Page 1

Corning

Optical Communications

Corning CORE System MA2000

User Manual

P/N 709C006503 REV:A00 DATE: APRIL 2014

Page 2

Warranties

Hardware

Corning Optical Communications warrants to the original purchaser (“Customer”) that for the duration of the warranty period,

one (1) year, commencing on the date of shipment of the Hardware, unless otherwise agreed in writing by Corning

Optical Communications (the “Hardware Warranty Period”), the Hardware furnished by Corning Optical Communications shall

be free in all material respects from defects in material and workmanship, and shall conform to the applicable portions of the

Specifications, as defined below (the “Hardware Warranty”). If notified by Customer of any such defects in material or

workmanship or nonconformity with applicable portions of the Specifications within the Hardware Warranty Period, Corning

Optical Communications shall promptly, at its own election and expense, repair or replace any such Hardware proven to be

defective under the terms of this Hardware Warranty. Such repair or replacement shall be Customer’s sole remedy and

Corning Optical Communications’ sole obligation in the event this Hardware Warranty is invoked. If any components

comprising a part of the Hardware are replaced or repaired during the Hardware Warranty Period, the Hardware Warranty

Period for such repaired or replaced components shall extend to the longer of (i) the balance of the Hardware Warranty

Period or (ii) three (3) months from the date of repair or replacement. For purposes of this Warranty, “Specifications” shall

mean the specifications and performance standards of the Products as set forth in documents published by Corning Optical

Communications s and delivered to Customer which contain technical specifications or performance standards for the

Products.

If Customer invokes this Hardware Warranty, it shall notify Corning Optical Communications promptly of the claimed defect.

Customer will allow Corning Optical Communications to inspect the Hardware at Customer’s location, or to return the

Hardware to Corning Optical Communications’ closest repair facility. For Hardware returned to Corning Optical

Communications’ repair facility, Customer shall be responsible for payment of all transportation and freight costs (including

insurance) to Corning Optical Communications’ repair facility, and Corning Opt ical Com munications shall be responsible for

all transportation and freight costs (including insurance) incurred in connection with the shipment of such Hardware to other

repair facilities of Corning Optical Communications and/or its return to Customer.

Notwithstanding the foregoing, in no event will Corning Optical Communications be liable for damage to Products resulting

from improper handling during or after shipment, misuse, neglect, improper installation, operation or repair (other than by

authorized Corning Optica l Com munications personnel), alteration, accident, or for any other cause not attributable to defects

in materials or workmanship on the part of Corning Optical Communications. Corning Optical Communications shall not

reimburse or make any allowance to Customer for any labor charges incurred by Customer for replacement or repair of any

goods unless such charges are authorized in advance in writing by Corning Optical Communications.

Software Warranty

Corning Optical Communications warrants to the original purchaser (“Customer”) that for the duration of the warranty period,

one (1) year, commencing on the date of shipment of the Software, unless otherwise agreed in writing by Corning

Optical Communications (the “Software Warranty Period”), the Software shall conform with, and perform the functions set

forth in the Specifications, and shall be free from defects in material or workmanship (the “Software Warranty”). In the event

the Software is proven to be defective under the terms of this Software Warranty, Corning Optical Communications shall

correct such defects or failure and ensure that the Software conforms with, and performs the functions set forth in, the

Specifications. Customer will allow Corning Optical Communications to inspect the Software at Customer’s location or to

return it to Corning O ptic a l Com munications’ closest repair facility.

Notwithstanding the foregoing, Corning Optical Communications shall have no obligation under the Software Warranty if the

Software is modified or used with hardware or software not supplied or approved by Corning Optical Communications or if the

Software is subject to abuse, improper installation or application, accident, electrical or environmental over-stress, negligence

in use, storage, transportation or handling.

Third-party software distributed with the Software may carry certain warranties which, to the maximum extent allowed by law,

Corning Optical Communications s hereby assigns, transfers and otherwise conveys to Customer, provided, however, that

Warranties P/N 709C006503 Page 2

Page 3

Corning Optical Communications itself provides no warranty of any kind, express, implied, statutory or otherwise, for any

third-party software provided hereunder.

Corning Optical Communications does not warrant any hardware, software or services not provided by Corning Optical

Communications.

THIS WARRANTY IS THE ONLY WARRANTY MADE BY CORNING OPTICAL COMMUNICATIONS AND IS IN

LIEU OF ALL OTHER WARRANTIES, EXPRESS OR IMPLIED INCLUDING, BUT NOT LIMITED TO, THE IMPLIED

WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE. CORNING OPTICAL

COMMUNICATIONSS SHALL NOT BE LIABLE FOR ANY OTHER DAMAGE INCLUDING, BUT

NOT LIMITED TO, INDIRECT, SPECIAL OR CONSEQUENTIAL DAMAGES ARISING OUT OF OR

IN CONNECTION WITH FURNISHING OF GOODS, PARTS AND SERVICE HEREUNDER, OR THE

PERFORMANCE, USE OF, OR INABILITY TO USE THE GOODS, PARTS AND SERVICE.

CORNING OPTICAL COMMUNICATIONS SALES AGENTS OR REPRESENTATIVES ARE NOT AUTHORIZED TO

MAKE COMMITMENTS ON WARRANTY RETURNS.

Returns

In the event that it is necessary to return any product against above warranty, the following procedure shall be followed:

1. Return authorization is to be received from Corning Optical Communications prior to returning any unit. Advise Corning

Optical Communications of the model, Serial number, and discrepancy. The unit may then be forwarded to Corning

Optical Communications, transportation prepaid. Devices returned collect or without authorization may not be accepted.

2. Prior to repair, Corning Optical Communications will advis e t he customer of our test results and any charges for repairing

customer-caused problems or out-of-warranty conditions etc.

3. Repaired products are warranted for the balance of the original warranty period, or at least 90 days from date of shipment.

Limitations of Liabilities

Corning Optical Communications’ liability on any claim, of any kind, including negligence for any loss or damage arising from,

connected with, or resulting from the purchase order, contract, quotation, or from the performance or breach thereof, or from

the design, manufacture, sale, delivery, installation, inspection, oper at ion or use of any equipment covered by or furnished

under this contact, shall in no case exceed the purchase price of the device which gives rise to the claim.

Except as expressly provided herein, Corning Optical Comm unications makes no warranty, expressed or implied, with

respect to any goods, parts and services provided in connection with this agreement inclu ding, but not limited to, the implied

warranties of merchantability and fitness for a particular purpose. Corning Optic a l Com munications shall not be liable for any

other damage including, but not limited to, indirect, special or consequential damages arising out of or in connection with

furnishing of goods, parts and service hereunder, or the performance, use of, or inability to use the goods, parts and service.

Reporting Defects

Note: Keep all packing material until you have completed the inspection.

The units were inspected before shipment and found to be free of mechanical and electrical defects. Examine the units for

any damage that may have been caused in transit. If damage is discovered, file a claim with the freight carrier immediately.

Notify Corning Optical Communications as soon as possible in writing.

Warranties P/N 709C006503 Page 3

Page 4

Warnings and Admonishments

There may be situations, particularly for workplace environments near high-powered RF sources, where recommended limits

for safe exposure of human beings to RF energy could be exceeded. In such cases, restrictive measures or actions may be

necessary to ensure the safe use of RF energy.

The equipment has been designed and constructed to prevent, as far as reasonably, practicable danger. Any work activity on

or near equipment involving installation, operation or maintenance must be, as far as reasonably, free from danger.

Where there is a risk of damage to electrical systems involving adverse weather, extreme temperatures, wet, corrosive or

dirty conditions, flammable or explosive atmospheres, the system must be suitably installed to prevent danger.

Equipment provided for the purpose of protecting individuals from electrical risk must be suitable for the purpose and properly

maintained and used. This covers a range of activities inclu di ng lifting, lowering, pushing, pulling, carrying, moving, holding or

restraining an object, animal or person from the equipment. It also covers activities that require the use of force or effort, such

as pulling a lever, or operating power tools.

Where some of the abovementioned activities are required, the equipment must be handled with care to avoid being

damaged.

Observe standard precautions for handling ESD-sensitive devices. Assume that all solid-state electro nic devices are ESDsensitive. Ensure the use of a grounded wrist strap or equivalent while working with ESD-sensitive devices. Transport, store,

and handle ESD-sensitive devices in static-safe environments.

RF Safet y

WARNING! To comply with FCC RF exposure compliance requirements, each individual antenna used for this product must

be fixed mounted in indoor permanent structures, providing a separation distance greater than 50 cm or more from all

persons during normal operation and must not be co-located with any other antenna for meeting RF exposure requirements.

The design of the antenna installation needs to be implemented in such a way so as to ensure RF radiation safety levels and

non-environmental poll uti o n during operation.

WARNING! Antenna gain should not exceed 12.5 dBi.

WARNING! The design of the antenna installation needs to be implemented in such a way so as to ensure RF radiation

safety levels and non-environmental pollution during operation.

Compliance with RF safety requirements:

• Corning Optical Communications products have no inherent significant RF radiation.

• The RF level on the downlink is very low at the downlink ports. Therefore, there is no dangerous RF radiation when the

antenna is not connected.

Power requirements for DC Inputs

WARNING! Only use a special DC supply cable with four connectors

WARNING! Always keep DC IN connectors connected during the product operation

WARNING! Disconnect all power from the equipment by means of an external circuit breaker before connecting or

disconnecting the DC IN connectors.

Warnings and Admonishments P/N 709C006503 Page 4

Page 5

Laser Safety

CAUTION!

Fiber optic ports of the MA2K system elements emit invisible laser radiation at the 1310/1550 nm wavelength window.

The laser apertures /outputs are the green SC/APC Bulkhead adapters located on the front panel of the equipment.

