Cornelius TEA URN Service Manual

Service Manual

TEA URN

POST-MIX

BEVERAGE DISPENSER

IMPORTANT:

TO THE INSTALLER.

It is the responsibility of the Installer to

ensure that the water supply to the

dispensing equipment is provided with

protection against backflow by an air gap as

defined in ANSI/ASME A112. 1.2-1979; or an

approved vacuum breaker or other such

method as proved effective by test.

IMI CORNELIUS INC.

One Cornelius Place

Anoka, MN. 55303–6234

Telephone (800) 238–3600

Facsimile (612) 422–3232

Water pipe connections and fixtures directly

connected to a potable water supply shall be

sized, installed, and maintained according to

Federal, State, and Local laws.

Part No. 312020000

December 7, 1993

Revised: July 8, 1994

Control Code A

THIS DOCUMENT CONTAINS IMPORTANT INFORMATION

This Installation Manual must be read and understood before starting to install or operate this equipment.

IMI CORNELIUS INC; 1993-94

Printed in U. S.A.-94

TABLE OF CONTENTS

GENERAL INFORMATION 1. . . . . . . . . . . . . . . . .

GENERAL DESCRIPTION 1. . . . . . . . . . . . . . .

UNIT DESCRIPTION 1. . . . . . . . . . . . . . . . . . . .

DESIGN DATA 1. . . . . . . . . . . . . . . . . . . . . . . . . .

THEORY OF OPERATION 1. . . . . . . . . . . . . . .

INSTALLATION 4. . . . . . . . . . . . . . . . . . . . . . . . . . .

RECEIVING 4. . . . . . . . . . . . . . . . . . . . . . . . . . . .

UNPACKING AND INSPECTION 4. . . . . . . . . .

IDENTIFICATION OF LOOSE-SHIPPED

PARTS 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

LOCATION SELECTION 4. . . . . . . . . . . . . . . . .

INSTALLATION 4. . . . . . . . . . . . . . . . . . . . . . . . .

PREPARING UNIT FOR OPERATION 5. . . . .

OPERATORS INSTRUCTIONS 6. . . . . . . . . . . . .

CHECK OR CHANGE NITROGEN

CYLINDER 6. . . . . . . . . . . . . . . . . . . . . . . . . . .

CHANGE CONCENTRATE TANK 6. . . . . . .

SERVICE AND MAINTENANCE 7. . . . . . . . . . . .

APPLICABLE WARNINGS, CAUTIONS AND

NOTES 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

MAINTENANCE SCHEDULE 7. . . . . . . . . . .

CHECK WATER FLOW RATE 7. . . . . . . . . .

CHECK CONCENTRATE-TO-WATER

RATIO 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CLEAN DISPENSING VALVES 8. . . . . . . . .

SANITIZING TANK TYPE CONCENTRATE

SYSTEMS 8. . . . . . . . . . . . . . . . . . . . . . . . . . .

SANITIZING BAG-IN-BOX CONCENTRATE

SYSTEMS 9. . . . . . . . . . . . . . . . . . . . . . . . . . .

CLEANING THE NITROGEN GAS CHECK

VALVE 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PAGE

PAGE

TROUBLESHOOTING 13. . . . . . . . . . . . . . . . . . . . .

WATER-TO-CONCENTRATE ‘‘RATIO’’ OF DISPENSED PRODUCT TOO LOW OR

TOO HIGH. 13. . . . . . . . . . . . . . . . . . . . . . . . . . . .

ADJUSTMENT OF DISPENSING VALVE CONCENTRATE FLOW REGULATOR DOES NOT

INCREASE WATER-TO-CONCENTRATE ‘‘RA-

TIO’’. 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ADJUSTMENT OF DISPENSING VALVE CONCENTRATE FLOW REGULATOR DOES NOT

DECREASE TO DESIRED WATER-TO-CONCEN -

TRATE ‘‘RATIO’’. 13. . . . . . . . . . . . . . . . . . . . . . . .

ONLY WATER DISPENSED. 13. . . . . . . . . . . . .

