Cornelius Viper E 2 Flavor, Viper E 4 Flavor, Viper E 3 Flavor Service Manual

Classic model

Carbon model

VIPER (E) 2 FLAVOR, VIPER (E) 3 FLAVOR

& VIPER (E) 4 FLAVOR

Service Manual

Release Date: November 06, 2008

Publication Number: 621260373SER

Revision Date: May 10, 2016

Revision: N

Visit the Cornelius web site at www.cornelius.com

for all your Literature needs.

The products, technical information, and instructions contained in this manual are subject to change without notice.

These instructions are not intended to cover all details or variations of the equipment, nor to provide for every possi

ble contingency in the installation, operation or maintenance of this equipment. This manual assumes that the person(s) working on the equipment have been trained and are skilled in working with electrical, plumbing, pneumatic,

and mechanical equipment. It is assumed that appropriate safety precautions are taken and that all local safety and

construction requirements are being met, in addition to the information contained in this manual.

This Product is warranted only as provided in Cornelius’ Commercial Warranty applicable to this Product and is subject to all of the restrictions and limitations contained in the Commercial Warranty.

Cornelius will not be responsible for any repair, replacement or other service required by or loss or damage resulting

from any of the following occurrences, including but not limited to, (1) other than normal and proper use and normal

service conditions with respect to the Product, (2) improper voltage, (3) inadequate wiring, (4) abuse, (5) accident,

(6) alteration, (7) misuse, (8) neglect, (9) unauthorized repair or the failure to utilize suitably qualified and trained per

sons to perform service and/or repair of the Product, (10) improper cleaning, (11) failure to follow installation, operating, cleaning or maintenance instructions, (12) use of “non-authorized” parts (i.e., parts that are not 100%

compatible with the Product) which use voids the entire warranty, (13) Product parts in contact with water or the

product dispensed which are adversely impacted by changes in liquid scale or chemical composition.

Contact Information:

To inquire about current revisions of this and other documentation or for assistance with any Cornelius product contact:

www.cornelius.com

800-238-3600

-

-

Trademarks and Copyrights:

This document contains proprietary information and it may not be reproduced in any way without permission from

Cornelius.

This document contains the original instructions for the unit described.

CORNELIUS INC

101 Regency Drive

Glendale Heights, IL

Tel: + 1 800-238-3600

Printed in U.S.A.

TABLE OF CONTENTS

Safety Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Read and Follow ALL Safety Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Safety Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Recognition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Different Types of Alerts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Safety Tips . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Qualified Service Personnel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Shipping And Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Mounting in or on a Counter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Cart Information and Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Manual Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Dispensed Product Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Overrun, as Applied to Carbonated Beverages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Overrun Definition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Overrun is a Variable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Specific Product Ingredients Affect Overrun . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

BRIX Affects Overrun . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Low Dispensing Volume Affects Overrun . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Carbonation Level in Liquid Product Affects Overrun . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Freezing Affects Overrun . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

System Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Theory of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

CO2 System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Water System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Syrup System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Control Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Control Panel Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Control Panel Buttons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Control Panel Menu Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

System Menus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Main Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Unit Data Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Error Status Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Error Log Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Setup Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Clock Setup Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Setting the Clock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Setting Daylight Savings Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Events Setup Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Setting Events . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Setting the Sleep and Wake up Times . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Setting Defrost Lockout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Viscosity Setup Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Options Setup Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Setting the Temperature Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Setting the Date Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Setting the Time Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Setting the POS Lighting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Setting the Type of Syrup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Maintenance Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Barrel Maintenance Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Purging a Barrel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Filling a Barrel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Run the Barrel Motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Rinsing a Barrel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Manual Diagnostic Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Totals Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

BRIX Setup Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Motor Setup Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Calibrating a Motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

System Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Security . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Pressure Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Maintaining Product Quality . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Dispensed Product Throughput . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Programmed Defrost Scheduling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Sleep Mode Recommendations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Viscosity Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Starting the Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Preventative Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Monthly Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Cleaning Air Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Semi-Annual Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Inspecting and Replacing Scraper Blades . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Cleaning the Syrup Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Servicing Motorman Dispensing Valves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Sanitizing the System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Emptying a Barrel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Flushing the System of Syrup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Sanitizing the Barrel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Flushing the System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Cleaning the Water Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Component Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Barrel Motor Seal Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Removing the Existing Seal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51

Installing a New Seal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Motor Seal Leak Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Barrel Motor Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Motor Run Capacitor Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Water Pump Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

CO2 Shutoff Solenoid Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Syrup and Water Shutoff Solenoid Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

CO2 Regulator Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Condenser Fan Motor Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Compressor Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Hot Gas Solenoid Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .59

Liquid Line Solenoid Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .60

Syrup Pressure Switch Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Water Pressure Switch Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Display Board Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Control Board Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Backward/Forward Compatibility with Older Software Versions . . . . . . . . . . . . . . . . . . . . . . . 63

Motor Board Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Troubleshooting the System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Troubleshooting Product Not Cold . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .66

Viper Service Manual

!

DANGER:

!

WARNING:

CAUTION:

!

!

SAFETY INSTRUCTIONS

READ AND FOLLOW ALL SAFETY INSTRUCTIONS

Safety Overview

• Read and follow ALL SAFETY INSTRUCTIONS in this manual and any warning/caution labels on the unit (decals,

labels or laminated cards).

• Read and understand ALL applicable OSHA (Occupational Safety and Health Administration) safety regulations before

operating this unit.

Recognition

Recognize Safety Alerts

This is the safety alert symbol. When you see it in this manual or on the unit,

be alert to the potential of personal injury or damage to the unit.

DIFFERENT TYPES OF ALERTS

Indicates an immediate hazardous situation, which if not avoided, WILL result in serious injury, death or equipment

damage.

Indicates a potentially hazardous situation, which if not avoided, COULD result in serious injury, death, or equipment

damage.

Indicates a potentially hazardous situation, which if not avoided, MAY result in minor or moderate injury or

equipment damage.

SAFETY TIPS

• Carefully read and follow all safety messages in this manual and safety signs on the unit.

• Keep safety signs in good condition and replace missing or damaged items.

• Learn how to operate the unit and how to use the controls properly.

• Do not let anyone operate the unit without proper training. This appliance is not intended for use by very young children

or infirm persons without supervision. Young children should be supervised to ensure that they do not play with the

appliance.

• Keep your unit in proper working condition and do not allow unauthorized modifications to the unit.

NOTE: The dispenser is not designed for a wash-down environment and MUST NOT be placed in an

area where a water jet could be used.

© 2008-2016, Cornelius Inc. - 1 - Publication Number: 621260373SER

Viper Service Manual

!

WARNING:

!

WARNING:

CAUTION:

!

!

WARNING:

!

WARNING:

QUALIFIED SERVICE PERSONNEL

Only trained and certified electrical, plumbing and refrigeration technicians should service this unit. ALL WIRING

AND PLUMBING MUST CONFORM TO NATIONAL AND LOCAL CODES. FAILURE TO COMPLY COULD

RESULT IN SERIOUS INJURY, DEATH OR EQUIPMENT DAMAGE.

IF THE SUPPLY CORD IS DAMAGED, IT MUST BE REPLACED BY THE MANUFACTURER, ITS SERVICE

AGENT OR SIMILARLY QUALIFIED PERSONS IN ORDER TO AVOID A HAZARD.