The product is Class 1/Hazard level 1

External optical power is less than 10 mW, Internal optical power is less than 500 mW.

To avoid eye injury never look directly into the optical ports, patchcords or optical cables. Do not stare into beam or view

directly with optical instruments. Always assume that optical outputs are on.

Only technicians familiar with fiber optic safety practices and procedures should perform optical fiber connections and

disconnections of MA2K devices and the associated cables.

Corning CORE System MA2000 has been tested and certified as a Class 1 Laser product to IEC/EN 60825-1 (2007). It also

meets the requirements for a Hazard Level 1 laser product to IEC/EN 60825-2: 2004 to the same degree.

Corning CORE System MA2000 system complies with 21 CFR 1040.10 and 1040.11 except for deviations pursuant to Laser

Notice NO. 50 (2007).

Care of Fiber Optic Connectors

Do not remove the protective covers on the fiber optic connectors until a connection is ready to be made. Do not leave

connectors uncovered when not connected.

The tip of the fiber optic connector should not come into contact with any object or dust.

Refer to the cleaning procedure for information on the cleaning of the fiber tip.

USE OF CONTROLS OR ADJUSTMENTS OR PERFORMANCE OF PROCEDURES OTHER THAN

THOSE SPECIFIED HEREIN MAY RESULT IN HAZARDOUS RADIATION EXPOSURE

Regulatory Compliance I nformation

WARNINGS!

• This is NOT a CONSUMER device. It is designed for installation by FCC LICENCEES and QUALIFIED INSTALLERS.

You

MUST have an FCC LICEN SE or express consent of an FCC Licensee to operate this device. Unauthorized use

may result in significant forfeiture penalties, including penalties in excess of $100,000 for each continuing violation.

ANTENNAS: Use only authorized and approved antennas, cables and/or coupling devices! The use of unapproved

•

antennas, cables or coupling devices could cause damage and may be of violation of FCC regulations. The use of

unapproved antennas, cables and/or coupling devices is illegal under FCC regulations and may subject the user to fines.

Laser Safety P/N 709C006503 Page 5

Page 6

Standards and Certifications

US

Warning!

Changes or modifications to this equipment not expressly approved by Corning Mobile Access could void the

user’s authority to operate the equipment.

Europe

NTRL Safety

Laser Safety

TRA

Corning Optical Communications products have met the approvals of the following certifying organizations:

Company Certification

ISO 9001: 2000 and ISO 13485: 2003

Product Certification

Radio Equipment and Systems

• FCC 47 CFR part 22 – for CELL Frequency Band

• FCC 47 CFR part 24 – for PCS Frequency Band

• FCC 47 CFR part 27 – for LTE and AWS Frequency Bands

• FCC CFR part 15 Subpart B

• FCC CFR part 90

Note: This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant

to Part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful

interference in a residential installation. This equipment generates, uses and can radiate radio frequency

energy and, if not installed and used in accordance with the instructions, may cause harmful interference to

radio or television reception, which can be determined by turning the equipment off and on, the user is

encouraged to try to correct the interference by one or more of the following measures:

- Reorient or relocate the receiving antenna.

- Increase the separation between the equipment and receiver.

-Connect the equipment into an outlet on a circuit different from that to which the receiver is connected.

-Consult the dealer or an experienced radio/TV technician for help.

Radio Equipment and Systems

• EN 301502 – for GSM/EGSM Frequency Bands

• EN 300609 – for DCS Frequency Bands

• EN 301908 – for UMTS Frequency Band

EMC

EN 301 489

UL 60950-1

IEC 60825-1, IEC 60825-2

TRA type approval for UAE

Licensee Contact Informat ion

Industrial Boosters may only be used by FCC licensees or those given express (individualized) consent of license. Corning

Corning Optical Communications certifies all of the VARs listed as licensed installers for CMA. For the list of licensed VARs,

please contact the CMA Tech Support Hotline: (US) 410-553-2086 or 800-787-1266.

Standards and Certifications P/N 709C006503 Page 6

Page 7

About this User Manual

Document Name

Acronym

Description

BDA

BDAC

BTS

BTSC

BU

DL

LOS

PS

RHU

RU

RIU

SC-450

UL

This user guide describes how to perform the physical installation of the Corning CORE System MA2000. The installation

procedures of other units (e.g. RIU, MA850/MA860, LTE) relevant to the system are detailed in their user manuals (see

‘Additional Relevant Documentation’ below).

Additional Relevant Documents

The following documents are required if the corresponding units are included in your system.

MA850/MA860 Installation and Configuration Guide

MobileAccess2000 700/800 Public Safety RHU Quick Start Guide

MobileAccess1000 / MobileAccess2000 User Manual Add end um

for 700 MHz LTE Solution

RIU Installation and Configuratio n Gu ide

SC-450 Installation and Configuration Guide

NMS MA 410/430 Installation and Configuration Guide

MA1000 MA2000 Commissioning Guide

MA Software Version Update Tool

List of Acronyms

Bi-Directional Amplifier

Bi-Directional Amplifier Conditioner

Base Transceiver Station

Base Transceiver Station Conditioner

Base Unit

Downlink

Line of Sight

Power Supply

Remote Hub Unit

Remote Unit

Radio Interface Unit

System Controller

Uplink

About this User Manual P/N 709C006503 Page 7

Page 8

Table of Contents

Warranties ................................................................................................................................. 2

Hardware ....................................................................................................................................................... 2

Software Warranty ........................................................................................................................................ 2

Returns .......................................................................................................................................................... 3

Limitations of Liabilities ................................................................................................................................. 3

Reporting Defects ......................................................................................................................................... 3

Warnings and Admonishments................................................................................................ 4

RF Safety ................................................................................................................................... 4

Compliance with RF safety requirements: .................................................................................................... 4

Power requirements for DC Inputs .......................................................................................... 4

Laser Safety .............................................................................................................................. 5

Care of Fiber Optic Connectors .................................................................................................................... 5

Regulatory Compliance Information ........................................................................................ 5

Standards and Certifications ................................................................................................... 6

Company Certification ................................................................................................................................... 6

Product Certification ...................................................................................................................................... 6

Licensee Contact Information .................................................................................................. 6

About this User Manual ............................................................................................................ 7

Additional Relevant Documents .................................................................................................................... 7

List of Acronyms ....................................................................................................................... 7

Table of Contents ...................................................................................................................... 8

1 Introduction ...................................................................................................................... 11

1.1 Features and Capabilities ................................................................................................................... 11

1.2 MA2000 System Architecture .............................................................................................................. 12

1.2.1 Headend Equipment ................................................................................................................. 13

1.2.2 Remote-End Equipment ............................................................................................................ 13

1.3 Application Examples .......................................................................................................................... 14

1.4 System Monitoring and Managem ent ................................................................................................. 16

2 MA2000 System Elements ............................................................................................... 17

2.1 Enclosure Types.................................................................................................................................. 17

2.1.1 MA2000 MRC............................................................................................................................ 17

Table of Contents P/N 709C006801 Page 8

Page 9

2.1.2 MA2000 - Lite ............................................................................................................................ 20

2.2 MA2000 Remote Location Units ......................................................................................................... 21

2.2.1 MA2000 RU............................................................................................................................... 21

2.2.1.1 MA2000 RU Front Panel .............................................................................................. 22

2.2.1.2 MA2000 RU Rear Panel .............................................................................................. 23

2.2.2 MA1200 Add-on ........................................................................................................................ 23

2.2.2.1 MA1200 Front Panel .................................................................................................... 24

2.2.2.2 MA1200 Rear Panel .................................................................................................... 25

2.2.3 8 x 4 Combiner .......................................................................................................................... 26

2.2.3.1 MA 8x4 Combiner Front Panel .................................................................................... 26

2.2.3.2 MA 8x4 Rear Panel ...................................................................................................... 27

2.3 MA Base Unit ...................................................................................................................................... 27

2.3.1 Base Unit Models ...................................................................................................................... 27

2.3.2 BU Panels ................................................................................................................................. 28

2.3.2.1 MA BU Front Panel ...................................................................................................... 28

2.3.2.2 BU Rear Panel ............................................................................................................. 29

3 Installation Guidelines ..................................................................................................... 30

3.1 Site Considerations ............................................................................................................................. 30

3.2 Infrastructure Preparation ................................................................................................................... 30

3.3 Environmental ..................................................................................................................................... 30

3.4 Installation Requirements .................................................................................................................... 30

3.5 Coaxial Cable Connections ................................................................................................................. 31

3.5.1 General Cable Installation Procedures ..................................................................................... 31

3.5.2 Cable Routing ........................................................................................................................... 31

3.6 Fiber Optic Requirements ................................................................................................................... 31

3.6.1 Authorized Optic Cables ........................................................................................................... 31

3.6.2 Fiber Optic Rules ...................................................................................................................... 32

3.7 RF Rules ............................................................................................................................................. 32

3.8 Coax Cable Lengths and Losses ........................................................................................................ 33

3.9 Antenna Specifications and Guidelines .............................................................................................. 34

3.9.1 Authorized Antennas and Required Specifications................................................................... 34

3.9.2 General Antenna Installation Guidelines .................................................................................. 34

3.10 Grounding Requirement ...................................................................................................................... 34

3.11 Manual Handling ................................................................................................................................. 34

3.12 Power Consumption, Connections and Power Supp lie s .................................................................... 35

3.12.1 Power Safety Instructions ......................................................................................................... 35

3.12.2 Power Consumption of Units .................................................................................................... 35

3.12.3 Cir cuit Br eak er s ........................................................................................................................ 35

3.12.4 Types of Power Supplies .......................................................................................................... 35

3.13 Installation Conventions ...................................................................................................................... 36

4 System Installation .......................................................................................................... 37

4.1 Pre-installation Instruc ti ons ................................................................................................................. 37

