Page 1

Corning Optical Network Evolution (ONE™)

User Manual

Page 2

About This Manual

This user guide provides all the information necessary to understand the architecture and general installation procedures and

requirements of Corning optical network evolution (ONE™) solutions system elements.

Note: The commi ssioning procedure, monitoring and management capabilities and configuration options of the Corning optical

network evolution (ONE) solutions elements are described in the HCM and web management user manual (MRU is included in

v1.6 and higher).

Warranties

Hardware

Corning Optical Communications Wireless, Inc. (“Corning”) warrants to the original purchaser (“Customer”) that for the duration

of the warranty period, one (1) year, commencing on the date of shipment of the Hardware, unless otherwise agree d in writin g

by Corning (the “Hardware Warranty Period”), the Hardware furnished by Corning shall be free in all material respects from

defects in material and workmanship, and shall conform to the applicable portions of the Specifications, as defined below (the

“Hardware Warranty”).

If notified by Customer of any such defects in material or workmanship or nonconformity with applicable portions of the

Specifications within the Hardware Warranty Period, Corning shall promptly, at its own election and expense, repair or replace

any such Hardware proven to be defective under the terms of this Hardware Warranty.

Such repair or replacement shall be Customer’s sole remedy and Corning sole obligation in the event this Hardware Warranty is

invoked. If any components comprising a part of the Hardware are replaced or repaired during the Hardw are Warranty Period,

the Hardware Warranty Period for such repaired or replaced components shall extend to the longer of (i) the balance of the

Hardware Warranty Period or (ii) three (3) months from the date of repair or replacement. For purposes of this Warranty,

“Specifications” shall mean the specifications and performance standards of the Products as set forth in documents published

by Corning and delivered to Customer which contain technical specifications or performance standards for the Products.

If Customer invokes this Hardware Warranty, it shall notify Corning promptly of the claimed defect.

Customer will allow Corning to inspect the Hardware at Customer’s location, or to return the Hardware to Corning closest repair

facility. For Hardware returned to Corning repair facility, Customer shall be responsible for payment of all transportation and

freight costs (including insurance) to Corning’ repair facility, and Corning shall be responsible for all transportation and freight

costs (including insurance) incurred in connection with the shipment of such Hardware to other repair facilities of Corning and/or

its return to Customer.

Notwithstanding the foregoing, in no event will Corning be liable for damage to Products resulting from improper handling during

or after shipment, misuse, neglect, improper installation, operation or repair (other than by authorized Corning personnel),

alteration, accident, or for any other cause not attributable to defects in materials or workmanship on the part of Corning.

Corning shall not reimburse or make any allowance to Customer for any labor charges incurred by Customer for replacement or

repair of any goods unless such charges are authorized in advance in writing by Corning.

Software Wa rranty

Corning warrants to the original purchaser (“Customer”) that for the duration of the warranty period, one (1) year, commencing

on the date of shipment of the Software, unless otherwise agreed in writing by Corning (the “Software Warranty Period”), the

Software shall conform with, and perform the functions set forth in the Specifications, and shall be free from defects in material

or workmanship (the “Software Warranty”). In the event the Software is proven to be defective under the terms of this Software

Warranty, Corning shall correct such defects or failure and ensure that the Software conforms with, and performs the functions

set forth in, the Specifications. Customer will allow Corning to inspect the Software at Customer’s location or to return it to

Corning’s’ closest repair facility.

Notwithstanding the foregoing, Corning shall have no obligation under the Software Warranty if the Software is modified or used

with hardware or software not supplied or approved by Corning or if the software is subject to abuse, improper installation or

application, accident, electrical or environmental over-stress, negligence in use, storage, transportation or handling.

Third-party software distributed with the Software may carry certain warranties which, to the maximum extent allowed by law,

Corning hereby assigns, transfers and otherwise conveys to Customer, provided, however, that Corning itself provides no

warranty of any kind, express, implied, statutory or otherwise, for any third-party software pr o vided her eu nder .

Corning does not warrant any hardware, software or services not provided by Corning.

THIS WARRANTY IS THE ONLY WARRANTY MADE BY CORNING AND IS IN LIEU OF ALL OTHER WARRANTIES,

EXPRESS OR IMPLIED INCLUDING, BUT NOT LIMITED TO, THE IMPLIED WARRANTIES OF MERCHANTABILITY AND

Corning Optical Communications DRAFT User Man ual I CMA-XXX-AEN I Page 2

Page 3

FITNESS FOR A PARTICULAR PURPOSE. CORNING SHALL NOT BE LIABLE FOR ANY OTHER DAMAGE INCLUDING,

BUT NOT LIMITED TO, INDIRECT, SPECIAL OR CONSEQUENTIAL DAMAGES ARISING OUT OF OR

IN CONNECTION WITH FURNISHING OF GOODS, PARTS AND SERVICE HEREUNDER, OR THE PERFORMANCE, USE

OF, OR INABILITY TO USE THE GOODS, PARTS AND SERVICE.

CORNING SALES AGENTS OR REPRESENTATIVES ARE NOT AUTHORIZED TO MAKE COMMITMENTS ON

WARRANTY RETURNS.

Returns

In the event that it is necessary to return any product against above warranty, the following procedure shall be followed:

1. Return authorization is to be received from Corning prior to returning any unit. Advise Corning of the model, Serial number,

and discrepancy. The unit may then be forwarded to Corning, transportation prepaid. Devices returned collect or without

authorization may not be accepted.

2. Prior to repair, Corning will advise the customer of our test results and any charges for repairing customer-caused problems

or out-of-warranty conditions etc.

3. Repaired products are warranted for the balance of the original warranty period, or at least 90 days from date of shipment.

Limitations of Liabilities

Corning’s liability on any claim, of any kind, including negligence for any loss or damage arising from, connected with, or

resulting from the purchase order, contract, quotation, or from the performance or breach thereof, or from the design,

manufacture, sale, delivery, installation, inspection, operation or use of any equipment covered by or furnished under this

contact, shall in no case exceed the purchase price of the device which gives rise to the claim.

Except as expressly provided herein, Corning makes no warranty, expressed or implied, with respect to any goods, parts and

services provided in connection with this agreement including, but not limited to, the implied warranties of merchantability and

fitness for a particular purpose. Corning shall not be liable for any other damage including, but not limited to, indirect, special or

consequential damages arising out of or in connection with furnishing of goods, parts and service hereunder, or the

performance, use of, or inability to use the goods, parts and service.

Reporting Defect s

The units were inspected before shipment and found to be free of mechanical and electrical defects. Examine the units for any

damage that may have been caused in transit. If damage is discovered, file a claim with the freight carrier immediately. Notify

Corning as soon as possible in writing.

Note: Keep all packing material until you have completed the inspection.

Warnings and Admoni s hm en ts

There may be situations, particularly for workplace environments near high-powered RF sources, where recommended limits

for safe exposure of human beings to RF energy could be exceeded. In such cases, restrictive measures or actions may be

necessary to ensure the safe use of RF energy.

The equipment has been designed and constructed to prevent, as far as reasonably, practicable danger. Any work activity on or

near equipment involving installation, operation or maintenance must be, as far as reasonably, free from danger.

Where there is a risk of damage to electrical sy stems involving adverse weather, extreme temperatures, wet, corrosive or dirty

conditions, flammable or explosive atmospheres, the system must be suitably installed to prevent danger.

Equipment provided for the purpose of protecting individuals from electrical risk must be suitable for the purpose and properly

maintained and used. This covers a range of activities including lifting, lowering, pushing, pulling, carrying, moving, holding or

restraining an object, animal or person from the equipment. It also covers activities that require the use of force or effort, such as

pulling a lever, or operating power tools.

Where some of the above mentioned activities are required, the equipment must be handled with care to avoid being damaged.

Observe standard precautions for handling ESD-sensitive devices. Assume that all solid-state electronic devices are

ESD-sensitive. Ensure the use of a grounded wrist strap or equivalent while working with ESD-sensitive devices. Transport,

store, and handle ESD-sensitive devices in static-safe environments.

Corning Optical Communications DRAFT User Man ual I CMA-XXX-AEN I Page 3

Page 4

Regulatory Compliance Information

WARNING!

• This is NOT a CONSUMER device. It is designed for installation by FCC LICENCEES and QUALIFIED INSTALLERS. You

MUST have an FCC LICENSE or express consent of an FCC Licensee to operate this device. Unauthorized use may result

in significant forfeiture penalties, including penalties in excess of $100,000 for each continuing violation.

• ANTENNAS: Use only authorized and approved antennas, cables and/or coupling devices! The use of unapproved

antennas, cables or coupling devices could cause damage and may be of violation of FCC regulations. The use of

unapproved antennas, cables and/or coupling devices is illegal under FCC regulations and may subject the user to fines.

RF Safety

To comply with FCC RF exposure compliance requirement, adhere to the following warnings:

ATTENTION!

Compliance with RF safety requirements:

• Corning products have no inherent significant RF radiation

• The RF level on the downlink is very low at the downlink ports. Therefore, there is no dangerous RF radiation when the

antenna is not connected.

CAUTION!

Use of controls, adjustments or performance of procedures other than those specified herein may result in hazardous radiation

exposure.

NOTICE: The 2.5 GHz input connector port is currently not operational and is not to be used. It is intended for future

applications.

Laser Safety

• Fiber optic ports of the Corning optical network evolution (ONE™) solutions emit invisible laser radiation at the 1310/1550

nm wavelength window.

• External optical power is less than 10 mW, Internal optical power is less than 500 mW.

• To avoid eye injury never look directly into the optical ports, patchcords or optical cables. Do not stare into beam or view

directly with optical instruments. Always assume that optical outputs are on.

• Only technicians familiar with fiber optic safety practices and procedures should perform optical fiber connections and

disconnections of the devices and the associated cables.

• Corning

IEC/EN 60825-1 (2007). It also meets the requirements for a Hazard Level 1 laser product to IEC/EN 60825-2: 2004 to the

same degree.

• Corning

pursuant to Laser Notice NO. 50 (2007).

optical network evolution (ONE) solution components have been tested and certified as a Class 1 Laser product to

optical network evolution (ONE) solutions complies with 21 CFR 1040.10 and 1040.11 except for deviations

Care of Fiber Optic Connectors

• Do not remove the protective covers on the fiber optic connectors until a connection is ready to be made. Do not leave

connectors uncovered when not connected.

• The tip of the fiber optic connector should not come into contact with any object or dust.

Corning Optical Communications DRAFT User Man ual I CMA-XXX-AEN I Page 4

Page 5

Licensee Contact Information

Document Name

CMA Lit Code

Headend control module (HCM) and web management GUI

user manual

-

Industrial Boosters may only be used by FCC licensees or those given express (individualized) consent of license. Corning

optical communications wireless certifies all of the VARs listed as licensed installers for Corning. For the list of licensed VARs,

please contact the Tech Support Hotline: (US) 410-553-2086 or 800-787-1266.

About This Manual

This user guide provides all the information necessary to understand the architecture and general installation procedures and

requirements of Corning

Note: The commissioning procedure, monitoring and management capabilities and configuration options of the Corning optical

network evolution (ONE) solution elements are described in the HCM and web management user manual.

optical network evolution (ONE™) solutions headend and intermediate elements.

Additional Relevant Documents

The following documents are required if the corresponding units are included in your system (these can be downloaded from the

Corning partner portal).

Campus connectivity fiber connectivity modules (FCM)

Datasheet

Mid-Power Remote Unit (MRU) datasheet CMA-422-AEN

Mid-Power Remote Unit (MRU) user manual CMA-438-AEN

Five band remote access unit (RAU5) datasheet CMA-377-AEN

Five band remote access unit with AWS3 (RAU5x) datasheet CMA-487-AEN

Five band remote access unit (RAU5/RAU5x) user manual CMA-482-AEN

CMA-421-AEN

Corning Optical Communications DRAFT User Man ual I CMA-XXX-AEN I Page 5

Page 6

Page 7

Table of Contents

1 Introduction ................................................................................................................................................. 11

1.1 About Corning Optical Network Evolution (ONE™) Solutions ..................................................................... 11

1.2 Key Features and Capabilities .................................................................................................................... 11

1.3 Basic System Architecture .......................................................................................................................... 12

1.4 User Controlled Service Group Distribution ................................................................................................. 13

1.4.1 Service Distribution via One Service Group ..................................................................................... 14

1.4.2 Service Distribution via Two Service Groups ................................................................................... 15

1.4.3 Service Distribution via Three Service Groups ................................................................................. 16

1.4.4 Service Distribution via Three Service Groups with Two IHUs ......................................................... 16

1.5 Web Management Application .................................................................................................................... 17

2 Unit Descriptions ......................................................................................................................................... 18

2.1 Integrated Headend Unit (IHU) Description ................................................................................................. 18

2.1.1 Control Module ................................................................................................................................ 19

2.1.1.1 Headend Control Module (HCM) ............................................................................................... 19

2.1.1.2 Auxiliary Control Module (ACM) ................................................................................................ 20

2.1.2 Radio Interface Module (RIM) .......................................................................................................... 21

2.1.3 Radio Expander (RIX) Module ......................................................................................................... 22

2.1.4 Optical Interface Module (OIM) ........................................................................................................ 23

2.1.5 Optical Expander Module (OIX) ....................................................................................................... 23

2.1.6 Power Supply Module (PSM) ........................................................................................................... 24

2.2 24

2.3 Six Mo d u le DC Power Supply Unit (PSU6) Description ............................................................................... 24

2.4 Mid-Power Remote Unit (MRU) ................................................................................................................... 26

3 Installation Guidelines ................................................................................................................................. 29

3.1 General System Specifications and Requirements ...................................................................................... 29

3.1.1 Environmental and Regulatory Specifications .................................................................................. 29

3.1.1.1 Temperature and Humidity ....................................................................................................... 29

3.1.1.2 Safety and Regulatory Approvals .............................................................................................. 29

3.1.2 Power and Heat Specifications Summary ........................................................................................ 30

3.1.3 Dimensions, Weight and Rack Specifications of Units ..................................................................... 30

Corning Optical Communications User Man ual I CMA-XXX-AEN I Page 7

Page 8

3.2 Infrastructure Preparation ........................................................................................................................... 30

