Page 1

Operator’s Manual

CORNELIUS INC

www.cornelius.com

ICE/BEVERAGE DISPENSERS

MODELS: TJ200/250/300B

TJ200/250/300BC

TJ200/250AB

TJ200/250ABC

TJ200/250/300KB

TJ200/250/300KBC

Part No. 91678

Release Date: March 26, 2002

Revision Date: May 12, 2014

Revision: F

THIS DOCUMENT CONTAINS IMPORTANT INFORMATION

This Manual must be read and understood before installing or operating this equipment

E Cornelius Inc; 2002–2005

PRINTED IN U.S.A

Page 2

TABLE OF CONTENTS

SAFETY PRECAUTIONS 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

GENERAL DESCRIPTION 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SPECIFICATIONS 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ICE MAKER 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FEED TUBE OR ICE MAKER INSTALLATION KIT 3. . . . . . . . . . . . . . . . . . . . . . . . .

INSTALLATION INSTRUCTIONS 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

OPERATING INSTRUCTION 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CLEANING INSTRUCTIONS 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DISPENSER 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

COL D PLATE 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

BEVERAGE SYSTEN 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

MAINTENANCE 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DAILY OR AS REQUIRED 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

WEEKLY OR AS REQUIRED 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

MONTHLY 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

GATE RESTRICTOR PLATE 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ADJUSTMENT 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TROUBLESHOOTING GUIDE 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page

BLOWN FUSE OR CIRCUIT BREAKER 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

GATE DOES NOT OPEN. AGITATOR DOES NOT TURN 10. . . . . . . . . . . . . . . . . . .

GATE DOES NOT OPEN OR IS SLUGGISH. AGITATOR TURNS. 10. . . . . . . . . . .

GATE OPENS. AGITATOR DOES NOT TURN. 10. . . . . . . . . . . . . . . . . . . . . . . . . . . .

ICE DISPENSES CONTINUOUSLY. 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SLUSHY ICE. WATER IN HOPPER. 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ICE SOLIDIFIED IN HOPPER OR ICE AT REAR CORNER ONLY. 10. . . . . . . . . . .

NO ICE IN HOPPER 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ICE PACKED IN HOPPER 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

BEVERAGES DO NOT DISPENSE. 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

BEVERAGES TOO SWEET. 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

BEVERAGES NOT SWEET ENOUGH. 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

BEVERAGES NOT COLD (UNITS WITH BUILT-IN COLD PLATE). 10. . . . . . . . . . .

EXPLODED VIEW UPPER AND LOWER PARTS LIST . . . . . . . . . . . . . . . . . . . . . . . . ..............22

Manufactured Under One or More of the Following Patent Numbers:

3,211,336, 3,274,792, 3,393,839 , 3,517,860, 3,739,842, 4,215,803, 4,227,377, 4,300,3594,346,824

Canadian Patent Numbers912,514 (10/72), 936,855 (11,73), 4,429,543, 4,921,149

Other Patents Pending

Page 3

TABLE OF CONTENTS (cont’d)

LIST OF FIGURES

FIGURE 1. GATE RESTRICTOR PLATE 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FIGURE 2. WIRING DIAGRAM TJ200 / 250 / 300-B 11. . . . . . . . . . . . . . . . . . . . . . . .

FIGURE 3. WIRING DIAGRAM TJ200 / 250 / 300—BC, AB, ABC, KB, KBC 12. . .

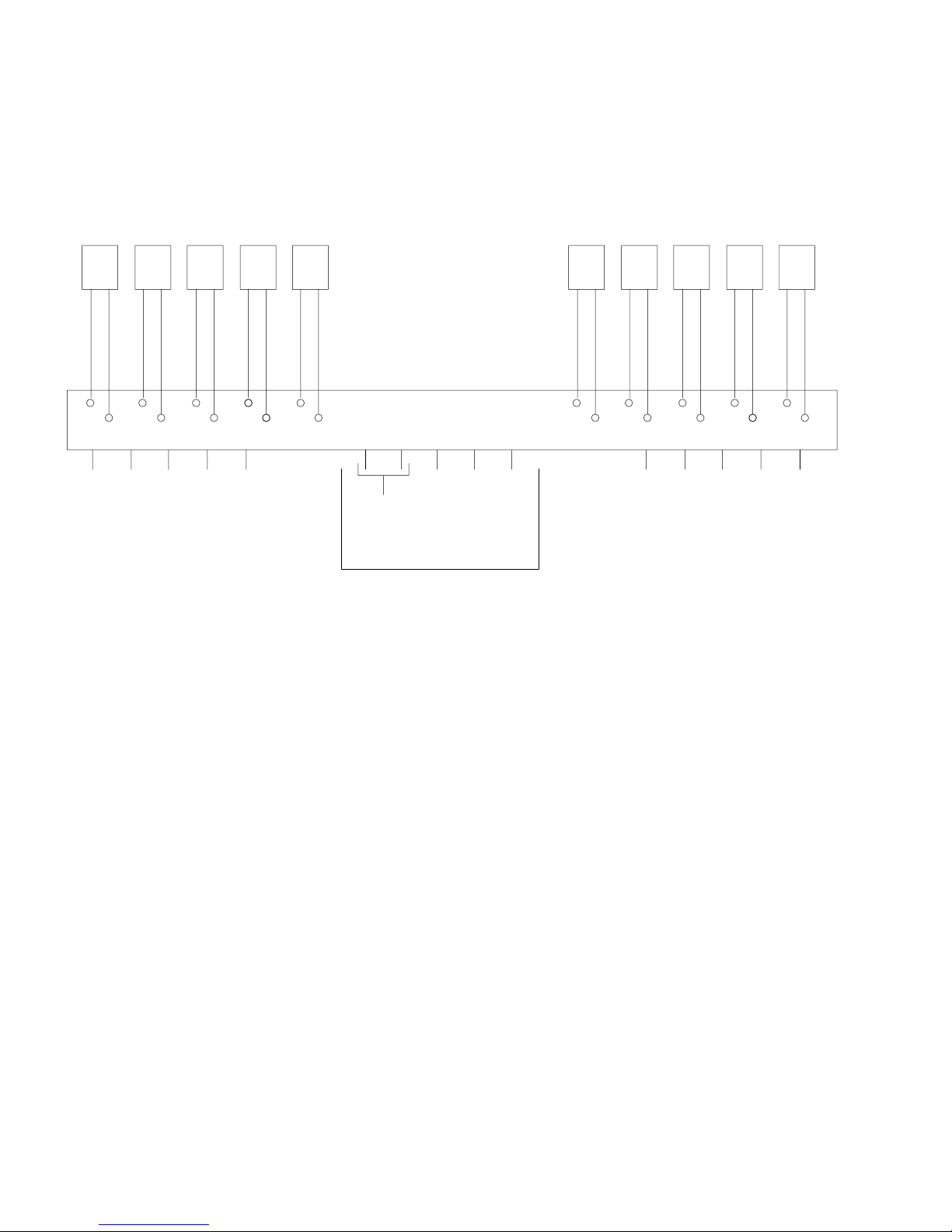

FIGURE 4. PLUMBING SCHEMATIC (8 VALVES) 13. . . . . . . . . . . . . . . . . . . . . . . . . .

