Page 1

Corning

MobileAccess

MobileAccessQX

User Manual

P/N: 709C0011101 REV: A00 Date: JANUARY2013

Page 2

Preface Material

RF Safety

To comply with FCC RF exposure compliance requirement, adhere to the following warnings:

Warning! Antennas used for this product must be fixed mounted on indoor permanent structures, providing a

separation distance of at least

75 cm from all persons during normal operation.

Warning! Each individual antenna used for this transmitter must be installed to provide a minimum separation

distance of 75 cm or more from all persons and must not be co-located with any other antenna for meeting RF

exposure requirements.

Warning! Antenna gain should not exceed 12.5 dBi.

Warning! The design of the antenna installation needs to be implemented in such a way so as to ensure RF

radiation safety levels and non-environmental pollution during operation.

ATTENTION

Compliance with RF safety requirements:

• MobileAccess products have no inherent

significant RF radiation

• The RF level on the d ownlink is ve ry low a t

the downlink ports. Therefore, there is no

dangerous RF radiation when the antenna

is not connected.

CAUTION

Use of controls, adjustments or performance of

procedures other than those specified herein may

result in hazardous radiation exposure.

Preface Material

P/N: 709C0011101

Page II

Page 3

Laser Safety

Fiber optic ports of the MobileAccessQX system

emit invisible laser radiation at the 1310/1550 nm

wavelength window.

The laser apertures /outputs are the green

SC/APC Bulkhead adapters located on the front

panel of the equipment.

External optical power is less than 10 mW,

Internal optical power is less than 500 mW.

To avoid eye injury never look directly into the

optical ports, patchcords or optical cables. Do not

stare into beam or view directly with optical

instruments. Always assume that optical outputs

are on.

Only technicians familiar with fiber optic safety

practices and procedures should perform optical

fiber connections and disconnections of

MobileAccessQX devices and the associated

cables.

Care of Fiber Optic Connectors

Do not remove the protective covers on the fiber

optic connectors until a connection is ready to be

made. Do not leave connectors uncovered when

not connected.

The tip of the fiber optic connector should not

come into contact with any object or dust.

Refer to the cleaning procedure for information

on the cleaning of the fiber tip.

MobileAccessQX has been tested and certified as

a Class 1 Laser product to IEC/EN 60825-1

(2007). It also meets the requirements for a

Hazard Level 1 laser product to IEC/EN 60825-2:

2004 to the same degree.

MobileAccessQX complies with 21 CFR 1040.10

and 1040.11 except for deviations pursuant to

Laser Notice NO. 50 (2007).

MobileAccessQX employs a Class 3B laser and

therefore the following label is affixed inside the

unit adjacent to the laser:

Preface Material

P/N: 709C0011101

Page III

Page 4

Standards and Certi f ication

Corning MobileAccess produc ts have met the approvals of the following certifying organizat ions:

Company Certification

ISO ISO 9001: 2 000 and ISO 13485: 2003

Product Certifications

US

Radio Equipment and Systems:

• FCC 47 CFR Part 22 – for CELL Frequency Band

• FCC 47 CFR Part 24 – for PCS Frequency Band

• FCC 47 CFR Part 27 – for 700 LTE and AWS Frequency Bands

EMC

• FCC 47 CFR Part 15 Subpart B

Note: This equipment has been tested and found to comply with the limits for a Class B digital device,

pursuant to Part 15 of the FCC Rules. These limits are designed to provide reasonable protection

against harmful interference in a residential installation. This equipment generates, uses and can

radiate radio frequency energy and, if not installed and used in accordance with the instructions, may

cause harmful interference to radio or television reception, which can be determined by turning the

equipment off and on, the user is encouraged to try to correct the interference by one or more of the

following measures:

- Reorient or relocate the receiving antenna.

- Increase the separation between the equipment and receiver.

-Connect the equipment into an outlet on a circuit different from that to which the receiver is

connected.

-Consult the dealer or an experienced radio/TV technician for help.

Warning! Changes or modifications to this equipment not expressly approved by Corning

MobileAccess could void the user’s authority to operate the equipment.

Europe

Radio Equipment and Systems

EN 301 502 – for GSM / EGSM Frequency Bands

Standards and Certification

P/N: 709C0011101

Page IV

Page 5

EN 300 328 – for WLAN 802.11b/g 2.4GHz Frequency Band

EN 301 893 – for WLAN 802.11a 5GHz Frequency Band

EMC

EN 301 489

Safety

EN 60950UL 60950

CAN/CSA-C22.2 No.60950

UL 2043

Laser

CDRH 21 CFR 1040.10, 1040.11 (Except for deviations per notice No.50, July 26, 2001)

Safety

IEC 60825-1, Amendment 2 (January 2001)

EN 60825-1

About this Guide and Other Relevant Documentation

This user guide describes how to perform the physical installation of the MA2000 systems. The installation

procedures of other units (e.g. RIU, SC-450) relevant to the system are detailed in their user manuals (see

Additional Relevant Documentation below).

Additional Relevant Documents

The following documents are required if the corresponding units are included in your system.

Document Name

RIU Installation and Configuration Guide

System Controller (SC-450) User Manual

MobileAccessQX Datasheet

MA Software Version Update Tool

About this Guide and Other

Relevant Documentation

P/N: 709C0011101

Page V

Page 6

List of Acronyms

BDA Bi-Direc tional Am plifier

BTS Base Transceiver Station

BTSC Base Transceiver Station Conditioner

BU Base Unit

DL Downlink

RU Remote (Hub )Unit

RIU Radio Interface Unit

RBS Radio Base Station

UL Uplink

List of Acronyms

P/N: 709C0011101

Page VI

Page 7

Table of Contents

Preface Material ........................................................................................................................ II

RF Safety .......................................................................................................................................... II

Laser Safety ..................................................................................................................................... III

Care of Fiber Optic Connectors .......................................................................................................... III

Standards and Certification ................................................................................................... IV

Company Certification ....................................................................................................................... IV

Product Certifications ........................................................................................................................ IV

About this Guide and Other Relevant Documentation .......................................................... V

List of Acronyms ..................................................................................................................... VI

Table of Contents ................................................................................................................... VII

1 Introduction ........................................................................................................................ 1

1.1 Key Features and Capabilities ....................................................................................................... 1

1.2 System Architecture ..................................................................................................................... 2

1.3 QX Interfaces and Internal Modules .............................................................................................. 4

1.3.1 QX Interfaces ..................................................................................................................... 4

1.3.2 QX Main Internal Modules ................................................................................................... 6

1.4 SCU-F Interfaces .......................................................................................................................... 7

2 Installation Guidelines ....................................................................................................... 8

2.1 Infrastructure Preparation ............................................................................................................ 8

2.2 Installation Requirements ............................................................................................................. 8

2.3 Coaxial Cable Connections ............................................................................................................ 8

2.3.1 General Cable Installation Procedures .................................................................................. 8

2.3.2 RF Rules ............................................................................................................................ 9

2.3.3 Coax Cable Lengths and Losses ........................................................................................... 9

2.4 Fiber Optic Rules ....................................................................................................................... 10

2.5 Power Consumption, Connections and Power Supplies ................................................................. 11

2.5.1 Power Safety Instructions ................................................................................................. 11

2.5.2 Types of Power Supplies ................................................................................................... 11

2.6 Installation Conventions ............................................................................................................. 11

3 System Installation .......................................................................................................... 12

3.1 Overview of Physical Installation ................................................................................................. 12

3.2 Unpacking and Inspection .......................................................................................................... 12

Table of Contents I P/N: 709C0011101 I Page VII

Page 8

3.3 Inserting an RHU/AO Module in to QX Chassis ............................................................................. 14

3.4 Mounting ................................................................................................................................... 16

3.4.1 Rack Mount Installations ................................................................................................... 16

3.4.1.1 Plan the rack installation ....................................................................................... 16

3.4.1.2 Rack Installation Safety Instructions ...................................................................... 17

3.4.1.3 Mounting QX Unit in 19-IN R ack ............................................................................ 17

3.4.1.4 Mounting SCU-F Unit ............................................................................................ 17

3.4.2 Wall Mount Installation ..................................................................................................... 18

3.4.2.1 QX Horizontal Wall Mount Installation .................................................................... 19

3.4.2.2 QX Vertical Wall Mount Installation ........................................................................ 21

3.5 Connections ............................................................................................................................... 24

3.5.1 QX Fiber Optic Connections ............................................................................................... 24

3.5.1.1 MIMO Configurations ............................................................................................ 25

3.5.2 RF Connections ................................................................................................................ 26

