Page 1

SPECIALTY BEVERAGE DISPENSER

NITROPRO MINI

Service and Preventative Maintenance Manual

Release Date: 2/15/19

Publication Number: 548000106SER

Revision Date: 2/15/19

Revision: Rev. 2.0 Model: CNB Mini

Visit web site http://cornelius-usa.com and create an account for all your literature needs.

Page 2

The products, technical information, and instructions contained in this manual are subject to change without notice. These

RECYCLE

instructions are not intended to cover all details or variations of the equipment, nor to provide for every possible contingency

in the installation, operation or maintenance of this equipment. This manual assumes that the person(s) working on the equip

ment have been trained and are skilled in working with electrical, plumbing, pneumatic, and mechanical equipment. It is

assumed that appropriate safety precautions are taken and that all local safety and construction requirements are being met,

in addition to the information contained in this manual.

This Product is warranted only as provided in Cornelius’ Commercial Warranty applicable to this Product and is subject to all of

the restrictions and limitations contained in the Commercial Warranty.

Cornelius will not be responsible for any repair, replacement or other service required by or loss or damage resulting from any

of the following occurrences, including but not limited to, (1) other than normal and proper use and normal service conditions

with respect to the Product, (2) improper voltage, (3) inadequate wiring, (4) abuse, (5) accident, (6) alteration, (7) misuse, (8)

neglect, (9) unauthorized repair or the failure to utilize suitably qualified and trained persons to perform service and/or repair

of the Product, (10) improper cleaning, (11) failure to follow installation, operating, cleaning or maintenance instructions, (12)

use of “non‐authorized” parts (i.e., parts that are not 100% compatible with the Product) which use voids the entire warranty,

(13) Product parts in contact with water or the product dispensed which are adversely impacted by changes in liquid scale or

chemical composition.

Contact Information:

To inquire about current revisions of this and other documentation or for assistance with any Cornelius product contact:

www.cornelius.com

800-238-3600

Trademarks and Copyrights:

This document contains proprietary information and it may not be reproduced in any way without permission from Cornelius.

‐

This document contains the original instructions for the unit described.

CORNELIUS INC

101 Regency Drive

Glendale Heights, IL

Tel: + 1 800‐238‐3600

Printed in U.S.A.

Correct Disposal of this Product

This marking indicates that this product should not be disposed with other household wastes throughout the EU. To prevent

possible harm to the environment or human health from uncontrolled waste disposal, recycle it responsibly to promote the

sustainable reuse of material resources. To return your used device, please use the return and collection systems or contact

the retailer where the product was purchased. They can take this product for environmental safe recycling.

Page 3

Table of Contents

1.0 SAFETY 1

2.0 OVERVIEW AND REQUIRED TOOLS 3

2.1 Nitropro Functions & Specifications 3

2.2 Key Components 4

2.3 Required Tools 6

3.0 SYSTEM OPERATION 7

3.1 Facility Supplies 7

3.2 Operating Processes 8

3.3 Component Functions

3.3.1 Tap Handles 10

3.3.2 Product Concentrate Pump 10

3.3.3 Water Inlet Solenoid 11

3.3.4 Air Compressor & Storage 11

3.3.5 Mixing-Infusion Manifold & Check Valves 11

3.3.6 Dispense Manifold 12

3.3.8 Mixing-Dispensing Assembly 12

3.3.9 Ice Bank Chilling System 13

3.3.10 Front-Door Control Switches 14

4.0 PREVENTATIVE MAINTENANCE 15

4.1 Overview 15

4.2 Maintenance Schedule 15

4.3 Annual Maintenance 15

4.3.1 Refrigeration Condenser & Cabinet Fan Cleaning 15

4.3.2 Ice Bank Level Check 15

4.3.3 Product Pump Mix-Ratio Verification 16

4.3.3.1 Measuring TDS (Total Dissolved Solids) 16

4.3.4 Components Visual Inspection 18

4.3.5 Ice-Bank Sensor & Agitator Check 18

4.3.6 Concentrate-Pump Hose Replacement 19

Page 4

Table of Contents

5.0 TROUBLESHOOTING 20

Table 5-1 - Systems-Level Troubleshooting 20

Table 5-2 - Drink-Quality Troubleshooting 21

Table 5-3 - Compressed Air & Infusion Troubleshooting 22

Table 5-4 - Dispensing-Function Troubleshooting 23

5.1 Air-Compressor Pressure Verification 24

6.0 COMPONENT REPLACEMENT 25

6.1 Safety Precautions 25

6.3 Access Panel Removal 25

6.3 Main PCB 27

6.4 Mixing-Dispensing Assembly Components 28

6.4.1 Air Pressure Regulator 28

6.4.2 Mixing - Infusion Manifold 29

6.4.3 Dispense Manifold 29

6.4.4 Concentrate Pump 30

6.5 Air Compressor 30

6.5.1 Compressor Air Filter Replacement 30

6.6 Water Inlet Solenoid 31

6.7 Power Supply (24Vdc) 31

6.8 Merchandiser LED Back-Lighting Panel 32

6.9 Ice Bank 32

6.9.1 Ice Sensor Probe 32

6.9.2 Agitator Motor 33

6.9.3 Ice Bank Controller 34

6.9.4 Refrigeration Components 35

6.10 Tap Microswitches 35

APPENDIX A - SYSTEM DRAWINGS 37

Page 5

Nitropro Mini Service Manual

!

!

!

!

1.0 SAFETY INSTRUCTIONS

Safety Overview

• Read and follow ALL SAFETY INSTRUCTIONS in this manual and any warning/caution labels on the

unit (decals, labels or laminated cards).

• Read and understand ALL applicable OSHA (Occupational Safety and Health Administration) safety

regulations before operating this unit.

Types of Alerts

!

DANGER: Indicates an immediate hazardous situation which if not avoided WILL result in

serious injury, death or equipment damage.

!

WARNING: Indicates a potentially hazardous situation which, if not avoided, COULD result in

serious injury, death, or equipment damage.

!

CAUTION: Indicates a potentially hazardous situation which, if not avoided, MAY result in

minor or moderate injury or equipment damage.

SAFETY TIPS

• Carefully read and follow all safety messages in this manual and safety labels on the unit.

• Keep safety labels in good condition and replace missing or damaged ones.

• Do not let anyone operate the unit without proper training. This appliance is not intended for use

by untrained or unauthorized persons without supervision.

• Maintain the unit in proper working condition and do not allow any unauthorized modifications.

NOTE: The dispenser is not designed for a wash-down environment and MUST NOT be placed in

an area where a water jet could be used.

QUALIFIED SERVICE PERSONNEL

WARNING:

Only trained and certified electrical, plumbing and refrigeration technicians should service this unit.

ALL WIRING AND PLUMBING MUST CONFORM TO NATIONAL AND LOCAL CODES. FAILURE TO COMPLYCOULD RESULT IN SERIOUS INJURY, DEATH OR EQUIPMENT DAMAGE. IF THE SUPPLY CORD IS DAMAGED,

IT MUST BE REPLACED BY THE MANUFACTURER, ITS SERVICE AGENT OR SIMILARLY QUALIFIED PERSONS

IN ORDER TO AVOID A HAZARD.

© 2019, Cornelius Inc. All Rights Reserved - 1 - Publication Number: 548000106SER

Page 6

Nitropro Mini Service Manual

!

!

!

!

1.0 SAFETY INSTRUCTIONS (CONT.)

SAFETY PRECAUTIONS

This unit has been specifically designed to provide protection against personal injury. To ensure continued protection observe the following:

DANGER:

Disconnect power to the unit before servicing while following all lock out/tag out procedures established by the user. Verify power is off to the unit before any work is performed.

FAILURE TO DISCONNECT THE POWER COULD RESULT IN SERIOUS INJURY, DEATH OR EQUIPMENT

DAMAGE.

CAUTION:

Always be sure to keep area around the unit clean and free of clutter. Failure to keep this area clean may

result in injury or equipment damage.

DO NOT STORE EXPLOSIVE SUBSTANCES SUCH AS AEROSOL CANS WITH A FLAMMABLE PROPELLANT IN

THIS APPLIANCE.

UNTRAINED AND UNAUTHORIZED INDIVIDUALS SHALL NOT OPERATE THE APPLIANCE OR PERFORM

ANY CLEANING OR USER-MAINTENANCE PROCEDURES.

SHIPPING AND STORAGE

CAUTION:

Before shipping, storing, or relocating the unit, the unit must be sanitized and all sanitizing solution

must be drained from the system. A freezing ambient environment will cause residual sanitizing solution

or water remaining inside the unit to freeze resulting in damage to internal components.

MOUNTING IN OR ON A COUNTER

DANGER:

When installing the unit in or on a counter top, the counter must be able to support a weight in excess of

140 lbs. (63.5 kg.) to insure adequate support for the unit.

FAILURE TO COMPLY COULD RESULT IN SERIOUS INJURY, DEATH OR EQUIPMENT DAMAGE.

THE APPLIANCE MUST BE ORIENTED IN A VERTICAL POSITION.

Publication Number: 548000106SER - 2 - © 2019, Cornelius Inc. All Rights Reserved

Page 7

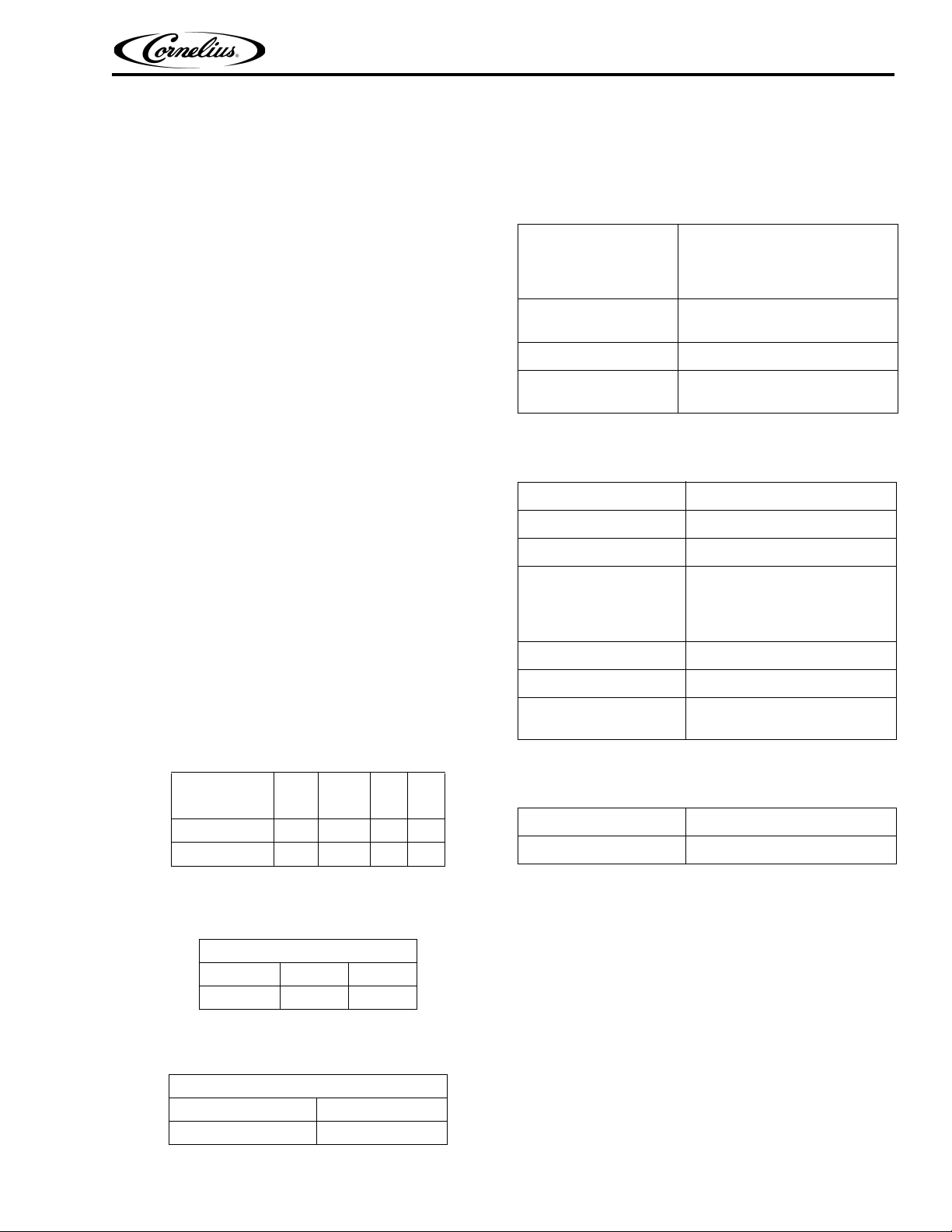

2.0 OVERVIEW AND REQUIRED TOOLS

2.1 Nitropro Functions & Specifications

The Nitropro Mini dispenses still or air-injected,

chilled Nitro coffee at the pull of a tap handle.