FIGURE 5. PLUMBING SCHEMATIC (10 VALVES) 14. . . . . . . . . . . . . . . . . . . . . . . . .

FIGURE 6. BEVERAGE SYSTEM WIRING 15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FIGURE 7. BEVERAGE SYSTEM SCHEMATIC “-B” MODELS 16. . . . . . . . . . . . . .

FIGURE 8. BEVERAGE SYSTEM SCHEMATIC “-BC” MODELS 17. . . . . . . . . . . . .

FIGURE 9. BEVERAGE SYSTEM SCHEMATIC -BC MODELS

19 X 28 COLD PLATES WITH FRONT INLET FITTINGS 18. . . . . . . .

FIGURE 10. MOUNTING TEMPLATE TJ200 / 250-B, BC, KB, KBC -

TJ200 / 250-AB, ABC 19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FIGURE 11. MOUNTING TEMPLATE TJ300 -

TJ250 WITH 19 X 28 COLD PLATE 20. . . . . . . . . . . . . . . . . . . . . . . . . . .

FIGURE 12. EXPLODED VIEW UPPER SECTION 21. . . . . . . . . . . . . . . . . . . . . . . . .

FIGURE 13. EXPLODED VIEW LOWER SECTION 22. . . . . . . . . . . . . . . . . . . . . . . .

FIGURE 14. SOLENOID ASSEMBLY 24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page

LIST OF TABLES

TABLE 1. SPECIFICATIONS 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 4

SAFETY PRECAUTIONS

This ice dispenser has been specifically designed to provide protection against personal injury and eliminates

contamination of ice. To insure continued protection and sanitation, observe the following

Always disconnect power to the dispenser before servicing or cleaning.

Never place hands inside of hopper or gate area without disconnecting power to the dispenser. Agitator rotation

occurs automatically when the dispenser is energized!

ALWAYS be sure the removable lid is properly installed to prevent unauthorized access to the hopper interior and possible contamination of ice.

ALWAYS be sure the upper and lower front panels are securely fastened.

ALWAYS keep area around the dispenser clean of ice cubes.

CAUTION: Dispenser cannot be used with crushed or flaked ice.

Use of bagged ice which has frozen into large chunks can void warranty. The dispenser

agitator is not designed to be an ice crusher. Use of large chunks of ice which “jam up”

inside the hopper will cause failure of the agitator motor and damage to the hopper. If bagged ice

is used, it must be carefully and completely broken into small, cube-sized pieces before filling into

the dispenser hopper.

GENERAL DESCRIPTION

The Remcor TJ200 and TJ300 series of ice dispensers solve your ice service needs the sanitary, space saving,

economical way. Designed to be manually filled with ice from any remote ice making source, or to be used with

one of several “piped ice” type ice makers or top-mounted “Ice cuber,”

These dispensers will dispense cubes (up 1-3/8” in size), cubelets, hard-chipped or cracked ice. Remcor dispensers cannot be used with crushed or flaked ice.

“B” models contain beverage faucets only and must be supplied with cold product from any remote cold plate or

refrigerated soda factory.

“BC” models contain beverage faucets and an internal cold plate system. They are designed to be supplied direct from syrup tanks and carbonator, with no additional cooling required.

The TJ250 with 19” x 28” cold plate is shipped with sink not installed. After beverage hook-up is complete, sink

is to be positioned with cabinet side flange slots and push sink in. Install side mounting pins to retain sink. Make

sure all drain connections are complete.

1 91678

Page 5

SPECIFICATIONS

Model Designation: TJ 1 2 -34 5

1 Ice Storage Capacity TJ200 = 200 lbs. TJ250 = 250 lbs. TJ300 = 300 lbs.

2 Cabinetry Options: (E) Neutral beige, baked enamel finish and wood grain vinyl-clad

upper front panel.

(S) All Stainless Steel.

3 Ice-Fill Options: (No Letter) Manually filled from remote ice maker.

(A) Automatic fill from a “piped ice” type ice maker.

(K) Automatic fill from a top-mounted “ice cuber”.

4 Beverage System Options: (B) Beverage faucets.

(BC) Beverage faucets and an internal cold plate system.

5 Sink: On models with a 19” x 28” cold plate, sink is removable.

Example: Model TJ250S-KBC has a 250 pound ice storage capacity with stainless steel cabinet,

beverage faucet, internal cold plate and is designed for automatic filling from a topmounted ice maker.

Table 1. Specifications

Model: TJ250 (19”x28” Cold

Plate)

Ice Storage: 250 lbs. 200 lbs. 250 lbs. 300 lbs.

Electrical: 115 Volts 1 Phase 60 Hertz, 6.0 Amps

Electrical

Connection:

Faucets Maximum number of 8 faucets available: 10

Drain Connection: 7/8” ID Hose 7/8” ID Hose 7/8” ID Hose 7/8” ID Hose

Dimensions: 32” W x 42-1/4” H x

Shipping Weight

“B”, “KB”, “AB” 220 lbs. 245 lbs. 260 lbs.

“BC”, “KBC”, “ABC” 320 lbs. 275 lbs. 300 lbs. 310 lbs.

“B”, “BC”, “KBC”, and “KB” models: supplied with 6’, 3-wire Cord with 3-prong Ground Type

Plug

“A” Models: Supplied with 2 x 4 junction box located in lower cabinet enclosure for permanent

wiring installation.