3.5.2.1 QX RF and Antenna Monitor ing Connections .......................................................... 26

3.5.2.2 RF MIMO Connections to SCU-F ............................................................................ 28

3.5.2.3 Daisy Chaining the AMU modules of Multiple QX Units to a Single SCU-F ................. 29

3.5.2.4 SCU-F to Broadband Antenna Connections ............................................................. 30

3.5.3 Grounding the QX Unit ...................................................................................................... 30

3.5.4 Power Connections ........................................................................................................... 31

3.6 Verifying Normal Operation ........................................................................................................ 32

4 Maintenance ..................................................................................................................... 34

4.1 Replacing an RHU/AO Module ..................................................................................................... 34

4.2 Replacing Fan Module ................................................................................................................ 36

5 Appendix A: System Specifications ............................................................................... 38

RF Parameters .................................................................................................................................. 38

Supported Services .................................................................................................................... 38

RF Parameters per Service at Antenna Port of Four Port Se rvice Combiner Uni t (SCU-F) ................. 39

Absolute Maximum Rating .......................................................................................................... 40

Optical Specifications ........................................................................................................................ 40

Environmental Specifications.............................................................................................................. 40

Standards and Approvals ................................................................................................................... 41

System Component Specifications ...................................................................................................... 42

Quad-Service Package (QX) ........................................................................................................ 42

Four - Port Service Combiner Unit (SCU-F) .................................................................................. 42

6 Appendix B: Ordering Information .................................................................................. 43

Table of Contents I P/N: 709C0011101I Page VIII

Page 9

supporting up to four services (currently,

Service support can be quickly added as

the chassis without any downtime or

e cascaded to provide various

combinations of SISO and MIMO services

distributed over the same antenna

MA2000 QX is managed by opening a Web

MobileAccessQX

four services. Currently supported:

or by different units and distributed

over a common DAS antenna

to a QX unit are routed over a single

Seamless service

the

QX (and the parallel service

All connections

swap, field

1 Introduction

MobileAccess2000 QX (QX) is a member of

the MobileAccess2000 family. It is a compact,

modular, cel lular i ndoor cov erage rem ote uni t

CELL/PCS, LTE and AWS).

All services are received from the head-end,

over a single optic fiber and reconverted to

RF for convergence and distribution over a

common DAS antenna infrastructure.

needed by inserting card like modules into

additional cabling. In addition, two QX units

can b

infrastructure.

session to the SC-450 Controller.

MA2000 QX operates along with an SCU-F

unit, which converges the services from one

or more MA2000 QX units and provides the

interface to the DAS infrastructure. Both QX

and SCU-F are described in this manual.

Figure 1-1

1.1 Key Features and

Capabilities

The following benefits are achieved with

the QX platform:

• Multi-S ervice Platform - Supports up to

CELL, PCS, AWS, 700 MHz LTE

• Multi-Operator Optimized Platform Services from a number of operators

can be supported by the same chassis

infrastructure.

• Optic Fiber savings - All se rvices r outed

optic fiber

• Modular Design upgrades – simply add a card in

conditioning module at the head end)

