Page 1

File : CS-SUP-MUTI-WTHERMAPP-E01.sxw

WaveTherm modules – application handbook page 1 of 65

Page 2

File : CS-SUP-MUTI-WTHERMAPP-E01.sxw

REVISIONS HISTORY

Rev. # Description Author Date Comments

1 Original document RCS 02/02/05 Version 1

2 Addon text FCC RCS 17/02/05 Version 2

SUPPORTED FIRMWARE VERSION

➢ WaveTherm - DALLAS

European Version

Manual version Firmware version Date

1.0 V 01.04 15/10/04

US Version

Manual version Firmware version Date

1.0 V 81.05 15/10/04

➢ WaveTherm - PT100

Manual version Firmware version Date

1.0 V 01.02 15/10/04

➢ WaveTherm - PT1000

Manual version Firmware version Date

1.0 V 01.00 15/10/04

This device complies with part 15 of the FCC rules. Operation is subject to the

following two conditions : this device may not cause harmful interference, and

this device must accept any interference received, including interference that

may cause undesired operation.

Caution : any changes or modifications not expressly approved by CoronisSystems could void the user's authority to operate the equipment.

WaveTherm modules – application handbook page 2 of 65

Page 3

File : CS-SUP-MUTI-WTHERMAPP-E01.sxw

TABLE OF CONTENTS

1 PRESENTATION........................................................................................................................... 6

2 REFERENCE DOCUMENTS......................................................................................................... 6

3 PRESENTATION OF THE WAVETHERM MODULES FUNCTIONALITIES................................ 7

3.1 SENSORS INTERFACE.........................................................................................................................7

3.2 READ TEMPERATURES.......................................................................................................................8

3.3 PERIODIC TEMPERATURE READING (DATALOGGING)..................................................................8

3.4 MANAGEMENT OF THRESHOLD ALARMS........................................................................................9

3.4.1 Threshold Alarm Detection.............................................................................................................9

3.4.2 Storage of Threshold Alarm occurences........................................................................................9

3.4.3 Transmission of a Threshold Alarm Frame.....................................................................................9

3.5 STORAGE OF CALIBRATION PARAMETERS..................................................................................10

3.6 WAKE-UP SYSTEM MANAGEMENT..................................................................................................10

3.7 AUTOMATIC TRANSMISSION OF FAULTS......................................................................................10

3.8 SENSOR FAULT DETECTION (IF SUPPORTED BY THE MODULE)............................................... 11

3.9 END OF BATTERY LIFE DETECTION................................................................................................11

4 DATA EXCHANGE PRINCIPLE WITH A WAVETHERM MODULE .......................................... 12

5 INFORMATION RELATIVE TO THE PROBES ASSOCIATED WITH THE WAVETHERM

MODULES ...................................................................................................................................... 15

5.1 DALLAS PROBES...............................................................................................................................15

5.1.1 Coding of temperatures for the DALLAS probe type DS18B20 ...................................................15

5.1.2 Probe ID........................................................................................................................................15

5.1.3 Setting of the probe coefficient parameters..................................................................................16

5.2 PT100 AND PT1000 PROBES.............................................................................................................17

5.2.1 Representation of temperature values..........................................................................................17

5.2.2 Calibration of radio module...........................................................................................................18

5.2.3 Setting of probe coefficient parameters........................................................................................19

6 MODIFICATION OF THE INTERNAL PARAMETERS................................................................21

6.1 INTERNAL PARAMETERS LIST ACCESSIBLE BY RADIO COMMANDS....................................... 21

6.1.1 Parameters common to all WAVETHERM versions.....................................................................21

6.1.2 Parameters specific to the WaveTherm – DALLAS module.........................................................22

6.1.3 Parameters specific to the WaveTherm – PT100 module............................................................22

6.1.4 Parameters specific to theWaveTherm – PT1000 module...........................................................23

6.1.5 Definition of the module control bytes...........................................................................................24

6.2 PRINCIPLE OF READING AND WRITING OF INTERNAL PARAMETERS......................................25

WaveTherm modules – application handbook page 3 of 65

Page 4

File : CS-SUP-MUTI-WTHERMAPP-E01.sxw

7 WAVETHERM MODULE FUNCTIONS ...................................................................................... 27

7.1 PARAMETER SETTING OF THE WAVETHERM MODULE...............................................................27

7.1.1 Reading of the module type..........................................................................................................27

7.1.2 Reading of the firmware version...................................................................................................28

7.1.3 Reading of the date and time of the module.................................................................................29

7.1.4 Setting the date and time of the module.......................................................................................30

7.1.5 Access to the user data area........................................................................................................31

7.1.6 Initialization of the sensors............................................................................................................33

7.2 READING THE CURRENT VALUE OF THE TEMPERATURE SENSORS........................................34

7.2.1 Information concerning precision..................................................................................................34

7.2.2 Description of the commands to be used.....................................................................................34

7.2.3 Reading the current ohmic values of the sensors.......................................................................36

7.3 WAKE-UP SYSTEM MANAGEMENT..................................................................................................37

7.3.1 Description of the parameters used..............................................................................................37

7.3.2 Choice of wake-up mode..............................................................................................................37

7.3.3 Set a new wake-up period............................................................................................................38

7.3.4 Set a fixed wake-up period for certain days of the week..............................................................38

7.3.5 Set day/night system parameter without distinction of days of the week.................................... 38

7.3.6 Set the day/night system parameters according to day of the week...........................................40

7.4 PARAMETER SETTING OF THE DATALOGGING MODE................................................................41

7.4.1 Description of the parameters used..............................................................................................41

7.4.2 Precision level of the measurement..............................................................................................41

7.4.3 Activating the datalogging mode...................................................................................................42

7.4.4 Index logging in time steps...........................................................................................................43

7.4.5 Index logging once a week...........................................................................................................44

7.4.6 Index logging once a month..........................................................................................................45

7.4.7 Reading the logged temperature values.......................................................................................46

7.5 ADVANCED DATALOGGING.............................................................................................................48

7.5.1 Description of the parameters used..............................................................................................48

7.5.2 Parameter setting of the Advanced Datalogging mode................................................................49

7.5.3 Principle of reading the temperature, and re-initializing the storage table....................................49

7.5.4 Reading the totality, or a part of the storage table........................................................................51

7.5.5 Structure of the data when two sensors are activated..................................................................54

7.5.6 Usage limit of the multi-frame mode.............................................................................................55

7.6 MANAGEMENT OF THRESHOLD ALARMS......................................................................................56

7.6.1 Description of the parameters used..............................................................................................56

7.6.2 Precision level of the measurement..............................................................................................57

7.6.3 Format of the temperature information.........................................................................................57

7.6.4 Principle of the detection modes...................................................................................................58

7.6.5 Selection of the threshold detection modes, and activation of the detection................................59

WaveTherm modules – application handbook page 4 of 65

Page 5

File : CS-SUP-MUTI-WTHERMAPP-E01.sxw

7.6.6 Configuration of the measurement period of the threshold detection...........................................59

7.6.7 Reading the threshold detection table..........................................................................................60

7.7 MANAGEMENT OF THE ALARM FRAMES........................................................................................61

7.7.1 Description of the parameters used..............................................................................................61

7.7.2 Configuration of the route to reach the alarm frames recipient.................................................... 61

7.7.3 Configuration of the alarms to be sent..........................................................................................62

7.7.4 Triggering an alarm frame............................................................................................................63

7.8 END OF BATTERY LIFE DETECTION................................................................................................64

7.8.1 Description of the parameters used..............................................................................................64

APPENDIX A : SET OF THE APPLICATIVE COMMANDS.............................................................................65

WaveTherm modules – application handbook page 5 of 65

Page 6

File : CS-SUP-MUTI-WTHERMAPP-E01.sxw

1 PRESENTATION

This document describes the functionalities of WaveTherm radio modules :

WaveTherm – DALLAS Used with DALLAS sensor

WaveTherm – PT100 Used with PT100 sensor

WaveTherm – PT1000 Used with PT1000 sensor

This document defines in an exhaustive way the applicatives data relating to serial dialog frames between a

Wavecard and a host equipment , used to reach the data of the WaveTherm radio module.

2 REFERENCE DOCUMENTS

Ref Title Reference Version Date

DR[1] WaveCard user handbook

WaveTherm modules – application handbook page 6 of 65

Page 7

File : CS-SUP-MUTI-WTHERMAPP-E01.sxw

3 PRESENTATION OF THE WAVETHERM MODULES FUNCTIONALITIES

3.1 SENSORS INTERFACE

➢ WaveTherm – DALLAS :

The module is designed to manage to the maximum two DALLAS temperature sensors (type

DS18B20).

This DALLAS sensor of 1-wire type integrates a 12-bit internal converter.

Each external sensor is connected to the module by a cable equipped with a BINDER connector of

3-pin type.

An automatic identification of the temperature sensors allows to memorize the identifier of the

sensors. This phase is automatically carried out when powering the module

and is also activated on a specific radio request (in this case, The module returns by radio the

identifiers of the sensors).

➢ WaveTherm – PT100 :

The WaveTherm-PT100 module has the possibility to manage 1 or 2 PT100 temperature sensors.

