COROB™ FIRST 70

Automatic Dispenser

User’s Manual

4002758 - ENGLISH

V1.0 - R2 (05/2014)

User’s Manual

Automatic Dispenser

COROB™ FIRST 70

Version 1.0 - R2 (05/2014)

© COPYRIGHT 2014, COROB S.p.A.

All rights reserved in all countries

If you require additional copies of this manual or further technical information about it, please write to:

COROB S.p.A.

Via Agricoltura 103 • 41038 San Felice s/P • Modena • Italy

Phone: +39-0535-663111 • Fax: +39-0535-663285

Web site: www.corob.com

Email: info.it@corob.com

COROB India Pvt. Ltd.

158, Dani Compound, Vidyanagari Marg, C.S.T. Road, Kalina, Santacruz (E), Mumbai - 400098

Maharashtra, India

p +91 22 6649 7777 • f +91 22 6649 7700

Factory: Plot No. 10 - 13 & 13 A, Daman Industrial Estate, Somnath Road, Daman - 396210

India

INTELLECTUAL PROPERTY RIGHTS AND DISCLAIMER

No part of this manual may be translated into any other languages and/or adapted and/or reproduced in any form, or by any means, electronic

or mechanical, including but not limited to photocopying and recording, without prior written permission of COROB S.p.A..

COROB™ is a registered trademark and/or commercial trademark used on an exclusive basis by COROB S.p.A. and its afliated companies

(hereinafter “COROB”).

A failure of a trademark to appear hereunder does not mean that COROB does not use the trademark in question nor does it constitute a waiver

by COROB of any related intellectual property rights.

Valuable proprietary technical information contained in the present manual are referring to proprietary know-how, designs, drawings and/or

applications used on an exclusive basis by COROB frequently covered by Patents and/or Patent Applications and thus protected by International

and National Intellectual Property Laws.

Unless otherwise indicated, all references to other companies other than COROB and its afliated companies, their names, data and addresses

used in the screens and/or examples are purely coincidental and serve as a reference only to clarify the use of the COROB™ products.

COROB has carefully reviewed the wording and imagines contained in the present manual, nevertheless COROB reserves the right to modify

and/or update the information herein to correct editorial errors and/or inaccuracy of the information herein without notice or commitment on its

part.

The present manual contains all information necessary for the foreseeable and normal use of the COROB™ products by the nal user.

The manual does not contain guidelines and/or information for product repair. For safety reasons, only trained and authorized technical personnel

should perform such interventions. Failure to do so may result in personal injury or damage to the product.

For the purpose mentioned above, COROB has appointed authorized technical personnel.

Authorized technical personnel shall mean technicians who have attended a technical training course held by COROB and/or its afliated companies.

Unauthorized interventions could void the warranty coverage of your COROB™ product pursuant to the sales contract or to the General Sales

Conditions of COROB. COROB can be held responsible only within the limits of the warranty coverage provided by the General Sales Conditions.

COROB does not intend to limit or exclude its liability against any statutory provisions under any applicable law. Therefore the reference to above

warranty limitations or exclusions may not apply.

The nal user can ask COROB or visit the web site www.corob.com for contact details about the nearest authorized technical service.

PRODUCT DISPOSAL AND RECYCLING

This equipment must not be disposed of with unsorted municipal waste. Carry

out a separate collection.

Pursuant to the WEEE Directive, collection, treatment, recovery and environmentally

sound disposal of Waste Electrical and Electronic Equipment (WEEE) shall be carried out

in compliance with the national measures of each EU-Member State implementing the

Directive.

For more information about proper disposal and recycling of your COROB™ product,

please contact the company at the address info.it@corob.com.

For the colorants remaining in the canisters, for the machine components most soiled

with colorant and if any products have been used on the machine that require special

disposal procedures, follow local regulations when disposing of waste.

COROB™ FIRST 70

COROB™ AUTOMATIC DISPENSER

QUICK GUIDE

At the beginning of the working day

• Check that the nozzle center is clean.

• Check that the sponge is clean and saturated; if it is necessary to saturate, use only appropriate liquid (the

choice of the liquid depends on the nature of the colorants, and must be done directly by the manufacturer

of the products used).

• Carry out system Initialization and Purge.

Things to remember

• Never turn the machine OFF.

• In the canisters, stirring of each colorant takes place automatically.

• Be careful not to ll the canisters with too much colorant. In case of overlling, refer as indicated in the

user’s manual.

• The colorant to be poured inside the canisters must be stirred manually. Do not use automatic shakers.

• Close the canisters with their lids immediately after lling operations.

• Remember to update accordingly the canisters lling levels via the management software.

• The sponge must be saturated at least twice a week (the frequency of intervention is indicative, since it

depends on the nature of colorants and the environment conditions).

At the end of the working day

• Rell the canisters.

• Update the canister lling levels in the management software.

• Shut down the computer. Do not shut off the machine.

It is recommended to carefully read the user’s manual.

CONTENTS

- 1

CONTENTS

1 GENERAL INFORMATION ......................................................................................................... 3

1.1 Purpose and use of this manual .........................................................................................3

1.1.1 Conventionally used graphics .................................................................................3

1.2 Identifying information.....................................................................................................3

1.3 Intended and improper use ..............................................................................................4

1.4 Denitions ................................................................................................................... 4

2 SAFETY ...................................................................................................................................5

2.1 General warnings ............................................................................................................5

2.2 Warnings on the use of colorants ....................................................................................... 6

2.3 Residual risks .................................................................................................................7

2.4 Position of labels .............................................................................................................8

3 FEATURES ...............................................................................................................................9

3.1 Description of the machine ...............................................................................................9

3.2 Description of units ....................................................................................................... 10

3.3 Standard and optional congurations ............................................................................... 11

3.4 Usable cans .................................................................................................................. 11