• Scalable MIMO Upgrades - U pg rad e an y

or all services from SISO to MIMO by

cascading another QX unit

• Small Footprint - 3 U height rack

• Simple maintenance -

and monitoring LEDs located on front

panel, Modular, hotreplaceable service modules, including

fan modules

• Web Management - Web management

via the SC-450 controller

Introduction I P/N: 709C0011101I Page 1

Page 10

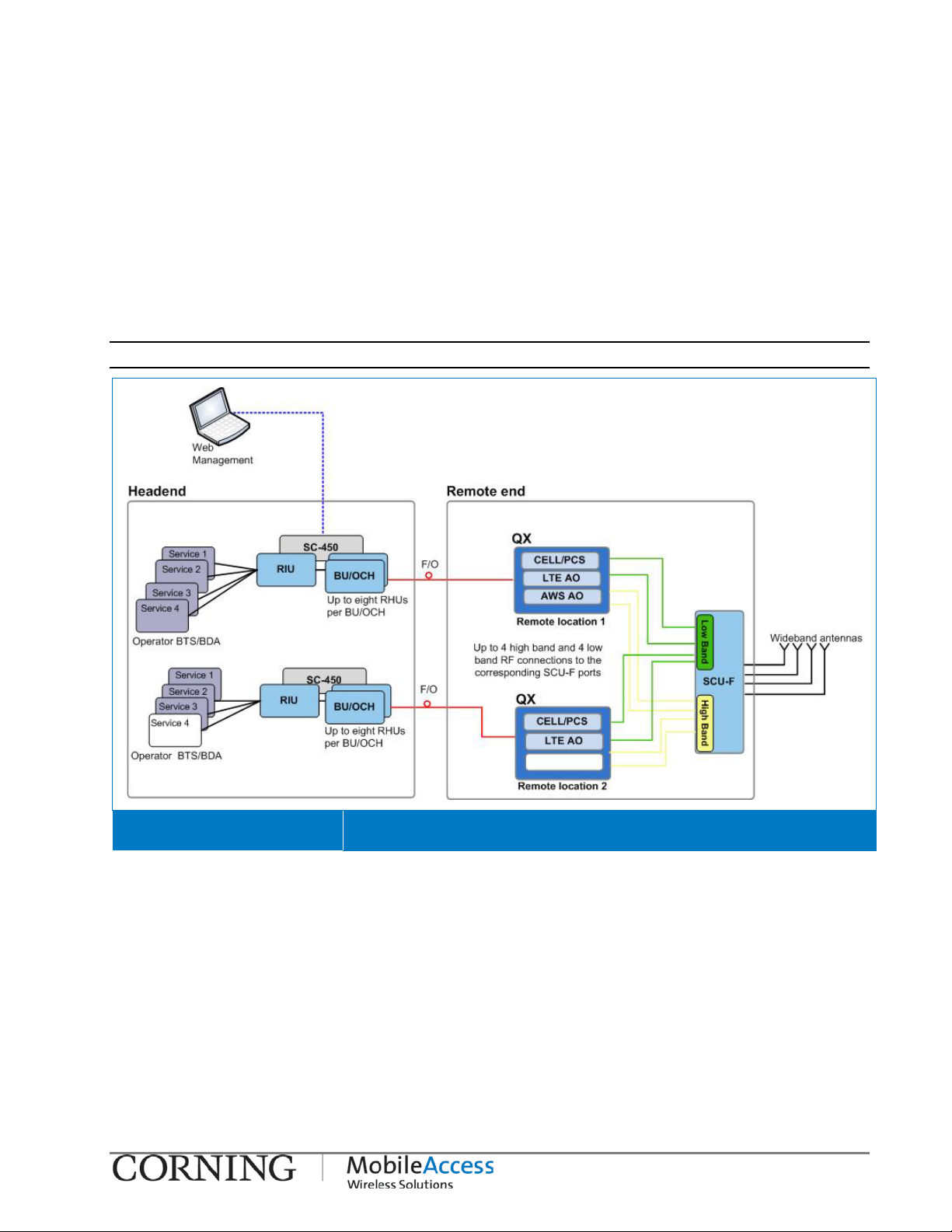

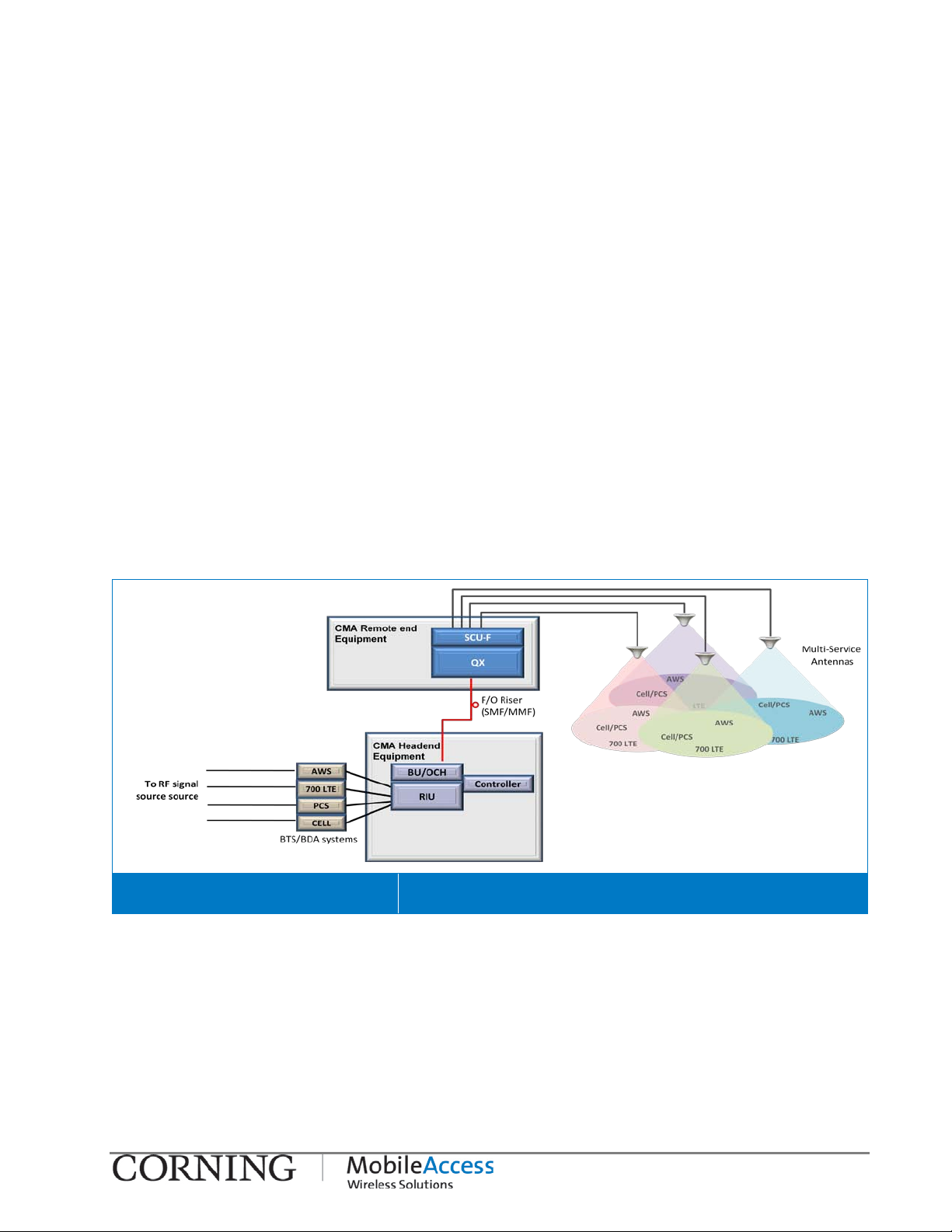

1.2 System Architecture

The QX and SCU-F are located at the floor level remote end. QX receives RF over optic service

signals from the head end, reconverts the signals to RF over copper, adjusts them to the

required level and outputs each service to dedicated interfaces. The signals are combined by

the SCU-F (along with services from other QX units) and distributed over a common DAS

(Distributed Antenna System) infrastructure.

In the uplink, cellular service signals received at the DAS are separated by the SCU-F and

routed to their dedicated QX ports. The signals are then converted to optic and forwarded to

the head-end for reconversion to RF and distribution to the relevant BTS or BDA systems.

Note: 3rd party equipment is sold separately (i.e. cabling, antennas).

QX Architecture Diagram Figure 1-2

Headend:

At the headend CMA elements provide interface to the wireless service provider’s network,

condition the signals and convert them to optical signals for transportation over fiber optics

towards the rem ote ends.

• Radio Interfac e Unit (RIU) - the RIU conditions and custom tunes the RF Downlink (DL)

signals from an ope rator’s si gnal source (BTS o r BDA) to ensu re a con stant RF level . In the

Uplink (UL), the signal (at the required level) is routed back to the operator’s signal source.

System Architecture I P/N 709C011101 I Page 2

Page 11

• RF to Optic converter unit – this can eit her be a Base Un it (BU) or an Optic al Contro l

Head End Unit (OCH), where th e OCH is QX model speci fic. These are wideband units that

convert the RF Downlink (DL) signals from the RIU into optical signals for routing over

single or multi-mode fiber optic cabling (SMF/MMF) to/from the QX units located at the

remote locations up to 2Km away.

• System Controller (SC-450) - the system controller enables centralized remote

management and control of MobileAccess elements. This unit connects directly to the RIU

and BU and/ or OC H an d all ow s man agem en t o f t hese as wel l as th ei r host ed el e ments (e.g.

QX) via a controller Web session.

Remote End:

At the remote end, the optical signal is reconverted to RF, filtered, amplified to the appropriate

level, combined with other signals and distributed over the b roadband antenna infrastructure.

The QX unit is installed, along with the Four Port Service Combiner Unit (SCU-F). The QX

system remote end consists of the following elements:

• QX - each QX unit provides coverage for four RF services (e.g. CELL, PCS, 700LTE and

AWS) via two types of service dedicated internal modules (RHU and AO). Each of these

modules is monitored via the Controller as an independent unit.

• Service Combiner Unit (SCU-F): a passive module that combines and distributes the UL

and DL signals from one or more QX units to (up to) four broadband antennas.

QX Solution System Architecture Figure 1-3

System Architecture I P/N 709C011101 I Page 3

Page 12

1.3 QX Interfaces and I nternal Modules

Service specific

F High band and Low Band

AMU service

Fan modules

AC power

slot

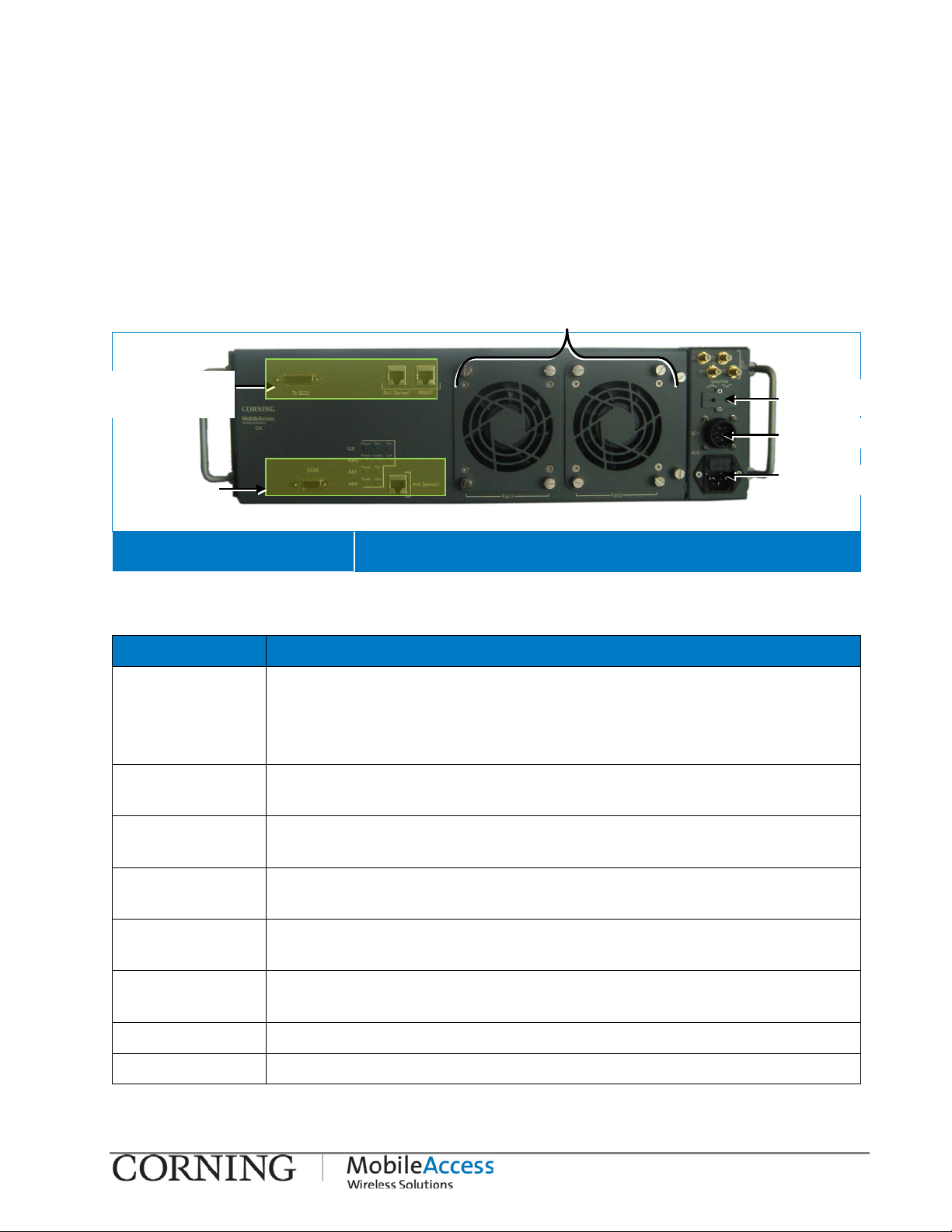

1.3.1 QX Interfaces

This section provides a full, detailed description of the QX unit and relevant interface

connections (Table

1-2) and LED indicators.

AMU connection

ports

ports

MobileAccessQX Front Panel Figure 1-4

Table 1-1. QX Front Panel Interfaces

Interface Description

DB-15 AMU (Antenna Monitoring Unit) port. Connect to parallel port on SCU-F.