4.1.1 Unpacking and Inspection ......................................................................................................... 37

4.2 Communication Room Installation ...................................................................................................... 37

Table of Contents P/N 709C006802 Page 9

Page 10

4.2.1 Rack Installation General Instructions ...................................................................................... 37

4.2.2 MA2000 MRC Wall Mount Installation ...................................................................................... 41

4.2.3 MRC Grounding - Integrated PS Wall Mount Model ................................................................. 43

4.2.4 MRC 2000 Rack Mount Installation .......................................................................................... 44

4.2.5 Fiber Optic Connections ........................................................................................................... 45

4.2.6 Power Connections ................................................................................................................... 45

4.2.6.1 Integrated Power Supply model................................................................................... 45

4.2.7 Antenna Connections ................................................................................................................ 46

4.3 MA2000-Lite Installation and Connections ......................................................................................... 46

4.3.1 Mounting MA2000-Lite .............................................................................................................. 48

4.3.2 MA2000-Lite Connections ......................................................................................................... 49

5 Upgrading and Configuration Examples ........................................................................ 50

5.1 Common USA Configurations ............................................................................................................. 50

5.1.1 iDEN/SMR wit h PC S Add -on .................................................................................................... 50

5.1.2 Cell/PCSH ................................................................................................................................. 52

5.1.2.1 Cell/PCSH and LTE 700 .............................................................................................. 52

5.2 AWS Add-On ....................................................................................................................................... 53

5.3 Public Safety 700/80 0 ......................................................................................................................... 53

5.4 Typical International Configurations .................................................................................................... 54

5.4.1 Typical Asian Configuration: Cell/DCS+ UMTS ........................................................................ 54

5.4.2 Typical European & Midd le East Conf igur at io n: EG SM/DCS + UMTS Configuration .............. 54

Appendix A : System Specifications ..................................................................................... 56

RF Parameters ............................................................................................................................................ 56

RF Frequency Range .......................................................................................................................... 56

Low Band ............................................................................................................................................ 57

High Band ............................................................................................................................................ 58

RF Parameters MA1200 Add-on ......................................................................................................... 59

System Specs ............................................................................................................................................. 60

Fiber Optic Specifications ................................................................................................................... 60

Absolute Maximum Rating .................................................................................................................. 60

Temperature Specifications ................................................................................................................ 60

Specifications of Units ................................................................................................................................. 61

MA 2000 MRC Remote Hub ............................................................................................................... 61

MA 2000 Lite ....................................................................................................................................... 61

MA 2000 Remote Unit ......................................................................................................................... 61

MA 1200 Add-On Specif ic ations ......................................................................................................... 61

Base unit Specifications ...................................................................................................................... 62

Appendix B: Ordering Information ........................................................................................ 63

Table of Contents P/N 709C006802 Page 10

Page 11

1 Introduction

Corning CORE S ystem MA2000 series provides enterprise level indoor cover a ge, of a wide r ang e of m ulti -op erator wire less

services over a single broadba nd infrastructure. Front-end wireless RF services are routed, over optic fibers, to MA2000

series hubs that are securely located in the telecommunication closets at each remote location. These modular service

aggregation platforms precisely combine multiple wireless service signals for simultaneous distribution over a common

broadband infrastructure.

Two remote service hub models are available:

•

MA2000-Lite – supports two remote units that are connected externally, where MA1200 Add-Ons and MA85 0/M A86 0

units can be integrated with the remote units.

•

MA2000 Cabinet (MRC) – internally houses a total of five remote units and MA1200 add-on units with which

MA850/MA860 can be integrated as an external assembly.

MA2000-Lite (left side) and MA2000 Cabinet (right side)

Figure 1-1

1.1 Features and Capabilities

• Multi-service platform that accommodates virtually any combination of wireless voice and data services eliminating the

need for separate overlay networks

• Scalable and future-safe – services can be added and removed without affecting existing operators or end-users

• MA2000-Lite components can be migrated to MA2000 MRC for increased capacity

• All active components are located in the communication closet/room

• Carrier class operation – MA2000 advanced signal handling ensures optimal performance for all services within a multi-

operator deployment

• Local and remote end-to-end monitoring and control through interface to SC-450 controller

• Conditioning and monitoring of input RF signals at the head-end through interface to MA-RIU

Note: Corning Opt ical Com munications has made the t r ansiti on to ‘2000M’ pr od uct s that s up por t b oth s i ng le mode fiber and

multimode fiber. The new Base Unit is des ignate d b y W BM (Wide Band M), an d the new RUs (Rem ote Un its) are indicated

as ‘2000M’ RUs, where t he suffix “M” indica tes that the product will support bot h single mode and m ultimode fiber us age

The new products have th e same packaging and perform ance and are fully backward compatible. Se e

multimode fiber use.

3.6 for details o n

.

Introduction P/N 709C006503 Page 11

Page 12

1.2 MA2000 System Architecture

The MA2000 solution com prises bot h headend and rem ote end e quipment providing an end-to-end comprehensi ve system

solution.

Note: Third-party equipment is sold separately (i.e. cabling, antennas).

At the head-end C orning CORE System elements provide interface t o the wireless service provider’s network , where the

signals can be conditioned through an active interface and transported over optic fiber to the remote end.

At the remote end, the o ptical signal is reconverted t o RF, amplified, filtered an d distributed over t he broadband antenna

infrastructure.

For end-to-end control, controllers ins talled at the hea d-end provid e direct interf ace to the MA elem ents and thr ough them ,

control over the remote end elements.

MA2000 System Architecture

Figure 1-2 shows a basic block diagram of the system operation. On the downlink, services from the BTS/BDA are

transferred via interfac e to the Base Un its (BUs ). T he interfac e, which m a y be passive (i.e. Interf ace Box ) or act ive (RIU) , is

used to attenuate the RF signals to the required levels, converge them and distribute them to the BUs. The BUs

wideband – they are not service specific.

At the BUs, the RF signals are c onverted to optical signals and transmitted over the opt ic fiber to (service-specific) RUs at

the remote locations. At the r emote locations, the RUs suppor ted by the hub (MRC or Lite) reconvert th e optical signal to

RF. The hub elements converg e the voice services together with 802.11 a/b/g data services (if MA850/M A860 units are

installed) and distribute them over the coax antenna infrastructure. The MA SC-450 (in installations with remote

management) provides monitoring and control of all active system elements.

Introduction P/N 709C006503 Page 12

Figure 1-2

are

Page 13

1.2.1 Headend Equipment

At the headend Corning CO RE System elements provide interface to t he wireless service provider’s network, where the

signals can be conditioned through an active interface and transported over optic fiber to the remote end.

Radio Interface Unit (RIU): The RIU conditions the RF Downlink (DL) signals from an operator’s signal source (BTS:

•

base-transceiver stations or BDA: bi-directional amplifiers) located inside the building. The RIU then custom tunes

incoming signals in order to ensure a constant level of RF before signals are passed to/from the Base Unit (BU). RF

Uplink (UL) signals from subscribers’ phones are received from the BU and transported back to the operator’s signal

source (BTS or BDA) and to the operator’s macro network outdoors.

•

Base Unit (BU): The BU converts RF Downlink (DL) signals received from the RIU into an optical signal. This optical

signal is then transported over single or multi-mode fiber optic cabling (SMF/MMF) to/from the MA2000 TSX units,

which are housed inside of IDF/Telc o/IT closets at the remote-end locations, for distribution throughout the facility.

Uplink (UL) signals from subscribers’ phones are received from the antennas and sent back to the TSX units through

the fiber connection to the head-end, where they are converted back from RF optical to RF electrical before being

passed on to the RIU.

•

System Controller (SC-450): The system controller enables centralized remote management and control of all Corning

CORE System MA2000 elements.

1.2.2 Remote-End Equipment

The remote end elem ents interface to the DAS infrastructure. At the r emote end, the optical signal is reconver ted to RF,

amplified, filtered and distributed over the broadband antenna infrastructure.

Remote Units (RUs) – Pre-configured service specific modules that support up to two voice services and perform the

•

optic to RF conversion on signals received from the BU at the remote locations. Signals are automatically filtered and

amplified for transport over broadband coax cable to a passive antenna. Uplink (UL) signals from the antennas are then

converted to optical signals before being transmitted back to the BU.

• MA1200 Add-On – Service specific module that provides support for an additional high band voice service. The AO is a

single service module coupled with an RHU to deliver an additional, third service at a lower incremental cost. The AO

receives RF signal from the RHU and amplifies it for transport across the broadband coax.

