Page 1

MA 1000 Installation and Configuration Guide

2.1.1.1 RHU 1000 Front Panel

The RHU 1000 front panel contains the fiber optic connections to the BU, four coax connections

to the antennas, power connections and status indicators.

If RHU 1000 and MA 1200 add-on units are installed, then the combined services are fed to the

coax infrastructure through the

the combined

antenna ports

NOTE: To provide alarms, the antenna must supply a DC resistance of up to 5K ohms.

data and voice

.

Figure 2-1. RHU 1000 Front Panel

RHU 1000 antenna ports

services are fed to the coax infrastructure through the

. However, if MA 850 is also installed,

MA 850

Table 2-1. RHU 1000 Front Panel Ports

Port Description

From Base

To Base

RS232 Upgrade and service connection (MA service personnel)

PWR DC power connection

Port 1-4 Coax connections to antennas

LED Description

COMM Active communication detected

LINK Optical link to BU detected

PWR DC power connected

Fiber Optic connections to- and from the Base Unit

Table 2-2. RHU 1000 Front Panel Indicators

11

Page 2

MA 1000 Installation and Configuration Guide

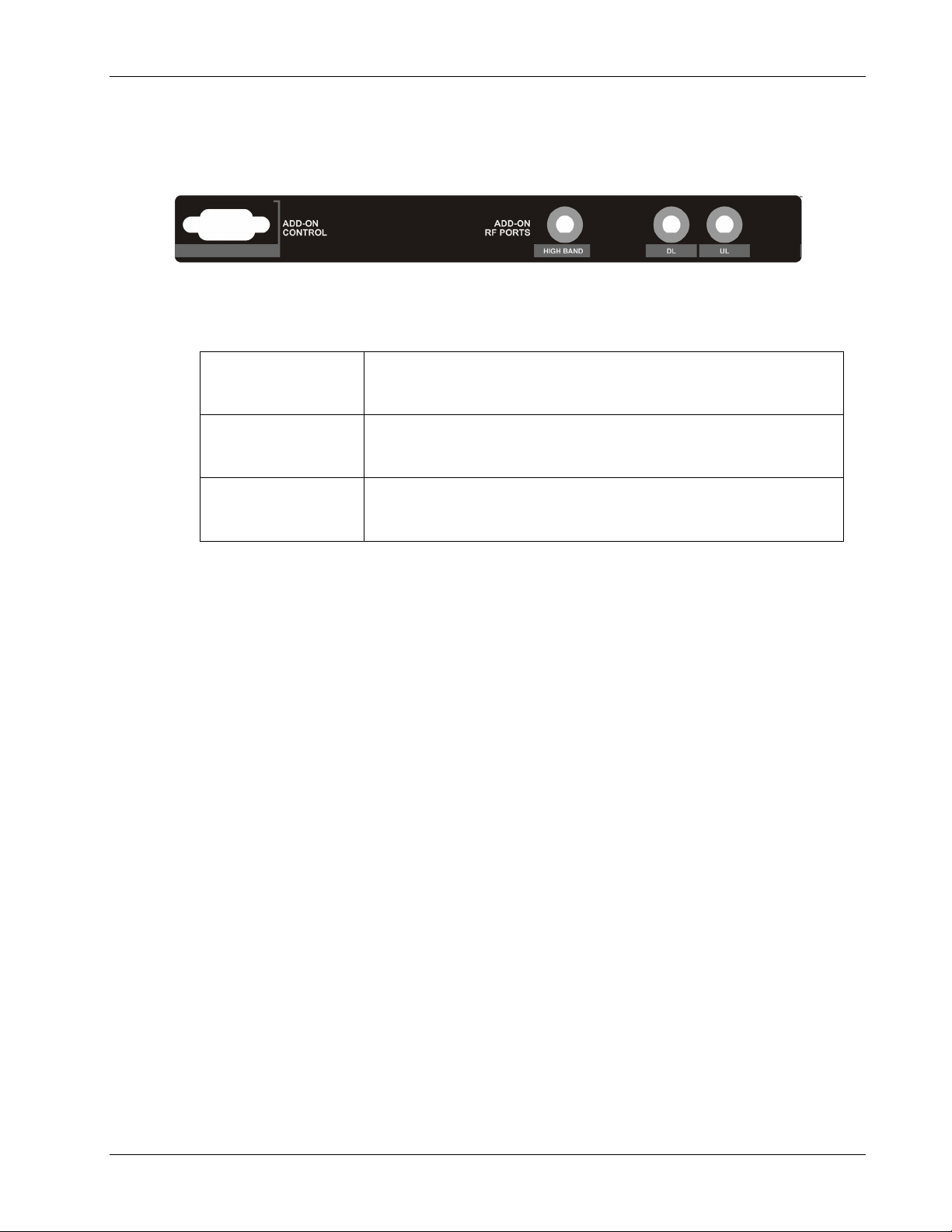

2.1.1.2 RHU 1000 Rear Panel

The RHU 1000 rear-panel provides the connections to an MA 1200 add-on unit.

Table 2-3. RHU 1000 Rear Panel Connectors

Add-on control Transmits the control signals from MA 1200 add-on module to the