Note that only one QX unit port can be connected to the parallel SCU-F

port. For installations with more than one QX, cascade QX AMU ports

using IN/OUT ports.

IN/OUT AMU cascading ports. Use in case there are more than one QX units

connected to the SCU-F.

DB-9 RS232 serial connection (D-Type 9); Serves as AMU console port for

service personnel

Optic port

DC power

Console Connect to network for AMU SW upgrade – for tech support personnel

QMA connectors

Optic Port Slot Slot used to guide the optic fiber to the RHU module fiber optic SC/APC

AC In Local AC power connection: 100-240VAC (use either AC or DC)

DC In Remote DC power connection: 25 to 48VDC (u s e either AC or DC)

only

Used for connecting to corresponding SCU-

QMA connectors.

port inside the chassis.

QX Interfaces and Internal Modules I P/N 709C011101 I Page 4

Page 13

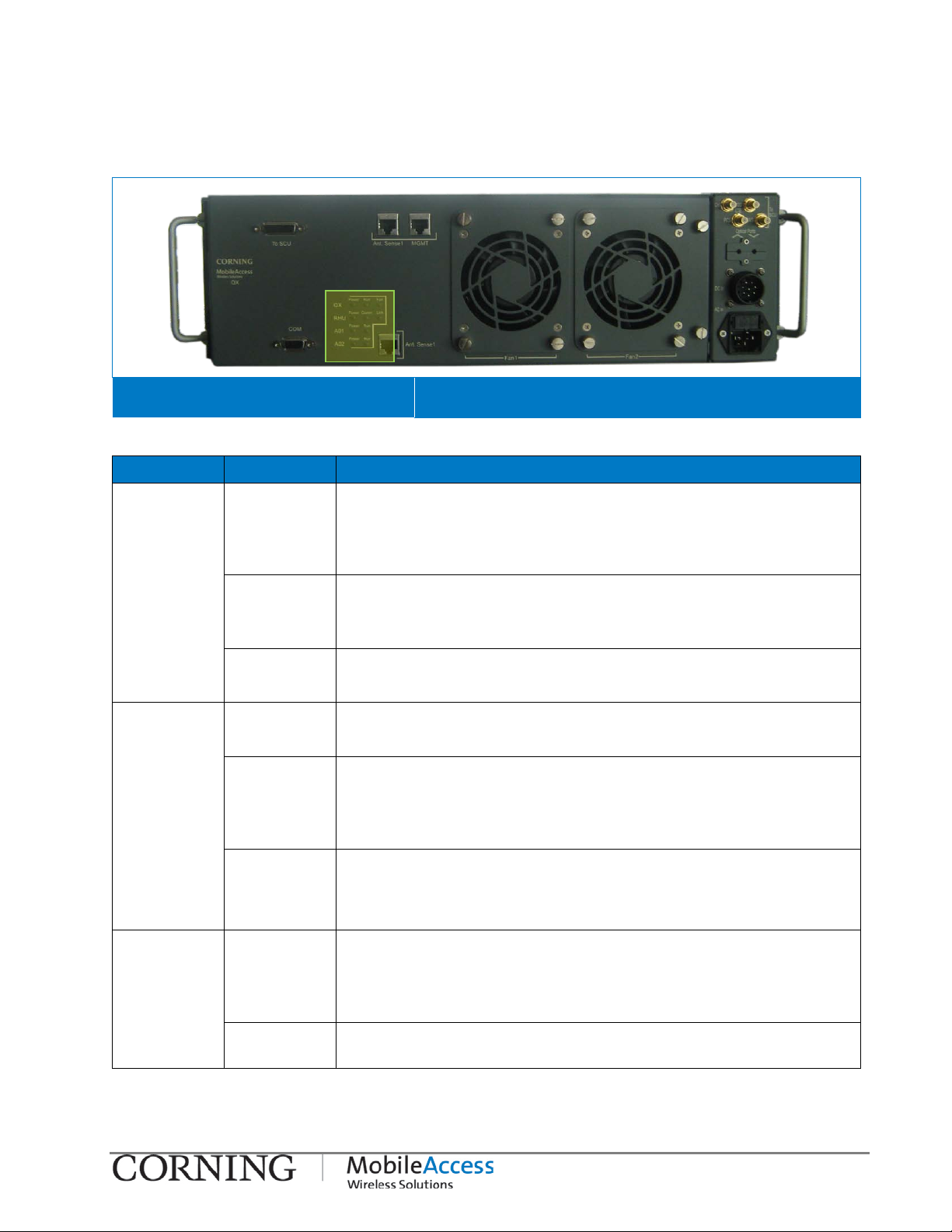

The QX front p an el sup port s t hre e grou p s of LEDs: sy st em l evel , fo r t he R HU and for each Ad d -

(blinks for

no external

on unit.

MobileAccessQX Front Panel Figure 1-5

Table 1-2: LEDs Descriptions:

Module LED Description

QX (system

level)

Power Steady Gr e en : Required power is supplied to AMU module

of QX chassis

Off: No power supplied to AMU module of QX

chassis

Run Steady Green: AMU module SW initialized

Blinking Green: AMU module SW is initializing

the duration of approx. 1 minute)

Fan Steady Gre en : Fan status normal

Blinking Green: Faulty fan, alarm triggered

RHU Power Steady Gr e en : Power input detected for RHU module

Off: No power detected for RHU module

Comm Blinking Green: Active communication detected –

connected and discovered by the BU/OCH

Steady Slow Blink: Faulty communication link -

communication is received

Link Stea dy Gr e en : Normal optical link level from BU/OCH-QX

Blinking Green: Low opt ic a l l in k level from BU / O C H-QX

Off: No optic a l l in k is present

AO1/AO2 Power Steady Gr e en : Power inpu t detected for first/second Add-

On unit

Run Blinking Green: Indicates that the Add-On module is in

Table 1-3: LED Descriptions

QX Interfaces and Internal Modules I P/N 709C011101 I Page 5

Off: No power det ected for f irst/secon d Add-On

unit

normal operating mode.

Page 14

1.3.2 QX Main Internal Modules

The QX main components consist of the following internal modules:

• Remote Hub Unit (RHU) – servi ce speci fic u nit , supports t wo voi ce ser vices, c onverts t he

optical signals received from the BU/OCH to RF signals (and vice versa) an d routes t hem t o

the coax antenna infrastructure (via the Four Port Service Combiner Unit – SCU-F).

• Add-On (AO) – adds an additional voice service to the host RHU (QX includes two AO

modules hosted by the RHU)

Note: The voice services are combined by the connected Service Combiner Unit (SCU).

• Antenna Mon itor ing Un it (AM U) – digital unit that enables antenna monitoring and relay

messaging of the following information:

• Antenna status

• Fans status

• Fans control

• AMU/QX alarms.

The AMU is connected to the SCU. The AMU modules of a number of QX units can be daisy

chained to a single SCU-F (see section

3.5.2.1).

• Fan Module – two extractable fans, simple to maintain and replace (see section

4.2).

QX Interfaces and Internal Modules I P/N 709C011101 I Page 6

Page 15

1.4 SCU-F Interfaces

15 port

connect to the broadband

Low Band (1-4) ports;

Antenna Ports 1-4

The SCU-F is a passive unit which interfaces to the QX RF service ports and internal AMU

module and to the DAS infrastructure. All of the interfaces are located on the front panel

(shown in Figure

SCU-F Front Panel Figure 1-6

Table 1-4. SCU-F Front Panel Interfaces

1-6).

DB-15 port to

QX DB-15 port

High Band (5-8) ports

Interface Description

DB-15 DB-15 port used to connect the SCU-F to the QX DB-

(internal AMU module port)

Antenna Ports N-Type RF antenna ports used to

antenna infrastructure

QMA Ports (Low/High) QMA type RF ports used to connect to the QX service ports:

Low: Ports 1-4 support low band service connections from the QX

High: Ports 5-8 support high band service connections fro m the QX

SCU-F Interfaces I P/N 709C01110 1 I Page 7

Page 16

2 Installation Guidelines

2.1 Infrastructure Prepar ati on

This following installation rules are based on the assumption that site survey and installation

planning (including power requirements) have been completed.

2.2 Installation Requ irements

The infrastructure preparation consists of two main phases:

Floor Planning : Planning the distribution of the antennas on each floor to provide the required

coverage.

Telecom Closet Planning : Planni ng the l ayout of th e devices an d cabl es in the tel ecom clos et

or shaft.

2.3 Coaxial Cable Connections

2.3.1 General Cable Installat ion Procedures

Observe the general cable installation procedures that meet with the building codes in your

area. The building code requires that all cabling be installed above ceiling level (where

applicable). The length of cable f rom the risers t o each antenna mu st be conceal ed above the

ceiling.

