Page 1

MILLENNIUM (MJ30-4 PB)

(MJ31-4 PB)

(MJ32-4 PB)

(MJ30-4 PC)

(MJ31-4 PC)

(MJ32-4 PC)

INSTALLATION & SERVICE

MANUAL

IMI CORNELIUS INC.

One Cornelius Place, Anoka, Minnesota 55303

Phone (800) 238-3600 or (612) 421-6120 Fax (612) 422-3255

Part No. 85318

Rev. B 2/99

Page 2

Table of Contents

Description ...............................................................................................................................Page 2

Specifications ...........................................................................................................................Page 3

Receiving & Unpacking...........................................................................................................Page 4

Installation................................................................................................................................Page 4-6

• Connect Drain

• Connect Water Supply

• Fill Ice Water Bath

• Connect Power Supply/Start Refrigeration

• Purge Air from System

• Connect B-I-B Concentrate

• Priming the Concentrate Pumps

• Sanitizing prior to Initial Use

• Apply Sealant to Base & Counter Top

Programming Instructions........................................................................................................Page 6

Brixing Concentrate .................................................................................................................Page 6

Cleaning & Sanitizing the System............................................................................................Page 7-8

• Flushing the Concentrate Lines & Valves

• Cleaning & Sanitizing the Concentrate Lines & Valves

Daily Cleaning & Maintenance................................................................................................Page 8

Maintenance of the Refrigeration System................................................................................Page 8-9

• Cleaning of the Refrigeration Components

• Ice Water Bath Cleaning

Troubleshooting Guide.............................................................................................................Page 10-17

Wiring Diagram........................................................................................................................Page 18

Exploded View/Parts Identification .........................................................................................Page 19-29

Recommended Spare Parts (Service Agents Only)..................................................................Page 32

Optional Accessories................................................................................................................Page 33

Warranty...................................................................................................................................Page 34

1

Page 3

General Description

The Millennium™ is a state of the art four product B-I-B juice

dispenser. It’s integral high performance, dual speed peristaltic mini

pumps eliminate the need to purchase separate B-I-B pumps. The

Millennium™ can draw product directly from the B-I-B’s up to 50

feet away (15 feet vertically) allowing for greater installation

flexibility! Additionally, the Millennium™ incorporates a unique

valve assembly which mixes the concentrates more thoroughly than

similar models.

Wilshire realizes that counter space is at a premium in any

operation. The Millennium™ maximizes the use of counter space by

providing four product capability in a 15 inch wide chassis. Because

the air circulation is through the top, the Millennium™ can be

installed with zero clearance in the back. For improved

serviceability, all components can be accessed through the top or

front without disturbing equipment placed on either side.

With it’s innovative compact design, reduced operating expense, ease of use and service we’re certain the

Millennium will meet the most demanding conditions for many years to come.

2

Page 4

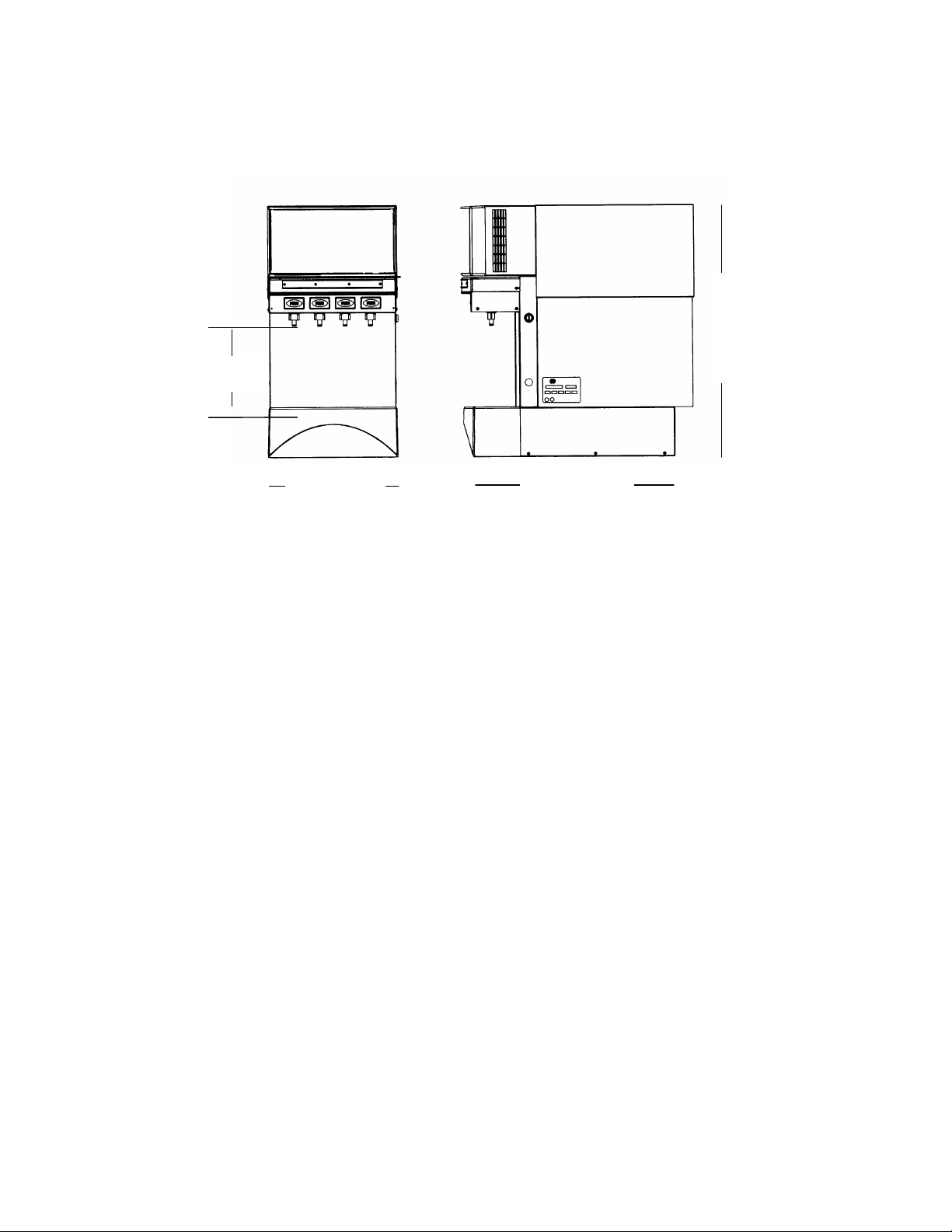

9-1/2 in.