36” D

TJ200 TJ250 TJ300

32” W x 38-1/2” H x

36” D

32” W x 42-1/4” H x

36” D

36” W x 44-1/4 H x

36” D

Operating Weight

(Less Ice Maker)

“B”, “KB”, “AB” 420 lbs 495 lbs. 560 lbs.

“BC”, “KBC”, “ABC” 570 lbs. 475 lbs. 550 lbs. 610 lbs.

291678

Page 6

ICE MAKER

REMCOR “A” and “K” model ice/beverage dispensers are designed to be used with one of several “piped ice”

type ice makers or top-mount “ice cubers.” These must be obtained from the appropriate manufacturer or distributor in your area.

The following ice makers are approved for use on the TJ150 “K” models:

FEED TUBE OR ICE MAKER INSTALLATION KIT

This kit contains parts and instructions necessary to connect the ice maker to the ice dispenser. Be sure the kit

you receive is proper for your ice maker. The following kits are approved for use on the TJ200 / 250 / 300 “A,”

“K” dispensers:

“A” MODEL DISPENSERS

KIT NUMBER ICE MAKER MODEL

1913 Reynolds CF-3-TT

1922 Reynolds CF-6-TT

1923 Jieto MD700

1924 Scotsman EC900

“B” MODEL DISPENSERS

KIT NUMBER ICE MAKER MODEL

1930 (TJ300) Ice-O-Matic C20 / 40 / 60

2097 (TJ250) Ice-O-Matic C20 / 40 / 60

1931 Manitowoc 200 / 400 / 600

1932 Kold Draft GT300 / 400 / 500 / 600

2011 Scotsman CM250 / 450 / 500 / 650

2012 Hoshizaki KM451 / 452 / 630 / 632

3 91678

Page 7

INSTALLATION INSTRUCTIONS

1. The ice dispenser must be sealed to the counter The template drawing (Figure 10 and 11) indicate openings which must be cut in the counter. Locate the desired position for the dispenser, then mark the outline

dimensions on the counter using the template drawings. Cut openings in counter.

Apply a continuous bead of NSF International (NSF) listed silastic sealant (Dow 732 or equal) approximately 1/4” inside of the unit outline dimensions and around all openings. Then position the unit on the counter

within the outline dimensions. All excess sealant must be wiped away immediately. “A” models must be

fastened in place with mounting hardware provided.

2. Carefully pull the beverage tubes, drain line and power cord through the large opeinings in the bottom of

the unit. See (Figure 10 and 11), MOUNTING TEMPLATES, for locating the required clearance holes in the

counter for these utility lines.

3. “A” and “K” Models Only: Install the ice maker according to the instructions supplied with the kit, and

manufacturer’s instructions supplied with the ice maker.

4. Connect the drain tube to an open drain. If additional piping is required, it must be 3/4” IPS (or equal). This

line must continually pitch downward away from the unit and must contain no traps, or improper drainage

will result.

5. Connect the beverage system product lines as indicated in Figure 7 (“B” Models), Figure 8 (“BC” Models)

and Figure 9 (“BC” Models with 19 x 28 cold plate and front inlet fittings.) This work should be done by a

qualified service person. Note that the hoses are marked with numbers (1 through 8) for syrup connections

and “CW” for carbonated water connection.

6. Clean the ice dispenser interior (see CLEANING INSTRUCTIONS).

7. Connect the dispenser cord to a 115 volt, 60 cycle, 3-wire grounded receptacle. “A” models must be permanently wired and conform to NEC and local codes.

91678 4

Page 8

OPERATING INSTRUCTION

1. Ice Dispensing: Depressing the operating lever activates a micro switch behind the front panel which energizes the agitator motor and gate solenoid. This causes the agitator to rotate and the gate slide to lift, allowing ice to push out the gate opening.

2. Ice level (Standard Models): When ice level light is on, remove the lid and fill the hopper with ice. Replace

lid to avoid contamination of ice.

CAUTION: Use caution to avoid spilling ice when filling dispenser. Clean up immediately

any spilled ice from filling or operating the unit. To prevent contamination of ice, the lid

must be stalled on the unit at all times.

Automatic Ice Filling (“A” models): While the ice maker is running, the ice entering the hopper from the feed

tube should be loose and in small pieces. Ice entering in the form of hard-packed cylinders indicates a restriction or distortion of the feed tube and could result in ice maker malfunction, if not corrected. The automatic agitation timer causes the ice to level which allows the entire storage bin to fill before the ice machine

shuts off. When the ice level remains at the deflector after agitation, the ice maker control capillary (ice

maker bulb) stops ice maker operation until the level drops and the bulbs warm up.

Immediately after ice maker shut-off, observe the ice in the hopper between the feed tube entrance and the

deflector. it should be loosely pressed against the top of the deflector, indicating correct thermostat operation. If the ice level is low or if the ice is packed hard against the deflector, it will be necessary to re-adjust

the ice maker bin control, according to the ice maker instructions. Adjust the control warmer to lower the

ice level and colder to raise the ice level.

Automatic Ice Filling (“K” Models): As the “A” models, the agitation tier causes the ice to level which allows

the entire storage bin to fill before the ice machine shuts off. The ice maker control capillary bulb maintains

the ice level in the storage hopper. Consult the instructions provided with the installation kit and the ice

maker manual for location and operation of the ice maker control.

Beverage System - Beverages may be dispensed by operating the lever on the appropriate faucets. On

units with cold plates (“c” models), periodic movement of the ice in the hopper is necessary to maintain the

level of ice on the cold plate. On initial start-up or after long idle perios with no use, dispensing ice for 20-30

seconds is necessary to fill the cold plate or warm beverages may be experienced.

5 91678

Page 9

CLEANING INSTRUCTIONS

WARNING: DISCONNECT POWER BEFORE CLEANING! Do not use metal scrapers, sharp

objects or abrasives on the ice storage hopper, top cover and the agitator disk, as damage

may result. Do not use solvents or other cleaning agents, as they may attack the plastic

material.

DISPENSER

1. Clean the ice dispenser interior at least once a month.

2. Remove the agitator bolt and lift off the agitator and the agitator disk, taking care not to lose the shaft key.

Wash with a mild detergent solution and rinse them thoroughly to remove all traces of detergent.

3. Carefully remove, wash and rinse all internal hopper components.

4. Wash down the inside of the hopper and top cover with a mild detergent solution and rinse thoroughly to

remove all traces of detergent.