The cable must be properly supported and maintained straight using tie-wraps, cable trays and

clamps or hangers every 10 feet (where practical above ceiling level). Where this is not

practical, the following should be observed:

• The minimum bending radius of 7” is required for the supplied ½” coax cable.

• Cable that is kinked or has a bending radius smaller tha n 7” must be replaced.

• Cable runs that span less than two floors should be s ecured to suit ably located mechan ical

structures.

• The cables should be supported only from the building structure.

Installation Guidelines I P/N: 709C0011101I Page 8

Page 17

x

2.3.2 RF Rules

• When using the MobileAccess system in an environment in which other indoor coverage

systems are i nstalled, it i s recommended (w here possible) that the antennas are placed at

least two meters apart

• When bending coax cables, verify that the bending radius does not exceed the coax

specifications.

• Use wideband antennas supporting a range of 800Mhz to 2 50 0 Mhz

• Use a VSWR met er (i.e. Site Master or equivalent) for checking coax cables, including the

antennas. (< 2). The VSWR must be measu red prior to termin ating the RUs in the remote

communication rooms

• Terminate all unused SCU ports with a 50 ohm load

2.3.3 Coax Cable Lengths and Losses

Use coax ½”, 50ohm, male-to-male QMA type, for connecting to SCU broadband antenna ports.

NOTE: The required distance between t he antennas (installe d in the ceiling) de pends on the infrastr ucture

and calculated path-loss. For example, if there is free space-loss between the a ntennas , a minim um dista nce

of 100 ft is required; if there are partitions (loss) between the antennas, a distance of less than 100 ft

between them is allowed.

Coax Length coax Loss (900Mhz) connector loss Total Loss

30 0.7 1.5 2.2

40 0.9 1.5 2.4

50 1.1 1.5 2.6

60 1.3 1.5 2.8

70 1.5 1.5 3

80 1.7 1.5 3.2

90 1.9 1.5 3.4

100 2.1 1.5 3.6

110 2.3 1.5 3.8

120 2.5 1.5 4

130 2.7 1.5 4.2

140 2.9 1.5 4.4

150 3.1 1.5 4.6

160 3.3 1.5 4.8

170 3.5 1.5 5

180 3.7 1.5 5.2

190 3.9 1.5 5.4

200 4.1 1.5 5.6

Coaxial Cable Connections I P/N 709C011101 I Page 9

Page 18

2.4 Fiber Optic Rules

Diamond p/n ENC/1045341 Beige boots,

Diamond p/n ENC/1045343 Black/Brown boots, 3

Diamond p/n ENC/1045344 Beige/Brown boots, 1

Diamond p/n ENC/1045345 Beige/Brown boots, 3

• Either single mode or multimode fiber can be used with QX products.

• Only Multimode fiber, 50/125 or 62.5/125um complying with ANSI/TIA/EIA-568-B series,

EN50173-1 or ISO/IEC 11801 can be used. The fiber length can be up to 300 meters

assuming the following qualifications:

• All fiber in a given length of fiber must be of the same core diameter.

• All Bulkhead adapters must be Single mode SC/APC (Green) adapters.

• All terminati ons cross connections or patche s must be direct fusion sp lice or MobileAccess

specified patch cords listed below.

900 microns pathcord for splicing, 2 Meters, 2xSC/APC

MA# 500001057

62.5/125/900

Diamond p/n ENC/1045340 Black boots, 50/125/900 MA# 500001058

Zipcord patchcord, 4xSC/APC, 50/125/900/2000/4500 micron

Diamond p/n ENC/1045342 Black/Brown boots, 1

Meter

Meter

Zipcord patchcord, 4xSC/APC, 62.5/125/900/2000/4500 micron

Meter

Meter

• Use only 8-degree SC APC connectors (green color).

• Use only fusion splice for connecting two fibers.

• Use minimum splicing/connectors to achieve minimum losses on the fibers (<0.5dB).

• Use precaution while installing, bending, or connecting fiber optic cables.

• Use an optical power meter and OTDR for checking the fiber optic cables.

• Make sure the envir onment is clean while connecting/splicing fiber optic cables.

• All fiber optic connections should be cleaned prior to attaching to termination points using a

dry cleaning device (i.e. Cletop or equivalent).

• Fiber connector protective caps should be installed on all non-terminated fibers and

removed just before they are terminated.

• Verify the Fiber Optic connections.

• Pay special attention while connecting the SC APC connecto rs - you must hear the “click”

when the connection is made.

MA# 50000105

MA# 500001060

MA# 500001061

MA# 500001062

Fiber Optic Rules I P/N 709C011101 I Page 10

Page 19

2.5 Power Consumption, Connections and Power

Supplies

2.5.1 Power Safety Instructions

SAFETY WARNINGS

When installing or selecting the power supplies :

• It is required to install a circuit breaker of 7.5A for the DC supply circuit.

• Be sure to disconnect all power sources before servicing.

• Calculat e the required power acc ording to the requi rements of the speci fic installation and

then determi n e th e con fi g urati on of the p ow er s uppl i es. Th e req ui red D C ca bl es wi ll th en be

determined by the selected PS configuration.

• Use only UL approved power supplies

• AC and DC power supply cables – only use the power cords supplied with the units

2.5.2 Types of Power Supplies

CMA supplies various power supplies that can be installed in a rack or mounted on a wall,

depending on your configuration.

2.6 Installation Conventions

Some of the basic installation conventions are listed below for the QX system:

• QX - usually placed in the communication shaft or closet of a corresponding floor so they

can be easily located. Each QX unit can typically cover a floor of up to 30,000 sq ft.

• Fiber optic cable - bundled fibers are terminated into the Base Units/Optical Control Hubs

in the main communication room. The fibers are then routed to each cov erage locations

where individual fibers terminate i n t o sp lice boxes. The splice box couples th e installed fiber

into the remote units. Enough spare fibers should be installed to take into account future

expansion of the system.

• For remote power supply configuration - cable bundles are routed from the main

communication room and individual wire pairs are terminated into the power feed of

individual units.

By providing power from a single distribution point, maintenance can be reduced and UPS

backup can be easily provided. The maximum distance from the source to the termination

spot is 1000 feet using 18 gauge wires.

In many locations local codes do not require power to be run through conduit if 100 watts

or less is used. Please consult the regulations in your local jurisdiction prior to deploying

remote power. When power cables require distances greater than 1000 feet 14 or 16

gauge wire may be used.

• On each floor - the antennas are connected to the Service Combiner Unit (SCU) using

coax cables.

Power Consumption, Connections and Power Supplies I P/N 709C011101 I Page 11

Page 20

3 System Installation

The following sections provide an overview of the installation procedure for the QX and an

SCU-F unit.

Note: The QX must be installed with the SCU (in rack installations - preferably below the SCU).

The QX can be mounted using o ne of the following options:

• 19-in Rack – pre-assembled rack ears

• Wall mount (interfaces facing front like in a rack installation) – supplied bracket

• Vertical wall mount –interfaces facing down - ordered separately (P/N AK-QX-ENC-WMT-V)

NOTE: Be sure to read the Installation Requirements (see section 2.2) and Power Consumption related

instructions (see 2.3.3section 2.5) before proceeding with the actual connections.

3.1 Overview of Physical Installation

Physical installation procedure steps

1. Unpacking and inspecting supplied items for QX and SCU-F units – see section 3.2.

2. Mounting SCU-F unit (not included – ordered separately)

3. Mounting QX unit

3.2 Unpacking and Inspection

This section provides instructions for opening the shipping box, verifying that all supplied items

have been received, and verifying that no ship p ing damage has occurred.

Unpack and inspect t he cartons according to the following procedure

1. Open the shipping carton and carefully unpack each unit from the protective packing

material.

2. Check for signs of external damage. If there is any damage, call your CMA service

representative.

System Installation I P/N: 709C0011101I Page 12

Page 21

3. Verify that all supplied items have been received for the QX (see Table 3-1) and Table 3-2).

Black, Straight, USA 10A ,UL,

DC, Power Cable with Open

to RJ45 communication

RJ45 to RJ45 communication

Table

Table 3-2: SCU-F Package Contents

3-1: Package Contents

Kit Item P/N Description QTY.

QX QX chassis - Empty chassis 1

AC Power Cable

DC Power Cable 705A030821

Flat Cable 705900003

RHU Module –

(service

specific)

AWS Add-On QMA Cable 705A042101 QMA to QMA straight cable,

LTE Add-On QMA Cable 705A042101 QMA to QMA straight cable,

Kit Item P/N Description QTY.