30 in. (76.2 cm)

(24.13 cm)

Specifications

15 in. (38.1 cm)

28.25 in. (71.75 cm)

Model Number .........................................................................................................................MJ30-4

Electrical Ratings .......................................................................... 115VAC / 1 Phase / 60 Hz, 10 Amps

Electrical Connection .................................................................... 3 Prong Plug w/ Ground (supplied)

....................................................................................................... 2 Prong Plug w/ Ground (supplied with

....................................................................................................... export modles)

Power Supply ................................................................................ 15 Amp @ 120 volts

....................................................................................................... 10 Amp @ 220 volts

Water Requirements...................................................................... 3/8 in. (9.5 mm.) SAE male flare inlet

....................................................................................................... 20-100psi (1.4-7bar) max. static

pressure

....................................................................................................... 3.0 oz. (88.7 ml.) water flow per second

Refrigeration.................................................................................. 8.5 oz. R-134a Refrigerant

....................................................................................................... 1/3 hp. Compressor

....................................................................................................... Test Pressures:

....................................................................................................... High 460 psi (31.2 bar)

....................................................................................................... Low 200 psi (13.5 bar)

....................................................................................................... Air Cooled Condenser

Recommended Clearance..............................................................18 in. (45.72 cm.) on top, 4 in. on sides

Weight........................................................................................... Shipping, 150 lbs (68.1 kg.)

....................................................................................................... Operation, 241 lbs (109.4 kg.)

Approvals ...................................................................................... U.L., C.U.L., N.S.F.

* Low speed rating is 2/3 of the high speed

3

Page 5

Receiving & Unpacking

1. Inspect the carton and note any damage,

regardless if it appears minor. If the carton is

damaged, note on the consignee copy of the

freight invoice “exterior carton damage concealed damage possible.”

4. Remove the four 9/16” (15 mm) retaining

bolts from the underside of the shipping

pallet by carefully tilting the dispenser from

side to side.

5. With the assistance of another person, lift

the dispenser from under the base and place

it on the counter.

2. Cut the plastic banding strap and remove the

exterior carton sleeve, internal fillers and

plastic bag around the dispenser. Carefully

inspect for damage.

Note: IMI Cornelius is not responsible for

damaged freight. If damage is found, you

must save all packaging material and

contact the freight carrier. Failure to

contact the carrier within 48 hours of

receipt may void your claim.

3. Confirm receipt of the installation kit

#720202300 packaged with the dispenser. If

any item is missing, contact our customer

service department at 1-800-238-3600

Monday - Friday between the hours of

8:00 AM and 4:30 PM CST.

Kit Contents:

Qty Description

4 3/8” barb

4 3/8” swivel nut

5 3/8”x3/8” elbow barb

6 3/8” nylon washer

10 #170 clamps

10 ft. 3/8” braided tubing

4 ft. 1/2” I.D. clear tubing

1 1/2”x1/2” 90o elbow

4 Generic B-I-B connectors

2 Flavor strip kits

1 Installation template

The dispenser is extremely heavy when

operational. Make certain the counter can

support a minimum of 300 lbs directly

below the dispenser.

Installation

Typically the dispenser is placed directly on the

counter and a food grade silicone sealant applied

around the base. However, an optional leg kit is

available. The following instructions assume the

optional leg kit will not be used.

Depending on the type of counter, it may be

necessary to provide access through

the counter at the rear of the dispenser

for the drain, power, water and

concentrate connections. Refer to the

template enclosed in the installation kit.

Connect Water Supply:

Water pipe connections and fixtures directly

connected to a potable water supply shall be

sized, installed, and maintained according to

federal, state, and local laws.

Wilshire recommends that a ½” O.D. copper

supply line with a shut-off valve and water filter

be located within 3-6 feet (0.91-1.83 m) of the

dispenser.

a. Assemble the 3/8” braided water supply line

furnished in the Installation Kit by attaching

the straight barb on one end and the elbow

barb on the other. Secure with clamps

provided.

