Page 1

UM_VE LTE 700 MHz MIMO_709C006202_Rev A00_08OCT10.doc

MobileAccessVE

LTE 700 MHz MIMO

Instant Coverage Solution

User Manual

P/N: 709C006202

REV: A00

Date: OCT 2010

User Manual

Page 2

Preface Material

MobileAccess

8391 Old Courthouse Road, Suite 300, Vienna, VA 22182

Tel: +1(866)436-9266, +1(703)848-0200 TAC: +1(800)787-1266, Fax: +1(703)848-0280

http://www.MobileAccess.com

LTE 700 MHz MobileAccessVE Instant Coverage Solution User Manual II

Page 3

Preface Material

Preface Material

© Copyright 2010, MobileAccess Networks Inc. All Rights Reserved.

This document contains confidential and proprietary information of MobileAccess and may not be copied, transmitted,

stored in a retrieval system or reproduced in any format or media, in whole or in part, without the prior written consent of

MobileAccess. Information contained in this document supersedes any previous manuals, guides, specifications, data

sheets or other information that may have been provided or made available to the user.

This document is provided for informational purposes only, and MobileAccess does not warrant or guarantee the

accuracy, adequacy, quality, validity, completeness or suitability for any purpose of the information contained in this

document. MobileAccess reserves the right to make updates, improvements and enhancements to this document and the

products to which it relates at any time without prior notice to the user. MOBILEACCESS MAKES NO WARRANTIES,

EXPRESS OR IMPLIED, INCLUDING, WITHOUT LIMITATION, THOSE OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE, WITH RESPECT TO THIS DOCUMENT OR ANY INFORMATION CONTAINED HEREIN.

Policy for Warrantee and Repair

MobileAccess tests and inspects all its products to verify their quality and reliability. MobileAccess uses every reasonable

precaution to ensure that each unit meets their declared specifications before shipment. Customers should advise their

incoming inspection, assembly, and test personnel about the precautions required in handling and testing our products.

Many of these precautions can be found in this manual.

The products are covered by the following warranties:

General Warranty

MobileAccess warrants to the original purchaser all standard products sold by MobileAccess to be free of defects in

material and workmanship for one (1) year from date of shipment from MobileAccess. During the warranty period,

MobileAccess will repair or replace any product that MobileAccess proves to be defective. This warranty does not apply to

any product that has been subject to alteration, abuse, improper installation or application, accident, electrical or

environmental over-stress, negligence in use, storage, transportation or handling.

Specific Product Warranty Instructions

All MobileAccess products are warranted against defects in workmanship, materials and construction, and to no further

extent. Any claim for repair or replacement of units found to be defective on incoming inspection by a customer must be

made within (30) days of receipt of shipment, or within (30) days of discovery of a defect within the warranty period.

This warranty is the only warranty made by MobileAccess and is in lieu of all other warranties, expressed or implied.

MobileAccess sales agents or representatives are not authorized to make commitments on warranty returns.

LTE 700 MHz MobileAccessVE Instant Coverage Solution User Manual III

Page 4

Preface Material

Returns

In the event that it is necessary to return any product against above warranty, the following procedure shall be followed:

1. Return authorization is to be received from MobileAccess prior to returning any unit. Advise MobileAccess of the model,

serial number, and discrepancy. The unit may then be forwarded to MobileAccess, transportation prepaid. Devices

returned collect or without authorization may not be accepted.

2. Prior to repair, MobileAccess will advise the customer of our test results and any charges for repairing customer-caused

problems or out-of-warranty conditions etc.

3. Repaired products are warranted for the balance of the original warranty period, or at least 90 days from date of

shipment.

Limitations of Liabilities

MobileAccess's liability on any claim, of any kind, including negligence for any loss or damage arising from, connected

with, or resulting from the purchase order, contract, quotation, or from the performance or breach thereof, or from the

design, manufacture, sale, delivery, installation, inspection, operation or use of any equipment covered by or furnished

under this contact, shall in no case exceed the purchase price of the device which gives rise to the claim.

EXCEPT AS EXPRESSLY PROVIDED HEREIN, MOBILEACCESS MAKES NO WARRANTY, EXPRESSED OR IMPLIED, WITH

RESPECT TO ANY GOODS, PARTS AND SERVICES PROVIDED IN CONNECTION WITH THIS AGREEMENT INCLUDING,

BUT NOT LIMITED TO, THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE.

MOBILEACCESS SHALL NOT BE LIABLE FOR ANY OTHER DAMAGE INCLUDING, BUT NOT LIMITED TO, INDIRECT,

SPECIAL OR CONSEQUENTIAL DAMAGES ARISING OUT OF OR IN CONNECTION WITH FURNISHING OF GOODS, PARTS

AND SERVICE HEREUNDER, OR THE PERFORMANCE, USE OF, OR INABILITY TO USE THE GOODS, PARTS AND SERVICE.

Reporting Defects

The units were inspected before shipment and found to be free of mechanical and electrical defects.

Examine the units for any damage that may have been caused in transit. If damage is discovered, file a claim with the

freight carrier immediately. Notify MobileAccess as soon as possible.

Note: Keep all packing material until you have completed the inspection

Safety Warnings

To comply with FCC RF exposure compliance requirement, adhere to the following warnings:

Warning! The Access Pod with its built-in antenna must be installed with a separation distance of at least 20cm from all

persons and must not be located in conjunction with any other antenna.

Warning! The outside antenna must be installed with a separation of at least 20cm from all persons and must not be

located in conjunction with any other antenna.

Warning! Use of this Access Pod with antennas other than those illustrated could be hazardous. Before using other

antennas, contact MobileAccess Support.

Caution: Double pole/neutral fusing (two fuses in the appliance inlet)

Approved Antennas for use with the MobileAccessVE Solution

The gain of external antennas connected to the VAPs should not exceed 10 dBi.

Compliance with RF Safety Requirements

MobileAccess products have no inherent significant RF radiation.

The RF level on the down link is very low at the downlink ports. Therefore, there is no dangerous RF radiation when the

antenna is not connected.

LTE 700 MHz MobileAccessVE Instant Coverage Solution User Manual IV

Page 5

Certification and Compliance to Standards

Category

Standards

Safety:

IEC 60950-1: 2003; UL-60950-1:2003; CAN/CSA – C22.2 No 60950-1-03

EMC:

47CFR 15.109 FCC Part 15

Radio:

FCC Part 27

ISO 9001

2000 and ISO 13485: 2003

Preface Material

LTE 700 MHz MobileAccessVE Instant Coverage Solution User Manual V

Page 6

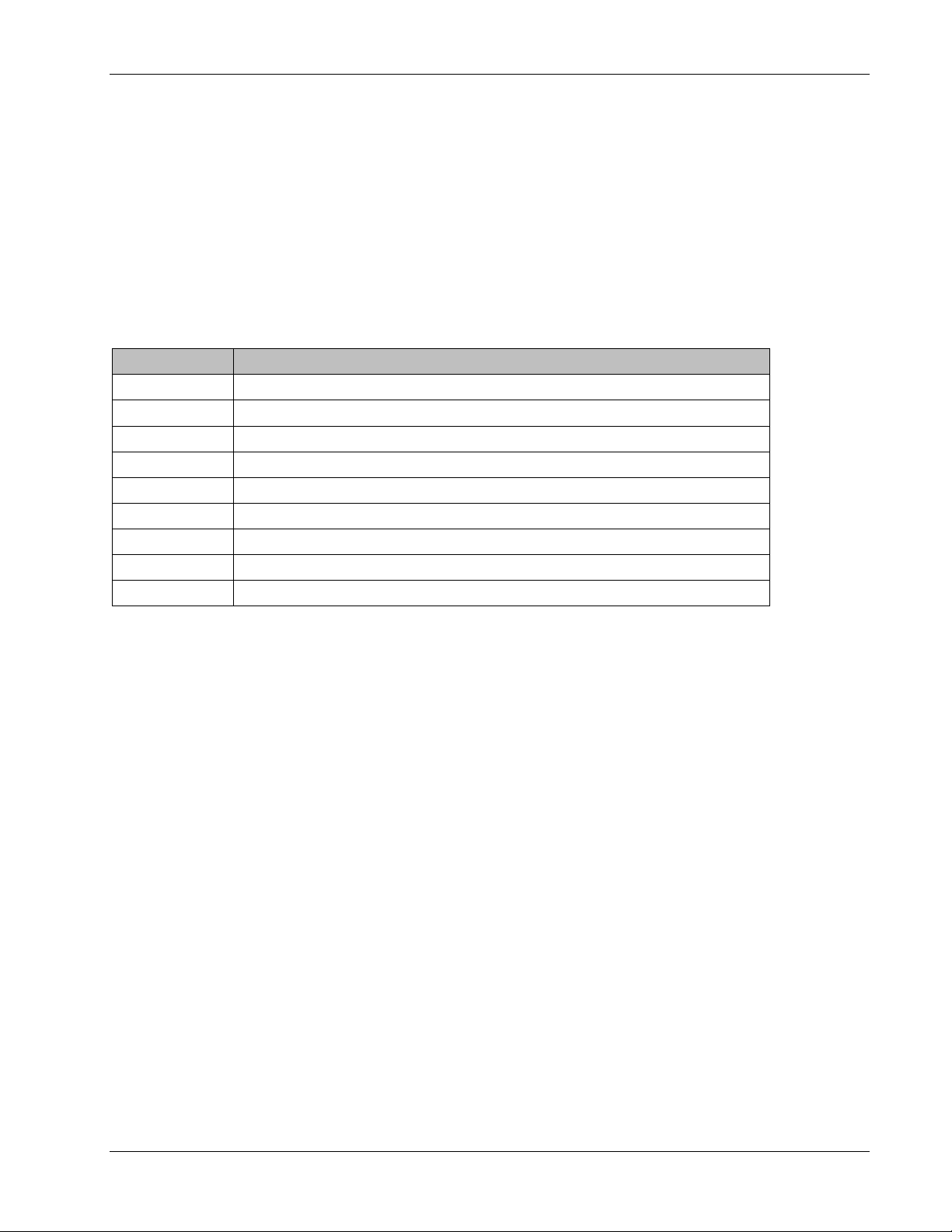

About This Guide

Abbreviation

Description

LTE

Long Term Evolution

MIMO

Multiple Input Multiple Output

PoE

Power Over Ethernet

PSE

Power Sourcing Equipment

SME

Small / Medium Enterprise

STP

Shielded Twisted Pair

UTP

Unshielded Twisted Pair

VAP

VE Access Pod

VCU

VE Control Unit

This guide provides essential product functionality with all the information necessary for proper

installation and configuration of the MobileAccessVE system.

List of Acronyms

Preface Material

LTE 700 MHz MobileAccessVE Instant Coverage Solution User Manual VI

Page 7

Table of Contents

1 Overview ............................................................................................................................. 1

1.1 Key Features and Capabilities ....................................................................................................... 2

1.2 System Architecture ..................................................................................................................... 3

1.3 System Elements ......................................................................................................................... 4

1.3.1 VE Control Unit (VCU) ......................................................................................................... 4

1.3.1.1 VCU Front Panel ..................................................................................................... 4

1.3.1.2 VCU Rear Panel ...................................................................................................... 6

1.3.2 VE Access Pod (VAP) .......................................................................................................... 6

1.4 System Monitoring and Management............................................................................................. 8

1.4.1 Integration with an External Fault Management System ........................................................ 8

2 Installation Workflow ......................................................................................................... 9

3 Infrastructure Requirements and Layout Planning ........................................................ 10

3.1 General Information on Location and Connections ....................................................................... 10

3.2 Infrastructure Requirements ....................................................................................................... 11

3.3 Coverage and Installation Planning ............................................................................................. 12

3.3.1 Types of Environments ..................................................................................................... 12

3.3.1.1 Standard Environment .......................................................................................... 13

3.3.1.2 Open Environment ............................................................................................... 13

3.3.1.3 Dense Environment: ............................................................................................. 13

3.3.1.4 Combination of Environments ............................................................................... 13

3.4 Planning VAP Layout .................................................................................................................. 14

3.4.1 RF Coverage Factors ......................................................................................................... 14

3.4.2 Mapping Locations ............................................................................................................ 14

3.4.3 Optional Directional Antennas ........................................................................................... 14

3.4.4 Installation Plan Example .................................................................................................. 15

4 VCU Unit Installation and Provisioning .......................................................................... 17

4.1 VCU Kit Contents ....................................................................................................................... 17

4.2 VCU Physical Installation ............................................................................................................ 18

4.2.1 Master VCU Installation ..................................................................................................... 18

4.2.1.1 Master VCU Alarm Output Connections .................................................................. 19

4.2.2 Slave VCU Installation ....................................................................................................... 20

4.3 Ethernet Cable Connections to VAPs............................................................................................ 21

LTE 700 MHz MobileAccessVE Instant Coverage Solution User Manual VII

Page 8

Table of Contents

4.3.1 Shifting Relevant Ethernet LAN Connections ....................................................................... 21

4.3.2 Operation with LAN utilizing Power over Ethernet (PoE) ...................................................... 23

4.4 Provisioning the VE Control Unit.................................................................................................. 23

4.4.1 Configure the Computer IP Parameters .............................................................................. 23

4.4.2 Provisioning the Master VCU Unit ...................................................................................... 24

4.4.3 Setting RF Parameters ...................................................................................................... 29

4.4.4 Verifying System Operation ............................................................................................... 31

4.4.5 Provisioning the Slave VCUs .............................................................................................. 34

5 VAP Installation and Provisioning .................................................................................. 35

5.1 VAP Installation ......................................................................................................................... 35

5.2 Desk and Wall Mount VAP Installations ....................................................................................... 36

5.2.1 VAP Kit Contents .............................................................................................................. 36

5.2.2 Desk Mount Installation .................................................................................................... 37

5.2.3 Wall Mount Installation ..................................................................................................... 38

5.3 Horizontal Ceiling Mount VAP Installations ................................................................................... 39

5.3.1 VAP Kit Contents .............................................................................................................. 39

5.3.2 Lowered Ceiling Installation .............................................................................................. 40

5.3.3 Concrete/Wood Ceiling Installation .................................................................................... 41

5.3.4 Connecting VAP and Verifying Normal Operation ................................................................ 43

5.4 Vertical Ceiling Mount VAP Installations ....................................................................................... 44

5.4.1 VAP Kit Contents .............................................................................................................. 44

5.4.2 Lowered Ceiling Installation .............................................................................................. 45

5.4.3 Concrete/Wood Ceiling Installation .................................................................................... 47

5.4.4 Connecting VAP and Verifying Normal Operation ................................................................ 49

5.5 Verifying VAP Coverage Area ...................................................................................................... 49

5.6 Naming the VAPs, Verifying Connections and Monitoring .............................................................. 50

5.7 Provisioning the VAPs ................................................................................................................. 50

5.7.1 Verifying Normal VAP Operation ........................................................................................ 50

5.7.2 Naming the VAP ............................................................................................................... 51

6 Navigating the Web Access Application ........................................................................ 52

6.1 Opening a Session and Authentication Levels .............................................................................. 52

6.2 About the MobileAccessVE Web Access Window .......................................................................... 53

6.3 Configuration Tab ...................................................................................................................... 54

6.3.1 Network Topology Tree .................................................................................................... 55

6.3.1.1 Removing Network Element from Baseline ............................................................. 56

6.3.2 Configuration Display Area ................................................................................................ 57

LTE 700 MHz MobileAccessVE Instant Coverage Solution User Manual VIII

Page 9

Table of Contents

6.4 Management Tab ....................................................................................................................... 58

7 VCU Monitoring and Configuration ................................................................................. 59

7.1 Viewing VCU General Information ............................................................................................... 59

7.2 Viewing VCU Alarms ................................................................................................................... 60

7.3 Master VCU RF Parameters ......................................................................................................... 61

8 VAP Monitoring and Configuration ................................................................................. 63

8.1 Viewing VAP General Information ............................................................................................... 63

8.2 Viewing VAP Alarms ................................................................................................................... 64

8.3 VAP RF Parameters .................................................................................................................... 65

9 Administrative Operations............................................................................................... 67

9.1 Changing Password .................................................................................................................... 67

9.2 Retrieving VCU IP Address .......................................................................................................... 68

9.3 IP Settings ................................................................................................................................ 69

9.4 SNMP Configuration Parameters ................................................................................................. 71

9.5 Upgrading (or Downgrading) VCU and VAP Software ................................................................... 72

9.5.1 Upgrading the VAP SW ..................................................................................................... 73

9.5.2 Upgrading the VCU SW ..................................................................................................... 75

10 Troubleshooting ............................................................................................................... 76

10.1 Finding a Specific VAP in the Building .......................................................................................... 76

10.2 Wireless Service is Not Available ................................................................................................. 78

10.3 PoE is Not Working .................................................................................................................... 78

10.4 Ethernet Service is Degraded ...................................................................................................... 79

10.5 No Service from Connected Access Pod ....................................................................................... 79

10.6 VCU Cannot be Monitored via SNMP ............................................................................................ 81

Appendices ............................................................................................................................. 82

Traps ............................................................................................................................................... 82

LTE 700 MHz MobileAccessVE Instant Coverage Solution User Manual IX

Page 10

1 Overview

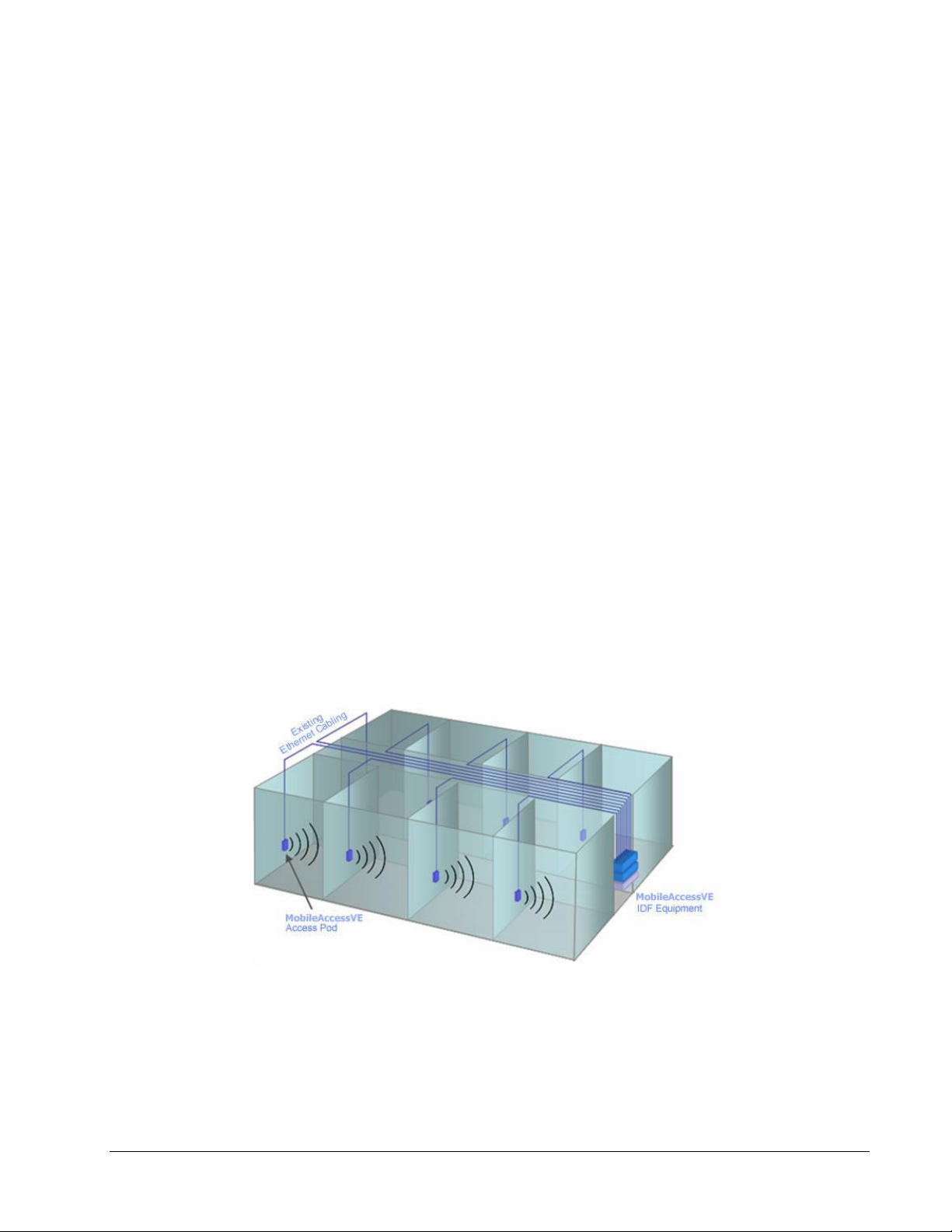

The MobileAccessVE LTE 700 MHz MIMO solution provides enhanced, cost effective, in-building

LTE MIMO coverage for any small-to-large sized enterprise environment. This solution is quickly

and easily deployed using the existing Ethernet cabling infrastructure without affecting existing

LAN services or performance.

