Cornelius WCC1000 Installation Manual

WCC1000/WCF1100 Series Retrofit Installation Instructions

!

WARNING:

!

WARNING:

!

WARNING:

!

WARNING:

Revision Date: March 19, 2014 www.cornelius.com Revision: D

RETROFIT INSTALLATION INSTRUCTIONS

WCC1000 / WCF1100 SERIES GEAR MOTOR CONVERSION KIT (631500319)

SAFETY

Before starting installation, read and understand all safety label and warnings on the machine. Also review and

understand all safety instructions in the owners, installation and service manuals.

Failure to comply could result in serious injury, death or damage to the equipment.

QUALIFIED SERVICE PERSONNEL

Only trained and certified electrical, plumbing and refrigeration technicians should service this unit.

All wiring and plumbing must conform to national and local codes. Failure to comply could

result in serious injury, death or equipment damage.

SAFETY PRECAUTIONS

This unit has been specifically designed to provide protection against personal injury. To ensure continued

protection observe the following:

Disconnect power to the unit before servicing. Follow all lock out/tag out procedures established by the user. Verify all

power is off to the unit before performing any work.

Failure to comply could result in serious injury, death or damage to the equipment.

Always be sure to keep area around the unit clean and free of clutter. Failure to keep this area clean may

result in injury or equipment damage.

© 2005-2014, Cornelius Inc. - 1 - Publication Number: 631500319INS

WCC1000/WCF1100 Series Retrofit Installation Instructions

The purpose of this kit is to convert a WCC1000 / WCF1100 to the current gear motor assembly. This requires

updating some of the exterior panels to accommodate the new, larger motor.

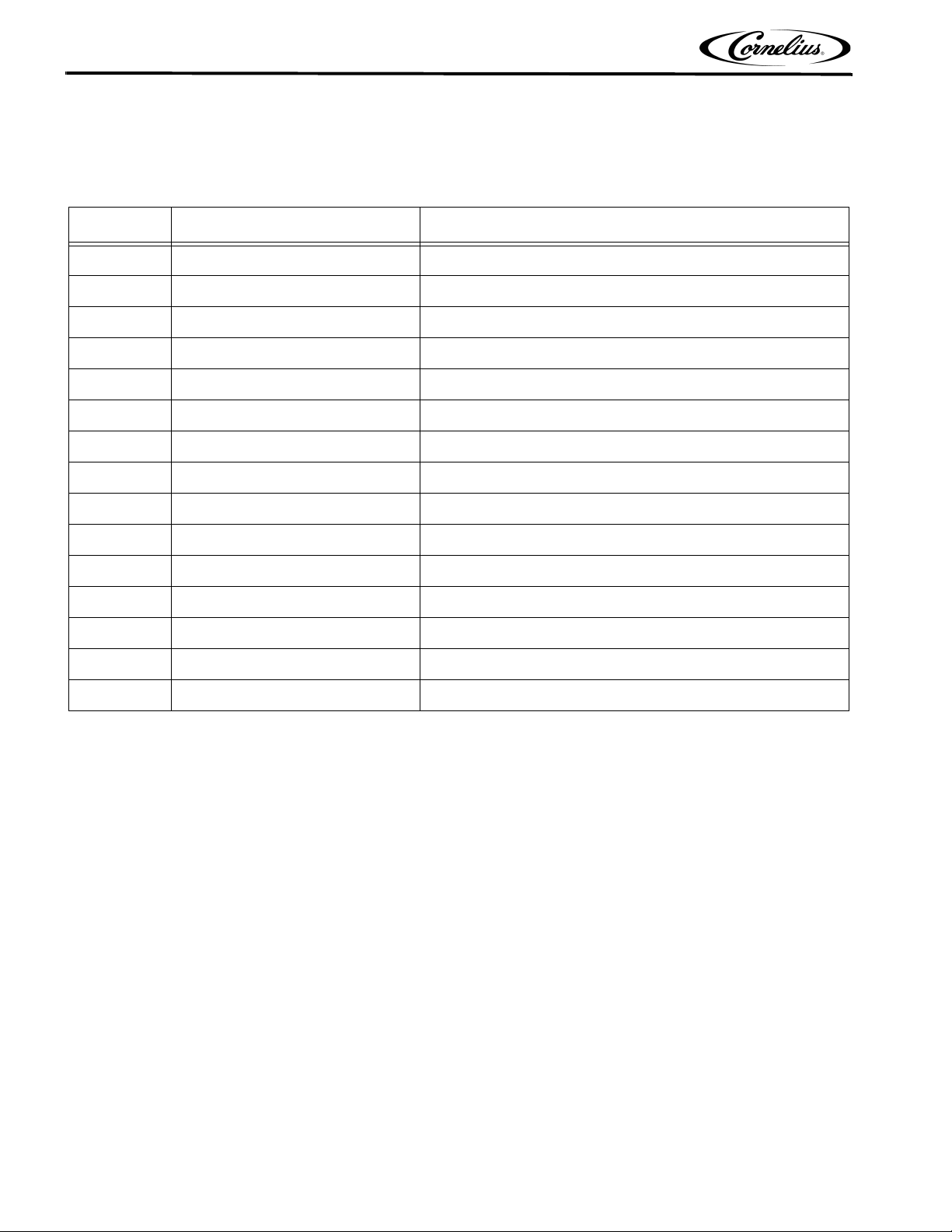

PARTS LIST:

Sl. No. Part No. Description

1 01022 Lock Washer (4)

2 02543 3/8-16 Hex Bolt (4)

3 638004441 Lower Spacer (2)

4 638007301-030 Flat Washer 2 in. OD X 1 in. ID

5 638007972-02 Screw #10 x 3/4 in. (2)

6 638036002-01 Front Panel, SS

7 638036004-01 Top Panel, SS

8 638036042 O-Ring, 3/16 in. x 2-3/4 in. ID

9 638090000-001 Gear Motor 230V/50-60Hz

10 638090051 Shaft Seal, 1 in.

11 638090053 E-Ring, Retaining

12 638090315 Mount, Shaft Seal, 3.5 in. D-Drive

13 638090316 Seat, Shaft Seal, 3.5 in. D-Drive

14 638090349 Motor Mounting Bracket

15 631500319INS Installation Instructions

GEAR MOTOR REMOVAL

1. Remove the top, front, and side panels in that order. Retain the side panels for re-use.

2. Remove the dispense tray cover and pull the auger assembly out of the evaporator. Set the cover and

auger assembly aside for reuse.

3. Disconnect the gear motor power transmission cable from the electrical box.

4. Remove the 4 hex head bolts and washers securing the base of the evaporator to the top of the gear motor

transmission. Set the 4 bolts and washers aside for reuse. Gently pry the base upward and lift the

evaporator off of the gear motor transmission.

5. Remove the 4 bolts holding the gear motor transmission and bracket to the frame, while supporting the

weight of the evaporator. Set the 4 bolts and washers aside for reuse.

6. Remove the gear motor and bracket assembly from the unit.

BRACKET AND SEAL ASSEMBLY

1. Assemble the gear motor to auger seals to match the diagram shown in Figure 1.

2. Carefully install the O-ring onto the shaft seal mount, taking care to not cut or score the surface. Coat the

O-ring with NSF food grade O-ring lubricant.

3. Place the shaft seal seat and shaft seal mount over the gear motor output shaft and push down until the

shaft seal seat and shaft seal mount rest flush on top of the gear motor transmission housing.

Publication Number: 631500319INS - 2 - © 2005-2014, Cornelius Inc.

Loading...

Loading...