5. Replace the agitator and other components.

6. Sanitize the inside of the hopper and agitator with a solution of 1 ounce of household bleach in 2 gallons of

water. (200 PPM)

7. Remove Ice Chute cover as follows:

A. Flex sides outward to disengage lower pins.

B. Lift Ice Chute cover to disengage upper pins.

C. Lower Ice Chute cover down out of unit. Note: it may be helpful to twist cover slightly.

8. With brush provided clean the inside of the ice chute and ice chute cover with a mild detergent solution and

rinse thoroughly to remove all traces of detergent.

9. Reverse steps above to reassemble ice chute.

10. Sanitize as described in Step 6.

COL D PLATE

1. Carefuly remove the lower front panel of the ice dispenser. On “BC models with 19 x 28 cold plate, remove

the beverage faucet panel.

2. Remove cold plate cover by lifting slightly in front and slide forward. On “BC” models with 19 x 28 cold

plate, the cover is two (2) pieces. Remove only the front cover.

3. Wash down the inside of the cold plate and cover with mild detergent solution and rinse. A small long handled brush wil be found helpful in reaching the corners.

4. Replace the cover, taking care that it is securely positioned in cold plate tray.

5. Replace and lower front panel, carefully feeding the tube and wires into the cabinet. Be sure not to pinch

any tubing or wires between the panel and cabinet.

BEVERAGE SYSTEM CLEANING AND SANITIZING INSTRUCTIONS

1. Prepare the following cleaning, rinsing and sanitizing solutions using a clean, empty figal (5 gallon syrup

tank) for each solution.

91678 6

Page 10

CLEANING TANK – Fill with a solution of 1/2 ounce of a mild liquid detergent (for example, Ivory liquid) to

1 gallon of warm (120_F) potable water.

RINSING TANK

– Fill with warm (120_F) potable water.

SANITIZING TANK – Fill with a chlorine sanitizing solution in the strength of 1/2 ounce of household

bleach (sodium hypochlorite) to 1 gallon of cold (ambient) potable water to obtain a solution strength of 200

PPM.

NOTE: Repeat the following procedure on each of the unit’s syrup product lines and beverage faucets.

2. Using a suitable pail or bucket, fill one with a detergent solution and a second container with a sanitizing

solution in the strengths as described in step 1.

A. Remove the syrup line quick disconnect fitting from the product tank and submerge in the detergent

solution. Clean with a nylon bristle brush (do not use a wire brush). Rinse with clean potable water.

B. Wearing sanitary gloves, next submerge the quick disconnect fitting in the sanitizing container for 15

minutes. Remove and air dry.

3. Hook-up the sanitized product line fitting (step 2) to the cleaning tank. Hook-up a gas disconnect fitting to

the tank and pressurize with 60 to 80 psig CO2. Energize the beverage faucet continuously for 1 minute to

remove all air bubbles. Continue to operate the faucet until liquid dispensed is free of any syrup. Cycle the

faucet for 15 seconds on, off and then immediately on again. Repeat this procedure for 15 cycles. Then

energize the faucet to remain flowing for 3 minutes.

4. Hook-up the rinsing tank and pressurize with 60 to 80 psig CO2. Flush the cleaning solution from the product line by cycling the faucet as described in step 3 and then energize the faucet to flow continuously for 3

minutes.

5. Hook-up the sanitizing tank and pressurize with 60 to 80 psig CO2. Flow the sanitizing solution through the

beverage faucet by cycling the faucet as described in step 3. Next energize the faucet continuously to flush

at least 2 cups of the sanitizing solution through the system. Finally deenergize the faucet and allow the

sanitizer to remain pressurized in the line to 20 minutes.

6. Wearing sanitary gloves. remove the faucet nozzle and diffuser. Repeat the cleaning and sanitizing procedures as described in step 2, then reassemble to the faucet.

7. Disconnect the sanitizing tank. Hook-up the product tank to the unit and to the CO

system. Energize the

2

faucet to flush the sanitizing solution from the syrup line and the faucet. Continue flow on the faucet until

only syrup is dispensed.

7 91678

Page 11

MAINTENANCE

The following dispenser maintenance should be performed at the intervals indicated:

DAILY or as required

Remove foreign material from the vending area sink to prevent drain blockage.

WEEKLY or as required

Clean vending area. Check for proper water drainage from the vending area sink.

MONTHLY

Clean and sanitize the hopper interior (see CLEANING INSTRUCTIONS).

If the dispenser fails to dispense ice when operated, check that the hopper has ice in it and that power is being

supplied to the unit. If the problem persists, check the following:

1. Determine if the agitator is rotating (check for the sound of ice movement in the hopper).

2. Observe whether the gate is operating.

After checking the above, refer to the TROUBLESHOOTING GUIDE for possible problem causes and corrective action.

91678

8

Page 12

GATE RESTRICTOR PLATE

CAUTION: Disconnect power to dispenser before installing, removing or adjusting

restrictor

INSTALL PLATE ON

STUDS AS SHOWN

ADJUSTMENT

This dispenser is provided with a gate restrictor plate, installed in its highest position.

This plate adjusts the rate of ice flow from the dispenser. In applications using buckets, carafes or other large

containers, the plate may be removed entirely for maximum ice flow. For glasses and cups, the plate may be

adjusted downward to reduce the flow of ice. The best position depends on the type of ice being used and the

size container, and must be found by trial and error. Adjustment is made by loosening the upper two ice chute

retaining nuts, sliding the restrictor plate to the desired position and re-tightening the nuts.

If the dispenser fail to dispense the ice when operated, check that the hopper has ice in it and that power is being supplied to the unit. If the problem persists, check the following.

1. Determine if the agitator is rotating (check for the sound of ice movement in the hopper).

2. Observe whether the gate is operating.

FIGURE 1. GATE RESTRICTOR PLATE

9 91678

Page 13

TROUBLESHOOTING GUIDE

Should your unit fail to operate properly, check that there is power to the unit and that the hopper contains ice. If

the unit does not dispense, check the following chart under the appropriate symptoms to aid in locating the defect.

Trouble Probable Cause

BLOWN FUSE OR CIRCUIT BREAKER A. Short circuit in wiring.

B. Defective gate solenoid.

C. Defective agitator motor.

GATE DOES NOT OPEN. AGITATOR DOES

NOT TURN

GATE DOES NOT OPEN OR IS SLUGGISH.

AGITATOR TURNS.