The VE solution distributes LTE MIMO service to VE Access Pods (VAPs) installed throughout the

enterprise, which distribute the services via integrated internal antennas (or optional external

antennas), and provide Ethernet connectivity and PoE pass-through to LAN terminals.

MobileAccessVE seamlessly coexists with the Enterprise LAN and does not consume LAN

capacity.

The VAPs are distributed on each floor and plug into existing standard Ethernet jacks. They are

powered via PoE technology and managed via a VE Control Unit (VCU) located in the floor’s

IDF/Telco closet. For site coverage that requires more than one VCU, several VCUs can be

aggregated under a single Master VCU. The Master VCU provides the interface to the carrier’s

capacity sources and management.

This enhanced LTE 700 MHz MIMO coverage solution can be quickly and easily installed with

minimal disturbance to the enterprise. In less than a few hours and with no additional cables

being required, a scalable and flexible solution is provided at a significantly lower total

installation cost.

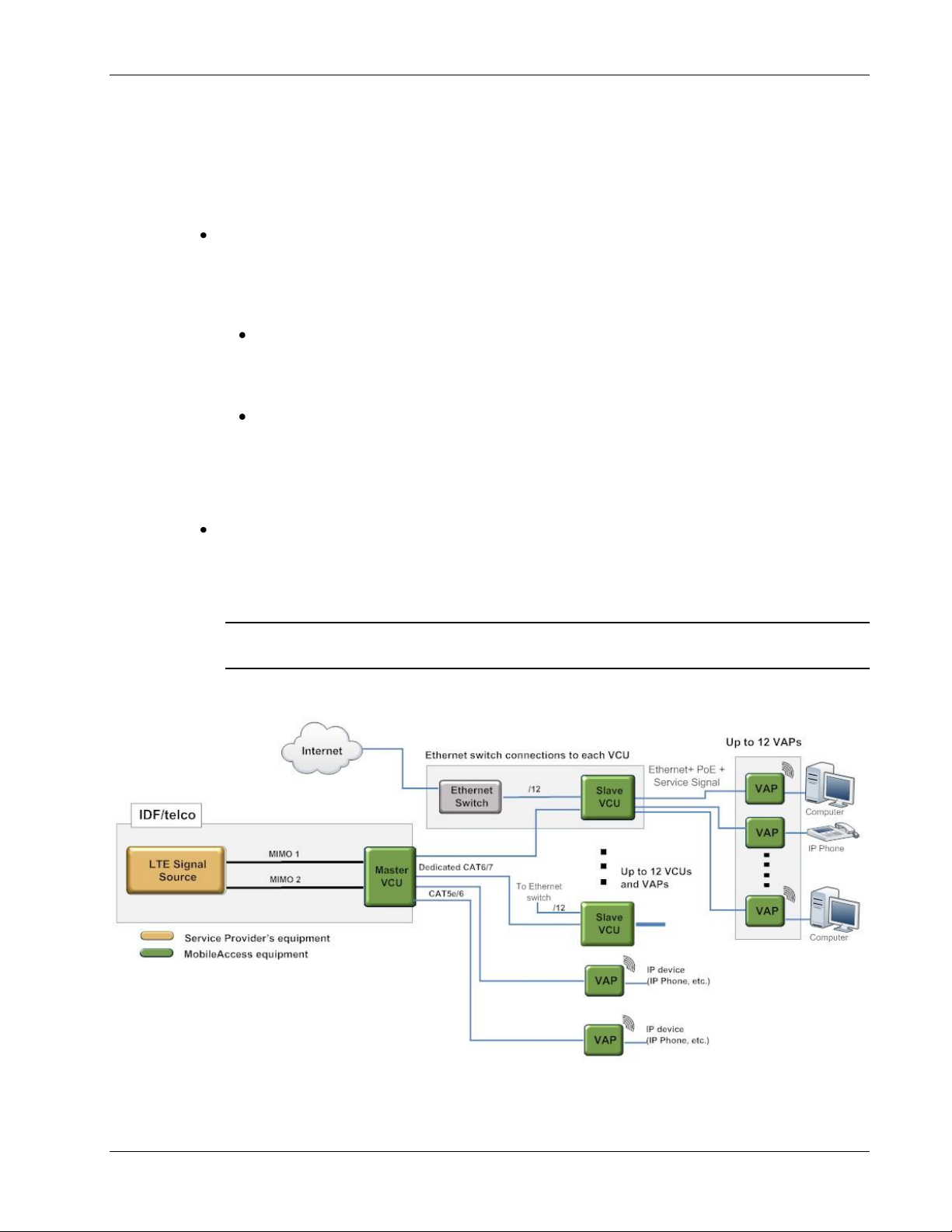

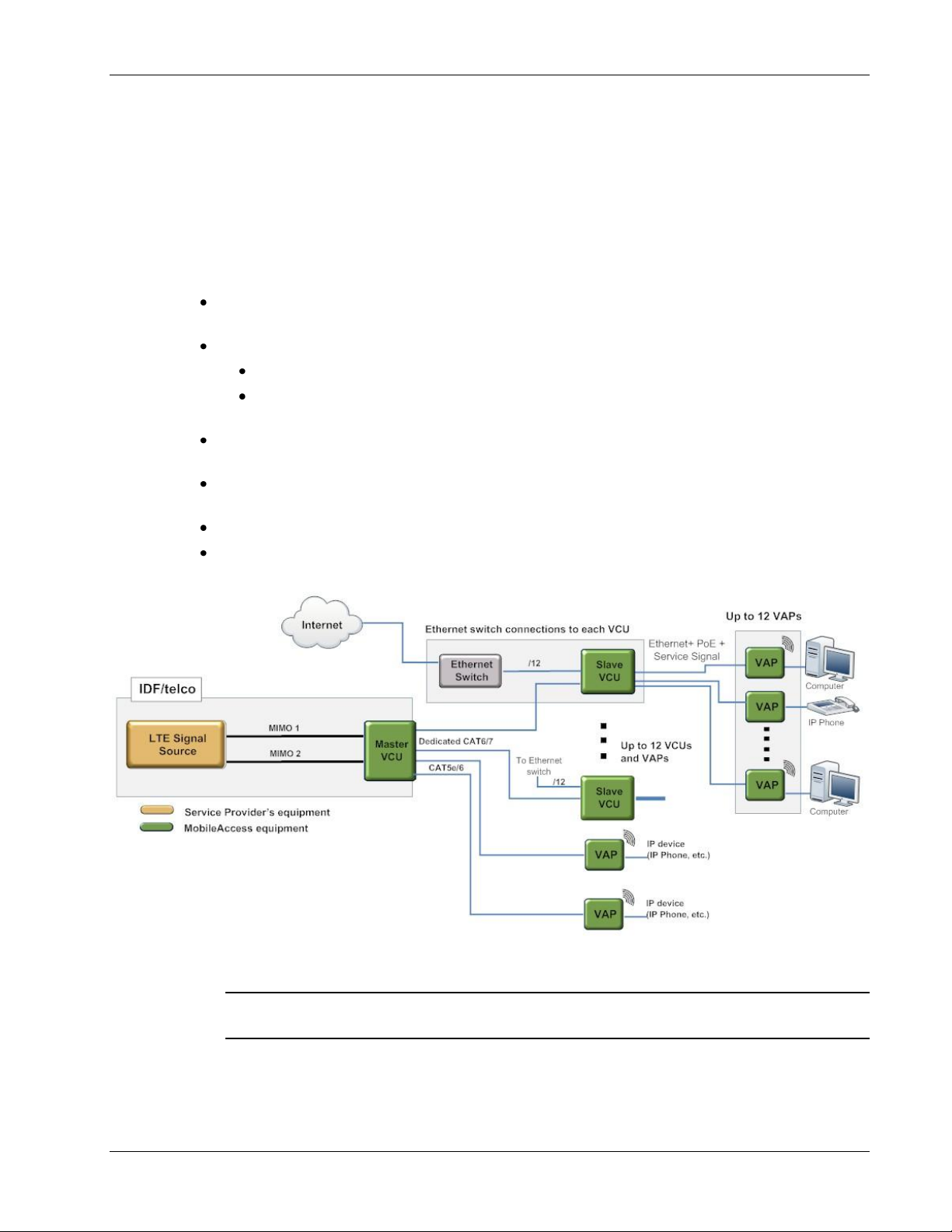

The following figures illustrate

In a single-tier installation the VCU is connected to both the service provider’s equipment and

the Ethernet switch, and distributes Ethernet and mobile services to up to 12 VAPs distributed

over one more adjacent floors.

single-tier

and

multi-tier

VE installations.

Figure 1-1. Single-Tier VE Installation

LTE 700 MHz MobileAccessVE Instant Coverage Solution User Manual 1

Page 11

Overview

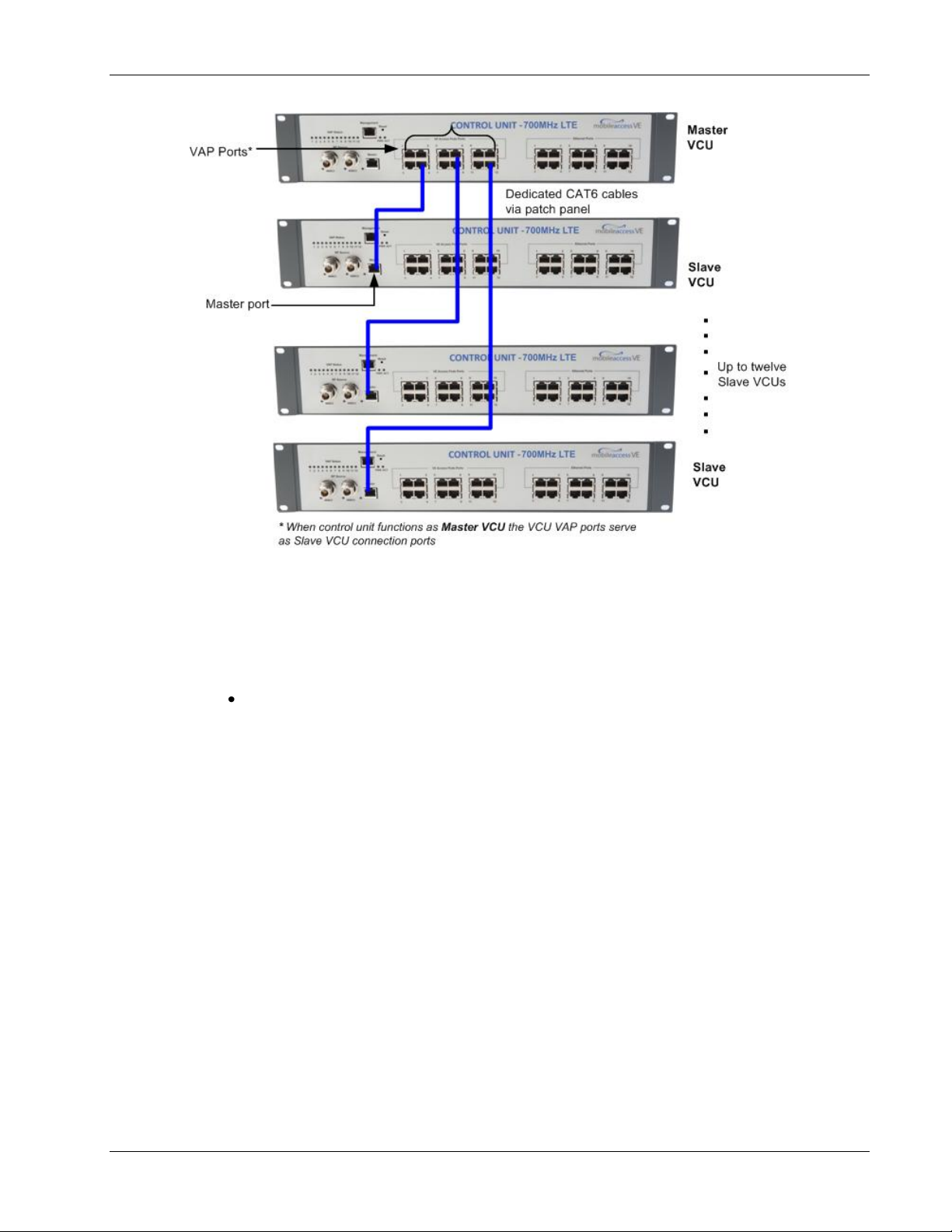

Multi-tier installation includes the Master VCU that supports up to 12 Slave VCUs. In this type of

installation the provider’s services are fed to the Master VCU through which the Slave VCUs are

controlled and managed.

Figure 1-2. Multi-Tier VE Installation

1.1 Key Features and Capabilities

Simple Installation - Deployed in only a few hours, with minimum disturbance to the

enterprise.

VAPs connect over existing CAT-5e/6 cabling infrastructure and existing Ethernet jacks.

VAPs are remotely powered using Power-over-Ethernet (PoE). Local power is not required.

Minimum macro-network impact with low power distributed coverage.

Seamlessly coexists with the Enterprise LAN and does not consume LAN capacity.

Connects to all types of capacity sources, including BTS, picocells, femtocells, and BDAs.

VAPs can easily be relocated for coverage modifications as needed.

Ease of expansion provides “pay as you grow” scalability.

Support of connected IP devices (Wi-Fi APs, IP phones, etc.) with Ethernet/IP pass through

and PoE maximizes placement flexibility.

Remote end-to-end system monitoring, management, and configuration via a single

connection to the master VCU using a standard web browser and SNMP.

Base Line feature that clearly shows VAPs/VCUs where communication has been lost.

LTE 700 MHz MobileAccessVE Instant Coverage Solution User Manual 2

Page 12

1.2 System Architecture

Note: If the Master VCU supports VAPs (in

addition to VCUs), the relevant Ethernet ports

are also connected to an Ethernet switch.

Main Elements - The MobileAccessVE solution is based on the following main elements:

VE Control Unit (VCU) – Provides interface to up to 12 VAPs, and the central interface for

managing the VE deployment. In Master/Slave mode, it can serve to expand the network

coverage with additional VCUs serving as Slaves and a single control point at the Master.

Slave mode is automatically detected when a Slave VCU detects that it is connected to the

Master VCU.

Master VE Control Unit (Master VCU) – Installed in the main IDF/Telco closet, the

Master VCU interfaces with the service provider’s RF capacity sources and provides

secure, central management to up to twelve VCUs and VAP devices in any combination.

The Master and Slave VCUs are connected using

Slave VE Control Unit (Slave VCU) – Installed in the IDF/Telco closet and used to

expand coverage to additional floors. Each VCU interfaces the Master VCU and up to 12

VAPs and 12 Ethernet connections.

VCUs distribute wireless service signals to each VAP along with PoE and where relevant,

Ethernet signals from the Ethernet switch, throughout the existing CAT-5e/6 infrastructure.

dedicated

Overview

CAT-6/7 cables.

VE Access Pod (VAP) – VAPs are pluggable antennas distributed at strategic locations on the

floor to provide Ethernet connection to an IP device and wireless coverage of the service via

integrated internal (or external) antennas. Power to VAPs is provided via PoE from the VCU.

Up to twelve VAPs can be connected to a single VCU using LAN cables (CAT-5e or higher).

Note: When the total number of VAPs in the deployment exceeds 72, consult with

MobileAccess support.

The following figure shows the Multi-tier VE LTE 700 MHz MIMO solution architecture.

LTE 700 MHz MobileAccessVE Instant Coverage Solution User Manual 3

Figure 1-3. VE Multi-Tier Basic Architecture

Page 13

The Master VCU distributes the wireless MIMO services from the service provider’s equipment to

Ethernet Ports 1-12

VAP Ports 1-12

Management

MIMO 2

MIMO 1

Master

Port

the Slave VCUs. At the Slave VCUs, the wireless MIMO services are converged with Ethernet

service and routed to the VAPs via the Ethernet LAN CAT-5e/6 cabling infrastructure.

The VAPs distribute the wireless LTE MIMO service via integrated internal antennas or optional

external antennas and provide Ethernet/IP connectivity, and PoE pass-through, to the connected

appliances such as Wi-Fi APs and IP phones.

1.3 System Elements

This chapter describes the interfaces of the VE Control Units and Access Pods.

1.3.1 VE Control Unit (VCU)

While operating as a Master VCU:

Interfaces to RF source(s) and to VCUs/VAPs.

Converges Wireless services and distribution to Slave VCUs.

Slave VCUs and VAP management and control.

Remote management of the entire deployment.

Overview

While operating as a Slave VCU:

Interfaces to Master VCU.

Converges Wireless services, Ethernet and PoE and interfaces to VAPs.

Management and control of connected VAPs.