3.2.1 Site Considerations ......................................................................................................................... 30

3.2.2 Installation Location Requirements .................................................................................................. 31

3.2.3 Safety Guidelines ............................................................................................................................ 31

3.2.4 Rack Safety and Installation Guidelines ........................................................................................... 31

3.2.4.1 Rack Safety Instructions ........................................................................................................... 31

3.2.4.2 Rack Installation Guidelines ...................................................................................................... 31

3.2.5 Power Safety and Power Requirements .......................................................................................... 31

3.2.5.1 Power Safety Instructions ......................................................................................................... 31

3.2.5.2 Types of Power Supplies .......................................................................................................... 32

3.2.5.3 Circuit Breakers ........................................................................................................................ 32

3.2.6 RF Coaxial Cable Guidelines ........................................................................................................... 33

3.2.6.1 Considerations for Cable Type and Installation Procedure Guidelines ...................................... 33

3.2.6.2 RF Rules .................................................................................................................................. 33

3.2.7 Fiber Optic Requirements ................................................................................................................ 33

3.2.7.1 Authorized Optic Cables ........................................................................................................... 33

3.2.7.2 Fiber Optic Rules ...................................................................................................................... 33

3.3 Antenna Specifications and Guidelines ....................................................................................................... 34

3.3.1 Authorized Antennas and Required Specifications .......................................................................... 34

4 IHU Installation ........................................................................................................................................... 35

4.1 General Installation Information .................................................................................................................. 35

4.2 IHU Installatio n ........................................................................................................................................... 36

4.2.1 Unpacking and Inspection ............................................................................................................... 36

4.2.2 (IHU Only) Assembling Cable Management Tray and RF Expander Connection ............................. 38

4.2.3 Assembling the Cable Management Tray to the Chassis ................................................................. 38

4.2.4 Assembling the Door Sleeve ........................................................................................................... 40

4.2.5 Mounting Chassis in 19-IN Rack ...................................................................................................... 41

4.2.6 Installing Modules ............................................................................................................................ 43

4.2.6.1 Module Locations in Chassis .................................................................................................... 43

4.2.6.2 Installing the Chassis Modules .................................................................................................. 44

Corning Optical Communications DRAFT User Manual I CMA-XXX-AEN I Page 8

Page 9

4.3 Grounding Chassis ..................................................................................................................................... 44

4.4 RF Connections .......................................................................................................................................... 44

4.4.1 RIM Connections to RF Source ....................................................................................................... 44

4.4.2 RF Expander Connections ............................................................................................................... 46

4.4.3 Pilot Clock Connections ................................................................................................................... 47

4.5 IHU Fiber Connections ................................................................................................................................ 47

4.6 Management Connections .......................................................................................................................... 48

4.7 Power Connections and Power Up ............................................................................................................. 48

4.7.1 AC Power Connection (PSM-AC) .................................................................................................... 48

4.7.2 DC Power Connection (PSM-DC) .................................................................................................... 49

4.8 Verifying Normal Operation ......................................................................................................................... 50

5 PSU6 Installation ........................................................................................................................................ 52

5.1 PSU6 Installation ........................................................................................................................................ 52

5.1.1 Items Required for PSU6 Installation ............................................................................................... 52

5.1.2 Installing the Power Supply Module ................................................................................................. 53

5.1.3 Mounting PSU6 ............................................................................................................................... 54

5.1.3.1 Rackmount ............................................................................................................................... 54

5.1.3.2 Wall Mount................................................................................................................................ 54

5.1.4 Grounding........................................................................................................................................ 55

5.1.5 DC Wiring Connections ................................................................................................................... 56

5.1.6 Power-up ......................................................................................................................................... 56

6 MRU Installation ......................................................................................................................................... 58

6.1 MRU Indoor Installation............................................................................................................................... 58

6.1.1 Unpacking and Inspection ............................................................................................................... 58

6.1.2 Mounting the MRU ........................................................................................................................... 59

6.1.2.1 Rack Installation ....................................................................................................................... 59

6.1.2.2 Wall Mount Installation .............................................................................................................. 60

6.1.3 Grounding MRU Chassis ................................................................................................................. 64

6.1.4 Fiber Connections ........................................................................................................................... 65

6.1.5 RF Antenna Connections ................................................................................................................. 65

6.1.6 Power Connections ......................................................................................................................... 66

Corning Optical Communications DRAFT User Manual I CMA-XXX-AEN I Page 9

Page 10

6.1.6.1 AC Models ................................................................................................................................ 66

6.1.6.2 DC Models ................................................................................................................................ 67

6.1.7 Verifying Normal Operation ............................................................................................................. 71

6.2 MRU Installation with Outdoor Enclosure .................................................................................................... 71

6.2.1 Items Required for Outdoor Installation ........................................................................................... 71

6.2.2 Pre-Installation Procedures ............................................................................................................. 72

6.2.3 MRU Installation in Cabinet ............................................................................................................. 74

6.2.4 MRU Connections ........................................................................................................................... 76

6.2.5 External Alarm Connections ............................................................................................................ 78

7 Appendix A: Specifications .......................................................................................................................... 81

7.1 Supported Services ..................................................................................................................................... 81

7.2 MRU Coupling Specifications ...................................................................................................................... 81

7.3 Optical ........................................................................................................................................................ 81

7.4 Power Specifications ................................................................................................................................... 82

7.4.1 IHU .................................................................................................................................................. 82

7.4.1.1 PSM-AC ................................................................................................................................... 82

7.4.1.2 PSM-DC ................................................................................................................................... 82

7.4.2 MRU Power ..................................................................................................................................... 82

7.5 Physical Specifications................................................................................................................................ 83

7.6 Environmental ............................................................................................................................................. 83

7.7 Standards and Approvals ............................................................................................................................ 83

7.8 PSU6 Specifications ................................................................................................................................... 84

7.9 Optical: Cabling, Unit/Modules Specifications ............................................................................................. 86

Cabling ....................................................................................................................................................... 86

Fiber Management ...................................................................................................................................... 86

8 Appendix B: Ordering Information ............................................................................................................... 87

8.1 IHU Assemblies, Modules, and Accessories ............................................................................................... 87

8.2 PSU6 .......................................................................................................................................................... 88

8.3 Cable Ordering Information ......................................................................................................................... 89

Cable Configurations .................................................................................................................................. 89

Corning Optical Communications DRAFT User Manu al I C MA-XXX-A EN I Pag e 10

Page 11

1 INTRODUCTION

1.1 About Corning Optical Network Evolution (ONE™) Solutions

Corning optical network evolution (ONE™) provides an all optical converged solution which provides a flexible in-building cellular

and network data coverage solution based on a fiber optic transport backbone. Fiber-to-the edge technology allows for virtually

unlimited bandwidth to support today and tomorrow’s growing demands of wireless users.

The fiber optic infrastructure is easily deployable via a wide range of preterminated composite cables and advanced end-to-end

equipment. Easy to design, Plug & Play

Dynamic service distribution group management allows precise service distribution control to meet changing density needs,

and provides further savings by enabling sharing of equipment at various levels for service providers (detailed in Section 1.4).

The solution utilizes single-mode (SM) fiber to extend up to three user configured service groups from the main headend to the

remote sites.

™

connectors significantly reduce installation cost and deployment time.

1.2 Key Features and Capabilities

• Comprehensive service support - SISO/MIMO services

• Supported services –LTE 2600 MHz, GSM, 800L, DCS and UMTS

• Flexible, configurable service distribution - advanced capacity and coverage management for better macro offload and

enhanced user experience.

• Broadband enabled:

− A range of ready-made fiber-optic (and power) composite cables simplify installation at all levels

− Fiber backbone unleashes unlimited RF Spectrum

− Easily scales to higher speeds requirements

• Scalable and customizable - infrastructure can be quickly expanded to support more services or increase coverage without

downtime

• Carrier-grade network management:

− Single-source, remote end-to-end field upgradable platform

− Ready for SON, HetNet and future network requirements.

• Management and control – alarm forward to NOC or standard element management system (EMS) via SNMP,

software-controlled outp ut po wer and opt ical li nk auto gain contr o l.

• Mid-power remote unit (MRU) provides the following:

− Multioperator-optimized platform - services from a number of operators can be distributed by the same remote unit.

− Cost effective higher power – optimizes and reduces the number of antennas required to cover open areas by offering

up to 33 dBm (2 W) composite power per frequency band.

− Operator grade performance – advanced signal handling, RF filtering and management ensures operator grade

performance.

− Optic fiber savings - all services routed to an MRU unit are routed over a single optic fiber pair

− Design and deployment flexibility – MRU remote unit available in AC or DC power supply options. Antenna splitting

schemes are possible due to the higher power output capability.

− Modular and Scalable Design – modular design enables adding new wireless services easily and cost-effectively without

disruption to workspaces or existing services. Supports external 2.5 GHz RF source.

− Simple installation and maintenance – all connections and status LEDs located on the front panel. MRU is modular, hot

swappable and field upgradable.

Corning Optical Communications DRAFT User Manual I CMA-XXX-AEN I Pag e 11

Page 12

Acronyms

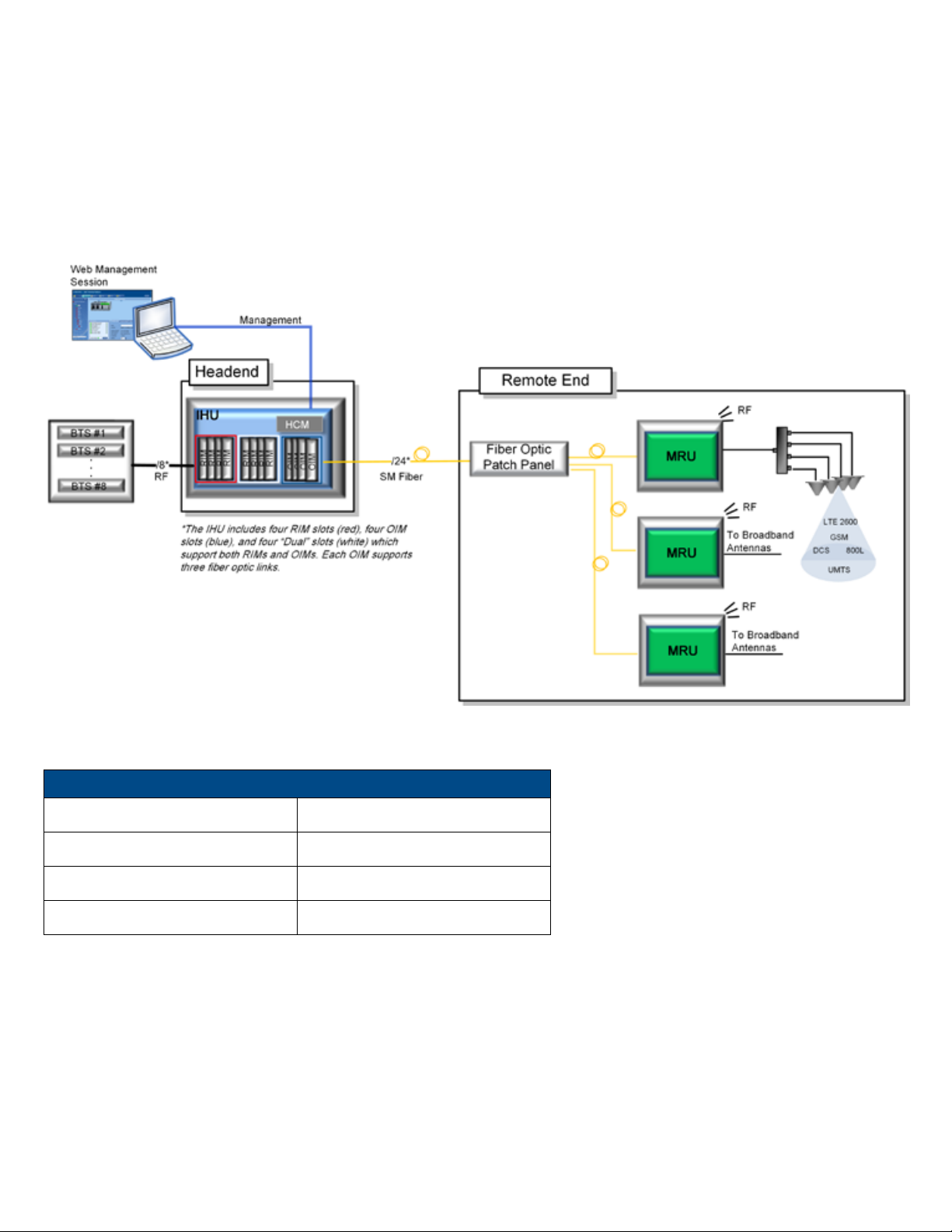

1.3 Basic System Architecture

Broadband RF distribution over fiber-optics infrastructure transfers converged wireless services from the IHU at the headend

towards the MRUs deployed at the remote-end locations according to user defined configuration. The IHU is a compact unit

designed to accommodate small/medium size deployments. The IHU interfaces up to eight RF sources, conditions the signals

and performs the RF to optic conversion of the signals which are then routed towards the MRU at the remote site over

single-mode fiber. Configuration and management of the system elements (i.e. IHU, and MRU) are performed via local/remote

connection to the headend control module installed in the IHU.

