Page 1

Corning

ONE™ Wireless Platform

User Manual

Page 2

Preface Material

CMA-331-AEN

Page 2

Page 3

Preface Material

CMA-331-AEN

Page 3

Preface Material

About This Manual

This user guide provides all the information necessary to understand the architecture and general installation procedures and

requirements of Corning® ONE™ Wireless Platform.

Note: The commissioning procedure, monitoring and management capabilities and configuration options of the ONE™

Wireless Platform elements are described in a dedicated User Manual (ONE™ HCM User Manual).

Hardware

Corning warrants to the original purchaser (“Customer”) that for the duration of the warranty period, one (1) year, commencing

on the date of shipment of the Hardware, unless otherwise agreed in writing by Corning (the “Hardware Warranty Period”), the

Hardware furnished by Corning shall be free in all material respects from defects in material and workmanship, and shall

conform to the applicable portions of the Specifications, as defined below (the “Hardware Warranty”).

If notified by Customer of any such defects in material or workmanship or nonconformity with applicable portions of the

Specifications within the Hardware Warranty Period, Corning shall promptly, at its own election and expense, repair or replace

any such Hardware proven to be defective under the terms of this Hardware Warranty.

Such repair or replacement shall be Customer’s sole remedy and Corning sole obligation in the event this Hardware Warranty is

invoked. If any components comprising a part of the Hardware are replaced or repaired during the Hardware Warranty Period,

the Hardware Warranty Period for such repaired or replaced components shall extend to the longer of (i) the balance of the

Hardware Warranty Period or (ii) three (3) months from the date of repair or replacement. For purposes of this Warranty,

“Specifications” shall mean the specifications and performance standards of the Products as set forth in documents published

by Corning and delivered to Customer which contain technical specifications or performance standards for the Products.

If Customer invokes this Hardware Warranty, it shall notify Corning promptly of the claimed defect.

Customer will allow Corning to inspect the Hardware at Customer’s location, or to return the Hardware to Corning closest repair

facility. For Hardware returned to Corning repair facility, Customer shall be responsible for payment of all transportation and

freight costs (including insurance) to Corning’ repair facility, and Corning shall be responsible for all transportation and freight

costs (including insurance) incurred in connection with the shipment of such Hardware to other repair facilities of Corning and/or

its return to Customer.

Notwithstanding the foregoing, in no event will Corning be liable for damage to Products resulting from improper handling during

or after shipment, misuse, neglect, improper installation, operation or repair (other than by authorized Corning personnel),

alteration, accident, or for any other cause not attributable to defects in materials or workmanship on the part of Corning.

Corning shall not reimburse or make any allowance to Customer for any labor charges incurred by Customer for replacement or

repair of any goods unless such charges are authorized in advance in writing by Corning.

Page 4

Preface Material

CMA-331-AEN

Page 4

Software Warranty

Corning warrants to the original purchaser (“Customer”) that for the duration of the warranty period, one (1) year, commencing

on the date of shipment of the Software, unless otherwise agreed in writing by Corning (the “Software Warranty Period”), the

Software shall conform with, and perform the functions set forth in the Specifications, and shall be free from defects in material

or workmanship (the “Software Warranty”). In the event the Software is proven to be defective under the terms of this Software

Warranty, Corning shall correct such defects or failure and ensure that the Software conforms with, and performs the functions

set forth in, the Specifications. Customer will allow Corning to inspect the Software at Customer’s location or to return it to

Corning’s’ closest repair facility.

Notwithstanding the foregoing, Corning shall have no obligation under the Software Warranty if the Software is modified or used

with hardware or software not supplied or approved by Corning or if the Software is subject to abuse, improper installation or

application, accident, electrical or environmental over-stress, negligence in use, storage, transportation or handling.

Third-party software distributed with the Software may carry certain warranties which, to the maximum extent allowed by law,

Corning hereby assigns, transfers and otherwise conveys to Customer, provided, however, that Corning itself provides no

warranty of any kind, express, implied, statutory or otherwise, for any third-party software provided hereunder .

Corning does not warrant any hardware, software or services not provided by Corning.

THIS WARRANTY IS THE ONLY WARRANTY MADE BY CORNING AND IS IN LIEU OF ALL OTHER WARRANTIES,

EXPRESS OR IMPLIED INCLUDING, BUT NOT LIMITED TO, THE IMPLIED WARRANTIES OF MERCHANTABILITY AND

FITNESS FOR A PARTICULAR PURPOSE. CORNING SHALL NOT BE LIABLE FOR ANY OTHER DAMAGE INCLUDING,

BUT NOT LIMITED TO, INDIRECT, SPECIAL OR CONSEQUENTIAL DAMAGES ARISING OUT OF OR IN CONNECTION

WITH FURNISHING OF GOODS, PARTS AND SERVICE HEREUNDER, OR THE PERFORMANCE, USE OF, OR INABILITY

TO USE THE GOODS, PARTS AND SERVICE. CORNING SALES AGENTS OR REPRESENTATIVES ARE NOT

AUTHORIZED TO MAKE COMMITMENTS ON WARRANTY RETURNS.

Returns

In the event that it is necessary to return any product against above warranty, the following procedure shall be followed:

1. Return authorization is to be received from Corning prior to returning any unit. Advise Corning of the model, Serial number,

and discrepancy. The unit may then be forwarded to Corning, transportation prepaid. Devices returned collect or without

authorization may not be accepted.

2. Prior to repair, Corning will advise the customer of our test results and any charges for repairing customer-caused problems

or out-of-warranty conditions etc.

3. Repaired products are warranted for the balance of the original warranty period, or at least 90 days from date of shipment.

Page 5

Preface Material

CMA-331-AEN

Page 5

Limitations of Liabilities

Corning’s liability on any claim, of any kind, including negligence for any loss or damage arising from, connected with, or

resulting from the purchase order, contract, quotation, or from the performance or breach thereof, or from the design,

manufacture, sale, delivery, installation, inspection, operation or use of any equipment covered by or furnished under this

contact, shall in no case exceed the purchase price of the device which gives rise to the claim.

Except as expressly provided herein, Corning makes no warranty, expressed or implied, with respect to any goods, parts and

services provided in connection with this agreement including, but not limited to, the implied warranties of merchantability and

fitness for a particular purpose. Corning shall not be liable for any other damage including, but not limited to, indirect, special or

consequential damages arising out of or in connection with furnishing of goods, parts and service hereunder, or the

performance, use of, or inability to use the goods, parts and service.

Reporting Defects

The units were inspected before shipment and found to be free of mechanical and electrical defects. Examine the units for any

damage that may have been caused in transit. If damage is discovered, file a claim with the freight carrier immediately. Notify

Corning as soon as possible in writing.

Note: Keep all packing material until you have completed the inspection

Warnings and Admonishments

There may be situations, particularly for workplace environments near high-powered RF sources, where recommended limits

for safe exposure of human beings to RF energy could be exceeded. In such cases, restrictive measures or actions may be

necessary to ensure the safe use of RF energy.

The equipment has been designed and constructed to prevent, as far as reasonably, practicable danger. Any work activity on or

near equipment involving installation, operation or maintenance must be, as far as reasonably, free from danger.

Where there is a risk of damage to electrical systems involving adverse weather, extreme temperatures, wet, corrosive or dirty

conditions, flammable or explosive atmospheres, the system must be suitably installed to prevent danger.

Equipment provided for the purpose of protecting individuals from electrical risk must be suitable for the purpose and properly

maintained and used. This covers a range of activities including lifting, lowering, pushing, pulling, carrying, moving, holding or

restraining an object, animal or person from the equipment. It also covers activities that require the use of force or effort, such as

pulling a lever, or operating power tools.

Where some of the above mentioned activities are required, the equipment must be handled with care to avoid being damaged.

Observe standard precautions for handling ESD-sensitive devices. Assume that all solid-state electronic devices are

ESD-sensitive. Ensure the use of a grounded wrist strap or equivalent while working with ESD-sensitive devices. Transport,

store, and handle ESD-sensitive devices in static-safe environments.

Regulatory Compliance Information

WARNINGS!

• This is NOT a CONSUMER device. It is designed for installation by FCC LICENCEES and QUALIFIED INSTALLERS. You

MUST have an FCC LICENSE or express consent of an FCC Licensee to operate this device. Unauthorized use may result

in significant forfeiture penalties, including penalties in excess of $100,000 for each continuing violation.

ANTENNAS: Use only authorized and approved antennas, cables and/or coupling devices! The use of unapproved

•

antennas, cables or coupling devices could cause damage and may be of violation of FCC regulations. The use of

Page 6

Preface Material

CMA-331-AEN

Page 6

unapproved antennas, cables and/or coupling devices is illegal under FCC regulations and may subject the user to fines.

See section 4.7 of this document.

RF Safety

To comply with FCC RF exposure compliance requirement, adhere to the following warnings:

Warning! Antennas used for this product m ust be fixed mounted on indoor permanent structures, providing a separation

distance of at least 50 cm from all persons during normal operation.

Warning! Each individual antenna used for this transmitter must be installed to provide a minimum separation distance of 50 cm

or more from all persons and must not be co-located with any other antenna for meeting RF exposure requirements.

Warning! Antenna gain should not exceed 12.5 dBi.

Warning! The design of the antenna inst allation needs to be implem ented in such a way so as to ens ure RF radiatio n safet y

levels and non-environmental pollution during operation.

ATTENTION!

Compliance with RF safety requirements:

• Corning products have no inherent significant RF radiation

• The RF level on the downlink is very low at the downlink ports. Therefore, there is no dangerous RF radiation when the

antenna is not connected.

CAUTION!

Use of controls, adjustments or performance of procedures other than those specified herein may result in hazardous radiation

exposure.

Laser Safety

• Fiber optic ports of the Corning™ ONE™ wireless platform emit invisible laser radiation at the 1310/1550 nm wavelength

window.

• External optical power is less than 10 mW, Internal optical power is less than 500 mW.

• To avoid eye injury never look directly into the optical ports, patchcords or optical cables. Do not stare into beam or view

directly with optical instruments. Always assume that optical outputs are on.

• Only technicians familiar with fiber optic safety practices and procedures should perform optical fiber connections and

disconnections of the devices and the associated cables.

• ONE™ has been tested and certified as a Class 1 Laser product to IEC/EN 60825-1 (2007). It also meets the requirements

for a Hazard Level 1 laser product to IEC/EN 60825-2: 2004 to the same degree.

• Corning

Notice NO. 50 (2007).

Care of Fiber Optic Connectors

• Do not remove the protective covers on the fiber optic connectors until a connection is ready to be made. Do not leave

connectors uncovered when not connected.

• The tip of the fiber optic connector should not come into contact with any object or dust.

®

ONE™ wireless platform complies with 21 CFR 1040.10 and 1040.11 except for deviations pursuant to Laser

Page 7

Preface Material

CMA-331-AEN

Page 7

Document Name

CMA Lit Code

Headend Control Module (HCM) and Web Management GUI

User Manual

Company Certification

ISO 9001: 2000 and ISO 13485: 2003

Licensee Contact Information

Industrial Boosters may only be used by FCC licensees or those given express (individualized) consent of license. Corning

Optical Communications Wireless certifies all of the VARs listed as licensed installers for Corning. For the list of licensed VARs,

please contact the Tech Support Hotline: (US) 410-553-2086 or 800-787-1266.