4

Page 6

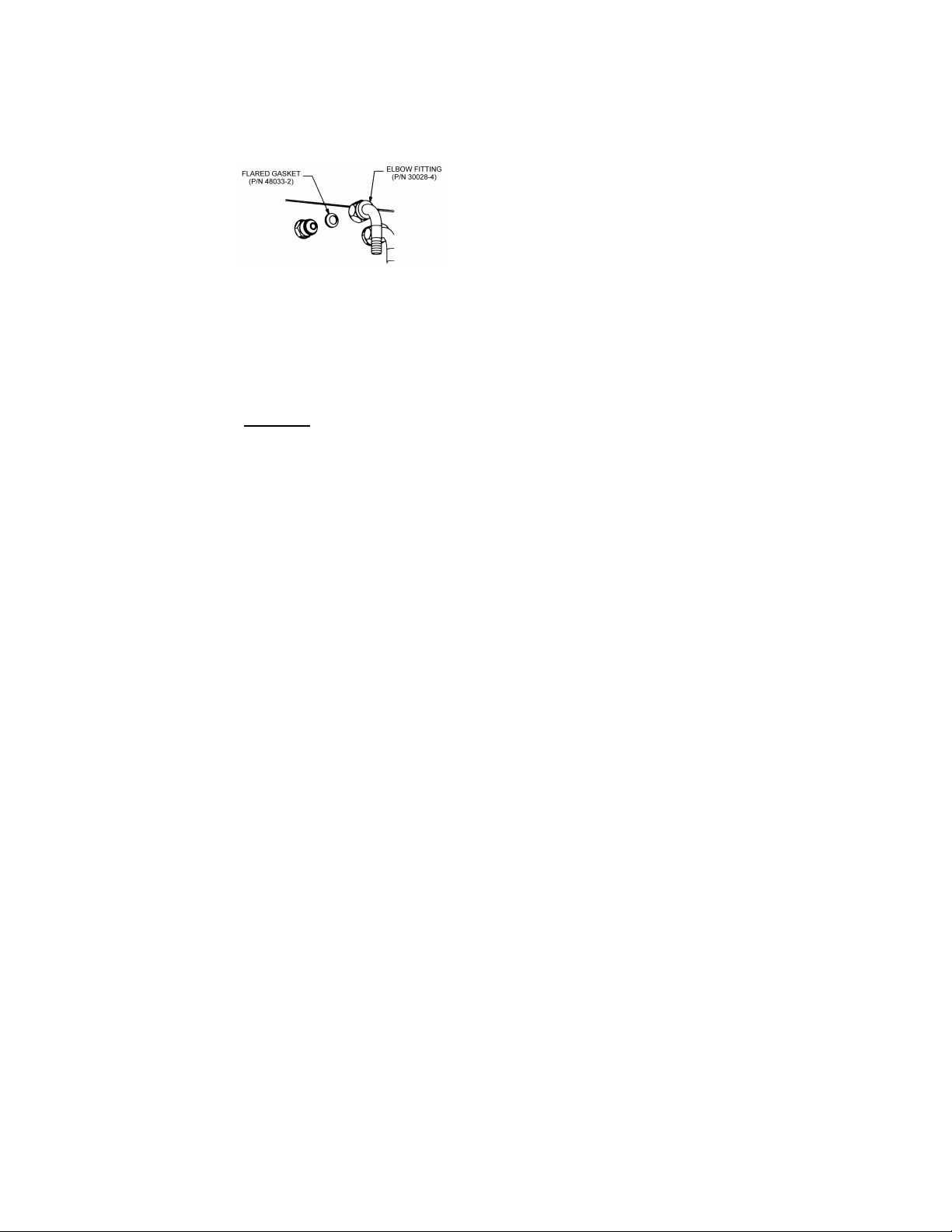

b. Insert a 3/8” nylon washer into the elbow

barb of the supply line. Connect the

assembled

supply line

to the water

inlet fitting

located on

the rear of

the dispenser.

c. Connect the water supply line to the shut

off. Turn on the water and check for leaks.

NOTE: The dynamic water pressure must be 20

PSIG (1.4 bar) minimum to ensure correct valve

flow control and must not exceed 100 PSIG

(7 bar) to avoid valve damage.

Connect B-I-B Concentrate

a. Attach the supplied 3/8” (9.5mm) elbow

barbs to the end of each 3/8” I.D. B-I-B

concentrate supply line (not supplied).

Secure with clamps provided. Insert a 3/8”

nylon washer into the elbow barb and

connect the supply lines to the rear of the

dispenser noting the valve numbering

(numbered 1-4 from left to right as viewed

from the front of the dispenser).

b. Route the concentrate supply lines to the

B-I-B location and attach the gray plastic

B-I-B connector (supplied) to the end of

each line. Secure with clamps provided.

Fill Ice Water Bath:

a. Remove the top cover

b. Remove the large red plastic plug from the

filler hole in the top of the refrigeration

deck.

c. Fill the water bath with cool water until it

begins to trickle out of the overflow tube.

d. Reinstall the red plastic plug and top cover.

Connect Power Supply / Start

Refrigeration:

a. Start the refrigeration system by plugging

the power cord into a 115 VAC (+ 10%),

15 amp grounded receptacle.

The Millennium forms an ice bank of

approximately 30 lbs (13.61 kg) in 4-5 hours at a

room temperature of 75oF (24oC). Once the ice

bank has grown to the proper size, the ice bank

control will shut down the refrigeration circuit.

NOTE: It is normal to see water trickle from

the over flow as the ice bank forms.

Connect Drain:

a. Attach the clear drain hose to the barb fitting

on the drip tray. Route the drain hose out

from the rear of the dispenser and connect it

to a suitable drain source, ensuring

compliance with all federal, state, and local

plumbing codes. Slide the drip tray into

place.

Purge Air from the Water Coil

Prior to initial use, purge all air from the valves

by pushing the dispensing switch repeatedly.

Continue until a steady flow of water is

observed. Repeat the above on the remaining

valves.

Priming the Concentrate Pumps

a. Turn off the water supply.

b. Connect the concentrate lines to their

respective B-I-B.

c. Depress and hold each start button until

concentrate is observed flowing from the

dispense nozzle.

d. Turn on the water supply.

5

Page 7

Sanitizing Prior to Initial Use

L.E.D.

CANCEL/POUR

The beverage system must be cleaned and

sanitized after installation is completed to safe

guard against any possible contaminants which

may have entered the system during transport or

installation. Refer to the “Cleaning & Sanitizing

the System” section of this manual for

procedures.

Apply Sealant to Base & Countertop

NOTE: The portion control has a full memory

retention in case of a power failure.

SMALL

S

MEDIUM

M

LARGE

L

▲▼

EXTRA-LARGE

XL

If the optional legs are not used to raise the

dispenser off the counter, the entire perimeter of

the base must be sealed at the counter top with

silicone (or other food grade approved sealant)

in order to comply with N.S.F. standards. Refer

to the template supplied in the Installation Kit.

Programming Portion

Control (optional)

a. Simultaneously, press and hold “S” (small)

and “XL” (extra large) push button switches

on the Coded Autoset Portion Control

Module until the LED light in the lower

right hand corner of the module starts

blinking. Release the switches. The blinking

LED indicates the programming mode is

active.

b. Place the cup under the white mixing valve

nozzle and push the selected size button

(small, medium, large, or extra large). Hold

the button in until the cup fills to the desired

portion, then release the button. Repeat the

above procedure for the remaining sizes.

CANCEL/POUR ▲▼:

a. Push and release cancel/pour button to stop

the valve from dispensing.

b. Push and hold for a continuous pour.

Brixing Concentrate

The following procedures describe how to adjust

the water to concentrate ratio (brix) according to

taste. Contact your concentrate supplier for

recommended brix ratios.

a. Remove the flavor strip cover above the

dispense valves.

b. Sample the finished drink. Increase or

decrease the water ratio by turning the water

flow control screw clockwise (more water)

or counterclockwise (less water) until the

desired water to concentrate ratio is

achieved. Repeat procedure on remaining

valves.

c. Replace the flavor strip cover.

c. After programming all the drink sizes, press

and release the “cancel/pour” ▲▼ switch to

return the Coded Autoset Portion Control to

the operational mode. The blinking LED

light will go out.

d. If at a future date, it is decided to change the

portion size of the drinks, the individual

sizes can be adjusted by the above

procedure. It is not necessary to reprogram

every size.

NOTE: If the flow control does not respond

there may be debris caught between the internal

ceramic spool and sleeve. Try dislodging the

debris by pressing the dispense switch several

times or turning the flow control adjustment

screw all the way in and out several times.

6

Page 8

Cleaning & Sanitizing the

System

c. Connect the bag valve to the gray bag

connector and submerse the parts in the

bucket of hot water.