RHU 1000 module. Connected to the MA 1200 add-on Control

From port.

High Band Connects to the 1200 Add-on High Band port. Provides the

interface to the Add-on RF service which is combined with the RHU

services and distributed through the common coax infrastructure.

DL, UL Transmit the RF signals to- and from- the MA 1200 add-on module.

These ports are connected to the corresponding ports on the MA

1200 rear panel: DL to DL, UL to UL.

Figure 2-2. RHU 1000 Rear

12

Page 3

MA 1000 Installation and Configuration Guide

2.1.2 RHU 800/900

RHU 800/900 supports iDEN and SMR technologies. The module is available in the following

configurations:

A) As a

B) As a

stand-alone module

procedure to RHU 1000 modules. The standalone module is illustrated below.

bracket assembly

illustrated below.

similar in its physical description, ports, LEDs and installation

that includes the module and the external filter elements as

Filter

Bracket

Figure 2-3. RHU 800/900 Front View

The following sections provide descriptions of the RHU 800/900 front and rear panel. The

installation of each type of module is described in section

13

4.3.3.

Page 4

MA 1000 Installation and Configuration Guide

2.1.2.1 RHU 800/900 Front Panel

The RHU 800/900 front panel ports and LEDs is the same as the

to section

2.1.1.1 for a detailed description of the LEDs and ports.

