CORVUS 7100-04702 Service Manual

THE CORVUS SERVICE

MANUAL

Floppy

**.

CORVUS SYSTEMS

* •

Disk

Drive

DISCLAIMER OF ALL WARRANTIES & LIABILITIES

Corvus

manualorwith

chantability,orfitness for any particular purpose.

licensed lias is:' The entire risk as to its qualityorperformance is with

Systems, Inc., its distributor,orits retailer. The

servicing, repair,orcorrection

Corvus

Corvus

consequential damages, so

Every effort

servicing of

ware along

material after the date of publication,

errorsoromissions.

Systems, Inc. makesnowarranties, either expressedorimplied, with respect to this

respect to

Systems, Inc.beliable for direct, indirect, incidentalorconsequential damages,

Systems, Inc.

has

been

Corvus

with

future products,

the

software described in this manual, its quality, performance, mer-

and

any incidentalorconsequential damages. Innoevent

has

been

advised of

the

above limitation

madetoinsure

products. However,

Corvus

the

that this

duetothe

Systems, Inc.

nor

can

Corvus

buyer

possibility of

may

not

manual

ongoing modification

Corvus

Systems, Inc. software is sold

assumes

such

apply

accurately

cannot

guarantee

Systems, Inc. accept responsibility for

the

buyer

and

not

Corvus

the entire cost of all necessary

even

damages.

to you.

documents

Some

the

and

updateofthe

the

accuracy of

statesdonot

operation

printed

soft-

NOTICE

Corvus

ual at any time

and

This manual is copyrighted

ment

any electronic

Corvus

Copyright© 1982byCorvus

Mirror®

Logicalc,""

Workstation,"" Tap

of

Systems, Inc. reserves

without

maybepurchasedbywriting to:

Corvus

2029 O'Toole Avenue

San Jose, CA 95131

Telephone: (408) 946-7700

TWX

may

Corvus

Systems, Inc.

not,inwholeorin

medium

Systems, Inc.

patent

pending, The

Time Travel Editing,""

Systems, Inc.

notice. Revised manuals

910-338-0226

Box,""

the

and

partbecopied, photocopied, reproduced, translatedorreduced

or

machine readable form

Systems, Inc. All rights reserved.

Passive Tap

right to make changes in the

and

update

contains proprietary information. All rights reserved. This docu-

without

Corvus

EdWord,""

Concept,"" Transporter,""

Constellation,"" Corvus,""

Box,""

Active Junction

product

sheets willbepublishedasneeded

prior

Corvus

Box,""

Omninet

describedinthis man-

consent, in writing, from

Corvus

OMNINET,TM

Systems,"" Personal

Unit""

are

Corvus

trademarks

FCC WARNING

This

equipment

used

in accordance

tions. As temporarily

limits for Class A

designedtoprovide

mentina residential area is likely to cause interferenceinwhich case the

expense willberequired to take whatever measures mayberequired to correct the interference.

generates, uses,

with

the

permittedbyregulation it has

computing

reasonable protection against

and

can radiate radio frequency

instruction manual,

devices

pursuanttoSubpart

energy

may

cause interference to radio communica-

not

been

tested for compliance with

J of

Part

such

interference.

andifnot

15 of FCC Rules, which

Operation

installed

of this equip-

user

at his

own

or

will

if

and

to

and

the

are

CORVUS DEALER SERVICE

CONCEPT

CORVUS

PERSONAL

8"

FLOPPY

SERVICE

SYSTEMS

WORKSTATION

DRIVE

MANUAL

PART NO.: 7100-04702

DOCUMENT

RELEASE DATE:

This

document

CAUTION,

procedure.

care

shouldbetakentoavoid this.

service technicionoroperator

NO.: CCC/12-01/1.1

JULY

10, 1983

contains

and

WARNING.

The

CAUTION indicates

three

typesofnotations.

The

NOTE

indicates

that

potential

The

WARNING indicates

exists,

and

extreme

These

are,inincreasing

some

actiontobe

damagetothe

care should be

orderofimportance,

takentospeedorsimplify a

equipmentoruser

that

potential

takentoavoid these.

harmorinjurytothe

data

NOTE,

exists,

and

CORVUS

DEALER SERVICE

TABLE

OF

CONTENTS

CORVUS

DEALER

SERVICE

TABLE

OF

CONTENTS

ListofFigures

ListofAssembly

Drawings

and

Schematics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

..

Drive Specifications V

CHAPTER

1.0

1.1

1.2

CHAPTER

2.0

2.1

2.2

2.3

1 -

OVERVIEW

ScopeofManual.

General

1.1.1

1.1.2

Description.

Drive

Interface

Diskettes

1.2.1

2 - FUNCTIONAL DESCRIPTION

Care

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .... . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Assembly.

Description.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .... . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

and

HandlingofDiskettes 1

ScopeofC:hapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Drive

Mechanism.

Block

Diagram

2.2.1

2.2.2

2.2.3

2.2.4

2.2.5

2.2.6

Concept

Index Pulse

Drive

Spindle

Carriage

Write/Erase

Read Amplifier

Interface.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Description.

Status

Drive

Positioner

. . . . . . . . . . . . . .... . . . . . . . . . . . . .... . . . . . . . . . . . . . . . . . .... . . . . . . . . . .

