CORRECT CRAFT Sport Nautique 216 User Manual

Dear Correct Craft Owner:

Congratulations on your purchase of a Sport Nautique 216 / Air Nautique 216.

You have chosen a boat that is unequaled “on the waters of the world” for

water-skiing and wakeboarding.

Since 1925, we have manufactured some of the finest products boat builders

can produce.

Your boat was manufactured with the latest marine technology and materials.

You have bought into a legacy handed down by W. C. Meloon over 78 years

ago. His dedication to building boats to the glory of God remains true today as

the cornerstone of our commitment in bringing to you the finest in water sports

boats. We continue to lead this industry in technology and design innovation.

Our heritage is a source of pride. Years of experience, including that of four

generations of Meloons have gone into the building of your boat. We hope that

you will enjoy it to the fullest.

Take a moment to review this owners manual for your boat. We have

assembled this manual to inform you about your boat and educate you further

on boating. There are many tips and tricks on care and maintenance sprinkled

throughout the manual, along with some cautions that will apply to your boat.

Boating is very important to us and we would like you to enjoy many years of

boating.

Welcome into the Nautique family.

Sincerely,

Walter N. Meloon

President/Chief Executive Officer

Trust in the Lord with all thine heart;

and lean not unto thine own understanding.

In all thy ways acknowledge him,

and he shall direct thy paths.

Proverbs 3:5-6

i

T ABLE OF C ONTENTS

Chapter 1. Overview ............................................... Chapter . Page

Dash Pod and Console Layout...................................1.1

Specifications..............................................................1.1

Keyless Ignition and Serial Switching.......................1.2

Multiple Keyless Ignition Codes................................1.3

Primary User Code.....................................................1.4

Erasing the User Codes ..............................................1.4

Key Functions.............................................................1.5

Dash Pod Switches.....................................................1.6

Bilge Pump.................................................................1.7

Bilge Pump Only Mode..............................................1.7

Navigation Lights ......................................................1.8

Anchor ........................................................................1.8

Ventilation Blower......................................................1.8

12 Volt Plug ...............................................................1.8

Engine Warning Light ...............................................1.8

Gauges ........................................................................1.8

Emergency Cut-off Switch ........................................1.9

Throttle .......................................................................1.9

Boarding Platform Safety............................................1.9

Pylon...........................................................................1.11

Lifting Rings ..............................................................1.12

Capacity Plate ...........................................................1.12

Hull Identification Number .......................................1.13

Driver’s Seat Adjustment ..........................................1.13

Fueling .......................................................................1.14

Ski Locker Latch.........................................................1.14

Love Seat ...................................................................1.14

Jump Seat....................................................................1.14

Walk Through Windshield..........................................1.14

Dash Cooler ...............................................................1.14

Stereo Option..............................................................1.14

Engine Box Latching/Lifting ....................................1.15

Engine Cooling Water Intake Shut-Off Valve............1.15

Stern Seat Bottom Cushion ......................................1.15

Bow Features..............................................................1.15

Trunk...........................................................................1.16

Manual Latch Release in Trunk .................................1.16

Fuel Tank Location ....................................................1.16

Optional Launch Control System...............................1.16

Winterizing Launch Control System..........................1.16

Optional Flight Control Tower (folding)...................1.17

Flight Clips.................................................................1.17

Boarding Platform Removal.......................................1.17

Battery Location..........................................................1.17

Correct Craft Cruise ...................................................1.17

Speedometer................................................................1.18

Tachometer .................................................................1.18

ii

Chapter 2. Faria Serial Bus Gauges........................2.1

Chapter 3. Engine Overview

Engine Check-List......................................................3.1

Fuel Injected Engine Does Not Start..........................3.2

Break In Procedure.....................................................3.4

General Notes..............................................................3.4

Chapter 4. Cautions and Warning Labels.................4.1

Chapter 5. Boat Handling /Safety Regulations........5.1

Chapter 6. Boat Care

Bilge Pump ................................................................6.1

Propeller ....................................................................6.2

Stuffing Box ...............................................................6.4

Quick Drain Oil..........................................................6.5

Salt Water Boating......................................................6.6

Battery Maintenance ...................................................6.6

Winterizing Your Boat................................................6.7

Gelcoat Care...............................................................6.8

Teak Care....................................................................6.9

Glass Care...................................................................6.9

Metal Care ..................................................................6.9

Vinyl Care...................................................................6.10

Tunable Rudder...........................................................6.11

Chapter 7. Trailering

Hitch ...........................................................................7.1

Security.......................................................................7.1

Towing Your Boat.......................................................7.1

Wiring.........................................................................7.1

Long Trips ..................................................................7.2

Chapter 8. Warranty and Owner Responsibility.......8.1

Chapter 9. Service Records & Order Forms

Warranty Transfer Application...................................9.1

Correct Craft Dealer/Nautique Service Center

Locations ....................................................................9.2

Nautique Friend Program...........................................9.3

NOA Membership Form ............................................9.4

Dash Plaque Order Form............................................9.6

Glossary......................................................................9.7

iii

iv

Chapter 1

O VERVIEW

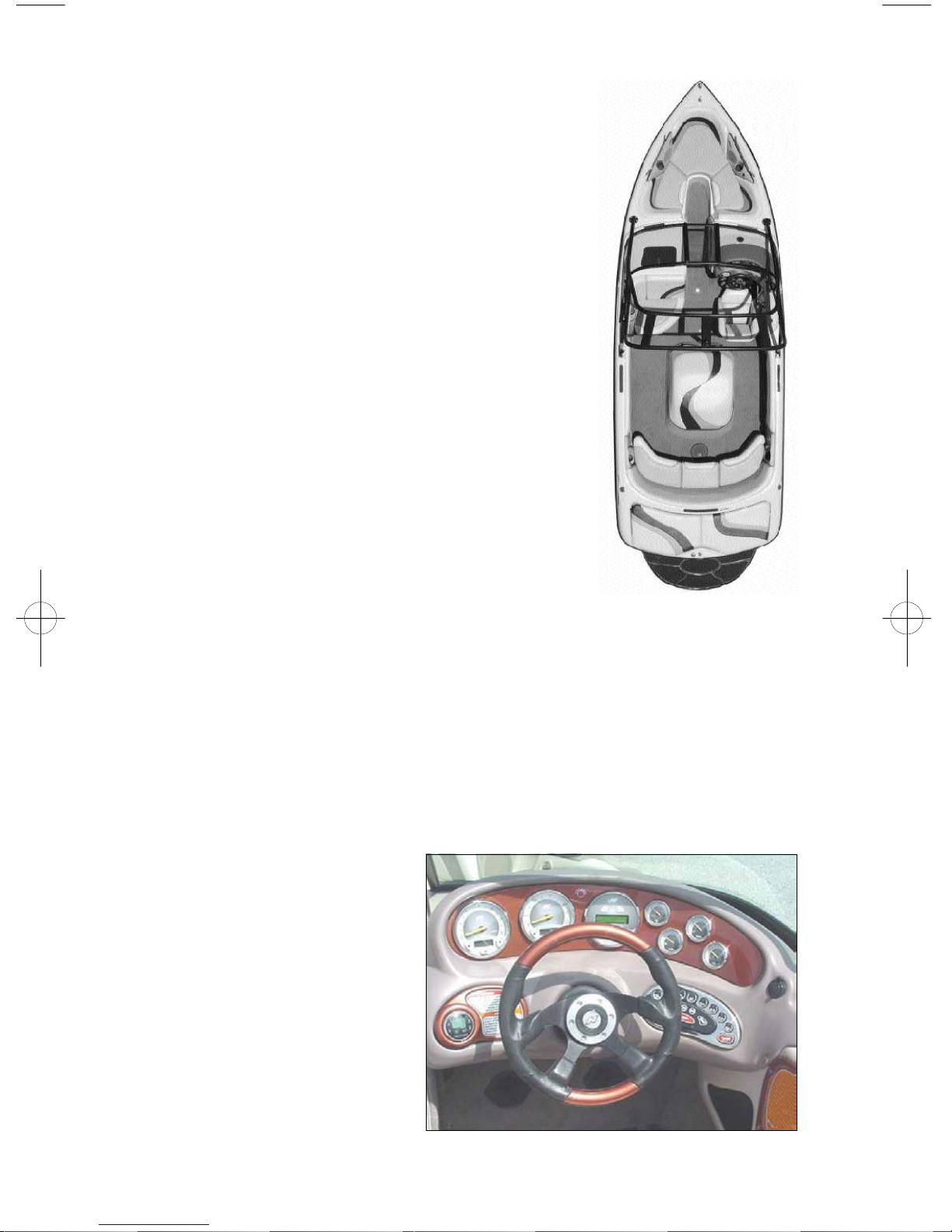

Specifications Sport Nautique 216 / Air Nautique 216

Length (without platform) . . . . . . . . . 21’ 7.5”’ (6.59 m)

Length (with platform) . . . . . . . . . . . . . 23’ 5.5” (7.15 m)

Beam (measured rubrail to rubrail) . . . . . . . 91” (2,31 m)

Draft . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24” (0.61 m)

Water line to top of Air Nautique

Flight Control Tower . . . . . . . . . . . . . . . . . . 83” (2,1 m)

Water line to top of Air Nautique

Flight Control Tower (folded forward). . . . . . . 58” (1.47 m)

Water ballast tank Capacity (Approx.. 400 lbs.) 50 Gal (189 ltr)

Approximate Weight. . . . . . . . . . . . . . . . 3280 lbs. (1,315 kg)

Lifting Rings (Distance between) . . . . . 19’ 9” (6.02 m)

Fuel Capacity . . . . . . . . . . . . . . . . . . 30 Gallons (114 ltr)

Max Capacity. . . . . . . . . . . . . . 10 people/1325 lbs. (602 kg)

Welcome to the Sport Nautique 216 / Air Nautique

216 family.

We realize you may be anxious to get your boat in

the water. This manual has been written to

familiarize and educate you about your boat so you will be more comfortable

out on the water. Your boat is built to provide you with the finest watersports

boat in the world. Whether you are slalom skiing or ripping on a wakeboard,

we trust you and your family will enjoy this boat for many years.

