Page 1

MobileAccess™

MobileAccess™ 1000/1200

MobileAccess™MobileAccess™

Installation and Configuration Guide

UM-1000, Revision 2.2

December 09, 2003

UM-1000, Revision 2.2 I

Page 2

Introduction MobileAccess™ 1000/1200

MobileAccess Ltd. Vienna, Virginia Tel: +1-703-848-0200

MobileAccess Ltd. Lod, Israel Tel: +972-8-9183888

http://www.mobileaccess.com

Email: sales@mobileaccess.com

Copyright © 2003 MobileAccess.

All rights reserved. Printed in Israel.

© 2003 by MobileAccess

This document contains confidential and proprietary information of MobileAccess

and may not be copied, transmitted, stored in a retrieval system or reproduced in

any format or media, in whole or in part, without the prior written consent of

MobileAccess. Information contained in this document supersedes any previous

manuals, guides, specifications, data sheets or other information that may have

been provided or made available to the user. This document is provided for

informational purposes only, and MobileAccess does not warrant or guarantee the

accuracy, adequacy, quality, validity, completeness or suitabilit y for any purpose of

the information cont ained in t his docum ent. MobileAccess reserves the right to make

updates, improvements and enhancements to this document and the products to

which it relates at any time without prior notice to the user. MOBILEACCESS

MAKES NO WARRANTIES, EXPRESS OR IMPLIED, INCLUDING, WITHOUT

LIMITATION, THOSE OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE, WITH RESPECT TO THIS DOCUMENT OR ANY

INFORMATION CONTAI NED HEREIN.

TRADEMA RK A CKNOWLEDGEMENT

MobileAccess

TM

is a registered trademarks of MobileAccess. This document contains

other trademarks, trade names and service marks of MobileAccess and other

organizations, all of which are the property of their respective owners.

II UM-1000, Revision 2.2

Page 3

MobileAccess™ 1000/1200 Introduction

POLICY FOR WARRANTEE AND REPAIR

MobileAccess tests and inspects all its products to verify their quality and reliability.

MobileAccess uses every reasonable precaution to ensure that each unit meets their

declared specifications bef ore shipment. Cust omers should advise their incoming inspection,

assembly, and test personnel about the precautions required in handling and testing our

products. Many of these precautions can be found in this manual.

The products are covered by the following warranties:

General Warranty

MobileAccess warrants to the original purc haser all standard products sold by MobileAccess

to be free of defects in material and workmans hip f or one (1) year from date of shipment from

MobileAccess. During the warranty period, MobileAccess will repair or replace any product

that MobileAccess proves to be defec tive. This warranty does not apply to any product that

has been subject to alteration, abuse, im proper installation or application, acc ident, electrical

or environmental over-stress, negligence in use, storage, transportation or handling.

RETURNS

Specific Product Warranty Instructions

All MobileAccess products are warranted against defects in workmanship, materials and

construction, and to no further extent. Any claim f or repair or r eplac ement of units found to be

defective on incoming inspec tion by a customer m ust be made within 30 days of receipt of

shipment, or within 30 days of discovery of a defect within the warranty period.

This warranty is the only warranty made by MobileAccess and is in lieu of all other

warranties, expressed or implied. MobileAccess sales agents or representatives are not

authorized to make commitments on warranty returns.

In the event that it is necessary to retur n any product against above warranty, the

following procedure shall be followed:

1. Return authorization is to be received from MobileAccess prior t o r eturning any

unit. Advise MobileAccess of the model, serial number, and discrepancy. The

unit may then be forwarded to MobileAccess, transportation prepaid. Devices

returned collect or without authorization may not be accepted.

2. Prior to repair, MobileAccess will advise the customer of our test r e sult s and any

charges for repairing cust om er -caused problems or out-of-warrant y conditions

etc.

3. Repaired products are warranted for t he balance of the original warranty period,

or at least 90 days from date of shipm ent.

UM-1000, Revision 2.2 III

Page 4

Introduction MobileAccess™ 1000/1200

LIMITATIONS OF LIABILITIES

MobileAccess's liability on any claim, of any kind, including negligence for any loss or

damage arising from, connected with, or resulting from the purchase order, contract,

quotation, or from the perform ance or breac h thereof, or from the design, m anufacture, sale,

delivery, installation, inspection, operation or use of any equipment covered by or furnished

under this contact, shall in no case ex ceed the purchase price of the device which gives rise

to the claim.

EXCEPT AS EXPRESSLY PROVIDED HEREIN, MOBILEACCESS MAKES NO WARRANTY, EXPRESSED OR

IMPLIED, W ITH RES PECT TO ANY GOODS, P ARTS A ND SERV ICES PROVI DED IN CONNECTI ON WITH THIS

AGREEMENT INCLUDING, BUT NOT LIMITED TO, T HE IMPLIED W ARRANTIES OF MERCHA NTABILITY AND

FITNESS FOR A PARTICULAR PURPOSE. MOBILEACCESS SHALL NOT BE LIABLE FOR ANY OTHER

DAMAGE INCLUDING, B UT NOT LIMITED TO, INDIRECT, S PECIAL OR CONSEQUENTIAL DAMAGES ARISING

OUT OF OR IN CONNECTION WITH FURNI SHING OF GOODS, P ARTS AND SERVICE HEREUNDER, OR THE

PERFORMANCE, USE OF, OR INABI LITY TO USE THE GOODS, PARTS A ND S ERVICE.

REPORTING DEFECTS

The units were inspected befor e shipment and found to be fr ee of mechanical and electr ical

defects.

Examine the units for any damage that may have been caused in transit. If damage is

discovered, file a claim with the freight carrier immediately. Notify MobileAccess as soon as

possible.

NOTE: Keep all packing material until you have completed the inspection

WARNING: To comply with FCC RF exposure com pliance requir em ents, antennas used for

this product must be f ixed mounted on indoor permanent structures , providing a separation

distance of at least 20 cm from all persons during normal operation.

WARNING: Antenna gain should not exceed 10dB.

WARNING: Each individual antenna used for this transm itter must be installed to provide a

minimum separation dis tance of 20 cm or mor e from all per sons and mu st not be co-located

with any other antenna for meeting RF exposure requirements.

IV UM-1000, Revision 2.2

Page 5

MobileAccess™ 1000/1200 Introduction

WARNING: The MobileAccessTM system uses an optical laser for transmitting voice and

data. The laser unit has the following output characteristics:

- Optical output power (mW): ≤3.0

- Wavelength (nM): 1310 ± 10

WARNING: Applying power to the MobileAccess™ cr eates a laser energy source operating

in class I as defined by IEC 60825-1, 21 CFR 1040.10 and 1040.11 except for deviations

pursuant to laser notice no. 50 (July 26, 2001). Use either an infrar ed viewer, optical power

meter or fluorescent screen for optical output verification.

WARNING: The use of controls or adjustm ents or perf ormanc e procedures other than those

specified herein may result in hazardous radiation exposure.

WARNING:

Compliance with RF safety requirements:

MobileAccess™ products have no inherent significant RF radiation.

The RF level on the down link is very low at the remote hub unit downlink ports . Therefore,

there is no dangerous RF radiation when the antenna is not connected.

The design of the antenna installation needs to be implemented in such a way so as to

ensure RF radiation safety levels and non- environmental pollution during operation.

ATTENTION: To avoid damaging your product, please observe the following:

• Always keep the optical c onnector covered. Use the fiber optic cable or a protective

cover. Do not allow any dirt and/or foreign material to get on the optical connector

bulkheads.

• T he optic al fiber jum per c able bend radius is 3 cm . Sm aller radii c an cause exc essive

optical loss and/or fiber breakage.

• For proper system performance only use cables equipped with

SC/APC connectors to connect to the MobileAccess system.

UM-1000, Revision 2.2 V

Page 6

Introduction MobileAccess™ 1000/1200

C

ERTIFICATION

MobileAccess products have met the approvals of the following certifying organizations:

ISO 9001

For US

FCC 47 CFT part 22,24,90

FDA-CDRH

For Canada

RSS-118, RSS-119, RSS-133

SPECIFICATIONS

Maximum ambient operating temperature: 50° C

Maximum ambient temperature in a rack: 50° C

….

VI UM-1000, Revision 2.2

Page 7

MobileAccess™ 1000/1200 Introduction

Preface

This user guide provides all the information necessary to install and configure the

MobileAccess 1000/1200 system.