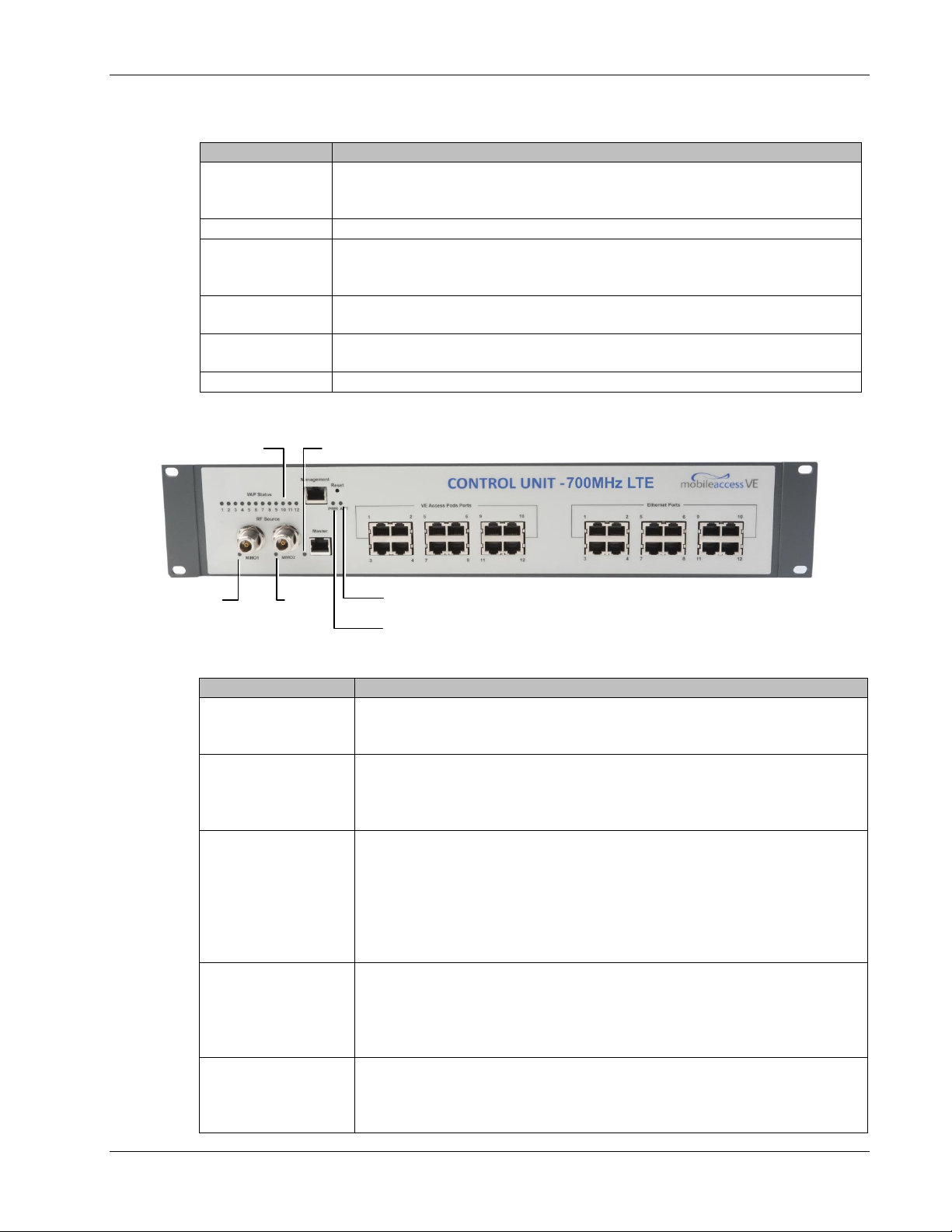

1.3.1.1 VCU Front Panel

The front panel supports the interfaces to the wireless LTE MIMO service (two channels –

corresponding to the two supported TDD MIMO channels) and includes interfaces to VAPs or

Slave VCUs depending on the configuration.

The following provides the front panel ports.

Figure 1-4. VCU Front Panel

LTE 700 MHz MobileAccessVE Instant Coverage Solution User Manual 4

Page 14

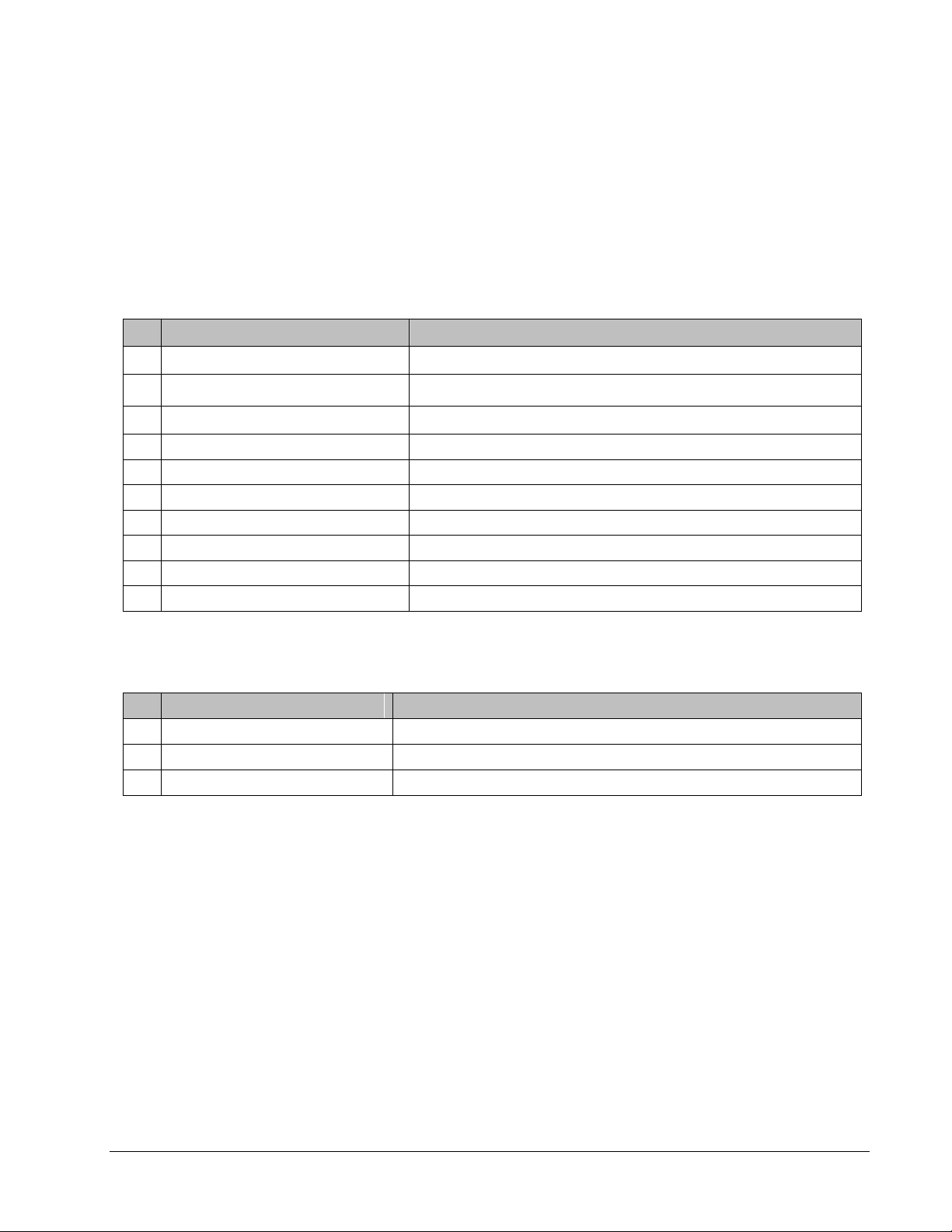

Table 1: VCU Ports Description

Ports

Description

MIMO1

MIMO2

RF connections (two TDD MIMO channels) to the service provider LTE

Signal Source equipment. N-Type female connectors. Coax cables.

Note: When supporting SISO service – only MIMO 1 connector is relevant.

Management

RJ45 web management connection.

VE Access Pod

Ports 1-12

VAP/VCU port connections.

For Master VCU – Connections to Slave VCUs or VAPs.

For Slave VCU – Connections to VAPs.

Ethernet Ports

1-12

Relevant only for Slave VCUs. Ethernet switch connections.

Master

Used for connecting a Slave VCU to the Master VCU in a multi-tier

deployment. Connects to one of the VAP ports of the Master VCU.

Reset

N/A in current version.

LED

Description

PWR

Indicates whether the VCU receives power:

Green - Power OK

Disabled - No power received by VCU

ACT

VCU activity LED:

Solid Green – During initialization

Blinking Green – Normal system operation

Fast Blinking Green – User activated

VCU Identify

on this VCU

VAP Status (One LED

per Port)

Indicates the status of the

corresponding

unit (VAP or VCU):

Blinking Green – Unit is initializing

Solid Green – Normal operation of unit

Solid Orange – Unit is faulty, or unmanaged. This can be due to

mismatch type, VoIP phone, etc.

Fast Blinking Green – User invoked “Identify” command on the unit

Off – No VAP or VCU connected to this port.

MIMO (One LED per

Channel)

Indicates the status of connected RF capacity source:

Green – Master VCU only. Normal RF level

Orange – Master VCU only. RF level is either too low, too

high, or service has been turned off by the user.

Off – VCU is Slave.

Master

Indicates the status of the connection to the Master VCU:

Off – Master mode (not connected to VCU)

Blinking Green – During Attachment process with Master VCU

Solid green – Slave (IF-IF) mode and connected to Master

PWR LED

ACT LED

VAP (1-12) Status LEDs

Master LED

MIMO1

LED

MIMO2

LED

The following provides a description of the front panel LEDs.

Overview

Table 2: VCU LEDs Description

LTE 700 MHz MobileAccessVE Instant Coverage Solution User Manual 5

Page 15

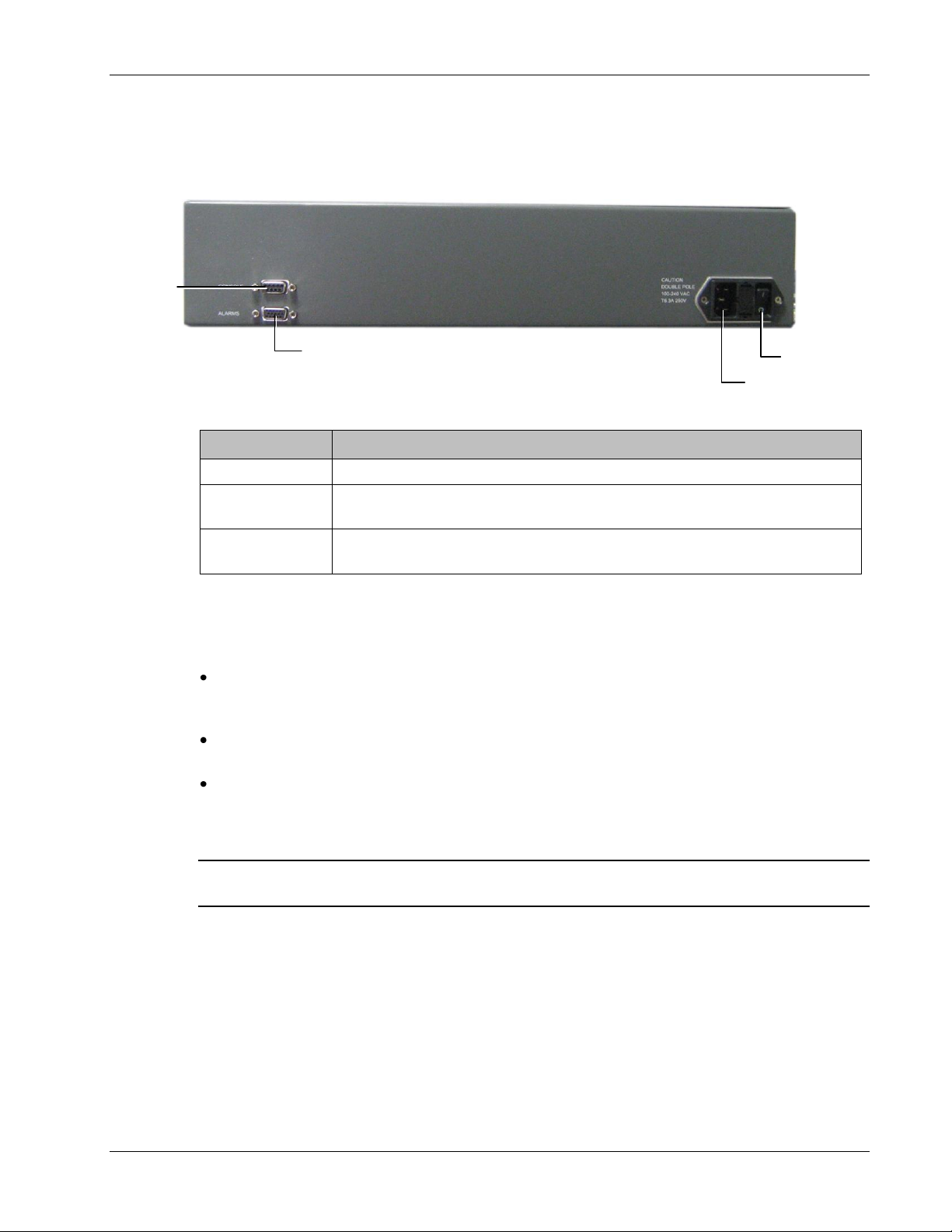

1.3.1.2 VCU Rear Panel

Connector

Description

Console

RS232 local connection for service personnel (D-Type 9)

Alarms

AUX alarms connections(See section 4.2.1.1).

In Master/Slave

configuration - relevant only for Master VCU.

Power Input

Standard 3-pins AC power connector equipped with an ON/OFF switch.

90-264V AC, 47-63 Hz AC; 350W power consumption maximum.

PWR On/Off

Switch

AC Connector

AUX Alarms

Console

Connector

The rear panel includes the following: power switch, AC input, AUX alarms, and service

personnel connections.

Table 3: VCU Rear Panel Description

Overview

Figure 1-5. VCU Rear Panel

1.3.2 VE Access Pod (VAP)

Each VAP supports:

Two interfaces for external antennas. By default, the VAP is set to transmit through the

external antennas.

RF tab of the VE Web GUI application.

An Ethernet port for physical Ethernet connection to devices such as a computer, IP phone or

Wi-Fi Access Point.

Two LED status indictors

The VAP is provided with brackets for either hanging the device on the wall or placing it on a flat

surface (such as a desk).

Note: Ceiling Mount Kits can be ordered separately. (P/N: Horizontal: AK-CEILING-MT-H or

Vertical: AK-CEILING-MT-V).

Note: Do not change the “External Antenna” option in VAP Config-Service

(See section 8.3).

LTE 700 MHz MobileAccessVE Instant Coverage Solution User Manual 6

Page 16

The following figure shows the desktop VAP.

LED

Description

Power

Solid Green - Power supplied to VAP

Off - No power supplied to VAP

Activity

Off - No power supplied to VAP or Overall Status of VAP is

faulty

Blinking Blue - Power on, VAP is initializing (connecting to VCU)

Solid Blue - Power on, unit operating normally

Fast Blinking Blue - User invoked “Identify” command on corresponding VAP

Blue LED (Activity and

Identify)

Green Led (Power)

External Antenna SMA

Connector

External Antenna SMA

Connector

RJ-45 Connector

to VCU

RJ-45 Connector to LAN

terminal (e.g. computer)

Front View

Rear View

Figure 1-6. VE Access Pod-Front

Overview

Table 4: VAP LEDs

The following figure shows the desktop VAP rear side and the underside view with the CAT-5e/6

patch-cord cable.

Figure 1-7. VE Access Pod-Rear

LTE 700 MHz MobileAccessVE Instant Coverage Solution User Manual 7

Page 17

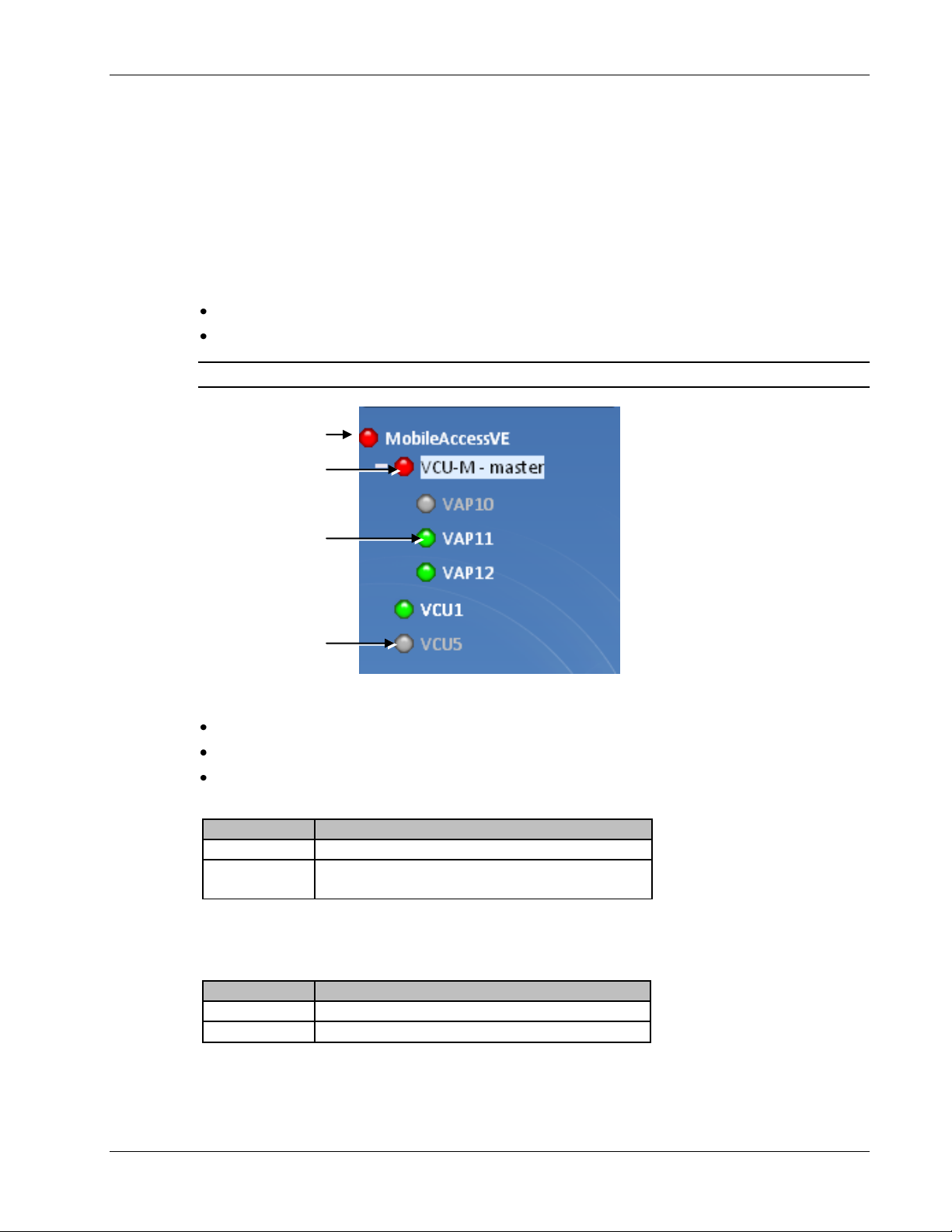

1.4 System Monitoring and Management

The MobileAccessVE system (Master VCU, Slave VCUs, and VAPs) is centrally managed via a

single Web connection to the Master VCU. The basic screen in the GUI is the Config tab, which

enables the user to view the system topology and setup parameters, Control Units, and all

Access Pods connected to the Control Units.

Note: When locally connecting to a specific Slave VCU, only the VAPs connected to this VCU can

be monitored. However, when connected to the Master, the entire deployment can be

monitored.

Overview

1.4.1 Integration with an External Fault Management System

The MobileAccessVE system can be seamlessly integrated into any existing Fault Management

(FM) system that supports SNMP events. The Master VCU generates a SNMP event for each

relevant system alarm and forwards this trap to the pre-configured IP address of the external

Fault Management system.

