Page 1

Quick Reference Guide for Viper FCB and FUB Units 620055004QRG

Page 1 June 8, 2012 Rev. A

Viper FCB/FUB Quick Reference Guide

Electrical Requirements:

215-245 VAC, 60 Hz supply voltage

2-Barrel: NEMAL6-20P Dedicated 20 Amp Circuit Required

3-Barrel: NEMA L6-30P Dedicated 30 Amp Circuit Required

4-Barrel: NEMA L6-30P Dedicated 30 Amp Circuit Required

NOTE: If voltage is less than 215 VAC or more than 245 VAC, then a Buck/Boost

transformer must be installed

Wiring:

All connections and wiring must comply with state and local codes.

Minimum Clearance Requirements:

Condenser air discharge is from the top of the unit. A minimum of 18 inches

clearance is required.

Cold air intake clearance is 2 inches on the sides of the unit or 2 inches in back.

Water Requirements:

25 psig flowing through 1/2” i.d. water supply line.

2 and 3-Barrels: At a volume of 100 GPH.

4-Barrel: At a volume of 150 GPH.

NOTE: If water requirements are less than minimum, then a water booster must

be installed. If water pressure is greater than 100 psig static, then a water regulator must be installed

CO2 Requirements (2 regulators):

1 dedicated regulator set to 75 psig for pump supply located within six feet of

machine.

1 dedicated regulator set to 70 psig for FUB or 75 psig for FCB.

Syrup Tubing Requirements:

Most syrups use 3/8” inside diameter tubing up to 75 feet. 1/2” inside diameter

tubing is required for greater distances.

For FUB units, the length of tubing runs must not exceed 100 ft. horizontally and 10

ft. of vertical lift.

NOTE: High viscosity syrups require 1/2” inside diameter tubing for all distances.

Before attempting to install or service this machine,

read this Quick Reference Guide!

For more detail, refer to manuals supplied with the unit.

For Technical Service: 1-800-238-3600 (US); www.cornelius.com (Global)

Page 2

Quick Reference Guide for Viper FCB and FUB Units 620055004QRG

Page 2 June 8, 2012 Rev. A

Plug the unit into the wall outlet and wait for initialization of the electronics and sold out alarms (there will be an audible beeping and display of the LCD screen).

SELECT

CLOCK SETUP

EVENTS SETUP

VISC SETUP

OPTION SETUP

12:51P

JUL 11

BACK MAIN MAINT GOSETUP

CLOCK

TIME 11:21:AM

DATE 01/01/11

12:51P

JUL 11

BACK DST - +CLOCK

SETUP

Program Electronics:

Set Clock

(& Daylight SavingsTime if applicable)

EVENT

DAY S UN

SLEEP 10:00 PM

WAKEUP 8:00 AM

DEFROST LOCK 1

DEFROST LOCK 2

DEFROST LOCK 3

12:51P

JUL 11

BACK CLEAR - +

Set Events:

(if applicable)

SETUP

DEFROST LOCKOUTS SHOULD ONLY BE SET AS NEEDED.

NOTE: Previous models required that you set defrost times

through the day to avoid barrel freeze ups. The Viper

defrosts automatically based on drinks sold.

Set Viscosity to 3 or 4:

VISC

#1 VISC RANGE 3 36-90

#2 VISC RANGE 4 40-96

12:51P

JUL 11

BACK CLEAR - +

SETUP

NOTE: Set viscosity to 3 for FUB and 4 for FCB units.

Turn POS Lighting ON

and Set to FUB or

FCB in Options:

OPTION

TEMP FORMAT oF

DATE FORMAT USA

TIME FORMAT 12HR

POS LIGHTI NG ALWAYS

#1 SYRUP TYPE FCB

#2 SYRUP TYPE FCB

12:51P

JUL 11

BACK

o

F oC

SETUP

Page 3

Quick Reference Guide for Viper FCB and FUB Units 620055004QRG

Page 3 June 8, 2012 Rev. A

Startup and Priming the System with Water, Syrup & CO2 (FCB units only)

ALWAYS TURN ON WATER BEFORE CO2.

Turn water supply on, then turn CO

2 supply on (set to 75 psi

for Viper) and slowly turn the CO

2 on to the BIB pumps (set to

75 psi for FCB or 70 psi for FUB), confirm CO

2 to expansion

tanks is set to 30 psi (See Figure 1).

Figure 1.

Turn three way valve to the BRIX position (See Figure 2) and

remove plug from end of sample tube (clear tygon tubing).

Figure 2.

Place a flat blade screwdriver into the solenoid cover slots (as

shown in Figure 3) and manually purge water and syrup systems into a bucket until all air has been evacuated.

Figure 3.

Go to the MAIN menu and select the Maintenance menu and then select BRIX Setup.

Place sample tube into cup and press GO. Cup will fill with a 3 second pour. Cycle three times and check the BRIX on the fourth pour with a refractometer (it should measure 13 BRIX). Pour a fifth drink to verify the reading. Adjust the syrup solenoid valve if BRIX is off-NEVER ADJUST THE WATER SOLENOID. When the process is complete, lift the water solenoid to clean the sample tube, then turn the three way valve to the BARREL position and plug the line.

Repeat for all barrels.