Revision History

The revision history for this document is shown in Table 1-1.

Table 1-1: Revision history

Version Date Description

1.0 April 2003 Initial version.

2.0 October 2003 Updated version to MobileAccess.

2.1 November 2003 Review and editing

2.2 December 2003 Adding and updating RHU 1200

UM-1000, Revision 2.2 VII

Page 8

Table of Contents

Chapter 1. Introduction...............................................................................................................................................1

1.1 About MobileAccess 1000/1200™.........................................................................................................................1

1.2 System Description................................................................................................................................................2

1.3 Base Unit to Remote Unit Configuration Options...................................................................................................4

1.4 MobileAccess Models............................................................................................................................................5

Chapter 2. Infrastructure Preparation .......................................................................................................................8

2.1 Basic Installation Rules..........................................................................................................................................8

2.1.1 Fiber Optic Rules........................................................................................................................................8

2.1.2 RF Rules.....................................................................................................................................................8

2.2 Power Consumption, Connections and Power Supplies........................................................................................9

2.2.1 Power Consumption of Units......................................................................................................................9

2.2.2 Power Supply Configurations.....................................................................................................................9

2.2.3 Types of Power Supplies..........................................................................................................................10

2.3 Single-building Installation...................................................................................................................................11

2.4 Horizontal Layout Installation...............................................................................................................................13

Chapter 3. Connections............................................................................................................................................14

3.1 Rack Installation ..................................................................................................................................................14

3.2 Module Descriptions and Connections.................................................................................................................15

3.2.1 Radio Interface Unit (RIU)........................................................................................................................15

3.2.1.1 RIU Front Panel........................................................................................................................15

3.2.1.2 RIU Rear Panel.........................................................................................................................16

3.2.1.3 RIU Connections.......................................................................................................................16

3.2.1.4 Connections to Additional BUs..................................................................................................17

3.2.2 Base Units................................................................................................................................................18

3.2.2.1 BU Front Panel.........................................................................................................................18

3.2.2.2 BU Rear Panel..........................................................................................................................19

3.2.2.3 Base Unit to RHU connections..................................................................................................19

3.2.3 Remote Hub Unit (RHU) 1000..................................................................................................................20

3.2.3.1 Wall Mount................................................................................................................................21

3.2.3.2 Connections..............................................................................................................................21

3.2.4 RHU 1200.................................................................................................................................................22

3.2.4.1 Assembly and Connections......................................................................................................23

3.2.5 MobileAccess 410/430 Controller.............................................................................................................25

3.2.5.1 Controller Front Panel...............................................................................................................25

3.2.5.2 Controller Rear Panel...............................................................................................................26

Chapter 4. Appendices.............................................................................................................................................27

4.1 Appendix I: Optical Test Procedure.....................................................................................................................27

4.1.1 Fiber Optic Cable Test..............................................................................................................................27

4.1.2 MobileAccess System Characteristics......................................................................................................27

4.1.3 Test Equipment ........................................................................................................................................28

UM-1000, Revision 2.2 VIII

Page 9

MobileAccess™ 1000/1200 Introduction

4.1.4 Optical Insertion Loss Measurement Test................................................................................................28

4.1.4.1 Method #1: Two Point Test.......................................................................................................28

4.1.4.2 Method #2: Single Point Test....................................................................................................29

4.1.5 Other Test Equipment..............................................................................................................................29

4.1.6 Optical Return Loss Measurement Test...................................................................................................30

4.1.7 Measurement Procedure..........................................................................................................................30

4.1.7.1 Measuring Power Input To Cable Being Tested.......................................................................30

4.1.7.2 Measuring Coupler Power Loss................................................................................................30

4.1.7.3 Measuring Return Power..........................................................................................................30

4.1.8 Results.....................................................................................................................................................31

4.1.9 Summary..................................................................................................................................................31

4.2 Appendix II: Link Measurements Form................................................................................................................32

4.3 Frequently Asked Questions................................................................................................................................33

UM-1000, Revision 2.2 IX

Page 10

Page 11

Chapter 1. Introduction

1.1 About MobileAccess 1000/1200™

MobileAccess™ 1000 family of products provides seamless coverage for voice and

data wireless services in difficult indoor environments where steel, concrete and

earth block RF signals, or in hig h-rise buildings where reception of multiple signals

causes interference.

The MobileAccess™ converged wireless networks solution is designed to serve

multiple wireless services through a single common cabling infrastructure.

Homogeneous coverage is pr ovided by antennas connected to Remote Hub Units

(RHUs) distributed throughout the coverage area.

The MobileAccess™ infrastructure is protocol-independent and can simultaneously

serve various services. Built-in alarm and control capabilities that enable remote

monitoring and control of t he system elem ent s ( including antennas).

Features

• Single cabling and antenna system for all ser vices and f requency bands

• Support for all current and future voice and data wireless services such as

PCS/CELLULAR, TDMA, CDMA, GSM, future 3G protocols, Paging, iDEN

and 802.11 (a,b,g) Wireless LAN

• Upgradeable to include additional services

• Eliminates RF interferences occurring where multiple antenna systems are

used to serve multiple services

• Enables fast deployment for corporate enterprises, property owners and

WSP’s of new services

• Reduces tenant disruption

• Low power required by the system eliminates the need for high power

BTS/RBS, reducing operator expenses

• Provides both local and remote monitoring and cont r o l capabilit ies

• Software programmable par am et ers including output power, AGC (on/off and

levels), and system gain

• Real time component setting capabilities for optimal performance (aging,

temperature, optical connectors, etc.,)