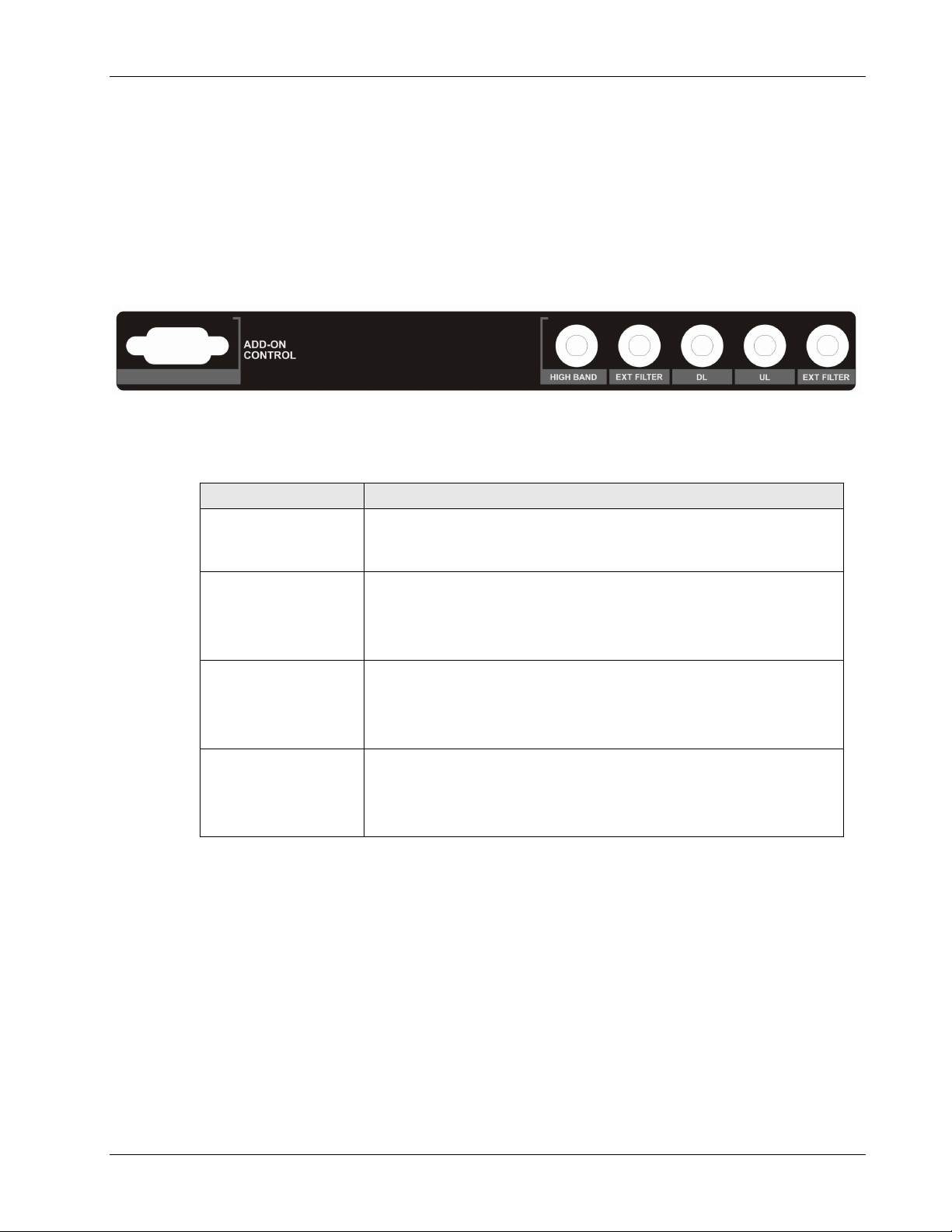

2.1.2.2 RHU 800/900 Rear Panel

The rear panel contains the 1200 add-on and the filter connections.

Figure 2-4. RHU 1000 Rear

Table 2-4. RHU 1000 Rear Panel Connectors

Port Description

EXT FILTER Connections to external filter (as illustrated in the following

section). In installations without a filter, the two EXT FILTER ports

are interconnected with a jumper.

Add-on control Connection to MA 1200 Add-on module.

Transmits the control signals from MA 1200 add-on module to the

RHU 1000 module. Connected to the MA 1200 add-on Control

From port.

High Band Connection to MA 1200 add-on module.

Connects to the 1200 Add-on High Band port. Provides the

interface to the Add-on RF service which is combined with the RHU

services and distributed through the common coax infrastructure.

DL, UL Connection to MA 1200 add-on module.

Transmit the RF signals to- and from- the MA 1200 add-on module.

These ports are connected to the corresponding ports on the MA

1200 rear panel: DL to DL, UL to UL.

RHU 1000 front panel

. Refer

14

Page 5

MA 1000 Installation and Configuration Guide

2.1.2.3 RHU 800/900 View of Filter Connection

The following figures illustrate the RHU 800/900 views with and without a filter.

NOTE: Note that the filter port connections are interconnected with a jumper in installations

without a filter.

Filter connections

Figure 2-5. Rear View of RHU 800/900 with Filter

Shorted filter connections

since no filter is installed

Figure 2-6. Rear View of RHU 800/900 without Filter

15

Page 6

MA 1000 Installation and Configuration Guide

2.1.3 MA 1200 Add-on

The MobileAccess 1200 Add-on module is a high power module, supporting a single frequency

band (low or high). It is designed to be integrated with a host

1000 module provides the following functionality for both units:

• Optical interface (to the BU) and conversion

• RF interface (to antennas) and conversion

• Control signals

In addition, MA 850 services can also be combined with MA 1200 add-on and RHU 1000

services. (However, in this type of configuration the combined services interface to the coax

infrastructure through the MA 850 ports.)

NOTE: The units are integrated through simple external cable connections between

corresponding ports.

