Cornelius SID650A-80-BC, SID650A-80-B, SID650W-80-B, SID650W-80-BC, SID650W-80 User Manual

...

SPIRAL ICEMAKER

DISPENSER

MODELS: SID650A/80

SID650A/80-B

SID650A/80-BC

SID650W/80

SID650W/80-B

Operator’s Manual

Distributed By:

Commercial Refrigeration Service, Inc.

WWW.IceCubes.NET

WWW.CorneliusParts.COM

(866) 423-6253

623-869-8881

SID650W/80-BC

220V, 60HZ, 1PH

Part No. 91704

August, 1995

THIS DOCUMENT CONTAINS IMPORTANT INFORMA

This Manual must be read and understood before installing or operating this equipment

REMCOR INC: 1995

TION

PRINTED IN U.S.A

TABLE OF CONTENTS

GENERAL INFORMATION 1..................................................

DESCRIPTION 1........................................................

INSTALLATION INSTRUCTIONS 2............................................

UNPACKING INSTRUCTIONS 2..........................................

INSTALLATION INSTRUCTIONS 2........................................

BEVERAGE SYSTEM 6..................................................

INSTALLATION 6..................................................

START-UP 6............................................................

OPERATING INSTRUCTIONS 9...............................................

MAINTENANCE 13...........................................................

REGULAR BASIS (OR AS REQUIRED) 13..................................

EVERY THREE MONTHS (OR AS REQUIRED) 13...........................

PERIODICALLY (OR AS REQUIRED) 13....................................

CLEANING INSTRUCTIONS 13...........................................

ICE MAKER SECTION 13............................................

DISPENSER SECTION 14...........................................

FOR UNITS WITH BEVERAGE SYSTEM 15.................................

COLD PLATE 15....................................................

BEVERAGE SYSTEM 15.............................................

TROUBLESHOOTING GUIDE 17...............................................

Page

MAINTENANCE/ADJUSTMENT PROCEDURES 30...........................

THERMOSTAT ALTITUDE ADJUSTMENTS 30.........................

BIN THERMOSTAT 30...............................................

ICE THICKNESS ADJUSTMENT 30...................................

CLEANING/REPLACE THE FILTER 31................................

CLEANING THE CONDENSER 31....................................

CLEARING EVAPORATOR FREEZE-UP 31............................

HARVEST TIME ADJUSTMENT 32....................................

MANUAL FILLING 32................................................

PARTS LIST 34..............................................................

WARRANTY 36..............................................................

i 91704

TABLE OF CONTENTS (cont’d)

