Page 1

Corning

ONE™ Wireless Platform

User Manual

APRIL 2013

Page 2

Preface Material

P/N 709C011801

Page 2

Preface Material

About This Manual

This user guide provides all the information necessary to understand the architecture and perform the installation of

Corning® ONE™ Wireless Platform.

Hardware

Corning warrants to the original purchaser (“Customer”) that for the duration of the warranty period, one (1) year,

commencing on the date of shipment of the Hardware, unless otherwise agreed in writing by Corning (the “Hardware

Warranty Period”), the Hardware furnished by Corning shall be free in all material respects from defects in material

and workmanship, and shall conform to the applicable portions of the Specifications, as defined below (the

“Hardware Warranty”).

If notified by Customer of any such defects in material or workmanship or nonconformity with applicable portions of

the Specifications within the Hardware Warranty Period, Corning shall promptly, at its own election and expense,

repair or replace any such Hardware proven to be defective under the terms of this Hardware Warranty.

Such repair or replacement shall be Customer’s sole remedy and Corning sole obligation in the event this Hardware

Warranty is invoked. If any components comprising a part of the Hardware are replaced or repaired during the

Hardware Warranty Period, the Hardware Warranty Period for such repaired or replaced components shall extend to

the longer of (i) the balance of the Hardware Warranty Period or (ii) three (3) months from the date of repair or

replacement. For purposes of this Warranty, “Specifications” shall mean the specifications and performance

standards of the Products as set forth in documents published by Corning and delivered to Customer which contain

technical specifications or performance standards for the Products.

If Customer invokes this Hardware Warranty, it shall notify Corning promptly of the claimed defect.

Customer will allow Corning to inspect the Hardware at Customer’s location, or to return the Hardware to Corning

closest repair facility. For Hardware returned to Corning repair facility, Customer shall be responsible for payment of

all transportation and freight costs (including insurance) to Cornings’ repair facility, and Corning shall be responsible

for all transportation and freight costs (including insurance) incurred in connection with the shipment of such

Hardware to other repair facilities of Corning and/or its return to Customer.

Notwithstanding the foregoing, in no event will Corning be liable for damage to Products resulting from improper

handling during or after shipment, misuse, neglect, improper installation, operation or repair (other than by

authorized Corning personnel), alteration, accident, or for any other cause not attributable to defects in materials or

workmanship on the part of Corning. Corning shall not reimburse or make any allowance to Customer for any labor

charges incurred by Customer for replacement or repair of any goods unless such charges are authorized in advance

in writing by Corning.

Page 3

Preface Material

P/N 709C011801

Page 3

Software Warranty

Corning warrants to the original purchaser (“Customer”) that for the duration of the warranty period, one (1) year,

commencing on the date of shipment of the Software, unless otherwise agreed in writing by Corning (the “Software

Warranty Period”), the Software shall conform with, and perform the functions set forth in the Specifications, and

shall be free from defects in material or workmanship (the “Software Warranty”). In the event the Software is proven

to be defective under the terms of this Software Warranty, Corning shall correct such defects or failure and ensure

that the Software conforms with, and performs the functions set forth in, the Specifications. Customer will allow

Corning to inspect the Software at Customer’s location or to return it to Cornings’ closest repair facility.

Notwithstanding the foregoing, Corning shall have no obligation under the Software Warranty if the

Software is modified or used with hardware or software not supplied or approved by Corning or if the Software is

subject to abuse, improper installation or application, accident, electrical or environmental over-stress, negligence in

use, storage, transportation or handling.

Third-party software distributed with the Software may carry certain warranties which, to the maximum extent

allowed by law, Corning hereby assigns, transfers and otherwise conveys to Customer, provided, however, that

Corning itself provides no warranty of any kind, express, implied, statutory or otherwise, for any third-party software

provided hereunder.

Corning does not warrant any hardware, software or services not provided by Corning.

THIS WARRANTY IS THE ONLY WARRANTY MADE BY CORNING AND IS IN LIEU OF ALL OTHER

WARRANTIES, EXPRESS OR IMPLIED INCLUDING, BUT NOT LIMITED TO, THE IMPLIED

WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE. CORNING

SHALL NOT BE LIABLE FOR ANY OTHER DAMAGE INCLUDING, BUT

NOT LIMITED TO, INDIRECT, SPECIAL OR CONSEQUENTIAL DAMAGES ARISING OUT OF OR

IN CONNECTION WITH FURNISHING OF GOODS, PARTS AND SERVICE HEREUNDER, OR THE

PERFORMANCE, USE OF, OR INABILITY TO USE THE GOODS, PARTS AND SERVICE.

CORNING SALES AGENTS OR REPRESENTATIVES ARE NOT AUTHORIZED TO MAKE

COMMITMENTS ON WARRANTY RETURNS.

Returns

In the event that it is necessary to return any product against above warranty, the following procedure shall be

followed:

1. Return authorization is to be received from Corning prior to returning any unit. Advise Corning of the model,

Serial number, and discrepancy. The unit may then be forwarded to Corning, transportation prepaid. Devices

returned collect or without authorization may not be accepted.

2. Prior to repair, Corning will advise the customer of our test results and any charges for repairing customer-caused

problems or out-of-warranty conditions etc.

3. Repaired products are warranted for the balance of the original warranty period, or at least 90 days from date of

shipment.

Page 4

Preface Material

P/N 709C011801

Page 4

Limitations of Liabilities

Corning’s liability on any claim, of any kind, including negligence for any loss or damage arising from, connected

with, or resulting from the purchase order, contract, quotation, or from the performance or breach thereof, or from the

design, manufacture, sale, delivery, installation, inspection, operation or use of any equipment covered by or

furnished under this contact, shall in no case exceed the purchase price of the device which gives rise to the claim.

Except as expressly provided herein, Corning makes no warranty, expressed or implied, with respect to any goods,

parts and services provided in connection with this agreement including, but not limited to, the implied warranties of

merchantability and fitness for a particular purpose. Corning shall not be liable for any other damage including, but

not limited to, indirect, special or consequential damages arising out of or in connection with furnishing of goods,

parts and service hereunder, or the performance, use of, or inability to use the goods, parts and service.

Reporting Defects

The units were inspected before shipment and found to be free of mechanical and electrical defects. Examine the

units for any damage that may have been caused in transit. If damage is discovered, file a claim with the freight

carrier immediately. Notify Corning as soon as possible in writing.

N ote: Keep all packing material until you have completed the inspection

Page 5

Warnings and Admonishments

P/N 709C011801

Page 5

Warnings and Admonishments

There may be situations, particularly for workplace environments near high-powered RF sources, where

recommended limits for safe exposure of human beings to RF energy could be exceeded. In such cases, restrictive

measures or actions may be necessary to ensure the safe use of RF energy.

The equipment has been designed and constructed to prevent, as far as reasonably, practicable danger. Any work

activity on or near equipment involving installation, operation or maintenance must be, as far as reasonably, free

from danger.

Where there is a risk of damage to electrical systems involving adverse weather, extreme temperatures, wet,

corrosive or dirty conditions, flammable or explosive atmospheres, the system must be suitably installed to prevent

danger.

Equipment provided for the purpose of protecting individuals from electrical risk must be suitable for the purpose

and properly maintained and used. This covers a range of activities including lifting, lowering, pushing, pulling,

carrying, moving, holding or restraining an object, animal or person from the equipment. It also covers activities that

require the use of force or effort, such as pulling a lever, or operating power tools.

Where some of the abovementioned activities are required, the equipment must be handled with care to avoid being

damaged.

Observe standard precautions for handling ESD-sensitive devices. Assume that all solid-state electronic devices are

ESD-sensitive. Ensure the use of a grounded wrist strap or equivalent while working with ESD-sensitive devices.

Transport, store, and handle ESD-sensitive devices in static-safe environments.

RF Safety

To comply with FCC RF exposure compliance requirement, adhere to the following warnings:

Warning! Antennas used for this product must be fixed mounted on indoor permanent structures, providing a separation

distance of at least 50 cm from all persons during normal operation.

Warning! Each individual antenna used for this transmitter must be installed to provide a minimum separation distance of 50 cm

or more from all persons and must not be co-located with any other antenna for meeting RF exposure requirements.

Warning! Antenna gain should not exceed 12.5 dBi.

Warning! The design of the antenna installation needs to be implemented in such a way so as to ensure RF radiation safety

levels and non-environmental pollution during operation.

Page 6

Company Certification

P/N 709C011801

Page 6

ATTENTION!

Compliance with RF safety requirements:

• Corning products have no inherent significant RF radiation

• The RF level on the downlink is very low at the downlink ports. Therefore, there is no dangerous RF radiation

when the antenna is not connected.

CAUTION!

Use of controls, adjustments or performance of procedures other than those specified herein may result in hazardous

radiation exposure.

Laser Safety

• Fiber optic ports of the ONE™ system emit invisible laser radiation at the 1310/1550 nm wavelength window.

• External optical power is less than 10 mW, Internal optical power is less than 500 mW.

• To avoid eye injury never look directly into the optical ports, patchcords or optical cables. Do not stare into beam

or view directly with optical instruments. Always assume that optical outputs are on.

• Only technicians familiar with fiber optic safety practices and procedures should perform optical fiber

connections and disconnections of ONE™ devices and the associated cables.

• ONE™ has been tested and certified as a Class 1 Laser product to IEC/EN 60825-1 (2007). It also meets the

requirements for a Hazard Level 1 laser product to IEC/EN 60825-2: 2004 to the same degree.

• ONE™ complies with 21 CFR 1040.10 and 1040.11 except for deviations pursuant to Laser Notice NO. 50

(2007).

• ONE™ employs a Class 3B laser and therefore the following label is affixed inside the unit adjacent to the laser:

Care of Fiber Optic Connectors

• Do not remove the protective covers on the fiber optic connectors until a connection is ready to be made. Do not

leave connectors uncovered when not connected.

• The tip of the fiber optic connector should not come into contact with any object or dust.

• Refer to the cleaning procedure for information on the cleaning of the fiber tip.

Company Certification

ISO 9001: 2000 and ISO 13485: 2003

Page 7

Table of Contents

P/N 709C011801

Page 7

TTaabbllee ooff CCoonntteennttss

Preface Material ................................................................................................................................................... 2

About This Manual ................................................................................................................................................. 2

Hardware ............................................................................................................................................................... 2

Software Warranty ................................................................................................................................................. 3

Returns .................................................................................................................................................................. 3

Limitations of Liabilities .......................................................................................................................................... 4

Reporting Defects .................................................................................................................................................. 4

Warnings and Admonis hments........................................................................................................................... 5

RF Safety ............................................................................................................................................................... 5

Laser Safety ........................................................................................................................................................... 6

Care of Fiber Optic Connectors .............................................................................................................................. 6

C ompany C ertification ......................................................................................................................................... 6

Table of Contents ................................................................................................................................................. 7

1 Introduc tion ................................................................................................................................................. 13

1.1 About ONE™ ................................................................................................................................................ 13

1.2 Key Features and Capabilities ....................................................................................................................... 14

1.3 General System Specifications and Requirements ........................................................................................ 14

1.3.1 Supported Browsers ............................................................................................................................. 14

1.3.2 Environmental and Regulatory Specifications ...................................................................................... 14

1.3.2.1 Temperature and Humidity ..................................................................................................... 14

1.3.2.2 Safety and Regulatory Approvals ........................................................................................... 15

1.3.3 Power Consumption of Units ................................................................................................................ 15

1.3.3.1 General Power Safety Instructions ......................................................................................... 15

1.3.4 Dimensions and Weight of Units .......................................................................................................... 16

1.3.5 Optical Specifications ........................................................................................................................... 16

1.3.6 Default Network and User Settings ...................................................................................................... 17

1.3.6.1 Default Network Parameters ................................................................................................... 17

1.3.6.2 System Administrator or "Super User" .................................................................................... 17

1.3.6.3 Default Group Admin .............................................................................................................. 17

Page 8

Table of Contents

P/N 709C011801

Page 8

1.4 Installation Guidelines ................................................................................................................................... 18