Figure 1-1. Corning

Optical Network Evolution (ONE™) Solutions Bas ic Arc hitec t ure

BTS = base station OIM = optic interface module

HCM = headend control module RIM = radio interface module

IHU = integrated headend unit SM = single mode

MRU = mid-power remote unit

Table 1-1. Acronyms in System Architecture

Corning Optical Communications DRAFT User Manual I CMA-XXX-AEN I Pag e 12

Page 13

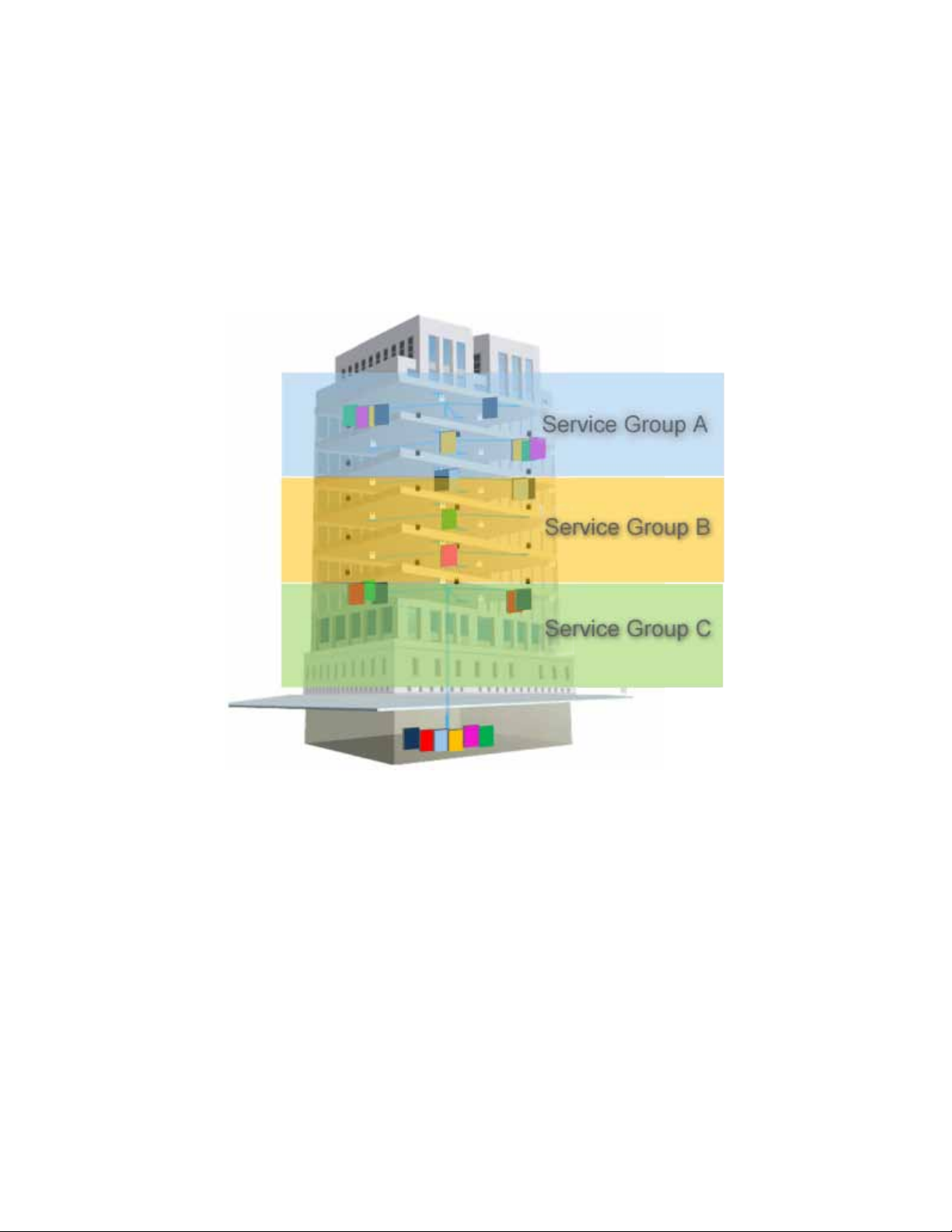

1.4 User Controlled Service Group Distribution

Corning optical network evolution (ONE™) solutions fiber-optics infrastructure allows various combinations of wireless services

to be routed from the headend to specified remote locations on each floor, according to user defined configurations. This allows

optimizing service coverage and provides equipment savings. While the fiber-optics infrastructure is common, the services can

be routed via service provider shared or dedicated equipment. By default, the system is configured to support a single service

group: all services are transferred to all remote locations. This default configuration can be easily modified according to site

requirements.

Figure 1-2 illustrates service distribution from the head-end to various locations on each remote floor. Each color represents a

specific service, where different combinations of services are distributed at various locations on the same floor according to

coverage requirements.

Figure 1-2. Illustration of Service Group Distribution

Corning Optical Communications DRAFT User Manual I CMA-XXX-AEN I Pag e 13

Page 14

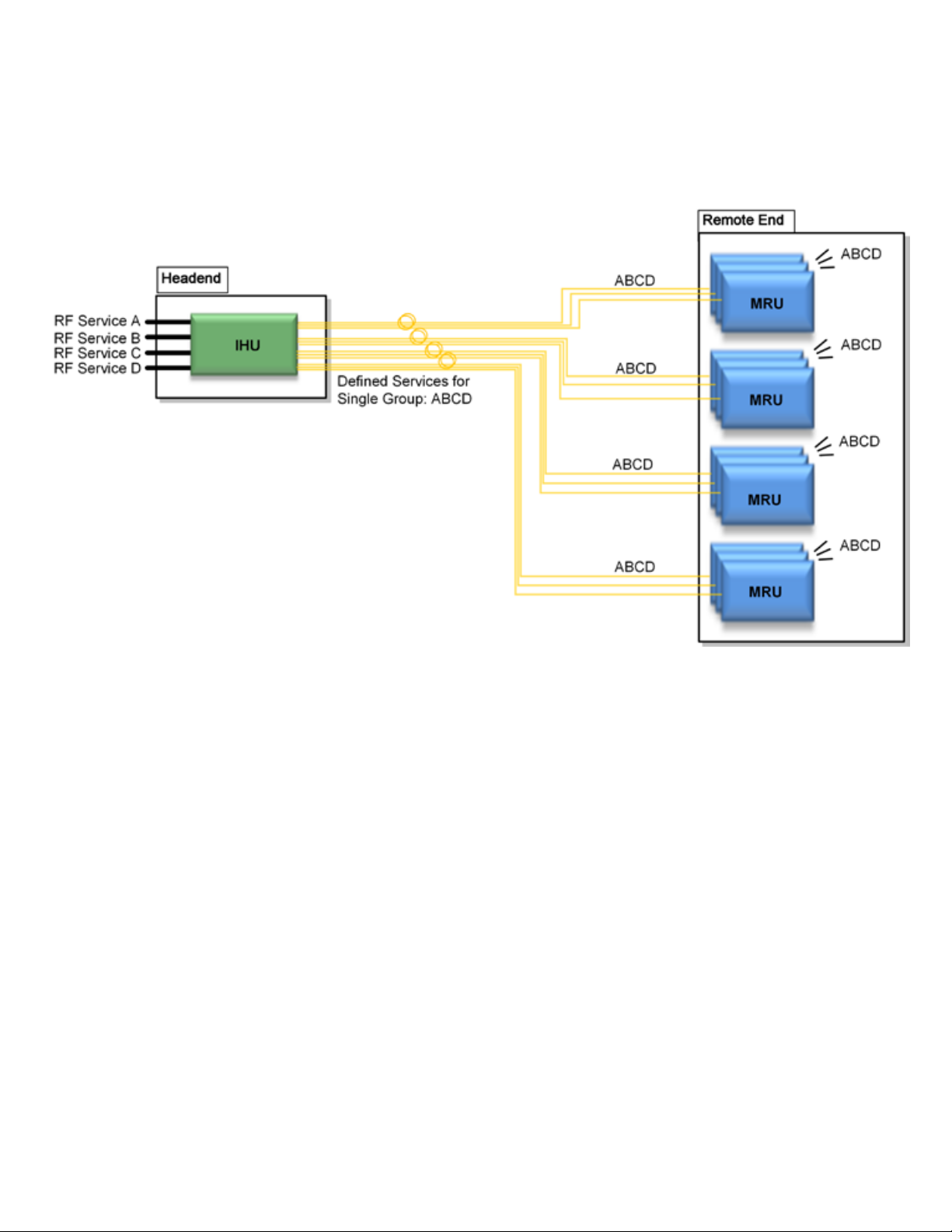

1.4.1 Service Distribution via One Service Group

In this example, all four services (A, B, C, and D) are routed to all remote units. In the illustrated topology, a single IHU

conditions the services and performs the RF-to-optic conversion after which all the configured services are routed to the remote

units for distribution over broadband antennas. Each IHU can support up to 24 remote-end units.

Figure 1-3. Distribution of a Single Service Group

Corning Optical Communications DRAFT User Manual I CMA-XXX-AEN I Pag e 14

Page 15

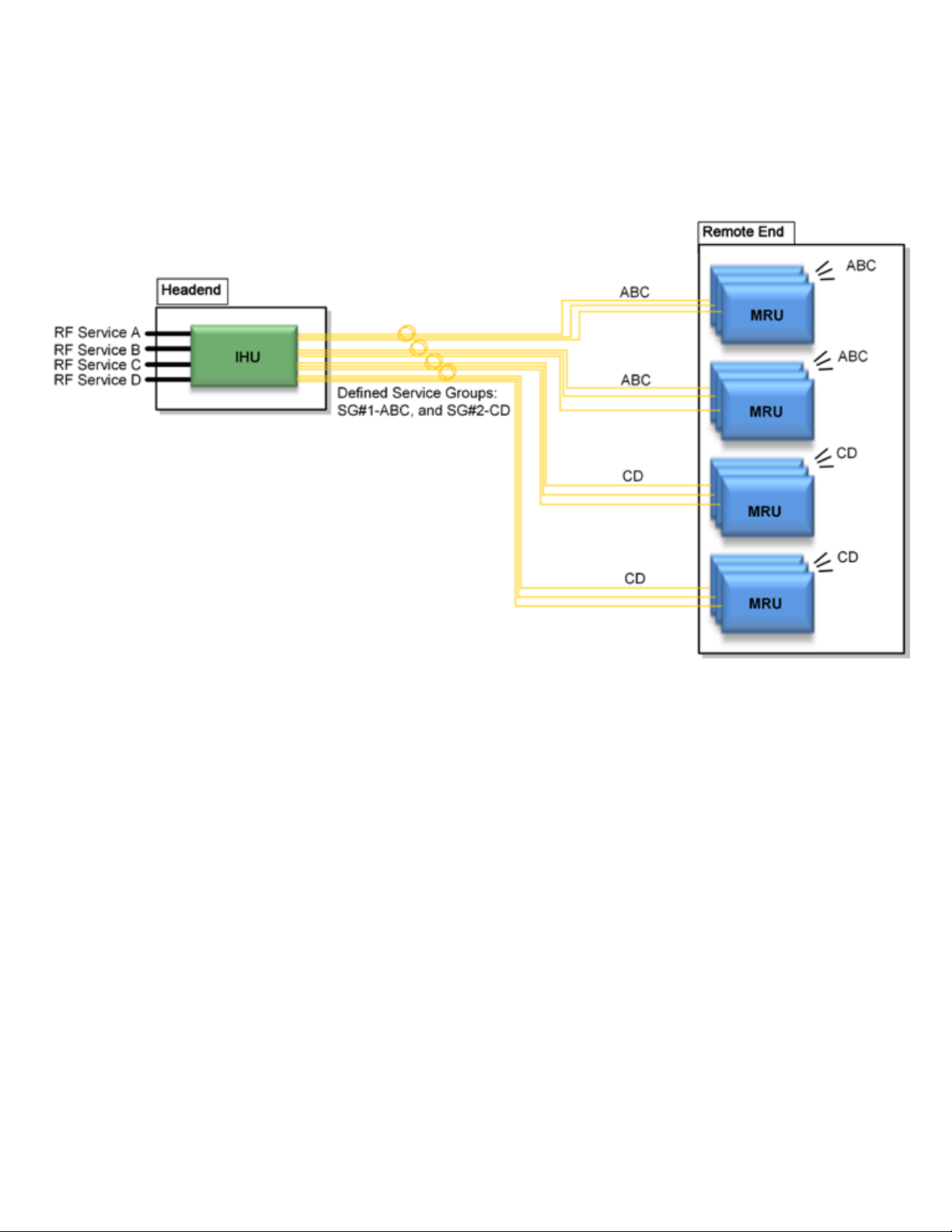

1.4.2 Service Distribution via Two Service Groups

In this example, two service groups are defined: SG#1: A,B,C and SG#2: C,D. When configuring a service group, the user

selects which services (according to RIMs) will be routed to which OIMs and then transferred over their optic links to their hosted

remote units for distribution.

Figure 1-4. Example of Distribution of Two Service Groups

Corning Optical Communications DRAFT User Manual I CMA-XXX-AEN I Pag e 15

Page 16

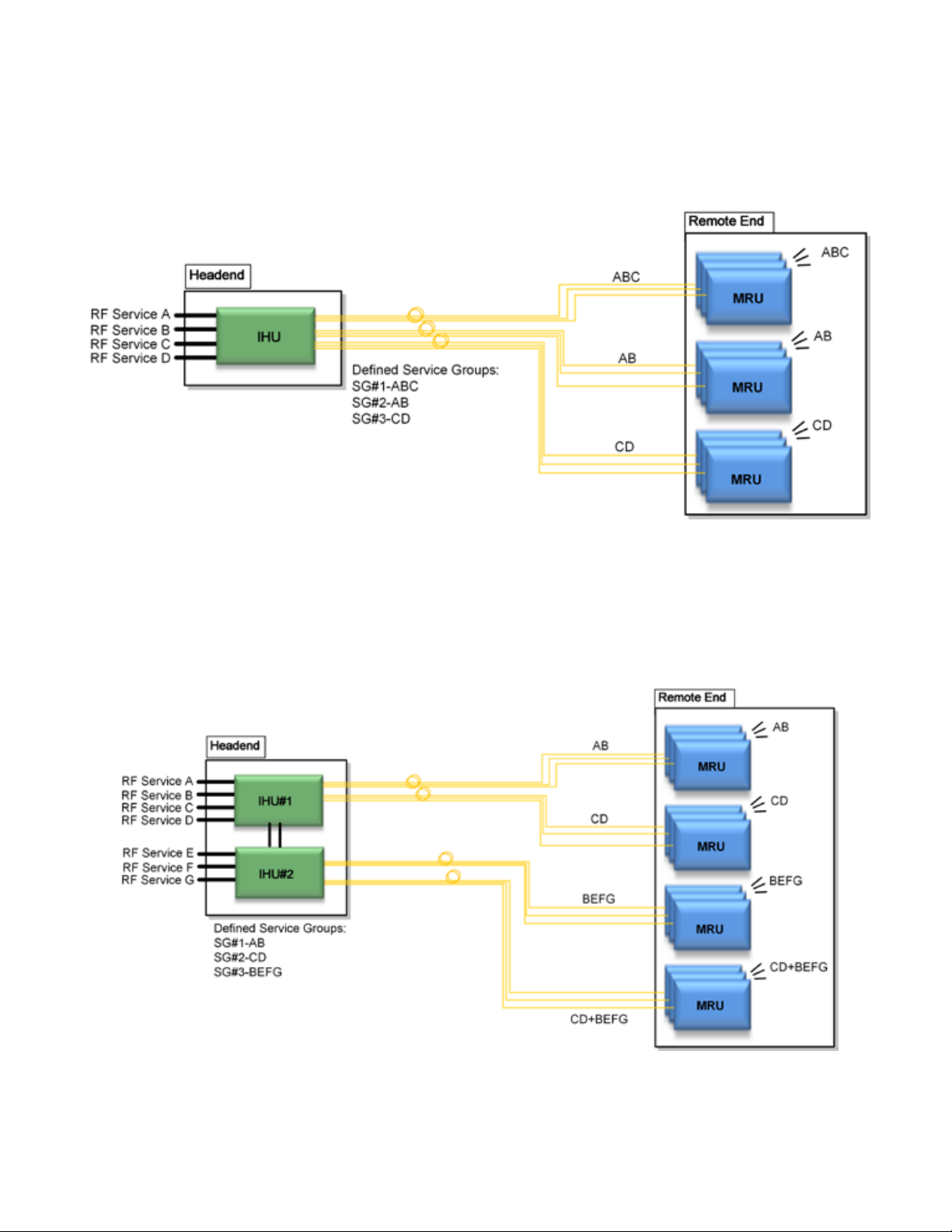

1.4.3 Service Distribution via Three Service Groups

In this example, three service groups are defined: SG#1: ABC, SG#2: AB, and SG#3: CD. Note that a service can be allocated

to any of the service groups at the same time. For example, services C and B are allocated to two of the service groups. The

services are routed to the OIMs for optic conversion. Each OIM can be configured to be included in any of the one, two or three

service groups in any combination and the corresponding services are routed from the OIM to its hosted remote-end units.

