)on

drives

are

daisy-chain (2, 3

procedures,

shipped

~HHHH

~

,,/---------t'/

1

234

o~

iffnlTln

5 6 7 8

the

with

refertothe

~7

--¥V

V

drive

2-80

Controller

the

switches

or

4).

Refertothe

appropriate

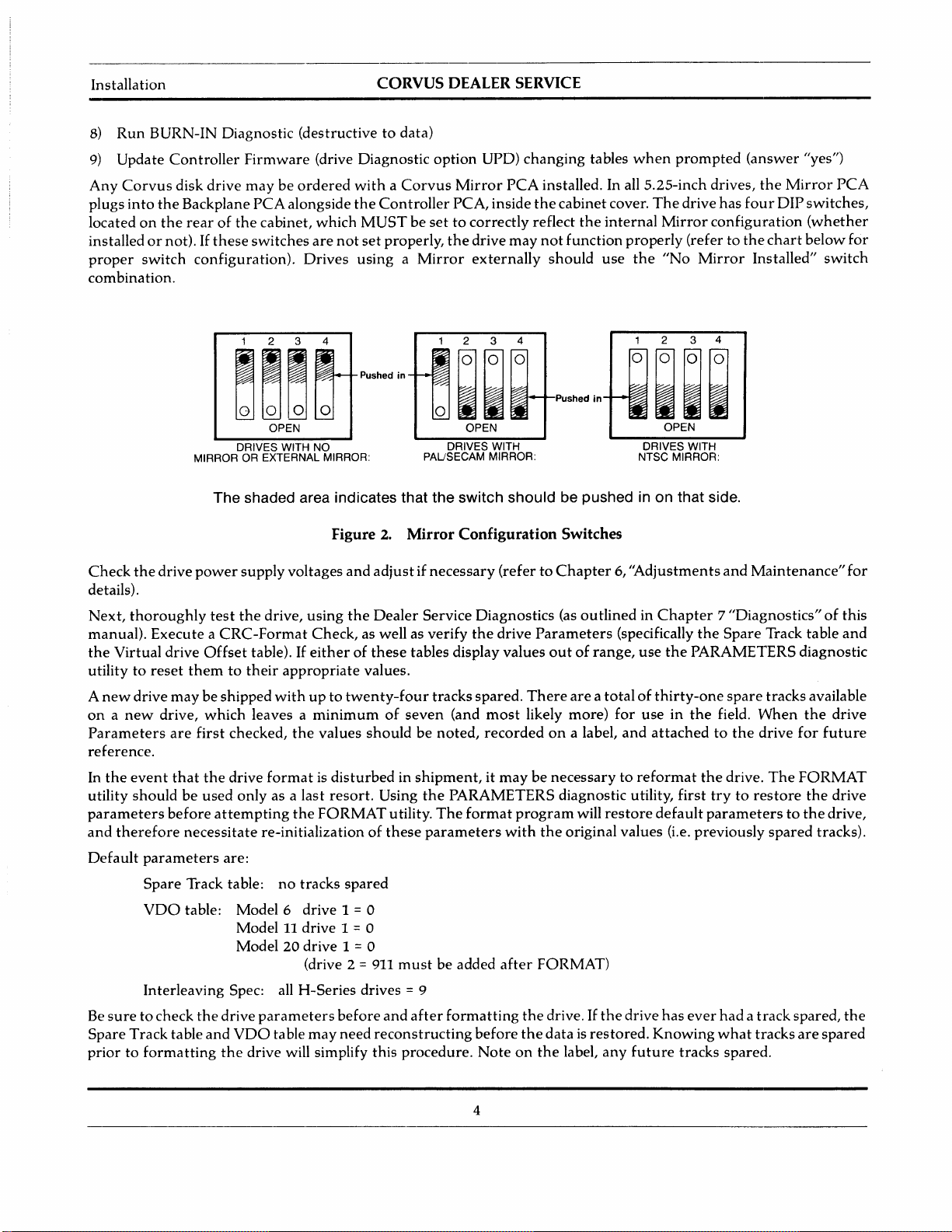

DRIVE ADDRESS 1

DRIVE ADDRESS 2

PCA

for

each

add-on

configuredasdrive1.Additional drives

Corvus

Corvus

"Disk

"Disk

System

System

drive

Installation

Installation

is

,,/----------1"/

1

234

5 6 7 8

DRIVE ADDRESS 3

~HHHH/

,c./---------t'/

1

234

~HHHH

~

5 6 7 8

DRIVE ADDRESS 4

___IV

Figure 4. Controller Address Switches

6

CORVUS

DEALER SERVICE

CHAPTER

3

OPERATION

--------------------------------_._-----------------------._--_.-.-

CORVUS DEALER SERVICE

CHAPTER 3

OPERATION

Operation

3.1 Scope of

This

chapter

control

are

switches

discussed,

Operation

operating

3.2

All

properly

system.

