Page 1

Installation Guide

Copyright Foxcom Wireless 200

Page 2

Notice

© 200 by Foxcom Wireless

This document contains confidential and proprietary information of Foxcom Wireless and

may not be copied, transmitted, stored in a retrieval system or reproduced in any format or

media, in whole or in part, without the prior written consent of Foxcom Wireless. Information

contained in this document supersedes any previous manuals, guides, specifications, data

sheets or other information that may have been provided or made available to the user. This

document is provided for informational purposes only, and Foxcom Wireless does not warrant

or guarantee the accuracy, adequacy, quality, validity, completeness or suitability for any

purpose of the information contained in this document. Foxcom Wireless reserves the right to

make updates, improvements and enhancements to this document and the products to which it

relates at any time without prior notice to the user. FOXCOM WIRELESS MAKES NO

WARRANTIES, EXPRESS OR IMPLIED, INCLUDING, WITHOUT LIMITATION,

THOSE OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE,

WITH RESPECT TO THIS DOCUMENT OR ANY INFORMATION CONTAINED

HEREIN.

Trademark Acknowledgement

LitennaTM and RFiberTM and ModuLite™ are registered trademarks of Foxcom Wireless. This

document contains other trademarks, trade names and service marks of Foxcom Wireless and

other organizations, all of which are the property of their respective owners.

Page 3

Foxcom Wireless Offices

ISRAEL - HEADQUARTERS

USA

Foxcom Wireless Ltd.

Tel: 972-8-918-3888 Tel: 1-866-4-FOXCOM

Foxcom Wireless Inc.

Foxcom Wireless Confidential and Proprietary Information

Document No. 43-93-005-05 X1 iii

Page 4

Page 5

ModuLite™ Installation Guide

Table of Contents

1. Front Chapter 1

1.1. Policy for Warranty and Repair 1

1.2. Conventions 3

1.3. Reporting Defects 4

1.4. RF Exposure Compliance 4

1.5. Precautions 5

1.5.1. Personal Safety 5

1.5.2. Equipment Safety 6

1.5.3. System Performance 6

1.5.4. Power Supply 6

2. Introduction to the ModuLite™ 7

2.1. Applications 8

2.2. Models 9

2.2.1. Certification 10

2.2.2. System Description 11

2.3. Product Drawings 12

2.3.1. Modular Base Unit- Four Ports 12

Modular Base Unit- Eight Ports 14

2.3.2.

2.3.3. Modular Remote Cabinet (

dimensions in millimeters

) 15

2.3.3.1. Isometric View 15

2.3.3.2. Front and Side View 15

2.3.3.3. Top View 16

2.3.3.4. Back View 16

2.3.3.5. Module Front Panel 17

3. Setup Tests 18

3.1. Pre RF Test 19

3.2. Flatness Test 20

3.3. Gain/IP3 Test 21

3.4. Uplink Network Test 22

4. Installation 23

4.1. General Installation 23

4.2. Environmental Data 24

4.3. Configuration Restrictions 25

Foxcom Wireless Confidential and Proprietary Information

Document No. 43-93-005-05 X1 iii

Page 6

ModuLite Installation Guide

4.4. Environmental Data 25

4.5. Protective Earthing 26

4.6. Wallmount Installation 26

4.7. Rackmount Installation 28

4.8. Fiber Installation 29

4.8.1. Fiber Optic Cable 32

4.8.2. ModuLite™ Installation Parts List 35

4.9. High Rise Installation 37

4.10. Horizontal Layout Installation 38

4.11.

Wireless LAN Installation 38

4.11.1. System Configuration with Modulite 810 39

4.11.2. System configuration with 840 41

4.11.3. Connecting to the Ethernet Line 43

5. Optical and RF Connections 44

5.1. Modular Base Unit (MBU) 44

5.1.1. BTS/RBS with one port 45

5.1.2. BTS/RBS with two ports 46

5.2. Modular Remote Cabinet (MRC) 47

6. Alarm Monitoring 48

7. Power Supply for ModuLite™ 49

7.1. Option One (Remote Power) 50

7.2. Option Two (Local Powering) 50

7.3. Option Three (Built-In Powering) 50

8. Optical Test Procedure 51

8.1. Fiber Optic Cable Test 51

8.2. Fiber Optic Cable – Terms 51

8.2.1. Optical Fiber 52

8.2.2. Connecting Fiber Optic Cable 54

8.2.3. Fiber Optic Cable Bending Loss 54

8.2.4. Coupler 54

8.3. Foxcom Wireless System Characteristics 55

8.3.1. Test Equipment 55

8.4. Optical Insertion Loss Measurement Test 56

8.4.1. Method #1: Two Point Test 56

Foxcom Wireless Confidential and Proprietary Information

Document No. 43-93-005-05 y iv

Page 7

ModuLite™ Installation Guide

8.4.2. Method #2: Single Point Test 57

8.4.3. Other Test Equipment 57

8.5. Optical Return Loss Measurement Test 58

8.5.1. Measurement Procedure 58

8.6. Results 59

8.7. Summary 59

9. Final Test 60

9.1. Modular Base Unit and Modular Remote Cabinet Connections 60

10.

11.

Maintenance / Mechanical Adjustment 61

Troubleshooting 61

Appendix A: Link Measurements Form 63

Foxcom Wireless Confidential and Proprietary Information

Document No. 43-93-005-05 X1 v

Page 8

ModuLite Installation Guide

List of Figures

Figure 1: ModuLite™ System ............................................................................................7

Figure 2: ModuLite™ Block Diagram..............................................................................11

Figure 3: Modular Base Unit 4 Ports................................................................................12

Figure 4: ModuLite™ Base 4 Unit Front Panels..............................................................12

Figure 5: ModuLite™ Base 4 Unit Back Panel................................................................13

Figure 6: Modular Base Unit 8 Ports................................................................................14

Figure 7: ModuLite™ Base 8 Unit Front Panels..............................................................14

Figure 8: ModuLite™ Base 8 Unit Back Panels................................................................14

Figure 9: Modular Remote Cabinet Front Panel...............................................................17

Figure 10: Network Analyzer Setup Test .........................................................................20

Figure 11: Spectrum Analyzer Setup Test.........................................................................22

Figure 12: Uplink Network Test.......................................................................................22

Figure 13: PCS Frequency Allocation...............................................................................25

Figure 14: ModuLite™ GND Standoff Assembly Sequence ............................................26

Figure 15: Wallmount Template.......................................................................................27

Figure 16: Procedure for Mounting on a Wall..................................................................28

Figure 17: Example - ModuLite

Figure 18: High Rise Installation......................................................................................37

Figure 19: Horizontal Layout Installation.........................................................................38

Figure 20: ModuLite™ MRC Interior with Wireless LAN Module ................................39

Figure 21: 802.11b Configuration ....................................................................................39

Figure 22: Connector Points on the WLAN Module........................................................40

Figure 23: WizLAN Converter.........................................................................................43

Figure 24: Example: One port BTS/RBS connected to 1 MBU 4 ports............................45

Figure 25: Example - One port BTS/RBS connected to 1 MBU 8 ports...........................46

Figure 26: Example - Two port BTS/RBS connected to 1 MBU 4 ports.........................46

Figure 27: Example- Two port BTS/RBS connected to 1MBU 8 ports............................47

Figure 28: Example - DC Power Supply in High Rise Installation...................................49

Figure 29: Fiber Optic Cable Structure..............................................................................53

Figure 30: Singlemode - Multimode Fibers.......................................................................53

Figure 31: Two Point Test.................................................................................................56

Figure 32: Single Point Test..............................................................................................57

Figure 33: Optical Return Loss Measurement...................................................................58

TM

Installation (fiber and coax).......................................31

Foxcom Wireless Confidential and Proprietary Information

Document No. 43-93-005-05 y vi

Page 9

ModuLite™ Installation Guide FRONT CHAPTER

List of Tables

Table 1: ModuLite™ Models .............................................................................................9

Table 2: Modular Base Unit Description...........................................................................13

Table 3: Modular Remote Cabinet Description................................................................17

Table 4: Required Equipment List....................................................................................18

Table 5: ModuLiteTM Installation Parts List......................................................................35

Table 6: ModuLite™ Installation Labor List.....................................................................36

Table 7: 25 Pin Alarm Pinouts ..........................................................................................48

Table 8: Power Supply Options.........................................................................................50

Table 9: Fiber Optic Cable Test Results...........................................................................59

Table 10: Optical LED States............................................................................................61

Table 11: Link Measurement Table...................................................................................63

Foxcom Wireless Confidential and Proprietary Information

Document No. 43-93-005-05 X1 vii

Page 10

Page 11

ModuLite™ Installation Guide FRONT CHAPTER

1. Front Chapter

1.1. Policy for Warranty and Repair

Foxcom Wireless tests and inspects all its products to verify their quality and reliability.

Foxcom Wireless uses every reasonable precaution to ensure that each unit meets their declared

specifications before shipment. Customers should advise their incoming inspection, assembly,

and test personnel about the precautions required in handling and testing our products. Many of

these precautions can be found in this manual.

The products are covered by the following warranties:

1. General Warranty

Foxcom Wireless warrants to the original purchaser all standard products sold by

Foxcom Wireless to be free of defects in material and workmanship for one (1) year from date of

shipment from Foxcom Wireless. During the warranty period, Foxcom Wireless will repair or

replace any product that Foxcom Wireless proves to be defective. This warranty does not apply

to any product that has been subject to alteration, abuse, improper installation or application,

accident, electrical or environmental over-stress, negligence in use, storage, transportation or

handling.

2. Specific Product Warranty Instructions

All Foxcom Wireless products are warranted against defects in workmanship, materials and

construction, and to no further extent. Any claim for repair or replacement of units found to be

defective on incoming inspection by a customer must be made within 30 days of receipt of

shipment, or within 30 days of discovery of a defect within the warranty period.

This warranty is the only warranty made by Foxcom Wireless and is in lieu of all other

warranties, expressed or implied. Foxcom Wireless sales agents or representatives are not

authorized to make commitments on warranty returns.