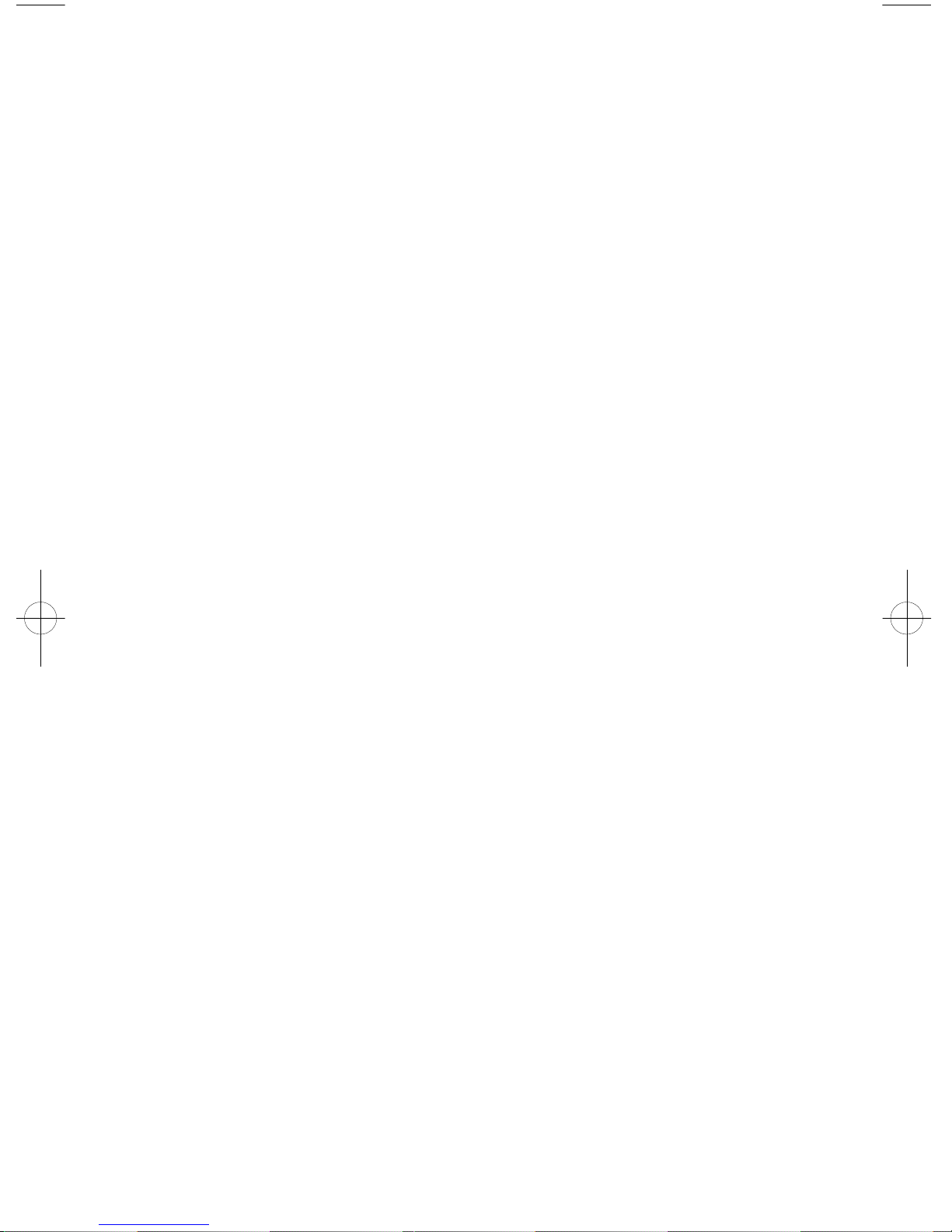

Let’s start by taking a look at the dash pod to familiarize yourself with the

locations of the gauges and switches. For 2003 Correct Craft offers three

different packages of options for your Nautique. These packages feature

equipment or gauges. Based on your purchase package, these may be

standard on your boat.

Consult your dealer for

clarification of the featured

package on your Nautique.

Dash Pod and Console Layout

Standard equipment on your

boat are the following

gauges: oil pressure, engine

coolant temperature,

speedometer, tachometer/

hour meter, fuel level,

voltage. Other equipment

based on your package may

Dash Pod

1.1

include: air/water temp gauge, clock, depthfinder,standard stereo remote

control or digital stereo remote control, Correct Craft Cruise or Perfect Pass

Digital Pro speed control. The optional gauges can be positioned on the

console located to the right of the drivers knee.

CAUTION: The keypad and switch control box will be damaged beyond repair if

the boat battery cables or the main power leads to the keypad and switch control

box are reversed. Be sure to use caution and avoid reversing these connections.

Keyless Ignition and Serial Switching

The ignition switch system is keyless and has three modes of operation.

Keyless Ignition

Locked Mode

When the boat battery is first connected, the unit is in locked mode. In this

mode, the horn, bilge pump, bilge blower, and code buttons are operational.

Unlocked Mode

Unlocked mode is entered after the user successfully enters the user code,

presses, and releases the start button. When the code keys are pressed, the

system indicator light to the right of the start button will turn on while the key

is pressed down. This indicates the button has actually been pushed. When

the system is unlocked, power is supplied to the boat and the system indicator

light will turn on. At this point all keypad buttons are operational and

actuating these buttons will control the corresponding boat functions. To put

the unit back in locked mode, the user must successfully enter the user code

then press the stop button. When the code keys are pressed, the system

indicator light to the right of the start button will turn off while the keys are

pressed down. Power will be cut to all of the accessories with the exception

of the horn, bilge pump, bilge blower and code buttons.

Run Mode

First enter the unlocked mode.

Pressing and releasing the start button quickly will put the unit in run mode.

When this is done, power is supplied to the engine ignition, but the engine will

1.2

not crank and the ignition indicator light just left of the start button is turned

on. If the start button is not pressed again within 15 minutes the unit will exit

run mode by shutting off power to the ignition and re-enter unlocked mode. If

the user presses and holds the start button, power is supplied to the ignition and

starter for as long as the user holds the start button down. All accessory

buttons are operational in this mode as well. Pressing the stop button will shut

off the engine and the unit is then put back in unlocked mode.

After the engine starts, release the start button.

Automatic Reversion to Locked Mode

If no keypad activity takes place for ten hours after unlocking, the system will

automatically revert to the locked mode. This helps to minimize battery drain.

Automatic Back-lighting

Pressing any keypad button will automatically turn the keypad back-lighting

on for ten seconds. This feature is useful for those that use their boat after dark

to find the appropriate keypad buttons.

Multiple Keyless Ignition Codes

The keyless ignition system has provision for three different ignition codes.

Any of the three codes may be used to unlock or lock the system.

The “Master Embedded Code” is programmed into the system at Correct Craft

Inc. and is not changeable, remaining with the boat for its life. This code can

be used to unlock the system, to lock the system and to erase the two user

codes.

The “Primary User Code” is programmed into the system by the owner with

the dealer’s help at the time of boat delivery. This code is used to unlock the

system, to lock the system, and to add or change the “Secondary User Code”.

The “Secondary User Code” is programmed into the system by the owner

when necessary. This code is only used to unlock or lock the system. The

“Secondary User Code” is excellent to use for limited access to the boat.

Programming and/or Changing Primary or Secondary User Code

Note: To help prevent battery drain, when you are finished using the boat

make sure you STOP the engine and LOCK the PME ignition system (two

steps). Note: The “System Indicator Light” is on the right-hand side of the

ignition keypad. The “Ignition Indicator Light” is on the left-hand side of the

ignition keypad.

Programming the Primary User Code

Make sure that the system indicator light is off. Until a primary user code is

set, the keyless ignition will behave as follows. Pressing start once will unlock

the system while pressing it a second time will start the engine. Pressing stop

1.3

once will turn off the engine while pressing it a second time will lock the

system.

To program the primary user code, press the 1/2 button and the 7/8 button at

the same time, putting the system in code programming mode. The system

indicator light will be flashing.

Enter a code from two to eight characters long and press start. For verification,

re-enter the code and press start again. The system indicator light should stop

flashing and stay on. If the light does not stop flashing, press stop and begin

again.

To lock the system re-enter either the primary user code or the master

embedded code and press stop.

Changing the Primary User Code

NOTE: The current primary code must be used to change to another primary

code.

Make sure that the system indicator light is off. Enter the primary user code

then press the 1/2 button and the 7/8 button at the same time. This puts the

system in code programming mode. The system indicator light will be

flashing.

Enter a code from two to eight characters long and press start. For verification,

re-enter the code and press start again. The system indicator light should stop

flashing and stay on. If the light does not stop flashing, press stop and begin

again.

To lock the system re-enter either the new primary user code or the master

embedded code and press stop. Please note, changing the primary code will

erase the secondary user code. The secondary code will need to be re-entered.

Programming or Changing the Secondary User Code

NOTE: The secondary code will only lock or unlock the system & can not be

used for any reprogramming

Make sure that the system indicator light is off. Enter the primary user code

and press the 1/2 button and the 5/6 button at the same time putting the system

in code programming mode. The system indicator light will be flashing.

Enter a code from two to eight characters long and press start. Re-enter the

code and press start again. The system indicator light should stop flashing and

stay on. If the light does not stop flashing, press stop and begin again.

To lock the system re-enter any of the three codes and press stop.

Erasing the User Codes

Make sure the system indicator light is off. Enter the master embedded code

and press the 1/2 button and the 7/8 button at the same time. This will erase

1.4

the system user codes.

The keyless ignition will now behave as if there are no codes in memory.

Pressing the start button will unlock the system and pressing the stop button

will lock it without entering a code. To program a primary user code, make

sure the system indicator light is off and press the 1/2 button and the 7/8 button

at the same time. This puts the system in code programming mode. The

system indicator light will be flashing. Follow the last two steps above to

complete programming the primary user code.

Key Functions

The following paragraphs describe the functions of individual keys on the

keypad. The keys will be described in order left to right. Each of the keys,

except for the “horn” key, has an indicator light on the top of the key. The

indicator light will be on if the function controlled by that key is on.

Function Keys

LCS or Ballast Control

The first three keys control the Launch Control System fill and drain pumps,

if the boat is equipped with a ballast tank or tanks. Various configurations can

include one single tank, two side tanks, or two side tanks and a forward

mounted tank. If the boat is equipped with a single tank the key labeled

“belly” will control the pumps for the tank. The keys for the two side tanks

are labeled “port” or “starboard” and the forward-mounted tank key is labeled

“belly.”

To turn on the fill pumps for any tank, push and quickly release the appropriate

key. This also turns on the indicator light at the top of the key. Pushing and

holding the appropriate key for a short time turns on the drain pumps and also

causes the indicator light for that key to begin flashing. Pushing and releasing

one of the keys, with either fill or drain pumps on, will turn off the pumps.

1.5

Please see the manual section covering optional LCS or ballast tanks for

complete operating instructions.

