Cornelius WCC1001 Installation Manual

CONTINUOUS FLOW ICEMAKER

Installation and Service Manual

500-Series

700-Series

1000-Series

2000-Series

Part No. 638085278

August 1, 2002

Revision D

THIS DOCUMENT CONTAINS IMPORTANT INFORMATION

This Manual must be read and understood before installing or operating this equipment

IMI CORNELIUS INC; 1997–2002

PRINTED IN U.S.A

TABLE OF CONTENTS

SAFETY INFORMATION 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

RECOGNIZE SAFETY INFORMATION 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

UNDERSTAND SIGNAL WORDS 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FOLLOW SAFETY INSTRUCTIONS 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

GENERAL DESCRIPTION 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SPECIFICATION CHART 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

INSTALLATION 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A. REMOVE ICEMAKER FROM CARTON 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B. CABINET REMOVAL 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C. PREPARATION OF INSTALLATION SITE 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

D. WATER INLET HOOK UP 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

E. DRAIN CONNECTION 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

F. ELECTRICAL SUPPLY 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

G. AUGER ENGAGEMENT 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

H. BIN CONTROL 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

INITIAL START UP, CHECKS AND ADJUSTMENT INSTRUCTIONS 8. . . . . . . . .

GUIDE TO SERVICE 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page

ICEMAKER CLEANING AND SANITIZING PROCEDURES 13. . . . . . . . . . . . . . . . .

MAINTENANCE 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

MONTHLY 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

QUARTERLY 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SEMI–ANNUALLY 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

WATER LEVEL CONTROL 15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

HOW WATER LEVEL CONTROL WORKS 15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PURPOSE 15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TO REPLACE WATER LEVEL CONTROL 15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TO REPLACE WATER LEVEL SAFETY SWITCH 15. . . . . . . . . . . . . . . . . . . . . . . . . .

REFRIGERATION SYSTEM 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

NOTE: THERMOSTATIC EXPANSION VALVE NO ADJUSTMENT 16. . . . . . . . . .

+10 LBS. DISCHARGE PRESSURE 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

WATER TEMPERATURE 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

AIR TEMPERATURE 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

REFRIGERATION SYSTEM ADJUSTMENTS 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

EXPANSION VALVE 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ADJUSTMENT AND TROUBLESHOOTING 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CONDENSER MODULATING VALVE 17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CONDENSER MODULATING VALVE REMOVAL 17. . . . . . . . . . . . . . . . . . . . . . . . . .

BIN CONTROL 18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

GEARMOTOR 18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

MOTOR CHECK 19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

START RELAY 19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TO REPLACE GEARMOTOR ASSEMBLY 20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

INSTALLATION AND SHAFT SEAL REPLACEMENT 20. . . . . . . . . . . . . . . . . . . . . . .

i

638085278

TABLE OF CONTENTS (cont’d)

AUGER AND EXTRUDING HEAD REMOVAL 21. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

INSTALLATION AND SHAFT SEAL REPLACEMENT 700 & 1000 21. . . . . . . . . . .

UPPER NUT AND BEARING ASSEMBLY 21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TO REPLACE BEARING 22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ELECTRICAL CHECKOUT 22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

OVERLOAD CHECK 22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

COMPRESSOR CHECK 22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CAPACITOR CHECK 23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SAFETY CONTROLS 23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TROUBLESHOOTING 27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

THE COMPRESSOR WILL NOT RUN 27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

THE COMPRESSOR STARTS BUT TRIPS REPEATEDLY ON THE

OVERLOAD PROTECTOR 27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

THE COMPRESSOR RUNS BUT WILL NOT REFRIGERATE 27. . . . . . . . . . . . . . .

REFRIGERATION AND ICEMAKER ASSEMBLY MODEL 500 SERIES 32. . . . . . .

REFRIGERATION AND ICEMAKER ASSEMBLY MODEL 700 SERIES 34. . . . . . .

REFRIGERATION AND ICEMAKER ASSEMBLY MODEL 1000 SERIES 36. . . . . .