The probes are connected to the module through impervious connectors allowing to connect 2, 3 or 4

wires probes.

➢ WaveTherm – PT1000 :

The WaveTherm-PT1000 module has the possibility to manage 1 or 2 PT1000 temperature sensors.

The probes are connected to the module through impervious connectors allowing to connect 2, 3 or 4

wires probes.

WaveTherm modules – application handbook page 7 of 65

Page 8

File : CS-SUP-MUTI-WTHERMAPP-E01.sxw

3.2 READ TEMPERATURES

The WaveTherm module has the following possibilities:

To read the current temperature ;

To transmit the last N temperatures stored, in one frame.

If two temperature sensors are used, then the WaveTherm return the last N/2 values of each sensor.

• WaveTherm – DALLAS : N = 48 temperatures

• WaveTherm – PT100 : N = 24 temperatures

• WaveTherm – PT1000 : N = 24 temperatures

3.3 PERIODIC TEMPERATURE READING (DATALOGGING)

Periodic reading of temperatures is available in two versions. In both cases, the module may be configured to

store the temperatures measured periodically (in time intervals ranging from a minute to several hours), once

a week or once a month.

➢ Standard datalogging :

Periodic collection of temperature measurements up to N temperatures. In this case, it functions in

'permanent loop' mode, i.e. the most recent measurements replace the oldest measurements.

WaveTherm – DALLAS : N = 48 temperatures;

WaveTherm – PT100 : N = 24 temperatures;

WaveTherm – PT1000 : N = 24 temperatures.

➢ Advanced datalogging:

Periodic collection of temperature measurements up to M temperatures. In this case, it functions in

'stop memory full' mode.

WaveTherm – DALLAS : M = 4500 temperatures;

WaveTherm – PT100 : M = 2000 temperatures;

WaveTherm – PT1000 : M = 2000 temperatures.

Remark : Only the 'Stop memory full' mode is currently operational : when the memory corresponding to N

temperatures is full, datalogging stops automatically.

A new parameter setting cycle must then be started with a specific radio command.

A future upgrade will enable permanent looping with indication of looping.

WaveTherm modules – application handbook page 8 of 65

Page 9

File : CS-SUP-MUTI-WTHERMAPP-E01.sxw

3.4 MANAGEMENT OF THRESHOLD ALARMS

The WaveTherm module detects when the values exceed the threshold levels (high or low) for a given period

of time.

The WaveTherm – PT100 and PT1000 may be configured with a precision level offering a more reliable

measurement even in environments with excessive interference (see chapter 7.2.1).

Three types of threshold alarm detection methods may be programmed :

immediate threshold alarm detection

threshold alarm detection for a given continuous period of time (successive mode)

threshold alarm detection for a total period of time (cumulative mode)

3.4.1 Threshold Alarm Detection

Threshold alarm detection requires periodic measurement of the temperature for a predefined period. The

value of this period enables establishment of the threshold alarm detection reactivity.

This period is set independent of the datalogging period. However, for power saving reasons, it is

recommendable to set the datalogging period as a multiple of the threshold alarm detection period.

The following parameters apply to this function:

High threshold alarm,

Low threshold alarm,

Threshold excess time (used in cumulative and successive mode),

Mode parameter setting byte (high threshold enabled, low threshold enabled, immediate,

successive or cumulative mode).

3.4.2 Storage of Threshold Alarm occurences

Threshold alarms are stored in a memory zone which may be accessed by radio. If the number of threshold

alarms exceeds the memory storage capacity, the oldest alarms recorded are deleted.

The following information is recorded in the table:

Threshold alarm detection date

Threshold alarm detection duration

The average value of all measurements recorded during the alarm period.

3.4.3 Transmission of a Threshold Alarm Frame

The module may be programmed to transmit a radio frame as soon as a threshold alarm is detected.

WaveTherm modules – application handbook page 9 of 65

Page 10

File : CS-SUP-MUTI-WTHERMAPP-E01.sxw

3.5 STORAGE OF CALIBRATION PARAMETERS

The WaveTherm module manage a non-volatile memory area accessible by radio command, and allowing to

store up to 32 bytes.

This area is not used by the internal process, and is generally used to store the parameters relative to the

calibration of the module, and can be read, or modified by specifying the start address, and the size of the

data.

3.6 WAKE-UP SYSTEM MANAGEMENT

In order to reduce module power consumption, a wake-up period parameter setting system is incorporated.

This system enables modification of the module wake-up period (default setting 1 s) by entering a time and

day of the week :

The wake-up period default value may be modified;

Two time-windows with different wake-up periods may be defined;

Each day of the week may be set in one of the following three cases :

• Wake-up period default setting

• Wake-up according to predefined time windows

• No wake-up period (for safety reasons, the module is not disabled on reception and it

wakes up every 10 seconds)

Note : The system is disabled by default and must be enabled by writing a specific profile in the

wake-up system status word.

3.7 AUTOMATIC TRANSMISSION OF FAULTS

The WaveTherm module offers the possibility to automatically transmit radio frames when an occurrence is

detected.

The following occurrences may provoke an automatic alarm:

Threshold detection (see chapter 7.6)

End of battery life detection (see chapter 7.8)

Probe fault detection (WaveTherm – PT100 and PT1000 only)

It is possible to select for each type of occurrence whether or not an alarm frame is to be sent.

The radio address of the receiver module and the repeater path must be preset with a radio signal.

WaveTherm modules – application handbook page 10 of 65

Page 11

File : CS-SUP-MUTI-WTHERMAPP-E01.sxw

3.8 SENSOR FAULT DETECTION (if supported by the module)

For all modules, temperature probe absence or error detection is carried out during a write request and is

indicated by the presence of a specific value which does not correspond to a possible temperature value.

However, in the case of the WaveTherm – PT100 and WaveTherm – PT1000 modules only, after

detection of a probe fault, the module carries out the following operations:

records the detection date in internal parameters (0x91 ; 0x92).

If required, transmits an immediate probe fault detection radio frame.

3.9 END OF BATTERY LIFE DETECTION

To detect the end of battery life, the WaveTherm module uses the power metering principle rather than

measurement of the battery voltage. Lithium batteries are, in particular during passivation, unsuitable for the

voltage measurement method to determine the remaining capacity.

The WaveTherm records and evaluates all events (measurements, transmissions) to decrement the power

meter according to the battery used. When the meter passes below a predefined threshold, the “end of

battery life” is signalled with the Application Status byte.

The initial value of the end-of-life meter is factory-set. It depends on the type and number of batteries used.

When the end of battery life is detected, the detection date is memorised and may be read with a radio

command.

Please refer to the WaveTherm module technical specifications, for more details on the life of the modules.

WaveTherm modules – application handbook page 11 of 65

Page 12

File : CS-SUP-MUTI-WTHERMAPP-E01.sxw

4 DATA EXCHANGE PRINCIPLE WITH A WAVETHERM MODULE

The WaveTherm module uses the WAVENIS protocol.

The choice of mode used is initiated by the read element which uses a different set of commands (see

WaveCard document) when sending commands to the WaveCard.

The following chart indicates the read modes possible as well as their typical applications.

Read mode Description Recommendations

Peer-to-peer Individual reading with re-transmission management

in case of no reply

Standard use

Polling This mode enables successive polling of several

modules in a single operation .

The principle consists of waking up several modules

with the 1st radio transmission.

To be used when module reading time is

an important factor.

Re-transmission not possible.

Broadcast and multicast (*) This mode enables use of a single frame to address

all radio modules within reception range.

The multicast mode may only address one group of

modules.

This mode enables reading of modules

without knowing their radio address.

Type of use: detection of radio modules

within range of the emitter module

(installation phases).

➢ Additional functions:

Additional

functions

Compatibility Description Recommendations

Repeater Only used in point-

to-point mode.

This function enables use of a radio module to relay

a frame which was not initially intended for this

module.

This is a default function of the WaveTherm module,

i.e. it may be read via several repeaters but may

also act as a repeater itself when reading another

unit.

This function is used when the caller

module and the target WaveTherm

module are outside radio range.

The maximum number of repeaters is

limited to 3.

Attention: collection of data in multi-frame mode (advanced datalogging) is not possible in

repeater mode.