1.4.1 Rack Mount Procedure ........................................................................................................................ 18

1.4.1.1 General Instructions ............................................................................................................... 18

1.4.1.2 Rack Installation Safety Instructions ....................................................................................... 19

1.4.2 Power Consumption, Connections and Power Supplies ....................................................................... 19

1.4.2.1 Power Safety Instructions ....................................................................................................... 19

1.4.2.2 Types of Power Supplies ........................................................................................................ 19

1.4.2.3 Circuit Breakers ...................................................................................................................... 19

1.5 System Architecture and Topologies ............................................................................................................. 20

1.5.1 RF Path ................................................................................................................................................ 20

1.5.2 Digital Path .......................................................................................................................................... 21

1.6 ONE™ WEB Management Application .......................................................................................................... 21

1.6.1 Overall Device Display - Configuration Tab .......................................................................................... 23

1.6.2 Session Access .................................................................................................................................... 23

1.7 User Controlled Sectorization ........................................................................................................................ 24

1.7.1 MIMO Configurations ........................................................................................................................... 25

1.7.2 Single Sector Example ......................................................................................................................... 25

1.7.3 Dual Sector Example ........................................................................................................................... 26

1.7.4 Tri-sector Example ............................................................................................................................... 26

1.7.5 Tri-sector Example with Two HEUs ...................................................................................................... 27

2 Unit Descriptions - R F Path ........................................................................................................................ 29

2.1 RF Path - Headend Components .................................................................................................................. 29

2.1.1 HEU (Headend Unit) ............................................................................................................................ 29

2.1.1.1 HCM (Headend Control Module) ............................................................................................ 30

2.1.1.2 RIM/RIM-M (RF Interface Module) .......................................................................................... 31

2.1.1.3 RIX (RF Expander Module) .................................................................................................... 33

2.1.1.4 PSM (Power Supply Module) .................................................................................................. 33

2.1.2 OIU (Optical Interface Unit) .................................................................................................................. 34

2.1.2.1 ACM (Auxiliary Control Module).............................................................................................. 35

2.1.2.2 OIM (Optical Interface Module) ............................................................................................... 36

Page 9

Table of Contents

P/N 709C011801

Page 9

2.1.2.3 OIX (Optical Expander Module) .............................................................................................. 37

2.2 RF Path Remote End Site Components ........................................................................................................ 38

2.2.1 ICU (Intermediate Centralized Unit) ..................................................................................................... 38

2.2.2 RAU (Remote Antenna Unit) ................................................................................................................ 39

2.2.2.1 RxU (Remote Expansion Unit) ................................................................................................ 40

3 Unit Descriptions - Digita l Path .................................................................................................................. 41

3.1 Digital Path Components ............................................................................................................................... 41

3.2 CEU (Centralized Ethernet Unit) ................................................................................................................... 41

3.2.1 CEM (Centralized Ethernet Module) ..................................................................................................... 42

3.3 GEM (Gigabit Ethernet Module) .................................................................................................................... 43

3.4 GEU-S (GEM Standalone) ............................................................................................................................ 44

4 Ins tallation – R F P ath E lements ................................................................................................................. 45

4.1 RF Headend Installation ................................................................................................................................ 45

4.1.1 HEU Installation ................................................................................................................................... 45

4.1.2 Example of HEU Master-Slave Installation ........................................................................................... 47

4.1.3 OIU Installation .................................................................................................................................... 47

4.2 RF Remote-End Installation .......................................................................................................................... 48

4.2.1 ICU Installation ..................................................................................................................................... 48

4.2.1.1 General Information ................................................................................................................ 48

4.2.2 RAU Installation ................................................................................................................................... 49

4.2.2.1 General Information ................................................................................................................ 49

4.2.3 RxU Installation .................................................................................................................................... 50

4.2.3.1 General Information ................................................................................................................ 50

5 Ins tallation – Digital Coverage E lements ................................................................................................... 51

5.1 CEU Installation ............................................................................................................................................ 51

5.2 GEM .............................................................................................................................................................. 52

5.2.1 GEM Installations with RAU Module ..................................................................................................... 52

5.2.2 GEU-S Installations .............................................................................................................................. 53

6 Commis sioning the Sys tem ....................................................................................................................... 55

6.1 Opening a Local Session .............................................................................................................................. 55

6.2 Configuring HCM Network Settings for Local and Remote Management ....................................................... 57

6.2.1 Default Network Parameters ................................................................................................................ 59

Page 10

Table of Contents

P/N 709C011801

Page 10

6.2.2 Ping Tool - Verifying IP Host Access .................................................................................................... 60

6.3 Required Pre-Setup Procedures ................................................................................................................... 61

6.4 Running the Setup Procedure ....................................................................................................................... 63

6.5 System Adjustment Procedure ...................................................................................................................... 73

6.6 About the Setup Tool .................................................................................................................................... 74

6.6.1 Overview of Setup Procedure .............................................................................................................. 75

6.6.2 Default Values Assigned in Setup Tool ................................................................................................ 76

6.6.3 Navigating the Setup Tool .................................................................................................................... 76

6.6.3.1 Module Owner ........................................................................................................................ 78

6.6.3.2 Zone Information .................................................................................................................... 79

6.6.3.3 MIMO-SETUP ........................................................................................................................ 81

6.6.3.4 RF Path .................................................................................................................................. 82

6.6.3.5 Max Input ............................................................................................................................... 84

6.6.3.6 ALC ........................................................................................................................................ 84

6.6.3.7 UL Gain .................................................................................................................................. 85

6.6.3.8 AGC ....................................................................................................................................... 87

6.6.3.9 Adjustment ............................................................................................................................. 89

7 Device Configuration .................................................................................................................................. 91

7.1 System Management (HCM) ......................................................................................................................... 93

7.2 HEU Configuration ........................................................................................................................................ 94

7.2.1 HEU ACM ............................................................................................................................................ 94

7.2.2 RIM ...................................................................................................................................................... 95

7.3 OIU Configuration ......................................................................................................................................... 97

7.3.1 OIU ACM ............................................................................................................................................. 97

7.3.2 OIM ...................................................................................................................................................... 98

7.4 RAU Configuration ........................................................................................................................................ 99

7.5 RxU Configuration ....................................................................................................................................... 101

7.6 Removing a Hosted Device from Baseline .................................................................................................. 103

8 Adminis tration ........................................................................................................................................... 105

8.1 Management Menu Tab .............................................................................................................................. 105

8.2 Multi User Account Management ................................................................................................................ 106

8.2.1 Defining User Groups ......................................................................................................................... 107

8.2.2 Defining User Accounts ...................................................................................................................... 109

Page 11

Table of Contents

P/N 709C011801

Page 11

8.2.3 Group Users Access Levels ............................................................................................................... 111

8.2.4 Modifying Passwords ......................................................................................................................... 112

8.2.4.1 System Admin Password Change ........................................................................................ 112

8.2.4.2 Group Admin Password Change .......................................................................................... 113

8.2.4.3 User Own Password Change ............................................................................................... 115

8.2.5 Session Timeout Settings................................................................................................................... 116

8.3 Backup & Restore Configurations ............................................................................................................... 117

8.4 Generating Device Reports ......................................................................................................................... 118

8.5 Activity Log .................................................................................................................................................. 120

8.6 Firmware Upgrade ...................................................................................................................................... 121

9 Monitoring and Troubles hooting ............................................................................................................. 123

9.1 Overview ..................................................................................................................................................... 123

9.2 Network Topology Tree - Fault Sourcing ..................................................................................................... 124

9.3 Fault Sourcing through the Device View and Alarms Tab ............................................................................ 126

9.3.1 HCM (System Management) Device View and Alarms ....................................................................... 126

9.3.2 ACM Device Alarms and View ........................................................................................................... 127

9.3.3 RIM Module Device View and Alarms ................................................................................................ 129

9.3.4 OIM Device View and Alarms ............................................................................................................. 130

9.3.5 RAU Device View and Alarms ............................................................................................................ 131

9.3.6 RxU View ........................................................................................................................................... 132

9.4 Masking Irrelevant Alarms ........................................................................................................................... 133

9.5 Events Display ............................................................................................................................................ 134

9.5.1 Filtering Displayed Events .................................................................................................................. 135

Page 12

Table of Contents

P/N 709C011801

Page 12

10 S NMP Management ................................................................................................................................... 137

10.1 SNMP Destination Address Configuration .......................................................................................... 137

10.2 Modifying the Read/Write Community Parameters ............................................................................. 138

10.3 SNMP Management using any Third Party SNMP Manager .............................................................. 138

10.4 Loading the MIB Files ........................................................................................................................ 139

10.5 Viewing the Traps .............................................................................................................................. 139

10.6 Binding Table ..................................................................................................................................... 140

10.7 Monitoring the Managed System ........................................................................................................ 141

10.8 List of Traps ....................................................................................................................................... 142

Appendix A: S pecifications ............................................................................................................................. 145

Supported Services ............................................................................................................................................ 145

RF Parameters per Service ................................................................................................................................ 145

Environmental, Standards and Optical ............................................................................................................... 146

Unit Specifications ............................................................................................................................................. 147

RF Coverage Component Specifications ............................................................................................ 147

Digital Coverage Component Specifications ...................................................................................... 150

Ordering Information .......................................................................................................................................... 153

HEU Chassis and Modules ................................................................................................................ 153

OIU Chassis and Modules .................................................................................................................. 153

Remote Units ..................................................................................................................................... 154

Digital Path Units ............................................................................................................................... 154

Accessories........................................................................................................................................ 154

Page 13

Introduction

P/N 709C011801

Page 13

1 Introduction

1.1 About ONE™

The Optical Network Evolution Platform (ONE™) by Corning provides a flexible in-building RF and network digital coverage

solution based on a fiber optic transport backbone.

The fiber-optics infrastructure is easily deployable via a wide range of pre-terminated composite cables and advanced

end-to-end equipment. Easy to design, Plug and Play™ connectors, significantly reduce installation cost and deployment time.

The ONE™ solution is an ideal fit for large, high-rise or campus-style deployments. It generates significant CAPEX savings and

OPEX savings through the use of user configurable sectorization and an infrastructure that is simple to deploy and efficient in

usage.

Dynamic sectorization management allows precise service distribution control to meet changing density needs, and provides

further savings by enabling sharing of equipment at various levels for service providers.

Radio source agnostic, remote units can be used as network extenders. Ethernet capability with dedicated fiber link for Wi-Fi

offload brings a higher level of granularity and support for devices and applications with very high speed requirements.