LIST OF FIGURES

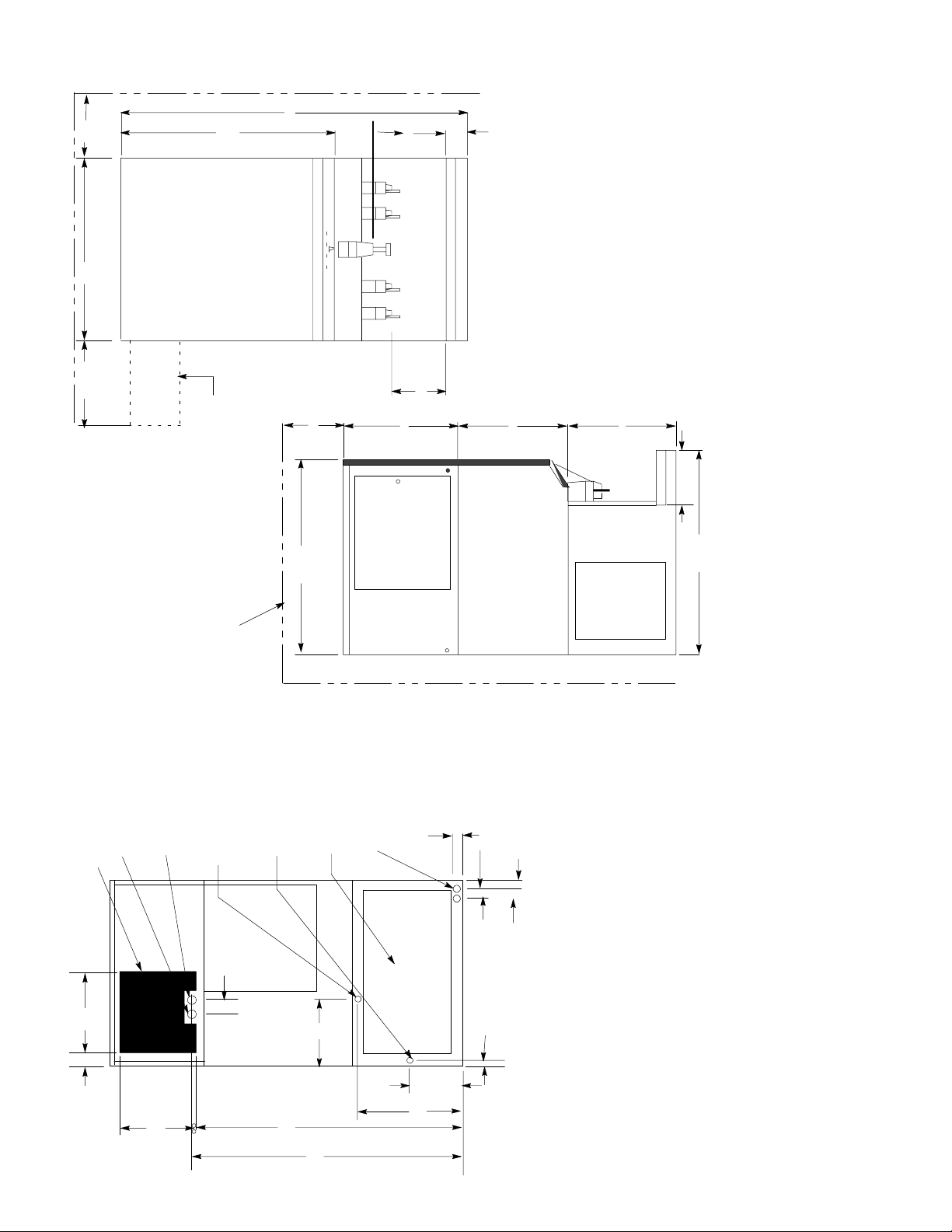

FIGURE 1. ELECTRICAL WIRING INSTALLATION INSTRUCTIONS 3.........

FIGURE 2. INSTALLATIONS DIMENSIONS 4...............................

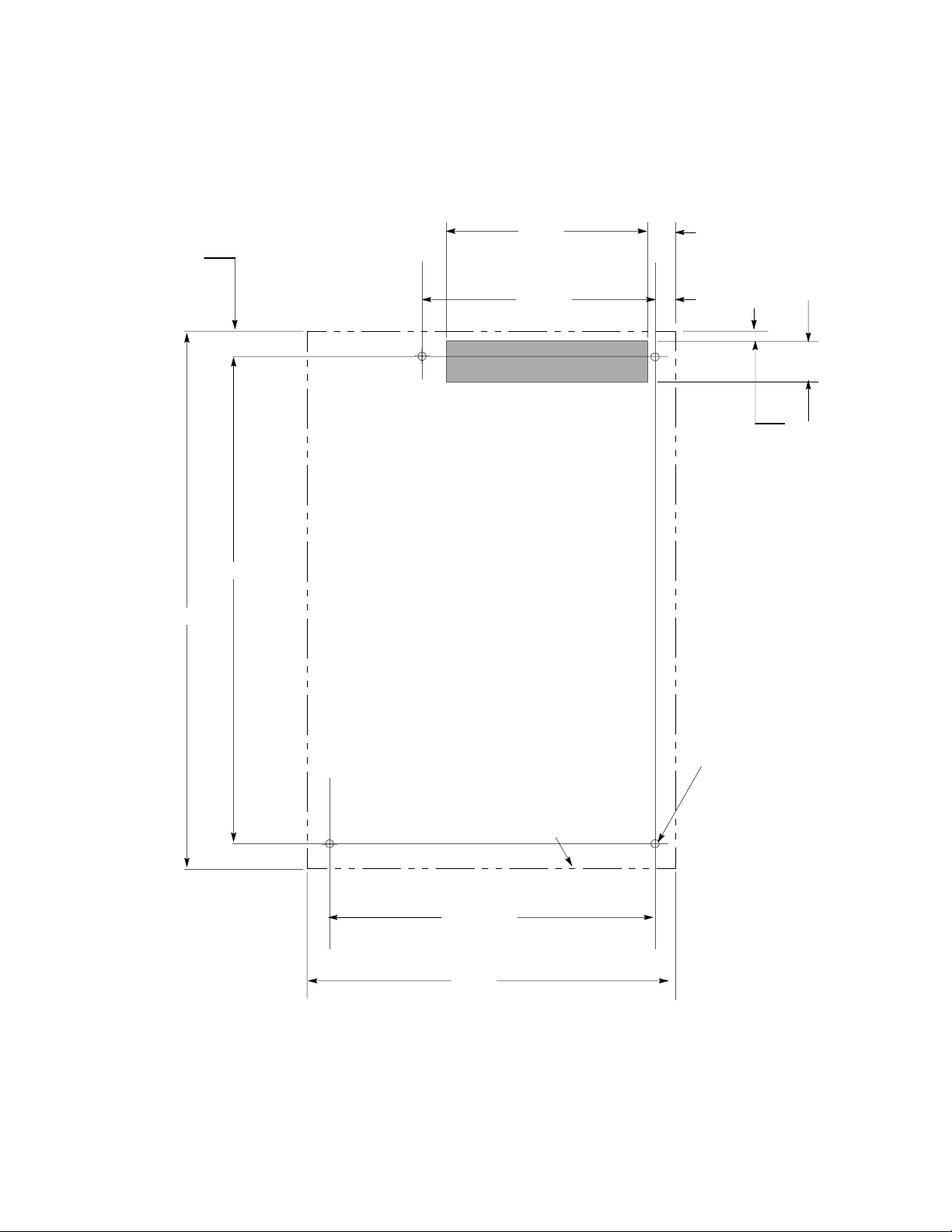

FIGURE 3. MOUNTING TEMPLATE MODEL SID650-80 5....................