• Modular design architecture

UM-1000, Revision 2.2 1

Page 12

Introduction MobileAccess™ 1000/1200

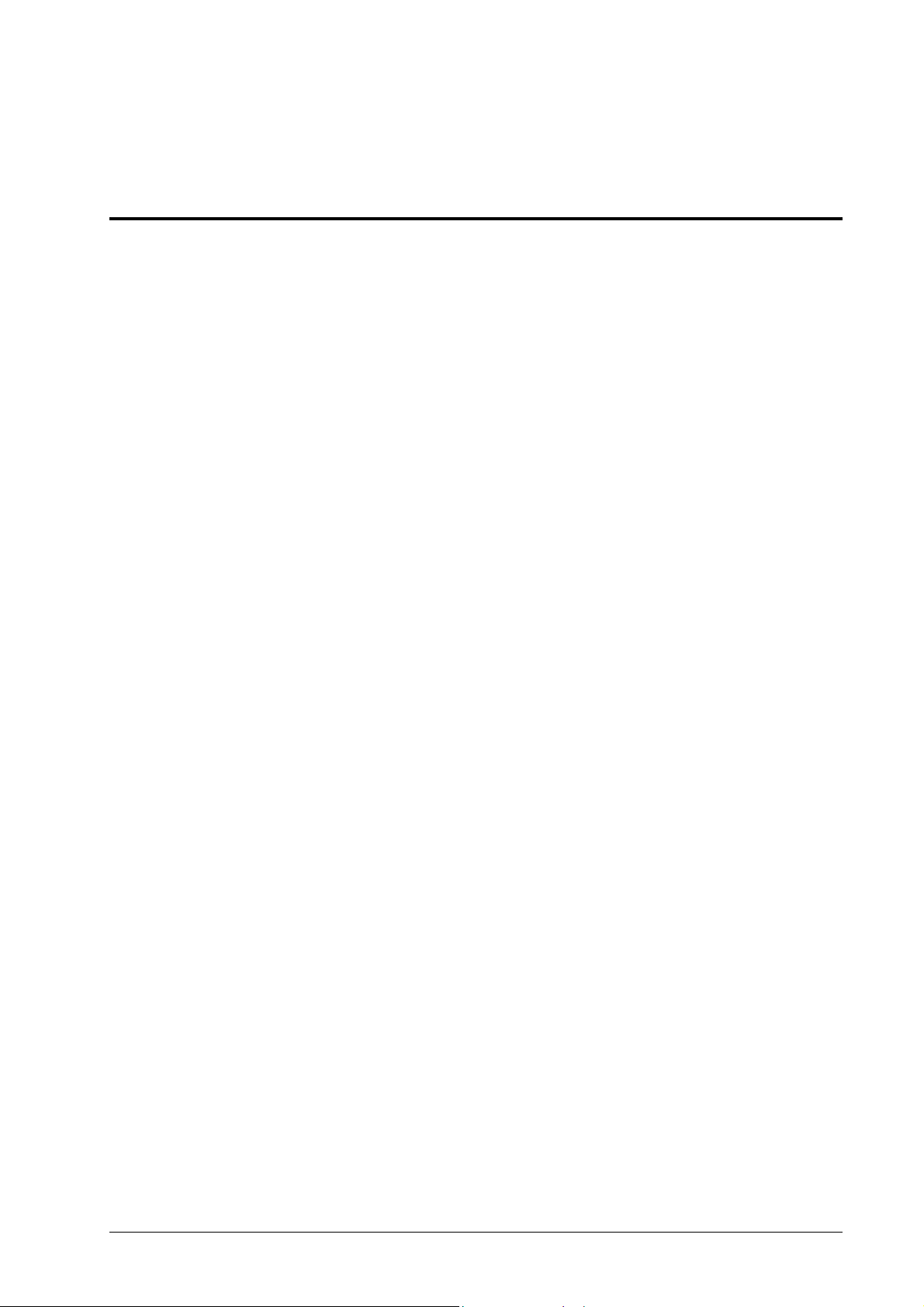

1.2 System Description

The MobileAccess™ system provides in-building coverage by routing RF signals

from (up to three) BTS or BDA units, t hrough optic f ibers to remote areas where the

signals are converted back to RF and interfaced to antennas covering the remote

area. All system elements can be remotely controlled and monit ored from a single

location.

The MobileAccess™ coax and Fiber Optic hybrid solution consists of the following

elements:

• Radio Interface Unit (RIU) – Provides direct, simple interface to up to three

BTS or BDA units supporting up to three dif ferent services. Connections can

be simplex or duplex.

RIU output signal is automatically adjust ed t o r espond to a range of BTS or BDA

output power levels. This significantly reduces or elim inates the need for

extensive manual site measurements and adjustments required to provide the

optimal input to the Base Units.

The RIU RF output signals are combined and fed via direct coax connection to

MobileAccess Base Units.

• Base Units (BUs) – convert the RF signal received f rom the RIU (or passive

interface) to an optic signal that is then split and routed via optic fiber to

Remote Hub Units located in rem ote locations. Each BU can support up to

eight RHUs.

• Remote Hub Units (RHUs) – converts the opt ic signal to an RF signal and

feeds it to the antennas in the rem ote areas in order to provide the required

coverage. Each RHU supports two diffe rent ser vices (one high-band and one

low-band) and provides coax connections to up to four antennas. The RHU

filters and amplifies the optic signal received from the BU according to the

service it supports.

A third service can be added using a MobileAccess 1200 add-on or independent

module.

Wireless LAN services can also be added to t he MobileAccess 1000 RHU by

connecting the MobileAccess 840 add-on module. This provides wireless LAN

signals to the antennas connected to the MobileAccess 1000 RHU.

• System Controller – provides monitoring and control to all MobileAccess

system elements, from a sing le locat ion.

2 UM-1000, Revision 2.2

Page 13

MobileAccess™ 1000/1200 Introduction

A block diagram of the MobileAccess™ system is given below.

Figure 1-1. MobileAccess™ System Block Diagram

The Base Units and controller (along with the power supplies and other elements

required for interface) are usually installed in the same rack in the communication

room, while the RHUs are distributed throughout the locations to be covered. In the

communication room located next to t he BTS or BDA, t he RIU is also inst alled in the

rack.

UM-1000, Revision 2.2 3

Page 14

Introduction MobileAccess™ 1000/1200

1.3 Base Unit to Remote Unit Configuration Options

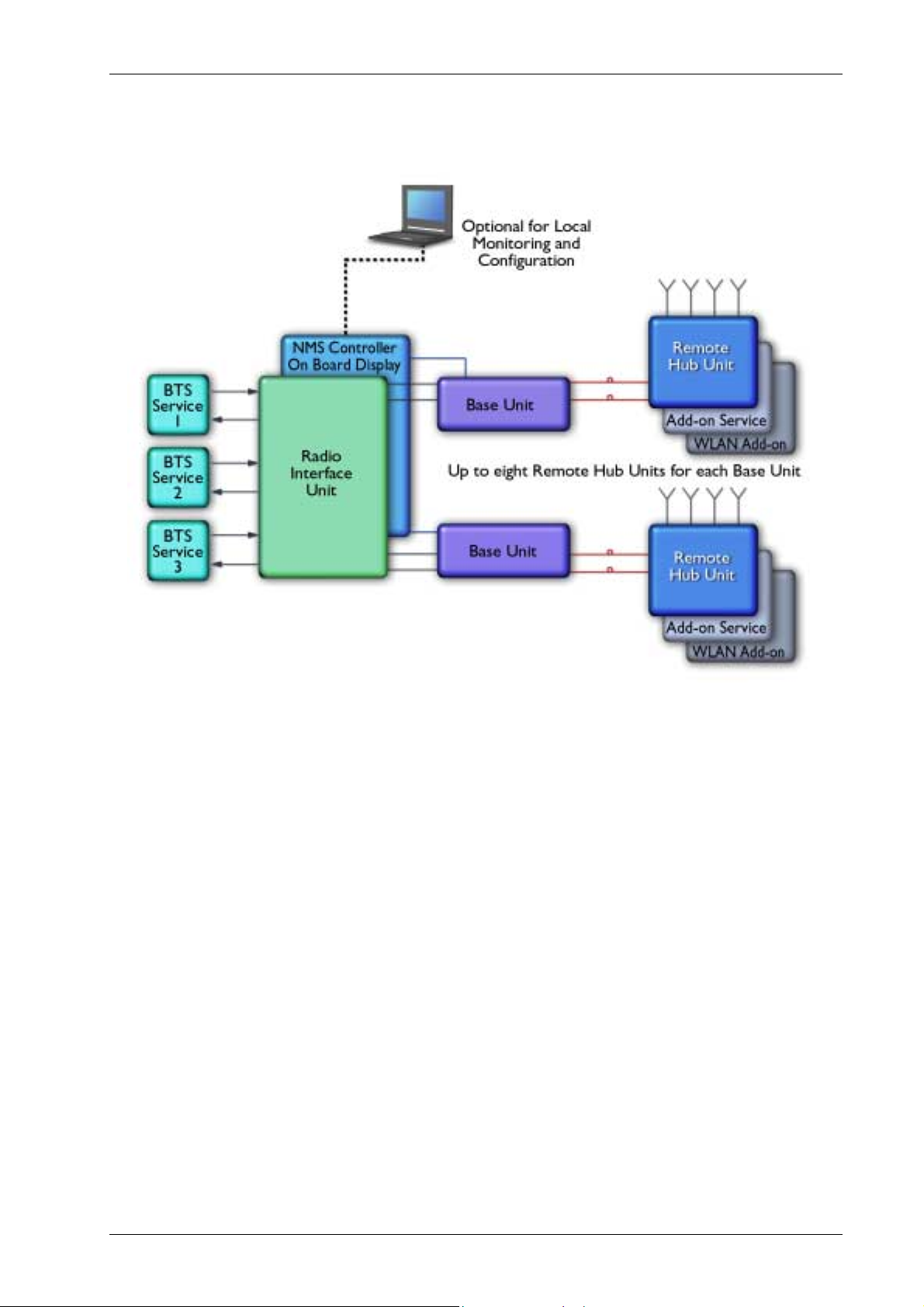

The MobileAccess™ 1000/1200 system includes three basic configuration options:

A) Basic configuration

In the basic configuration, depicted below, the Base Unit drives a single or dual

band, MobileAccess™ 1000 RHU. The dual band RHU consists of a low band

service (cellular 800, iDEN, Paging, or GSM 900) and a high band service (PCS

1900 or DCS 1800).