Foxcom Wireless Confidential and Proprietary Information

1

Document No. 43-93-005-05 X1

Page 12

ModuLite Installation Guide FRONT CHAPTER

3. Returns

In the event that it is necessary to return any product against above warranty, the following

procedure shall be followed:

a. Return authorization is to be received from Foxcom Wireless prior to returning any unit.

Advise Foxcom Wireless of the model, serial number, and discrepancy. The unit may then

be forwarded to Foxcom Wireless, transportation prepaid. Devices returned collect or

without authorization may not be accepted.

b. Prior to repair, Foxcom Wireless will advise the customer of our test results and any

charges for repairing customer-caused problems or out-of-warranty conditions etc.

c. Repaired products are warranted for the balance of the original warranty period, or at least

90 days from date of shipment.

4. Limitations of Liabilities

Foxcom Wireless's liability on any claim, of any kind, including negligence for any loss or

damage arising from, connected with, or resulting from the purchase order, contract, quotation,

or from the performance or breach thereof, or from the design, manufacture, sale, delivery,

installation, inspection, operation or use of any equipment covered by or furnished under this

contact, shall in no case exceed the purchase price of the device which gives rise to the claim.

EXCEPT AS EXPRESSLY PROVIDED HEREIN, FOXCOM WIRELESS MAKES NO

WARRANTY, EXPRESSED OR IMPLIED, WITH RESPECT TO ANY GOODS, PARTS

AND SERVICES PROVIDED IN CONNECTION WITH THIS AGREEMENT

INCLUDING, BUT NOT LIMITED TO, THE IMPLIED WARRANTIES OF

MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE.

FOXCOM WIRELESS SHALL NOT BE LIABLE FOR ANY OTHER DAMAGE

INCLUDING, BUT NOT LIMITED TO, INDIRECT, SPECIAL OR CONSEQUENTIAL

DAMAGES ARISING OUT OF OR IN CONNECTION WITH FURNISHING OF

GOODS, PARTS AND SERVICE HEREUNDER, OR THE PERFORMANCE, USE OF,

OR INABILITY TO USE THE GOODS, PARTS AND SERVICE.

Foxcom Wireless Confidential and Proprietary Information

Document No. 43-93-005-05 y

2

Page 13

ModuLite™ Installation Guide FRONT CHAPTER

1.2. Conventions

In this manual the following special formats are used:

Note

Notes contain information detailing the current topic.

CAUTION

CAUTIONS CONTAIN INFORMATION REGARDING SITUATIONS OR MATERIALS

THAT COULD DAMAGE YOUR PRODUCT.

! Warning

WARNINGS CONTAIN INFORMATION REGARDING DANGEROUS FUNCTIONS.

Foxcom Wireless Confidential and Proprietary Information

3

Document No. 43-93-005-05 X1

Page 14

1.3. Reporting Defects

The units were inspected before shipment and found to be free of mechanical and

electrical defects.

Examine the units for any damage that may have been caused in transit. If damage is

discovered, file a claim with the freight carrier immediately. Notify Foxcom Wireless as

soon as possible.

Refer to Policy for Warranty and Repair for further details.

Note

Keep all packing material until you have completed the inspection.

1.4. RF Exposure Compliance

!! Warning

TO COMPLY WITH FCC RF EXPOSURE COMPLIANCE REQUIREMENTS,

ANTENNAS USED FOR THIS PRODUCT MUST BE FIXED MOUNTED ON INDOOR

PERMANENT STRUCTURES, PROVIDING A SEPARATION DISTANCE OF AT LEAST

20 CM FROM ALL PERSONS DURING NORMAL OPERATION.

ANTENNAS MUST BE SEPARATED FROM EACH OTHER, ACCORDING TO THE

SPECIFIC FCC STANDARD. FOR MODEL 810/840 ANTENNAS MUST BE MOUNTED

SO THAT THERE IS AT LEAST 2M SEPARATION BETWEEN ANY TWO ANTENNAS

!! Warning

Each individual antenna used for this transmitter must be installed to provide a minimum

separation distance of 20 cm or more from all persons and must not be co-located with

any other antenna for meeting RF exposure requirements.

Page 15

ModuLite™ Installation Guide FRONT CHAPTER

1.5. Precautions

1.5.1. Personal Safety

The ModuLite™ system uses an optical laser for transmitting voice and data. The laser unit has

the following output characteristics:

• Optical output power (mW): ≤3.0

• Wavelength (nM): 1310 ± 10

! Warning

APPLYING POWER TO THE MODULAR BASE UNIT AND MODULAR REMOTE

CABINET WILL CREATE A LASER ENERGY SOURCE OPERATING IN CLASS I AS

DEFINED BY IEC 60825-1, 21 CFR 1040.10 AND 1040.11 EXCEPT FOR DEVIATIONS

PURSUANT TO LASER NOTICE NO. 50 (JULY 26, 2001). USE EITHER AN INFRARED

VIEWER, OPTICAL POWER METER OR FLUORESCENT SCREEN FOR OPTICAL

OUTPUT VERIFICATION.

! Warning

THE USE OF CONTROLS OR ADJUSTMENTS OR PERFORMANCE PROCEDURES

OTHER THAN THOSE SPECIFIED HEREIN MAY RESULT IN HAZARDOUS

RADIATION EXPOSURE.

! Warning

COMPLIANCE WITH RF SAFETY REQUIREMENTS:

THE MODULITE™ HAS NO INHERENT SIGNIFICANT RF RADIATION.

THE RF LEVEL ON THE DOWNLINK IS VERY LOW AT THE MODULAR REMOTE

CABINET DOWNLINK PORTS. THEREFORE, THERE IS NO DANGEROUS RF

RADIATION WHEN THE ANTENNA IS NOT CONNECTED.

THE DESIGN OF THE ANTENNA INSTALLATION NEEDS TO BE IMPLEMENTED IN

SUCH A WAY SO AS TO ENSURE RF RADIATION SAFETY LEVELS AND NONENVIRONMENTAL POLLUTION DURING OPERATION.

Foxcom Wireless Confidential and Proprietary Information

5

Document No. 43-93-005-05 X1

Page 16

ModuLite Installation Guide FRONT CHAPTER

1.5.2. Equipment Safety

To avoid damaging your product, please observe the following:

1. Always keep the optical connector covered. Use the fiber optic cable or a protective cover. Do

not allow any dirt and/or foreign material to get on the optical connector bulkheads.

2. The optical fiber jumper cable bend radius is 3 cm. Smaller radii can cause excessive optical

loss and/or fiber breakage.

1.5.3. System Performance

! Warning

FOR PROPER SYSTEM PERFORMANCE USE ONLY CABLES EQUIPPED WITH

SC/APC CONNECTORS TO CONNECT TO THE FOXCOM WIRELESS MODULITE™

SYSTEM.

SC/APC Connector

1.5.4. Power Supply

! Warning

DISCONNECT BOTH POWER SOURCES BEFORE SERVICING.

CAUTION

______________________________________________

______________________________________________

________________

FOR CONTINUED PROTECTION AGAINST RISK OF FIRE, REPLACE ONLY WITH

SAME TYPE AND RATINGS OF FUSES.

Foxcom Wireless Confidential and Proprietary Information

Document No. 43-93-005-05 y

6

Page 17

ModuLite™ Installation Guide INTRODUCTION TO THE MODULITE™

2. Introduction to the ModuLite™

Infrastructure for multiple services is currently provided through two different methods. The first

method is a parallel infrastructure based on a fiber or hybrid fiber-copper solution. In this system,

even though all operators provide mutual services with a potential for sharing, a complete

infrastructure is deployed for every operator. Multiple antennas need to be installed in every

radiation zone. Isolation between antennas is hard to control, and as a result, cross antenna

interference may cause degraded performance.

The second available solution is based on coax. Coax has different attenuation levels for

different frequencies. This leads to design constraints because the coax needs to match the

highest frequencies serviced and their respective attenuation levels. This requirement leads to

higher costs resulting from the larger diameter coax and from a more labor-intensive installation.

Foxcom Wireless’s ModuLite

TM

is a new approach. The ModuLite™ is a high-performance, cost

effective and modular In-Building system designed for multiple wireless services. It is

technically superior to other available infrastructures, and provides WSP’s and building

operators with an advanced platform for expansion and upgradability.

Figure 1: ModuLite™ System

The ModuLite™ has unique advantages:

• Low attenuation: Singlemode fiber optic cables have virtually no attenuation (0.38dB/Km),

relieving the need to install amplifiers or any other signal enhancing in-line devices. This factor

alone greatly reduces the engineering and installation costs.

Foxcom Wireless Confidential and Proprietary Information

Document No. 43-93-005-05 X1 7

Page 18

ModuLite Installation Guide INTRODUCTION TO THE MODULITE™

• Low noise: High bandwidth signals can be set over singlemode fibers without encountering

noise problems, and transmitted over great distances.

• Multi Services: Same infrastructure is used either supporting single service or multiple

services, due to the pseudo infinite bandwidth of singlemode fiber optic cable.

2.1. Applications

The ModuLite™ addresses both public and private markets in order to provide RF distribution

solutions for various structure types:

• Typical Public Market

o Malls

o Airports

o

Conventions Centers

o

Hospitals

• Typical Private Market

o Office Buildings

o Business Centers

o Campus

Three types of applications are very common for both markets:

• High Rise Buildings

• Horizontal Structures

• Campus type

Foxcom Wireless’ ModuLite™ addresses these application types with a powerful answer, while

still flexible and future expandable. There are no limitations for building height or structure

spread.

