Instruction Manual

For All Corning® Hot Plates, Stirrers,

Stirrer/Hot Plates with Digital Displays, and

External Temperature Controller (6795PR)

Corning Cat. No.

230V 230V

Model No. Product Top Plate Size 120V 100V (Non-Europe) (Europe)

PC-400D Hot Plate 5 x 7 in. 6795-400D 6797-400D 6798-400D 6796-400D

(12.7 x 17.8 cm)

PC-410D Stirrer 5 x 7 in. 6795-410D 6797-410D 6798-410D 6796-410D

(12.7 x 17.8 cm)

PC-420D Stirrer/ 5 x 7 in. 6795-420D 6797-420D 6798-420D 6796-420D

Hot Plate (12.7 x 17.8 cm)

PC-600D Hot Plate 10 x 10 in. 6795-600D 6797-600D 6798-600D 6796-600D

(25.4 x 25.4 cm)

PC-610D Stirrer 10 x 10 in. 6795-610D 6797-610D 6798-610D 6796-610D

(25.4 x 25.4 cm)

PC-620D Stirrer/ 10 x 10 in. 6795-620D 6797-620D 6798-620D 6796-620D

Hot Plate (25.4 x 25.4 cm)

6795PR External All Models 6795PR

Temperature

Controller

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

About This Manual

This manual is designed to assist you in the optimal usage of your Corning®

hot plate, stirrer, stirrer/hot plate, or external temperature controller.

The manual contains English, German, French, Italian, Spanish, and Polish

versions and are also available at

Table of Contents

1.0 Safety Information ....................... 2

2.0 Operating Conditions .................... 3

Product Voltages

Hot plates, stirrers, and stirrer/hot plates are available in different voltages.

Before initial use, check that the unit you received is the correct voltage for

your location.

Warranty Registration

Register your product warranty online at

3.0 Product Controls and Indicators .......... 4

4.0 Product Connections ..................... 4

5.0 Stirring Instructions ...................... 5

6.0 Heating Instructions ..................... 6

7.0 Heating Operation ...................... 7

7.1 Principles ............................ 7

7.2 Safety ............................... 9

8.0 Repair ................................... 9

9.0 Maintenance ............................ 9

10.0 Optional Accessories .................... 11

11.0 Replacement Parts ...................... 12

12.0 Technical Specifications ................ 12

13.0 Size and Dimensions .................... 13

14.0 Troubleshooting ........................ 13

15.0 Product Disposal ........................ 14

16.0 Warranty ............................... 15

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

1

1.0 Safety Information

This instruction manual contains important operating and maintenance

instructions that must be read, understood, and followed by the product

user. Failure to use this product according to this instruction manual may

degrade or defeat the protection normally provided by this product. Read

this instruction manual prior to product use and keep this instruction

manual for future reference.

Product Symbols

Caution – Risk of Danger: Cautions there is material in the

instruction manual which must be read, understood, and

followed in order to preserve product safety features.

Caution – Hot Surface: Cautions that the top plate is too

hot to touch.

Indicates that the unit is plugged into power supply.

Indicates that the accessory external temperature

controller is properly plugged into the unit.

Warnings

Personal Injury

w Do not use this product in a manner other than as stated in the Operating

Conditions section as the protection provided by the equipment may be

impaired.

w This product is designed for use in laboratory environments by persons

knowledgeable in safe laboratory practices.

w Always wear safety glasses and other appropriate protective equipment

when operating this product.

Electric Shock

w This product must be connected to a grounded power outlet for safe

functioning.

w Use only the power cord supplied with the product.

w The power cord is the device available for full disconnect from mains input.

w Position the product for use so the power cord can be easily disconnected

without having to move the product.

w Disconnect the power cord before moving or cleaning the unit.

Product Damage

w Keep the product dry and clean.

w Do not immerse the product for cleaning.

w The ceramic top may break if impacted.

w The maximum gross weight placed on the top surface must not exceed

25 lbs. (11 kg).

w These units are not explosion- or spark-proof.

w Do not heat or stir volatile or flammable materials.

w Do not operate this product near volatile or flammable materials.

w Do not use this product with a metal vessel.