Figure 1-2. MobileAccess 1000 Basic BU – RHU Configuration

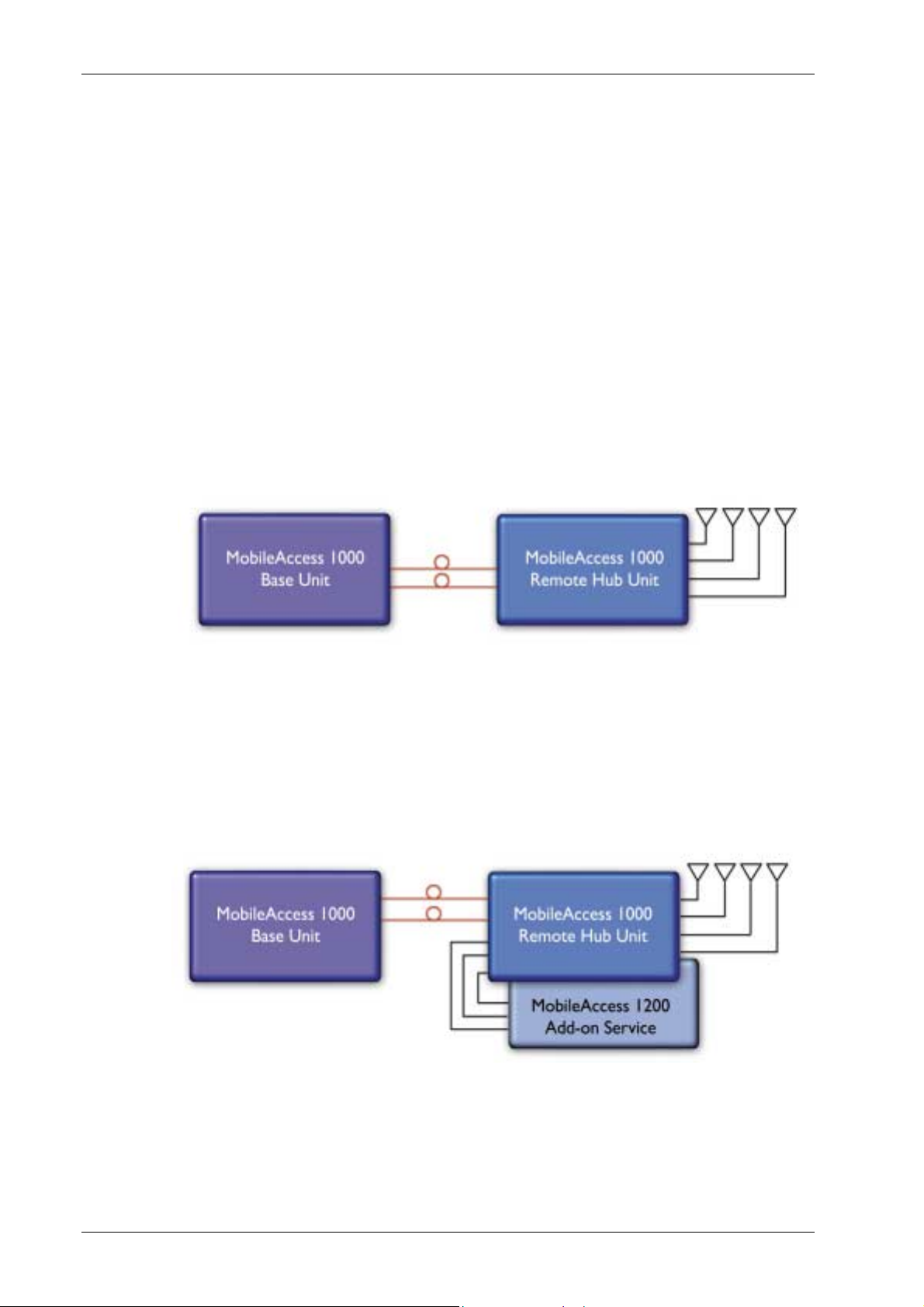

B) Using the MobileAccess 1200 add-on unit to provide an additional

service

In the second option, a MobileAccess™ 1200 add-on unit can be added in order to

provide an additional service. The add-on unit can be Cellular, PCS, UMTS, 3G, or

any future service.

Figure 1-3. MobileAccess 1000/1200 BU – RHU Plus Add-On

4 UM-1000, Revision 2.2

Page 15

MobileAccess™ 1000/1200 Introduction

C) Using the MobileAccess 800 WLAN module to provide access to high

data-rate service

In the third conf iguration, depicted below, the W LAN module (MobileAccess™ 800)

is added. The W LAN module may also be added without the MobileAccess™ 1200

unit.

Figure 1-4. MobileAccess 1000/1200 BU – RHU Plus Add-on Plus WLAN Configuration

1.4 MobileAccess Models

Table 1-1: MobileAccess™ BU Models

MobileAccess Universal Base Units (1000, 1200, 2000 support)

WB-B8U Wide Band Base 8 Unit supporting 8 RHUs

WB-B4U Wide Band Base 4 Unit supporting 4 RHUs

Table 1-2: MobileAccess™ RHU Models with Add-on Capabilities

MobileAccess 1000 RHUs (ready for add-on units)

1000S-CELL-4 Single band-Cellular, 4 ports

1000S-IDEN-4 Single band-iDEN, 4 ports

1000S-PCS-4 Single band-PCS 4 ports

1000D-IDEN-PCS4 Dual band-iDEN/PCS, 4 ports

1000D-SMR-PCS4 Dual band-SMR/PAGING/PCS, 4 ports

1000D-CELL-PCS4 Dual band-Cell/PCS, 4 ports

1000D-CELL-DCS4 Dual band Cell/DCS 4P ready for add-on units

1000D-CL-M-DCS4 Dual band Cell multi operator/DCS 4P ready for add-on units

1000D-GSM-DCS4 Dual band GSM/DCS 4P ready for add-on units

1000D-GSMO-DCS4 Dual band GSM orange/DCS 4P ready for add-on units

UM-1000, Revision 2.2 5

Page 16

Introduction MobileAccess™ 1000/1200

Table 1-3: MobileAccess™ RHU Models

MobileAccess 1000 RHUs (Litenna compatible)

10L-D-IDEN-PCS4 Dual band-iDEN/PCS, 4 ports, LBC

10L-D-SMR-PCS4 Dual band-SMR/PAGING/PCS, 4 ports, LBC

10L-D-CELL-PCS4 Dual band-Cell/PCS, 4 ports, LBC

10L-D-CELL-DCS4 DB Cell/DCS 4P ready for add-on units-LBC

10L-D-CL-M-DCS4 DB Cell multi opr/DCS 4P ready for add-on units-LBC

10L-D-GSM-DCS4 DB GSM/DCS 4P ready for add-on units-LBC

10L-D-GSMO-DCS4 DB GSM orange/DCS 4P ready for add-on units-LBC

Table 1-4: MobileAccess™ 1200 RHU Models

MobileAccess 1200 RHU

1200-PCS-SA-1 Stand Alone high power PCS , one port

1200-UMTS-SA-1 Stand Alone high power UMTS, one port RHU

1200-PCS-AO Add-on RHU supporting a PCS service

1200-UMTS-AO Add-on RHU supporting UMTS service

Table 1-5: MobileAccess™ UMTS Ready RHU Models

MobileAccess 1200 RHU(Litenna UMTS Ready compatible)

12L-UMTS-AO Add-on RHU supporting UMTS service LBC

Table 1-6: MobileAccess™ Controller Models

Network Controller

410 Network Controller – Serial Interface (dial-up)

430 Network Controller –Ethernet/IP Interface

Table 1-7: MobileAccess™ Management System

Network Management System

NMS-SW-SERVER GUI and server S/W package (one per site)

NMS-SW-MFEE NMS annual S/W maintenance fee (per 430-CTLR)

6 UM-1000, Revision 2.2

Page 17

MobileAccess™ 1000/1200 Introduction

Table 1-8: MobileAccess™ RIU

Radio Interface Unit

RIU-IM Radio Interface Unit

RIU-BTSC-CELL BTS Conditioner for Cellular

RIU-BTSC-IDEN BTS Conditioner for iDEN

RIU-BTSC-PCS BTS Conditioner for PCS

RIU-BTSC-SMR BTS Conditioner for SMR-Paging

RIU-BTSC-GSM BTS Conditioner for GSM 900MHz

RIU-BTSC-GSM-O BTS Conditioner for GSM 900MHz for Orange

RIU-BTSC-DCS BTS Conditioner for DCS 1800MHz

RIU-BTSC-UMTS BTS Conditioner for UMTS 2100MHz

UM-1000, Revision 2.2 7

Page 18

Infrastructure Preparation MobileAccess™ 1000/1200

Chapter 2. Infrastructure Preparation

This following installation rules are based on the assumption that site survey and

installation planning (including power requirem ent s ) have been complet ed.