SAFETY PRECAUTIONS

This unit has been specifically designed to provide protection against personal injury. To ensure continued

protection observe the following:

Disconnect power to the unit before servicing following all lock out/tag out procedures established by the user. Verify

all of the power is off to the unit before any work is performed.

Failure to disconnect the power could result in serious injury, death or equipment damage.

Always be sure to keep area around the unit clean and free of clutter. Failure to keep this area clean may result in

injury or equipment damage.

SHIPPING AND STORAGE

Before shipping, storing, or relocating the unit, the unit must be sanitized and all sanitizing solution must be

drained from the system. A freezing ambient environment will cause residual sanitizing solution or water

remaining inside the unit to freeze resulting in damage to internal components.

MOUNTING IN OR ON A COUNTER

When installing the unit in or on a counter top, the counter must be able to support a weight in excess of 450 lbs. to

insure adequate support for the unit.

Failure To Comply Could Result In Serious Injury, Death Or Equipment Damage.

NOTE: Many units incorporate the use of additional equipment such as ice makers. When any

addition equipment is used you must check with the equipment manufacturer to determine

the additional weight the counter will need to support to ensure a safe installation.

CART INFORMATION AND MOUNTING

These carts are also designed with movable wheels that act as outriggers to provide stability to the unit when it is

being moved.

The above listed mounting bolts must be installed and the wheels extended and locked in the outboard position prior

to moving the unit.

Failure to comply could result in serious injury, death or equipment damage.

Publication Number: 621260373SER - 2 - © 2008-2016, Cornelius Inc.

Viper Service Manual

INTRODUCTION

MANUAL OVERVIEW

The organization of this manual allows the user to scan quickly to the subject of interest along the left side of a

page and to read the detail about the subject or procedure on the right side of the page. The manual provides the

detail needed for newcomers to the industry while allowing experienced technicians to skip over the details and

move quickly through the material.

This manual is designed as a guide to the technician in maintaining and servicing the Viper system. The Viper

system is simple in design and has built-in features and diagnostic controls to help the service technician quickly

and accurately service the machine.

The unit consists of multiple freeze barrels that each contain an internal beater driven by a rear mounted electric

motor, a refrigeration system, timer-controlled, automatic hot gas defrost system and interconnecting tubing and

controls required to dispense the product.

Some of the system features and functions are listed below:

• Simple User Interface LCD Display

• Real Time Clock

• Incoming Line Voltage Sensing

• Pressure Sensing of Incoming Water, Syrup and CO

2

• System Error Handling

• Error Log

• Viscosity Control

© 2008-2016, Cornelius Inc. - 3 - Publication Number: 621260373SER

Viper Service Manual

DISPENSED PRODUCT CONDITIONS

Overrun, as Applied to Carbonated Beverages

Overrun Definition

Overrun is defined as product expansion that takes place in the frozen carbonated drink. It is caused primarily by

gas breakout and secondarily by freezing.

CO

2

Overrun is a Variable

The percentage or degree of overrun depends on a number of factors. The specific syrup, BRIX, low dispensing

volume, carbonation level in the liquid product and freezing of the product. These items all affect overrun. After

these factors have been considered, desired viscosity (product consistency) adjustment may be made on the

unit. The viscosity adjustment adjusts product texture from very wet to light.

Specific Product Ingredients Affect Overrun

Each syrup has its own specific formulation of makeup. Fruit flavors contain citric acids that colas do not. Colas

also differ in ingredients from one brand to another. Each product formulation has its own peculiarities regarding

the way the product absorbs carbonation and the way it releases carbonation.

BRIX Affects Overrun

Sugar in carbonated drinks is like anti-freeze in water. The higher the BRIX, the greater the resistance of the

product to freezing. Conversely, in products with lower BRIX, freezing takes place at higher temperatures than for

high-BRIX products. Thus, BRIX affects overrun because the amount of sugar in a drink has a direct bearing on

the product’s freezing characteristics.

Low Dispensing Volume Affects Overrun

When a unit sits idle for a period of time with no drinks being dispensed, CO2 gas in the system takes a “set”.

When the first few drinks are drawn off after an idle period, CO

is dispensed. The result is that these first drinks have less overrun than drinks dispensed during peak-use

periods.

2 gas has less tendency to break out as the drink

Carbonation Level in Liquid Product Affects Overrun

The higher the specific carbonation level in a given product, the greater the potential for carbonation breakout in

frozen carbonated form of that drink. For example, drinks with 3.0 volume of carbonation have more gas breakout

in frozen carbonated form and more overrun than drinks that contain 2.0 volumes of CO

2 gas.

Freezing Affects Overrun

Freezing causes approximately a 5-7 percent expansion in dispensed frozen carbonated drinks. The degree of

freezing is limited because the finished drink is intended to be sipped through a straw. This is not possible if the

product is too “solid”.

Publication Number: 621260373SER - 4 - © 2008-2016, Cornelius Inc.

Viper Service Manual

SYSTEM OVERVIEW

INTRODUCTION

The Viper unit consists of the following systems and hardware:

Multiple freeze barrels, each containing an internal scraper bar driven by an AC motor.

A refrigeration system and an intelligent, hot gas defrost system.

The components are enclosed in a powder-coated steel frame to prevent corrosion. It is covered with ventilated

cladding panels and a lighted merchandiser. The cladding is easily removable to facilitate installation, service and

maintenance.

Each barrel has a transparent faceplate, with an integral relief valve and a removable, self-closing dispensing valve

mounted on the front. A removable drip tray, with cup rest is located directly below the dispensing valves.

A programmable control system with a control panel that controls operational and diagnostic functions and settings

is located behind the merchandiser.