2.0 Operating Conditions

Corning hot plates, stirrers, and stirrer/hot plates are designed to provide

safe functioning under the following conditions:

w Indoor use

w Altitude up to 6,500 feet (2,000 meters)

w Ambient temperatures of 0°C to 30°C

w Product should be placed on a flat surface at least 12 in. (30.5 cm) from

walls, 48 in. (122 cm) from ceilings, and 12 in. (30.5 cm) from other hot

plates if using multiple units.

w Maximum relative humidity of 80% for temperatures up to 31°C, decreasing

linearly to 50% relative humidity at 40°C.

w Pollution Degree 2: Any foreign matter that may accumulate on or within

the product during normal use is not electrically conductive.

w Installation Category II: Product is designed for connection to an electrical

branch circuit inside a building with main supply voltage fluctuations not

exceeding ±10% of the nominal voltage.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

32

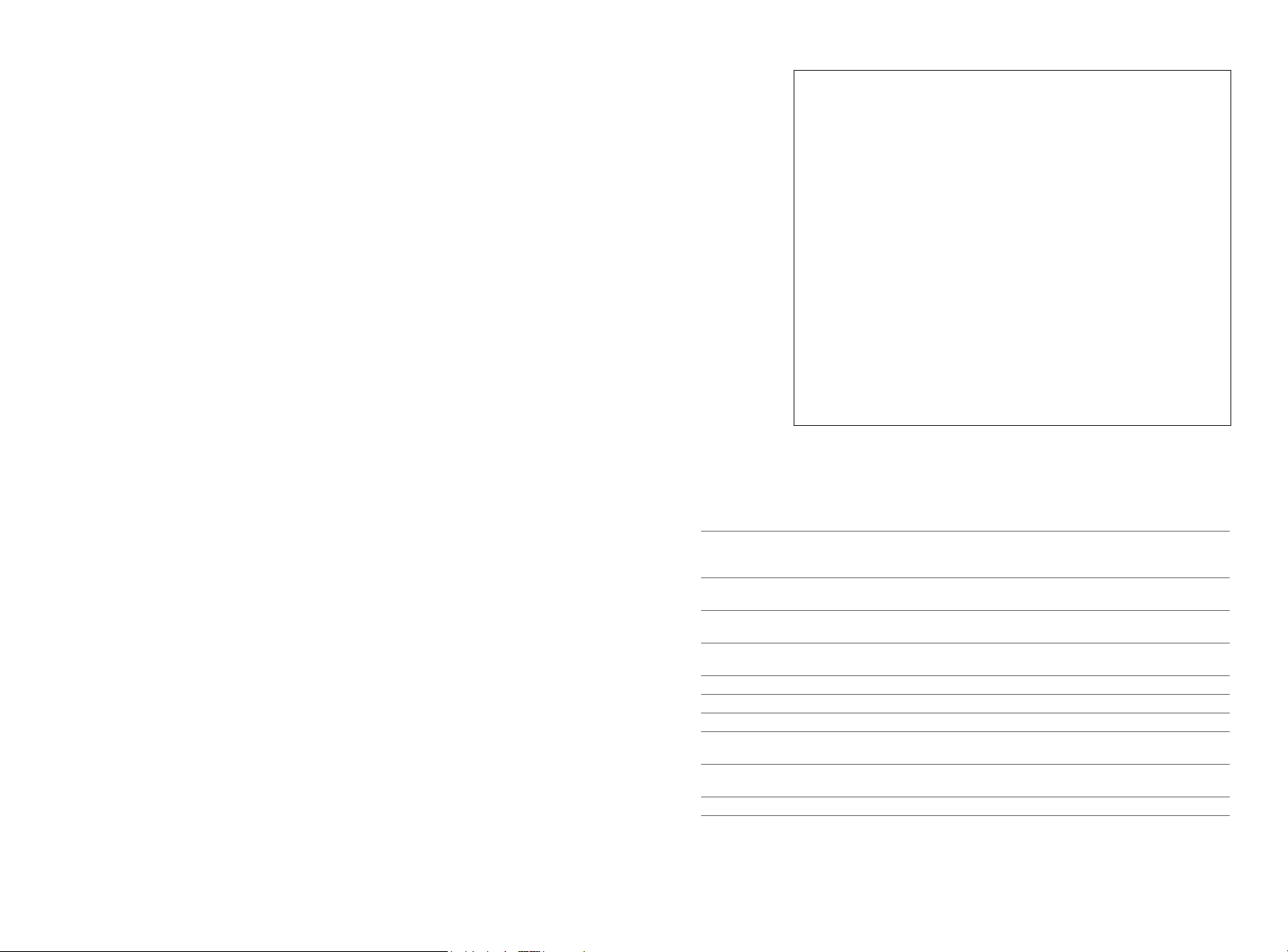

3.0 Product Controls and Indicators

1

7

3

2

6

5

4

1. Power Indicator: Illuminates at all times when the product is properly

connected to input power.

2. Stir Control Knob: Turn the knob all the way counterclockwise to turn off

stirring function. Turn the knob clockwise to set desired stirring speed.

3. Stirring Speed Display: Shows the speed set for stirring

4. Heat Control Knob: Turn the knob all the way counterclockwise to turn

off heating function. Turn the knob clockwise to set the desired heating

temperature.

5. Heating Temperature Display: Shows the temperature set for heating.

6. Hot Top Indicator: Illuminates when the temperature of the top is too

hot to touch (greater than ~60°C).

7. Temperature Probe In-Use Indicator: Illuminates when the external

temperature probe is connected to the unit.

4.0 Product Connections

1. Power Cord Input: Connect the supplied power cord into this connector.

2. External Temperature Controller Input: Connect the optional External

Temperature Controller (Corning Cat. No. 6795PR) into this connector.