2.1 Basic Installation Rules

2.1.1 Fiber Optic Rules

• Use only single mode fiber for indoor applicat ions.

• Use only SC/APC connectors (green color).

• Use only fusion splice for connecting two f ibers.

• Use minimum splicing/connectors to achieve minimum losses on the fibers

(<0.5dB).

• Use precaution while installing, bending, connecting fiber optic.

• Use an optical power meter and OTDR for checking the fiber optic cables.

• Make sure the environment is clean while connecting/splicing fiber optic

cables.

• Verify the Fiber Optic connections. You may use the Optical Test Procedure

described in Appendix I: Optical Test Procedure.

• Pay special attention while connecting the SC/APC connectors - you must

hear the “click” when the connection is made.

2.1.2 RF Rules

• Use coax ½”, 50ohm, male-to-male N-type, ( 6-7dB for 1Ghz, 11dB f or 2Ghz)

for connecting to RHU port s.

• Use coax RG223, 50ohm, male-to-male N-t ype for connecting RF side from

the Base Unit to the BTS/RBS side.

• When using the MobileAccess™ system in an environment in which other

indoor coverage systems are installed, pay special attention t o the isolation

between antennas (distance must exceed 2 meter).

• Use special attention while bending coax cables, according the coax

specification.

• Use any antennas suitable to the desired frequency.

• Use VSWR meter (Site Master) for checking coax cables, including the

antennas. (<2).

• Unused RHU and RIU ports should be terminated with a 50ohm load.

8 UM-1000, Revision 2.2

Page 19

MobileAccess™ 1000/1200 Infrastructure Preparation

2.2 Power Consumption, Connections and Power Supplies

Calculate the required power according to the requirements of the specific

installation and then determine the config ur ation of t he power supplies. The r equir ed

DC cables will then be determined by the selected PS configuration.

2.2.1 Power Consumption of Units

Table 2-1. MobileAccess™ Power Requirements

Unit Type Voltage Input

RIU 20 to 48VDC 10W

Base Unit 20 to 48VDC 14W

Remote Hub Unit 1000 20 to 48VDC 25W

Add-on Unit 1200 20 to 48VDC 50W

410/430 Controller 20 to 48VDC 10W

2.2.2 Power Supply Configurations

Two Power Supply configurations are usually in use:

• Individual connections - each PS is located adjacent t o the BU or RHU unit

it will serve

• Central connection – a single power supply supplies the power for all BUs

and RHUs

Power

Consumption

UM-1000, Revision 2.2 9

Page 20

Infrastructure Preparation MobileAccess™ 1000/1200

2.2.3 Types of Power Supplies

MobileAccess supplies various power supplies that can be installed in a rack or

mounted on a wall, depending on your configuration. Four power supply options are

available:

Table 2-2: MobileAccess™ Power Supplies

Power Supply

LPS-48V-40W Local AC/DC Converter 40W

LPS-48V-100W Local AC/DC Converter 100W

RPS-200-N-48 Non-redundant 200W 110/220V Wall Mount

RPS-500-R-48 Redundant 500W 110/220V Chassis Mount

RPS-1000-R-48 Redundant 1000W 110/220V Chassis Mount

RPS-14-50W-48 Remote power supply,14 modules of 50W,48V

RPS-14-100W-48 Remote power supply,14 modules of 100W,48V

RPS-6M-220 Remote power supply enclosure,6 Modules,220v in-48VDC

RPS-600W-220 Remote power supply module 600W/48VDC,220V in

RPS-1200W-220 Remote power supply module 1200W/48VDC,220V in

10 UM-1000, Revision 2.2

Page 21

MobileAccess™ 1000/1200 Infrastructure Preparation

2.3 Single-building Installation

Single building installation conventions:

• Base Units – placed in the same location (usually in the communication

room).

• RHUs – usually placed in the communication shaf t of t he corresponding f loor

so they can be easily located. A single RHU can typically cover a floor of up

to 30,000 sq ft.

• Fiber optic cable - Bundled fiber from the Patch Panel located in the

communication room rack is also r outed through the building shaft to splice

boxes located every three floor s where a Splice Box is used to split a tube of

six fibers to three pairs of fibers. A pair of fibers is routed to the

corresponding floor, to t he floor above and to the floor below.

• Single source power cable – a single thick power cable runs from the

communication room through the building shaft. The power is distributed to

each floor using two thin cables that are connected t o the thick power cable

using DC clamps. The thin cables pr ovide power to the individual RHUs on

each floor.

• On each floor, connect F/O and power to the cor responding RHU. Connect

antennas to RHU using via coax cables.

UM-1000, Revision 2.2 11

Page 22

Infrastructure Preparation MobileAccess™ 1000/1200

The following page shows an example of routing of Fiber Optic and power cables in

a multi story building using the installat ion conventions previously described.

Floor 30

DC

Cable

Fiber Optic

Cable

D.C

Clamp

2 Pigtail

Fibers

RHU

Floor 9

SC/APC

Jumpers

B8U

19" Rack

Patch panel

Power Supply

SC/APC

PigTail

Splice

box

2 Pigtail

Fibers

Splice

box

2 Pigtail

Fibers

RHU

RHU

RHU

Floor 8

Floor 7

Floor 2

Figure 2-1- Fiber Optic and Power Cables Routing Example

12 UM-1000, Revision 2.2

Page 23

MobileAccess™ 1000/1200 Infrastructure Preparation

2.4 Horizontal Layout Installation

Horizontal layout installation conventions:

• Connect a separate optic fiber to every site location, where a site may include

more than one RHU.

• The connection may be t o a splice box or directly to the RHU (depending on

the site configuration) .

The following figure shows a horizontal layout installation with three RHUs

connected to a number of antennas.

H

G

F

Figure

C

RHU

I

CELL

SITE

2-2: Horizontal Layout Installation

BU

D

RHU

E

A

B

UM-1000, Revision 2.2 13

Page 24

Connections MobileAccess™ 1000/1200

Chapter 3. Connections

3.1 Rack Installation

It is recommended to install the following MobileAccess system modules in a 19”

rack (usually in the communication room):

• RIU 3U

• BU 1U

• MobileAccess 410/430 controller 1U

• Fiber Optic patch panel and splice tray

• Power supply/supplies (MobileAccess – 3U for each unit, units from other

manufacturers may vary in size)

Verify that the rack height can support all t he units to be installed, where you may

also want to consider future expansions.

The following image describes shows the recommended locations of the

MobileAccess elements in the rack in order to facilitate and simplify the cabling

connections. Note that the MobileAccess 410/430 controller is at eye level to

provide an easy view of the LED indicators and LCD display and easy access to the

local and remote monitoring connections.

Fiber Optic Patch Panel

and Tray (variable size)

MobileAccess Controller (1U)

MobileAccess Base Unit 1 (1U)

MobileAccess Base Unit 2 (1U)

MobileAccess Base Unit 6 (1U)

MobileAccess RIU (3U)

At eye level

Figure 3-1: Recommended Order In Rack

14 UM-1000, Revision 2.2

MobileAccess

Power Supply (3U)

Page 25

MobileAccess™ 1000/1200 Connections

3.2 Module Descriptions and Connections

3.2.1 Radio Interface Unit (RIU)

Each RIU can support up to three BTS Conditioner (BTSC) sub-modules, where

each sub-module provides interface to a BT S or BDA. The BTS or BDA service must

correspond to the type of BTSC to which it is connect ed.

Each RIU can be connected to four 8-port Base Units (real panel connections) or

eight 4-port Base Units. The RIU can be expanded to support additional BU by

using splitters and combiners connected to the fr ont panel connect ors.

Note: All connections are via RG223 coax cables with 1/2" N-type male connectors

3.2.1.1 RIU Front Panel

The RIU fr ont panel contains all the indicators and LEDs. T he wiring connect ions on

the front panel are used t o com bine the RF signals into a single signal that is applied

to all BUs.

Power Supply BTS Conditioners

Figure 3-2. RIU Front Panel

Table

3-1. RIU Front Panel Indicators

LED Description

P.S UNIT PWR

BTS CONDITIONER RUN

BTS CONDITIONER DL OVERLOAD

BTS CONDITIONER DL L OW

ON – input signal is at the required level.

Flashing -- CPU is running and software loaded

Continuous Red – RF switch is disconnected to protect

the system. This may be due to:

• Unpredicted power rise for which the attenuation

response was insufficient to compensate and reduce

the power to the required level.