Additional Relevant Documents

The following documents are required if the corresponding units are included in your system (these can be downloaded from the

Corning partner portal).

Campus Connectivity Fiber Connectivity Modules (FCM)

Datasheet

Mid-Power Remote Unit (MRU) Datasheet CMA-422-AEN

Mid-Power Remote Unit (MRU) User Manual CMA-438-AEN

5 band remote access unit (RAU5) datasheet CMA-377-AEN

CMA-421-AEN

Page 8

Page 9

Table of Co ntents

CMA-331-AEN

Page 9

TTaabbllee ooff CCoonntteennttss

Preface Material ..................................................................................................................................................... 3

About This Manual ................................................................................................................................................. 3

Hardware ............................................................................................................................................................... 3

Software Warranty ................................................................................................................................................. 4

Returns .................................................................................................................................................................. 4

Limitations of Liabilities .......................................................................................................................................... 5

Reporting Defects .................................................................................................................................................. 5

Warnings and Admonishments .............................................................................................................................. 5

Regulatory Compliance Information ....................................................................................................................... 5

RF Safety ............................................................................................................................................................... 6

Laser Safety ........................................................................................................................................................... 6

Company Certification ............................................................................................................................................ 7

Licensee Contact Inform a tion ................................................................................................................................. 7

Table of Contents ................................................................................................................................................... 9

1 Introduction ................................................................................................................................................. 15

1.1 About Corning

®

ONE™ Wireless Platform .................................................................................................. 15

1.2 Key Features and Capabilities .................................................................................................................... 16

1.3 General System Specifications and Requirements ...................................................................................... 16

1.3.1 Environmental and Regulatory Specifications .................................................................................. 16

1.3.1.1 Temperature and Humidity ....................................................................................................... 16

1.3.1.2 Safety and Regulatory Approvals .............................................................................................. 17

1.3.2 Power Specifications ....................................................................................................................... 17

1.3.2.1 Power Input and Consumption .................................................................................................. 17

1.3.2.2 Cable Gauge Requirements ..................................................................................................... 19

1.3.2.3 Power, Heat and Rack Specifications ....................................................................................... 20

1.3.2.4 Remote End Distance and Power Draw Matrix ......................................................................... 21

1.3.3 Dimensions and Weight of Units ...................................................................................................... 22

1.3.4 Optical Specifications ...................................................................................................................... 23

1.4 System Architecture and Topologies ........................................................................................................... 24

1.4.1 RF Path ........................................................................................................................................... 25

1.4.2 Ethernet Path .................................................................................................................................. 27

Page 10

Table of Co ntents

CMA-331-AEN

Page 10

DRAFT

1.5 WEB Management Application.................................................................................................................... 28

1.6 User Controlled Service Group Distribution ................................................................................................. 29

1.6.1 Single Service Group Example ........................................................................................................ 30

1.6.2 Dual Service Group Example........................................................................................................... 31

1.6.3 Tri Service Group Example .............................................................................................................. 31

1.6.4 Tri Service Group Example with Two HEUs ..................................................................................... 32

1.6.5 Example of FMM-to-FRM Service Distributio n ................................................................................. 32

2 Unit Descriptions - RF Path ......................................................................................................................... 35

2.1 RF Path - Headend Components ................................................................................................................ 35

2.1.1 HEU................................................................................................................................................. 36

2.1.1.1 HCM ......................................................................................................................................... 37

2.1.1.2 ACM ......................................................................................................................................... 38

2.1.1.3 RIM/RIM-M ............................................................................................................................... 39

2.1.1.4 FRM.......................................................................................................................................... 40

2.1.1.5 RIX ........................................................................................................................................... 41

2.1.1.6 ETM .......................................................................................................................................... 42

2.1.1.7 PSM.......................................................................................................................................... 42

2.1.2 OIU .................................................................................................................................................. 44

2.1.2.1 ACM ......................................................................................................................................... 45

2.1.2.2 OIM........................................................................................................................................... 45

2.1.2.3 FMM ......................................................................................................................................... 46

2.1.2.4 OIX ........................................................................................................................................... 47

2.1.3 IHU .................................................................................................................................................. 48

2.2 RF Path Remote End Site Components ...................................................................................................... 50

2.2.1 ICU .................................................................................................................................................. 51

2.2.2 RAU................................................................................................................................................. 52

2.2.3 RAU5 ............................................................................................................................................... 54

Page 11

Table of Co ntents

CMA-331-AEN

Page 11

DRAFT

3 Unit Descriptions - Ethernet Path ................................................................................................................ 56

3.1 Ethernet Path Components ......................................................................................................................... 56

3.2 CEU ............................................................................................................................................................ 57

3.2.1 CEM ................................................................................................................................................ 57

3.3 GEM ........................................................................................................................................................... 59

3.4 GEU-S ........................................................................................................................................................ 61

4 Installation Guidelines ................................................................................................................................. 62

4.1 Infrastructure Preparation ........................................................................................................................... 62

4.2 Installation Requirements ............................................................................................................................ 62

4.2.1 Installation Location Requirements .................................................................................................. 62

4.3 Safety Guidelines ........................................................................................................................................ 62

4.4 Rack Installation Guidelines ........................................................................................................................ 63

4.4.1 Rack Safety Instructions .................................................................................................................. 63

4.5 Power Requirements .................................................................................................................................. 64

4.5.1 Power Safety Instructions ................................................................................................................ 64

4.5.2 Types of Power Supplies ................................................................................................................. 64

4.5.3 Circuit Breakers ............................................................................................................................... 64

4.6 RF Coaxial Cable Guidelines ...................................................................................................................... 65

4.6.1 General Cable Installation Procedures ............................................................................................ 65

4.6.2 RF Rules ......................................................................................................................................... 65

4.6.3 Coax Cable Lengths and Losses ..................................................................................................... 66

4.7 Antenna Specifications and Guidelines ....................................................................................................... 67

4.7.1 Authorized Antennas and Required Specifications .......................................................................... 67

4.7.2 General Installation Guidelines ........................................................................................................ 67

4.8 Fiber Optic Requirements ........................................................................................................................... 68

4.8.1 Authorized Optic Cables .................................................................................................................. 68

4.8.2 Fiber Optic Rules ............................................................................................................................. 68

Page 12

Table of Co ntents

CMA-331-AEN

Page 12

DRAFT

4.9 Power Safety Instructions ........................................................................................................................... 69

5 Appendix E: Specifications .......................................................................................................................... 70

Supported Services .............................................................................................................................................. 70

RF Parameters per Service (RAU) ....................................................................................................................... 71

RF Parameters per Service (RAU5) ..................................................................................................................... 72

RF Parameters for FCM Solution ......................................................................................................................... 72

FCM System Typical Performance (@25 degrees system gain 0 dB) .................................................................. 72

Optical Specifications ........................................................................................................................................... 73

Environmental Specifications ............................................................................................................................... 73

Standards and Approvals ..................................................................................................................................... 74

RF Path: Coverage Component Specifications .................................................................................................... 75

Headend Unit (HEU) ................................................................................................................................... 75

RF Path: Coverage Component Specifications (continued) .................................................................................. 76

Headend Unit (HEU) (continued) ................................................................................................................ 76

RF Path: Coverage Component Specifications (continued) .................................................................................. 77

Optical Interface Unit (O IU) ......................................................................................................................... 77

RF Path: Coverage Component Specifications (continued) .................................................................................. 78

Optical Interface Unit (OIU) (continued) ...................................................................................................... 78

Integrated Headend Unit (IHU) .................................................................................................................... 78

RF Path: Coverage Component Specifications (continued) .................................................................................. 79

Interconnect Unit (ICU) ............................................................................................................................... 79

Remote Access Unit (RAU) ......................................................................................................................... 79

RF Path: Coverage Component Specifications (continued) .................................................................................. 80

Remote Access Unit (RAU) (continued) ...................................................................................................... 80

RF Path: Coverage Component Specifications (continued) .................................................................................. 81

5 Band Remote Access Unit (RAU5) (continued) ........................................................................................ 81

RF Path: Coverage Component Specifications (continued) .................................................................................. 82

Cavity Duplexer for LTE 700 MHz ............................................................................................................... 82

RF Path: Coverage Component Specifications (continued) .................................................................................. 83

Cavity Duplexer for LTE 700 MHz (continued) ............................................................................................ 83

Cavity Duplexer for 800 MHz ...................................................................................................................... 83

Fiber Connectivity Module (FCM) Specifications .................................................................................................. 84

Fiber Main Module (FMM) ........................................................................................................................... 84

Fiber Remote Module (FRM)....................................................................................................................... 84

Ethernet Coverage Component Specifications ..................................................................................................... 84

Central Ethernet Unit (CEU) ........................................................................................................................ 84

Page 13

Table of Co ntents

CMA-331-AEN

Page 13

DRAFT

Ethernet Coverage Component Specifications (continued) .................................................................................. 85

Gigabit Ethernet Module (GEM) .................................................................................................................. 85

Standalone Gigabit Ethernet Unit (GEU-S) ................................................................................................. 85

Optical: Cabling, Unit/Modules Specifications ...................................................................................................... 86

Cabling ....................................................................................................................................................... 86

Fiber Management ...................................................................................................................................... 86

6 Appendix F: Ordering Information ............................................................................................................... 87

HEU and OIU Assemblies and Modules ............................................................................................................... 87

Remote Units ....................................................................................................................................................... 88

FCM Solution Modules ......................................................................................................................................... 89

SFP+ Modules ..................................................................................................................................................... 89

Ethernet Path Units .............................................................................................................................................. 90

Accessories ......................................................................................................................................................... 90

Hardware ............................................................................................................................................................. 91

Cable Ordering Information .................................................................................................................................. 92

Cable Configurations .................................................................................................................................. 92

Page 14

Page 15

Introduction

CMA-331-AEN

Page 15

1 Introduction

1.1 About Corning® ONE™ Wireless Platform

The Corning® ONE™ wireless platform is an all optical c onverg ed so lut io n, unifying cellular, Wi-Fi and Ethernet backhaul. The

platform provides a flexible in-building cellular and network data coverage solution based on a fiber optic transport backbone.

Fiber-to-the edge technology allows for virtually unlimited bandwidth to support today and tomorrow’s growing demands of

wireless users.

The fiber optic infrastructure is easily deployable via a wide range of preterminated composite cables and advanced end-to-end

equipment. Easy to design, Plug and Play™ connectors, significantly reduce installation cost and deployment time.

Dynamic service distribution group management allows precise service distribution control to meet changing density needs,

and provides further savings by enabling sharing of equipment at various levels for service providers. Various combinations of

services are allowed for routing from the headend to specified remote locations on each floor, according to user defined

configurations (via the Web management GUI). This allows optimizing service coverage and provides equipment savings.

While the fiber-optics infrastructure is common, the services can be routed via service provider shared or dedicated equipment.

By default, the system is configured to support a single service group: all services are transferred to all remote locations. This

default configuration can be easily modified according to site requirements.

Built-in Gigabit Ethernet support enables offload, expansion and best-use of Wi-Fi resources while the integrated antenna

provides flexibility for ease and cost.