Introduction

Corvus

reflecting

bezel display

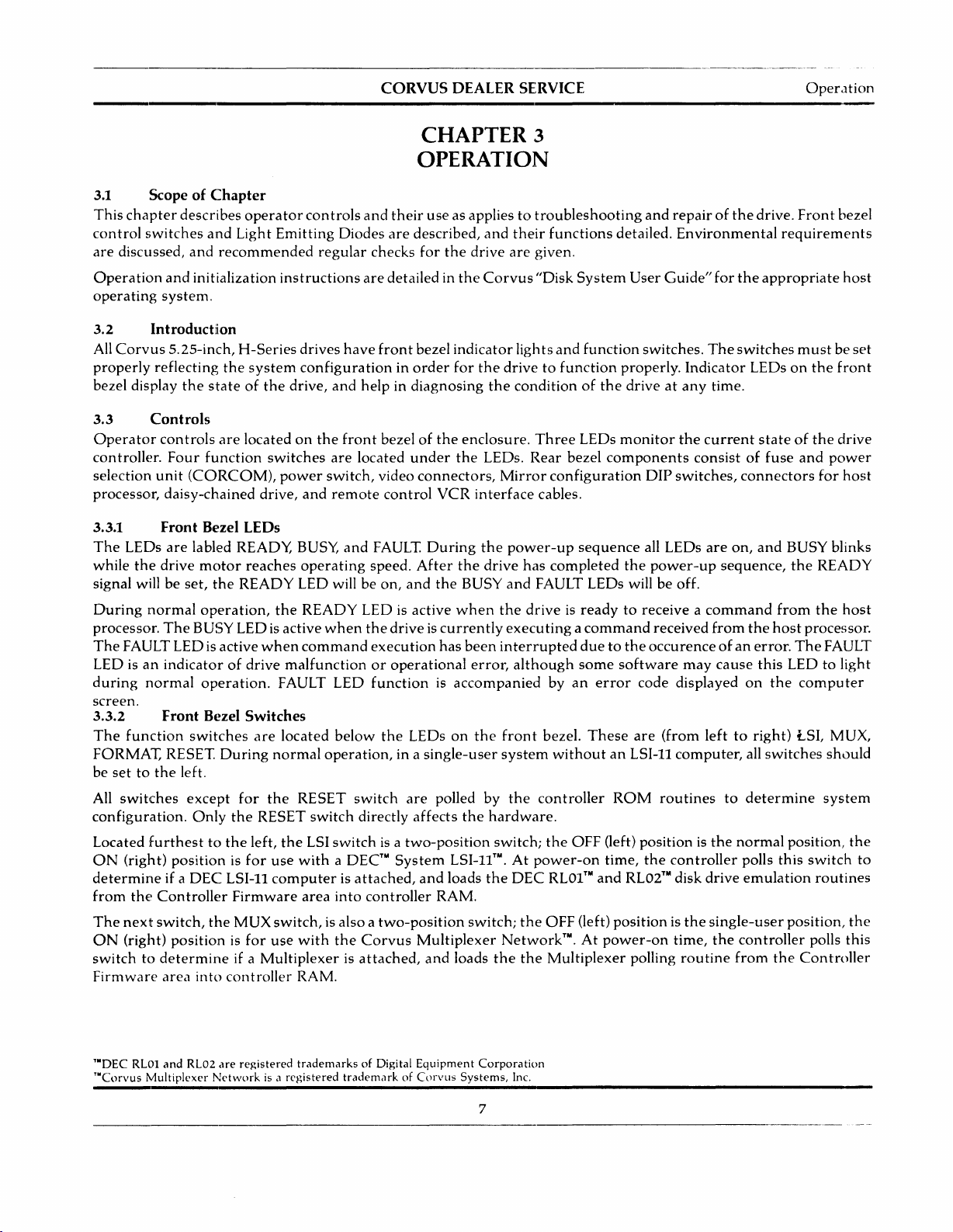

3.3

Operator

Controls

controls

controller.

selection

unit

Chapter

describes

and

and

and

initialization

S.2S-inch,

the

stateofthe

Four

function

(CORCOM),

operator

Light

Emitting

recommended

instructions

H-Series

the

system

are

locatedonthe

switches

power

processor, daisy-chained drive,

3.3.1 Front Bezel LEOs

The

LEOs

are

labled READ'Y,

the

drive

while

signal will be

During

processor.