2

1

To Connect the External Temperature Controller

1. Turn the Stir Control Knob and Heat Control Knob to the OFF position.

2. Disconnect power cord.

3. Insert temperature controller connector into the input connector.

4. Reconnect power cord.

5. Product is now ready for use with the External Temperature Controller.

Repeat the above process when disconnecting the Temperature Controller.

5.0 Stirring Instructions

for

1. Fill the vessel with solution to be stirred.

2. Place the stir bar into the vessel.

3. Place the vessel in the center of the top surface.

4. Turn Stir Control Knob until the Stirring Speed Display shows the

5. When desired stirring is complete, turn the Stir Control Knob to the OFF

6. Heating and stirring can be performed simultaneously with the PC-420D

NOTE: The viscosity of the stirred material will affect the ability of the

stir bar to remain coupled to the rotating ring magnet. Materials of high

viscosity must be stirred at slower speed settings.

PC-410D, PC-420D, PC-610D, PC-620D Models

desired speed. The speed setting can be adjusted according to the table

below.

Operating Range (rpm) Adjustable Increment (rpm)

60 - 100 5

100 - 200 10

200 - 400 20

400 - 1,150 50

w Flashing Display: The number will FLASH when the actual stirring

speed is not at set speed.

w Constant Display: The number will not flash when the actual stirring

speed is at the set speed. The number will remain constantly ON when

the actual stirring speed is at the set speed.

position. Allow stir bar to cease rotation before removing the vessel from

the unit.

and PC-620D models, which offer both heating and stirring functions.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

54

6.0 Heating Instructions

Without External Temperature Controller for PC-400D, PC-420D,

PC-600D, and PC-620D Models

1. Fill the vessel with solution to be heated.

2. If using a PC-420D or PC-620D model and the stirring function, place the

stir bar into the vessel.