Page

LIST OF FIGURES

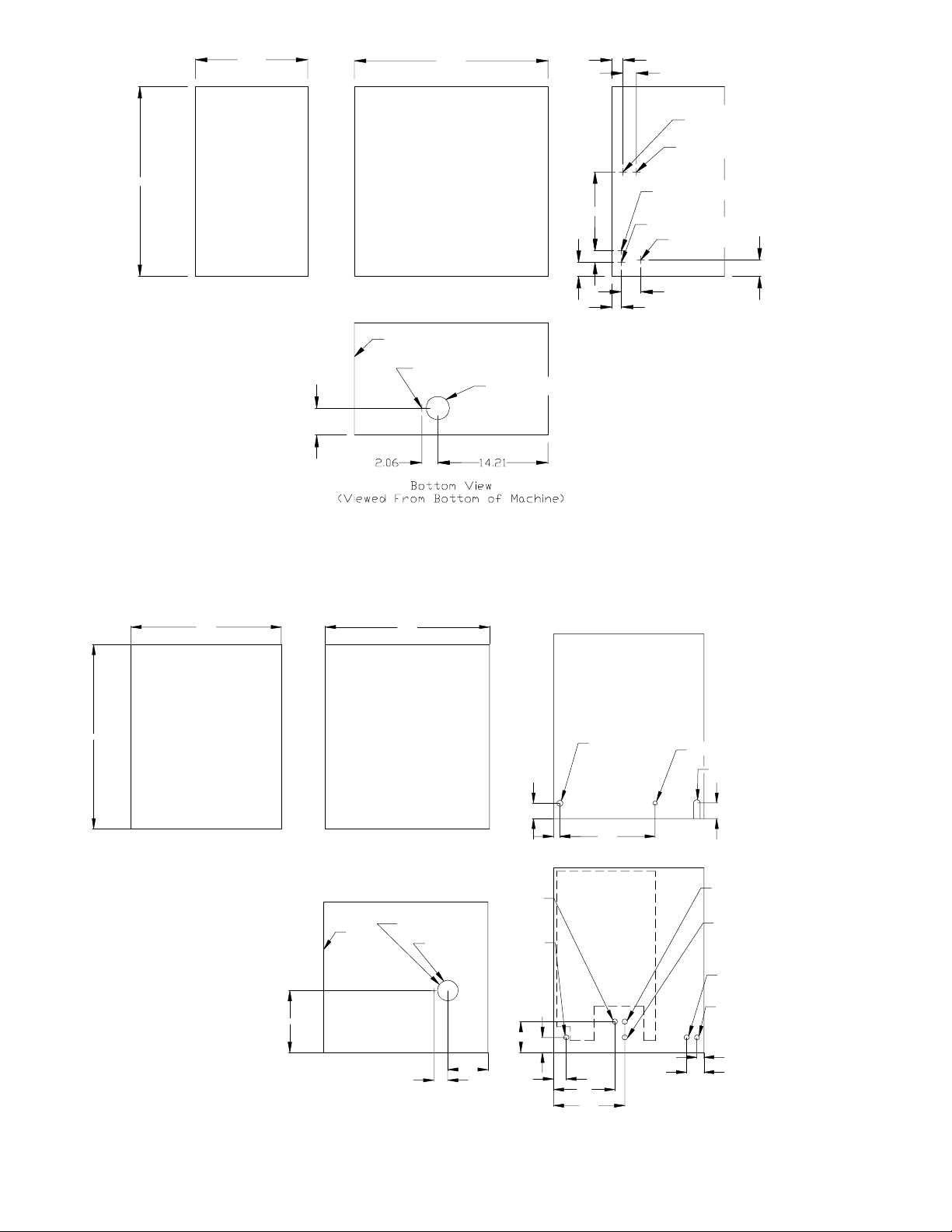

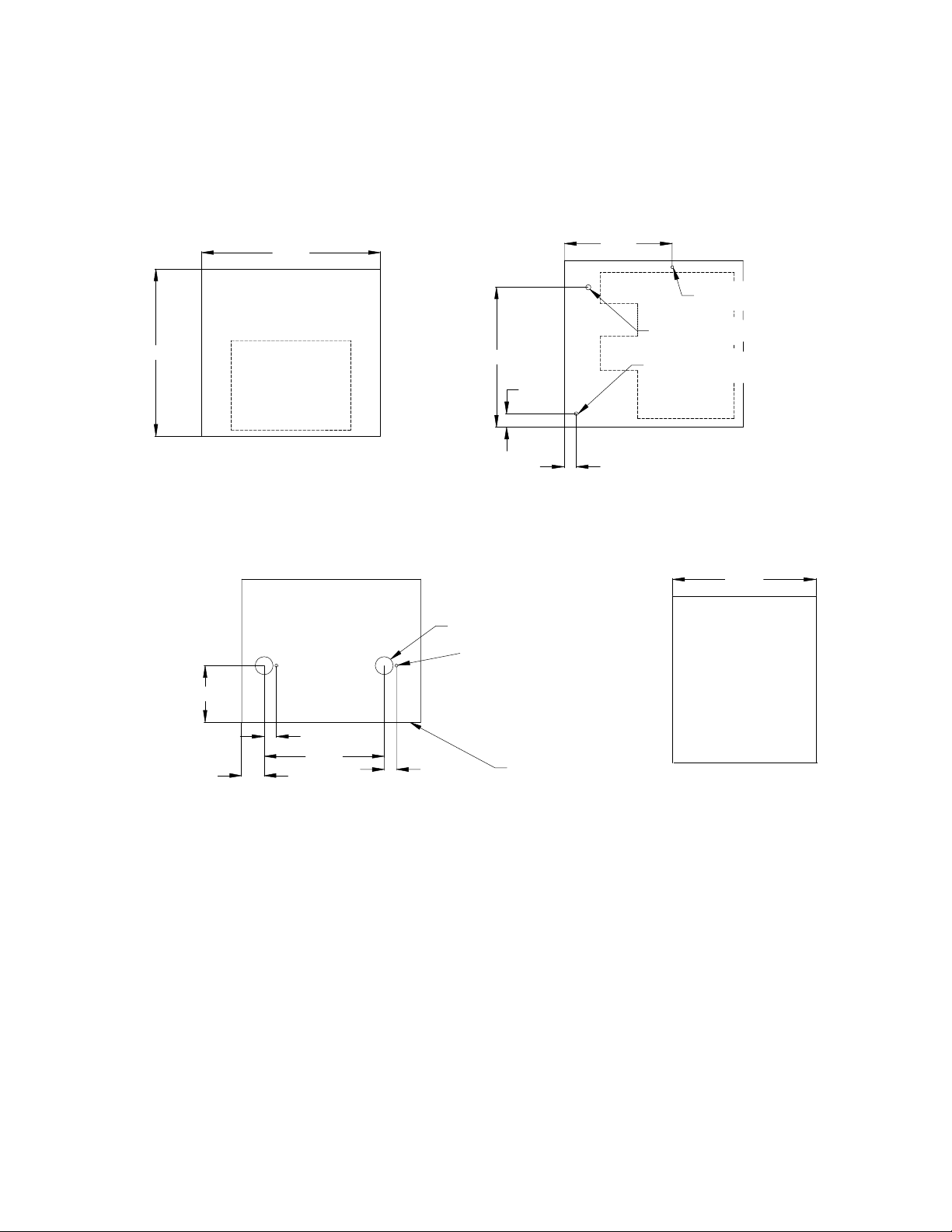

FIGURE 1. SERIES 500 & 700 DIMENSION DRAWING (SHIPPING WT.