Foxcom Wireless Confidential and Proprietary Information

Document No. 43-93-005-05 y 8

Page 19

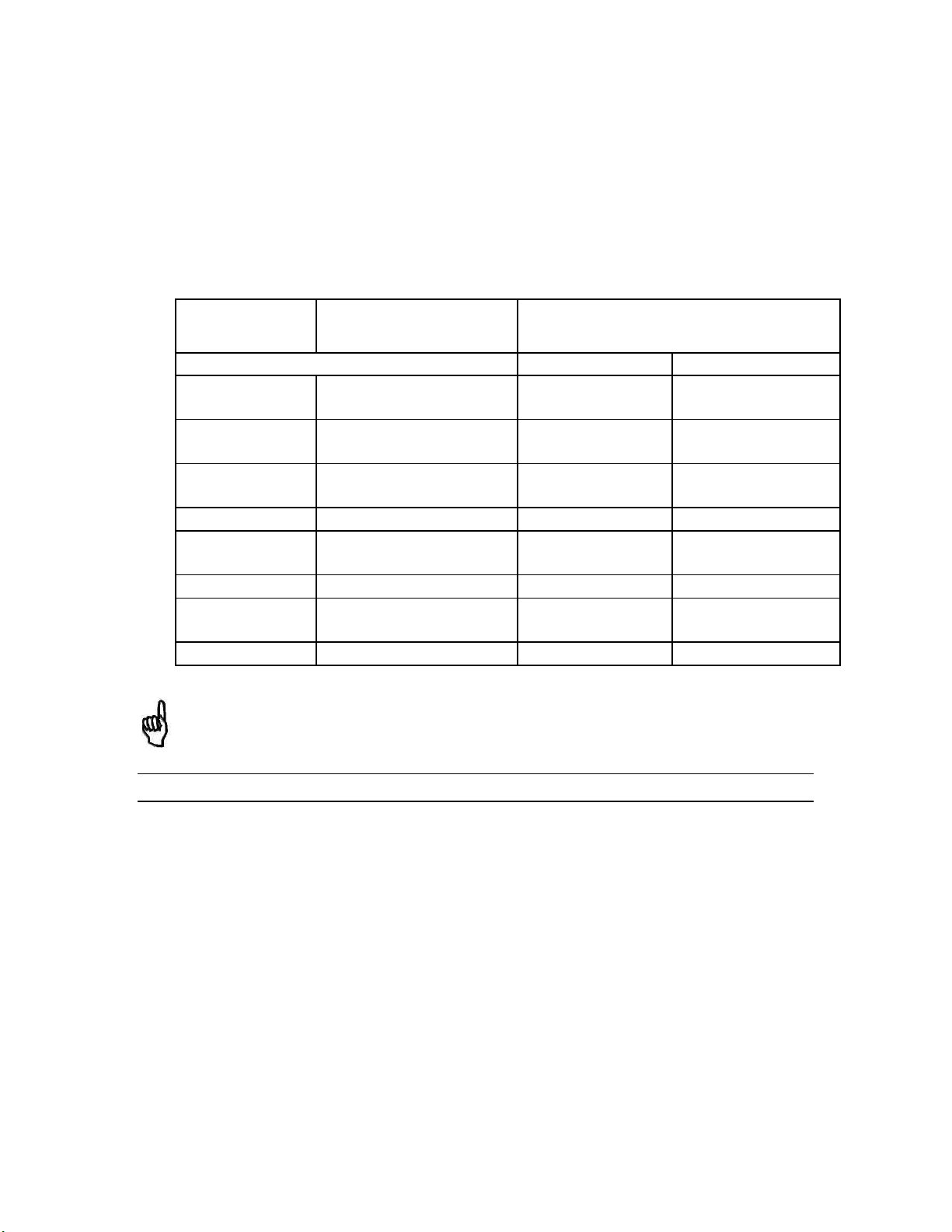

2. 2 Models

ModuLite™ products come in various models, each model covering a different frequency

spectrum and standard.

Table 1: ModuLite™ Models

System

Configuration

Uplink Downlink

U.S. Market

iDEN/PCS 806-824;

Paging/PCS 899-902;

European &

Asian Markets

UMTS-FDD 1920 - 1980 2110 - 2170

Cellular/DCS 824-849;

iDEN 811-821 856-866

Service Frequency Range (MHz)

Cellular/PCS 824-849;

1850-1910

1850-1910

1850-1910

WLAN/UNLICENSED 2412-2462 2412-2462

900/DCS 890-915;

1710-1785

1710-1785

Note

Detailed specifications for all models appear in the ModuLite

TM

Data Sheet

869-894;

1930-1990

851-869;

1930-1990

928-941;

1930-1990

935-960;

1805-1880

869-894;

1805-1880

Page 20

2.2.1 Certification

Foxcom Wireless products have met the approvals of the following certifying

organizations:

ISO 9001

For Europe

0681

For US

FCC 47 CFR part 15,22,24,90

CAUTION

In order to remain compliant with FCC Rule Section 15,204 for unlicensed operation in the 2.4

GHz ISM band, the Modulite 810/840 configuration must be as follows:

Access Point: CISCO 1200: FCC ID: LDK102042

Smart amplifier: Shockwave. Model: AMP – 24 – 1W

4 by 4 Service Combiner Hybrid Matrrix 4x4 Wlan 0.8-2.5 GHz model: HC-44-1

Coax cable, Access point to Amplifier Input Type: LMR–195-PUC, Minimum length: 14 Inch

(Attenuation 0.5 dB), TIMES MICROWAVE SYSTEMS.

Maximum antenna gain: 5 dBi (ex: Mars Antenna model MA-CM36-15)

Modifications not expressly approved by Foxcom Wireless could void the user's authority to operate this

equipment.

FDA-CDRH

UL

For Canada: RSS-118, RSS-119, RSS-133

Page 21

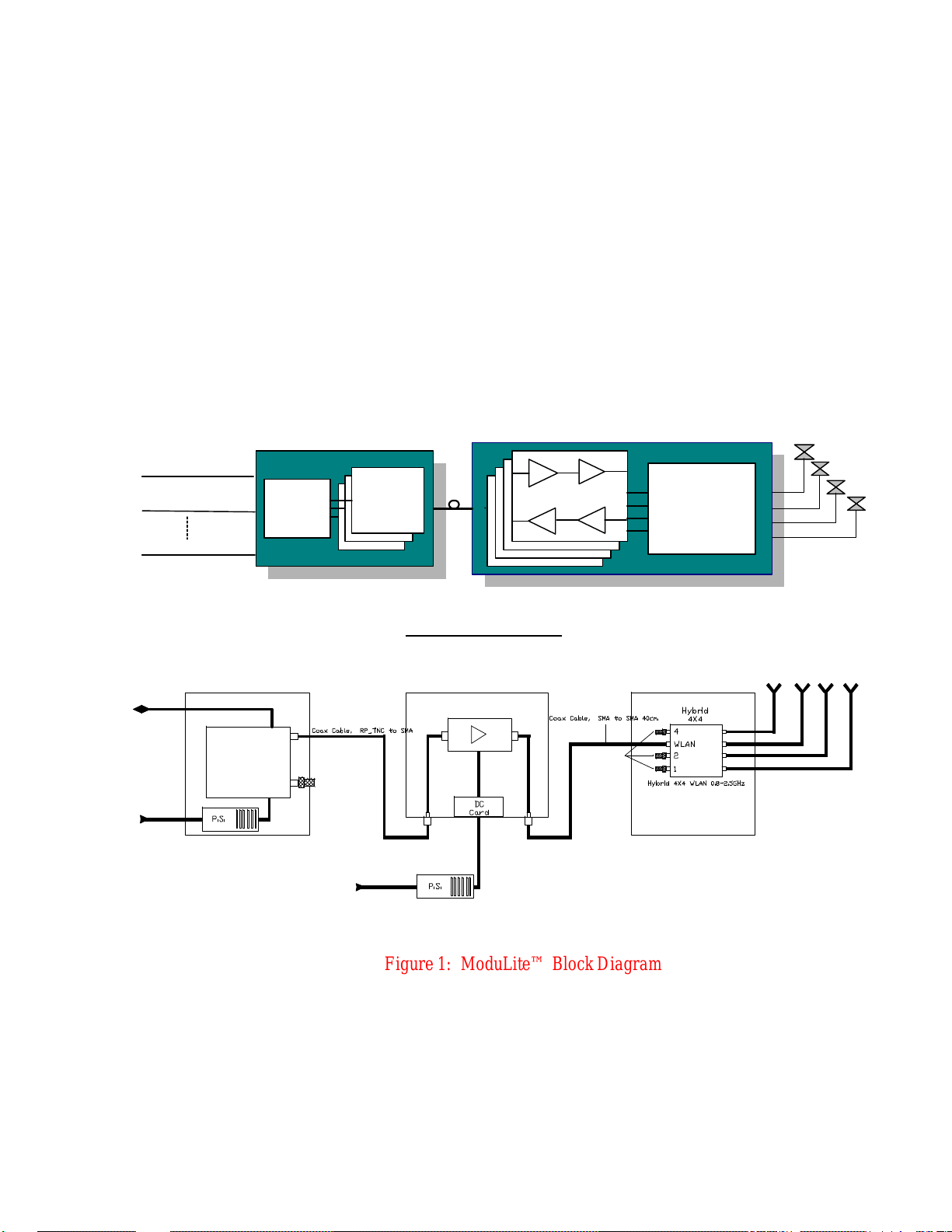

System Description

MRC

MBU

The MBU converts RF signals from the RF source (Base Stations/off- air repeater) to an optical signal

using direct modulation technology. Each BU module can support two to four services, depending on

the application. The MBU is connected via a single mode fiber optic cable to the MRC.

The MRC is comprised of modular remote units, each supporting two to four services, yet each

modular remote unit has sub RF channels in order to maximize the performance of each specific

service in terms of IMD suppression and dynamic range. Each MRC can contain four modular remote

units, hence at least eight services. The RF modules can be added as required to support the required

services. The MRC converts the optical signal to RF, performs filtering and enhanced signaling via its

Remote Interface Module, and connects to a single antenna via a single coax cable.

The ModuLite’s TM main features are as follows:

· Single cabling and antenna system for all services

o enables fast deployment for WSP’s of new services

o reduces tenant disruption

o simplifies maintenance

The ModuLiteTM is a new system for the provision of In-Building multiple wireless

services. Its high performance yet cost effective structure efficiently enables the addition

of new wireless services.