The dispenser must be cleaned and sanitized

after installation and as required by state and

local health departments, or every 3 months

minimum. Your state or local health codes may

require more frequent and extensive sanitizing

procedures.

Cleaning and Sanitizing Equipment

and Supplies:

• Recommended sanitizer/cleaner:

Stera-Sheen® Green Label prepared to

ensure 200 ppm of available chlorine

(one-2 oz. packet/1 gallon (3.8 L) of water =

200 ppm). Solution temperature should be

between 80°F - 100°F (26.7°C - 37.8°C).

• One clean 5 gallon (19 L) bucket

• One clean 1 gallon (3.9 L) container or

bucket

• Clean non-abrasive clothes

• A small brush

• Three empty bag in the box bags (to cut

valve fittings off)

Flushing the Concentrate Lines &

Valves

Cleaning and sanitizing is not required for

potable water circuits. Potable water lines

should remain connected and operational during

the cleaning and sanitizing procedures for juice

circuits.

a. Fill the 5 gallon (19 L) bucket with clean

extremely hot tap water, approximately

140oF (60oC).

b. Take the three empty bag in the boxes and

remove the bags from the carton. With

scissors, cut the bag valve off of the bag and

clean the valve by rinsing it under hot tap

water.

d. Depress and hold the dispense button until

the concentrate has been fully purged from

the product lines and valves.

IMPORTANT

Do Not flush more than three valve circuits

simultaneously.

e. Once the concentrate is purged, pulse each

valve for 15 seconds on and then release the

button. Repeat this pulsing for 15 cycles for

each circuit being cleaned. Once the 15

cycles have been completed, allow each

valve to dispense for 3 continuous minutes.

f. Remove the nozzles and static mixers from

the dispenser and rinse them under hot tap

water to remove any remnant of excess

concentrate. Repeat for each circuit to be

cleaned.

g. Replace the nozzles and static mixers into

their proper location.

h. Discard any remaining hot water left in the

bucket.

Cleaning & Sanitizing the

Concentrate Lines and Valves

a. Prepare 5 gallons (19 L) of Stera-Sheen®

Green Label cleaning and sanitizing solution

by mixing one 2 oz. packet/1 gallon (3.8 L)

of potable water. This will provide enough

sanitizing solution to clean and sanitize all 4

concentrate circuits for most installations.

Installations that have 50 or more feet of

concentrate line may require more sanitizing

solution.

IMPORTANT

Use potable water at 80°F-100°F (26.7°C-

26.7°C) to create solution. Water

temperatures above this range will

breakdown the chlorine count and minimize

sanitation.

7

Page 9

b. Submerse the bag connector and bag valve

assembly into the bucket of sanitizing

solution.

Daily Cleaning and

Maintenance

c. Depress and hold the dispense button until

sanitizing solution is dispensed through the

mixing valves nozzle.

d. Pulse each valve for 15 seconds on and then

release the button. Repeat this pulsing for 15

cycles for each circuit being sanitized. Once

the 15 cycles have been completed, allow

the sanitizing solution to stand in the

product lines and valves for 30 minutes.

e. While waiting, remove the nozzles and static

mixers and place them into a separate

container with 2 qts. (1.9 L) of sanitizing

solution. Agitate vigorously using the small

brush to remove any excess concentrate.

Allow the parts to soak for 30 minutes.

f. Clean the dispensing valves mixing chamber

with the brush and sanitizing solution (this is

the cavity from which the nozzle is

removed).

a. On a daily basis, clean the external cabinet

splash areas using a clean damp cloth.

Remove and wash the cup rest, dispensing

nozzles, and static mixers with clean water.

Wipe dry with a clean soft cloth.

b. Wipe the drip tray in place on the unit, wash

the tray out with a mild soap solution, then

rinse the tray by pouring water down the

drip tray’s drain.

c. Clean all external surfaces of the dispenser

with a sponge and a mild soap solution.

Rinse the sponge out with clean water, then

wring the excess water from the sponge and

wipe all external surfaces of the dispenser.

d. Wipe the dispenser dry with a clean soft

cloth. DO NOT USE ABRASIVE TYPE

CLEANERS. Install the cup rest,

dispensing nozzles, and static mixers on the

dispenser.

g. Replace the nozzles and static mixers into

their proper locations and discard the

sanitizing solution used to soak them in.

Note: Do not reuse the sanitizing solution used

to clean the nozzles, static mixers, etc.

h. Activate the dispensing valves for two more

cycles (15 seconds on then off) with

sanitizing solution then run solution

continuously through the dispensing valves

for 2 minutes.

i. Disconnect the bag valves from the gray bag

connectors and re-connect the bag

connectors to their appropriate product bags.

j. Depress and hold each dispense button until

juice appears at the outlet of the dispensing

nozzle. Dispense and discard two 8 oz.

(237 ml) cups of juice and verify that there

is no chlorine off taste

Maintenance of the

Refrigeration System

Cleaning of the refrigeration components

should be performed by a qualified service

technician.

a. Continuous maintenance of this dispenser is

a basic requirement for proper operation and

sanitation, including all support equipment

utilized in the daily operation of this

equipment.

b. Cleaning of the Refrigeration Components:

c. Disconnect the power before removing the

top bonnet of the dispenser.

d. The dispenser’s ventilation grilles and the

condenser fins should be cleaned

periodically to maintain efficient

refrigeration and to avoid compressor

failure. The condenser fins can be cleaned

8

Page 10

with a vacuum cleaner or a soft bristle

brush.

e. Clean the exterior surfaces of the

compressor, agitator motor, fan motor, and

fan blade with a damp cloth to wipe off the

accumulated dust.

Ice Water Bath Cleaning

The water bath should be cleaned to obtain

maximum cooling efficiency. It is recommended

that the water bath be cleaned two to four times

annually, depending upon local conditions

and/or as required by state and local health

departments.

A convenient time to do this is at the time the

dispenser is being sanitized. To save time, the

water bath can be drained while the dispenser is

being sanitized.

a. Remove the cup rest and splash panel to

access the water bath’s drain hose. Extend

the drain hose to a suitable waste receptacle

and allow the water bath to drain.

b. Remove the dispenser’s top bonnet by

removing the two screws located on the top

of the bonnet. While lifting the bonnet up

and away from the dispenser, unplug the

merchandiser electrical cord from the power

strip located on the refrigeration deck.

c. In order to remove the refrigeration deck for

the water bath and evaporator cleaning,

remove the two screws that secure the deck

to the cabinet structure. Unplug the

refrigeration deck’s main power strip cord

from the dispenser’s power cord. Disconnect

the red, white and blue 12 pin plugs from the

electrical box. Disconnect the key switch a

by unplugging the white 2 pin plug at the

transformer.