ONLY CONCENTRATE DISPENSED. 14. . . . .

NO CONCENTRATE OR WATER

DISPENSED. 14. . . . . . . . . . . . . . . . . . . . . . . . . . .

LIST OF FIGURES

FIGURE 1. POST MIX TEA URN 1. . . . . . . . . . . .

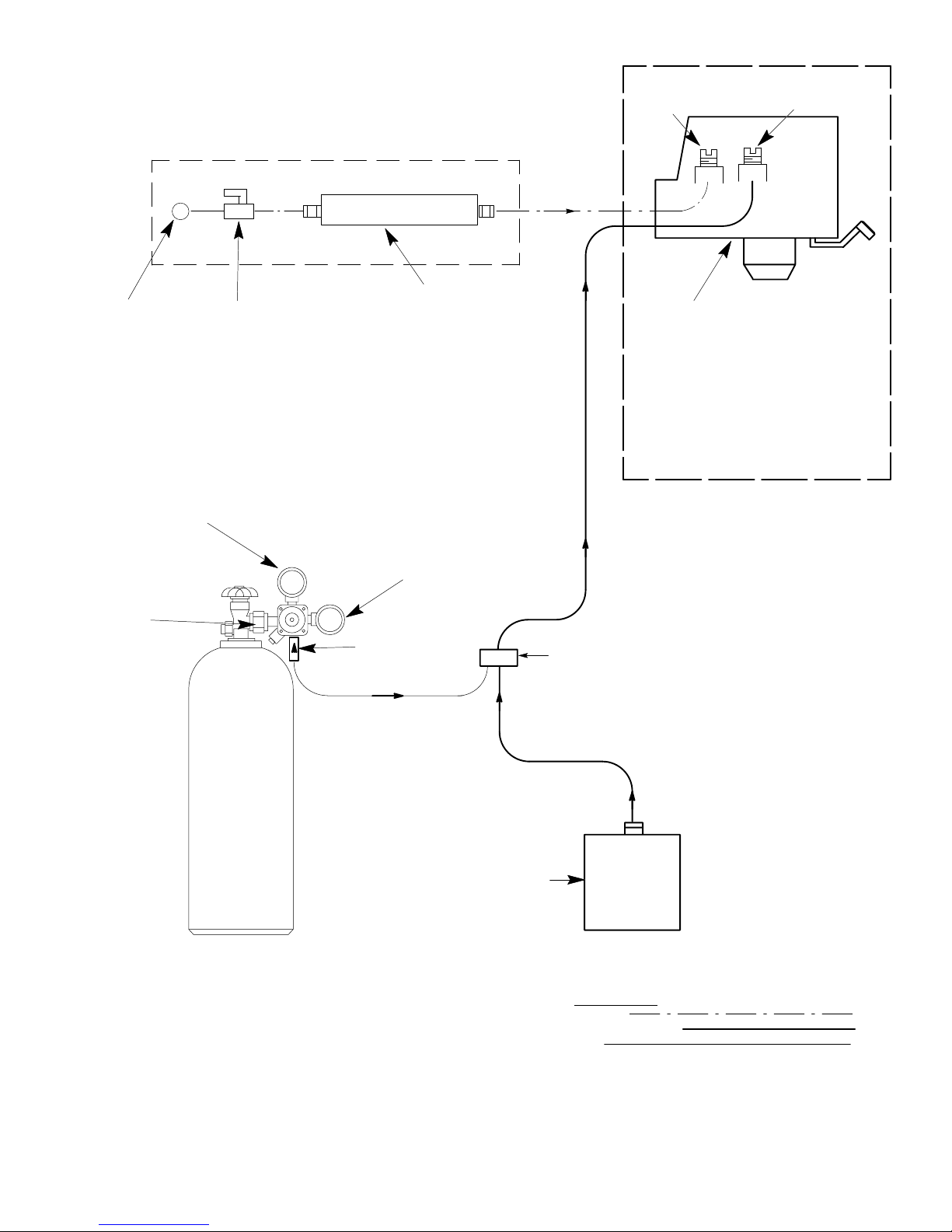

FIGURE 2. FLOW DIAGRAM FOR CONCENTRATE

TANK UNIT 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FIGURE 3. FLOW DIAGRAM FOR BAG-IN-BOX

CONCENTRATE UNIT 3. . . . . . . . . . . . . . . . . . . . .

