Cornelius MJ30-4 PC, MJ32-4 PC, MJ30-4 PB, MJ31-4 PC, MJ31-4 PB User Manual

...

MILLENNIUM (MJ30-4 PB)

(MJ31-4 PB)

(MJ32-4 PB)

(MJ30-4 PC)

(MJ31-4 PC)

(MJ32-4 PC)

INSTALLATION & SERVICE

MANUAL

IMI CORNELIUS INC.

One Cornelius Place, Anoka, Minnesota 55303

Phone (800) 238-3600 or (612) 421-6120 Fax (612) 422-3255

Part No. 85318

Rev. B 2/99

Table of Contents

Description ...............................................................................................................................Page 2

Specifications ...........................................................................................................................Page 3

Receiving & Unpacking...........................................................................................................Page 4

Installation................................................................................................................................Page 4-6

• Connect Drain

• Connect Water Supply

• Fill Ice Water Bath

• Connect Power Supply/Start Refrigeration

• Purge Air from System

• Connect B-I-B Concentrate

• Priming the Concentrate Pumps

• Sanitizing prior to Initial Use

• Apply Sealant to Base & Counter Top

Programming Instructions........................................................................................................Page 6

Brixing Concentrate .................................................................................................................Page 6

Cleaning & Sanitizing the System............................................................................................Page 7-8

• Flushing the Concentrate Lines & Valves

• Cleaning & Sanitizing the Concentrate Lines & Valves

Daily Cleaning & Maintenance................................................................................................Page 8

Maintenance of the Refrigeration System................................................................................Page 8-9

• Cleaning of the Refrigeration Components

• Ice Water Bath Cleaning

Troubleshooting Guide.............................................................................................................Page 10-17

Wiring Diagram........................................................................................................................Page 18

Exploded View/Parts Identification .........................................................................................Page 19-29

Recommended Spare Parts (Service Agents Only)..................................................................Page 32

Optional Accessories................................................................................................................Page 33

Warranty...................................................................................................................................Page 34

1

General Description

The Millennium™ is a state of the art four product B-I-B juice

dispenser. It’s integral high performance, dual speed peristaltic mini

pumps eliminate the need to purchase separate B-I-B pumps. The

Millennium™ can draw product directly from the B-I-B’s up to 50

feet away (15 feet vertically) allowing for greater installation

flexibility! Additionally, the Millennium™ incorporates a unique

valve assembly which mixes the concentrates more thoroughly than

similar models.

Wilshire realizes that counter space is at a premium in any

operation. The Millennium™ maximizes the use of counter space by

providing four product capability in a 15 inch wide chassis. Because

the air circulation is through the top, the Millennium™ can be

installed with zero clearance in the back. For improved

serviceability, all components can be accessed through the top or

front without disturbing equipment placed on either side.

With it’s innovative compact design, reduced operating expense, ease of use and service we’re certain the

Millennium will meet the most demanding conditions for many years to come.