160 LBS. APPROX). 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FIGURE 2. SERIES 1000 DIMENSION DRAWING (SHIPPING WT. 210

LBS. APPROX). 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FIGURE 3. SERIES WCC2001–A AND WCF2201–A DIMENSION DRAWINGS 5

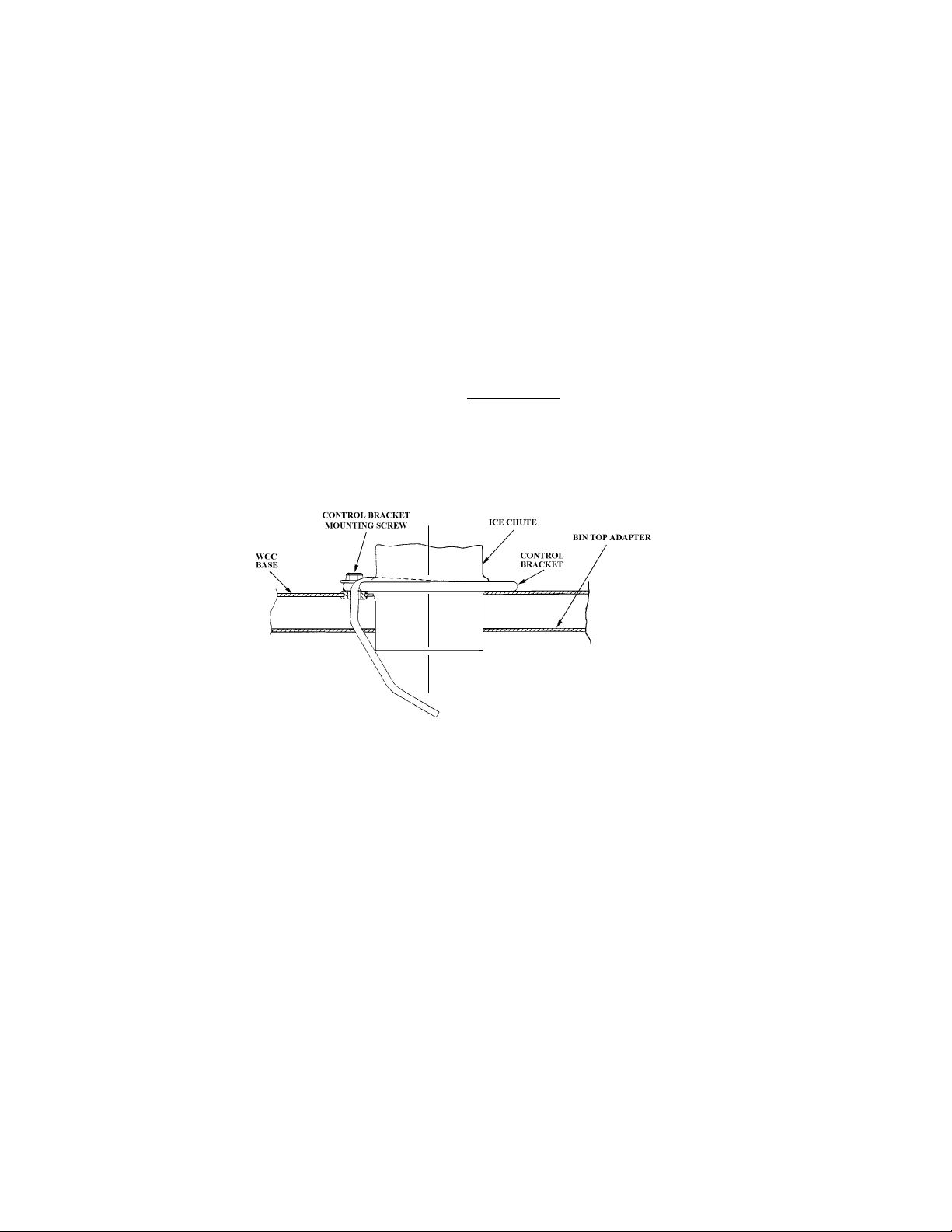

FIGURE 4. BIN CONTROL 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

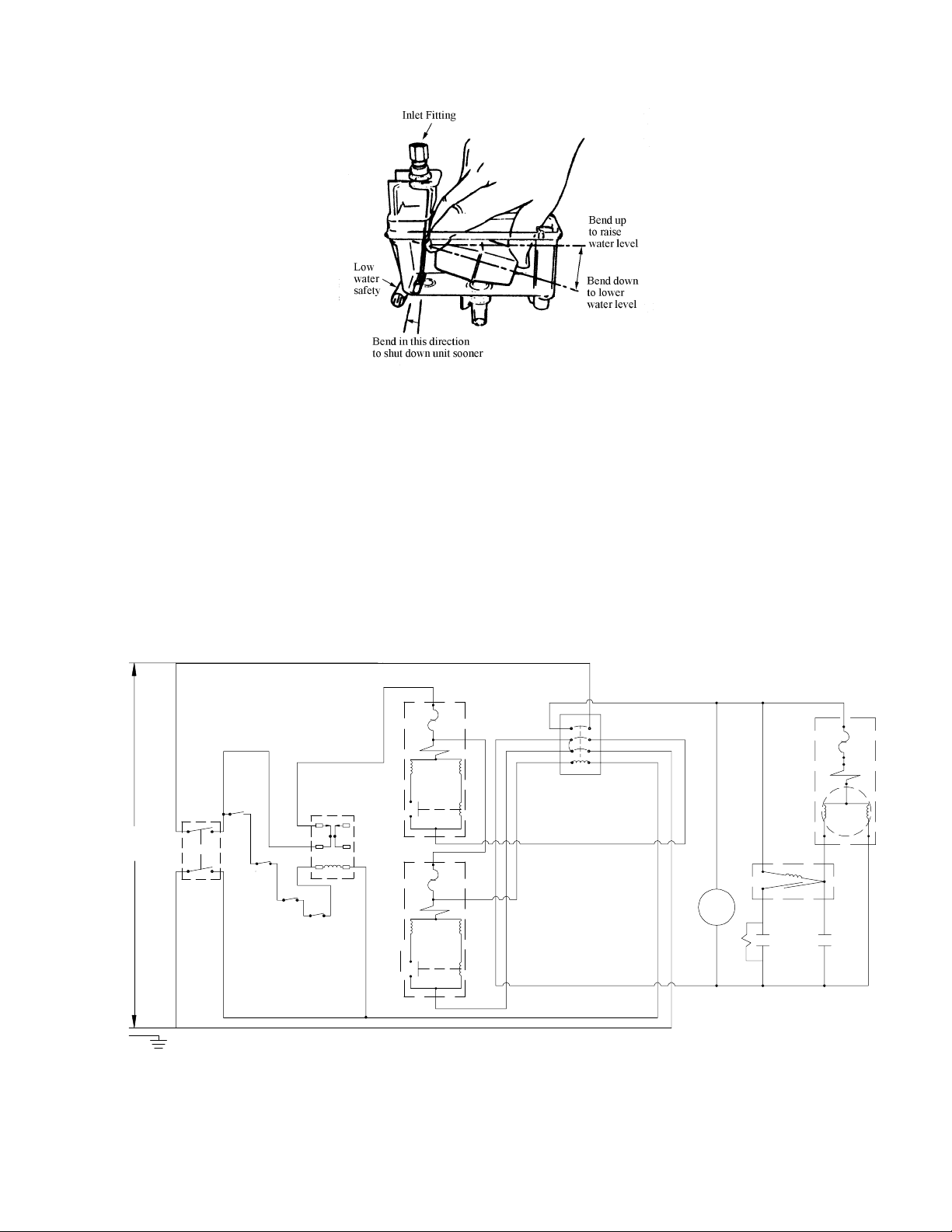

FIGURE 5. ICEMAKER FLOAT ASSEMBLY 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FIGURE 6. SCHEMATIC AND WIRING DIAGRAM WCC2001–A AND

WCF2201–A9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FIGURE 7. SCHEMATIC AND WIRING DIAGRAM WCC500–A, WCC500–W,

WCC700–A, WCC700–W, WCF510–A, WCF510–W, WCF710–A,

& WCF710–W10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FIGURE 8. SCHEMATIC AND WIRING DIAGRAM WCC701–A, WCC701–W,

WCC1001–A, WCC1001–W WCF711–A, WCF711–W, WCF1101–A,

& WCF1101–W10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FIGURE 9. SCHEMATIC AND WIRING DIAGRAM WCF1101R, WCC1001R,

WCF1102R, & WCC1102R 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FIGURE 10. SCHEMTIC AND WIRING DIAGRAM WCC502, WCC702, WCC1002,

WCF512, WCF712, & WCF1102 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FIGURE 11. SCHEMTIC AND WIRING DIAGRAM WCC2001-R AND

WCF2201-R 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FIGURE 12. UPPER NUT AND BEARING ASSEMBLY 14. . . . . . . . . . . . . . . . . . . . .

FIGURE 13. EXPANSION VALVE 17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FIGURE 14. ADJUSTMENT SCREW 17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FIGURE 15. BIN CONTROL SWITCH 18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FIGURE 16. GEARMOTOR ASSEMBLY 20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FIGURE 17. SHAFT SEAL 500 20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FIGURE 18. AUGER AND EXTRUDING HEAD REMOVAL 20. . . . . . . . . . . . . . . . .

638085278

ii

TABLE OF CONTENTS (cont’d)

FIGURE 19. SHAFT SEAL 700 & 1000 21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FIGURE 20. OVERLOAD CHECK 22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FIGURE 21. COMPRESSOR CHECK 22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FIGURE 22. GEAR MOTOR OVERLOAD 23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FIGURE 23. REFRIGERATION AND ICEMAKER ASSEMBLY MODEL 2000 SERIES

