Page 1

UM_MobileAccessHX WCS

Corning

Mid-Power HX WCS DAS System

User Manual

Page 2

UM_MobileAccessHX WCS

Warranties

Hardware

Corning Optical Communications Wireless, Inc. (“Corning”) warrants to the original purchaser (“Customer”) that

for the duration of the warranty period, one (1) year, commencing on the date of shipment of the Hardware,

unless otherwise agreed in writing by Corning (the “Hardware Warranty Period”), the Hardware furnished by

Corning shall be free in all material respects from defects in material and workmanship, and shall conform to the

applicable portions of the Specifications, as defined below (the “Hardware Warranty”).

If notified by Customer of any such defects in material or workmanship or nonconf ormity with applicable portions

of the Specifications within the Hardware Warranty Period, Corning shall promptly, at its own election and

expense, repair or replace any such Hardware proven to be defective under the terms of this Hardware Warranty.

Such repair or replacement shall be Customer’s sole remedy and Corning’s’ sole obligation in the event this

Hardware Warranty is invoked. If any components comprising a part of the Hardware are replaced or repaired

during the Hardware Warranty Period, the Hardware Warrant y Period for such repaired or replaced components

shall extend to the longer of (i) the balance of the Hardware Warranty Period or (ii) three (3) months from the date

of repair or replacement. For purposes of this Warranty, “Specifications” shall mean the specifications and

performance standards of the Products as set forth in documents published by Corning

Corning and delivered to Customer which contain technical specifications or performance standards for the

Products.

If Customer invokes this Hardware Warranty, it shall notify Corning promptly of the claimed defect.

Customer will allow Corning to inspect t he Hardware at Customer’s location, or to return the Hardware to Corning’

closest repair facility. For Hardware returned to Corning’s’ repair facility, Customer shall be responsible for

payment of all transportation and freight costs (including insurance) to Corning’s’ repair facility, and Corning shall

be responsible for all transportation and freight costs (including insurance) incurred in connection with the

shipment of such Hardware to other repair facilities of Corning and/or its return to Customer.

Notwithstanding the foregoing, in no event will Corning be liable for damage to Products resulting from improper

handling during or after shipment, misuse, neglect, improper installation, operation or repair (other than by

authorized Corning person nel), alteration, accident, or for any other cause not attributable to defects in materials

or workmanship on the part of Corning. Corning shall not reimburse or make any allowance to Customer for any

labor charges incurred by Customer for replacement or repair of any goods unless such charges are authorized in

advance in writing by Corni ng.

Software Warranty

Corning warrants to the original purc haser (“Customer”) that for the duration of the warranty period, one (1) year,

commencing on the date of shipment of the Software, unless otherwise agreed in writing by Corning

(the “Software Warranty Period”), the Software shall conform with, and perform the functions set forth in the

Specifications, and shall be free from defects in material or workmanship (the “Software Warranty”). In the event

the Software is proven to be defective under the terms of this Software Warranty, Corning shall correct such

defects or failure and ensure that the Software conforms with, and performs the functions set forth in, the

Specifications. Customer will allow Corning to inspect the Software at Customer’s location or to return it to

Corning’s closest repair facility.

Notwithstanding the foregoing, Corning shall have no obligation under the Software Warranty if the

CMA-318-AEN Page 2

Warranties

Page 3

Warranties

P/N 709C015102

Page 3

Software is modified or used with hardware or software not supplied or approved by Corning or if the Software is

subject to abuse, improper installation or application, accident, electrical or environmental over-stress, negligence

in use, storage, transportation or handling.

Third-party software distributed with the Software may carry certain warranties which, to the maximum extent

allowed by law, Corning hereby assigns, transfers and otherwise conveys to Customer, provided, however, that

Corning itself provides no warranty of any kind, express, implied, statutory or otherwise, for any third-party

software provided hereunder.

Corning does not warrant any hardware, software or services not provided by Corning.

THIS WARRANTY IS THE ONLY WARRANTY MADE BY CORNING AND IS IN LIEU OF ALL OTHER

WARRANTIES, EXPRESS OR IMPLIED INCLUDING, BUT NOT LIMITED TO, THE IMPLIED WARRANTIES OF

MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE. CORNING S SHALL NOT BE LIABLE

FOR ANY OTHER DAMAGE INCLUDING, BUT NOT LIMITED TO, INDIRECT, SPECIAL OR CONSEQUENTIAL

DAMAGES ARISING OUT OF OR

IN CONNECTION WITH FURNISHING OF GOODS, PARTS AND SERVICE HEREUNDER, OR THE

PERFORMANCE, USE OF, OR INABILITY TO USE THE GOODS, PARTS AND SERVICE. CORNING SALES

AGENTS OR REPRESENTATIVES ARE NOT AUTHORIZED TO MAKE COMMITMENTS ON WARRANTY

RETURNS.

Returns

In the event that it is necessary to return any product against above warranty, the following procedure shall be

followed:

1. Return authorization is to be received from Corning prior to returning any unit. Advise Corning of the model,

Serial number, and discrepancy. The unit may then be forwarded to Corning, transportation prepaid. Devices

returned collect or without authorization may not be accepted.

2. Prior to repair, Corning will advise the customer of our test results and any charges for repairing customercaused problems or out-of-warranty conditions etc.

3. Repaired products are warranted for the balance of the original warranty period, or at least 90 days from date

of shipment.

Limitations of Liabiliti es

Corning’s liability on any claim, of any kind, including negligence for any loss or damage arising from, connected

with, or resulting from the purchase order, contract, quotation, or from the performance or breach thereof, or from

the design, manufacture, sale, deliver y, installa tio n, in s pection , oper at ion or use of any equ ipment covered by or

furnished under this contact, shall in no case exceed the purchase price of the device which gives rise to the

claim.

Except as expressly provided herein, Corning makes no warranty, expressed or implied, with respect to any

goods, parts and services provided in connection with this agreement including, but not limited to, the implied

warranties of merchantability and fitness for a particular purpose. Corning shall not be liable for any other damage

including, but not limited to, indirect, special or consequential damages arising out of or in connection with

furnishing of goods, parts and service hereunder, or the performance, use of, or inability to use the goods, parts

and service.

Page 4

Warranties

P/N 709C015102

Page 4

Reporting Defects

The units were inspected before shipment and found to be free of mechanical and electrical defects. Examine the

units for any damage that may have been caused in transit. If damage is discovered, file a claim with the freight

carrier immediately. Notify Corning as soon as possible in writing.

Note: Keep all packing material until you have completed the inspection

Page 5

Warnings and Admonishments

P/N 709C015102

Page 5

Warnings and Admonishments

There may be situations, particularly for workplace environments near high-powered RF sources, where

recommended limits for safe exposure of human beings to RF energy could be exceeded. In such cases,

restrictive measures or actions may be necessary to ensure the safe use of RF energy.

The equipment has been designed and constructed to prevent, as far as reasonably, practicable danger. Any

work activity on or near equipment involving installation, operation or maintenance must be, as far as reasonably,

free from danger.

Where there is a risk of damage to electrical systems involv ing adver se w eath er, ex tr eme temperatures, wet,

corrosive or dirty conditions, flammable or explosive atmospheres, the system must be suitably installed to

prevent danger.

Equipment provided for the purpose of protecting individuals from electrical risk must be suitable for the purpose

and properly maintained and used. This covers a range of activities including lifting, lowering, pushing, pulling,

carrying, moving, holding or restraining an object, animal or person from the equipment. It also covers activities

that require the use of force or effort, such as pulling a lever, or operating power tools.

Where some of the abovementioned activities are required, the equipment must be handled with care to avoid

being damaged.

Observe standard precautions for handling ESD-sensitive devices. Assume that all solid-state electronic devices

are ESD-sensitive. Ensure the use of a grounded wrist strap or equivalent while working with ESD-sensitive

devices. Transport, store, and handle ESD-sensitive devices in static-safe environments.

RF Safety

WARNING! To comply with FCC RF exposure compliance requirements, each individual antenna used for this

transmitter must be installed to provide a separation distance greater than 115 cm or more from all persons during

normal operation and must not be co-located with any other antenna for meeting RF exposure requirements.

WARNING! Antenna gain should not exceed 12.5 dBi.

WARNING! Each individual antenna used for this transmitter must be installed to provide a separation distance

greater than 115 cm or more from all persons and must not be co-located with any other antenna for meeting RF

exposure requirements.

WARNING! The design of the antenna installation needs to be implemented in such a way so as to ensure RF

radiation safety levels and non-environmental pollution during operatio n.

Compliance with RF safety requirements:

• Corning products have no inherent significant RF radiation.

• The RF level on the downlink is very low at the downlink ports. Therefore, there is no dangerous RF radiation

when the antenna is not connected.

Power requirements for DC Inputs

WARNING! Only use a special DC supply cable with connector

WARNING! Always keep DC IN connectors connected during the product operation

Page 6

RF Safety

P/N 709C015102

Page 6

WARNING! Disconnect all power from the equipment by means of an external circuit breaker before connecting

or disconnecting the DC IN connectors.

WARNING! UL certified power supply.

Page 7

Laser Safety

P/N 709C015102

Page 7

Laser Safety

Fiber optic ports of the MobileAccessHX system emit invisible laser radiation at the 1310/1550 nm wavelength

window.