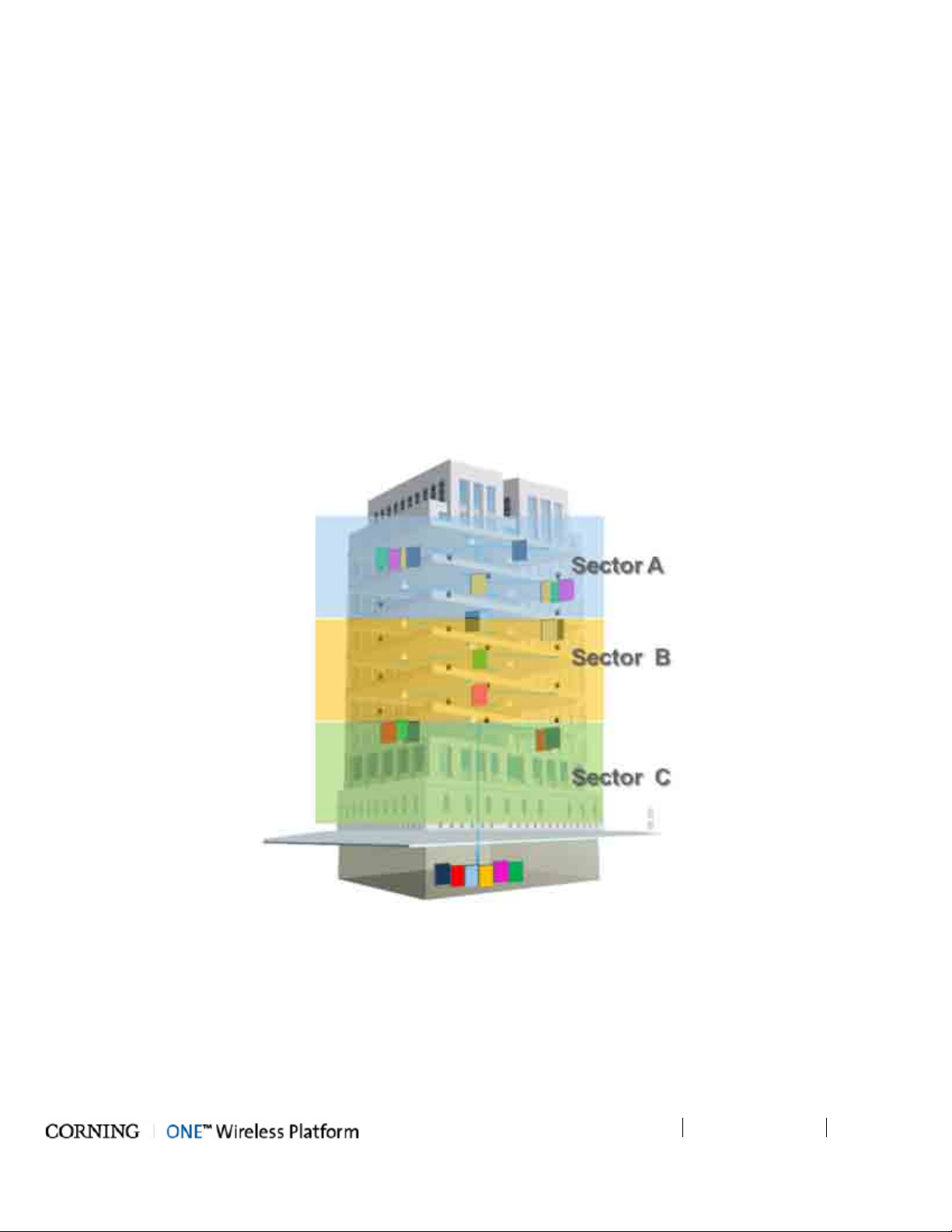

Figure 1-1. Illustration of Precise Service Distribution over Selected Remote Areas

Page 14

Introduction

P/N 709C011801

Page 14

1.2 Key Features and Capabilities

• Comprehensive Service Support - SISO/MIMO services. Currently – CELL, PCS, LTE700 and AWS

• Flexible, user controlled sectorization - Advanced capacity and coverage management for better macro offload and

enhanced user experience.

• Broadband enabled:

• A range of ready-made fiber-optic (and power) composite cables simplify installation at all levels.

• Fiber backbone unleashes unlimited RF Spectrum

• Easy scales to higher speeds requirements

• Ethernet Support - Dedicated fiber link for Ethernet backhaul, enables optimal use and offload of Wi-Fi resources.

• Scalable and customizable - Infrastructure can be quickly expanded to support more services or increase coverage

without downtime

• Carrier Grade Network Management:-

• Single-source, remote end-to-end field upgradable platform.

• Ready for SON, HetNet and future network requirements.

1.3 General System Specifications and Requirements

1.3.1 Supported Browsers

ONE™ system Web GUI Management has been optimized to operate on the following browsers:

• Microsoft Internet Explorer v7.0 and higher

• Mozilla Firefox v3.2 and higher

• Sun Solaris Mozilla

• Google Chrome 8.0 and higher

1.3.2 Environmental and Regulatory Specifications

1.3.2.1 Temperature and Humidity

The environmental specifications listed below are relevant to all ONE™ solution devices.

Operating Storage

Temperature 0°C to +50°C (32°F to 122°F) -20 C to 85 C (-4°C to 185°C)

Humidity 95% (non-condensing) 95% (non-condensing)

Table 1-1. Temperature and Humidity Specifications

Page 15

Introduction

P/N 709C011801

Page 15

1.3.2.2 Safety and Regulatory Approvals

The safety and regulatory specifications listed below are relevant to all ONE™ devices.

Regulation/Standard

Approval

Category

Laser Safety

EMC

FDA/CE 21 CFR 1040.10 and 1040.11 except for deviations pursuant to laser notice no.

50 (July 26, 2001) and IEC 60825-1, Amendment 2 (January 2001)

CE EN 301 489, EN55022, EN 61000

FCC 47 CFR Part 15, 22, 24, 27

UL 60950

Safety

CAN/CSA-C22.2 No.60950-1-03

Fire Safety UL 2043 (Applicable for Antenna Unit Only)

Table 1-2. Safety and Regulatory Approvals

1.3.3 Power Consumption of Units

This section summarizes to power requirements of all ONE™ RF and digital coverage devices.

1.3.3.1 General Power Safety Instructions

• Use only UL approved power supplies.

• Use only the power cables (AC and DC) and any other relevant accessories provided with the unit to connect the power

supply to the ONE™ units.

• All devices connect to 110 to 240VAC power source.

RF Head End Units

HEU

Power Consumption for Full

Chassis

Chassis with 12 RIMs and 2 RIX:

200W

OIU

Chassis with 12 OIMs and 2 OIX:

300W

Table 1-3. RF Headend Units Power Consumption

RF Remote End Units Max. Power Consumption

RAU (alone) 31W

RxU 21.5W

Table 1-4. RF Remote End Units Power Consumption

Digital Remote End Units Power Consumption

GEM installed in RAU 4.5W

GEM installed in Docking station 4.5W

Table 1-5. Digital Path Remote End Power Specifications

Page 16

Introduction

P/N 709C011801

Page 16

1.3.4 Dimensions and Weight of Units

1.28 x 3.79 x 5.95 in [32.7 x 96.3 x 151.3 mm]

The tables below describe the physical specifications of the ONE™ units.

Table 1-6. RF Path Headend Units

Unit

Dimensions (H x W x D) US

Weight: lbs [kg]

[International]

HEU

7 x 17.3 x 18.95 in [177.8 x 440 x 481.7 mm]

Chassis: 37 lbs [16.8 kg]

Per RIM: 1.9 lbs [0.9 kg]

Per RIX: 1.54 lbs [0.7 kg]

HCM: 2.2 lbs [1.0 kg]

PSM: 1.98 lbs [0.9 kg]

OIU

7 x 17.3 x 18.95 in [177.8 x 440 x 481.7 mm]

Chassis: : 37 lbs [16.8 kg]

Per OIM: 0.7Kg [1.5lbs]

Per OIX: 1.54 lbs [0.7 kg]

ACM: 2.2 lbs [1.0 kg]

PSM: 1.98 lbs [0.9 kg]

Table 1-7. RF Path Remote Units

Unit

Dimensions (H x W x D) US

Weight: lbs [kg]

[International]

ICU 17 x 15 x 19.2 in [430.5 x 379.8 x 488 mm] 5.5 lbs [2.5 kg] – without PSM

RAU (including

mounting bracket)

13.1 x 13.1 x 4 in [332.7 x 332.7 x 101.6 mm]

RAU only = 7.05 lbs [3.2Kg];

RAU+RxU+GEM = 14 lbs [5.5 Kg]

Table 1-8. Digital Path Units

Unit

Dimensions (H x W x D) US

Weight: lbs [kg]

[International]

GEM

GEU-S

5.01 x 10.51 x 3.26 in (including mounting

1.1 lbs [0.5 kg]

2.64 lbs [1.2 kg]

bracket) [127.5 x 267 x 83 mm]

1.3.5 Optical Specifications

Parameter Specification

Optical Output Power <9 dBm

Max. Optical Budget 5 dB

Optical Connector

Fiber Type Corning SMF-28 or Compatible

Wavelength

Maximum Distance (headend to remote end) 2Km (SMF)

Table 1-9. Optical Specifications

OIM: MTP connector

RAU: LC/APC SM

1310±10nm (Standard)

Page 17

Introduction

P/N 709C011801

Page 17

1.3.6 Default Network and User Settings

1.3.6.1 Default Network Parameters

The following table identifies the default settings for each of the Network Ethernet ports located on the front panel of the HCM.

Port Name Configuration

DHCP: off

LOCAL

LAN

Internal

Table 1-10. Default Network Port Parameters

1.3.6.2 System Administrator or "Super User"

One System Administrator or "Super User" is available. This user has the highest access level, does not belong to any group and

is the only user that can create groups.

IP: 193.168.1.1

Subnet Mask: 255.255.0.0

DHCP: Client, or Static IP (default)

IP: 192.168.1.1

Subnet Mask: 255.255.0.0

DHCP: server on (this local port is set by default set to act as a DHCP Server and provide an

IP address to the connected computer so no configuration of the computer is required)

IP: 11.0.0.1

Subnet Mask: 255.0.0.0

NOTE: Upon initial login, the System Administrator should create user groups. Each new group created along with a default

Group Administrator.

User Name admin (cannot be modified)

Password default provided by Corning (and should be changed immediately)

Group none (leave blank)

Table 1-11. User Default Info

1.3.6.3 Default Group Admin

Groups can only be created by the Admin user. As a group is created, a default Group Administrator is automatically generated

for that group. The Group Administrator User Name and Password are based on the group name. For example, if the group is

named 'accounting', the default Group Administrator name will be accounting_Admin (note capital ‘A’ in Admin).

The Group Administrator is authorized to create and manage the users for his/her group. See section group passwords for

detailed description of default group_ Admin user.

Page 18

Introduction

P/N 709C011801

Page 18

1.4 Installation Guidelines

The following installation assumes that site survey and installation planning (including power requirements) have been

completed. This includes planning the distribution of antennas to provide the required coverage, as well as planning the layout

of the devices and cables in the telecom closet or shaft.

1.4.1 Rack Mount Procedure

These guidelines are relevant to the system components which are installed in 19-in communication racks:

• RF Path components: HEU, OIU and ICU

• Digital Coverage components: CEU

1.4.1.1 General Instructions

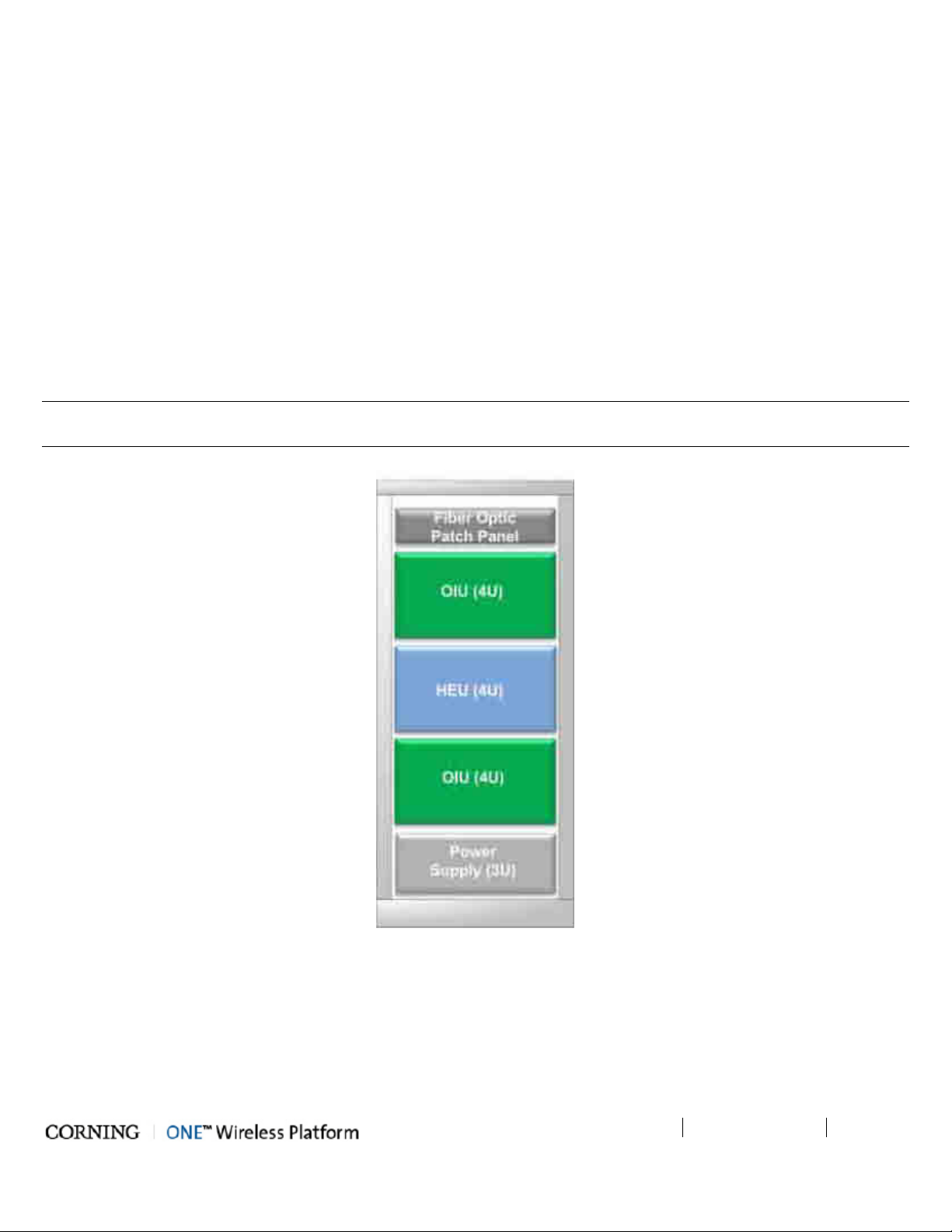

Verify that the rack height can support all the units to be installed, where you may also want to consider future installations. The