EXPLODED VIEW AND PARTS LIST 30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FIGURE 24. REFRIGERATION AND ICEMAKER ASSEMBLY MODEL

500 SERIES 31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FIGURE 25. REFRIGERATION AND ICEMAKER ASSEMBLY MODEL

700 SERIES 33. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FIGURE 26. REFRIGERATION AND ICEMAKER ASSEMBLY MODEL

1000 SERIES 35. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FIGURE 27. WATER LEVEL CONTROL ASSEMBLYMODEL WCC500/700/1000

SERIES EXPLODED VIEW AND PARTS LIST 37. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FIGURE 28. FRONT END ASSEMBLY MODEL 500 SERIES

EXPLODED VIEW AND PARTS LIST 38. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FIGURE 29. FRONT END ASSEMBLY MODEL 700 SERIES

EXPLODED VIEW AND PARTS LIST 39. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FIGURE 30. FRONT END ASSEMBLY MODEL 1000 & 2000 SERIES

EXPLODED VIEW AND PARTS LIST 40. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FIGURE 31. ELECTRICAL BOX ASSEMBLY MODEL 500 AND 700 SERIES 41. .

FIGURE 32. ELECTRICAL ASSEMBLY MODEL 1000 AND 2000 SERIES 42. . . . .

WARRANTY 43. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page

iii

638085278

SAFETY INFORMATION

Recognize Safety Information

This is the safety-alert symbol. When you see this

symbol on our machine or in this manual, be alert to

the potential of personal injury.

Follow recommended precautions and safe operating

practices.

Understand Signal Words

A signal word - DANGER, WARNING, CAUTION is

used with the safety-alert symbol. DANGER identifies

the most serious hazards.

DANGER

Safety signs with signal word DANGER or WARNING

are typically near specific hazards.

General precautions are listed on CAUTION safety

signs. CAUTION also calls attention to safety messages in this manual.

WARNING

CAUTION

Follow Safety Instructions

Carefully read all safety messages in this manual and on your machine safety signs. Keep safety signs in

good condition. Replace missing or damaged safety signs. Learn how to operate the machine and how to

use the controls properly. Do not let anyone operate the machine without instructions. Keep your machine in

proper working condition. Unauthorized modifications to the machine may impair function and/or safety and

affect the machine life.

CAUTION: Very high discharges pressure is present in system. Quick disconnects on your

gages will minimize danger and loss of refrigerant.