WaveTherm modules – application handbook page 12 of 65

Page 13

File : CS-SUP-MUTI-WTHERMAPP-E01.sxw

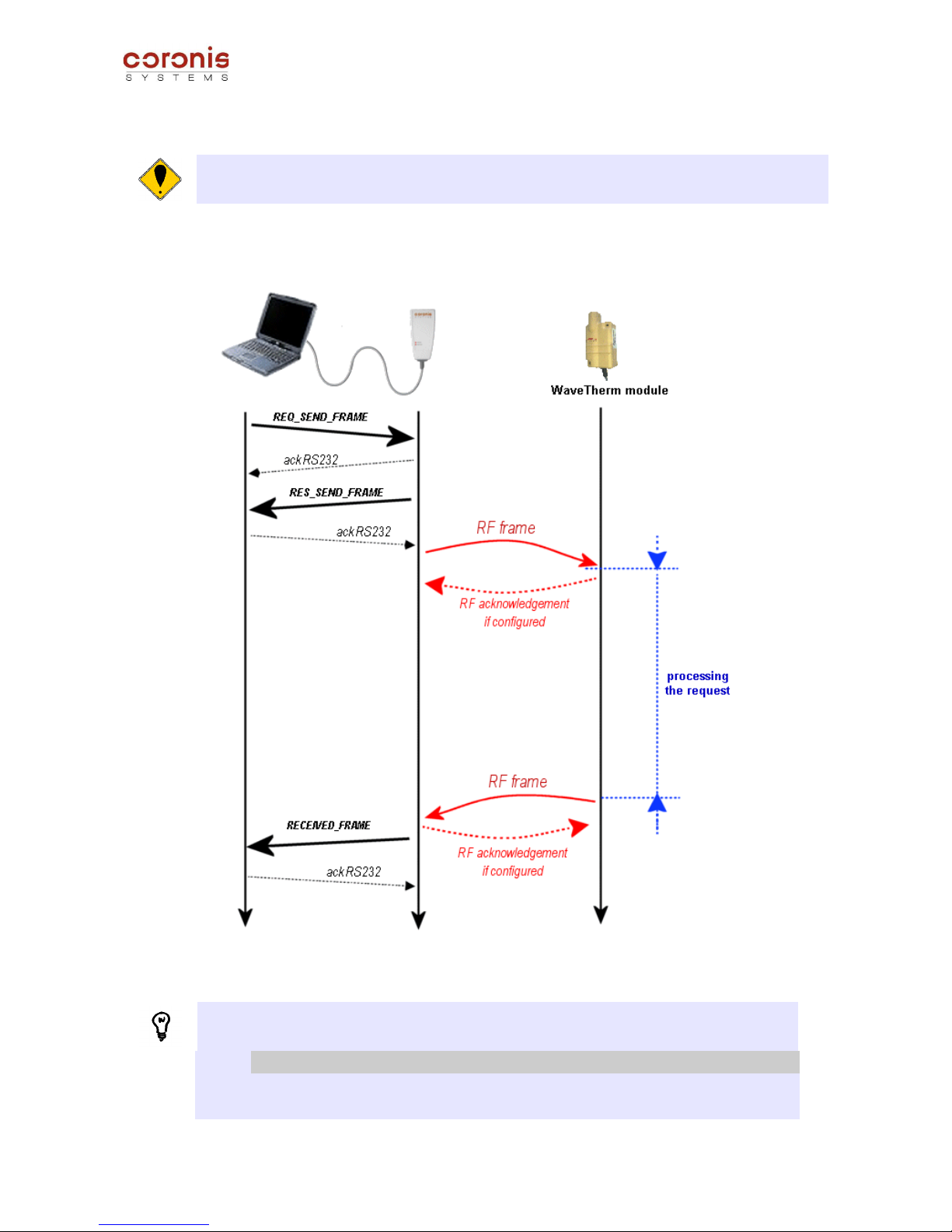

➢ Example in Point-to-point mode :

Remark : Generally, the exchanges examples given in this document will be in Point-to-point mode,

except when the context depends directly on the mode of exchanges.

This type of radio exchange allows to send a request, then to await a response of the remote equipment.

Note : the commands of Point-to-point exchanges, have the following format: (all the exchanges

modes are treated in document [DR1])

CMD NAME DESCRIPTION

0x20 REQ_SEND_FRAME

Request to send a radio frame with the waiting for the radio response.

0x30 RECEIVED_FRAME

Received radio frame by the radio board.

WaveTherm modules – application handbook page 13 of 65

Page 14

File : CS-SUP-MUTI-WTHERMAPP-E01.sxw

The data field of each command must be formatted according to the following table :

CMD

DATA

6 bytes variable ( max : 152 bytes)

0x20

Radio address from equipment to reach

Data to transmit

0x30

Radio address from transmitter

equipment

Received Data

the first byte of the field 'data to transmit' (or 'Received Data') contains an applicative command (or its

acknowledgement). That allows to the receptor of the frame to identify the type of requests (or of responses).

Data to Transmit or Received Data

1 byte 151 bytes

REQ_SEND_FRAME Applicative command Data relating to the request

RECEIVED_FRAME

Acknowledgement of the

applicative command

Data relating to the response

The commands set is available in Appendix A.

ATTENTION, This document describes only the format of the fields 'Data to Transmit', 'Received Data'.

These fields are directly dependent on the access to the functionalities of the WaveTherm modules. The

other fields of the radio frame depend on the exchanges modes chosen, and are detailed in document

[DR1].

WaveTherm modules – application handbook page 14 of 65

Page 15

File : CS-SUP-MUTI-WTHERMAPP-E01.sxw

5 INFORMATION RELATIVE TO THE PROBES ASSOCIATED WITH THE

WAVETHERM MODULES

5.1 DALLAS Probes

5.1.1 Coding of temperatures for the DALLAS probe type DS18B20

These probes have a resolution of 12 bits and their value is coded on two bytes (MSB first)

Negative values are expressed in two's complements with addition of a sign.

MSB LSB MSB LSB

Most Significant Byte Leasr Significant Byte

b7 b6 b5 b4 b3 b2 b1 b0 b7 b6 b5 b4 b3 b2 b1 b0

S S S S 2

7

2

6

2

5

2

4

2

3

2

2

2

1

2

0

2

-1

2

-2

2

-3

2

-4

Unit : Celsius degree (°C)

Bits [b7:b3] : sign bit.

Remark: The hexadecimal value 0x4FFF indicates the absence of a probe, or a connection error between

the module and the probe.

Some temperature values:

Temperature Binary value (MSB First) Hexadecimal value

+125°C 0000 0111 1101 0000 0x07D0

+85°C 0000 0101 0101 0000 0x0550

+25°C 0000 0001 1001 0000 0x0190

0°C 0000 0000 0000 0000 0x0000

-10.125°C 1111 1111 0101 1110 0xFF5E

-55°C 1111 1100 1001 0000 0xFC90

5.1.2 Probe ID

The probe ID corresponds to a unique code attributed to each DALLAS temperature probe in the factory.

This code is composed of 8 bytes defined as follows:

MSByte LSByte

1 byte 6 bytes 1 byte

Family Code Serial n° (48 bits) CRC Code

The family code is used to distinguish between the probes used:

Probe DS18S20 : 0x10

Probe DS18B20 : 0x28

WaveTherm modules – application handbook page 15 of 65

Page 16

File : CS-SUP-MUTI-WTHERMAPP-E01.sxw

5.1.3 Setting of the probe coefficient parameters

The precision of DALLAS probes is indicated by the manufacturer as ±0.5°C (-10°C to +85°C) and requires

no calibration before use.

However, it is possible to improve this precision if the user wishes to calibrate the probe. In this case, the

WaveTherm module contains a 32-byte memory zone for storage of transfer coefficients after calibration.

Initially, two parameters was created (size: 2 bytes per parameter), each one being able to store the value of

a coefficient of transfer.

After calibration, this allowed to refine measurement with a 2 degrees polynomial to the maximum.

Thereafter, a more important memory area was implemented, in order to store user data. Users can use this

area for whatever they want, but in order to increase the measurement precision, this 32-bytes area allows to

store a more significant number of coefficients.

Consequently the polynomial used can be superior degrees to 2; and allows to obtain a finer sleeking of

information. Management of this memory area is described further in chapter 7.1.5.

Remark : To maintain compatibility with old versions of the modules (Is)Thermeter), the storage

parameters of the coefficients are always existing, and are accessible by commands of reading and

writing of internal parameters.