QMA Cable 705A042101 QMA to QMA straight cable,

Flat Cable (preconnected)

705900007

705A042601

Length=1.8-2.5m , 110V

Edges. Length=5m

RJ45

cable. Length 2m-2.15m

R/A,0.141", Length=430mm

cable. Length=700mm

R/A,0.141", Length=430mm

R/A,0.141", Length=430mm

1

1

1

2

1

1

1

SCU-F

SCU-F SCU-F Four Port Service Combiner Unit with 1

DB-15 to DB-15

Digital Cable

705A042301

Used for connecting the SCU-F DB-15

port to the QX DB-15 port (internal

AMU module interface)

1

Unpacking and Inspection I P/N 709C011101 I Page 13

Page 22

3.3 Inserting an RHU/AO Module in to QX Chassis

The QX chassis and Remote Hub Unit (RHU) and Add-On (AO) modules are provided separately,

whereas the m odules must be inserted in to the chassis. T his require s opening the QX chassis

front panel door and inserting the modules into their respective slots.

The RHU/AO m odules are hot swappabl e and can be i nserted eith er before or a fter the syst em

installation.

To insert an RHU/AO Module

1. Open the QX door, by unscrewing the two captive screws.

QX Front Door Screws Figure 3-1

2. Referring to the slot allocation labels inside of the cha ssis door, position the service modu le

in the relevant slot with the handle facing front. Refer to Figure

3-2.

IMPORTANT!

Dummy modules must be inserted in unoccupied slots for termination.

Slot A llocations for Servic e Modules Figure 3-2

NOTE 1: Termination modules are required for unoccupied slots – ordered separately.

NOTE 2: W hen i nstalli ng a n LTE AO un it, an indicat ion of the us e of a n inter nal or ex ternal f ilter m ust b e

selected – via the GUI.

3. Slide the module towards the back of the unit and fit the module ejectors in to the side

notches of the slot (verify that the screws are unscrewed). Refer to Figure

3-3.

Inserting an RHU/AO Module in to QX Chassis I P/N 709C011101 I Page 14

Page 23

Positioning New Module in De signated Slot Figure 3-3

4. Push the module all the wa y back until it “clicks” in to t he chassis backplane.

5. Close ejectors and close both captive screws to secure the module in place. Refer to Figure

3-4.

6. For each Add-On module, connect the internal DC power feed to the module DC power

connector. Refer to Figure

3-4.

Securing Module in Slot and DC Connections Figure 3-4

NOTE: The RHU service module does not have an internal power feed connection.

Inserting an RHU/AO Module in to QX Chassis I P/N 709C011101 I Page 15

Page 24

3.4 Mounting

3.4.1 Rack Mount Installations

3.4.1.1 Plan the rack installation

NOTE: The unit can also be wall mounted using dedicated brackets (ordered separately). For wall mounted

units – it is recommended to install the service modules first.

1. Verify that the height of the rack can support QX unit being installed, as well as additional

equipment, SCU-F, AC or DC power, and space for the broadband coax connection. Also

consider room for fu t u re exp a n sions.

2. If the SCU-F supports more than one QX chassis – install in between QX units. See Figure

3-5.

3. To maintain low center gravity, ensure that heavier equipment is installed near the bottom

of the rack, and that the rack is loaded from top to bottom.

QX and SCU-F Locations in Rack Figure 3-5

Mounting I P/N 709C011101 I Page 16

Page 25

3.4.1.2 Rack Installation Safety Instructions

Review the following guidelines to help ensure your safety and protect the equipment from

damage during the installation.

• Only trained and qualified personnel should be allowed to install or replace this equipment.

• Verify that ambient temperature of the environment does not exceed 50°C (122°F)

• To maintain a low center of gravity, ensure that heavier equipment is installed near the

bottom of the rack and load the rack from the bottom to the top.

• Ensure that adequate airflow and ventilation within the rack and around the installed

components so that the safety of the equipment is not compromised. It is recommended to

allow for at least about 2 cm of airspace between devices in the rack.

3.4.1.3 Mounting QX Unit in 19-IN Rack

NOTE: The QX can also be mounted on wall – see section 3.4.2

Install the QX in the 19-in rack below the SCU-F (recommended) and secure with preassembled ra c k ea r s.

3.4.1.4 Mounting SCU-F Unit

1. Assemble the SCU-F Routing Bracket as follows:

• Unscrew the two screws l oca t ed on t h e far right of th e SC U -F front pan el. Save the screws

for next step.

• Assemble the supplied Routing Bracket on to the right side of the SCU-F front panel using

the two screws previously removed. See Figure

3-6.

SCU-F with Assembled Routing Bracket Figure 3-6

2. Install the SCU-F unit in the 19-in rack and secure with the factory-assembled rack ears.

Mounting I P/N 709C011101 I Page 17

Page 26

SCU-F Pre-assembled Rack Ears Figure 3-7

3.4.2 Wall Mount Installation

There are two wal l mount installa tion options for the QX unit, whereas the SCU -F can also be

mounted on top of the QX chassis so as to accommodate connections between the units:

a. Horizontal Wall Mount (provided with QX) - QX unit is mounted in a horizontal alignment

so that the front panel interfaces face towards the front (as in rack installations). See 0.

b. Vertical Wall Mount (ordered separately: P/N AK-QX-ENC-WMT-V) – QX unit is mounted

in a vertical alignment so that the front panel interfaces face towards the side. See Figure

3-8.

QX Vertical Wall Mount Alignment Figure 3-8

Mounting I P/N 709C011101 I Page 18

Page 27

3.4.2.1 QX Horizontal Wall Mount Installation

To mount the QX horizont ally on the wall

1. Mark and drill the installation holes in the wall, using the bracket as a guide. There are two

options, as show n in Figure

• Holes A1 and A2 are used for securing the brackets to the wall in a fixed position

• Holes B2, B2 and B3 are used for hanging the assembly on anchors

3-9:

QX Horizontal Wall Mount Bracket Holes Figure 3-9

2. Assemble the brackets on to the QX unit by securing each bracket to the side of the QX

chassis using (6) 6-32X5/16' Flat Head 100', Phillips screws (supplied) as shown in Figure

3-10.

Horizontal Wall Mount Bracket

Assembly

Figure 3-10

Mounting I P/N 709C011101 I Page 19

Page 28

3. Optional – mount the SCU-F unit on to the QX chassis:

• Remove the QX side rack ears (pre-assembled) to access the holes required for

assembling SCU-F

• Secure each SCU-F bracket to the side of the QX chassis using the six (6) supplied

screws, as shown in Figure

3-11.

SCU-F to QX Assembly for Wall mount

Installation

4. Mount the assembly on the wall using one (or both) of the mo unting options - hang the QX

on the anchors (previously prepared in wall) and/or secure to wall using the three (3)

additional holes (screws not supplied).

Horizontal Wall Mount Bracket

Assembly – Rear View

Note: When mounted on t he wall, there will be appr oximately 60mm (2.36”) of s pace between the wall

and the back of the QX unit.

Figure 3-11

Figure 3-12

Mounting I P/N 709C011101 I Page 20

Page 29

3.4.2.2 QX Vertical Wall Mount Installation

Note: Vertical Wall Mount brackets are ordered separately (P/N AK-QX-ENC-WMT-V).

To mount the QX vert ically on the wall

1. Verify that the following items are included in the accessory kit:

Item QTY. Image

Vertical Wall Mount Bracket for QX chassis 2

Screw,4-40X5/16',Flat-HD, 100', Philips, Nerosta

2. Remove the factory assem bled rack ears from the sides of the QX chassis so as to access

the relevant screw holes for assembling the QX vertical wall mount brackets. See Figure

16

3-13.

QX Rack Ears Figure 3-13

Mounting I P/N 709C011101 I Page 21

Page 30

3. Assemble the vertical wall mount brackets on to the sides of the QX chassis using the eight

(8) provided screws, as shown in Figure

3-14

Vertical Wall Mount Bracket Assembly Figure 3-14

Note: You may want to mark the mounting holes on the wall (according to brackets) prior to mounting.

4. Select the appropriate location on wall for the QX unit. Verify that:

• There is enough free space around the unit for ventilation

• Location enables opening the enclosure door to the side

5. (If not already marked) Mark the mounting holes on the wall according to the bracket holes

and drill appropriate holes.

Mounting I P/N 709C011101 I Page 22

Page 31

6. Optional – mount the SCU-F unit on to the QX chassis by securing each SCU-F bracket to the

side of the QX chassis with the six (6) supplied screws, as shown in Figure

SCU-F to QX Assembly for Wall mount Installation Figure 3-15

3-15.

7. Mount the QX chassis on the wall with the panel interfaces facing towards the side, as

shown in Figure

QX (with SCU-F on top) Vertical Mount Installation – Front View Figure 3-16

3-16.