•

MA850/MA860 – Module that supports data services

Introduction P/N 709C006503 Page 13

Page 14

1.3 Application Examples

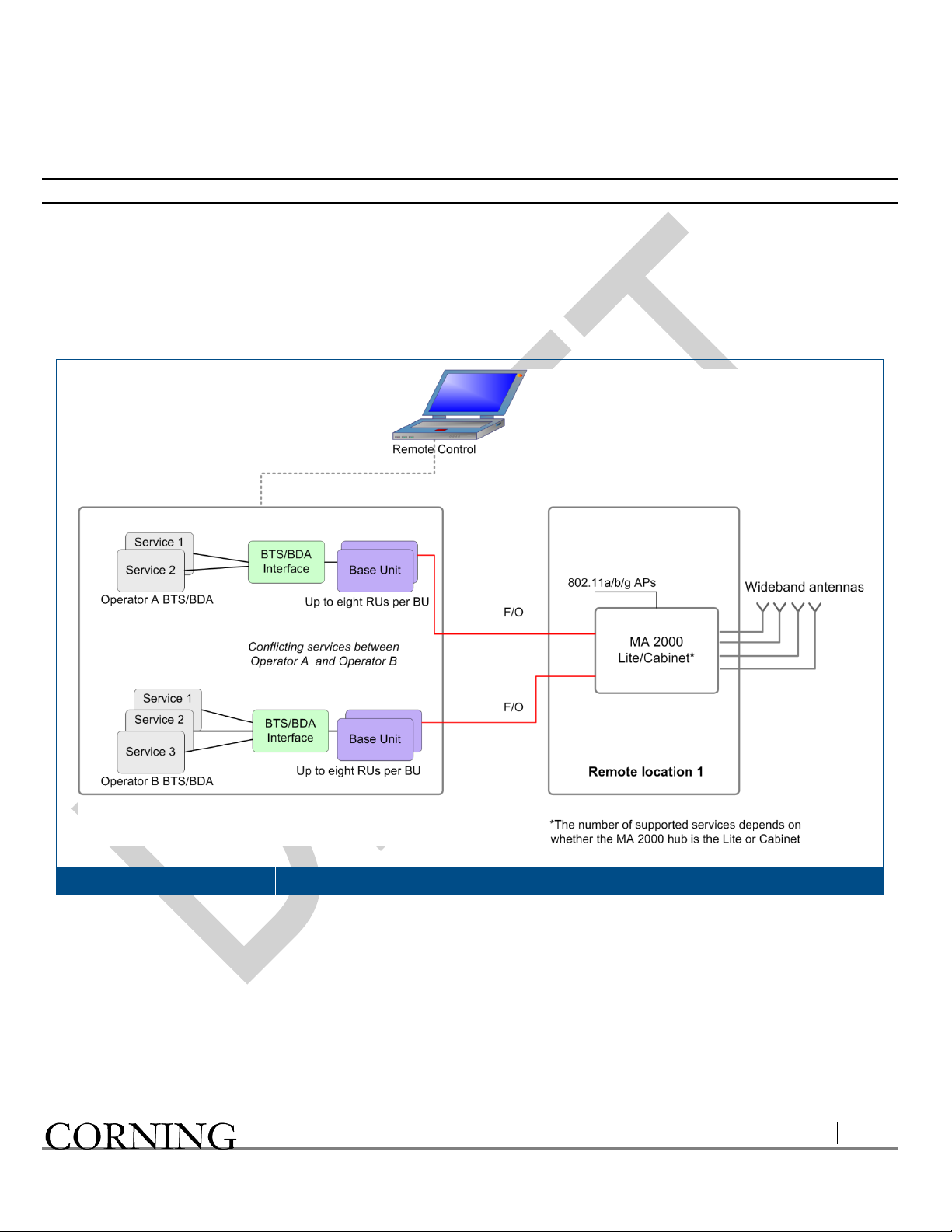

Figure 1-3 shows an example of an MA2000 Cabinet based solution. Five services from two different operators are

distributed, where services from Operator A conflict with those from Operator B.

The converted optical sign a l is r outed f r om the BUs dir ec tl y to the corresponding R Us in each Ca bin et o ver o ptic f iber . Each

BU supports connections to 8 RHUs. Additional BUs are required for connection to more RUs.

Services 1 and 2 are distri buted through one of the RHUs supported in each Cabi net. Services 3, 4 and 5 are distributed

through the second RU and the MA1200 unit connected to that RU.

MA850 and MA860 converge 802.11a/b/g data services with the voice services to be distributed through a common

infrastructure of coax and wideband antennas.

Example of MA2000 Cabinet Architecture

Introduction P/N 709C006503 Page 14

Figure 1-3

Page 15

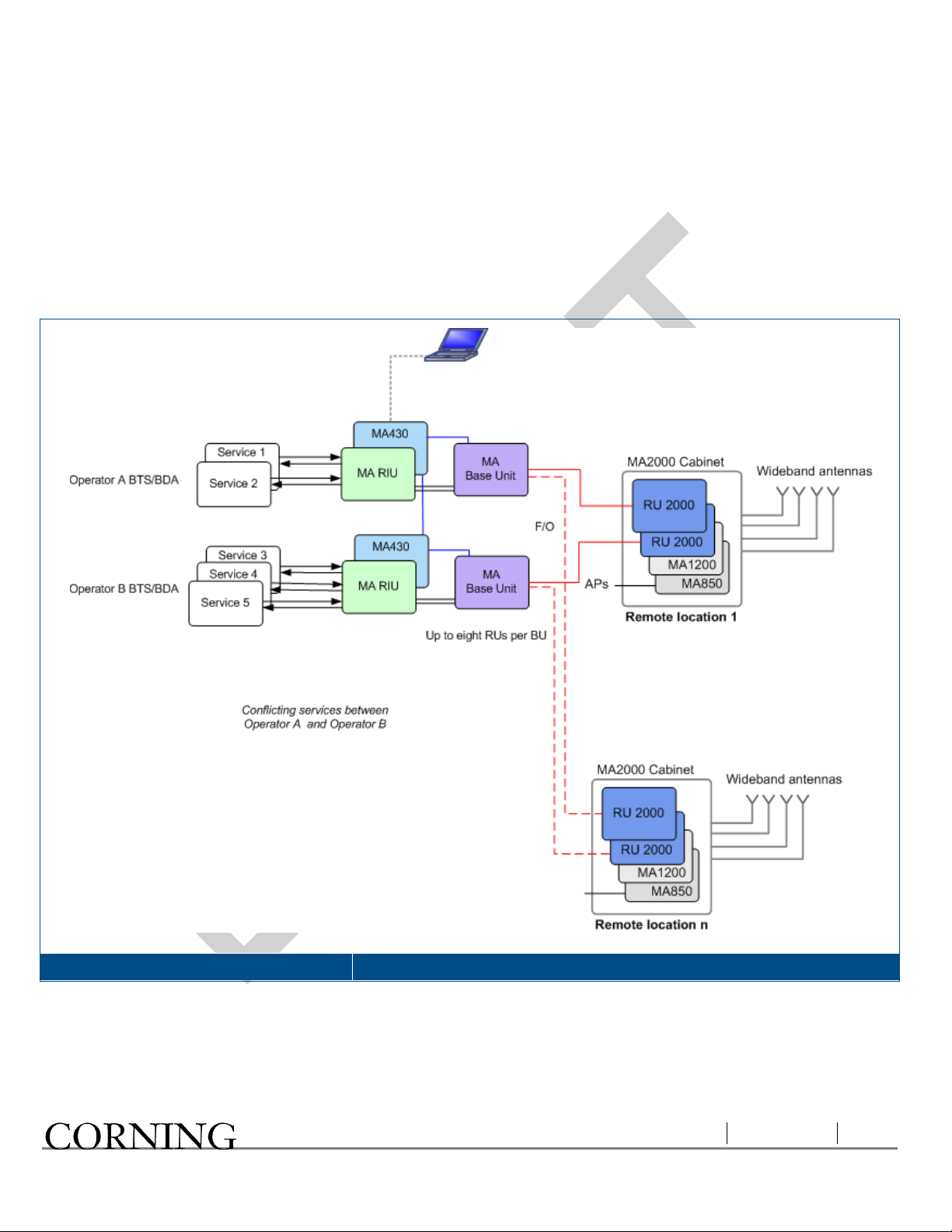

Figure 1-4 shows an exam ple of an MA2000-Lite based solution. Four services from two different operators are distributed.

The converted optical signal is routed from the BUs directly to the corresponding RUs over optic fiber.

Services 1 and 2 are distributed through one of the RUs supported by MA2000-Lite. Services 3 and 4 are distributed

through the second RU. The combiner and filter provides interface to the antennas.