The ModuLiteTM is a hybrid fiber coax modular solution designed to serve multiple

wireless services using a single common cabling infrastructure. The cabling infrastructure

includes a fiber optic cable, a single coax cable, and a single antenna.

The ModuLiteTM has two main modules, the MBU (Modular Base Unit) and the MRC

(Modular Remote Cabinet). Both components are designed such that they can be located

in easily accessible area, such as the communication room, the communication closet, or

in the riser.

Service 1

Service 2

Service n

RF

Interface

Optical

Module

MRU

RIM

ModuLite 810 Stand Alone

ModuLite 810

Ethernet

110VAC

Access

Point

48VDC

50 Ohm Ter.

110VAC

Amplifier

50 Ohm Ter.

48VDC

Figure 1: ModuLite™ Block Diagram

Page 22

ModuLite Installation Guide INTRODUCTION TO THE MODULITE™

1U12”

3

MBU MBU

• Upgradeable to include more than eight services per Modular Remote Cabinet (MRC),

including 3G technologies

• Eliminates RF interferences occurring in parallel infrastructures due to cross antenna

coupling

• Minimal input power to ModuLite™ (~0dBm) - No need for high power BTS/RBS, less

expenses for the operators.

• MCU-Alarm Interface with open collector and dry contact alarms – the alarm loopback is

activated when there is a broken or faulty optical fiber or no power in system.

• Low attenuation: Singlemode fiber optic cables have virtually no attenuation (0.38dB/Km),

relieving the need to install amplifiers or any other signal enhancing in-line devices. This

factor alone greatly reduces the engineering.

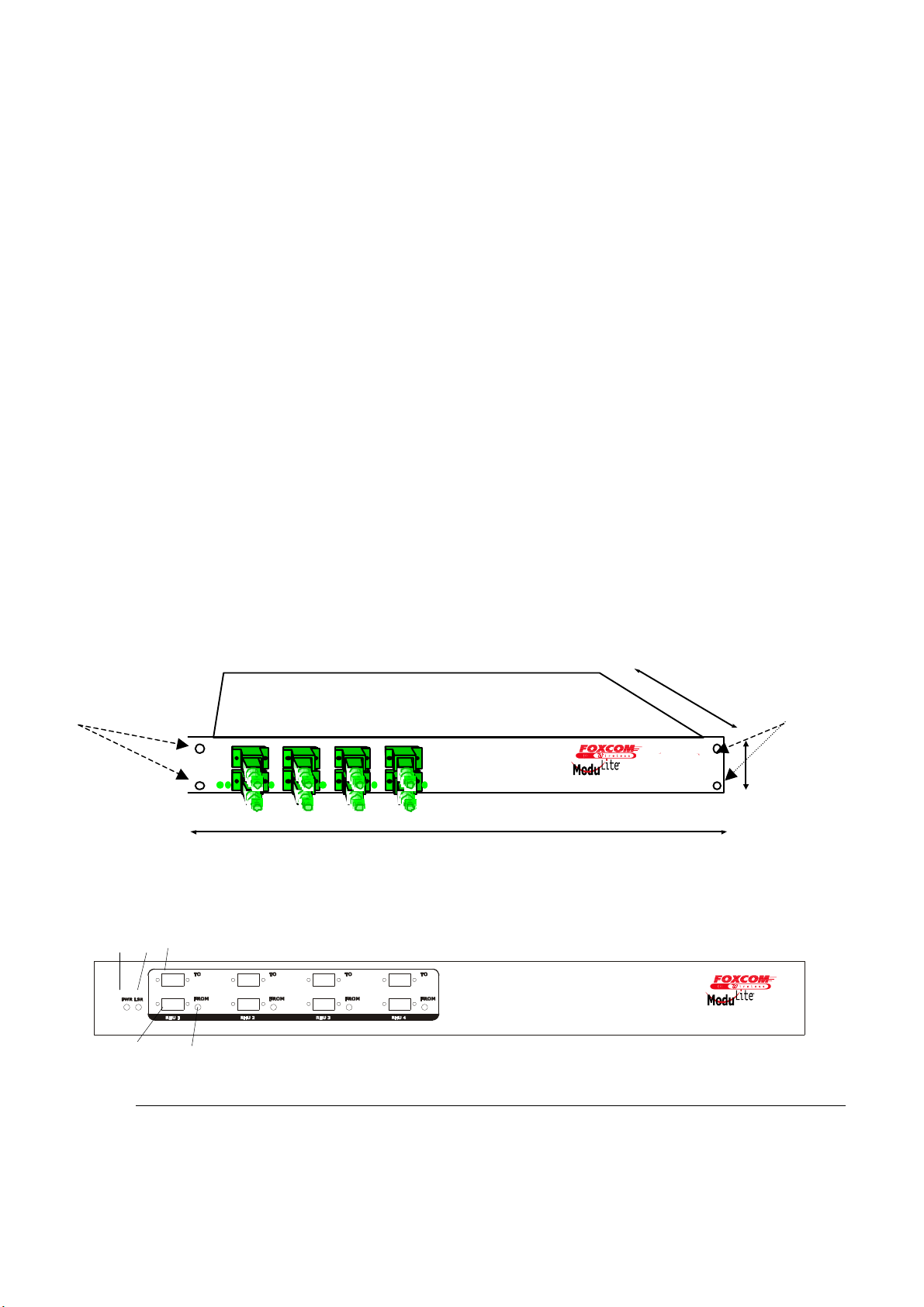

2.3. Product Drawings

Holes for

rackmount

installation

The following drawings show sample front and rear panels of the ModuLite™ units.

2.3.1. Modular Base Unit- Four Ports

1

4

Figure 3: Modular Base Unit 4 Ports

19”

Holes for

rackmount

installation

2

5

Figure 4: ModuLite™ Base 4 Unit Front Panels

Foxcom Wireless Confidential and Proprietary Information

Document No. 43-93-005-05 y 12

Page 23

ModuLite™ Installation Guide INTRODUCTION TO THE MODULITE™

6 9 7 8

Figure 5: ModuLite™ Base 4 Unit Back Panel

Table 2: Modular Base Unit Description

Number Description

1. Laser Output connection to MRC

2. Optical Diode Input from MRC

3. Power LED indicator

4. Modular Base Unit Laser operational LED

indicator

5. Modular Remote Cabinet Laser operational

LED indicator

6. Coax input from cellular headend

7. Power input connector

8. 25 pin Alarm connector

9. Coax output to cellular headend

Foxcom Wireless Confidential and Proprietary Information

Document No. 43-93-005-05 X1 13

Page 24

ModuLite Installation Guide INTRODUCTION TO THE MODULITE™

MBU

2.3.2. Modular Base Unit- Eight Ports

”

U

”

Figure 6: Modular Base Unit 8 Ports

Figure 7: ModuLite™ Base 8 Unit Front Panels

Figure 8: ModuLite™ Base 8 Unit Back Panels

Foxcom Wireless Confidential and Proprietary Information

Document No. 43-93-005-05 y 14

Page 25

ModuLite™ Installation Guide INTRODUCTION TO THE MODULITE™

2.3.3. Modular Remote Cabinet (dimensions in millimeters)

2.3.3.1. Isometric View

19´ brackets

2.3.3.2. Front and Side View

mounting brackets

carrying cradle

19´ brackets

Foxcom Wireless Confidential and Proprietary Information

Document No. 43-93-005-05 X1 15

Page 26

ModuLite Installation Guide INTRODUCTION TO THE MODULITE™

Mounting bracket

Fiber optic cable

4

2.3.3.3. Top View

entrance

DC power input

Antenna ports 1-

2.3.3.4. Back View

Fans

Wallmount bracket

Rackmount brackets

AC power input

Wall mount bracket

Note: Depending on the user’s preference, either wallmount or rackmount brackets will be

assembled.

Foxcom Wireless Confidential and Proprietary Information

Document No. 43-93-005-05 y 16

Page 27

ModuLite™ Installation Guide

PORT1PORT2PORT3

OPT.D

C

FROMBASETOBAS

E

20-48VD

C

POWERINPU

T

UL

3 4

6

2

7

2.3.3.5. Module Front Panel

1

DL/

RF IN OUT

FILTERS

Number Description

1. RF In/Out

2. Filters

3. Optical LED for laser operation

4. DC power LED for power operation

5. DC power connector

6. Optical input connector from Modular Base

Unit

7. Laser output connector to Modular Base Unit

Modular Remote Unit

Cellular/PCS

5

Figure 9: Modular Remote Cabinet Front Panel

Table 3: Modular Remote Cabinet Description

Foxcom Wireless Confidential and Proprietary Information

Document No. 43-93-005-05 X1 17

Page 28

ModuLite Installation Guide SETUP TESTS

3. Setup Tests

This ModuLite™ product has been checked thoroughly before reaching the customer. Foxcom

Wireless attests to the suitability of this product for operation. Where the customer desires to

check the fitness of the product, the appropriate tests are listed on the following pages.

The following describes the equipment required for testing the system at setup.

Table 4: Required Equipment List

Required Setup Equipment Quantity

HP8753C Network Analyzer or equivalent

HP85046A S Parameter test set or equivalent 1

HP8594E Spectrum Analyzer or equivalent 1

Power supply /48 @ 5A 1

Signal generator HP8648B or equivalent 2

Amplifier Mini-circuit ZKL-2 or equivalent 1

Digital Multi-meter 1

RF Combiner Mini-Circuit ZAPD-21 or equivalent

with N connectors

High-grade 50-ohm phase matched cables:

N to N cables

N to SMA cables (in N remote type)

SMA to SMA cables (in SMA remote type)

Optical power meter (1310 nm) of EXFO model

number FOT-22A or equivalent

4 * Singlemode duplex fiber optic cable with SC/APC

connectors

Calibration kit, including

Through (N-female to N-female)

Short (N-female)

50 ohm (N-female)

1

1

4

2

3

1

3m

Foxcom Wireless Confidential and Proprietary Information

Document No. 43-93-005-05 y 18

Page 29

ModuLite™ Installation Guide SETUP TESTS

This section explains the following test procedures:

• Pre RF Test

• Flatness Test

• Gain/IP3 Test

• Uplink Network Test

In order to carry out the tests, the following connections need to be made. (The tests can be

performed on one service or several services simultaneously according to the implemented

application).