LTE 700 MHz MobileAccessVE Instant Coverage Solution User Manual 8

Page 18

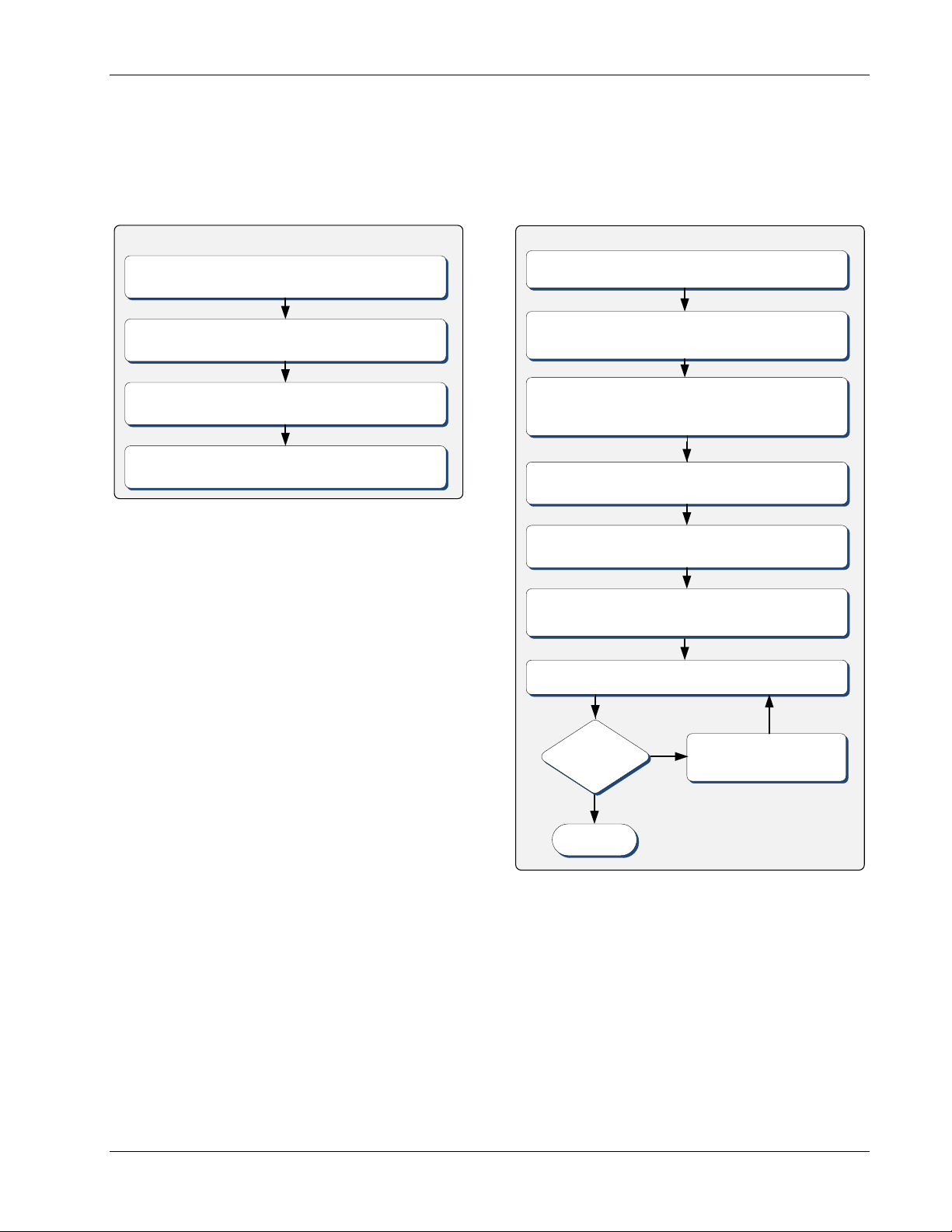

2 Installation Workflow

Verify that all infrastructure requirements are met (includes

verifying that the jacks are wired to the patch panel in the

communication rooms).

Check that Ethernet jacks are available

in all planned VAP locations.

Plan the floor coverage and VAP locations

according to the type/density of the site.

Installation Workflow

Determine the communication rooms to which the VAP

infrastructure is connected (locations for the Slave VCUs).

Install the Master VCU in the IDF/telco shaft.

Complete

Open a local session to the Master VCU and configure the system

parameters (IP, and service parameters: Central Frequency , Max

expected Pin).

Perform a “walk test” and verify coverage around the floor.

Change VAPs locations or

add VAPs

Met

Coverage?

No

Install the Slave VCUs and connect them to the Master VCU (verify

that the VCU/VCH LED is green, and RF LEDs turned OFF).

Install the VAPs and connect them to the Ethernet jacks. Connect

the Ethernet appliance (if exists) to the VAP. Check that the VAP is

operational (Blue LED lit). Check that Ethernet connection is OK.

Yes

Install the RF signal sources, connect them to the master VCU

(through passive interfaces) and check that the RF signals are

received by the VCU (i.e. that the RF LEDs are green).

Connect the VCU

VAP

ports to the patch panel, and

the Ethernet Switch to the VCU

Ethernet

ports.

1. Infrastructure Preparation

2. Installation Procedure

The following figure summarizes the main steps of the installation procedure:

Installation Workflow

LTE 700 MHz MobileAccessVE Instant Coverage Solution User Manual 9

Page 19

Infrastructure Requirements and Layout Planning

Note: If the Master VCU supports VAPs (in

addition to VCUs), the relevant Ethernet ports

are also connected to an Ethernet switch.

3 Infrastructure Requirements and Layout

Planning

3.1 General Information on Location and Connections

Service provider’s RF equipment - macrocell, microcell, picocell, femtocell, BDA, etc. connects

to the VCU through a passive interface.

VCUs:

Master VCU installed at the main IDF/Telco cabinet and connected to all VCUs.

Slave VCUs installed at the IDF/Telco cabinet of each covered floor and connected to the

Master VCU, the Ethernet switch, and the VAPs through the cabling patch panel.

Wireless service signals from Master VCU to VCUs – Routed through dedicated Ethernet CAT-

6/7 cabling.

Wireless service signals from VCUs to the VAPs – Routed through existing Ethernet CAT-5e/6

cabling infrastructure.

VAP location and mounting. Connection to existing Ethernet jack and external antennas.

VAP power source - No power connections required. VAPs are power fed from VCU using PoE

(Power over Ethernet) technology.

Note: connecting both VAPs and slave VCUs simultaneously to the master VCU is supported

for VE networks running SW version 2.6 and above.

LTE 700 MHz MobileAccessVE Instant Coverage Solution User Manual 10

Figure 3-1. VE Multi-Tier Basic Architecture

Page 20

3.2 Infrastructure Requirements

Ethernet standards specify that the maximum distance between an Ethernet switch and an

appliance (computer, WLAN AP, etc) should not exceed 100m (300ft). Therefore, when VE

shares the IT LAN, the maximum distance for a given cable run cannot be longer than 100m

(300ft) between the Ethernet switch and appliance, including all patch cords (from switch to

VCU, from VCU to patch panel, from RJ-45 outlet to VAP, and from VAP to appliance).

Typically the horizontal cabling system will be connected to patch-panels in the communication

rooms. The entire cabling system, including the patch panels and patch cords, should adhere to

the CAT-5e/6 standard. Specifically all pairs of the CAT-5e cable should be wired in the patch

panels and patch cords.

1. IDF/Telco closet space for one or more VCUs depending on the number and locations of the

installed VCUs: (48.3cm x 51.3cm x 8.88cm) per VCU.

Note: When planning the IDF/Telco shaft, take the RF equipment (picocell/microcell or BDA)

and the VCU into consideration.

2. 350 Watts of AC power to the VCU IDF/Telco closet.

Infrastructure Requirements and Layout Planning

3. Building infrastructure:

CAT-5e/6 cabling, Shielded Twisted Pair (STP)

24 AWG minimum diameter for CAT-5e cabling

Dedicated CAT-6/7 STP cable from Master VCU to Slave VCUs with run lengths NOT

exceeding 100m (300ft) and no shorter than 10m (33ft).

CAT-5e/6 STP cable from VCU to each VAP with run lengths NOT exceeding 100m

(300ft) and no shorter than 10m (33ft). VAPs can be connected over existing CAT-5e/6

cabling infrastructure and existing Ethernet jacks without affecting the LAN.

Note: Verify with the IT department that the existing cables can support the VE installation.

If available, review the infrastructure documentation to determine cable types and lengths.

If the infrastructure documentation is not available, attempt to visually identify the cable

type. Depending on the cable vendor, the cable type may be listed on the cable sheath. It is

recommended to use a Fluke cable tester to measure the cable length of the most remote

VAPs

.

4. Master VCU Cable Connections:

(2) N-type female, 50 ohm interfaces to carrier equipment

(Up to 12) RJ-45 interfaces to Slave VCUs and/or VAPs

(1) RJ-45 interface to Management

(1) D-Type 9 pins RS-232 interface for local craft

(1) D-Type 15 pins interface for External Alarms (dry contacts)

5. Slave VCU Cable Connections:

(1) RJ-45 interface to Master VCU (Not used in small single-tier deployments)

(12) RJ-45 interfaces to VAPs

(12) RJ-45 interfaces to Ethernet Switch for LAN service

(1) D-Type 9 pins RS-232 interface for local craft

LTE 700 MHz MobileAccessVE Instant Coverage Solution User Manual 11

Page 21

Infrastructure Requirements and Layout Planning

3.3 Coverage and Installation Planning

Note: The following section provides information required for planning the VAP installation on a

single floor. In a multi-tier installation, this procedure is performed for each individual floor.

The maximal coverage area of each VAP is affected by the density and type of environment

being covered. Therefore, it is recommended to determine the location in two phases:

Plan the

Select the

or desk mounted and an option for an external antenna is available.

The supplied services (wireless only or Ethernet and wireless) depend on the jack to which the

VAP is connected:

If the jack supports an active Ethernet connection, the VAP will distribute LAN traffic along

with the wireless service. (See section 4.3).

If the jack is not currently active (not connected to an Ethernet switch), the VAP will distribute

only the wireless services.

This section provides information on coverage criteria in various types of environments (Open,

Standard, Dense and Merged) and provides rules-of-thumb for various installations of the VAPs.

ideal

location of each VAP in order to achieve complete coverage of the floor.

exact

location according to the location feasibility, where each VAP unit may be wall

Note: Section 3.4 provides a detailed example of installation planning in various types of

environment. It is recommended to review this example after reading this section.

3.3.1 Types of Environments

This section describes the different types of installation environments and provides guidelines for

best coverage of each type of space.

The coverage guidelines in this section are conservative “rule of thumb” estimates of RF

coverage per VAP, meant to be used in scenarios in which detailed designs are not performed.

When the coverage layout is designed, the coverage per VAP is expected to increase by up to

33%. Coverage estimates in this section assume 25% overlap between the coverage areas of

neighboring VAPs to ensure robust, full coverage throughout the enterprise with no “dead

zones”.

LTE 700 MHz MobileAccessVE Instant Coverage Solution User Manual 12

Page 22

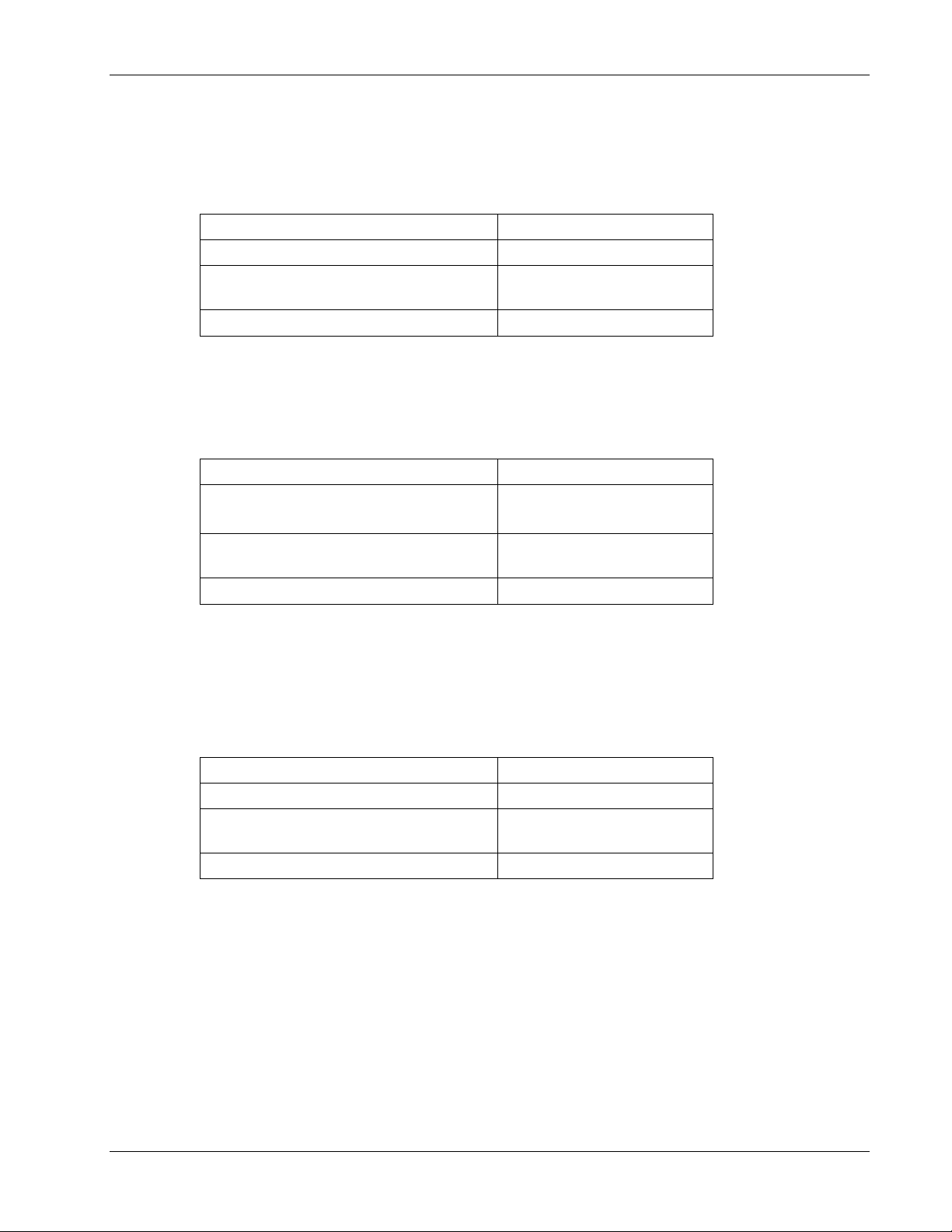

3.3.1.1 Standard Environment

Signal Propagation from VAP

56 feet (19 m)

Recommended Spacing between VAPs

112 feet (38 m)

Recommended Maximum distance of

VAPs from outer walls

56 feet (19 m)

Coverage area per VAP

9,900 sqft (920 sqm)

Signal Propagation from VAP

64 feet (21 m)

Recommend spacing between VAPs

128 feet (42 m)

Recommended maximum distance of

VAPs from outer walls

64 feet (21 m)

Coverage area per VAP

12,750 sqft (1,185 sqm)

Signal Propagation from VAP

41 feet (13.5 m)

Recommended Spacing between VAPs

82 feet (27 m)

Recommended Maximum distance of

VAPs from outer walls

41 feet (13.5 m)

Coverage area per VAP

5,300 sqft (495 sqm)

A traditional office environment with offices, hallways, and scattered cubicles.

Table 5: Standard Environment Installation Distances

3.3.1.2 Open Environment

An environment with minimal obstacles (e.g. walls). This type of space can be a large

conference or meeting room, cubical areas, lobby, or atrium.

Table 6: Open Environment Installation Distances

Infrastructure Requirements and Layout Planning

3.3.1.3 Dense Environment:

A dense environment consists of a relatively large amount of walls, offices, equipment, tall file

cabinets, bookshelves, and other items that could potentially impact the wireless signal.

Examples include dense offices, hospitals, and manufacturing spaces.

Table 7: Dense Environment Installation Distances

3.3.1.4 Combination of Environments

In areas with a combination of environments, place VAPs on the border between the different

environment types, slightly closer to the denser area.

For example, in a cubical area with the outside wall having offices, simply locate the VAPs a little

closer to the outside offices

the floor plan map in section 3.4.3.). To ensure maximal coverage, VAPs can be re-located or

added. If a coverage gap is detected, the VAPs can be re-located until coverage gaps are filled.

to provide coverage through the office walls. (See VAPs 11 and 13 in

LTE 700 MHz MobileAccessVE Instant Coverage Solution User Manual 13

Page 23

3.4 Planning VAP Layout

The following section describes the steps of planning VAPs along the covered floor. At the end of

this section an example of a planning map is provided.

Note: It is highly recommended to use a floor plan when planning the VAPs locations.

3.4.1 RF Coverage Factors

It is important to note the type of factors that can severely impact RF coverage, and should be

avoided:

Metallic Structures such as elevators, high file cabinets, and some moveable metallic

partitions severely degrade RF signals. All efforts should be made to locate VAPs in front of, or

above metallic objects (desks, filing cabinets) to allow the signal to propagate.

Wall Materials such as concrete, tile, and cinderblock, as well as bathroom fixtures typically

have fairly high signal attenuation and should be considered as dense spaces.

Types of Glass that have metallic coatings can affect RF coverage, typically exterior or

mirrored. However this issue is not normally encountered inside a building.

Infrastructure Requirements and Layout Planning

3.4.2 Mapping Locations

To Map the VAP Locations

1. Map out the available Ethernet jack locations and mark all CAT-5e/6 drop locations on the

floor plan map.

TIP: The size and number of the ceiling tiles can be used to measure distances.

2. Using the floor plan and the VAPs coverage guidelines as provided in section 3.4.3, mark

approximately where you would like to place each VAP in the facility.

VAPs may be added or removed as needed for optimal coverage.

3. For each jack being used to connect a VAP, check if the jack is already connected to the

Ethernet switch. .

4. Connect the Ethernet cables corresponding to the selected jacks according to section 4.3.

5. It is also recommended to check the area where each VAP will be installed to ensure the

installation is feasible.

3.4.3 Optional Directional Antennas

Each VAP has an integrated internal antenna that provides isotropic radiation. To prevent

interference and improve coverage, connect directional antennas to VAPs installed near outer

walls. The VAP antenna parameter must be set accordingly via the Web GUI. (See section 8.3).