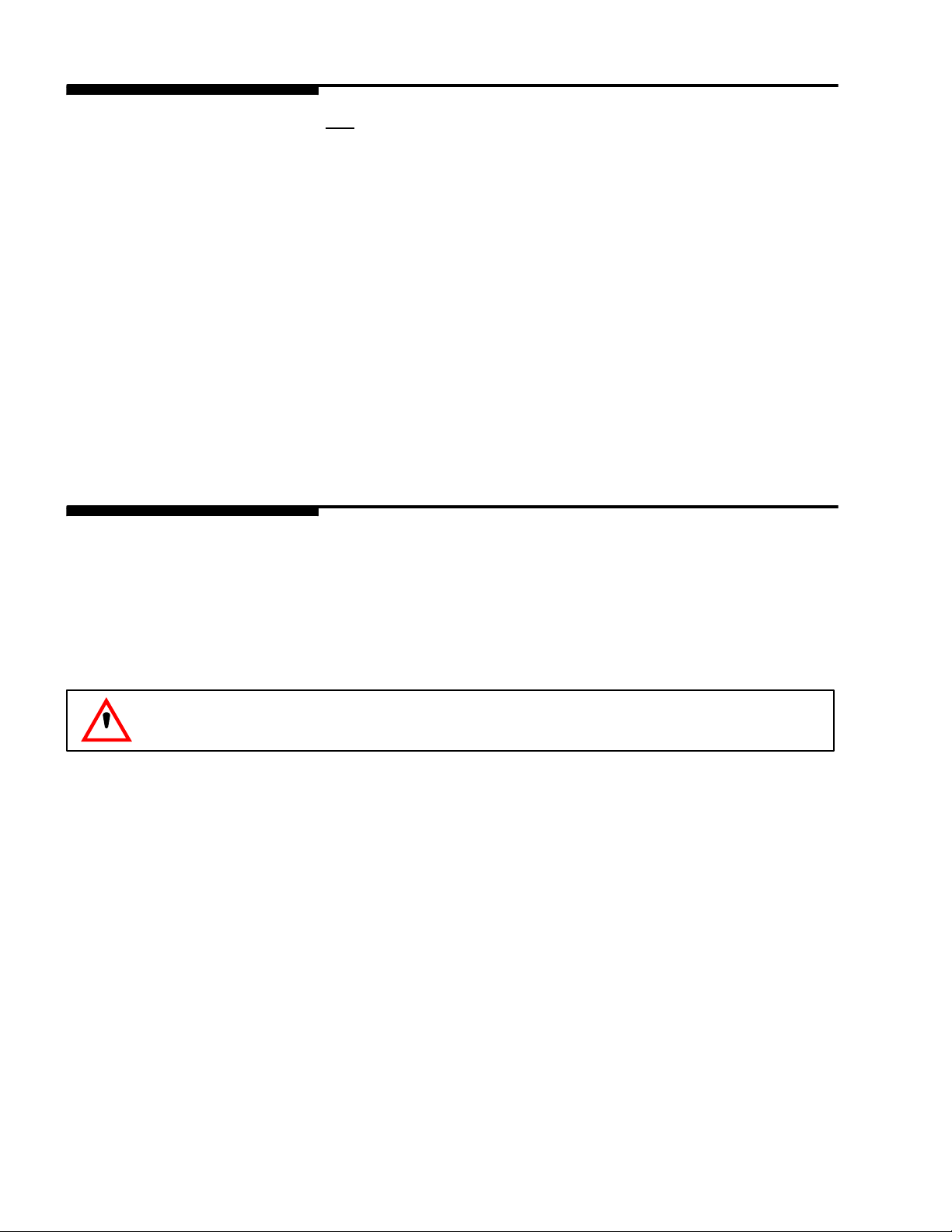

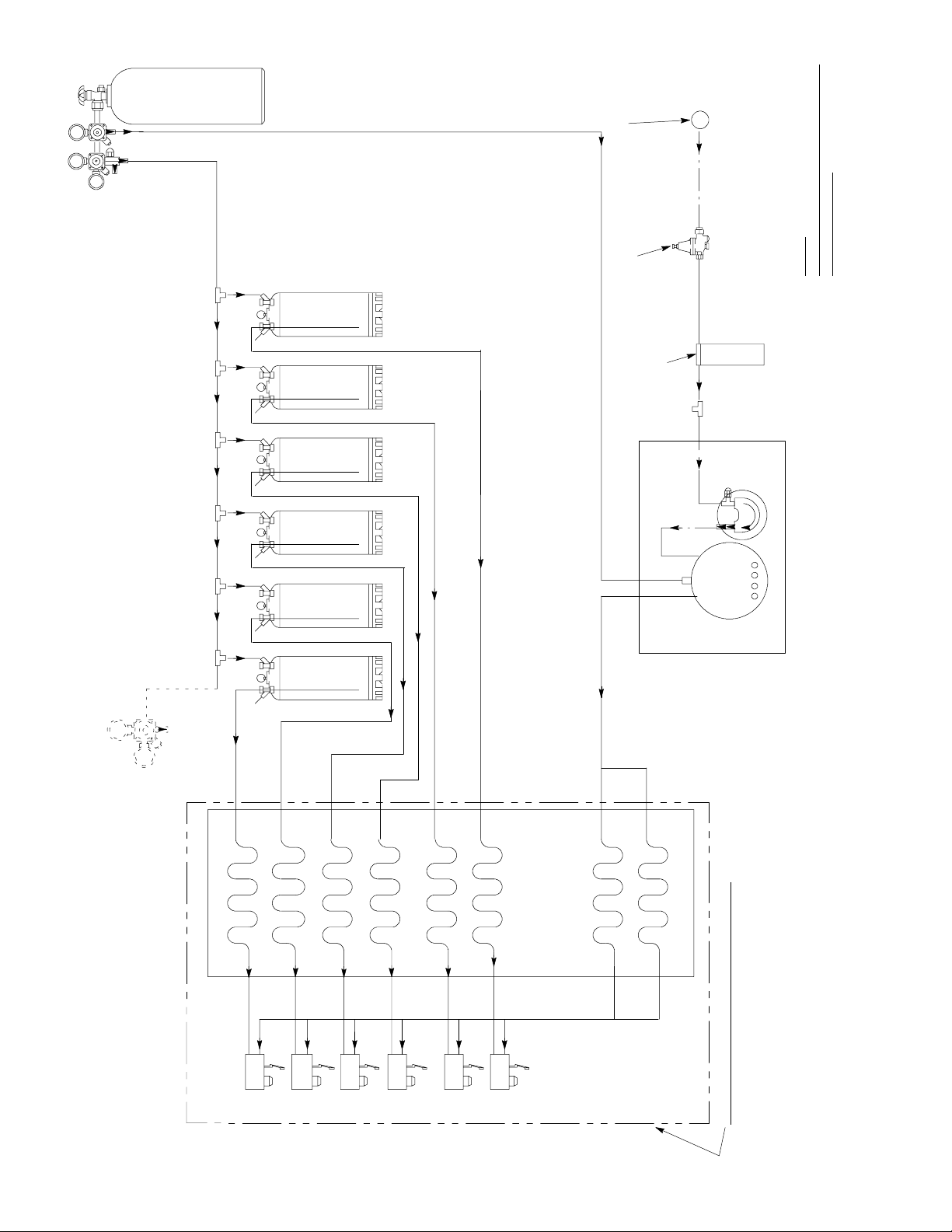

FIGURE 4. BEVERAGE SYSTEM SCHEMATIC B MODELS 