Figure 1-5. Example of Distribution of Three Service Groups

1.4.4 Service Distribution via Three Service Groups with Two IHUs

This example shows the distribution of three service groups with two IHUs. In this topology, the services routed via the two

IHUs can be grouped in any combination between the two, providing up to three service groups. Each OIM in the IHUs can be

configured to support any combination of service groups and the corresponding services are routed from to the hosted remote

units.

Figure 1-6. Example of Distribution of Three Service Groups with two IHUs

Corning Optical Communications DRAFT User Manual I CMA-XXX-AEN I Pag e 16

Page 17

Tab

Description

Management

Displayed upon login by default. Displays general module information and

selected site devices.

manager are not considered events display.

Config

Set-up tool used for initial system set-up, commissioning of system devices

and adjustment procedure.

options and IP settings required for receiving traps.

Profiles

Enables creating complete system configuration and setup profile offline and

activating at a later time (software v1.8 and higher).

Location

Enables importing maps and icons to graphically display the geographical

for the system elements (software v1.8 and higher).

Multilink

Displays list of all of the setups configured in the same network and enables

access to authorized users (software v2.0 and higher).

Help

Provides access to online help

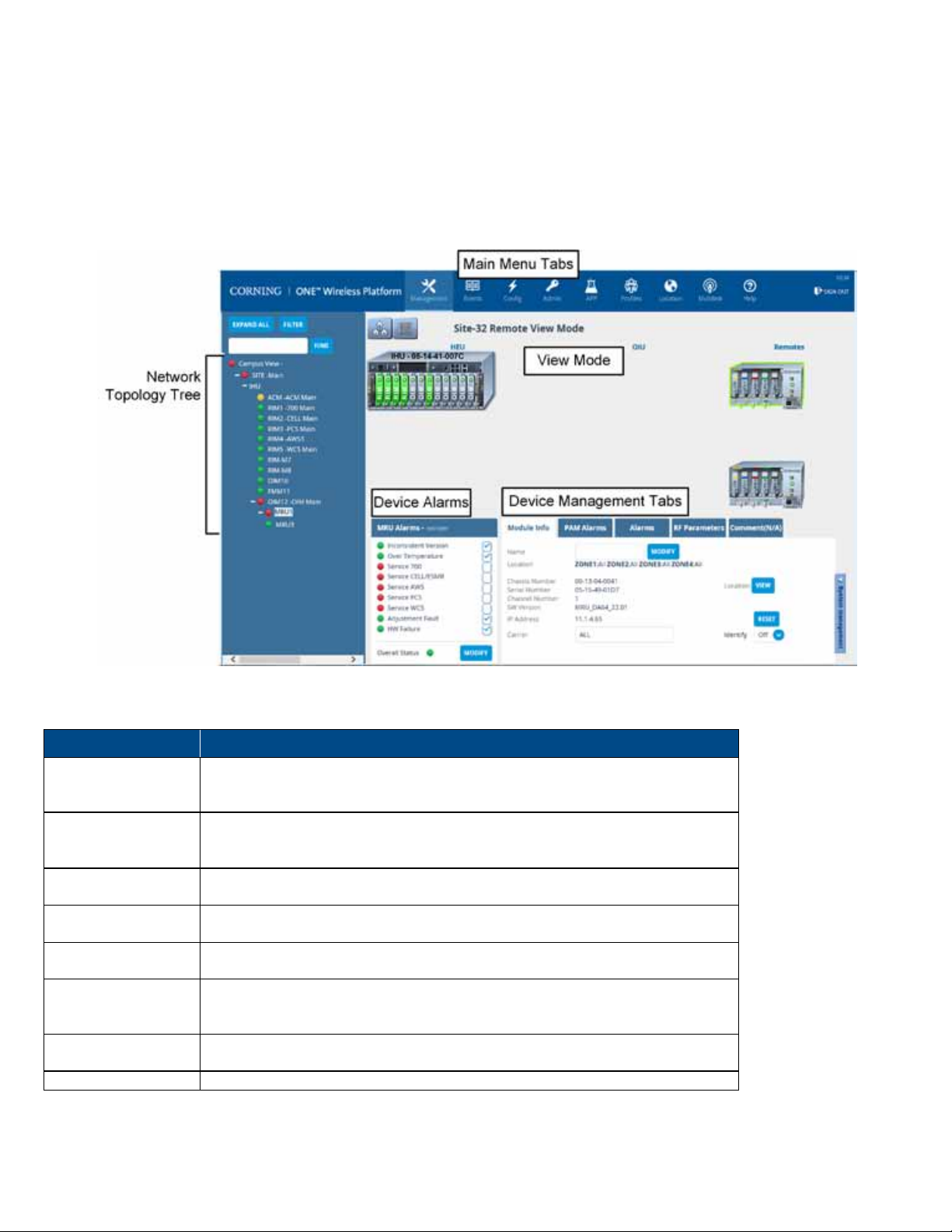

1.5 Web Management Application

The headend control module (HCM) enables centralized, system-level element management and

end-to-end, single source setup and management of the active RF components after their physical installation

provides c

omprehensive

.

Note: Refer to the Corning optical network evolution (ONE™) solutions HCM and Management GUI user manual for a complete

description of the Web management application.

Figure 1-7 shows the Mana gement window, displayed by default upon login.

Figure 1-7. Example of Management Window (Software v2.2)

The main menu bar includes the following tabs:

device alarms and provides the configuration options for the available

Events Displays the events that occurred on the monitored devices and enables

generating reports. Configuration changes that are initiated by the network

Admin Provides administration options such as firmware upgrade, user management

location and types of sites as well as the floor plans and map power settings

Table 1-2. Main Menu Tabs

Corning Optical Communications DRAFT User Manual I CMA-XXX-AEN I Pag e 17

Page 18

2 UNIT DESCRIPTIONS

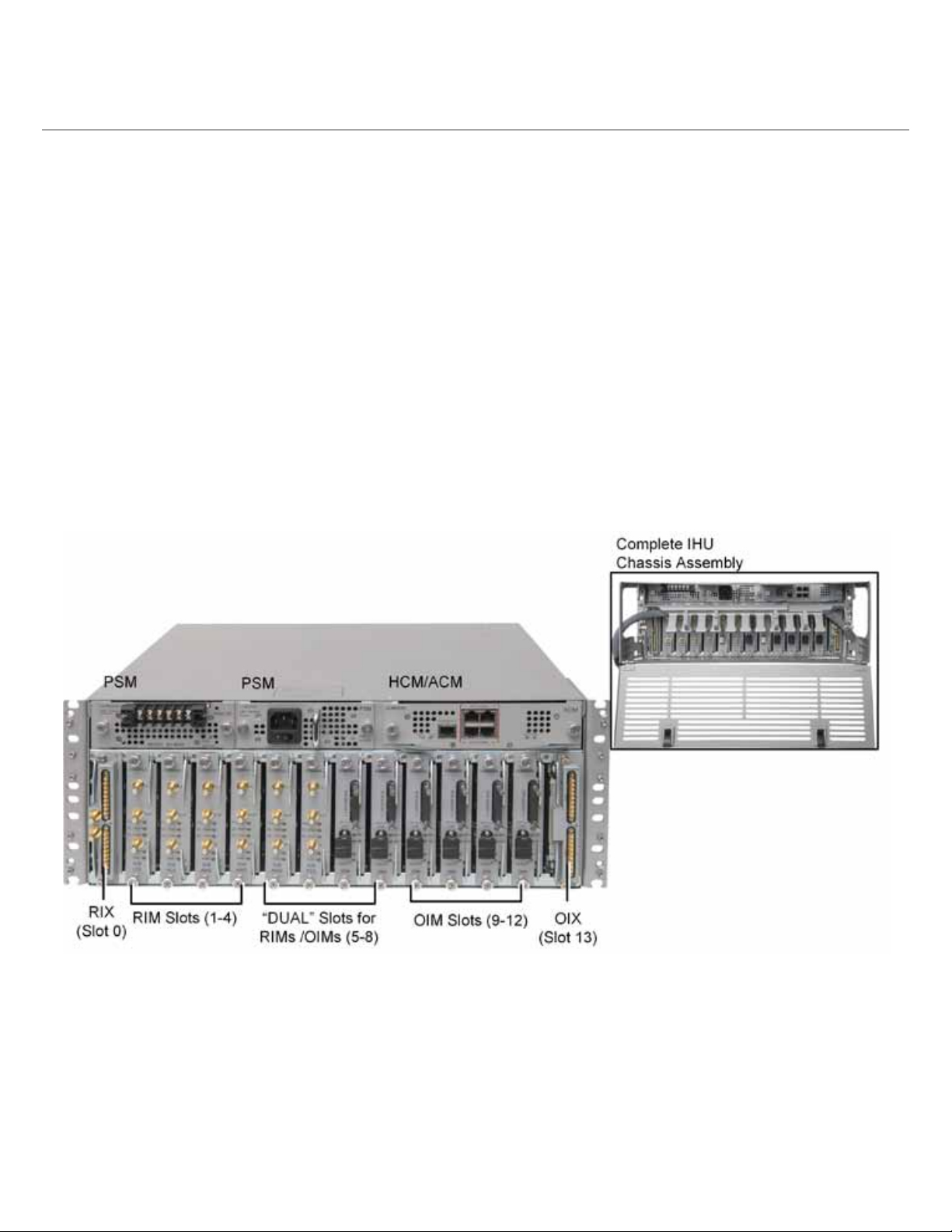

2.1 Integrated Headend Unit (IHU) Description

The IHU is a compact unit which interfaces the RF sources (via RIMs), conditions the signals, performs the RF- to-optic

conversion of the received signal (via OIMs), and distributes the wireless RF services to the remote units over the fiber optic

infrastructure to the remote site. The IHU supports expansion connections to one additional IHU. Single source management is

provided by the HCM installed in one of the IHUs.

Figure 2-1 provides an example of an IHU with four RIM modules (for RF interface and conditioning), five OIU modules for RF to

optic conversion and routing to the fiber optic infrastructure, and three FMM modules (for topologies with campus connectivity).

The slots are color coded according to the type of modules that can be inserted in those slots:

• Red labeled slots – RIM slots

• Blue labeled slots – OIM slots

• White labeled slots – can host RIMs and OIMs

Note the following:

•

The IHU also includes a preassembled cable management tray with routed ERFC cable (shown in inset) used for connecting

the RIX and OIX.

•

The type and number of modules installed in an HEU chassis can vary according to the specific topology.

Figure 2-1. Example of IHU Front Panel with Installed Modules

The IHU performs the following main functions:

• Conditions (up to 8 including “Dual Slots”) RF sources to a level required for feeding to the OIMs.

• Enables the configuration of up to three RF service groups.

• Performs the RF-to-optic conversion of the RF services and forwards the services over the fiber optic infrastructure to the

remote site. Each OIU supports between 4-8 SM optic fibers.

For additional services or density, two IHU units can be cascaded, where both IHUs are managed from the headend control

module (HCM) installed in one of the units. The IHU installation procedure is detailed in Chapter 4.

Corning Optical Communications DRAFT User Manual I CMA-XXX-AEN I Pag e 18

Page 19

Module

Description

Control

Module

RIM

RIX

PSM

OIM

2.1.4

OIX

Error! Reference source not found.

IHU hosts the following modules:

One of the following control modules is installed in each IHU:

• HCM (Headend Control Module) - one HCM per system. See section 2.1.1.1.

• ACM (Auxiliary Control Module) - installed in second IHU if installed. See section 2.1.1.2.

Radio interface module – up to 12 per HEU. See section 2.1.2.

RF expander module – interface to OIX. See section 2.1.3.

Power supply module – AC and DC models can be ordered. Each IHU supports two PSMs for

redundancy, where the same PSM type does not need to be installed in both slots. (Section

Note: If one module is installed, it must be installed in the left slot. If two modules are installed,

both must be powered on.

2.1.4).