Shower

The shower is turned on or off by pressing and releasing the key. The indicator

light is on whenever the shower is on.

Heater

The heater key controls four different heater functions. Pushing and releasing

the “heater” key scrolls from “off” to “low speed” to “medium speed” to “high

speed” and back to “off.” The indicator light for this key is on if the heater is

running at anyof the three speeds.

Courtesy / Docking Lights

A quick push and release of this key turns on the indicator light and the

courtesy lights, while a push and slight hold turns on the indicator light and the

docking lights. Both the courtesy and docking lights can be turned on at the

same time, but only if the courtesy lights are turned on first. If either or both

of the two light functions are on, please note that the indicator light turns on

and a push and release will turn off any of the lights that are on.

Navigation / Anchor Light

A quick push and release of this key turn on the navigation lights and the

indicator light, while a push and slight hold will only turn on the anchor light

and will also cause the indicator light to flash. A push and release of the key

turns off either of the lights.

Bilge Pump

The bilge pump(s) is turned on or off by pressing and releasing the key. The

indicator light is on whenever the pump(s) is on.

Bilge Blower

The bilge blower is turned on or off by pressing and releasing the key. The

indicator light is on whenever the blower is on.

Horn

The horn key is strictly a momentary switch. The horn will blow whenever the

key is pushed and will stop when the key is released.

Dash Pod Switches

All dash pod switches interface with a sealed circuit breaker box located under

the bow. The circuit breaker box consists of sixteen soft opaque flexible vinyl

tubular shields which cover sixteen circuit switches. When the circuits are

functioning, the tubular shield is somewhat flexible. A tripped circuit breaker

will extend and fill the tubular shield, causing it to be inflexible. To locate a

1.61.6

tripped circuit breaker, run your fingers over the two rows of switches and

locate the switch shield that has become inflexible. To re-set, simply press in

the extended circuit switch shield.

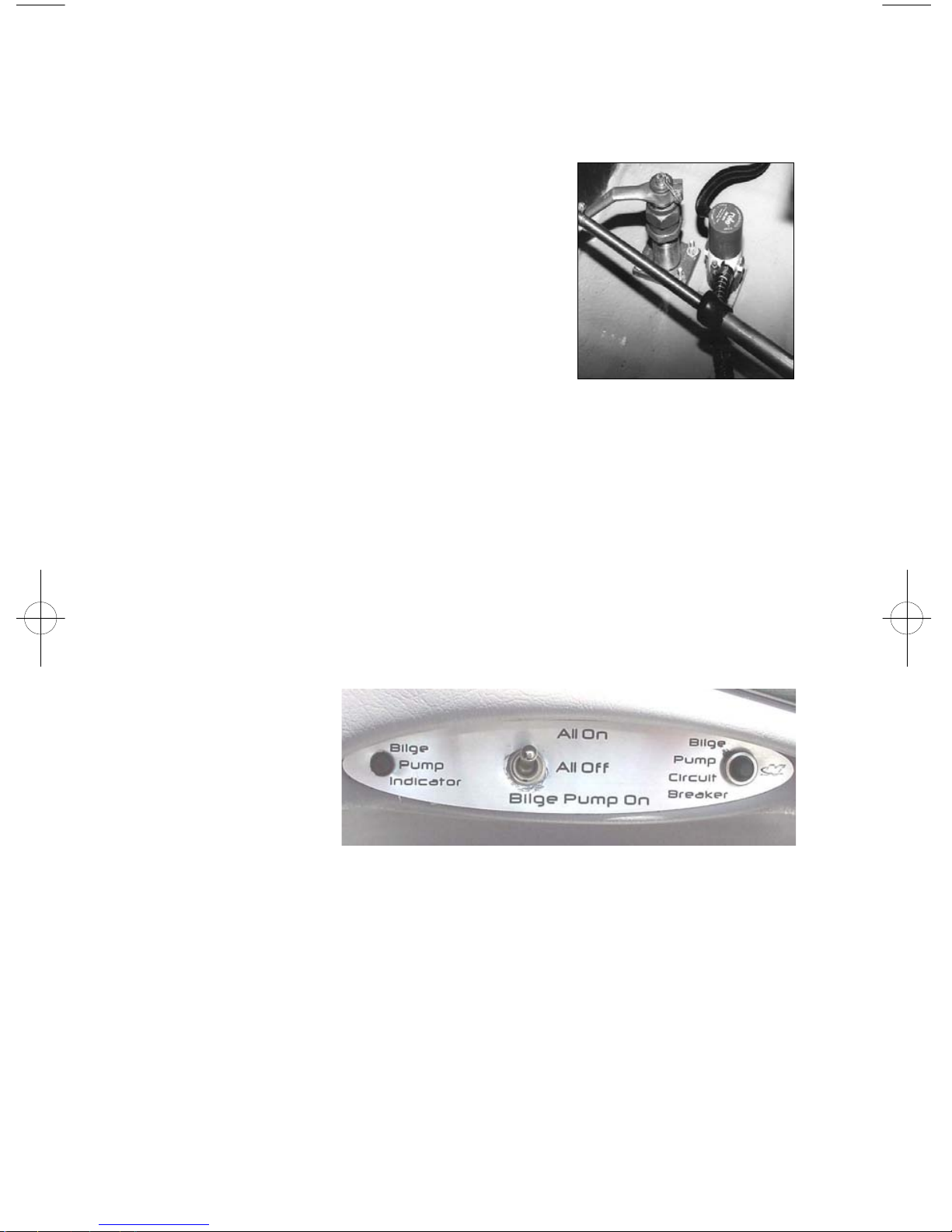

Bilge pumps

The bilge pump switch turns on the bilge pumps.

There is a bilge pump down by the pylon and

another bilge pump back by the rudder. When

you push the bilge pump key on the keypad, both

pumps will come on and run for several moments

to “sense” if there is water in the bilge. If there

is water in the bilge, they will remain on until the

water is pumped out. If there is no water in the

bilge, they will turn off. If you want immediate

Bilge Pump

pump action, turn the switch off and then back on

again. The pumps will turn on periodically to determine if there is water in the

bilge. If so, they will remain on until the water is pumped out. Trash in bilge

can hurt bilge pump and fill pumps for ballast systems.

Note: The “Bilge” switch must be turned on for this feature to operate.

This will not drain significant power from the battery unless the bilge

pumps are required to run frequently because of a leak or excessive

rainwater. This pumping system should not be relied on over an extended

period of time. We suggest you frequently inspect your boat.

Bilge Pump Only Mode

This feature is

activated by a

switch located

below the gauges

on the side

console. The

switch has three

positions, on, off

PME Bypass

and bilge. If the boat is going to sit for more than a few days with the bilge

pump on, it is important that the switch is set in the “bilge” position to

minimize battery drain. This will activate the bilge pump and shut off power

to the Serial Switching and Keyless Ignition System. It is important to

remember that the engine or other accessories can not be used unless the

switch is in the “on” position.

Located with the switch is a circuit breaker and indicator light for the bilge

pump. The circuit breaker is only active when the switch is in the “bilge”

position. The indicator light will come on anytime the bilge pump is activated.

1.7

Navigation Lights

This switch controls the navigation lights. The law requires the bow light and

the 360 degree light (located at the transom) be turned on while running the

boat after sunset or before dawn.

Anchor

This switch turns on the 360 degree light. Insert this light pole into the

receptacle located on the transom and push the anchor switch on the pod to turn

this light on. This light is required by law to be on after sunset and before

dawn when the boat is not moving.

Accessories

There is an accessory button provided that controls power to a yellow wire

coiled up near the control box. Power to this wire is protected by a 10-amp

circuit breaker. Attaching an accessory to this wire should be done by

someone knowledgeable in DC electrical wiring.

Ventilation Blower

This switch turns on the blower in the bilge. This blower must be turned on

for four (4) minutes prior to engine ignition and also at anytime when the boat

is operated at slow speeds.

12 Volt Plug

This plug can be utilized to power cellular phones, video cameras or various

other electronics. This plug is powered through a ten (10) amp breaker.

Engine Warning Light

This light is in the center of the dash pod between the speedometer and the

tachometer and indicates high engine temperature.

Horn This is a momentary switch.

Gauges on the Pod

• Volt This gauge tells you how many volts the alternator is producing. During

normal running, it should read 13-14 volts. Running a heater, shower or

stereo amplifier will draw power from the alternator and possibly drop

voltage below normal. If this occurs, the battery will not charge correctly.

• Temp This tells you the temperature of the coolant in the engine.

• Oil Pressure This gauge tells you the engine oil pressure.

• Tachometer / Hour Meter This gauge indicates the revolutions per minute the

engine is turning, and the total accumulated engine hours.

• Speedometer Your Nautique is equipped with a speedometer by Faria. For a

detailed analysis of your speedometer, refer to the Faria speedometer section

1.8

at the end of this chapter or in Chapter 2.

• Emergency Cut-off Switch There is an emergency cut-off switch for the

protection of you and your passengers. The clip at the end of the cord must

be attached securely to the driver. Check the system by attaching the clip to

the switch, start the boat and then pull the clip off the switch. The engine

should stop. UNDER NO CIRCUMSTANCES SHOULD YOU OPERATE

THE BOAT IF THIS SYSTEM DOES NOT FUNCTION PROPERLY. If it

does not function correctly, contact your Correct Craft dealer to have the

problem corrected.

• Throttle The throttle control consists of the

throttle lever, a lock out ring and a neutral

button. The neutral button is a push-button at

the bottom of the throttle lever which allows the

throttle to be advanced without the transmission

being engaged. The throttle lever must be in the

neutral position to start the engine.

The throttle arm has three detent positions.

Throttle

Note: When in a detent position the throttle arm

will resist movement, but can be moved with sufficient pressure. Neutral

detent is straight up. Forward detent is approximately 30 degrees toward the

bow, and reverse detent is approximately 30 degrees toward the stern. Moving

the throttle from neutral detent to either forward or reverse detent will shift the

boat into that gear. The engine will remain at idle speed. To increase (forward

or reverse) engine speed and therefore boat speed, continue to rotate the

throttle arm past the detent.

Note: When shifting out of neutral, it is best to pause in the appropriate detent

before applying additional throttle.

The lockout ring mechanism prevents unintentional shifting into forward or

reverse. To operate the throttle lever, you must lift the lockout ring. DO NOT

shift quickly from forward into reverse. Stay in the neutral position until

the boat has lost speed before shifting into reverse. Shifting should not be

attempted above 1200 RPM except in emergency situations.