Opening a tap automatically engages the product

mixing pump (as well as the air pump for the

injected-coffee selection). The dispensing unit

requires facility electrical and water inputs; Nitro

infusion gas is generated within the unit.

• Coffee syrup from a product container is automatically mixed with water at the selected

ratio (with mix ratios user-selectable via a DIP

switch on the main control PCB)

• Nitro coffee is created via its dispensing circuit

including a gas-infusion (air-injection) manifold prior to the tap (dispensing) valve

• Metering of the product concentrate is performed by a servo-driven, peristaltic pump

• Water inlet rate is fixed and controlled by an

inlet solenoid valve assembly that also provides pressure limiting and flow control

• Chilling of the product cabinet and mix water

is performed by an automatically-controlled

ice bank at the base of the enclosure

Water Supply Pressure

Water Supply

Flow Rate

Water Temperature 40 - 90° F. (4.4 - 32.2° C)

Water Inlet Size

Table 2-5 - General | Dimensions | Weight

Unit Height 34.05 in. (86.5 cm)

Unit Width 10.44 in. (26.5 cm)

Unit Depth 24.47 in. (62.2 cm)

Clearance

Requirements

Unit Weight (Dry) 120 lbs (54.4 kg)

Operating Weight 185 lbs (84.0 kg)

Ambient Operating

Temperature

Nitropro Mini Service Manual

Table 2-4 - Water Requirements

35 psig (241 kPa) Min.

90 psig (621 kPa) Max.

(if >90 psi, install external pressure regulator, set @ 50 psi)

3 fl. oz. (88.7 ml) per

second, minimum

3/8 in. (0.95 cm) SAE male flare

fitting on dispenser

Back: 4” (10.16 cm)

Top: 12” (30.48 cm)

Sides: 4” (10.16 cm)

50 to 90 °F (10 to 32 °C)

Table 2-1 - Electrical Specifications

Models

Mini 115 5 1 60

CNB

CNB

Mini 230 2 1 50

VAC Amps Ph Hz

Ice Bank Capacity 7-8 lbs. (3.2-3.6 kg.)

Temp. Pull Down Time 3 hours at 75 °F (24 °C)

Table 2-6 - Ice Bank Specifications

Table 2-2 - Refrigerant Type

Refrigerant

Oz Grams Type

5.64 160 R-134a

Table 2-3 - Refrigeration Nameplate Values

Pressure psi (kPa) [bar]

High

side Low side

315 (2171.9) [21.7

© 2019, Cornelius Inc. All Rights Reserved - 3 - Publication Number: 548000106SER

] 140 (965.3) [9.7]

Page 8

Nitropro Mini Service Manual

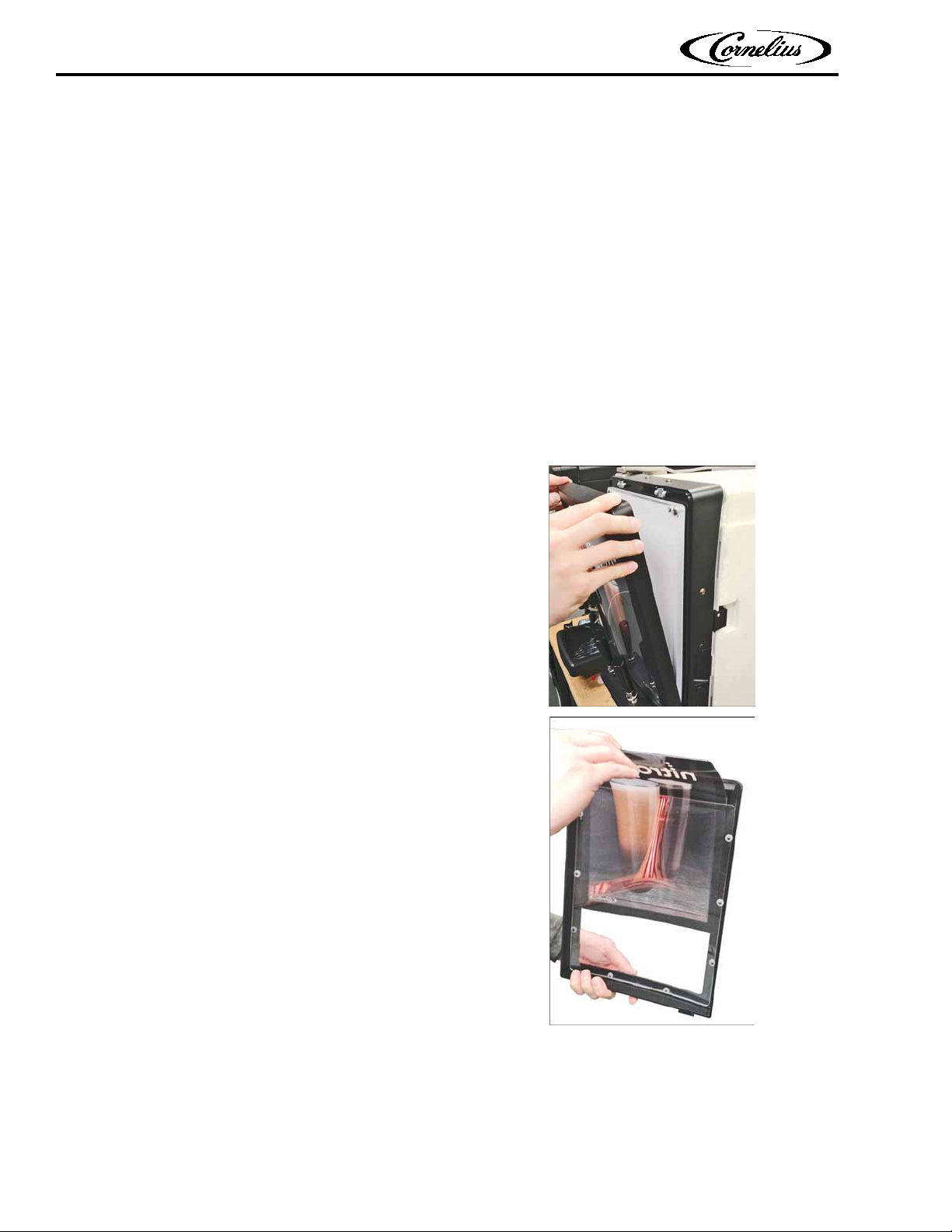

Figure 2-1 - Front LED-Backed Merchandiser Removal

2.0 BREWER OVERVIEW AND REQUIRED TOOLS (Cont.)

2.2 Key Components

The Nitropro Mini consists of these main controls

and components (refer to Figs. 2-1 and 2.2).

Dispensing Taps (for Still & Nitro Coffee)

Allow coffee dispensing. Pulling of tap

handle triggers switch that activates outlet

solenoid valve (in dispense manifold); also

turns on water inlet solenoid valve and

concentrate pump to initiate flow.

Ice Bank (Water Reservoir and Refrig. Unit)

Water/ice-filled reservoir for chiller lines.

Includes controller to manage refrigeration

compressor, bath agitator, circulation pump

and temperature/ice sensor.

Air Compressor & Storage Chamber

Provides air to the gas-infusion manifold.

Stores compressed air to support high drink

volumes. The compressor is independent

and is activated by the storage-chamber

pressure switch. Storage outlet routes to a

pressure regulator prior to entering the

infusion manifold.

System Controller Board (Main PCB)

Manages system events and device

interactions. Includes adjustable DIP switch

for concentrate-pump ratio selection. Also

includes PCB switches for fine-tuning the

ratio selection.

24Vdc Power Supply

Provides power to Main PCB and the air

compressor.

Concentrate Pump

Meters input of coffee product from BIB

(Bag In Box) to mixing manifold. Peristaltic

pump, servo-motor driven.

Product-Mixing & Gas-Infusion Manifold

Interconnected plastic blocks with check

valves and a mixing chamber for mixing, airinjecting and routing of coffee concentrate,

water and air to the dispense manifolds.

Three check valves control flow routing by

preventing backflow.

Dispense Manifolds

Tap-handle activated, outlet solenoid valve.

Outlet valve allows product dispensing.

Water-Inlet Solenoid Valve/Regulator

Solenoid valve allows water inlet.

Regulator limits inlet pressure & flow rate.

Publication Number: 548000106SER - 4 - © 2019, Cornelius Inc. All Rights Reserved

Page 9

Nitropro Mini Service Manual

2.0 BREWER OVERVIEW AND REQUIRED TOOLS (Cont.)

2.2 Key Components (Cont.)

Figure 2-2 - Main Components

© 2019, Cornelius Inc. All Rights Reserved - 5 - Publication Number: 548000106SER

Page 10

Nitropro Mini Service Manual

2.0 BREWER OVERVIEW AND REQUIRED TOOLS (Cont.)

2.3 Required Tools

These tools are required for conducting the various procedures in this manual. You may find it

helpful to review the Troubleshooting and Component Replacement sections to determine what

additional tools you might prefer to include.

HAND TOOLS

ELECTRICAL TOOLS

Multimeter - Digital VOM

1000V/10A ac/dc, milliohm to megohm, millivolt,

auto-ranging, ±2.5% +1 digit accuracy

Wrenches - SAE Open-end or Combination

(1/4” through 7/8”)

Wrenches - Adjustable

(2” x 6”- 8” Length, Crescent)

Nut Driver Set - SAE

Pliers - Adjustable

Channel-Lock/Knipex-style

Pliers - Needlenose

Flat Screwdriver

3/16”

Phillips Screwdrivers

#2 & #0 (6” Length)

#2 Stubby or Flex-shaft

Diagonal Cutting Pliers

Pick Set - Dental Type

Magnetic Pickup Wand

Temp erat ure Mete r & P rob e

±2.5% +1 digit accuracy

Cordless Drill or Screwdriver

With Screwdriver Bits / Nut Drivers

Flashlight

Portable Vacuum Cleaner

With hose and crevice tool

SUPPLIES

O-Ring Lubricant/Sealant Food-Grade Silicone

Dow Corning Molykote 111 or equiv.