3. Place vessel in the center of the top surface.

4. Turn Heat Control Knob until the Heating Temperature Display shows

the desired temperature. The temperature setting can be adjusted in 5°C

increments.

w Flashing Display: The number shown on the Heating Temperature

Display will FLASH

set temperature.

w Constant Display: The number shown on the Heating Temperature

Display will remain constantly ON when the actual heating temperature

is at the set temperature.

w Hot Top Indicator: The Hot Top Indicator will be ON at all times when

the temperature of the top surface is too hot to touch (greater than

60°C).

~

w The Hot Top Indicator will FLASH when the Heat Control Knob is

turned OFF

w The Hot Top Indicator will be OFF when the temperature of the top is

less than

~

Caution: The Hot Top Indicator will turn OFF when the power cord is

disconnected from the product even if the temperature of the top surface

is still too hot to touch.

With External Temperature Controller, Corning Cat. No. 6795PR

for PC-400D, PC-420D, PC-600D, PC-620D, and 6795PR Models

1. Connect the External Temperature Controller to the connector on the

back of the unit.

w Temperature Probe in Use Indicator: This will illuminate when the

External Temperature Controller is properly connected.

2. Fill the vessel with solution to be heated.

3. If using a PC-420D or PC-620D model and the stirring function, place the

stir bar into the vessel.

4. Place the vessel in the center of the top surface.

when the actual heating temperature is not at the

but the top surface is still too hot to touch.

60°C.

5. Insert the tip of the External Temperature Probe into the solution.

w The tip should be located in the center of the vessel and at

approximately one-half of the depth of the solution.

6. Secure the position of the External Temperature Controller by using a

ring stand/support rod and clamp.

w Ensure the cable of the External Temperature Controller does not come

into contact with the heating surface.

7. Turn the Heat Control Knob until the Heating Temperature Display

shows the desired heating temperature.

w Flashing Display: The number shown on the Heating Temperature

Display will FLASH when the actual heating temperature is not at the

set temperature.

w Constant Display: The number shown on the Heating Temperature

Display will remain constantly ON when the actual heating temperature

is at the set temperature.

w Hot Top Indicator: The Hot Top Indicator will be ON at all times when

the temperature of the top surface is too hot to touch (greater than

60°C).

~

w The Hot Top Indicator will FLASH when the Heat Control Knob is

turned OFF

w The Hot Top Indicator will be OFF when the temperature of the top is

less than

but the top surface is still too hot to touch.

60°C.

~

Caution: The Hot Top Indicator will turn OFF when the power cord is disconnected from the product even if the temperature of the top surface is

still too hot to touch.

7.0 Heating Operation

7.1 Principles

The heating element and a temperature sensor are located just beneath

the ceramic top surface of the product. The microprocessor-controlled heat,

generated by the heating element, is based upon the sensor temperature

and the value set on the Heating Temperature Display. When the sensor

temperature is not within range of the value set on the display, the display

will FLASH

will remain constantly ON.

The Heating Temperature Display does not indicate the actual temperature

of materials placed on top of the product or the actual temperature of the

ceramic top surface.

. When the sensor temperature is within range, the value displayed

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

76

The following table shows a typical difference between the temperature

set on the Heating Temperature Display and the actual temperature

measurement of the ceramic top surface.

Actual Actual

Temp. Set Top Surface Temp. Set Top Surface

on Display (°C) Temp. (°C) on Display (°C) Temp. (°C)

50 45 350 285

100 85 400 325

150 125 450 365

200 165 500 405

250 205 550 440

300 245

(This information was taken using a 6795-420D with no top load in 20°C

ambient conditions).

Using the External Temperature Controller (Corning Cat. No. 6795PR) enables

precision temperature control of materials placed in vessels on top of

the product.

When the External Temperature Controller is connected to the product, the

closed loop control process is extended to include temperature input from

the External Temperature Controller. The microprocessor-controlled heat,

generated by the heating element, is based upon the sensor temperature

located in the tip of the External Temperature Controller and the value set

on the Heating Temperature Display. When the sensor temperature is not

within range of the value set on the display, the display will FLASH. When

the sensor temperature is within range, the value displayed will remain

constantly ON

.