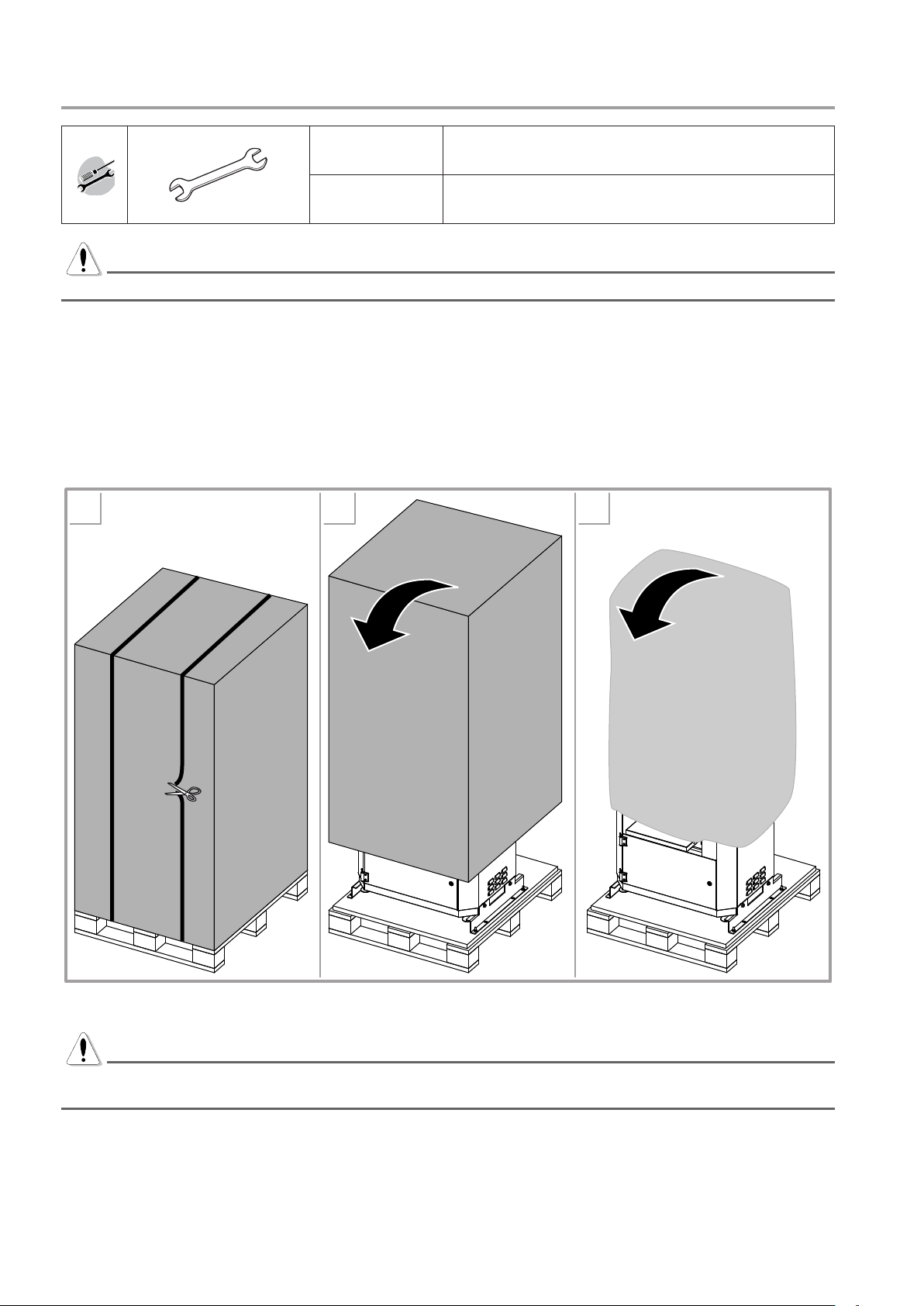

4 SHIPPING, HANDLING AND UNPACKING ............................................................................... 13

4.1 General warnings .......................................................................................................... 13

4.2 Environment conditions of the installation site .................................................................. 13

4.3 Unpacking and placement .............................................................................................. 14

4.3.1 Standard material supplied .................................................................................. 15

4.4 Installation ................................................................................................................... 16

4.5 Packing and handling ..................................................................................................... 16

5 START-UP .............................................................................................................................17

5.1 General warnings .......................................................................................................... 17

5.2 Control devices and connections ...................................................................................... 18

5.3 Electrical connection and start-up .................................................................................... 19

5.4 Initialization ................................................................................................................. 20

5.5 Use of the off-line button ............................................................................................... 20

5.6 Shut-down ................................................................................................................... 20

6 USING THE DISPENSER ......................................................................................................... 23

6.1 General warnings .......................................................................................................... 23

6.2 At the beginning of the working day................................................................................. 23

6.3 Running the machine .................................................................................................... 23

6.3.1 Adjusting the can shelf height .............................................................................. 24

6.3.2 Loading the can ................................................................................................. 24

6.3.3 Using the adapter .............................................................................................. 24

6.3.4 Dispensing ........................................................................................................ 26

6.4 Automatic timed stirring ................................................................................................. 26

6.5 Relling the canisters ..................................................................................................... 27

6.6 Troubleshooting ............................................................................................................ 29

7 ORDINARY MAINTENANCE ....................................................................................................31

7.1 General warnings .......................................................................................................... 31

7.2 Maintenance table ......................................................................................................... 31

7.3 Products to be used ....................................................................................................... 31

7.4 External cleaning .......................................................................................................... 32

7.5 Cleaning the nozzle center .............................................................................................. 32

7.6 Cleaning and moistening the humidier cap sponge ........................................................... 33

8 TECHNICAL SPECIFICATIONS ...............................................................................................35

8.1 Technical data ............................................................................................................... 35

CONTENTS

2 -

8.2 Dimensions .................................................................................................................. 36

8.3 Warranty ...................................................................................................................... 36

COROB™ FIRST 70

GENERAL INFORMATION - 3

1 GENERAL INFORMATION

1.1 Purpose and use of this manual

This manual, inserted in the product packing, contains instructions on the use and routine maintenance needed

to uphold the machine’s performance over time.