Connect the Modular Base Units corresponding with the service optical output to the Modular

Remote Cabinet’s optical input via fiber optic cable.

Connect power to all units being tested (20V-48V DC).

Use the relevant setup test for each Modular Base Unit to each Modular Remote Cabinet.

3.1. Pre RF Test

To carry out the Pre RF Test, the following procedure needs to be carried out.

1. Make sure all DC LED’s are lit on both units.

2. Measure Tx optical output power for all lasers.

3. Output power should be 1.8-3.7dBm (with optical power meter).

4. On the Modular Remote Cabinet, make sure that the optical LED’s is lit on all services.

5. On the Modular Base Units, make sure the Rx optical LED’s are lit.

Foxcom Wireless Confidential and Proprietary Information

Document No. 43-93-005-05 X1 19

Page 30

ModuLite Installation Guide SETUP TESTS

3.2. Flatness Test

To carry out the Flatness Test, the following procedure needs to be carried out.

1. Connect the Network Analyzer to the service designated Modular Base Unit. On the

Network Analyzer, the Modular Base Unit (according to the service) connects to port 2

2. On the Network Analyzer, the Modular Remote Cabinet connects to port 1 (see Figure 10).

3. After calibrating the network, set Network Analyzer to:

S21

Measure

Log

Format

Scale 1db/div

4. Apply with the required F1 and F2 should be according to Product Spec.

5. Measure the difference between the highest and the lowest signal point (which should be

as specified in the data sheet).

Network Analyzer

Port 2 Port 1

RF In RF Out

ModuLite

Base Unit

20-48V 20-48V

Opt Out Opt In

ModuLite

Remote Unit

Figure 10: Network Analyzer Setup Test

Foxcom Wireless Confidential and Proprietary Information

Document No. 43-93-005-05 y 20

Page 31

ModuLite™ Installation Guide SETUP TESTS

3.3. Gain/IP3 Test

To carry out the Gain/IP3 Test, the following procedure needs to be carried out.

1. Set the 2 tone signal from the 2 signal generators. RF signals F1 and F2 should be

according to Product Spec.

2. Combine the signals with ZAPD-21 combiner or equivalent.

3. Connect the 2-tone signal to the input of the base (see Figure 11).

4. Set Spectrum Analyzer to:

Video BW 10khz

RBW 100khz

Attenuation 20db

Span 30Mhz

Center freq. Refer to Product Spec.

Ref level 10dbm

5. Connect the RF cable from the Modular Remote Cabinet output to the Spectrum

Analyzer.

6. Measure output Gain/IP3 from all test MRC’s downlink outputs.

7. IP3 is determined by:

IP3= power tone + (power tone – power IM3)/2.

SG1

SG2

RF Combiner

RF

In

ModuLite

Base Unit

DC

In

20-48V 20-48V

Opt

Out

Opt

In

Remote Cabinet

ModuLite

DC

In

Spectrum

Analyzer

RF

Out

Foxcom Wireless Confidential and Proprietary Information

Document No. 43-93-005-05 X1 21

Page 32

ModuLite Installation Guide SETUP TESTS

Figure 11: Spectrum Analyzer Setup Test

3.4. Uplink Network Test

To carry out the Noise Floor test, the following procedure needs to be carried out.

1. Connect the Spectrum Analyzer to the designated Modular Base Unit uplink port.

Connect 50ohm terminators to the MRC ports, and to all Modular Base Unit uplink ports

except for the tested port (see Figure 12).

2. Extra amplification (25db) is applied between Modular Base Unit and Spectrum

Analyzer in order to measure the noise floor.

3. Set Spectrum Analyzer to:

Video BW 300hz

RBW 1khz

Attenuation 0db

Span 0hz

Center freq. Refer to Product Spec.

Ref level -50dbm

Marker noise ON

4. The noise figure is formulated as: -174 + Gsystem + noise floor

(On the MRC, all unused ports must be terminated with 50ohm load.)

Spectrum

Analyzer

RF In

Out

AMP

RF

2

1

ModuLite

Base Unit

Uplink

DC

In

20-48V

Opt

Out

Opt

In

Remote Cabinet

Figure 12: Uplink Network Test

RF

Out

ModuLite

DC

In

20-48V

Foxcom Wireless Confidential and Proprietary Information

Document No. 43-93-005-05 y 22

Page 33

ModuLite™ Installation Guide INSTALLATION

4. Installation

The following sections describe the ModuLiteTM installation.

• General Installation.

Fiber Installation.

•

• Hi Rise Installation.

• Horizontal Layout Installation.

4.1. General Installation

The ModuLite™ components need to be set up, followed by performance verification before

installing the system. Foxcom Wireless suggests that a 19” rack-mountable Splice Tray be used at

the Modular Base Unit to facilitate optical fiber splicing. In the rack, the Splice Tray is mounted

above or below the Modular Base Unit (depending on direction of the incoming cables).

The MBU and MRC units should be installed in a communication room that provides access

to authorized personnel only. The units are maintenance free. In the event of failure, only

authorized personnel should handle the units.

Set up procedures for the Modular Base Unit (MBU) and Modular Remote Cabinets (MRC) are for

the following installations:

High-rise installations.

•

Horizontal layout installation.

•

For both installations, setting up the Modular Base Unit and Modular Remote Cabinets consists of

the following steps:

1. Determine antenna placement by system engineer: When an area needs RF cellular

augmentation, a RF engineer needs to determine the type and the location for each antenna. The RF

engineer should consider all relevant RF parameters (RF propagation models, isolation between

antennas in accordance with the appropriate standard, and environmental conditions) as well as

landlord limitations.

2. Determine the amount of antennas required. This number, in turn, determines the number of

Modular Remote Cabinets to be used. The number of Modular Remote Cabinets has a direct

influence on the type and the number of fibers to be installed.

3. Pull fiber optic cable and copper cables through building. Install fiber optic cable according to

the optic design (see Figure 17) Prepare 10% to 15% more fibers than are actually required. In order

to supply D.C power to the Modular Remote Cabinets remotely, copper cables need to be installed

in parallel to the fiber optic cable (see Figure 17).

Foxcom Wireless Confidential and Proprietary Information

Document No. 43-93-005-05 X1 23

Page 34

ModuLite Installation Guide INSTALLATION

4. Install Modular Base Unit in 19” rack. The number of Modular Base Units depends on the

number of Modular Remote Cabinets. Each Modular Base Unit is installed with four screws on the

front panel (two on each side) connecting to the 19” rack.

5. Install patch panel/splice tray cabinet with SC/APC adaptors in a 19” rack or wallmount

near Modular Base Units. All fibers are installed in the patch panel, in which the backside is the

fiber optic cable/cables coming from the remote side, and in the front side are SC/APC adaptors and

SC/APC jumpers to the Modular Base Units.

6. The fiber contractor splices fiber cable to the SC/APC connectorized pigtails. In the

communication room the fiber contractor splices/connects the fiber optic cable/cables coming from

the remote end with SC/APC connectorized pigtails inside the patch panel cabinet. The pigtails

connector will be connected to the SC/APC adaptors on the patch panel (from the inside).

7. Connect SC/APC jumpers between SC/APC adaptors on the patch panel to the Modular

Base Units. For every optic link (MBU--MRC) there are two fibers – one uplink and one downlink

per service.

8. Connect BTS/RBS to Modular Base Units via ½” coax cable RG223 or similar with 50Ω

impedance according the RF design (see paragraph optical and RF connections).

9. In the remote end connect pigtail/jumpers fibers from the splice box to each MRC. One splice

box can support several MRC’s according to the optical design (normally three MRC’s).

10. Connect antennas to Modular Remote Cabinet via ½” or 3/8” or similar coax cable with 50Ω

impedance and N-type male to male.

11. Connect power supply to Modular Base Unit and Modular Remote Cabinet (refer to power

planning). Each Modular Base Unit will be connected with D.C. cables (+, -) directly to the planned

power supply. The MRC’s will be connected to the D.C. cables through D.C. clamping coming

from the communication room.

4.2. Environmental Data

Maximum ambient operating temperature: 50° C

Maximum ambient temperature in a rack: 50° C

Foxcom Wireless Confidential and Proprietary Information

Document No. 43-93-005-05 y 24

Page 35

ModuLite™ Installation Guide INSTALLATION

E

E

1850 1870 1890 1910 1930 1950 1970 1990

4.3. Configuration Restrictions

MHz

A

15

5

M

Hz

B

15

MHz

M

Hz

F

C

5

5

M

Hz

15

MHz

A

MHz

15

B

5

M

Hz

15

MHz

5

M

Hz

M

Hz

F

5

C

15

MHz

UPLINK DOWNLINK

Figure 13: PCS Frequency Allocation

The following configuration restrictions apply: (Please refer to Figure 13 above.)

• PCS operator operating on block A and the Paging operator must not reside on the same MRU.

• PCS operator operating on block B and the SMR operator must not reside on the same MRU.

PCS operator operating on block A and B and the SMR and Paging operators must not reside

•

on the same MRU.

• The PCS band is divided into six blocks. Blocks A, B, and C are 15 Mhz and blocks D, E, and F

are 5 Mhz. Only two adjacent blocks can be used on the same MRU. The adjacent blocks are:

A and D, B and E, and F and C.

4.4. Environmental Data

Maximum ambient operating temperature: 45° C

Maximum ambient temperature in a rack: 45° C

Foxcom Wireless Confidential and Proprietary Information

Document No. 43-93-005-05 X1 25

Page 36

ModuLite Installation Guide INSTALLATION

SIDE VIEW

TOOTH WASHER

FLAT WASHER

HOUSING WALL

GND STANDOFF

TERMINAL LUG

4.5. Protective Earthing

See Figure 14 below, which describes how to connect the ground to the MRC. Connect the GND wire to

the GND of the rack (for a rackmount) or to the GND of the building (for a wallmount).