7................

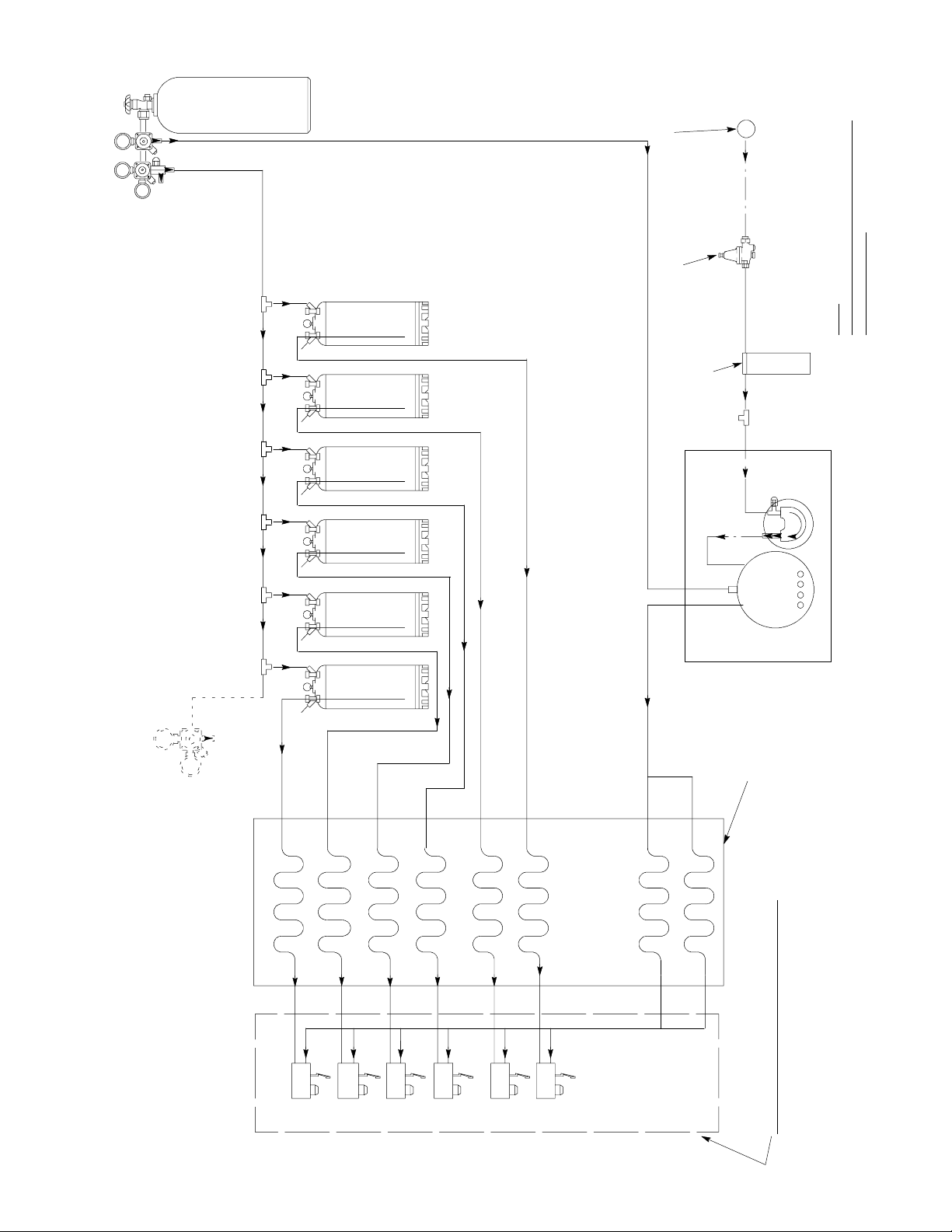

FIGURE 5. BEVERAGE SYSTEM SCHEMATIC ”BC”MODELS 8..............