A. No power.

B. Bent depressor plate (does not actuate switch).

C. Defective dispensing switch.

A. Defective gate solenoid.

B. Weak gate spring.

GATE OPENS. AGITATOR DOES NOT TURN. A. Agitator motor protector tripped.

B. Defective agitator motor.

C. Defective agitator relay.

ICE DISPENSES CONTINUOUSLY. A. Stuck or bent depressor plate (does not release

switch).

B. Defective dispensing switch.

C. Improper switch installation.

SLUSHY ICE. WATER IN HOPPER. A. Blocked drain.

B. Unit not level.

C. Ice maker malfunction.

ICE SOLIDIFIED IN HOPPER OR ICE AT

REAR CORNER ONLY.

NO ICE IN HOPPER A. Ice maker malfunction.

ICE PACKED IN HOPPER A. Defective or improperly adjusted ice maker control

BEVERAGES DO NOT DISPENSE. A. No 24 Volt power to faucets.

BEVERAGES TOO SWEET. A. Carbonator not working.

A. Defective or improperly adjusted ice maker

thermostat.

(not shutting off).

B. No CO2 pressure.

BEVERAGES NOT SWEET ENOUGH. A. Empty syrup tank.

BEVERAGES NOT COLD (UNITS WITH

BUILT-IN COLD PLATE).

Refer to manufacturer’s instructions for troubleshooting ice maker.

B. No CO2 pressure in carbonator.

C. Faucet brix requires adjusting.

B. Faucet brix requires adjusting.

A. Unit standing with no ice use - no ice in cold plate

cabinet.

1091678

Page 14

LOW ICE

LIGHT

ICE LEVEL

T’STAT

BLU

TERMINAL

BLOCK

120V.

60HZ

BLK

1PH

OPTIONAL PORTION CONTROL

OR

RED

DISPENSE

SWITCH

WHT

PORTION

TIMER

WHT

BRNYEL

WHT

WHT

GATE

SOLENOID

BRN

BLK

WHT

AGITATOR

MOTOR RELAY

AGITATOR

MOTOR

DISPENSE

1 1/4 AMP

TIME DELAY

YEL

YEL

BUTTON

RED

SERVICE INFORMATION

DANGER!

7

8

ELECTRIC SHOCK HAZARD. DISCONNECT POWER BEFORE SERVICING UNIT.

SOLENOID

ADJUSTMENT

WHEN REPLACING SOLENOID

ADJUST TO 7/8 AS SHOWN

BEFORE TIGHTENING

MOUNTING SCREWS

FUSE

FIGURE 2. WIRING DIAGRAM TJ200 / 250 / 300-B

11

91678

Page 15

WHT

120V.

60HZ

1PH

WHT

BLK

TERMINAL

BLOCK

WHT

WHT

BRN

WHT

BLK

WHT

BLK

AGITATOR

MOTOR RELAY

AGITATOR

MOTOR

DISPENSE

BLU

BUTTON

C

NO

NC

AGITATOR

TIMER

RED

1 1/4 AMP

TIME DELAY

FUSE

YEL

YEL

RED

OPTIONAL PORTION CONTROL

PORTION

TIMER

OR

RED

WHT

DISPENSE

SWITCH

BRNYEL

FIGURE 3. WIRING DIAGRAM TJ200 / 250 / 300—BC, AB, ABC, KB, KBC

GATE

SOLENOID

SERVICE INFORMATION

DANGER!

7

8

1291678

ELECTRIC SHOCK HAZARD. DISCONNECT POWER BEFORE SERVICING UNIT.

SOLENOID

ADJUSTMENT

WHEN REPLACING SOLENOID

ADJUST TO 7/8 AS SHOWN

BEFORE TIGHTENING

MOUNTING SCREWS

Page 16

1234 5678

VALVES

WW WW

S1 S2 S3 S4 S5 S6 S7 S8

S1 S2 S3 S4 S5 S6 S7 S8

SYRUP

INLETS

OR NONĆCARBONATED

NOTE: 1) TO SERVICE COLDPLATE INLET FITTINGS,

SINK HAS TO BE REMOVED. TO REMOVE,

DISCONNECT SINK DRAIN CONNECTIONS,

THEN LIFT TWO (2) SIDE MOUNTING PINS

AND PULL SINK FORWARD. REVERSE TO

RECONNECT.

MANIFOLDS

BEHIND

VALVES

COLDPLATE

5

1,2 6,7,8

3,4

WATER INLETS

MAY BE CARBONATED

SYRUP

INLETS

2) MAKE SURE ALL DRAIN CONNECTIONS

ARE PROPERLY POSITIONED FOR

DRAINING AFTER SERVICE, BEFORE

PANELS ARE INSTALLED.

FIGURE 4. PLUMBING SCHEMATIC (8 VALVES)

13

91678

Page 17

1234

5

VALVES

6789

10

S1 S2 S3 S4

S1 S2 S3 S4

SYRUP

INLETS

NOTE: 1) TO SERVICE COLDPLATE INLET FITTINGS,

S5

S5

1,5,6,7,

8,9,10

MAY BE CARBONATED

SINK HAS TO BE REMOVED. TO REMOVE,

DISCONNECT SINK DRAIN CONNECTIONS,

THEN LIFT TWO (2) SIDE MOUNTING PINS

AND PULL SINK FORWARD. REVERSE TO

RECONNECT.

2) MAKE SURE ALL DRAIN CONNECTIONS

ARE PROPERLY POSITIONED FOR

DRAINING AFTER SERVICE, BEFORE

PANELS ARE INSTALLED.

COLDPLATE

3

WATER INLETS

OR PLAIN WATER

S6 S7 S8 S9

S6

SYRUP

INLETS

S10

S9S7 S8

S1042

FIGURE 5. PLUMBING SCHEMATIC (10 VALVES)

1491678

Page 18

120 VAC

LN

60 HZ

1 PH

COLD PLATE MOTOR (OPTIONAL)

TRANSFORMER

24V.