WING NUT

GND WIRE

16 AWG

Figure 14: ModuLite™ GND Standoff Assembly Sequence

4.6. Wallmount Installation

(The following instructions apply to an installation on a concrete wall. For any other type of wall,

contact the manufacturer.)

Please refer to Figure 15 and to Figure 16.

1. Attach the alignment template to the wall.

2. Using the template as a guide, drill seven holes for concrete anchors. Insert seven concrete

anchors (McMaster-Carr catalogue number 92403A200, or equivalent). The middle holes

are designated for the mounting bracket. The other four holes are for the wallmount bracket.

3. Carefully and thoroughly fasten the anchors to the wall.

Foxcom Wireless Confidential and Proprietary Information

Document No. 43-93-005-05 y 26

Page 37

ModuLite™ Installation Guide INSTALLATION

Three holes

4. Remove the three screws from the anchors in the holes designated in Figure 15 for the

mounting bracket. In the other four anchors loosen but do not remove the screws.

5. Using the screws removed from the mounting bracket anchors, attach the mounting bracket

through the three holes.

6. Insert the mounting bracket attached to the rear of the MRC into the mounting bracket

attached to the wall while maneuvering the four wallmount brackets into the four screws

previously loosened but not removed. Do not tighten these four screws so that the MRC

can be removed without requiring any tools.

for

mounting

bracket

Figure 15: Wallmount Template

Foxcom Wireless Confidential and Proprietary Information

Document No. 43-93-005-05 X1 27

Page 38

ModuLite Installation Guide INSTALLATION

–

Wallmount brackets

not necessary for

rackmount

installation

Figure 16: Procedure for Mounting on a Wall

Rackmount brackets–

not necessary for

wallmount installation

4.7. Rackmount Installation

For a rackmount installation, attach the MRC to the rack using the rackmount brackets (see Figure

16). The MRC should be hung in the lower section of the rack. Use 12 mm M6 screws.

The MRC requires a clearance of 10 cm above the unit. If a heating source is installed beneath the

MRC, a buffer must be placed between the MRC and the surface.

For MBU rackmount installation, see Figure 3. Use 12 mm M6 screws.

Foxcom Wireless Confidential and Proprietary Information

Document No. 43-93-005-05 y 28

Page 39

ModuLite™ Installation Guide INSTALLATION

Patch Panels

Splice trays

Power

4.8. Fiber Installation

The following procedure describes the process for setting up fiber optic cable for the system (see

Figure 17).

1. Pull fiber optic cable and DC cable through building structure

Comparison: Coax

complex vs. Fiber

solution

2. Install splice tray (when used) in 19” rack near Modular Base Unit.

Base 4 Units

Foxcom Wireless Confidential and Proprietary Information

Document No. 43-93-005-05 X1 29

Page 40

ModuLite Installation Guide INSTALLATION

3. Near Modular Base Unit, install patch panel cabinet (SC/APC adaptors) for fiber optic

cable connections.

4. Connect (3/125/900) pigtail with SC/APC connectors between splice tray and patch panel

cabinet.

5. Connect (3/125/3000) SC/APC jumpers between the corresponding Modular Base Unit and

patch panel.

6. Install splice box near MRC (refer to optic planning).

7. Connect fiber optic cable to splice box and (3/125/3000) pigtails to MRC.

Foxcom Wireless Confidential and Proprietary Information

Document No. 43-93-005-05 y 30

Page 41

ModuLite™ Installation Guide INSTALLATION

∼

Floor 32

DC

Cable

Fiber Optic

Cable

Jumpers

MBU

19" Rack

Patch panel

Splice tray

PigTail

2-8 Fibers

Splice

box

Splice

box

2-8 Fibers

MRC

MRC

MRC

MRC

Floor 9

Floor 7

Floor 2

Power Supply

Figure 17: Example - ModuLite

TM

Installation (fiber and coax)

Foxcom Wireless Confidential and Proprietary Information

Document No. 43-93-005-05 X1 31

Page 42

ModuLite Installation Guide INSTALLATION

4.8.1. Fiber Optic Cable

Before connecting the cable, clean the inside adaptor of the ModuLite™ according to the following

instructions:

Foxcom Wireless Confidential and Proprietary Information

Document No. 43-93-005-05 y 32

Page 43

ModuLite™ Installation Guide I NSTALLATION

Clean the connectors as follows:

Foxcom Wireless Confidential and Proprietary Information

Document No. 43-93-005-05 X1 33

Page 44

ModuLite Installation Guide INSTALLATION

To connect the cable:

• Line Up the Polarity Key.

Insert the connector.

•

Foxcom Wireless Confidential and Proprietary Information

Document No. 43-93-005-05 y 34

Page 45

ModuLite™ Installation Guide INSTALLATION

Connect patch panel and

Connect patch panel and

4.8. 2. ModuLite™ Installation Parts List

The following parts are needed for setting up the ModuLiteTM Base and Modular Remote

Cabinets. A fiber contractor handles cable splicing in order to connect the units. The fiber

contractor needs to use the parts list from Table 5 to arrange all equipment necessary for setting up

and installing the ModuLiteTM.

Table 5: ModuLiteTM Installation Parts List

The following tables refer to a full configuration 32 floor building:

Equipment Description Quantity Comment

Coax cable (per 1m) according to

the technology (7-8dB loss for

Connect MRC to

antenna.

As needed

100m in 1000MHz)

Antenna As planned

Optical cable (8*9) 72 fibers –

singlemode fiber

Optic cable for short

distance & protected

Total=500m

environments (tight

buffer type).

Patch panel 72 cabinet with

SC/APC adaptors.

Connect jumpers to base

and pigtails to splice tray.

2

Splice box Connects optic cable

11 1 per 3

from Cabinet and pigtails

to MRC.

Splice tray Tray-1*50 connects cable

4 In some

optic and pigtails near

Modular Base Unit.

9/125/3000 3m optical jumpers

with SC/APC connector

Connect patch panel to

MBU.

256

(simplex).

9/125/900 5m Pigtail with

SC/APC connectors (B)

9/125/3000 15m Pigtail with

SC/APC connectors (R)

splice tray.

splice tray.

344

168

Electricity cables (per 1m) Delivers power to units. According

to length.

Electricity ducts (per 1m) Ducts for moving cables

though building.

According

to length.

Coax connectors n-type Cable connectors As needed

Foxcom Wireless Confidential and Proprietary Information

Document No. 43-93-005-05 X1 35

floors

cases in

patch panel

If needed

Page 46

ModuLite Installation Guide INSTALLATION

Table 6: ModuLite™ Installation Labor List

Labor Description Quantity Comment

Installing splice box + splicing

fibers

Installing patch panel cabinet +

splicing fibers

Installing Foxcom Wireless

equipment

Installing optic cable

(per 1m)

Installing the box and

opening fibers at MRC.

Installation of the box and

opening fibers at MBU.

Installing Modular Base

Units and MRC’s.

Pull and install optic cable

through building.

Installing coax cable antennas Install cable antennas on

each floor

Installing electricity ducts (per 1m) Install cables through

ducts in building.

Installing electricity cables Install cables through

ducts in building.

System checking and report. Trouble shooting and walk

test.

11

256

36

If needed

Foxcom Wireless Confidential and Proprietary Information

Document No. 43-93-005-05 y 36

Page 47

ModuLite™ Installation Guide INSTALLATION

4.9. High Rise Installation

In a high-rise installation, all MBU’s are placed in the same location. The MBU’s are connected to

the BTS/RBS (see BTS/RBS connection – page 44). An MRC can be located on every floor

according to the RF design. The fiber optic cable runs from the MBU to every floor and terminates

at the splice box located on every three floors of the building. Normally, every splice box connects

three MBU’s. From the splice box, the fiber optic jumpers connect to the associated MRC. From

each MRC, a coax cable delivers the signal to the antenna.

MRC

MBU’s

MBU¶s

Figure 18: High Rise Installation

Foxcom Wireless Confidential and Proprietary Information

Document No. 43-93-005-05 X1 37

Page 48

ModuLite Installation Guide INSTALLATION

BU

A

H

E

LLSIT

EUNIT

D

B

MRCM

CELL

E

C

FGIHM

MRC

4.10. Horizontal Layout Installation

In a horizontal layout installation, one fiber optic cable connects the MBU to every installed MRC.

The fiber optic cable terminates at a splice box located near the MRC and from the splice box

connects to the associated MRC.

D

R

R

C

M

E

C

A

SIT

BU

G

I

B

F

Figure 19: Horizontal Layout Installation

4.11. Wireless LAN Installation

C

CE

BAS

E

Two products are available in the Modulite 800 Series:

Modulite 810 1 AP

Modulite 840 1-4 Ap’s

Figure 20 shows the 810 module in the MRC:

Foxcom Wireless Confidential and Proprietary Information

Document No. 43-93-005-05 y 38

Page 49

ModuLite™ Installation Guide INSTALLATION

Auxiliary Modle

Figure 20: ModuLite™ MRC Interior with Auxiliary Modle

4.11. 1. System Configuration with Modulite 810

depicts the system configuration for Wireless LAN as part of the ModuLite™ product. The

Auxiliary Modle including power amplifier and power supply DC/DC that resides in the MRC

cabinet. The access point module is connected via a power amplifier that is used to increase the

coverage area of the access point. The power amplifier is connected to the 4*4 hybrid combiner

that sums the cellular services signals together with the Wireless LAN signal and then sends the

signal to four antennas. See Figure 22 for connector points from the Auxiliary Modle.