The

FAULT LED is active

LED is

during

set,

normal

The

an

indicatorofdrive

normal

motor

BUSY LEDisactive

reaches

the

READY LED will be on,

operation,

the

when

operation.

FAULT LED

screen.

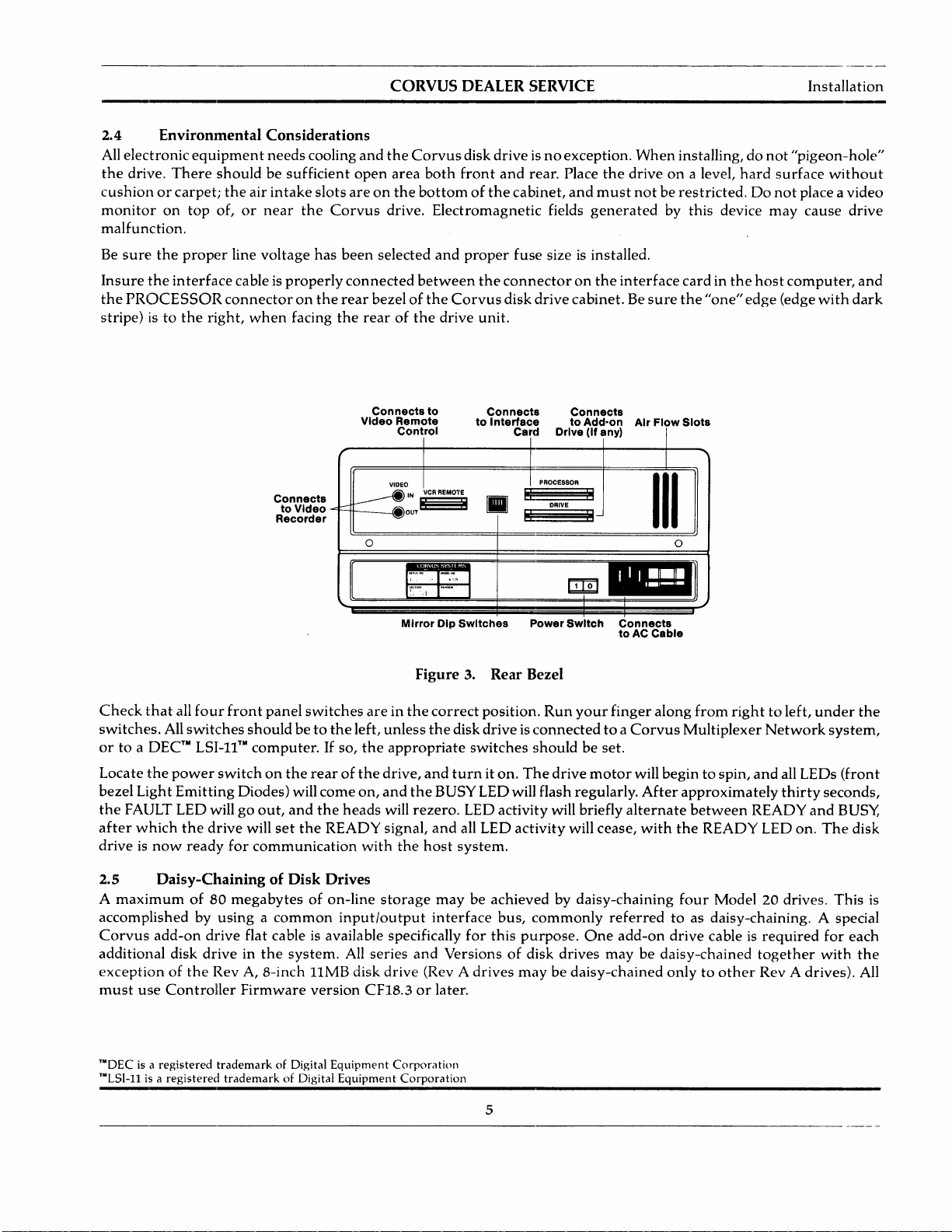

3.3.2

The

FORMAT,

be

settothe

All

configuration.