Read this manual carefully before using the machine.

The manual is to be considered an integral part of the machine, and must be stored until it is fully

dismantled.

The manual contains all information available at the time of preparation regarding the machine and any

accessories; for accessories, the manual includes any variations or changes that involve different operating

procedures.

Should it be lost or partially ruined, so that its contents can no longer be read in full, you must request a new

manual from the manufacturer.

Some of the illustrations in this manual were taken from prototypes; some details may differ on

machines in standard production.

1.1.1 Conventionally used graphics

Boldface type is used to highlight notes or information of particular importance to a topic.

DANGER

Indicates a risk of personal injury.

WARNING

Indicates a risk of damage to the machine that could interfere with its operation.

Indicates important instructions referring to precautionary rules and/or measures to adopt.

Indicates situations and/or operations that involve the management software installed on the

computer.

Indicates that to carry out the intervention described, the use of the specied tools is required.

1.2 Identifying information

The machine has an identication plate (chapter 2.4), indicating:

1. Manufacturer’s name.

2. Marking.

3. Machine model.

4. Year of manufacture.

5. Serial number.

6. Electrical specications.

Do not remove or tamper with the identication plate in any way.

4 - GENERAL INFORMATION

1.3 Intended and improper use

The machine must be used only within the limitations set forth by the technical specications and according to

the procedures described in this manual.

Any use other than that stated, which cannot be implied or deduced from this manual, is to be considered

prohibited.

1.4 Denitions

A person familiar with the methods to produce paints or similar products, assigned to

OPERATOR

MAINTENANCE

TECHNICIAN

operate and use the machine by its controls and to load and unload production materials

with all safety devices enabled. He or she must work only in safety conditions and is

allowed to carry out routine maintenance operations.

Specialist prepared and trained in a technical eld (mechanical and electrical) and

assigned to work on the machine to perform adjustments, repair breakdowns or carry out

maintenance.

COROB™ FIRST 70

SAFETY - 5

2 SAFETY

2.1 General warnings

COMPULSORY

• Read the user’s manual carefully before carrying out any operation on the machine.

• The machine must be used only for its intended purpose.

• Pay close attention to the signs on the machine.

• The substances that may be used on the machine -- such as colorants, paints, solvents, lubricants and

cleansers -- may be hazardous to your health; handle, store and dispose of these substances in keeping

with current regulations and the instructions provided with the product.

• Only qualied and appropriately trained personnel (MAINTENANCE TECHNICIANS) are authorized to access

the machine parts protected by panels for maintenance and repair interventions.

• During routine maintenance operations, scrupulously follow the safety instructions given in the corresponding

chapters before accessing the dangerous area.

PROHIBITED

• The OPERATOR must not carry out operations reserved to the MAINTENANCE TECHNICIAN. The manufacturer

CANNOT BE HELD RESPONSIBLE for damages deriving from the non-observance of this prohibition.

• It is strictly forbidden to bypass or disable the protections and any safety devices present on the machine.

• The panels must be kept closed at all times.

• THE MACHINE IS NOT EXPLOSION-PROOF AND MUST NOT BE USED IN AREAS AT RISK FOR

EXPLOSION.

• If the machine catches re, never use water. Use only dry powder or carbon dioxide re extinguishers, and

strictly follow the instructions and warnings indicated by the manufacturer and listed on the extinguisher.

ELECTRICAL DANGER

• In the event of a sudden power outage, when power returns the machine will automatically be switched on

to allow the automatic processes to prevent products from drying out.

• The machine must not be powered by a power source having specications other than those listed on the

identication plate.

• Incorrect grounding may lead to the risk of electrical shock; always plug the machine into a socket that

ensures proper grounding. The line must be protected from overloads, short-circuits and direct contacts

according to current accident prevention regulations.

• To prevent any risk of electric shock or injuries, the machine must be used indoors only.

• Always unplug the power supply cable from the socket outlet before carrying out any maintenance

operations.

• The machine is isolated from the power supply line when the power cable is disconnected; it must therefore

be installed near an easily accessible mains socket outlet.

• Do not use extension cords to power the machine.

• Do not use multisockets to connect other equipment to the same socket that powers the machine.

• Periodically check the condition of the power supply cable; if it is damaged, replace it with a new cable

supplied by the manufacturer.

6 - SAFETY

2.2 Warnings on the use of colorants

DANGER

The machine is suitable for use with tinting products in general. Scrupulously follow the instructions for use

given on the colorant package and carefully read the SAFETY DATA SHEET that the dealer or manufacturer

of the product is required to provide. Observe all of the safety instructions provided. When compulsory, use

personal protection equipment for eyes and hands.

Below are some of the most common warnings and safety precautions provided by colorant manufacturers.

1. Harmful if swallowed.

2. Avoid eye and skin contact. In case of eye and skin contact, rinse with plenty of water.

3. Keep out of the reach of children.

4. When compulsory, wear protecting equipment for eyes and hands.

5. In case of accidental product leaks or spills, thoroughly ventilate the area and proceed as indicated in this

manual and in the instructions provided with the product itself.

6. Do not dispose of colorant in the sewage system. Follow local regulations when disposing of waste.

COROB™ FIRST 70

2.3 Residual risks

SAFETY - 7

Risk Preventive measure

Risk of crushing during the cans

loading and unloading operations,

also when using adapters to

adjust the can position.

Risk of electrocution if you

perform any operation without

rst cutting off electrical power.

Risk of electrocution caused by

high leakage current.

Dorsal/lumbar injuries caused by

handling of heavy loads.

Contact or inhalation of colorants

during the canister relling

operations.

Contact or inhalation of colorants

during the cleaning operations of

the nozzle center and moistening

of the humidier cap sponge.

Fire due to the use of colorants

containing volatile solvents.