Note: It will be necessary to melt the ice bank

to be able to pull the refrigeration deck up and

away from the dispenser. Warm water may be

used to accelerate the melting. In order to

prevent ice bank control damage, do not direct

the warm water stream on to the sensing bulb

of the ice bank control. Never use an ice pick

or other instrument to remove ice from the

evaporator. Such practice can result in a

punctured refrigerant circuit or damage to the

water bath tank.

d. Once the ice bank is sufficiently melted, lift

the entire refrigeration deck up and away

from the water bath by lifting the deck using

it’s service handle strap.

e. Prepare 1 gallon (3.9 L) of cleaning and

sanitizing solution (see “Sanitizing the

Concentrate Lines & Valves”). Pour the

cleaning and sanitizing solution into the

water bath and clean the sides and bottom of

the tank, the product coils, and associated

brackets with a fiber brush.

f. Utilizing the cleaning and sanitizing solution

in the water bath, the fiber brush, and a

clean cloth soaked with sanitizing solution,

clean the refrigeration deck’s evaporator

coils, agitator motor shaft and blade, and the

ice bank sensing bulb.

g. Drain the cleaning and sanitizing solution

from the water bath and rinse/flush all the

components with clean water.

h. Re-install the refrigeration deck into the

water bath and secure with two screws.

i. Connect the refrigeration deck’s power strip

to the dispenser’s power cord. Connect the

red, white and blue 12 pin plugs to the

electrical box. Connect the key switch to the

transformer.

j. Fill the water bath with cool potable water

until water begins to flow from the overflow

tube.

k. Plug the merchandisers power cord into

power strip located on the refrigeration deck

and re-install the top bonnet. Secure the

bonnet assembly with two screws.

l. Install the splash panel and cup rest and plug

the dispenser’s power cord into the electrical

outlet.