FIGURE 6. WIRING SCHEMATIC SID 850/250 9............................

FIGURE 7. WIRING SCHEMATIC 10........................................

FIGURE 8. WIRING DIAGRAM 11..........................................

FIGURE 9. REFRIGERATION SCHEMATIC 12...............................

FIGURE 10. HARVEST TIMER 33..........................................

LIST OF TABLES

TABLE 1. SPECIFICATIONS 1............................................

TABLE 2. LBS./24-HOUR ICE PRODUCTION 1.............................

Page

91704

ii

GENERAL INFORMATION

DESCRIPTION

The Remcor S.I.D. (Spiral Ice Maker/Dispenser) is a unique, self-contained, counter top style unit that automatically makes hard,

made by a new, patented process on a spiral-shaped, stainless steel evaporator and produces true cube quality

ice on the outside of the tubes. There are no augers; no compressing of flaked ice; no bearings; and no high

gear motor loads in the ice-making process. The unit has been designed to be simple, yet effective, to provide

many yearsof trouble-free operation.

Compressor: 3/4 Horsepower

Refrigerant: R-502 / 2 lbs. (Air Cooled); 2-1/4 lbs. (Water Cooled)

Voltage: 220/1/60

AMPS: 15

Circuit Ampacity: 20

Fuse Size: 20A Time-Delay

Ice Storage Capacity: 80 lbs.

Ice Making Capacity: Up t o 750 lbs./24 Hours

Shipping Weight: 350 lbs.

clear cube quality ice and stores it in a sealed hopper for sanitary dispensing. The ice is

Table 1. SPECIFICATIONS

Table 2. LBS./24-HOUR ICE PRODUCTION

AirTemp. WaterTemperature

40° 50° 60° 70° 80° 90°

60° 750 704 663 627 594 564

70° 682 650 607 580 550 520

80° 625 586 552 522 495 470

90° 565 530 499 472 447 425

1 91704

INSTALLATION INSTRUCTIONS

UNPACKING INSTRUCTIONS

1. With the unit upright, carefully remove the shipping crate. Inspect for shipping damage and report any such

damage to t he shipper immediately.

2. Unlock and open the hinged service door on the upper left side panel.

3. Remove shipping tape from the ice drop cover, storage hopper cover, water float valve and agitator in the

storage hopper.

4. Remove shipping tape from air inlet filter and sink grill.

INSTALLATION INSTRUCTIONS

NOTE: A Cornelius Model XXXX water filter(or equal) ice maker quality water treatment unit MUST BE

INSTALLED in the water supply line to the ice maker. Failure to do so may result in poor

quality ice, low production output, and may cause premature failure of the ice maker

evaporator and void the extended evaporator warranty.

This ice maker is provided with a stainless steel

product. But, some of the chemicals in treated and untreated water, specifically chlorine and

sulphur (sulphide), have the ability to attack stainless steel and cause premature failure. An

initial investment in proper water treatment will pay for itself in increased production, quality

and long life of the product.

Location

1.

Locate the ice maker/dispenser indoors in a well-ventilated area. Avoid exposure to direct sunlight and/or

heat caused by radiation.

Ambient room temperature must be in the range of 60° to 90°F. Do not install unit in an enclosed area

where heat build up could be a problem. For proper airflow f or the refrigeration system, allow a 6

ance at the back of the unit

Consult Figure 1 for utility connection location.

Consult Figure 2 for dimensions for mounting the unit to the counter with the hardware provided. Note that

the unit must be level for proper operation.

The unit m ust be sealed

which must be cut in the counter. Locate the desired position for the unit, then mark the outline dimensions

and cut-out locations using the template drawing. Cut openings in counter.

Apply a continuous bead of NSF International (NSF) listed silastic sealant (Dow 732 or equal) approximately 1/4

within the outline dimensions. All excess sealant must be wiped away.

inside of the unit outline dimensions and around all openings. Then position the unit on the counter

anda12 clearance at the right side panel.

to the counter. The mounting template drawing (Figure 2) indicated the openings

evaporator designed to last the life of the

clear-

Plumbing

2.

Connect the ice maker to a cold, potable water source suitable for drinking. Do not install the unit on a

water softener line. It is recommended that a hand shut-off valve and strainer be used on the incoming

supply line. A 1/4

ter supply hook up (See Figure 1 ). For proper operation, the incoming water supply pressure must be in the

range of 30--90 PSIG. Install a pressure regulating valve if above this range.

outside diameter compression tube fitting is provided at the back of the unit for t he wa-

291704

IMPORTANT: To ensure proper ice maker operation and also to reduce the frequency of water-related

service problems, a water filter should be installed. Remcor recommends the use of IMI Cornelius filter,

model number 81COR01PS.

For specific recommendations on these filter systems for your local conditions, consult with a distributor in your

area or contact the filter manufacturer.