Optical interface module - converts the RF to three optical links (see Section

Optical interface expander - interface to RIX (see Section

Table 2-1. IHU Modules

)

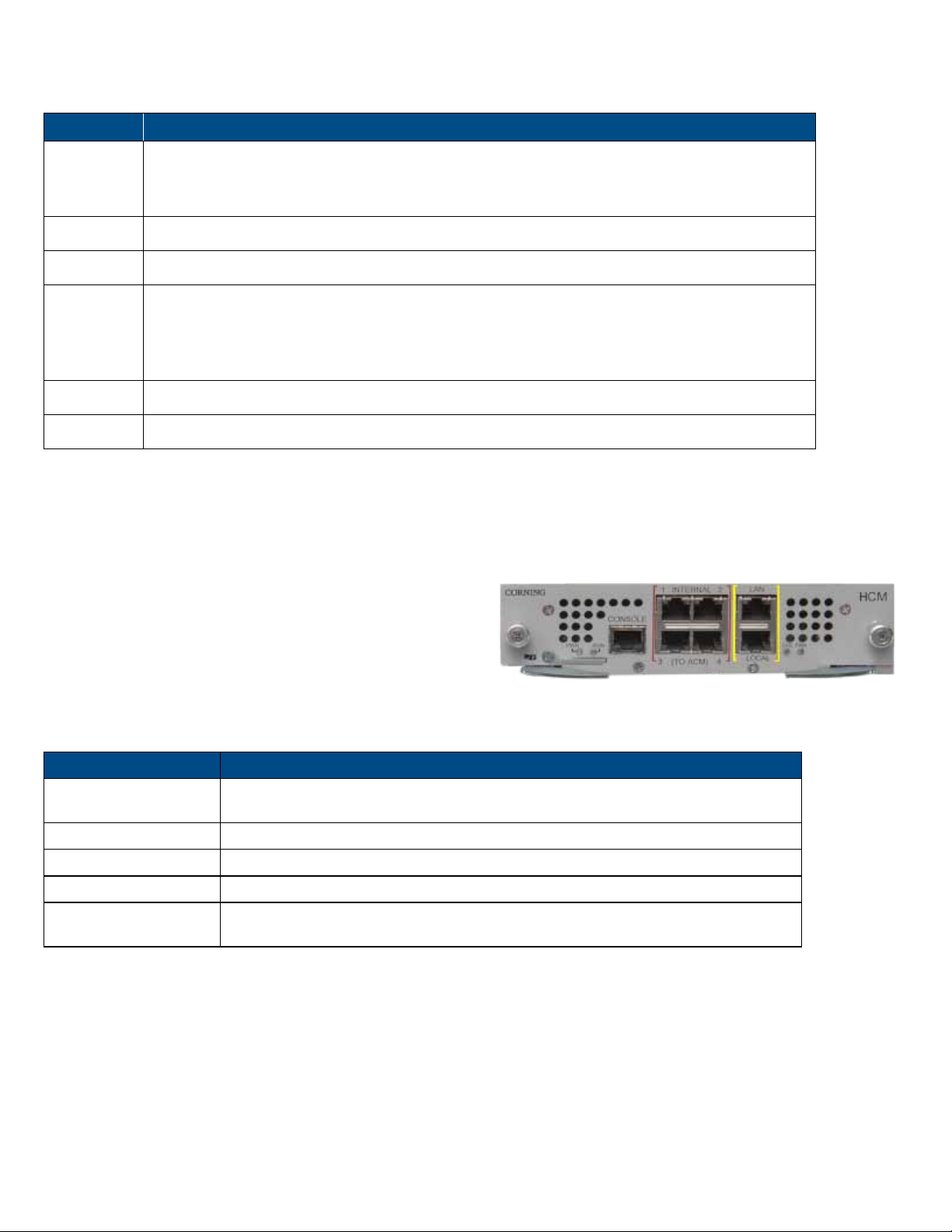

2.1.1 Cont rol Module

2.1.1.1 Headend Control Module (HCM)

This is a system control module that provides management

and control capabilities for all headend and remote-end

devices in a setup. One HCM is installed per setup in an IHU.

The HCM directly interfaces to the corporate LAN. It can be

connected to (up to) four auxiliary control modules (ACMs)

installed in additional headend units.

Table 2-2 and Table 2-3 provide a description of the HCM ports and LED status indicators.

Port Description

INTERNAL (TO ACM)

LAN RJ-45, 1 Gb Ethernet port - connects to the corporate LAN for remote management

Four RJ45, 100 Mb Ethernet ports - used for management of connected OIU

systems (and/or Auxiliary HEUs).

Figure 2-2. HCM Module

).

LOCAL RJ-45, 1 Gb Ethernet port - local configuration and management

CONSOLE RJ-45, serial port - local configuration for service personnel

SD Card Slot

Table 2-2. HCM Interface Ports

Corning Optical Communications DRAFT User Manual I CMA-XXX-AEN I Pag e 19

Supports micro SD cards up to 32 GB (used for saving and importing configuration

files between different HEU chassis)

Page 20

LED

Description

Off – no power is supplied to the unit

PWR

RUN

SYS Steady green – overall status of the managed system is ok

FAN

Table 2-3. HCM LED Description

Steady green - power input detected by HCM

Blinking green – HCM Boot up sequence complete and module software up and

running

Off – no power supplied to the unit

Steady green – normal operation status for all fans

Red – fault indicated in at least one fan

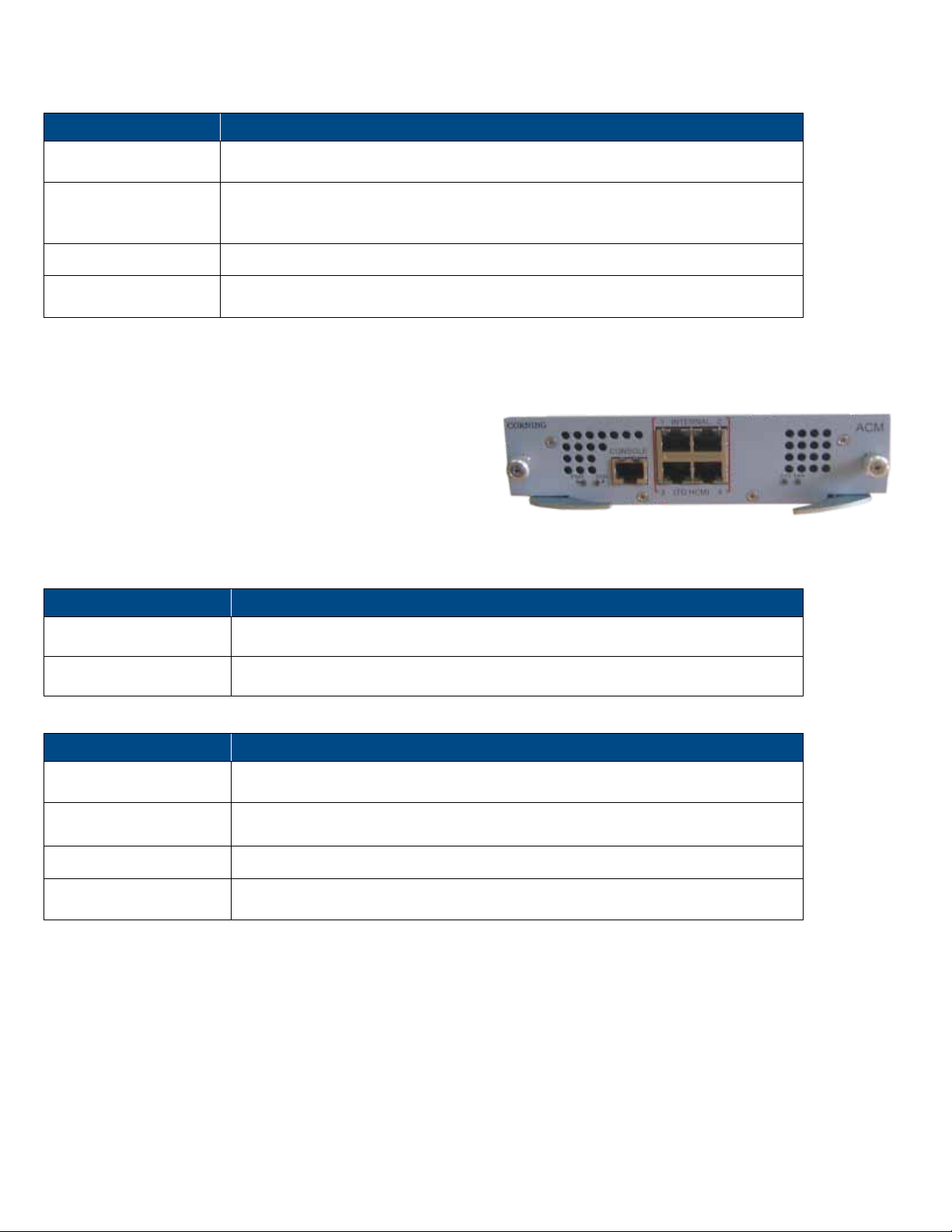

2.1.1.2 Auxiliary Control Module (ACM)

The ACM is installed in any additional IHU chassis (other than

the one in which the HCM is installed).

The ACM provides the interfaces for remote management and

control capabilities of the host chassis and connected remotes

via a local connection to the HCM (see section

Table 2-4 and Table 2-5 provide a description of the ACM ports and LED status indicators.

2.1.1.1).

Figure 2-3. ACM Module

Port Description

INTERNAL (TO HCM) Four RJ-45, 100 Mb Ethernet management ports - interface to HCM and/or other

ACMs

Console One RJ-45, serial port used for basic IP configuration and local connection for

service personnel

Table 2-4. ACM Ports Description

LED Description

PWR

RUN

SYS Steady green – overall status of the managed system is ok

FAN

Table 2-5. ACM LED Indicators Description

Steady green - power input detected by ACM

Off – no power is supplied to the unit

Blinking green – ACM Boot up sequence complete and module SW up and running

Off – no power supplied to the unit

Steady green – normal operation status for all fans

Red – fault indicated in at least one fan

Corning Optical Communications DRAFT User Manual I CMA-XXX-AEN I Pag e 20

Page 21

Port

Description

LED

Description

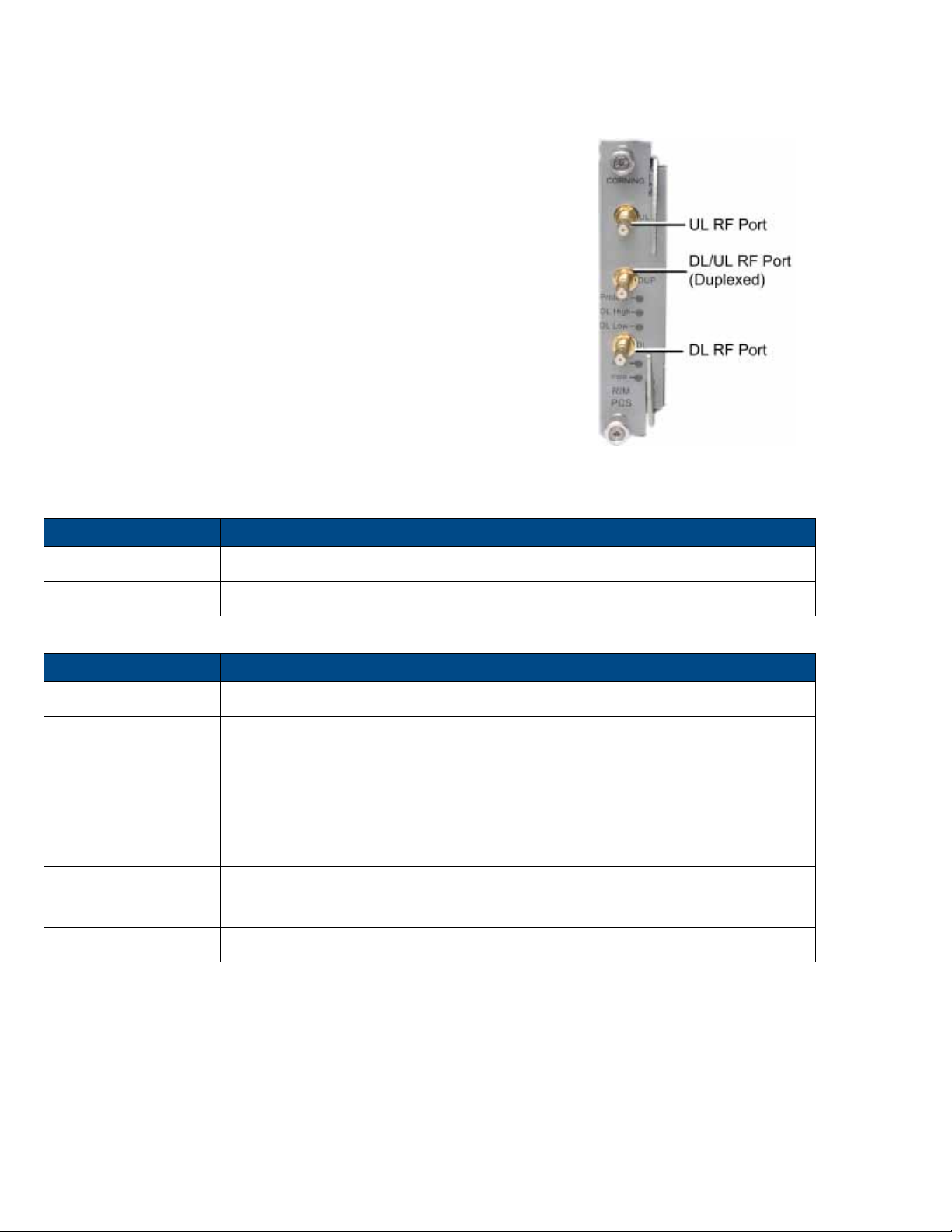

2.1.2 Radio Interface Module (RIM)

The RIM/RIM-M is a service specific RF conditioning module

that interfaces to the RF signal source. An IHU chassis can

support between 4-8 RIMs.

Each RIM supports both Simplex and Duplex RF connectors.

LEDs provide status indications on signal level and module

operation status.

Figure 2-4. RIM

Table 2-6 and Table 2-7 provide a description of the RIM ports and LED status indicators.