RHU 1000

module. The RHU

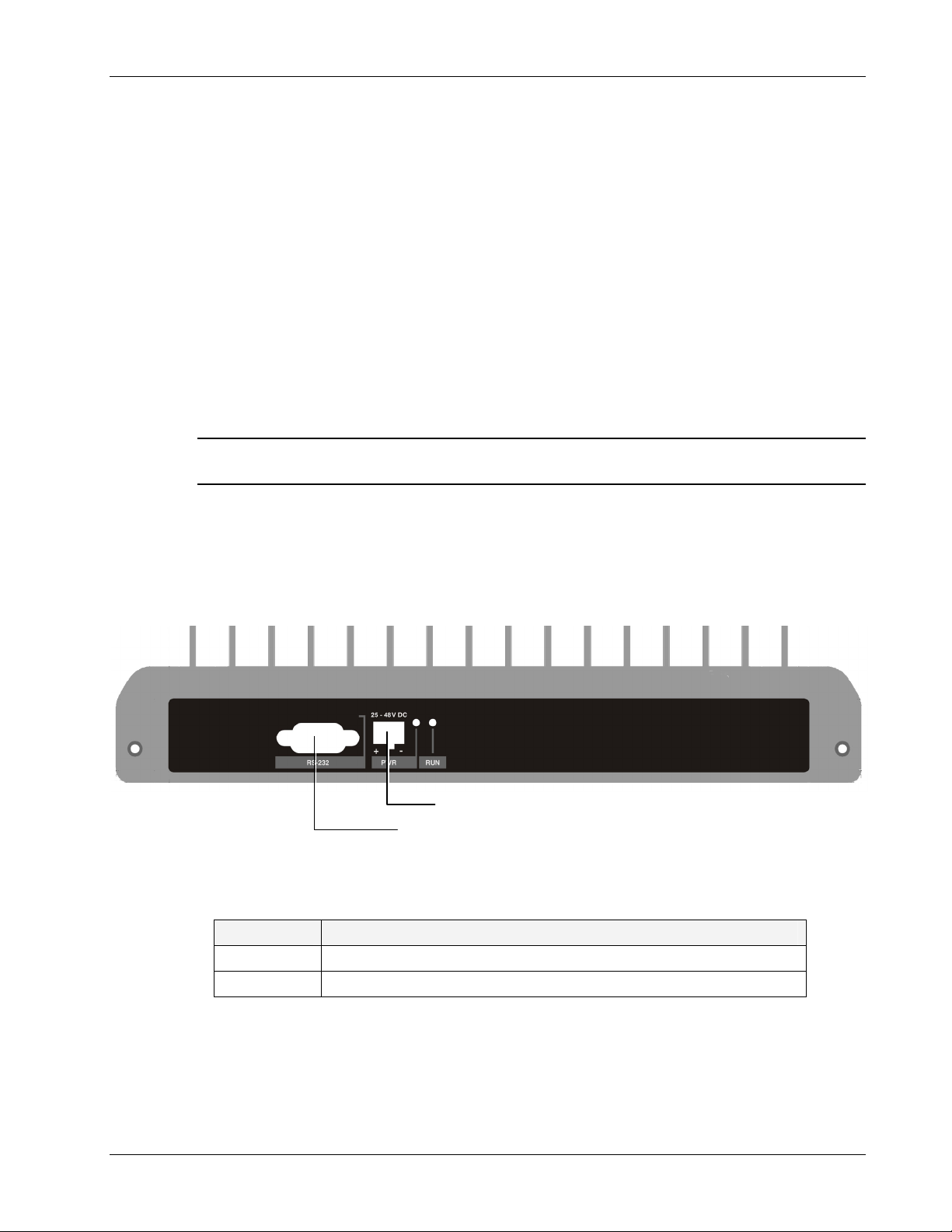

2.1.3.1 MA 1200 Front Panel

The RHU 1200 front panel contains the power connection and status LEDs. (The RS-232

connector is reserved for MA service personnel).

Figure 2-7. RHU 1200 Front panels

Table 2-5. MobileAccess 1200 Front Panel Indicators

LED Description

RUN When blinking, indicates that the RHU is in normal operating mode.

