Cornelius TS-009 Repair Manual

REFRIGERATION INSTALLATIONS LIMITED

Unit D9 Newton Business Park

Cartwright Street

Hyde

Cheshire SK14 4EH

Telephone: +44 (0)161 366 1110 Fax: +44 (0)161 366 1190

HOME ICE

CREAM MAKER

MODEL TS-009

REPAIR MANUAL

© The images and text within this document are the copyright of Refrigeration

Installations Limited. No part of this document may be reproduced in any form or by

any means without the prior written permission of the copyright owners.

Document Reference: WI 9 Page 1 of 1

Issue 02

REFRIGERATION INSTALLATIONS LIMITED

Unit D9 Newton Business Park

Cartwright Street

Hyde

Cheshire SK14 4EH

Telephone: +44 (0)161 366 1110 Fax: +44 (0)161 366 1190

Index

1. Revision Status and Authority for Issue

2. Purpose

3. Scope

4. Responsibilities

5. Health and Safety

6. Abbreviations and Definitions

7. Parts Overview

8. Fault Identification

9. Unit Dismantling

10. Repair

10.1 Motor Replacement

10.2 Cooling Fan Replacement

10.3 On/Off Switch Replacement

10.4 PCB and Motor Connector Replacement

10.5 Mains Lead Replacement

10.6 Compressor Replacement

11. Unit Reassembly

12. Test

Document Reference: WI 9 Page 2 of 2

Issue 02

REFRIGERATION INSTALLATIONS LIMITED

Unit D9 Newton Business Park

Cartwright Street

Hyde

Cheshire SK14 4EH

Telephone: +44 (0)161 366 1110 Fax: +44 (0)161 366 1190

1. Revision Status and Authority for Issue

Document

Comments Changed By Date

Issue Level

01 First issue Raised by CRP 08-04-05

Reviewed,

02

Updated and

Minor Errors

Corrected.

Authority to release Issue 02:

CRP 23-05-05

S LLoyd Managing Director 23-05-05

Name Position Date

Document Reference: WI 9 Page 3 of 3

Issue 02

REFRIGERATION INSTALLATIONS LIMITED

Unit D9 Newton Business Park

Cartwright Street

Hyde

Cheshire SK14 4EH

Telephone: +44 (0)161 366 1110 Fax: +44 (0)161 366 1190

2. Purpose

The purpose of this document is to provide a reference to facilitate

the diagnosis and repair of faults to the TS-009 Home Ice Cream

Maker.

3. Scope

This document covers versions of the Home Ice Cream Maker

Model TS-009 supplied by Refrigeration Installations Limited. All

versions are covered by these instructions, although most

photographs show the TS-009AS, and there may be slight

variations in functionality, such as the Control Panel Display and

detailed internal layout, however the basics of machine

dismantling, repair and reassembly are generally applicable. If in

doubt contact Refrigeration Installations Limited.

4. Responsibilities

The responsibility for the preparation of and modifications to this

document rests with RIL.

Repair to any Home Ice Cream Maker should only be carried out

by competent qualified personnel and we recommend that any

spare or replacement parts fitted be either supplied by, or

approved by, RIL.

The use of spare or replacement parts from other sources may

invalidate any guarantee or warranty on machines purchased in

the UK from RIL or one of its approved distributors.

Document Reference: WI 9 Page 4 of 4

Issue 02

REFRIGERATION INSTALLATIONS LIMITED

Unit D9 Newton Business Park

Cartwright Street

Hyde

Cheshire SK14 4EH

Telephone: +44 (0)161 366 1110 Fax: +44 (0)161 366 1190

5. Health and Safety

The Home Ice Cream Maker is mains electricity powered and any

checks or repairs must be carried out by qualified personnel and in

full compliance with any relevant national or local legislation or

codes of practice concerning the safety of personnel working with

electrical equipment.