LTE 700 MHz MobileAccessVE Instant Coverage Solution User Manual 14

Page 24

3.4.4 Installation Plan Example

The following figure shows a floor plan map with all required marks:

Infrastructure Requirements and Layout Planning

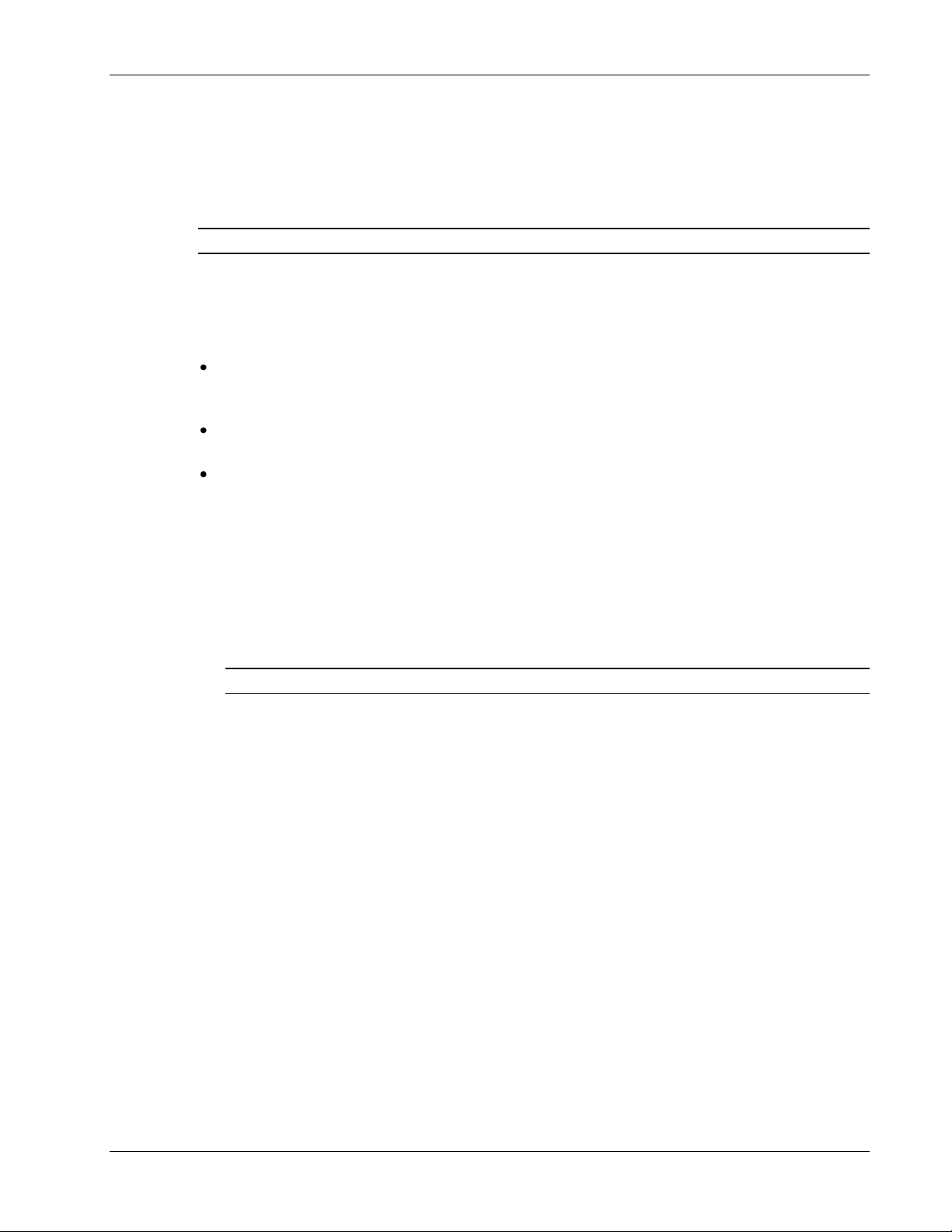

Figure 3-2. Floor Plan Example

Notes:

The red VAP coverage circles have an approximate radius of 41, 56, and 64 foot (13.5, 19,

and 21 meters) for the small, medium, and large circles respectively, which are drawn

according to the guidelines given in section 3.3.1.

VAP 3 is surrounded by the bathroom and stairwell which are considered dense objects and

would reduce coverage in that area by the other VAPs.

VAP 5 is an example of a unit that provides good coverage down the hallways in an Open

Environment.

VAPs 11 and 13 are placed closer to the offices to provide better coverage to them, but on the

open side will actually cover a much greater area. This is why the coverage is larger and

shown here more as an oval than a circle.

The area between VAPs 7 and 14 would probably be the lowest coverage spot in the building

because of the bathrooms and stairwell on either side. If after the system is installed, this

area is still a little low on coverage, a VAP can be added, but it may also be covered by VAP

14.

Note: The plan can be modified at any time by moving the units around or by adding units.

LTE 700 MHz MobileAccessVE Instant Coverage Solution User Manual 15

Page 25

Infrastructure Requirements and Layout Planning

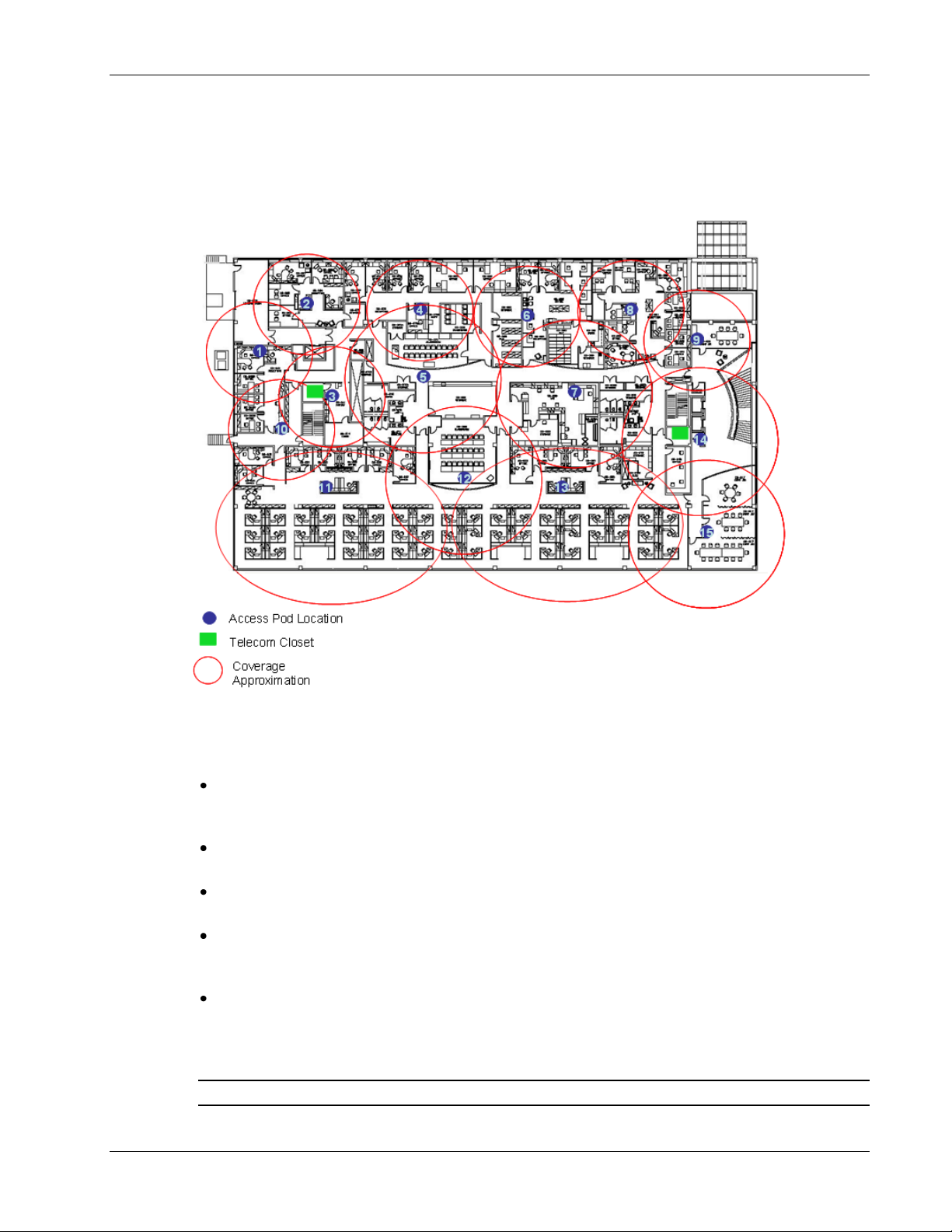

The following figure depicts an actual measured quantified coverage of a floor area planned

according to the above rules.

Figure 3-3. Distributed VAPs propagation, 12dBm output power @ 1.8 GHz

LTE 700 MHz MobileAccessVE Instant Coverage Solution User Manual 16

Page 26

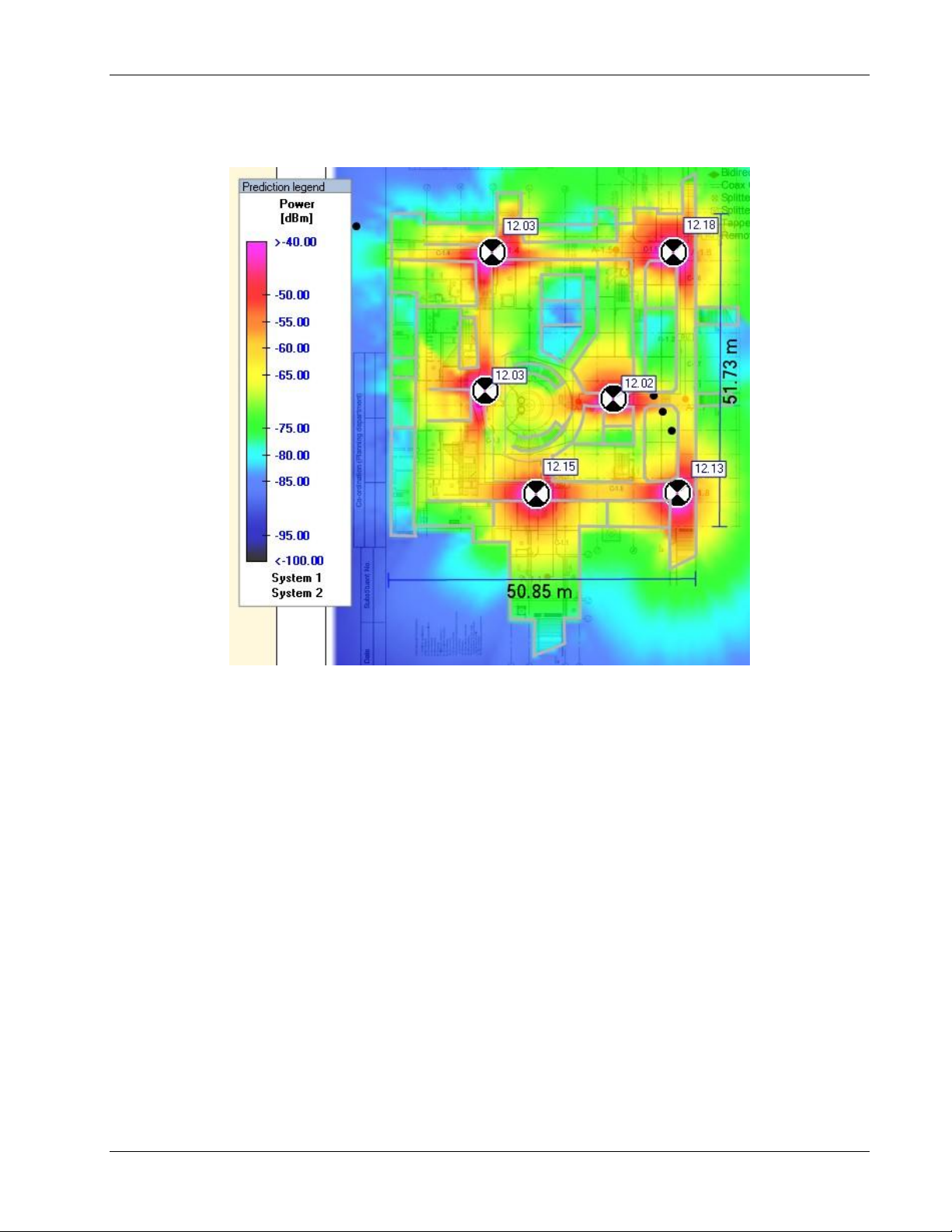

VCU Unit Installation and Provisioning

Description

Unit

VE LTE 700 MHz MIMO Control Unit

(VCU) Kit

Power Cord

VE SW CD

Local Configuration Cable (Crossed RJ45 cable)

Brackets Used to secure the VCU to a

19” rack (Shipped assembled to the

VCU)

4 VCU Unit Installation and Provisioning

This chapter describes the installation and

(VCU) located on each floor.

In addition, this chapter describes the how to shift the relevant Ethernet connections required

for the VAPs.

These steps should only be performed after planning the floor coverage and installation

locations, as described in the previous sections.

4.1 VCU Kit Contents

The VE VCU Kit includes:

Table 8: VCU Kit

basic configuration procedures

for VE Control Units

LTE 700 MHz MobileAccessVE Instant Coverage Solution User Manual 17

Page 27

4.2 VCU Physical Installation

This section describes the physical installation and connections of the Master VCU, Slave VCUs

and the VAP Ethernet connections to the relevant VCUs.

4.2.1 Master VCU Installation

The VE Control Unit can be installed as a Master VCU and control up to (12) Slave VCUs and

VAPs and is installed in the main IDF/Telco closet. This section describes the Master VCU

installation procedures.

Note: When Master VCU only supports Slave VCUs (no VAPs), the control units’ Ethernet Ports

are not relevant and are not in use.

1. Install the Master VCU in the main IDF/Telco closet. The Master VCU can be installed in a

rack, placed on a shelf, or secured using the supplied bracket.

2. Apply power to the Master VCU and verify that the PWR LED is lit. Also verify that the unit

ACT LED completes initialization (blinking light) and shows a solid green light.

VCU Unit Installation and Provisioning

3. Connect (or request the service provider’s service personnel to connect) the provider’s

signal source (macrocell, microcell, BTS, or BDA etc.) to the Master VCU front panel RF

ports (through passive interface). Power on the signal sources.

Note: The RF Source LED (See following figure) of the connected port on the Master VCU

should be lit GREEN, indicating that the Master VCU senses the RF signal from the source at

the expected level (according to Max Expected Pin). After connecting the capacity source, if

the LED remains RED verify that the Max Expected Pin is configured properly and service is

enabled.

4. To connect VCU Slaves to the Master VCU: connect the Master VCU VAP ports to the

Slave VCUs Master ports via the patch-panel that feeds the dedicated CAT-6/7 cabling

system.

5. To connect Auxiliary alarms refer to section 4.2.1.1.

Note: Connector located on the

controller rear panel.

6. According to VAPs layout plan, as explained in section 3.4.2, connect the Ethernet switch

cables. (See section 4.3 for more detailed explanation).

If the requested jack is already in use, disconnect it from the Ethernet switch and re-

connect it to the corresponding Ethernet port in the Slave VCU front panel.

LTE 700 MHz MobileAccessVE Instant Coverage Solution User Manual 18

Page 28

VCU Unit Installation and Provisioning

RF Ports

Note: When functioning as a Master VCU and

supporting only Slaves (no VAPs), the control

units’ Ethernet Ports are not relevant. The

Ethernet ports are only relevant when supporting

mixed mode – Slave VCUs and VAPs.

VAP Ports 1-4; 5-8; 7-12

ACT LED

VAP Status

LEDs

Alarms Port for Auxiliary

Connections

Note: After the Slave VCUs are connected (according to section 4.2.2), verify that that the

Master VCU VAP Status LEDs, which correspond to the connected Slave VCUs complete

initialization (blinking light) and show a solid green light.

4.2.1.1 Master VCU Alarm Output Connections

Note: For Master/Slave VCU configuration, the Alarms are relevant only for the Master VCU.

The auxiliary connections are performed through the Master VCU rear panel Alarms port. See

following figure.

The controller can provide Major and Minor Output Alarms. These alarms can be connected

directly to either the auxiliary input of the Base Station or to any additional dry-contact

application.

A Major Alarm is generated when there is an alarm condition in one or more VCUs, while a Minor

Alarm is generated when there is an alarm condition in one or more of the VAPs.

Note: If only one alarm is required (Minor or Major) an external connection of a wire jumper

between pins 8 and 13 is necessary (Normally closed).

LTE 700 MHz MobileAccessVE Instant Coverage Solution User Manual 19

Page 29

Connect the relevant alarms according to the connector pinout below.

8 – Major Error Signal (Normally closed)

7 – Minor Error Signal (Normally open)

11 – Major COM

12 – Minor COM

15 –Major Error Signal (Normally open)

13 – Minor Error Signal (Normally closed)

11

15

8

Major Alarm

12

7

13

Minor Alarm

PWR LED

Master LED

RF Source LEDs

(One per service)

Table 9. Alarms Connector – used pins

4.2.2 Slave VCU Installation

1. Install the Slave VE Control Unit (VCU) in the IDF/Telco closet corresponding to the floor

being covered. The Slave VCU can be installed in the rack using the supplied bracket. Apply

power to the Slave VCUs and note that the VCU PWR LED is lit. Note that the unit ACT LED

completes initialization (solid light) and shows a blinking green light. See Figure 4-1.

VCU Unit Installation and Provisioning

Figure 4-1. VCU PWR, RF and Master LEDs

2. Connect the Slave VCU front panel Master port to the Master VCU VAP port via the patch

panel using dedicated CAT-6 cables. Verify that the Master LED completes initialization

(blinking light) and shows a solid green light. The (RF) MIMO LEDs (of both services) should

turn OFF.

LTE 700 MHz MobileAccessVE Instant Coverage Solution User Manual 20

Page 30

VCU Unit Installation and Provisioning

Figure 4-2. Master and Slave VCU Connections

3. Connect the Slave VCU VAP ports to the patch-panel that feeds the existing structured CAT5e/6 cabling system.

4. According to VAPs layout plan, as explained in section 3.4.2, connect the Ethernet switch

cables. (See section 4.3 for more detailed explanation).

If the requested jack is already in use, disconnect it from the Ethernet switch and re-

connect it to the corresponding Ethernet port in the Slave VCU front panel.

4.3 Ethernet Cable Connections to VAPs

This section describes the how to perform the relevant Ethernet LAN connections to the VAPs

from the VCUs via the Ethernet switch (See section 4.3.1) and provides a description of the PoE

transferred between the VCU and the VAPs. (See section 4.3.2).