CAUTION: Unit requires separate electrical line. See instruction manual for proper fuse

size.

WARNING: There must be adequate clearance around icemaker. Allow minimum 6” air

intake and 4” air exhaust for air exhaust and panel removal.

NOTE: Unit must be installed per local plumbing and electrical codes. See Installation manual for

unit requirements. Failure to do so may cause damage to unit, which would void unit warranty.

NOTE: Using any parts other than genuine factory manufactured parts relieves the manufacturer of all

liability.

NOTE: Manufacturer reserves the right to change specifications at any time.

1

638085278

THIS PAGE LEFT BLANK INTENTIONALLY

638085278

2

GENERAL DESCRIPTION

This section gives the Unit description, theory of operation, and design data for continuous flow icemaker series

500, 700, 1000, and 2000.

IMPORTANT: To the user of this manual – This manual is a guide for installing, operating, and maintaining this equipment. Refer to the Table of Contents for page location for detailed information pertaining to questions that arise during installation, operation, service, or maintenance of this equipment.

SPECIFICATION CHART

Models Condensing VAC HZ PH Wire Comp. Fan GRMTR

Unit RLA Amps Amps

Refrigerant

Oz. Type

Circuit

Fuse

WCC500–A Air Cooled 115 60 1 2 10.1 1.1 2 24 R404A 20

WCC500–W Water Cooled 115 60 1 2 10.1 N/A 2 11 R404A 20

WCC502–A Air Cooled 220/240 50 1 2 5.3 0.5 1.6 24 R404A 20

WCC502–W Water Cooled 220/240 50 1 2 5.3 N/A 1.6 11 R404A 20

WCF510–A Air Cooled 115 60 1 2 10.1 1.1 2 24 R404A 20

WCF510–W Water Cooled 115 60 1 2 10.1 N/A 2 11 R404A 20

WCF512–A Air Cooled 220/240 50 1 2 5.3 0.5 1.6 24 R404A 20

WCF512–W Water Cooled 220/240 50 1 2 5.3 N/A 1.6 11 R404A 20

WCC700–A Air Cooled 115 60 1 2 12 1.6 2 24 R404A 20

WCC700–W Water Cooled 115 60 1 2 12 N/A 2 13 R404A 20

WCC701–A Air Cooled 208/230 60 1 2 7.7 1.6 2 24 R404A 20

WCC701–W Water Cooled 208/230 60 1 2 7.7 N/A 2 13 R404A 20

WCC702–A Air Cooled 220/240 50 1 2 8.2 0.5 1.6 24 R404A 20

WCC702–W Water Cooled 220/240 50 1 2 8.2 N/A 1.6 13 R404A 20

WCF710–A Air Cooled 115 60 1 2 12 1.6 2 24 R404A 20

WCF710–W Water Cooled 115 60 1 2 12 N/A 2 13 R404A 20

WCC711–A Air Cooled 208/230 60 1 2 7.7 1.6 2 24 R404A 20

WCC711–W Water Cooled 208/230 60 1 2 7.7 N/A 2 13 R404A 20

WCF712–A Air Cooled 220/240 50 1 2 8.2 0.5 1.6 24 R404A 20

WCF712–W Water Cooled 220/240 50 1 2 8.2 N/A 1.6 13 R404A 20

WCC1001–A Air Cooled 208/230 60 1 2 7.5 0.85 2 26 R404A 20

WCC1001–W Water Cooled 208/230 60 1 2 7.5 N/A 2 17 R404A 20

WCC1002–A Air Cooled 220/240 50 1 2 8.9 0.85 2 26 R404A 20

WCF1101–A Air Cooled 208/230 60 1 2 7.5 0.85 2 26 R404A 20

WCF1101–W Water Cooled 208/230 60 1 2 7.5 N/A 2 17 R404A 20

WCF1102–A Air Cooled 220/240 50 1 2 8.9 0.85 2 26 R404A 20

WCC1001–R Remote 220/240 60 1 2 7.5 N/A 2 120 R404A 15

WCF1101–R Remote 208/230 60 1 2 7.5 N/A 2 120 R404A 15

WCC2001-A Air-Cooled 208/230 60 1 2 12.9 .85 (2) 2 46 R404A 25

WCC2001-R Remote 220/240 60 1 2 12.9 1.7 (2) 2 220 R404A 25

WCC2001-W Water Cooled 208/230 60 1 2 12.9 N/A (2) 2 28 R404A 25

WCC2002-A Air Cooled 220/240 50 1 2 11.4 .85 (2) 2 46 R404A 25

WCF2201-A Air-Cooled 208/230 60 1 2 12.9 .85 (2) 2 46 R404A 25

WCF2201-W Water Cooled 208/230 60 1 2 12.9 N/A (2) 2 28 R404A 25

WCF2202-A Air Cooled 220/240 50 1 2 11.4 .85 (2) 2 46 R404A 25

NOTE: For units not listed in above chart, refer to nameplate or contact factory service.

WCC500

90 80

70 60

Water Temperature Deg. F

–50 –70 –90 –100

Air Temperature Deg. F

400

380

360

340

320

300

280

Capacity Lbs./24 hr.

260

240

50

90 80 70 60 50

WCC700

Water Temperature Deg. F

–50 –70 –90 –100

Air Temperature Deg. F

650

600

550

500

450

400

350

Capacity Lbs./24 hr.

90 80 70 60 50

WCC1000

Water Temperature Deg. F

–50 –70 –90 –100

Air Temperature Deg. F

3

1100

1000

900

800

700

600

638085278

Capacity Lbs./24 hr.

14.50

25.00 1.38

1.75

INLET 3/8 FLARED

WATER COOLED ONLY

OUTLET 3/8 FLRE

WATER COOLED ONLY

24.50

FRONT

10.15

1.50

1.81

SIDE

FRONT

BIN CONTROL PROBE

ICE DISCHARGE

3.50

DRAIN 3/8 ID TYGON TUBE

WATER IN 1/4 FLARE

ELECTRIC 7/8 DIA

2.50

1.19

BACK VIEW

AIR OR WATER COOLED

FIGURE 1. SERIES 500 & 700 DIMENSION DRAWING (Shipping Wt. 160 lbs. Approx).