6. Abbreviations and Definitions

Front The side of the unit nearest to the refrigeration barrel

Left The left hand side of the unit when viewed from the

Front

IC Integrated Circuit (A complex semiconductor circuit)

PCB Printed Circuit Board

Rear The side of the unit nearest the Control Panel Display

Right The right hand side of the unit when viewed from the

Front

RIL Refrigeration Installations Limited

SSD Static Sensitive Device (An electronic component such

as an IC or transistor which may be damaged if a build

up of static electricity is discharged through the

component)

Document Reference: WI 9 Page 5 of 5

Issue 02

REFRIGERATION INSTALLATIONS LIMITED

Unit D9 Newton Business Park

Cartwright Street

Hyde

Cheshire SK14 4EH

Telephone: +44 (0)161 366 1110 Fax: +44 (0)161 366 1190

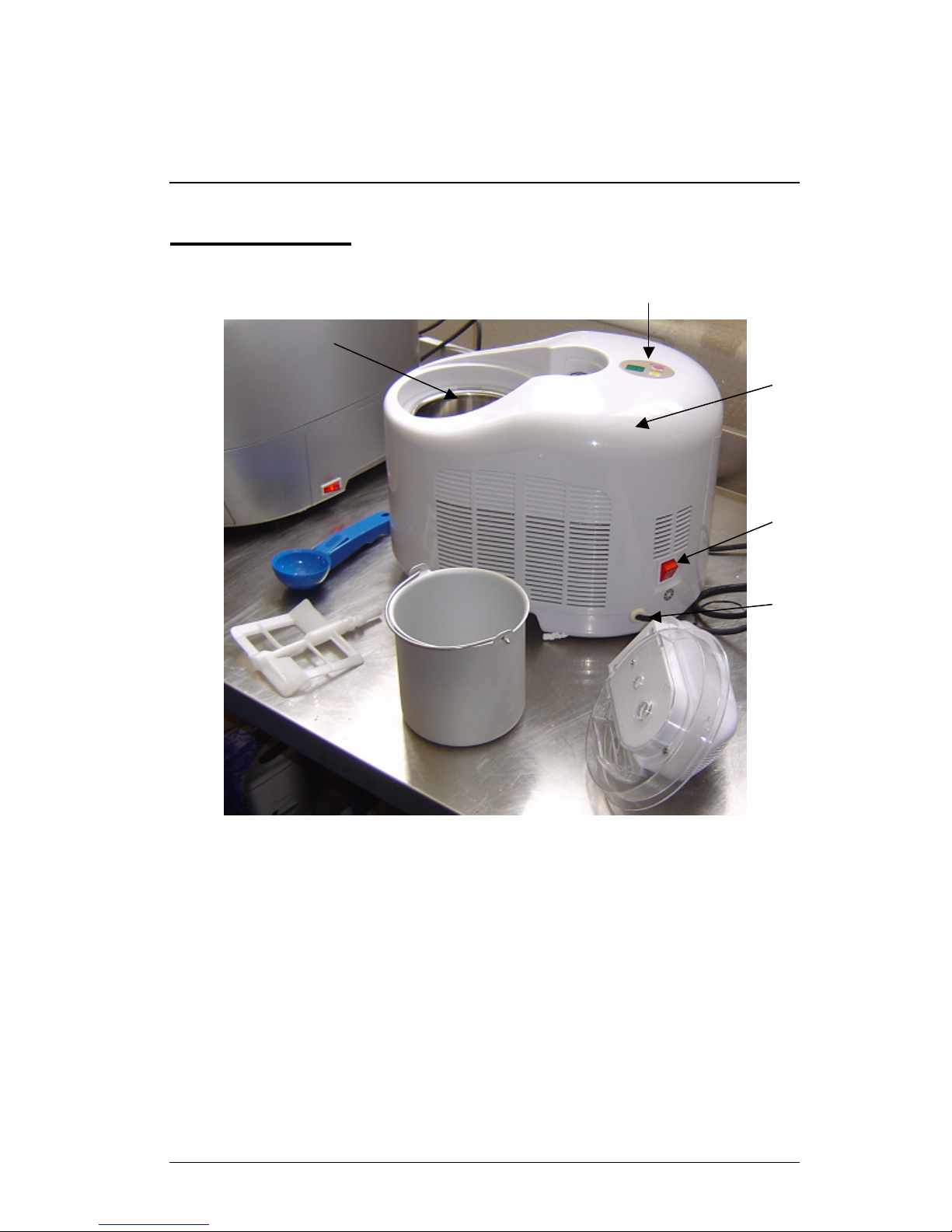

7. Parts Overview

E

D

F

C

B

A

A Top Motor Assembly B Ice Cream Container

C Paddle D Refrigeration Barrel

E Control Panel Display F Appliance Body

G

H

G On/Off Switch H Mains Entry Cable

Document Reference: WI 9 Page 6 of 6

Issue 02

REFRIGERATION INSTALLATIONS LIMITED

Unit D9 Newton Business Park

Cartwright Street

Hyde

Cheshire SK14 4EH

Telephone: +44 (0)161 366 1110 Fax: +44 (0)161 366 1190

7. Parts Overview (Continued)

Detail of Control Panel Displays:

TS-009AS TS-009A

8. Fault Identification

8.1 Machines returned for repair will rarely have an accurate

technical description of the suspected fault. ‘Not Working’, ‘Not

Freezing’, ‘Noisy’ or no stated reason are the most common

complaints. Normally any reported faults should not be believed,

although they should be borne in mind whilst carrying out the

following fault identification methodology. The order in which the

checks are to be carried out is a recommended sequence,

experience may lead to faster ways of finding faults. However as a

full record of checks and inspections carried out may need to be

kept, it is suggested that this sequence is followed.

8.2 The first step is a visual inspection of the equipment in order to

determine any physical damage to the unit and its mains electricity

lead, and to determine the condition of the 13 Ampere fuse. Mains

leads and fuses should be replaced as appropriate.