BEVERAGE

FAUCET

(TYPICAL)

FIGURE 6. BEVERAGE SYSTEM WIRING

15

91678

Page 19

16

91678

OPTIONAL-FOR DIET

OR ROOT BEER

5-15 PSIG

15-50 PSIG

S1 S2 S3 S4 S5 S6 S7 S8

SYRUP

TANKS

CO2 TANK

FAUCETS

1

2

3

4

5

6

7

8

CW

CW

60-100 PSIG

NOTE: REFERENCE ONLY

NOT FOR CONSTRUCTION

REGULATORS

WATER

SUPPLY

FILTER

OPTIONAL: PRESSURE

REGULATOR

CARBONATOR

COLD PLATE OR

ICE BANK

REMCOR ”B” ICE/BEVERAGE DISPENSER

ITEMS OUTSIDE OF BROKEN LINES NOT

INCLUDED WITH UNIT.

FAUCETS 5 THRU 8 ARE OPTIONAL.

FIGURE 7. BEVERAGE SYSTEM SCHEMATIC “-B” MODELS

Page 20

17

91678

OPTIONAL-FOR DIET

OR ROOT BEER

5-15 PSIG

15-50 PSIG

S1 S2 S3 S4 S5 S6 S7 S8

SYRUP

TANKS

CO2 TANK

FAUCETS

1

2

3

4

5

6

7

8

CW

CW

60-100 PSIG

NOTE: REFERENCE ONLY

NOT FOR CONSTRUCTION

REGULATORS

WATER

SUPPLY

FILTER

OPTIONAL: PRESSURE

REGULATOR

CARBONATOR

COLD PLATE

REMCOR ”BC” ICE/BEVERAGE

DISPENSER ITEMS OUTSIDE

OF BROKEN LINES NOT

INCLUDED WITH UNIT.

FAUCETS 5 THRU 8 ARE OPTIONAL.

FIGURE 8. BEVERAGE SYSTEM SCHEMATIC “-BC” MODELS

Page 21

18

91678

OPTIONAL-FOR DIET

OR ROOT BEER

5-15 PSIG

15-50 PSIG

S1 S2 S3 S4 S5 S6 S7 S8

CO

2

TANK

REGULATORS

FAUCETS

1

2

3

4

5

6

7

8

COLD PLATE

SYRUP

TANKS

60-100 PSIG

NOTE: REFERENCE ONLY

NOT FOR CONSTRUCTION

WATER

SUPPLY

FILTER

OPTIONAL: PRESSURE

REGULATOR

CARBONATOR

WATER HOOK

UPS-MAY BE

CARBONATED

OR PLAIN WATER

AS REQUIRED

1,2

3,4

5

6,7,8

S1

S2

S3

S4

S5

S6

S7

S8

NON-CARB WATER

REMCOR ”BC” ICE/BEVERAGE

DISPENSER ITEMS OUTSIDE

OF BROKEN LINES NOT

INCLUDED WITH UNIT.

FIGURE 9. BEVERAGE SYSTEM SCHEMATIC -BC MODELS 19 X 28 COLD PLATES WITH FRONT INLET FITTINGS

Page 22

19

91678

6

1 1/4

63 1/8 14 2 1/8

32

3/4

2 25/32

36

6

1 1/4

63 1/8

16

14 2 1/8

19 1/4

2

3/4

2 25/32

10 1/2

16

36

1 1/4

2 5/32 27 11/16

32

TJ 200/250-B, BC, KB, KBC

TJ 200/250-AB, ABC

OUTLINE OF UNIT

OUTLINE OF UNIT

SEE NOTE 2

SEE NOTE 3

SEE NOTE 4

NOTES:

1. SHADED AREAS INDICATE OPENINGS IN CABINET

BOTTOM NEEDED FOR UTILITIES.

2. 1 1/8 DIA. ACCESS HOLE FOR ELECTRICAL SUPPLY CONDUIT.

3. FOUR 3/8 DIA. HOLES FOR SECURING UNIT TO COUNTER.

4 1/2 DIA. ACCESS HOLE FOR ICEMAKER CONTROL BULB.

FIGURE 10. MOUNTING TEMPLATE TJ200 / 250-B, BC, KB, KBC - TJ200 / 250-AB, ABC

Page 23

20

91678

6

1 1/4

63 1/16 14 2 1/16

36

3/4

4 3/32

36 3/64

OUTLINE OF UNIT

16 3/4

32

36

OUTLINE OF UNIT

TJ 300

TJ 250 WITH 19 x 28 COLDPLATE

6 15/16

17 9/16

4 1/2

NOTE: SHADED AREAS INDICATE OPENINGS

IN COUNTER REQUIRED FOR UTILITIES

AND BEVERAGE TUBING.