Wear appropriate personal protective equipment

(shoes and gloves).

The operator is not authorized to access the machine

parts protected by panels.

Before removing the panels, unplug the power supply

cable from the mains socket outlet.

Power the machine through a grounded socket outlet. chapter 5.3

Do not exceed the weight limits stated by the

current regulations in force (kg 20 for women, kg

30 for men).

Keep the room suitably ventilated.

Wear appropriate personal protective equipment

(safety goggles, gloves and mask).

Do not use naked ames, electrical tools or other

types of devices that could cause sparks or re

hazards close to the machine.

The room in which the machine is installed must be

spacious, with good ventilation (air exchange) and no

type of parts must be positioned against or stocked

close to the machine.

Canister top up must be carried out opening one canister

at the time.

If during this operation, some colorant should spill out of

the canister, immediately disconnect the machine from

the mains before cleaning.

Re. in the

manual

chapter 6

chapter 2.1

chapter 6

chapter 2.2

chapter 6.5

chapter 2.2

chapter 7

chapter 4.2

chapter 6.5

8 - SAFETY

2.4 Position of labels

2

COROB India Pvt. Ltd. - Mumbai

c/o Daman Factory:

Plot No. 10-13&13A,

Daman Industrial Estate,

Somnath Road - Daman - India

MODEL

YEAR

S/N

XXXXXXXX

Volt Hz

Watt Amper

XXXXX

XXX

20xx

beforeconnectingpower supply.

Max

rating2A

Groundconnectionessential

XXXXX

WARNING

Highleakagecurrent.

Max

rating2A

Max

rating2A

WARNING

High leakage current.

Ground connection essential

before connecting power supply.

Max

rating 2A

Max

rating 2A

Max

rating 2A

3

1

Figure 1

1. Identication plate (chapter 1.2)

2. Label “General warnings” .........................................................................................code - 4025565

3. Label “Warning - High leakage current” ...................................................................... code - 4000539

Do not remove or make illegible the safety or instruction labels. Replace any label which has become

illegible or is missing, by requesting it to the manufacturer.

COROB™ FIRST 70

FEATURES - 9

3 FEATURES

3.1 Description of the machine

The COROB™ FIRST 70 automatic dispenser is a device to automatically dispense uid colorant products into

containers (metal or plastic canisters, cans or bins) of the size indicated in this manual, pre-lled with base, to

produce nished products such as paints, dyes, enamels, and inks of the desired hue, chosen by means of the

machine management software.

Small and compact, the machine is available in the versions with 12 or 16 dispensing circuits.

3

4

2

1

Figure 2

The dispenser consists of:

1. Dispensing area and can handling system.

2. Off-line button.

3. Upper cover.

4. Canister lling area.

The dispenser is fully managed by a normal personal computer that can be provided upon request, since it is

not supplied as standard together with the machine. The manufacturer can also supply a wide range of software

applications to manage all of the machine’s functions.

10 - FEATURES

3.2 Description of units

Canisters

The machine canisters are suitable for containing the product to be dispensed.

A cover in the upper part of the machine provides access for lling the

canisters.

Nozzle Center

The ends of the dispensing pipes coming from the canisters converge and are

attached to the nozzle center, from which the tinting product to ll the can is

dispensed.

Shelf

The can shelf allows for the correct positioning of the can under the dispensing

nozzles.

The Retractable shelf is removable and can be positioned at the desired

height by simply inserting it in the slots provided.

An adapter is provided to position smaller Quart (1-liter, height 100 mm)

and Pint-size (0.5-liter, height 70 mm) cans.

Nozzle Humidier Cap

Colorants tend to dry out; this tendency may be more or less strong depending

on the type of colorant and the environment conditions (temperature, relative

humidity, etc.). To prevent colorants from drying out in the nozzle center,

the machine is equipped with a humidier cap which requires constant

maintenance.

The Sliding cap is a simple cap, which opens thanks to the push applied

to the opening bar while the can is being positioned. The cap closes when

the can is removed. The system checks that the cap is properly opened

and conrms the can presence to begin dispensing.

COROB™ FIRST 70

FEATURES - 11

3.3 Standard and optional congurations

Canister capacity 2.5 liters

Number of circuits 12 / 16

Circuit with Standard pump standard

Sliding cap standard

Retractable manual shelf standard

Support for Monitor/LCD optional

Support for keyboard optional

Support for mouse/label printer optional

PC side placement holder optional (only for 12 circuits version)

3.4 Usable cans

400 mm

MAX

MIN

115 mm

(with adapter)

MAX

320 mm

(270 with hole in the

center)

MIN

46 mm

12 - SHIPPING, HANDLING AND UNPACKING

COROB™ FIRST 70

SHIPPING, HANDLING AND UNPACKING - 13

4 SHIPPING, HANDLING AND UNPACKING

4.1 General warnings

DANGER

To avoid personal injuries and property damage, use the utmost care and caution when handling the machine,

and carefully follow the instructions given in this chapter.

The packing must be handled only by skilled personnel using appropriate handling equipment.