To directly control the temperature of liquid in a vessel on the top surface,

place the External Temperature Controller into the liquid and connect the

Controller to the product. The Heating Temperature Display shows the

temperature of the liquid and can be used to adjust the temperature of

the liquid.

See Section 10.0 for ordering information.

Caution: The top surface and the vessel used may be at substantially higher

temperatures than indicated by the setting on the Heating Temp erature

Display as the controller regulates the liquid temperature inside the vessel.

7.2 Safety

The microprocessor-controlled system has built-in error routines to detect

product operation in some unfavorable conditions. The type of error routines which may be active in a product varies depending upon the functionality of the model and the operating software version.

If an error routine is engaged, the product will typically shut down. Some

error routines will display an error code number in the left digital location

of the Heating Temperature Display when the product is shut down.

A product shut down by an error routine must be disconnected and reconnected to mains input before it can be used again.

Caution: Error routines built into these products do not substitute the need

to use these products per the specified operating conditions and according

to safe laboratory practices. There are potential failure modes in product

functionality or in the process of use that could result in uncontrolled or

unexpected heating of the top surface. Reaction plans should be developed

and safety precautions put in place based on the worse case scenario that

any materials placed on the top surface could be subjected to a continuous

supply of heat, raising the material temperature to levels in excess of 550°C.

8.0 Repair

There are no direct user serviceable components inside this series of

products. A list of available replacement parts are listed in Section 11.0.

9.0 Maintenance

Power

Caution: Disconnect power to the product by unplugging the power cord

before performing any maintenance or inspection procedures.

w Inspect the power cord regularly and replace if damaged. Use only

replacement power cords available from Corning or Corning authorized

product distributors.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

98

Ceramic Top Plate

w These products are supplied with a Pyroceram® top that is easy to clean

and highly resistant to scratches, corrosion, and chemical attack.

w The ceramic top may break during use if not properly maintained.

w Keep the ceramic top clean. A nonabrasive cleaner may be used to clean

the ceramic top.

w Inspect the ceramic top for damage during cleaning.

w Discontinue product use if the ceramic top is chipped, etched, or shows

excessive scratching. A replacement top can be ordered (Section 11.0).

General

w It is important to keep this product dry and clean.

w Remove minor exterior liquid spills promptly.

w Clean exterior surfaces with a nonabrasive cleaner. Do not reconnect

product to power input until all cleaned surfaces have dried.

w If liquid or wet solid material gets inside the product, immediately

disconnect the power to the product and discontinue use.

Accessories (Shown with Corning Cat. No. 6795-420D)

10.0 Optional Accessories

Corning Cat. No. Description

6795PR External Temperature Controller for digital display Hot Plates and

Hot Plate/Stirrers. Use with all PC-400D, 420D, 600D, and 620D models.

FEP-coated stainless steel.

440129 Vertical Support Rod. Supplied as two 9 in. (22.86 cm) rods which can be

screwed together. Use with all PC-XXXD series products. Stainless steel.

440140 Boss Head Clamp. Use for connecting the 440141 Holding Rod at a 90° angle

to the 440129 Support Rod. Aluminum.

440141 Holding Rod. Use for holding the 6795PR External Temperature Controller in

position. Aluminum.

6795KIT Universal Accessories Kit includes: 6795PR, 6970SR, and 440129

6795-420KIT Kit includes: 6795-420D Stirrer/Hot Plate, 6795PR, 6970SR, and 440129

6795-620KIT Kit includes: 6795-620D Stirrer/Hot Plate, 6795PR, 6970SR, and 440129