THEORY OF OPERATION

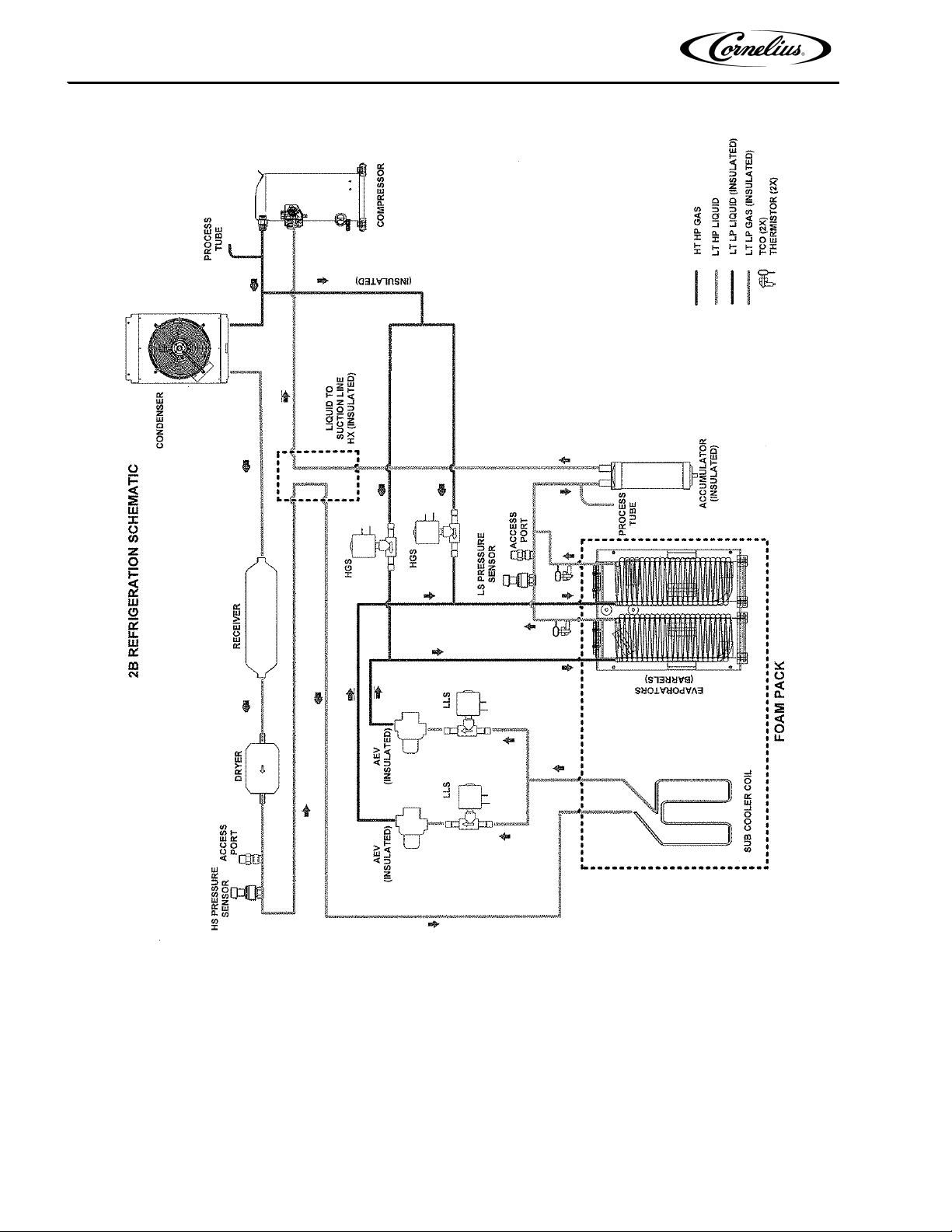

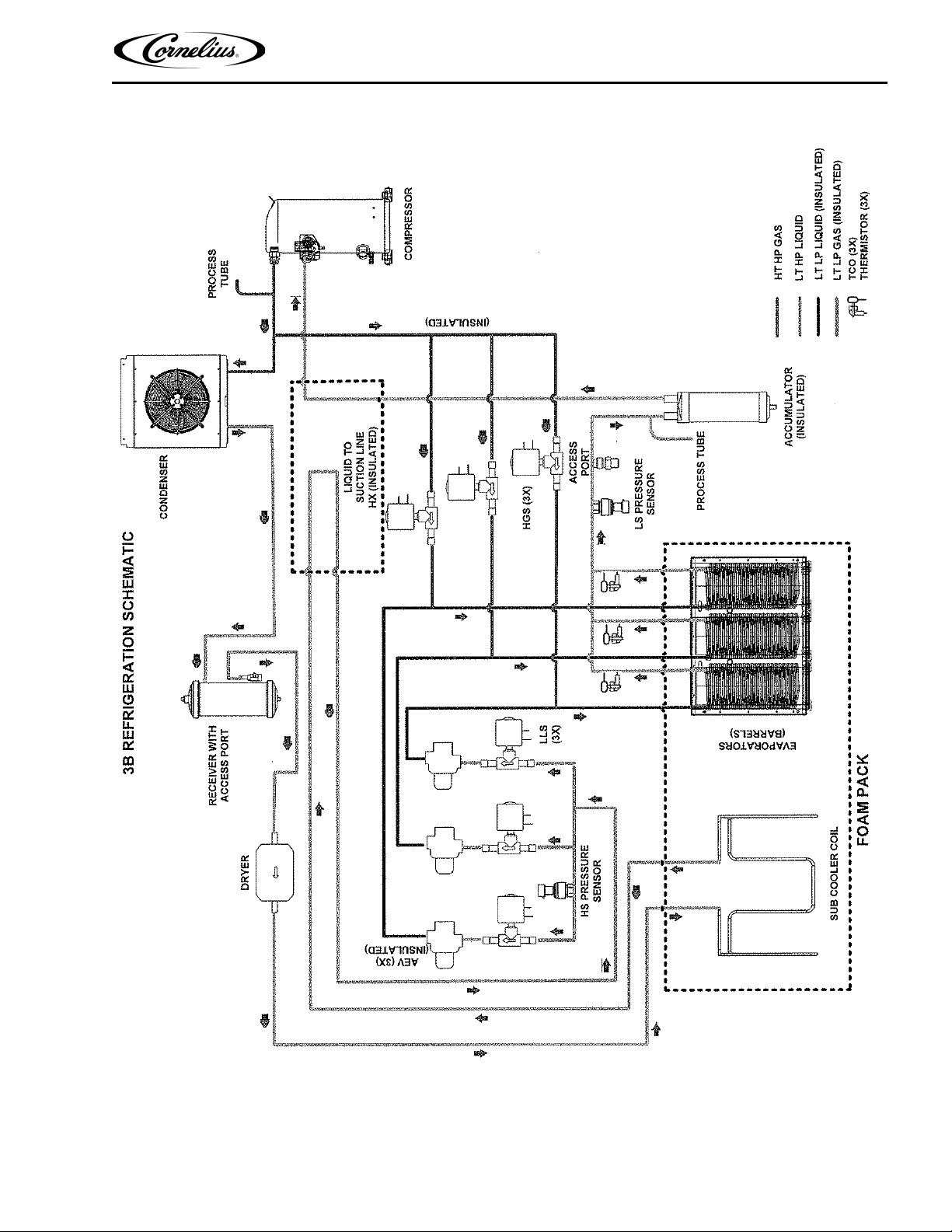

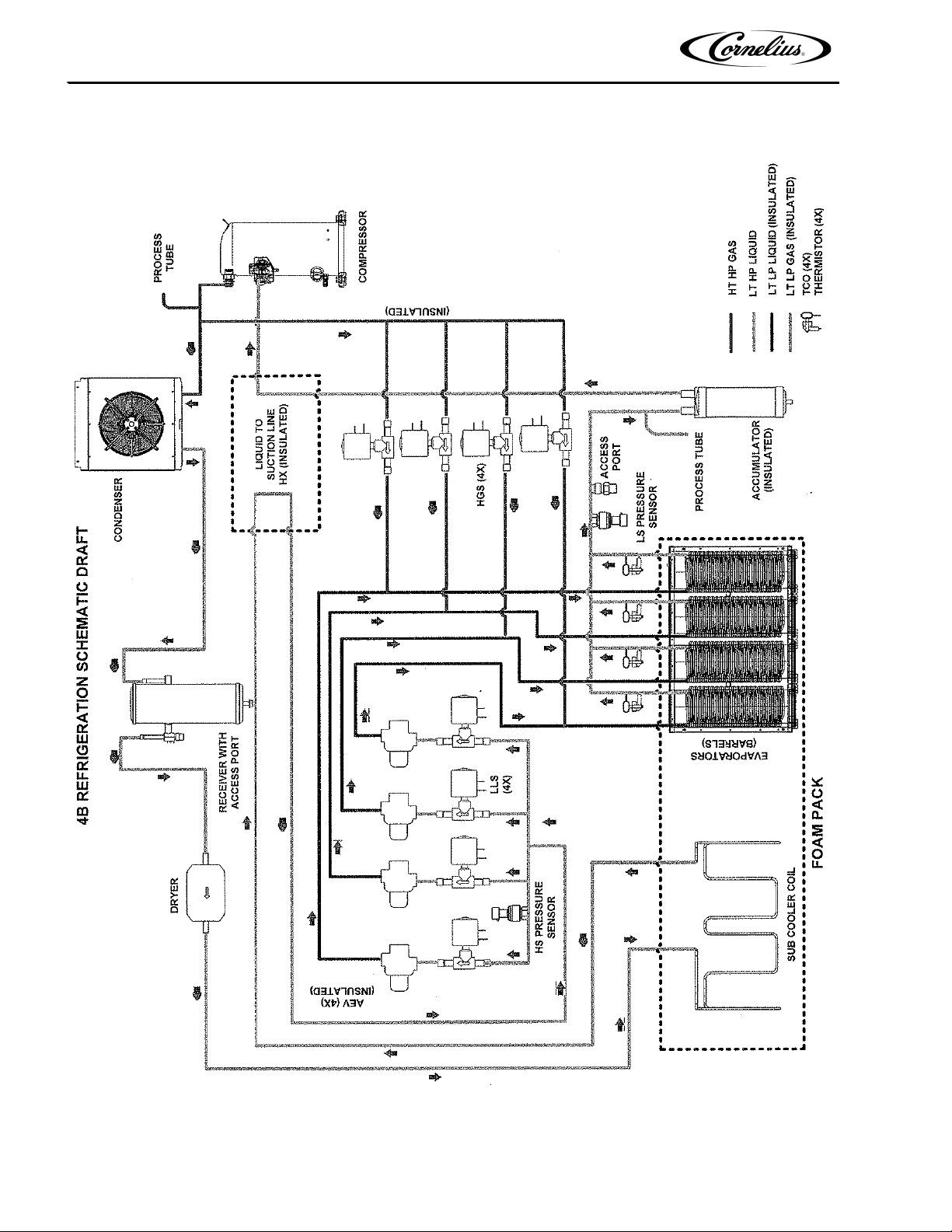

The refrigeration system schematic is shown in Figure 1.. It provides the basic configuration for the Viper

refrigeration system.