Solvent - Nonflammable

Tefl on T hre ad- sea lin g Ta pe

Lint-free Cloth Rags

Cleaning Brushes

Bristle and Wire

Air Pressure Gauge

Capable of 100 psi (689 kPa)

with high-pressure hose and

1/4”push-connect fitting

Hose-Clamp Crimping/Cutting Tool

Oetiker HIP 2800 Es

Publication Number: 548000106SER - 6 - © 2019, Cornelius Inc. All Rights Reserved

Page 11

3.0 SYSTEM OPERATION

Figure 3-1 - Power Input

Figure 3-2 - Water Input

This section describes how the Nitropro Mini dispenser operates. By grasping the details of the

operating process for still and Nitro coffee dispensing, you will have the knowledge to detect

many of the common malfunctions.

3.1 Facility Supplies

Electrical: Depending on model and application,

the unit operates from either 115Vac or 230Vac

that enters the unit through a back-panel cord

socket, as shown in Fig 3-1. Input AC power is supplied to the ice bank controller (which manages

the refrigeration compressor and the ice-bath agitator motor). AC power is also routed to the

24Vdc power supply which provides power to the

Main PCB and the air pump. The Main PCB then

provides 24V power to the remainder of the DC

components.

Nitropro Mini Service Manual

Water: Store water enters the unit through a rear

inlet solenoid valve within the pressure range

indicated in Figure 3-2. The inlet solenoid valve

activates when a dispensing tap is pulled. The

inlet solenoid assembly also provides input pressure control [29 psi (200 kPa) - fixed] and flow-rate

limiting within the range of 1 to 1.25 fluid ounces

(29.6 to 37 ml) per second.

Inlet water is first routed to the ice bank for chilling and then is supplied to the mixing-infusion

manifold.

© 2019, Cornelius Inc. All Rights Reserved - 7 - Publication Number: 548000106SER

Page 12

Nitropro Mini Service Manual

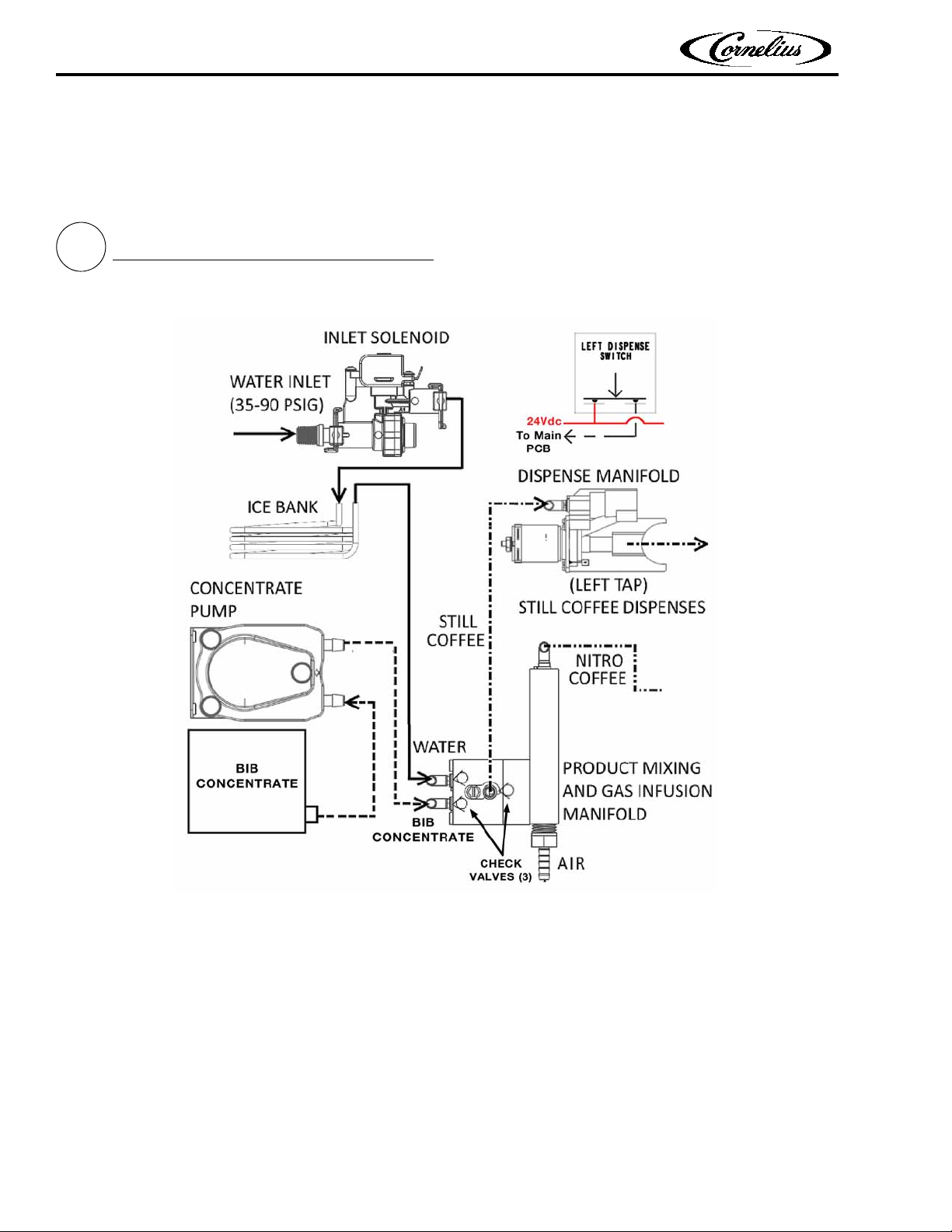

1

Left Tap Handle - Still Coffee Dispensing

Figure 3-3 - Still Coffee Dispense Process

Step 1) Left tap handle is pulled.

Step 2) Left Dispense switch is depressed, activating (via Main PCB):

Dispense Manifold Solenoid Valve (allows front dispensing)

Concentrate Pump (delivers coffee concentrate to Mixing Manifold)

Inlet Solenoid (delivers water to Mixing Manifold)

Action: Water and coffee concentrate combine in the mixing manifold and then flow to

the dispense manifold and into the serving cup. NOTE: There is no flow in the Nitro-coffee circuit and infusion manifold since its dispense valve is closed. The low-pressure path

is to the still-coffee dispense manifold in which the dispense solenoid valve is open.

3.0 SYSTEM OPERATION (Cont.)

3.2 Operating Processes

Publication Number: 548000106SER - 8 - © 2019, Cornelius Inc. All Rights Reserved

Page 13

3.0 SYSTEM OPERATION (Cont.)

2

Right Tap Handle - Nitro Coffee DispensingRight Tap Handle - Nitro Coffee Dispensing

Figure 3-4 - Nitro Coffee Dispense Process

Step 1) Right tap handle is pulled.

Step 2) Right Dispense switch is depressed, activating (via Main PCB):

Dispense Manifold Solenoid Valve (allows front dispensing)

Concentrate Pump (delivers coffee concentrate to Mixing Manifold)

Inlet Solenoid (delivers water to Mixing Manifold)

Action: Water and coffee concentrate combine in the mixing manifold, are then infused

with air in the gas infusion manifold and then flow to the Nitro dispense manifold and

into the serving cup. NOTE: There is no flow in the still-coffee circuit since its dispense

valve is closed. The low-pressure path is to the Nitro-coffee dispense manifold in which

the dispense solenoid valve is open.

3.2 Operating Processes (Cont.)

Nitropro Mini Service Manual

© 2019, Cornelius Inc. All Rights Reserved - 9 - Publication Number: 548000106SER

Page 14

Nitropro Mini Service Manual

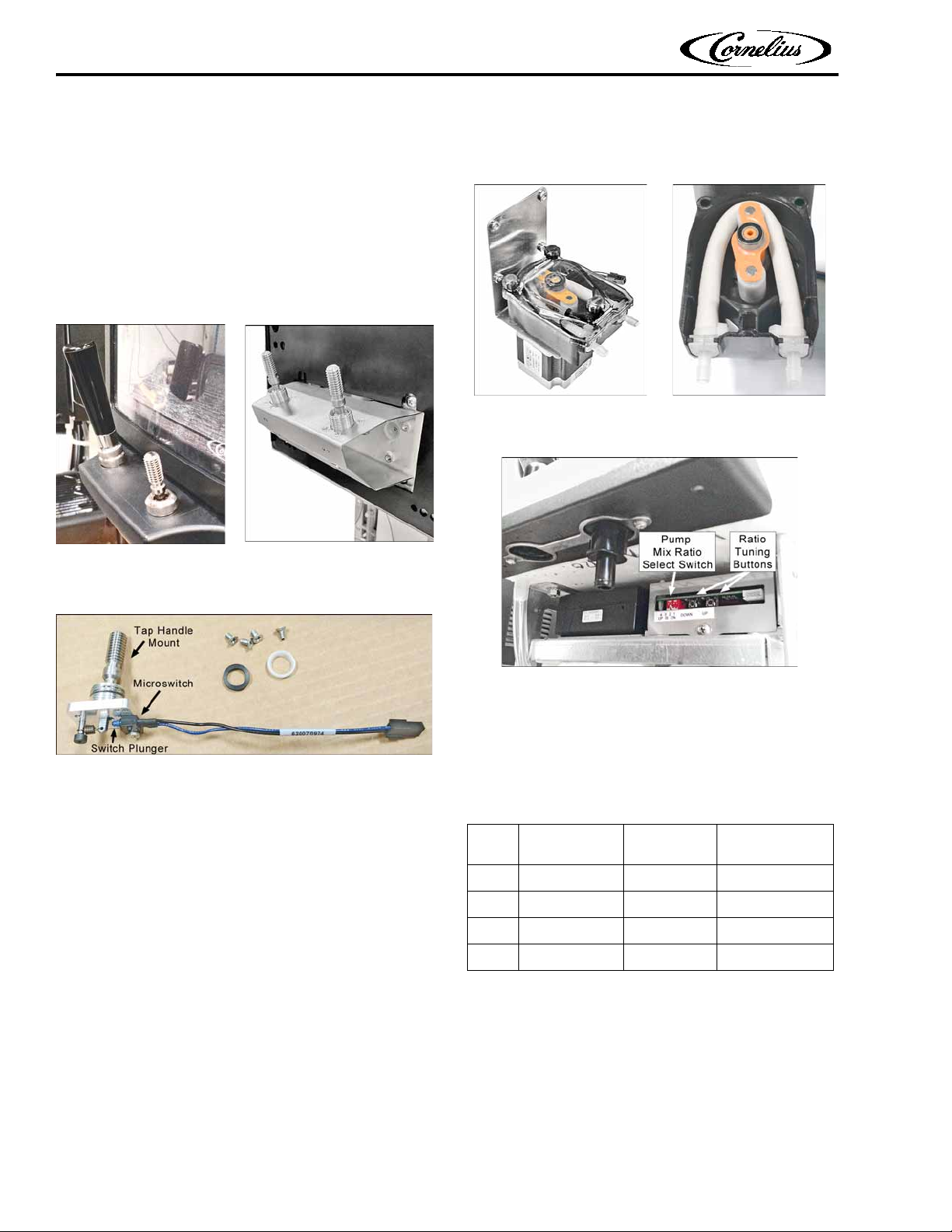

Figure 3-5 - Tap Handles / Microswitch Assemblies

Figure 3-6 - Microswitch Assembly

Figure 3-7 - Concentrate Pump

Figure 3-8 - Ratio Select Switch & Tuning Buttons

3.0 SYSTEM OPERATION (Cont.)

3.3 Component Functions

3.3.1 Tap Handles

The dispensing tap handles (Fig.3-5), when pulled,

activate microswitches (Fig. 3-6) that signal the

Main PCB to activate specific components, as described previously in section 3.2.