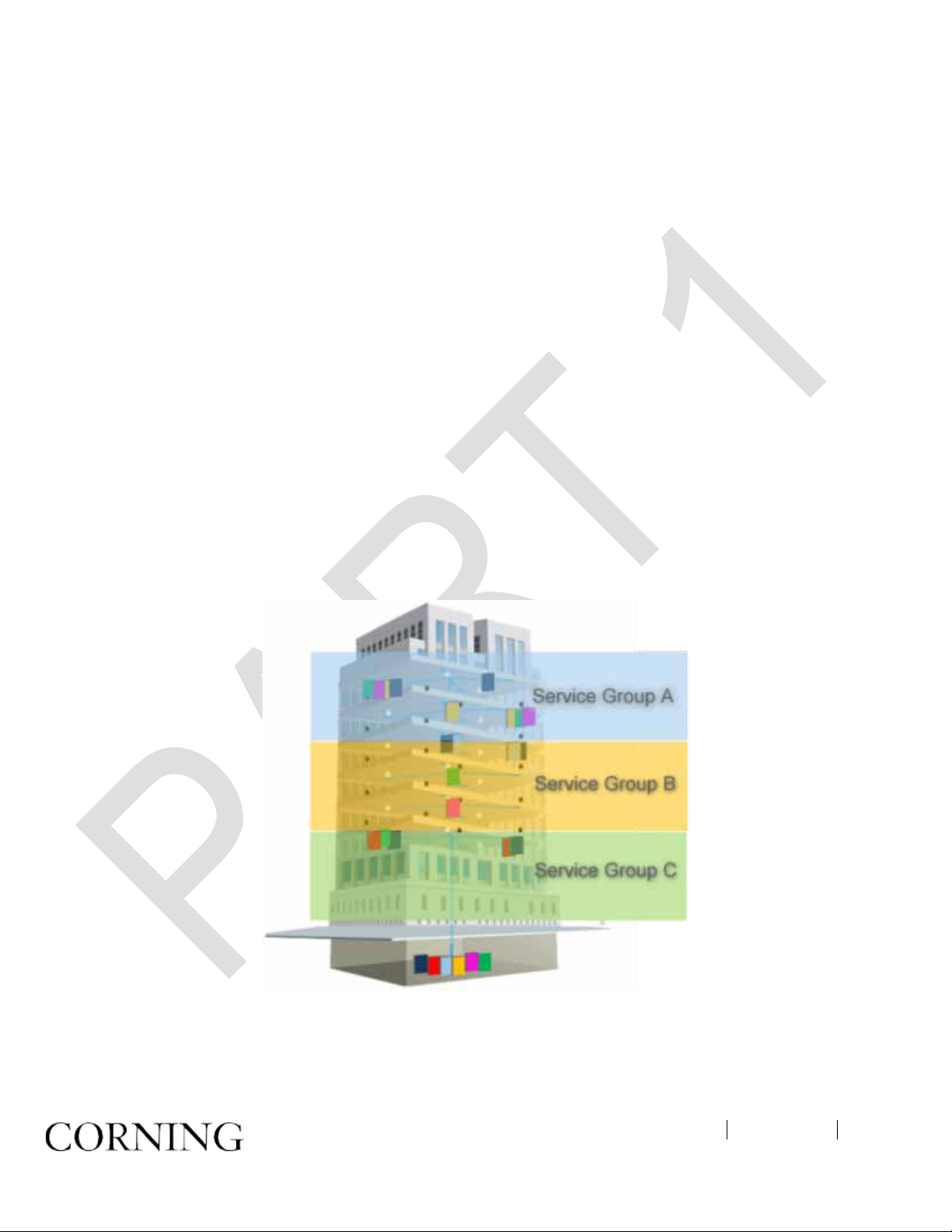

The following figure illustrates service distribution from the head-end to various locations on each remote floor. Each color

represents a specific service, where different combinations of services are distributed at various locations on the same floor

according to coverage requirements.

Figure 1-1. Illustration of Precise Service Distribution over Selected Remote Areas

In addition, the Corning

point-to-point extension of cellular services along with 10 Gb Ethernet to a distance of up to 12.4 miles. The solution utilizes

single mode (SM) fiber to extend up to three user configured service groups from the main headend to a remote site.

ONE wireless platform campus connectivity solution (FCM) comprising two modules enables

Note: Refer to FCM datasheet for solution specifications (can be downloaded from Corning partner portal).

Page 16

Introduction

CMA-331-AEN

Page 16

Operating

Storage

1.2 Key Features and Capabilities

• Comprehensive service support

• Supported services - LTE700, ESMR, CELL, PCS, AWS, WCS, and TDD 2500 MHz

• Flexible, configurable service distribution - advanced capacity and coverage management for better macro offload and

enhanced user experience.; Point-to-point connectivity and BTS hoteling in star topologies (via FCM modules)

• Fiber conservation – via FCM solution, enables single fiber transport of all RF services and 10 Gb Ethernet over a distance

of 12.4 mi

• Broadband enabled:

• A range of ready-made fiber-optic (and power) composite cables simplify installation at all levels

• Fiber backbone unleashes unlimited RF Spectrum

• Easy scales to higher speeds requirements

®

• Ethernet Support - dedicated fiber link for Ethernet backhaul, enables optimal use and offload of Wi-Fi

resources.

• Scalable and customizable - infrastructure can be quickly expanded to support more services or increase coverage without

downtime

• Carrier-grade network management:

• Single-source, remote end-to-end field upgradable platform

• Ready for SON, HetNet and future network requirements.

1.3 General System Specifications and Requirements

1.3.1 Environmental and Regulatory Specifications

1.3.1.1 Temperature and Humidity

The environmental specifications listed below are relevant to all Corning ONE™ solution devices.

Temperature 0°C to +50°C (32°F to 122°F) -20° C to 85° C (-4°F to 185°F)

Humidity 95% (non-condensing) 95% (non-condensing)

Table 1-1. Temperature and Humidity Specifications

Page 17

Introduction

CMA-331-AEN

Page 17

Regulation/Standard

Category

Approval

RF Head End Units

Power Input

Power Consumption for Full Chassis

RAU + Add-On Modules

Max. Power Consumption

Power Input Range

1.3.1.2 Safety and Regulatory Approvals

The safety and regulatory specifications listed below are relevant to all Corning® ONE™ wireless platform devices.

Laser Safety

EMC

FDA/CE 21 CFR 1040.10 and 1040.11 except for deviations pursuant to laser notice no.

50 and IEC 60825-1

CE EN 301 489, EN55022, EN 61000

FCC 47 CFR Part 15, 22, 24, 27

UL 60950

IEC 60825-1:2007

Safety

IEC 60825-2:2010

CAN/CSA-C22.2 No.60950-1-03

Fire Safety UL 2043 (applicable for RAU5 only)

Table 1-2. Safety and Regulatory Approvals

1.3.2 Power Specifications

Note: This section provides the power specifications for the headend units and the RAU/RAU5 (including GEM). For MRU

specifications refer to MRU datasheet (CMA-422-AEN) and user manual (CMA-438-AEN). These can be downloaded from

Corning partner portal.

1.3.2.1 Power Input and Consumption

HEU AC power source: 100 to 220 V AC

DC power source: 48 V DC

Chassis with 12 RIMs and two RIX: 200 W

OIU AC power source: 100 to 220 V AC

Chassis with 12 OIMs and two OIX: 300 W

DC power source: 48 V DC

IHU AC power source: 100 to 220 V AC

Fully Loaded chassis: 300 W

DC power source: 48 V DC

Table 1-3. RF Headend Units Power Consumption

RAU (alone) 37 V; 35 W 35 – 57 V DC

RAU + GEM 37 V; 39 W

Table 1-4. RAU Power and Current Consumption for Main Power Input

Page 18

Introduction

CMA-331-AEN

Page 18

Unit

Device

Input Range

Power Consumption

RAU5 + Add-O n Mod ul es

Max. Power Consumption

Power Input Range

RAU5 (alone)

RAU5 + GEM

Unit

Device

Input Range

Power Consumption

Digital Remote End Units

Power Input Range

Power Consumption

See Table 1-6

See Table 1-6

RAU For two PoE ports of 802.3af 43- 57 V DC 43 V; 30 W

For two PoE ports of 802.3at 52- 57 V DC 52 V; 62 W

Table 1-5. RAU Power and Current Consumption for Secondary Input

44.5 V; 50 W 37 – 57 V DC

44.5 V; 52 W

Table 1-6. RAU5 Power and Current Consumption for Main Power Input

RAU5 For two PoE ports of 802.3af 43- 57 V DC 46 V; 31.5 W

For two PoE ports of 802.3at 52- 57 V DC 52.5 V; 62 W

Table 1-7. RAU5 Power and Current Consumption for Secondary Input

CEU 110 to 240 V AC (Fully occupied) 50 W

GEM installed in RAU

GEU-S 42-57 V DC 4.5 W

Table 1-8. Digital Path Remote End Power Specifications

Page 19

Introduction

CMA-331-AEN

Page 19

RAU

SISO

(ft)

RAU

SISO

+

GEM

(ft)

RAU SISO

+

GEM

Supporting

PoE

RAU SISO

+

GEM

Supporting

PoE+

(ft)

GEU-S

(ft)

GEU-S

Supporting

PoE

(ft)

GEU-S

Supporting

PoE+

(ft)