The laser apertures /outputs are the green SC/APC Bulkhead adapters located on the front panel of the

equipment.

The product is Class 1/Hazard level 1

External optical power is less than 10 mW, Internal optical power is less than 500 mW.

To avoid eye injury never look directly into the optical ports, patchcords or optical cables. Do not stare into beam

or view directly with optical instruments. Always assume that optical outputs are on.

Only technicians familiar with fiber optic safety practices and procedures should perform optical fiber connections

and disconnections of MobileAccessHX devices and the associated cables.

MobileAccessHX has been tested and certified as a Class 1 Laser product to IEC/EN 60825-1 (2007). It also

meets the requirements for a Hazard Level 1 laser product to IEC/EN 60825-2: 2004 to the same degree.

MobileAccessHX complies with 21 CFR 1040.10 and 1040.11 except for deviations pursuant to Laser Notice NO.

50 (2007).

Care of Fiber Optic Connectors

Do not remove the protective covers on the fiber optic connectors until a connection is ready to be made. Do not

leave connectors uncovered when not connected.

The tip of the fiber optic connector should not come into contact with any object or dust.

Regulatory Compliance Information

WARNINGS!

• This is NOT a CONSUMER device. It is designed for installation by FCC LICENCEES and QUALIFIED

INSTALLERS. You MUST have an FCC LICENSE or express consent of an FCC Licensee to operate this

device. Unauthorized use may result in significant forfeiture penalties, including penalties in excess of

$100,000 for each continuing violation.

• ANTENNAS:

(1) Use only authorized and approved antennas, cables and/or coupling devices! The use of unapproved

antennas, cables or coupling devices could cause damage and may be of violation of FCC regulations.

The use of unapproved antennas, cables and/or coupling devices is illegal under FCC regulations and

may subject the user to fines.

(2) Caution messages for use of unauthorized antennas, cables, and/or coupling devices not conforming

with ERP/EIRP and/or indoor -only restrictions.

Page 8

Standards and Certifications

P/N 709C015102

Page 8

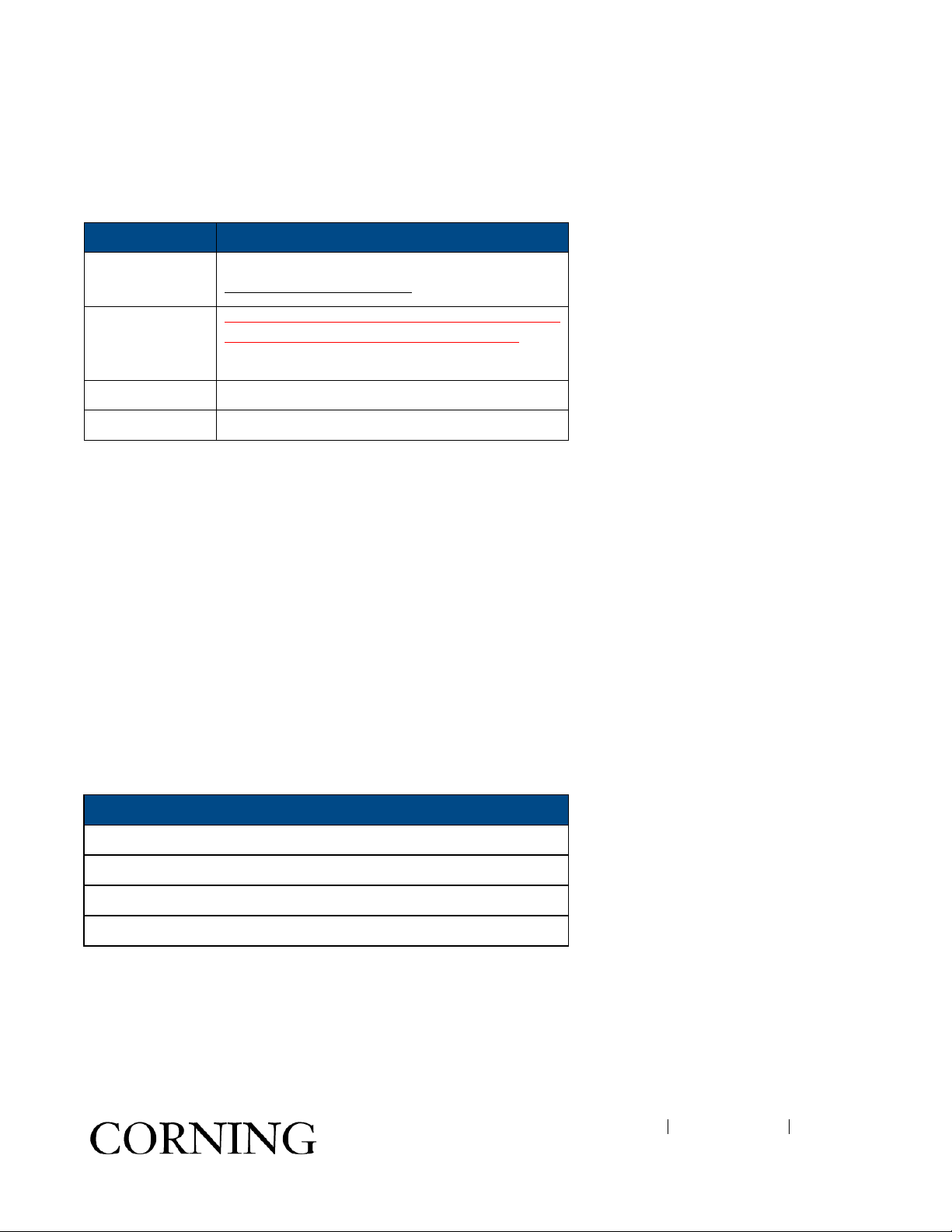

Standards and Certifications

Corning products have met the approvals of the following certifying organizations:

Category Standards

Safety: UL 60950-1

CAN/CSA-C22.2 No.60950

Laser Safety:

Radio: FCC 47: Part 2, 27

ISO: ISO 9001: 2000 and ISO 13485: 2003

SCDRH 21 CFR 1040.10, 1040.11 (Except for

deviations per notice No.50, July 26, 2001)

IEC/EN 60825-1:1994+A1:2002+A2:2001

Licensee Contact Information

Industrial Boosters may only be used by FCC licensees or those given express (individualized) consent of license.

Corning certifies all of the VARs listed as licensed installers for Corning. For the list of licensed VARs, please

contact the Corning Tech Support Hotline: (US) 410-553-2086 or 800-787-1266.

About this Guide

This Installation Guide describes how to perform the physical installation of the MobileAccessHX unit. The

installation procedures of other units (e.g. RIU, OCH-HX, SC-450) relevant to the system are detailed in their user

manuals (see Additional Relevant Documentation below).

Additional Relevant Documents

The following documents are required if the corresponding units are included in your system.

Document Name

RIU Installation and Configuration Guide

MA2000 User Manual (includes BU information)

System Controller (SC-450) User Manual

MA Software Version Update Tool

Page 9

List of Acronyms

P/N 709C015102

Page 9

List of Acronyms

BTS

BTSC

BU

DL

HX

MUX

PA

PSU

RCU

RIU

RU

SC-450

UL

Base Transceiver Station

Base Transceiver Station Conditioner

Base Unit

Downlink

High Power Remote

Multiplexer

Power Amplif ier

Power Supply Unit

Remote Control Unit

Radio Interface Unit

Remote Unit (module)

System Controller

Uplink

Page 10

Table of Contents

P/N 709C015102

Page 10

Table of Contents

Warranties ................................................................................................................................ 2

Hardware ....................................................................................................................................................... 2

Software Warranty ........................................................................................................................................ 2

Returns .......................................................................................................................................................... 3

Limitations of Liabilities ................................................................................................................................. 3

Reporting Defects ......................................................................................................................................... 4

Warnings and Admonishments ............................................................................................... 5

RF Safety .................................................................................................................................. 5

Compliance with RF safety requirements: .................................................................................................... 5

Power requirements for DC Inputs ................................................................................................................ 5

Laser Safety .............................................................................................................................. 7

Care of Fiber Optic Connectors .................................................................................................................... 7

Regulatory Compliance Information ....................................................................................... 7

Standards and Certifications ................................................................................................... 8

Licensee Contact Information ................................................................................................. 8

About this Guide ...................................................................................................................... 8

List of Acronyms ...................................................................................................................... 9

Table of Contents ................................................................................................................... 10

1 Introduction ..................................................................................................................... 13

1.1 Key Features and Capabilities ............................................................................................................ 14

1.2 System Architecture ............................................................................................................................ 15

1.3 System Monitoring and Managem ent ................................................................................................. 16

1.4 HX Unit Description ............................................................................................................................. 17

1.4.1 HX WCS External Interfaces ..................................................................................................... 18

1.4.2 Internal Module Interfaces ........................................................................................................ 20

1.5 External Passive Module (EPM).......................................................................................................... 23

2 Installation Guidelines .................................................................................................... 24

2.1 Site Considerations ............................................................................................................................. 24

2.2 Environmental ..................................................................................................................................... 24

2.3 Installation Requirements .................................................................................................................... 24

Page 11

Table of Contents

P/N 709C015102

Page 11

2.4 Fiber Optic Requirements ................................................................................................................... 25