PWR Power ON

Power connector

MA service connector

16

Page 7

MA 1000 Installation and Configuration Guide

2.1.3.2 MA 1200 Rear Panel

The RHU 1200 rear panel contains the connections to the RHU 1000 and MA 850.

RHU 1000 Add-on control

MA 850 Add-on control

Figure 2-8. RHU 1200 Rear Panel

To RHU 1000 High, DL and

UL connectors.

Table 2-6. RHU 1200 Rear Panel Connectors

Add-on Control Transmits the control signals between the MA 1200 module and the

MA 850 and RHU 1000 modules.

From – receives control signals from the RHU 1000. Connected to

the RHU 1000 Add-on Control connector.

To – Future option.

DL, UL Transmit the RF signals to- and from- the MA 1200 add-on module.

These ports are connected to the corresponding ports on the MA

1000 rear panel: DL to DL, UL to UL.

High RF service output port connected to the RHU 1000 rear-panel High

port.

2.1.4 MA-850 Module

NOTE: This section provides a brief overview of the MA 850 module. For detailed information

on installation and connections, refer to the MA 850 Installation and Configuration Guide.

MobileAccess 850

Points. It significantly expands 802.11 coverage and enables distributing data and voice services

over the same coax and antenna infrastructure used by MA 1000 system.

provides a

secure

and

centralized

connection for 802.11a/b/g Access

MA 850 may be assembled on top of the RHU 1000 or MA 1200 add-on. It is integrated into the

MA 1000 system by interconnecting the appropriate connectors. The combined signals of the

MA 1000 system input to the MA 850 module and then distributed through the same coax

broadband antenna infrastructure

17

connected to the MA 850.

Page 8

MA 1000 Installation and Configuration Guide

MA 850 may be remotely monitored through the RHU 1000 system to which it is integrated, and

remotely configured through a point-to-point Ethernet connection.

The MA 850 front and rear panels, connectors and connections are described in detail in the

following sections.

2.1.4.1 MA 850 Front Panel

The MA 850 front panel contains the antenna ports interfaces, local configuration interface and

power connection.

NOTE: Whether connected alone or integrated with RHU 1000 modules, the coax infrastructure

is connected to the MA 850 coax ports.

The following figure shows the MA 850 front panel.

Antenna ports

Power

Connections to

corresponding antenna

ports of remote unit

Local RS232 connection

for configuration

Figure 2-9. MobileAccess 850 Front View

Table 2-7. MA 850 Front Panel Connections

Front Panel Description

Mobile Services Four SMA female connections to which the antenna port of the

MA 1000 system are connected.

To be terminated with 50 ohm terminations when not in

use.

Antenna Ports Four n-type female antenna connections

Local Local connection for setup

DC Power connection: 20V to 48V from a standard power supply

18

Page 9

MA 1000 Installation and Configuration Guide

2.1.4.2 MA 850 Rear Panel

The MA 850 rear panel contains the connections to the APs, the Ethernet port for remote

configuration and the connection to the MA 1200 add-on control (if an MA 1200 add-on unit is

installed)

Connection to

add-on control

Figure 2-10. MobileAccess 850 Rear View

Table 2-8. MA 850 Reart Panel Connections

Rear Panel Description

802.11b,g APs Connection to up to four 802.11b/g APs, where associated LED

Lite under the following conditions:

• Green: indicates where AP should be connected after

configuration

• Green flickering: Link with AP established but no data is

received

• Red: AP transmitting data

802.11a APs Connection to up to four 802.11a APs

Connection to

control

Connection to MA 1200 To connector on the rear panel. Used for

viewing antenna status

Ethernet port Connection to network for Web configuration

802.11 b/g APs

connections

Ethernet

Port

802.11 a APs

connections

19

Page 10

MA 1000 Installation and Configuration Guide

2.2 Radio Interface Unit (RIU)

The RIU is an operator dedicated unit that interfaces to up to three BTS sources and

automatically adjusts the signal output according to changing environmental conditions in order

to provide optimal coverage for the site. The RIU is remotely monitored and managed.

Each RIU can support up to three BTS Conditioner (BTSC) sub-modules, where each sub-

module provides interface to a BTS or BDA of

the same type of service

.