1.3.2.2 Cable Gauge Requirements

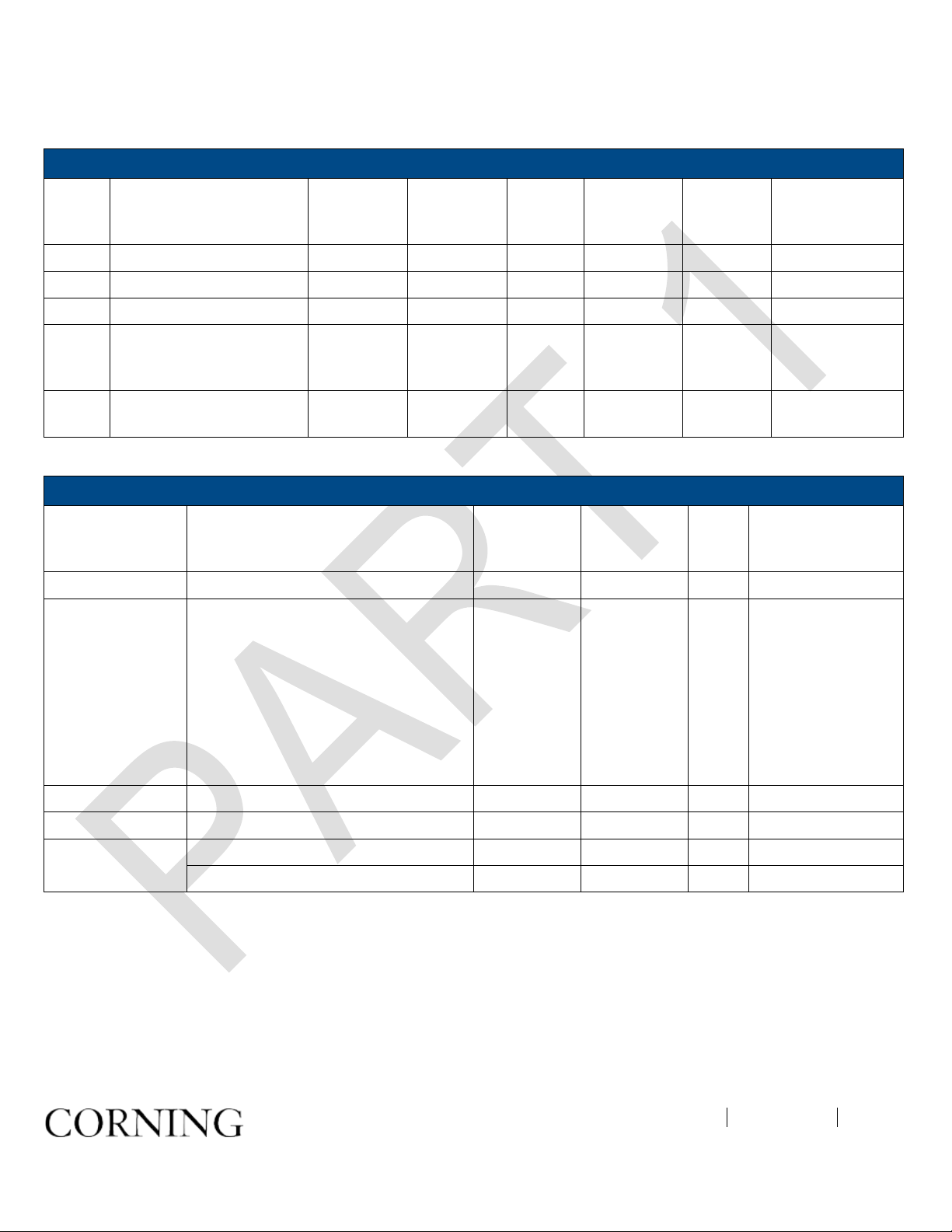

Table 1-9 provides the information required to calculate the required power supply for the remote units.

Note: Table also applies to RAU5.

22AWG 540 490 410 100 2000 310 80

20AWG 870 780 650 160 3200 500 130

16AWG 2200 1900 1600 400 8200 1200 350

14AWG 3500 3100 2650 650 1350 2000 550

Table 1-9. Required Cable Gauge

Page 20

Introduction

CMA-331-AEN

Page 20

Headend/Telco Rms

Ceilings

1.3.2.3 Power, Heat and Rack Specifications

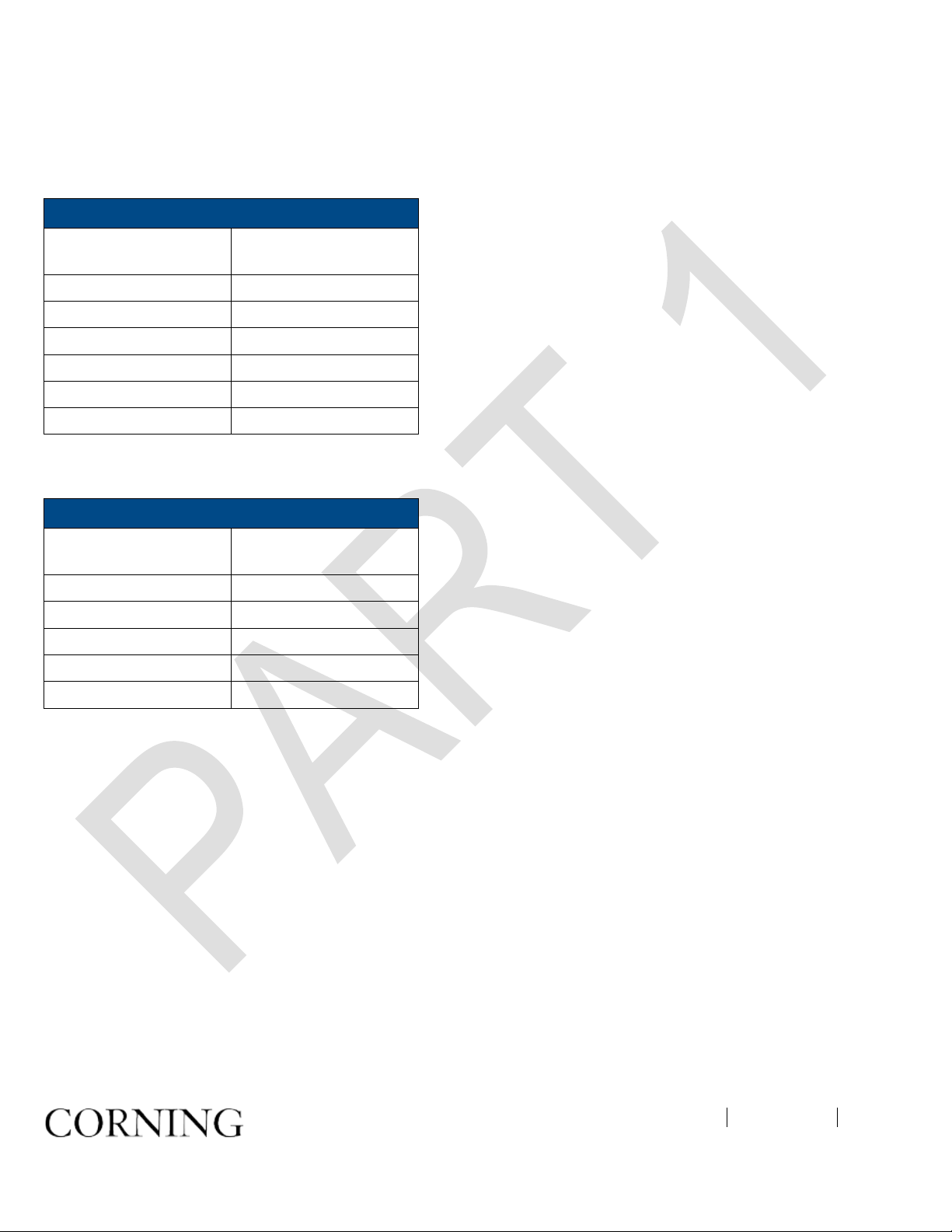

Table 1-10 and Table 1-11 provide the power, heat and rack specifications for the headend and remote end ceiling equipment.

P/N Description

Min-Max

Voltage

(VAC)

Max Power

Draw

(Watts)

No. of

Units

Heat

(BTU/hr)

Rack

Space

19-in (RU)

Dimensions (in)

HxWxD

HEU Headend Unit 100 -220 200 1 680 4 7 x 17.3 x 18.9

OIU Optical Interface Unit 100 - 220 300 1 1020 4 7 x 17.3 x 18.9

IHU Integrated Headend Unit 100 – 220 300 1 1020 4 7 x 17.3 x 15.5

CEU

Centralized Ethernet Unit

110 - 240 50 1 170 1 1.75 x 17 x 8.5

(3 x CEMs – Centralized

Ethernet Modules)

ICU

Interconnect Unit (4 x 200

110 - 240 930 1 442 1 1.75 x 17 x 19.2

W PSMs)

Table 1-10. Power, Heat and Rack Specifications for Headend Equipment

Unit Description

Min-Max

Voltage

(VDC)

Max Power

Draw (Watts)

Heat

(BTU/

hr)

Dimensions (in)

RAU Remote Access Unit 37 - 57 35 119 13.1 x 13.1 x 4

RAU5 5 Band Remote Access Unit 37 - 57 50 171

Without mounting

bracket: 3.2 x 12.9 x

9.8 in (82.1 x 337.3

x 249.4 mm)

With mounting

bracket: 5.25 x 13.1

x 13.1 in (133.35 x

332.74 x 332.74

mm)

GEM Gigabit Ethernet Module 37 - 57 4 14 1.3 x 3.8 x 5.9

GEU-S Gigabit Ethernet Unit - Standalone 37 - 57 4 14 5 x 10.5 x 3.3

GEM Supporting

PoE

For two PoE ports of 802.3af: 43V; 30W

For two PoE ports of 802.3at: 52V; 62W

Table 1-11. Power, Heat and Rack Specifications for Ceiling Equipment (Remote End)

Page 21

Introduction

CMA-331-AEN

Page 21

RAU SISO

GEM Supporting PoE 802.3af

1.3.2.4 Remote End Distance and Power Draw Matrix

Note: RAU values apply to RAU5 as well unles s RAU 5 specif ic all y indicat ed.

Table 1-12, Error! Reference source not found., Table 1-13 and Table 1-14 provide the distance and power draw specifications

for the remote end units.

Composite 16 AWG

Draw (Watts)

Tether Distance (ft.)

10 - 50 36

60 - 270 37

280 - 480 38

490 - 690 39

700 - 850 40

860 - 900 41

*Min/Max VDC = 37/57 @ 1.49 Amps, 85% efficiency

Table 1-12. Remote End Distance and Power Draw for (Standalone) RAU SISO

Composite 16 AWG

Draw (Watts)

Tether Distance (ft.)

10 - 40 31

50 - 340 32

350 - 660 33

670 - 890 34

900 35

*Min/Max VDC = 43/57 @ 1.49 Amps, 85% efficiency

Table 1-13. Remote End Distance and Power Draw for GEM w/PoE.3af

Page 22

Introduction

CMA-331-AEN

Page 22

GEM Supporting PoE 802.3at

Unit

Dimensions (H x W x D)

Weight: lbs [kg]

Composite 16 AWG

Tether Distance (ft.)

Draw (Watts)

Composite 16 AWG

Tether Distance (ft.)

Draw (Watts)

10 - 80 64 590 - 620 73

90 - 170 65 630 - 670 74

180 - 230 66 680 - 710 75

240 - 300 67 720 – 750 76

310 - 370 68 760 – 790 77

380 - 420 69 800 - 820 78

430 - 470 70 830 - 850 79

480 - 530 71 860 - 890 80

540 - 580 72 900 81

*Min/Max VD C = 52/57 @ 1.49 Amps, 85% efficiency

Table 1-14. Remote End Distance and Power Draw for GEM w/PoE.3at

1.3.3 Dimensions and Weight of Units

Table 1-15, Table 1-16 and Table 1-17 describe the physical specifications of the Corning® ONE™ headend and remote end

units.

Note: Refer to MRU datasheet for MRU physical dimensions and weight.