22.00

24.00

2.12

27.00

FRONT

9.04

0.94 13.94

SIDE

W/C INLET

3/8” FPT

FRONT

(VIEWED FROM BOTTOM OF MACHINE)

BIN CONTROL PROBE

ICE DISCHARGE

2.06

BOTTOM VIEW

5.87

POWER INLET

7/8” DIA.

BACK VIEW

(AIR COOLED)

ELECTRICAL 7/8” DIA.

2.25

AIR EXHAUST

4.50

2.19

1.88

9.00

10.44

WATER UB 1/4” MALE FLARE

DRAIN 3/8” ID TYGON TUBE

2.25

(REMOTE)

DISCHARGE LINE

1/2 PUNCTURE FITTING

W/C OUTLET 3/8” FPT OR

REMOTE COND. LIQ. LINE

3/8 PUCTURE FITTING

DRAIN 3/8” ID TUBE

WATER INLET

1/4” MALE FLARE

1.00

2.50

638085278

FIGURE 2. SERIES 1000 DIMENSION DRAWING (Shipping Wt. 210 lbs. Approx).

4

28.06

30.00

AIR INLET

23.50

18.13

WATER IN

ELECTRICAL 7/8 DIA.

DRAIN 3/8 I.D. TUBE

2.25

FRONT

9.50

2.06

20.13

3.81

BOTTOM

VIEWED FROM BOTTOM OF MACHINE

ICE DISCHARGE

BIN CONTROL PROBE

2.06

BACK

2.06

24.00

FRONT

SIDE

FIGURE 3. SERIES WCC2001–A AND WCF2201–A DIMENSION DRAWINGS

5

638085278

THIS PAGE LEFT BLANK INTENTIONALLY

638085278

6

INSTALLATION

This section covers unpacking and inspection, selecting location, installing unit, preparing for operation, and operation.

A. REMOVE ICEMAKER FROM CARTON

1. Keep unit in the upright position, remove carton and pallet from unit and inspect unit for damage. Upon inspection of unit, if any damage is found, file a claim with carrier immediately.

2. Locate startup card either on outside of container or on plastic liner. Fill in proper information and send one

copy to factory, and other copy to distributor. Postage is prepaid.

B. CABINET REMOVAL

1. Front Panel—Remove 4 screws and pull forward.

2. Top Panel—Remove screws and lift upward. 4 screws 500/700, 6 screws 1000.

3. Side Panel—Remove 4 screws and pull forward.

4. Back Panel—Should not be removed.

C. PREPARATION OF INSTALLATION SITE

1. The refrigeration system on air cooled units requires airflow, so a well ventilated area should be chosen. A

minimum of 6 inches must be maintained, free of any obstructions, for air intake. A minimum of 4 inches

clearance is required for air exhaust.

2. The unit can be installed either on an ice storage bin or ice dispenser using the proper adapter kits. (Refer

to sales literature for information.) The install is kit provided with each icemaker and adapter kits will supply

everything to locate unit correctly. In all cases the icemaker should be sealed all around the base with an

NSF listed sealant. (63804815B)

D. W ATER INLET HOOK UP

1. Water Inlet—fitting is a 1/4 SAE male flare located at the rear of the unit. Connect water supply with a 1/4

SAE flare nut and 1/4” copper or flexible tubing or larger.

2. Water Pressure—Unless otherwise specified, the unit is designed to operate on water pressures between

10 P.S.I. and 90 P.S.I. (NOTE: for pressures above 90 P.S.I. a regulator must be installed.)

3. Condenser Inlet Connections—Use a separate 3/8 copper line or larger water line. Connect to 3/8 FPT

fitting on water modulating valve.

4. Filter/Conditioners are recommended on supply lines to icemakers. Never run the water supply to water

cooled condenser through filter/conditioner, it uses up the cartridge unnecessarily and a saturated cartridge

can starve the icemaker causing premature component damage. Separate water supplies are recommended.

NOTE: Unit must be installed per local plumbing code BOCA.

E. DRAIN CONNECTION

1. Overflow Line—is a 3/8 I.D. flexible tube located at the rear of the unit. Extend this line to proper drain.

2. Condenser Outlet—is a 3/8 FPT located on the rear panel.

NOTE: Unit must be installed per local plumbing code. BOCA.

7

638085278

F. ELECTRICAL SUPPLY

1. Power Access—is provided with a 7/8 dia. knockout hole in the rear panel. Route incoming power in

conduit, through rear panel to icemaker electrical control box. Make connections to wires provided in the

control box and ground lug/screw.

2. Fused Line—should be checked and sized according to electrical rating shown on unit nameplate.

G. AUGER ENGAGEMENT

Be certain that auger is fully engaged to lower drive and extruding head is fully engaged into evaporator.

H. BIN CONTROL

1. Remove tape holding control to white ice chute and also remove control bracket mounting screw located in

base of unit behind electrical box. (Screw will be used later to fasten bin control bracket to base of unit).

2. Slide control and bracket down chute to base of unit. very carefully guide control and bracket through 1/2

hole in front of ice chute. Use CAUTION to be sure control goes into bin, not between base of unit and

bin top.

3. Check location of bin control, it should be directly under ice chute at a 45_ angle. With control in place use

mounting screw that was removed in step 1 to secure bracket to base. See Figure 4

FIGURE 4. BIN CONTROL

INITIAL START UP, CHECKS AND ADJUSTMENT INSTRUCTIONS

NOTE: Do not start unit before completing installation steps on pages 7 and 9.