3.3.2 Coffee Concentrate Pump

This pump (Fig.3-7) draws coffee concentrate

from the chilled Bag In Box (BIB) and meters it to

the mixing manifold at a specific, user-selected

ratio to the input water (which is supplied at a

fixed pressure and flow rate).

Mixing ratios are adjusted by changing the DIP

switch settings on the Main PCB mounted

beneath the cabinet, as shown in Figure 3-8.

Adjustment of these settings changes the speed

of the peristaltic pump to provide more or less

concentrate per unit time.

The selectable ratios provide, from one gallon of

concentrate, the coffee yields shown in Table

3-1. (NOTE: Select one ratio - one switch ON.)

Table 3-1 - Concentrate Pump Ratios

Ratio

3:1 Switch 1 ON 1 4

4:1 Switch 2 ON 1 5

5:1 Switch 3 ON 1 6

7:1 Switch 4 ON 1 8

Main PCB

Switch Setting

Concentrate

Gallons

Coffee Yield

Gallons

Ratio Tuning Buttons: One press of a button

changes the pump motor speed by 5 RPMs (or by

0.02 - 0.08 of the average TDS value).

The peristaltic pump is driven by a 24V DC servo

motor. A maintenance kit for the pump includes a

replacement pump hose with nipple ends.

Publication Number: 548000106SER - 10 - © 2019, Cornelius Inc. All Rights Reserved

Page 15

3.0 SYSTEM OPERATION (Cont.)

Figure 3-9 - Water Inlet Solenoid

Figure 3-10 - Air Compressor and Air Storage

Figure 3-11 - Mixing-Infusion Manifold & Check Valves

Nitropro Mini Service Manual

3.3 Component Functions (Cont.)

3.3.3 Water Inlet Solenoid

This device controls the water input to the mixing

manifold. It also limits input pressure to 29 psi

(200 kPa) and limits the water flow rate within the

range of 1 to 1.25 fluid ounces (29.6 to 37 ml) per

second.

3.3.4 Air Compressor & Storage

The 24Vdc air compressor provides air to the mixing-infusion manifold to produce Nitro coffee. It

operates independently so that stored air is

always available when the Nitro-coffee tap is activated. The pressure switch stops compressor

operation when a storage-chamber pressure of 80

psi (552 kPa) is detected. The pressure-relief valve

activates at 95 psi (655 kPa) in the event of

pump-motor runaway.

3.3.5 Mixing-Infusion Manifold & Check Valves

The mixing manifold has two halves and is connected to the air-infusion manifold. Three check

valves prevent reverse flow in the supply lines and

chambers. The assembled check valves snap into

place in the manifold.

© 2019, Cornelius Inc. All Rights Reserved - 11 - Publication Number: 548000106SER

.

Page 16

Nitropro Mini Service Manual

Figure 3-12 - Dispense Manifold Assembly

Figure 3-13 - 24Vdc Power Supply

Figure 3-14 - Mixing-Dispensing Assembly

3.0 SYSTEM OPERATION (Cont.)

3.3 Component Functions (Cont.)

3.3.6 Dispense Manifold

There is a dispense manifold for each coffee type.

It receives the mixed coffee and dispenses it

through a solenoid valve that is electrically activated by the tap handle. During operation (when

open) the solenoid plunger, to which a valve seat

is attached, retracts to allow flow through the

valve orifice (Fig. 3-12).

3.3.8 Mixing-Dispensing Assembly

This removable assembly performs the mixing,

air-injection and dispensing functions of the unit.

It consists of the components identified in Figure

3-14. The air-pressure regulator allows user

adjustment of the air-infusion pressure for Nitro

coffee. The assembly is mounted in the chilled

cabinet.

3.3.7 Power Supply (24Vdc)

This unit provides DC power for the air compressor and the Main PCB.

Publication Number: 548000106SER - 12 - © 2019, Cornelius Inc. All Rights Reserved

Page 17

3.0 SYSTEM OPERATION (Cont.)

Figure 3-15 - Ice Bank and Controller Module

Figure 3-16 - Ice Bank Sensor & Agitator Motor

3.3 Component Functions (Cont.)

3.3.9 Ice Bank Chilling System

In the base of the unit resides the insulated ice

bank assembly. It is comprised of a refrigeration

unit (in the rear of the enclosure), a water/ice reservoir, an agitator/circulation pump to control ice

formation and circulate cooling water, an ice sensor and a control module, The control module

manages the refrigeration system and the agitator

based on feedback from the ice sensor. Water

from the inlet solenoid is routed through a stainless steel coil in the ice bank for chilling. As well,

cooling lines from the circulation pump are routed

into the product cabinet where a fan circulates

chilled air.

Nitropro Mini Service Manual

© 2019, Cornelius Inc. All Rights Reserved - 13 - Publication Number: 548000106SER

Page 18

Nitropro Mini Service Manual

Figure 3-17 - Front Door Switches

3.0 SYSTEM OPERATION (Cont.)

3.3 Component Functions (Cont.)

3.3.10 Front-Door Control Switches

These two switches control the merchandiser LED

backlight on the front of the door and the dispensing circuit, as indicated below.

Door Light: On/Off switch turns LED backlight on

or off.

Dispense Motor: A 3-position switch for normal

operation (ON), system shutoff (OFF) and for performing sanitizing procedures (CLEAN). In CLEAN

mode, this switch sets the concentrate pump to

the water/cleaning-agent mixing ratio (5:1). When

the switch is returned to the ON position, the mixing ratio returns to that selected on the pump

mix-ratio switch bank (Fig. 3-8).

Publication Number: 548000106SER - 14 - © 2019, Cornelius Inc. All Rights Reserved

Page 19

4.0 PREVENTATIVE MAINTENANCE

Figure 4-1 - Fans

Figure 4-2 - Ice Bank Fill & Overflow Tubes

Nitropro Mini Service Manual

4.1 Overview

Perform the procedures in this section at the

intervals indicated to ensure consistent, safe and

clean operation of the unit. These are provided in

addition to the routine cleaning and sanitizing

procedures included in the Installation & Operation manual.

4.2 Maintenance Schedule

Table 4-1 - Maintenance Schedule

Procedure Section

Refrig. condenser & cabinet fan cleaning 4.3.1 12

Ice bank level check 4.3.2 12

Concentrate pump mix ratio verification 4.3.3 12

Components visual inspection 4.3.4 12

Concentrate-pump hose replacement 4.3.5 12

Interval

(Months)

4.3 Annual Maintenance

4.3.2 Ice Bank Level Check

The water level in the ice bank may require periodic topping off to ensure optimal operation.

Check and refill it as indicated below.

The fill tube is located behind the front splash

panel and is capped with a red plug.

The small, black, overflow tube, connected to an

internal standpipe, will emit water during manual

refill when the water level reaches the full mark.

4.3.1 Refrigeration Condenser & Cabinet Fan

Cleaning

To ensure optimal cooling efficiency, clean the fan

blades and grilles of any collected dust and debris.

(The use of compressed or canned air to clean the

refrigeration condenser fan blades is adequate.)

NOTE: When the fill tube is in its stored position (as shown in Fig. 4-2) it also serves as a

‘sight glass’ indicating the bank water level.

1) Remove the drip tray and splash panel to reveal

the front of the ice bank.

2) Observe the fill tube and the water level in it. If

the water level is below the top of the tube arc,

add water to the ice bank.

3) Add filtered store water through the fill tube

after extending it from its storage position and

removing the red cap. Add water until a trickle

runs out of the black overflow tube.

4) Cap the fill tube and return it to its storage

position.

© 2019, Cornelius Inc. All Rights Reserved - 15 - Publication Number: 548000106SER

Page 20

Nitropro Mini Service Manual

Figure 4-3 - Ratio Select Switch & Tuning Buttons

4.0 PREVENTATIVE MAINTENANCE (Cont.)

4.3.3 Product Pump Mix-Ratio Verification

It is important to ensure consistency in the dispensed coffee, thus the coffee-concentrate/water

mixing ratios must be verified. Since the ratios are

selected via the Main PCB DIP switch setting, and

may sometimes require adjustment using the tuning buttons, a routine check of the ratios is essential. Follow the applicable procedure below to

verify/adjust each of the four mixing ratios.

Table 4-2 - Mix Ratio Main PCB Switch Settings

Ratio

3:1 Switch 1 ON 1 4

4:1 Switch 2 ON 1 5

5:1 Switch 3 ON 1 6

7:1 Switch 4 ON 1 8

Main PCB

Switch Setting

Concentrate

Gallons

Coffee Yield

Gallons

1) Set the DIP switch for a ratio (Fig. 4-3).

5) Stir the sample thoroughly, and measure the

TDS of the drink (refer to the TDS measuring

procedures in section 4.3.3.1).

6) If the TDS matches the desired range of the

product, no further adjustments are necessary.

If the TDS is above/below required value, use

the ‘UP’ or ‘DOWN’ Ratio Tuning buttons as

necessary to achieve the desired value. (One

press of a tuning button changes the pump

motor speed by 5 RPMs; or by 0.02 - 0.08 of

the average TDS value.

NOTE: Dispense a 16 oz. drink to purge the previous setting before measuring again.

NOTE: Make adjustments in 1-2 button pushes

to avoid overshooting the target value.

7) Once the desired value is reached, the setup is

complete and should be stable with standard

maintenance of the equipment.

8) Perform the previous steps for the remaining

three ratios to verify/adjust them.

2) Prior to installing, shake the concentrate BIB.

NOTE: If concentrate is not properly thawed, it

will adversely affect the amount of concentrate

dispensed. Thawed concentrate should be

between 35 °F (1.6 °C) to 40 °F (4.4 °C) and

have no ice particles remaining in it.

3) Dispense approximately 16 oz. of drink and discard. This is done to purge any water or coffee

dispensed using the previous settings.

4) Draw an 8 oz. drink into a clean dry cup, and

measure the temperature to confirm the drink

is between 35 to 45°F.

NOTE: The adjusted ratio settings will not be

reset by Clean mode or power loss.

NOTE: If a coffee concentrate flavor, manufacturer or ratio type is changed, repeat this process to set the ratio accurately. Conducting this

process is not necessary when changing BIBs of

the same type of coffee concentrate.

4.3.3.1 Measuring TDS (Total Dissolved Solids)

There are three methods that may be used to

check/calibrate the ratio setting of the equipment.

1. Using a TDS Meter

2. Using a Brix Meter/Refractometer

3. Manually Checking Volume Ratio

For each method, access the mix-ratio control

switches (Fig. 4-3) by removing the splash panel.

NOTE: Only one ratio select switch is allowed to

be On, with all others Off.

NOTE: Drink temperature must be maintained

to properly set the ratio of the unit.

Publication Number: 548000106SER - 16 - © 2019, Cornelius Inc. All Rights Reserved

Page 21

4.0 PREVENTATIVE MAINTENANCE (Cont.)

Nitropro Mini Service Manual

4.3.3.1 Measuring TDS (Total Dissolved Solids)

(Cont.)