400430 PTFE-coated magnetic stir bar, .39 x 2 in. (1 x 5.1 cm) – recommended size

for all PC-610D and 620D models

401435 PTFE-coated magnetic stir bar, .39 x 1 in. (1 x 2.5 cm) – recommended size

for all PC-410D and 420D models

6970SR Stir bar retriever, polypropylene

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

1110

11.0 Replacement Parts

Corning Cat. No. Description Model Usage

411007 Power cord PC-400D/410D/420D, 120V

410956 Power cord PC-600D/610D/620D, 120V

411021 Power cord PC-400D/410D/420D and PC-600D/610D/620D, 100V

410942 Power cord PC-400D/410D/420D and PC-600D/610D/620D,

230V (UK plug)

440124 Power cord PC-400D/410D/420D and PC-600D/610D/620D,

230V (Euro Plug)

Contact Corning Ceramic top plate/ PC-400D/410D/420D, All Voltages

Customer Service element assembly,

5 x 7 in.

Contact Corning Ceramic top plate/ PC-600D/610D/620D, All Voltages

Customer Service element assembly,

10 x 10 in.

Contact Corning PC control board —

Customer Service

440135 Control knob All models

12.0 Technical Specifications

Power

120V/60Hz 100V/60Hz 230V/50Hz 230V/50Hz Temp. Stir Range

Model No. Type (6795 models) (6797 models) (6796 models) (6798 models)1 Range2 (rpm) Weight

PC-400D Hot 628W/ 548W/ 628W/ 628W/ 5°C-550°C — 6.0 lbs.

Plate 5.3A 5.5A 2.7A 2.7A (41°F-1,022°F) (2.7 kg)

PC-600D Hot 1043W/ 1043W/ 1043W/ 1043W/ 5°C-550°C — 10.0 lbs.

Plate 8.7A 10.5A 4.5A 4.5A (41°F-1,022°F) (4.5 kg)

PC-410D Stirrer 73W/ 78W/ 73W/ 73W/ — 60-1,150 7.0 lbs.

0.7A 0.8A 0.3A 0.3A (3.2 kg)

PC-610D Stirrer 73W/ 78W/ 73W/ 73W/ — 60-1,150 11.5 lbs.

0.7A 0.8A 0.3A 0.3A (5.2 kg)

PC-420D Stirrer/ 698W/ 623W/ 698W/ 698W/ 5°C-550°C 60-1,150 7.0 lbs.

Hot Plate 5.9A 6.3A 0.3A 0.3A (41°F-1,022°F) (3.2 kg)

PC-620D Stirrer/ 1113W/ 1113W/ 1113W/ 1113W/ 5°C-550°C 60-1,150 11.5 lbs.

Hot Plate 9.3A 11.2A 4.8A 4.8A (41°F-1,022°F) (5.2 kg)

1

Cat. Nos. beginning with 6798 in 230V are non-European configuration models.

2

The Temperature Range using the External Temperature Controller is 5°C - 200°C (41°F - 392°F).

13.0 Size and Dimensions

Model No. Top Plate Size Product Dimensions

PC-400D/410D/420D 5 x 7 in. 4.25 x 7.75 x 11 in.

(12.7 x 17.8 cm) (10.8 x 19.7 x 28 cm)

PC-600D/610D/620D 10 x 10 in. 4.625 x 11 x 15.375 in.

(25.4 x 25.4 cm) (11.75 x 19.7 x 39.05 cm)

14.0 Troubleshooting

w I have a beaker of water on my hot plate and set the temperature for

550°C. Why does the display setting blink and not remain constant?

The display will blink at any time when the temperature sensor is not

within range of the set temperature value. The temperature measured

by the sensor is a composite of the temperature of the heating element

located beneath the sensor, the ceramic top above the sensor, and the

very small air space around the sensor. Water requires a substantial

amount of heat in order to boil yet remains at a constant temperature

of 100°C for the duration of the boiling process. Although the heating

element is producing maximum heat at the 550°C setting, the water

consumes this heat so quickly during the boiling process that the heat

is unable to raise the temperature measured by the sensor to within the

range of the 550°C set value.

w How long does it take to bring a beaker of water to a boil?