2.4.1 Authorized Optic Cables ........................................................................................................... 25

2.4.2 Fiber Optic Rules ...................................................................................................................... 25

2.5 RF Coaxial Cable Guidelines .............................................................................................................. 26

2.5.1 General Cable Installation Procedures ..................................................................................... 26

2.5.2 RF Rules ................................................................................................................................... 26

2.5.3 Coax Cable Lengths and Losses .............................................................................................. 26

2.5.4 Cable Routing ........................................................................................................................... 27

2.6 Antenna Specifications and Guidelines ............................................................................................... 27

2.6.1 Authorized Antennas and Couplers .......................................................................................... 27

2.6.2 General Antenna Installation Guidelines ................................................................................... 28

2.7 Grounding Requirement ...................................................................................................................... 28

2.8 Manual Handling ................................................................................................................................. 28

2.9 Installation Requirements .................................................................................................................... 28

3 HX Physical Installation .................................................................................................. 29

3.1 Unpacking and Inspection ................................................................................................................... 29

3.2 Mounting .............................................................................................................................................. 30

3.2.1 General Instructions .................................................................................................................. 30

3.2.2 Rack Mount Installation ............................................................................................................. 30

3.2.2.1 Rack Installation General Safety Instructions .............................................................. 30

3.2.2.2 Mounting HX WCS in 19-in Rack ................................................................................. 31

3.2.3 Wall-Mount Installation .............................................................................................................. 33

3.2.3.1 Assembling EPM to HX WCS (for Configurations with EPM) ...................................... 33

3.2.3.2 Horizontal Wall Mount Installation ...............................................................................

3.2.3.3 Vertical Wall Mount Installation .................................................................................... 38

3.3 Connections......................................................................................................................................... 42

3.3.1 RF and Fiber Connections ........................................................................................................ 42

3.3.1.1 Installations with Additional HX Unit ............................................................................ 42

3.3.1.2 Installations with MA1000/MA2000 Remote ................................................................ 45

3.3.2 Ground Connection ................................................................................................................... 48

3.3.3 Power Connections ................................................................................................................... 49

3.4 Verifying Normal Operation ................................................................................................................. 50

34

Appendix A: System Specifications...................................................................................... 51

RF Parameters ............................................................................................................................................ 51

Optical Specifications .................................................................................................................................. 52

Physical Specifications................................................................................................................................ 53

Environmental Specifications ...................................................................................................................... 53

Standards and Approvals ............................................................................................................................ 54

Supported Services ............................................................................................................................. 51

RF Parameters per Service Antenna Port ........................................................................................... 51

RF Parameters for Diplexer External Input Port .................................................................................. 52

Page 12

Table of Contents

P/N 709C015102

Page 12

Appendix B: Ordering Information ........................................................................................ 55

MobileAccessHX WCS Remote Units ......................................................................................................... 55

Page 13

CMA-318-AEN

Page 13

• Introduction

MobileAccessHX WCS is a mid-power, remote solution designed t o be int egrat ed into ex istin g Mobi leAcc ess1000

(MA1000) and MobileAcce ss2000 (MA2000) D istributed Antenna S ystems (DAS) alread y deployed in the fi eld. It

is a fiber fed, compact unit whic h provides support f or the WCS 2300 MHz band and is designed to com plement

the MA1000/MA2000 and other MobileAccessHX flavors while enhancing RF open space coverage for largescale public venues such as campuses, stadiums, convention centers, hotels, airports and train stations.

Using low-loss fiber optic cabling, remote units can cover distances of up to 12.75 mi (2 km) from the BTS signal

sources at the headend. HX WCS requires minimum addition of hardware to the headend (WCS BTSC) and

utilizes existing fiber and antenna overlay. HX WCS MIMO takes full advantage of MIMO technology by using

spatial multiplexing to deliver higher spectral efficiency and preventing the degradation of quality while

significantly increasing throughput on the same spectrum.

HX WCS Figure 1-1

오류! 지정한 스타일은 사용되지 않습니다.

Page 14

CMA-TBD-AEN

Page 14

1.1 Key Features and Capabilities

• Service Platform: Accommodates LTE and provides SISO/MIMO configuration for WCS band.

• Cost-Effective High Power: Optimizes and reduces the number of antennas required to cover open areas

by offering up to 33 dBm (2 W) composite power per frequency band.

• Scalability: Supports either SISO or MIMO service in a single compact enclosure.

• Operator-Grade Operation: Advanced signal handling and management ensures operator-grade

performance in multi-operator deployments.

• Design and Deployment Flexibility: Antenna splitting schemes are possible due to the higher power output

capability.

• Compatibility: Connects existing MobileAccess1000, MobileAccess2000 and MobileAccessHX remote units

to allow common antenna overlay; Shares a common headend and EMS in a single deplo yment .

• Monitoring and Web Management: All status LEDs are located on front panel; Web management via the

SC-450 controller (v7.2 and higher)

오류! 지정한 스타일은 사용되지 않습니다.

Page 15

CMA-TBD-AEN

Page 15

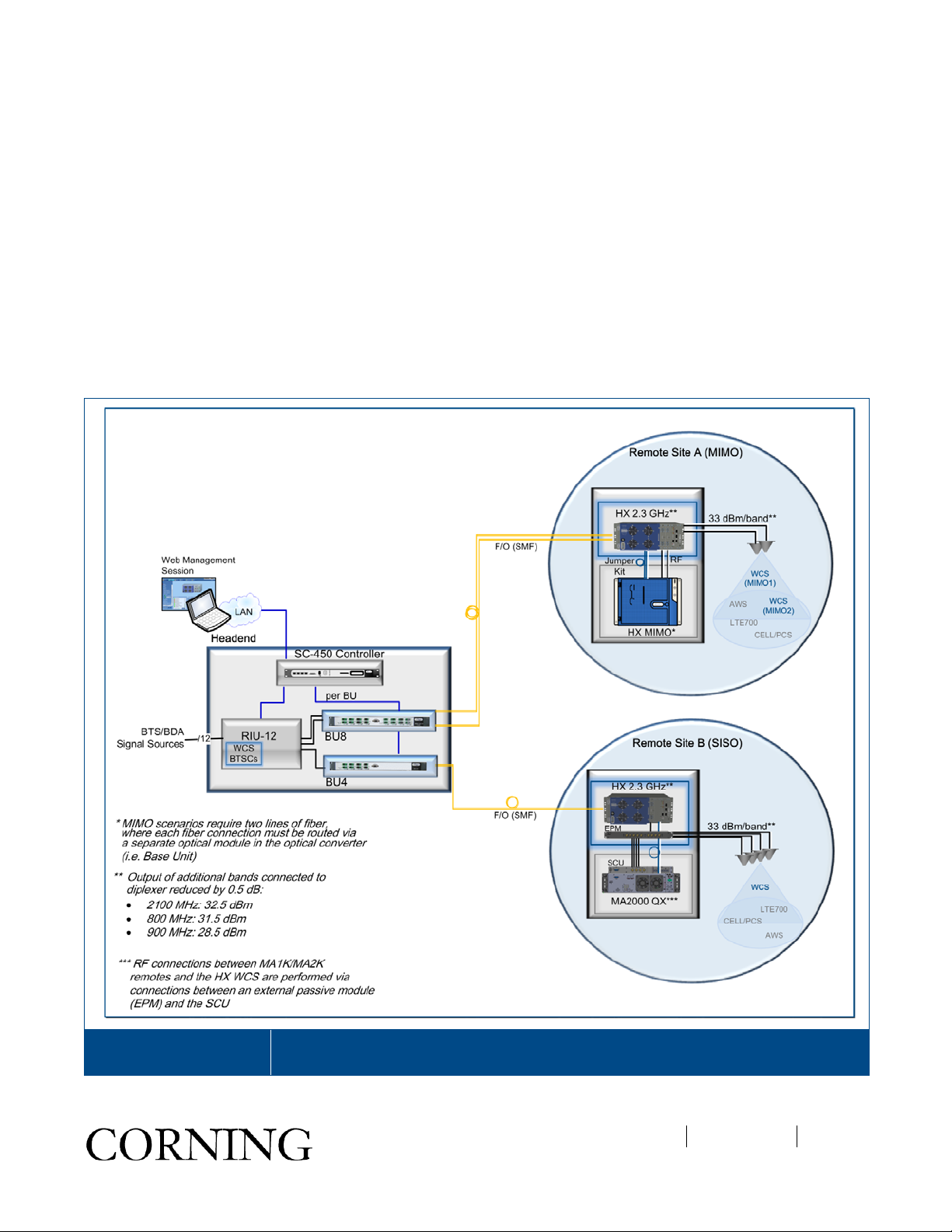

1.2 System Architecture

MobileAccessHX WCS provides a complete solut ion consisting of HX remote un it(s) at the r emote locations and

headend elements.

In the downlink, at t he headend , the BT S or BDA sign al is condit ioned by the RIU, ensuring a c onstant RF level.

The conditioned signa l is then converted by the Base Unit (BU) to an opt ical signal for transport over si ngle or

multi-mode fiber to the HX remote unit, located at the remote location. In the uplink, the process is reversed.