Example of MA2000-Lite Architecture

Figure 1-4

Introduction P/N 709C006503 Page 15

Page 16

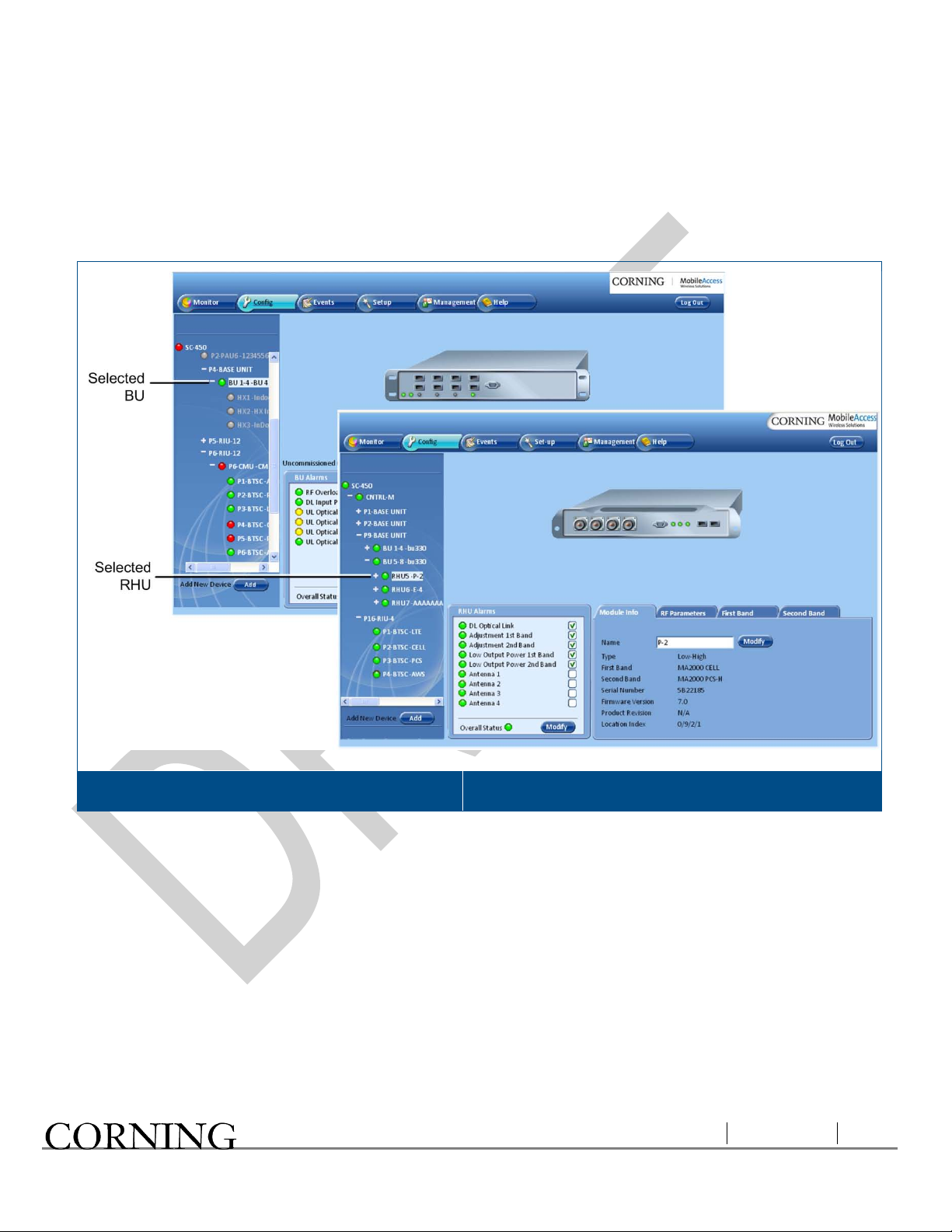

1.4 System Monitori ng and Management

The MA2000 system elements are centrally manage d via the CORE SC-450 Control ler. The elements are displayed i n a

hierarchal corresponding to their physical connections in the topology tree of the Management GUI.

The following shows t he Configuration tabs of the selected BU and RHU. Refer to the SC-450 Controller User Manual for

information on how to configure and manage MA2000 elements .

Example of MA2000 BU and RHU Configuration Tabs

Introduction P/N 709C006503 Page 16

Figure 1-5

Page 17

2 MA2000 System Elements

This chapter provides a full, detailed description of each of the system elements and their individual connections. The

element descriptions are organized according to the following sections:

• Enclosures types – MRC (MA2000 Remote Cab in et) and Lit e

• Remote Location Elements:

• MA2000 Remote Units (RUs)

• MA1200 Add-on

• Base Unit

Note: The following elem ents are fully described in their corresponding user guides: MA RIU, MA 850 /MA860, SC-450

Controller, MCT/NMS Management Application (described in MA410/MA430 Installation and Configuration Guide).

2.1 Enclosure Types

This section describes both types of enclosures (MRC/Lite) and their external connections.

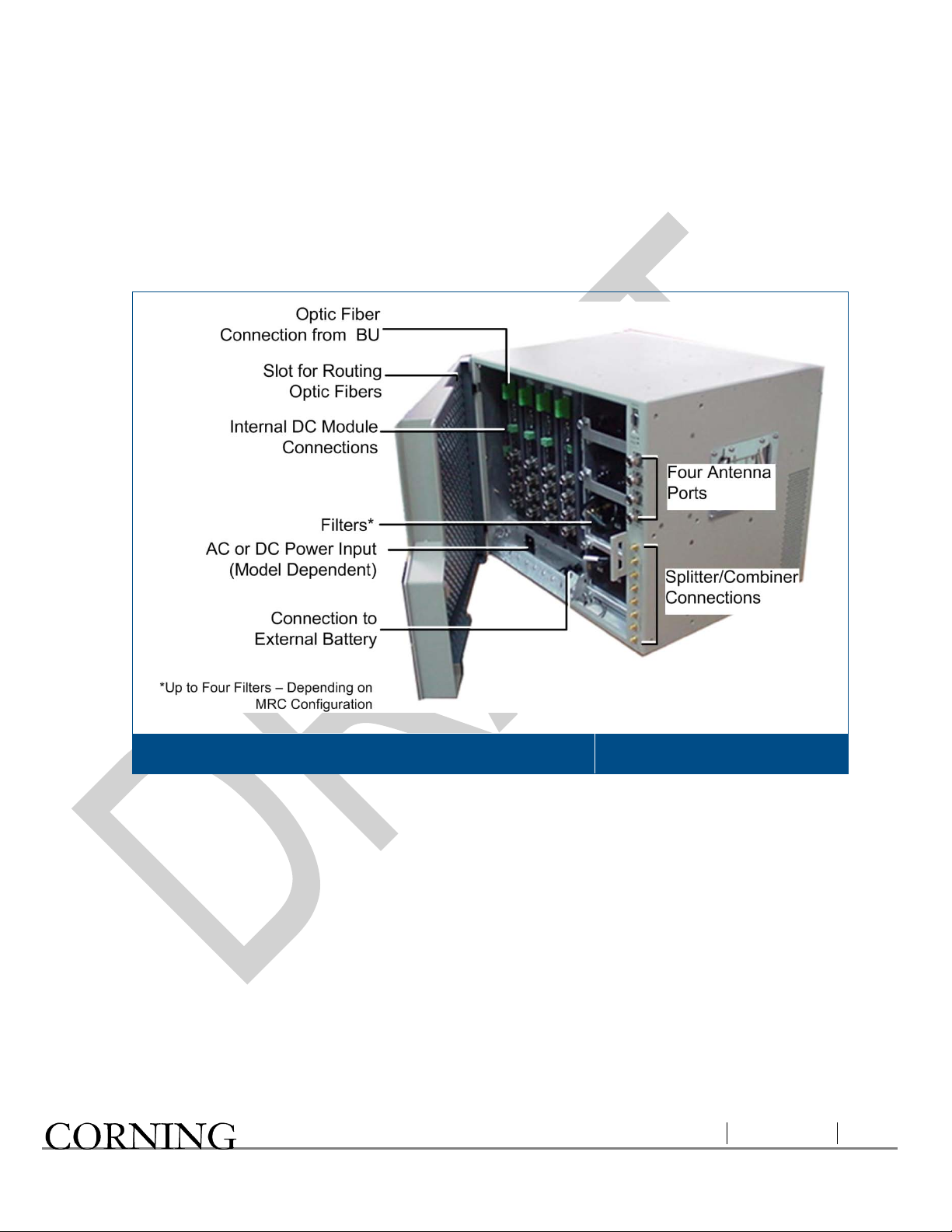

2.1.1 MA2000 MRC

MA2000 MRC Closed Cabinet View

MA2000 Cabinet supports the following functions:

• Compactly houses up to five MA2000 RHU and MA1200 modules and the required filters

Figure 2-1

Note: The number of modules that can be housed depends on the models, required filtering, etc.

• MA850/MA860 can be connected externally

• Converges all voice services and provides a single interface to the antennas through external connections

• Wall mounted or rack mounted

MA2000 System Elements P/N 709C006503 Page 17

Page 18

• Supplied in two models with differing power supply:

• Integrated power supply – fed from an external AC power source. The MA2000 RHU an MA1200 Add-on modules

are internally connected to the power supply. This model includes a battery connection as well.

• External power supplies – power is routed to external connectors from which power is routed internally to each

MA2000 RHU and MA1200 Add-On module

Open door views

Figure 2-2 s ho ws a n op en MA2000 MRC c a bin et, inte grated power supply model , w ith f our MA2000 RHU modules an d f our

filters. (For clarity, the internal connections are demonstrated separately in Figure

2-3).

MA2000 MRC Open Cabinet View (without Internal Connections)

MA2000 System Elements P/N 709C006503 Page 18

Figure 2-2

Page 19

Figure 2-3 shows the MA2000 MRC with the cabling. The antenna ports of the individual modules are c onnected to the

relevant filters and to the 8 x 4 Combiner. The PS connections of each module are also connected to cables that are

internally routed to the integrated PS (a full detailed description of the connections is provided in chapter

The fiber optic connections are not displayed.

Note:

5).

MA2000 MRC Open Cabinet View (without Internal Connections)