2

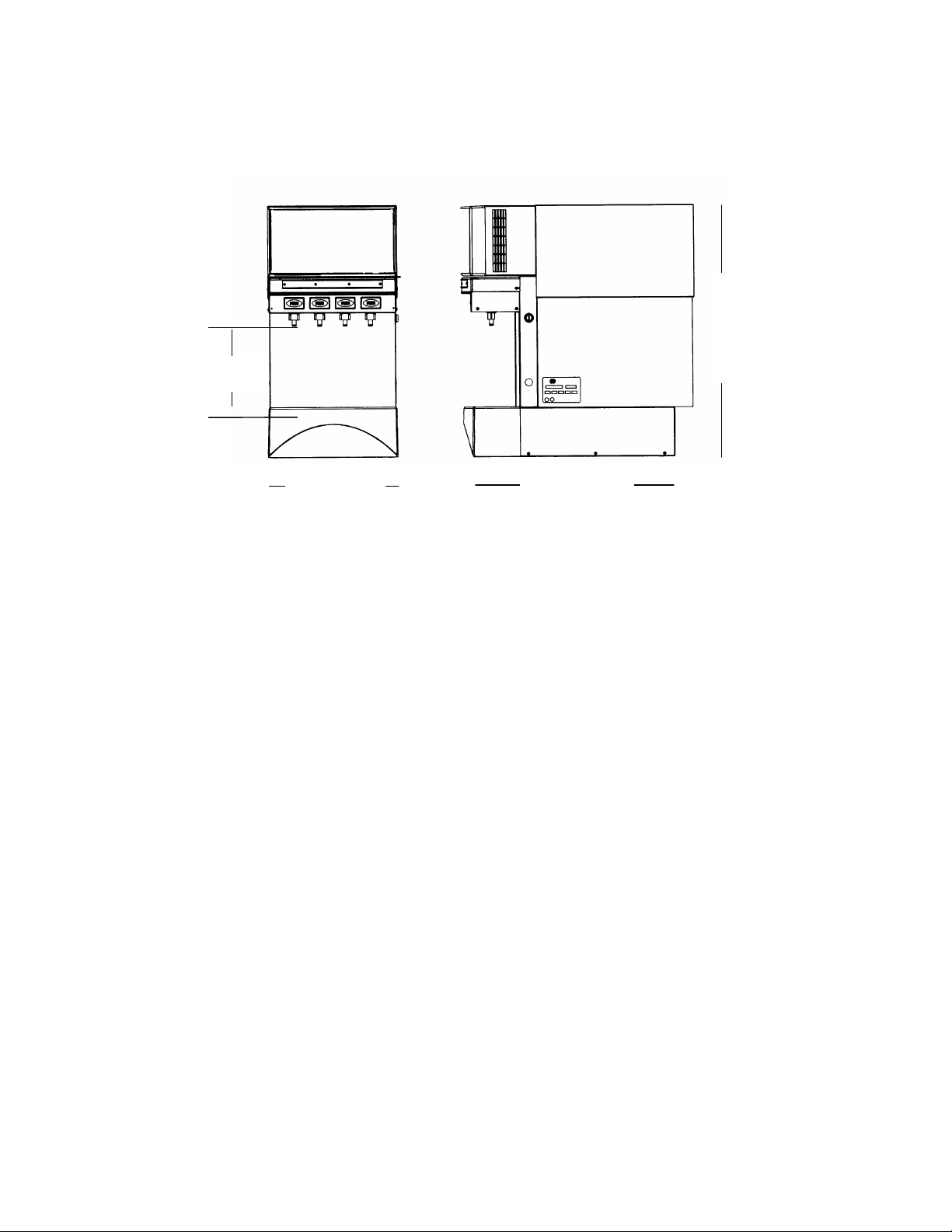

9-1/2 in.

30 in. (76.2 cm)

(24.13 cm)

Specifications

15 in. (38.1 cm)

28.25 in. (71.75 cm)

Model Number .........................................................................................................................MJ30-4

Electrical Ratings .......................................................................... 115VAC / 1 Phase / 60 Hz, 10 Amps

Electrical Connection .................................................................... 3 Prong Plug w/ Ground (supplied)

....................................................................................................... 2 Prong Plug w/ Ground (supplied with

....................................................................................................... export modles)

Power Supply ................................................................................ 15 Amp @ 120 volts

....................................................................................................... 10 Amp @ 220 volts

Water Requirements...................................................................... 3/8 in. (9.5 mm.) SAE male flare inlet

....................................................................................................... 20-100psi (1.4-7bar) max. static

pressure

....................................................................................................... 3.0 oz. (88.7 ml.) water flow per second

Refrigeration.................................................................................. 8.5 oz. R-134a Refrigerant

....................................................................................................... 1/3 hp. Compressor

....................................................................................................... Test Pressures:

....................................................................................................... High 460 psi (31.2 bar)

....................................................................................................... Low 200 psi (13.5 bar)

....................................................................................................... Air Cooled Condenser

Recommended Clearance..............................................................18 in. (45.72 cm.) on top, 4 in. on sides

Weight........................................................................................... Shipping, 150 lbs (68.1 kg.)

....................................................................................................... Operation, 241 lbs (109.4 kg.)

Approvals ...................................................................................... U.L., C.U.L., N.S.F.

* Low speed rating is 2/3 of the high speed

3

Receiving & Unpacking

1. Inspect the carton and note any damage,

regardless if it appears minor. If the carton is

damaged, note on the consignee copy of the

freight invoice “exterior carton damage concealed damage possible.”

4. Remove the four 9/16” (15 mm) retaining

bolts from the underside of the shipping

pallet by carefully tilting the dispenser from

side to side.

5. With the assistance of another person, lift

the dispenser from under the base and place

it on the counter.

2. Cut the plastic banding strap and remove the

exterior carton sleeve, internal fillers and

plastic bag around the dispenser. Carefully

inspect for damage.

Note: IMI Cornelius is not responsible for

damaged freight. If damage is found, you

must save all packaging material and

contact the freight carrier. Failure to

contact the carrier within 48 hours of

receipt may void your claim.

3. Confirm receipt of the installation kit

#720202300 packaged with the dispenser. If

any item is missing, contact our customer

service department at 1-800-238-3600

Monday - Friday between the hours of

8:00 AM and 4:30 PM CST.

Kit Contents:

Qty Description

4 3/8” barb

4 3/8” swivel nut

5 3/8”x3/8” elbow barb

6 3/8” nylon washer

10 #170 clamps

10 ft. 3/8” braided tubing

4 ft. 1/2” I.D. clear tubing

1 1/2”x1/2” 90o elbow

4 Generic B-I-B connectors

2 Flavor strip kits

1 Installation template

The dispenser is extremely heavy when

operational. Make certain the counter can

support a minimum of 300 lbs directly

below the dispenser.

Installation

Typically the dispenser is placed directly on the

counter and a food grade silicone sealant applied

around the base. However, an optional leg kit is

available. The following instructions assume the

optional leg kit will not be used.

Depending on the type of counter, it may be

necessary to provide access through

the counter at the rear of the dispenser

for the drain, power, water and

concentrate connections. Refer to the

template enclosed in the installation kit.

Connect Water Supply:

Water pipe connections and fixtures directly

connected to a potable water supply shall be

sized, installed, and maintained according to

federal, state, and local laws.

Wilshire recommends that a ½” O.D. copper

supply line with a shut-off valve and water filter

be located within 3-6 feet (0.91-1.83 m) of the

dispenser.