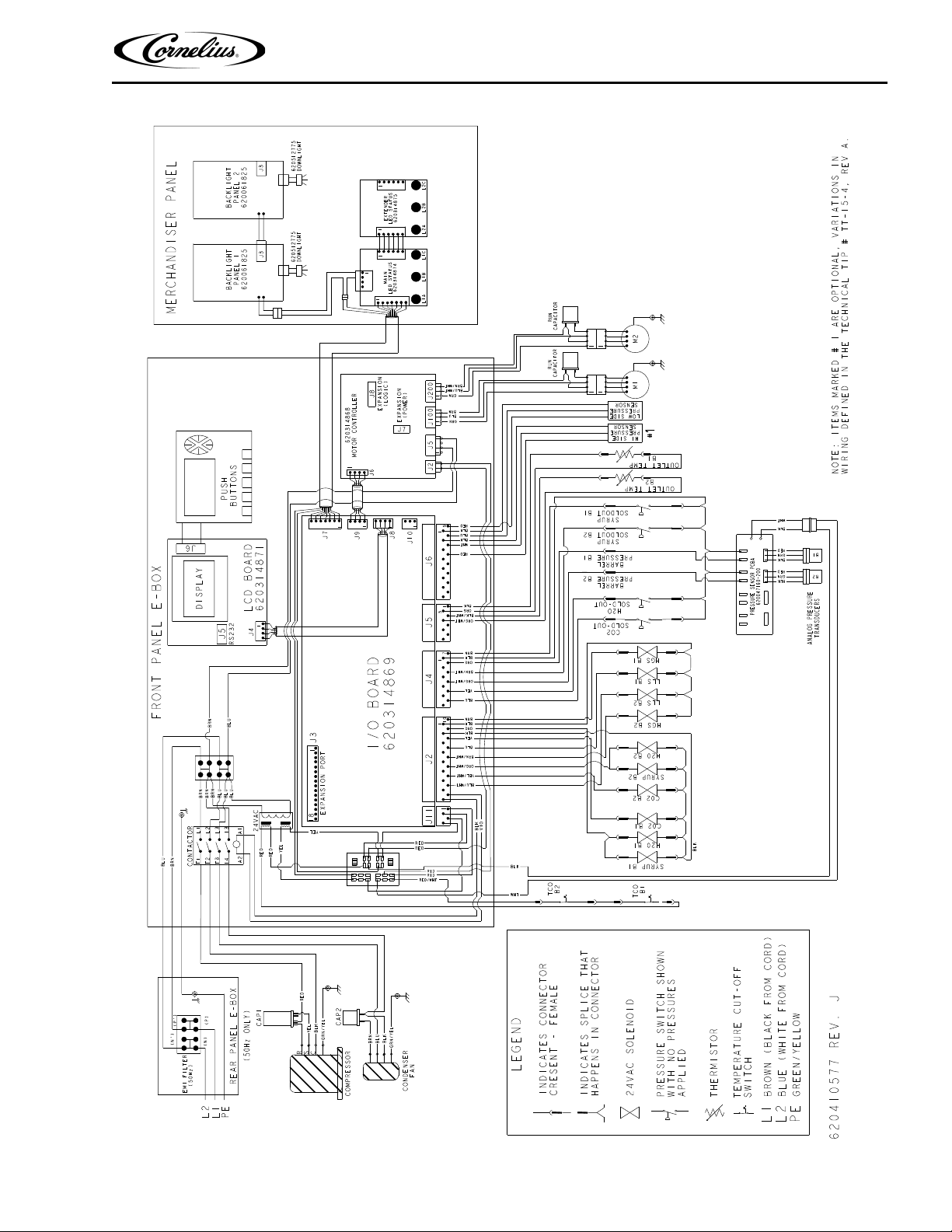

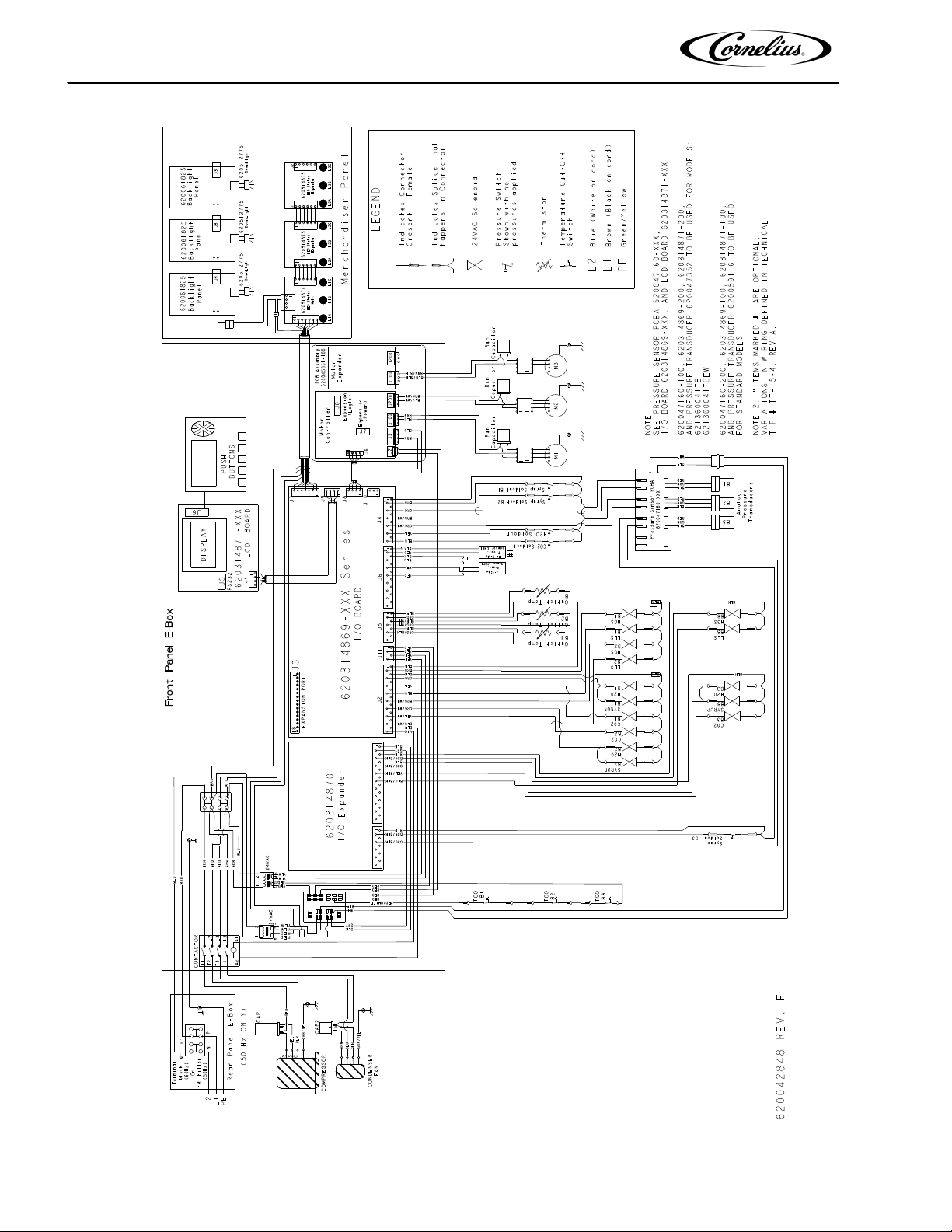

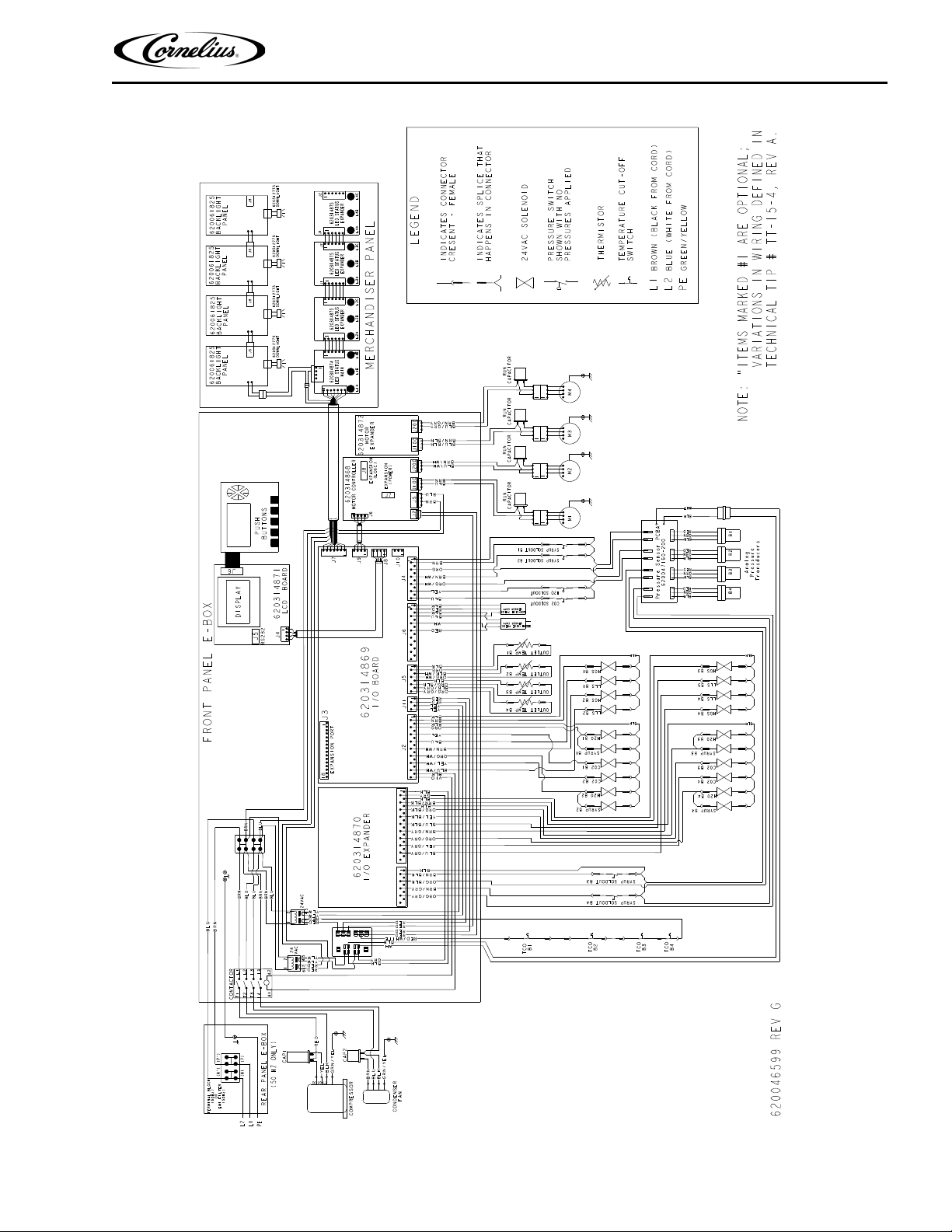

The wiring diagram of the 2-Barrel Viper unit is shown in Figure 4, the wiring diagram of the 3-Barrel Viper unit is

shown in Figure 4. and the wiring diagram of the 4-Barrel Viper unit is shown in Figure 5.. These diagrams show the

details of the electrical connections in the unit.

© 2008-2016, Cornelius Inc. - 5 - Publication Number: 621260373SER

Viper Service Manual

Figure 1. Viper System 2-Barrel Refrigeration Schematic

Publication Number: 621260373SER - 6 - © 2008-2016, Cornelius Inc.

Viper Service Manual

Figure 2. Viper System 3-Barrel Refrigeration Schematic

© 2008-2016, Cornelius Inc. - 7 - Publication Number: 621260373SER

Viper Service Manual

Figure 3. Viper System 4-Barrel Refrigeration Schematic

Publication Number: 621260373SER - 8 - © 2008-2016, Cornelius Inc.