Mounting I P/N 709C011101 I Page 23

Page 32

3.5 Connections

The system connections required for the QX consist of the following:

• Fiber optic connections to the RF to fiber optic converter unit at the headend – BU or OCH

• RF and Antenna connections:

• RF service connections to the four port Service Combiner Unit (SCU-F)

• Antenna connections between the SCU and the broadband antennas

• (QX) AMU module connections to SCU

• Power – Local (AC) or Remote (DC)

The connections are described in the following sections.

3.5.1 QX Fiber Optic Connections

Note: Keep in mind the rule s for handl i ng and co nne cting F/O cables. The F/O cab les will be connected to t he

associated BU/OCH in the communication room at a later phase.

To connect fiber optic cabling

1. (If not already installed) Install splice box near the QX chassis.

2. Referring to Figure

panel) and set aside. Route the fiber thro ugh the slot and connect to the RHU SC/APC

To/From ports, Refer to Figure

3. Replace the fiber slot tab (both parts).

Removing Fiber Slot Tab Figure 3-17

3-16, remove the tab (both parts) covering the fiber slot (located on port

3-18 .

Connections I P/N 709C011101 I Page 24

Page 33

Routing Fiber to Connection Port Figure 3-18

Note: See section 3.5.1.1 for MIMO connections to RF to Fiber optic converter unit (BU/OCH).

3.5.1.1 MIMO Configurations

Two QX units supporting the LTE700 and AWS bands can provide MIMO service coverage.

For MIMO configurations

Connect the fiber optic port of each of the two QX units’ supporting the LTE 700 and AWS

(SISO) bands to a different BU/OCH optic module (see section

connections). See Figure

3-19 for example of MIMO connections to OCH.

3.5.1 for description of

Note: Connections are the same between QX and Base Unit (BU) as for OCH.

QX to OCH MIMO Connections Figure 3-19

Connections I P/N 709C011101 I Page 25

Page 34

3.5.2 RF Connections

This section provides information describing the following connections:

• RF (SISO) and antenna monitoring connections betwee n QX and SCU-F

• MIMO connections between QX and SCU-F

• SCU-F to broadband antenna infrastructure connections

3.5.2.1 QX RF and Antenna Monitoring Connections

To connect the RF service and antenna connections (refer to Figure 3-20)

1. Connect the QMA to QMA RF jumper cables (provided with each ordered service module) to

the service specific QX RF QMA connector.

2. Route the cables through the assembled SCU-F Routing Bracket (see

3. Connect the other side of the jumper cables to the relevant SCU-F low band (ports 1-4)

and/or high band (ports 5-8) QMA ports.

The connections shown in Figure

CELL/PCS/700LTE/AWS services:

• QX High-freq uency b and mob ile servi ce to SCU -F High Ports (1 - 4) (e.g. AWS and PCS)

(shown in blue)

• QX Low-frequency band mobile service to SCU-F Low Ports (5 - 8) (e.g. CELL and

LTE700) (shown in red)

IMPORTANT! Terminate any unused ports.

NOTE: Refer to section 3.5.2.2for connections required for MIMO configurations.

3-20 show an example of c onnections perfo rmed for the

3.4.1.4).

Connections I P/N 709C011101 I Page 26

Page 35

04. Connect the QX internal AMU module (for antenna sensing) to the SCU by connecting the

DB15 female connector to the corresponding SCU DB15 female connector, using

corresponding cable provided with the SCU-F (P/N 705A042301). See Figure

3-20.

QX RF and Antenna Connections

Figure 3-20

Connections I P/N 709C011101 I Page 27

Page 36

3.5.2.2 RF MIMO Connections to SCU-F

Two QX units supporting the LTE700 and AWS bands can be deployed in a MIMO configuration.

The LTE700 and AWS RF service ports of both QX units are connected to the corresponding low

band and high band SCU-F ports. See Figure

3-21.

QX RF and Antenna Connec t io ns Figure 3-21

Connections I P/N 709C011101 I Page 28

Page 37

3.5.2.3 Daisy Chaining the AMU modules of Multiple QX Units to a Single SCU-F

NOTE: If installing m ore tha n one QX unit, t hey can be i nterconnected so that th e antenna sense function is

performed by a single AMU (Antenna Monitoring Unit) located inside the QX unit.

Connect one of the two front panel ANT. Sense1 RJ45 connectors of the QX unit directly

connected to the SCU-F DB-15 port to the ANT. Sense1 p ort of the additiona l QX unit using

the RJ45 to RJ45 cable provided with the QX (P/N 705900003). It is recomm ended to conne ct

the ports closest to each other. See Figure

3-22.

Daisy Chaining AMU to SCU-F Connections

Connections I P/N 709C011101 I Page 29

Figure 3-22

Page 38

3.5.2.4 SCU-F to Broadband Antenna Connections

To connect the broadband antennas

The QX is connected to the antenna infrastructure via the Service Combiner Unit (SCU-F).

Connect the SCU-F front panel N-Type RF Antenna Ports to the broadband antennas. See Figure

3-23.

Note: Terminate any unused antenna ports with 50 ohm t erminators.

SCU-F to Antennas Connections

Figure 3-23

3.5.3 Grounding the QX Unit

Ground the QX cabinet via the grounding lug located on the rear.

QX Grounding Lug Figure 3-24

Connections I P/N 709C011101 I Page 30

Page 39

3.5.4 Power Connections

The QX supports both local powering (100-240VAC) and remote powering (25 to 48VDC)

options. Both types of power cables are provided with the unit (see section

Connect the power source to the QX using either Local or Remote power (both are supported):

AC In - Local Power: 100-240VAC (Integrated AC/DC converter)

DC In - Remote Power: 25 to 48VDC

3.2).

Refer to for Figure

QX Power Connection Interfaces Figure 3-25

3-25 location of power connectors.

Connections I P/N 709C011101 I Page 31

Page 40

3.6 Verifyin g Normal Operation

Required power is supplied to AMU

Power input detected for RHU

Normal optical link level from

No optical link is detected from

Boot up sequence for first/second

On unit complete and

Boot up sequence for first/second

Upon powering up the QX remote unit:

• Confirm the fans are working after powering

• Verify normal operation:

Module LED Description

QX Power Steady Green:

module of QX chassis

Off:

Run Steady Green:

Blinking

Green:

Fan Steady Green:

Red:

RHU Power Steady Green:

Off: No power detected for RHU module

Comm Blinking

Green:

Red: Faulty communication link

Link Steady Green:

Blinking

Green:

No power supplied to AM U module of QX

chassis

AMU module SW initialized

AMU module SW is initializing (blinks for

the duration of approx. 1 minute)

Fan status normal

Faulty fan, alarm triggered

module

Active communication detected

BU/OCH-QX

Low optical link level from BU/OCH-

QX

AO1/AO2 Power Steady Gr e en : Power input detected for first/second

Run Steady Green:

Verifying Normal Operation I P/N 709C011101 I Page 32

Off:

BU/OCH-QX

Add-On unit

Off: No power detected for first/second

Add-On unit

Addfunctioning

Blinking

Green:

Add-On unit in process

Page 41

LED Indication of Normal Operation Figure 3-26

Verifying Normal Operation I P/N 709C011101 I Page 33

Page 42

4 Maintenance

This section provides maintenance information on the following:

• Replacing existing RHU/AO modules currently in QX chassis

• Replacing the QX chassis fan modules (in case of faulty fans)

4.1 Replacing an RHU/AO Module

This section describes how to replace an existing RHU and/or RHU/AO module. The RHU and AO

modules are easily removed from/added to the QX chassis, while the procedure does not

require powering off the unit (hot-swap).

To Replace an RHU/AO Module

1. Open the QX door, by unscrewing the two screws.

QX Front Door Screws Figure 4-1

Replacing an RHU/AO Module I P/N 709C011101 I Page 34

Page 43

2. To remove a module:

NOTE: For partia l conf iguratio ns, a “dummy ” m odule i s inser ted in the unus ed ser vice mo dule s lot. Does

not include connections.

• Disconnect F/O (RHU) or DC power connection (Add-On) – where relevant

• Open the captive screws securing the module in place

• Open the ejectors and Pull the module out (using the handle)

Removing Service Module Figure 4-2

3. To insert a module – refer to section 0

4. Connect the F/O and power connections to the corresponding ports on the module front

panel.

5. Close the QX chassis door and secure the screws.

6. Connect the relevant RF SMA connector, located on the QX front panel (door), to the SCU.

7. Configure new service via the SC-450 Controller (refer to SC-450 User Manual).

Replacing an RHU/AO Module I P/N 709C011101 I Page 35

Page 44

4.2 Replacing Fan Module

In case of faulty fans, they are easily replaced while the procedure does not require powering

off the unit (hot-swap).