CAUTION: LOADING AND UNLOADING OF PASSENGERS FROM

A DOCK OR FROM THE WATER SHOULD ONLY BE DONE AFTER

THE ENGINE HAS BEEN TURNED OFF.

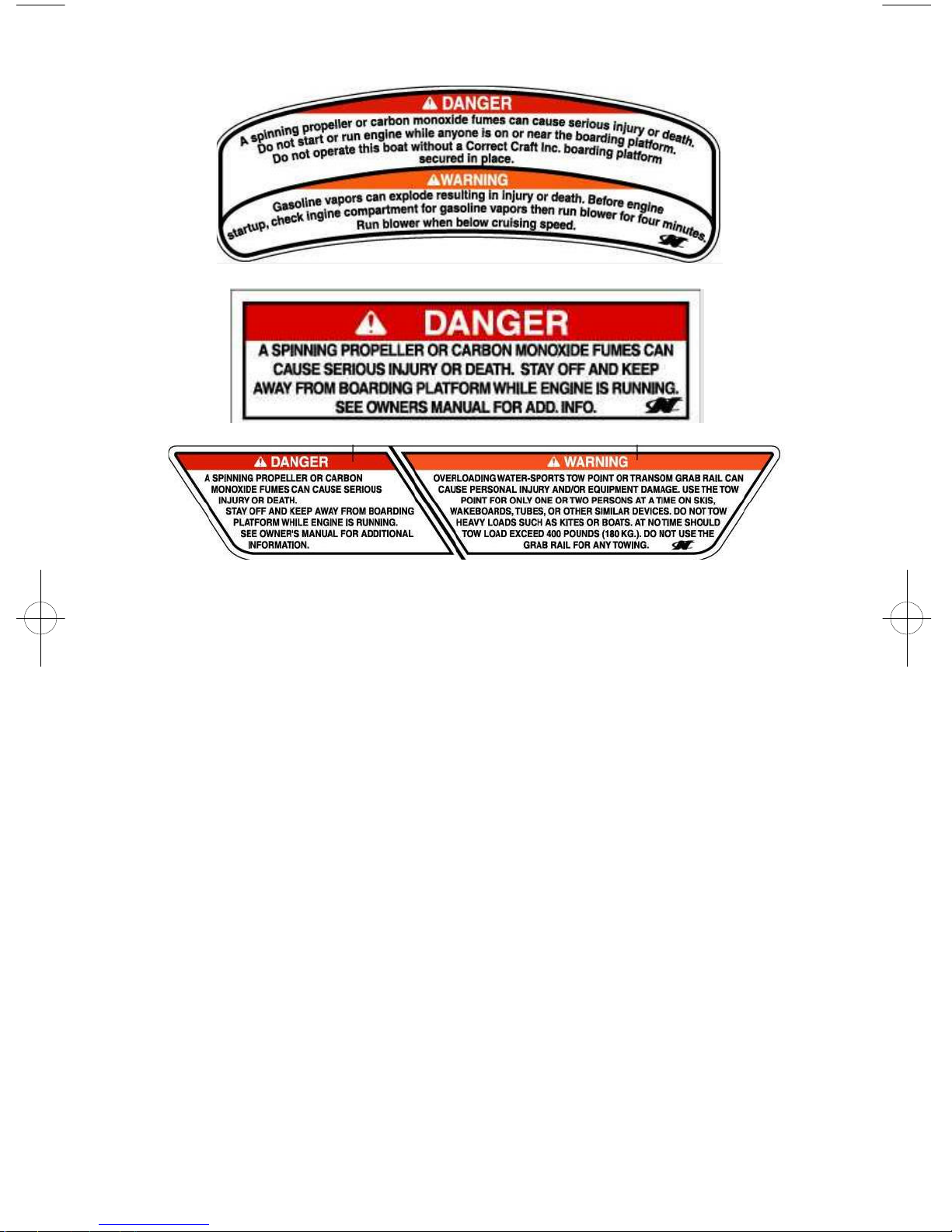

Boarding Platform Safety

The boarding platform of your boat is a very convenient feature that greatly

enhances the water towed sports experience. There are however, some serious

safety concerns regarding the use of the platform. Correct Craft, Inc. has

placed warning labels at the driver’s position, on the deck at the rear of the

occupant area, and on the transom.

1.9

It is very important to read and be familiar with the information contained in

these labels and to always adhere to the boat operation practices described on

them. The United States Coast Guard issued a SAFETY ALERT on August

28, 2001 that cover some of the issues of improper use of the boarding

platform. The SAFETY ALERT and portions of the accompanying

information follow:

SAFETY ALERT:

The United States Coast Guard advised boaters not to “Teak/Drag Surf.”

Recent boating fatalities revealed that carbon monoxide (CO) emitted from a

vessel’s exhaust resulted in CO poisoning and the death of at least six teak

surfers. “Teak/Drag Surfing” places the individual in position directly

exposed to the CO in the engine’s exhaust. This may result in a loss of

coherent responses and even death. In addition, “Teak/Drag Surfing”

dangerously exposes the individual to a possible propeller injury, and since it

is done without a life jacket (PFD), it significantly increases the probability of

drowning. Therefore, the Coast Guard stresses, “Teak/Drag Surfing” is a very

dangerous activity and advises boaters not to participate in it.

The Coast Guard pointed out that carbon monoxide is one of the most

dangerous gases. It strikes before you know you are exposed and it impairs in

a way that can and too often doeslead to death. That is why it is so important

to the Coast Guard that in every circumstance where it can be avoided, it is.

1.10

“Why is it dangerous? It is like playing with a loaded gun,” Evans said. He

then noted, “As I explained in the previous advisory, “Teak/Drag Surfing”

entails individuals taking hold of the swim platform of a vessel while it is

underway. After a large wake builds up, they let go of the platform and body

surf. This puts the individual directly in the path of the vessel’s exhaust where

they breathe in dangerous levels of carbon monoxide. If that in itself is not

dangerous enough, the individuals are also in a position that a slight

miscalculation may throw them in to a spinning propeller. “And, it doesn’t

stop there, Evans said, in order to “Teak/Drag Surf” you cannot wear a life

jacket, the two do not go together. So, all this is a receipe for tragedy. A

tragedy that the Coast Guard wants to see averted, and that is why we are reissuing this alert.”

Pylon

The ski pylon is manufactured from high strength aluminum alloy that is

engineered for durability. It is hard coat anodized and impregnated with a

PTFE (teflon) material. If the pylon becomes loose, stop using the pylon and

take the boat to your Correct Craft dealer for service.

PYLON--WARNING/CAUTION--AVOID PERSONAL INJURY. THIS WATER

SKI PYLON WAS DESIGNED FOR WATER SKIING ONLY. ANY OTHER

USES, SUCH AS PARASAILING, KITE FLYING, TOWING OTHER BOATS

AND/OR USING AN EXTENDED PYLON, ECT., MAY OVERSTRESS THE

PYLON POSSIBLY CAUSING PERSONAL INJURY AND/OR EQUIPMENT

DAMAGE. DO NOT SIT BEHIND (AFT) THE TOW PYLON WHEN TOWING

SKIERS.

CAUTION: ALTHOUGH THE EXTENDED PYLON AND BAREFOOT

BOOMS HAVE BECOME POPULAR ADDITIONS TO MANY TOURNAMENT

INBOARDS, CORRECT CRAFT STRONGLY OBJECTS AND OPPOSES THE

USE OF ANY PYLON EXTENSION WHETHER UP OR TO THE SIDE OF

ANY OF IT’S PRODUCTS. THE USE OF PYLON EXTENSIONS CAN ALTER

THE HANDLING CHARACTERISTICS OF THE BOAT, POSSIBLY

RESULTING IN DANGEROUS INSTABILITY, WHICH COULD THEN LEAD

TO LOSS OF CONTROL; A SITUATION WHICH COULD CAUSE SERIOUS

OR FATAL INJURY TO THE BOAT DRIVER, PASSENGER(S), PERSON(S)

BEING TOWED, AND ANYONE ELSE WHO MIGHT BE IN THE VICINITY

OF SUCH A MISHAP.

CAUTION: CORRECT CRAFT DOES NOT APPROVE OF ANY

STRUCTURAL CHANGES, ADDITIONS OR MODIFICATIONS TO OUR

PRODUCTS. ANY TIME A DEALER OR CONSUMER MAKES A

CHANGE(S) TO OUR PRODUCT, THEY DO SO AT THEIR OWN RISK AND

SOLE LIABILITY. CORRECT CRAFT, INC. WILL NOT BE HELD LIABLE

FOR UNAUTHORIZED CHANGES, WHETHER DELETIONS OR

ADDITIONS, TO THE ORIGINAL EQUIPMENT / PRODUCT

MANUFACTURED AND SOLD BY CORRECT CRAFT, INC., EVEN IF

SUCH CHANGES, ADDITIONS, ECT. ARE MADE BY AN “AUTHORIZED”

DEALER, CUSTOMER, PROMOTIONAL REPRESENTATIVE OR ANY

1.11

OTHER PERSON, KNOWN OR UNKNOWN TO CORRECT CRAFT, INC.

Lifting rings

Your boat has lifting rings at the bow and at the stern. These are designed to

lift your boat in a steady and secure manner. Be certain to use a winch that has

a lifting capacity sufficient for your boat. See boat weight specs in the front of

this manual. These weights are dry weight. You must add the weight of the

battery, fuel, and gear to the dry weight.

CAUTION: DRAIN THE BILGE AND/OR LAUNCH CONTROL

SYSTEM AND/OR AFTERMARKET WATER BLADDERS(S) TO

ELIMINATE EXCESS WATER BEFORE YOU LIFT THE BOAT.

Note: Only use a hook that will pass easily through the lifting ring without

binding. This is very important. A hook that is too large or off-center could

break the lifting ring.