Turn on water supply (if unit is water cooled turn water on to condenser also) turn on main power switch (located on top of electrical box), and make the following system checks:

NOTE: If unit will not start be sure water reservoir is full. Low water safety control must be properly

adjusted to start and shut down unit. If water level drops below bottom of reservoir, unit must shut

down. Adjustment is made by moving magnet up or down.

Water Level—If necessary adjust float by bending float arm up or down as needed, push float assembly down

until unit stops running. Release float and unit will restart. Keep water in reservoir at level line while unit is in

operation. See Figure 5

Low Water Safety Control—Adjust magnet by bending magnet arm as needed to shut unit down if water level

drops below bottom of reservoir.

Bin Control—Place ice around probe, unit should shut down in one minute. Remove ice from around probe,

unit should start in two minutes.

638085278

8

NOTE: For altitudes over 1000 feet above sea level, adjust range screw (behind end cover). Half turn

max. raises setting 4_F approx.

FIGURE 5. ICEMAKER FLOAT ASSEMBLY

Water modulating valve (water cooled units only)—Opening point of condenser water modulating valve

should be set to maintain proper operating pressure in the refrigeration system high side. (see chart on page

16). Closing point of valve should be set low enough to close valve during compressor stand by periods. To

raise, turn counterclockwise, to lower turn clockwise.

NOTE: If any of these checks or adjustments cannot be achieved, refer to Troubleshooting Section of

this manual or call for factory assistance at 1–800–Service.

BLK

BLK

3

208/230

VAC

BLK

ON/OFF

SWITCH

RED

RED

BLK

BIN CONTROL LEFT

RED

BIN CONTROL RIGHT

ANTI – FREEZE

RELAY

4

7

B

WTR LVL CONTROL

LEFT

WTR LVL CONTROL

RIGHT

6

RED

5

2

4

1

B

A

GEAR MOTOR LEFT

BRN

RED

MAIN

CONTACTOR

RED

RED

RED

RELAY

5

1

FAN

START

CAPACITOR

BRN

A

GEAR MOTOR RIGHT

C

COMPRESSOR

S

2

RUN

CAPACITOR

R

RED

FIGURE 6. SCHEMATIC AND WIRING DIAGRAM WCC2001–A AND WCF2201–A

9

638085278

115 VAC

BLACK

SERVICE

SWITCH

WHITE

WATER

COOLED

ONLY

BIN

CONTROL

SWITCH

LOW WATER

SAFETY

SWITCH

HIGH PRES.

CUTOUT

SWITCH

AUX BIN

CONTROL

SWITCH

7A4

COMPRESSOR

1

2

5

AUGER

GEAR

MOTOR

START

RELAY

B

START CAP.

RUN CAP.

C

S

R

FAN MOTOR

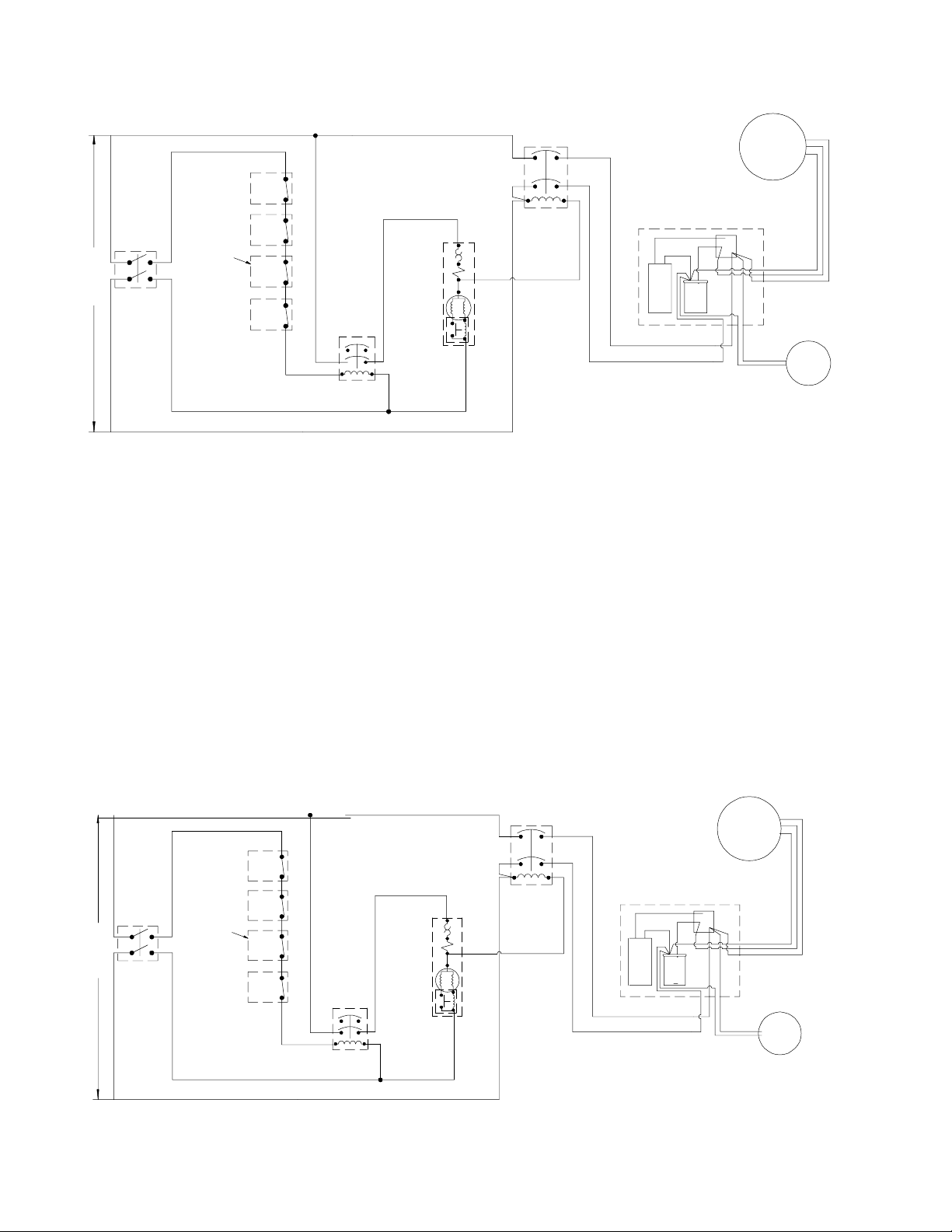

FIGURE 7. SCHEMATIC AND WIRING DIAGRAM WCC500–A, WCC500–W, WCC700–A, WCC700–W,

WCF510–A, WCF510–W, WCF710–A, & WCF710–W

208/230

60 HZ.

BLACK

SERVICE

SWITCH

WATER

COOLED

ONLY

BIN

CONTROL

SWITCH

LOW

WATER

SAFETY

SWITCH

HIGH PRES.