FIGURE 4. RATIO CUP AND CONCENTRATE BYPASS ASS’Y (SF-1 SINGLE FLAVOR DISPENSING

VALVE) 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FIGURE 5. NITROGEN GAS CHECK VALVE 10.

LIST OF TABLES

TABLE 1. DESIGN DATA 1. . . . . . . . . . . . . . . . .

TABLE 2. LOOSE-SHIPPED PARTS 4. . . . . .

i 312020000

GENERAL INFORMATION

IMPORTANT: To the user of this manual – This

manual is a guide for installing, operating, and

maintaining this equipment. Refer to the Table of

Contents for page location for detailed

information pertaining to questions that arise

during installation, operation, service, or

maintenance of this equipment.

GENERAL DESCRIPTION

This section provides a description, theory of

operation, and design data for the Tea Urn Post-Mix

Beverage Dispenser, hereinafter referred to as a

Unit.

UNIT DESCRIPTION

The Unit (see Figure 1) is compact and intended for

countertop installation. The Unit dispenses

liquid-base concentrate combined with water to

create a finished drink. The Unit is operated by

pressing against a lever arm which extends below

the dispensing valve Cover.

Components are mounted on a stainless steel

enclosure which rests on the countertop. External

connections required are a plain water source and a

source of concentrate.

DESIGN DATA

Design data for all Units is given in Table 1.

Table 1. Design Data

Unit Part Numbers:

Unit with Drip Tray and Cup Rest 416401

Unit without Drip Tray and Cup

Rest

Overall Dimensions (approximate): With Cup Rest &

Drip Tray

Height 25 inches

Width 9 inches

Depth 15 inches

Weights (approximate):

Shipping 11 pounds

Dry Weight 8 pounds

Dispensing Rate (approx.) 1–1/2

Ambient Operating Temperature 40_F to 100_F

416402

ounces/sec

FIGURE 1. POST MIX TEA URN

THEORY OF OPERATION

(see Figure 2)

Note: The gas-operated concentrate pump in the

system, which provides concentrate to the

Dispenser, may be driven by carbon dioxide

(CO2) gas or by compressed air or an electrically

operated pump may be used in place of the

gas-operated pump.

The concentrate is stored in a collapsible bag within

a sturdy box which is called a bag–in–box. When the

dispensing valve is opened, a pump operated by gas

pressure delivers concentrate from the bag-in-box to

the dispensing valve. At the same time, plain water

also enters the dispensing valve. Concentrate and

plain water meet simultaneously at the dispensing

valve resulting in a finished drink being dispensed.

Dispensing continues from the valve as long as the

dispense lever is held down.

The dispensing valve components are accessible by

removing hex nut securing cover to the valve, then

remove cover. The dispensing valve can be removed

from the Unit entirely by releasing two latches.

Concentrate and plain water connections are made

to flared fittings on back side of the Unit.

Operating Pressures:

Water Inlet Supply Line 40 to 125 psig

Components are mounted on a Stainless Steel

Enclosure which may be fastened to the countertop.

The Unit is available with or without a removable Drip

Tray and Cup Rest.

1

312020000

WATER SOURCE

WATER FILTER INSTALLATION FOR FILTERS

WITHOUT BUILT-IN W ATER SHUTOFF VALVE

FILTER

SHUTOFF

VALVE

ADJUSTABLE

WATER FLOW

REGULATOR

SF‘–1 DISPENSING VALVE

DISPENSER

ADJUSTABLE

CONCENTRATE

FLOW REGULATOR

PRIMARY CO

REGULATOR

COUPLING

2

ASS’Y

CARBON DIOXIDE (CO2) GAS

CYLINDER

CO2 CYLINDER PRESSURE

GAS CHECK

VALVE

GAGE

CONCENTRA TE PUMP

(SEE NOTE)

NOTE: CONCENTRATE PUMP MAY

ALSO BE DRIVEN BY NITROGEN

GAS, COMPRESSED AIR, OR AN

ELECTRICALLY OPERATED PUMP

MAY BE USED IN PLACE OF THE

GAS OPERATED PUMP.