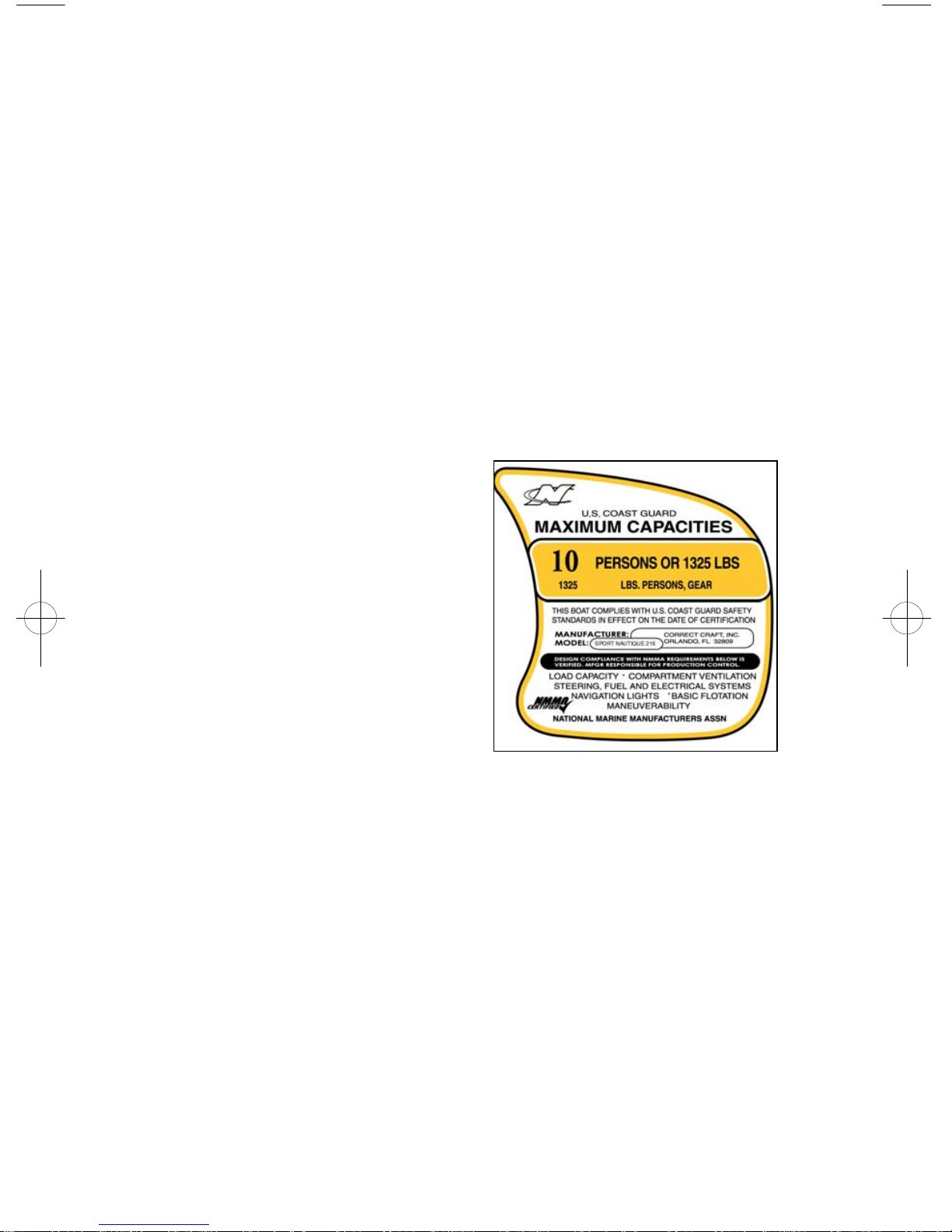

Capacity Plate

The capacity plate is used by boat

manufacturers participating in the

National Marine Manufacturers

Association certification program.

Correct Craft has submitted your model

for inspection and compliance with their

guidelines.

The capacity plate has the following

information permanently printed on it. It

is attached to the boat by the throttle for

the operator to read before they drive the

boat.

• The total weight of persons, gear and

other items which the boat is capable of

Capacity Plate

carrying under normal conditions. This

weight must include any water added to

ballast other than the Launch Control System.

• The maximum number of persons allowed on the boat.

This information on the capacity plate applies under normal conditions and

special care must be used in any other than normal conditions.

Check the capacity plate on your boat and abide by these limits.

NOTE: CORRECT CRAFT, INC. INSTALLS A PERMANENT

WAKE ENHANCEMENT BALLAST TANK SYSTEM IN SOME

MODELS. THE FULL WEIGHT OF THIS SYSTEM HAS

ALREADY BEEN CONSIDERED IN THE BOAT WEIGHT AND

THEREFORE DOES NOT INFLUENCE MAXIMUM CAPACITY,

UNLIKE PORTABLE BALLAST TANKS OR WEIGHTS, WHICH

MUST BE INCLUDED AS PART OF THE GEAR WEIGHT.

1.12

CAUTION: A FULLY LOADED NAUTIQUE WILL HANDLE

DIFFERENTLY THAN A LIGHTLY LOADED ONE. DRIVE AND

TURN YOUR NAUTIQUE WITH THIS IN MIND. AS

WAKEBOARDING HAS DEVELOPED, WE HAVE WITNESSED

THE ADVENT OF BALLAST SYSTEMS WHICH ADD WEIGHT

AND INCREASE THE SIZE OF THE WAKE. THE SIMPLEST

BALLAST SYSTEM ON THE MARKET IS THE WATER

BALLAST TYPE, SUCH AS THE ‘LAUNCH PAD”. IT IS NOT

UNCOMMON TO SEE OPERATORS USE SUCH SYSTEMS AND

THEN PUT ADDITIONAL PEOPLE IN THEIR BOAT. PLEASE BE

ADVISED THAT THIS PRACTICE CAN LEAD TO

OVERLOADING OF YOUR BOAT. EACH CORRECT CRAFT,

INC. BOAT HAS A REQUIRED CAPACITY LABEL THAT MEETS

THE MAXIMUM WEIGHT OF PEOPLE, GEAR, AND BALLAST

THAT CAN BE PLACED IN THE BOAT. ALWAYS BE AWARE OF

THE LOAD IN YOUR BOAT AND DO NOT LOAD THE BOAT IN

EXCESS OF THE LISTED CAPACITY. THE QUEST FOR THE

“PHATTEST” WAKE HAS CAUSED SOME TO EXCESSIVELY

OVERLOAD THEIR BOATS. THIS MAY ADVERSELY AFFECT

THE OPERATION OF THE BOAT, POSSIBLY RESULTING IN

INJURY TO PERSONS INSIDE AND/OR OUTSIDE OF THE BOAT.

AVOID PERSONAL INJURY. DO NOT OVERLOAD YOUR

NAUTIQUE.

Hull Identification Number

The hull identification number is a requirement of the U.S. Coast Guard for

boat manufacturers. It is a standardized numbering system that assigns a

specific sequence of numbers and letters to a specific boat. This number is

molded into the hull. You will find it on the right-hand side of the transom just

below the rubrail. Write this number down in your records and keep it in a safe

place away from the boat.

Here is a brief explanation to help you understand the hull number:

The first three digits represent Correct Craft, Inc.(CTC). The next five digits

are the boat’s serial number. The following digit is a letter from “A” through

“L” designating the month the boat was made.

There are three remaining numbers. The first of

these represent the last digit of the year the boat

was built. The final two numbers state the

MODEL year. A boat built in July of 2002 is

actually a 2003 model boat.

Driver’s Seat Adjustment

There is a lever under the driver’s seat on the left

side that allows the seat to slide.

Drivers Seat Adjustment

1.13

Fueling

There is a fuel fill on the port and starboard side for added convenience.

Remove the slotted fuel fill cap to put gas in the boat. There is a special “key”

for this cap. Use caution when fueling your boat. Never fuel your boat

unattended. Use care to avoid being splashed by fuel, or spilling fuel.

Ski Locker Latch

Push down on the raised portion of the latch and the handle of the latch will

pop up. Lift the ski locker door with this handle. Due to various environmental

conditions, equipment and other items should not be left in storage

compartments for a long time. All storage compartments that get wet or damp

should be left open to the air to dry.

Love Seat

Access storage under the bow area by lifting up on the bottom of the love seat

cushion. The entire love seat will hinge upward to allow access. You can leave

this seat in the “up” position to help dry the carpet.

Jump Seat

This optional seat can be placed between the love seat and the drivers seat or

behind the drivers seat.

Walk Through Windshield Opening/Latching

There are two latches on the inside starboard edge of the walk-through

windshield. Rotate both of these latches until the door can be opened. Always

have this closed and latched when towing the boat.

Dash Cooler

The dash cooler can be used to store misc. items or drinks. There is a drain

installed in this box. Do not depend on this cooler to keep valuables or

electronics dry. We suggest keeping these sort of items in a specialized dry

bag.