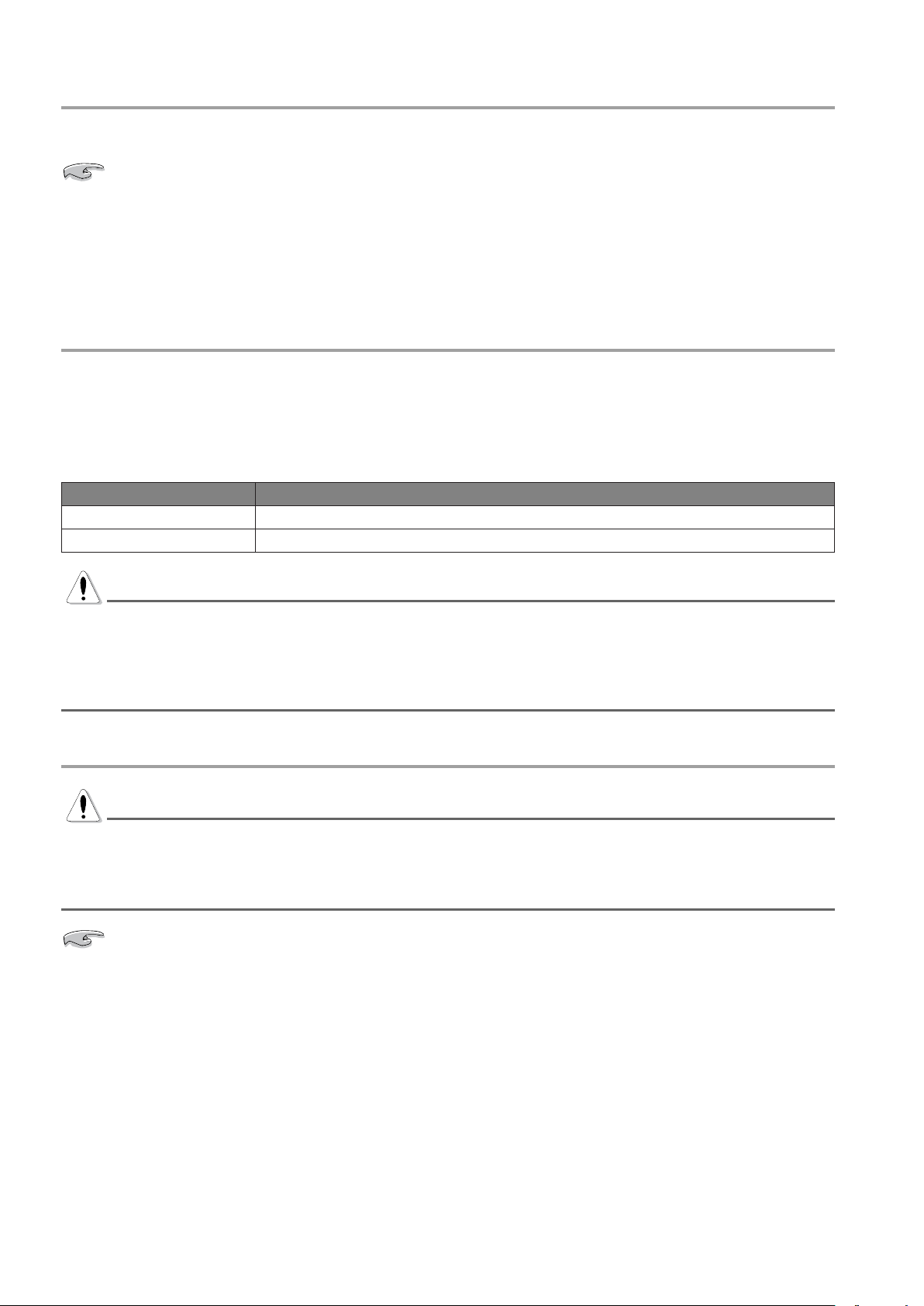

4.2 Environment conditions of the installation site

Environment requirements for the site where the machine is to be used:

• Clean and dust-free.

• With level and stable oor.

• Fitted with a grounded power supply socket.

• Equipped with sufcient lighting to ensure good visibility from every point of the machine.

• Ventilated to prevent the concentration of harmful fumes.

• Temperature between 10 °C (50 °F) and 40 °C (104 °F) and relative humidity between 5% and 85%,

without condensation.

WARNING

The environment working conditions are strictly related to the type of colorants used (ask for information

from the paint manufacturer). The requirements indicated above are valid for the machine only.

Do not place the machine near heat sources or in direct sunlight. Also humidity sources should be avoided.

The machine must be used indoors only.

Environment conditions outside the values indicated (chapter 8.1) may cause serious damage to the machine,

especially the electronic equipment.

DANGER

When using colorants containing volatile solvents the room in which the machine is installed must be

spacious, with good ventilation (air exchange) and no type of parts must be positioned against or stocked

close to the machine.

If the machine is installed near a wall, keep it at least 10 cm away to allow the upper cover to be

opened and prevent the cables from being crushed.

14 - SHIPPING, HANDLING AND UNPACKING

4.3 Unpacking and placement

1 x 15 mm

2 x 17 mm

1 x 14 mm

1 x 17 mm

DANGER

The following procedure must be carried out by at least 3 people.

Store the packing material for future use, or dispose of it according to current regulations. In any case, we

recommend that you keep it for the entire duration of the machine warranty.

Make sure the packing has not suffered any damage or tampering during shipping; if so, contact the

authorized technical service or your dealer.

1. Cut the straps wrapped around the packing.

2. Remove the covering from the pallet.

3. Remove machine wrapping.

1

2 3

To remove the mounting brackets that secure the

machine to the pallet

To adjust machine feet

Figure 3

DANGER

Should the machine appear damaged during shipping, do not attempt to start it and contact the authorized

technical service or dealer.

4. Remove the two brackets A that hold the machine to the base of the pallet.

COROB™ FIRST 70

4

A

SHIPPING, HANDLING AND UNPACKING - 15

Figure 4

a

c

b

Figure 5

5. With one person at the right side and another person on the left side, lift the machine straight up until the

pallet is free and can be removed by the third person.

6. Lower machine feet to support and level the machine properly, and make sure that the wheels are not

resting.

4.3.1 Standard material supplied

d

After unpacking the machine, make sure the following items are present:

1. Power supply cable. 2. Computer power cables.

3. USB cable. 4. RS232 cable.

5. Spare fuses. 6. Panel key.

7. Spare parts for humidier cap. 8. Equipment software tools standard CD.

9. User’s manual. 10. Adapter for Quart (1-liter) and Pint-size (0.5-liter) cans.

Depending on the options specied on the purchase order, you may also nd:

• Management software and protection key.

• Any accessories to be installed on the machine.

Make sure that all of the above items are included in the packing; if not, contact the manufacturer.