.....

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Logic. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Control.

. . . . . . . . . . . . . . . . . . . . . .... . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Control

Control

and

Digitizer.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

..

..

..

..

..

..

..

..

..

..

..

..

..

iii

IV

1

1

1

1

1

3

3

3

3

3

3

4

4

6

7

CHAPTER

3.0

3.1

3.2

3.3

3.4

ScopeofC:hapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cover

:Power Supply Removal

:Power

:Rear ConIlectors

CHAPTER

4.0

4.1

4.2

ScopeofC:hapter

ListofTools

Drive

4.2.1

4.2.2

4.2.3

4.2.4

4.2.5

4.2.6

4.2.7

4.2.8

3 -

DISASSEMBLY

Disassembly

Harness

4 -

CHECKS

Adjustments

Spindle

Cats

Head

Index

4.2.4.1

4.2.4.2

4.2.4.3

Track

Amplitude

Azimith

Load

AND

ASSEMBLY

and

Assembly 9

Removal

and

Devices

AND ADJUSTMENTS

Drive

Motor

Eye

Alignment

Carriage

Sensor

Zero

Arm

Adjustment

Checks

and

Index-To-Data

Index

Sensor

Index Pulse Width

Sensor

Check

Check

Check

Adjustment

PROCEDURES

-. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Adjustments

Burst

Check

Adjustment

Check

and

Adjustment

..

9

10

10

10

12

12

12

..

12

13

15

15

15

16

17

18

19

20

21

CORVUS

DEALER

SERVICE

4.3

4.4

CHAPTER

5.0 Scope

5.1 Diagnostics

5.2

5.3

5.4

5.5

Interface

4.3.1

4.3.2

4.3.3

Power

Supply

5 - TROUBLESHOOTING

of

5.1.1

5.1.2 Test

System

5.2.1

5.2.2

5.2.3

Floppy

5.3.1

5.3.2

5.3.3

Level

Drive

Interface

Troubleshooting

APPENDICES

Appendix A

Appendix B

Appendix C

Appendix D

Glossary.

Part

Schematic

Assembly

Controller

Bias Voltage

Range

Adjustment

Pre

com

p

Adjustments

Chapter

Operation

Descriptions

Troubleshooting.

Interface

Floppy

Drive

Concept

Unit

Power

Supply

Diskette

Power

Harness

Controller

Guide

Numbers

Drawings.

Checks

and

Adjustments

Adjustment

~ ~

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Controller

and

Cable

Workstation

Drive

Unit

;

Card

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Diagrams

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

21

22

22

22

23

24

24

24

24

..

25

26

26

26

26

26

27

27

27

..

28

..

30

..

31

32

..

38

ii

CORVUS DEALER SERVICE

LIST

OF

FIGURES

CORVUS DEALER SERVICE

LIST

2-1 FunctioIlal Block Diagram 4

2-2

2-3

2-4

3-1

3-2

3-3

4-1 Drive Circuit Board Assembly, Test Points

4-2

4-3

4-4

4-5

4-6

4-7

4-8

4-9

4-10 Head

4-11 Head

4-12

4-13

4-14

5-1 Floppy

5-2

FM Recording Magnetization

Write

Operation

Read Timing

Cover

Installation 9

Drive

Power

Left

Cover

Hub

Center

Cats

Eye

Pattern

Timing Diagram 6

Diagram.

Connector

Line

and

Track Locations

Head Module Retaining and

Index-to-Data

Index

Sensor

Burst

Retaining Screws

Profiles.

. . . . . . . . . .... . . . . . . . . .... . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cam

Screws

and

Negative Going Pulse Width . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Track00Sensor

Optimum

Azimuth

Azimuth

Load

Arm

Interface

Power

Controller

Supply

[)rive

Interface

Controller

Head

Adjustment

Azimuth

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Alignment

Acceptable Lower Limit

Acceptable Upper Limit " 21

Adjustment,

Front

View 21

Card

Adjustments

Installation

Installation

OF

FIGURES

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .... . . . . . . . .

Adjustment

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

..

..

..

..

..

20

20

22

23

25

26

5

7

10

11

13

13

14

15

16

17

18

18

iii

CORVUS DEALER SERVICE

LIST OF ASSEMBLY DRAWINGS

AND

SCHEMATICS

CORVUS DEALER SERVICE

'LIST

Drive Schematics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . .

Controller

Schematic

OF

ASSEMBLY

DRAWINGS

AND

SCHEMATICS

Assembly Drawings

Mechanism.

Power

Left

Cover

DC

Cable 41

Logic Board

Floppy

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Supply.

Controller

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

0 • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • •

..

32

37

..

38

..