9

Page 11

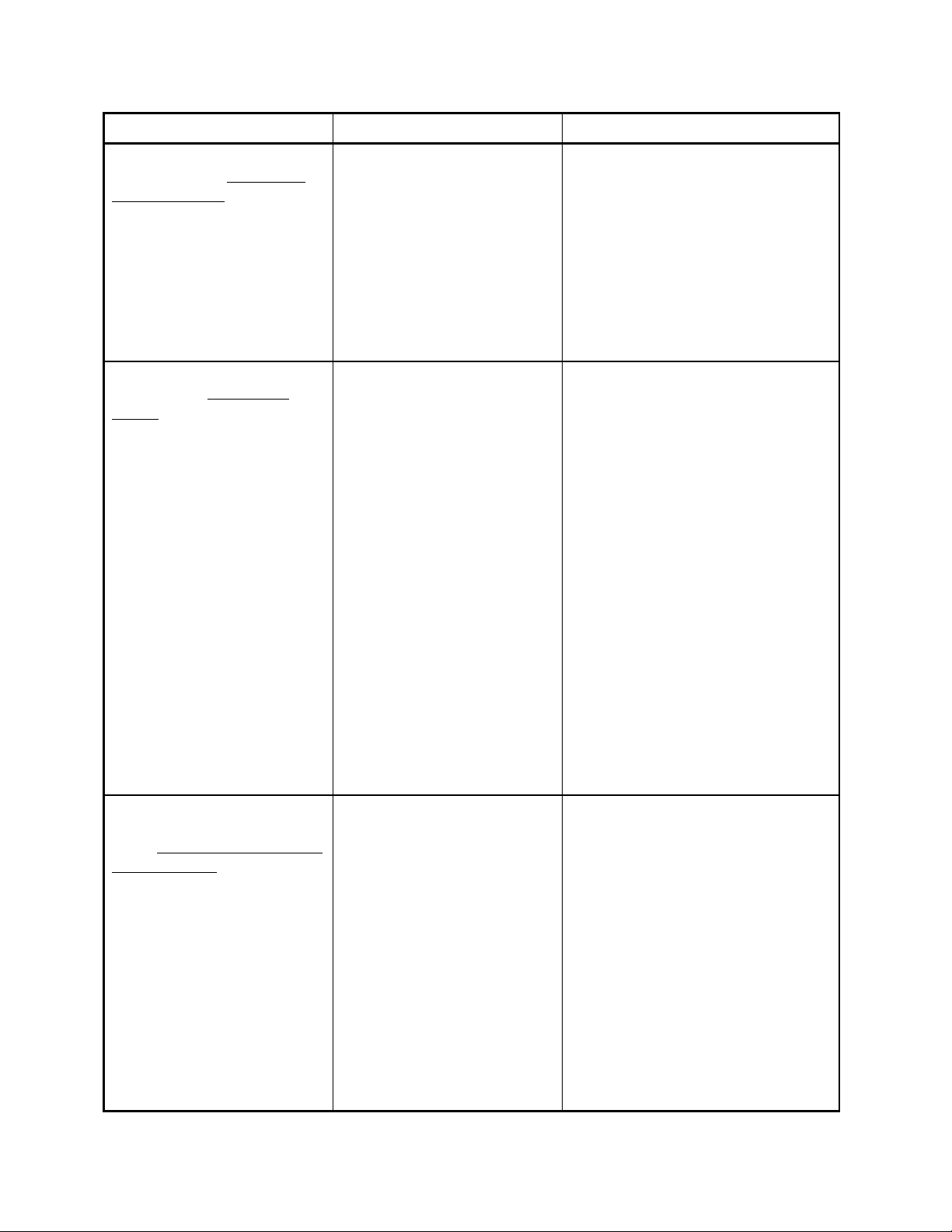

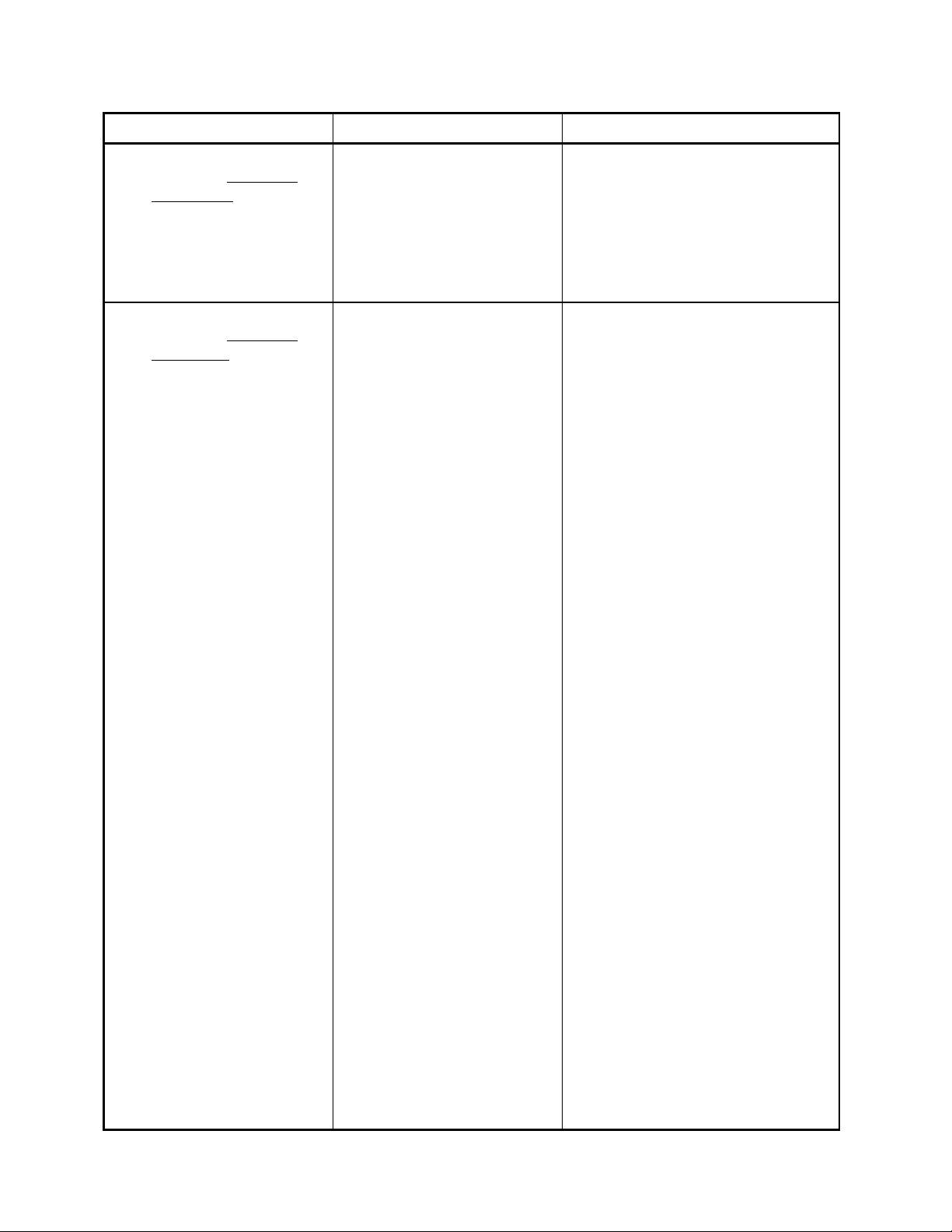

Troubleshooting Guide

Problem Probable Cause Remedy

DISPENSER IS TOTALLY

INOPERATIVE

DISPENSER WILL NOT

COOL

Drink temperature should be

35-45°F (2-7°C)

No power present at the

source.

Power is present at the

source...dispenser is still

inoperative.

Refrigeration shut off switch

is in the off position.

Low water bath level.

Depleted ice bank ( not

applicable after period of

heavy usage.)

Check the power circuit for a blown

fuse or tripped circuit breaker. Check

the supply line for the proper

amperage and voltage

ratings.....dedicated 15 amps /115

volts.

Check the power cord connection

located behind the front splash panel.

Refrigeration shut off switch is

located on the top of the dispenser .

This switch will disable the

compressor and the condenser fan

motor. Be sure the switch is in the on

position.

Check water bath level. If 2 gallons

or more are added, cause of problem

has been confirmed.

Check compressor. If running, allow

the system time to recover

(approximately 1 hour). If

compressor is not running or the

system is not recovering see the

Refrigeration System

Troubleshooting section.

WITH POWER PRESENT,

UNIT WILL NOT DISPENSE

ALL VALVES.

Defective Ice bank control.

Key lock switch in the OFF

position.

Transformer not connected or

defective.

Fuse blown between the

transformer and voltage

regulator boards.

10

See Refrigeration System

Troubleshooting section.

Check position of the key lock

switch. Check for loose wire

connections. Run continuity check,

replace as needed.

Check the connection between the

power strip and the transformer.

Check transformer output at terminal

junction on control box for 26 VAC.

Check the fuse located in the

electrical box, left side. This box is

located on the refrigeration deck and

will require the removal of the upper

bonnet. Replace fuse as needed.