Viper Service Manual

Figure 4. Viper 2-Barrel Wiring Diagram (W/Transducer)

© 2008-2016, Cornelius Inc. - 9 - Publication Number: 621260373SER

Viper Service Manual

Figure 5. Viper 3-Barrel Wiring Diagram

Publication Number: 621260373SER - 10 - © 2008-2016, Cornelius Inc.

Viper Service Manual

Figure 6. Viper 4-Barrel Wiring Diagram

© 2008-2016, Cornelius Inc. - 11 - Publication Number: 621260373SER

Viper Service Manual

FCB Unit

ylppuS2OC

BIB Syrup

BIB Syrup

BIB Pump

C

E

D

A

F

I

Water Filter

Connections

Tubing

1/2 Inch Beverage Tubing

3/8 Inch Beverage Tubing

1/4 Inch Beverage Tubing

3/8 Inch Tygon Tubing

A

B

C

D

E

F

1/2 Inch Hose Barb to 3/4 NPT

1/4 Inch Female Flare Nut and Barb (1/4)

Direct Connection to Syrup

Outlet on Syrup Pump

Direct Connection to CO2

Inlet on Syrup Pump

Direct Connection to Syrup

Inlet on Syrup Pump

1/2 to 3/8 Inch Fitting Reducer

Water Inlet

Syrup Line 1

Syrup Line 2

CO2 Inlet

BIB Syrup

BIB Syrup BIB Pump

C

E

D

G

BIB Pump

C

E

D

BIB Pump

C

E

D

Syrup Line 3

Syrup Line 4

G

¼ Inch Cross Barb

K

H

J

H

CO2 Regulator

I

3/8 Inch TEE Barb

J

3/8 Inch Flare Nut and Barb (3/8)