Figure 2-3

MA2000 System Elements P/N 709C006503 Page 19

Page 20

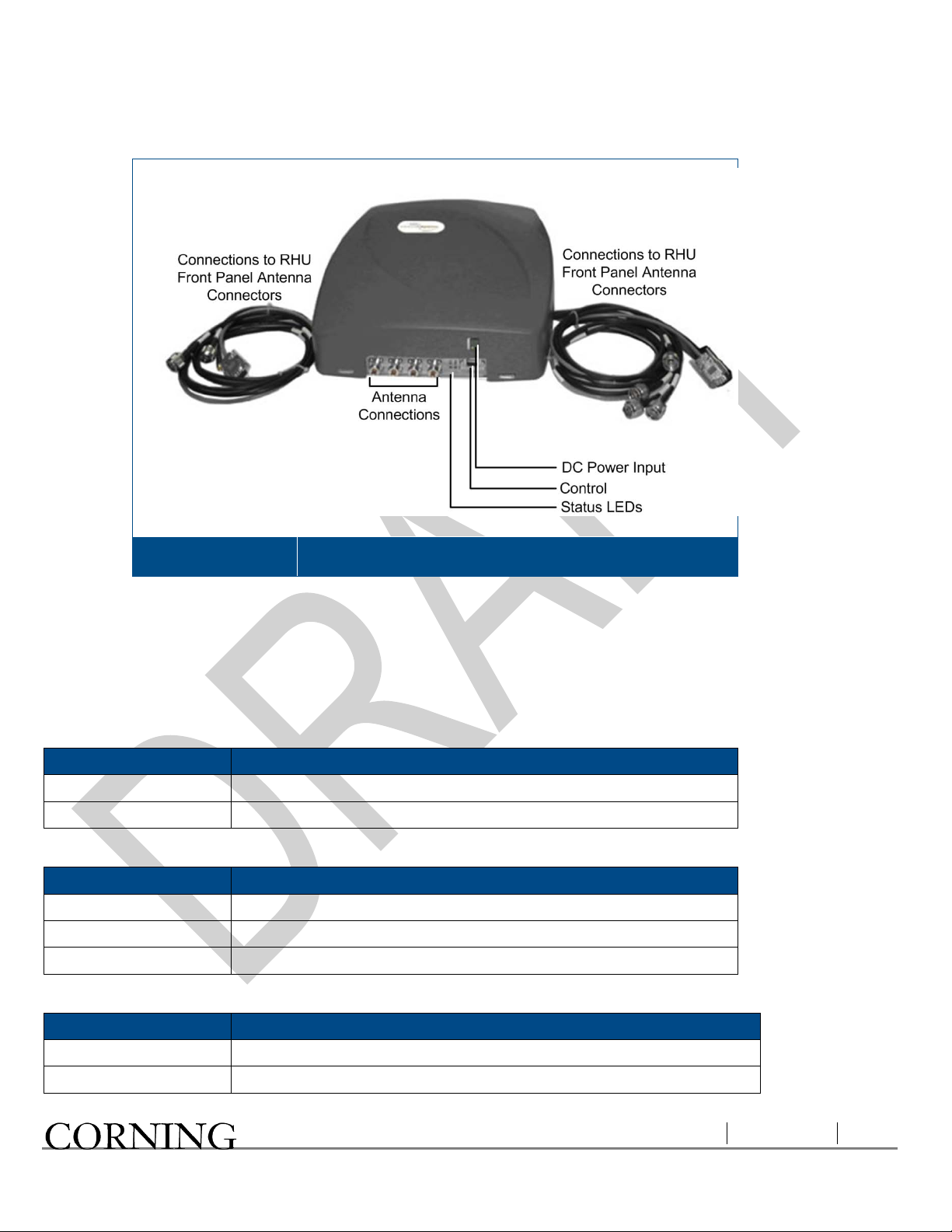

2.1.2 MA2000 - Lite

Cable Connector

Description

Connector

Description

LEDs

Description

The MA2000-Lite is designed to support up to 8 voice services, in addition to 802.11 data services.

MA2000-Lite System

Figure 2-4

MA2000-Lite capabilities:

• External connections to two MA2000 RHUs (to which MA1200 Add-on units can be added)

• Internal filters and combiner (converges all services)

• Connection to MA850/MA860 for support of 802.11a/b/g data services

• External power supplies

The MA2000 enclosure contains two sets of cables, each providing connections to two MA2000 RUs.

Four N-type connectors Coax connections to corresponding antennas

1x DB-9 connector Connection to RU front panel RS232 connector

The following table describes the MA2000-Lite front panel connectors.

Ant-1 to Ant-4 (N-type) Coax connections to corresponding antennas

Control Control connector for MA service personnel.

Power 20 to 48V DC power input

The following table describes the front panel LEDs.

Run Module is operating properly.

Power Green – required power is suppl ied .

MA2000 System Elements P/N 709C006503 Page 20

Page 21

2.2 MA2000 Remote Location Units

Service specific units loca ted at each remote locatio n convert the optical s ignals received fr om the Base Units to RF signals

and route them to the coax antenna infrastructure.

The voice services are converged by an 8x4 Combiner unit that is installed in the Cabinet enclosure and the Lite

Note:

module.

The following types of service specific elements are available:

• Remote Units (RUs) – support two voice services

• MA1200 Add-On – adds an additional (third) voice service to the host RU to which it is connected.

• MA850/MA860 – converges data services from 802.11a/b/g APs and distributes them over the same coax and antenna

infrastructure

Note: The MA850/MA860 is described in detail in the MA850/MA860 Configuration and Installation guide.

2.2.1 MA2000 RU

MA2000 RU is a service specific module that is either housed in th e M A20 00 Ca b inet or connected externall y to the M A2000Lite module.

It provides the following functions:

• Performs the optic to RF (and vice versa) conversion at the remote locations

• Supports two services – high-band and low-band

• Interfaces to the optic fiber from the BU

• Add-On ready – MA1200 can be added to support an additional services

• Remote management - requires connection of host BU connection to an SC-450 controller

Note: MA2000 also supports management via MA410/MA430 controllers.

MA2000 System Elements P/N 709C006503 Page 21

Page 22

2.2.1.1 MA2000 RU Front Panel

LED

Description

The MA2000 RU front pan el contains the fiber optic connecti ons to the BU, four coax connectio ns to the antennas, power

connections and status indicators.

MA2000 RU Front Panel

0 Front Panel Indicators

COMM Active communication detected

LINK Optical link to BU detected

PWR DC power connection.

Figure 2-5

20 to 48VDC

MA2000 System Elements P/N 709C006503 Page 22

Page 23

2.2.1.2 MA2000 RU Rear Panel

Add-on control:

Add-on Control

From

DL, UL:

The MA2000 RU rear panel provides the co ntro l, RF interf ace an d optic int erfac e ports th at enable c onnec ting t o an MA1200

Add-On unit.

MA2000 RHU Rear Panel

Transmits the control signals from MA1200 Add-On module to the

MA2000 RU module. The

MA1200 Add-On

Transmit the RF signals to- and from- the MA1200 Add-On module.

These ports are connected to the corresponding ports on the MA1200

rear panel: DL to DL, UL to UL.

Figure 2-6

port is connected to the

port.

2.2.2 MA1200 Add-on

The MA1200 Add-On module is used to pro vide support for an additional serv ice to an MA 200 0 RU. The host MA 2000 RU

and the MA1200 Add-On are int erconnected and either housed in a MA2000 Cabin et or connected ex ternally to a M A2000Lite ‘enclosure’.

MA1200 Add-On provides the following functions:

• Single service – either low-band or high-band

• Installed only as an addition to a MA2000 RU

Note: MA1200 Add-on does NOT interface directly to the fiber optic infrastructure, does not perform the optic to RF

conversion and does not interface to the antennas. All these functions are provided by the host MA2000 RU unit.

MA2000 System Elements P/N 709C006503 Page 23

Page 24

2.2.2.1 MA1200 Front Panel

LED

Description

LED

Description

The MA1200 f ront pane l contains the power c onnectio n and status LEDs. (The RS-232 connector is r eserved f or MA service

personnel). The figure below shows the MA 1200 front view. It is followed by a description of the connections and LEDs.

MA2000 1200 AO Front Panel

Table 2-1. MA1200 Front Panel Connectors

RS232 Servicing connector to be used by MA service personnel for maintenance.

PWR DC Power connection.

25 to 48VDC

Table 2-2. MA1200 Front Panel LEDsndicators

RUN When blinking, indicates that the RU is in normal operating mode.

PWR Power ON

Figure 2-7

MA2000 System Elements P/N 709C006503 Page 24

Page 25

2.2.2.2 MA1200 Rear Panel

Add-on Control:

From –

Add-on Control

To

DL, UL:

High:

The MA1200 rear panel contains the control connectors and the RF connections to the MA2000 RU and MA850/MA860.

MA2000 1200 AO Rear Panel

Table 2-3. MA1200 Rear Panel Connectors

Transmits the control signals between the MA1200 module and

the MA850/MA860 and MA2000 RU modules.

Connected to the MA2000 RU

– feeds control signals to MA850/MA860 (in configurations

that include MA850/MA860)

Transmit the RF signals to- and from- the MA1200 add-on

module. These ports are connected to the corresponding ports

on the MA 2000 rear panel: DL to DL, UL to UL.

Service RF output port. Connected to combiner/splitter to be

combined with other services supported by the MA2000 system.

Figure 2-8

receives control signals from the MA2000 RU.

connector.

MA2000 System Elements P/N 709C006503 Page 25

Page 26

2.2.3 8 x 4 Combiner

Connector

Description

Ant-1 to Ant-4 (N-type)

Connections to corresponding antennas

Setup

Future Option

Note: This unit is internal to the MA2000 system – both Cabinet and Lite models.

This unit is installed in the MA2 000 system Cabinet and MA 2000-Lite enclosures . It combines the RF outputs of the RUs in

the corresponding system and provides a common interface to the coax antenna infrastructure.

The 8x4 Combiner provides the following capabilities:

• Supports up to eight RF voice service connections: four high-band and four low-band

• Supports four antenna interface ports (located externally on the MA2000-Lite)

• Provides low RF loss and high isolation for the input devices

2.2.3.1 MA 8x4 Combiner Front Panel

The front panel of the unit contains the four antenna interface ports, LEDs and control port.

8 x 4 Combiner Front Panel

2-4 describes the front panel connectors.

Table

Table

2-4. 8 x 4 Front Panel Interfaces

Figure 2-9

MA2000 System Elements P/N 709C006503 Page 26

Page 27

2.2.3.2 MA 8x4 Rear Panel

SMA Connectors

Description

Low Band

Four connectors (ports 1-4) for the low-band outputs of the corresponding remote

Control

Interfaces to the Digital card (that enables antenna monitoring)

The rear panel of the unit contains four low-band and four high-band ports as well as the control port.

8 x 4 Combiner Rear Panel

Table 2-5 describes the 8 x 4 rear panel connectors.

2-5. 8 x 4 Combiner Rear Panel Connectors

Table

unit. Refer to Chapter 5 for the connections relevant to each configuration.

High Band Four connectors (ports 5-8) for the high-band outputs of the corresponding remote

unit. Refer to Chapter

Figure 2-10

5 for the connections relevant to each configuration.

2.3 MA Base Unit

The BU (Base U nit) is a wideband de vice that performs the conversion bet ween the BTS/BDA (pas sive or active) interf ace

RF signal and the remote units’ optic signal.