16 - SHIPPING, HANDLING AND UNPACKING

4.4 Installation

Once the machine has been unpacked and placed in its operating site, it must be installed.

WARNING

Only qualied and appropriately trained personnel are authorized to install the machine.

4.5 Packing and handling

To repack the machine, follow the unpacking instructions in reverse order. We recommend reusing the original

packing any time the dispenser must be moved or shipped.

Use appropriate equipment to move the packed machine. If stored, the machine must be kept in a protected,

dry environment, not subjected to harsh weather, to avoid damaging the electrical components.

WARNING

Do not stack items on the packing.

COROB™ FIRST 70

START-UP - 17

5 START-UP

5.1 General warnings

DANGER

THIS EQUIPMENT MUST BE GROUNDED.

Check the grounding of the power supply system before connecting the machine.

The computer and any other devices connected to the machine via a serial line or connected to the computer

itself must be powered via the auxiliary sockets.

Do not connect equipment other than computer, label printer or calibration scale to the machine auxiliary

sockets.

Do not use extension cords to power the machine.

Do not use multisockets to connect other equipment to the same socket that powers the machine.

WARNING

Do not attempt to power the machine from a source having specications other than those listed on the

identication plate.

The machine is isolated from the power supply line when the power plug is disconnected; it must therefore

be installed near an easily accessible mains socket outlet.

Do not use multisockets to connect other equipment to the machine auxiliary sockets.

18 - START-UP

5.2 Control devices and connections

6

5

7

3

2

0

1

4

Figure 6

1. Machine main switch.

2. Fuse compartment.

3. Main plug.

4. Auxiliary sockets.

5. RS232 serial port.

6. USB serial port.

7. Off-line button with ON lamp. To interrupt machine functions, without shutting it off.

The value of fuses is shown in the technical specications table

(chapter 8.1).

Power supply to the computer and other equipment (calibration

scale or label printer).

For the connection to the management computer.

COROB™ FIRST 70

5.3 Electrical connection and start-up

START-UP - 19

1

0

2

0

3

b

0

a

Figure 7

If the ON lamp is blinking, make sure that the off-line button is released.

If the computer and monitor do not come on, make sure the power cables have been properly connected,

and that the corresponding switches have been turned on.

When the software is launched it offers the operator a series of procedure requests, including

initialization (chapter 5.4).

20 - START-UP

5.4 Initialization

INITIALIZATION is a preparatory phase that must be carried out when the machine is turned on.

If the computer is turned off and back on again, initialization is not strictly necessary, even if required

by the software; it is solely at the discretion of the operator.

Moreover, initialization must be carried out in the following cases:

• At the beginning of each work shift, even if only the computer had been shut down.

• To send new operating parameters set via the management software.

For more information about the Initialization function, refer to the software user’s manual.

5.5 Use of the off-line button

When the off-line button is pressed, all functions of the machine are interrupted; the ON lamp blinks to indicate

that the machine is switched on but with the functions blocked. In these conditions, any commands coming

from the computer are refused.

After interrupting the machine functions, it will be possible to carry out canister relling.

The status of the ON lamp highlights the condition in which the machine is:

Status of the ON lamp Meaning

ON The machine is ON and ready to receive commands coming from the computer.

OFF The machine is OFF.

WARNING

Pressing the off-line button while a formula is being dispensed will cause dispensing to be interrupted. Once

the machine has been restored to normal operation, IT WILL NOT BE POSSIBLE to continue dispensing the

formula previously interrupted.

After you have pressed the off-line button, when normal operation is restored, it is necessary to carry out

machine initialization (chapter 5.4).

5.6 Shut-down

WARNING

WE RECOMMEND THAT YOU NEVER SHUT DOWN THE MACHINE, even when closed for business,

because the automatic, timed functions help keep the colorant preserved and homogeneous.

Should it be essential to shut down the machine, avoid keeping it off for extended periods of time. When the

machine is not being used, shut off only the computer.

Very little power is used by the machine itself when inactive or during a stirring cycle.

COROB™ FIRST 70

Shut off the machine as follows:

START-UP - 21

1

0

2

Figure 8

22 - USING THE DISPENSER

COROB™ FIRST 70

USING THE DISPENSER - 23

6 USING THE DISPENSER

6.1 General warnings

DANGER

The machine must be used by a single operator.

It is strictly forbidden to bypass and disable the safety devices and protections.

Do not, for any reason, place your hands in the dispensing area when running the machine, except for loading

and unloading the cans.

The panels must be kept closed at all times.

6.2 At the beginning of the working day

At the beginning of each work shift, always carry out the following operations:

• Check that the nozzle center is clean.

• Check that the sponge is clean and saturated; if it is necessary to saturate, use only appropriate liquid (the

choice of the liquid depends on the nature of the colorants, and must be done directly by the manufacturer

of the products used).

• Carry out system Initialization and Purge.

6.3 Running the machine

The operator is guided in running the machine by the management software, which displays the instructions to

be carried out and the actions performed by the machine.

Steps Reference

Make the selections from the management software (selection of the product,

formula and cansize).

Adjust shelf position. chapter 6.3.1

Place the can on the shelf. chapter 6.3.2

Via the software, enter the formula dispensing command. chapter 6.3.4

When dispensing is nished, remove the can and proceed with another

dispensing process.

24 - USING THE DISPENSER

6.3.1 Adjusting the can shelf height

Keeping the two side buttons pressed, insert the shelf in the appripriate guide based on the size of the can to

be used. Release the two buttons to lock the shelf in place.

Figure 9

WARNING

The shelf position must be such that it allows the can to push the cap bar open.

6.3.2 Loading the can

Place the can on the shelf to push the cap opening

bar inward and thus cause it to open.

Figure 10

6.3.3 Using the adapter

The adapter to position Quart (1-liter) and Pint-size (0.5-liter) cans is made up of two spacers (A and B).