Connect two (2) 3/4

unit. These lines must pitch downward

IPS (or equal) drain lines to the 3/4 threaded drain connections at the lower rear of the

to an open drain and must contain no traps or improper drainage

will result.

NOTE: In areas where consistently warm water temperatures are encountered, the use of a Remcor PreCooler in the water line is recommended to maximize the ice production of this unit. Contact Remcor

for more information on this product.

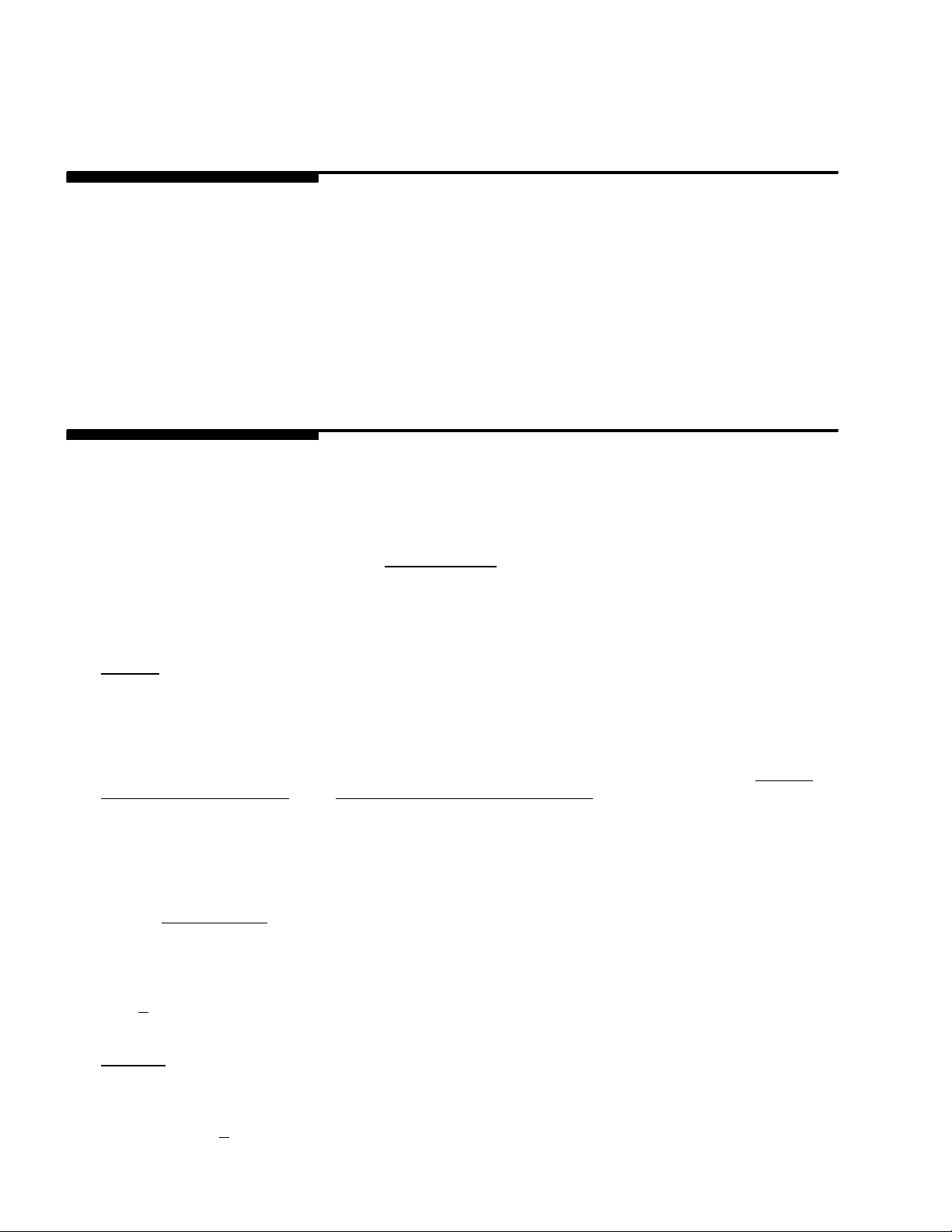

Electrical

3.

A 4 x 2 junction box is located at the rear of the unit for the supply hook-up. Connect the ice maker to its

own individual circuit per the national electric code and local code. See SPECIFICATIONS for ampacity

and fuse size.

IMPORTANT: The wire size must be adequate for the ampacity rating, and the supply voltage must be

within a range of ± 10% for proper ice maker operation.

NOTE:Theunitsrequirea2wire

system plus earth ground for proper operations.

BROWN (HOT)

SUPPLY CONDUIT

BLUE (NEUTRAL)

220V

1 PHASE

60 HERTZ

REAR VIEW -- BOTTOMSECTION SERVICE PANEL REMOVED

GREEN (GROUND)

FIGURE 1. ELECTRICAL WIRING INSTALLATION INSTRUCTIONS

3

91704

12

AIR FLOW

29

49

11 -1/8

31/2

22

16 1/4

FRONT

9

12

DOOR WITH

LOCK FOR

ACCESS TO

ICE STORAGE

AREA.

28 3/4

CLEARANCE NECESSARY

ONLY IF UNITS ARE

INSTALLEDINANEN-

CLOSED SPACE.