39

••

40

42

43

iv

CORVUS DEALER SERVICE

SPECIFICATI()NS

CORVUS

DEALER

SERVICE

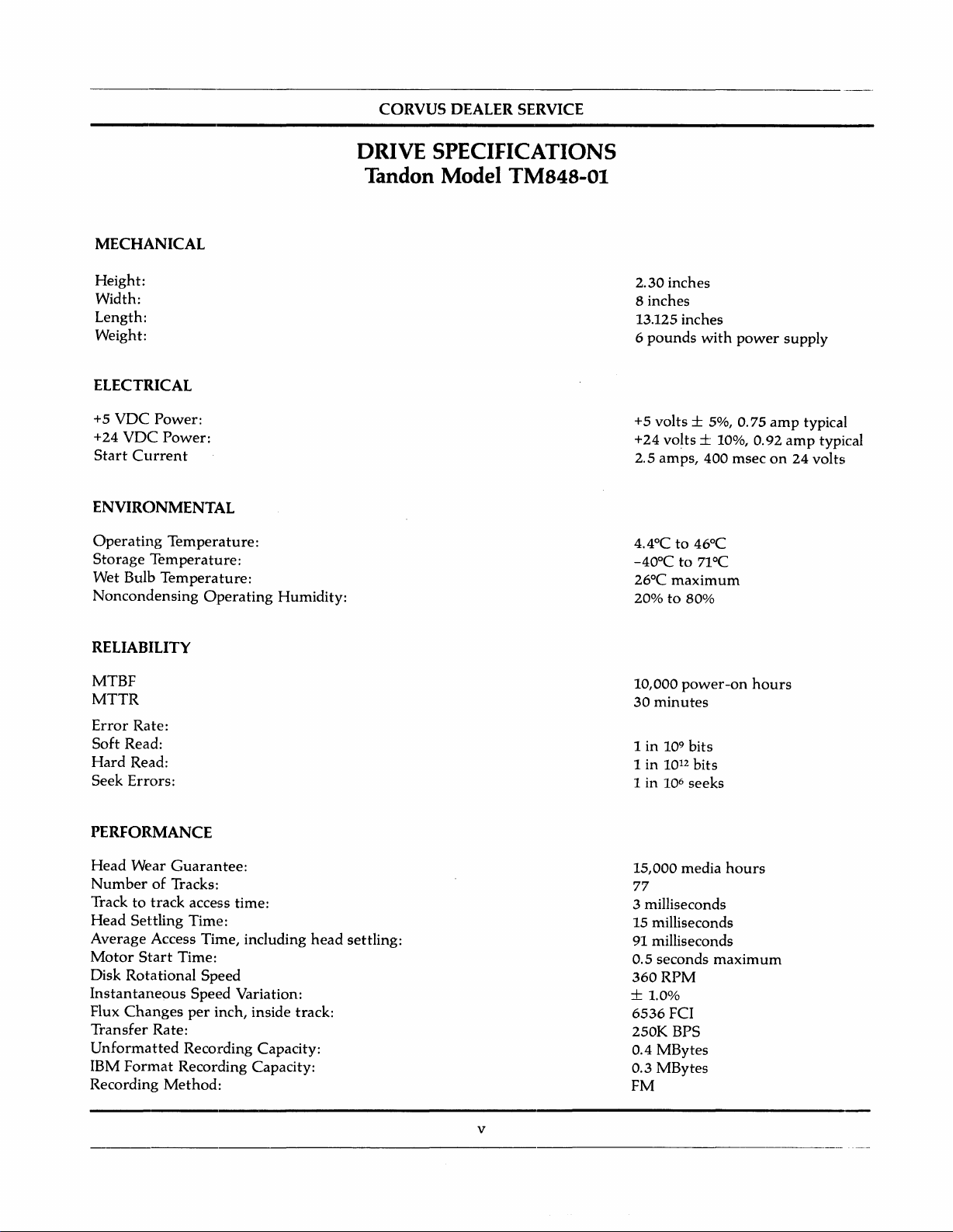

MECHANICAL

Height:

Width:

Length:

Weight:

ELECTRICAL

+5

VDC

Power:

+24

VDC

Power:

Start

Current

ENVIRONMENTAL

Operating

Storage

Wet Bulb

Noncondensing

Temperature:

Temperature:

Temperature:

Operating

Humidity:

DRIVE

SPECIFICATIONS

Tandon Model TM848-01

2.30 inches

8 inches

13.125 inches

6

pounds

+5 volts ± 5%, 0.75

+24

2.5

4.4°Cto46°C

-40°Cto71°C

26°C

20%to80%

with

vo~ts

± 10%, 0.92

amps,

400

maximum

power

msecon24

supply

amp

amp

typical

typical

volts

RELIABILITY

MTBF

MTTR

Error

Rate:

Soft

Read:

Hard

Read:

Seek

Errors:

PERFORMANCE

Head

Wear

Guarantee:

NumberofTracks:

Track

to

track

access time:

Head

Settling

Average

Motor

Disk

Instantaneous

Flux

Transfer

Unformatted

IBM

Recording

Start

Rotational

Changes

Format

Time:

Access Time, including

Time:

Speed

Speed Variation:

per

Rate:

Recording Capacity:

Recording Capacity:

Method:

head

inch, inside track:

settling:

10,000

30

1in109bits

1

1 in 10

15,000 media

77

3 milliseconds

15 milliseconds

91

0.5 seconds

360

power-on

minutes

in

1012bits

6

seeks

milliseconds

RPM

maximum

± 1.0%

6536

FCI

250K BPS

MBytes

0.4

0.3

MBytes

FM

hours

hours

v

CORVUS DEALER SERVICE

CHAPTER

OVERVIEW

1

CORVUS DEALER SERVICE

1.0

This

Disk

procedure.