Document Reference: WI 9 Page 7 of 7

Issue 02

REFRIGERATION INSTALLATIONS LIMITED

Unit D9 Newton Business Park

Cartwright Street

Hyde

Cheshire SK14 4EH

Telephone: +44 (0)161 366 1110 Fax: +44 (0)161 366 1190

8. Fault Identification (Continued)

8.3 Plug the machine into the mains electrical supply and switch on

the On/Off switch located in the rear of the right hand panel. The

On/Off switch should illuminate.

8.4 If the Control Panel Display is type AS (with separate

START/STOP button) the timer will show a setting between 0 and

60 minutes. Press the TIMER SET button and the display should

count down to 0 from its initial value and then reset to 60. Reset to

10 minutes then press the START/STOP button. The paddle will

start to turn and freezing of the Ice Cream Container will

commence. Allow the machine to run for the setting time of 10

minutes and ensure it stops. During the running time confirm that

the Ice Cream Container/Refrigeration Barrel are freezing.

8.5 If the Control Panel Display is of the A type (no separate

START/STOP button) the timer will indicate a number of minutes,

normally 25 but the value is not critical. Pressing the up and down

buttons will increase and decrease the set time. Ensure that both

work and then set the time to 10 minutes. Machine start up (the

Paddle will begin to turn) is automatic after about 10 seconds from

switch on or ten seconds after the last timer adjustment. As in 8.4

ensure the Ice Cream Container is freezing.

8.6 Lack of freezing could indicate a compressor fault, cooling

system fault or cooling fan fault. See Section 9.

8.7 If the Paddle fails to turn a motor failure or connection problem

may be the cause. One of the most common problems reported by

users is the paddle not turning and this is normally due to a bad

electrical connection or lack of electrical connection between the

contacts in the Top Motor Assembly and the Appliance Body. If the

Top Motor Assembly is not seated fully and correctly there is a

high possibility of open circuits. The reasons for Top Motor

Assembly seating problems are incorrect positioning of the seal

and incorrect Ice Cream Container orientation and handle position.

Document Reference: WI 9 Page 8 of 8

Issue 02

Loading...

Loading...