FIGURE 11. MOUNTING TEMPLATE TJ300 - TJ250 WITH 19 X 28 COLD PLATE

Page 24

27

28

10

21

19

20

12

13

9

11

8

25

24

26

22

23

FIGURE 13. EXPLODED VIEW UPPER SECTION

19

18

17

16

15

29

6

4

3

2

1

5

30

7

FIGURE 12. EXPLODED VIEW LOWER SECTION

21

91678

Page 25

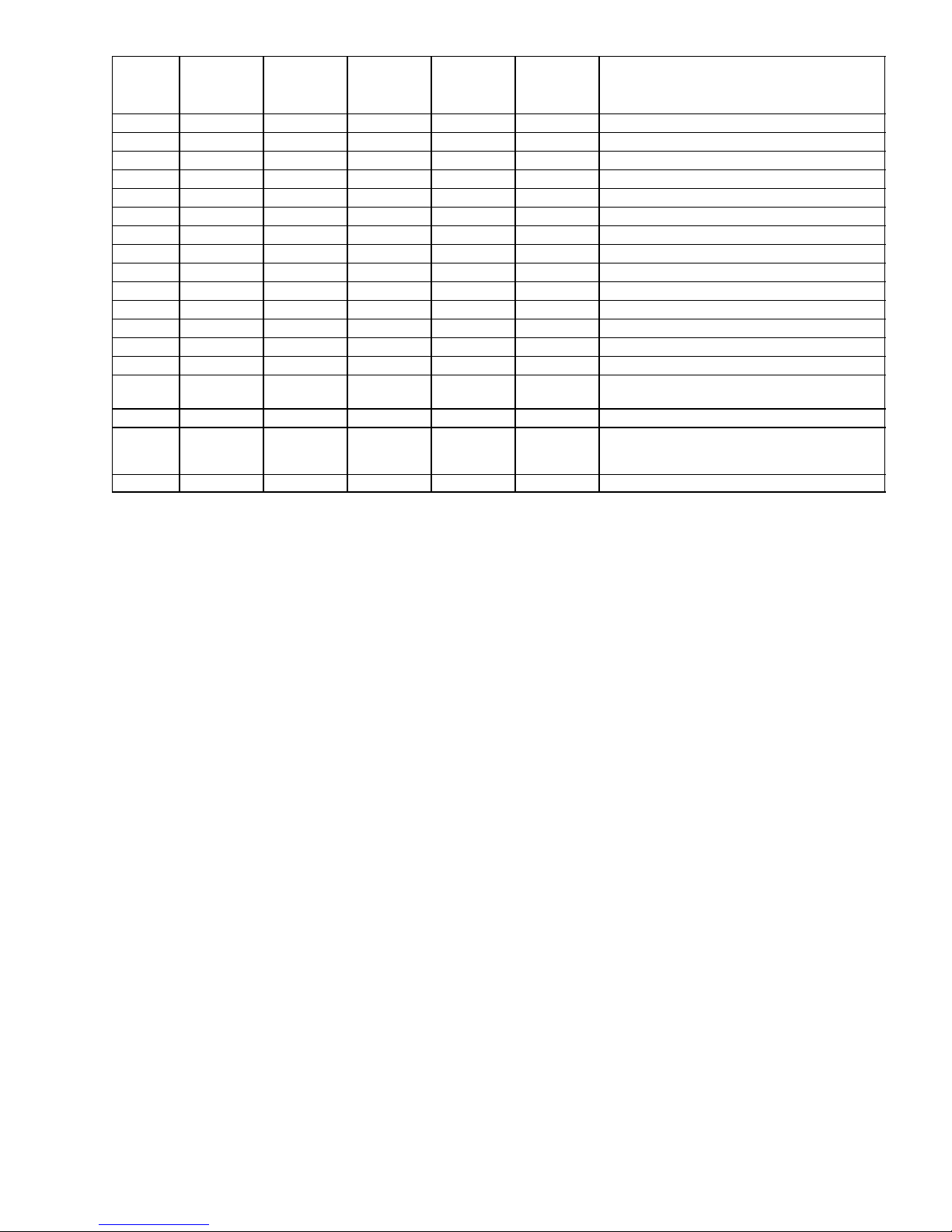

EXPLODED VIEW UPPER AND LOWER PARTS LIST

Part No.

TJ250–BC

Item No.

10 ––––– ––––– 22441 ––––– ––––– Bracket-Ice Deflector

11 ––––– 31001 ––––– ––––– ––––– Ice Level Thermostat

12 30960 30960 30960 30960 30960 Terminal Board

13 ––––– 31205 ––––– ––––– ––––– Ice Level Light

14 31091 31091 31091 31091 31433 Transformer-Beverage Faucets (Not Shown)

15 31197–1 31197–1 31197–1 31197–1 31617–1* Agitator Motor Kit (Includes motor, seak, hardware

16 50967 50967 50967 50967 50967 Insulation (Agitator Motor)

17 50891 50891 50891 50891 51101 Motor Shaft Seal

18 22402 22402 22402 22402 22402 Bracket-Hopper Seal

19 51891 51891 51891 51891 51891 Gate Gasket

20 ––––– ––––– 22519 ––––– ––––– Ice Diverter

21 22081 22081 22081 22081 22081R Gate Restrictor

22 21491 21491 21491 21491 21491 Gate Slide

23 53015 53015 53015 53015 53015 Ice Chute Back Section

24 Solenoid Assembly

25 22082 50962 50962 22082 25454R Lid-Removable

26 22084 50963 50963 22084 25452 Cover Assembly - Rear

27 ––––– 22047 22047 22047 25744 Agitator (TJ200)

28 ––––– ––––– 22339 ––––– ––––– Deflector Assembly

29 ––––– ––––– 31116 ––––– ––––– Cold Plate Agitator Motor

19x28 CP

1 22644 22644 22644 22644 27107 Depressor Retainer

2 22777 22777 22777 22777 27472 Depressor Lever

3 31007 31007 31007 31007 31007 Switch Boot

4 31163 31163 31163 31163 31163 Boot Adapter

5 02070 02070 02070 02070 30895 Dispensing Switch

6 70496 70496 70496 70496 70710 Sink Grill

7 –––––

–––––

52163 51032 51032 51032 ––––– Sink (Cold Plate Units)

10145 ––––– ––––– ––––– 10145 Sink Mtg. Pin

70928 70928 70928 70928 70928 Cold Plate Drain Spring

–––––

–––––

08052 08052 08052 08052 08052 Splashguard Kit (Two clear side guards)

8 31375 31375 31375 31375 31375 Mercury Relay

9 31763 ––––– 31763 31763 620314803 Agitation Timer

30794 30794 30794 30794 30794 Agitator Motor Heater

70341 70341 70341 70341 70341 Heater Spring, 3 per, req’d

53016 53016 53016 53016 53016 Ice Chute Cover

31094 31094 31094 31094 31470 Solenoid

70438 70438 70438 70438 70438 Rebuilding Kit

22047 22047 22047 22047 ––––– Agitator (TJ250)

––––– ––––– 22857 ––––– ––––– Agitator, Cold Plate Motor

––––– ––––– 31134 ––––– ––––– Capacitor, Cold Plate Agitator Motor

Part No.

TJ200/250

B, BC

–––––

51024–1

–––––

–––––

20858 20858 20858 Agitator Keyway (Fits inside shaft of the agitator)

Part No.

TJ200/250

AB, ABC

–––––

51024–1

–––––

–––––

Part No.

TJ200/250

KB, KBC

–––––

51024–1

–––––

–––––

Part No.

TJ300

KBC Description

52782 Sink

28059

28512R

Drip Tray TJ2XX (32 x 6–3/4 Three)

Drip Tray Extension (35 x 9.6)

Drip Tray Extension (36 x 9.5 Three sided)

and key) *31617–1 does not include key

2291678

Page 26

Part No.

TJ250–BC

Item No.