Base Unit capabilities

• Supports all services distributed by Corning CORE Systems

• Fiber connection to up to 8 RUs

• Setup and monitoring through connection to the host SC-450 controller and NMS software application

• Dry contact alarms

• Front panel indicators providing status on optical link internal circuitry and signal level

2.3.1 Base Unit Models

Two models of MA BUs are available:

• B4U - four port unit comprising one optical module supporting optic connections to up to four RHUs

• B8U – eight port unit comprising two optical modules supporting optic connections to up to eight RHUs

Each optical module is separately accessed and managed in the MCT and NMS management applications.

Note:

MA2000 System Elements P/N 709C006503 Page 27

Page 28

2.3.2 BU Panels

LED

Description

2.3.2.1 MA BU Front Panel

The front panel contains the optical connections and indic ators. Each four-port element has a dedicated set of indicators

(PWR, LSR and Link 1 to Link 4 or Link 5 to Link 8).

B4U and B8U Front Panels

Table 2-6. MA BU Front Panel Indicators

PWR Power input detected for the corresponding unit.

20 to 48VDC

LSR

Link 1-4, 5-8

ON - laser circuitry for the corresponding element (group of four ports) is

functioning correctly.

ON - the optical link to/from the connected remote functions within the

specifications in both directions.

Blinking - optical power from remote is lower than required

Figure 2-11

MA2000 System Elements P/N 709C006503 Page 28

Page 29

2.3.2.2 BU Rear Panel

Connector

Description

The BU rear panel contains the RF connections, Alarms, NMS and power connections.

Note: Figure

2-12 shows the rear panel of an 8-port BU. A 4-port BU contains a single UL and a single DL RF connector.

B8U Rear Panel

Figure 2-12

Table 2-7. MA BU Rear Panel Connections

Uplink output

Uplink connectors to be connected on BTS/BDA side. For an 8-port BU, both UL connectors

must be connected.

Downlink input

Downlink connectors to be connected on the BTS/BDA side. For an 8-port BU, both DL

connectors must be connected.

Com Port

Connection to SC-450 controller, rear panel RS485 port.

RS485

Alarms

Dry-contact connections to BTS/BDA (normally closed). Relevant only for system without SC450 controller.

PWR Power connection: 20 to 48VDC

MA2000 System Elements P/N 709C006503 Page 29

Page 30

3 Installation Guidelines

This following installation rules are based on the assumption that site survey and installation planning (including power

requirements) have been completed.

3.1 Site Consider ations

• The distance between the service antenna and the coverage area should correspond to LOS requirements for maximum

coverage area.

• The maximum fiber path loss is 6 dB.

• The system delay of the optical system must be taken into consideration when there are neighboring BTS sites

overlapping in coverage.

3.2 Infrastructure Preparati on

The infrastructure preparation consists of two main phases:

A.

Floor Planning: Planning the distribution of the antennas on each floor to provide the required coverage.

B.

Telecom Closet Planning: Planning the layout of the devices and cables in the telecom closet or shaft. This includes the

MA850/MA860, 802.11 Access Points, cabling and other voice service distribution systems that are relevant to the specific

installation.

3.3 Environmenta l

Humidity has an advers e effect on the reliability of the equipm ent. It is recommended to install the equ ipment in locations

having stable temperature and unrestricted air-flow.

The installation location for the system should be well ventilated. The equipment has been designed to operate at the

temperature range and humidity level as stated in the product specifications with a relative humidity of max. 90% and

temperatures ranging as follows:

Operating: 0 to 50

Storage: -20°C to 85°C (-4°F to 185°F)

o

C (-4° to 185°F)

3.4 Installation Requirements

• Mounting surface shall be capable of supporting the weight of the equipment.

• In order to avoid electromagnetic interference, a proper mounting location must be selected to minimize interference from

electromagnetic sources such as large electrical equipment.

• Working space available for installation and maintenance for each mounting arrangement. Ensure unrestricted airflow.

• Ensure grounding connector is within reach of the ground wire.

• Ensure a power source is within reach of the power cord and the power source has sufficient capacity.

• Where appropriate, ensure unused RF connectors are terminated.

• Do not locate the equipment near large transformers or motors that may cause electromagnetic interference.

• Reduce signal loss in feeder cable by minimizing the length and number of RF connections.

• Ensure the equipment will be operated within the stated environment (refer to datasheet).

• Where appropriate, confirm available of suitably terminated grade of RF and optical fiber.

• Observe handling of all cables to prevent damage.

Installation Guidelines P/N 709C006503 Page 30

Page 31

3.5 Coaxial Cable Connections

3.5.1 General Cable Installation Procedures

Note: The installer should be familiar with the ANSI/TIA/EIS-568 Cabling Standard gui del in es.

Observe the general cable installation proc edures that m eet with the building c odes in your ar ea. The building c ode requires

that all cabling b e installed abov e ceiling level (where applicabl e). The length of cable fr om the risers to ea ch antenna m ust

be concealed above the ceiling.

The cable must be properly su pported and maintained straight using velcro cable ties, cable trays and clamps or hanger s

every 10 feet (where practical above ceiling level). Where this is not practical, the following should be observed:

• The minimum bending radius of the supplied ½” coax cable should be 7”.

• Cable that is kinked or has a bending radius smaller than 7” must be replaced.

• Cable runs that span less than two floors should be secured to suitably located mechanical structures.

• The cables should be supported only from the building structure.

• All cables shall be weather-resistant type

• Cable length - determined by the system installation plan. When calculating the cable length, take into account excess

cable slack so as not to limit the insertion paths.

3.5.2 Cable Routing

.

Ensure all cables, e.g. power cable, feeder cable, optic fiber, commissioning cable, connecting are properly routed and

secured so that they are not damaged.

3.6 Fiber Optic Req ui rements

3.6.1 Authorized Optic Cables

• Either single mode or multimode fiber can be used with Corning CORE 2000M products , whil e MA2000 products can

only be used with single mode fiber.

• Only Multimode fiber, 50/125 or 62.5/125um complying with ANSI/TIA/EIA-568-B series, EN50173-1 or ISO/IEC 11801

can be used. The fiber length can be up to 300 meters assuming the following qualifications:

• All fiber in a given length of fiber must be of the same core diameter.

• All Bulkhead adapters must be Single mode SC APC (Green) adapters.

• All terminations, cross connections or patches must be direct fusion splice or Corning Optical Communications specified

patch cords according to the listed below:

900 microns patchcord for splicing, 2 Meters, 2 x SC APC

Diamond p/n ENC/1045341 Beige boots, 62.5/125/900

Diamond p/n ENC/1045340 Black boots, 50/125/900

Zipcord patchcord, 4 x SC APC, 50/125/900/2000/4500 micron

Diamond p/n ENC/1045342 Black/Brown boots, 1Meter

MA# 500001057

MA# 500001058

MA# 50000105

Diamond p/n ENC/1045343 Black/Brown boots, 3 Meter

Zipcord patchcord, 4 x SC APC, 62.5/125/900/2000/4500 micron

Installation Guidelines P/N 709C006503 Page 31

MA# 500001060

Page 32

Diamond p/n ENC/1045344 Beige/Brown boots, 1 Meter MA# 500001061

Diamond p/n ENC/1045345 Beige/Brown boots, 3 Meter MA# 500001062

3.6.2 Fiber Optic Rules

ATTENTION!

Please also refer to the Laser Safety section in the document Preface.

• Use only 8-degree SC/APC connectors (green color).

• Use only fusion splice for connecting two fibers.

• Fiber optic cables require proper handling. Do not stretch, puncture, or crush the fiber cable(s) with staples, heavy

equipment, doors, etc.

• Always maintain the minimum bending radius specified by the cable manufacturer. The minimum bend radius is usually

10 times the cable's outer diameter. In the case of single optical fiber that is not in a cable, the minimum bending radius

to be observed is 30 mm.

• Pay special attention w hile c onnec ti ng the SC APC connectors - ensure that you hear a “click”, indicating a secure

connection

• Use minimum splicing/connectors to achieve minimum losses on the fibers.

• Use precaution while installing, bending, or connecting fiber optic cables.

• Use an optical power meter and OTDR for checking the fiber optic cables.

• Make sure the environment is clean while connecting/splicing fiber optic cables.

• All fiber optic connectors should be cleaned prior to connecting to the system

• Fiber connector protective caps should be installed on all non-terminated fibers and removed just before they are

terminated.

• Check the fiber optic connections.

• Never look directly into the end of a fiber that may be carrying laser light. Laser light can be invisible and can damage

your eyes.

3.7 RF Rules

• Use coax RG223, 50ohm, male-to-male N-type for RF connections from the BUs to the BTS/RBS and to the RIU.

• When using the Corning CORE System in an environment in which other indoor coverage systems are installed, it is

recommended (where possible) that the antennas are placed at least two meters apart

• When bending coax cables, verify that the bending radius does not exceed the coax specifications.

• Use wideband antennas supporting a range of 800 MHz to 2500 MHz

• Use a VSWR meter (i.e. Site Master or equivalent) for checking coax cables, including the antennas. (<2). The VSWR

must be measured prior to terminating the RUs in the remote communication rooms

• Terminate all unused RHU, AO and RIU ports with a 50 ohm load

• Make sure that the VSWR measured at the coax cable meets the product specification. The VSWR must be measured

prior to terminating the RHU RF ports in the remote communication rooms.

Installation Guidelines P/N 709C006503 Page 32

Page 33

3.8 Coax Cable Lengths and Losses

Coax Length

Coax Loss

(900 MHz)

Connector

Loss

Total Loss

Use coax ½”, 50ohm, male-to-male N-type, for connecting to RHU and antenna ports.