OPTION 1: USING A TDS METER

A TDS meter measures the Total Dissolved Solids

in a drink. For coffee, it measures the level of

extraction and can be used to ensure that the correct mix ratio is achieved. If the TDS target is

known, a TDS meter allows for a simple process to

measure and ensure proper calibration.

1) Follow instructions for the TDS meter to ensure

proper calibration and zero setting prior to

starting this process.

2) Follow steps 1-5 in section 4.3.3 previously.

3) Using a straw, transfer a small sample of the fin-

ished drink to the TDS meter lens.

4) Check the TDS value on the meter.

5) Adjust the unit ratio setting with the tuning

buttons and purge the system by dispensing a

16 oz. drink after each adjustment.

NOTE: Since this method measures TDS, the

‘UP’ tuning button will adjust TDS up, and the

‘DOWN’ button will adjust TDS down.

OPTION 2: USING A BRIX REFRACTOMETER

A Brix refractometer is used to measure the sugar

content in aqueous solutions. This method may

not apply to all coffee concentrates, but many

concentrates have natural sugars that allow a Brix

refractometer to be used. In order to use this

method, the target Brix value must be known for

the coffee concentrate.

1) Follow instructions for the Brix refractometer

to ensure proper calibration and zero setting

prior to starting this process.

2) Follow steps 1-5 in section 4.3.3 previously.

3) Using a straw, transfer a small sample of the fin-

ished drink to the Brix refractometer meter

lens.

4) Check the Brix value on the meter.

5) Adjust the unit ratio setting with the tuning

buttons and purge the system by dispensing a

16 oz. drink after each adjustment.

NOTE: Since this method measures Brix, the

‘UP’ tuning button will adjust Brix up, and the

‘DOWN’ button will adjust Brix down.

OPTION 3: MANUALLY CHECKING VOLUME

RATIO

Additional Supplies

• Weighing scale

Following steps explain measuring the water-tocoffee-concentrate ratio using weight.

NOTE: Weight can be substituted by volume if a

weighing scale is not handy.

1) Follow steps 1-5 in section 4.3.3 previously.

2) Pull the Left & Right Tap Handles for 10 seconds

one after the other to make sure coffee is dispensing.

3) Set 10 seconds timer.

4) Pull the Left Tap Handle for 10 seconds to dispense the coffee and weigh the product dispensed.

5) Divide #4 by the total parts to get the target

coffee concentrate dispense weight.

6) a) If the total dispense is 300 grams and desired

ratio is 5:1, divide by 6 to get 50 grams concentrate target for a 10 second pour.

b) If the total dispense is 300 grams and desired

ratio is 4:1, divide by 5 to get 60 grams concentrate target for a 10 second pour.

c) If the total dispense is 300 grams and desired

ratio is 3:1, divide by 4 to get 75 grams concentrate target for a 10 second pour.

7) Turn off water to the unit.

8) Pull the Left Tap Handle for 5 seconds or until

coffee is darker and only concentrate is dispensed.

© 2019, Cornelius Inc. All Rights Reserved - 17 - Publication Number: 548000106SER

Page 22

Nitropro Mini Service Manual

Figure 4-4 - Dispense Manifold Assembly

Figure 4-5 - Concentrate Pump & Overhaul Kit

Pump Closed

Pump Open

Pump Hose

4.0 PREVENTATIVE MAINTENANCE (Cont.)

4.3.3.1 Measuring TDS (Total Dissolved Solids)

(Cont.)

OPTION 3: MANUALLY CHECKING VOLUME

RATIO (Cont.)

9) Set 10 seconds timer and dispense concentrate

by pulling the Left Tap Handle.

10) a) If weight is greater than #6 target, use the

‘DOWN’ button on controller to slow the concentrate motor down.

b) If weight is less than #6 target, use the ‘UP’

button on controller to speed up the concentrate motor.

11) Set 10 seconds timer and dispense concen-

trate by pulling the Left Tap Handle until target value from #6 is within +/- 2 grams of

target.

12) Turn water on to unit.

13) Pull the Left Tap Handle for 10 seconds until

coffee is dispensed.

14) Pull the Right Tap Handle for 10 seconds until

coffee is dispensed.

4.3.4 Components Visual Inspection

the solenoid valve plunger seal and o-ring on

the orifice insert (Fig. 4-4). Replace as the manifold assembly as required.

Cabinet Fan (Fig. 4-1): Verify operation.

Refrigeration System (Fig. 4-1): Verify ade-

quate airflow through condenser coil. Clean as

needed.

4.3.5 Concentrate-Pump Hose Replacement

Over time, the concentrate-pump internal hose

can become less pliable and the rotor and top

bearing significantly worn. To prevent a disruptive

failure, install a new pump hose annually as

described below.

1) Check the condition of each system component

for the following conditions and replace per

the instructions in section 6.0 if any are

observed.

Air/Water Hoses: Cracking, bulging, leaking.

Hose Connectors: Cracking, leaking, worn or

distorted o-rings or seals.

Ice Bank & Inlet Solenoid Spring Housing (Fig.

3-9): Water Discoloration, Contamination, Sed-

iment. (Attempt drain and flush before replacing component.)

Main PCB (Fig. 2-2): Corrosion or signs of overheated components.

Dispense Manifolds (Fig. 3-12): Check o-rings

on top portion of dispensing tubes and on the

dispensing tube, outlet-cap nipple that inserts

into the manifold. If the manifold drips, check

Publication Number: 548000106SER - 18 - © 2019, Cornelius Inc. All Rights Reserved

Page 23

4.0 PREVENTATIVE MAINTENANCE (Cont.)

Figure 4-6 - Mixing-Dispensing Assembly Removed

Pump Hose Installation

Nitropro Mini Service Manual

1) Inside the cabinet, disconnect the water and air

lines at the back of the chamber.

2) Pull each tap to relieve line pressure.

3) Shut off power to the Nitropro unit.

4) In the cabinet, unplug the wiring connector

from the mixing-dispensing assembly and

remove the assembly. Place it on the countertop (Fig. 4-6).

5) Disconnect the two hoses from the pump, note

or mark their locations for reassembly.

13) Reinstall the mixing-dispensing assembly into

the cabinet, making sure to reconnect the

plumbing and electrical connectors.

14) Confirm pump operation by dispensing both

product types until air is purged from the

lines.

6) Remove the four screws securing the pump

bracket to the assembly baseplate (access from

underneath).

7) Open the pump cover by removing the three

thumbscrews.

8) Lift out the pump rotor and bearing. Slide out

the two pump-hose nipples from the pump

housing.

9) Clean the pump-hose chamber as required.

10) Install the new pump hose. When installing it,

orient the rotor as shown in the upper photos

of Fig. 4-5 so that only one point on the hose

must be compressed.

11) Reinstall the pump cover.

12) Install the pump on the baseplate and recon-

nect the hoses.

© 2019, Cornelius Inc. All Rights Reserved - 19 - Publication Number: 548000106SER

Page 24

Nitropro Mini Service Manual

5.0 TROUBLESHOOTING

Table 5-1 - Systems-Level Troubleshooting

Malfunction Possible Causes Corrective Action

Unit will not operate

No Cooling

A. No power to unit due to tripped circuit

breaker

B. Loose or broken wiring connection to

24Vdc power supply

A. Line voltage not within nameplate specs.

causing compressor overload trip

B. No water in water ice bath or water level

very low, exposing ice bank sensing probe

C. Malfunctioning ice-bank controller or

sensing probe

D. Cabinet fan inoperative resulting in warm

concentrate (water continues to cool)

E. Compressor short cycles on overload

F. Compressor starts, hums, trips overload

G. Defective compressor overload or start

capacitor

H. Compressor starts but does not switch off

of motor-start winding

I. Refrigerant leak

A. Reset facility circuit breaker. Confirm

that breaker is correct size & no other

equipment is operating on the same

circuit. Also confirm that supply voltage is

within ±10% of name plate specification

B. Repair connection, confirm 24Vdc

output. Replace power supply as required.

A. Contact an electrician

B. Fill ice bath to proper water level (see

section 4.3.2)

C. Replace

D. Replace

E. Shut off, determine cause

F. Seized or shorted compressor, replace

G. Test & replace

H. Relay or compressor is defective. Test &

replace faulty item

I. Repair leak, evacuate & recharge system

A. Door switch is off

Merchandiser LED back-lighting panel not working

Publication Number: 548000106SER - 20 - © 2019, Cornelius Inc. All Rights Reserved

B. Harness not connected

C. No power to Main PCB control board or

board has failed

A. Turn on Door Light switch inside door

B. Remove LED panel, check harness

connections

C. Measure power input to Main PCB.

Replace fuse or board if necessary (see Fig.

6-1)

Page 25

Nitropro Mini Service Manual

5.0 TROUBLESHOOTING (Cont.)

Table 5-2 - Drink-Quality Troubleshooting

Malfunction Possible Causes Corrective Action

Dispensed coffee is too weak

Dispensed coffee is too strong

Excessive foam in Nitro

coffee

A. Incorrect ratio DIP switch selected for

product ratio being used

B. Brix adjustment needs to be made

C. Concentrate hose or pump-motor malfunction

A. Incorrect ratio DIP switch selected for

product ratio being used

B. Brix adjustment needs to be made

C. Water pressure too low

A. Air regulator in cabinet not set properly

B. Regulator not holding set point. Pressure

reading is drifting upwards

C. Air-storage pressure-switch malfunction

(causing high pressure)

A. Confirm product ratio and select

appropriate ratio DIP switch

B. Using the ratio-tuning buttons located

behind the splash panel, press the UP

button to increase pump speed and

recheck Brix measurement

C. Verify BIB connection and harness connection to concentrate pump

A. Confirm product ratio and select

appropriate DIP switch

B. Using the ratio-tuning buttons located

behind the splash panel, press the DOWN

button to decrease pump speed and

recheck Brix measurement

C. Verify water supply to unit is in range

A. Pull regulator knob outward turn CW for

more air or CCW for less air injection

B. Bleed off all pressure and reset

regulator. If after setting pressure the

gauge reading continues to drift upward,

replace the regulator

C. Inside cabinet, connect pressure gauge

to air outlet quick disconnect (see Sec.