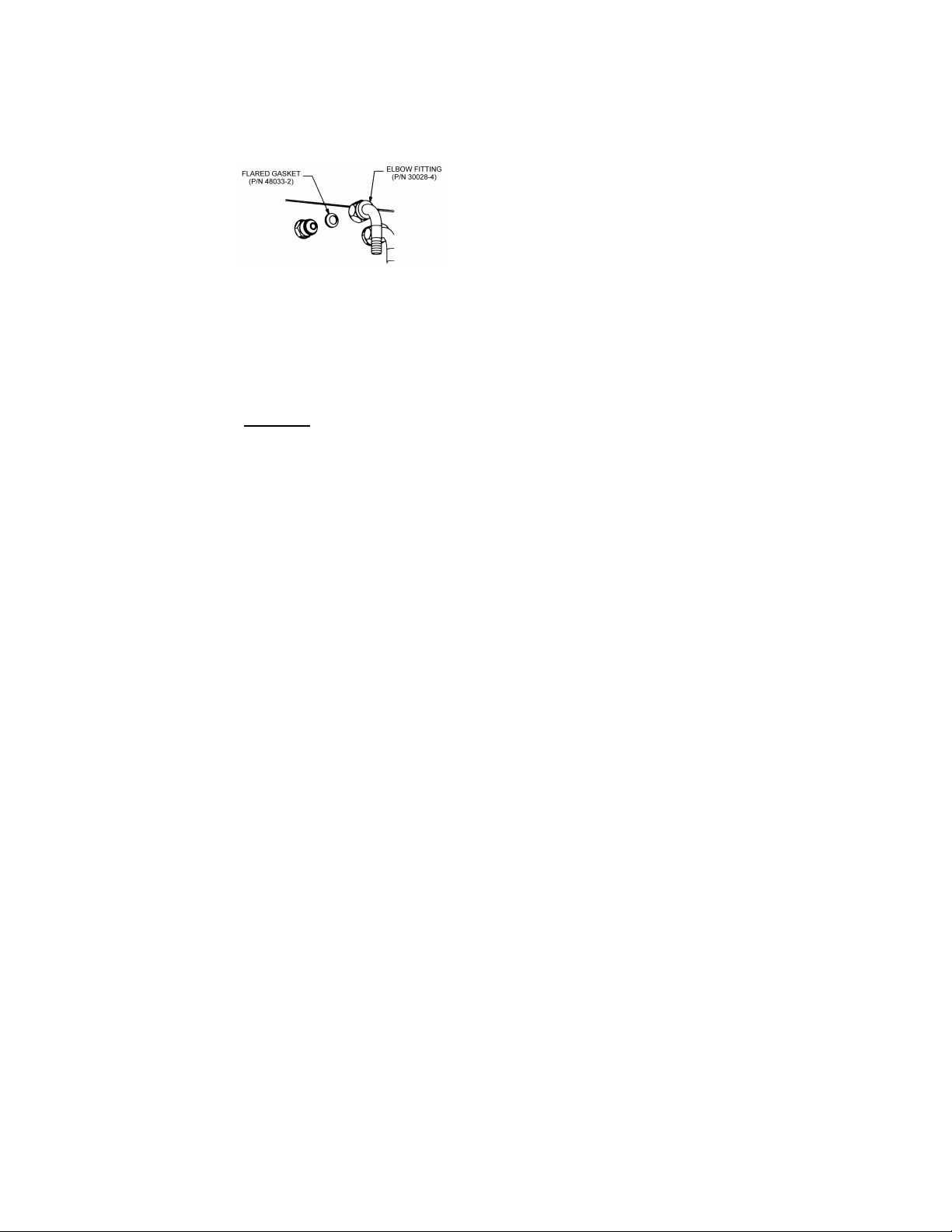

a. Assemble the 3/8” braided water supply line

furnished in the Installation Kit by attaching

the straight barb on one end and the elbow

barb on the other. Secure with clamps

provided.

4

b. Insert a 3/8” nylon washer into the elbow

barb of the supply line. Connect the

assembled

supply line

to the water

inlet fitting

located on

the rear of

the dispenser.

c. Connect the water supply line to the shut

off. Turn on the water and check for leaks.

NOTE: The dynamic water pressure must be 20

PSIG (1.4 bar) minimum to ensure correct valve

flow control and must not exceed 100 PSIG

(7 bar) to avoid valve damage.

Connect B-I-B Concentrate

a. Attach the supplied 3/8” (9.5mm) elbow

barbs to the end of each 3/8” I.D. B-I-B

concentrate supply line (not supplied).

Secure with clamps provided. Insert a 3/8”

nylon washer into the elbow barb and

connect the supply lines to the rear of the

dispenser noting the valve numbering

(numbered 1-4 from left to right as viewed

from the front of the dispenser).

b. Route the concentrate supply lines to the

B-I-B location and attach the gray plastic

B-I-B connector (supplied) to the end of

each line. Secure with clamps provided.

Fill Ice Water Bath:

a. Remove the top cover

b. Remove the large red plastic plug from the

filler hole in the top of the refrigeration

deck.

c. Fill the water bath with cool water until it

begins to trickle out of the overflow tube.

d. Reinstall the red plastic plug and top cover.

Connect Power Supply / Start

Refrigeration:

a. Start the refrigeration system by plugging

the power cord into a 115 VAC (+ 10%),

15 amp grounded receptacle.

The Millennium forms an ice bank of

approximately 30 lbs (13.61 kg) in 4-5 hours at a

room temperature of 75oF (24oC). Once the ice

bank has grown to the proper size, the ice bank

control will shut down the refrigeration circuit.

NOTE: It is normal to see water trickle from

the over flow as the ice bank forms.

Connect Drain:

a. Attach the clear drain hose to the barb fitting

on the drip tray. Route the drain hose out

from the rear of the dispenser and connect it

to a suitable drain source, ensuring

compliance with all federal, state, and local

plumbing codes. Slide the drip tray into

place.

Purge Air from the Water Coil

Prior to initial use, purge all air from the valves

by pushing the dispensing switch repeatedly.

Continue until a steady flow of water is

observed. Repeat the above on the remaining

valves.

Priming the Concentrate Pumps

a. Turn off the water supply.

b. Connect the concentrate lines to their

respective B-I-B.

c. Depress and hold each start button until

concentrate is observed flowing from the

dispense nozzle.

d. Turn on the water supply.