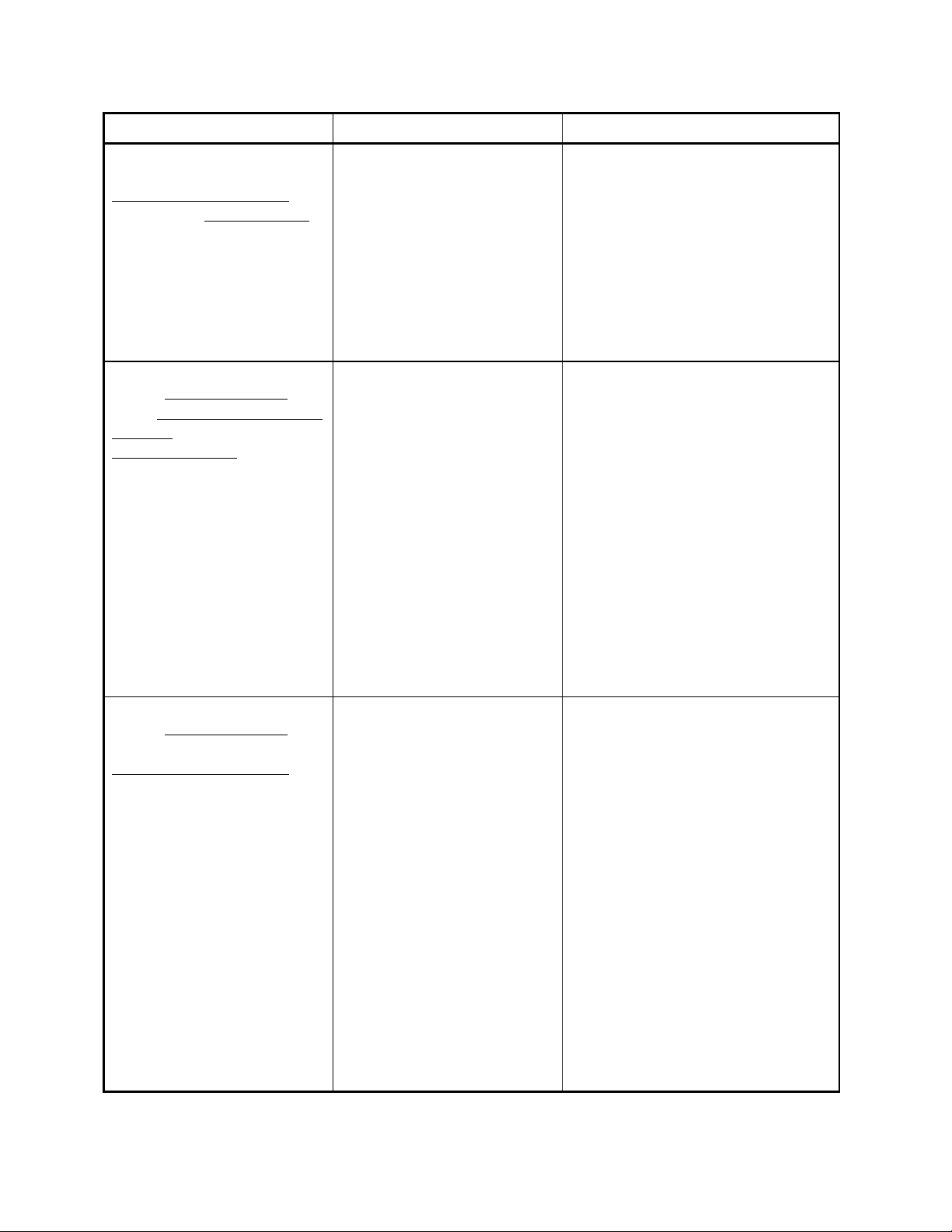

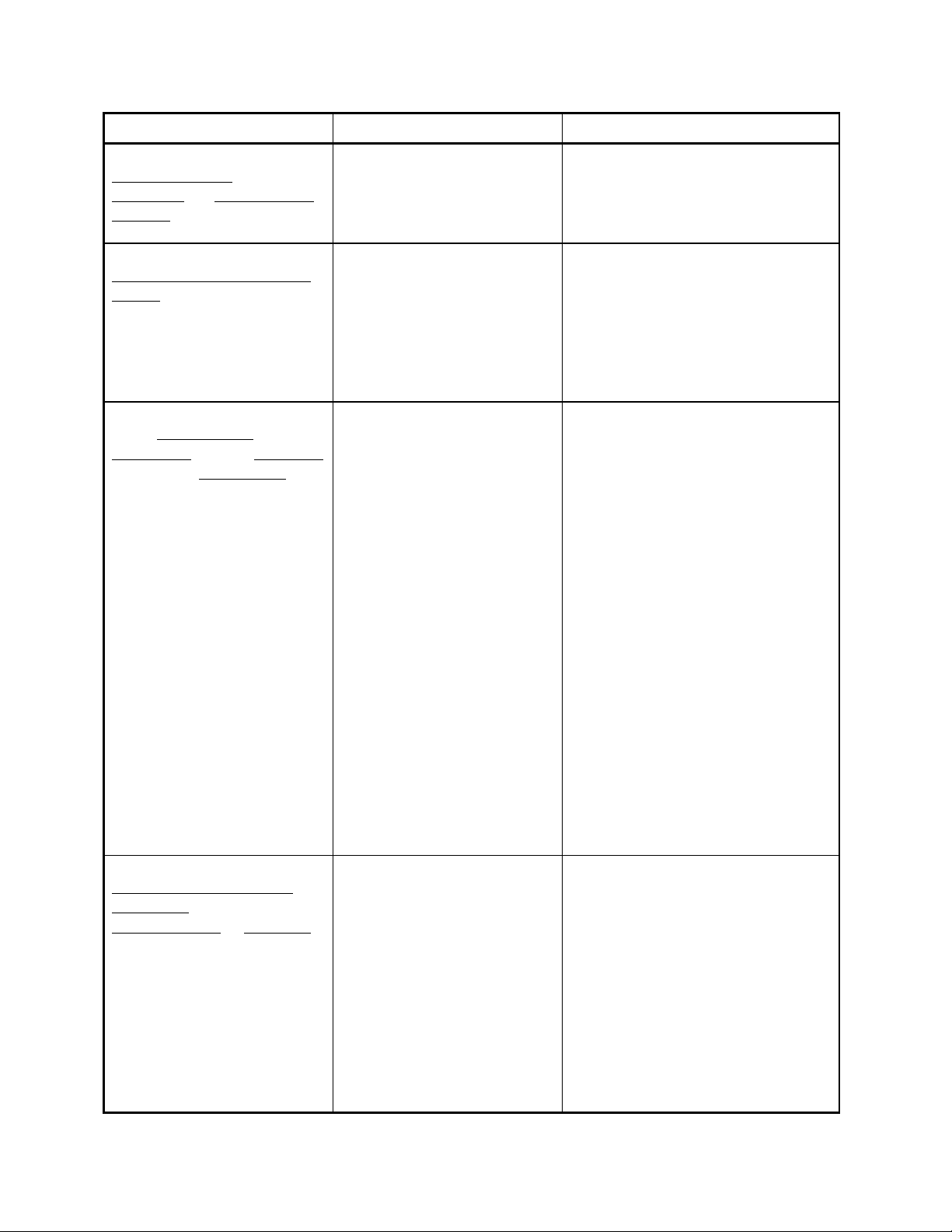

Page 12

Troubleshooting Guide

Problem Probable Cause Remedy

UNIT DISPENSING

CONCENTRATE ONLY NO

WATER TO ALL VALVES

FROM SINGLE VALVE

UNIT WILL NOT DISPENSE

WATER OR

CONCENTRATE.

No water reaching dispenser

from the water supply line.

Water pressure over 100 psi or

7 bar. High pressure will not

allow the water solenoids to

open.

Freeze up of water coil.

Inoperative or defective push

button switch, or portion

control board.

Defective Voltage Regulator

(VRB) board.

Check line to see if the water is shut

off at the source.

Install regulator onto incoming water

line to reduce the pressure to between

30 and 80 psi. (2-5- bar).