DL/UL UL and DL simplex connections to the RF signal source

DUP Duplexed UL and DL connection to the RF signal source

Table 2-6. RIM Ports Description

Protect N/A

DL High Provides indication on DL RF level in conditioner module:

• Off - DL RF input level in threshold range

• Steady red – signal is 3 dB above max. expected power

DL Low Provides indication on DL RF level in conditioner module:

• Off - DL RF input level in threshold range

• Steady red – no signal or 15 dB below max. expected power

RUN

PWR On - input power is wi thin required range

Table 2-7. RIM LED Descriptions

• Blinking green - power on and module software has initialized and is up and

running

• Off - no power

Corning Optical Communications DRAFT User Manual I CMA-XXX-AEN I Pag e 21

Page 22

Port

Description

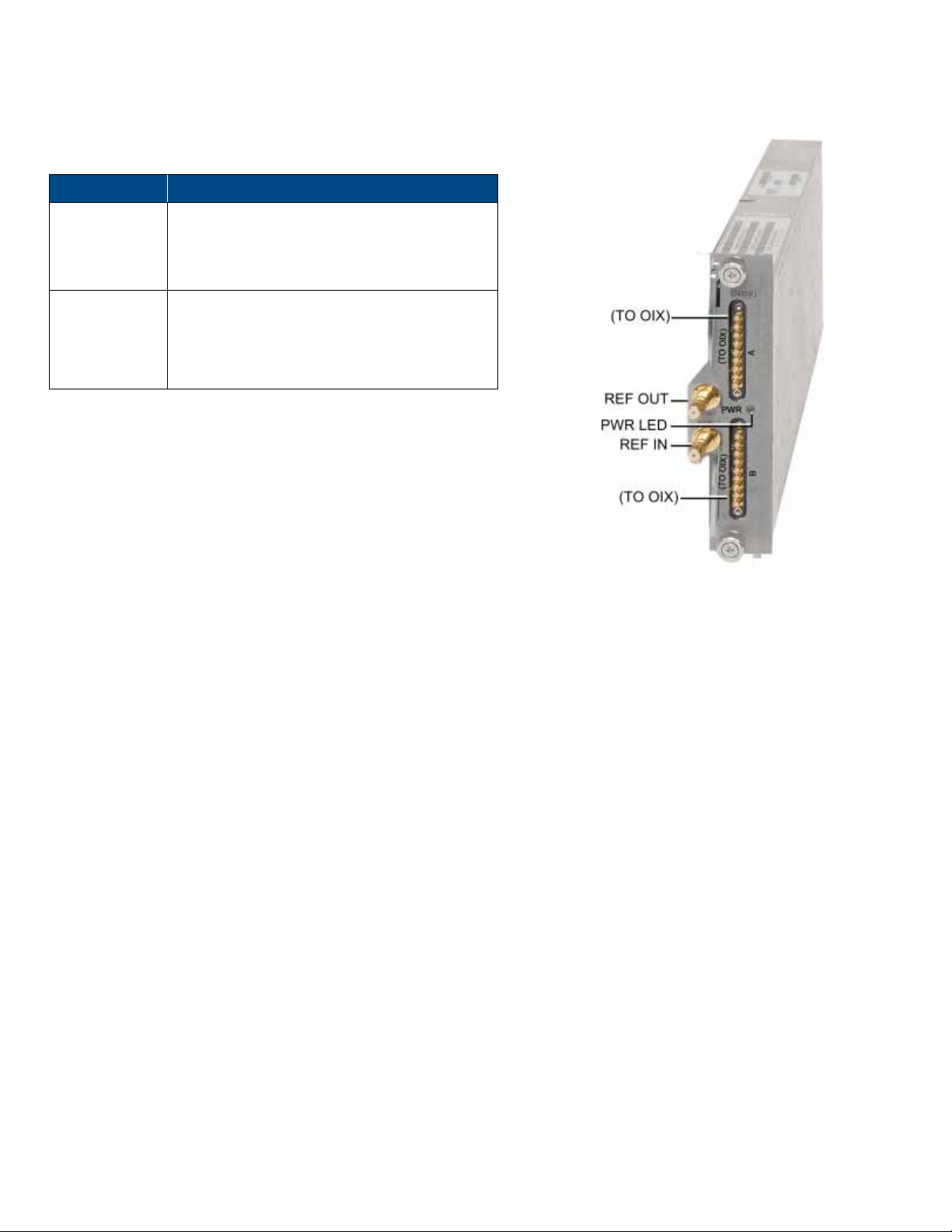

2.1.3 Radio Expander (RIX) Module

The RIX module provides the RF interface to the OIX module. Each

IHU includes one RIX.

Two 9 – pin connectors which serve as the RF

(TO OIX)

REF OUT/REF

IN

Table 2-8. RIX Ports Description

interfaces to the OIX. RIX supports

connections to two OIXs via an Expander cable

(ERFC).

Two QMA connectors used for reference clock

signal connections between RIX modules.

Note: The reference clock passes from the

Main HEU to all auxiliary chassis.

Figure 2-5. RIX Module Interfaces

Corning Optical Communications DRAFT User Manual I CMA-XXX-AEN I Pag e 22

Page 23

Port

Description

LED

Description

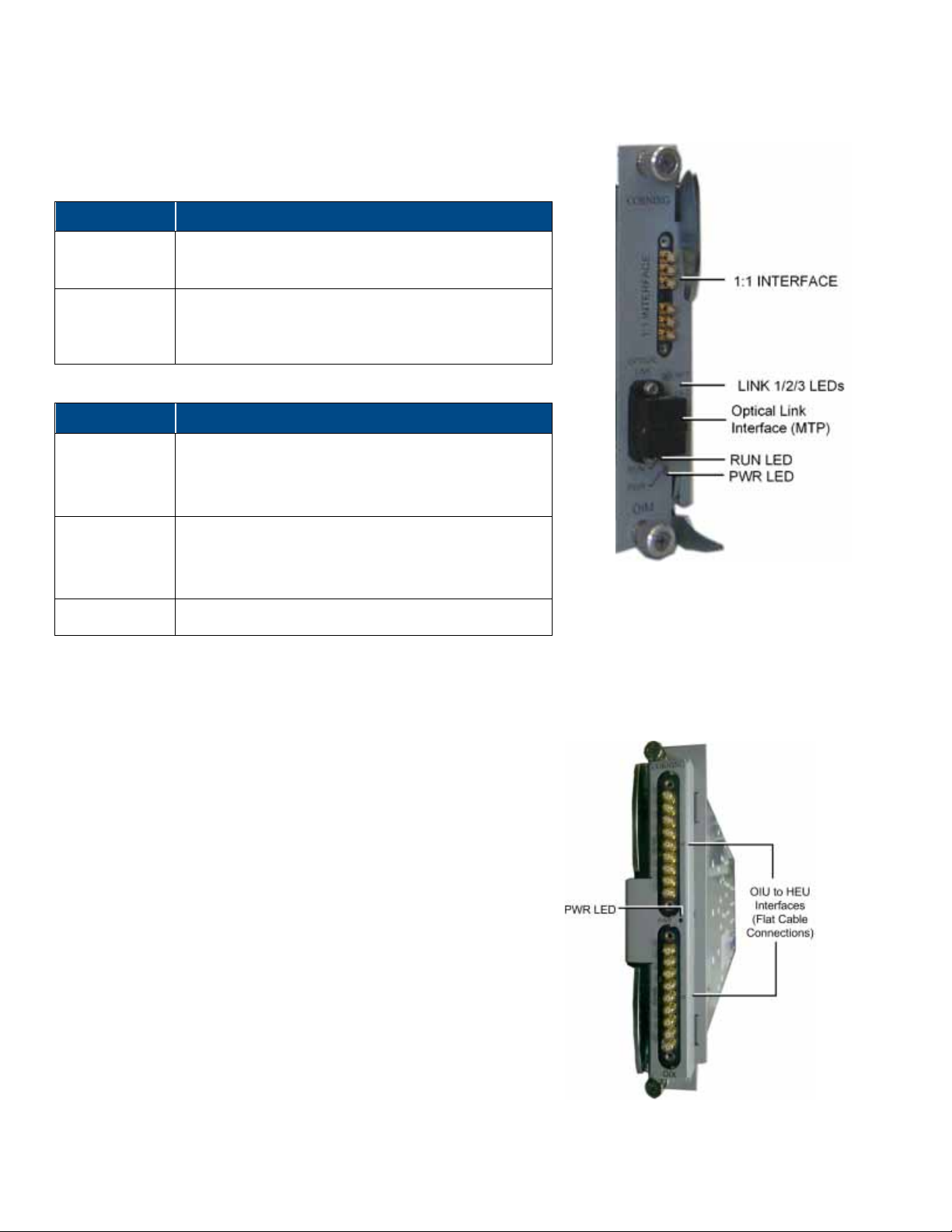

2.1.4 Op t ical Interface Module (OIM)

The OIM is a wideband RF to F/O (and vice-versa) me dia conversion

module. Up to 12 OIM units can be installed in each OIU, where each OIM

can support connections up to three remote units connections.

®

OPTICAL LINK

Female MTP

connection; SM fiber

Connector for optical interface

1:1

INTERFACE

Table 2-9. OIM Ports Description

Link 1-3

RUN

PWR Steady Green – Input power detected in OIM

Table 2-10. OIM LED Descriptions

Six pin SMP jack connector for 1:1 direct signal

transportation, three UL and three for DL enables (DL

and UL) broad band connection to each optical link

Steady Green - optic al link power to/from the

connected remote is normal

Off - no optical power from remote detected

Blinking Green – OIM module software has initialized

and is up and running

Off – Power off

2.1.5 Optical Expander Module (OIX)

The OIX provides the RF interface to two RIX modules via two

9-pin connectors.

Figure 2-6. Optical Interface Module

.

Figure 2-7. OIX Interfaces

Corning Optical Communications DRAFT User Manual I CMA-XXX-AEN I Pag e 23

Page 24

PSM-AC

PSM-DC

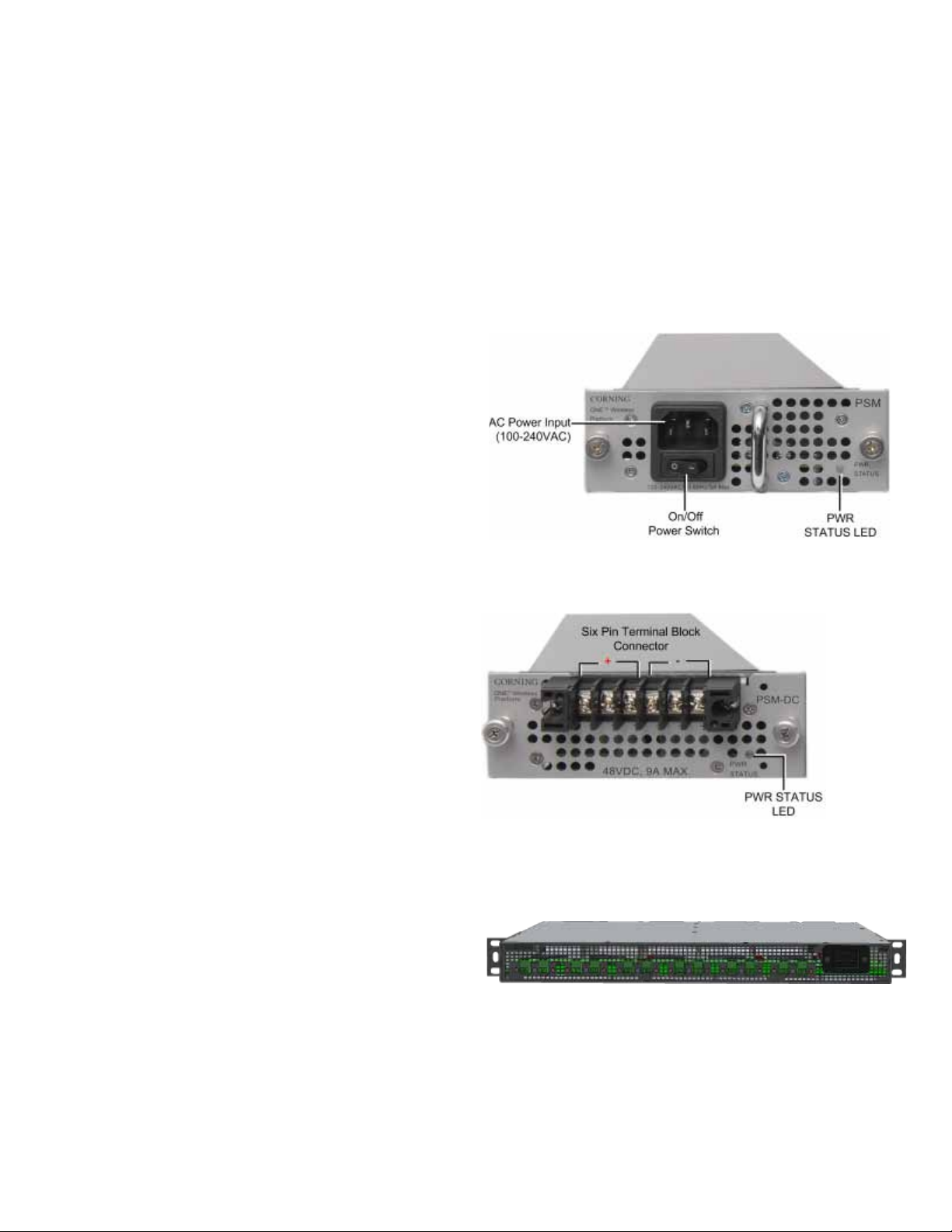

2.1.6 P ower Supply Module (PSM)

Two types of power supply modules are available:

• PSM-AC: 100 – 240 VAC (power rating 300 W);

• PSM-DC: 48 V DC; 9 A maximum (power rating 300 W).

Note the following:

• Each IHU can support two PSMs, where the second PSM provides redundancy in case one of the supplies fails.

• In cases that a single power supply module is installed, it must be installed in the LEFT slot.

• Both types of PSM modules (AC and DC) can be installed in the same chassis (at the same time).

• If two PSM modules are installed, both must be connected to their respective power source and turned on at all times.

The PSM-AC includes an AC power connector, on/off switch

and power status LED.

Figure 2-8. PSM-AC

PSM-DC power source rating:

48 V DC; 9 A Max.; 300 W

The PSM-DC includes a six pin terminal block connector,

supporting up to three DC wire pairs.