5

Sanitizing Prior to Initial Use

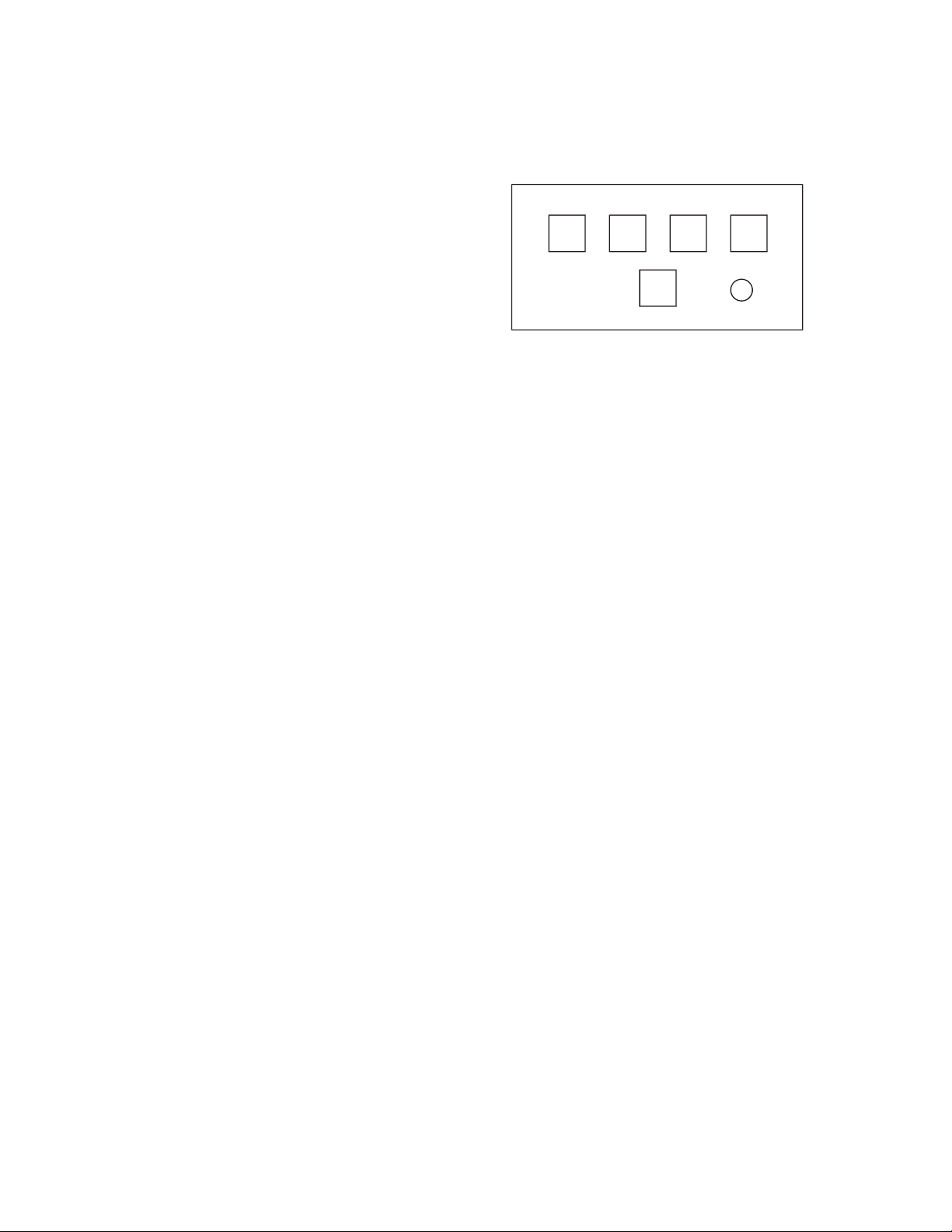

L.E.D.

CANCEL/POUR

The beverage system must be cleaned and

sanitized after installation is completed to safe

guard against any possible contaminants which

may have entered the system during transport or

installation. Refer to the “Cleaning & Sanitizing

the System” section of this manual for

procedures.

Apply Sealant to Base & Countertop

NOTE: The portion control has a full memory

retention in case of a power failure.

SMALL

S

MEDIUM

M

LARGE

L

▲▼

EXTRA-LARGE

XL

If the optional legs are not used to raise the

dispenser off the counter, the entire perimeter of

the base must be sealed at the counter top with

silicone (or other food grade approved sealant)

in order to comply with N.S.F. standards. Refer

to the template supplied in the Installation Kit.

Programming Portion

Control (optional)

a. Simultaneously, press and hold “S” (small)

and “XL” (extra large) push button switches

on the Coded Autoset Portion Control

Module until the LED light in the lower

right hand corner of the module starts

blinking. Release the switches. The blinking

LED indicates the programming mode is

active.

b. Place the cup under the white mixing valve

nozzle and push the selected size button

(small, medium, large, or extra large). Hold

the button in until the cup fills to the desired

portion, then release the button. Repeat the

above procedure for the remaining sizes.

CANCEL/POUR ▲▼:

a. Push and release cancel/pour button to stop

the valve from dispensing.

b. Push and hold for a continuous pour.