The HX Remote Un it (SIS O/MIMO ) cons ists of a c om pact e nclosure that houses the RF m odul e, po wer ele m ents

and the required interf ac es . T he R F m odule s upports t he WCS band. An interfac e dupl exin g por t is l oc ate d o n the

remote to allow additi ona l HX r em otes to be co nnec t e d s o tha t t he ser vices f rom all HX remotes c an be com bin ed

into one antenna port.

The System Controller (SC-450 v7.2) enables local and r emote management, as well as c ontrols all MA1000,

MA2000, and HX elements from a single, centralized location.

HX WCS Architecture

Diagram

•

Figure 1-2

오류! 지정한 스타일은 사용되지 않습니다.

Page 16

CMA-TBD-AEN

Page 16

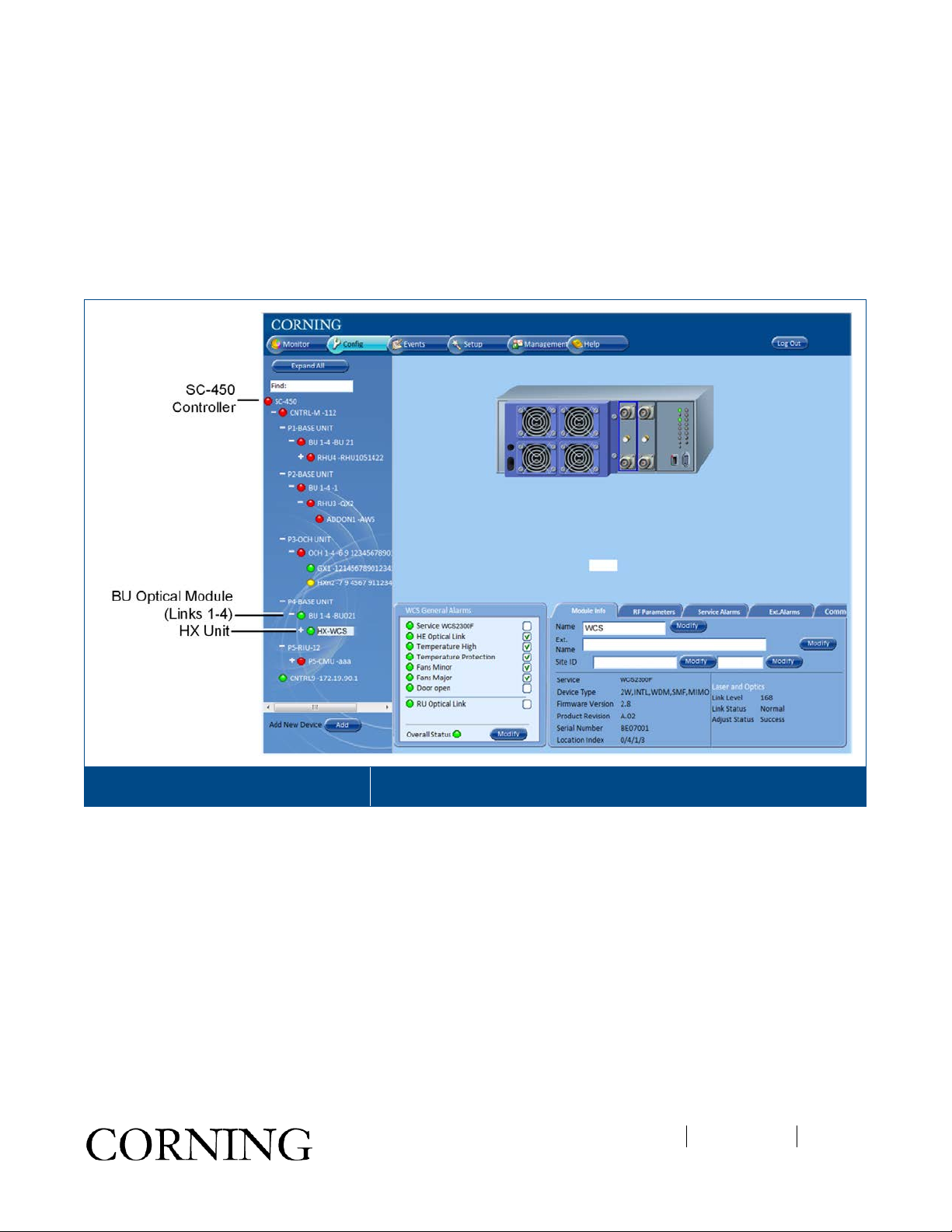

1.3 System Monitoring and Management

The HX WCS rem ote unit is centrall y managed via the SC-450 C ontroller (v7.2 and higher). Note that HX is no t

directly connected to the controller. The HX is managed and configured via the BU to which it is connect ed

Figure 1-3 shows the Configuration tabs of the sel ected HX unit. Refer to the SC-450 Controller User Manual

(v7.2 and higher) for information on how to configure and manage the HX WCS remote unit.

Example of HX WCS Configuration Tab Figure 1-3

오류! 지정한 스타일은 사용되지 않습니다.

Page 17

CMA-TBD-AEN

Page 17

1.4 HX Unit Description

The HX WCS unit consists of the following main modules:

• RCU – Remote Control Unit; Includes status LEDs for each module and control ports

• HX-WCS MUX – Multiplexer [ANT. 1 MUX (right) for SISO; ANT. 2 MUX (left) for MIMO] includ ing int erf ac es

to RF antennas and to MA1000/MA2000 units; combines signal sources additional external RF signals (when

connected to HX unit and MA1000/MA2000 remote) while providing the proper filtering into a single antenna

port

• HX Module – [ANT. 1 (right) for SISO; ANT. 2 (left) for MIMO] Internal module that interfaces to the optical

converter unit (Base Unit) connects via an SMF pair and supports one service. The HX WCS module

provides the additional amplification on the DL signals routed from the BU towards the Multiplexer.

• Power Supply - DC power; Internal module

The unit plot plan is provided on the left side of the enclosure door:

HX WCS Unit Plot Plan Figure 1-4

The following sections provide details on the front panel and internal module interfaces.

오류! 지정한 스타일은 사용되지 않습니다.

Page 18

CMA-TBD-AEN

Page 18

1.4.1 HX WCS External Interfaces

Ext. Alarms

DB-9 female external alarm connector for external dry contact alarm connections

Fan Modules

MUX

1

MUX 2

Opening for Routing

Power Cable

Opening for Routing

Fiber

Antenna

DL Test Coupling Port

RS-232 Console

Ethernet

RCU

Grounding Lug

Wideband RU (-0.5dB) Port

External Alarms Port

The HX WCS front panel includes the multiplexer interfaces (e.g. antenna por t, DL T est port, w ideband RU port),

system level status LEDs and service maintenance ports.

Note: Both SISO and MIMO models include two sets of multiplexer RF interfaces. For SISO models, the RF

connections will be performed via the connec tors corresponding to th e installed HX remot e unit module (inside

chassis): Left MUX for Left HX WCS Module and Righ t MUX for Right HX WCS Module. (See section 1.4.2 for

internal modules.)

HX WCS Front Panel Interf ac es Figure 1-5

Table 1-1 provides a description of the front panel connectors.

Connector Description

ANT 4.3-10 Type duplexed antenna port

WB-RU 4.3-10 Type duplexed wideband remote unit expansion port for interfacing to external RF In

source (i.e. HX4 remote) so that additional services are combined with those of the HX and

distributed from the duplexed HX antenna port

DL Test CPL.

SMA-Type female 50Ω connector (40 dB ± 2 dB) used for RF DL test

Port

RS-232 D-Type 9 pin female console port used for connecting to engineering GUI

RJ-45 Ethernet connection for local craft

Ext. 1 / Ext. 2 DB-9 female (Future option)

GND Two-hole, standard barrel grounding lug

Table 1-1. HX Front Panel Connectors

오류! 지정한 스타일은 사용되지 않습니다.

Page 19

CMA-TBD-AEN

Page 19

Refer to Figure 1-6 and Table 1-2 for description of HX status LEDs.

HX WCS RCU Module Status LEDs Figure 1-6

Note: Module 1 and Module 2 LEDs corres pond to installed modules [ Module 1 for ANT . 1 (SISO); Module 2 for

ANT. 2 (MIMO)].

LED State Description

From HE

(from

headend)

Run Blinking green

Off

Power input detected

Unit powered off

Comm Green Short blink upon receiving FSK message

(Off at any other time)

Link Steady green Optical link level is above normal threshold

Blinking green Optical link level is lower than Normal threshold but

above no-link threshold

Off Optical link level is below No link threshold

Status Green / Yellow / Red Color according to device’s overall status

To Remote Comm Green Short blink upon receiving FSK message

(Off at any other time)

Link Steady green Optical link level is above normal threshold

Blinking green Optical link level is lower than Normal threshold but

above no-link threshold

오류! 지정한 스타일은 사용되지 않습니다.

Page 20

CMA-TBD-AEN

Page 20

LED State Description

Device

Service

Green

Service status is ok

Red

Any service alarm is se t

Ant.

Green

VSWR alarm is clear

Red

VSWR alarm is set

Temp.

Green

Over Temp and Temperature Protection alarms are

clear

Red

Over Temp or Temperature Protection alarms is

set

Fan

Green

Fan alarm is clear

Yellow

Fan alarm is set (minor) for first fan faulty

Red

Fan alarm is set (major) for other fan faulty.