Figure 2-9. DC Power Supply Module

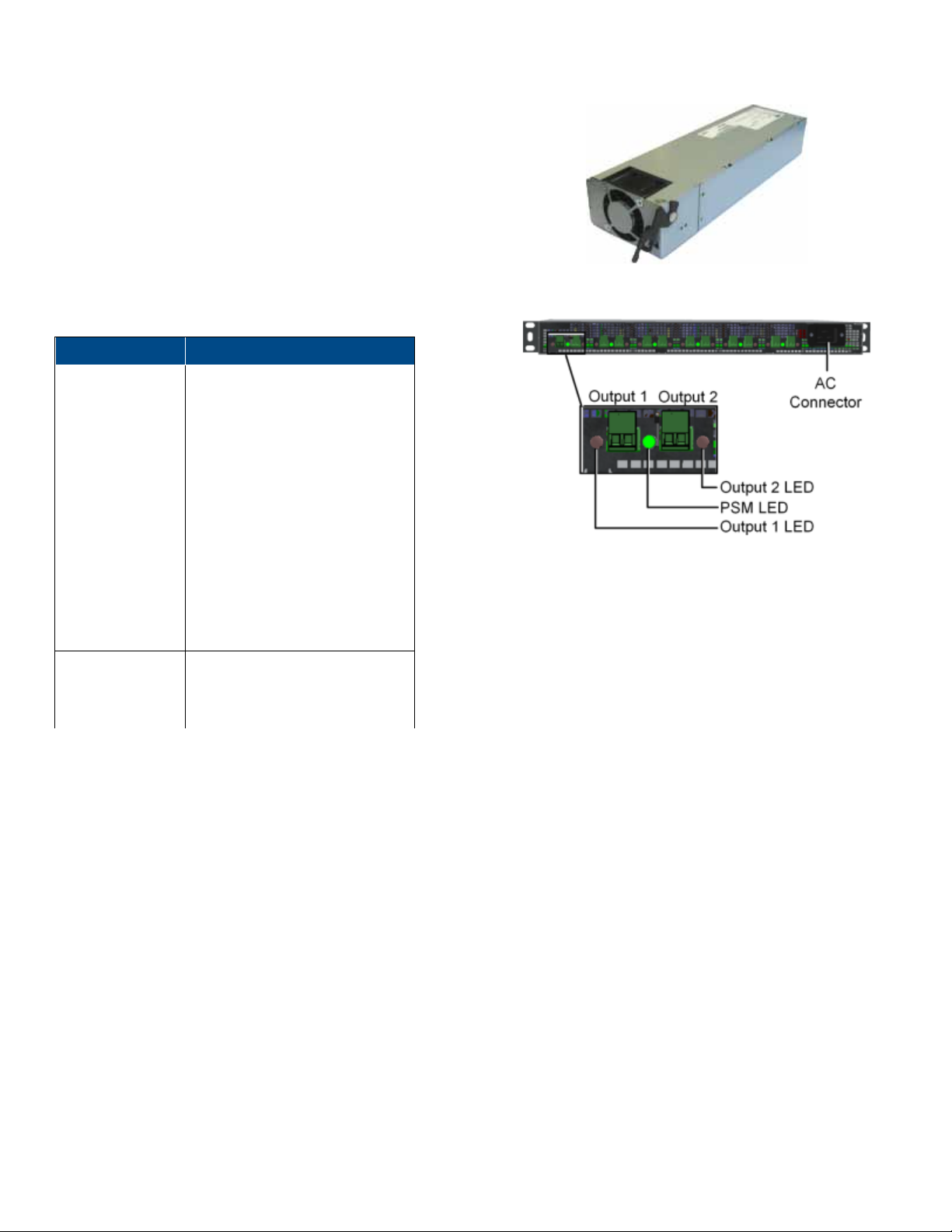

2.2 Six Module DC Power Supply Unit (PSU6) Description

PSU6 is a compact, scalable DC enclosed power supply used

for feeding Corning optical network evolution (ONE™)

solutions elements.

Power outputs:

• Up to 12 outputs of 57 VDC

• 100 W per output

• Total power of 1200 W

Figure 2-10. PSU6 Fro nt P ane l

Refer to Section 7.8 for complete specifications.

Corning Optical Communications DRAFT User Manual I CMA-XXX-AEN I Pag e 24

Page 25

LED

Description

PSU6 supports up to six modules, where each module

provides two DC outputs. All interfaces are located on the front

panel. Modules are inserted and removed via the rear panel.

The status of each module is indicated by a dedicated LED:

PSM LED Green – power OK

Red - indicates one (or more)

of the following:

• Insufficient input power

• Problem with output load at

one or both PSM output

ports

• PSM over temperature

protection set

• Fan failure

Off in one PSM – PSM is off

Off in all PSMs – no power input

detected

Figure 2-11. PSU6 Power Sup ply Module

Figure 2-12. AC Input Power Connector and PSU6 LEDs

Output LED 1/2 Off – normal operation

Red – short circuit or overload

detected

Table 2-11. PSU6 LED Description

Corning Optical Communications DRAFT User Manual I CMA-XXX-AEN I Pag e 25

Page 26

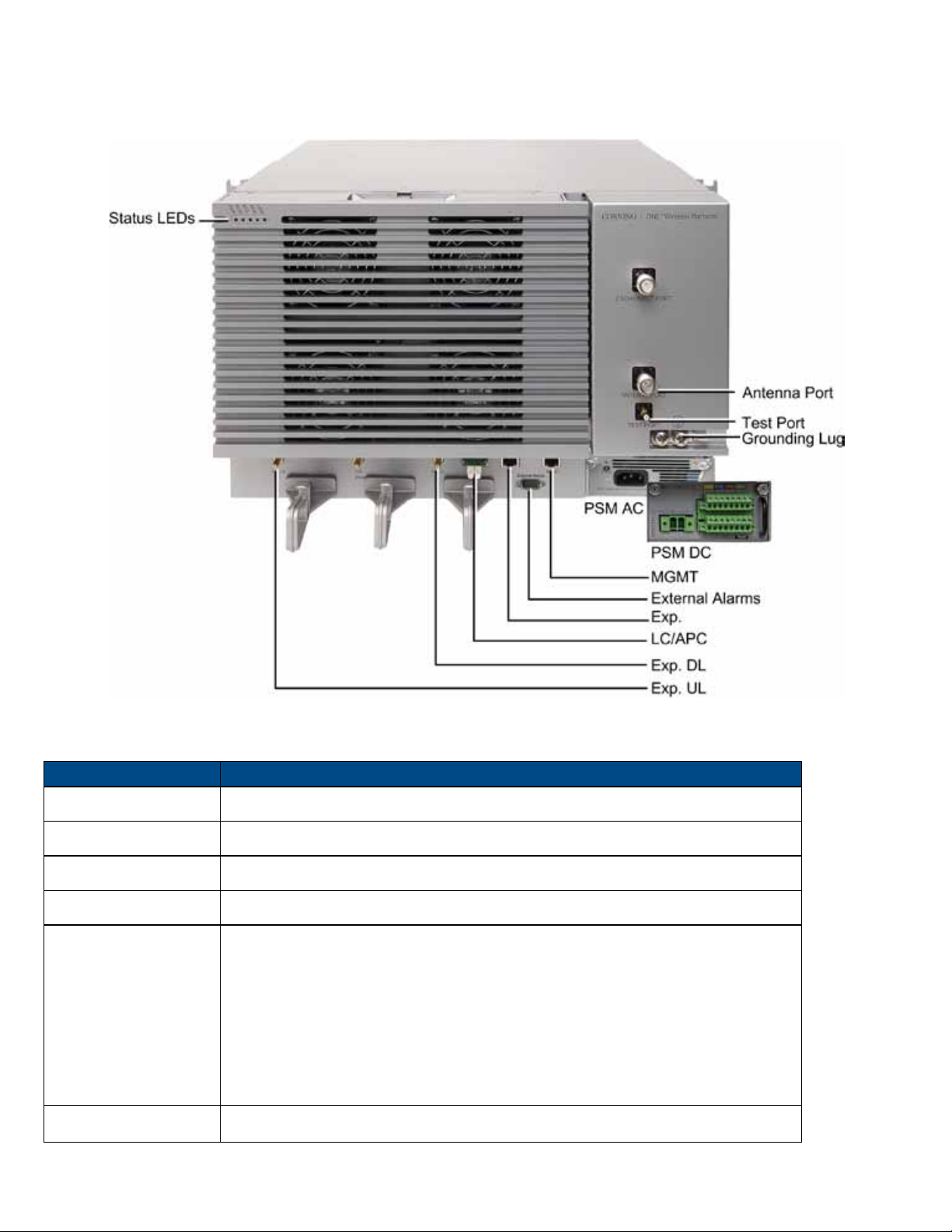

2.3 Mid-Power Remote Unit (MRU)

This section provides detailed descriptions of the MRU chassis and main modules and interfaces. This includes port and LED

interface descriptions. The MRU comprises the following main modules:

• Power amplifier modules (PAM) – internal service specific power amplifier module that interfaces to an optical interface

module (OIM) at the headend site via a single-mode fiber pair and supports one service. MRU supports up to seven bands.

The PAM provides the additional amplification on the DL signals routed from the OIM towards the multiplexer; PAMs are

pre-installed in designated slots according to supported band.

• Multiplexer – combines the UL and DL RF signals of the supported services in addition to external RF signal (future option

for connecting to external 2.5 GHz signal source) while providing the proper filtering into a single duplexed antenna port.

• Optical Module – includes the fiber optic, RF expansion and external alarm interfaces

• Power supply module (PSM) - local AC or remote DC power feed (model dependent);

• Fan module (FAM) – integrated fan module comprised of four fans which are also monitored via the web GUI

The MRU includes front panel interfaces (e.g. antenna, fiber optic connection and LED status indicators) as well as status

indicators per each internal module (which are accessed by opening the cabinet door. The following sections provide details on

the front panel and internal module interfaces.

Figure 2-13 MRU Main Modules

Corning Optical Communications DRAFT User Manual I CMA-XXX-AEN I Pag e 26

Page 27

SMA RF ports for UL and DL connections to add-on unit (supporting any band

across the supported spectrum: 300 MHz to 3 GHz)

The MRU front panel includes the RF and fiber optic interfaces in addition to the system level status LEDs and service

maintenance ports. The internal PAM modules each include a PWR/STS LED.

Figure 2-14. MRU External Inter f ac es

Table 2-2 and Table 2-3 provide a description of the MRU interface ports and LED status indicators.

Port Description

ANTENNA PORT 4.3-10 Type RF duplexed RF antenna port

TEST PORT QMA coupling test port used for UL and DL measurements during system operation

2.5 GHz INPUT PORT N/A (Future option); 4.3-10 Type RF port for 2.5 GHz external RF source

GND Two-hole, standard barrel grounding lug

PSM Power Connector Model dependant:

AC models – AC connector connected to power source using provided AC power

cable only

DC models - two types of terminal block connectors:

• CLASS2 (default) – two “DC In” 8-pin terminal block connectors for remote feed:

one pair for each PAM ( total of five pairs) and one pair for the FAM+OPTM; one

RSV pair

• CLASS1 – one “DC-In” 2-pin terminal block for local plant feed

Exp. UL/DL

Corning Optical Communications DRAFT User Manual I CMA-XXX-AEN I Pag e 27

Page 28

LED

Description

PWR

Steady green:

Required power is supplied to MRU chassis

Off:

No power input detected

green:

Rapid blinking

green:

“Identify” feature has been enabled via the management GUI

Off:

No power inpout detected

Steady green:

Normal operation; overall status OK

Steady red:

Indicates generated alarm in unit

rm

indicator.

FAM

Steady green:

All four fans are operating at normal speed (fan alarms clear)

Steady red:

Fault detected in at least one fan (fan alarm set)

LINK

Steady green:

Optical link level from optical module above normal threshold

Steady red:

Optical link level is lower than normal threshold

(PAM)

Steady green:

Power and status of power amplifier module OK. No alarms active.

Steady red:

One or more alarms are active.

Port Description

List. Mode N/A

OPTIC LC APC port for single-mode fiber optic connection

MGMT RJ45 Ethernet connection for MRU local management connection

External Alarms DB9 female external alarm connector for external dry contact alarm connections

Exp. RJ45 Ethernet connection for Add-On local craft

Table 2-12. MRU Interface Ports

RUN Blinking

STS

Blinking red: “Over temperature” alarm active.; Indicates temperature has exceeded

Note: Temperature alarm is set as first priority and overrides any other ala

Table 2-13. MRU LED Descriptions

Unit is running and operational

threshold (with door open)

Corning Optical Communications DRAFT User Manual I CMA-XXX-AEN I Pag e 28

Page 29

Operating

Storage

Regulation/Standard

Category

Approval

3 INSTALLATION GUIDELINES

Note the following:

• It is assumed that the site survey and installation planning (including power requirements) have been completed.

• Specifications of remote units are described in the corresponding datasheets and installation manuals.

This chapter provides installation guidelines for the Corning optical network evolution (ONE

following installation rules are based on the assumption that the site survey and installation planning (including power

requirements) have been completed. This includes planning the distribution of antennas to provide the required coverage, as

well as planning the layout of the devices and cables in the telecom closet or shaft.

3.1 General System Specifications and Requirements

This section includes the environmental and physical specifications for the following units: HEU, OIU, IHU, CEU, ICU and

PSU6.

3.1.1 Environmental and Regulatory Specifications

3.1.1.1 Temperature and Humidity

The environmental specifications listed below are relevant to all Corning optical network evolution (ONE™) solution devices.

™

) IHU, PSU6, and MRU. The

Temperature 0°C to +50°C (32°F to 122°F) -20° C to 85° C (-4°F to 185°F)

Humidity 95% (non-condensing) 95% (non-condensing)

Table 3-1. Temperature and Humidity Specifications

3.1.1.2 Safety and Regulatory Approvals

The safety and regulatory specifications listed below are relevant to all Corning optical network evolution (ONE™) solution

devices.