shouldbereturnedtoCorvus

All

in a

This

1.1 General Description

The

Workstation.

interfaceiscomposedofa single

base

1.1.1 Drive Assembly

The

Corvus

All electronic

the

mountedtothe

Scope of Manual

manualisdesigned

Drive

and

the

Except

information

separate

first

Corvus

unit.

mechanism

Systems

drive

in this

manualoraddendum.

chapter

cabinetisthe

will briefly describe

Floppy

The

floppy is a Single-sided, single-density drive

and

andisincorporatedinthe

componentsofthe

floppy chassis assembly.

for

interface. A

for

the

power

manual

Disk

Drive

internal

power

service technicians

electronics

CHAPTER

OVERVIEW

who

troubleshooting

supply,

via a

appliestothe

providesanadditional

Interface

drive

receptacle,

the

Return

the

are

are

mountedona single circuit

guideisincluded

internal

Merchandise

single-sided,

drive,

the

Controller

manufacturedbyTandon

drive cabinet.

fuse

holder,

perform

partsofthe

Authorization

single-density

interface,

data

storage

Card

and

on/off

1

maintenanceorwarranty

which

drive

and

which

a cable.

switch,

will direct

are

not

(RMA).

drive only.

the

diskettes.

and

boot

device

uses

eight-inch

The

card

Corporation™.

board

locatedinthe

and

interface

the

replaceable. In

Subsequent

for

plugs

connectors.

serviceonthe

techniciantothe

such

models will be

the

Corvus

standard

into

slot

The

power

drive's chassis.Atthe

Concept

floppy diskettes.

threeofthe

supplyis

The

Corvus

appropriate

cases,

provided

power

Floppy

the

drive

covered

Personal

The

Concept

rear

supply

by

of

is

1.1.2 Interface Description

The

floppy

fifty-pin

associatedcircuits.

included).

The

Interface

adjustments

1.2 Diskettes

The

floppy

diskette

For

be

turned

diskette

The

floppy

has a slot

mustbecoveredtowriteonthe

1.2.1 Care and Handling of Diskettes

Itisimportant

maintained.Adamagedorcontaminated

the

read/write

interfaceiscomposedofan

twisted

Data

counterclockwise,tothe

leveristurned

cutinthe

pair

cable,

which

Data

transfers

transfers

Controller

willbecoveredinChapter

operates

insertion,

driveisequipped

that

headsofthe

between

Card

with

standard

operator

clockwise,

with

protective

the

diskettebecared

drive.

Interface

is acceptable.

between

the

Controller

has

three

Four.

eight-inch, single-sided, single density,

accessisprovided

straight-up

until

perpendicular

a Write

jacket.

When

diskette.

for,

Controller

the

drive

and

adjustment

via a

position,

Protect

diskette

Sensor.

the

slotisUNCOVERED,

handled,

can

Card

The

Controller

and

the

Controller

the

Concept

potentiometers:

slot

locatedonthe

for

diskette

with

the

door,

This

sensor

and

stored

impairorprevent

and

a fifty-pin flat

usesanintelligent Floppy

areinthe

are

eight-bit

bias voltage,

soft-sectored

frontofthe

loading.

and

operatesinconjunction

properlysothat

Once

the

disketteisnow

the

disketteiswrite

recoveryofdata,

ribbon

formofraw

parallel.

range,

drive.

the

the

integrityofthe

cable.

Some

Controller

serial

data

and

precomp

diskettes.

The

Diskette

disketteisfully

loaded.

with

the

PROTECTED.

recorded

and

can

resultindamage

drives

chip

(clock pulses

adjust.

Lever

inserted,

diskette

The

use

and

These

must

the

which

slot

data

a

is

to

T1'Tandon

is a

trademarkofTandon

Corporation

1

Overview

CORVUS DEALER SERVICE

Following

1) Keep

2) Keep diskettes in

3)

4)

these

the

Do

not

bendorfold

Store

diskettesatroom

guide

diskettes

liquids.

5)

REMOVE

DISKETTES

can cause noisetobe

Floppy

recommended

diskettes

haveanoperating

that

lines will increase

away

from

their

protective

the

diskettes. Be

temperatures

BEFORE

writtenonthe

back-up

copiesofall valuable

diskette

magnetic

jackets

careful

POWERING

diskette

in a

fields.

when

covered

reliability

Don't

not

when

ON

and

renderitunusable.

lifeofabout40hours.

databekept

and

place

in use.

inserting

container

OR

OFF

This

time

in a safe place.

extend

the

lifeofthe

diskettes:

diskettesontelevisionsormonitors.

Never

touch

the

them

away

THE

varies

precision

into

the

drive.

from

contamination

DRIVE.

Random

dependingonenvironment

surfaceofthe

suchassmokeorspilled

spikes

during

diskettes.

poweronor

and

usage. It is

off

2

CORVUS DEALER SERVICE

CHAPTER 2

FUNCTIONAL DESCRIPTION

CORVUS DEALER SERVICE

CHAPTER 2

FUNCTIONAL DESCRIPTION

Functional

Description

2.0

This

Controller.