30 Beverage Faucets

N/A 70439

N/A ––––– 32366 32366 32366 ––––– Lighted Display (Obsolete)

N/A –––––

N/A ––––– 91797 91797 91797 ––––– Gen. Graphics (obsolete)

19x28 CP

40366 40366 40366 40366 40366 McCann “Pepsi”

40324 40324 40324 40324 40324 McCann “Coke”

40391 40391 40391 40391 40391 McCann Non-Carbonated

40444 40444 40444 40444 40444 McCann Fast Flow

40400 40400 40400 40400 40400 Cornelius “Pepsi”

40445 40445 40445 40445 40445 Cornelius Fast Flow

40404 40404 40404 40404 40404 Dole

40483 40483 40483 40483 40483 Dole Fast Flow

40446 40446 40446 40446 40446 Concessions

40447 40447 40447 40447 40447 Concessions Fast Flow

––––– ––––– ––––– ––––– 51802 Beverage Drip Shield

40944 40944 40944 40944 40944 Lancer (lever)

41050 41050 41050 41050 41050 Lancer (push button)

70927

–––––

–––––

Part No.

TJ200/250

B, BC

70439

70927

–––––

–––––

–––––

Part No.

TJ200/250

AB, ABC

70439

70927

–––––

–––––

–––––

Part No.

TJ200/250

KB, KBC

70439

70927

–––––

–––––

–––––

Part No.

TJ300

KBC Description

70439

70927

32367

91204

51877

4” Leg Black Plastic (Sold by the each)

4” Leg Caster (Sold by the each)

Lighted Merchandiser (Use 91204 or 51877)

Graphics 7–11

Clear Merchandiser Panel (18–13/16 x 35–13/16)

23

91678

Page 27

22

17

19

22

4

1

4

18

21

16

15

14

19

13

9

2

3

5

22

20

6

8

11

10

12

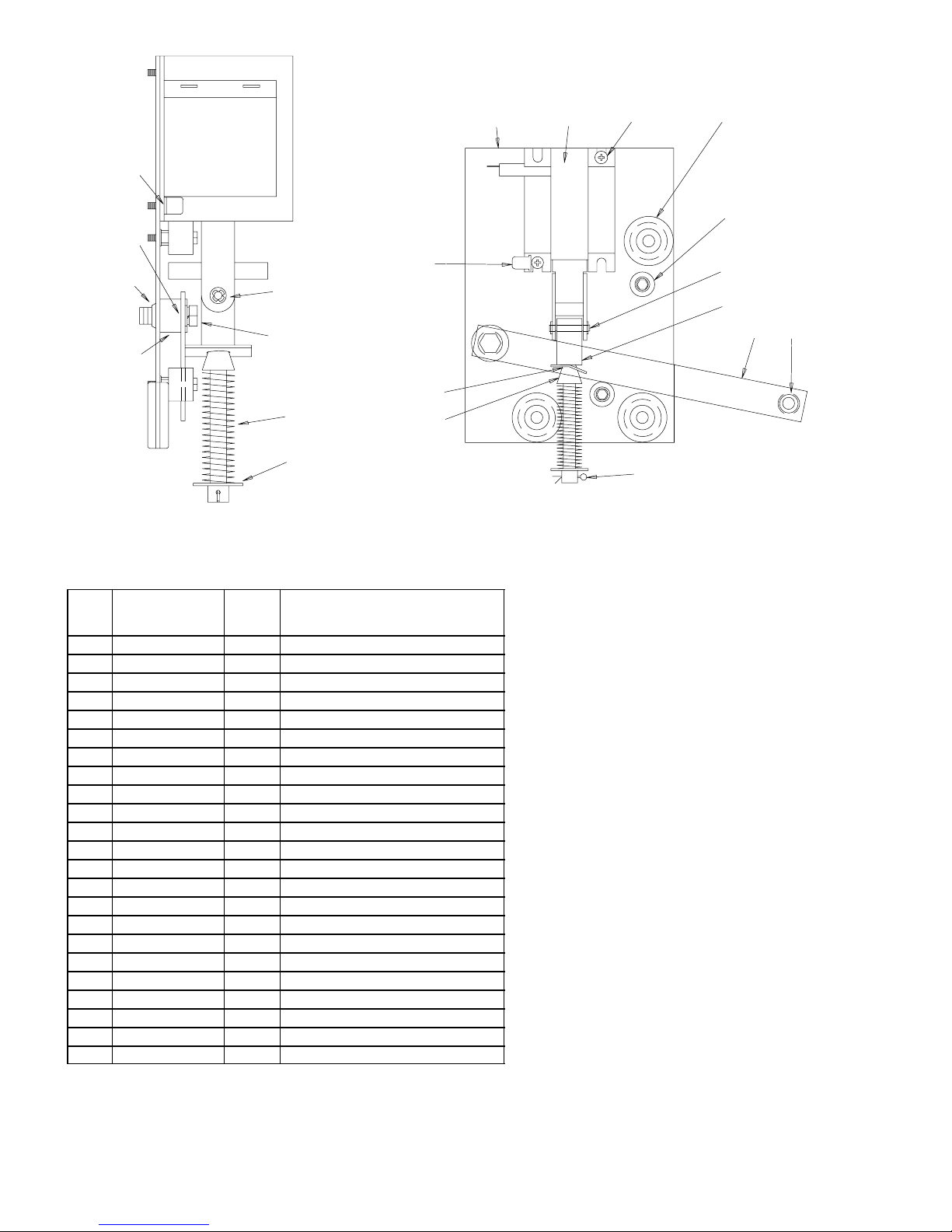

FIGURE 14. SOLENOID ASSEMBLY

Index

Part No. Qty. Name

No.

1 22889 1 Solenoid Mounting Plate

2# 31551 1 Solenoid Service Kit

3 70171 2 8–32 x 3/8 Phil Tr HD Screw

4 70121 2 No. 8 Lockwasher

5 50752 3 Isolator

6* 50753 2 Bumper Assembly

7* 70423 1 Cotter Pin

8* 10080 1 Gate Lift Rod

9 10081 1 Gate Lift Rod Bushing

10 50754 1 Gate Arm Bearing

11 22890 1 Gate lift Arm

12 70043 1 Flatwasher

13* 70422 1 Spring

14 70263 1 1/4-20 x 3/4 Hex Hd Screw

15 70048 1 1/4 Lockwasher

16 70066 1 1/4 Flatwasher

17 10077 1 Pivot Bearing

18 30227R 1 1/4 Quick Connect Tab

19 50305 –– Lubricant

20* 21592 1 Solenoid Linkage Pin

21* 70433 2 Retainer Ring

22 51088 –– Loctite

––* 70438 –– Rebuilding Kit

7

NOTE: * Parts supplied with rebuilding kit.

# 31551 solenoid supplied with items 20 & 21.

2491678

Loading...

Loading...