Each RIU can be connected to

Base Units.

Additional BUs can be supported by using splitters and combiners connected to the front panel

Expansion connectors.

The following figures shows an RIU with three BTSC sub-modules.

four

8-port Base Units (real panel connections) or to

Figure 2-11. RIU

eight

4-port

Note: All connections are via RG223 coax cables with 1/2" N-type male connectors

ATTENTION

The RIU is factory set to 0dB gain on the uplink and downlink. In order to operate

properly, an ADJUSTMENT process is required in the field.

Any unused input and output connectors MUST be terminated with 50 ohms –

otherwise the ADJUSMENT procedure results may be affected.

20

Page 11

MA 1000 Installation and Configuration Guide

g

2.2.1.1 RIU Front Panel

The RIU front panel contains the indicators and expansion connectors for the connection of

additional BUs.

Power Supply

BTS Conditioners

Figure 2-12. RIU Front Panel

Table 2-9. RIU Front Panel Indicators

LED Description

P.S UNIT PWR ON – input signal is at the required level.

BTS CONDITIONER RUN Flashing -- CPU is running and software loaded

BTS CONDITIONER DL

OVERLOAD

Continuous Red – RF switch is disconnected to protect the system. This may

be due to:

• Unpredicted power rise for which the attenuation response was

insufficient to compensate and reduce the power to the required level.

• Software problem detected.

Flashing: When the BTSC DL output power is more than 3dB of the calibrated

value.

BTS CONDITIONER DL

LOW

Continuous Red – if the BTSC DL power is at least 15dB lower than the

calibrated BTSC max power level. This condition also triggers an event.

Expansion connectors - for

connectin

additional BUs

21

Page 12

2.2.1.2 RIU Rear Panel

The rear-panel provides all the connections on the BTS side and on the BU side as well as

connections to the MobileAccess 410/430 controller and the power connection. Two types of

BTS side connections are available for each BTS conditioner: simplex and duplex.

BU connections; one UL and one DL

connection for every group of four

ports (single OPTM) on the BU.

MA 1000 Installation and Configuration Guide

BTS/BDA simplex connections

BTS/BDA duplex connections

Power

Figure 2-13. RIU Rear Panel showing the RF Connection

2.3 MA Base Units

The BUs (Base Units) perform RF to optical conversion of the signal on the BTS/BDA side. Each

can support up to two services (provided by the same operator). Two models of MA BUs are

available: four-port unit – supporting four RHUs, and eight-port unit supporting up to eight

RHUs. The RHU models correspond to the services supplied through the BUs.

The BU (and all the corresponding remote units) may be remotely monitored and managed via

the MA NMS (Network Management System).

The BUs are usually installed in the telecom room adjacent to the BTS/BDA signal source. RF

ports on the rear panel provide interface to the BTS side (through connection to RIU or passive

interface), while optic ports on the front panel provide interface to the RHUs (Remote Units).

This following sections describe the MA BU front and rear panels, including indicators and

connectors.

MA Controller

connection

22

Page 13

MA 1000 Installation and Configuration Guide

2.3.1.1 MA BU Front Panel

The front panel contains the optical connections and indicators. The BU is available in two

configurations: Four-port - and Eight-port BUs. The eight-port BU consists of two four-port

elements where each four-port element has a dedicated set of indicators (PWR, LSR and Link 1

to Link 4 or Link 5 to Link 8).

Four ports and corresponding indicators

Figure 2-14. Eight-Port MA BU Front Panel

Four ports and corresponding indicators

Figure 2-15. Four-Port BU Front Panel

Table 2-10. MA BU Front Panel Indicators

LED Description

PWR Power input detected for the corresponding unit.

LSR ON - laser circuitry for the corresponding element (group of four ports) is

functioning correctly.

Link 1-4, 5-8 ON - the optical link to/from the connected remote functions within the

specifications in both directions.

Blinking - optical power from remote is lower than expected by at least 2 dBm

23

Page 14

2.3.1.2 BU Rear Panel

The BU rear panel contains the RF, Alarms, NMS and power connections. Note that there are

two uplink and two downlink RF connections to the BTS side (to an Interface Box or RIU) - each

individual uplink and downlink connection corresponds to a four-port BU element. For a fourport BU, one uplink and one downlink port is connected; for an eight-port BU, two uplink and

two downlink ports are connected.