Brixing Concentrate

The following procedures describe how to adjust

the water to concentrate ratio (brix) according to

taste. Contact your concentrate supplier for

recommended brix ratios.

a. Remove the flavor strip cover above the

dispense valves.

b. Sample the finished drink. Increase or

decrease the water ratio by turning the water

flow control screw clockwise (more water)

or counterclockwise (less water) until the

desired water to concentrate ratio is

achieved. Repeat procedure on remaining

valves.

c. Replace the flavor strip cover.

c. After programming all the drink sizes, press

and release the “cancel/pour” ▲▼ switch to

return the Coded Autoset Portion Control to

the operational mode. The blinking LED

light will go out.

d. If at a future date, it is decided to change the

portion size of the drinks, the individual

sizes can be adjusted by the above

procedure. It is not necessary to reprogram

every size.

NOTE: If the flow control does not respond

there may be debris caught between the internal

ceramic spool and sleeve. Try dislodging the

debris by pressing the dispense switch several

times or turning the flow control adjustment

screw all the way in and out several times.

6

Cleaning & Sanitizing the

System

c. Connect the bag valve to the gray bag

connector and submerse the parts in the

bucket of hot water.

The dispenser must be cleaned and sanitized

after installation and as required by state and

local health departments, or every 3 months

minimum. Your state or local health codes may

require more frequent and extensive sanitizing

procedures.

Cleaning and Sanitizing Equipment

and Supplies:

• Recommended sanitizer/cleaner:

Stera-Sheen® Green Label prepared to

ensure 200 ppm of available chlorine

(one-2 oz. packet/1 gallon (3.8 L) of water =

200 ppm). Solution temperature should be

between 80°F - 100°F (26.7°C - 37.8°C).

• One clean 5 gallon (19 L) bucket

• One clean 1 gallon (3.9 L) container or

bucket

• Clean non-abrasive clothes

• A small brush

• Three empty bag in the box bags (to cut

valve fittings off)

Flushing the Concentrate Lines &

Valves

Cleaning and sanitizing is not required for

potable water circuits. Potable water lines

should remain connected and operational during

the cleaning and sanitizing procedures for juice

circuits.

a. Fill the 5 gallon (19 L) bucket with clean

extremely hot tap water, approximately

140oF (60oC).

b. Take the three empty bag in the boxes and

remove the bags from the carton. With

scissors, cut the bag valve off of the bag and

clean the valve by rinsing it under hot tap

water.

d. Depress and hold the dispense button until

the concentrate has been fully purged from

the product lines and valves.

IMPORTANT

Do Not flush more than three valve circuits

simultaneously.

e. Once the concentrate is purged, pulse each

valve for 15 seconds on and then release the

button. Repeat this pulsing for 15 cycles for

each circuit being cleaned. Once the 15

cycles have been completed, allow each

valve to dispense for 3 continuous minutes.

f. Remove the nozzles and static mixers from

the dispenser and rinse them under hot tap

water to remove any remnant of excess

concentrate. Repeat for each circuit to be

cleaned.

g. Replace the nozzles and static mixers into

their proper location.

h. Discard any remaining hot water left in the

bucket.

Cleaning & Sanitizing the

Concentrate Lines and Valves

a. Prepare 5 gallons (19 L) of Stera-Sheen®

Green Label cleaning and sanitizing solution

by mixing one 2 oz. packet/1 gallon (3.8 L)

of potable water. This will provide enough

sanitizing solution to clean and sanitize all 4

concentrate circuits for most installations.

Installations that have 50 or more feet of

concentrate line may require more sanitizing

solution.

IMPORTANT

Use potable water at 80°F-100°F (26.7°C-

26.7°C) to create solution. Water

temperatures above this range will

breakdown the chlorine count and minimize

sanitation.

7

b. Submerse the bag connector and bag valve

assembly into the bucket of sanitizing

solution.

Daily Cleaning and

Maintenance

c. Depress and hold the dispense button until

sanitizing solution is dispensed through the

mixing valves nozzle.

d. Pulse each valve for 15 seconds on and then

release the button. Repeat this pulsing for 15

cycles for each circuit being sanitized. Once

the 15 cycles have been completed, allow

the sanitizing solution to stand in the

product lines and valves for 30 minutes.

e. While waiting, remove the nozzles and static

mixers and place them into a separate

container with 2 qts. (1.9 L) of sanitizing

solution. Agitate vigorously using the small

brush to remove any excess concentrate.

Allow the parts to soak for 30 minutes.

f. Clean the dispensing valves mixing chamber

with the brush and sanitizing solution (this is

the cavity from which the nozzle is

removed).

a. On a daily basis, clean the external cabinet

splash areas using a clean damp cloth.

Remove and wash the cup rest, dispensing

nozzles, and static mixers with clean water.

Wipe dry with a clean soft cloth.

b. Wipe the drip tray in place on the unit, wash

the tray out with a mild soap solution, then

rinse the tray by pouring water down the

drip tray’s drain.

c. Clean all external surfaces of the dispenser

with a sponge and a mild soap solution.

Rinse the sponge out with clean water, then

wring the excess water from the sponge and

wipe all external surfaces of the dispenser.

d. Wipe the dispenser dry with a clean soft

cloth. DO NOT USE ABRASIVE TYPE

CLEANERS. Install the cup rest,

dispensing nozzles, and static mixers on the

dispenser.

g. Replace the nozzles and static mixers into

their proper locations and discard the

sanitizing solution used to soak them in.

Note: Do not reuse the sanitizing solution used

to clean the nozzles, static mixers, etc.

h. Activate the dispensing valves for two more

cycles (15 seconds on then off) with

sanitizing solution then run solution

continuously through the dispensing valves

for 2 minutes.

i. Disconnect the bag valves from the gray bag

connectors and re-connect the bag

connectors to their appropriate product bags.

j. Depress and hold each dispense button until

juice appears at the outlet of the dispensing

nozzle. Dispense and discard two 8 oz.