2.1 Drive Mechanism

The

The

ejector.

clampingofthe

brushless

The

electronics.

disketteisinserted

Protect

When

to

increasing

Data

circuits.

In

1.

2.

3.

ScopeofChapter

chapter

drive

disketteisaccurately

headispositioned

performingawrite

0.012

recovery

addition,

A

track00sensor

The

The

diskette.

will

describe

The

electronics will be

consistsofa spindle drive

Closing

status

inch

two

Write

the

diskettetothe

DC

motor.

The

stepper

output

(nominal).

the

space

electronics include a low-level

the

drive

index

sensors,

Protect

diskette

The

over

into

signal is availabletothe

between

has

that

sensor

the

functional

positioned

lever

drive

head

is loaded

the

motor

the

rotates

drive,

operation,

Tunnel

the

the

following

senses

eachofwhich

disables

operationofthe

presentedata block

system,ahead

when

inserted

activates

hub.

desired

the

a 0.013-inch

erasing

tracks.

when

the

cone

The

drive

into

contact

trackbymeansofa

3.6

degreestocauseaone-track

Write

Protect

interface.

wide

helps

prevent

head

sensors:

the

Head

consistsofan

the

write

Drive

Mechanism,

diagram

positioning

by plasticguides.

and

hubisdrivenata

with

the

Sensor

(nominal)

crosstalk

amplifier, a differentiator, a

Carriage

LED light

electronics

level.

system,

clamp

recording

stepper

disables

data

Assembly

whenever

andaread/write/erase

The

positionisensuredbythe

system,

between

resultingincenteringofthe

constant

medium

motor

linear

the

write

trackisrecorded.

is positionedatTrack 00.

source

andaphototransistor.

the

Drive

Electronics,

speedof360

whenever

and

band

movement.

electronicsofthe

tracksbyerasing

zero

write-enable

RPM

the

assembly

This

trackisthen

crossing

Whenawrite-protected

tabisremoved

system.

backstop

by a

servo-controlled

diskette

and

drive,

the

outer

detector,

and

Interface

and

diskette

lever

is latched.