5.1). Gauge should read 75 to 85 psi (517

to 586 kPa). If reading is outside of range,

replace pressure switch

Warm drinks

Concentrate is warm, water is

cold

A. Environment around dispenser too warm

B. Excessive demand on dispenser

C. Dirty condenser coil

D. Inoperative condenser fan

E. Defective ice bank control module

F. Refrigerant low due to leak in system

G. Defective ice probe

A. Cabinet fan malfunction

B. Product box too close to fan

C. Agitator motor/pump malfunction or

output is restricted

D. Loss of refrigerant charge due to leak in

system

A. Relocate dispenser

B. Add a water precooler or a second

dispenser to divide usage load

C. Clean condenser coil

D. Replace condenser fan motor

E. Test & replace if necessary

F. Repair leak and recharge system

G. Check and replace as necessary

A. Check/replace fan

B. Move product box away from fan

C. Check/replace agitator motor, check

water lines & flow

D. Repair leak, recharge system

© 2019, Cornelius Inc. All Rights Reserved - 21 - Publication Number: 548000106SER

Page 26

Nitropro Mini Service Manual

5.0 TROUBLESHOOTING (Cont.)

Table 5-3 - Compressed Air & Infusion Troubleshooting

Malfunction Possible Causes Corrective Action

No gas infusion on right side

tap (no foam in Nitro coffee)

Air compressor not turning

on

Air compressor cycling on/off

too frequently

Air compressor runs

continuously

A. Infusion air regulator in cabinet is not set

properly

B. The air compressor did not activate or is

cycling on/off

C. Sparger (infusion manifold) clogged, dirty

D. Stuck check valve

A. Malfunctioning pressure switch

B. Malfunctioning 24 Vdc power supply

C. No voltage to air compressor

D. Malfunctioning air compressor

A. Leak in the compressed air circuit

B. Air-storage relief valve not fully seating

C. Pressure switch malfunction

A. Leak in the compressed air circuit

B. Malfunctioning pressure switch

C. Air-storage relief valve not fully seating

due to obstruction

D. Air-storage relief valve worn out

A. Pull regulator knob outward, turn CW

for more air injection or CCW for less

B. See air compressor symptoms

C. Preform the weekly sanitize/cleaning

procedure (per Install-Operator manual)

D. Flush out, same as C above.

A. Check pressure switch for continuity

with zero pressure in system. If circuit is

open, replace switch

B. Confirm output voltage is 24VDC at

power supply. Replace as required

C. Measure for 24VDC at compressor,

inspect wire connections, power supply

D. If air compressor is receiving 24 Vdc,

replace it

A. Leak check circuit starting at compressor

through to air regulator in cabinet. Repair

or replace defective component

B. Pull relief valve ring and purge any

possible debris. If it continues to leak,

replace relief valve

C. Check pressure switch per Sec. 5.1.

A. Leak check circuit starting at compressor

through to air regulator in cabinet. Repair

or replace defective component

B. Check pressure switch for continuity

with zero pressure in system. If circuit is

open, replace switch

C. Pull relief valve ring and purge any

possible debris. If it continues to leak,

replace relief valve

D. Hold down relief valve stem and allow

air compressor to cycle & shut off at 80 psi.

Release stem and if it still leaks, replace

the relief valve

Publication Number: 548000106SER - 22 - © 2019, Cornelius Inc. All Rights Reserved

Page 27

Nitropro Mini Service Manual

5.0 TROUBLESHOOTING (Cont.)

Table 5-4 - Dispensing-Function Troubleshooting

Malfunction Possible Causes Corrective Action

Nothing dispenses when tap

handle is pulled (refrigeration

is operating)

No water dispensed, concentrate only

A. Door inner Dispense Motor switch is off

B. Mixing-Dispensing assembly wiring

harness is disconnected

C. Door interlock switch is open

D. Tap microswitch is not activating

E. Dispense solenoid valve or water inlet

solenoid not opening

F. Clogged orifice at dispense manifold valve

or in dispense-tube cap

G. No output from 24 Vdc power supply

H. No power to Main PCB or board has

failed

A. Water line inside cabinet is disconnected

from mixing-dispensing assembly

B. No water to dispenser, supply is off

C. Water inlet solenoid (at the rear of unit)

is clogged, binding or defective

D. Freeze-up of water coil in ice bank

A. Turn on Dispense Motor switch

B. Connect harness in cabinet-wall socket

C. Door must be closed to allow

dispensing. Check interlock switch

operation & replace if necessary

D. Remove tap handle and inspect lever for

damage, verify switch operation, replace as

required (see section 6.10)

E. Verify 24 Vdc at both solenoids when

dispense switches are activated

F. Preform the weekly sanitize/cleaning

procedure in Install-Operator manual

G. Confirm power supply output voltage is

a steady 24 Vdc

H. Measure 24 Vdc input to board. Replace

fuse or board if necessary (see Fig. 6-1)

A. Reconnect water quick-disconnect

B. Restore water supply

C. Confirm 24 Vdc is present at solenoid

during dispensing; confirm solenoid coil is

not open-circuited; replace as required

D. Unplug dispenser & allow ice bank to

thaw for 2-4 hrs. Verify operation of

agitator motor & ice bank control; replace

components as required

No concentrate dispensed,

water only

Unit continues to dispense

after tap handle is released or

dispenses without operator

action

Product continuously drips

from dispense tube in OFF

mode

Pulsing effect in coffee stream

while dispensing

A. BIB hose end not fully engaged into

connector on mixing-dispensing assembly

platform in cabinet

B. Concentrate too cold, not properly

thawed

C. Malfunctioning pump motor

D. No power to Main PCB or board failed

A. Dispense lever or dispense microswitch is

stuck in ON position

A. Water inlet solenoid at rear of unit or

dispense manifold solenoid valve is not

shutting off completely

A. Facility water pressure low, below 30 psi

B. Water inlet solenoid binding or pressure-

control components are malfunctioning

C. Concentrate pump malfunctioning

A. Check connector o-rings, fully insert BIB

hose end into connector

B. Concentrate should be 35 to 40 °F (1.7 to

4.5 °C) with no ice prior to loading

C. Verify BIB hose connection and wiring

harness connection to pump

D. Measure 24 Vdc power input to board.

Replace fuse or board if necessary (see Fig.

6-1)

A. Remove tap lever shroud (sec. 6.10) and

inspect dispense switch and wiring harness

A. Flush/clean solenoid(s), replace parts as

necessary (see sections 6.4.3 & 6.6)

A. Correct water supply pressure to ensure

constant 35-90 psi (2.5-6.2 bar) is being

provided to unit

B. Clean and/or replace as necessary

C. Verify operation, replace as necessary

© 2019, Cornelius Inc. All Rights Reserved - 23 - Publication Number: 548000106SER

Page 28

Nitropro Mini Service Manual

Figure 5-1 - Air Inlet Line

5.0 TROUBLESHOOTING (Cont.)

5.1 Air-Compressor Pressure Verification

This procedure is a measurement of the air pressure in the air storage chamber to determine if

the air pump is working properly and shutting off

when the pressure is approximately 80 psi (552

kPa).

1) Shut off power to the Nitropro unit.

2) Inside the cabinet, disconnect the dispenseassembly air line from the back wall air inlet.

Connect a 100 psi (689 kPa) air pressure gauge

with a quick-connect fitting to the Air Inlet line

(Figure 5-1).

3) Apply power to the unit.

4) Dispense a Nitro coffee drink or two to trigger

air-compressor operation.

5) Observe the pressure gauge.

6) The compressor should stop running at a reading of 75 to 85 psi (517 to 586 kPa). If the pressure is out of range, check for leaks and check/

replace the storage-chamber pressure switch.

Publication Number: 548000106SER - 24 - © 2019, Cornelius Inc. All Rights Reserved

Page 29

6.0 COMPONENT REPLACEMENT

!

WARNING!

!

CAUTION!

Nitropro Mini Service Manual

This section provides instructions or guidelines on

replacing the various Nitropro Mini components.

6.1 Safety Precautions

Disconnect power to the unit before servicing or replacing electrical components. Follow all lock out/tag out procedures

established by the user. Verify all power is

disconnected from the unit before performing any work. Failure to comply could result

in serious injury, death or damage to the

equipment.

When replacing or testing electronic components, be sure to wear a static strap connected to chassis ground. This protects the

electronic components from any static discharge while working on the unit. (This specifically applies to handling of a new Main

PCB or an Ice-Bank Controller module.)

NOTE: Use the hinge cover to collect the panel

screws removed.

6.2 Access Panel Removal

Follow the steps in the photos below to remove

the access panels in the required order.

© 2019, Cornelius Inc. All Rights Reserved - 25 - Publication Number: 548000106SER

Page 30

Nitropro Mini Service Manual

6.0 COMPONENT REPLACEMENT (Cont.)

6.2 Access Panel Removal (Cont.)

Publication Number: 548000106SER - 26 - © 2019, Cornelius Inc. All Rights Reserved

Page 31

6.0 COMPONENT REPLACEMENT (Cont.)

Figure 6-1 - Main PCB Housing Removed

6.3 Main PCB

1) Shut off power to the Nitropro Mini and unplug

its power cord from the wall receptacle.

2) Remove the drip tray and splash plate.

3) Remove the Phillips screw securing the metal

housing of the Main PCB (Fig. 6-1).

4) Withdraw the Main PCB from the unit and

unplug its three wiring connectors.

5) Replace and secure new PC board/mounting

plate assembly in the unit with the supplied

screw.

6. Setup the mix-ratio select switches by following

the procedure in the install manual or section

4.3.3 of this manual.

Nitropro Mini Service Manual

7. Apply power to the unit and confirm that the

green, heartbeat LED on the PCB is blinking,

indicating that the board is functioning properly.

© 2019, Cornelius Inc. All Rights Reserved - 27 - Publication Number: 548000106SER

Page 32

Nitropro Mini Service Manual

Figure 6-2 - Mixing-Dispensing Assembly in Cabinet

Figure 6-3 - Mixing-Dispensing Assembly in Cabinet

6.0 COMPONENT REPLACEMENT (Cont.)

6.4 Mixing-Dispensing Assembly

Components

This assembly contains multiple components that

typically must be unfastened from the baseplate

(underside mounting screws) or from the upper

brackets employing through-hole mounting.

Assembly Removal from Cabinet

1) In the cabinet, disconnect the air/water supply

lines and the wiring connector.

2) Pull the assembly release latch (Fig. 6-2) forward and then lift the assembly out of the cabinet and place it on a bench or countertop.

3) Replace components by following the appropriate instructions below.

6.4.1 Air Pressure Regulator

1) Unscrew the black, threaded ring under the

regulator adjustment knob and the bracket.

Withdraw the regulator from its mounting

bracket to access the air hoses.

2) Unfasten the air hoses. noting or marking their

locations. Remove the regulator.

3) On the old regulator, turn its adjustment knob

clockwise and count the turns until it stops.

4) On the new regulator, turn its adjustment knob

clockwise until it stops (closed). Then open it

the number of turns counted in step 3.

Publication Number: 548000106SER - 28 - © 2019, Cornelius Inc. All Rights Reserved

Page 33

6.0 COMPONENT REPLACEMENT (Cont.)

Figure 6-4 - Mixing Manifold Hose Fittings Removal

!

CAUTION!

Figure 6-5 - Hose Clamp Removal (Oetiker Tool)

Figure 6-6 - Dispense Manifold Assembly

6.4.1 Air Pressure Regulator (Cont.)

5) Connect the new regulator to the air hoses.

6) Reinstall the regulator in reverse order.

7) Confirm operation and adjust as required.

6.4.2 Mixing - Infusion Manifold

1) On the underside of the assembly baseplate,

remove the screws securing the mixing-infusion manifolds (Fig. 6-3).

2) Use tape and a marker to label the five hoses.

3) Loosen the C-plate retainer screws where the

four hoses connect to the manifold (Fig. 6-4).

6) Remove the hose and unscrew the threaded,

hose-nipple fitting. Clean off the Teflon tape

and apply new tape (or use an NSF 61 pipesealing dope, such as T Plus 2 by Rector Seal).

7) Remove the mixing-infusion manifold and place

the new one in the mixing-dispensing assembly.

Nitropro Mini Service Manual

4) Move a retainer plate aside and rotate the hose

fitting back and forth while withdrawing it

from the manifold. Remove the four fittings.

Check/replace their o-rings as needed.