• Software problem detected.

Flashing: When the BTSC DL output power is more than

3dB of the calibrated value.

Continuous Red – if the BTSC DL power is at least 15dB

lower than the calibrated BTSC max power level. This

condition also triggers an event.

8W Splitter

8W Combiner

UM-1000, Revision 2.2 15

Page 26

Connections MobileAccess™ 1000/1200

3.2.1.2 RIU Rear Panel

The rear-panel provides all the connections on t he BTS side and on the BU side as

well as connections to the MobileAccess 410/430 controller and the power

connection. Two types of BTS side connections are available for each BTS

conditioner: simplex and duplex.

ATTENTION

1. The RIU is factory set to 0dB gain on the uplink and

downlink. In order to operate properly, an ADJUSTMENT

process is required in the field.

2. Any unused input and output connectors MUST be

terminated with 50 ohms – otherwise the ADJUSMENT

procedure results may be affected.

3.2.1.3 RIU Connections

1. Connect each Base Unit to the corresponding pair of RF outputs on the RIU

2. Connect the BTS/BDA connections (either simplex or duplex), the controller,

MobileAccess 1000 BU

connections (pair per BU)

rear panel. Note that one uplink and one downlink RIU rear-panel connector

is used to connect one OPTM (four ports from the BU). To connect

additional BUs, refer to Connections t o Addit ional BUs.

and the power connections.

BTS/BDA simplex

connection

BTS/BDA duplex

connection

DC power input

MobileAccess 410/430

controller connection

Figure

16 UM-1000, Revision 2.2

3-3. RIU Rear Panel showing the RF Connection

Page 27

MobileAccess™ 1000/1200 Connections

3.2.1.4 Connections to Additional BUs

To connect more than four 8-port BUs or more than eight 4-port BUs to the RIU,

Connect an 8W splitter to the Downlink connector on the RIU front panel and an 8W

combiner to the Uplink connector on the RIU front panel and connect additional BUs

to the uplink and downlink connections.

BTSCBTSC

BTSCBTSC

Compartment*

BTSCBTSC

Expansion ports

External 1:8 splitter

/combiner

Combiners

/Splitters

UL and DL

connections to

four BU8 modules

UL and DL connections

to up to four additional

BU8 modules

UM-1000, Revision 2.2 17

Page 28

Connections MobileAccess™ 1000/1200

3.2.2 Base Units

Depending on the Base Unit model, each Base Unit drives up to four or eight

remotes via duplex F/O connection, where each remote can be as far as 2

kilometers (1¼ miles) from the BU. Eig ht port BU consist of two four port BU that

are integrated.

During power-up, the Base Unit identifies the active connected RHUs that are

connected to that Base Unit and each of the corresponding link LEDs is lit according.

3.2.2.1 BU Front Panel

The front panel contains all the opt ical connections. The following figures show the

two configurations in which the BU is available.

Figure 3-4. Eight Port MobileAccess 1000 Base Unit Front Panel

Figure 3-5. Four Port MobileAccess 1000 Base Unit Front Panel

Table 3-2. MobileAccess BU 1000 Front Panel Indicators

LED Description

Link 1-8

LSR

PWR Power ON

ON - the optical link between the BU and RHU functions within the

specifications in both directions.

Blinking - optical power from RHU exceeds 2dBm.

ON - laser circuitry for the corresponding RHUs (1-4 or 5-8) is

functioning correctly.

18 UM-1000, Revision 2.2

Page 29

MobileAccess™ 1000/1200 Connections

3.2.2.2 BU Rear Panel

The BU rear panel contains all the RF connections.

Pair of uplink and downlink connections

for interface to BTS side (all four

connectors must be connected)

Figure 3-6. Base Hub Unit Rear Panel (RF Connections)

Table

3-3. MobileAccess 1000 Front Panel Indicators

Connector Description

Uplink output Uplink connectors to be connected on BTS side.

Alarms connector

Downlink input Downlink connectors to be connected on the BTS side.

Com Port RS485 Connection to MobileAccess 410/430 controller.

PWR Power connection

3.2.2.3 Base Unit to RHU connections

1. It is assumed that the patch panel cabinet ( SC/ APC adapt or s) for fiber optic

cable connections is installed in the rack near the Base Units.

2. Connect (3/125/900) pigtail with SC/APC connectors between splice

tray and patch panel cabinet.

3. Connect (3/125/3000) SC/APC jumper s bet ween the corr esponding

Base Unit and patch panel.

4. Connect the fiber optic cables f r om the Base Unit to the RHU’s

through the patch panel cabinet.

Laser output connection

to RHU

Optical diode input

from RHU

RS232 connection for

monitoring

RHU LED indicators

(Link 1 to 8)

Base Unit Laser

operational LED indicator

Power indicator

Figure 3-7. Base Hub Unit Rear Panel (RF Connections)

UM-1000, Revision 2.2 19

Page 30

Connections MobileAccess™ 1000/1200

3.2.3 Remote Hub Unit (RHU) 1000

Supports two different frequency bands depending on the RHU 1000 model.

Output composite power per antenna port is in the range of 14 to 20 dBm

(depending on the served protocol). In order to supply antenna alarms, the

antenna must provide a DC resistance of up to 5K ohms.

Optical input/output connectors

to/from Base Units

RS232 connector for MobileAccess

service personnel

DC power connector

Cellular external

antennas connections

Figure 3-8. RHU 1000

Figure 3-9. RHU 1000 Rear Panel

Table 3-4. MobileAccess 1000 Front Panel Indicators

LED Description

Link

RUN

When on constantly, the LED indicates that the received optical

power from BU functions within the specifications.

When it blinking, it indicates that the optical power from BU is

higher than 2dBo.

When blinking, indicates that the CPU in the RHU is in normal

operating mode.

DC Power ON

20 UM-1000, Revision 2.2

Page 31

MobileAccess™ 1000/1200 Connections

3.2.3.1 Wall Mount

RHU 1000 is usually mounted on a wall in a clean indoor environment – RF ports

facing down.

Assembly instructions

1. Place the unit against the wall and mark t he four holes to be drilled in the wall.

2. Drill four holes 8mm in diameter and inser t the appropriate sized plastic plugs in

each hole.

3. Secure the RHU 1000 to the wall using four screws, 4.5m m diameter, 40mm

long.

Figure 3-10. RHU 1000 Wall Mount

3.2.3.2 Connections

1. Install splice box near RHU (refer to Figure 2-1).

2. Connect fiber optic cable to splice box and to SC/APC pig tails to RHU

3. For the downlink, connect the fiber opt ic cable pigtails from splice box

coming from the Base Unit por t to the corresponding Remote Hub

Unit port.

4. Connect the Remote Hub Unit to antennas according to the RF

engineers design. (up to 4 antennas per RHU) .

5. For the uplink, connect the f iber optic cable pigtails from splice box

from the Remote Hub Unit to the uplink port that connect s to the Base

Unit.

UM-1000, Revision 2.2 21

Page 32

Connections MobileAccess™ 1000/1200

6. Connect the power to each RHU according to power design planning

(local or remote power supply).

7. Verify that 50ohm terminators are placed on the unused uplink and

downlink connectors.

3.2.4 RHU 1200

High power module, supporting a single frequency band (low or high). The frequency

band depends on the model. RHU 1200 is supplied in two configurations: add-on

and standalone.

RHU 1200 add-on model is assembled onto the RHU 1000 model using the supplied

bracket. RHU 1200 does not requir e any additional RF or optic infrastructure since

all signals are received through the RHU 1000 unit to which RHU 1200 is

assembled.

SMA Uplink, Downlink

and High

Connection to

RHU 1000

DC Power

Figure 3-11. RHU 1200 Front and Rear panels

Figure 3-12. RHU 1200 Rear Panel

22 UM-1000, Revision 2.2

Page 33

MobileAccess™ 1000/1200 Connections

Figure 3-13. RHU 1200 Front Panels

Table

3-5. MobileAccess 1000 Front Panel Indicators

LED Description

RUN

DC Power ON

When blinking, indicates that the CPU in the RHU is in normal

operating mode.

3.2.4.1 Assembly and Connections

Refer to Figure 3-14.

ATTENTION

To prevent damaging the SMA connectors,

be sure to tighten using a torque of 8lb.