Parameter 0x25 : parameter A relating to sensor 1

Parameter 0x26 : parameter B relating to sensor 1

Parameter 0x27 : parameter A relating to sensor 2

Parameter 0x28 : parameter B relating to sensor 2

WaveTherm modules – application handbook page 16 of 65

Page 17

File : CS-SUP-MUTI-WTHERMAPP-E01.sxw

5.2 PT100 and PT1000 probes

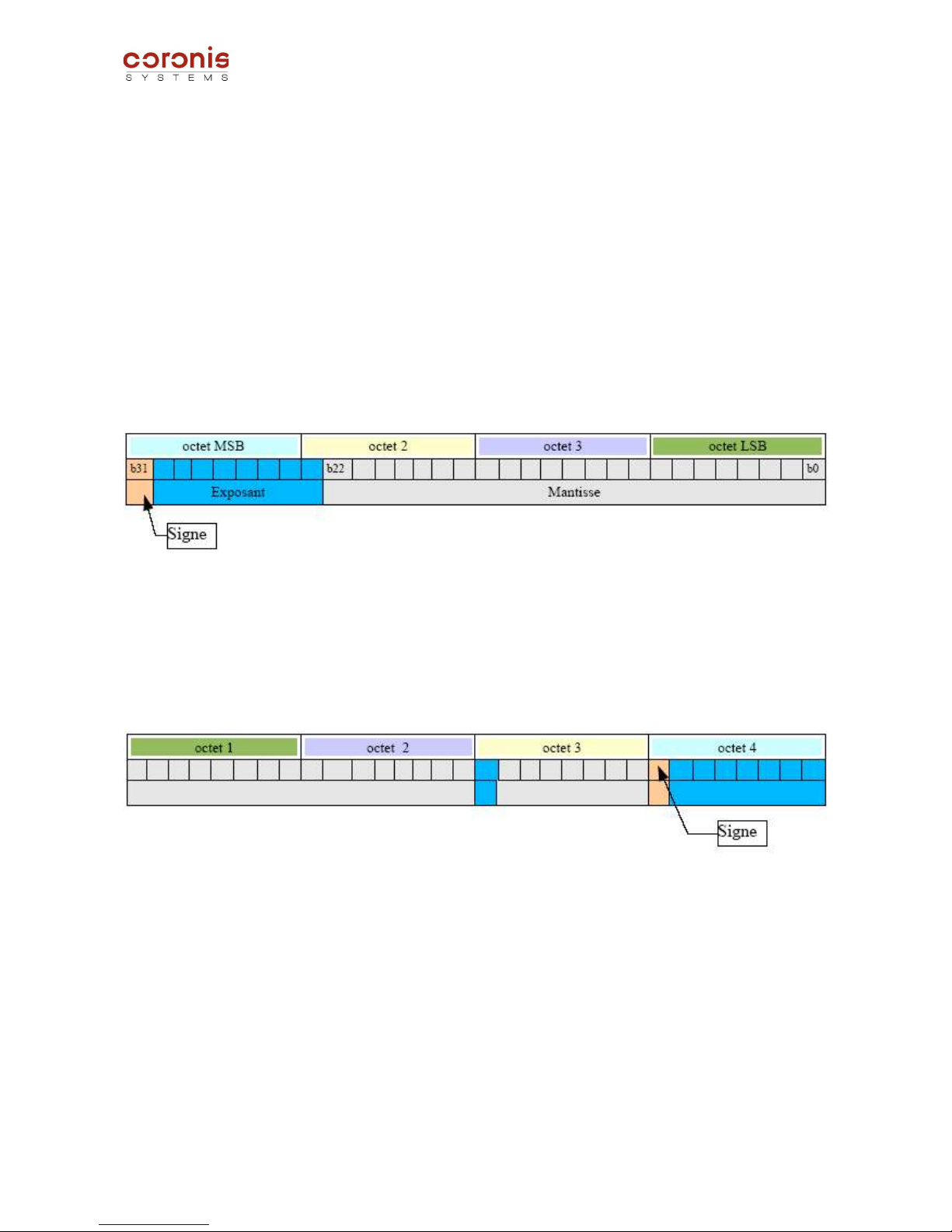

5.2.1 Representation of temperature values

Due to the high level of precision required of the temperature values processed by the module,

WaveTherm PT100 or PT1000 are true numbers (with a mantissa and exponent).

They are represented in the form of a 32-bit floating number.

The format used is the standard IEEE format with precision coded on 32 bits (+/-5.8774e-39 to

+/- 170,14e36)

➢ Theoretic representation of a floating IEEE 32-bit in bytes :

➢ Representation of the floating numbers in the radio buffer:

The radio module represents the 32-bit floating data in its buffers by coding them in LSB first. This is the

standard representation format used by the compilers C/C++ on PC.

A shift of the exponent allow to code it from E-127 to E+128

WaveTherm modules – application handbook page 17 of 65

Page 18

File : CS-SUP-MUTI-WTHERMAPP-E01.sxw

5.2.2 Calibration of radio module

➢ Factory calibration

The precision of PT100 and PT1000 probes is such that the WaveTherm module measurement chain

requires calibration.

This calibration is carried out automatically in the factory and the product is supplied ready for use.

➢ Re-calibration on site

Re-calibration on site is possible under certain conditions.

To carry out this operation, it will be necessary to connect two calibration precision resistances.

Remark: Calibration is therefore only possible on WaveTherm PT100 (or PT1000) modules equipped with

two probe inputs.

The WaveTherm PT100 and PT1000 modules possess two module calibration parameters. These

parameters are accessible in read-only and are updated with a calibration command

They contain the internal reference resistance values used during temperature measurement.

Parameter 0x30 : value of the internal reference resistance very low

Parameter 0x31 : value of the internal reference resistance very high

Calibration is therefore carried out using precision calibration resistances for accurate measurement of the

internal reference resistances and storage of the associated results in internal parameters. These values are

then used during temperature measurement.

Remark : Calibration resistance value:

- for WaveTherm – PT100 : 60 and 160 ohms.

- for WaveTherm – PT1000 : 160 and 1600 ohms.

➢ Associated radio commands

Applicative Command Description

0x08 Request to calibrate the radio module

0x88 Response to the request to calibrate the radio module

contents of REQ_SEND_FRAME request

Data Field (max : 152 bytes)

Applicative

Command

Value of the internal

reference resistance very low

(float - LSB First)

Value of the internal reference

resistance very high

(float - LSB First)

1 byte 4 bytes 4 bytes

0x08

The fields concerning the values of the internal reference resistors must be indicated with 32-bits

floating numbers ( LSbyte first). A more precise description of the 32-bits floating number format is

indicated in chapter 5.2.

WaveTherm modules – application handbook page 18 of 65

Page 19

File : CS-SUP-MUTI-WTHERMAPP-E01.sxw

contents of RECEIVED_FRAME response

Data Field (max : 152 bytes)

Acknowledgement

of the applicative

command

Status de l'étalonnage

Reference resistance

A

(LSB First)

Reference resistance

B

(LSB First)

1 byte 1 byte 4 bytes 4 bytes

0x88

0x00 : calibration OK

0xFF : calibration error

Resistances A and B are restored in the 32-bits floating numbers format (LSB first). Format described in

chapter 5.2.

5.2.3 Setting of probe coefficient parameters

The PT100 and PT1000 probes have a coefficient providing a linear temperature response.

Remark : The European standard EN60751 relative to probes defines 3 coefficients A,B and C used in

the calculation of the relationship : resistance = f (temperature).

In the -200 to 0°C range : R = R0[1+At + Bt

2

+ C(t – 100°C)t3)

in the -0°C to 850°C range: R = R0(1+At + Bt

2

)

R0 : Resistance at 0°C

A, B and C: transfer coefficients

As the WaveTherm module operating mode consists of measuring the probe resistance and then calculating

the temperature, it requires coefficients in order to calculate the relationship between these values:

temperature = f (resistance)

and not resistance = f (temperature).

The relationship T = f(R) must therefore be calculated according to the relationship provided in standard

EN60751.

The following polynomial is used:

T = C7.R7 + C6.R6 + C5.R5 + C4.R4 + C3.R3 + C2.R2 + C1.R + C

0

where C7, C6, C5, C4, C3, C2, C1, and C0 are the parameters to be transferred to the radio module

The coefficients to be transferred to the radio module are based on the coefficients A,B and C (given by the

manufacturer of the PT100 or PT1000 probes) in a mathematical formula. When required, CORONIS is able

to provide a utility enabling calculation of these coefficients. There are 8 in total (coeff A to H).

They are managed with standard internal parameters read and write commands. (see chapter 6.2).

WaveTherm modules – application handbook page 19 of 65

Page 20

File : CS-SUP-MUTI-WTHERMAPP-E01.sxw

All coefficients are regarded by the radio module as a single parameter.

Parameters Description

0x32 Coefficients of probe 1

0x33 Coefficients of probe 2

Each parameter is composed of 8 coefficients of 32 bits (floating IEEE) with a total size of 32 bytes.

The coefficients are represented in the radio buffer during use of the parameter read/write commands as

follows :

Remark: Coeff A : C

0

Coeff E : C

4

Coeff B : C

1

Coeff F : C

5

Coeff C : C

2

Coeff G : C

6

Coeff D : C

3

Coeff H : C

7

WaveTherm modules – application handbook page 20 of 65

Page 21

File : CS-SUP-MUTI-WTHERMAPP-E01.sxw

6 MODIFICATION OF THE INTERNAL PARAMETERS

6.1 INTERNAL PARAMETERS LIST ACCESSIBLE BY RADIO COMMANDS

6.1.1 Parameters common to all WAVETHERM versions

The table below describes the internal parameters accessible by standard read and write commands.