To replace faulty fan(s)

1. Unscrew the four screws securing the fan to the chassis door. See Figure 4-3.

Unscrewing Fan Module Screws Figure 4-3

2. Pull out the fan module and disconnect the cable. See Figure 4-4.

Disconnect cab le

Removing Existing Fan Module Figure 4-4

3. Connect new fan module.

4. Fit the new fan module into place in the chassis door, as shown in Figure

4-5.

Replacing Fan Module I P/N 709C011101 I Pag e 36

Page 45

Insert fan module

so that the metal

plates are on each

side

Inserting New Fan Module Figure 4-5

5. Tighten the four fan module screws so it is secured to the QX front door panel.

Replacing Fan Module I P/N 709C011101 I Pag e 37

Page 46

5 Appendix A: System Specifications

RF Parameters

Supported Services

Technologies Band Frequency Range

Uplink (UL) Downlink (DL)

CDMA/WCDMA**/TDMA/GSM/LTE* CELL800 824-849 869-894

CDMA/WCDMA**/TDMA/GSM/LTE* PCS1900 1850-1915 1930-1995

WCDMA**/LTE* AWS1200 1710-1755 2110-2155

LTE

700 MHz 698-716

776-787

(*)WCDMA service is ba sed on 3GPP standar ds, LTE ser vice may dep loyed in the future due to F requencies re-farming

planned by the Carriers as well

(**)WCDMA service is based on 3GPP2 CDMA2000 standards.

728-746

746-757

Replacing Fan Module I P/N 709C011101 I Pag e 38

Page 47

RF Parameters per Service at Antenna Port of Four Port Service Combiner Unit (SCUF)

The RF Parameters listed in the tables in this section reflect the specification s at each of the

four antenna ports of the SCU-F when combined with the QX.

RF Parameters

QX RF

Parameter s at

Antenna Port of

SCU-F

Max Output Power per

Antenna Port

1 Operator

CELL

TDMA/CDMA/

CDMA/WCDMA/

WCDMA

DL UL DL UL DL UL DL UL

16 - 20 - 21 - 21 -

PCS

TDMA/GSM

AWS

WCDMA

700 MHz

LTE

(Composite)

2 Operators 13 - 17 - 18 - 18 4 Operators 10 - 14 - 15 - 15 8 Operators 7 - 11 - 12 - - 12 Operators 5 - 9 - 10 - - Mean Gain (dB) 1 16 - 20 3 21 3 21 4***

Pin (dBm) 0 - 0 - 0 - 0 Input IP3 (dBm)

AGC OFF Min

Input IP3 (dBm)

AGC ON Min

- -5 - - - - -

- 5 - -6 - - - -

Input IP3 (dBm) - - - - - -7 - -10

SFDR2 (dB) - 71 - 3 - 66 - 55

Max Intermod

Distortion (dBm)

-13* - -13* 64 * - ** -

Max NF (dB) - 20 - 20 - 20 - 20

Gain Flatness/Ripple

(dB) 3

* WCDMA compiles with 3GPP TS 25.106 V5.0.0 (2002-03) table 9.4 spectrum emission mask.

** Out of band and spurious emissions compliant to FCC.

***Default Conditioner (BTSC) UL Gain=+3dB

1

Factory set mean gain BU-RHU without RIU. May be field adjusted using controller s ystem.

2

SFDR for CDMA services is calculated in 100KB/sec.

3

Gain Flatness/Ripple is specified for the non-duplexed port of the system. Overall system typical values.

±2.0 ±2.0 ±1.0

Error! Use the Home tab to apply Heading 1 no numbering to the text that you want to appear here. I CMA-xxx-AEN I Page 39

Page 48

2 dB for fiber + 1 dB for connectors

Multi Mode Fiber (MMF): 50/125 µm or

62.5/125 µm (Minimum qualifications with

1 or

Absolute Maximum Rating

Total RF Input Power to BU/OCH 10 dBm

Total RF Input Power to QX RHU Module 20 dBm out-of-band; -10 dBm in-band

Optical Specifications

Optical Output Power < 3.0 mW

Max. Optical Budget

(assumed) = 3 dB total. 300 m Multi-mode

Optical Loss per Mated-pair Connectors 0.5 dB (max)

Optical Connectors SC/APAC

Fiber Type Single Mode Fiber (SMF): 9/125 µm

ANSI/TIA/EIA-568-B series, EN50173-

ISO/IEC 11801

Wavelength 1310 ± 10 nm

Maximum Distance Between Base Unit and

Remote Unit

2 km

Environmental Specifications

Operating Temperature -5°C to +55°C (23°F to 131°F)

Storage Temperature -20°C to 85°C (-4°F to 185°F)

Humidity 10% to 95%, non-condensing

Error! Use the Home tab to apply Heading 1 no numbering to the text that you want to appear here. I CMA-xxx-AEN I Page 40

Page 49

Standards and Approvals

Laser Safety CDRH 21 CFR 1040.10, 1040.11 (Except for

deviations per notice No.50, July 26, 2001)

IEC 60825-1, Amendment 2 (January 2001)

EN 60825-1

CE Radio Equipment and Systems

EN 301 502 – for GSM / EGSM Frequency

Bands

EN 300 328 – for WLAN 802.11b/g

2.4GHz Frequency Band

EN 301 893 – for WLAN 802.11a 5GHz

Frequency Band

EMC

EN 301 489

FCC Radio Equipment and Systems: FCC 47 CFR

Part 22, 24, 27, 90

EMC: FCC 47 CFR Part 15 Subpart B

Safety EN 60950UL 60950

CAN/CSA-C22.2 No.60950

UL 2043

Error! Use the Home tab to apply Heading 1 no numbering to the text that you want to appear here. I CMA-xxx-AEN I Page 41

Page 50

(OCH-QX):

AMU Master-Slav e con nections

Local connection to AMU module for

SW DL (for service personnel):

(for service personnel):

System Component Specifications

Quad-Service Package (QX)

Supported Services CELL850; PCS1900; LTE700; AWS2100

Ports To Service Combiner U nit (SCU): (4) 50Ω QMA ports

To Base Unit/Optical Control Hub

To SCU-4: (1) DB15 connector

RS232 local connection to AMU module

(2) SC/APC ports

(2) RJ45 ports

(1) RJ45 port

(1) DB9 connector

Power

Physical Dimensions

Cooling Features Active heat dissipation (Fan)

Local Power: 100-240VAC (Integrated AC/DC converter)

Remote Power: 25 to 48VDC

Max Power Consumpt ion: 118W

Mounting: 19” Rack or Wall (pre-assembled brackets)

17.1x14.5x5.2 (in) 434x369x133 (mm) (WxDxH)

Weight: ~40 lb (~18 kg)

Four - Port Service Combiner Unit (SCU-F)

Supported Services

Ports

Physical Dimensions

High band (1710 MHz - 2170 MHz) and low band (698 MHz –

960 MHz) RF services

To QX: (8) 50Ω QMA connectors

To Wideband antennas: (4) N-Type 50Ω connectors

For local maintenance: (1) DB15 conne ctor

Mounting: 19” Rack (pre-assembled brackets)

Error! Use the Home tab to apply Heading 1 no numbering to the text that you want to appear here. I CM A-xxx-AEN I Page 42

17.04x1.72x10.63 (in) 434x440x270 (mm) (WxDxH)

Weight: 6.6 lb (3 kg)

Page 51

6 Appendix B: Ordering Information

NOTE: The information listed below is updated up to the document publishing date. Refer to the

QX datasheet for the most updated ordering information.

QX Chassis and Modules

Part Number Description

2000-QX-B-QC

2000-QX-B-QCF

2000-C85P19-B-RHM

2000-C85P19-B-RHM

2000M-C85P19-B-RHM QX LTE SISO Add-on module;

2000-L70-B-AM QX AWS SISO Add-on module

2000-A17-B-AM

QX Chassis without Public Safety Support (termination modules not

included; no coexistence with Public Safety)

QX Chassis with Public Safety Support (termination modules not included;

supports coexistence with Public Safety)

QX Cell & PCS SISO Remote Hub Module (with Single-Mode Fiber

Support)

QX Cell & PCS SISO Remote Hub Module (with Multi-mode Mode Fiber

Support)

QX Cell & PCS SISO Remote Hub Module (with Single-Mode Fiber

Support)

QX Accessory Kits

Part Number Description

2000-QX-B-FAM QX field replaceable Fan

2000-SCU-8-4-F 8 x 4 Service Combiner Unit with all connectors in the front

2000-L70-B-TM QX LTE SISO Add-on port termination module;

2000-A17-B-TM QX AWS SISO Add-on port termination module;

AK-QX-ENC-WMT-V QX mounting brackets and screws to mount the chassis flush to the wall

Error! Use the Home tab to apply Heading 1 no numbering to the text that you want to appear here. I CMA-xxx-AEN I Page 43

Loading...

Loading...