For systems that include MA 430 controllers, the RS 485 port is connected to the MA 410/430

controller to enable remote monitoring and management of the BU from a central location. For

systems without remote management, the Alarms dry-contact connector pins can be connected

to the BTS to provide alarms functionality.

MA 1000 Installation and Configuration Guide

Pair of uplink and downlink RF

connections for interface to BTS

Figure 2-16. MA BU Rear Panel (RF Connections)

Table 2-11. MobileAccess 1000 Rear Panel Connections

Connector Description

Uplink output Uplink connectors to be connected on BTS side.

Downlink input Downlink connectors to be connected on the BTS side.

Com Port RS485 Connection to MobileAccess 410/430 controller.

PWR Power connection

Alarms Dry-contact connections to BTS/BDA (normally closed).

Alarms drycontact

MA 410/430

Power

Relevant only for system without MA 410/430 controllers.

24

Page 15

MA 1000 Installation and Configuration Guide

p)

T

2.4 MobileAccess NMS System

NOTE: This section provides general information on the MobileAccess 410/430 Controller. For

detailed information on the controller, configuration and connections refer to the Mobile Access

NMS User

The MobileAccess controllers enable managing and controlling the MobileAccess system

elements. All the monitoring and control operations can be performed from the Master’s

location.

Two MobileAccess controller configurations are provided: MobileAccess 410 and MobileAccess

430. The models differ in their remote access capabilities:

• MobileAccess 410 provides point-to-point connectivity implemented via either direct

• MobileAccess 430 provides client/server management capability over TCP/IP network

’

s Guide.

RS232 connection or via connection to a DSPN phone line

with enhanced monitoring and control capabilities (in addition to the connectivity

options provided by MobileAccess 410).

NOTE: The MobileAccess 430 front panel is differentiated from the MobileAccess 410 front

panel by the SNMP Agent Card that provides TCP/IP management capabilities.

Controller Front Panel

Local RS232

connection (for IP

address setu

Figure 2-17. MobileAccess 410 Front Panel

Major, Minor LED

indicators

Master/Slave configuration

CP/IP connection

Run and

Power LEDs

LCD alarm display

corresponding to Major

and Minor LEDs

Local RS232 connection to Laptop

(MA 300 for Remote controller)

Figure 2-18. MobileAccess 430 Front Panel

25

Page 16

MA 1000 Installation and Configuration Guide

Controller Rear Panel

Note: The rear panels for the MobileAccess 410 and MobileAccess 430 are the same.

MA BU and RIU

inputs

BTS alarms output

General purpose

alarms input (MA 300).

Figure 2-19. MobileAccess 410/430 Rear Panel

Slave controller

connections

DC Input

26

Page 17

33

SSiittee PPrreeppaarraattiioonn

3.1 Infrastructure Preparation

This following installation rules are based on the assumption that site survey and installation

planning (

including power requirements

) have been completed.

3.2 Installation Requirements

The infrastructure preparation consists of two main phases:

A. Floor Planning: Planning the distribution of the antennas on each floor to provide the

required coverage.

B. Telecom Closet Planning: Planning the layout of the devices and cables in the telecom

closet or shaft. This includes the MA 850, 802.11 Access Points, cabling and other voice

service distribution systems that are relevant to the specific installation.

3.3 Coaxial Cable Connections

3.3.1 General Cable Installation Procedures

Observe the general cable installation procedures that meet with the building codes in your

area. The building code requires that all cabling be installed above ceiling level (where

applicable). Each length of cable from the risers to each antenna must be concealed above

ceiling.

The cable must be properly supported and maintained straight using tie-wraps, cable trays and

clamps or hangers every 10 feet (where practical above ceiling level). Where this is not

practical, the following should be observed:

• The minimum bending radius of the supplied ½” coax cable should be 7”.

• Cable that is kinked or has a bending radius smaller than 7” must be replaced.

• Cable runs that span less than two floors should be secured to suitably located

mechanical structures.