N° Description

Size

(in bytes)

Access

right

Default value

Hexa. Decimal

0x01 Operating Mode 1 R/W

Depending of the

module used (see 6.1.5)

0x02 WakeUp system status word 1 R/W 0 0

0x03 Default WakeUp period (in second) 1 R/W 0x01 1

0x04 Start time for 1st time window 1 R/W 0x07 7

0x05 WakeUp period for 1st time window (in second) 1 R/W 0x01 1

0x06 Start time for 2nd time window 1 R/W 0x12 18

0x07 WakeUp period for 2nd time window (in second) 1 R/W 0x01 1

0x08 Enalbe time windows by day of the week 1 R/W 0xFF 255

0x09 Enable WakeUp periods by day of the week 1 R/W 0x00 0

0x0A number of loop of the datalogging storage table 1 R 0x00 0

0x0B Number of temperature values stored in the table (LSB first) 2 R 0x0000 0

0x19 Numbers of retries of transmission of alarm frames 1 R/W 0x03 3

0x1A Delay between two retries of transmission of alarm frames 1 R/W 0x3C 60

0x20 Application Status 1 R/W 0x80 128

0x22 Alarm Configuration byte 1 R/W 0x00 0

0x80 Measurement Period (datalogging in time steps) 1 R/W 0x13 19

0x81 Start hour of the datalogging in time steps 1 R/W 0x08 8

0x82 Day of the week, or of the month (datalogging) 1 R/W 0x01 1

0x83 Time of measurement (datalogging once a week, or once a month) 1 R/W 0x08 8

0x85 Group number to use in polling mode 1 R/W 0x00 0

0x90 Date of detection of end of battery life 6 R/W 0 0

0xA1 Firmware version 1 R - -

0xA2 Battery life duration counter 2 R

Depending of the power

supply profile

0xB0 Number of repeaters used to transmit an alarm frame 1 R/W 0x00 0

0xB1 Address of the 1st repeater used to transmit an alarm frame 6 R/W - -

0xB2 Address of the 2nd repeater used to transmit an alarm frame 6 R/W - -

0xB3 Address of the 3rd repeater used to transmit an alarm frame 6 R/W - -

0xB4 Address of the recipient of the alarm frame 6 R/W

0x010A030

000BD

-

WaveTherm modules – application handbook page 21 of 65

Page 22

File : CS-SUP-MUTI-WTHERMAPP-E01.sxw

6.1.2 Parameters specific to the WaveTherm – DALLAS module

N° Description

Size

(in bytes)

Access

right

Default value

Hexa. Decimal

0x25 Parameter A relative to the sensor 1 2 R/W

0xFFFF -

0x26 Parameter B relative to the sensor 1 2 R/W 0xFFFF -

0x27 Parameter A relative to the sensor 2 2 R/W 0xFFFF -

0x28 Parameter B relative to the sensor 2 2 R/W 0xFFFF -

0x23 Measurement period of the threshold detection (in minutes) 1 R/W 0x00 0

0x15 High Threshold Alarm – Sensor 1 2 R/W 0x01A0 26°C

0x16 Low Threshold Alarm – Sensor 1 2 R/W 0x0100 16°C

0x17 High Threshold Excess Time – Sensor 1 (multiple of the measurement

period of threshold detection)

1 R/W 0x04 4

0x18 Low Threshold Excess Time – Sensor 1 (multiple of the measurement

period of threshold detection)

1 R/W 0x04 4

0x2B High Threshold Alarm – Sensor 2 2 R/W 0x01A0 26°C

0x2C Low Threshold Alarm – Sensor 2 2 R/W 0x0100 16°C

0x2D High Threshold Excess Time – Sensor 2 (multiple of the measurement

period of threshold detection)

1 R/W 0x04 4

0x2E Low Threshold Excess Time – Sensor 2 (multiple of the measurement

period of threshold detection)

1 R/W 0x04 4

6.1.3 Parameters specific to the WaveTherm – PT100 module

N° Description

Size

(in bytes)

Access

right

Default value

Hexa. Decimal

0x0C Precision level of the measurement 1 R/W 0x00 0

0x21 Extended Application Status 1 R/W 0x00 0

0x23 Measurement period of the threshold detection (in minutes) 1 R/W 0x00 0

0x15 High Threshold Alarm – Sensor 1 4 R/W 0x0000C041 24°C

0x16 Low Threshold Alarm – Sensor 1 4 R/W 0x0000A041 20°C

0x17 High Threshold Excess Time – Sensor 1 (multiple of the measurement

period of threshold detection)

1 R/W 0x04 4

0x18 Low Threshold Excess Time – Sensor 1 (multiple of the measurement

period of threshold detection)

1 R/W 0x04 4

0x2B High Threshold Alarm – Sensor 2 4 R/W 0x0000C041 24°C

0x2C Low Threshold Alarm – Sensor 2 4 R/W 0x0000A041 20°C

0x2D High Threshold Excess Time – Sensor 2 (multiple of the measurement

period of threshold detection)

1 R/W 0x04 4

0x2E Low Threshold Excess Time – Sensor 2 (multiple of the measurement

period of threshold detection)

1 R/W 0x04 4

0x30

Value of the internal reference resistance very low

(32-bit float in LSB First)

4 R 0x00000000 0 Ω

0x31

Value of the internal reference resistance very high

(32-bit float in LSB First)

4 R 0x00000243 130 Ω

0x32 Coefficients of probe 1 32 R/W - -

0x33 Coefficients of probe 2 32 R/W - -

0x91 Date of probe fault detection on sensor 1 6 R/W 0 0

0x92 Date of probe fault detection on sensor 2 6 R/W 0 0

WaveTherm modules – application handbook page 22 of 65

Page 23

File : CS-SUP-MUTI-WTHERMAPP-E01.sxw

6.1.4 Parameters specific to theWaveTherm – PT1000 module

N° Description

Size

(in bytes)

Access

right

Default value

Hexa. Decimal

0x0C Precision level of the measurement 1 R/W 0x00 0

0x21 Extended Application Status 1 R/W 0x00 0

0x23 Measurement period of the threshold detection (in minutes) 1 R/W 0x00 0

0x15 High Threshold Alarm – Sensor 1 4 R/W 0x0000C041 24°C

0x16 Low Threshold Alarm – Sensor 1 4 R/W 0x0000A041 20°C

0x17 High Threshold Excess Time – Sensor 1 (multiple of the measurement

period of threshold detection)

1 R/W 0x04 4

0x18 Low Threshold Excess Time – Sensor 1 (multiple of the measurement

period of threshold detection)

1 R/W 0x04 4

0x2B High Threshold Alarm – Sensor 2 4 R/W 0x0000C041 24°C

0x2C Low Threshold Alarm – Sensor 2 4 R/W 0x0000A041 20°C

0x2D High Threshold Excess Time – Sensor 2 (multiple of the measurement

period of threshold detection)

1 R/W 0x04 4

0x2E Low Threshold Excess Time – Sensor 2 (multiple of the measurement

period of threshold detection)

1 R/W 0x04 4

0x30

Value of the internal reference resistance very low

(32-bit float in LSB First)

4 R 0x00002A44 680 Ω

0x31

Value of the internal reference resistance very high

(32-bit float in LSB First)

4 R 0x0080BB44 1500 Ω

0x32 Coefficients of probe 1 32 R/W - -

0x33 Coefficients of probe 2 32 R/W - -

0x91 Date of probe fault detection on sensor 1 6 R/W 0 0

0x92 Date of probe fault detection on sensor 2 6 R/W 0 0

WaveTherm modules – application handbook page 23 of 65

Page 24

File : CS-SUP-MUTI-WTHERMAPP-E01.sxw

6.1.5 Definition of the module control bytes

➢ Definition of the Operating Mode byte (0x01) :

MSB LSB

Operanting Mode

Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

-

Threshold

Detection Mode

0 : successive mode

1 : cumulative mode

Low Threshold

Detection

0 : deactivated

1 : activated

High Threshold

Detection

0 : deactivated

1 : activated

Datalogging

00 : deactivated

01 : time steps

10 : once a week

11 : once a month

Stop Mode of the

Datalogging

0 : permanent loop

1 : stop memory full

-

Attention, it is advised the greatest prudence when modifying the parameter setting of the Operation

Mode variable. Indeed, the modifications on this variable generally requires the update of the associated

parameters.

Defautl value :

WaveTherm – DALLAS : 0x0A

WaveTherm – PT100 : 0x08

WaveTherm – PT1000 : 0x08

➢ Definition of the Application Status byte (0x20) :

It is possible to reinitialize to zero the bits by a write to the Application Status parameter.

MSB LSB

Application Status

Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

Reset

detection

0: not

detected

1: detected

Low

Threshold of

sensor 2

0: not

detected

1: detected

High

Threshold of

sensor 2

0: not

detected

1: detected

Low

Threshold of

sensor 1

0: not

detected

1: detected

High

Threshold of

sensor 1

0: not

detected

1: detected

number of detected

sensors

0 : 0 or 1 sensor

detected

1 : 2 sensors detected

-

End of

battery life

0: not

detected

1: detected

➢ Definition of the Extended Application Status byte (0x21) :

MSB LSB

Extended Application Status

Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

- - - - - -

Probe fault on

sensor 2

0: not detected

1: detected

Probe fault on

sensor 1

0: not detected

1: detected

Remark : The probe fault bits are set only when a problem is detected on WaveTherm – PT100, and

WaveTherm – PT1000 probes.

WaveTherm modules – application handbook page 24 of 65

Page 25

File : CS-SUP-MUTI-WTHERMAPP-E01.sxw

6.2 PRINCIPLE OF READING AND WRITING OF INTERNAL PARAMETERS

Document [DR1] details the exchanges modes, and their associated requests; with an aim of sending data to

a distant module.

This chapter details the data field in order to configure the internal parameters of the WaveTherm modules.

DATA Field

1 byte Max = 151 bytes

REQ_SEND_FRAME Applicative Commands Data

RECEIVED_FRAME

Acknowledgement of the

applicative commands

Data

There are two commands used to configure the internal parameters of the WaveTherm modules, and each

one has a corresponding acknowledgement command.