Stereo Option

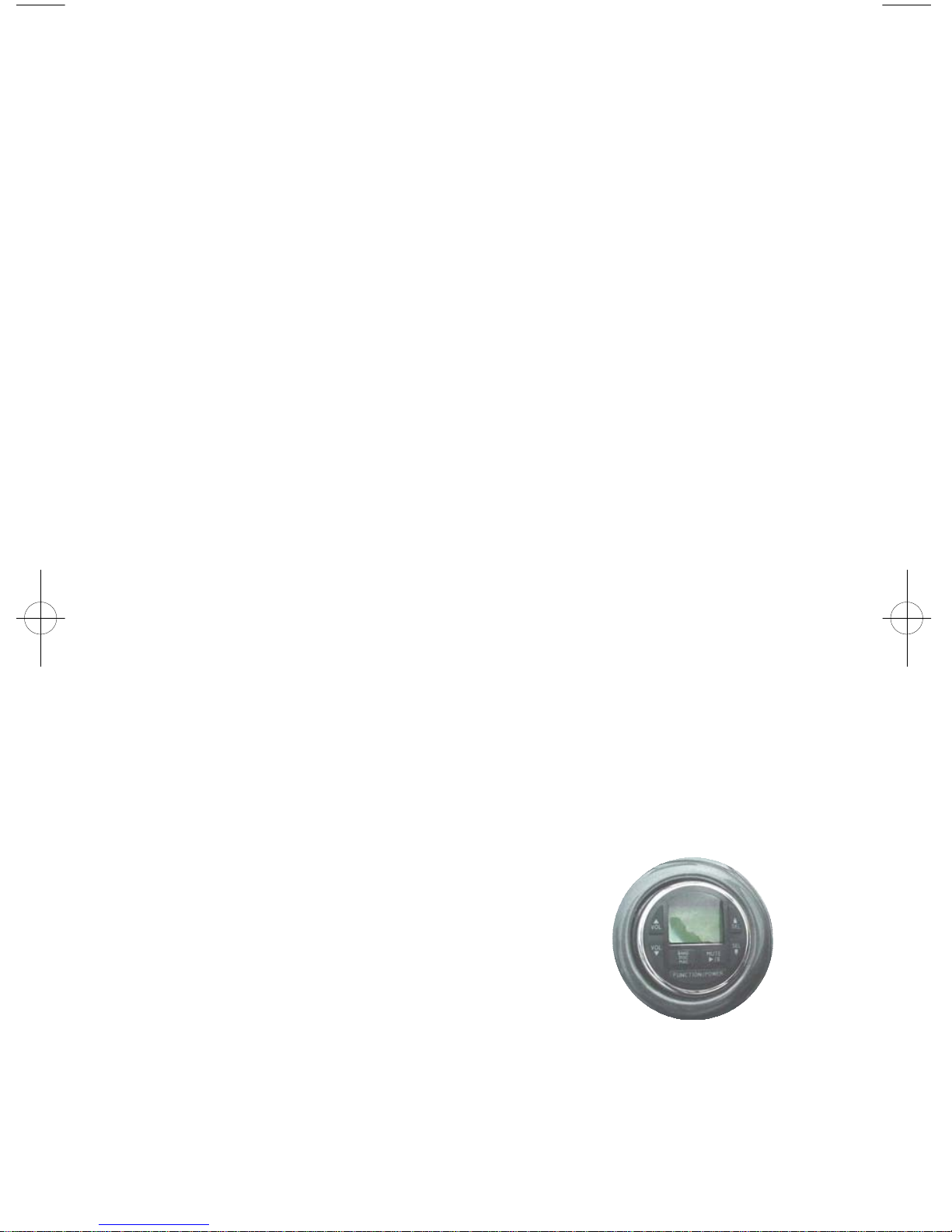

All Nautiques are stereo ready. Signature models have

been pre-wired for your dealer to install a stereo. Limited

and Team Edition Nautiques come with a Clarion stereo

with Clarion speakers or a Kicker upgrade speaker

system. Correct Craft mounts all of its stereos in the glove

box on the dash of your Nautique. A standard or digital

remote control is mounted on the lower left side of the

Stereo Remote Control

dash pod. The digital remote control displays all

necessary control functions at your fingertip. Consult your dealer for the

stereo configuration in your boat.

1.14

Engine Box Latching/Lifting

There are two rubber latches that hold the top of

the engine box to the base. Pull on the top of

these latches and the upper part or the engine box

will be released. Lift up on the engine box handle

and the gas shocks will help you lift the engine

box. This “clam-shell” design allows you to

check the engine without lifting the entire engine

box. You can leave the top open to dry the bilge.

Engine Cooling Water Intake Shut-Off Valve

Your boat is equippd with a shut-off valve (seacock) on the engine cooling water intake. This

valve can be viewed and manipulated by opening

both upper and lower sections of the engine box.

The valve is located on the starboard side of the

transmission. The valve is open whenever the

handle is in line with the valve body. It is closed

when the handle is perpendicular to the valve

body. The valve can be left in the open position

all the time unless emergency conditions require

closing the valve to stop a leak or eliminate the

possibility of leakage.

Engine Box Latching

Engine Cooling Water Intake Shut-

Off Valve

Stern Seat Bottom Cushion

The stern seat bottom cushion can be

removed by releasing the port and

starboard hold down strap. The seat

cushion can then be lifted out of the

boat and stored under the bow.

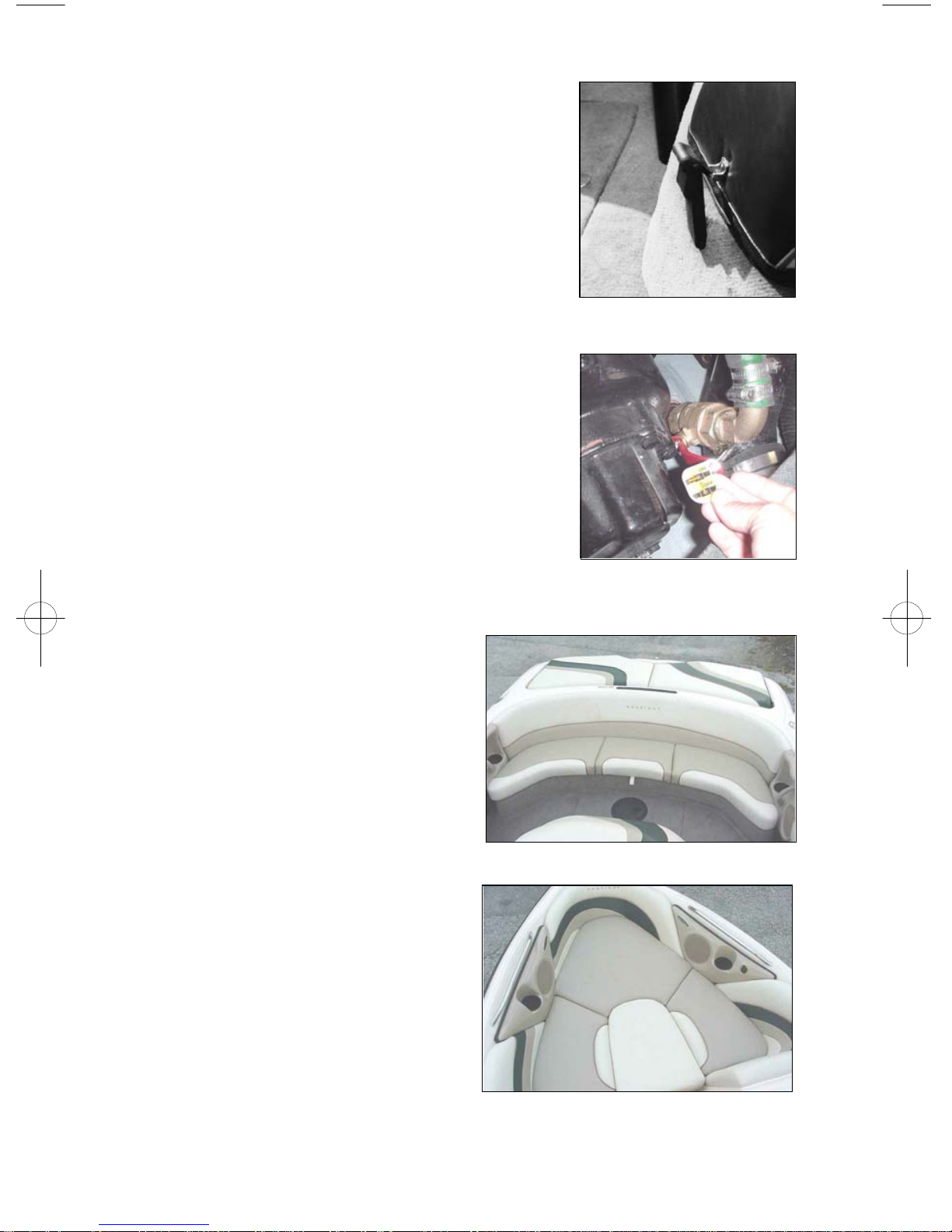

Bow Features of Your Nautique

The open bow section of your boat

has removeable cushions. The

center section can be removed and

stored in the trunk or under the love

seat. The cushion on the starboard

side of the bow section can be

removed exposing an insulated

cooler. Storage on the port side and

front section is also revealed by the

removal of cushions. The speaker

mods on both the port and starboard

side house optional speakers, as well

Stern Seat Bottom Cushion

Bow Section

1.15

as a standard hot plug.

Trunk

There is 17cubic feet of storage available inside the trunk (less with the ballast

tank system). This is an excellent place to store skis, wakeboards and other

gear.

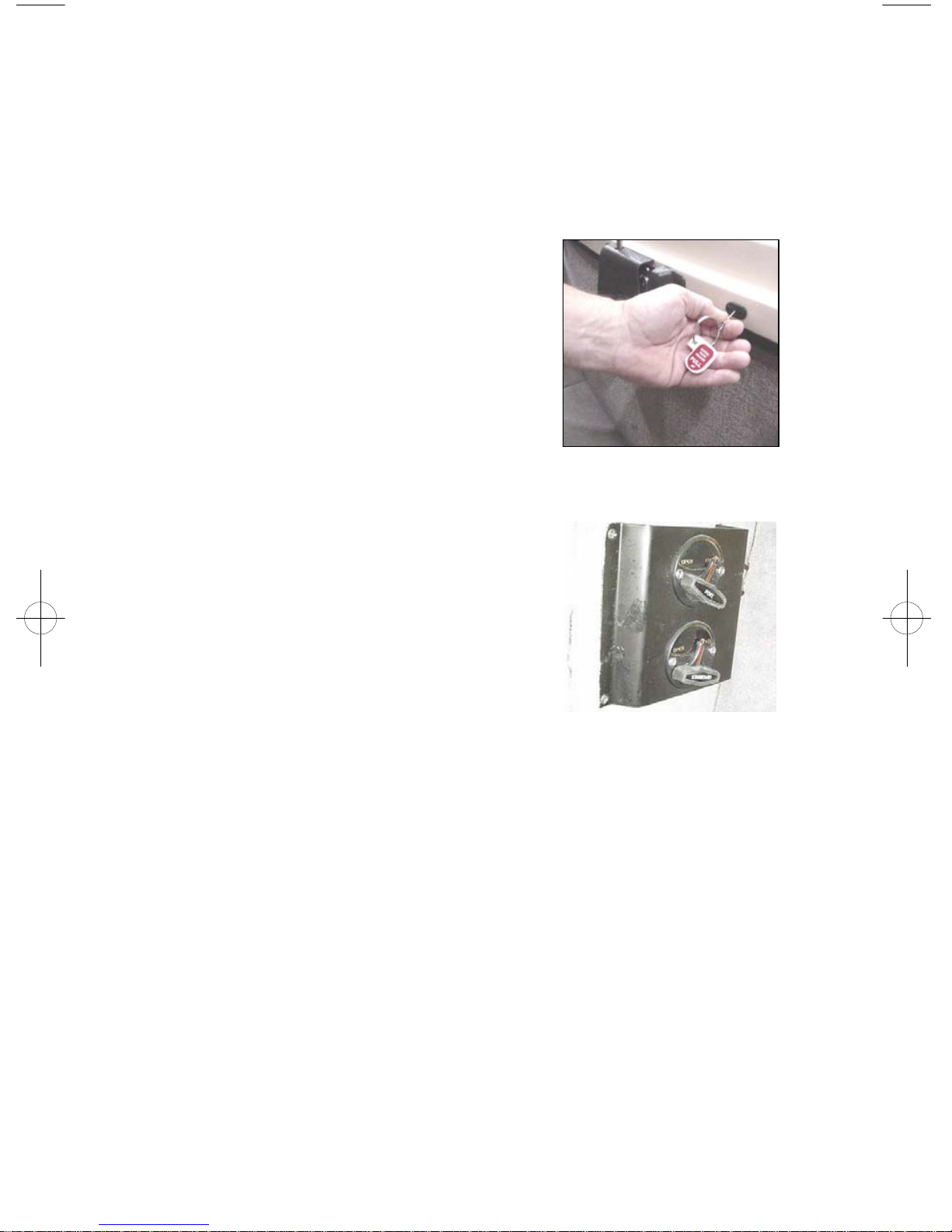

Manual Latch Release in Trunk

Should the hatch latch need to be released from

the inside there is a ringed pin that when pulled

from the inside will release the latch mechanism.