K

3/8 to 1/4 Inch Fitting Reducer

H

H

B

Max 3 Feet

J

K

K

K

K

F

3 Feet Typical

115 Psig

75 Psig

75 Psig

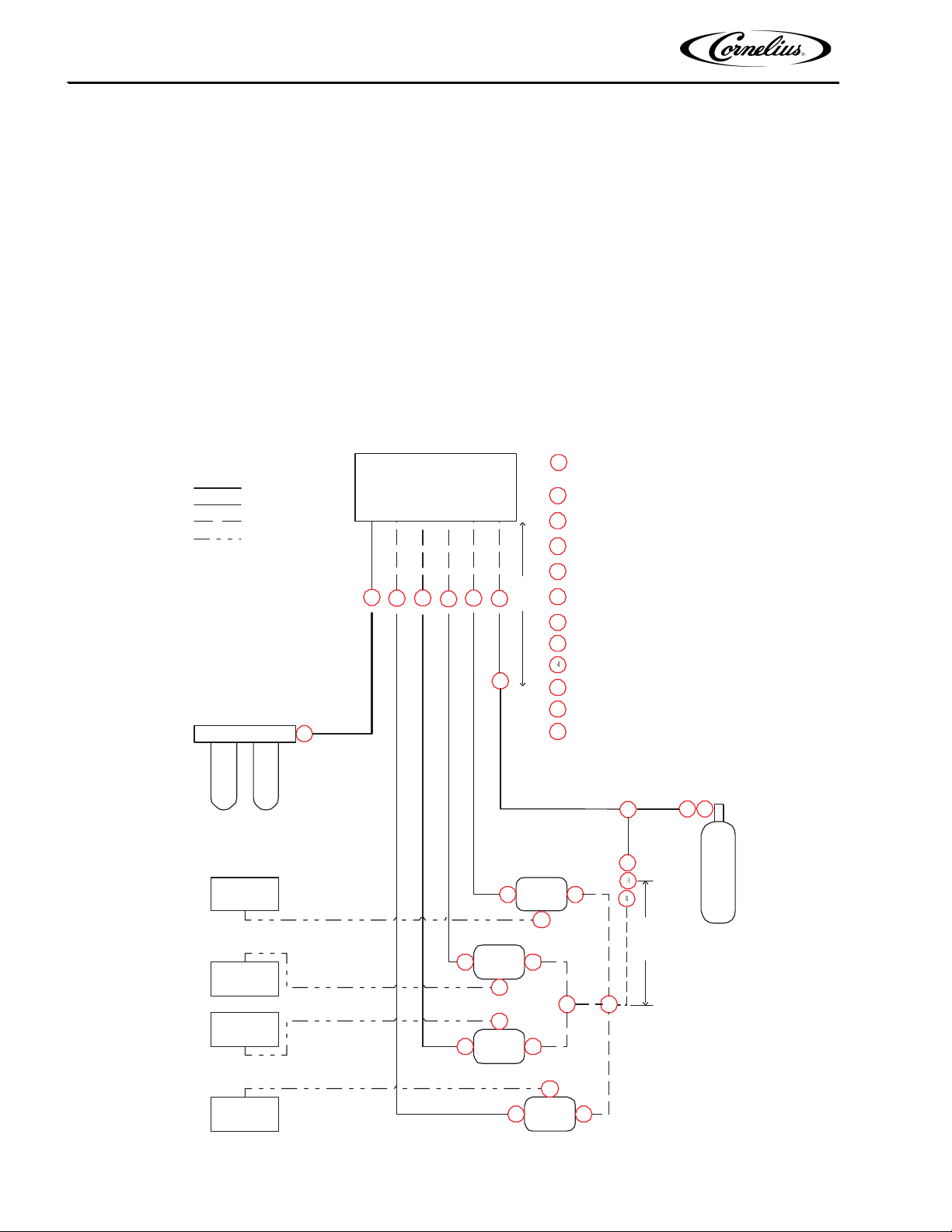

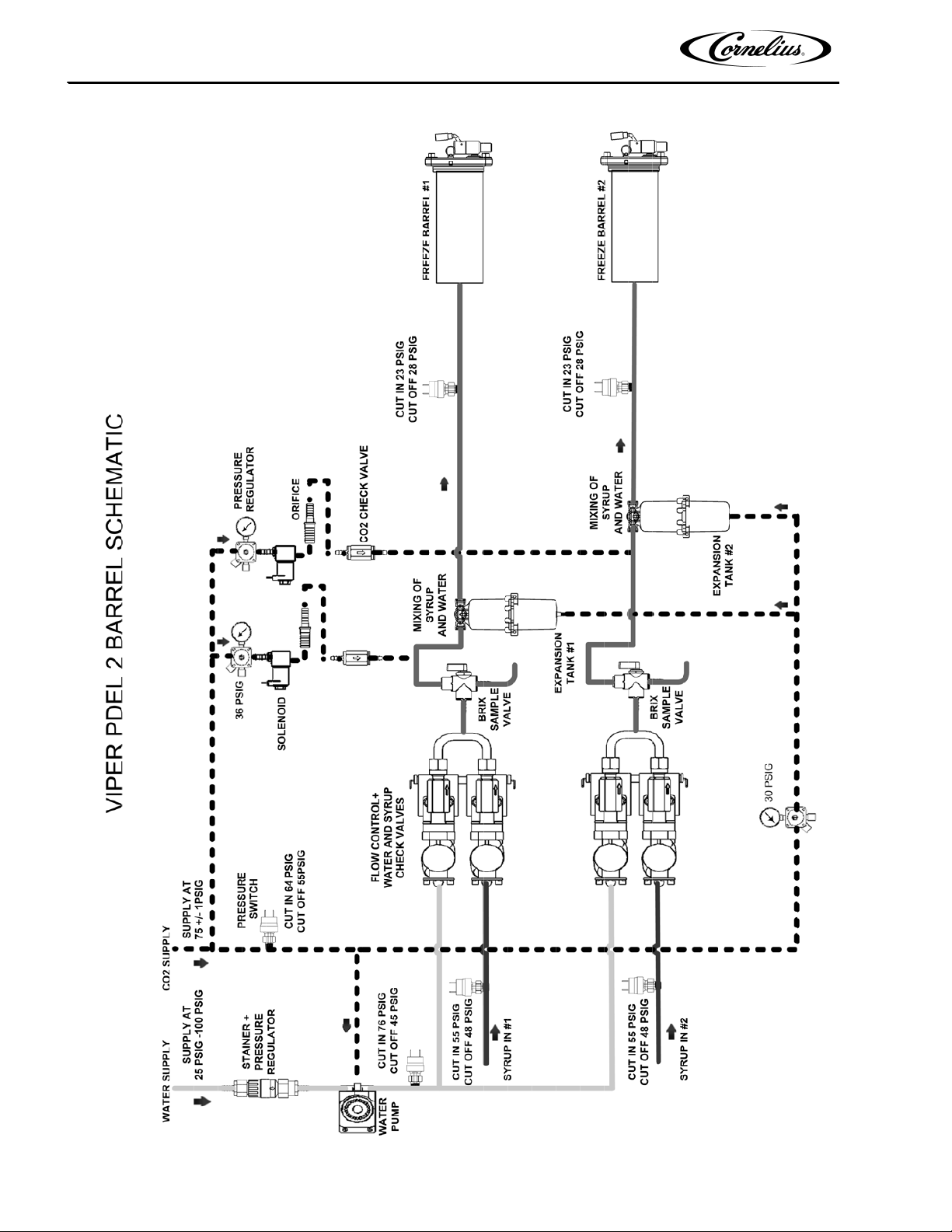

An overall schematic of the three delivery systems contained in the unit are shown in Figure 8., Figure 9. and Figure

10. The CO

diagram. The CO

2 system is on top, the water system is in the middle and the syrup system is at the bottom of the

2 system interacts with both the water and syrup systems. It provides pressure and carbonation for

the syrup/water product mix.

CO2 System

A CO2 tank or bulk CO2 supply delivers carbon dioxide gas (CO2) to an adjustable secondary CO2 regulator

assembly that is attached to the tank as shown in Figure 7. The CO

pump, the expansion tank regulator and the secondary CO

2 enters the expansion tank regulator and is reduced to approximately 30 psig to feed holding pressure on the

CO

2 tank regulators.

expansion tank. This provides a force to work against the barrel pressure when the product freezes and expands.

2 also enters the secondary regulators. These regulators are used to adjust barrel overrun/expansion for various

CO

products. The pressure settings for various types of syrup are shown in Table 1.. Overrun CO

the CO

From the in-line check valve, the CO

2 control solenoids through preset orifices and on to the in-line check valves.

2 flows into the product line.

2 system also supplies CO2 to the water boost

2 pressure is applied to

Publication Number: 621260373SER - 12 - © 2008-2016, Cornelius Inc.

Figure 7. Cylinder CO2 Connection

Viper Service Manual

Table 1. provides guidelines for machine settings based on general syrup type. Several factors, including syrup

formulation, level of citric acids, etc, will impact settings. These settings are to provide initial adjustments to achieve

product overruns in the 80-120% range.

Table 1.

Syrup Type

FCB Syrup w/

Foaming Agent

FCB Syrup w/o

Foaming Agent

FUB FUB 7 N/A 30

Syrup Type

Set

FCB 4 34-36 PSIG 30

FCB 4 32-36 PSIG 30

Viscosity Pressure Expansion

NOTE: For citric syrups, adjust the CO2 pressures down by 2-4 PSIG from the above to compensate

for the lower CO

2 adsorption.

© 2008-2016, Cornelius Inc. - 13 - Publication Number: 621260373SER

Viper Service Manual

Figure 8. 2-Barrel System Schematic

Publication Number: 621260373SER - 14 - © 2008-2016, Cornelius Inc.