figure below illustrates the recommended physical location of the headend elements in the rack, so as to facilitate and simplify

the cabling connections.

NOTE: The configuration is for a single operator. If the site is serviced by more than one operator, each operator often installs

their equipment in a separate rack.

Figure 1-2. Example of Communication rack Installation

Page 19

Introduction

P/N 709C011801

Page 19

1.4.1.2 Rack Installation Safety Instructions

The following guidelines help ensure your safety and protect the equipment from damage during the installation.

• Only trained and qualified personnel should be allowed to install or replace this equipment.

• Verify that ambient temperature of the environment does not exceed 50°C (122°F)

• If installed in a closed or multi-unit rack, the ambient temperature of the rack environment must be taken into consideration

in terms of exceeding the maximum rated ambient temperature (indicated in the previous item).

• To maintain a low center of gravity, ensure that heavier equipment is installed near the bottom of the rack and load the rack

from the bottom to the top.

• Ensure that adequate airflow and ventilation within the rack and around the installed components so that the safety of the

equipment is not compromised. It is recommended to allow for at least about 2 cm of airspace between devices in the rack.

• Verify that the equipment is grounded as required – especially the supply connections.

1.4.2 Power Consumption, Connections and Power Supplies

1.4.2.1 Power Safety Instructions

SAFETY WARNINGS!!!! When installing or selecting the power supplies:

• Be sure to disconnect all power sources before servicing.

• Calculate the required power according to the requirements of the specific installation and then determine the configuration

of the power supplies. The required DC cables will then be determined by the selected PS configuration.

• Use only UL approved power supplies

• Install external over-current protective devices for the system according to the requirements described in Power

Consumption of Units section (on page 15).

1.4.2.2 Types of Power Supplies

CMA supplies various power supplies that can be installed in a rack or mounted on a wall, depending on your configuration.

1.4.2.3 Circuit Breakers

Calculate the required fuse protection while referring to Power Consumption of Units section (on page 15). Also, when

Install fuse protections for the system taking into account that there may be other CMA system elements that require external

fuse protection.

Page 20

Introduction

P/N 709C011801

Page 20

1.5 System Architecture and Topologies

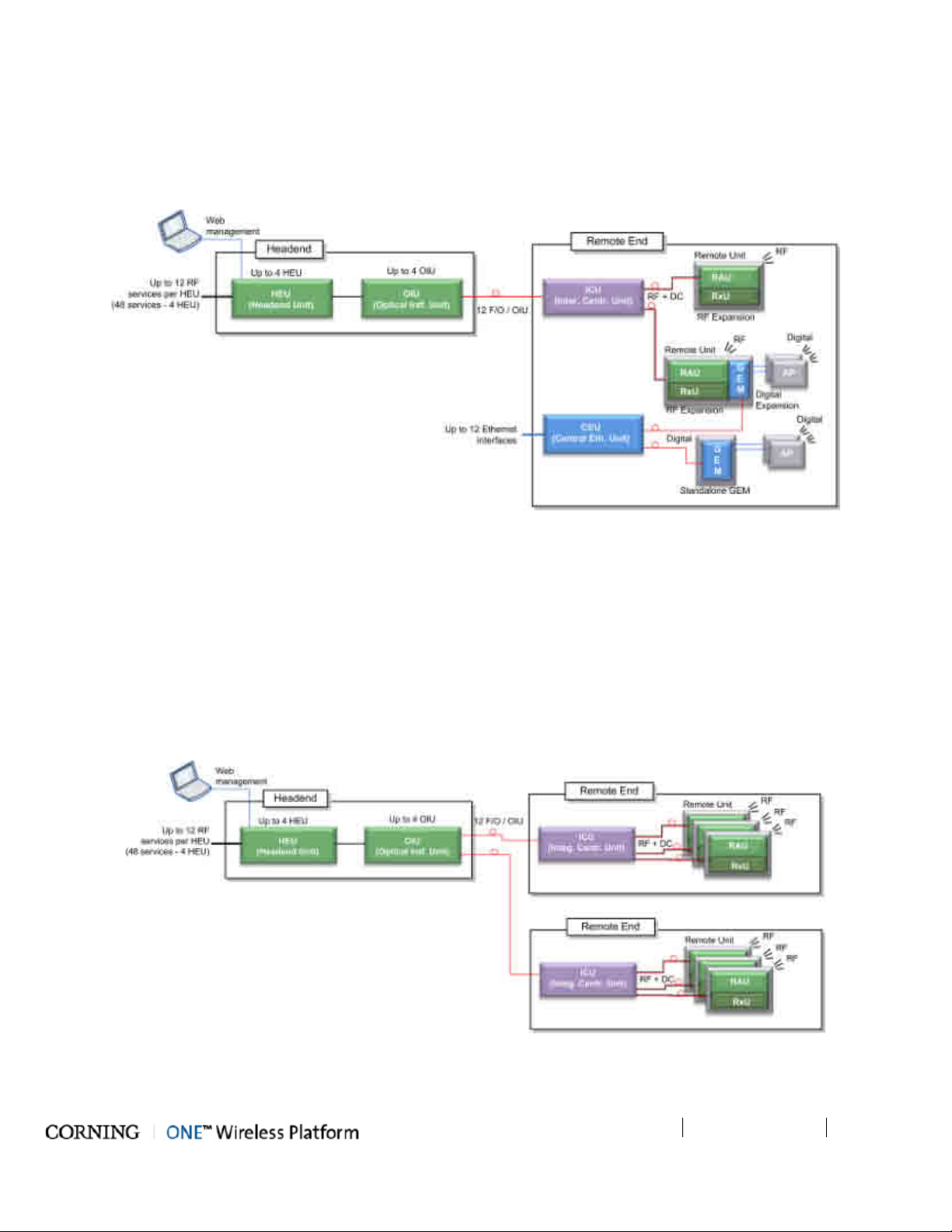

The ONE™ solution fiber-optic infrastructure is used to transmit both RF and digital services:

• RF services – fiber-optics infrastructure transfers converged wireless services from the headend towards Remote Antenna

Units (RAU) deployed at the remote end locations according to user defined configuration.

• Digital services – fiber-optics infrastructure transfers Digital services from the corporate LAN to Gigabyte Ethernet Modules

(GEM) and then 3

Figure 1-3. ONE™ Solution Basic Architecture

rd

party equipment deployed on each floor.

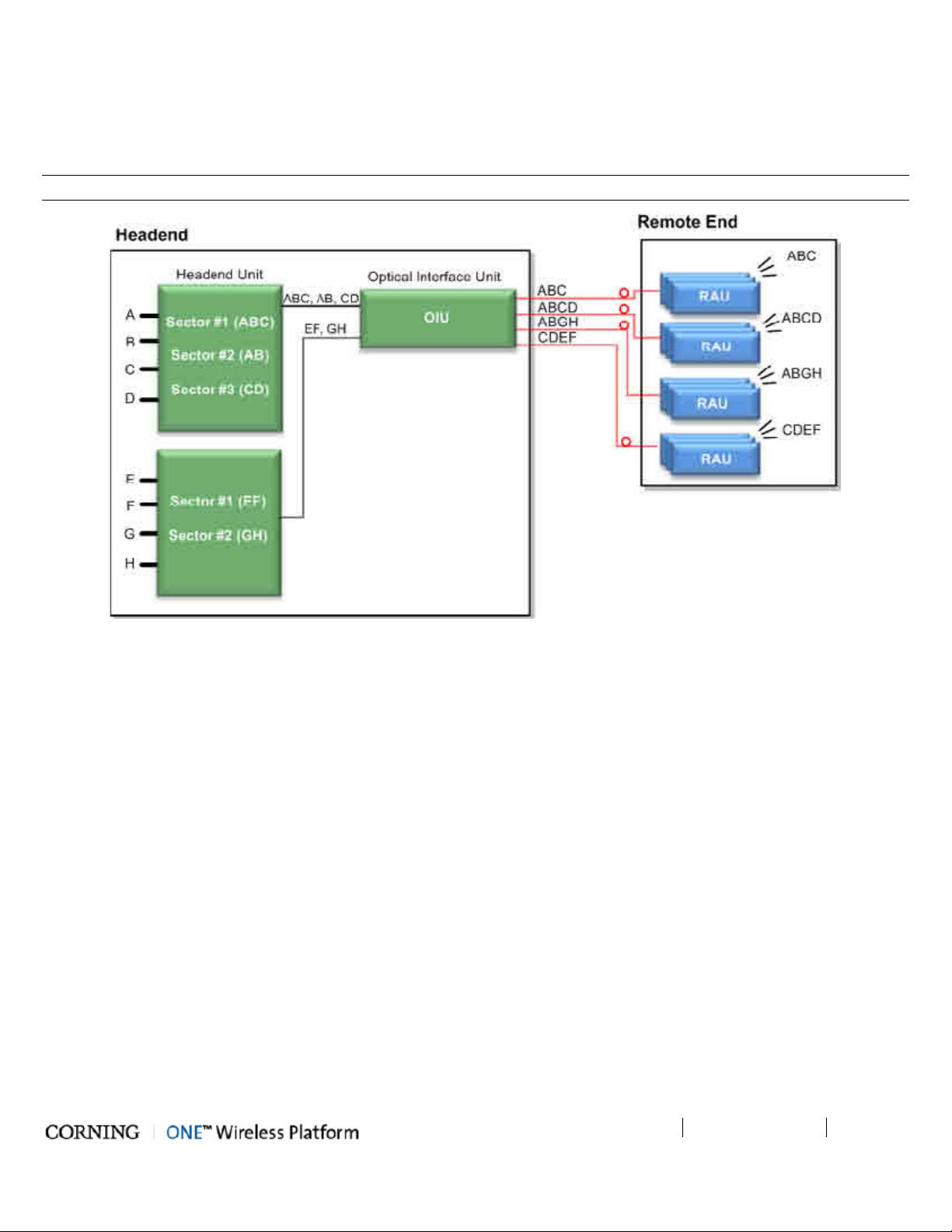

1.5.1 RF Path

At the headend, RF signals from the RF signal sources (e.g. BTS/BDA) are conditioned by service specific (conditioner) modules

in the HEU (Headend Unit) and organized into (up to three) user configurable sectors. The conditioned RF signals are converted

to optic signals by the (wideband) OIU (Optic Interface Unit) and specific sectors are routed towards selected remote locations

according to user defined configurations.