(237 ml) cups of juice and verify that there

is no chlorine off taste

Maintenance of the

Refrigeration System

Cleaning of the refrigeration components

should be performed by a qualified service

technician.

a. Continuous maintenance of this dispenser is

a basic requirement for proper operation and

sanitation, including all support equipment

utilized in the daily operation of this

equipment.

b. Cleaning of the Refrigeration Components:

c. Disconnect the power before removing the

top bonnet of the dispenser.

d. The dispenser’s ventilation grilles and the

condenser fins should be cleaned

periodically to maintain efficient

refrigeration and to avoid compressor

failure. The condenser fins can be cleaned

8

with a vacuum cleaner or a soft bristle

brush.

e. Clean the exterior surfaces of the

compressor, agitator motor, fan motor, and

fan blade with a damp cloth to wipe off the

accumulated dust.

Ice Water Bath Cleaning

The water bath should be cleaned to obtain

maximum cooling efficiency. It is recommended

that the water bath be cleaned two to four times

annually, depending upon local conditions

and/or as required by state and local health

departments.

A convenient time to do this is at the time the

dispenser is being sanitized. To save time, the

water bath can be drained while the dispenser is

being sanitized.

a. Remove the cup rest and splash panel to

access the water bath’s drain hose. Extend

the drain hose to a suitable waste receptacle

and allow the water bath to drain.

b. Remove the dispenser’s top bonnet by

removing the two screws located on the top

of the bonnet. While lifting the bonnet up

and away from the dispenser, unplug the

merchandiser electrical cord from the power

strip located on the refrigeration deck.

c. In order to remove the refrigeration deck for

the water bath and evaporator cleaning,

remove the two screws that secure the deck

to the cabinet structure. Unplug the

refrigeration deck’s main power strip cord

from the dispenser’s power cord. Disconnect

the red, white and blue 12 pin plugs from the

electrical box. Disconnect the key switch a

by unplugging the white 2 pin plug at the

transformer.

Note: It will be necessary to melt the ice bank

to be able to pull the refrigeration deck up and

away from the dispenser. Warm water may be

used to accelerate the melting. In order to

prevent ice bank control damage, do not direct

the warm water stream on to the sensing bulb

of the ice bank control. Never use an ice pick

or other instrument to remove ice from the

evaporator. Such practice can result in a

punctured refrigerant circuit or damage to the

water bath tank.

d. Once the ice bank is sufficiently melted, lift

the entire refrigeration deck up and away

from the water bath by lifting the deck using

it’s service handle strap.

e. Prepare 1 gallon (3.9 L) of cleaning and

sanitizing solution (see “Sanitizing the

Concentrate Lines & Valves”). Pour the

cleaning and sanitizing solution into the

water bath and clean the sides and bottom of

the tank, the product coils, and associated

brackets with a fiber brush.

f. Utilizing the cleaning and sanitizing solution

in the water bath, the fiber brush, and a

clean cloth soaked with sanitizing solution,

clean the refrigeration deck’s evaporator

coils, agitator motor shaft and blade, and the

ice bank sensing bulb.

g. Drain the cleaning and sanitizing solution

from the water bath and rinse/flush all the

components with clean water.

h. Re-install the refrigeration deck into the

water bath and secure with two screws.

i. Connect the refrigeration deck’s power strip

to the dispenser’s power cord. Connect the

red, white and blue 12 pin plugs to the

electrical box. Connect the key switch to the

transformer.

j. Fill the water bath with cool potable water

until water begins to flow from the overflow

tube.

k. Plug the merchandisers power cord into

power strip located on the refrigeration deck

and re-install the top bonnet. Secure the

bonnet assembly with two screws.

l. Install the splash panel and cup rest and plug

the dispenser’s power cord into the electrical

outlet.

9

Troubleshooting Guide

Problem Probable Cause Remedy

DISPENSER IS TOTALLY

INOPERATIVE

DISPENSER WILL NOT

COOL

Drink temperature should be

35-45°F (2-7°C)

No power present at the

source.

Power is present at the

source...dispenser is still

inoperative.

Refrigeration shut off switch

is in the off position.

Low water bath level.

Depleted ice bank ( not

applicable after period of

heavy usage.)

Check the power circuit for a blown

fuse or tripped circuit breaker. Check

the supply line for the proper

amperage and voltage

ratings.....dedicated 15 amps /115

volts.

Check the power cord connection

located behind the front splash panel.

Refrigeration shut off switch is

located on the top of the dispenser .

This switch will disable the

compressor and the condenser fan

motor. Be sure the switch is in the on

position.

Check water bath level. If 2 gallons

or more are added, cause of problem

has been confirmed.

Check compressor. If running, allow

the system time to recover

(approximately 1 hour). If

compressor is not running or the

system is not recovering see the

Refrigeration System

Troubleshooting section.

WITH POWER PRESENT,

UNIT WILL NOT DISPENSE

ALL VALVES.

Defective Ice bank control.

Key lock switch in the OFF

position.

Transformer not connected or

defective.

Fuse blown between the

transformer and voltage

regulator boards.

10

See Refrigeration System

Troubleshooting section.

Check position of the key lock

switch. Check for loose wire

connections. Run continuity check,

replace as needed.

Check the connection between the

power strip and the transformer.

Check transformer output at terminal

junction on control box for 26 VAC.

Check the fuse located in the

electrical box, left side. This box is

located on the refrigeration deck and

will require the removal of the upper

bonnet. Replace fuse as needed.

Troubleshooting Guide

Problem Probable Cause Remedy

UNIT DISPENSING

CONCENTRATE ONLY NO

WATER TO ALL VALVES

FROM SINGLE VALVE

UNIT WILL NOT DISPENSE

WATER OR

CONCENTRATE.