HEU

OIU

IHU

7 x 17.3 x 18.95 in (177.8 x 440 x 481.7 mm)

7 x 17.3 x 18.95 in [177.8 x 440 x 481.7 mm]

7 x 17.3 x 15.5 in [177.8 x 440 x 394 mm]

Table 1-15. RF Path Headend Units

Chassis: 37 lbs (16.8 kg)

Per RIM: 1.9 lbs (0.9 kg)

Per RIX: 1.54 lbs (0.7 kg)

Per FRM: 2.42 lbs (1.1 kg)

HCM: 2.2 lbs (1.0 kg)

PSM: 1.98 lbs (0.9 kg)

Chassis: : 37 lbs (16.8 kg)

Per OIM: 1.5 lb (0.7 kg)

Per OIX: 1.54 lb (0.7 kg)

Per FMM: 2.42 lbs (1.1 kg)

ACM: 2.2 lb (1.0 kg)

PSM: 1.98 lb (0.9 kg)

Chassis: 30 lbs (14 kg)

Per RIM: 1.9 lbs (0.9 kg)

Per RIX: 1.54 lbs (0.7 kg)

Per OIM: 1.5 lb (0.7 kg)

Per OIX: 1.54 lb (0.7 kg)

ACM: 2.2 lb (1.0 kg)

PSM: 1.98 lb (0.9 kg)

Page 23

Introduction

CMA-331-AEN

Page 23

Unit

Dimensions (H x W x D)

Weight: lbs [kg]

Unit

Dimensions (H x W x D)

Weight: lbs (kg)

Parameter

Specification

ICU 1.74 x 17 x 19.2 in (44.4 x 431.8 x 11.96 mm) 5.5 lb (2.5 kg) – without PSM

RAU (including

13.1 x 13.1 x 4 in (332.7 x 332.7 x 101.6 mm) RAU only = 7.93 lb (3.6 kg);

mounting bracket)

RAU5 (including

mounting bracket)

Without external antenna: 3.6* x 12.9 x 10.4 in (90 x

327 x 264 mm)

*3.6 in (90 mm) without standard mounting bracket; 4.4 in (111 mm)

with standard mounting bracket

RAU5 only: 10 lbs (4.5 kg)

With external antenna and skirt: 6.1 x 5.3 x 5.3 in (154 x

334 x 334 mm)

Table 1-16. RF Path Remote Units

CEU: CEU

1.71 x 17 x 8.5 in (43.65 x 431.8 x 216 mm)

7.55 lb (3.4 kg)

(with mounting ears: W = 19 in/482.8 mm)

CEM

1.41 x 3.94 x 7.68 in (36 x 100.14 x 195.14 mm)

1.44 lb (0.65 kg)

GEM 1.28 x 3.79 x 5.95 in (32.7 x 96.3 x 151.3 mm) 1.1 lb (0.5 kg)

GEU-S 5.01 x 10.51 x 3.26 in (including mounting bracket)

(127.5 x 267 x 83 mm)

2.64 lb (1.2 kg)

Table 1-17. Ethernet Path Units

1.3.4 Optical Spe ci fications

Optical Output Power < 9 dBo

Max. Optical Budget 5 dB

Optical Connector

OIM: MTP

RAU: LC APC SM

Fiber Type

Corning

Wavelength 1310±10 nm (Standard)

Table 1-18. Optical Specifications

®

connector

®

SMF-28® or Compatible

Page 24

Introduction

CMA-331-AEN

Page 24

1.4 System Architecture and Topologies

The Corning® ONE™ wireless platform solution fiber-optic infrastructure is used to transmit both RF and Ethernet services:

• RF services – Broadband RF distribution over fiber-optics infrastructure transfers converged wireless services from the

headend towards remote-end units (e.g. RAU5) deployed at the remote end locations according to user defined

configuration.

• Ethernet services – fiber-optics infrastructure transfers digital services from the corporate LAN to Gigabyte Ethernet

modules (GEM) and then 3

rd

party equipment deployed on each floor.

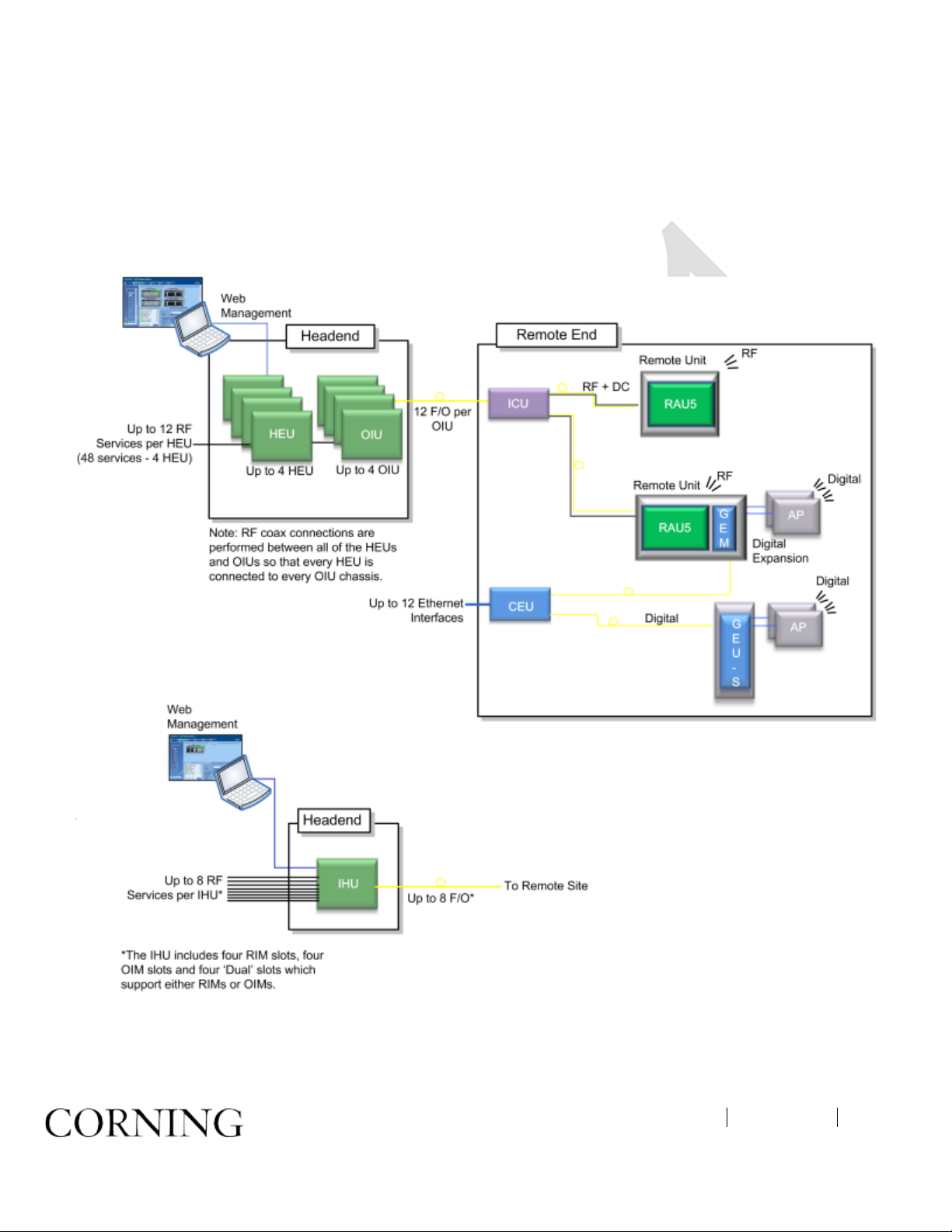

Figure 1-2. Corning ONE Wireless Platform Basic Architecture

Page 25

Introduction

CMA-331-AEN

Page 25

Acronyms

HEU = Headend unit

RIM = Radio interface module

RAU5 = 5 Band remote access unit

GEM = Gigabit Ethernet module

RIM = Radio interface module

GEU-S = Gigabit Ethernet

Unit-Standalone

ICU = Interconnect unit

IHU = Integrated headend unit

CEU = Centralized Ethernet unit

OIU = Optical Interface unit

OIM = Optical Interface module

Table 1-19. Acronyms in System Architecture

1.4.1 RF Path

At the headend, RF signals from the RF signal sources (e.g. BTS/BDA) are conditioned by service specific (conditioner)

modules in the headend unit (HEU) and organized into (up to three) user configurable sectors. The conditioned RF signals are

converted to optic signals by the (wideband) optic interface unit (OIU) and specific sectors are routed towards selected remote

locations according to user defined configurations.

The optic fibers at the OIU are routed to the integrated centralized unit (ICU) at the remote end. From the ICU the optic fibers are

distributed along with DC to the remote access units (RAU5).

For small/medium size deployments an integrated headend unit (IHU) can be installed at the headend. The IHU is a compact

headend unit that interfaces up to eight RF sources, conditions the signals and performs the RF to optic conversion of the

signals which are then routed towards the remote site.

Note: A fully occupied OIU (12 OIMs) supports up to 36 RAUs; Each IHU can support up to eight OIMs (with four RIMs)

supporting up to 24 RAUs.

Page 26

Introduction

CMA-331-AEN

Page 26

Figure 1-3. Corning

®

ONE™ Solution RF Path Architecture

Page 27

Introduction

CMA-331-AEN

Page 27

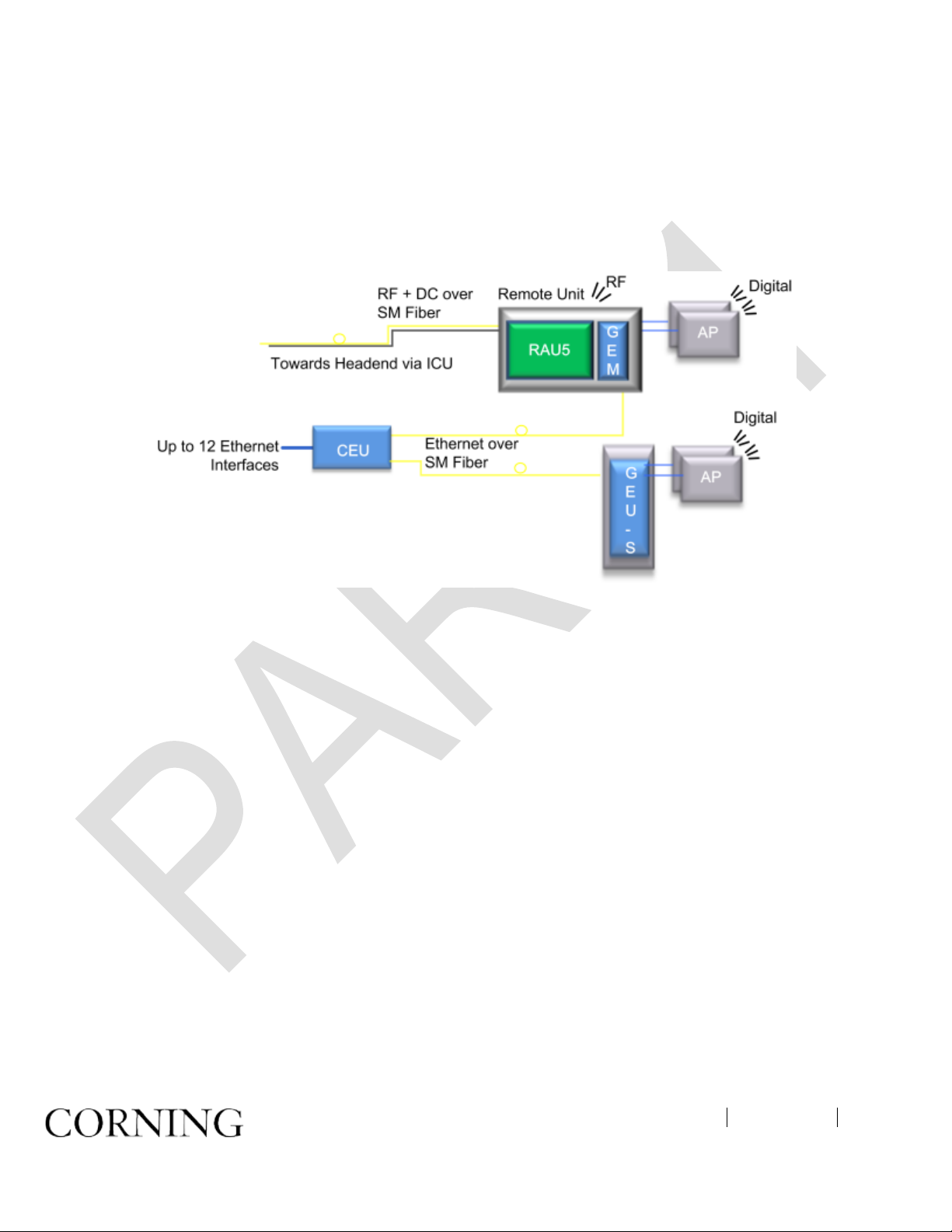

1.4.2 Ethernet Path

The digital services from the corporate LAN (received via Ethernet Switch) are converted to optic signals by the centralized

Ethernet unit (CEU) and routed over optic fibers towards the GEM units. The optical traffic is then converted to 1 GbE by the

Gigabit Ethernet modules (GEM) modules and distributed to two third party equipment such as access points, Ethernet switch,

etc.