The optic fibers at the OIU are routed to the ICU (Integrated Centralized Unit) at the remote end. From the ICU the optic fibers

are distributed along with DC to the Remote Antenna Units (RAU).

Figure 1-4. RF coverage Architecture

Page 21

Introduction

P/N 709C011801

Page 21

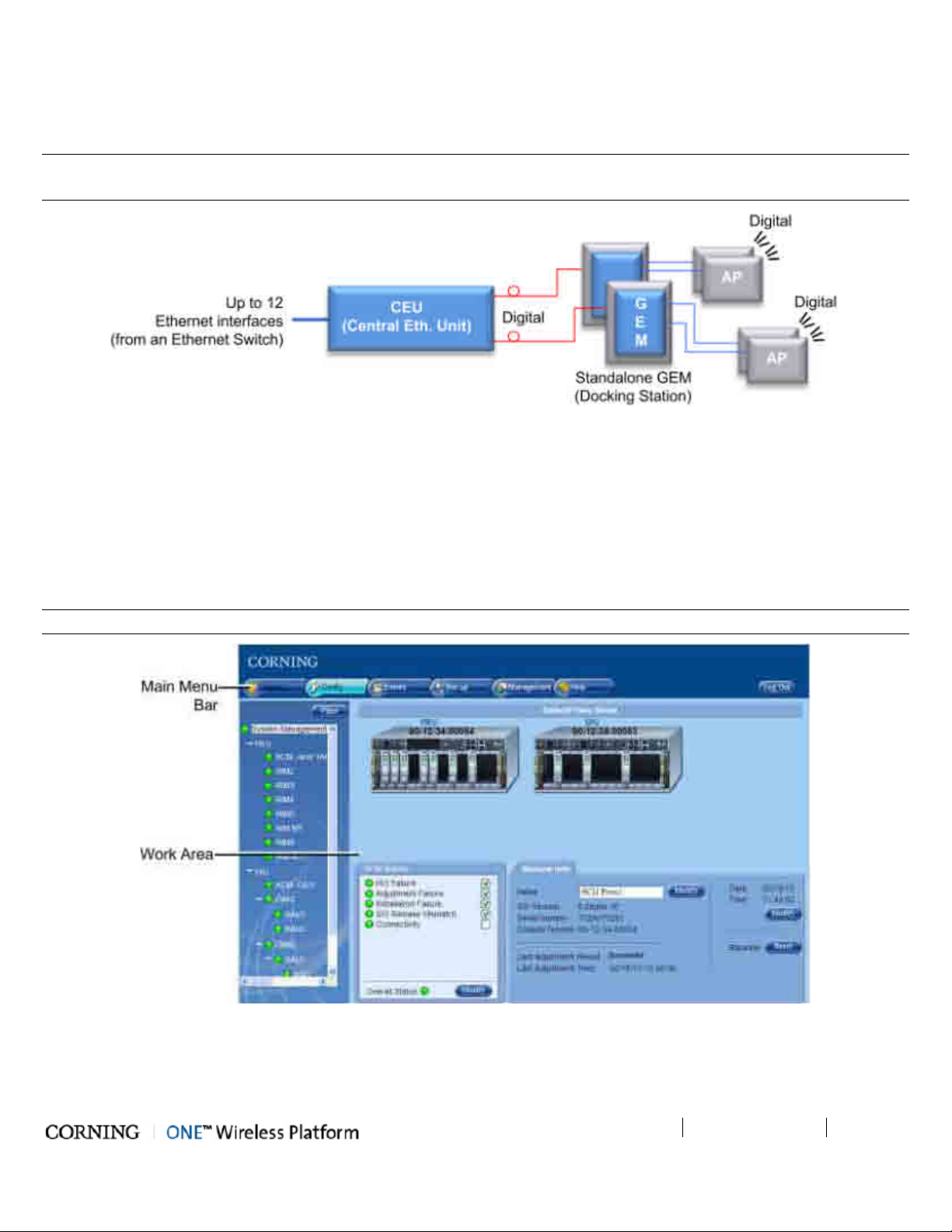

1.5.2 Digital Path

The Digital services from the corporate LAN (received via Ethernet Switch) are converted to optic signals by the CEU (Centralized

Ethernet Unit) and routed over optic fibers towards the GEM units. The optical traffic is then converted to 1GbE by the GEM

(Gigabit Ethernet Modules) modules and distributed to two third party equipment such as Access Points, Ethernet switch, etc.

NOTE: GEMs can be connected to the CEU either directly, or via an ICU (described under RF Path (on page 20)). In that case,

the ICU can also provide DC to the GEMs.

Figure 1-5. ONE™ Solution Digital Path Architecture

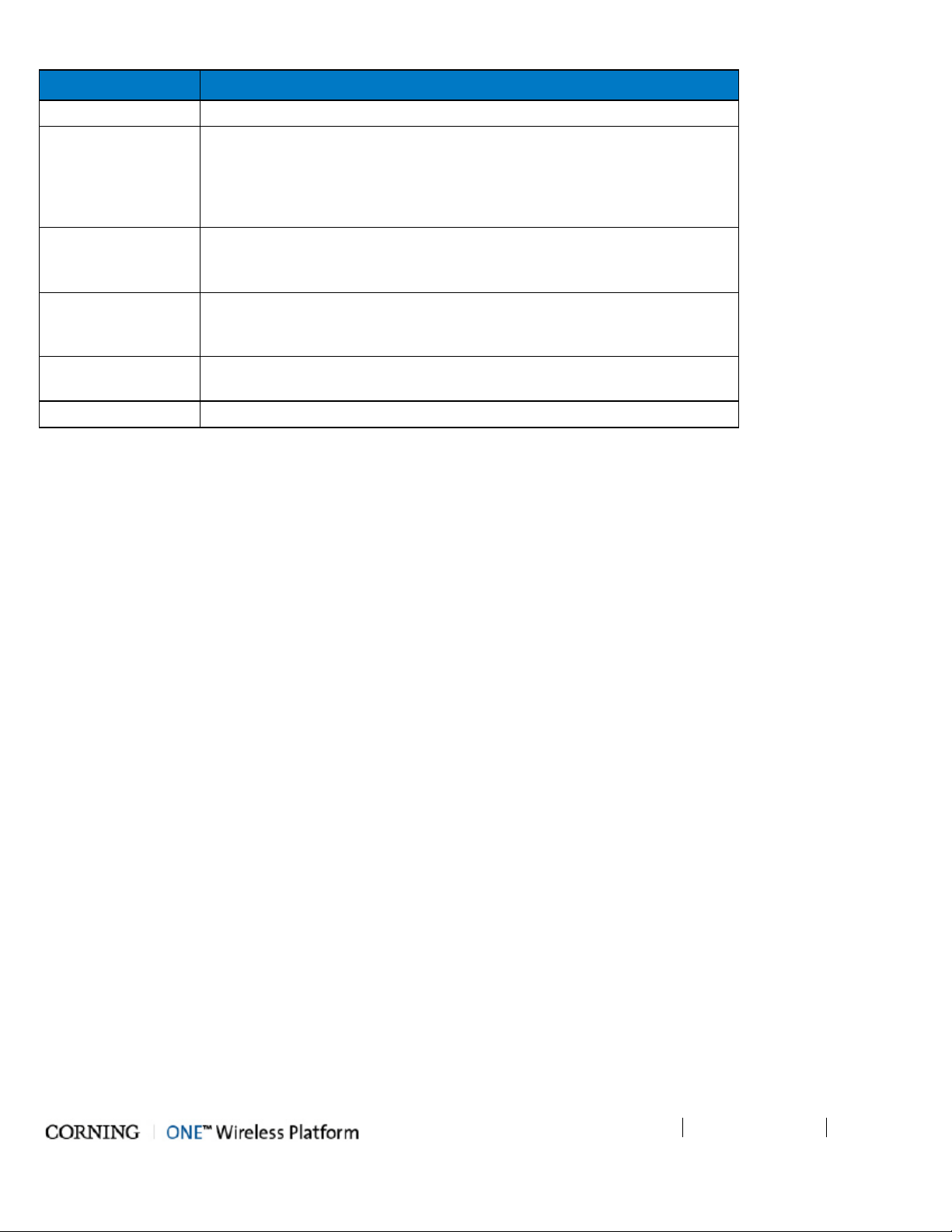

1.6 ONE™ WEB Management Application

The ONE™ solution consisting of the HEU and its hosted elements is managed via a WEB session to the HEU. The GUI based WEB

management application provides all the required configuration, management and monitoring options for the ONE™ system.

The ONE™ Web management application consists of the Main Menu bar, where the displayed side-bar and work area options

vary according to the selected menu option.

NOTE: The available tabs and capabilities vary depending on the access level used to open your session.

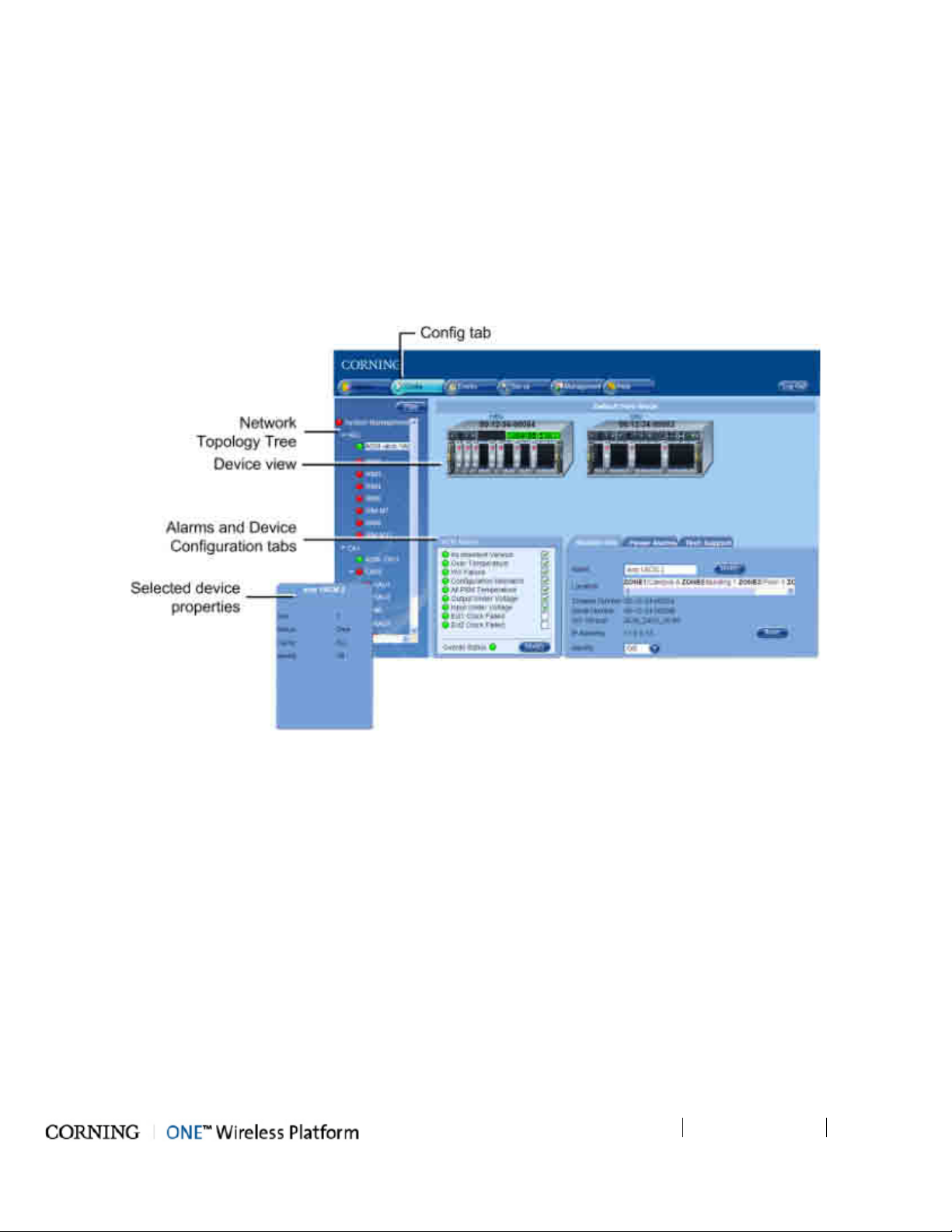

Figure 1-6. Main Window (Config Tab - Default Display)

Page 22

Introduction

P/N 709C011801

Page 22

The Main Menu Bar includes the following tabs:

on

Tab Description

Monitor N/A

Config

Displayed upon login by default. Displays general module information and

device alarms and provides the configuration options for the available

selected site devices. A brief description is given in Overall Device

Display - Config Tab (on page 22). A detailed description is given in

Device Configuration section (on page 91).