Off Optical link level is below No link threshold

LED State Description

Table 1-2. HX WCS RCU Status LED Descriptions

1.4.2 Internal Module Interfaces

The HX internal modules include two main modules (see Figure 1-7):

• PSU – Power supply module; includes DC In connector and status LEDs

• HX Module – one for SISO cabinets and two for MIMO (the interfaces are the same for each module);

comprises an optical module and power amplifier; interfaces to the base unit; Left HX Module corresponds to

left HX MUX.

오류! 지정한 스타일은 사용되지 않습니다.

Page 21

CMA-TBD-AEN

Page 21

HX (MIMO) Internal Modules – PSU (Left) and HX WCS Modules (Middle and Right) Figure 1-7

Module Interface Description

PSU Power connector 34-48 V DC input; 6 pin DC terminal block connector

HX Module Optic Port (SC APC fiber-optic pair connector; SMF ; connection

towards Base Unit (BU)

(SC APC fiber-optic pair connector; SMF; connection

towards additional remote unit

Extension UL/DL SMA type (future option)

Table 1-3. HX WCS Internal Module Connectors

Module LED Description

PSU Run Steady green – required power input detected

Off – no power input

PSU Off – normal operation

Steady red – faulty PSU module; In more than 10%

difference than the rated DC output, the red LED occurs.

HX-WCS

Module

BU Link Off – No optical link

Blinking green – Low optical link level

Steady green – Normal optical link level

Run Off – no power input

오류! 지정한 스타일은 사용되지 않습니다.

Page 22

CMA-TBD-AEN

Page 22

Module LED Description

Blinking green – power input detected

Remote Link

Note: Indicates link status

between HX WCS and additional

remote unit connected.

Off – No optical link

Blinking green – Low optical link level

Steady green on – Normal optical link level

Table 1-4. HX WCS Internal Module LEDs

오류! 지정한 스타일은 사용되지 않습니다.

Page 23

CMA-TBD-AEN

Page 23

1.5 External Passive Module (EPM)

band input ports interface to service

The External Passive Mod ule (EPM) is required when in inst allations with an existing M A1000/MA2000 remote

unit (e.g. MA2000 QX) . The EPM is used to com bine up to four low ban d output wideband s ignals with the hig h

band HX WCS output s ignal. The module includes a 1:4 spl itter for the high band (i.e. W CS) and four internal

diplexers that combine the 2.3 GHz signal with the wideband signal received from the MA1000/MA2000 remote.

The EPM interfaces to the HX WCS and to the service combiner unit (SCU) of the MA1000/MA2000 remote.

External Passive Module – Front (Top) and Rear (Bottom) Panels Figure 1-8

Refer to Table 1-5 for a description of the EPM interfaces.

Panel Connector Description

Front HIGH I/O One Mini DIN 4.3-10 high-band input por t interfaces to HX-

WCS

Rear ANT Four Mini DIN 4.3-10 combined output ports interface to

wideband antennas

LB Four N-Type low-

combiner unit (SCU) on MA1000/MA2000.

Table 1-5. EPM Front and Rear Panel Interfaces

오류! 지정한 스타일은 사용되지 않습니다.

Page 24

CMA-318-AEN

Page 24

• Installation Guidelines

This chapter describes the installation procedure for the HX WCS remote unit.

1.6 Site Considerations

• The distance between the HX service antenna and the coverage area should correspond to LOS (Line of

Sight) requirements for maximum coverage area.

• The maximum fiber path loss is 3 dB.

• The system delay of the optical system must be taken into consideration when there are neighboring BTS

sites overlapping in coverage.

1.7 Environmental

Humidity has an adv erse effect on the rel iability of the equipm ent. It is recomm ended to install the e quipment in

locations having stable temperature and unrestricted air-flow.

The installation locat ion f or the s ystem s hould be well vent ilated. T he equ ipm ent has bee n des igned to oper ate at

the temperature r ange and humidit y level as stated i n the product specifications with a relative h umidity of m ax.

90% and temperatures range of -40 to 65

o

C (-40° to 149°F).

1.8 Installation Requirements

• Mounting surface shall be capable of supporting the weight of the equipment.

• In order to avoid electromagnetic interference, a proper mounting location must be selected to minimize

interference from electromagnetic sources such as large electrical equipment.

• Working space available for installation and maintenance for each mounting arrangement. Ensure

unrestricted airflow.

• Ensure grounding connector is within reach of the ground wire.

• Ensure a power source is within reach of the power cord and the power source has sufficient capacity.

• Where appropriate, ensure unused RF connectors are terminated.

• Do not locate the equipment near large transformers or motors that may cause electromagnetic interference.

• Reduce signal loss in feeder cable by minimizing the length and number of RF connections.

• Ensure the equipment will be operated within the stated environment (refer to datasheet).

• Where appropriate, confirm available of suitably terminated grade of RF and optical fiber.

• Observe handling of all cables to prevent damage.

오류! 지정한 스타일은 사용되지 않습니다.

Page 25

CMA-TBD-AEN

Page 25

1.9 Fiber Optic Requirements

1.9.1 Authorized Optic Cables

• Only single mode fiber can be used with HX WCS product

• All fiber in a given length of fiber must be of the same core diameter.

• All bulkhead adapters must be single mode SC APC (Green) adapters.

• All terminations, cross connections or patches must be direct fusion splice or Corning specified patch cords

listed below.

900 microns pathcord for splicing, 2 Meters, 2xSC/APC

Diamond p/n ENC/1045341 Beige boots, 62.5/125/900 MA# 500001057

Diamond p/n ENC/1045340 Black boots, 50/125/900 MA# 500001058

Zipcord patchcord, 4xSC/APC, 50/125/900/ 200 0/4 500 micron

Diamond p/n ENC/1045342 Black/Brown boots, 1 Meter MA# 50000105

Diamond p/n ENC/1045343 Black/Brown boots, 3 Meter MA# 500001060

Zipcord patchcord, 4xSC/APC, 62.5/125/900/2000/4500 micron

Diamond p/n ENC/1045344 Beige/Brown boots, 1 Meter MA# 500001061

Diamond p/n ENC/1045345 Beige/Brown boots, 3 Meter MA# 500001062

1.9.2 Fiber Optic Rules

ATTENTION!

Please also refer to the laser safety section in the document preface.

• Fiber optic cables require proper handling. Do not stretch, puncture, or crush the fiber cable(s) with staples,

heavy equipment, doors, etc.

• Always maintain the minimum bending radius specified by the cable manufacturer. The minimum bend radius

is usually 10 times the cable's outer diameter. In the case of single optical fiber that is not in a cable, the

minimum bending radius to be observed is 30 mm.

• Use SC APC connectors (green color) 8 deg only.

• Pay special atte ntion w hi le connec ti ng the SC APC connectors - ensure that you hear a “click”, indicating a

secure connection

• Use minimum splicing/connectors to achieve minimum losses on the fibers.

• Use precaution while installing, bending, or connecting fiber optic cables.

• Use an optical power meter and OTDR for checking the fiber optic cables.

• Make sure the environment is clean while connecting/splicing fiber optic cables.

• All fiber optic connectors should be cleaned prior to connecting to the system

• Fiber connector protective caps should be installed on all non-terminated fibers and removed just before they

are terminated.

• Check the fiber optic connections.

오류! 지정한 스타일은 사용되지 않습니다.

Page 26

CMA-TBD-AEN

Page 26

• Never look directly into the end of a fiber that may be carrying laser light. Laser light can be invisible and can

damage your eyes.

1.10 RF Coaxial Cable Guidelines

1.10.1 General Cable Insta llation Procedures

Note: The installer should be familiar with the ANSI/TIA/EIS-568 Cabling Standard guidelin es .

Observe the genera l cable installation procedur es that meet with the buildi ng codes in your area. The bu ilding

code requires that all cabling be installed above ceiling level (where applicable). The length of cable from the

risers to each antenna may need to be concealed above the ceiling.

The cable must be pro perly supporte d and maintaine d straight us ing velcro c able ties, c able trays and c lamps or

hangers every 10 f eet (where practical above cei ling level). Where this is not practical, the following shou ld be

observed:

• The minimum bending radius of the supplied ½” coax cable should be 7”.

• Cable that is kinked or has a bending radius smaller than 7” must be replaced.

• Cable runs that span less than two floors should be secured to suitably located mechanical structures.

• The cables should be supported only from the building structure.

• All cables shall be weather-resistant type

• Cable length - deter mined by the system installation plan. When calculating the cable length, take into

account excess cable slack so as not to limit the insertion paths.

.

1.10.2 RF Rules

• Use coax RG-223, 50 ohm, for RF connections between HX units and DAS antennas.

• When using the Corning system in an environment in which other indoor coverage systems are installed, it is

recommended (where possible) that the antennas are placed at least two meters apart

• When bending coax cables, verify that the bending radius does not exceed the coax specifications.

• Use wideband antennas supporting a range of 700 MHz to 2600 MHz

• Terminate all unused HX RF ports with a 50 ohm load

• Make sure that the VSWR measured at the coax cable meets the product specification The VSWR must be

measured prior to terminating the HX RF ports in the remote communication rooms.

1.10.3 Coax Cable Lengths and Loss e s

Use the compatible jumper to connect the coax connector to the external antenna.