Located

ON

determine

from

The

ON

switchtodetermine

Firmware

Front Bezel Switches

function

switches

(right)

the

next

(right)

switches

RESET

left.

except

Only

furthesttothe

positionisfor

if a

DEC

Controller

switch,

the

positionisfor

area

into

are

During

for

the

normal

the

RESET

left,

use

LSI-II

computerisattached,

Firmware

MUX

switch,

use

if a

Multiplexerisattached,

controller

controls

drives

Diodes

regular

have

and

their

are

checks

are

detailed in

front

use

described,

for

the

bezel

configurationinorder

drive,

and

helpindiagnosing

front

bezelofthe

are

switch,

and

remote

BUS'Y,

and

operating

READY

when

command

located

LED is active

under

video

connectors,

control

FAULT

speed.

the

driveiscurrently

After

and

VCR

During

the

execution

has

malfunctionoroperational

functionisaccompanied

located

the

below

operation,

RESET

switch

LSI

switchisa

switch

directly

withaDEC™

the

LEOsonthe

in a

single-user

are

affects

two-position

System

polled

and

area

into

with

is also a

the

Corvus

controller

two-position

RAM.

Multiplexer

and

RAM.

as appliestotroubleshooting

and

their

drive

the

Corvus

indicator

for

the

the

enclosure.

the

LEOs.

Mirror

interface

the

the

drive

BUSY

when

the

functions

are

given.

"Disk

lights

and

drivetofunction

conditionofthe

Three

Rear

bezel

configuration

cables.

power-up

has

completed

and

FAULT LEOs willbeoff.

driveisreadytoreceiveacommand

detailed.

System

function

LEOs

components

sequence

executingacommand

been

interrupted

error,

although

duetothe

some

byanerror

front

bezel.

These

system

by

the

hardware.

switch;

LSI-II™.Atpower-on

loads

the

switch;

withoutanLSI-II

the

controller

the

DEC

RLOI™

the

OFF

ROM

OFF

(left) positionisthe

time,

and

(left)

positionisthe

Network™.Atpower-on

loads

the

the

Multiplexer

and

repairofthe

Environmental

User

Guide"

switches.

properly.

Indicator

driveatany

monitor

DIP

the

switches,

all LEOs

the

power-up

received

occurenceofan

software

may

code displayed

are

(from

computer,

routines

the

controller

RLO2™

disk

time,

polling

routine

drive.

for

the

appropriate

The

switches

LEOsonthe

time.

current

stateofthe

consistoffuse

connectors

are

on,

and

sequence,

from

from

the

host

error.

cause

this

on

the

lefttoright)

all

switches

to

determine

normal

polls

this

drive

emulation

single-user

the

controller

from

the

Front

bezel

requirements

host

mustbeset

front

drive

and

power

for

host

BUSY blinks

the

READY

the

host

processor.

The

FAULT

LEDtolight

computer

LSI, MUX,

should

system

position,

the

switch

routines

position,

polls

the

this

Controller

to

TO'DEC

TI·Corvus

RUn

and

Multiplexer

RLo2

Networkisa

are

registered

trademarksofDigital

registered

trademarkofCorvus

Equipment

Corporation

Systems,

7

Inc.