Events

Displays the events that occurred on the monitored devices and enables

generating reports. Configuration changes that are initiated by the network

manager are not considered events display. See Events Display section.

Set-up

Set-up tool used for initial system set-up, commissioning of system devices

and adjustment procedure. See About the System Setup Tool section (

page 74) for details.

Management

Provides administration options such as firmware upgrade, user management

options and IP settings required for receiving traps.

Help Provides access to Online Help

Table 1-12. Main Menu tabs

Page 23

Introduction

P/N 709C011801

Page 23

1.6.1 Overall Device Display - Configuration Tab

The Config window is displayed by default upon login and includes the following for each selected element:

• Network Topology Tree - hierarchically displays the connected and available site devices and their status.

• Device Configuration Tabs - device specific which include the configurable parameters (e.g. service control, RF parameters)

and general information (e.g. device name, Firmware version)

• Device View - visualization of device, with LEDs corresponding to the device status. Device view can be used for fault

sourcing at a glance.

• Alarms - displays the device alarms for fault sourcing and provides alarm masking options

Note the following:

• The device selected in the Network Topology Tree appears green in the Device View Mode area

• Point to module in Device View to display property info

Figure 1-7. Config Tab

1.6.2 Session Access

• Number of simultaneous sessions - the HCM supports up to three simultaneous sessions for multiple users (local/remote

access).

• Login Priorities - the login of users is enabled according to priority – when the maximum amount of multiple users are logged

in, the HEU terminates the session running for the lowest level user logged in the longest (user receives alert message and

force logout is performed) in order to enable a higher access level user to login to the system. A message indicating logon

denial appears when the maximum number of users is logged in and a lower level user attempts to log in to the system.

Page 24

Introduction

P/N 709C011801

Page 24

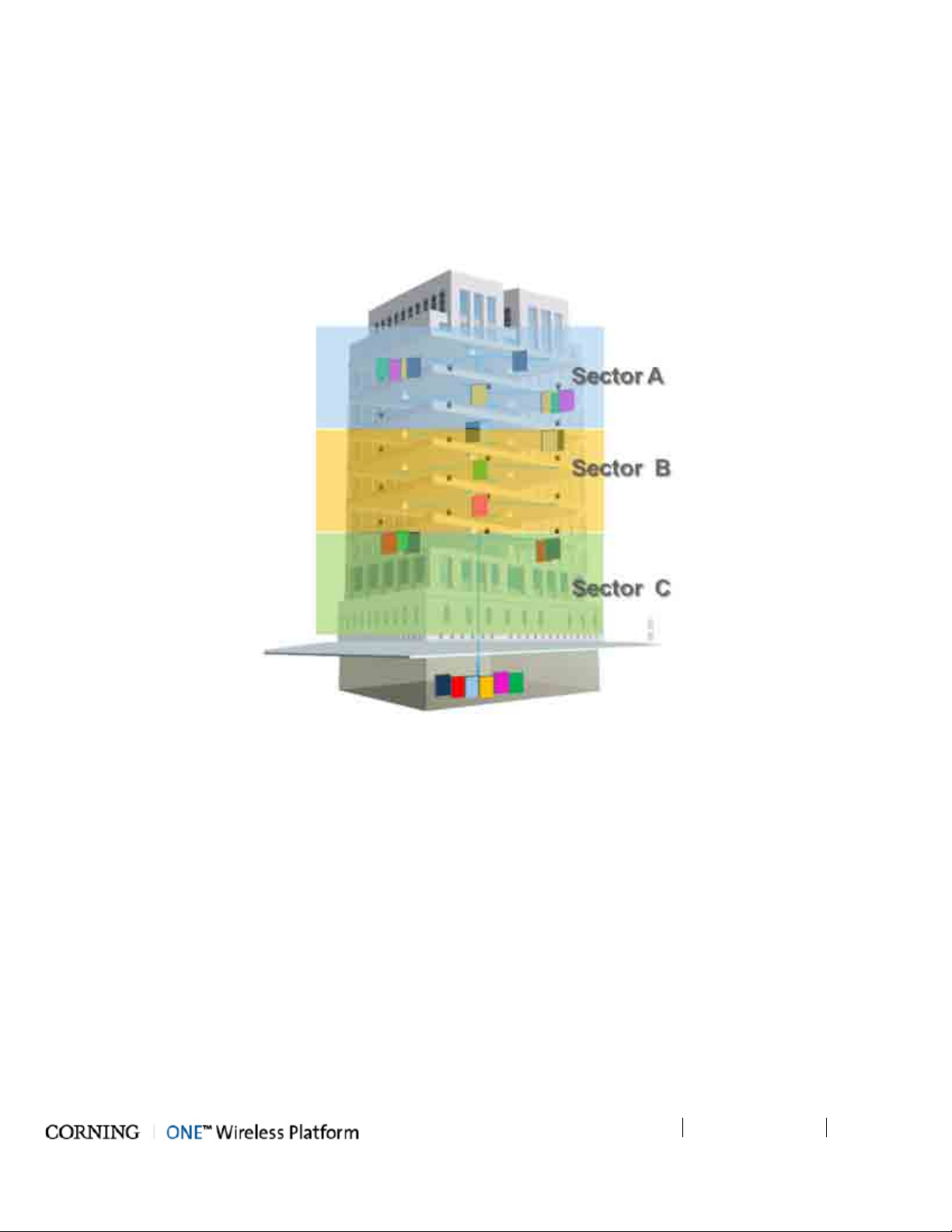

1.7 User Controlled Sectorization

ONE™ fiber-optics infrastructure allows various combinations of SISO and MIMO services to be routed from the headend to

specified remote locations on each floor, according to user defined configurations. This allows optimizing service coverage and

provides equipment savings. While the fiber-optics infrastructure is common, the services can be routed via service provider

shared or dedicated equipment. By default, the system is configured to support a single sector: all services are transferred to all

remote locations. This default configuration can be easily modified according to site requirements.

The following figure illustrates service distribution from the head-end to various locations on ach remote floor. Each color

represents a specific service, where different combinations of services are distributed at various locations on the same floor

according to coverage requirements.

Figure 1-8. Illustration of Sectorization

Page 25

Introduction

P/N 709C011801

Page 25

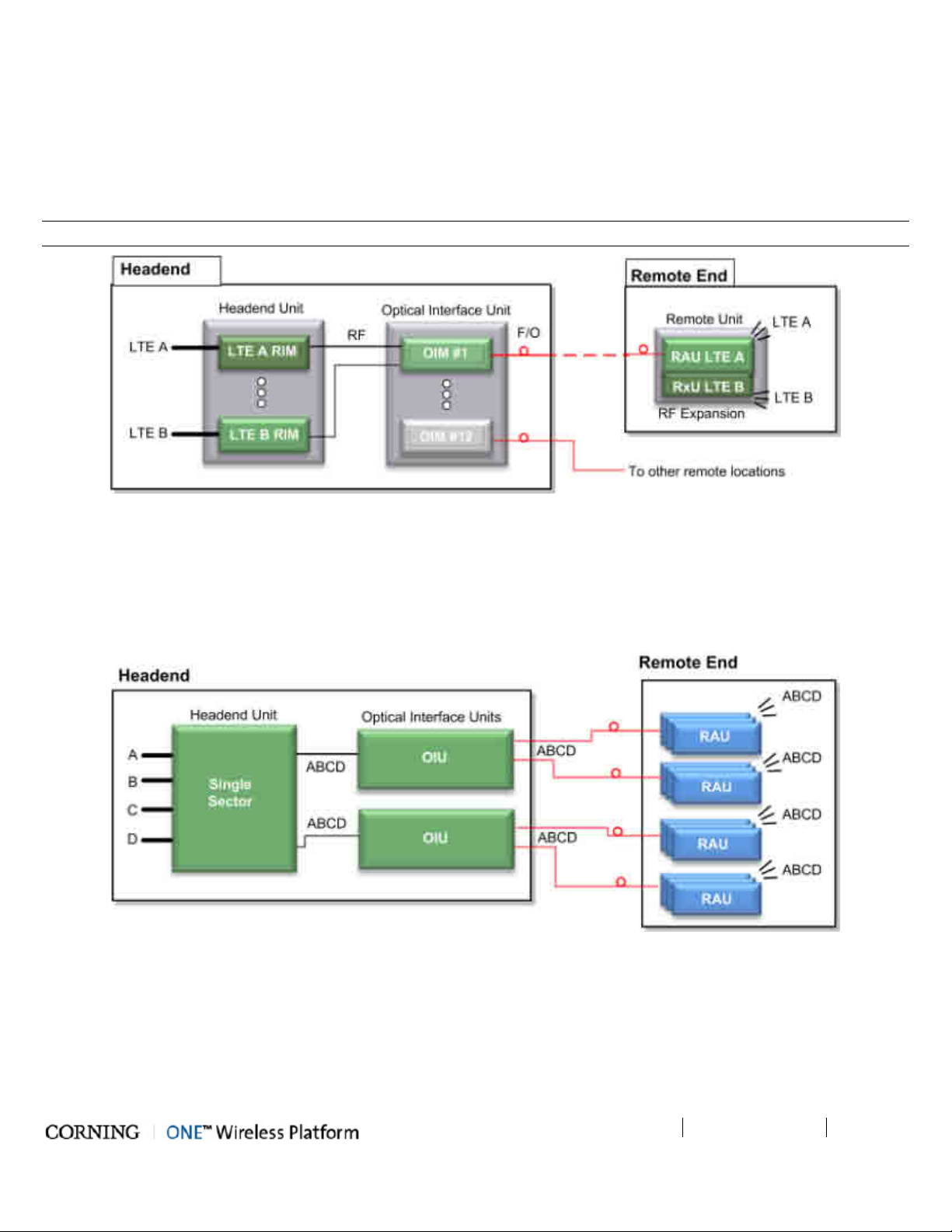

1.7.1 MIMO Configurations

MIMO topologies provide more density by using two independent RF paths for the same service, where the independent paths

are implemented by dedicated modules along the path.

MIMO configuration is implemented by routing the two RF bands over dedicated RF paths at both the entry point (in the Headend

Unit) and at the exit point (at the Remote Unit). Note that the Optical Interface Unit is wideband and the services are combined

in a single OIM for routing to the same Remote End Unit. At the Remote End Unit, the services are distributed by two dedicated

modules.

NOTE: MIMO configuration can also be implemented by two separate Remote End Units.

Figure 1-9. Example of MIMO Configuration

1.7.2 Single Sector Example

In this example, all four services (A,B,C,D) are routed to all (up to 72) remote locations. In the illustrated topology, a single HEU

conditions the services and feeds them to two OIU systems for conversion to optic signals. Each OIU supports up to 36 RAU

(Remote Antenna Units).