Note: The required distance between the antennas (installed in the ceiling) depends on the infrastructure and

calculated path-loss.

Coax

Length

30 0.7 1.5 2.2

Coax Loss

(900 MHz)

Connector

Loss

Total Loss

40 0.9 1.5 2.4

50 1.1 1.5 2.6

오류! 지정한 스타일은 사용되지 않습니다.

Page 27

CMA-TBD-AEN

Page 27

Coax

Length

60 1.3 1.5 2.8

70 1.5 1.5 3

80 1.7 1.5 3.2

90 1.9 1.5 3.4

100 2.1 1.5 3.6

110 2.3 1.5 3.8

120 2.5 1.5 4

130 2.7 1.5 4.2

140 2.9 1.5 4.4

150 3.1 1.5 4.6

160 3.3 1.5 4.8

170 3.5 1.5 5

180 3.7 1.5 5.2

190 3.9 1.5 5.4

Coax Loss

(900 MHz)

Connector

Loss

Total Loss

200 4.1 1.5 5.6

Table 2-6. Typical Coax Cable Lengths and Losses

1.10.4 Cable Rout ing

Ensure all cables, e.g. power cable, feeder cable, optic fiber, commissioning cable, connecting are properly

routed and secured so that they are not dam aged.

1.11 Antenna Specifications and Guideline s

Determine the antenna installation configuration, acc ording to the transmission and coverag e requirements and

the installation site conditions.

1.11.1 Authorized Antennas a nd Couplers

• External antennas - No limitation on any vendor of available external antennas with respect to the following

requirements:

• Omni Directional or Directional

• Supported frequency range: wideband antennas supporting a range of 700 MHz to 2600 MHz

• Gain: up to 12.5 dBi

• Impedance: 50 Ohm

• Types of couplers/splitters – depends on number of splits

• Couplers – Use N-Male to N-Female broadband coupler separately ordered from Corning (P/N AK-

1COUPLER-NM-NF) or the equivalent:

오류! 지정한 스타일은 사용되지 않습니다.

Page 28

CMA-TBD-AEN

Page 28

• Broadband frequency: 698 – 2700 MHz

• -40 dB coupling (QMA coupling port)

• Max. VSWR/Return Loss: 5:1 / 16 dB

• Max. Insertion Loss (dB): 0.2

• Impedance: 50 ohms

1.11.2 General Antenna Installation Guidelines

• The wideband antenna should be installed at a convenient location, free of metallic obstruction (can also be

installed in plenum spaces).

• Install the connected antenna at the designated height and tune it roughly toward the Service coverage area.

• Each individual antenna used for this transmitter must be installed to provide the separation distance as

specified in the FCC grant from all persons during normal operation and must not be co-located with any

other antenna for meeting RF exposure requirements

1.12 Grounding Requirement

Verify that the equipm ent has been wel l ground ed (ref er to the groun ding lug o n the bot tom right c orner of the HX

WCS front panel). T his incl udes ante nnas and all cabl es connect ed to the s ystem . Ensure lightn ing protec tion for

the antennas is properly grounded. Also, see section 3.3.2.

1.13 Manual Handling

During transportation and i ns tal lat ion, tak e nec es s ar y hand li ng prec aut ions t o a vo id potential physical injur y to the

installation personnel and the equipment.

1.14 Installation Requirements

• Working space available for installation and maintenance for each mounting arrangement. Ensure

unrestricted airflow.

• Ensure grounding connector is within reach of the ground wire.

• Ensure a power source is within reach of the power cord and the power source has sufficient capacity.

• Where appropriate, ensure unused RF connectors are terminated.

• Do not locate the equipment near large transformers or motors that may cause electromagnetic interference.

• Reduce signal loss in feeder cable by minimizing the length and number of RF connections.

• Ensure the equipment will be operated within the stated environment (Appendix A: System Specifications).

• Where appropriate, confirm available of suitably terminated grade of RF and optical fiber.

• Observe handling of all cables to prevent damage.

오류! 지정한 스타일은 사용되지 않습니다.

Page 29

CMA-TBD-AEN

Page 29

• HX Physical Installation

This chapter describes the mounting procedure and physical connections for the HX WCS Remote Unit.

1.15 Unpacking and Inspection

Unpack and inspect the cartons according to the following procedure

1. Open the shipping carton and carefully unpack each unit from the protective packing material.

2. Verify that all of the item required for installing the HX WCS have been received (refer to Table 3-1). If any

of the listed items are missing, contact your Corning representative.

3. Check for signs of external damage. If there is any damage, call your Corning service representative.

HX Kit Item Quantity

HX WCS Remote Unit:

• HX-WCS-SISO-NU*

• HX-WCS-SISO-PLUS*

• HX-WCS-MIMO**

*SISO models include one HX-WCS Module

and one slot cover (blank panel for

unoccupied HX-WCS Module

**MIMO slot) ; MIMO models include two

HX-WCS Modules

19-in rack brackets (factory assembled) –

(default mounting option) for rack-mount

installations

Flat Head Screw UNC 6-32, 8mm; Stainless

Steel

Wall Mount Bracket (Belly-to-Wall)

Assembly: Bracket

Pan Head Screw Sems UNC 6-32, 11 mm;

Stainless Steel; Used for securing bracket to

HX sides

1

2

(RT/LT)

12

2

(RT/LT)

20

Table 3-7. HX WCS Package Items List

오류! 지정한 스타일은 사용되지 않습니다.

Page 30

CMA-TBD-AEN

Page 30

1.16 Mounting

The HX WCS unit is installed in t he communication room via one of the follo win g opti ons (e ac h type of installation

requires a different pair of brackets):

• Rack mount - rack ears preassembled

• Vertical wall mount (i.e. Belly-to-Wall; cabinet door faces side)

• (Optional) Horizontal - (i.e. Back-to-Wall; cabinet door faces front); separately ordered kit: AK-HX-ADDON-

B2W-MNT

1.16.1 General Instructions

• HX WCS remotes should be installed in a communication room that provides access only to authorized

personnel.

• The units are maintenance free. In the event of failure, only authorized personnel should handle the units.

• Only trained and qualified personnel should be allowed to install or replace this equipment.

• Verify that ambient temperature of the environment does not exceed 65°C (149°F)

1.16.2 Rack Mount Installation

1.16.2.1 Rack Installation General Safety Instructions

Review the followin g guidelines to help ensure your s afety and protect the equipm ent from damage during t he

installation.

• To maintain a low center of gravity, ensure that heavier equipment is installed near the bottom of the rack and

load the rack from the bottom to the top.

• Ensure that adequate airflow and ventilation within the rack and around the installed components so that the

safety of the equipment is not compromised.

오류! 지정한 스타일은 사용되지 않습니다.

Page 31

CMA-TBD-AEN

Page 31

1.16.2.2 Mounting HX WCS in 19-in Rack

Note the following:

• The HX WCS requires 4U rack height availability

• If the HX WCS unit is to be installed with an existing MA1000/MA2000 remote the EPM (1U) should be

installed in between the remote units in order to facilitate the connections

• Rack nuts and screws not provided (depend on rack type)

To mount the HX WCS in a 19-in rack:

1. Determine the location of the HX WCS in the rack.

2. Secure the unit to the communication racks’ vertical uprights via at least two bracket holes on each side

(one top and one middle) using the appropriate rack nuts and screws.

Refer to Figure 3-1 and Figure 3-3 for examples of rack installations.

Examples of HX WCS Rack Installations with Additional HX and MA2000 QX Remote Units Figure 3-9

오류! 지정한 스타일은 사용되지 않습니다.

Page 32

CMA-TBD-AEN

Page 32

Examples of HX WCS Rack Installations with Additional MA2000 TSX Remote Units Figure 3-10

오류! 지정한 스타일은 사용되지 않습니다.

Page 33

CMA-TBD-AEN

Page 33

1.16.3 Wall-Mount Installation

IMPORTANT! The wall-mount installation procedures in this section are for c oncrete/brick walls. For other wall

types, installer is responsible for following standard practices using the appropriate tools and materials.

The following sections provide instructions for both vertical (“be lly-to-wall”) and horizontal ( optional “b ack -to wall”)

wall-mount installation types.

Note the following:

• If the HX WCS is to be installed in conjunction with the EPM, the latter must be assembled to the HX unit

before mounting the HX on the wall. Refer to 3.2.3.1.

• When selecting the installation location, make sure that there is enough clearance distance from the bottom

to open the HX WCS chassis door.

1.16.3.1 Assembling EPM to HX WCS (for Configurations with EPM)

To assemble EPM onto HX WCS

1. Remove the factory assembled rack ears from the sides of the unit.

2. Fixed hole is at the top of the EPM unit for wall mounting. See Figure 3-3.

Assembling Brackets to EPM Figure 3-11

오류! 지정한 스타일은 사용되지 않습니다.

Page 34

CMA-TBD-AEN

Page 34

3. Place the EPM onto the top of the HX WCS unit and using six UNC 6-32, 11mm screws, assemble the

EPM onto the top sides of the HX WCS unit for top side. See Figure 3-4.