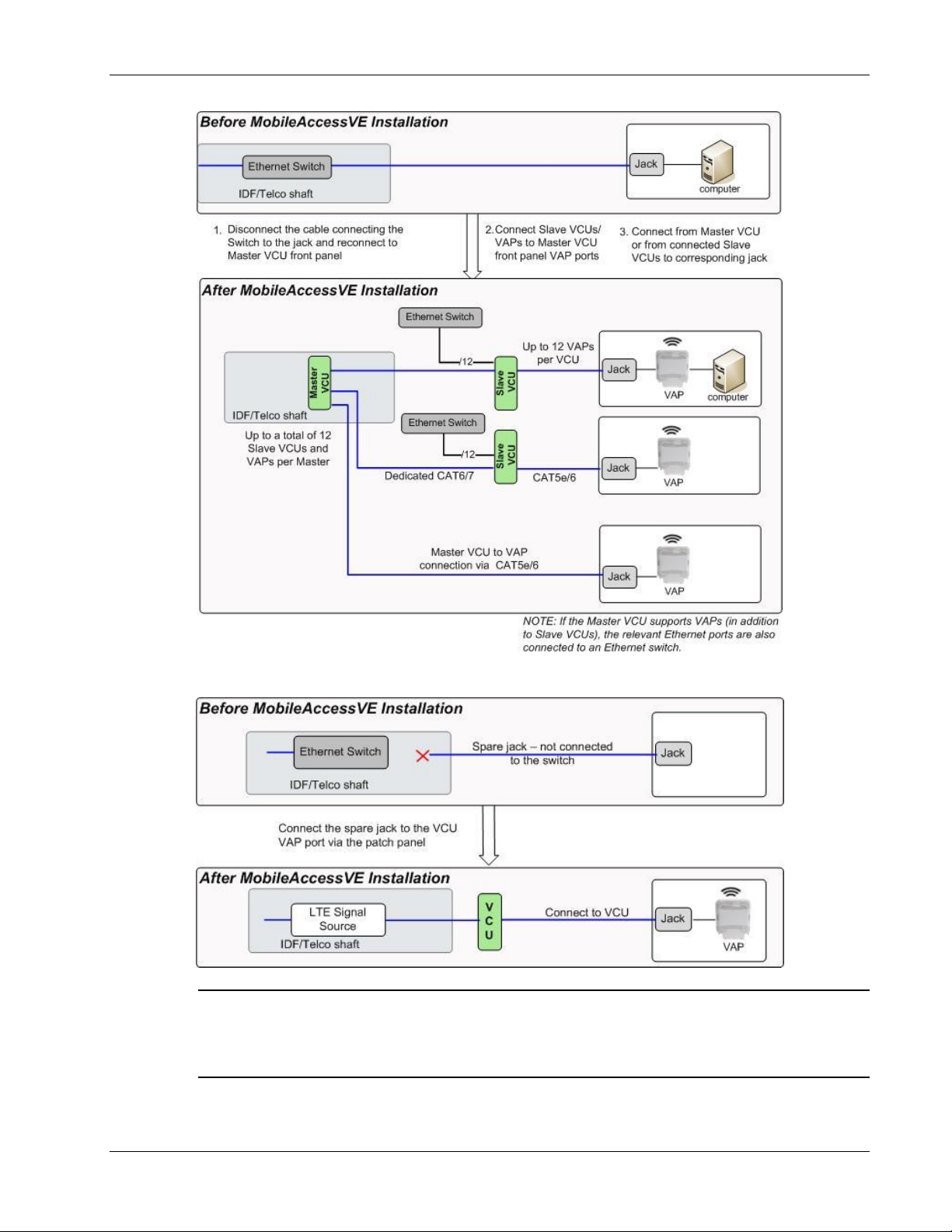

4.3.1 Shifting Relevant Ethernet LAN Connections

For VAPs installed on currently ACTIVE Ethernet ports, shift the relevant Ethernet LAN

connections to the Ethernet ports on the Master or Slave VCU.

LTE 700 MHz MobileAccessVE Instant Coverage Solution User Manual 21

Page 31

VCU Unit Installation and Provisioning

For VAPs installed on currently INACTIVE Ethernet ports, connect as follows.

Note: After the Slave VCUs are installed and connected to the correct ports in the patch panels,

please proceed with the VAP installation as described in chapter 5 . However, it is recommended

to complete the VCU provisioning first (See section 4.4) because when installing the VAPs they

will instantly provide the wireless service and the installer will be able to check the coverage.

LTE 700 MHz MobileAccessVE Instant Coverage Solution User Manual 22

Page 32

VCU Unit Installation and Provisioning

4.3.2 Operation with LAN utilizing Power over Ethernet (PoE)

Power over Ethernet (PoE) is a technology that enables passing electrical power over the

Ethernet cabling. Power can either come from a PoE-enabled Ethernet device (e.g. switch) or

from a “mid-span” device built specifically for "injecting" power into the Ethernet cabling.

PoE can operate over two different pairs in a CAT-5e/6 cable. These two methods are referred to

as “alternative a” and ”alternative b”. All PoE compatible appliances, such as WLAN APs and IP

phones, support both alternatives and automatically detect and use the power on the

appropriate pairs (alternative a or b).

MobileAccessVE supports sharing LAN infrastructures that use either 802.3af PoE or 802.3at

PoE.

In the current release MobileAccessVE supports operation with “alternative a” PoE.

Note: Future enhancements will support coexistence with “alternative b” PoE. If this is currently

required, consult MobileAccess.

4.4 Provisioning the VE Control Unit

This chapter describes how to set the basic parameters required for operation and remote

management of the Master VCU using the Web GUI. The configuration dialogs are fully

described in Chapter 6 .

The Master or Slave mode is automatically detected according to the VCU's physical connection.

If a connection to another VCU is detected, the VCU will be identified as a Slave, otherwise it will

assume the role of a Master.

Notes:

1. The initial configuration of the Master VCU is performed via local connection using a cross-

cable and connecting to VCUs default IP address. After performing the initial configuration

and assigning the Master VCU an IP address, the system can be connected, monitored, and

configured via a remote management connection.

2. The configuration and management of all of the system units (VCUs and VAPs) is performed

via local or remote connection to the Master VCU unit.

4.4.1 Configure the Computer IP Parameters

Configure the computer local LAN connection to operate in the same subnet as the default VCU

IP address. Note that the procedure may vary slightly depending on the operating system

installed on your computer. The following procedure is for Windows XP.

To Configure the Computer’s IP Parameters:

1. Click the Start menu and choose Control Panel.

2. In the Control Panel, click Network and Internet Connections.

3. Click Network Connections and then double-click Local Area Connection.

LTE 700 MHz MobileAccessVE Instant Coverage Solution User Manual 23

Page 33

VCU Unit Installation and Provisioning

The Local Area Connections Properties dialog box appears with the General tab displayed by

default.

4. In the Items list, select “Internet Protocol (TCP*IP)” and click the Properties button.

5. The “Internet Protocol (TCP/IP) Properties” dialog appears.

Note: The Master VCU is supplied with the default IP address 192.168.1.1.

In order to communicate with the unit, it is necessary to assign your computer a

IP

address in the same subnet: 192.168.1.2 to 192.168.1.250.

(i.e. 192.168.1.9 as shown in the example).

Define the subnet mask as shown: 255.255.255.0

6. Click OK.

7. The computer communication parameters are now defined and you can open a session to

the Master VCU and provision the unit.

Static

4.4.2 Provisioning the Master VCU Unit

1. Perform a local connection to the Master VCU unit by connecting the Master VCU front panel

Management port and a laptop computer.

LTE 700 MHz MobileAccessVE Instant Coverage Solution User Manual 24

Page 34

VCU Unit Installation and Provisioning

2. Open a web browser and type the Master VCU IP address in the address bar (Default:

192.168.1.1).

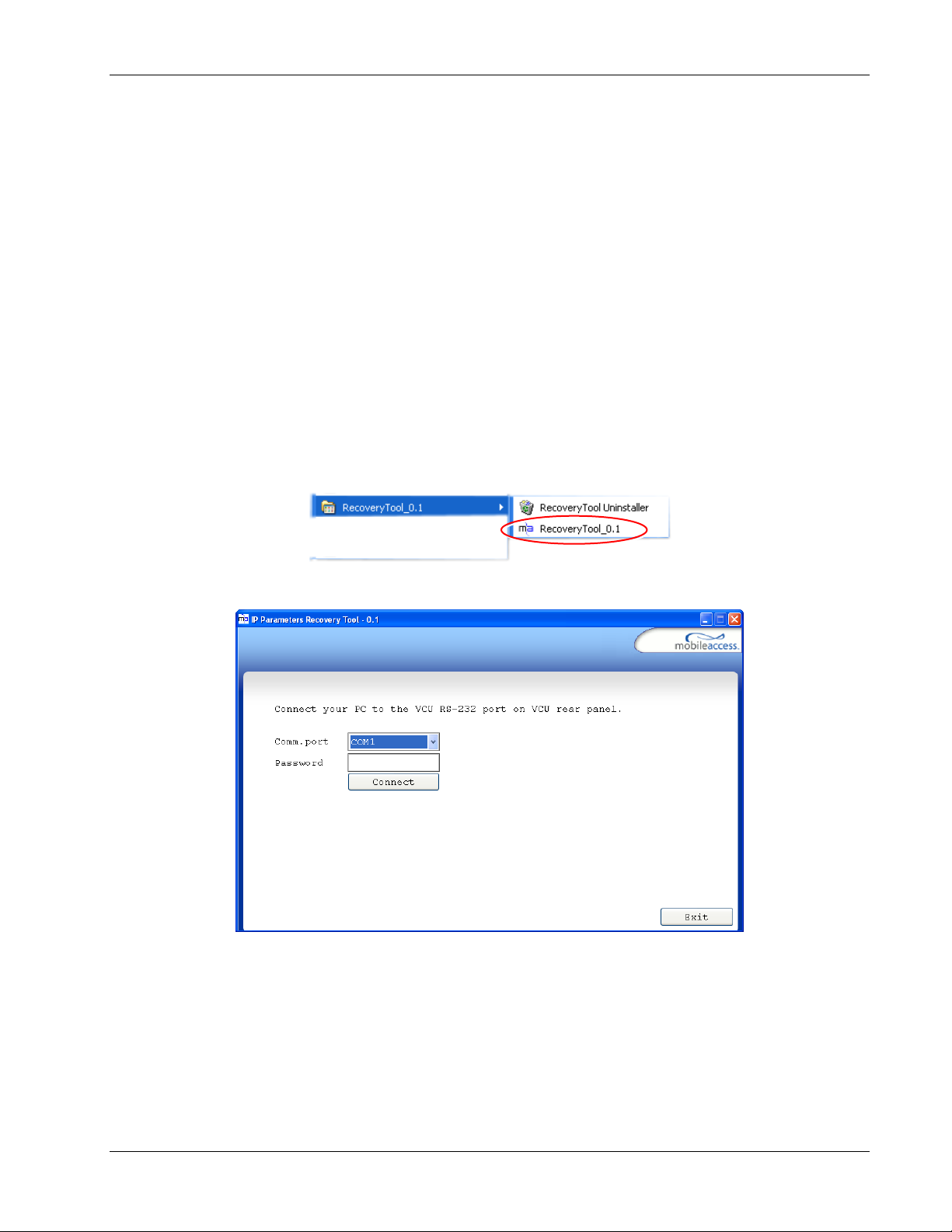

Note: If you have forgotten the VCU IP address and/or want to change it, it can be retrieved

via the IP Recovery Tool application provided on the Setup CD. See 9.2.

The Login window appears.

3. Type the User Name “engineer” and enter the Password “eng”.

The MobileAccessVE Web GUI appears.

LTE 700 MHz MobileAccessVE Instant Coverage Solution User Manual 25

Page 35

VCU Unit Installation and Provisioning

Network

Topology Tree

Sub-tabs

that

correspond

to each

main tab

Main Menu

Bar

Modify Button

IP Settings

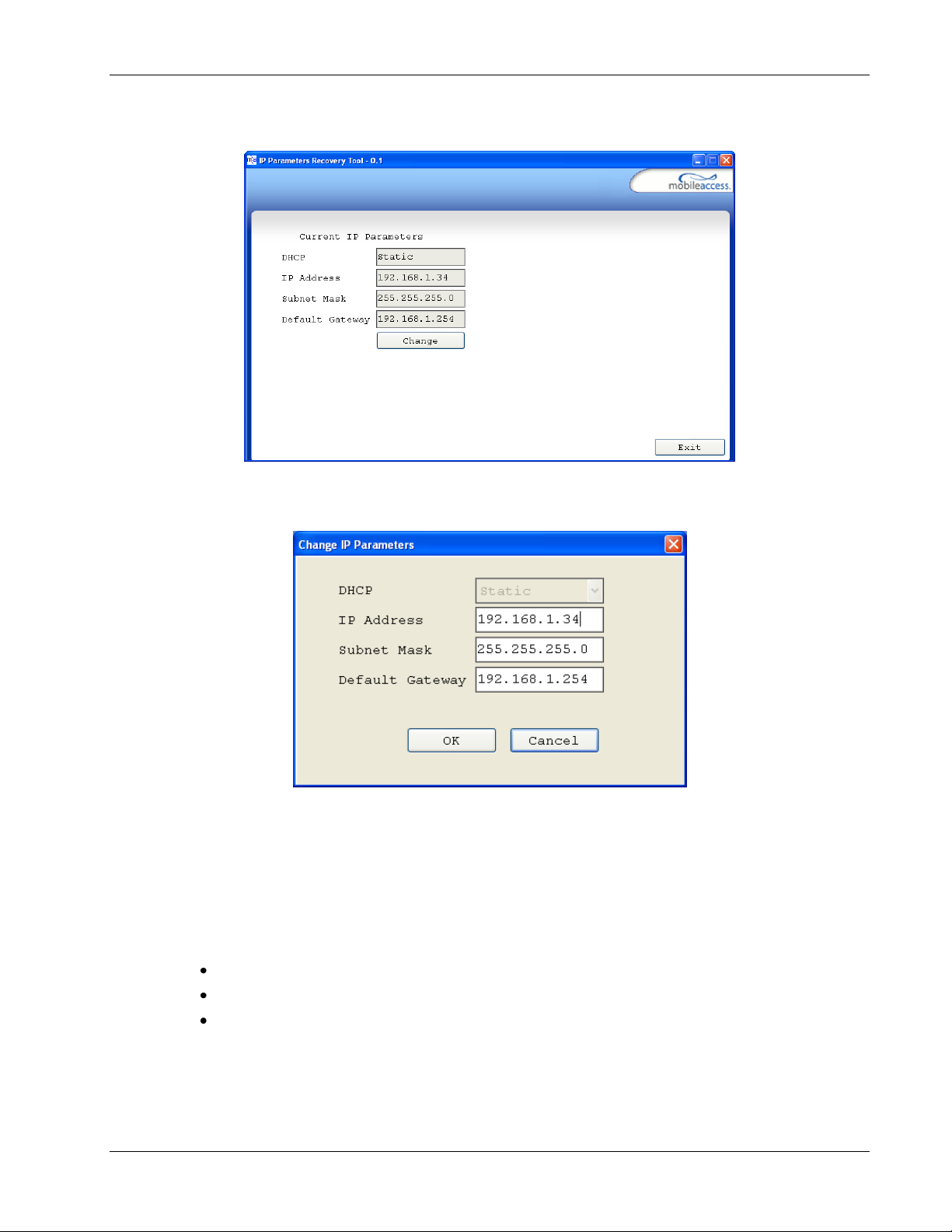

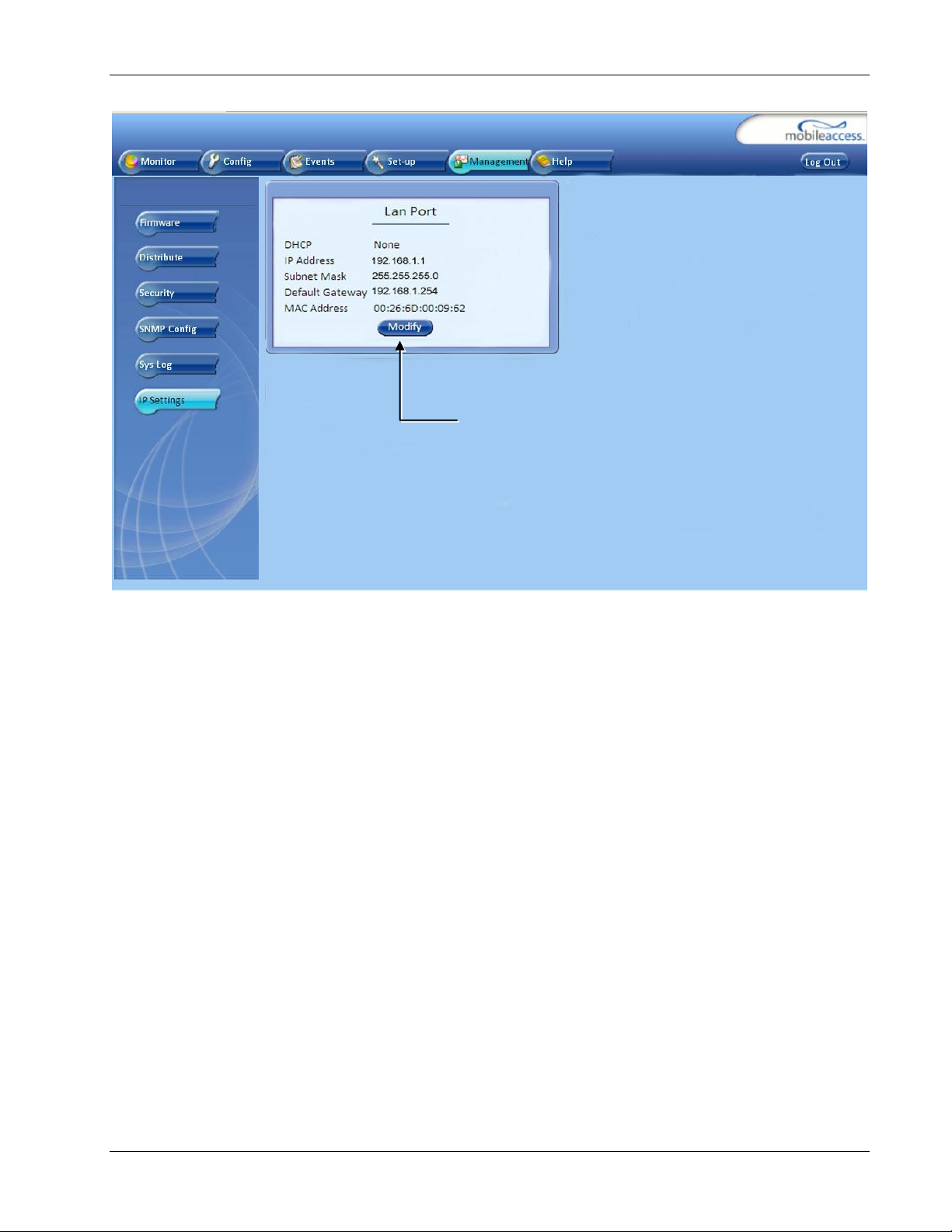

4. Choose the Management tab in the main menu bar and click the IP Settings tab on the

side bar.

Note: See section 6.4 for a description of the Management tab.

5. Click the Modify button to define the STATIC IP Address according to existing LAN.

Note: After the initial IP configuration, the Master VCU can be accessed remotely via

Ethernet.

LTE 700 MHz MobileAccessVE Instant Coverage Solution User Manual 26

Page 36

Set the Static IP address parameter (DHCP is not currently available)

Default definitions:

• The Default IP Address: 192.168.1.1

• The Default Subnet Mask: 255.255.255.0

• The Default Gateway: 192.168.1.254

Click OK.

6. Log out and then log in again with the new IP settings.

VCU Unit Installation and Provisioning

7. Select the Config tab in the main menu bar.

Note: See section 6.3 for a complete description of the Config tab.

LTE 700 MHz MobileAccessVE Instant Coverage Solution User Manual 27

Page 37

VCU Unit Installation and Provisioning

Click Modify

button.

Config Tab

Master VCU

8. The Master VCU appears in the Network Topology Tree as VCU-M. Select the Master VCU

by clicking on it.

9. Before configuring the Master VCU it is recommended to give the unit an identifiable name.

To assign the Master VCU an identifiable name:

Select the Module Info Tab and click the Modify button.

LTE 700 MHz MobileAccessVE Instant Coverage Solution User Manual 28

Page 38

VCU Unit Installation and Provisioning

Type the unit name in the Controller Name dialog and click OK.

numeric characters are allowed.