Note: GEMs can be connected to the CEU either directly, or via an ICU (described in section 1.4.1 ). In that case, the ICU can

also provide DC to the GEMs.

Figure 1-4. Corning ONE™ Solution Ethernet Path Architecture

Page 28

Introduction

CMA-331-AEN

Page 28

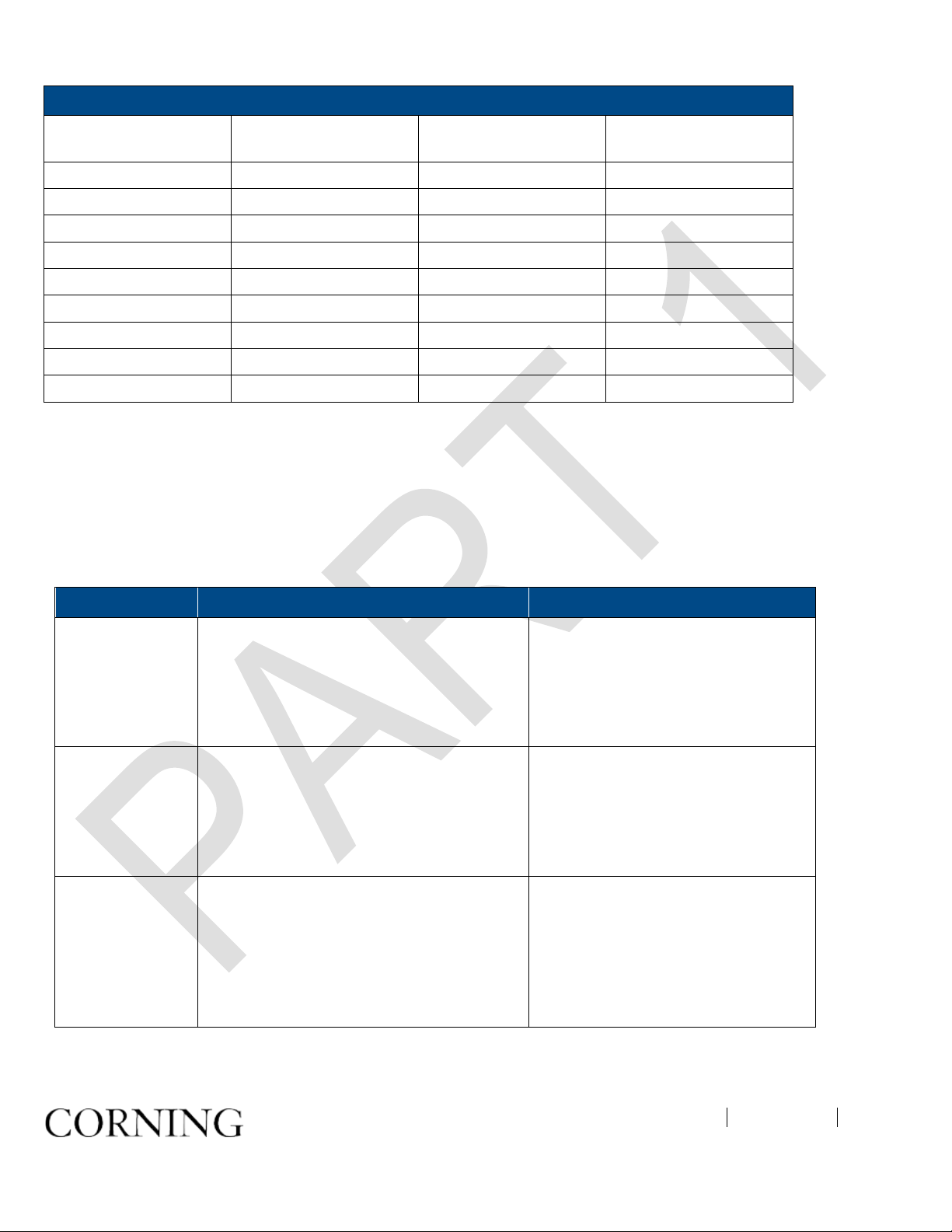

Tab

Description

Management

Displayed upon login by default. Displays general module information and

selected site devices.

Events

Displays the events that occurred on the monitored devices and enables

manager are not considered events display.

Config

Set-up tool used for initial system set-up, commissioning of system devices

and adjustment procedure.

Admin

Provides administration options such as firmware upgrade, user management

options and IP settings required for receiving traps.

Profiles

Enables creating complete system configuration and setup profile offline and

activating at a later time.

Location

Enables importing maps and icons to graphically display the geographical

for the system elements.

Help

Provides access to Online Help

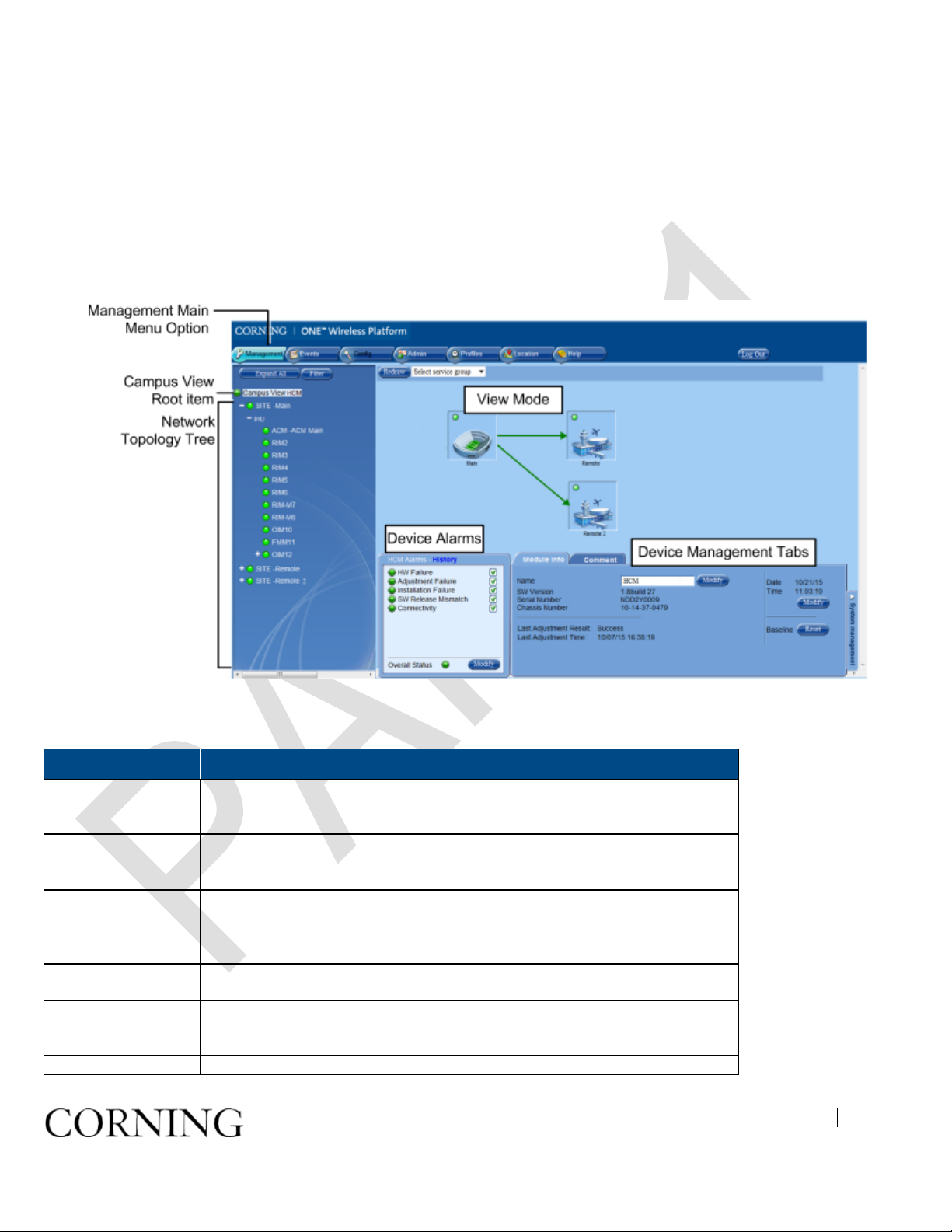

1.5 WEB Management Application

The Corning® ONE™ wireless platform headend control module (HCM) enables centralized, system-level element management

and

provides c

system components after their physical installation

Note: Refer to the Corning ONE HCM and Management GUI user manual for a complete description of the Web management

application.

Figure 1-5 shows the Management window, displayed by default upon login (shows installation with m ultip le sites via

FMM-to-FRM connections).

omprehensive end-to-end, single source setup and management of the Corning ONE wireless platform active RF

.

Figure 1-5. Main Window (Management Tab - Default Display)

The main menu bar includes the following tabs:

device alarms and provides the configuration options for the available

generating reports. Configuration changes that are initiated by the network

location and types of sites as well as the floor plans and map power settings

Table 1-20. Main Menu Tabs

Page 29

Introduction

CMA-331-AEN

Page 29

1.6 User Controlled Service Group Distribution

Corning® ONE™ fiber-optics infrastructure allows various combinations of SISO services to be routed from the headend to

specified remote locations on each floor, according to user defined configurations. This allows optimizing service coverage and

provides equipment savings. While the fiber-optics infrastructure is common, the services can be routed via service provider

shared or dedicated equipment. By default, the system is configured to support a single service group: all services are

transferred to all remote locations. This default configuration can be easily modified according to site requirements.

The following figure illustrates service distribution from the head-end to various locations on each remote floor. Each color

represents a specific service, where different combinations of services are distributed at various locations on the same floor

according to coverage requirements.

Figure 1-6. Illustration of Service Group Distribution

Page 30

Introduction

CMA-331-AEN

Page 30

1.6.1 Single Service Group Example

In this example, all four services (A,B,C,D) are routed to all (up to 72) remote locations. In the illustrated topology, a single HEU

conditions the services and feeds them to two OIU systems for conversion to optic signals. Each OIU supports up to 36 RAU

(Remote Access Units).