1. Place the shelf at its maximum height.

COROB™ FIRST 70

USING THE DISPENSER - 25

Quart-size can (1 liter)

2. Place spacer A aligned with the

position indicators marked on the

shelf surface.

3. Place the can on the adapter.

1

Pint-size can (0.5 liter)

with sliding cap with sliding autocap

2. Join spacer A with spacer B,

making sure that the COROB

mark is straight so that the

spacer prole can open

and hold the humidier cap

open, then place the adapter

aligned with the position

indicators marked on the

shelf surface.

2

A

2. Join spacer A with spacer

B, then place the adapter

aligned with the position

indicators marked on the

shelf surface.

A

B

Figure 11

B

3

26 - USING THE DISPENSER

6.3.4 Dispensing

When the dispensing command is entered, the machine begins to dispense the products included in the formula

in the set amounts.

The dispensing system depends on the machine version (sequential or simultaneous).

6.4 Automatic timed stirring

Colorant stirring is a timed process, activated automatically to properly store the product in the canisters and

keep it in ideal, homogeneous conditions for dispensing, through the movement of stirring paddles inside

canisters.

The duration and the interval between one stirring cycle and another can be customized via the conguration

software (refer to the CorobTECH user’s manual), based on the nature of the products used on the machine.

We recommend to keep the canisters closed with their corresponding lids; do not insert hands in the

canister even when no colorant is present.

When an automatic timed process is in progress, the machine can still be used; the process will be suspended

and restarted after a few seconds that the machine is inactive.

COROB™ FIRST 70

6.5 Relling the canisters

USING THE DISPENSER - 27

1

4

2

5 cm

2”

3

Figure 12

1. Push the off-line button (chapter 5.5).

2. Open the machine upper cover.

3. Remove the lid of the canister to be lled.

Shake the container of colorant to be poured into the canister manually. Do not use automatic

shakers.

4. Make sure that the bottle draining system is correctly positioned, then add the desired colorant to the

canister, by pouring it directly on the bottle drainer, so as to avoid spattering or creating air emulsions in

the colorant.

WARNING

To avoid colorant spills from the shaft of the stirring system, it is essential that you DO NOT REMOVE the

bottle drainer while topping up. The colorant level MUST NOT exceed the maximum level, placed at 5 cm from

the upper edge of the canister. Colorant spills cause the circuit pumping unit to be blocked.

5. Close the canister with its corresponding lid.

6. Repeat the above steps to ll other canisters.

7. Close the machine upper cover and restore the machine by releasing the off-line button (chapter 5.5).

28 - USING THE DISPENSER

8. Update the colorant level value for the topped up canisters in the machine management software (refer to

the software user’s manual).

WARNING

In case of improper actions, which caused canister overlling with colorant:

• In case the colorant has poured inside the machine, do not try to clean; turn the machine off at once and

contact an authorized service center.

• If, on the contrary, the product has already poured out of the canister, it is necessary to shut off the

machine immediately and clean with paper or a moistened cloth. Whenever possible, leave the colorant to

dry itself and remove with a spatula.

• If the product has not yet come out of the canister borders, it is necessary to avoid closing the canister

with its lid and provide immediately to dispense the exceeding colorant until the correct level is reached.

Clean carefully the upper border of the canister with paper or a moistened cloth before closing it with the

lid.

NEVER USE WATER OR SOLVENT-BASED CLEANING PRODUCTS TO CLEAN THE MACHINE.

DANGER

When using colorants containing volatile solvents the canister top up must be carried out opening one

canister at the time.

WARNING

Failure to update the colorant levels in the canisters may compromise the accuracy of the hue produced or,

worse yet, lead to emptying the machine canisters and circuits.

If “SOLVENT FREE” colorants are used, or those that dry out quickly, we recommend that you keep the

canisters full at all times by topping up frequently.

After topping up the colorant, it is advisable to carry out the stirring process using the functions provided in the

management software, to eliminate any air that may be emulsied and incorporated into the colorant.

Here below you will nd a reference diagram to perform canister lling.

MAX

2.5 l

2.6 qt

2 l

2.1 qt

1.8 l

1.9 qt

1.2 l

1.3 qt

0.5 l

0.5 qt

Figure 13

COROB™ FIRST 70

6.6 Troubleshooting

Problem Cause Solution

Check the connections at the back of the

machine (chapter 5.3).

Set the main switch to the ON position (I)

(chapter 5.3).

Replace any blown fuse inside the fuse

compartment (chapter 5.2).

Wait a few minutes and try to restart the

machine. If the problem persists, contact

the authorized technical service.

Contact the authorized technical service.

Turn the machine on (chapter 5.3) and

restart the management software.

Check the connections at the back of the

machine (chapter 5.3).

Use the conguration and calibration

software to make sure you have correctly

congured the port used to communicate

with the machine.

Repair the computer serial port or USB

port.

Replace the communication cable using

manufacturer’s original spare parts.

From the management software dispense

approx. 100 cc of colorant from the

pumping unit involved (chapter 6.3).

If the problem involves many circuits,

repeat the above operation for one circuit

at a time, so as to recycle the colorant

dispensed.

If the problem persists, contact the

authorized technical service.

Release the off-line button, in order to

restore machine operation (chapter 5.5).

Carry out machine initialization (chapter

5.4).

The machine does not turn

on.

The management software

shows an error in the

communication protocol.

Colorant dripping from some

nozzles.

The ON lamp blinks and

the machine refuses the

commands.

Power supply is missing.

Main switch in OFF position (O).

One or more fuses may be blown

up.

The power supply unit is in

overcurrent.

Electrical connections are

defective.

Machine is OFF.

Machine disconnected from the

computer.

Computer serial port or USB port

wrongly congured or defective.

Serial cable damaged.

Connection defective. Contact the authorized technical service.

The valve of the pumping unit

does not work correctly.

The off-line button is pressed.