6

15-5/8

AIR FLOW

15 3/4

17 5/8

67/8

29 1/4

LEFT SIDE

FIGURE 2. INSTALLATIONS DIMENSIONS

ACCESS PANEL

FOR SERVICE AND

BEVERAGE HOOK-

CONDENSER WATER IN

AIR DISCHARGE GRILL

CONDENSER WATER OUT

21/2 12

3/8-NPT (WATER COOLED ONLY)

3/8-NPT (WATER COOLED ONLY)

12

*ICEMAKER WATER IN

1/4 O.D. TUBE COMP.FITTING

21/2

8 15/16

ELECTRICAL INPUT

34 3/8

UP

11

34 7/8

13/16

*3/4-FPTDRAIN (2)

6 15/16

16 5/8

4

17/8

7/8

11/4

REAR

91704

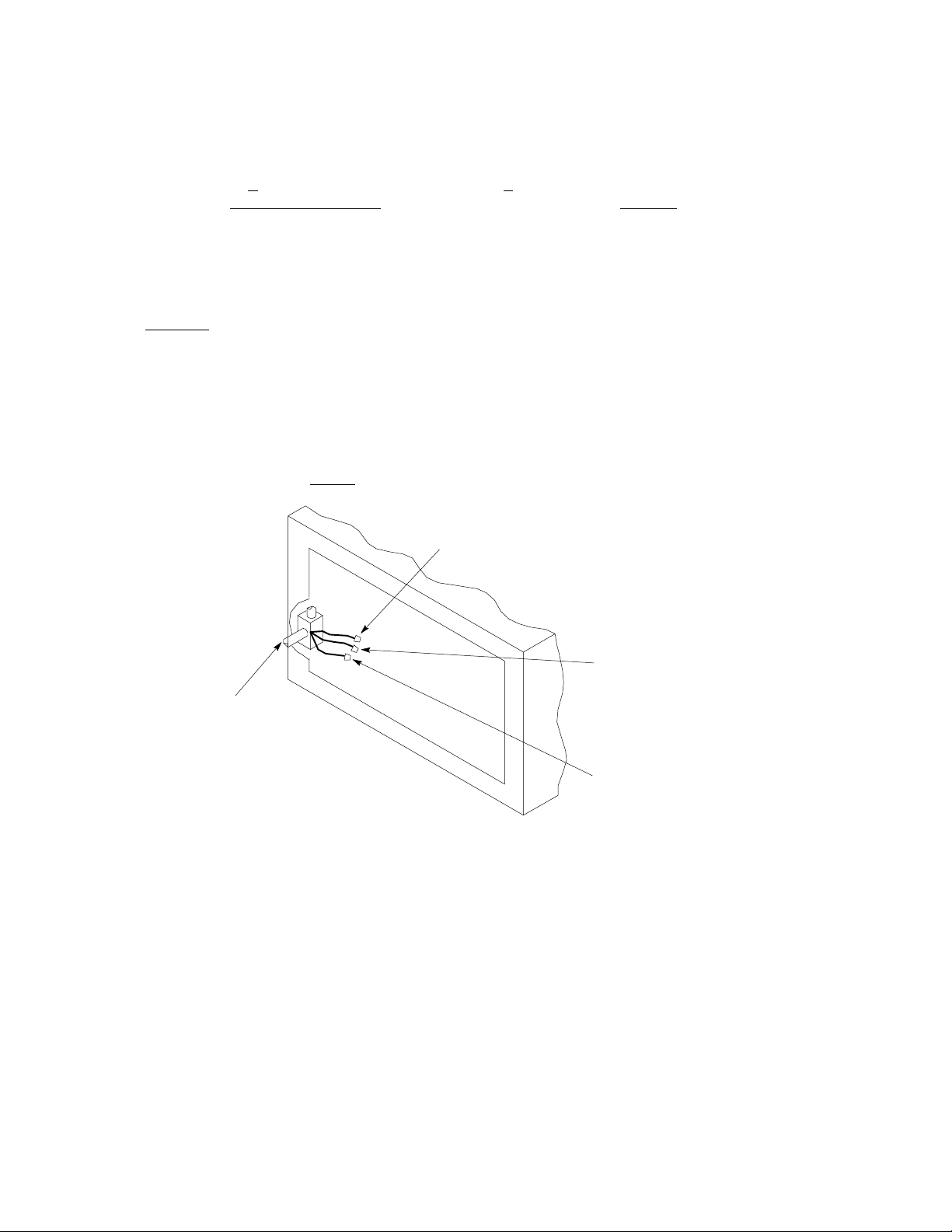

1 -5/8-IN.

14-IN.

1- 29/32-IN.

29- 1/4-IN.

26-IN.

15- 7/8-IN.

1-5/8-IN.

2-- 9/16-IN.

5/8-IN.

UNIT OUTLINE FRONT

18 -3/4-IN.

22-IN.

NOTE: SHADED AREA INDICATES OPENING IN CABINET BOTTOM

FOR BEVERAGE TUBING FOR --B, --BC MODELS ONLY

FIGURE 3. MOUNTING TEMPLATE MODEL SID650-80

5 91704

3/8 DIA.

4 PLACES

BEVERAGE SYSTEM

“B”models contain beverage faucets only and must be supplied with cold product from any remote cold plate or

refrigerated soda factory. “BC”units have a built-in cold plate, in addition to the beverage faucets and are designed to be supplied direct from syrup tanks and carbonator with no additional cooling required.