No water reaching dispenser

from the water supply line.

Water pressure over 100 psi or

7 bar. High pressure will not

allow the water solenoids to

open.

Freeze up of water coil.

Inoperative or defective push

button switch, or portion

control board.

Defective Voltage Regulator

(VRB) board.

Check line to see if the water is shut

off at the source.

Install regulator onto incoming water

line to reduce the pressure to between

30 and 80 psi. (2-5- bar).

Refer to the Refrigeration System

Troubleshooting section.

Check for loose or broken wire

connections at the switch. Check the

continuity of switch. Replace as

needed.

The VRB boards are contained in the

electrical box mounted on the

refrigeration deck.. There is one for

each valve.

CAUTION: Access to this panel

requires the removal of the upper

bonnet while the dispenser is

energized and operational.

Check the power input for 26 VAC

and the output for 28 VDC.

FROM SINGLE VALVE,

UNIT IS DISPENSING

CONCENTRATE ONLY.

Inoperative water valve

solenoid coil.

Solenoid makes clicking

sound when energized, but

still does, not function.

Flow control binding or

defective.

11

Check to see all wire connections are

secured at the coil. Check power for

26 VDC. If power is present, coil

maybe defective , replace as needed.

Armature maybe stuck, disassemble

and check function. Return spring

could also be defective replace as

needed.

Disassemble the coil assembly and

check plunger seal for defects.

Replace as required. Inspect valve

seat for restrictions.

Disassemble flow control assembly

and check the spool and sleeve

assembly . Be sure the spool moves

freely within the sleeve and there are

no restrictions.

Troubleshooting Guide

Problem Probable Cause Remedy

FROM SINGLE VALVE,

UNIT IS DISPENSING

WATER ONLY.

Concentrate container empty.

BIB connector is not engaged

or improperly installed.

Air leak in product suction

line.

No power at the pump motor.

Defective gear motor

assembly.

Replace.

Check BIB connector for proper

installation. Plunger should be

completely inserted with concentrate

filling the line to the dispenser.

Check the 3/8 flare connection where

the product line attaches to the unit.

Tighten fitting using a flare gasket. If

line is drawing air, pump will not

prime.

Check for broken or loose wire

connection going to pump motor.

Check for 26 VDC at pump motor

when the dispense button is

energized.

Check motor function by energizing

circuit with the dispense button. If

motor runs, but pump does not turn, a

broken gear box is indicated. The

pump motor and gear box are

replaced as a unit.

DISPENSER IS BRIXING

OUT TOO HIGH.

Pump running backwards.

Defective concentrate pump

tubing.

Supply water pressure too low.

Defective flow control.

Check the direction of pump

rotation...correct rotation is clockwise

as viewed from the front of the unit.

If pump is turning in a counter

clockwise direction, this indicates the

pump wires are reversed.

Check the pump tubing for ruptures,

wear, etc. Replace as needed

following the instructions printed in

this manual.

Water pressure must be 20 psi

flowing or above.

Disassemble and check flow control

assembly for binding, defective

compensating spring , trapped debris.

Be sure the spool moves freely within

the sleeve, replace parts as needed.

12

Troubleshooting Guide

Problem Probable Cause Remedy

DISPENSER IS BRIXING

OUT TOO HIGH. (Cont.)

DISPENSER IS BRIXING

OUT TOO LOW.

Low viscosity or highly

concentrated concentrate.

Example 11 to 1 ratio.

Supply water pressure is too

high.

Defective or improperly

regulating flow control .

Locate the pump switches grouped

behind the front splash panel. They

are marked SPEED SWITCH with

the corresponding valve number.

Placing the switch in the low position

slows down the concentrate pumping

rate requiring less water to brix.

Water pressure has a high limit of

100 psi/ 7 bar or over. Place regulator

in supply line to bring pressure down

to 4 bar/ 50 psi flowing.

High water pressure will cause the

flow control not to regulate properly.

If the problem exists after the

pressure has been reduced to 50 psig/

4 bar, the flow control maybe

defective.. Disassemble and check the

spool and sleeve function and the

compensating spring . Replace parts

as required.

Speed switch in the low

position.

Air leak in the concentrate

suction line.

Worn concentrate pump

tubing.

Defective poppet valve and or

spring.

Pump speed switch is in the low

position. Move switch to high

increasing the pumping rate of the

concentrate.

Check that the concentrate line

connection is secured tightly to the

dispenser with the proper gaskets.

Check the connector at the

concentrate source to be sure it is

properly attached.

Remove the front half of the

concentrate pump and inspect the

tubing . Worn or stretched tubing will

decrease the amount of concentrate

pumped. After 1 year tubing should

be replaced.

Disassemble the right side of the

valve which contains the syrup

poppet assembly. Be sure the valve is

not binding, free of debris, return

spring is actuating and the diaphragm

is not torn or punctured.

13

Troubleshooting Guide

Problem Probable Cause Remedy

WATER LEAKS FROM

BOTTOM OF DISPENSING

VALVE.

WATER CONTINUOUSLY

DRIPS FROM NOZZLE.

UNIT CONTINUES TO

DISPENSE AFTER BUTTON

HAS BEEN RELEASED.

Nozzle pieces improperly

assembled.

Water solenoid valve not

shutting off tightly.

Inoperative or defective push

button switch, or portion

control board.

Relay on voltage regulator

board hangs up or is stuck

open.

Static mixer inserted in nozzle body

upside down. Cone shaped end must

be visible when remounting the

nozzle assembly to the dispenser.