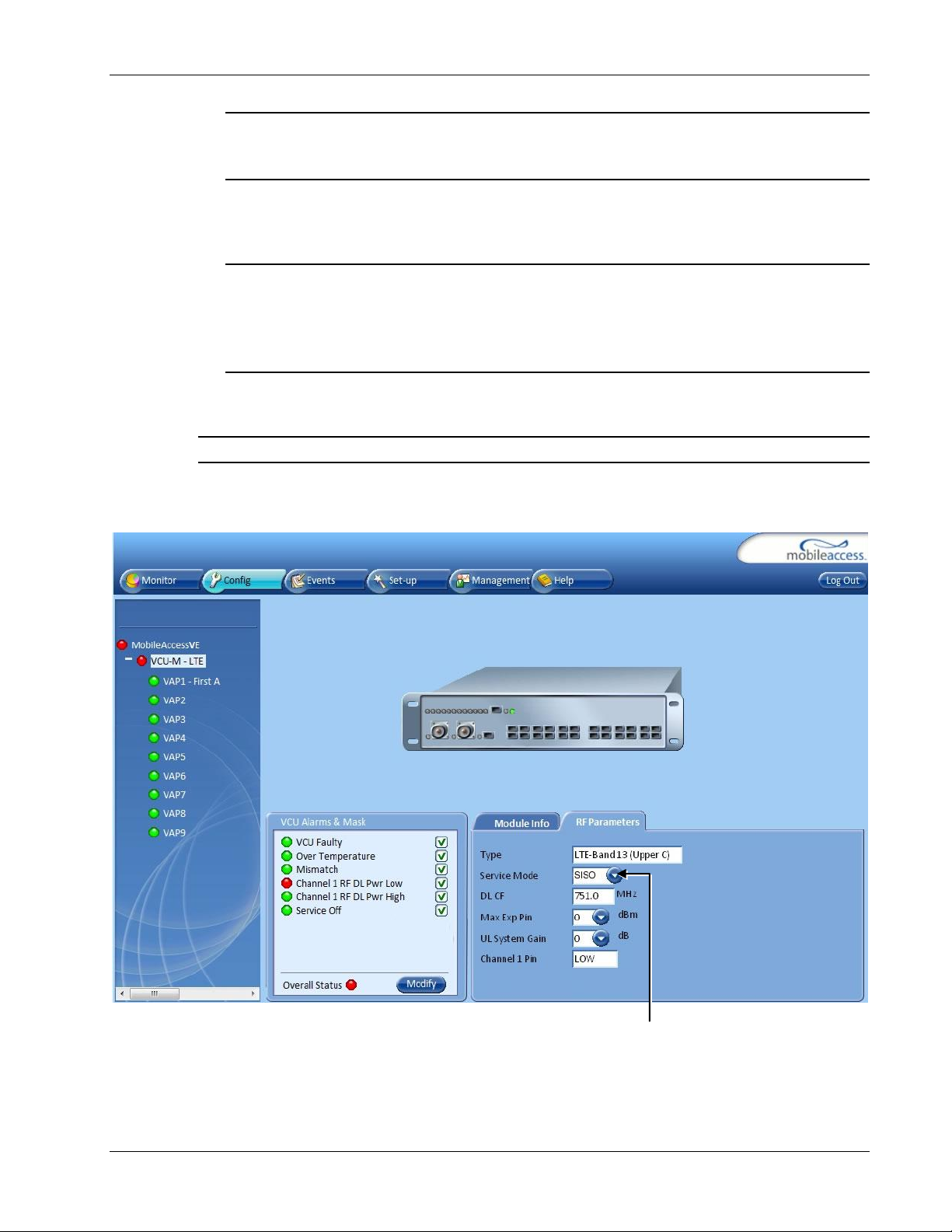

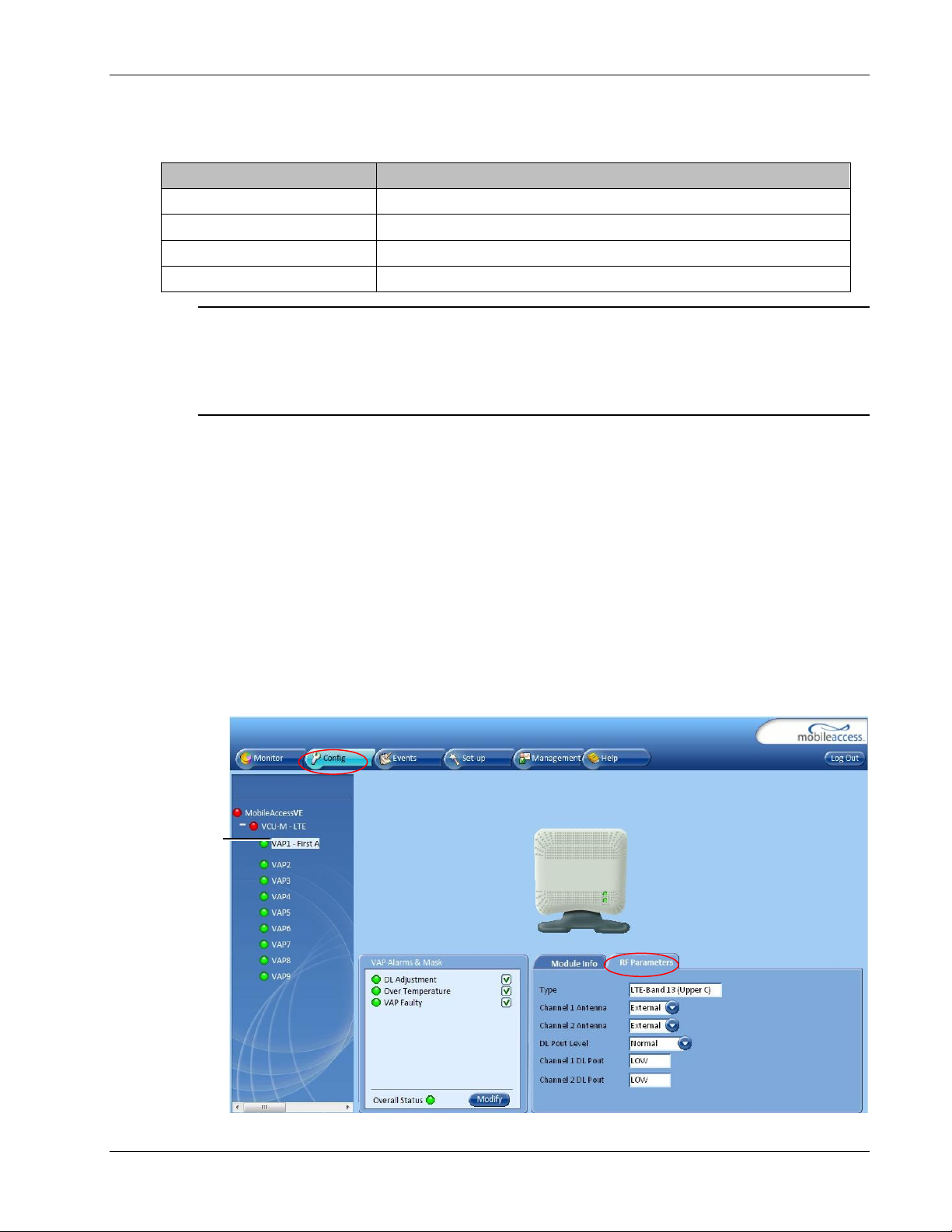

4.4.3 Setting RF Parameters

In a Master-Slave mode (multi-tier architecture) the RF parameters are only configured for the

Master VCU unit.

Set the RF parameters according to the LTE Signal Source transmission configuration (MIMO or

SISO). Each type of configuration is defined through a dedicated tab.

This section describes the MIMO and the SISO configuration procedures.

To Configure the MIMO RF Parameters:

Note: Up to 17 alpha-

1. Select the Master VCU in the topology tree and then select the RF Parameters tab. Verify

that the Service Mode parameter is defined as MIMO.

LTE 700 MHz MobileAccessVE Instant Coverage Solution User Manual 29

Page 39

VCU Unit Installation and Provisioning

Service Mode

drop-down list

Note: The MIMO DL CF parameter is Read Only and pre-defined for the supported 10 MHz

block. The MIMO DL CF parameter defines the same DL central frequency from the Base

Station for Channel 1 and Channel 2.

2. Define Max expected power of BTS (0-33dBm).

3. Define UL System Gain (-15 to 5dB)

Notes:

1. Max expected Pin parameter can be obtained from your service provider.

2. The remaining parameters are predefined to their default values. (Service Bandwidth is

set to 10MHz per channel).

3. Any updates of the service definition (Service Mode) are sent to all connected VAPs.

To Configure the SISO RF Parameters:

Note: The RF tab is displayed for MIMO by default.

1. Select the Master VCU in the topology tree and select the SISO option in the Service Mode

drop-down list. The RF parameters tab will display the SISO RF parameters.

2. Define Max expected power of BTS (0-33dBm).

3. Define UL System Gain (-15 to 5dB)

LTE 700 MHz MobileAccessVE Instant Coverage Solution User Manual 30

Page 40

Notes:

Alarm

Description

VCU Faulty

RED - VCU fault. Remove and re-apply power to VCU. If

problem persists, replace VCU.

Over Temperature

Temperature of unit exceeds normal range.

Service Off

User has disabled the service.

Channel 1 RF DL Pwr Low

RED - DL RF Power is lower by 15dBm (or more) from the Max

Expected Pin.

Channel 1 RF DL Pwr

High

RED - the input power exceeds the maximum expected Pin by

more than 3 dB.

Channel 2 RF DL Pwr Low

RED - DL RF Power is lower by 15dB (or more) from the Max

Expected Pin.

Channel 2 RF DL Pwr

High

RED - the input power exceeds the maximum expected Pin by

more than 3 dB.

Overall Status

Indicates Fault (RED) level or GREEN if there are no faults.

1. Max expected Pin and SISO DL CF parameters can be obtained from your service

provider.

2. The remaining parameters are predefined to their default values. (Service Bandwidth is

set to 10 MHz).

3. Any updates of the service definition (DL CF or Service Mode) are sent to all connected

VAPs.

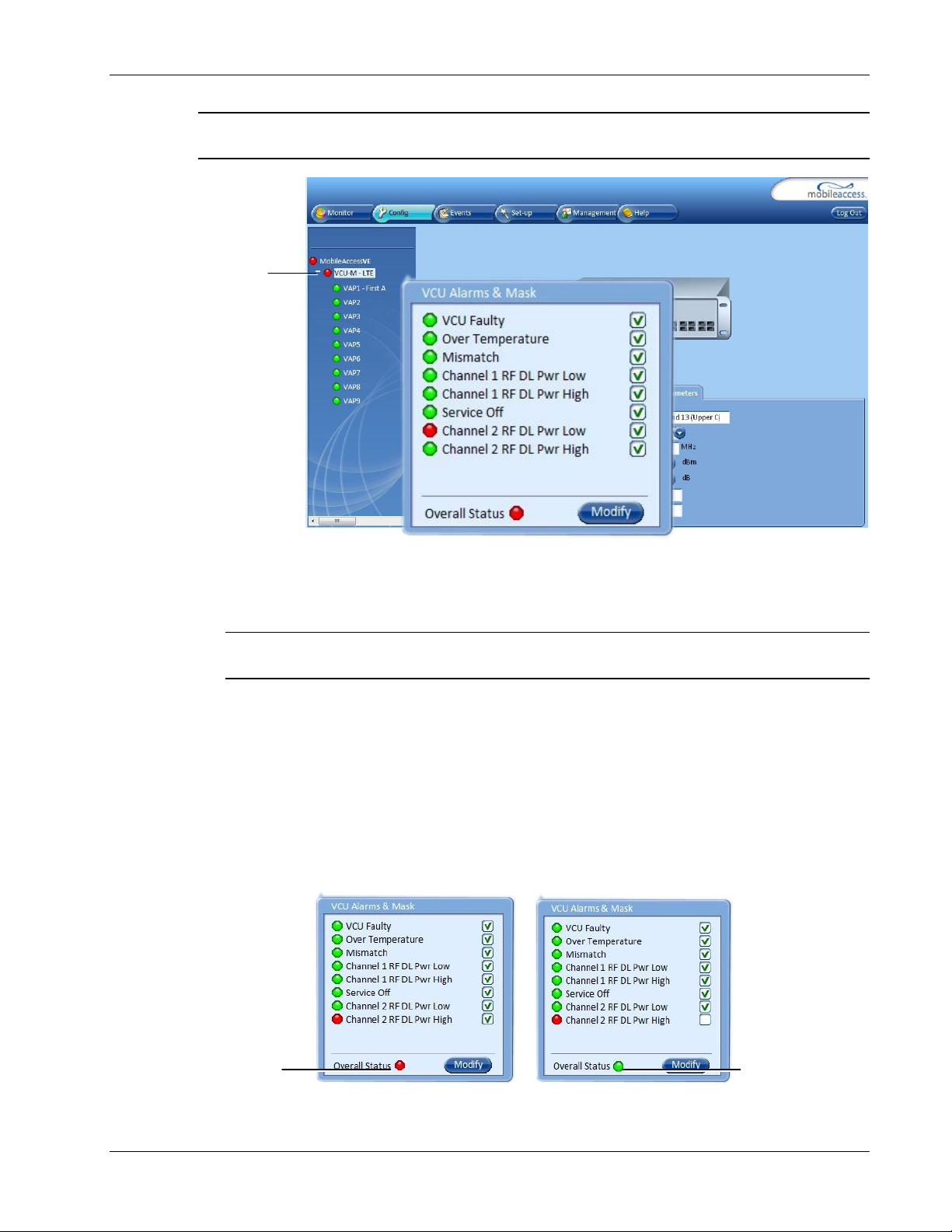

4.4.4 Verifying System Operation

To verify proper operation of the system, refer to the VCU Alarms and Mask sub-tab (in the

Config tab). The following figure illustrates the MIMO alarms.

VCU Unit Installation and Provisioning

Note: SISO alarms are similar, however only Channel 1 alarms appear.

1. Verify that all the alarms are GREEN.

Refer to the alarm descriptions in the following table.

Note: When SISO service is used only the Channel 1 alarms are relevant.

LTE 700 MHz MobileAccessVE Instant Coverage Solution User Manual 31

Page 41

VCU Unit Installation and Provisioning

Overall Status RED

Click VCU Master

Overall Status GREEN

Note: To briefly check the VCU status, click on the VCU name in the Topology Tree. The VCU

icon will appear, showing the LEDs status.

2. Mask irrelevant alarm conditions to avoid affecting the overall status of the unit. See

following example.

For Example

Note: Channel DL signal refers to the MIMO/SISO DL signal from the BS side towards the

remote units (VAPs).

In the example below “Channel 2 RF DL Pwr High” alarm is masked (Disabled). This is the

alarm

for the DL signal (from the BS side)

.

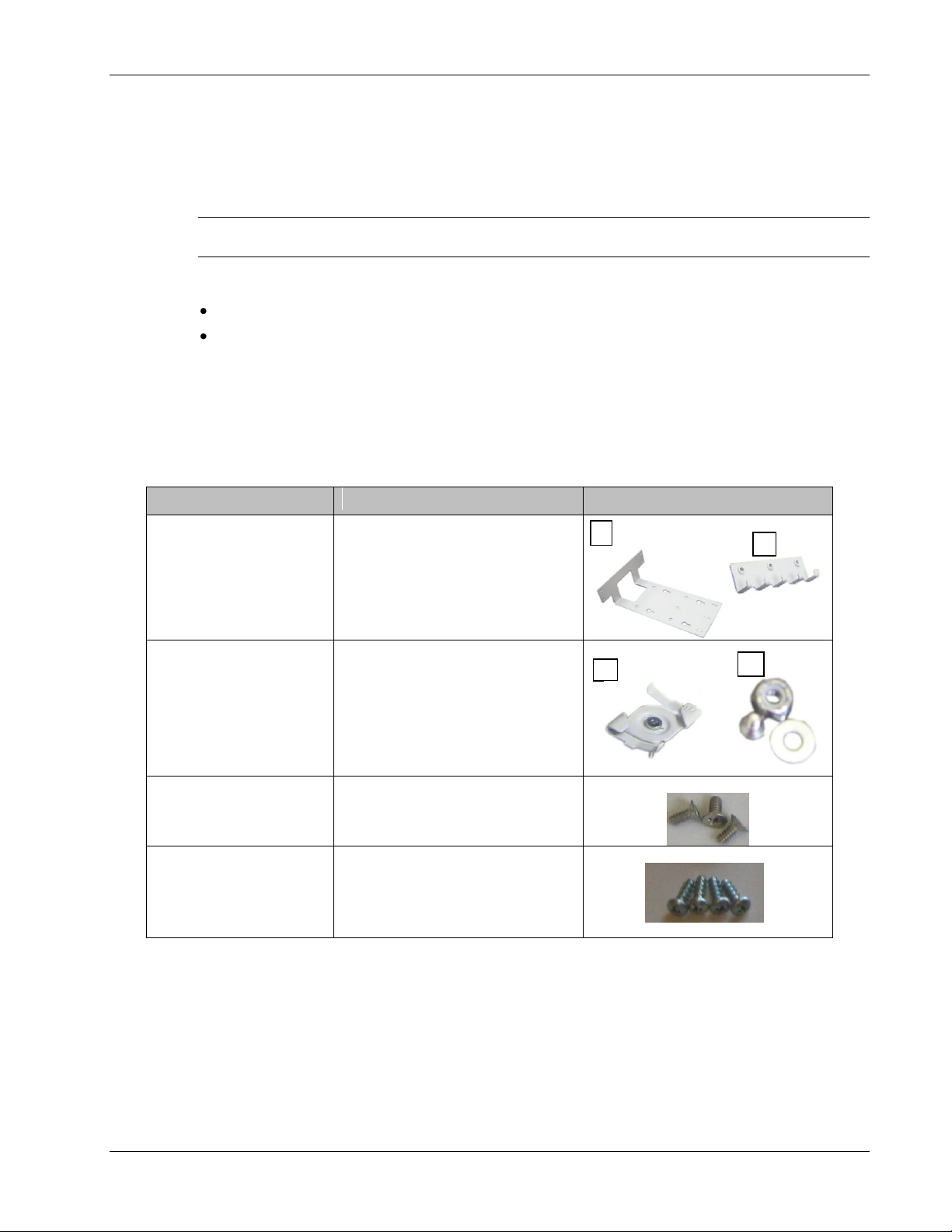

The left dialog shows the alarm response when Channel 2 DL RF Pwr High alarm is enabled

and a fault corresponding to that alarm is detected. (MIMO 2 DL RF Power exceeds the

defined range). The overall status will be RED indicating a fault.

The right side dialog shows the alarm response when Channel 2 DL RF Pwr High alarm is

masked (Disabled). The Channel 2 DL RF Pwr High LED will appear RED; but, the overall

status will be GREEN, showing NO Fault.

Figure 4-3. Service2 Service Off Alarm – Unmasked Figure 4-4. . Service2 Service Off Alarm –Masked

LTE 700 MHz MobileAccessVE Instant Coverage Solution User Manual 32

Page 42

VCU Unit Installation and Provisioning

Master VCU icon

Note: To briefly check the VCU status, click on the VCU name in the Topology Tree. The VCU

icon will appear, showing the LEDs status.