Applicatives

Commands

Description

0x10 Request of parameter(s) reading

0x90 Acknowledgement of the request of parameter(s) reading

0x11 Request of parameter(s) writing

0x91 Acknowledgement of the request of parameter(s) writing

Remark : In the command byte coding, the Response frame type are taking the Request command byte

value with the MSB bit set to 1.

It is possible to access up to 9 parameters simultaneously for writing or reading (all for

reading, or all for writing).

➢ Format of access for parameter(s) reading

contents of request REQ_SEND_FRAME

Data Field (max : 152 bytes)

Applicative

command

Number of

parameters

to be read

Number of the

1st parameter

Size of the 1

st

parameter

Number of the

2nd parameter

Size of the 2

nd

parameter

...

1 byte 1 byte 1 byte 1 byte 1 byte 1 byte ...

contents of response RECEIVED_FRAME

Data field (max : 152 bytes)

Acknowledgement

of the applicative

command

Number of

parameters

read

Number of

the 1

st

parameter

Size of the

1

st

parameter

Data of the

1

st

parameter

...

Number

of the n

th

parameter

Size of the

n

th

parameter

Data of

the n

th

parameter

1 byte 1 byte 1 byte 1 byte variable ... 1 byte 1 byte variable

n

max

= 9

When a parameter is not known by the system, or the size is configured with a wrong value, the

corresponding data byte in response is set to 0xFF.

WaveTherm modules – application handbook page 25 of 65

Page 26

File : CS-SUP-MUTI-WTHERMAPP-E01.sxw

➢ Format of access for parameter (s) writing

Contents of request REQ_SEND_FRAME

Data field (max : 152 bytes)

Applicative

command

Number of

parameters

read

Number of

the 1

st

parameter

Size of the

1

st

parameter

Data of the

1

st

parameter

...

Number

of the n

th

parameter

Size of the

n

th

parameter

Data of

the n

th

parameter

1 byte 1 byte 1 byte 1 byte variable ... 1 byte 1 byte variable

n

max

= 9

Contents of response RECEIVED_FRAME

Data Field (max : 152 bytes)

Acknowledgement

of the applicative

command

Number of

parameters

written

Number of

the 1

st

parameter

Update Status

Number of the

2nd parameter

Update Status ...

1 byte 1 byte 1 byte 1 byte 1 byte 1 byte ...

'Update Status' : 0x00 : update OK

0xFF : update error

Attention, some of the parameters are limited, i.e. their values should not be written out of the limits.

If a value is written out of the limits, the value will be written but not managed, the status of writing will be

OK.

Example: parameter 0x04 (hour of the first time-window) this parameter is set up from 0 to 23. Thus if

value 40 is set, it will be written, but is not managed by the system.

WaveTherm modules – application handbook page 26 of 65

Page 27

File : CS-SUP-MUTI-WTHERMAPP-E01.sxw

7 WAVETHERM MODULE FUNCTIONS

7.1 Parameter setting of the WaveTherm module

some of the parameters of module information are accessible by standard internal parameters read and write

commands, described in chapter 6.2; whereas other parameters of information are accessible by specific

applicative commands.

7.1.1 Reading of the module type

The module type is obtained by interrogating the WaveTherm module, with the GET_TYPE command.

Applicative Commands Description

0x20 Request to read the module type

0xA0 Response to the request to read the module type

Remark : In the command byte coding, the Response frame type are taking the Request command byte

value with the MSB bit set to 1.

➢ Contents of request REQ_SEND_FRAME

Data Field (max : 152 bytes)

Applicative command -

1 bytce -

0x20 -

➢ Contents of response RECEIVED_FRAME

Data Field (max : 152 bytes)

Acknowledgement

of the applicative

command

Module Type RSSI level *

Current Awakening

period

(in second)

Equipment Type

1 byte 1 byte 1 byte 1 byte 1 byte

0xA0 0x19 : WaveTherm Default value = 0x01 0x19 for WaveTherm

* the RSSI level (Received Signal Strength Indicator) indicates the reception level of the received frame.

This parameter can be used for the installations but is not useful from an application point of view.

The equipment type indicates if a Wavenis module is integrated in more complex equipment. The

equipment type, and module type have the same value :

Module Type :

WaveTherm – DALLAS : 0x19

WaveTherm – DALLAS (US version) : 0x33

WaveTherm – PT100 : 0x29

WaveTherm – PT1000 : 0x28

WaveTherm modules – application handbook page 27 of 65

Page 28

File : CS-SUP-MUTI-WTHERMAPP-E01.sxw

7.1.2 Reading of the firmware version

The firmware version of the module is obtained by interrogating the distant module with

GET_FIRMWARE_VERSION command.

Applicative

command

Description

0x28 Request of reading the firmware version (GET_FIRMWARE_VERSION)

0xA8 Response to the request of reading the firmware version

➢ Contents of request REQ_SEND_FRAME

Data Field (max : 152 bytes)

Applicative command Data

1 byte -

0x28 -

➢ Contents of response RECEIVED_FRAME

Data Field (max : 152 bytes)

Acknowledgement

of the applicative

command

Character 'V' in

ASCII format

Mode of transmission Firmware version

1 byte 1 byte 2 bytes 2 bytes

0xA8 0x56 Default value = 0x00A3

Remark 1 :The coding of the US firmware version takes the standard coding with the MSbit set to 1.

Example : firmware = 0x0104

firmware ( US version) = 0x8104

Remark 2 : Possible values for the mode of transmission

Value

868 MHz single channel 4800 baud 0x0012

868 MHz frequency hopping 9600 baud 0x00A3

Frequency Band from 902 Mhz to 928 Mhz – frequency hopping – 19200 baud

(US version)

0x00B9

WaveTherm modules – application handbook page 28 of 65

Page 29

File : CS-SUP-MUTI-WTHERMAPP-E01.sxw

7.1.3 Reading of the date and time of the module

Applicative

command

Description

0x12 Request to read the date and time of the module

0x92 Response to request to read the date and time of the module

Remark : In the command byte coding, the Response frame type are taking the Request command byte

value with the MSB bit set to 1.

➢ Contents of request REQ_SEND_FRAME

Data Field (max : 152 bytes)

Applicative command Data

1 byte -

0x12 -

➢ Contents of response RECEIVED_FRAME

Data Field (max : 152 bytes)

Acknowledgement

of the applicative

command

Day Month Year

Day of the

week

Hour Minute

1 byte 1 byte 1 byte 1 byte 1 byte 1 byte 1 byte

0x92 (1) (2)

(1) Year = current year - 2000

(2) day of the week : value from 0 to 6

Value Day of Week

0 Sunday

1 Monday

2 Tuesday

3 Wednesday

4 Thursday

5 Friday

6 Saturday

WaveTherm modules – application handbook page 29 of 65

Page 30

File : CS-SUP-MUTI-WTHERMAPP-E01.sxw

7.1.4 Setting the date and time of the module

Applicative

command

Description

0x13 Request to set the date and time of the module

0x93 Response to request to set the date and time of the module

Remark : In the command byte coding, the Response frame type are taking the Request command byte

value with the MSB bit set to 1.

➢ Contents of request REQ_SEND_FRAME

Data Field (max : 152 bytes)

Applicative

command

Day Month Year

Day of the

week

Hour Minute

1 byte 1 byte 1 byte 1 byte 1 byte 1 byte 1 byte

0x13 (1) (2)

(1) Year = current year - 2000

(2) day of the week : value from 0 to 6

Value Day of Week

0 Sunday

1 Monday

2 Tuesday

3 Wednesday

4 Thursday

5 Friday

6 Saturday

➢ Contents of response RECEIVED_FRAME

Data Field (max : 152 bytes)

Acknowledgement of

the applicative

command

Update Status -

1 byte 1 byte -

0x93

0x00 : update OK

0xFF : update error

-

WaveTherm modules – application handbook page 30 of 65

Page 31

File : CS-SUP-MUTI-WTHERMAPP-E01.sxw

7.1.5 Access to the user data area

The WaveTherm module manage a non-volatile memory area accessible by radio command, and allowing to

store up to 32 bytes.

This area is generally used to store the parameters relative to the calibration of the module, and can be read,

or modified by specifying the start address, and the size of the data.

Commande

Applicative

Description

0x16 Request to read the user data area

0x96 Response to the request to read the user data area

0x17 Request to write the user data area

0x97 Response to the request to write the user data area

➢ Access in Reading

To read the user data area, the user has to specify the address of the first byte to be read, and the total

number of bytes to be read.

Remark : Even if the size of the memory area is of 32 bytes, the address of the first element to be read is

coded on two bytes ; because this area is more important on other equipments.