Figure 1-10. Single Sector Configuration

Page 26

Introduction

P/N 709C011801

Page 26

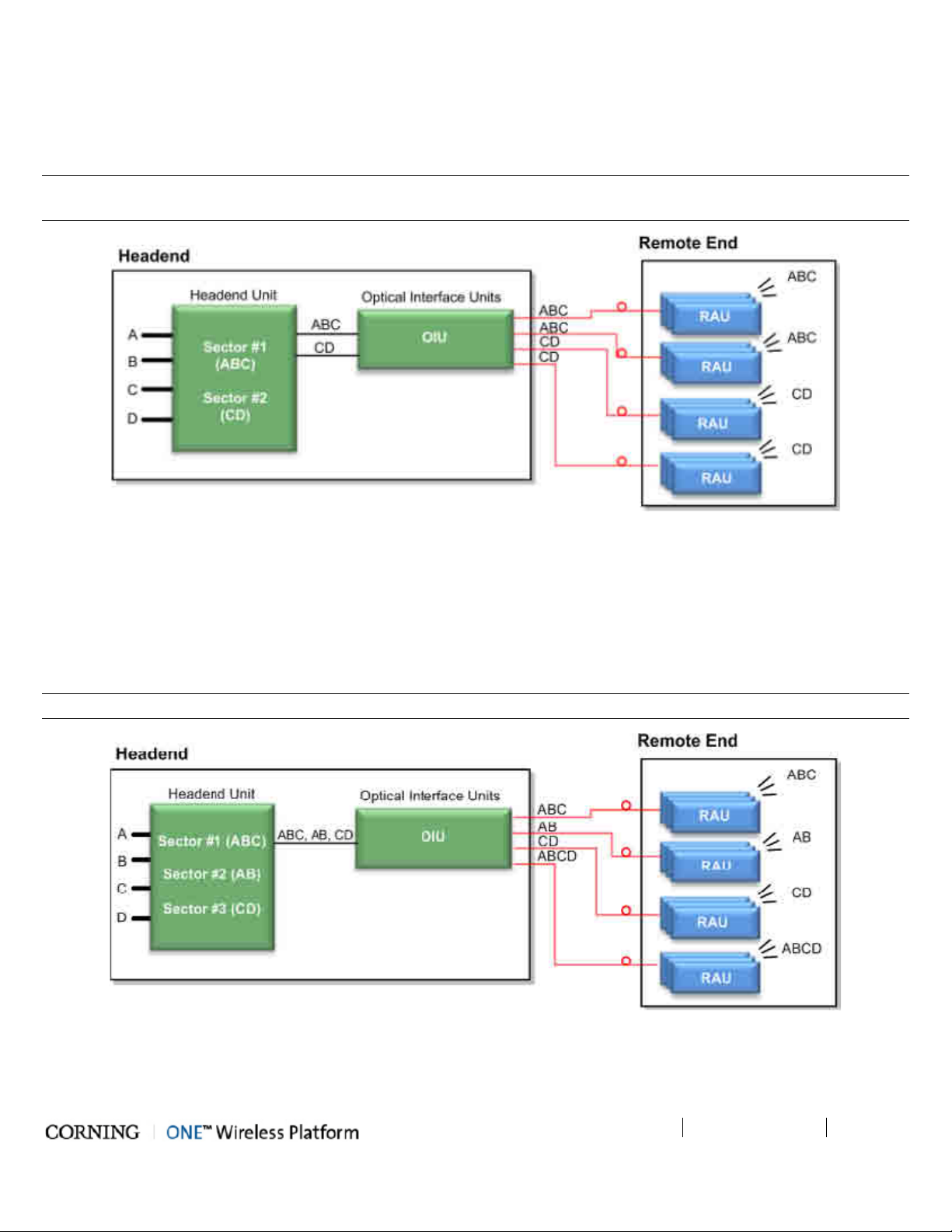

1.7.3 Dual Sector Example

In this example, two sectors (groups/layers) of services are defined: A,B,C and C,D. Note that a service can be allocated to any

of the sectors at the same time. For example, service C is allocated to both Sectors. Both sectors are routed to the OIU for optic

conversion. Each OIU module (OIM) can be configured to support either one or (if they do not have a common band) to both

sectors and the corresponding services are routed from the OIM to its hosted RAU units.

NOTE: In the example below, band C is common to both Sector #1 and #2; therefore, an OIM cannot be assigned both sectors

(i.e. ABC + CD).

Figure 1-11. Example of Dual Sector Configuration

1.7.4 Tri-sector Example

In this example, three sectors (groups/layers) of services are defined: ABC, AB,CD. Note that a service can be allocated to any

of the sectors at the same time. For example, services C and B are allocated to two of the sectors. The sectors are routed to

the OIU for optic conversion. Each OIU module (OIM) can be configured to support either one, two or three sectors in any

combination and the corresponding services are routed from the OIM to its hosted RAU units.

NOTE: An OIM cannot support two sectors that have a common band (e.g. ABC and BC, or ABC and CD).

Figure 1-12. Example of Tri-sector Configuration

Page 27

Introduction

P/N 709C011801

Page 27

1.7.5 Tri-sector Example with Two HEUs

This tri-sector example supports two HEUs. In this topology, one HEU supports three sectors (groups/layers) and the other two

sectors for a total of five sectors. These groups of services are all routed towards a common OIU. Each OIU module (OIM) can

be configured to support any (legal) combination of sectors and the corresponding services are routed from the OIM to its hosted

RAU units.

NOTE: Multiple sectors allocated to the same OIM cannot share any identical frequency bands.

Figure 1-13. Example of Tri-sector Configuration with Two HEUs

Page 28

Page 29

Unit Descriptions - RF Path

P/N 709C011801

Page 29

2 Unit Des criptions - R F P ath

This chapter provides detailed descriptions of the ONE™ solution components. The descriptions are organized according to RF

and Digital path headend and remote end components. This includes port and LED interface descriptions.

2.1 RF Path - Headend Components

ONE™ RF Path coverage solution includes the following headend elements:

• HEU – Headend Unit

• OIU – Optical Interface Unit

Figure 2-1. RF Path Headend Components

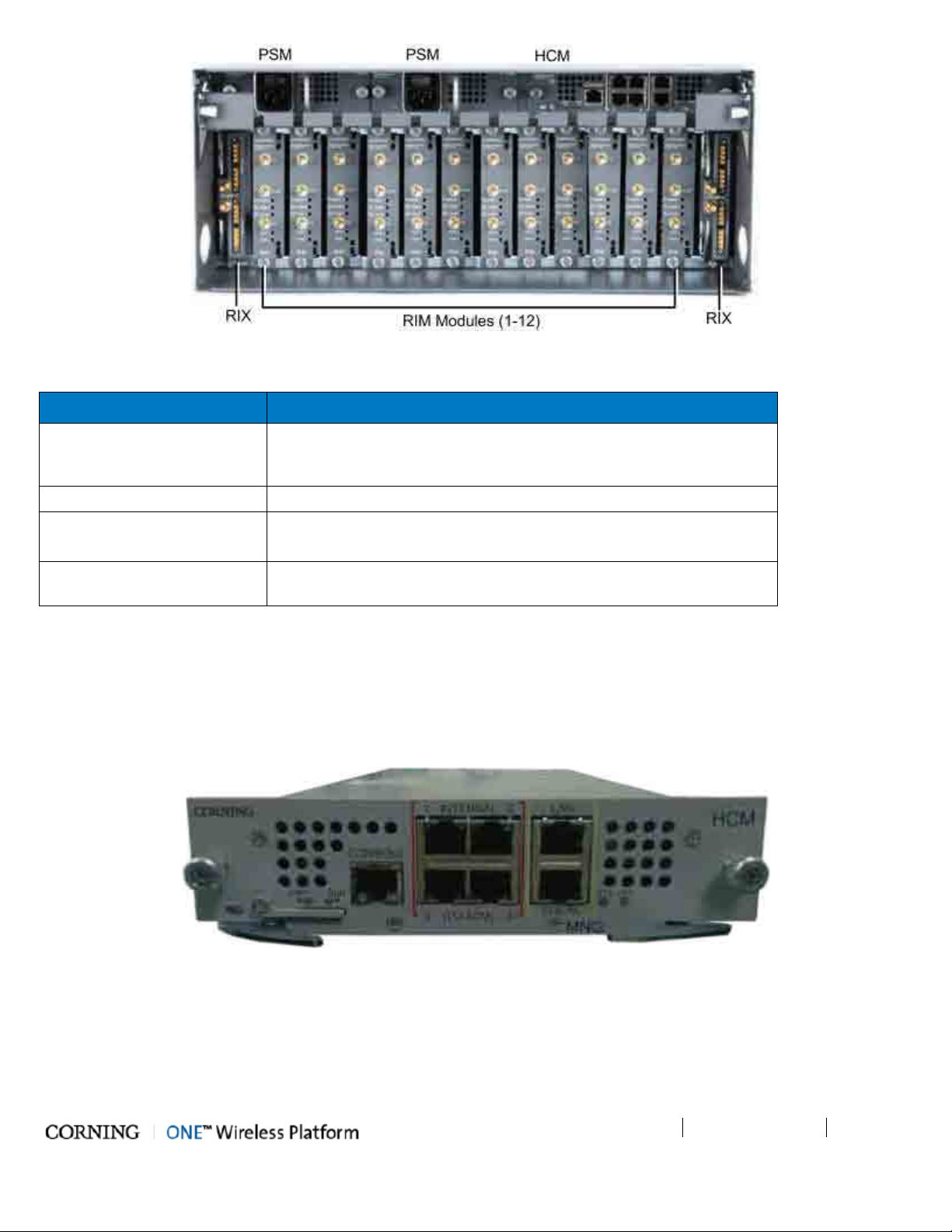

2.1.1 HEU (Headend Unit)

The HEU performs the following main functions:

• Conditions (up to 12) RF sources to a level required for feeding to the Optical Interface Unit (OIM).

• Enables the configuration of up to three sectors consisting of groups of RF services.

• Provides single source control and management of the ONE™ solution RF path.

Each HEU supports up to 12 services. For additional services or density, two or more HEU units can be cascaded in a

Master/Slave configuration that is managed from the Master HEU. For HEU installation procedure, see section Installation –

RF Path Elements (on page 45).

Page 30

Unit Descriptions - RF Path

P/N 709C011801

Page 30

Figure 2-2. HEU Front Panel with Installed Modules

Module Description

HCM (Headend Control

Module) (on page 30)

Provides system management and control functions. In Master/Slave

configurations, HCM is installed in the Master and ACM (on page 34) in

the Slave.

PSM (Power Supply Modules) 110-230VAC. If two are installed, both must be powered on.

RIX (RF Expander Module) – Service specific conditioner units.

OIX (Expander Module (on

page 32))

Used to interface with the parallel Expander Unit on the HEU.

Table 2-1. OIU Front Panel Interface Definitions

2.1.1.1 HCM (Headend Control Module)

The HCM provides management and control capabilities for the ONE™ system. Each INTERNAL port is dedicated to a single OIU

(see OIU (on page 33)) management connection. The HCM module includes Local and LAN management ports and LED status

indicators.

Figure 2-3. HCM Module

Page 31

Unit Descriptions - RF Path

P/N 709C011801

Page 31

used for management of connected OIU systems

Port Description

INTERNAL (TO ACM)

[4] RJ45, 100Mb Ethernet ports (and/or HEU Slaves).

LAN RJ45, 1Gb Ethernet port - connects to the corporate LAN for remote management

LOCAL RJ45, 1Gb Ethernet port - local configuration and management

CONSOLE RJ45, serial port - local configuration for service personnel

SD Card Slot Supports uSD cards up to 32GB (used for example for saving configuration files)

Table 2-2. HCM Ports

LED Description

PWR

Steady Green - Power supplied to unit

Off – No power is supplied to the unit

Steady Green – HCM Boot up sequence complete and functioning

RUN

Blinking Green – HCM Boot up sequence in process

Off – No power supplied to the unit

SYS Indicates overall status of the managed system

FAN

Green – Normal operation status

Red – Faulty fan (s)

Table 2-3. LED Description

2.1.1.2 RIM/RIM-M (RF Interface Module)

Up to 12 service specific conditioning modules are installed in the HEU chassis. Each RIM supports both Simplex and Duplex RF

connectors. RIM-M modules support MIMO services (e.g.700 MHz LTE, AWS). LEDs provide status indications on signal level and

module operation.