Assembling EPM onto HX WCS Figure 3-12

1.16.3.2 Horizontal Wall Mount Installation

Additional required tools and materials

• Philips/electric screwdriver

• Four anchors for mounting brackets on wall (anchor type depends on surface type)

To mount the HX WCS unit on the wall:

1. Remove the factory assembled rack brackets from the sides of the HX WCS unit.

2. Using ten UNC 6-32, 11 mm screws for each bracket (provided in HX kit), assemble the wall-mount

brackets to the sides of the HX WCS as shown in Figure 3-5.

오류! 지정한 스타일은 사용되지 않습니다.

Page 35

CMA-TBD-AEN

Page 35

Wall-Mount Bracket Assembly Figure 3-13

3. Referring to bracket hole dimensions in Figure 3-6 (units in mm), prepare the appropriat e anchors and

mount as follows:

• Mark four holes (minimum of two on per bracket) on the wall for drilling the anchors

• Drill four holes, using a hammer drill.

• Fill the holes with silicon to help weather-proof the drilled holes and to prevent erosion.

• Tap in expanding lead shield anchors

Wall-Mount Bracket Hole Dimensions Figure 3-14

4. Insert two bolts in top anchors and tighten until bolt head is 0.5” from surface of wall. See Figure 3-7.

오류! 지정한 스타일은 사용되지 않습니다.

Page 36

CMA-TBD-AEN

Page 36

Inserting First two Bolts in Anchors Figure 3-15

5. Hang the unit and bracket assembly onto the two bolts using the key holes.

6. Insert remaining bolts (two on each side) through remaining bracket holes into anchor.

7. Tighten all four bolts.

8. Verify that HX unit is tightly secured and does not shake.

Refer to Figure 3-8 for HX WCS wallmount examples with additional MA2000 remote.

오류! 지정한 스타일은 사용되지 않습니다.

Page 37

CMA-TBD-AEN

Page 37

Example of HX WCS with Assembled EPM Alongside MA2000 TSX Remote Figure 3-16

오류! 지정한 스타일은 사용되지 않습니다.

Page 38

CMA-TBD-AEN

Page 38

1.16.3.3 Vertical Wall Mount Installation

The vertical wall-mount brackets are optional and ordered separately.

Unpack and inspect the carton as follows:

1. Open the shipping carton and carefully unpack each unit from the protective packing material.

2. Verify that all of the items required for wall mount installation have been received (refer to Table 3-2). If

any of the listed items are missing, contact your Corning representative.

3. Check for signs of external damage. If there is any damage, call your Corning service representative.

Wall Mount Bracket (Back-to-Wall)

Quantity

Assembly Kit

Bracket

Pan Head Screw Sems UNC 6-32, 11 mm;

2

(RT/LT)

16

Stainless Steel; Used for securing bracket to

HX sides

Table 3-8. HX WCS Wall-Mount Brackets Package Items List

Additional required tools and materials

• Philips/electric screwdriver

• Hammer drill

• Two anchors for hanging brackets on wall (anchor type depends on surface type) and four bolts for secure

installation

오류! 지정한 스타일은 사용되지 않습니다.

Page 39

CMA-TBD-AEN

Page 39

To mount the HX WCS unit on the wall:

1. Remove the factory assembled rack brackets from the sides of the HX WCS unit.

2. Using eight UNC 6-32, 11 mm screws for each bracket (provided in HX kit), assemble the wall-mount

brackets to the rear of the HX WCS side panels.

3. Referring to Figure 3-9, prepare appropriate anchors and bolts for drilling.

Wall-Mount Bracket Dimensions Figure 3-17

4. Using bracket holes as a template, mark holes for drilling in wall.

오류! 지정한 스타일은 사용되지 않습니다.

Page 40

CMA-TBD-AEN

Page 40

5. Insert two bolts in top anchors and tighten until bolt head is 0.5” from surface of wall. See Figure 3-10.

Inserting First two Bolts in Anchors Figure 3-18

6. Hang the unit and bracket assembly onto the two bolts using the key holes.

7. Insert remaining bolts (two on each side) through remaining bracket holes into anchor and tighten.

8. Verify that HX WCS unit is tightly secured and does not shake.

Refer to Figure 3-11 for HX WCS wall mount examples with additional MA2000 remote.

오류! 지정한 스타일은 사용되지 않습니다.

Page 41

CMA-TBD-AEN

Page 41

Example of HX WCS with Assembled EPM Alongside MA2000 TSX Remote Figure 3-19

오류! 지정한 스타일은 사용되지 않습니다.

Page 42

CMA-TBD-AEN

Page 42

1.17 Connections

Note that the HX WC S is an upgrade unit and as such the RF and fiber connec tions also interface the existin g

MA1000/MA2000 rem ote units. W here relevant, t he RF and fiber connections reference ex isting HX and M A2000

QX as examples of connections to existing remotes.

1.17.1 RF and Fibe r Connections

1.17.1.1 Installations with Additional HX Unit

1. Connect the HX WCS MUX “WB RU” 4.3-10 Type duplexed RF port to the HX duplexed antenna port.

Note: For SISO installat ions the connections are fro m HX WCS ‘ANT. 1 MUX to HX ‘ANT ENNA PORT 1’; For

MIMO installations additional connections are performed between HX WCS ‘ANT. 2 MUX’ to HX ‘ANTENNA

PORT 2.

RF Connections Between HX WCS and Existing HX (Left-SISO; Right – MIMO) Figure 3-20

오류! 지정한 스타일은 사용되지 않습니다.

Page 43

CMA-TBD-AEN

Page 43

2. Connect broadband antenna coax to ANT port of HX-WCS MUX module (two for MIMO models) and to

broadband DAS antennas.

ATTENTION! Terminate any unused RF ports with a 50 ohm termination load.

Example of HX WCS Antenna Connections (SISO) Figure 3-21

3. Open the cabinet doors for both HX WCS and HX remotes to access optic fiber connection ports.

오류! 지정한 스타일은 사용되지 않습니다.

Page 44

CMA-TBD-AEN

Page 44

4. Disconnect the fiber connection from the existing HX remote (from the base unit) and re-connect to the

bottom SC APC optic port of the HX-WCS module (Right ANT. 1 module for SISO and Left ANT. 2 module

for MIMO)

• Downlink: Connect the fiber optic cable pigtails from splice box, whic h comes from the BU port, to the

corresponding HX RU module (MIMO models include two service modules with fiber connections).

• Uplink: Connect the fiber optic cable pigtails from splice box, which comes from the RU service module(s), to

the uplink port that connects to the BU.

Note: Keep in mind the rules for handling and connecting F/O cables. The F/O cables will be connected to

the associated BU in the communication room at a later phase.

Example of HX WCS (MIMO) Fiber Connections to Existing HX Figure 3-22

오류! 지정한 스타일은 사용되지 않습니다.

Page 45

CMA-TBD-AEN

Page 45

1.17.1.2 Installations with MA1000/MA2000 Remote

This section provides ins tructions on how to perform expansion c onnections between the HX W CS unit and an

MA1000/MA2000 rem ote unit. The RF connections between the H X WCS unit and an MA1000/MA20 00 remote

require an EPM unit which interf aces bet ween the H X W CS and the ser vice com biner uni t (SCU) re quired f or the

MA1000/MA2000 remote.

IMPORTANT! Two EPM units are required for MIMO installations – each one connects to an HX WCS ‘ANT .”

Port.

To connect expansion connections

1. Connect the HX WCS MUX “ANT” 4.3-10 Type duplexed RF port to the EPM front panel high band Mini

DIN 4.3-10 input port. See Figure 3-15.

Example of Connection between HX WCS and EPM Figure 3-23

오류! 지정한 스타일은 사용되지 않습니다.

Page 46

CMA-TBD-AEN

Page 46

2. Connect the four rear panel EPM lo w-b and N-Type input ports to the corresponding SCU N-Type

ANTENNA PORT S”.

Note: The location of the SCU ‘ANTENNA PORTS” differ depending on model:

• SCU-4/SCU-8 units - antenna ports located on rear panel

• SCU-F/SCU-FT - antenna ports located on front panel

Example of Connection between HX WCS and EPM Figure 3-24

3. Connect the four EPM rear panel Mini DIN 4.3-10 ‘ANT’ output ports to the wideband antennas .

오류! 지정한 스타일은 사용되지 않습니다.

Page 47

CMA-TBD-AEN

Page 47

4. Open cabinet door to access HX WCS module(s) with the fiber optic interface, route the DL and UL fibers

Example of HX WCS Fiber optic Connections to BU and MA2000 Remote Indoor Connections

(MIMO)

through the front door slot and (see Figure 3-17) and connect as follows:

• Optic fiber connections to/from headend (BU):

o Downlink: Connect the fiber optic cable pigtails from splice box, leading from the BU port, to the

corresponding HX WCS module “From HE” SC APC optic port (MIMO models include two service

modules with fiber connections).

o Uplink: Connect the fiber optic cable pigtails from splice box, which comes from the HX WCS service

module(s), “From HE” SC APC uplink port to the BU.

• Using fiber optic jumpers, connect the HX WCS module “To RU” SC APC optic to the SC APC optic port of

the MA1000/MA2000 remote unit.

IMPORTANT! Keep in mind the rules for handling and connecting F/O cables.

오류! 지정한 스타일은 사용되지 않습니다.

Figure 3-25

Page 48

CMA-TBD-AEN

Page 48

Note: EPM and SCU not shown in Figure 3-17 for clarity.