Figure 1-7. Single Service Group Configuration

Page 31

Introduction

CMA-331-AEN

Page 31

1.6.2 Dual Service Group Example

In this example, two service groups are defined: A,B,C and C,D. Note that a service can be allocated to any of the service

groups at the same time. For example, service C is allocated to both service groups. Both service groups are routed to the OIU

for optic conversion. Each OIU module (OIM) can be configured to support either one or (if they do not have a common band) to

both service groups and the corresponding services are routed from the OIM to its hosted RAU units.

Note: In the example below, band C is common to both Service groups #1 and #2; therefore, an OIM cannot be assigned both

service groups (i.e. ABC + CD) .

Figure 1-8. Example of Dual Service Group Configuration

1.6.3 Tri Service Group Example

In this example, three service groups are defined: ABC, AB, CD. Note that a service can be allocated to any of the service

groups at the same time. For example, services C and B are allocated to two of the service groups. The services are routed to

the OIU for optic conversion. Each Optical Interface Module (OIM) can be configured to be included in either one, two or three

service groups in any combination and the corresponding services are routed from the OIM to its hosted RAU units.

Note: An OIM cannot support two service groups that have a common band (e.g. ABC and BC, or ABC and CD).

Figure 1-9. Example of Three Service Group Configuration

Page 32

Introduction

CMA-331-AEN

Page 32

1.6.4 Tri Service Group Example with Two HEUs

This tri-service group example supports two HEUs. In this topology, the services routed via the two HEUs can be grouped in any

combination between the two, providing up to three service groups. These groups of services are all routed towards a common

OIU. Each OIU module (OIM) can be configured to support any (legal) combination of service groups and the corresponding

services are routed from the OIM to its hosted RAU units.

Note: Multiple service groups allocated to the same OIM cannot share any identical frequency bands.

Figure 1-10. Example of Tri-Service Group Configuration with Two HEUs

1.6.5 Example of FMM-to-FRM Service Distribution

The example in Figure 1-11 illustrates the basic FMM-to-FRM connectivity for extending conditioned services from a main site

where the RF sources are deployed to remote sites at a distance of up to 12.4 miles (20 km). Three service groups can be

configured to transfer services over one FCM link.

On the downlink, RF signals are conditioned by the RIMs then converted by the FMM to an optical signal transporting it to the

remote FRM along with the 10 GbE transport.

At the remote site, the FRM converts the received optical signal to RF signals to feed different remote units with user-defined

service groups. The 10 GbE transport pipe will be forwarded to the Ethernet switches.

Figure 1-11. Example 1 of FMM-to-FRM Service Distribution

Page 33

Introduction

CMA-331-AEN

Page 33

The example in Figure 1-12 illustrates a differentiation of service groups. In addition to all of the configured service groups being

transmitted to all of the remote units at the main site, two of the service groups (2 and 3) are transported to the remote site and

then to different remote units.

Figure 1-12. Example 2 of FMM-to-FRM Service Distribution

Page 34

Page 35

Unit Desc riptions - RF Path

CMA-331-AEN

Page 35

2 Unit Descriptions - RF Path

This chapter provides detailed descriptions of the Corning® ONE™ wireless platform components. The descriptions are

organized according to RF and Digital path headend and remote end components. This includes port and LED interface

descriptions.

2.1 RF Path - Headend Components

Corning ONE wireless platform RF Path coverage solution includes the following headend elements:

• HEU – Headend Unit

• OIU – Optical Interface Unit

• IHU – Integrated Headend Unit (IHU performs both HEU and OIU functions)

Figure 2-1. RF Path with HEU and OIU Headend Components

Figure 2-2. RF Path with IHU Headend Component

Page 36

Unit Desc riptions - RF Path

CMA-331-AEN

Page 36

Module

Description

HCM

Headend control module -

ACM

2.1.1 HEU

The headend unit (HEU) performs the following main functions:

• Conditions (up to 12) RF sources to a level required for feeding to the optical interface unit (OIM).

• Enables the configuration of up to three sectors consisting of groups of RF services.

• Main HEU – includes HCM module enabling single source control and management of the Corning

platform RF path

• Auxiliary HEU – includes ACM modules and is managed via the HCM in the Main HEU

Note: Only one HEU per system can be installed with an HCM module and serves as the “Main HEU”. Any additional HEU

chassis are installed with ACM modules and are considered “Auxiliary HEUs”.

Each HEU supports up to 12 services. For additional services or density, two or more HEU units can be cascaded so that the

Auxiliary HEUs are managed from the Main HEU (via the HCM). For HEU installation procedure, see section

source not found..

®

ONE™ wireless

Error! Reference

Figure 2-3. Example of HEU with Installed Mod ules

HEU hosts the following modules:

HEU in which the HCM is installed serves as the main HEU. See section

Auxiliary control module - provides interfaces for management of domestic modules via HCM;

Installed in HEUs’ in configurations with more than one HEU. See section

RIM

Radio interface module – RF source conditioner; provides the service specific RF interface to

provides overall system management and control functions. The

2.1.1.1.

2.1.1.2.

Page 37

Unit Desc riptions - RF Path

CMA-331-AEN

Page 37

Module

Description

the RF source; Up to 12 RIMs can be hosted by the HEU; See section 2.1.1.3.

FRM

Fiber remote module - performs the optic-to-RF conversion of the cellular services at the

remote end of the FMM-to-FRM link (FCM solution); interfaces to FMM via SM fiber and

Ethernet fiber (for 10 GbE transport)

RIX RF expander module; RIM to OIX interface module; See section 2.1.1.5.

ETM

Expander termination module; For configurations with one RIX an ETM is required for

terminating the unused Expander slot. See section

2.1.1.6.

PSM Power supply modules:

PSM-AC:100 - 240 V AC

PSM-DC: 48 V DC

Note: If two are installed, both must be powered on. See section 2.1.1.7.

Table 2-1. HEU Modules

2.1.1.1 HCM

Overall system management and control capabilities are performed via the HCM, which is installed in an HEU or IHU chassis

(one HCM per system installation). The headend unit hosting the HCM module serves as the Main headend unit (any additional

HEU/IHU chassis is installed with an ACM).

The HCM directly interfaces to the corporate LAN and to up to four ACM modules installed in additional HEU/IHU/OIU chassis

(see section

2.1.2). The HCM includes Local and LAN management ports and LED status indicators.

Figure 2-4. HCM Module

Table 2-2 and Table 2-3 provide a description of the HCM ports and LED status indicators.

Page 38

Unit Desc riptions - RF Path

CMA-331-AEN

Page 38

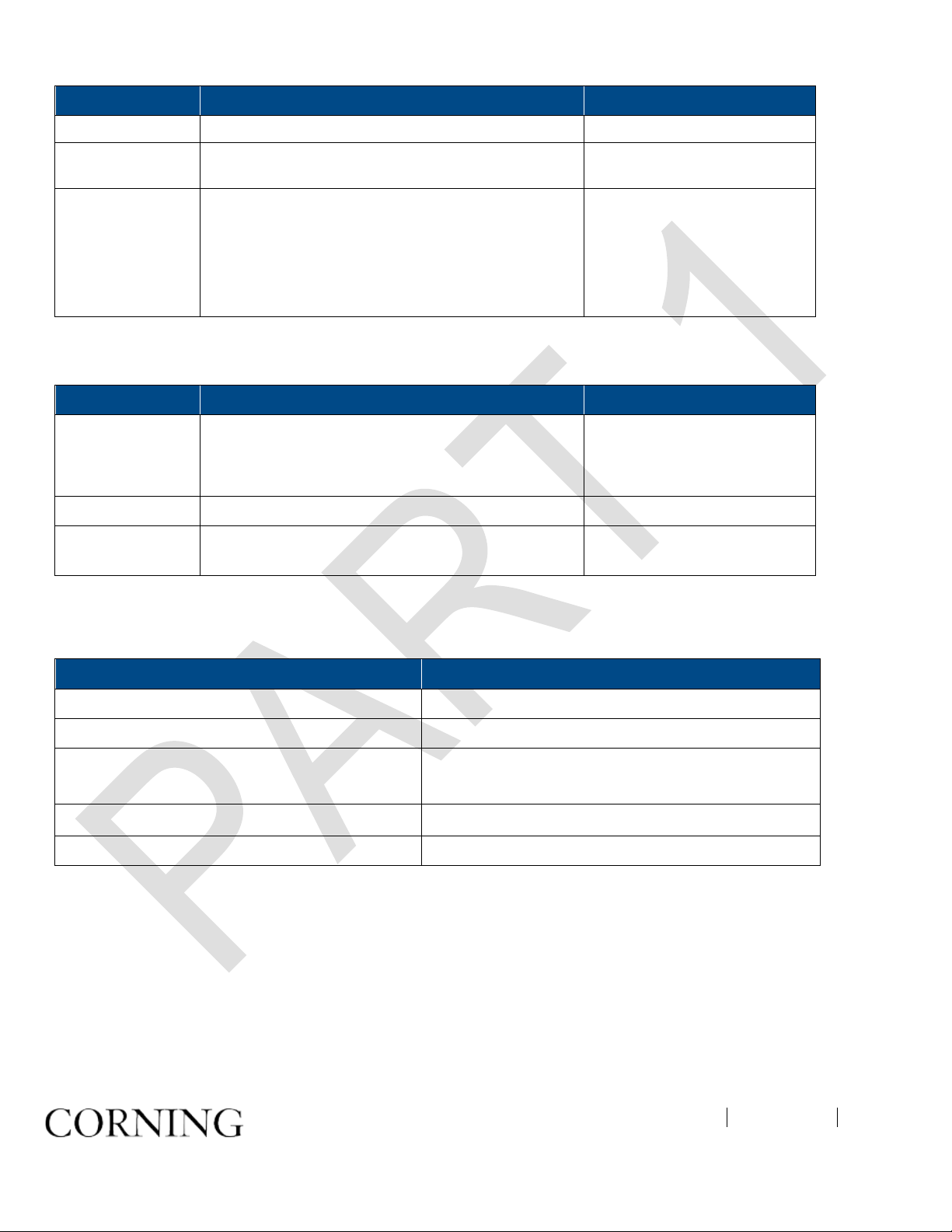

LED

Description

Blinking Green – HCM Boot up sequence complete and module SW up and running

(TO HCM)

Port Description

INTERNAL (TO ACM)

Four RJ45, 100Mb Ethernet ports - used for management of connected OIU systems

(and/or HEU Slaves).

LAN RJ-45, 1Gb Ethernet port - connects to the corporate LAN for remote management

LOCAL RJ-45, 1Gb Ethernet port - local configuration and management

CONSOLE RJ-45, serial port - local configuration for service personnel

SD Card Slot

Supports USD cards up to 32 GB (used for saving and importing configuration files

between different HEU chassis)

Table 2-2. HCM Ports

PWR

RUN

Steady Green - Power input detected by HCM

Off – No power is supplied to the unit

Off – No power supplied to the unit

SYS Steady Green – Overall status of the managed system is ok

FAN

Steady Green – Normal operation status for all fans

Red – Fault indicated in at least one fan

Table 2-3. HCM LED Description

2.1.1.2 ACM

The ACM is installed in any additional HEU/IHU* chassis in installations with more than one HEU/IHU (one HEU is installed with

the HCM).