USING THE DISPENSER - 29

30 - ORDINARY MAINTENANCE

COROB™ FIRST 70

ORDINARY MAINTENANCE - 31

7 ORDINARY MAINTENANCE

7.1 General warnings

DANGER

Before carrying out any maintenance operations, you must turn off the machine and unplug the power supply

cable from the mains socket outlet.

During machine maintenance operations there is a high risk of contact with the coloring product; strictly

follow the indications of chapter 2.2.

7.2 Maintenance table

WARNING

The frequencies indicated are approximate, since they depend on the type of colorants, environment conditions

and frequency of use of the machine.

Frequency

Operations

Initialize and purge machine

Clean the nozzle center

Check the sponge is clean

Check the sponge is saturated

Moisten the sponge

Clean the sponge

Clean the dispenser externally

beginning

of shift

twice a

week

when

necessary

7.3 Products to be used

We recommend to use products compatible with the type of colorants in the machine when cleaning the nozzle

center and moistening the humidier cap sponge.

Type of colorant Suggested product

Solvent-based colorants slow-evaporating solvent, compatible with the colorants used

Water-based colorants water

Mixed systems

Should growths form in the cap or in the sponges, it is advisable to use the following uids:

• Propylene glycol solution, 50% by volume, in water;

• AgCl solution in water;

• Bleach (dilution 1%).

the choice depends on the type of vehicles used to produce the colorants; for

more information, contact the dealer or colorant manufacturer.

32 - ORDINARY MAINTENANCE

7.4 External cleaning

WARNING

NEVER USE WATER OR SOLVENT-BASED CLEANING PRODUCTS TO CLEAN THE MACHINE.

In case the colorant has poured inside the machine, do not try to clean; turn the machine off at once and

contact an authorized service center.

In case of paint spills, clean the machine immediately.

1. Disconnect power supply (chapter 5.6).

2. Clean coverings, panels and control devices of the machine, to remove dirt, dust and any colorant stains,

using a soft and dry cloth, or slightly moistened with a mild cleansing solution.

3. Connect power supply and switch on the machine (chapter 5.3).

See the manufacturer manual for instructions on cleaning the computer.

7.5 Cleaning the nozzle center

1. Disconnect power supply (chapter 5.6).

2. Open the cap by pushing the opening bar inward with your hand.

3. Accurately clean the nozzles using a sharp tool; remove any dried colorant residue delicately, to avoid

damaging the ends of the circuits.

4. Bring back the cap in its closed position.

5. Connect power supply and switch on the machine (chapter 5.3).

Figure 14

COROB™ FIRST 70

ORDINARY MAINTENANCE - 33

7.6 Cleaning and moistening the humidier cap sponge

In case of sponge replacement, use only those supplied with the machine.

1. Disconnect power supply (chapter 5.6).

2. Open the cap by pushing the opening bar inward with your hand.

3. Unscrew the sponge holding cup and remove it.

4. Bring back the cap in its closed position.

5. Wash the sponge holding cup, check the condition of the sponge and moisten as needed. The level of the

humidifying liquid must not exceed the height of the sponge. If it is very dirty, remove the sponge from the

cap and wash it thoroughly. If the sponge is severely damaged, replace it.

6. Open the cap with your hand and reinstall the sponge holding cup.

7. Connect power supply and switch on the machine (chapter 5.3).

Figure 15

34 - ORDINARY MAINTENANCE

COROB™ FIRST 70

TECHNICAL SPECIFICATIONS - 35

8 TECHNICAL SPECIFICATIONS

8.1 Technical data

Power supply Single-phase 100 - 240 V ~ ± 10%

Frequency 50/60 Hz

Fuses* F 10 A

Maximum power absorbed*

Noise level Level of equivalent acoustic pressure: < 70 dB (A)

Environment working conditions**

Vibrations

Dispensing technology bellow pump

Dispensing system sequential or simultaneous

Type of canisters all-purpose (POM acetalic resin)

Type of valves check valves

Dispensing center internal

Nozzle center ow diameter*** 31 mm

Machine 110 kg (12 circuits version) - 148 kg (16 circuits version)

****

Packed machine 140 kg (12 circuits version) - 175 kg (16 circuits version)

* The power information is purely indicative, and depends strictly on the machine conguration.

** The environment working conditions are strictly related to the type of colorants used (ask for information from the paint manufacturer).

The data shown are valid for the machine only.

*** Hole diameter for pre-punched cans = ow diameter + 15 mm.

**** Data refer to the machine with empty canisters.

180/250 W - simultaneous

90 W - sequential

Temperature: between 10 °C (50 °F) and 40 °C (104 °F)

Relative humidity: between 5% and 85%, without condensation

The machine does not transmit vibrations to the oor that may

compromise the stability and precision of any nearby equipment.

Standard circuit

Flow rate (theoretical at 100 rpm) 0.2 l/min

Minimum dispensed quantity*

1/384 US oz

(0.077 ml)

Theoretical resolution* 0.00625 cc/step

* Values highly affected by the nature of the colorants and their rheological properties.

36 - TECHNICAL SPECIFICATIONS

8.2 Dimensions

700 mm - 27.6”

12C 700 mm - 27.6”

16C 880 mm - 34.6”

340 mm - 13.4”

420 mm - 16.5”

1420 mm - 55.9”

8.3 Warranty

In order for the warranty to be valid, please complete the form included in the machine packing, and send it to

the address listed on the form itself.

Contact our authorized and qualied personnel only for all your service needs. Use only original spare

parts for all maintenance and replacement interventions.

Altering or removing the guards and safety devices provided on the machine will not only void the warranty

immediately, but is also dangerous and illegal.

The manufacturer may not be held liable for personal injury or property damage caused by improper use of the

equipment or tampering with the guards and safety devices installed on the machine.

The following shall void the manufacturer’s warranty:

• Improper use of the machine.

• Failure to observe the instructions and maintenance rules set forth in the manual.

• Making or having changes and/or repairs made on the machine by personnel outside the service organization

authorized by the manufacturer and/or made using non-original spare parts.

COROB™ FIRST 70

Loading...

Loading...