1.17.2 Ground Connection

Required tools and components

The following additional (not supplied) tools and components are required for connecting the system ground:

• Grounding wire - grounding wire should be sized according to local and national installation requirements.

The provided grounding lug supports 14 AWG to 10 AWG stranded copper (or 12 AWG to 10 AWG solid)

wire conductors.

Note: The length of the grounding wire depends on the proximity to proper grounding facilities.

• Phillips-head screwdriver

• Crimping tool to crimp the grounding wire to the grounding lug.

• Wire-stripping tool to remove the insulation from the grounding wire

To ground the HX WCS

1. Use a wire-stripping tool to remove approximately 0.4 inch (10.9 mm) of the covering from the end of the

grounding wire.

2. Insert the stripped end of the grounding wire into the open end of the grounding lug.

3. Crimp the grounding wire in the barrel of the grounding lug. Verify that the ground wire is securely

attached to the ground lug by holding the ground lug and gently pulling on the ground wire.

4. Prepare the other end of the grounding wire and connect it to an appropriate grounding point at the site to

ensure adequate earth ground.

HX WCS Grounding Lug Figure 3-26

오류! 지정한 스타일은 사용되지 않습니다.

Page 49

CMA-TBD-AEN

Page 49

1.17.3 Pow er Conne c t ions

WARNING! Before connect ing or disconn ecting grou nd or power wires to th e chass is, ensure that p ower is

disconnected from the DC circuit. To disc on nect p owe r , locate the c irc uit br eaker on th e p ane l b oar d t hat s erv ic es

the DC circuit, and switch the circuit breaker to the OFF position. Verify zero voltage at the power terminals on the

chassis before proceeding.

DC power specifications

• Power source rating: 34-48 V DC

• Max Consumption: SISO = 90 W; MIMO = 150 W

• Compatible wire size for plug: 30~12 AWG

• No. of required pairs: Minimum of one pair (up to three)

• Max. current consumption for connector: for 20 AWG = 4.5 A; (max. 5A)

To connect DC power:

Note: The internal power connections and other connections should already be connected.

1. Open cabinet door, if not already open, to access Power Supply Unit (PSU).

HX WCS PSU DC Connector Figure 3-27

2. Connect the DC wires leading from the power source to the Dinkle 2ESDFM terminal block plug according

to indicated pin out on the PSU DC terminal block:

오류! 지정한 스타일은 사용되지 않습니다.

Page 50

CMA-TBD-AEN

Page 50

• Identify the positive and negative terminals on power source feed positions. The wiring sequence is positive

to positive and negative to negative.

• Open the terminal block screw and insert appropriate feed into the terminal block plug

• Torque the terminal block captive screw (above the installed wire lead), using a ratcheting torque screwdriver.

Recommended torque is 0.49N•m.

• Repeat above steps for all feeds

• Insert the plug into HX WCS PSU DC terminal block.

1.18 Verifying Normal Operation

1. Verify that the fans are operational.

2. Verify system normal operation via the system and service LEDs – refer to section 1.4.1 (Table 1-2) and

section 1.4.2 (Table 1-4) for LED descriptions.

Note: The HX WCS monito r ing and management capa bilit ies are per for m ed vi a th e hos t BU unit. Ref er to t he SC 450 (v7.2 and higher) User Manual for the configuration and management options.

오류! 지정한 스타일은 사용되지 않습니다.

Page 51

Appendix A: System Specifications

Technologies

2 Operators (dBm)

30

Mean Gain (dB) 1

33

31

Gain Flatness/Ripple (dB)

+/- 1.5

RF Parameters

Supported Services

Band

Frequency Range

Uplink Downlink

LTE* 2300 LTE2300 2305 - 2315 MHz 2350 – 2360 MHz

* LTE compiles with 3GPP TS 36.106 V10.6.0 (2012-12) table 9.1 unwanted emission.

RF Parameters per Service Antenna Port

LTE2300 MHz

RF Parameters DL UL

Max Output Power Per Antenna

Port

1 Operator (Composite)3 (dBm)

4 Operators (dBm) 27

8 Operators (dBm) 24

Pin1 (dBm) 0

Input IP3 (dBm) AGC OFF Typical -15

Max. Intermod Distortion (dBm) -13

NF (dB) Typical

RF Output Port Impedance 50 ohm

2

1

Factory set mean gain BU without RIU. May be field adjusted using controller system.

2

Gain Flatness/Ripple is specified for the non-duplexed port of the system.

33

6

Appendix A: System Specifications

CMA-318-AEN Page 51

Page 52

Appendix A: System Specifications

CMA-318-AEN

Page 52

RF Parameters for Diplexer External Input Port

RF Parameters

Frequency Range

Insertion Loss

Isolation

Return Loss

Power Rating

40 dB Min.@ 2305~2315 MHz

Optical Specifications

Max. Optical Budget

Optical Connector

Fiber Type

Wavelength

Maximum Distance Between BU and

Remote Cabinet

698 – 2155 MHz

0.6 dB

16 dB Min.

Avg.100 W

3 dB

SC/APC

Single-mode: 9/1 25µm (Minim um qualifications with ANSI/TIA/E IA-

568-B series, EN50173-1 or ISO/IEC 11801)

1310 ± 10 nm

2 km

Page 53

Appendix A: System Specifications

CMA-318-AEN

Page 53

Physical Specifications

x W x

PLUS / 43lbs (19.5

Interfaces

Power

Chassis:

• One Min DIN 4.3-10 duplexed antenna (‘ANT’) port per multiplexer (one for SISO

units; two for MIMO units)

• One Min DIN 4.3-10 duplexed ‘Expansion’ port per multiplexer (one for SISO

units; two for MIMO units) for interfacing external RF In source

• One SMA-Type female 50Ω port for DL test port per multiplexer (one for SISO

units; two for MIMO units)

• One female RJ-45 local craft port

• One D-Type 9 pin female console port (engineering GUI)

• One six pin pluggable terminal block connector; three VCC and GND pairs

• One two hole grounding lug with 6 gauge wire

• One DB-9 female external alarm connector for external dry contact alarm

connections

Module:

• Four SC APC optical connectors

• Two SMA UL/DL Extension Port connectors

• Power Input: 34-48 V DC

• Maximum operating voltage : 28-60 V DC

• Max Power Consumption: 90 W (SISO models); 150 W (MIMO models)

Physical Mounting: Wall or 19-in Rack

Cooling Feature Active heat dissipation (Fan)

•

Dimensions (H

D):

Weight:

SISO Services conf iguration: 48lbs (21.77kg) f or SISOkg) for SISO-NU

MIMO Services configuration: 55 lbs (24.95 kg)

7.0 x 19 x 15.4 in (176.5 x 492 x 392 mm)

Environmental Specifications

Operating Temperature

Storage Temperature

Humidity

Enclosure

-40°C to +65°C (-40°F to 149°F)

-40°C to +85°C (-40°F to 185°F)

10% to 95%, non-condensing

IP20

Page 54

Appendix A: System Specifications

CMA-318-AEN

Page 54

Laser Safety

Safety

Radio

RoHS

Standards and Approvals

• CDRH 21 CFR 1040.10, 1040.11 (Except for deviations per notice

No.50)

• IEC/EN 60825-1:1994+A1:2002+A2:2001

• UL 60950-1

• CAN/CSA-C22.2 No.60950

• FCC 47: Part 2, 27

• RoHS 6 compliant

Page 55

Appendix B: Ordering Information

CMA-318-AEN

Page 55

Appendix B: Ordering Information

Part Number

Description

Kit

Part Number

Description

Corning Optical Communications Wireless, Inc. • 13221 Woodland Park rd, Suite 400 • Herndon, VA 20171 USA

866

products

without prior notification. All other trademarks are the properties of their respective owners. Corning MobileAccess is ISO 9

Communications

UM

Note: T he information liste d below is updated up to the doc ument publishing da te. Refer to the HX datashe et for

the most updated ordering information.

MobileAccessHX WCS Remote Units

HX WCS Remotes

Service Supported Part Number Description

WCS SISO

WCS SISO

WCS MIMO

HX-WCS-SISO-NU

HX-WCS-SISO-PLUS

HX-WCS-MIMO

RIU Conditioner Modules

RIU--BTSC-WCS RIU-4 conditioner for WCS band

RIU-12-CNDTR-WCS RIU-12 conditioner for WCS band

Upgrade kits

WCS Module

HX-WCS-MODULE

MobileAccessHX SISO onl y rem ot e with suppor t

for WCS band (Non MIMO upgradable in the

field)

MobileAccessHX SISO remote with support for

WCS band (MIMO upgradable in the field)

MobileAccessHX MIMO remote with support for

WCS band

MobileAccessHX WCS band module for upgrade

from SISO to MIMO

Accessory Kits*

Part Number Description

AK-HX-1K2K-HXN-COMB

AK-HX-ADDON-B2W-MNT

-436-9266 • FAX: 703-848-0280 • Tech Support Hotline: 410-553-2086 or 800-787-1266 • www.corning.com/opcomm

_HX WCS_709C017601 A00 _29JUNE2015

. All rights reserved. Published in the USA.

MobileAccessHX accessory kit combining 1K/2K and HX; External passive

module

reserves the right to improve, enhance and modify the features and specifications of Corning Optical Communications

001 certified. © 2013 Corning Optical

Loading...

Loading...