Laser Safety

EMC

Safety

Table 3-2. Safety and Regulatory Approvals

FDA/CE 21 CFR 1040.10 and 1040.11 except for deviations pursuant to laser

notice no. 50 and IEC 60825-1

CE EN 301 489, EN55022, EN 61000

FCC 47 CFR Part 15, 22, 24, 27

UL 60950

IEC 60825-1:2007

IEC 60825-2:2010

CAN/CSA-C22.2 No.60950-1-03

Fire Safety UL 2043 (applicable for RAU5 only)

Corning Optical Communications DRAFT User Manual I CMA-XXX-AEN I Pag e 29

Page 30

Unit

Description

Min-Max Voltage (VAC)

Max Power Draw

(Watts)

No. of

Units

Heat (BTU/hr)

Unit

Dimensions (H x W x D)

Rack Space

19-in (RU)

Weight: lbs [kg]

3.1.2 Power and Heat Specifications Summary

Table 3-3 provides the power, heat and rack specifications for the equipment installed in the headend/telco rooms.

IHU Integrated headend unit 100 – 220 300 1 1020

PSU6 Six Unit DC power supply unit

Table 3-3. Power and Heat Specifications

85 to 265

1200

(100 W per port)

1 512

(typical at 100 V in)

3.1.3 Dimensions, Weight and Rack Specifications of Units

Table 3-4 describes the physical specifications of the Corning optical network evolution (ONE™) solution units described in this

manual.

IHU 7 x 17.3 x 15.5 in

[177.8 x 440 x 394 mm]

PSU6 1.73 x 17.51 x 13.74 in

[44 x 445 x 349 mm]

4 Chassis: 30 lbs (14 kg)

Per RIM: 1.9 lbs (0.9 kg)

Per RIX: 1.54 lbs (0.7 kg)

Per OIM: 1.5 lb (0.7 kg)

Per OIX: 1.54 lb (0.7 kg)

ACM: 2.2 lb (1.0 kg)

PSM: 1.98 lb (0.9 kg)

1

Enclosure: 6.22 lb (2.825 kg)

Per PSM-I module: 0.8 lb (0.36 kg)

MRU

Table 3-4. Dimensions, Weight and Rack Specifications of Headend/Intermediate Units

10.5 x 17.5* x 15.75 in (266.7 x 445 x 400 mm)

*without rac k brack ets

6

Chassis without PAMs: 48 lbs (21.8 kg)

Each PAM: 4.7 lbs (2.15 kg)

3.2 Infrastructure Preparation

The following installation rules are based on the assumption that the site survey and installation planning (including power

requirements) have been completed.

3.2.1 S it e Considerations

• The distance between the MRU service antenna and the coverage area should correspond to line of sight (LoS)

requirements for maximum coverage area.

• The maximum fiber path loss is 5 dB.

• The system delay of the optical system must be taken into consideration when there are neighboring BTS sites overlapping

in coverage.

Corning Optical Communications DRAFT User Manual I CMA-XXX-AEN I Pag e 30

Page 31

3.2.2 Installation Location Requirements

• Mounting surface shall be capable of supporting the weight of the equipment.

• In order to avoid electromagnetic interference, a proper mounting location must be selected to minimize interference from

electromagnetic sources such as large electrical equipment.

• Working space available for installation and maintenance for each mounting arrangement.

• Ensure unrestricted airflow.

• Ensure grounding connector is within reach of the ground wire.

• Ensure a power source is within reach of the power cord and the power source has sufficient capacity.

• Where appropriate, ensure unused RF connectors are terminated.

• Do not locate the equipment near large transformers or motors that may cause electromagnetic interference.

• Reduce signal loss in feeder cable by minimizing the length and number of RF connections.

• Ensure the equipment will be operated within the stated environment (refer to Appendix A: Specifications or unit datasheet).

• Where appropriate, confirm available of suitably terminated grade of RF and optical fiber.

• Observe handling of all cables to prevent damage.

3.2.3 S af ety Guidelines

Before installing the equipment review the following safety information:

• Follow all local safety regulations when installing the equipment.

• Only qualified personnel are authorized to install and maintain the Repeater.

• Ground specified equipment with the provided grounding bolt

• Do not use the grounding bolt to connect external devices.

• Follow Electro-Static Discharge (ESD) precautions.

• Use low loss cables to connect the antennas

3.2.4 Rac k Safety and Installation Guidelines

3.2.4.1 Rack Safety Instructions

The following guidelines are relevant to the rack installed units. Review the following guidelines to help ensure your safety and

protect the equipment from damage during the installation.

• Only trained and qualified personnel should be allowed to install or replace this equipment.

• Verify that ambient temperature of the environment does not exceed 50°C (122° F)

• To maintain a low center of gravity, ensure that heavier equipment is installed near the bottom of the rack and load the rack

from the bottom to the top.

• Ensure that adequate airflow and ventilation within the rack and around the installed components so that the safety of the

equipment is not compromised. It is recommended to allow for at least about 2 cm of airspace between devices in the rack.

• Verify that the equipment is grounded as required – especially the supply connections.

3.2.4.2 Rack Installation Guid el i nes

• To maintain a low center of gravity, ensure that heavier equipment is installed near the bottom of the rack and load the rack

from the bottom to the top.

• Verify that the rack height can support the unit to be installed, where you may also want to consider future installations.

− IHU rack height = 4U

− PSU6 rack height =1U

− MRU rack height = 6U

3.2.5 Power Safety and Power Requirements

This section summarizes the power requirements of devices described in this manual.

3.2.5.1 Power Safety Instructions

Corning Optical Communications DRAFT User Manual I CMA-XXX-AEN I Pag e 31

Page 32

SAFETY WARNINGS! When installing or selecting the power supplies:

• Use only the power cables (AC and DC) and any other relevant accessories provided with the unit to connect the power

supply to the system components.

• For MRU AC models – only use the provided AC power cable (straight, U.S 10 A ,UL, L = 1.8-2.5 m ,black,110 V ) to connect

the power supply to the MRU.

• Be sure to disconnect all power sources before servicing.

• Calculate the required power according to the requirements of the specific installation and then determine the configuration

of the power supplies. The required DC cables will then be determined by the selected PS configuration.

• Use only UL approved power supplies

• Install external over-current protective devices for the system according to the requirements described in section 3.1.2 -

Power and Heat Specifications Summary..

• Types of Power Supplies - Corning supplies various power supplies that can be installed in a rack or mounted on a wall,

depending on your configuration.

3.2.5.2 Types of Power Supplies

Corning supplies various power supplies that can be installed in a rack or mounted on a wall, depending on your configuration.

3.2.5.3 Circuit Breakers

Calculate the required fuse protection while referring to section 3.1.2 - Power and Heat Specifications Summary. Al so , take into

account when installing fuse protections for the system that there may be other Corning system elements that require external

fuse protection.

Corning Optical Communications DRAFT User Manual I CMA-XXX-AEN I Pag e 32

Page 33

Vertical

Horizontal

3.2.6 RF Coaxial Cable Guidelines

3.2.6.1 Considerations for Cable Type and Installation Proce dur e Gui d el ines

Note: The installer should be familiar with the ANSI/TIA/EIS-568 Cabling Standard guidelin es .

• Observe the general cable installation procedures that meet with the building codes in your area.

• The building code requires that all cabling be installed above ceiling level (where applicable). The length of cable from the

risers to each antenna must be concealed above the ceiling.

• The cable must be properly supported and maintained straight using velcro cable ties, cable trays and clamps or hangers

every 10 feet (where practical above ceiling level).

Where this is not practical, the following should be observed:

− The minimum bending radius of the supplied ½” coax cable should be 7”.

− Cable that is kinked or has a bending radius smaller than 7” must be replaced.

− Cable runs that span less than two floors should be secured to suitably located mechanical structures.

− The cables should be supported only from the building structure.

• All cables shall be weather-resistant type

• The cable length is determined by the system installation plan. When calculating the cable length, take into account excess

cable slack so as not to limit the insertion paths.

3.2.6.2 RF Rules

• Use coax RG-223, 50 ohm, male-to-male N-type to QMA for RF connections from the RIMs to the BTS/RBS and to the

RAUs.

• When using the Corning system in an environment in which other indoor coverage systems are installed, it is recommended

(where possible) that the antennas are placed at least two meters apart

• When bending coax cables, verify that the bending radius does not exceed the coax specifications.

• Use a VSWR meter (i.e. Site Master or equivalent) for checking coax cables, including the antennas. (<2). The VSWR must

be measured prior to terminating the RAUs at the remote locations.

.

3.2.7 Fiber Optic Requirements

3.2.7.1 Authorized Optic Cables

The following specified optic cables are authorized for use with Corning optical network evolution (ONE™) products:

Plug & Play™ Plenum Optical cables

MTP Fiber Connectors

12 – 144 fibers

2-sided or 1-sided

Armored, non-armored

Composite Plenum Tether Assemblies

Fiber: LC APC, 2 – 24 fibers

Cu: 16 AWG, 14 AWG, 12 AWG; 2 – 12 Conductors

Armored, non-armored

3.2.7.2 Fiber Optic Rules

• Use only MTP® or LC APC connectors

• UniCam connectors can be used for field termination

• Use only fusion splice for connecting two fibers

• Use minimum splicing/connectors to achieve minimum losses on the fibers (< 0.5 dB)

• Use precaution while installing, bending, or connecting fiber optic cables:

− Fiber optic cable is sensitive to excessive pulling, bending and crushing forces. Consult the cable specification sheet for

the cable you are installing.

− Do not bend cable more sharply than the minimum recommended bend radius.

− Do not apply more pulling force to the cable than specified.

Corning Optical Communications DRAFT User Manual I CMA-XXX-AEN I Pag e 33

Page 34

− Do not crush the cable or allow it to kink. Doing so may cause damage that can alter the transmission characteristics of

the cable. The cable may have to be replaced.

• Use an optical power meter and light source for checking the fiber optic cables

• Make sure the environment is clean while connecting/splicing fiber optic cables

• All fiber optic connectors should be cleaned prior to connecting to the system

• Fiber connector protective caps should be installed on all non-terminated fibers and removed just before they are

terminated.

• Pay special attention while connecti ng the LC APC connectors – ensure that you hear a “click”, indicating a secure

connection

• Never look directly into the end of a fiber that may be carrying laser light. Laser light can be invisible and can damage your

eyes.

3.3 Antenna Specifications and Guidelines

Determine the antenna installation configuration, according to the transmission and coverage requirements and the installation

site conditions.

3.3.1 A ut horized Antennas and Required Specifications

• External antennas - no limitation on any vendor of available external antennas with respect to the following requirements:

− Omni Directional or directional

− Supported frequency range: wideband antennas supporting a range of 700 MHz to 2600 MHz

− Gain: up to 12.5 dBi

− Impedance: 50 Ohm

• Couplers – Use N-Male to N-Female broadband coupler separately ordered from Corning (P/N AK-1COUPLER-NM-NF)

or the equivalent:

− Broadband frequency: 300 – 3000 MHz

− -20 dB coupling (SMA coupling port)

− Maximum VSWR/return loss:12 dB

− Maximum insertion loss (dB): 0.2

• Number of antennas that can be connected (with cables/splitters) – it is not recommended to connect more than one

antenna per connector since 1:1 connectivity is reduced with each split.

• Types of couplers/splitters – depends on number of splits (not recommended)

Corning Optical Communications DRAFT User Manual I CMA-XXX-AEN I Pag e 34

Page 35

4 IHU INSTALLATION

This chapter describes the installation for the IHU, PSU-6, and MRU equipment. A section is dedicated to gen eral inf or mation

relevant for the installation of the HEU, OIU and IHU, followed by dedicated installation sections for each type of equipment.

Note: For specific guidelines on infrastructure planning, design and installation, please consult with a Corning product line

manager or Corning approved installer.

4.1 General Installation Information

Note the following inform atio n:

• The IHU chassis and modules are supplied separately and must be inserted by the user. Only the fan module is factory

installed in the chassis rear.

• The IHU is installed at the intermediate distribution frame (IDF), adjacent (or as close as possible) to each other to facilitate

the connections.

• The expander cable (ERFC) interconnecting the OIX and RIX modules are provided in lengths ranging from 16 to 59 in so as

to accommodate a range of HEU-OIU rack installation configurations.

• HCMs and ACMs are not hot-swappable.

• Hot-swappable modules: RIMs, OIMs, PSMs, FAMs, RIXs and OIXs.

• If a redundant power supply is provided, both supplies must be installed, connected to res pec ti ve AC or DC power and

switched on.

• All components of a system installation are controlled and managed via a single HCM which is installed in the IHU chassis.

Note: The management connections for the Corning optical network evolution (ONE™) solution elements are detailed in the

HCM and Web management GUI user manual.

Corning Optical Communications DRAFT User Manual I CMA-XXX-AEN I Pag e 35

Page 36

IHU Kit

Quantity

Item

RIM Kit (up to 8 according to order)

Quantity

Item

OIM Kit (up to 8 according to order)

Quantity

Item

RIX Module Kit

Quantity

Item

4.2 IHU Installation

4.2.1 Unpacking and Inspection

Unpack and inspect the cartons as follows:

1. Open the shipping cartons and carefully unpack each unit from the protective packing material.

2. Verify that all the items required for installing the chassis according to the items listed in the corresponding sections. If any of

the listed items are missing, contact your Corning representative.

3. Check for signs of external damage. If there is any damage, call your Corning representative.

Integrated headend unit chassis

Fan Module (S-FAM) – single unit hosting 4 fans

(installed in the chassis rear)

RJ45/RJ45 communicati on c able L=2m-2.15m (P/N 705900003) –

HCM management cable

Cable Management Tray - includes management tray with routed

ERFC cable and door sleeve

ERFC (Expander Cable) - RF interface cable between RIX and OIX

modules; 9 pin SMP to SMP connector; L=34 in

radio interface module (service specific) 1

1

1

1

1

Optical Interface Module (OIM) 1

MTP-LC APC Harness Cable (P/N 37HP900162-006F) - connector

for splitting fibers (6) leading from OIM to (FMU) Edge module

Radio Expander Module – expands the RF sources to the OIM

modules via the OIX

Pilot Transport Cable (P/N: PCKC47*) – Single QMA to QMA cable;

L = 47 in; used for passing reference clock signal connections

between RIX modules.