5) Carefully remove the threaded, hose-nipple fitting from the infuser manifold by first removing the hose clamp using side cutters or the

recommended Oetiker HIP 2800 Es crimping/

cutting tool (see Fig. 6-5). Cut the clamp open.

8) Reinstall the hoses in reverse order. When

tightening the threaded, hose-nipple fitting in

the infuser manifold, tighten it finger tight and

then rotate it 2 to 3 turns to prevent leakage.

Use the Oetiker crimping tool to install the

hose clamp on the hose-nipple fitting.

9) Secure the manifold assembly to the baseplate

by reinstalling the underside screws.

10) Reinstall the mixing-dispensing assembly in

the cabinet, operate the dispenser and check

all the manifold hose connections for leaks.

6.4.3 Dispense Manifold

1) Remove the assembly-underside screws that

secure the manifold (Fig. 6-6) to the baseplate.

Be careful to avoid damaging the tubing

when removing the hose clamp.

© 2019, Cornelius Inc. All Rights Reserved - 29 - Publication Number: 548000106SER

2) Unplug the two solenoid wires and disconnect

the hose from its port.

Page 34

Nitropro Mini Service Manual

Figure 6-7 - Air Compressor and Storage Chamber

6.0 COMPONENT REPLACEMENT (Cont.)

6.4.3 Dispense Manifold (Cont.)

3) Remove the dispense manifold and replace it

by following the previous steps in reverse

order.

6.4.4 Concentrate-Pump

Refer to section 4.3.5 Concentrate-Pump Hose

Replacement for pump removal instructions.

6.5 Air Compressor Removal

The air compressor (Fig. 6-7) is located in the left

rear of the enclosure and is mounted on a carrier

plate to allow removal.

1) Shut off the power to the dispenser and unplug

the power cord from the wall receptacle.

2) Remove the top, back, and left access panels

from the dispenser.

3) With power off, pull the relief valve ring to

depressurize the air storage chamber.

4) Install the new air filter by firmly pressing the

air hose into each filter-connector end.

4) Disconnect the air line from the storage chamber top cover.

5) Remove the 4 screws indicated in Figure 6-7.

6) Remove the compressor partially from the

enclosure and disconnect the black ground

wire from the motor and the red wire from the

4 amp breaker terminal.

7) At this point you may service the compressor

by replacing the pressure switch, relief valve,

check valve, motor/compressor assembly or

the storage chamber gasket. Otherwise, transfer the plumbing components necessary to the

new compressor and install them in reverse

order.

6.5.1 Compressor Air Filter Replacement

1) Perform steps 1 -3 shown above in section 6.5.

2) Note the orientation of the air filter (Fig. 6-7).

3) Disconnect the air filter from the air line by

pressing on the dark gray ring on the hose side

of each connector while withdrawing the hose.

Publication Number: 548000106SER - 30 - © 2019, Cornelius Inc. All Rights Reserved

Page 35

6.0 COMPONENT REPLACEMENT (Cont.)

Figure 6-8 - Water Inlet Solenoid & Mounting

Figure 6-9 - 24Vdc Power Supply & Mounting

Nitropro Mini Service Manual

6.6 Water Inlet Solenoid

7) Connect the dispenser water hose to the

replacement solenoid.

8) Reinstall the solenoid in reverse order.

6.7 Power Supply (24Vdc)

1) Shut off power to the dispenser and unplug the

power cord from the wall receptacle.

2) Remove the enclosure top panel and then the

right-side access panel from the dispenser.

3) Disconnect the AC wiring from the top of the

power supply (Fig. 6-9).

1) Shut off the water supply to the unit and then

dispense a still coffee (left tap handle) drink to

relief any water pressure in the lines.

2) Shut off power to the dispenser and unplug the

power cord from the wall receptacle.

3) Remove the enclosure top panel and then the

right-side and rear access panels from the dispenser.

4) Disconnect the water-supply hose from the

inlet solenoid.

5) Remove the two back-panel, Phillips screws

securing the inlet solenoid bracket.

6) Partially remove the inlet solenoid and then

remove the dispenser water-inlet hose from it.

© 2019, Cornelius Inc. All Rights Reserved - 31 - Publication Number: 548000106SER

4) Remove the screws securing the power supply

to the enclosure rail.

5) Remove the power supply partially from the

enclosure and disconnect the DC wiring from

the bottom terminals. Then remove it entirely.

6) Install the new power supply in reverse order.

Page 36

Nitropro Mini Service Manual

Figure 6-10 - Merchandiser LED Backlight Removal

Figure 6-11 - Ice Sensor Probe

6.0 COMPONENT REPLACEMENT (Cont.)

6.8 Merchandiser LED Back-Lighting Panel

This panel is mounted to the cabinet door behind

the merchandiser window. Its control module can

be accessed by removing the light panel.

1) Shut off power to the dispenser and unplug the

power cord from the wall receptacle.

2) Remove the merchandiser window by pulling

firmly on the frame molding surrounding it, at

the top, as shown in Figure 6-10.

6.9 Ice Bank

The Ice Bank consists of multiple components that

are replaceable. They include:

1) Ice Sensor Probe

2) Agitator/Pump Motor & Bath Impeller

3) Electronic Control Module

4) Refrigeration Components

6.9.1 Ice Sensor Probe

3) Remove the corner screws securing the light

panel to the cabinet door.

4) Disconnect the wiring at the back of the panel.

5) Connect the new panel wiring and reinstall the

light panel in reverse order.

Publication Number: 548000106SER - 32 - © 2019, Cornelius Inc. All Rights Reserved

1) Shut off power to the dispenser and unplug the

power cord from the wall receptacle.

2) Remove the enclosure top panel and then the

left-side and rear access panels from the enclosure.

NOTE: The ice sensor is located at the left-rear

of the enclosure (Fig. 6-12) and sensor removal

may be performed from the enclosure rear.

Page 37

6.0 COMPONENT REPLACEMENT (Cont.)

Figure 6-12 - Ice Sensor & Control Module Locations

Figure 6-13 - Agitator Motor Location & Underside

Nitropro Mini Service Manual

6.9.1 Ice Sensor Probe (Cont.)

It is recommended, for easier sensor-cable

routing and plugging/unplugging from the control module, to remove the air compressor unit

for improved access.

3) Unplug the sensor cable from the ice-bank controller module.

4) Remove the two black thumbscrews securing

the ice sensor probe and then lift the sensor

out of the ice bank. Note its orientation.

6.9.2 Agitator Motor

The agitator motor is located centrally on the ice

bank cover plate (Fig. 6-13). Obtain the most convenient access by removing the air compressor.

Remove the thumbscrew shown to unfasten the

agitator motor from its mounting.

5) Install the new sensor in the ice bank. Route its

cable to the controller module and plug it in.

© 2019, Cornelius Inc. All Rights Reserved - 33 - Publication Number: 548000106SER

Page 38

Nitropro Mini Service Manual

Figure 6-14 - Agitator Wiring Socket on Controller Module

Figure 6-15 - Agitator Pump Hose Orientations

Figure 6-16 - Ice Bank Controller Module Removal

6.0 COMPONENT REPLACEMENT (Cont.)

6.9.2 Agitator Motor (Cont.)

1) Shut off power to the dispenser and unplug the

power cord from the wall receptacle.

2) Remove the enclosure top panel and then the

left-side and rear access panels.

3) Remove the air compressor from the left side of

the enclosure (refer to section 6.5).

4) Unplug the agitator-motor wiring plug from the

ice bank controller module socket (Fig. 6-14).

NOTE: You can obtain access to the controller

wiring sockets by removing the splash shield

and the Main PCB housing refer to section 6.3).

6.9.3 Ice Bank Controller

1) Shut off power to the dispenser and unplug the

power cord from the wall receptacle.

5) Loosen the thumbscrew at the base of the agitator motor (Fig. 6-13).

2) Remove the enclosure top panel and then the

left-side access panel.

3) Remove the drip tray, splash panel and the

Main PCB housing (refer to section 6.3).

4) Unplug the four wiring connectors from the ice

bank controller module (Fig. 6-16).

6) Lift and angle the motor assembly to withdraw

it from the ice bank.

7) Install the replacement motor in reverse order.

Publication Number: 548000106SER - 34 - © 2019, Cornelius Inc. All Rights Reserved

Page 39

6.0 COMPONENT REPLACEMENT (Cont.)

!

WARNING!

Figure 6-17 - Tap Handle/Microswitch Mounting

Nitropro Mini Service Manual

6.9.3 Ice Bank Controller (Cont.)

5) Slide the controller to the right, off its mounting and remove the controller.

6) Install the replacement controller in the reverse

manner.

6.9.4 Refrigeration Components

Only trained and certified refrigeration

technicians should service the Nitropro

Mini refrigeration system components.

FAILURE TO COMPLY COULD RESULT IN

SERIOUS INJURY, DEATH OR EQUIPMENT

DAMAGE.

ALL REFRIGERATION SERVICE PROCEDURES MUST CONFORM TO LOCAL CODES,

ENVIRONMENTAL AND PROFESSIONALPRACTICE STANDARDS.

6.10 Tap Microswitches

Each tap handle activates a microswitch connected to the Main PCB. The microswitches are

mounted on the base plates of the tap handle

assemblies. Access is achieved by removing the

tap-handles and the mounting rings that secure

each mechanical activator assembly.

1) Shut off power to the dispenser and unplug the

power cord from wall receptacle.

2) Carefully unscrew each tap handle from its activator-pin assembly (Fig. 6-17).

3) Unscrew and remove each retainer ring as

shown.

Ensure that the refrigerant charge is captured by appropriate equipment before the

system is opened for the servicing of pressurized components.

NOTE: It may be helpful to the refrigeration technician to review the dispenser-particular guidance

in the following Troubleshooting tables and specific Malfunctions of section 5.0 Troubleshooting.

Table 5-1: No cooling

Table 5-2: Warm drinks; Concentrate is

warm, water is cold

Additionally, refrigeration information in section

2.1 Nitropro Functions & Specifications should be

helpful:

Table 2-2 - Refrigerant Type

4) Carefully lift the surrounding plastic housing off

of the tap-handle mounts to expose the

microswitch assemblies.

© 2019, Cornelius Inc. All Rights Reserved - 35 - Publication Number: 548000106SER

Page 40

Nitropro Mini Service Manual

Figure 6-18 - Tap Handle Microswitch Assembly

6.0 COMPONENT REPLACEMENT (Cont.)

6.10 Tap Microswitches (Cont.)

5) Remove the 4 screws securing each tap-handle

switch assembly to the metal bracket and disconnect the wiring leads (Fig. 6-18).

6) Remove the switch assembly and install the

new one. Mount the assembly on the support

bracket and reconnect the wiring leads.

7) Reinstall the plastic cover over the tap-handle

switch mountings and secure with the

threaded retainer rings. Reinstall the tap handles.

8) Verify operation of the taps.