Figure 2-4. RIM Module

Page 32

Unit Descriptions - RF Path

P/N 709C011801

Page 32

The following tables provide a description of the RIM ports and LED status indicators.

Port Description

DL/UL UL and DL simplex connections to the RF signal source

DUP Duplexed UL and DL connection to the RF signal source

Table 2-4. RIM Ports Description

LED Description

Green – RF signal is at normal level

Protect

Red (Blinking) - Indicates the RF signal is too high and that the protection

mechanism is enabled

DL High

DL Low

Provides indication on DL RF level in conditioner module:

Red – Signal is 2 dB above max. expected power

Provides indication on DL RF level in conditioner module::

Red – No signal or 15 dB below max. expected power

Steady Green - Power on and module SW has initialized and is up and

running

RUN

Blinking Green- Fault detected (e.g. RIM module SW halted) orSW

upgrade in process

Off - No power

PWR On - Input power is within required range

Table 2-5. RIM LED Descriptions

Page 33

Unit Descriptions - RF Path

P/N 709C011801

Page 33

2.1.1.3 RIX (RF Expander Module)

The RIX Expander module provides the RF interface to the OIU unit. Two RIX Expander modules can be installed in each HEU

chassis, to support up to four OIU (per HEU). If only one Expander module is installed, it is required to terminate the empty slot

with the supplied termination.

NOTE: The OIU Expander Modules are similar in appearance to the HEU Expander modules but are NOT INTERCHANGEABLE.

Each Expander module is indicated as RIX or OIX on the bottom of the module.

Figure 2-5. RIX Expander Module Interfaces

2.1.1.4 PSM (Power Supply Module)

NOTE: The Power Supply modules and installation are the same for the HEU and OIU chassis. If two power supplies are

installed, both must be switched ON to begin system operation.

The HEU (and OIU) chassis can support two power supply modules (110-240VAC), where the second power supply provides

redundancy in case one of the supplies fails. If two modules are installed, both must be connected to the AC outlet and turned

on at all times.

Figure 2-6. Power Supply Module

Page 34

Unit Descriptions - RF Path

P/N 709C011801

Page 34

2.1.2 OIU (Optical Interface Unit)

The OIU interfaces to the HEU, performs the RF to optic conversion of the received signal and distributes the wireless RF services

to the RAU units over the fiber optic infrastructure to the remote site. Each OIU supports up to 12 SM optic fibers (one fiber per

OIM), which are routed to up to 36 RAU (three Remote Antenna Units per OIM).

Figure 2-7. OIU Front Panel with Installed Modules

Module Description

ACM (Auxiliary Control

Module) (on page 34).

Auxiliary Control Module – interfaces with the HEU's HCM to provide

remote management capabilities.

PSM (Power Supply Modules) 110-230VAC. If two are installed, both must be powered on.

OIM (Optical Interface

Module) (on page 35)

OIX (Expander Module (on

page 32))

Wideband, optical to RF (and vice versa) conversion units.

Used to interface with the parallel Expander Unit on the HEU.

Table 2-6. OIU Front Panel Interface Definitions

Page 35

Unit Descriptions - RF Path

P/N 709C011801

Page 35

2.1.2.1 ACM (Auxiliary Control Module)

The ACM provides basic control functions (only) for the host chassis via a local connection. The ACM module can be remotely

managed via an HCM (on page 30) connection.

Figure 2-8. ACM Module

Port Description

INTERNAL

(TO HCM)

[4] RJ45, 100Mb Ethernet ports used for OIU and/or HEU slave management connections

Console [1] RJ45, serial port used for basic IP configuration and local connection for service personnel

Table 2-7. ACM Ports Description

LED Description

PWR

Steady Green - Power supplied to unit

Off – No power is supplied to the unit

Steady Green – HCM Boot up sequence complete and functioning

RUN

Blinking Green – HCM Boot up sequence in process

Off – No power supplied to the unit

SYS Indicates overall status of the managed system

FAN

Green – Normal operation status

Red – Faulty fan (s)

Table 2-8. ACM LED Indicators Description

Page 36

Unit Descriptions - RF Path

P/N 709C011801

Page 36

2.1.2.2 OIM (Optical Interface Module)

The OIM is a wideband RF to F/O (and vice-versa) media conversion module. Up to 12 OIM units can be installed in each OIU,

where each OIM can support up to three Remote Antenna Unit (RAU) connections.

Figure 2-9. Optical Interface Module

Port

Description

Optical Link MTP Connector for optical interface connection; SMF

Expansion

[6] Kenpole connector for 1:1 direct signal transportation, 3 UL and 3 for DL

Enables (DL and UL) broad band connection to each optical link

Table 2-9. OIM Ports Description

LED Description

ON - the optical link to/from the connected remote functions within the

Link 1-3

specifications in both directions.

Blinking - optical power from remote is lower than required

RUN Steady Green – SW Boot up sequence complete and functioning

PWR Steady Green – Power input detected for corresponding module

Table 2-10. OIM LED Descriptions

Page 37

Unit Descriptions - RF Path

P/N 709C011801

Page 37

2.1.2.3 OIX (Optical Expander Module)

Each OIX Expander module provides the RF interface to up to two HEU units via two 9-pin connectors. Two OIX Expander

modules can be installed in each OIU chassis. Up to four OIU units can be hosted by an HEU. If only one Expander module is

installed, it is required to terminate the empty slot with the supplied termination.

NOTE: The OIU Expander Modules are similar in appearance to the HEU Expander modules but are NOT INTERCHANGEABLE.

Each Expander module is indicated as RIX or OIX on the bottom of the module.

Figure 2-10. OIX Expander Module Interfaces

Page 38

Unit Descriptions - RF Path

P/N 709C011801

Page 38

2.2 RF Path Remote End Site Components

The RF coverage solution remote end components comprise the following elements:

• ICU (Intermediate Centralized Unit) - forwards optics along with DC to the RAU and its sub-modules.

• RAU (Remote Antenna Unit) - provides RF distribution and includes internal antennas. It can also encase data distribution

module (GEM).

• RxU (Remote Expansion Unit) - installed in the RAU. Provides support for two additonal RF services for a total of 6 services

per RAU.

Figure 2-11. RF Path Remote End Components

A detailed description of the remote end components is provided in the following sections

2.2.1 ICU (Intermediate Centralized Unit)

NOTE: The ICU can also be used on the digital path.

The ICU is installed at the floor level. It provides the LC/APC optical interface along with DC power to the RAU RF (and data)

sub-modules. The optical and DC signals are routed via a composite cable connected between the ICU and hosted RAU modules.

The optics signal is provided via one or two dedicated Edge modules that convert MTP optic interfaces to LC/APC interface; the

DC power is provided by up to four dedicated power supplies. A single power connection feeds all ICU power supply modules.

Figure 2-12. ICU Front Panel Interfaces and Modules

Page 39

Unit Descriptions - RF Path

P/N 709C011801

Page 39

Interface Description

Power Connectors

LC/APC

Up to eight DC power connectors, depending on number of power supply

modules installed.

SM optics connectors implemented by up to two Edge modules inserted

from the rear: six connectors per Edge module.

AC Power Input 110-230VAC power input to unit.

Table 2-11. ICU Front Panel Interface Descriptions

Edge modules and power supplies are extracted and inserted from the rear of the unit.

Figure 2-13. ICU Rear Panel Interfaces and PSM Modules

2.2.2 RAU (Remote Antenna Unit)

The RAU distributes up to four RF services via internal antennas (external antennas are optional). The RF services are received

over optic cables and converted for distribution over internal (or optionally external) antennas.

Figure 2-14. RAU Module

NOTE: The RAU enclosure can host two additional modules: RxU for MIMO support and GEM for digital coverage. See relevant

sections for details on these modules.

Page 40

Unit Descriptions - Digital Path

P/N 709C011801

Page 40

Interface Description

in case of PoE clients. Used when GEM modules are installed

MGMT RJ45 local management connection

DC power inputs

PWR

Main - connect to DC (from composite cable)

Secondary –

(in addition to Main)

F/O LC/APC SM connectors for UL and DL optic connections

Listening Mode N/A

RF Filter (e.g. LTE, CELL)

External Antenna

QMA RF ports for external cavity filter use (In/Out). For CELL and LTE

filters.

Optional connection to broadband external antennas. Requires GUI

configuration (internal antenna is enabled by default).

Table 2-12. RAU Interfaces

2.2.2.1 RxU (Remote Expansion Unit)

The RxU is an Add-on to the RAU which provides support for MIMO services (i.e. 700MHz LTE, AWS).

Figure 2-15. RxU Interfaces

Module Description

Filter Filter connections to the corresponding filter.

RF Connection to external antenna, used for above-ceiling installation.

External Antenna

(Both the RxU and the RAU antennas are used since this implements a MIMO

configuration)

External RF Filters QMA RF ports for external cavity filter use. For CELL and LTE filters.

RUN LED Indicates SW is up and running.

Table 2-13. RxU Front Panel Interface Connections

Page 41

Unit Descriptions - Digital Path

P/N 709C011801

Page 41

3 Unit Des criptions - Digital Path

This chapter provides detailed descriptions of the Digital Path components.

3.1 Digital Path Components

The digital path comprises the following elements - located at the remote end

• CEU – Centralized Ethernet Unit

• GEM – Gigabit Ethernet Module -

NOTE: The GEM module can be installed in two configurations: in the RAU enclosure or (as illustrated below) as a standalone

unit in a Docking Station.

Figure 3-1. ONE™ Digital Path Architecture

3.2 CEU (Centralized Ethernet Unit)

The CEU is a Centralized Ethernet-over-Fiber Media Converter Unit. Located at the remote end, it converts Ethernet media (from

a LAN switch) to fiber media for routing towards GEM modules. The CEU hosts three Centralized Media Converter Modules

[CEMs]. Each module supports four Ethernet ports (LAN switch connections) and four F/O connectors (towards GEM modules).

Figure 3-2. CEU Front Panel with Installed CEM Module

Figure 3-3. CEU Rear Panel

Page 42

Unit Descriptions - Digital Path

P/N 709C011801

Page 42

3.2.1 CEM (Centralized Ethernet Module)

The CEU supports up to three CEM modules, where each CEM supports four Ethernet ports (LAN switch connections) and four

F/O connectors (towards GEM modules). All interfaces (except for power) are located on the front panel (see section CEM).

Figure 3-4. CEM Interfaces (Installed in CEU)

The CEM module interfaces include Ethernet connections to the Ethernet switch, F/O connections and LED status indicators.

The following table provides a description of the CEM ports.

Port Description

ETH Four ETH connections to LAN switch

F/O

USB port

[4] 10/100/1000BASE-T RJ-45 connectors to [4] LC/UPC fiber connectors (using SFP

–small-form pluggable module)

USB serial port - service port

PWR Steady Green – Power input detected for corresponding module

Table 3-1. Ports Description

Page 43

Unit Descriptions - Digital Path

P/N 709C011801

Page 43

3.3 GEM (Gigabit Ethernet Module)

The GEM converts the received optical signal to two Ethernet digital connections, which are then routed along with PoE to two

remote access points. The GEM module can be installed in the following configurations:

• Installed in RAU - as an optional plug-in module (see RAU (on page 39))

• As a standalone module (GEU-S) - (see section GEU-S Installations (on page 52))

Figure 3-5. GEM Interfaces

The following tables provide descriptions of the ports and LED indicators.

Port Description

PORT A/PORT B

FC/APC [1] LC/UPC Fiber optic port

Table 3-2. GEM Port Interfaces

LED Description

PoE (PORT A/PORT B) Indicates power supplied to connected AP

Link

RUN Steady Green – GEM module SW is up and running

Table 3-3. GEM LED Indicator Descriptions

[2] RJ45 ports supporting 10/100/1000Base-T copper interface with

PoE+ 802.3at PSE capability for connections to remote access points

ON - the optical link to/from the connected remote functions within the

specifications in both directions.

Blinking - optical power from remote is lower than required