Fuel Tank Location

The fuel tank is located beneath the stern seat. To

inspect the hose connections, lift the trunk lid and

remove the curtain behind the fuel tank.

Manual Latch Release

Launch Control System (Ballast Tank Valves)

Your Nautique may come equipped with rigid

ballast tanks. Correct Craft offers a unique fill

and empty system. By opening the flow rite

valves located underneath the dash to your left

knee and then pressing the port and starboard

ballast button on the keypad on the right side of

the dash, the tanks will fill. When the tanks are

full, press the buttons again and the pump will

turn off. Then close the valves. To empty,

reverse this process by opening the valves and

Flow Rite valves

press and momentarily hold the port and starboard ballast buttons causing a

blinking light to appear. Monitor your ballast tank gauge located on the

console to determine when the tanks are empty. Then turn off pump and

close valves.

Winterization of Optional Launch Control System

In order to winterize the Launch Control System, take the following steps:

1. Make sure the launch control system seacocks (located in the bilge - see

your local dealer) are open. Empty the system completely using the drain

pumps.

2. Remove the stern seat base, engine box, and removable floor section from

the boat. Each tank has a drain hose located adjacent to the muffler on the

appropriate stringer. Remove the cap from the drain hose and allow the tank

to drain until it stops. Reach under the fuel tank and remove the empty hoses

from the empty pumps. Remove the fill hoses from the fill pumps under the

front of the engine. Raise and lower the bow of the boat while the system is

1.16

draining to insure that water is removed from the pumps.

3. Re-install all hoses, put the caps back on the drains hoses, and put the rest

of the boat together.

Folding Instructions for Optional Flight Control Tower

In order to fold the Flight Control Tower forward, grasp the knobs found under

the support structure on the port and starboard sides of the tower. Unscrew the

threaded bolts. Rock the tower forward. The tower will rest on the grab rails

of the bow section of the boat. In the folded position, it is also recommended

that the tower be securely strapped to the grab rails. In order to reposition the

tower in the upright position, simply reverse the steps.

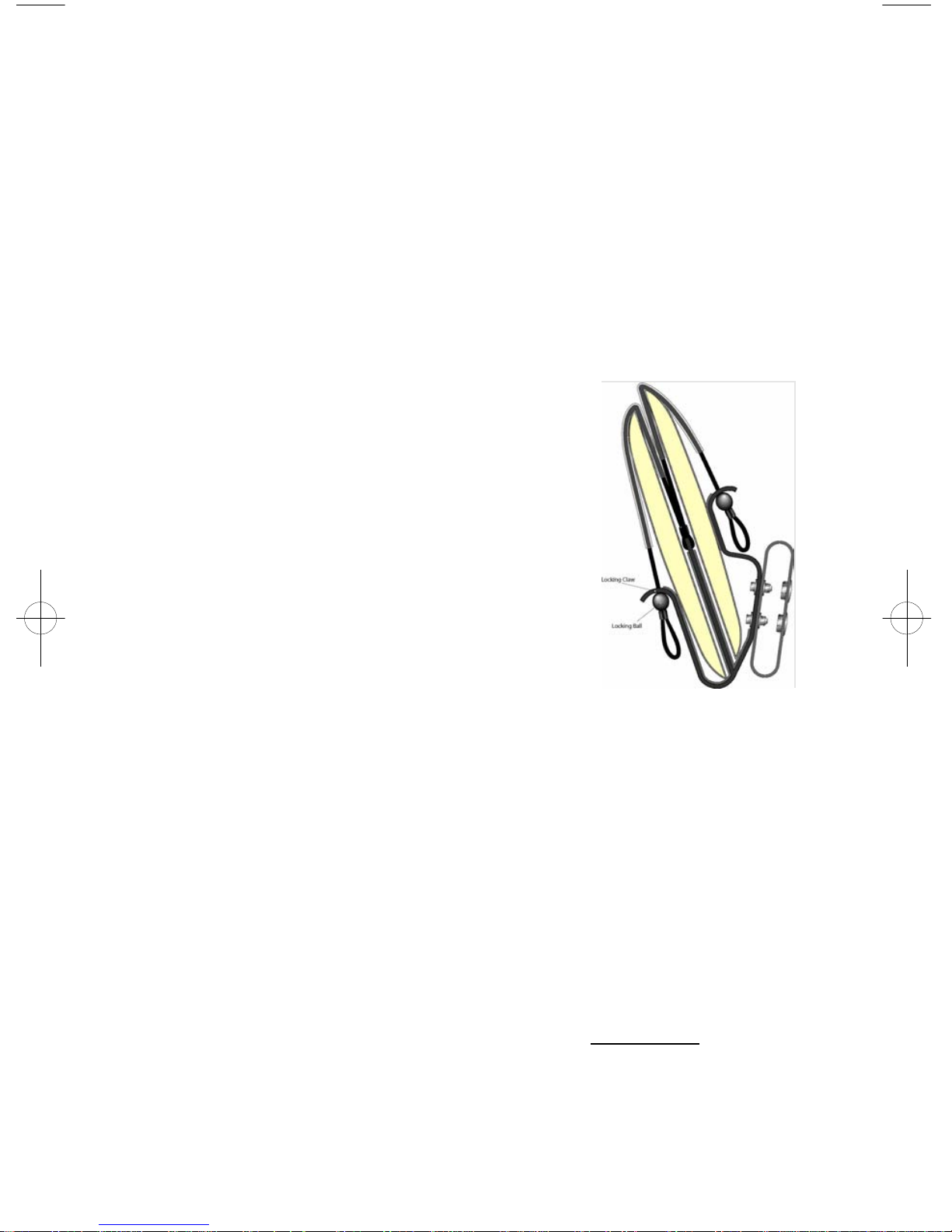

Flight Clips

One set (4) of flight clips will hold a maximum of 4

wakeboards. Do not attempt to overload Flight

Clips with more than one piece of equipment per

slot. When loading boards into flight clips always

insert boards into individual slots so that the board

bottoms are facing each other. Always visually

inspect bungee to insure that the locking ball is

securely in the locking claw (see illustration).

WARNING! Avoid personal injury or property

damage caused by flying objects. Remove any

items from flight clips when trailering boat.

Boarding Platform Removal

Flight Clips

Pull the two pins that are located in the mounting

brackets and lift the platform vertically.

Battery Location

The battery is located under the floor in front of the motor box.

Optional Correct Craft Cruise

Turn system ON (light blinks slowly, indicating system is armed)

Drive to desired speed, prese ENGAGE and the system takes control of the

throttle (Light stays on steady)

Pull back on the throttle and the system disengages. (Light blinks rapidly,

indicating RESUME function is ready)

Accelerate again and the system resumes control automatically at the last

speed used.

RESUME key feature will recall the last speed used even if the system was

shut off, completely powered down or the DISENGAGE function was used.

To go back to the previous speed, press RESUME and drive to the desired

1.17

speed.

Press both keys and the system will DISENGAGE,but remains armed. (Light

blinks slowly) This feature may be used when the operator wishes to go to

manual driving. To return to the last speed used, press the RESUME key and

drive to the desired speed. If the speed is to be changed, drive to that speed

and press engage.

INCREASE / DECREASE key can be pressed when the system is engaged to

change speed in 25 RPM increments to fine tune the speed.

User tips:

Always return to neutral and let the engine idle for two or three seconds before

turning the engine off Regularly check the black servo knob on the control

unit to make sure it is turned snugly in a clockwise direction. To do this, turn

the engine off and lift the top half of the engine box. Please note, the servo

knob cannot be moved if the engine is on.

Regularly check the set screw on the side of the black knob for tightness.

The boat speed will decrease in sharp turns. If you are towing skiers, you may

wish to manually increase the throttle or use the DISENGAGE feature to

maintain speed in sharp turns.

When towing wakeboarders, accelerate slightly past desired speed prior to

engaging the speed control.

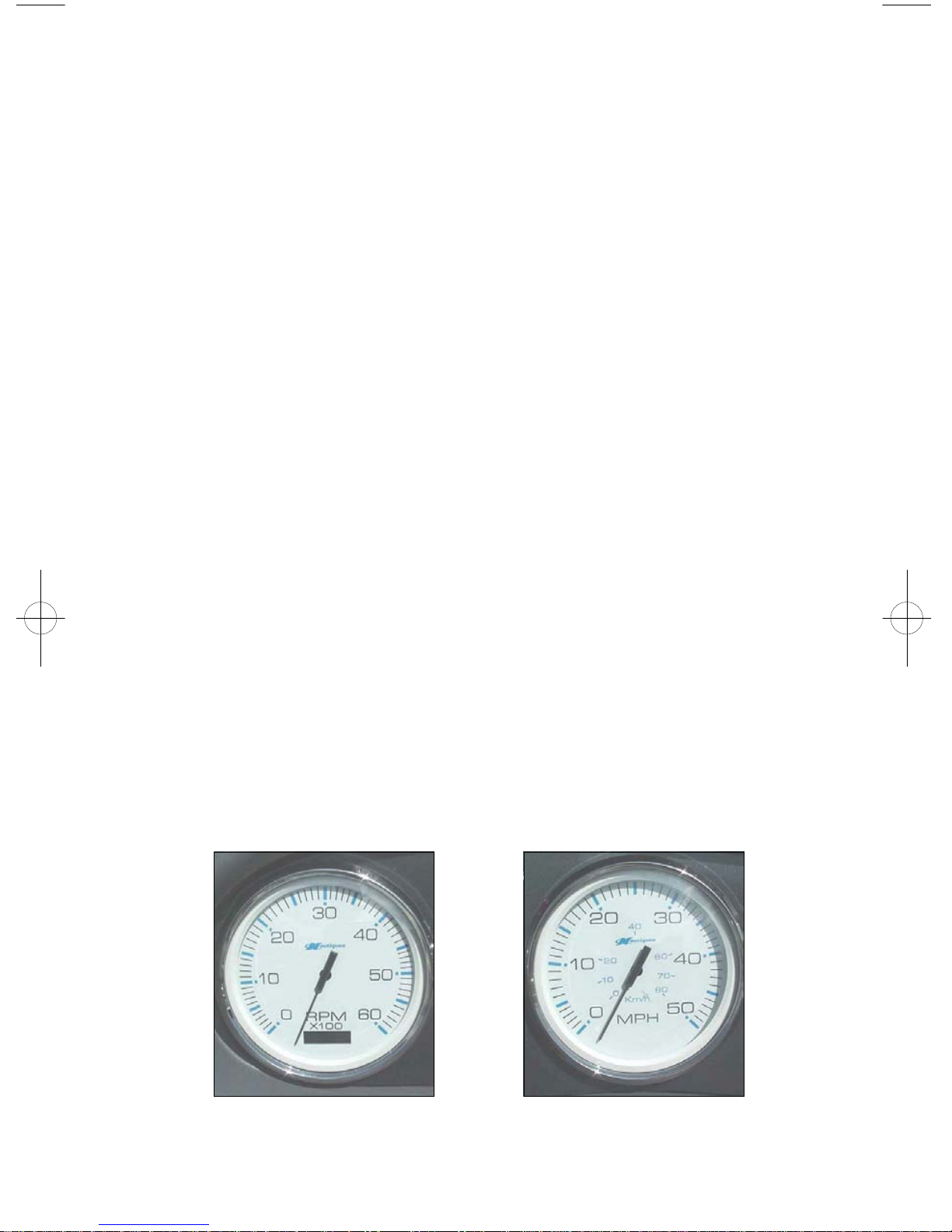

Standard Faria Instruments

All Signature Series Nautiques feature 5” Faria speedometers and tachometers.