Publication Number: 548000106SER - 36 - © 2019, Cornelius Inc. All Rights Reserved

Page 41

APPENDIX A - SYSTEM DRAWINGS

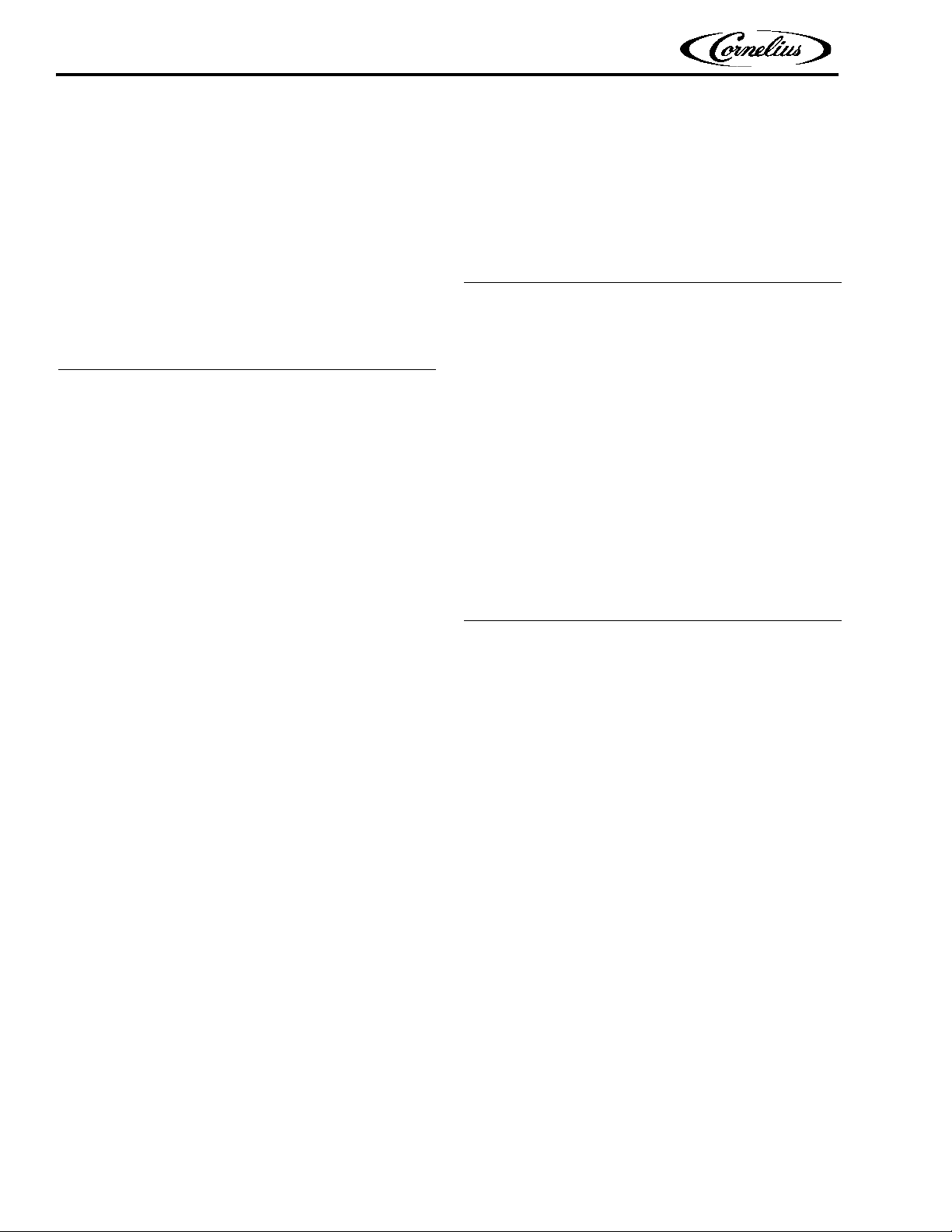

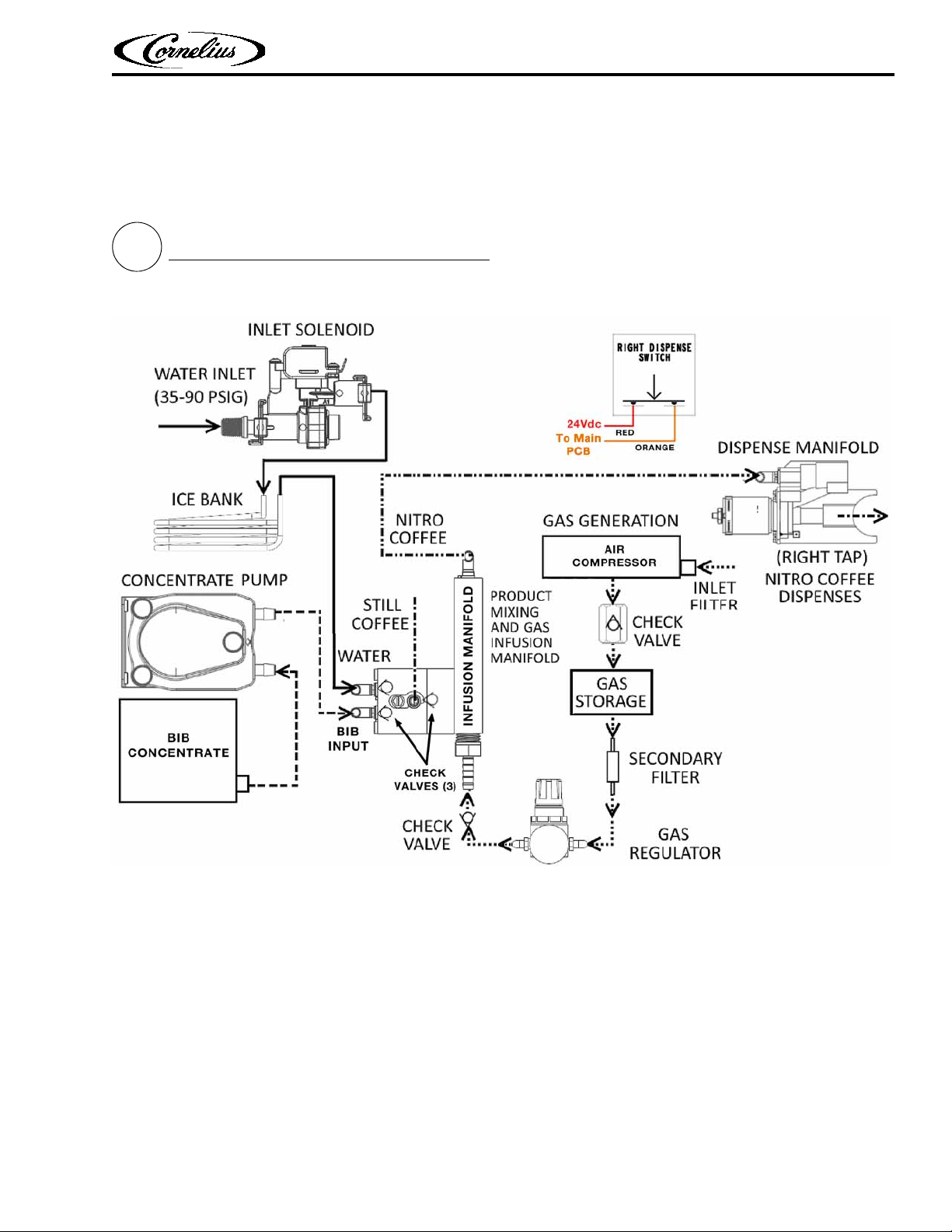

Figure A-1 - Plumbing Diagram

Nitropro Mini Service Manual

© 2019, Cornelius Inc. All Rights Reserved - 37 - Publication Number: 548000106SER

Page 42

Nitropro Mini Service Manual

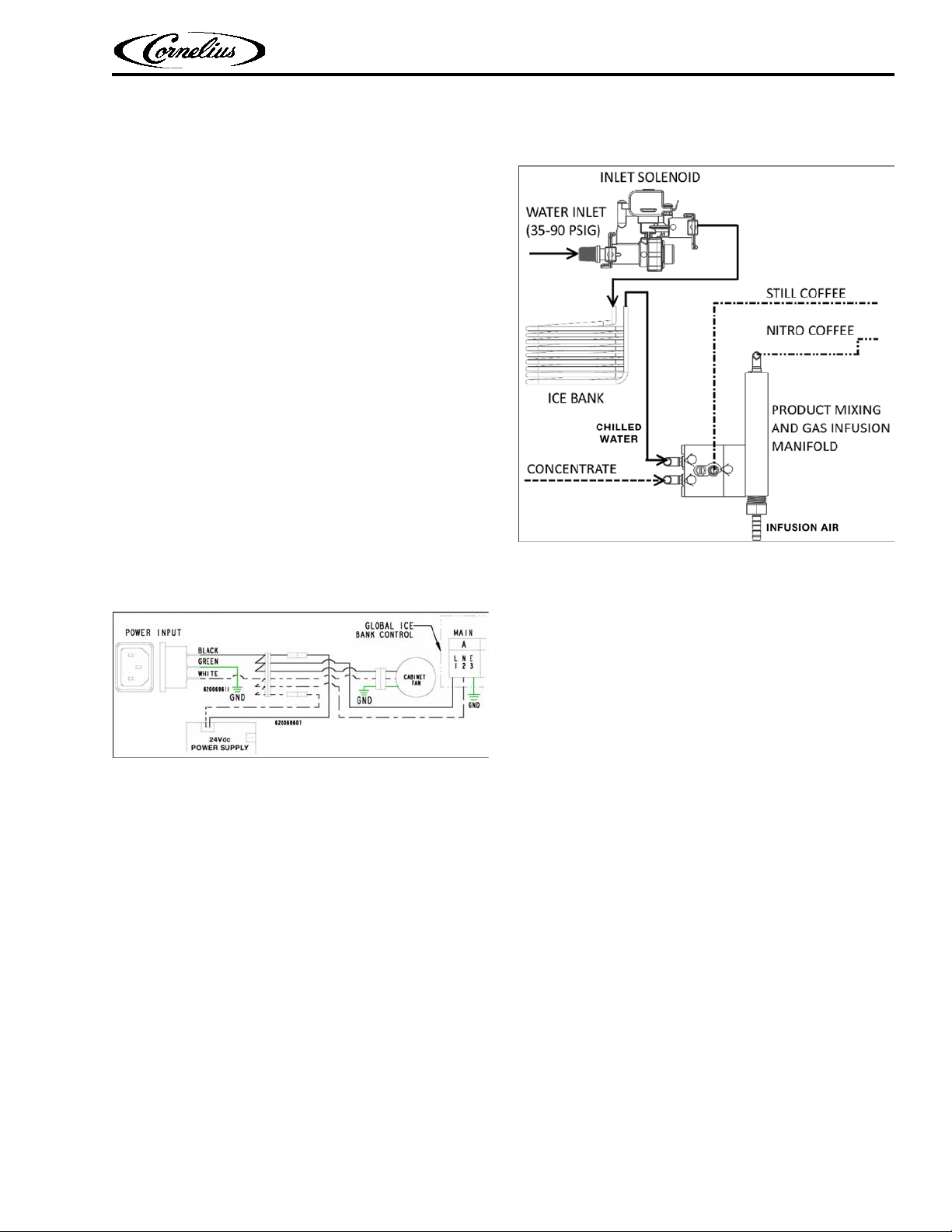

Figure A-2 - Electrical Diagram

APPENDIX A - SYSTEM DRAWINGS (Cont.)

Publication Number: 548000106SER - 38 - © 2019, Cornelius Inc. All Rights Reserved

Page 43

Nitropro Mini Service Manual

© 2019, Cornelius Inc. All Rights Reserved - 39 - Publication Number: 548000106SER

Page 44

Nitropro Mini Service Manual

Publication Number: 548000106SER - 40 - © 2019, Cornelius Inc. All Rights Reserved

Page 45

Cornelius Inc.

www.cornelius-usa.com

Loading...

Loading...