1. On the RHU 1200 front panel, short ( i nt erconnect ) t he pair of SMA Downlink

connectors to each other using the ‘U-shaped’ jumpers, and the pair of SMA

Uplink connectors to each other. Using the second U-shaped jumper.

2. Position the supplied bracket on the RHU 1000 and secure the bracket to the

RHU 1000 using the four supplied 6-32 NC screws.

3. Position the RHU 1200 unit on the bracket and secure the RHU 1200 to the

bracket using the four supplied 8-32 screws.

4. Interconnect the RHU 1000 and RHU 1200 SMA Uplink, Downlink and High

connectors on the rear panels of both unit s using the three straight jumpers.

5. Interconnect the RHU 1000 and RHU 1200 D-type 9-pin connectors on the rear

panels of both units using the supplied flat-cable.

6. Connect the power to the RHU 1200 front- panel DC connect or .

UM-1000, Revision 2.2 23

Page 34

Connections MobileAccess™ 1000/1200

Figure 3-14. RHU 1200 to RHU 1000 Assembly

Figure 3-15. RHU 1200 to RHU 1000 Completed Assembly

24 UM-1000, Revision 2.2

Page 35

MobileAccess™ 1000/1200 Connections

3.2.5 MobileAccess 410/430 Controller

NOTE: This section provides general information on the MobileAccess 410/430 Controller. For detailed

information on the controller, configuration and connections refer to the Mobile Access NMS User’s

Guide.

The MobileAccess controllers enable managing and controlling the MobileAccess

system elements. All the monitoring and contr ol operations can be performed f rom

the Master’s location.

Two MobileAccess controller configurations are provided: MobileAccess 410 and

MobileAccess 430. The models differ in their r em ote access capabilities:

• MobileAccess 410 provides point-to-point connectivity implemented via either

direct RS232 connection or via connection to a DSPN phone line

• MobileAccess 430 provides client/server management capability over TCP/IP

network with enhanced monitoring and control capabilities (in addition to the

connectivity options provided by MobileAccess 410).

NOTE: The MobileAcces s 430 front panel is diff erentiated from the MobileAccess 410 front

panel by the SNMP Agent Card that provides TCP/IP management capabilities.

3.2.5.1 Controller Front Panel

Local RS232

connection (for IP

address setup)

Figure 3-16. MobileAccess 410 Front Panel

Local RS232 connection to Laptop (MA 300

for Remote controller)

TCP/IP connection

Major, Minor

LED indicators

Master/Slave configuration

Run and

Power LEDs

LCD alarm display

corresponding to Major

and Minor LEDs

Figure 3-17. MobileAccess 430 Front Panel

UM-1000, Revision 2.2 25

Page 36

Connections MobileAccess™ 1000/1200

3.2.5.2 Controller Rear Panel

Note: The rear panels for the MobileAccess 410 and MobileAccess 430 are the same.

MA BU and RIU

inputs

Figure 3-18. MobileAccess 410/430 Rear Panel

General purpose

alarms input

BTS alarms output

(RF2MobileAccess).

Slave controller

connections

DC Input

26 UM-1000, Revision 2.2

Page 37

MobileAccess™ 1000/1200 Appendices

Chapter 4. Appendices

4.1 Appendix I: Optical Test Procedure

This section describes the methods applied to test fiber optic cable’s optical insertion

loss and return loss.

4.1.1 Fiber Optic Cable Test

Due to the extended distances that analog signal tr ansmissions travel on cable, the

major challenge is to determine the st atus of the cable.

In order to determine that the cables are functioning, technical personnel need to

perform optical power tests.

The optical power tests covered in this document are:

• Optical insertion loss measurement test

• Optical return loss measurement test

4.1.2 MobileAccess System Characteristics

The MobileAccess™ system consists of the following characteristics:

• Singlemode fiber

• Wavelength 1310nm

• Fiber Optic Cable Measurement Tests

Cable can be measured through several procedures. This docum ent describes the

following tests:

• Optical insertion loss measurement test

• Optical return loss measurement test

These tests are intended to be performed by technical personnel that deal with

MobileAccess systems. Other equipment can be used to perform these tests,

however the results have to be the same as will appear in the fiber optic cable test

results table (Table

4-1), at the end of this document.

The insertion loss measurement determines whether the optical signal power

traveling the cable leng th is strong enoug h to be received by the photo diode, in the

receiver.

UM-1000, Revision 2.2 27

Page 38

Appendices MobileAccess™ 1000/1200

Following the completion of the insertion loss test, the return loss test determines the

optical signal power that returns to the laser. The return power affects the laser,

changing the laser’s base current.

4.1.3 Test Equipment

In order to perform t hese tests, the following equipment is necessar y:

• Light source (for wavelength 1310nm , 0dbm )

• Optical power meter

• Optical coupler (hosed and connectorized)

• Fiber optic jumper

• Adapter parts for the cable connect or s

For information about equipm ent suppliers, contact MobileAccess.

4.1.4 Optical Insertion Loss Measurement Test

The optical insertion loss measurement tests the attenuation of the cable. The

insertion loss’ value should be minimal and remain in scale to 0.4dB/Km.

The insertion loss measurement can be performed in two methods:

• Two point test

• Single point test

4.1.4.1 Method #1: Two Point Test

Connection description: Light source connected at one end of the cable and an

optical power meter at the other end.

Light

source

Figure 4-1: Two Point Test

1. Connect light source directly to the optical power meter.

2. Measure light source signal power, verifying power of 0dBm.

3. Connect light source to cable end.

Optical

power

meter

4. Connect optical power meter to cable at other end.

5. Measure light source signal power using the optical power meter.

6. Calculate the difference bet ween two signals (dB) :

(Insertion loss)dB = (Light source signal at one end)dBm – (Measured signal at other end)dBm

28 UM-1000, Revision 2.2

Page 39

MobileAccess™ 1000/1200 Appendices

4.1.4.2 Method #2: Single Point Test

Connection description: This method assumes that there are two parallel fibers on

the path to be tested. Connect fiber jumper at end of the cable being tested to

another parallel cable. Connect the light source, optical power meter and optical

jumper as shown in Figure

simultaneously.

4-2. This measurement can test two cables

Light

source

Optical

power

meter

Connector

Figure 4-2: Single Point Test

Fiber optic jumper

1. Use optic jumper to connect the two cables.

2. Connect light source directly to the optical power meter.

3. Measure the power of light source signal , verif y power of 0dBm .

4. Connect a light source and optical power meter to one end of each cable.

5. Measure the power of the signal.

6. Calculate the difference bet ween the two signals in dB

(Insertion loss)dB =(Light source signal)dBm– (Measure signal)dBm

4.1.5 Other Test Equipment

The optical insertion loss measurement test can be performed with more

sophisticated measurement equipment.

For information on other types of test equipment contact MobileAccess.

UM-1000, Revision 2.2 29

Page 40

Appendices MobileAccess™ 1000/1200

4.1.6 Optical Return Loss Measurement Test

Connection description: Connect a light source and optical power to the inputs. If the

coupler has one output, connect the test ed cable to this output. If the coupler has

two outputs make a pigtail at the second out put .

Light

source

Optical

power

meter

IN OUT

1

2

3

Cable Being Tested

4

Optical Coupler

"Optical Terminator"

(pigtail)

Figure 4-3: Optical Return Loss Measurement

4.1.7 Measurement Procedure

4.1.7.1 Measuring Power Input To Cable Being Tested

• Verify that light source power is at 0dBm.

• Connect a light source to connector #1.

• Connect optical power meter to connector #3.

• Measure signal power (P3), power should be approximately –4dBm.

4.1.7.2 Measuring Coupler Power Loss

• Move power meter from connector #3 to connector #2.

• Move light source from connector #1 to connector #3.

• Measure power loss of coupler (Lc).

4.1.7.3 Measuring Return Power

To measure return power:

• Move light source from connector #3 to connector #1.

• Connect cable being tested to output connector #3.

• If coupler has two outputs, then make a pigtail at second output.

• If cable is longer than 100 met er , then cable needs to be isolated.

30 UM-1000, Revision 2.2

Page 41

MobileAccess™ 1000/1200 Appendices

To isolate cable:

1. Find place near test point where winding the cable into a pigtail is possible.

1. Make pigtail.

2. If cable is shorter than 100 met er , then verify that cable is disconnected at end.

3. Measure the return light power (P2), connector #2.

Calculating Return Loss

Calculate the difference bet ween the sig nals in dB.