its associated

and

a Write

tunnel

and

erased

edges

digitizing

from

disk

and

and

the

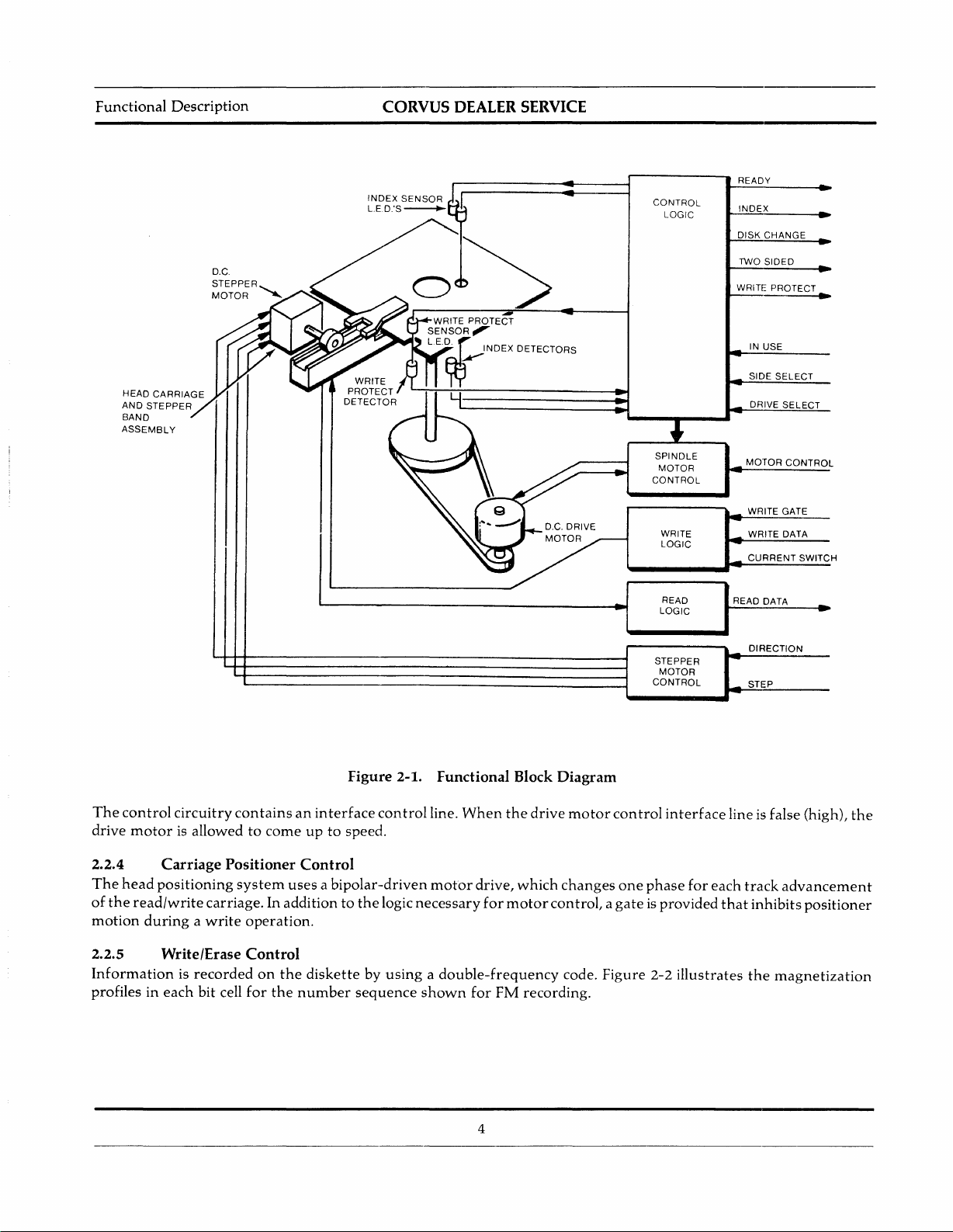

2.2

Figure

The

1) Index Pulse

2)

3)

2.2.1 Index Pulse

An

LED, a

phototransistor,

phototransistorispassedonto

presentedonthe

2.2.2

There

2.2.3

The

motor/tachometer.

Block Diagram Description

2-1 is a

drive

Drive

Spindle

index pulse is

functional

consistsofsix

Shaper

Status

phototransistor,

Logic

Drive

Control

providedtothe

light

index

block

from

pulse

Drive Status Logic

are

five

status

logic lines:

Spindle Drive Control

spindle drive

system

The

servo

functional

andapulse

diagramofthe

groups:

Controller

the

LED

strikes

the

pulse

interface

Write

Protect,

consists

electronics

of

drive.Itshouldbereferredtoin

Carriage

4)

Write/Erase

5)

Read

6)

via

the

index pulse

shaping

shaping

line.

a spindle

are

network.

the

phototransistor,

network,

Track00Sensor, Two-Sided Disk, Ready, Disk

assembly

locatedonthe

As

which

printed

3

interface

the

producesapulse

driven

Position

Control

Amplifier

line.

index

causingitto

hole in

through

circuit board.

conjunction

Control

and

The

index

conduct.

for

a drive belt by a

with

Digitizer

circuitry

the

disk passes

each

The

hole

Change

the

following sections.

consistsofan

an

index LED-

signal

from

the

detected.

This

(see

section

brushless

index

index

pulse

2.3).