BRIX

Val ves

Screwdriver

Pressing

Val ve

Page 4

Quick Reference Guide for Viper FCB and FUB Units 620055004QRG

Page 4 June 8, 2012 Rev. A

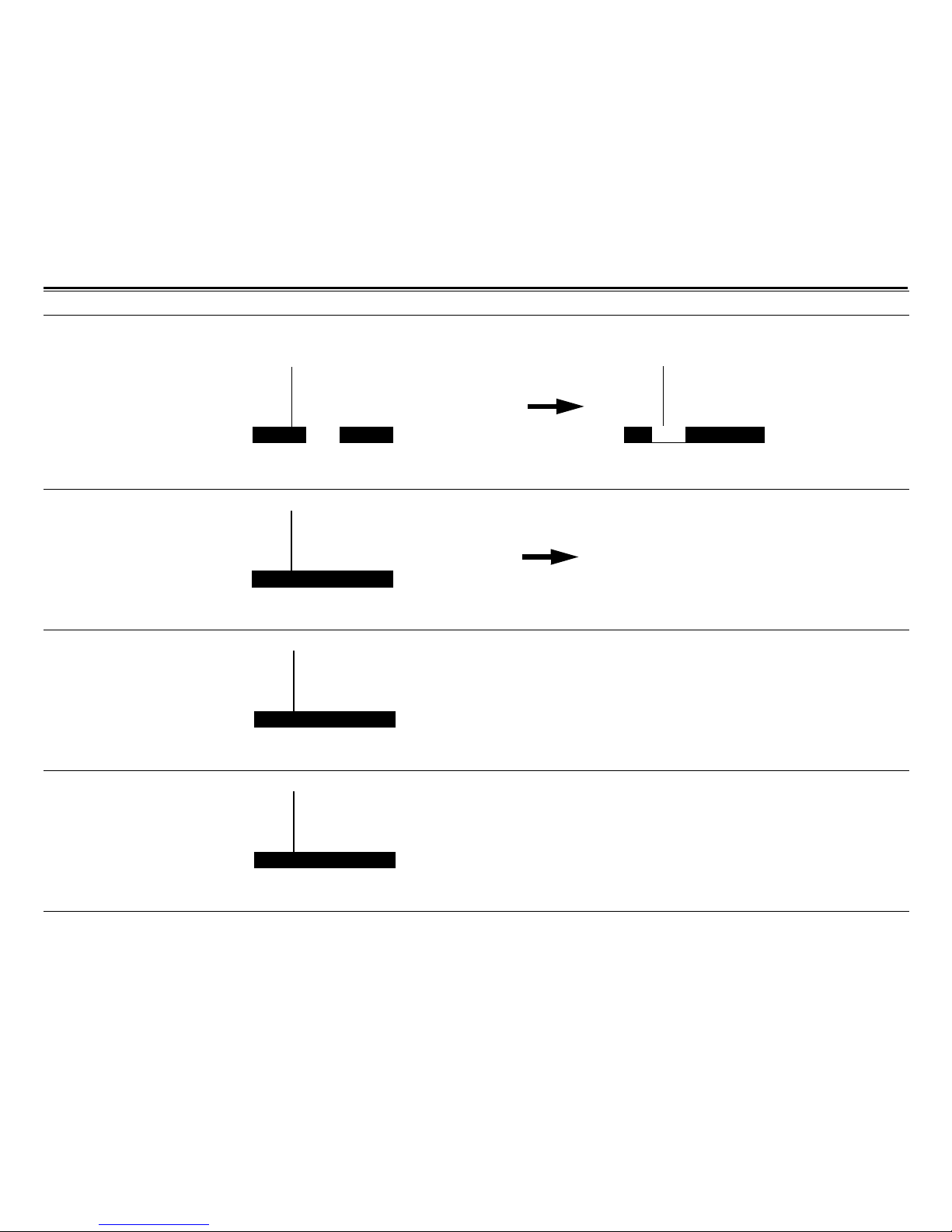

Filling the Barrel/Motor Calibration/Freeze down

Select BARREL MAINT and press GO. (See Figure 5b.)

Set the beverage CO2 pressure on the front

gauges (see Figure 4a) to approximately 36 psi

then select PURGE (see Figure 4b) and open the

faceplate pressure relief valve for approximately 30

sec. to displace the air in the barrel with CO

2. Push

STOP.

Figure 4a.

Figure 4b.

Select FILL (see Figure 5a.) and open the faceplate

pressure relief valve (see Figure 5b) until the barrel

is filled to scribe line from the top of the faceplate,

then release the valve and push STOP.

NOTE:

For FUB units, fill the barrel to the top of

the barrel.

Figure 5a. Figure 5b.

Repeat for all barrels.

Select MOTOR SETUP and press GO.

Select CAL for all motors and a 5 min. timer will start its countdown (Motors must always be set to Motor Type 1 for 60 Hz.).

After countdown, menu should display PASS.

Go back to the Main Menu and press SPIN for all motors and the viscosity display (number on the right of the LCD display) should read between 18-22, if not, calibrate the motor(s) again.

When all numbers are within the 18-22 range, stop all motors and press ON. Barrels should be frozen within approximately 15 to 20 minutes.

SELECT

BARREL MAINT

MANUAL DIAG

TOTALS

BRIX SETUP

MOTOR SETUP

SYSTEM

12:51P

JUL 11

BACK MAIN SETUP MAINT GO

MAINT

BARREL

#1 PURGE

#2 OFF

12:51P

JUL 11

BACK PURGE FILL SPIN

MAINT

BARREL

#1 PURGE

#2 OFF

12:51P

JUL 11

BACK PURGE FILL SPIN

MAINT

FCB

Faceplate

Relief

Fill

Level

Val ve

& Frutista

FUB Fill

Line

Loading...

Loading...