Contents of the request REQ_SEND_FRAME

Data Field (max : 152 bytes)

Applicative

Command

MSB address of

the fisrt byte to

be read

LSB address of

the fisrt byte to

be read

Number of bytes to be

read

1 byte 1 byte 1 byte 1 byte

0x16 0x00 from 0 to 31 from 0 to 31

Contents of the response RECEIVED_FRAME

Data Field (max : 152 bytes)

Acknowledgement

of the applicative

command

MSB address of

the fisrt byte to

be read

LSB address of

the fisrt byte

to be read

Number of bytes read Data read

1 byte 1 byte 1 byte 1 byte variable

0x96 0x00 from 0 to 31 from 0 to 31

WaveTherm modules – application handbook page 31 of 65

Page 32

File : CS-SUP-MUTI-WTHERMAPP-E01.sxw

➢ Access in Writing

The user has to specify the address of the first byte to be written, the total number of bytes to be written, and

then the data.

Contents of the request REQ_SEND_FRAME

Data Field (max : 152 bytes)

Applicative

Command

MSB address of the

fisrt byte to be written

LSB address of the fisrt

byte to be written

Number of bytes to

be written

Data

1 byte 1 byte 1 byte 1 byte variable

0x17 0x00 from 0 to 31 from 0 to 31

Contents of the response RECEIVED_FRAME

Data Field (max : 152 bytes)

Acknowledgement of

the applicative

command

MSB address of the

fisrt byte to be

written

LSB address of the

fisrt byte to be

written

Number of bytes

written

1 byte 1 byte 1 byte 1 byte

0x97 0x00 from 0 to 31 0x00 if Error

Example : Reading a part of the memory area

The user wants to read 5 bytes from memory area, starting from the tenth bytes.

WaveTherm modules – application handbook page 32 of 65

1st byte

2nd byte

10th byte

...

11th byte

32th byte

12th byte

13th byte

14th byte

...

Address : 0x00

Address : 0x01

Address : 0x09

Address : 0x1F

LSB address of the 1st byte to be read = 0x09

5 bytes to be read

Page 33

File : CS-SUP-MUTI-WTHERMAPP-E01.sxw

7.1.6 Initialization of the sensors

The initialization command returns the number of sensors detected.

Remark : For the WaveTherm – DALLAS only, when the sensors are detected, the module returns their

identifier.

Applicative

Command

Description

0x04 Request to initialize the sensors

0x84 Response to the request to initialize the sensors

Contents of the request REQ_SEND_FRAME

Data Field

(max : 152 bytes)

Applicative command

1 byte

0x04

Contents of the response RECEIVED_FRAME

Data Field (max : 152 bytes)

Acknowledgement

of the applicative

command

Number of sensors detected

Identifier of the

sensor 1

Identifier of the

sensor 2

1 byte 1 byte 8 bytes 8 bytes

0x84

0x00 : no sensor

0x01 : 1 sensor detected

0x02 : 2 sensors detected

(*) (*)

(*) the identifier field is filled only when using WaveTherm – DALLAS, and if the sensor is detected ; Else the

field is not used ( 0 byte ).

The probe ID corresponds to a unique code attributed to each DALLAS temperature probe in the factory.

This code is composed of 8 bytes defined as follows:

MSByte LSByte

1 byte 6 bytes 1 byte

Family Code Serial number (48 bits) CRC Code

The family code is used to distinguish between the probes used :

probe DS18S20 : 0x10

probe DS18B20 : 0x28

➢ Case of the WaveTherm - PT100 ; and WaveTherm PT1000 modules :

During initialization, if only one sensor is used, it can be connected indifferently to the input 1 or 2.

If the sensor is initialized on input 2, it will correspond to the Sensor 1, i.e. when reading the temperature

value, the first temperature information returned correspond to the Sensor 1 (see chapter 7.2).

WaveTherm modules – application handbook page 33 of 65

Page 34

File : CS-SUP-MUTI-WTHERMAPP-E01.sxw

7.2 READING THE CURRENT VALUE OF THE TEMPERATURE SENSORS

The WaveTherm module has the possibility to read the current temperature when the sensors are wired, and

initialized. If not the input relative to the sensor not wired (or initialized) returns the following values :

WaveTherm – DALLAS : 0x4FFF

WaveTherm – PT100 : 0xFFFFFFFF

WaveTherm – PT1000 : 0xFFFFFFFF

In addition, this command returns the Operating Mode, and Application Status bytes.

7.2.1 Information concerning precision

Compatibility : - WaveTherm – PT100

- WaveTherm – PT1000

Temperature measurement may be started with one of several precision levels (0 to 3). In general, precision

level 0 is sufficient. The other precision levels are used in difficult environments.

The aim of these precision levels is to compensate for measurement errors induced by the 50 Hz frequency.

In practice, this precision is increased by increasing the number of measurement sequences for the same

temperature. Each measurement sequence is offset in relation to the previous sequence by 50Hz.

The precision levels may be described as follows,

Precision = 0x00 : normal precision (fastest measurement)

Precision = 0x01 : high precision

Precision = 0x02 : very high precision

Precision = 0x03 : maximum precision (slowest measurement)

Remark: Above all, the primary function is to preserve measurement precision, even in an

environment with considerable interference, and not to improve the measurement precision of the

probe itself.

Furthermore, the higher the precision, the higher the module power consumption. It is therefore

important to find the best possible consumption/precision compromise.

The choice of the precision level is coded in the command used to read the current value of the temperature

sensors.

7.2.2 Description of the commands to be used

Applicative Command Description

0x01 Request to read the current temperature values

0x81 Response to the request to read the current temperature values

WaveTherm modules – application handbook page 34 of 65

Page 35

File : CS-SUP-MUTI-WTHERMAPP-E01.sxw

Contents of request REQ_SEND_FRAME

Data Field (max : 152 bytes)

Applicative Command Precision level

1 byte 1 byte

0x01 (*)

(*) The precision field is used only for the modules :

- WaveTherm – PT100

- WaveTherm – PT1000

The WaveTherm – DALLAS doesn't support the precision capability. In this case the precision field

doesn't exist (size = 0 byte).

Thus, the format of the reponse varies according to the module used :

➢ WaveTherm – DALLAS :

Contents of the response RECEIVED_FRAME

Data Field (max : 152 bytes)

Acknowledgement

of the Applicative

Command

Operating

Mode

Application

Status

MSB

Temperature

A

LSB

Temperature

A

MSB

Temperature

B

LSB

Temperature

B

1 byte 1 byte 1 byte 1 byte 1 byte 1 byte 1 byte

0x81 (*) (*) (*) (*)

(*) These fields are set only if the sensors are wired, and initialized, otherwise the returned value is 0x4FFF.

The format of the temperature is described in chapters 5.1.1 and 5.2.

➢ WaveTherm – PT100 and WaveTherm – PT1000 :

Contents of the response RECEIVED_FRAME

Data Field (max : 152 bytes)

Acknowledgement

of the Applicative

Command

Operating

Mode

Application

Status

Temperature A

(Float 32 bits

LSB First)

Temperature B

(Float 32 bits

LSB First)

1 byte 1 byte 1 byte 4 bytes 4 bytes

0x81 (*)

(*) These fields are set only if the sensors are wired, otherwise the returned value is 0xFFFFFFFF.

WaveTherm modules – application handbook page 35 of 65

Page 36

File : CS-SUP-MUTI-WTHERMAPP-E01.sxw

7.2.3 Reading the current ohmic values of the sensors

Compatibility : - WaveTherm – PT100

- WaveTherm – PT1000

When using WaveTherm – PT100, or PT100 modules, it is possible to read the current ohmic value of the

sensors.

This type of reading may be started with one of several precision levels (0 to 3). In general, precision

level 0 is sufficient. The other precision levels are used in difficult environments (refer to chapter 7.2.1).

Applicative Command Description

0x07 Request to read the current ohmic value of the sensors

0x87 Response to request to read the current ohmic value of the sensors

Contents of request REQ_SEND_FRAME

Data Field (max : 152 bytes)

Applicative Command Precision level

1 byte 1 byte

0x07

Contents of the response RECEIVED_FRAME

Data Field (max : 152 bytes)

Acknowledgement

of the Applicative

Command

Operating

Mode

Application

Status

Resistance A

(32-bit Float

LSB First)

Resistance B

(32-bit Float

LSB First)

1 byte 1 byte 1 byte 4 bytes 4 bytes

0x87

The format of the temperature is described in chapters 5.1.1 and 5.2.

WaveTherm modules – application handbook page 36 of 65

Page 37

File : CS-SUP-MUTI-WTHERMAPP-E01.sxw

7.3 WAKE-UP SYSTEM MANAGEMENT

In order to reduce module power consumption, a wake-up period parameter setting system is incorporated.

This system enables modification of the module wake-up period (default setting 1 s) by entering a time and

day of the week :

The wake-up period default value may be modified;

Two time-windows with different wake-up periods may be defined;

Each day of the week may be set in one of the following three cases :

• Wake-up period default setting

• Wake-up according to predefined time windows

• No wake-up period (for safety reasons, the module is not disabled on reception and it

wakes up every 10 seconds)

7.3.1 Description of the parameters used

Parameter

number

Description

Size

(in bytes)

Access

rights

Default value

0x01 Operating mode 1 R/W

Depending of the

module used

(see 6.1.5)

0x02 Wake-up system status word 1 R/W 0x00

0x03 Default wake-up period (in s) 1 R/W 0x01

0x04 Start time for 1st time window (in hour) 1 R/W 0x07

0x05 Wake-up period - 1st time window (in s) 1 R/W 0x01

0x06 Start time for 2nd time window (in hour) 1 R/W 0x12

0x07 Wake-up period - 2nd time window (in s) 1 R/W 0x01

0x08 Enable time windows by day of week 1 R/W 0xFF

0x09 Enable wake-up periods by day of week 1 R/W 0x00

7.3.2 Choice of wake-up mode

These modes are directly dependant on the 'wake-up system status word' configuration and the values of

parameters associated with each mode.