is

DC

Functional

Description

CORVUS DEALER SERVICE

The

control

drive

2.2.4

The

head

of

the

motion

2.2.5

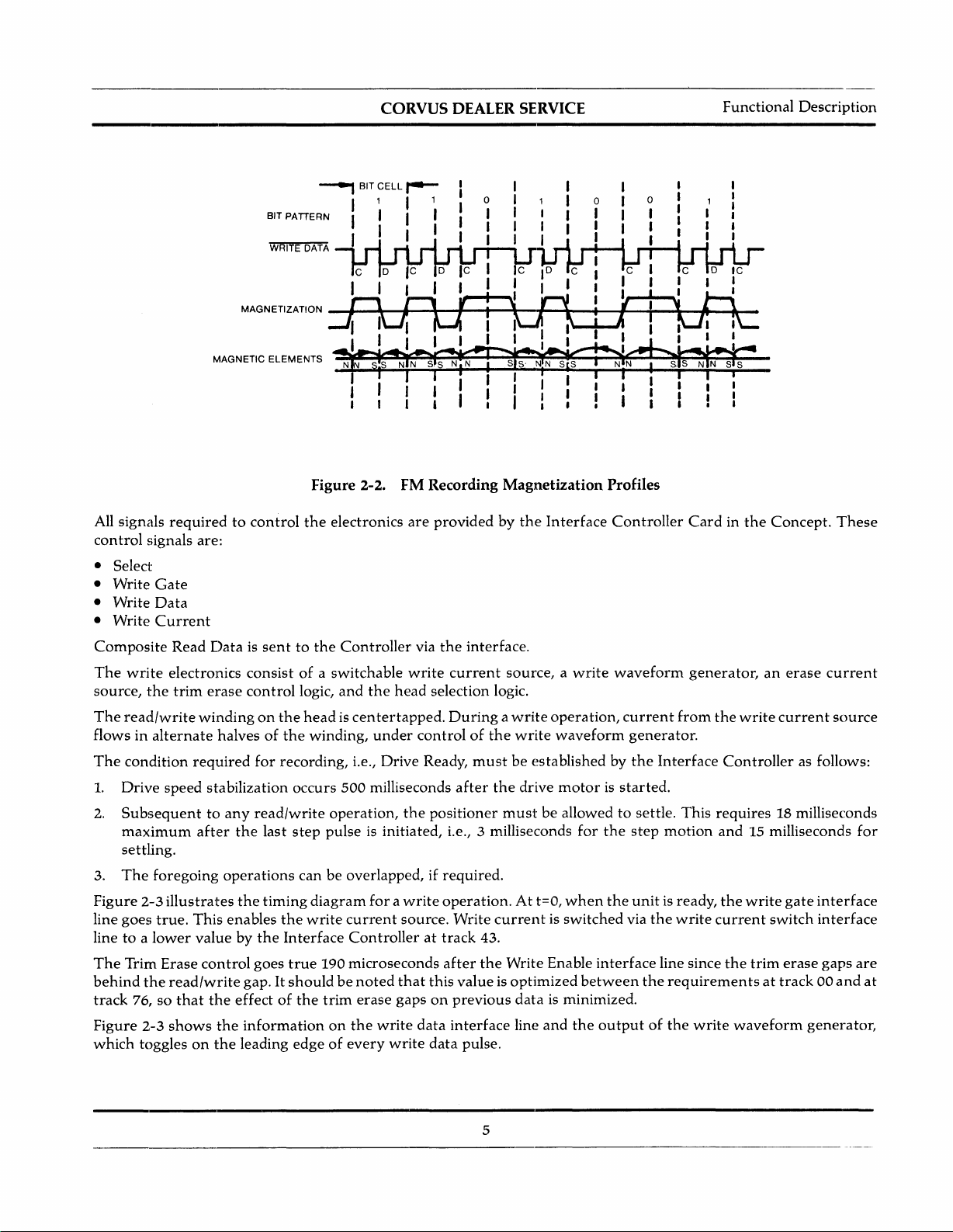

Informationisrecordedonthe

profilesineach

circuitry

motor

is allowedtocomeupto

Carriage

positioning

read/write

duringawrite

containsaninterface

Positioner

carriage. In additiontothe

Write/Erase

bit cell

system

operation.

Control

for

the

Figure

speed.

2-1.

control

Functional Block Diagram

line.

When

the

Control

usesabipolar-driven

logic

diskettebyusingadouble-frequency

number

sequence

motor

necessary

shown

drive,

for

for

4

motor

FM

drive

motor

control

which

changes

control,agateisprovided

code.

recording.

one

Figure

interface

phase

2-2

line is false (high),

for

each

that

illustrates

track

advancement

inhibits

the

magnetization

the

positioner

CORVUS DEALER SERVICE

........,

BIT

CELL

I 1 I 1

BIT PATTERN I I

WRITE DATA I I

,.......

Functional

Description

All signals

control

requiredtocontrol

signals are:

• Select

• Write

• Write

• Write

Composite

The

source,

The

Gate

Data

Current

Read

write

electronics

the

trim

read/write

flowsinalternate

The

condition

1.

Drive

2.

Subsequenttoany

maximum

required

speed

after

settling.

3.