LTE 700 MHz MobileAccessVE Instant Coverage Solution User Manual 33

Page 43

4.4.5 Provisioning the Slave VCUs

Selected Slave

VCU-

Click Modify to

Assign Name

Note: The Slave VCUs management and configuration is performed through a remote connection

to the Master VCU, via the web management. Before provisioning the Slave VCUs verify that the

Master VCU unit, to which it is connected, has been provisioned (See section 4.4.1).

The Slave VCU RF parameters are set via the Master VCU, therefore there is no need to

configure the RF parameters individually for each connected Slave VCU. It is recommended to

assign each Slave VCU an identifiable name.

To Assign a Name to a Slave VCU:

1. Connect to the Master VCU unit (either locally as explained in section 4.4.1 or remotely) and

select the Slave VCU to be provisioned from the Network Topology Tree.

VCU Unit Installation and Provisioning

Each VCU has a default name of the form “VCUPx-name”, where:

Px - Master VCU port number to which the Slave VCU is connected

Name - User-defined name

2. To assign the Slave VCU an identifiable name:

Select the Module Info Tab

Click the Modify button

Type the unit name and click OK.

LTE 700 MHz MobileAccessVE Instant Coverage Solution User Manual 34

Note: Up to 17 alpha-numeric characters are allowed.

Page 44

VAP Installation and Provisioning

5 VAP Installation and Provisioning

This section provides a description of the VE Access Pods (VAPs) installation, verification, and

monitoring procedures.

5.1 VAP Installation

The VAPs installation procedure consists of connecting each VAP to the Ethernet jack in the

appropriate location to provide optimal coverage (See sections 3.4).

It is recommended to install the VAPs in places located high up so as to maximize the provided

coverage per VAP.

Note: Mounting a VAP beneath a desk or in another secluded location (e.g. office corner)

decreases the effective coverage of the VAP increasing the need for a higher number of VAPs to

cover the same area.

There are three main types of VAP mounting installations:

Desk Mount – Used for VAPs mounted on locations such as desks, cubical walls, and filing

cabinets. (See section 5.2.2).

Wall Mount – Used for VAPs mounted on walls (recommended high up). (See section 5.2.3).

Ceiling Mount – Used for VAPs to be installed in the ceiling. There are two types of ceiling

mount installations:

Horizontal

Vertical –See 5.4.

The LTE VAP is provided with the Desk/Wall mount kit, which also includes the RJ-45 cable for

connecting the VAP to the Ethernet jacks. (See section 5.2.1). If the VAP is to be installed on the

ceiling then an additional kit is provided, depending on whether the installation is horizontal (See

section 5.3.1) or vertical (See section 5.4.1).

VAP Installation Considerations

Placing units in an open area.

Availability of CAT-5e/6 infrastructure.

The VAPs plug into standard (RJ-45) Ethernet connection jacks.

If the jack being used is already connected to Ethernet switch. (See sections 3.4.2 and 4.3).

Aesthetics of the VAP location.

LTE 700 MHz MobileAccessVE Instant Coverage Solution User Manual 35

Page 45

VAP Installation and Provisioning

Kit Items

Unit

VE Access Pod (VAPs)

Wall Mount Adaptor (Features double

sided sticky tape located on rear for

fast installation.)

Desk Mount Adaptor

(8) Screws:

o (4) Short Screws – Used to secure

adaptor to pod

o (4) Longer Screws – Used to

secure wall mount adaptor to the

wall (“anti-theft” installation)

RJ-45 Jumper Cable

Front

Rear – showing tape

Long screws

Short screws

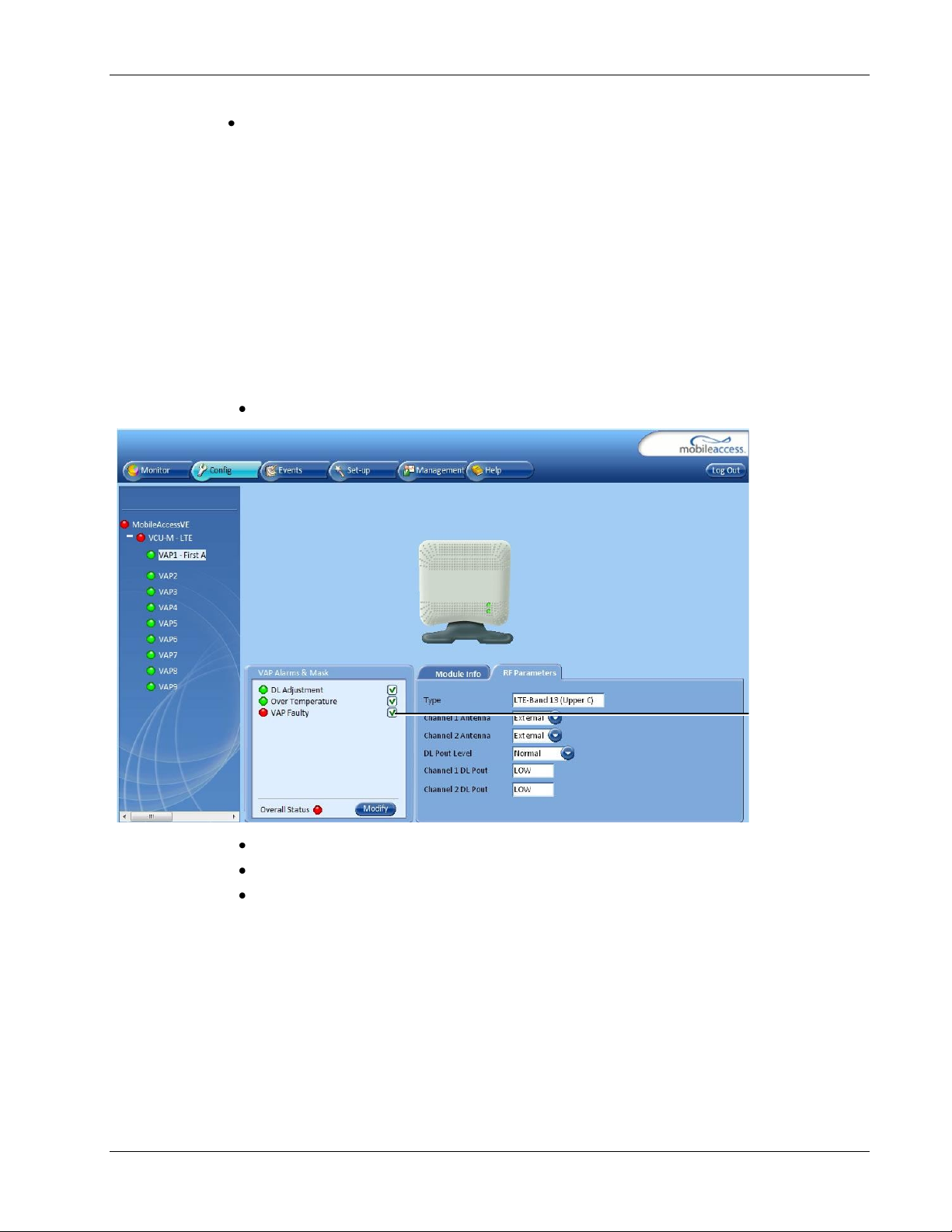

5.2 Desk and Wall Mount VAP Installations

5.2.1 VAP Kit Contents

The LTE 700 MHz VE Access Pod (VAP) Kit includes:

Note: The provided VAP kit includes two mounting options: Desk Mount and Wall Mount. See

sections 0 and 5.4. Ceiling Mount kits can be ordered separately.

Table 10: Desk and Wall Mount VAP Kit

LTE 700 MHz MobileAccessVE Instant Coverage Solution User Manual 36

Page 46

Desk Mount Adaptor

Ext. Antenna SMA

Connectors*

RJ-45 to LAN

Connection

RJ-45 to

VCU

Access Pod

Assembly - Front View

Assembly - Rear View

Activity –

Blue LED

Pwr –

Green LED

+

=

5.2.2 Desk Mount Installation

Note: All components (adaptor, screws, and cables) are included in the VAP Kit.

Place the VAP on the Desk Mount.

Secure the Desk Mount adaptor to the VE Access Pod using the (4) short screws.

Connect the VAPs RJ-45 VCU connector to the Ethernet jack leading to the VCU via RJ-45

cable supplied with VAP.

Place the VAP on a flat surface according to the planned location.

Plug the other end of the cable into the VCUs (RJ-45) Ethernet jack.

When using an external antenna, connect the Ext. Antenna SMA connector(s) to the external

antenna(s).

Note: The maximum external antenna gain should not exceed 10 dBi.

Verify that the VAP receives power and connects to the VCU via the LEDs on the unit (both

the GREEN LED and the BLUE LED should be lit).

(Note: External antenna is enabled by default).

VAP Installation and Provisioning

LTE 700 MHz MobileAccessVE Instant Coverage Solution User Manual 37

Page 47

Access Pod

Wall Mount

Assembly

Blue LED

Green LED

5.2.3 Wall Mount Installation

Note: All components (adaptor, screws, and cables) are included in the VAP Kit.

Attach the VAP’s wall mount adaptor to the wall in the planned location, using the double

sided sticky tape located on the rear or secure it using the longer screws.

Place the VAP on the Wall Mount.

Secure the Wall Mount adaptor to the VE Access Pod using the (4) short screws.

VAP Installation and Provisioning

+ =

Connect the VAPs RJ-45 VCU connector to the Ethernet jack leading to the VCU (via RJ-45

cable supplied with VAP).

Plug the other end of the cable into the VCUs (RJ-45) Ethernet jack.

Connect the Ext. Antenna SMA connector(s) to the external antenna(s). (Note: External

antenna is enabled by default).

Note: The maximum external antenna gain should not exceed 10 dBi.

Verify that the VAP receives power and connects to the VCU via the LEDs on the unit (both

the GREEN LED and the BLUE LED should be lit).

Figure 5-1. VAP Mounted on Wall

LTE 700 MHz MobileAccessVE Instant Coverage Solution User Manual 38

Page 48

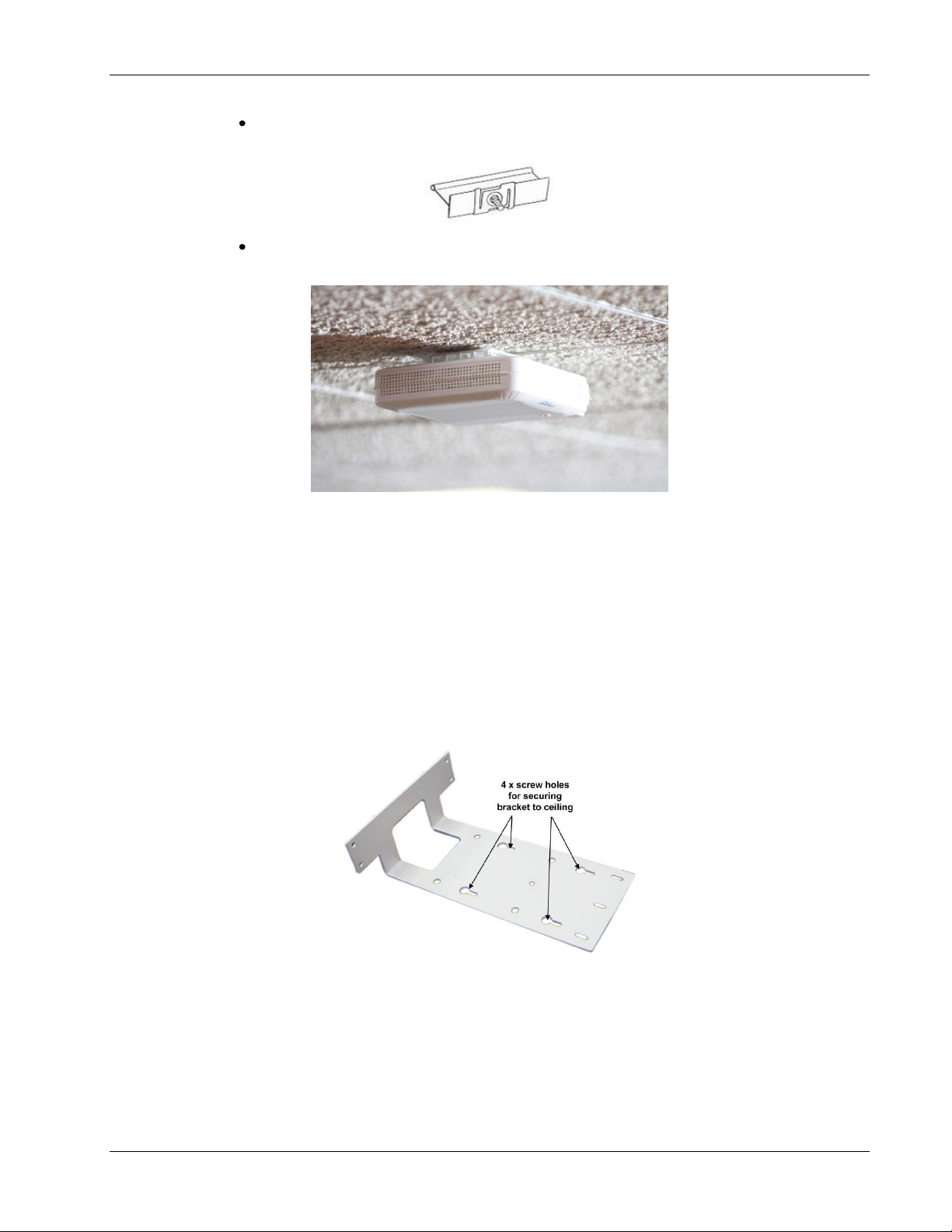

VAP Installation and Provisioning

Kit Items

Description

Unit

Mounting Brackets

A) Ceiling Bracket

B) Locke Bracket

“Twist on” Track Light

Clip Assembly

Used for installation on lowered

ceilings.

A) Track Light Clip

B) Screw, Bolt, and Washer

(3) Flat Head Screws

100', 4/40 x ¼

[NEROSTA]

Used for assembling brackets

together

(4) Self Screws

3dim L=8 ,Flat HD 90

[Steel zinc]

Used to secure bracket assembly to

VAP

A

B

A

B

5.3 Horizontal Ceiling Mount VAP Installations

Note: The VAP and required RJ-45 cable are supplied in the provided VE LTE VAP kit (See

section 5.2.1).

The Horizontal installation procedure varies depending on the type of ceiling:

Lowered ceilings (See section 5.3.2).

Concrete/Wood ceilings (See section 5.3.3).

5.3.1 VAP Kit Contents

Please verify that the VAP Ceiling Mount Installation kit (P/N AK-VAP-CEILING-MT-H)

includes the items listed below.

Table 11: Horizontal Ceiling Mount VAP Kit

LTE 700 MHz MobileAccessVE Instant Coverage Solution User Manual 39

Page 49

5.3.2 Lowered Ceiling Installation

To Install VAP in Lowered Ceiling

1.

Loosely

(Note: The assembly will be secured at a later stage.)

2. Assemble the Track Light Clip to the Ceiling Bracket (top side) using the provided washer

and bolt.

assemble the two brackets (Ceiling and Locke) using the (3) Flat Head Screws.

VAP Installation and Provisioning

3. Hook the assembly onto the VAP rear panel grid and fit to the bottom of VAP.

4. Secure the assembled brackets to the bottom of the VAP using the (4) Self Screws.

5. Adjust the bracket assembly to firmly fit the VAP and tighten the (3) screws securing the

assembly.

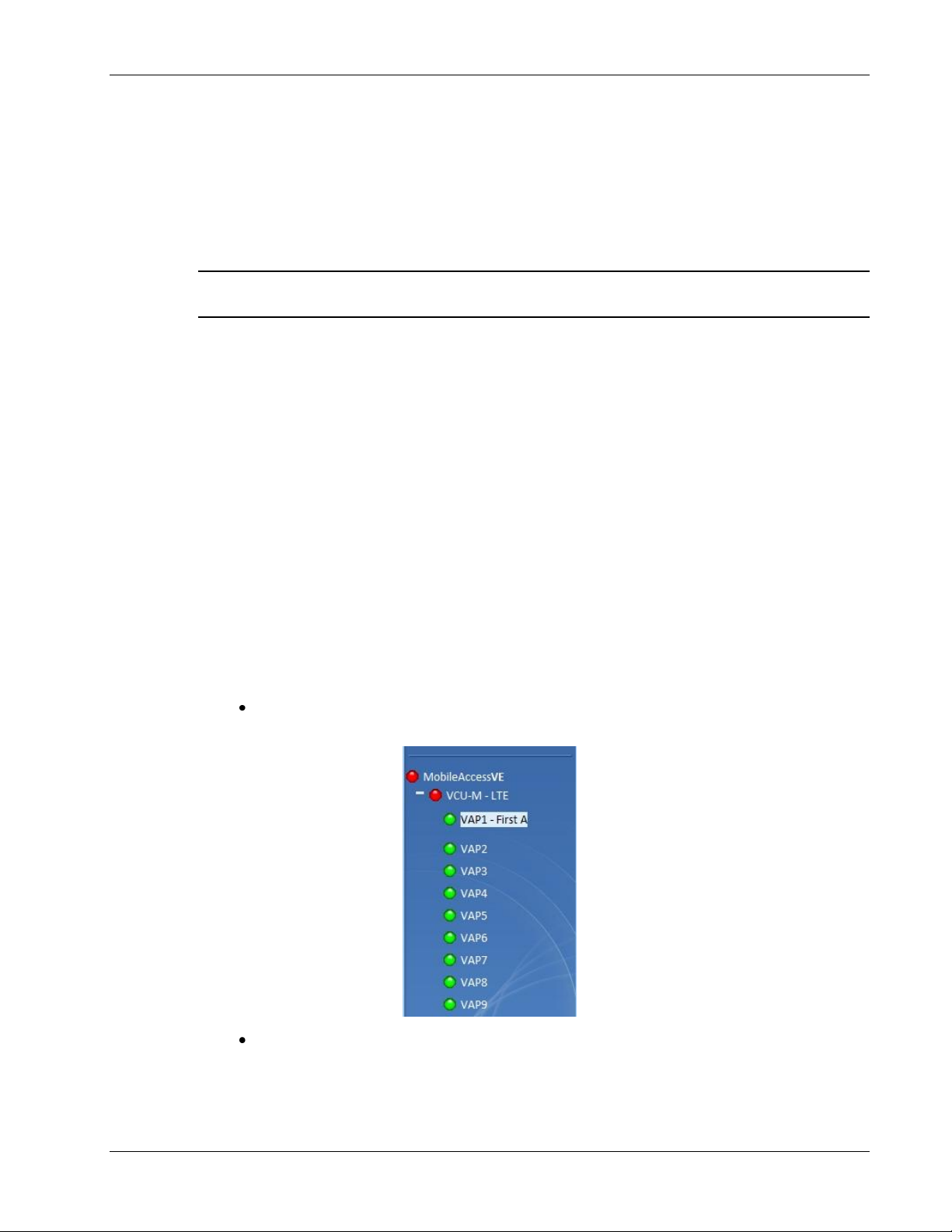

6. Mount the VAP on the lowered ceiling as follows:

Enlarge large flanges over opposite sides of T-bar.

Note: Apply slight pressure as Twist

Clip is made of spring steel.

LTE 700 MHz MobileAccessVE Instant Coverage Solution User Manual 40

Page 50

VAP Installation and Provisioning