(Return loss)dB = (P2)dBm – (P3)dBm + (Lc)dB

4.1.8 Results

The following table is to be filled in by technical personnel testing the fiber optic

cables.

Test Measurement Pass Range Pass/Fail

Optical insertion loss <0.5 dB/Km

Optical return loss < -50 dB

4.1.9 Summary

If the fiber fails in the optical insertion loss or optical return loss tests, then the

connector needs to be cleaned. Connector cleaning is carried out according to a

standard cleaning procedure. Following cleaning, t he fiber needs t o be tested again.

If the failure continues in the fiber following cleaning, then the technical personnel

need to refer to the f iber opt ic cable manuf actur er’s troubleshoot ing guide. If the fiber

passes the optical insertion loss and optical return loss test s, then the tested fiber

optic cable is considered suitable for use with MobileAccess equipment

Table 4-1: Fiber optic Cable Test Results

UM-1000, Revision 2.2 31

Page 42

Appendices MobileAccess™ 1000/1200

4.2 Appendix II: Link Measurements Form

To smoothly carry out link measurements, ref er to table Table 4- 1: Fiber optic Cable

Test Results. This table aids system evaluation and provides necessary feedback t o

MobileAccess.

The following issues should be taken into account:

• Measure the optical power for every link with an optical meter and light

source, according to the number of links or RHU’s.

• Measure the typical signal strength (RSSI) for every installed antenna.

• Check coax cable connection between RHU and every installed antenna.

Table 4-2: Link Measurement Table

System

Link

Power Meter

(mW)

Ant1 Ant2 Ant3 Ant4 Ant1 Ant2 Ant3 Ant4

RSSI (dBm)

Coax Cable (OK/Fail)

RHU1

RHU2

RHU3

RHU4

••••

••••

••••

••••

••••

••••

32 UM-1000, Revision 2.2

Page 43

4.3 Frequently Asked Questions

What optical parameters are recommended in order for the MobileAccess network to

1.

operate with the highest performance?

Answer. Three parameters are specified for every installation:

• Single-mode Fiber: Corning SMF 28 or equivalent

• Back Reflection: Less than 45 dB of back reflection @1310 nm

• Loss: Total end to end optical loss should be less than 1.5 dB @1310 nm

What does MobileAccess recommend as the best method to achieve these

2.

parameters for a reliable system?

Answer. The end to end fiber backbone should include only fusion splicing or APC

polished connectors for all fiber interconnections.

Which optical connector type does MobileAccess recommend for the highest

3.

performance network with long term reliability?

Answer. We use the SC/APC connector for MobileAccess products and this is the

connector that we would recommend in the building infrastructure as well. We have found

that this connector is the optimal connector from a cost versus performance perspective for

use with our products. It offers a consistently low back reflection and low loss. It is currently

the lowest cost connector in its performance class

In green field turnkey installations, MobileAccess will use only SC/APC connectors in the

network in order to warrant system performance

Are connectors other than SC/APC recommended or allowed as long as they are

4.

APC?

Answer. Any connector with an APC polish may be used in the fiber link. The APC polish

is available as an option on most fiber optic connectors. There is a list of popular

connectors that are available with an APC polish at the end of this FAQ.

APC is an abbreviation for Angle Polished Connector. The APC polish consistently

provides the lowest back reflection. The high performance analog nature of the

MobileAccess products makes this low back reflection for required for optimum

performance.

It should be noted, however, that the SC/APC connector is the only connector type that

directly connects to the MobileAccess antenna system products.

My installer says that he has a connector with very low back reflection and loss but

5.

it does not have an APC polish. Is this non-APC connector acceptable?

MobileAccess 1000/1200 User’s and Installation Guide 33

Page 44

Appendices MobileAccess™ 1000/1200

Answer. We have found that only the APC polish can offer consistently low levels of back

reflection with a high level of reliability.

There are connectors on the market with UPC, SPC and PC polishes that specify low back

reflection. The problem with these various polishes is that they are very fragile. A small

particle or even environmental changes can cause dramatic changes in the optical

performance. As a result performance degrading back reflection may suddenly appear

some time after the initial installation.

The APC, however, is much more robust and resistant to back reflections due to the

superior method used to eliminate back reflections. APC connectors are trouble free and

maintenance free. Once installed, there is no physical or environmental mechanism by

which the back reflection performance can be significantly changed.

If non-APC connectors are installed by the customer and provided for use with the

MobileAccess System, future system performance may be impacted and issues resulting

from a degradation of the fiber backbone performance are not warranted by MobileAccess.

What skills and experience should I look for when choosing a fiber cable installer?

6.

Answer. Choose an installer who has experience with fusion splicing and APC connectors.

Only factory polished APC pigtails should be used and they should be fusion spliced to the

backbone cable.

Many installers lack experience with low back reflection singlemode links. This is because

the lower optical performance LAN data links which are more commonly installed in the

premises environment do not have stringent back reflection requirements. Installers who

have worked with the Telephone carriers or CATV installations, on the other hand, are

much more aware of low back reflection requirements.

What test documentation should I require from my fiber cable installer? Should I

7.

require OTDR traces?

Answer. When using APC connectors, documentation of the fiber loss measurements of

each end to end fiber link is sufficient. A 1310nm light source and optical power meter are

the only instrumentation required to perform this testing. Back reflection from APC

connectors and splices are so consistently low, that back reflection measurements are not

required.

If, however, a non-APC connector is used, the back reflection measurements of each link

should also be documented. An optical back reflection meter should be used for these

tests. Unfortunately, most installers are not equipped with a back reflection meter. This is

another reason that use of the non-APC connector is strongly discouraged.

An OTDR trace lacks the resolution required to evaluate the closely spaced splice

junctures and connection pairings that are typical of In-building installations. OTDR traces

are only useful on long fiber spans where the fiber events are spaced at long intervals from

one another.

What are the maximum acceptable optical loss limits that are recommended for the

8.

connectors, splices and optical fiber?

Mated connector pair: <0.5 dB

Fusion splice: <0.04 dB

Optical fiber cable: <0.4 dB/Km

Total end to end link: <1.5 dB

I have a non-APC Singlemode fiber infrastructure already installed. Do I have to

9.

install a totally new infrastructure for MobileAccess equipment?

34 UM-1000, Revision 2.2

Page 45

MobileAccess™ 1000/1200 Appendices

Answer. As stated above, the APC polished connector is the most robust and reliable

solution and is the only recommendation of MobileAccess.

However existing backbone with UPC polished connectors could be used if they were

tested and found to have less than -45 dB back reflection and less than 0.5 dB loss per

mated pair connection.

Again, the end to end performance of each fiber link should meet or exceed the

MobileAccess specifications. As long as this occurs, MobileAccess will warrant system

performance. However, fiber backbone performance degradation will be a principle

suspect if system performance issues arise in the future. Issues resulting from a

degradation of the fiber backbone performance are not warranted by MobileAccess.

I have heard that there is an 8 degree APC and a 12 degree APC polish. Which of

10.

these is compatible with Mobile Access Equipment?

Answer. The 8-degree angled APC polish is compatible with our equipment. This is by far

the most popular APC polish available on the market. So much so, that it is usually referred

to as simply "APC".

There is a 12 degree angled APC polish available as well, but it is rare. This 12 degree

angled polish is not compatible to MobileAccess equipment and should not be mated to an

8 degree APC. It is however acceptable for use in the fiber backbone.

What are the various connectors that MobileAccess would recommend?

11.

Answer.

1. SC/APC (Most popular connector, Quick push-pull mating)

2. LC/APC (Small form factor (SFF), there is a good chance that this will replace the

SC/APC as the most popular connector in the U.S. but there are competitors shown

below)

3. LX.5/APC (SFF, Not extremely popular yet, Has backing of some vendors)

4. Diamond E2000/APC (Excellent but expensive and not extremely popular outside of

Europe. Especially popular in Germany.)

5. FC/APC (Generally replaced by the SC/APC - Uses a threaded coupling nut, secure

even in high vibration environments but does not permit quick connection)

6. MU/APC (SFF, half the size of the SC/APC, more popular in Japan)

7. Diamond F3000/APC (SFF, new, not popular, could be compatible to the LC)

Once again, it must be noted that the SC/APC is the only connector type that may be

directly connected to the MobileAccess antenna system products.

UM-1000, Revision 2.2 35

Loading...

Loading...