The

foregoing

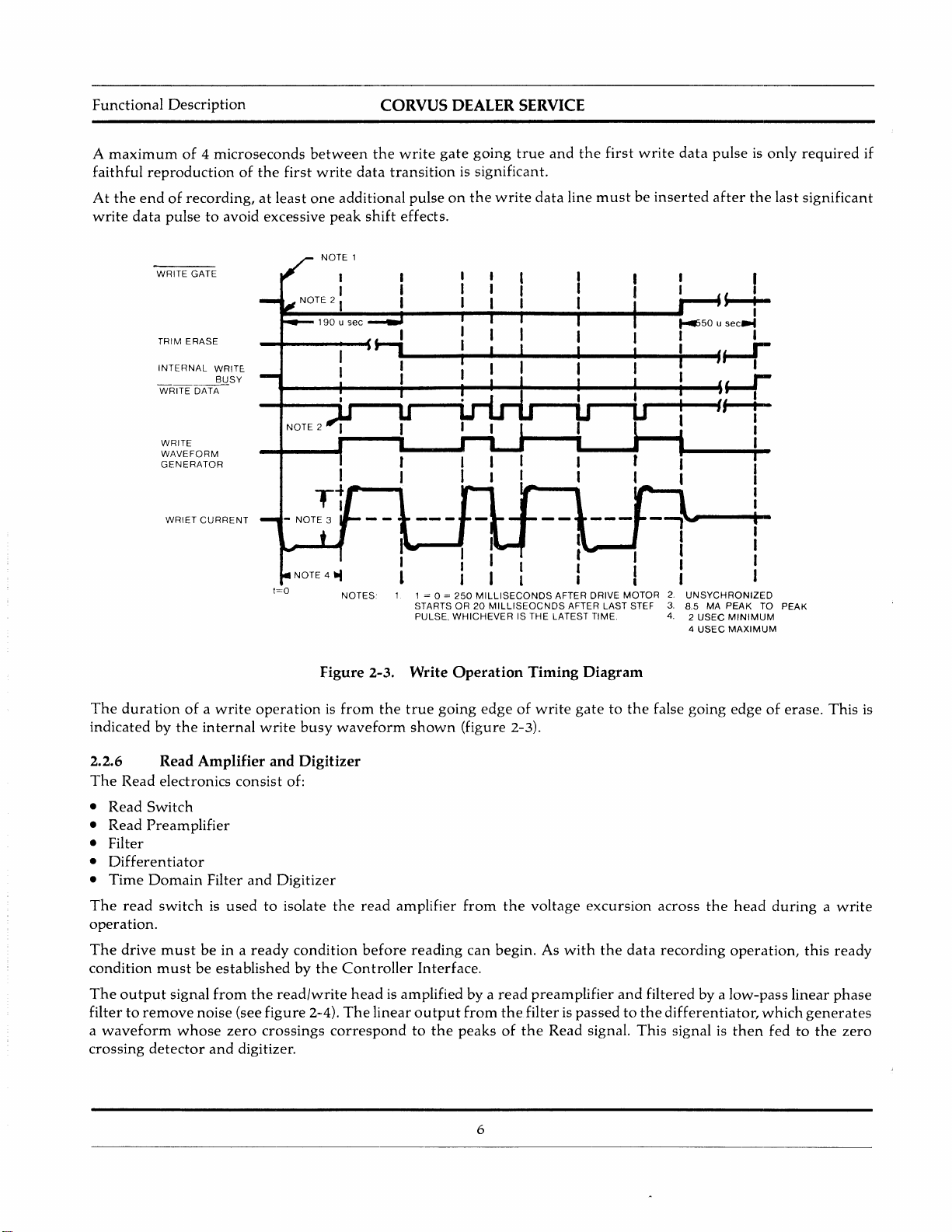

Figure

line

linetoa

The

behind

track

Figure

which

2-3

illustrates

goes

true.

lower

Trim

Erase

the

read/write

76,

so

that

2-3

shows

togglesonthe

This

valuebythe

Dataissenttothe

consistofa

erase

control

windingonthe

halvesofthe

for

recording,

stabilization

occurs

read/write

the

last

step

operations

the

timing

enables

the

Interface

control

goes

true

gap. It

shouldbenoted

the

effectofthe

the

informationonthe

leading

edgeofevery

Figure

the

logic,

2-2.

electronics

Controller

switchable

and

the

FM

are

via

write

head

headiscentertapped.

winding,

pulse

under

controlofthe

Le.,

Drive

Ready,

500

milliseconds

operation,

the

is initiated, i.e., 3 milliseconds

canbeoverlapped, if

diagram

write

forawrite

current

source.

Controllerattrack

190

microseconds

that

trim

erase

gapsonprevious

write

data

write

Recording Magnetization Profiles

providedbythe

the

interface.

current

selection logic.

Duringawrite

mustbeestablished by

after

the

positioner

required.

operation.Att=O,

Write

currentisswitched

43.

after

the

this

valueisoptimized

interface

data

pulse.

Interface

source,awrite

operation,

write

waveform

Controller

waveform

current

generator.

the

drive

motorisstarted.

mustbeallowedtosettle.

for

the

step

when

the

unit

via

Write Enable

data

is minimized.

line

and

interface

between

the

outputofthe

the

Cardinthe

Concept.

generator,anerase

from

the

write

current

Interface

motion

is ready,

the

write

line since

Controller

This

requires18milliseconds

and15milliseconds

the

write

gate

current

the

trim

switch

erase

as follows:

requirementsattrack00and

write

waveform

generator,

These

current

source

for

interface

interface

gaps

are

at

5

Functional

A

maximum

faithful

At

write

reproductionofthe

the

endofrecording,atleast

data

Description

of4microseconds

between

first

one

pulsetoavoid excessive

write

additional

peak

CORVUS DEALER SERVICE

the

write

gate

going

true

data

transition

shift

pulseonthe

effects.

is significant.

write

and

data

the

first

line

mustbeinserted

write

data

pulseisonly

after

the

required

last

significant

if

The

durationofa

indicated

WRITE GATE

TRIM ERASE

INTERNAL

WRITE DATA

WRITE

WAVEFORM

GENERATOR

WRIET

by

the

WRIT~

BUSY

CURRENT

write

internal

......

_-+-_-i-_--t

NOTE 2

I

Tt

Figure

operationisfrom

write

busy

waveform

~-...,..

.....i~-~-~-...jI

-~-"'---..a..-___lI~_4~

1 = 0 =

250

STARTS OR20MILLISEOCNDS

PULSE,

WHICHEVER

2-3.

Write Operation Timing Diagram

the

true

going

shown

(figure

I

MILLISECONDS

IS THE LATEST TIME.

edgeofwrite

2-3).

I

t""'--

I

I I

AFTER DRIVE

AFTER LAST STEF

gatetothe

MOTOR

...

I I

........

2.

UNSYCHRONIZED

3.

8.5 MA

4.2USEe

4

false

going

s--:...

50usec

....

H-r

I I

PEAK

MINIMUM

USEC

MAXIMUM

edgeoferase.

I

I

TO PEAK

This

is

2.2.6

The

Read

•

•

Read

Read Amplifier and Digitizer

Read electronics

Switch

Preamplifier

• Filter

•

Differentiator

•

Time

Domain

The

read

switchisusedtoisolate

operation.

The

drive

mustbein a

condition

The

mustbeestablishedbythe

output

signal

filtertoremove

a

waveform

crossing

whose

detector

Filter

from

noise

and

consist

and

ready

the

(see

zero

digitizer.

of:

Digitizer

condition

read/write

figure

2-4).

crossings

the

read

amplifier

before

Controller

reading

Interface.

headisamplifiedbya

The

linear

output

correspondtothe

from

the

can

begin. As

read

from

the

filterispassedtothe

peaksofthe

6

voltage

excursion

with

the

preamplifier

Read signal.

data

and

filteredbya

This

across

the

recording

operation,

low-pass

differentiator,

signal is

head

duringawrite

which

then

fedtothe

this

linear

generates

ready

phase

zero

Loading...

Loading...