• The cables should be supported only from the building structure.

27

Page 18

MA 1000 Installation and Configuration Guide

3.3.2 Fiber Optic Rules

• Use only single mode fiber for indoor applications.

• Use only 8-degree SC/APC connectors (green color).

• Use only fusion splice for connecting two fibers.

• Use minimum splicing/connectors to achieve minimum losses on the fibers (<0.5dB).

• Use precaution while installing, bending, or connecting fiber optic cables.

• Use an optical power meter and OTDR for checking the fiber optic cables.

• Make sure the environment is clean while connecting/splicing fiber optic cables.

• All fiber optic connections should be cleaned prior to attaching to termination points

using a dry cleaning device (i.e. Cletop or equivalent).

• Fiber connector protective caps should be installed on all non-terminated fibers and

removed just before they are terminated.

• Verify the Fiber Optic connections. You may use the Optical Test Procedure described at

the end of this manual.

• Pay special attention while connecting the SC/APC connectors - you must hear the

“click” when the connection is made.

3.3.3 RF Rules

• Use coax RG223, 50ohm, male-to-male N-type for RF connections from the

BUs to the BTS/RBS and to the RIU.

• When using the MobileAccess™ system in an environment in which other indoor

coverage systems are installed, it is recommended (where possible) that the antennas

are placed at least two meters apart

• When bending coax cables, verify that the bending radius does not exceed the coax

specifications.

• Use wideband antennas supporting a range of 800Mhz to 2500Mhz

• Use a VSWR meter (i.e. Site Master or equivalent) for checking coax cables, including

the antennas. (<2). The VSWR must be measured prior to terminating the RHUs in the

remote communication rooms

• Terminate all unused RHU and RIU ports with a 50 ohm load

28

Page 19

MA 1000 Installation and Configuration Guide

3.3.4 Coax Cable Lengths and Losses

Use coax ½”, 50ohm, male-to-male N-type, (6-7dB for 1Ghz, 11dB for 2Ghz) for connecting to

RHU and RHU ports.

Coax Length coax Loss (900Mhz) connector loss Total Loss

30 0.7 1.5 2.2

40 0.9 1.5 2.4

50 1.1 1.5 2.6

60 1.3 1.5 2.8

70 1.5 1.5 3

80 1.7 1.5 3.2

90 1.9 1.5 3.4

100 2.1 1.5 3.6

110 2.3 1.5 3.8

120 2.5 1.5 4

130 2.7 1.5 4.2

140 2.9 1.5 4.4

150 3.1 1.5 4.6

160 3.3 1.5 4.8

170 3.5 1.5 5

180 3.7 1.5 5.2

190 3.9 1.5 5.4

200 4.1 1.5 5.6

29

Page 20

MA 1000 Installation and Configuration Guide

3.3.5 Power Consumption, Connections and Power Supplies

3.3.6 Power Safety Instructions

SAFETY WARNINGS

• When installing or selecting the power supplies:

• Be sure to disconnect all power sources before servicing.

• Battery replacement in units - only the MA 410/430 controller has batteries. MA

410/430 Controller lithium type battery should only be replaced by MobileAccess service

personnel. Risk of exploding if battery is replaced by an incorrect type. Dispose

of used batteries according to the instructions.

• Calculate the required power according to the requirements of the specific installation

and then determine the configuration of the power supplies. The required DC cables will

then be determined by the selected PS configuration.

• Use only UL approved power supplies

• AC and DC power supply cables – use only the power cords supplied with the units

• Install external over-current protective devices for the system according to the

requirements described in section

3.3.9.

3.3.7 Power Consumption of Units

Table 3-1. MobileAccess™ Power Requirements

Unit Type Voltage Input Typical Power

Consumption

Remote Unit 1000 20 to 48VDC 25W

Add-on Unit 1200 25 to 48VDC 50W

RIU 20 to 48VDC 12W

Base Unit 20 to 48VDC 14W

410/430 Controller 20 to 48VDC 10W

MA 850 20 to 48VDC 20W

Maximum Current

Consumption

1.25A

2.0A

0.6A

0.7A

0.5A

1.0A

30

Loading...

Loading...