The required distance between the antennas (installed in the ceiling) depends on the infrastructure and calculated path-

Note:

loss. For example, if ther e is free space-loss between the antennas, a minimum distance of 100 ft is required; if there are

partitions (loss) between the antennas, a distance of less than 100 ft between them is allowed.

Table 3-1. Typical Coax Cable Lengths and Losses

30 0.7 1.5 2.2

40 0.9 1.5 2.4

50 1.1 1.5 2.6

60 1.3 1.5 2.8

70 1.5 1.5 3

80 1.7 1.5 3.2

90 1.9 1.5 3.4

100 2.1 1.5 3.6

110 2.3 1.5 3.8

120 2.5 1.5 4

130 2.7 1.5 4.2

140 2.9 1.5 4.4

150 3.1 1.5 4.6

160 3.3 1.5 4.8

170 3.5 1.5 5

180 3.7 1.5 5.2

190 3.9 1.5 5.4

200 4.1 1.5 5.6

Installation Guidelines P/N 709C006503 Page 33

Page 34

3.9 Antenna Specifications and Guidelin es

Determine the antenna installation configuration, according to the transmission and coverage requirements and the

installation site conditions.

3.9.1 Authorized Antennas and Required Specifications

External antennas - No limitation on any vendor of available external antennas with respect to the following requirements:

• Omni Directional or Directional

• Supported frequency range: wideband antennas supporting a range of 700 MHz to 2500 MHz

• Gain: up to 12.5 dBi

• Impedance: 50 Ohm

• Types of couplers/splitters – depends on number of splits

3.9.2 General Antenna Installation Guidelines

• The wideband antenna should be installed at a convenient location, free of metallic obstruction (can also be installed in

plenum spaces).

• Install the connected antenna at the designated height and tune it roughly toward the Service coverage area.

• Each individual antenna used for this transmitter must be installed to provide the separation distance as specified in the

FCC grant from all persons during normal operation and must not be co-located with any other antenna for meeting RF

exposure requirements

3.10 Grounding Requirement

Verify that the equipm ent has been well groun ded (refer to the gro unding lug located on t he rear of the MRC c abinet). This

includes antennas and all cables connected to the system. Ensure lightning protection for the antennas is properly grounded.

3.11 Manual Hand lin g

During transportation and installation, take necessary handling precautions to avoid potential physical injury to the installation

personnel and the equipment.

Installation Guidelines P/N 709C006503 Page 34

Page 35

3.12 Power Consu mption, Connections and Power Supplies

Unit Type

Voltage Input

Typical Pow er

Consumption

Maximum Current

Consumption

36 to 60 VDC

3.12.1 Power Safety Instructions

SAFETY WARNINGS

• When installing or selecting the power supplies:

• Be sure to disconnect all power sources before servicing.

• Calculate the required power according to the requirements of the specific installation and then determine the

configuration of the power supplies . The req uire d DC cables will then be deter mined by the selected PS configuratio n.

• Use only UL approved power supplies

• AC and DC power supply cables – only use the power cords supplied with the units

• Install external over-current protective devices for the system according to the requirements described in section

3.12.2 Power Consumption of Units

Table 3-2. Power Requirements

3.12.2.

MA2000 Remote Cabinet 20 to 48VDC 25W 1.25A

MA2000-Lite 20 to 48VDC 3W 0.15A

RU 2000 20 to 48VDC 25W 1.25A

Add-on Unit 1200 25 to 48VDC 50W

RIU 20 to 48VDC 12W

Base Unit 20 to 48VDC 14W

MA410/MA430 Controller 20 to 48VDC 10W

SC-450 Controller

MA850/MA860 20 to 48VDC 20W

10W

2.0A

0.6A

0.7A

0.5A

0.2A

1.0A

3.12.3 Circuit Breakers

Install fuse protections for the system according to the following criteria:

• The following system elements require external fuse protection: RIUs, BUs, and SC-450 Controllers.

• Referring to Table 3-2, calculate the required fuse protection.

• Example: a set of three elements consisting of a BU, RIU and SC-450 controller requires a 2A circuit breaker.

3.12.4 Types of Power Supplies

Corning Optical Communications supplies various power supplies that can be installed in a rack or mounted on a wall,

depending on your configuration.

Installation Guidelines P/N 709C006503 Page 35

Page 36

3.13 Installation Convent i ons

Some of the basic installation conventions are listed below for the MA 2000 system:

• Base Units – are usually concentrated in the same location, most often in the main communication room.

• Remote Cabinet/Lite – usually placed in the communication shaft or closet of a corresponding floor so they can be easily

located. Each cabinet (or MA2000-Lite) can typically cover a floor of up to 30,000 sq ft.

• Fiber optic cable - bundled fibers are terminated into the Base Units in the main communication room. The fibers are

then routed to each coverage locations where individual fibers terminate into splice boxes. The splice box couples the

installed fiber into the remote units. Enough spare fibers should be installed to take into account future expansion of the

system.

For example, for thr ee rem ote u nits , s ix f iber s ar e r eq uired. Ho w ever , to al lo w for f utur e expansion, it is recom mended to

install additi on a l optic fibers to be connected to additional RHUs.

The following figure illustrates fiber optic routing to Remote Cabinets.

Illustration of Fiber Optic Routing

For remote power supply configuration - cable bundles are routed from the main communication room and individual wire

•

pairs are terminated into the power feed of individual units.

By providing power from a single distribution point, maintenance can be reduced and UPS backup can be easily

provided. The maximum distance from the source to the termination spot is 1000 feet using 18 gauge wires.

In many locations local codes do not require power to be run t hrou gh c on dui t if 100 watts or less is us ed. Pl e ase c ons ult

the regulations in your local j urisdiction prior to deplo ying remote power. W hen power cables require d istances greater

than 1000 feet 14 or 16 gauge wire may be used.

•

On each floor - the antennas are connected to the Remote Cabinet or MA2000-Lite system using coax cables.

Installation Guidelines P/N 709C006503 Page 36

Figure 3-1

Page 37

4 System Installation

This chapter describes how the communication room and cabinet are installed.

Be sure to read the installation requirements (see Chapter 3) before proceeding with the actual connections.

Note:

4.1 Pre-installation Instructions

In order to describe the installation process clearly, it will be described as consisting of two logical parts:

A.

Telecommunications room – installing the RIUs, BUs, SC-450 controller, and the required

telecommunication room close to the RF signal source. This installation may differ between single and multi-building

topologies.

B.

Remote locations – two types of installations:

• MRC Cabinet

• MA2000-Lite

The installations f or two basic topologi es are described i n detail: for sing le building and for multi-building. B y understanding

the two generic installations you will be able to address any variations in system deployment.

passive equipment

in the

Note: F or installations that include the N MS - once the installatio n has been completed, it can be v erified using the MCT

application (NMS User’s Guide) and the devices monitored using the NMS Manager (NMS User’s Guide).

4.1.1 Unpacking and Inspection

This section provides instructions for open ing the shipping boxes, verifying that all parts ha ve been received, and ver ifying

that no shipping damage has occurred.

Unpack and inspect the cartons according to the following procedure

1. Open the shipping carton and carefully unpack each unit from the protective packing material.

2. Check for signs of external damage. If there is any damage, call your Corning Optical Communications service

representative.

4.2 Communication Room Installation

The Communication Room installation consists of the following basic steps:

1. Unpacking and inspecting the MA2000 units (see 4.1.1)

2. Mounting the RIUs, BUs and SC-450 controller in the mounting rack (see

3 RF connections BTS/BDA connec ti ons .

4. RF connections to the Base Units.

5. Connecting the SC-450 control connections to the units

6. Connecting DC power to the units

4.2)

4.2.1 Rack Installation General Instructions

Note: Usually, each operator installs the equipment that supports their services in a separate rack.

System Installation P/N 709C006503 Page 37

Page 38

It is recommended to install the following Corning CORE system modules in a 19” rack in the communication room

• RIU Chassis 3U, RIU Lite 2U

• BU 1U

• MA410/MA430 controller 1U

• Fiber Optic patch panel and splice tray

• Power supply/supplies (Corning – 3U for each unit; units from other manufacturers may vary in size)

Verify that the rack height can support all the units to be installed, where you may also want to consider future expansions.

Figure

simplify the cabling connections.

4-1 s hows the recommended physica l location of the Corning CORE elem ents in the rack in order to facilitate and

The configuration is for a single operator. If the site is ser viced by more than one operator ,

each operator often installs their equipment in a separate rack.

Note: Note that the CORE 430/SC-450 controller is at eye level to provide an easy view of the LED indicators and LCD

display and easy access to the local and remote monitoring connections.

The following figure shows a typical installation for a two field design.

Recommended Order in the Communication Room Rack

Figure 4-1

System Installation P/N 709C006503 Page 38

Page 39

Review the following guidelines to help ensure your safety and protect the equipment from damage during the installation.

• Only trained and qualified personnel should be allowed to install or replace this equipment.

• Verify that ambient temperature of the environment does not exceed 50°C (122°F)

• To maintain a low center of gravity, ensure that heavier equipment is installed near the bottom of the rack and load the

rack from the bottom to the top.

• Ensure that adequate airflow and ventilation within the rack and around the installed components so that the safety of the

equipment is not compromised. It is recommended to allow for at least about 2 cm of airspace between devices in the

rack.

• Verify that the equipment is grounded as required – especially the supply connections. BU Connections

This section describes t he i ns tal lat ion f or the Bas e U nit s with th e RF s ignal supplied from an MA RIU Lit e. If an RIU s ystem is

installed, refer to the RIU Installation and Configuration Guide for detailed instructions on the RIU connections.

Note:

It is assumed that the patch pa nel cabinet (SC APC a daptors) for fiber optic cable conn ections is installed in the r ack

near the BUs.

To connect the BU

1. Connect fiber jumper between splice tray and patch panel cabinet.