Operation

CORVUS DEALER SERVICE

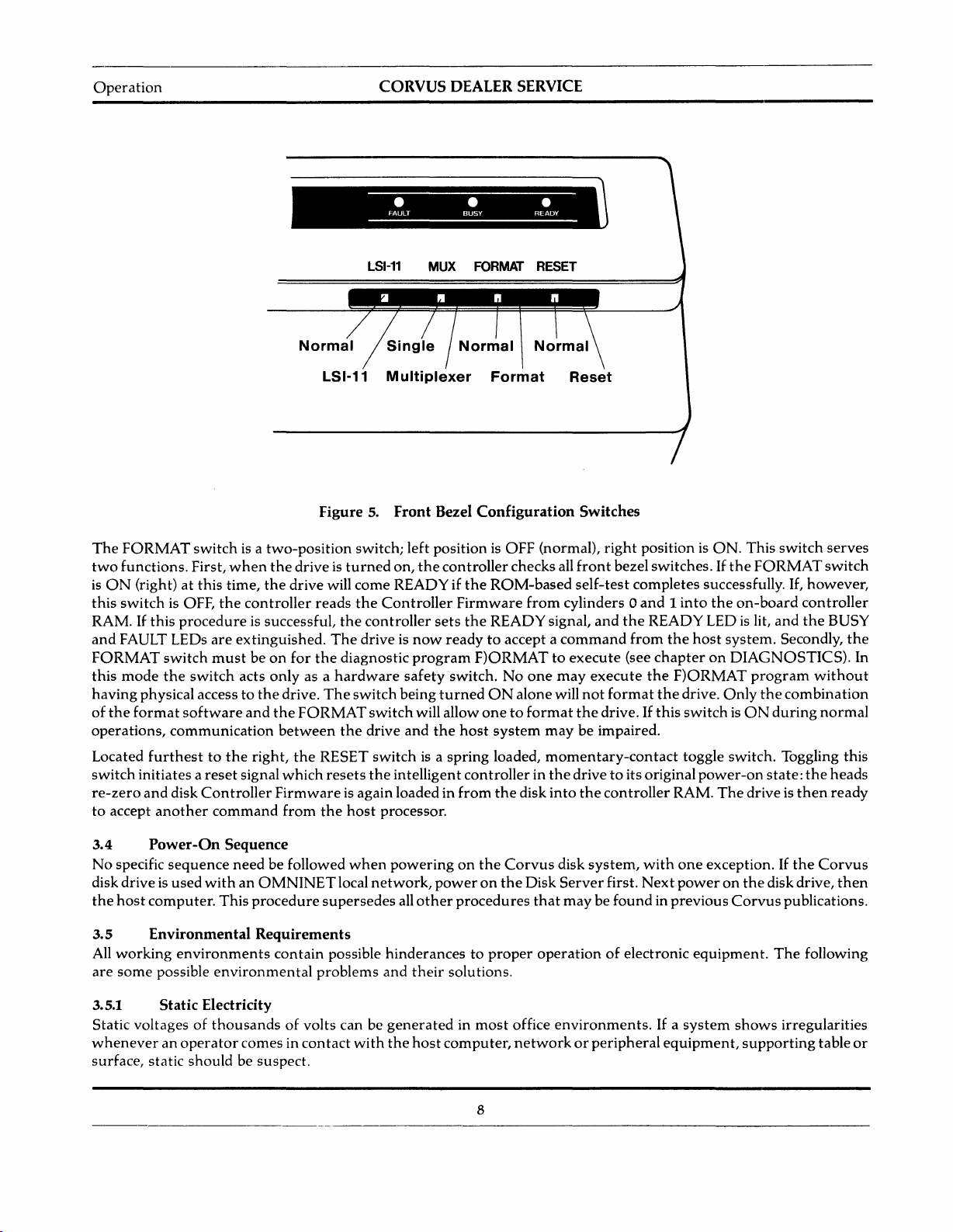

The

FORMAT

two

functions.

is

ON

(right)atthis

this

switch

RAM.Ifthis

and

FAULT LEOs

FORMAT

this

mode

having

of

physical accesstothe

the

format

operations,

Located

switch

re-zero

to

furthesttothe

initiates a

and

accept

another

switch

is a

First,

when

time,

is OFF,

the

controller

procedure

are

extinguished.

switch

the

mustbeon

switch

acts

software

communication

reset

signal

disk

Controller

command

LSI-11

LSI-11

Figure 5. Front Bezel Configuration Switches

two-position

the

driveisturned

the

drive will

is successful,

for

only

as a

drive.

and

the

FORMAT

between

right,

the

which

switch; left positionisOFF (norma!),

come

reads

the

Controller

the

controller

The

drive is

the

diagnostic

hardware

The

switch

switch

the

drive

RESET

resets

switchisa

the

Firmwareisagain loadedin

from

the

host

processor.

MUX

Multiplexer

on,

the

controller

READY if

sets

now

readytoaccept a

program

safety

switch.Noone

being

turned

will allow

and

the

spring

intelligent

Format

Reset

checks all

the

ROM-based

Firmware

the

from

READY

cylinders 0

signal,

command

F)ORMATtoexecute

may

ON

alonewill

onetoformat

host

system

loaded,

maybeimpaired.

momentary-contact

controllerinthe

from

the

disk

into

right

position is

front

bezelswitches.Ifthe

self-test

completes successfully. If,

and1into

and

the

READY LED

from

the

(see

chapteronDIAGNOSTICS).

execute

not

the

the

format

the

drive.Ifthis

F)ORMAT

drive.

switchisON

toggle switch. Toggling this

drivetoits original

the

controller

RAM.