These gauges are white faced with large tick marks for easy reading with high

contrast pointer. The gauges are paddle wheel driven with potentiometer

adjustments. Should your boat be packaged as a Limited or Team Edition,

refer to the Faria Serial Bus chapter regarding your speedometer and

tachometer.

Faria Analog Tachometer

Faria Analog Speedometer

1.18

Owner’s Manual

Serial Bus

for CorrectCraft®

Pleasurecraft GM Engines

ISO151A ECR#2370 05/10/02

IS0151

Visual /Audible Alert Messages

Easy Installation

Waterproof Connections

Easy to Read Digital Displays

Easy to use Depth Sounder

Multiple Interfaces

M

M

Index

Initial Setup

Selecting the Fuel Tank Size Page 2

Operation

General Page 2

Speedometer/Depth Sounder

Speedometer Calibration Page 3

Dual Pitot Operation Page 4

Depth Sounder Page 4

Canceling Depth Alarms Page 4

Shallow Alarm Page 5

Deep Alarm Page 5

Keel Offset Page 6

Units Page 6

Speedometer Mode Display Sequence- Figure 1 Page 7

Tachometer/Fuel Monitor

General Page 8

Canceling System Alarms Page 8

Engine Hourmeter Page 8

Hours Remaining Page 9

Engine Temperature Page 9

Voltmeter Page 9

Oil Pressure Page 9

Instrument Lighting Page 9

Tachometer Mode Display Sequence - Figure 2 Page 10

LCD Alarm Condition Displays Page 10-11

Installation/Harness wiring guide for PleasureCraft GM Engines

Gateway Page 13

Gateway Harness connections

Figure 3 Typical Power Connections Page 14

Figure 4 Typical Instrument Connections Page 14

Figure 5 PleasureCraft GM Engine ECU Connection Page 15

Figure 6 Transducer and Pitot Tube Connections Page 15

Figure 7 Miscellaneous Connections Page 16

Wire Harness/Connections - Table 1 Page 17

Page 2

M

Mode

Button

Down

Button

Up

Button

Initial Setup

The setup function is normally only used

for a new installation. It is not required to

follow this procedure every time the

instruments are turned on.

The tachometer is used to initialize the

fuel tank size required for the fuel

management function. Press the “mode M”

button while the power is turned on, to

enter the “setup” mode.

The LCD will show the cur rent fuel tank

size selection. The choices are displayed

with the “Up” or “Down” buttons. After

selecting the closest tank size, press and

hold the “mode M” button for 3 seconds to

save the selected size and start normal

instrument operation.

Select from one of the following fuel tank

capacity options:

29 gallon

30 gallon (default)

35 gallon

39 gallon

50 gallon

Operation

General

The Faria® Serial Bus™ system is

designed to receive information from the

engine ECU and various individual

sensors throughout the boat. This

information is transformed into digital

data which is distributed to analog and

digital instruments via a single cable

consisting of two shielded, twisted pairs of

conductors.

Each instrument selects the data which is

applicable and displays it as if it was being

received from the sender directly. One of

the two pairs of conductors carries the data

while the other pair of conductors carry

the power for the instruments.

The tachometer and speedometer each

have three push buttons which allow the

different functions of each instrument to

be activated. Following is a description of

these functions.

M

Mode

Button

S ystem

The system consists of:

• One Gateway box to interface with

MEFI IV ECU and external senders

and sensors.

• One 5” Tachometer with Fuel

Monitor

• One 5” Speedometer with Depth

Sounder

• optional second 5” Speedometer

• Various 2” instruments, including but

not limited to

• Voltmeter

• Oil Pressure gauge

• Fuel gauge

• Engine Temperature gauge

• others as specified.

Page 3

M

Mode

Button

M

Mode

Button

M

Mode

Button

Down

Button

Up

Button

Speedometer / Depth Sounder

The Serial Bus Speedometer / Depth

Sounder provides both the functions of a

speedometer and a depth sounder. The

analog speedometer is a stepper motor

instrument which looks like a standard

analog device but which is actually a

digital instrument. On small pointer

movements you may occasionally see the

pointer moving in the one third degree

“steps” that represent the accuracy of the

instrument.

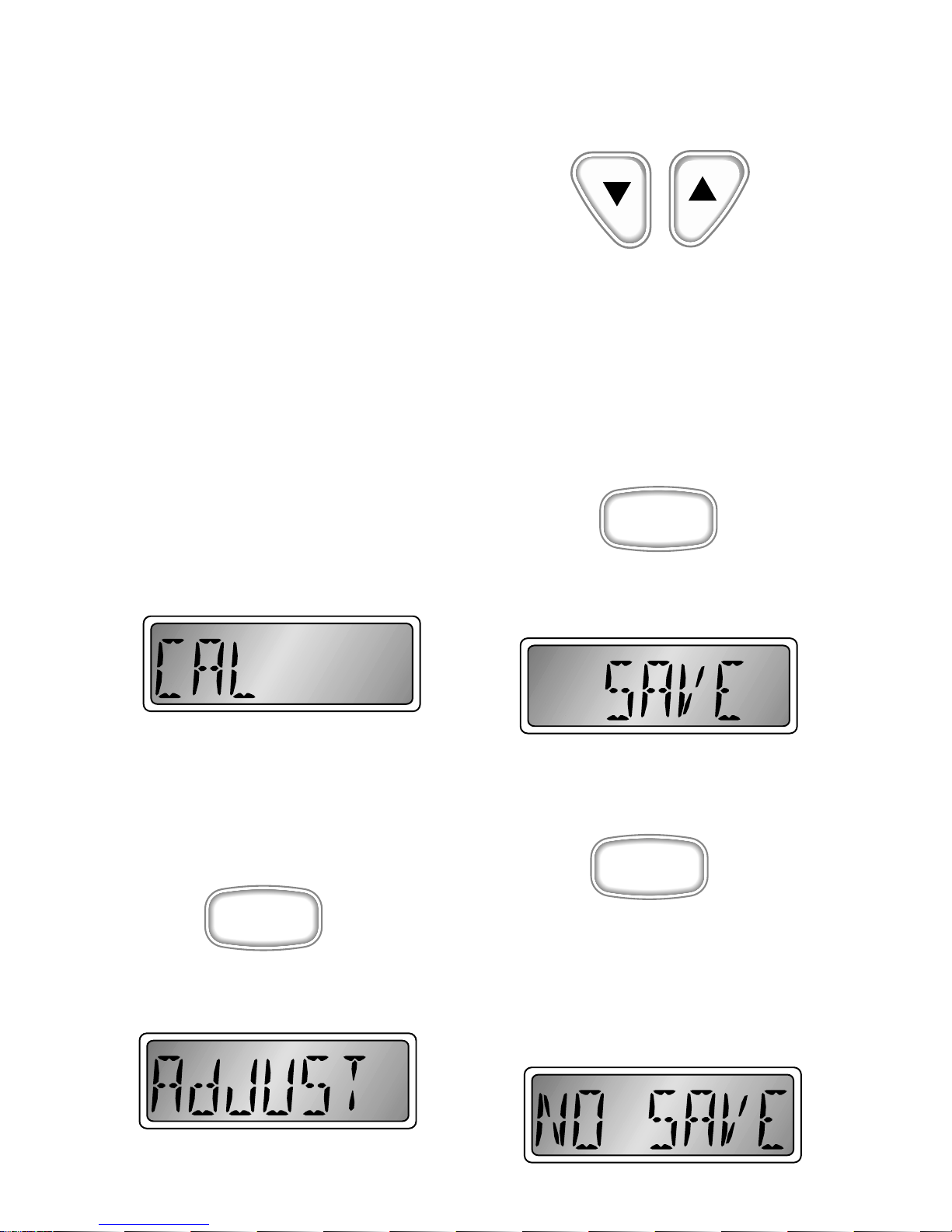

Speedometer Calibration

The analog speedometer displays the

speed of the boat through the water. The

speedometer is calibrated at the factory for

normal installations which use a pitot tube

sensor. As significant variation has been

found in various installations, the

speedometer can be easily calibrated to a

known reference such as a radar gun or

GPS. The LCD will display;

When the unit is operating in normal

mode (i.e. pitot status information on the

LCD), push a nd hold the “mode M” button

down for 2 seconds will cause the

speedometer to go to the calibration mode.

The LCD will show “AdJUST”.

Run the boat at a constant 30 MPH as

measured by the GPS or radar. Adjust the

speedometer pointer by pressing the “Up”

or “Down” buttons until the speedometer

matches the GPS or radar speed.

When finished, press the “mode M” button

to exit the adjustment screen. The operator

has the option of saving or canceling the

adjustment procedure. The options can be

selected using the “Up” or “Down”

buttons. To save the calibration setting,

press and hold the “mode M” button for 2

seconds when the display shows “SA VE”

To exit the adjustment procedure without

saving, press and hold the “mode M”

button for 2 seconds when the display

shows “NO SAVE”. Multiple runs in

opposite directions may be necessary to

compensate for errors due to water

currents.

Loading...

Loading...