Wake-up system status word

Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

- - - - - -

Enable day-of-week selection

0 : disabled

1 : enabled

Enable time windows

0 : disabled

1 : enabled

Wake-up system

status word

Wake-up mode

0x00 Case n°1 : Periodic wake-up, without distinction of day of the week

0x01

Case n°2 : Periodic wake-up in specific time windows for certain days of the week, periodic wake-up

for the other days

0x02 Case n°3 : Periodic wake-up for certain days of the week, periodic wake-up disabled for the other days

0x03

Case n°4 : Periodic wake-up in specific time windows for certain days of the week, periodic wake-up

for some days and periodic wake-up disabled for the remaining days

Remark: before enabling a specific wake-up mode, the parameters associated with this mode must

first be set.

WaveTherm modules – application handbook page 37 of 65

Page 38

File : CS-SUP-MUTI-WTHERMAPP-E01.sxw

7.3.3 Set a new wake-up period

The WaveTherm module wake-up default setting is every second. The wake-up period may be easily

modified by entering a new value in the 'default wake-up period parameter'.

Attention, the value associated with this parameter may not exceed 10 seconds.

Attention, an erroneous value of this parameter involves a wake-up every second, the maximum

value is 0x0A (10 seconds).

7.3.4 Set a fixed wake-up period for certain days of the week

The wake-up system parameters may be set to allow disabling of WaveTherm module periodic wake-up for

certain days of the week.

In practice, when periodic wake-up is disabled, the WaveLog polls every 10 seconds.

The parameter setting procedure is as follows :

disable periodic wake-up for certain days, with the 'Enable periodic wake-up for certain days of

the week' parameter.

Enable selection of the days of the week, with the 'wake-up system status word' parameter;

'wake-up system status word' = 0x02

In this way, on days when periodic wake-up is disabled, the module polls every 10 seconds, whereas for the

rest of the week the module wakes up at the default period setting.

Enable wake-up periods by day of week

Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

-

Sunday

0 : enabled

1 : disabled

Saturday

0 : enabled

1 : disabled

Friday

0 : enabled

1 : disabled

Thursday

0 : enabled

1 : disabled

Wednesday

0 : enabled

1 : disabled

Tuesday

0 : enabled

1 : disabled

Monday

0 : enabled

1 : disabled

Attention, the coding of each bit is reversed, compared to the parameter ' Enable time windows by

day of the week'.

7.3.5 Set day/night system parameter without distinction of days of the week

The wake-up system parameters may be set to enable configuration of the time windows with different wakeup periods.

Whether the user wants a distinction of the days of the week, or not; the parameter ' Enable time

windows by day of the week' must be suitably configured. Thus in the case of a time windows

activation without distinction of the days of week, every day of the week must be enabled (' Enable

time windows by day of the week' = 0x7F).

WaveTherm modules – application handbook page 38 of 65

Page 39

File : CS-SUP-MUTI-WTHERMAPP-E01.sxw

The time windows function as follows,

Set the start time for the first time window and its wake-up period ;

Set the start time for the second time window and its wake-up period ;

Select the days of the week during which the time windows are enabled ;

'Enable time windows by day of the week' = 0x7F

Validate the time window mode with the 'wake-up system status word'.

'Wake-up system status word' = 0x01

Note: The format of the parameters 'Start time for time windows' is expressed in hour, and its value

lies between 0 and 23.

For example, if the start time of time windows at 12h00; the value 0x0C should be configured.

The format of the wake-up periods of each time windows, is the same one as the default wake-up

period; i.e. it is expressed in seconds, and cannot exceed value 0x0A.

The format of the applicatives commands for reading and writing internal parameters, is described in chapter

6.2.

Enable time windows by day of week

Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

-

Sunday

0 : enabled

1 : disabled

Saturday

0 : enabled

1 : disabled

Friday

0 : enabled

1 : disabled

Thursday

0 : enabled

1 : disabled

Wednesday

0 : enabled

1 : disabled

Tuesday

0 : enabled

1 : disabled

Monday

0 : enabled

1 : disabled

Attention, the coding of each bit is reversed, compared to the parameter ' Enable wake-up periods

by day of the week'.

WaveTherm modules – application handbook page 39 of 65

Page 40

File : CS-SUP-MUTI-WTHERMAPP-E01.sxw

7.3.6 Set the day/night system parameters according to day of the week

The day/night system according to the day of the week parameter setting procedure is the same as that

described in the previous chapter with the exception that the “Enable time window according to the day of the

week” parameter is only set for days required.

For example, we wish to enable the time window from Monday to Wednesday.

The 'Enable time windows according to day of the week' parameter is set to 0x07.

In this way, the module wakes up during these time windows for a period set in the associated parameters

with a specific start time for each window from Monday to Wednesday.

For the other days of the week, the wake-up mode depends on the 'wake-up system status word' :

'Wake-up system status word' = 0x01

the bit 1 is not enabled, thus the parameter 'Enable wake-up periods by day of week' is not

used ; so the rest of the week, the module uses the default wake-up period.

'Wake-up system status word' = 0x03

the bit 1 is enabled, thus the parameter 'Enable wake-up periods by day of week' is used, so

the wake-up for the rest of the week will depend on this parameter.

Days with wake-up period enabled : default wake-up period

days with wake-up period disabled : periodic wake-up disabled (polling every 10 sec.)

The format of the applicatives commands for reading and writing internal parameters, is described in chapter

6.2.

WaveTherm modules – application handbook page 40 of 65

Page 41

File : CS-SUP-MUTI-WTHERMAPP-E01.sxw

7.4 PARAMETER SETTING OF THE DATALOGGING MODE

The Datalogging mode enables periodic logging of temperatures at each input (by selecting the precision

index for PT100 and PT1000 probes). The frequency of these readings may be set in three modes:

index logging in time steps

index logging once a week

index logging once a month

When the storage table is full, the most recent measurements crush the oldest values , this mode is called

permanent loop.

The standard datalloging doesn't support the 'Stop Memory Full' Capability. Thus, it cannot be enabled in the

Operating Mode byte.

7.4.1 Description of the parameters used

According to the datalogging type ( time steps, once a week, once a month), some specific parameters must

be used.

Parameter

number

Description

Size

(in bytes)

Access

Right

Default value

0x01 Operating mode 1 R/W

Depending of the

module used

(see 6.1.5)

0x0C Precision level of measurement 1 R/W 0x00

0x80 Measurement period (datalogging in time steps) 1 R/W 0x13

0x81 Start hour of the datalogging in time steps 1 R/W 0x08

0x82 Day of the week, or of the month 1 R/W 0x01

0x83 Time of measurement (datalogging once a week, or once a month) 1 R/W 0x08

These specific parameters must be initialized before activating the datalogging mode.

7.4.2 Precision level of the measurement

Compatibility : - WaveTherm – PT100

- WaveTherm – PT1000

Temperature measurement may be started with one of several precision levels (0 to 3). In general, precision

level 0 is sufficient. The other precision levels are used in difficult environments.

The aim of these precision levels is to compensate for measurement errors induced by the 50 Hz frequency.

In practice, this precision is increased by increasing the number of measurement sequences for the same

temperature. Each measurement sequence is offset in relation to the previous sequence by 50Hz.

WaveTherm modules – application handbook page 41 of 65

Page 42

File : CS-SUP-MUTI-WTHERMAPP-E01.sxw

The precision levels may be described as follows,

Precision = 0x00 : normal precision (fastest measurement)

Precision = 0x01 : high precision

Precision = 0x02 : very high precision

Precision = 0x03 : maximum precision (slowest measurement)

Remark: Above all, the primary function is to preserve measurement precision, even in an

environment with considerable interference, and not to improve the measurement precision of the

probe itself.

Furthermore, the higher the precision, the higher the module power consumption. It is therefore

important to find the best possible consumption/precision compromise.

The precision level in datalogging mode is selected by configuring the parameter 0x0C.

7.4.3 Activating the datalogging mode

The datalogging mode is activated (or deactivated) by setting the bits [b3:b2] in the Operating Mode byte. In

standard datalogging, the 'Stop Memory Full' mode is not allowed.

➢ Operating Mode :

MSB LSB

Operanting Mode

Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

-

Threshold

Detection Mode

0 : successive mode

1 : cumulative mode

Low Threshold

Detection

0 : deactivated

1 : activated

High Threshold

Detection

0 : deactivated

1 : activated

Datalogging

00 : deactivated

01 : time steps

10 : once a week

11 : once a month

Stop Mode of the

Datalogging

0 : permanent loop

1 : stop memory full

-