Disassemble water solenoid located

at the valve and check for foreign

material in the valve seat. Check the

armature for binding, check the

plunger and the seat for defects.

Replace parts as needed.

Check the operation of the push

button for sticking. Check continuity

of switch. Replace as needed.

CAUTION: Access to this panel

requires removal of the bonnet while

the dispenser is plugged in and

operational. *Voltage regulator board

is found in the electrical box mounted

to the refrigeration deck. There is one

board for each valve. Gently tap the

relay. If dispensing stops, relay was

hung up . If tapping the relay solves

the problem, it should be noted that if

a relay sticks once , it will probably

stick again. Replace as needed.

TWO OR MORE PUMPS

OPERATE WHEN ONLY

ONE BUTTON IS PUSHED.

Defective Voltage Regulator

(VRB) Board.

Insulator pad missing or not

properly positioned between

the transistor on VRB board

and mounting bracket.

14

Pull the connector marked DOOR ,

lower right hand connector on the

VRB board. If the unit still continues

to dispense the VRB board is

defective and needs to be replaced.

On the valve that is dispensing in

error, check the insulator pad

between the transistor on the top of

the VRB board and the mounting

bracket. If this pad is missing or

improperly aligned, the VRB board

will make contact with the bracket.

Current will run through the bracket

and set off the valve. Refer to

drawing found in this manual.

Troubleshooting Guide

Problem Probable Cause Remedy

TWO OR MORE PUMPS

OPERATE WHEN ONLY

ONE BUTTON IS PUSHED.

(Cont.)

WITH POWER PRESENT

DISPENSER WILL NOT

COOL

Drink temperature should be

35-45°F

2-7°C

VRB Board mounting screw

insulator is missing or

improperly installed.

Refrigeration shut off switch

is in the off position.

Depleted ice bank (not

applicable after period of

heavy usage.)

Check the corresponding VRB board

to the valve that is dispensing in

error. Where the screw mounts the

transistor to the bracket, be sure that

the spacer bushing is present and the

screw is not over tightened. Screw

contact with the bracket will cause a

short and the firing of the valve when

other valves are energized.

Refrigeration shut off switch is

located on the top of the dispenser.

This switch will disable the

compressor and condenser fan motor.

Be sure the switch is in the on

position.

Remove rear bonnet covering the

refrigeration deck. CAUTION should

be observed when working in this

area as the dispenser is energized and

operational. Check to see if the

compressor is running . If so allow

the system to recover (approximately

1 hour).

WITH POWER PRESENT

COMPRESSOR WILL NOT

RUN.

(Compressor shell is cold to

touch.)

COMPRESSOR RUNS BUT

NO COOLING IS TAKING

PLACE.

Loose or broken wire

connections.

Defective compressor start

component.

Ice bank control not connected

or defective.

Low refrigerant charge.

Refrigerant restriction.

Check the wire connections at the

compressor. Be sure they are tightly

secured.

Check the compressor start relay.

Replace as required.

Check the ice bank control

connections. To test, place jumper

between the 2 leads. If the

compressor starts ,the ice bank

control is defective.

Contact a refrigeration service

technician. They will check for leaks

(sign of oil at joints and fitting) and

will recharge if necessary.

Refrigeration technician will examine

the system for, kinks in lines,

restrictions, etc. Heat exchanger may

need to be replaced.

15

Troubleshooting Guide

Problem Probable Cause Remedy

COMPRESSOR RUNS BUT

NO COOLING. TRIPPING

OVERLOAD.

(Compressor shell is hot to

touch).

Condenser fan not running.

Inadequate air flow through

the dispenser.

Blocked condenser fins.

Ambient air over 100°F 38°C.

Check that the condenser fan is

running. If the fan is binding or

turning slowly, an overload condition

will occur.

Air flow is top front in, exhaust out

the rear. NEVER PLACE

ANYTHING ON TOP OF THE

DISPENSER. This will block the

airflow over heating the compressor

and causing it to trip the overload.

Remove the rear bonnet and check

the condenser fins. If unit is run in a

dusty environment, condenser fins

can become clogged, stopping the air

flow.

Brush out and clean with vacuum.

If the dispenser is working in an

environment over 100° ambient or is

drawing in discharged air, during a

heavy period, the unit may trip the

overload.

UNIT IS DISPENSING

CONCENTRATE ONLY

REFRIGERATION SYSTEM

HAS BEEN RUNNING FOR

EXTENDED PERIOD

WITHOUT SHUTTING OFF

FROZEN WATER COIL.

Defective overload.

Defective compressor.

Insufficient water level in the

water bath.

Agitator motor not operating.

Improperly located ice bank

control sensor.

Overload works on shell temperature

and amperage draw and can be

defective. Replace as needed.

Refrigeration technician will verify if

the compressor is defective and needs

to be replaced.

See the Start-up and Operation

Section of this manual. Be sure the

water bath is filled to fill line.

Check the agitator motor located on

the refrigeration deck. Be sure it is

plugged in and receiving power.

Check that the impeller is not

obstructed. Replace if needed.

Melt the ice bank and check the

location of the sensing bulb. Be sure

it is all the way down to the bottom

of the tube.

16

Troubleshooting Guide

Problem Probable Cause Remedy

UNIT IS DISPENSING

CONCENTRATE ONLY

REFRIGERATION SYSTEM

HAS BEEN RUNNING FOR

EXTENDED PERIOD

WITHOUT SHUTTING OFF

FROZEN WATER COIL.

Compressor not cycling off. Check the ice bank control. Be sure

that the control has not overheated

and fused the contacts together.

Replace as required.

17

Loading...

Loading...