BAG-IN-BOX

CONCENTRATE

CONTAINER

LINE LEGEND

WATER

CONCENTRATE

GAS

FIGURE 2. FLOW DIAGRAM (BAG-IN-BOX CONCENTRATE SYSTEM)

2312020000

INSTALLATION

This section describes receiving, unpacking,

selecting location, and installation of the Unit.

RECEIVING

Each Unit is completely tested under operating

conditions and thoroughly inspected before

shipment. At time of shipment, the carrier accepts

the Unit and any claim for damage in transit must be

made with the carrier. Upon receiving Unit from the

delivering carrier, carefully inspect the carton for

visible indication of damage. Any damage or

irregularities should be noted at time of delivery (or

not later than 15 days from date of delivery) and

immediately reported to the delivering carrier.

Request a written inspection report from the Claims

Inspector to substantiate claim. File claim with the

delivering carrier, not with IMI Cornelius Inc.

UNPACKING AND INSPECTION

Unpack Unit as follows:

1. Carefully remove packaging material.

2. Retain Service Manual and loose-shipped parts.

3. Inspect all parts of the Unit for evidence of

damage. If such evidence is found, file a claim

against the carrier.

IDENTIFICATION OF LOOSE-SHIPPED

PARTS

1. CUP REST (item 1) fits inside DRIP TRAY (item

2).

2. DRIP TRAY (item 2) supports cup rest and

receives product spillage.

3. TAPERED PLASTIC GASKETS (item 3) seal

water and concentrate connections at rear of

Unit.

4. ADAPTER FITTING (item 4) connects 3/8 in.

O.D. plain water source line to the Unit.

5. DECAL KIT (item 5). Decals for product

identification on the Unit and front of dispensing

valve – Instructions for applying decals included.

6. SERVICE MANUAL (item 6). A guide to

installation, operation, and maintenance of the

Unit.

7. MOUNTING SCREWS (item 7) for mounting

Unit Base to counter, if desired.

8. HOLE PLUGS (item 8) to close inlet openings in

back of Unit if inlet lines are routed down

through counter top.

9. SCREW (item 9) to secure cover on top of the

Unit.

4. Remove loose-shipped parts from poly bags

and check their identity and quantity against

Table 2.

Table 2. Loose-Shipped Parts

Qty

Item

No.

1 397180-039 Cup Rest 1

2 397179-039 Drip Tray 1

3 178025-100 Tapered Plastic

4 770716-020 Adapter Fitting,

5 312071-000 Decal Kit 1 1

6 312020–000 Service Manual 1 1

7 312971-000 Mounting Screws 2 2

8 300098-000 Hole Plugs 2 2

9 151707 Screw, Thd Rolling,

Part No. Name

Gasket

7/16-20 Female by

5/8-18 Male

8–32 By 3/8 in. long

41-6401

41-6402

Unit

22

11

22

SELECTING LOCATION

This Unit may be island-mounted or installed on a

front or rear countertop provided that the following

requirements are satisfied. Unit may be fastened to

countertop using screws through Unit Base.

Qty

Unit

1. Locate Unit near a source of cold (100° F max)

plain water having a pressure of 40 to 125 psig.

2. Locate Unit to minimize length of concentrate

line.

To comply with National Sanitation Foundation (NSF)

requirements within the United States, Unit base

must be sealed to countertop when screws are used

to fasten Unit Base to countertop. Proceed as follows

to seal base to countertop.

1. Tilt up to expose bottom of base.

2. Liberally apply silastic sealant (such as Dow

Corning RTV 731 or equivalent) on base bottom

edges.

Note: Do not move Unit after positioning or seal

from base to countertop will be broken.

3 312020000

Loading...

Loading...