Figure 21: 802.11b Configuration

Foxcom Wireless Confidential and Proprietary Information

Document No. 43-93-005-05 X1 39

Page 50

ModuLite Installation Guide INSTALLATION

to the

4*4 hybrid

“RF out” Connection

Power Output: Can be used

to power the WizLan

“RF in” Connection

to the Access Point

Figure 22: Connector Points on the Auxiliary Modle

Foxcom Wireless Confidential and Proprietary Information

Document No. 43-93-005-05 y 40

Page 51

ModuLite™ Installation Guide INSTALLATION

4.11. 2. System configuration with 840

The Modulite 840 supports 1- 4 AP¶s and is used when there is a request to support increased

capacity in the same location. The following drawing describes the system configuration.

ANT

ANT

ANT

ANT

AP

MRC

cisco

AP

cisco

AP

cisco

AP

cisco

optional

Modulite

optional

Modulite

optional

Modulite

optional

Modulite

Modulite

Figure 23 - system configuration with Modulite 840

Antenna

Antenna

Antenna

Antenna

The MRC antenna ports are connected to the 840 Cellular ports and are combined with the AP WLAN

signal of the AP and the Modulite 810. The Modulite 810 is an optional module. The combined signal

WLAN (from the AP’s and the Modulite 810) and the Cellular/PCS signal from the MRC are combined

together and distributed to 4 antennas.

The following table describes the configuration when a different number 1-4 AP are connected to the

840.

Foxcom Wireless Confidential and Proprietary Information

Document No. 43-93-005-05 X1 41

Page 52

ModuLite Installation Guide INSTALLATION

# of Access Points Access point designator Connected to Antenna

1 AP 1 1,2,3,4

2 AP1 1,2

AP2 3,4

3 AP1 1,2

AP2 3

AP3 4

4 AP1 1

AP2 2

AP3 3

AP4 4

Indoor Wide band Antennas

Combining the Cellular and the WLAN services requires using wide band antennas. Attached are the

recommended antennas tested and approved by Foxcom Wireless.

Vendor Catalog number Gain [dBi]

Mars Antennas MA-CM36-15 2 low band

3-4 high band

5 WLAN 802.11b

Celwave A08818DC00-28T0 2.1

Antenna ASP-3561 2

Foxcom Wireless Confidential and Proprietary Information

Document No. 43-93-005-05 y 42

Page 53

ModuLite™ Installation Guide INSTALLATION

Tx

P

ower

4.11. 3. Connecting to the Ethernet Line

The connection to the Ethernet line can be accomplished in two different ways:

1. Via local connection, or

2. Concentrated remote location.

The local connection can be made by connecting each MRC located at each floor (in a typical

configuration) to the nearest Ethernet line on the same floor. The RJ45 should be connected by cable

to the nearest Ethernet line. The advantage in this configuration is that one can save on fiber

installation that runs from each floor to a central location to be connected to the Ethernet.

The remote connection can be accomplished by using two WizLans (see next page). These two

components are used to convert Ethernet to a fiber optic signal and vice versa.

The Ethernet signal will be converted to fiber optic signal in the amplifier module and sent via the

fiber optic cables to the second converter located next to the remote Ethernet connection (located in

the communication room of the building).

The following steps should be used to connecting the access point to the Ethernet:

1. The Ethernet to fiber optic converter can be mounted on the wall. Use two screws to

connect the WizLAN (Ethernet to fiber optic converted) to the wall.

2. Connect the fiber optic cables to the WizLAN.

3. Connect the WizLAN to the power adapter. (AC to 5 VDC power supply.)

4. Connect the Ethernet link to the WizLAN.

To Ethernet

Rx

Figure 24: WizLAN Converter

Foxcom Wireless Confidential and Proprietary Information

Document No. 43-93-005-05 X1 43

Page 54

ModuLite Installation Guide OPTICAL AND RF CONNECTIONS

5. Optical and RF Connections

The following sections describe the ModuLite™ optical and RF connections.

• MBU- Modular Base Unit

• MRC- Modular Remote Cabinet

5.1. Modular Base Unit (MBU)

The MBU can be considered as main Hub connected to each specific service.

There are two set-up options for the MBU:

• BTS/RBS with one port

• BTS/RBS with two ports

Foxcom Wireless Confidential and Proprietary Information

Document No. 43-93-005-05 y 44

Page 55

ModuLite™ Installation Guide OPTICAL AND RF CONNECTIONS

5.1.1. BTS/RBS with one port

1. BTS/RBS must be connected to a duplexer (standard), via 50Ω (RG223) coax cable.

2. The downlink port is connected through attenuators to the designated input of the Modular

Base Unit, according to the service and required input power.

3. When more than one ModuLite™ Base 4 Unit is used to the same service, splitters are

required to connect to the other Modular Base Unit inputs from the same service.

4. The uplink from the Modular Base Unit will only combine the required ports and connected to

the duplexer uplink port via 50Ω (RF 223) coax cable.

5. Connect the fiber optic cables from the Modular Base Unit to the MRC’s through the patch

panel cabinet.

6. Connect the power supply to the units locally or remote, according to power design planning.

Note

All Coax cables are male-to-male 50Ω.

Attenuator

Duplexer

ModuLite

BTS

Base 4 Unit

Interface Box

Figure 25: Example: One port BTS/RBS connected to 1 MBU 4 ports

2way

ModuLite

Base 8 Unit

2way

BTS

Duplexer

Attenuator

Interface Box

Foxcom Wireless Confidential and Proprietary Information

Document No. 43-93-005-05 X1 45

Page 56

ModuLite Installation Guide OPTICAL AND RF CONNECTIONS

Figure 26: Example - One port BTS/RBS connected to 1 MBU 8 ports

5.1.2. BTS/RBS with two ports

1. The BTS/RBS downlink port should be connected via a 50Ω (RG223) coax cable to the

corresponding Modular Base Unit input via an attenuator.

2. The downlink coax cable coming from the BTS/RBS should be split using splitters to all

Modular Base Unit input ports (split according to need).

3. The input power for each Modular Base Unit should be calculated to meet the product

specifications according to each service.

4. For the uplink, only necessary ports will be combined and connected to the BTS/RBS

uplink port with suitable combiner. All unused ports should be terminated with 50Ω load.

Note

All cables are coax jumpers (male to male 50Ω ).

Attenuator

BTS

Interface Box

ModuLite

Base 4 Unit

Figure 27: Example - Two port BTS/RBS connected to 1 MBU 4 ports

Attenuator

BTS

2way

ModuLite

Base 8 Unit

2way

Interface Box

Foxcom Wireless Confidential and Proprietary Information

Document No. 43-93-005-05 y 46

Page 57

ModuLite™ Installation Guide OPTICAL AND RF CONNECTIONS

Figure 28: Example- Two port BTS/RBS connected to 1MBU 8 ports

5.2. Modular Remote Cabinet (MRC)

1. For the downlink, connect the fiber optic cable pigtails from splice box coming from the

Modular Base Unit port to the corresponding Modular Remote Cabinet port (according to

the service).

2. Connect the Modular Remote Cabinet to antennas according to the RF engineers design

using ½” or 3/8” coax cable. (Up to four antennas per MRC).

3. For the uplink, connect the fiber optic cable pigtails from splice box from the Modular

Remote Cabinet to the uplink port that connects to the Modular Base Unit corresponding to

the same service.

4. Connect the power supply to each MRC according to power design planning.

Foxcom Wireless Confidential and Proprietary Information

Document No. 43-93-005-05 X1 47

Page 58

ModuLite Installation Guide ALARM MONITORING

6. Alarm Monitoring

The Modular Base Unit has a 25 pin D-type connector that is connected to 4 dry contact relays

(MB4U). Each of the relays indicates the status of the link between the MBU and one of the

MRC’s. This capability provides the status of the optical communications for each service. The

relay connections on the 25pin D-type connector can be connected directly to the BTS alarm

relays and can be monitored from the remote end.

In order to transmit the ModuLite™ system as a “major alarm”, all dry contact pins need to be

connected in a serial (cascade) formation, for Normally Closed alarm. All dry contacts need to be

connected in parallel formation, for Normally Open alarm.

Note

For further information contact Foxcom Wireless

Table 7: 25 Pin Alarm Pinouts

Pin Type of Alarm Port

1 Dry Contact 4 1

2 Dry Contact 4 2

3 Open Collector 4

4 Dry Contact 1 1

5 Dry Contact 1 2

6 Open Collector 1

7 Dry Contact 2 1

8 Dry Contact 2 2

9 Open Collector 2

10 Dry Contact 3 1

11 Dry Contact 3 2

12 Open Collector 3

13 Dry Contact 8 1

14 Dry Contact 8 2

15 Open Collector 8

16 Dry Contact 5 1

17 Dry Contact 5 2

18 Open Collector 5

19 Dry Contact 6 1

20 Dry Contact 6 2

21 Open Collector 6

22 Dry Contact 7 1

23 Dry Contact 7 2

24 Open Collector 7

25 - -

Foxcom Wireless Confidential and Proprietary Information

Document No. 43-93-005-05 y 48

Page 59

ModuLite™ Installation Guide POWER SUPPLY FOR MODULITE™

2

7. Power Supply for ModuLite™

The power supplies to drive the ModuLite™ can be purchased from Foxcom Wireless. The

power supplies will be installed into a rack or mounted on a wall and will provide power for both

the Modular Base Units and Modular Remote Cabinets.

The example below (Figure 29) depicts a ModuLite™ system consisting of CDMA800,

GSM1800, and GSM Dual Band, with 500W/ 48VDC AC/DC converters providing power for a

total of 1.5A per unit.

Between the AC/DC converters and the units, a circuit breaker (maximum 10A) must be

installed, either in the AC/DC converter or nearby.

MRC 32

MRC 26

2.5mm

Clamping

Connector

MBU 1 MBU 4

2.5mm

2

10A

48VDC

Fuse Fuse

AC/DC

1

110/220

VAC

10A

AC/DC

16mm

48VDC

2

2

110/220

VAC

MRC 13

MRC 7

MRC 6

MRC 1

AC/DC

3

48VDC

Fuse

110/220

VAC

2

2.5mm

2

2.5mm

BASE

STATION

Fuse10A

AC/DC

2

16mm

6

2

16mm

48VDC

10A

110/220

VAC

Figure 29: Example - DC Power Supply in High Rise Installation

Foxcom Wireless Confidential and Proprietary Information

Document No. 43-93-005-05 X1 49

Page 60

ModuLite Installation Guide POWER SUPPLY FOR MODULITE™

The power supply that drives the ModuLite™ system can be purchased from Foxcom Wireless.