Installation

1. Locate the required openings in the counter top for the beverage lines as shown in Figure 3.

2. For “B”models, carefully pull the beverage tubes through the bottom opening in the unit and through the

clearance opening in the counter.

3. For “BC”models, tube fittings are provided at the rear of the unit on the cold plate for syrup and water line

hook-up respectively.

4. Connect the beverage system product lines as indicated in Figure 3 (“B”units) and Figure 4 (“BC”units).

This work should be done by a qualified service person. Note that the hosesare marked with numbers

(1 through 6) for syrup connection and “CW”for carbonated water connection.

START-UP

1. Open the hinged service door on t he upper left side panel. Remove ice drop cover and storage hopper cover.

2. Turn on water to ice maker. Make sure that the proper water level is attained in the float chamber before

starting unit.

3. Depress the flush switch for 30 seconds to verify that the water dump valve operates and that the water

drain lines are open and not plugged.

WARNING: To prevent possible injury, do not stick fingers or hand into ice maker nozzle or

hopper with power applied to unit.

4. Put the “Stop/Run”switch in the “run”position. Observe that the ice maker goes through proper ice making

and harvest cycles. If unit malfunctions, consult the Troubleshooting Guide.

NOTE: Due to meltage loss because of a warm storage hopper, it will take longer to fill the hopper the

first time than when the ice maker has been operating continuously .

5. Depress the vend switch lever. Check that both the gate solenoid and agitator motor are energized simultaneously to lift the gate slide and rotate the agitator in the storage hopper, respectively. If either component

malfunctions, consult the Troubleshooting Guide. Replace the ice drop and hopper covers.

6. For beverage units, start up the beverage system and adjust the faucets to the proper brix. Contact your

local syrup distributor for complete information on the beverage system. For units with a build-in cold plate,

it will take approximately one (1) hour from initial machine start-up for cold plate to be at full capacity.

7. The bin therm o stat is calibrated at an atmospheric pressure equivalent at 500 feet above sea level. For

locations at higher elevations, it may be necessary to re-adjust these controls. Consult the Maintenance/

Adjustment Procedures section.

691704

TANK

2

CO

WATER SUPPLY

REGULATORS

SYRUP TANKS

N0TE

FOR REFERENCE ONLY -- NOT FOR

CONSTRUCTION.

OPTIONAL

PRESSURE REGULATOR

FILTER

15-50 PSIG

60-100 PSIG

CARBONATOR

S1 S6S5S2 S4S3

OPTIONAL FOR DIET OR ROOTBEER

COLD PLATE OR RE-

5-15 PSIG

1

2

FAUCETS

3

4

5

6

CW

CW

FRIGERATED ICE BANK

ITEMS OUTSIDE OFBROKENLINES NOT

INCLUDED WITH UNIT.

REMCOR “--B”ICEMAKER/DISPENSER

7

FIGURE 4. BEVERAGE SYSTEM SCHEMATIC B MODELS

91704

REGULATORS

TANK

2

CO

WATER SUPPLY

SYRUP TANKS

OPTIONAL

PRESSURE REGULATOR

FILTER

15-50 PSIG

60-100 PSIG

NOTE:

FOR

FOR REFERENCE ONLY -- NOT

CONSTRUCTION.

OPTIONAL FOR DIET OR ROOTBEER

CARBONATOR

S1 S6S5S2 S4S3

1

2

5-15 PSIG

3

4

5

6

CW

CW

FIGURE 5. BEVERAGE SYSTEM SCHEMATIC “BC”MODELS

COLD PLATE

91704

FAUCETS

ITEMS OUTSIDE OFBROKENLINES NOT

INCLUDED WITH UNIT.

REMCOR “--BC”ICEMAKER/DISPENSER

8

OPERATING INSTRUCTIONS

A temperature sensing control bulb located in the storage hopper starts and stops the ice-making process in

response to ice level in the hopper. With this ice level control “calling”for ice (hopper ice level is low), ice begins

to form on the stainless steel tubing coilsin the evaporator section of the ice-maker. Ice continues to “grow”on

the evaporator coil until it contacts the ice thickness probe (low voltage conductivity sensor). At this point, the

conductivity probe triggers the harvest timer motor. The harvest timer contains five (5) cam operated switches

which function as detailed in the following table.

Table 3. HARVEST CYCLE

Time Cam Switch Action

0--86 Seconds #1 Timer motor energized.

1--23 Seconds #4 Water dump valve open.

1--36 Seconds #2 Hot gas solenoid valve open.

Air pump off.

Condenser fan motor off.

36--90 Seconds #2 Air pump on.

Condenser fan motor on.

Hot gas solenoid valve closed.

35--60 Seconds #3 Harvest motor on.

44--48 Seconds #5 Hopper agitator motor operates.

When ice contacts the ice lever control bulb in the storage hopper, the control will shut down the ref rigeration

system. If this signal occurs during the harvest cycle, the harvest cycle will be completed before shutdown

occurs.

To dispense ice, push the lever located on the lower front panel. Ice will flow from the ice chute until the lever is

released.

For units with a built-in cold plate, ice will automatically fill the cold plate cabinet. Allow one (1) hour for the cold

plate to reach its maximum capacity. Start up the beverage system and adjust the faucets to the proper brix.

Pushing t he lever on any faucet will provide beverage of the appropriat e flavor.

9 91704

Loading...

Loading...