ON.

the

on-board

host

system.

Only

power-on

The

This

switch

FORMAT

is

lit,

and

program

the

during

state:

drive is

serves

switch

however,

controller

the

BUSY

Secondly,

without

combination

normal

the

heads

then

ready

the

In

3.4

No

disk driveisused

the

3.5

All

are

3.5.1 Static Electricity

Power-On

specific

sequence

Sequence

need

be followed

withanOMNINET

host

computer.

This

procedure

Environmental Requirements

working

some

environments

possible

environmental

contain

when

local

supersedes

possible

problems

Static voltagesofthousandsofvolts can be

wheneveranoperator

surface, static

should

comes in

be suspect.

contact

with

poweringonthe

network,

poweronthe

all

other

procedures

hinderancestoproper

and

their

solutions.

generatedinmost

the

host

computer,

8

Corvus

disk

system,

Disk

Server

that

first.

maybefoundinprevious

operationofelectronic

office

environments.Ifa

networkorperipheral

with

one

Next

poweronthe

system

equipment,

exception.Ifthe

disk drive,

Corvus

equipment.

The

shows

supporting

Corvus

then

publications.

following

irregularities

table

or

CORVUS DEALER SERVICE

Operation

Staticismost

humidity

humidity

3.5.2

easily

helps

prevent

is70percent

Line Noise

Electrical noiseonthe

and

dropouts

Located in

power

If

line. Also,

powerissuspect,

devicesonthe

voltage

as well as low line voltage

the

CORCOM

the

the

same

regulatororisolation

effectofline voltage

the

Corvus

and

uninterrupted

3.5.3

Althoughinmost

drive

Corvus

3.6

Inherentinthe

maintenance.

field-serviceable

drive

from

cooling

equipment,

power

Temperature

environments,

must

operate

disk

within

is15degrees

Periodic Maintenance

designofthe

The

sealed disk

components.

Since contamination

removing the cover

generated

in a cool and

dry

enviromnent,

static electricity buildup,

some

typeofhumidifying device can be helpful. Ideal relative

to75percent.

power

lineisa

power

power

supplyiscapableofhandling

problem

circuit,orpoor

transformerinthe

fluctuationsonthe

line noisecaused by

elevators, etc.

major

selection

may

lie in

external

causeofinconsistent

are

just

someofthe

unitisa line filter capableofhandling

dropoutsofuptothree

poor

continuityofthe

supplytothe

Corvus

other

To

lessen

power

drive, while

high-loadelectrical

circuit.

the

building.

impact

supply (UPS)isrecommended.

the

disk drive needsnoactual

(see"Specification"atbeginningofthis manual).

fahrenheit

Winchester

per

hour.

technologydisk devices, is

mechanismofthe

Corvus

CAUTION:

of

the atmosphere In the mechanism necessitates replacementofthe unit,

to

the sealed mechanism voids all warranties.

usually associated

equipment

common

causesofdrive malfunction.

with

operation. Voltage spikes,

most

complete

building wiring, noisyorhigh

Power

The

constant

the

isolation

equipment

of

warm-up

the

disk drive requires

can be improved by including a

voltage

transformer

such

frequent

freedom

power

time,

The

temperature

there

from

no

cold weather. Since increased

"brownouts"

minor

electrical noiseonthe

power

cycles.

power-consumption

constant

regulator

will beeffective in

as photocopy machines,

interruption,

are

the

maintenance,

will help minimize

temperature

change

need

for

regular

maximum

and

the

useofan

limits

preventive

contains

protecting

heating

that

for

the

the

the

no

3.6.1 Regular Checks

Power

opened,

adjustment

Duetoslight oxidation build-uponcable

supplyvoltages will

check

the

power

procedures).

change

with

time,

and

supply voltagestoverify

connectors

socketed controller ICs periodically will also help

should

that

and

insure

bechecked periodically. Each

they

are

within

IC pins,

specified tolerances (refertochapter

reseating

the

flatcable

reliability.

9

time

the

and

Corvus

power

drivecabinet

connectors

is

7 for

and

Loading...

Loading...