Four power supply options are available.

7.1. Option One (Remote Power)

In this option the MBU is connected to the power supply via electrical cables. In order to power

the MRC from the power supply, two copper electrical wires running through the building

(separately from the fiber optic cables) supply power to each MRC in parallel. For this

configuration, electrical power calculations need to be made. This option is shown in Figure 29.

7.2. Option Two (Local Powering)

In this option the power supply type is a standalone configuration. Power for both the MBU and

MRC’s will be supplied separately. In this configuration each unit will be co-located with a

power supply. This will not require running long electrical cables.

7.3. Option Three (Built-In Powering)

In this option the power supply type for the MRC’s is A.C. Each MRC will come with a built-in

power supply source. To power the MBU’s, local D.C. power will be used. This will not require

running long electrical cables.

Table 8: Power Supply Options

Materials Model

Local power supply LPS-150-N-2A

Remote power supply (no redundancy) RPS-200-N-48

Remote power supply (fully redundant) RPS-150-R-48

Remote power supply (fully redundant) RPS-500-R-48

Remote power supply (fully redundant) RPS-1000-R-48

Note

For further information refer to Foxcom Wireless Power Supply manual and Power Supply

Planning Rules.

Foxcom Wireless Confidential and Proprietary Information

Document No. 43-93-005-05 y 50

Page 61

ModuLite™ Installation Guide OPTICAL TEST PROCEDURE

8. Optical Test Procedure

This section describes the methods applied to test fiber optic cable’s optical insertion loss and

return loss.

8.1. Fiber Optic Cable Test

Due to the extended distances that analog signal transmissions travel on cable, the major

challenge is to determine the status of the cable.

In order to determine that the cables are functioning, technical personnel need to perform optical

power tests.

The optical power tests covered in this document are:

• Optical insertion loss measurement test

• Optical return loss measurement test

In order to explain the testing procedures, the terms related to these tests need to be explained.

8.2. Fiber Optic Cable – Terms

Fiber optic cable is produced in a variety of formats with different characteristics. The following

terms define the various aspects of fiber optic cable:

• Fiber optic cable

Jacket

Buffer

Fiber

Optical fiber

•

Core

Clad

Singlemode

Multimode

• Fiber optic connection

Splice

Fusion

Foxcom Wireless Confidential and Proprietary Information

Document No. 43-93-005-05 X1 51

Page 62

ModuLite Installation Guide OPTICAL TEST PROCEDURE

Mechanical

Connector

• Bending Loss

Minimum bending radius

• Coupler

8.2.1. Optical Fiber

Fiber optic cable is described by the amount of fibers contained within.

The cable described by the following terms:

• Glass

• Buffer

• Jacket

GLASS

Glass is the middle fiber in the cable. The data sent over the cable travels through the glass.

BUFFER

The buffer is the plastic coating that covers the fiber optic cable. The buffer protects the glass

from moisture and other damage.

JACKET

The jacket covers the buffer, providing greater protection to the glass.

The fiber consists of:

Core

•

Clad

•

The central part of a fiber is known as the core, and the material surrounding the core is known

as the clad. The clad has a lower index of refraction than the core, allowing light to be

completely reflected off the surface between the core and the clad. As a result, propagated light

remains entirely within the core. The cross-section of the cable is expressed as the core diameter

Foxcom Wireless Confidential and Proprietary Information

Document No. 43-93-005-05 y 52

Page 63

ModuLite™ Installation Guide OPTICAL TEST PROCEDURE

followed by the clad diameter. For example, a 9/125 fiber has a core diameter of 9µm and a clad

diameter of 125µm.

clad

{

core

The cables are available in two different modes, each with different propagation properties:

Property Core Clad Attenuation

clad

{

{

Figure 30: Fiber Optic Cable Structure

9µm 125µm

λ1

λ1

λ2

λ3

Singlemode

Multimode

Multimode

Singlemode

fiber

Multimode fiber

@1310nm

9 125

50 125

9 µm 125 µm

50 µm 125 µm

62.5 µm 125 µm

.38 dB/Km

1 dB/Km

(For illustration only)

Figure 31: Singlemode - Multimode Fibers

Foxcom Wireless Confidential and Proprietary Information

Document No. 43-93-005-05 X1 53

Page 64

ModuLite Installation Guide OPTICAL TEST PROCEDURE

8.2.2. Connecting Fiber Optic Cable

The following are needed in order to carry out a fiber optic connection:

• Splice

• Connector

SPLICE

A splice consists of cutting the fiber optic cable across the cable’s diameter and combining the

opening with another fiber optic cable.

A splice can be carried out in the following methods:

Fusion – following the splice, the cables are warmed and the two fiber optic cables are melted

together.

Mechanical – following the splice, a hard connection is made between the two fiber optic

cables.

CONNECTOR

In order to add or connect additional fiber optic cable, a connector is used to make the

connection. There are several types of connectors:

• FC/PC

• SC/PC

• SC/APC (used by ModuLite™)

8.2.3. Fiber Optic Cable Bending Loss

When the cable has bends or interior irregularities, then the optical signal becomes weaker,

known as Bending Loss. The sharper the bend, the higher the loss. Such losses increase the

cable’s attenuation.

Note

When installing fiber optic cable, the minimum bending radius needs to be noted in order to

prevent excessive bending of the cable, causing additional loss.

8.2. 4. Coupler

Foxcom Wireless Confidential and Proprietary Information

Document No. 43-93-005-05 y 54

Page 65

ModuLite™ Installation Guide OPTICAL TEST PROCEDURE

Light from the cable can be split or combined, using a Coupler. Couplers split light with

minimal loss, from one to two fibers or combine light from two fibers into a single fiber.

8.3. Foxcom Wireless System Characteristics

The ModuLite™ system consists of the following characteristics:

• Singlemode fiber

• Wavelength 1310nm

• Fiber Optic Cable Measurement Tests

Cable can be measured through several procedures. This document describes the following tests:

• Optical insertion loss measurement test

• Optical return loss measurement test

These tests are intended to be performed by technical personnel that deal with Foxcom Wireless

systems. Other equipment can be used to perform these tests, however the results have to be the

same as will appear in the fiber optic cable test results table (Table 9) at the end of this

document.

The insertion loss measurement determines whether the optical signal power traveling the cable

length is strong enough to be received by the photo diode, in the receiver. Following the

completion of the insertion loss test, the return loss test determines the optical signal power that

returns to the laser. The return power affects the laser, changing the laser’s base current.

8.3.1. Test Equipment

In order to perform these tests, the following equipment is necessary:

• Light source (for wavelength 1310nm , 0dbm)

• Optical power meter

• Optical coupler (hosed and connectorized)

• Fiber optic jumper

• Adapter parts for the cable connectors

For information about equipment suppliers, contact Foxcom Wireless.

Foxcom Wireless Confidential and Proprietary Information

Document No. 43-93-005-05 X1 55

Page 66

ModuLite Installation Guide OPTICAL TEST PROCEDURE

8.4. Optical Insertion Loss Measurement Test

The optical insertion loss measurement tests the attenuation of the cable. The insertion loss’

value should be minimal and remain in scale to 0.4dB/Km.

The insertion loss measurement can be performed in two methods:

q

Two point test

q

Single point test

8.4. 1. Method #1: Two Point Test

Connection description: Light source connected at one end of the cable and an optical power

meter at the other end.

Light

source

Optical

power

meter

Figure 32: Two Point Test

1. Connect light source directly to the optical power meter.

2. Measure light source signal power, verifying power of 0dBm.

3. Connect light source to cable end.

4. Connect optical power meter to cable at other end.

5. Measure light source signal power using the optical power meter.

6. Calculate the difference between two signals (dB):

(Insertion loss)dB = (Light source signal at one end)dBm – (Measured signal at other end)dBm

Foxcom Wireless Confidential and Proprietary Information

Document No. 43-93-005-05 y 56

Page 67

ModuLite™ Installation Guide OPTICAL TEST PROCEDURE

8.4.2. Method #2: Single Point Test

Connection description: This method assumes that there are two parallel fibers on the path to be

tested. Connect fiber jumper at end of the cable being tested to another parallel cable. Connect

the light source, optical power meter and optical jumper as shown in Figure 33. This

measurement can test two cables simultaneously.

Light

source

Optical

power

meter

Connector

Fiber optic jumper

Figure 33: Single Point Test

1. Use optic jumper to connect the two cables.

2. Connect light source directly to the optical power meter.

3. Measure the power of light source signal , verify power of 0dBm.

4. Connect a light source and optical power meter to one end of each cable.

5. Measure the power of the signal.

6. Calculate the difference between the two signals in dB:

(Insertion loss)dB =(Light source signal)dBm– (Measure signal)dBm

8.4.3. Other Test Equipment

The optical insertion loss measurement test can be performed with more sophisticated

measurement equipment.

For information on other types of test equipment contact Foxcom Wireless.

Foxcom Wireless Confidential and Proprietary Information

Document No. 43-93-005-05 X1 57

Page 68

ModuLite Installation Guide OPTICAL TEST PROCEDURE

8.5. Optical Return Loss Measurement Test

Connection description: Connect a light source and optical power to the inputs. If the coupler has

one output, connect the tested cable to this output. If the coupler has two outputs make a pigtail

at the second output.

Light

source

Optical

power

meter

Optical Coupler

"Optical Terminator"

1

2

(pigtail)

IN OUT

Figure 34: Optical Return Loss Measurement

8.5.1. Measurement Procedure

Measuring Power Input To Cable Being Tested

• Verify that light source power is at 0dBm.

• Connect a light source to connector #1.

3

Cable Being Tested

4

Connect optical power meter to connector #3.

•

• Measure signal power (P3), power should be approximately –4dBm.

Measuring Coupler Power Loss