CUTOUT

SWITCH

AUX BIN

CONTROL

SWITCH

74

AB

AUGER

GEAR–

MOTOR

START

RELAY

COMPRESSOR

1

2

5

START CAP.

RUN CAP.

C

S

R

FAN

MOTOR

RED

FIGURE 8. SCHEMATIC AND WIRING DIAGRAM WCC701–A, WCC701–W, WCC1001–A, WCC1001–W

WCF711–A, WCF711–W, WCF1101–A, & WCF1101–W

638085278

10

BLK

ANTI–FREEZE

RELAY

4

7

GEAR MOTOR

MAIN

CONTACTOR

START

5

2

1

RELAY

START

CAP

RUN

CAP

C

R

S

208/230

VAC

CRANK

CASE

HEATER

ON/OFF

SWITCH

WATER

LEVEL

LOW

PRESSURE

AUX BIN

CONTROL

CONTROL

MCC1001R

PUMP

DOWN

SWITCH

BIN

RED

SOLENOID

CONTROL

TO

COMPRESSOR

MCC701R

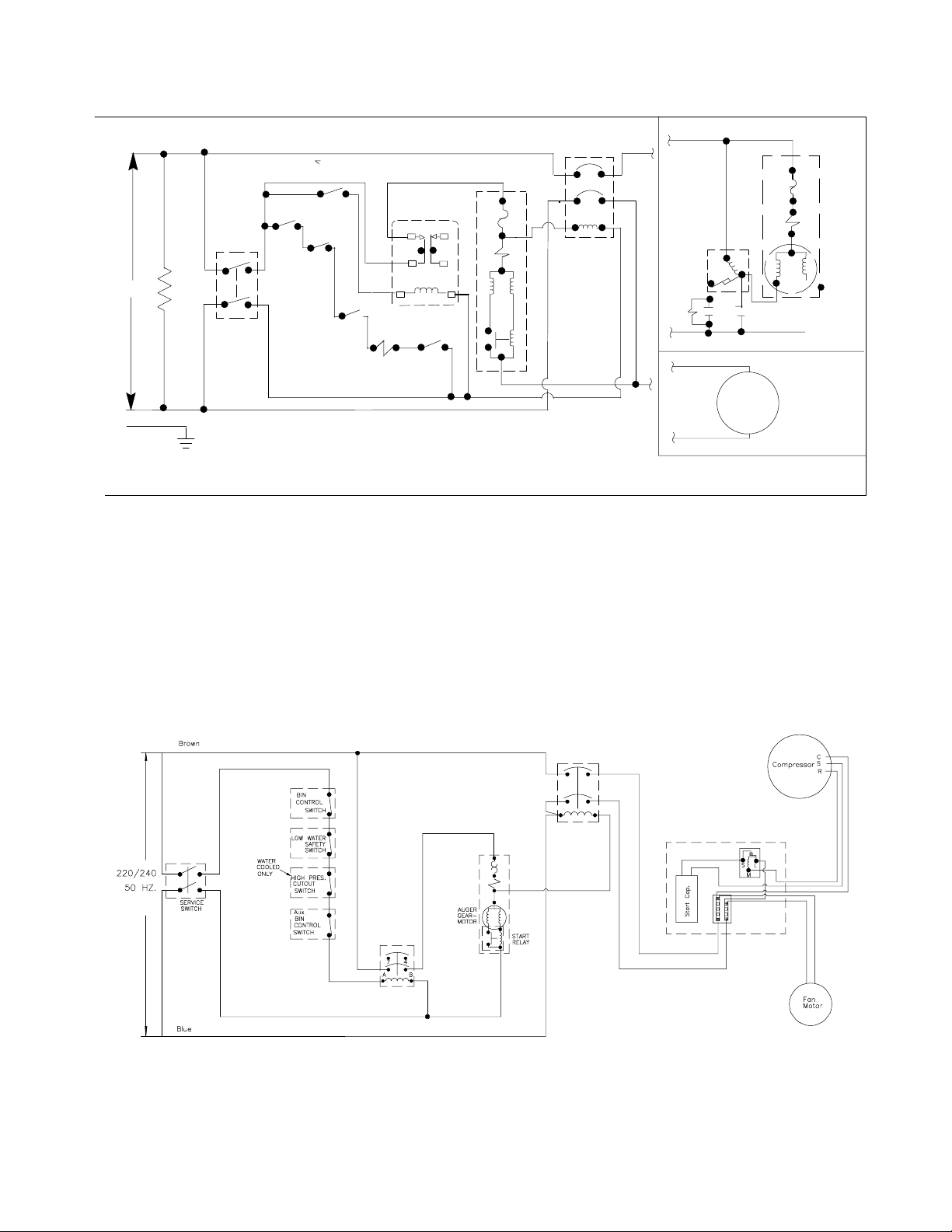

FIGURE 9. SCHEMATIC AND WIRING DIAGRAM WCF1101R, WCC1001R, WCF1102R, & WCC1102R

COMPRESSOR

FIGURE 10. SCHEMTIC AND WIRING DIAGRAM WCC502, WCC702, WCC1002,

WCF512, WCF712, & WCF1102

11

638085278

Loading...

Loading...