Using a 600 mL PYREX® beaker with 400 mL of water at 25°C, it takes

approximately 15 minutes to bring the water to a full, rolling boil.

w Can I use a metal tray on top of my Corning

No. The metal will act as a heat sink, and have a high probability of

creating an abnormal heating condition. If an abnormal condition is

detected, the product will shut down. A metal vessel will also scratch the

ceramic top plate.

w The stir bar keeps decoupling. Why and what can I do to stop this?

These units are programmed to minimize decoupling. However, liquid

viscosity, stir bar magnetic strength, vessel used, and speed changes

can cause decoupling. High viscosity liquids must be stirred at slower

speed settings. The magnetic strength of stir bars can weaken over time

and may need to be replaced. The vessels used need to have thin, flat

bottoms to insure optimal performance. Rapid decreases in stir speed

can cause decoupling as the magnet slows down quicker than the stir bar

and the liquid.

w What size vessel should I use?

The vessels used on the top of a hot plate must not be larger than the

top plate.

®

hot plate?

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

1312

w Corning sells replacement parts. Can I do the repairs myself instead of

sending it in to Corning’s equipment repair department?

When repairs are completed by Corning or a Corning authorized repair

facility, the performance and safety of the product will be verified before

being returned to you. We do sell replacement parts so customers can

complete repairs themselves. It is recommended that only people knowledgeable in electronics complete those repairs. There is no warranty or

return on equipment replacement parts.

15.0 Product Disposal

According to Directive 2012/19/EU of the European Parliament and Council

of 4th July 2012 on waste and electronic equipment (WEEE) as amended,

Corning® Hot Plates, Stirrers, and Stirrer/Hot Plates are marked with the

crossed-out wheeled bin and must not be disposed of with domestic waste.

Consequently, the buyer shall follow the instructions for reuse and recycling

of waste electronic and electrical equipment (WEEE) provided with the

products and available at the following link:

16.0 Warranty

Corning Incorporated (Corning) warrants that this product will be free from

defects in material and workmanship for a period of two (2) years from

date of purchase. CORNING DISCLAIMS ALL OTHER WARRANTIES WHETHER

EXPRESSED OR IMPLIED, INCLUDING ANY IMPLIED WARRANTIES OF

MERCHANTABILITY OR OF FITNESS FOR A PARTICULAR PURPOSE. Corning’s

sole obligation shall be to repair or replace, at its option, any product or

part thereof that proves defective in material or workmanship within

the warranty period, provided the purchaser notifies Corning of any such

defect. Corning is not liable for any incidental or consequential damages,

commercial loss or any other damages from the use of this product.

This warranty is valid only if the product is used for its intended purpose

and within the guidelines specified in the supplied instruction manual.

This warranty does not cover damage caused by accident, neglect, misuse,

improper service, natural forces, or other causes not arising from defects

in original material or workmanship. This warranty does not cover motor

brushes, fuses, light bulbs, batteries, or damage to paint or finish. Claims

for transit damage should be filed with the transportation carrier.

In the event this product fails within the specified period of time because

of a defect in material or workmanship, contact Corning Customer Service

Corning’s Customer Service team will help arrange local service where

available, coordinate a return authorization number, or provide a return

authorization number and shipping instructions. Products received without

proper authorization will be returned. All items returned for service should

be sent postage prepaid in the original packaging or other suitable carton, padded to avoid damage. Corning will not be responsible for damage

incurred by improper packaging. Corning may elect for onsite service for

larger equipment.

Some states do not allow limitation on the length of implied warranties

or the exclusion or limitation of incidental or consequential damages. This

warranty gives you specific legal rights. You may have other rights which

vary from state to state.

No individual may accept for, or on behalf of Corning, any other obligation

of liability, or extend the period of this warranty.

For your reference, make a note of the model and serial number, date of

purchase, and supplier here.

Model No. _______________________________________________________________

Serial No. ________________________________________________________________

Date Purchased ___________________________________________________________

Supplier _________________________________________________________________

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

1514

Loading...

Loading...