Viper Service Manual

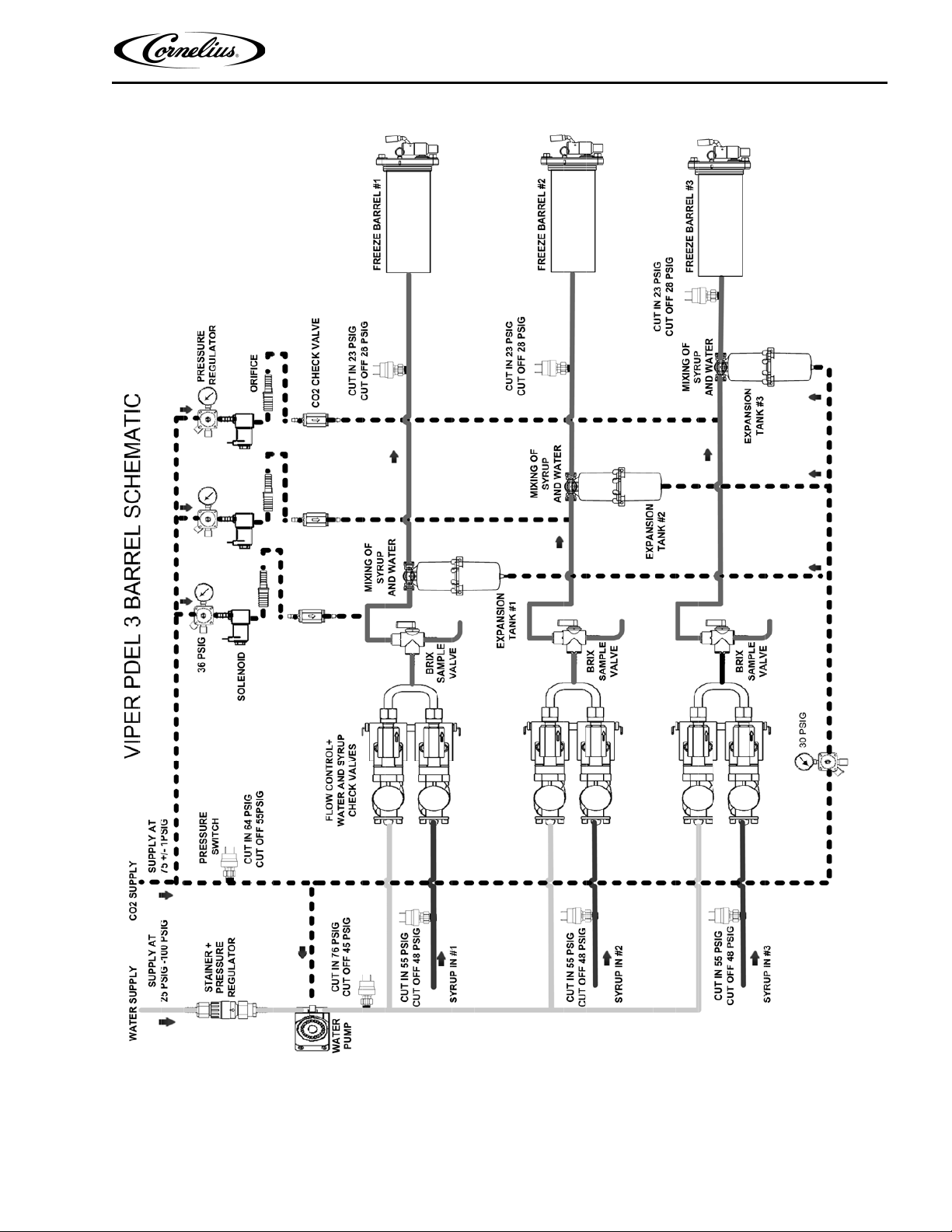

Figure 9. 3-Barrel System Schematic

© 2008-2016, Cornelius Inc. - 15 - Publication Number: 621260373SER

Viper Service Manual

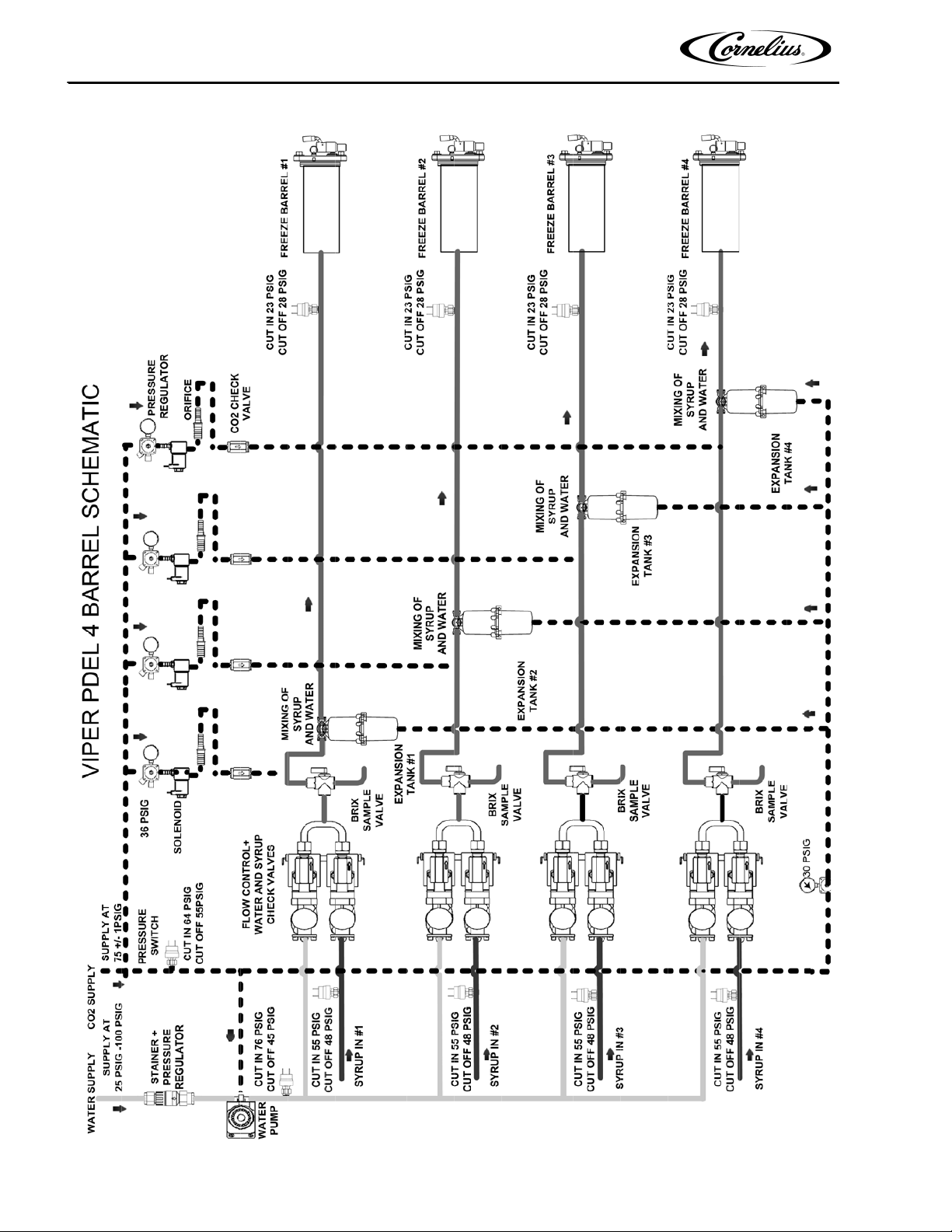

Figure 10. 4-Barrel System Schematic

Publication Number: 621260373SER - 16 - © 2008-2016, Cornelius Inc.

Viper Service Manual

Water System

Incoming water flows to a water pressure regulator that is preset to 30 psig. It flows through the water booster pump,

to the regulator and through a sold-out switch.

Once through the boost pump, the water supply is split to each barrel and is fed to the water flow controls. From the

flow rate control, the water passes through a single ball check valve and mixes with the syrup in a wye fitting for

injection into the freeze barrel.

Syrup System

Syrup enters the unit through a sold-out switch. It enters a similar flow control to the water system, passes through a

single-ball check valve and into the wye fitting where it meets the water for injection into the freeze barrel.

CONTROL PANEL

Introduction

The Viper unit uses a microprocessor based control system that monitors and controls all of the major systems and

components of the machine. Temperatures and pressures are monitored, along with pumps, valves and the

refrigeration system. They are managed by the control system to provide a consistently high quality product with

optimal efficiency.

The control system is set up by the service provider to perform the tasks necessary to keep the Viper unit operating

correctly. In addition to controlling the unit, the control system keeps track of the diagnostic information used when

adjusting and/or repairing the machine.

The control system needs to be accessed in the following situations:

• Installing the Viper

• Modifying Operating Characteristics

• Checking Performance

• Servicing/Repairing the Machine

• Checking for Error Messages

The control system is accessed using the control panel located behind the lighted merchandiser. The control panel

contains an LCD display and buttons shown in

There are 2 levels of access to the control panel: The first level can be accessed by the operator for normal

operation and the second level is used by qualified service technicians for installation and service functions. The

service functions can be secured (locked out) so that an operator does not have access to them. The control panel

has a structured organization of menus. The outline of this structure is shown in

menu is not visible when the security feature is on.

The first menu that is displayed after the unit is powered up and stabilized is the BARREL STATUS or HOME menu,

shown in

Figure 11. This menu is displayed when the unit is running in normal operation.

Figure 11.

Figure 12. The Maintenance sub-

Control Panel Display

The control panel display has two main areas. The first area is the menu display area. This area presents

information about the status and settings of the machine. It also displays menus of actions that are taken to modify

the functioning of the machine.

© 2008-2016, Cornelius Inc. - 17 - Publication Number: 621260373SER

Loading...

Loading...