The ACM provides the interfaces for remote management and control capabilities of the host chassis and connected modules

via a local connection to the HCM (see section

*Note: The ACM is also installed in each OIU chassis.

Figure 2-5. ACM Module

Table 2-4 and Table 2-5 provide a description of the ACM ports and LED status indicators.

Port Description

INTERNAL

Four RJ45, 100Mb Ethernet ports used for OIU and/or HEU slave management connections

Console One RJ45, serial port used for basic IP configuration and local connection for service

personnel

2.1.1.1).

Table 2-4. ACM Ports Description

Page 39

Unit Desc riptions - RF Path

CMA-331-AEN

Page 39

Red – Fault indicated in at least one fan

Port

Description

LED Description

PWR

RUN

Steady Green - Power input detected by ACM

Off – No power is supplied to the unit

Blinking Green – ACM Boot up sequence complete and module SW up and running

Off – No power supplied to the unit

SYS Steady Green – Overall status of the managed system is ok

FAN

Steady Green – Normal operation status for all fans

Table 2-5. ACM LED Indicators Description

2.1.1.3 RIM/RIM-M

The RIM/RIM-M module is a service specific RF conditioning module (up to 12 are installed in an HEU chassis) which interfaces

to the RF signal source. Each RIM supports both Simplex and Duplex RF connectors. LEDs provide status indications on signal

level and module operation.

Note: RIM-M modules support MIMO services (e.g.700 MHz LTE, AWS).

Figure 2-6. RIM Module

Table 2-6 and Table 2-7 provide a description of the RIM ports and LED status indicators.

DL/UL UL and DL simplex connections to the RF signal source

DUP Duplexed UL and DL connection to the RF signal source

Table 2-6. RIM Ports Description

Page 40

Unit Descript ions - RF Path

CMA-331-AEN

Page 40

LED

Description

Protect N/A

Provides indication on DL RF level in conditioner module:

DL High

Off - DL RF input level in threshold range

Steady Red – Signal is 3 dB above max. expected power

Provides indication on DL RF level in conditioner module:

DL Low

Off - DL RF input level in threshold range

Steady Red – No signal or 15 dB below max. expected power

Blinking Green - Power on and module SW has initialized and is up and

RUN

running

Off - No power

PWR On - Input power is within required range

Table 2-7. RIM LED Descriptions

2.1.1.4 FRM

The fiber remote module installed in a RIM slot of an HEU/IHU at the remote site and performs the optic-to-RF conversion of the

cellular services extended from the fiber main module (FMM) at the main site.

Figure 2-7.FRM

Page 41

Unit Desc riptions - RF Path

CMA-331-AEN

Page 41

Port

Description

LED

Description

Table 2-6 and Table 2-7 provide a description of the RIM ports and LED status indicators.

Optical Transport LC APC SM fiber connector for optical transport

10 GbE LC UPC fiber connector for 10 GbE connection

Table 2-8. FRM Ports Description

Optical Link Steady green - optical link power to/from the connected remote is normal

Off – no optical power from remote detected

SW Run Blinking green –FRM software has initialized and is up and running

Off – power off

PWR On - power input detected in FRM

Table 2-9. FRM LED Descriptions

2.1.1.5 RIX

The RIX Expander module provides the RF interface to the OIU unit. Up to two RIX Expander modules are installed in each

HEU chassis, providing support for up to four OIU (via OIU Expander modules - OIX).

IMPORTANT! An unoccupied Expander slot must be terminated with an (Expander Termination Module)

Note: The RIX and OIX Expander modules are similar in appearance but are NOT INTERCHANGEABLE. Each Expander

module is indicated as RIX or OIX on the bottom of the module.

Figure 2-8. RIX Expander Module Interfaces

Page 42

Unit Desc riptions - RF Path

CMA-331-AEN

Page 42

Port

Description

(TO OIX)

Two 9 – pin connectors which serve as the RF interfaces to the OIX (in the

OIU). RIX supports connections to two OIXs via an Expander cable (ERFC).

Two QMA connectors used for reference clock signal connections between

REF OUT/REF IN

RIX modules.

Note: The reference clock passes from the Main HEU to all Auxiliary chassis.

Table 2-10. RIX Ports Description

2.1.1.6 ETM

The ETM is required for HEU/OIU units in which only one corresponding RIX/OIX module is installed. The unoccupied RIX/OIX

slot must be terminated with an ETM.

Figure 2-9. Expander Termination Module

2.1.1.7 PSM

Two types of Power Supply Modules are available:

• PSM-AC: 100 – 240 VAC;

• PSM-DC: 48 V DC; 9 A Max.

Note: The power rating for both PSM types is 300 W

• Each headend unit chassis (i.e. HEU/OIU/IHU) can support two PSM modules, where the second PSM provides redundancy

in case one of the supplies fails.

• Both types of PSM modules (AC and DC) can be installed in the same chassis.

• If two modules are installed, both must be connected to their respective power source (AC or DC) and turned on at all times.

Page 43

Unit Desc riptions - RF Path

CMA-331-AEN

Page 43

PSM-AC

The PSM-AC includes an AC power connector, on/off switch and Power Status LED. See Figure 2-10.

Figure 2-10. PSM-AC Power Supply Module

PSM-DC

The PSM-DC power source rating is 48 V DC; 9 A Max.; 300 W. The PSM-DC includes a six pin terminal block connector,

supporting up to three DC wire pairs.

Figure 2-11. DC Power Supply Module

Page 44

Unit Desc riptions - RF Path

CMA-331-AEN

Page 44

Module

Description

ACM

2.1.2 OIU

The OIU interfaces to the HEU/IHU, performs the RF to optic conversion of the received signal and distributes the wireless RF

services to the RAU units over the fiber optic infrastructure to the remote site. Each OIU supports up to 12 SM optic fibers (one

fiber

Figure 2-12. OIU Front Panel with Installed Modules

OIU hosts the following modules:

Auxiliary control module - provides interfaces for management of domestic modules via HCM;

Installed in HEUs’ in configurations with more than one HEU. See section

2.1.1.2.

OIM Optical interface module; converts the RF to three Op t ic al links (see section 2.1.2.2)

FMM

Fiber main module; installed in an OIM slot at the main site; performs the RF-to-optic

conversion of the allocated service groups and transmits the cellular services along with 10

Gb Ethernet to the remote side where the FRM is installed.

OIX Optical interface expander; OIU to HEU interface module (see section 2.1.2.4).

Note: For configurations with one OIX an ETM (Expander termination module) is required for

ETM

terminating the unoccupied OIX slot. See section

Expander termination module; For configurations with one RIX an ETM is required for

terminating the unused Expander slot. See section

2.1.1.6.

2.1.1.6.

Page 45

Unit Desc riptions - RF Path

CMA-331-AEN

Page 45

Module

Description

Port

Description

LED

Description

PSM Power supply module:

PSM-AC:100 - 240 V AC

PSM-DC: 48 V DC

Note: If two are installed, both must be powered on. See section 2.1.1.7.

Table 2-11. HEU Modules

2.1.2.1 ACM

See section 2.1.1.2.

2.1.2.2 OIM

The OIM is a wideband RF to F/O (and vice-versa) media conversion module. Up to 12 OIM units can be installed in each OIU,

where each OIM can support up to three Remote Access Unit (RAU) connections.

Figure 2-13. Optical Interface Module

OPTICAL LINK

1:1 INTERFACE

Table 2-12. OIM Ports Description

Female MTP

®

Connector for optical interface connection; SMF

Six pin SMP jack connector for 1:1 direct signal transportation, three UL and

three for DL Enables (DL and UL) broad band connection to each optical link

Page 46

Unit Desc riptions - RF Path

CMA-331-AEN

Page 46

LED

Description

Port

Description

Link 1-3

RUN

Steady Green - optic al link power to/from the connected remote is normal

Off - no optical power from remote detected

Blinking Green – OIM module SW has initialized and is up and running

Off – Power off

PWR Steady Green – Input power detected in OIM

Table 2-13. OIM LED Descriptions

2.1.2.3 FMM

The fiber main module installed in a OIM slot of an OIU/IHU at the remote site and performs the RF-to-optic conversion of the

cellular services received from the BTS signal sources, extending them along with 10 Gb Ethernet to the FRM module at the

remote site.

Figure 2-14.FMM

Table 2-6 and Table 2-7 provide a description of the RIM ports and LED status indicators.

Optical Transport LC APC SM fiber connector for optical transport

10 GbE LC UPC fiber connector for 10 GbE connection

REF IN/OUT QMA ports for reference clock connections between FMMs

Table 2-14. FRM Ports Description

Page 47

Unit Desc riptions - RF Path

CMA-331-AEN

Page 47

LED

Description

Optical Link Steady green - optical link power to/from the connected remote is normal

Off – no optical power from remote detected

SW Run Blinking green – FMM software has initialized and is up and running

Off – power off

PWR On - power input detected in FRM

Table 2-15. FRM LED Descriptions

2.1.2.4 OIX

Each OIX Expander module provides the RF interface to up to two HEU units via two 9-pin connectors. Two OIX Expander

modules are installed in each OIU chassis. Up to four OIU units can be hosted by an HEU.

Note: The OIU Expander Modules are similar in appearance to the HEU Expander modules but are NOT interchangeable. Each

Expander module is indicated as RIX or OIX on the bottom of the module.

Figure 2-15. OIX Expander Module Interfaces

Page 48

Unit Desc riptions - RF Path

CMA-331-AEN

Page 48

Module

Description

HCM

ACM

RIM

OIM

FMM

2.1.3 IHU

The IHU combines both HEU and OIU functionality in a single compact chassis. The IHU interfaces to the RF sources (via RIM

modules), conditions the signals, performs the RF to optic conversion of the received signal and distributes the wireless RF

services to the RAU units over the fiber optic infrastructure to the remote site.

Figure 2-16. IHU Front Panel with Installed Modules

Note: The IHU also includes a pre-assembled Cable management Tray with routed ERFC cable (shown in inset) used for

connecting the RIX and OIX modules.

IHU hosts the following modules:

Headend Control Module; overall system management module (see section 2.1.1.1)

Auxiliary control module - provides interfaces for management of domestic modules via HCM;

Installed in HEUs’ in configurations with more than one HEU. See section

2.1.1.2.

Radio interface module - RF source conditioner; provides the service specific RF interface to

the RF source (see Section

2.1.1.3); Up to four RIMs are supported in slots 2-5 (marked in

red); Up to four additional RIMs are supported in “Dual” slots 6 – 9 (marked in white);

Optical interface module - converts the RF to three O p t ic al li n ks (see section 2.1.2.2). Up to

four OIMs are supported in slots 10 – 13 (marked in blue); Up to four additional OIMs are

supported in “DUAL”’ slots 6 – 9 (marked in white)

Fiber main module - installed in an OIM slot at the main site; performs the RF-to-optic

conversion of the allocated service groups and transmits the cellular services along with 10

Gb Ethernet to the remote side where the FRM is installed. See Section

2.1.2.3. Up to four