Refer to the Refrigeration System

Troubleshooting section.

Check for loose or broken wire

connections at the switch. Check the

continuity of switch. Replace as

needed.

The VRB boards are contained in the

electrical box mounted on the

refrigeration deck.. There is one for

each valve.

CAUTION: Access to this panel

requires the removal of the upper

bonnet while the dispenser is

energized and operational.

Check the power input for 26 VAC

and the output for 28 VDC.

FROM SINGLE VALVE,

UNIT IS DISPENSING

CONCENTRATE ONLY.

Inoperative water valve

solenoid coil.

Solenoid makes clicking

sound when energized, but

still does, not function.

Flow control binding or

defective.

11

Check to see all wire connections are

secured at the coil. Check power for

26 VDC. If power is present, coil

maybe defective , replace as needed.

Armature maybe stuck, disassemble

and check function. Return spring

could also be defective replace as

needed.

Disassemble the coil assembly and

check plunger seal for defects.

Replace as required. Inspect valve

seat for restrictions.

Disassemble flow control assembly

and check the spool and sleeve

assembly . Be sure the spool moves

freely within the sleeve and there are

no restrictions.

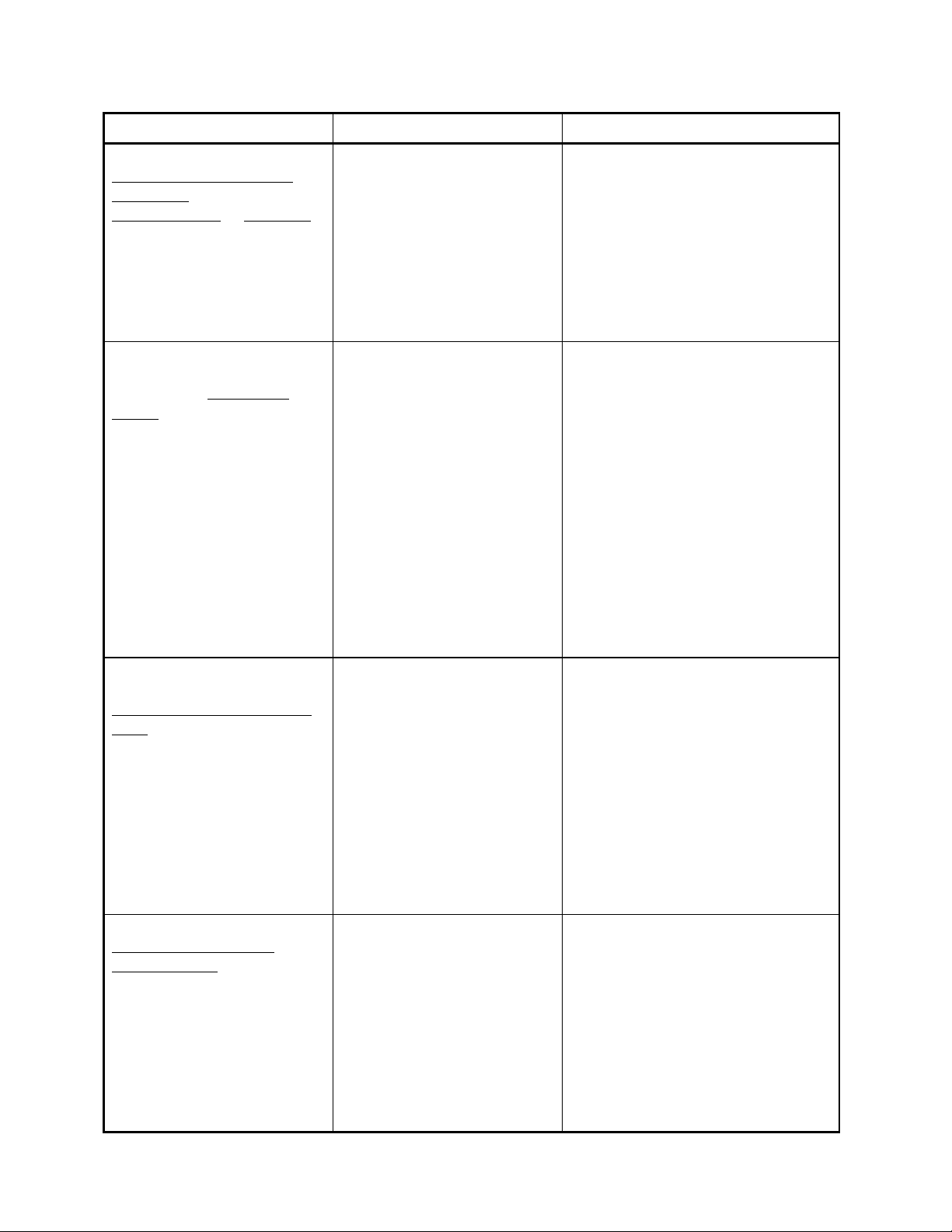

Page 13

Troubleshooting Guide

Problem Probable Cause Remedy

FROM SINGLE VALVE,

UNIT IS DISPENSING

WATER ONLY.

Concentrate container empty.

BIB connector is not engaged

or improperly installed.

Air leak in product suction

line.

No power at the pump motor.

Defective gear motor

assembly.

Replace.

Check BIB connector for proper

installation. Plunger should be

completely inserted with concentrate

filling the line to the dispenser.

Check the 3/8 flare connection where

the product line attaches to the unit.

Tighten fitting using a flare gasket. If

line is drawing air, pump will not

prime.

Check for broken or loose wire

connection going to pump motor.

Check for 26 VDC at pump motor

when the dispense button is

energized.

Check motor function by energizing

circuit with the dispense button. If

motor runs, but pump does not turn, a

broken gear box is indicated. The

pump motor and gear box are

replaced as a unit.

DISPENSER IS BRIXING

OUT TOO HIGH.

Pump running backwards.

Defective concentrate pump

tubing.

Supply water pressure too low.

Defective flow control.

Check the direction of pump

rotation...correct rotation is clockwise

as viewed from the front of the unit.

If pump is turning in a counter

clockwise direction, this indicates the

pump wires are reversed.

Check the pump tubing for ruptures,

wear, etc. Replace as needed

following the instructions printed in

this manual.

Water pressure must be 20 psi

flowing or above.

Disassemble and check flow control

assembly for binding, defective

compensating spring , trapped debris.

Be sure the spool moves freely within

the sleeve, replace parts as needed.

12

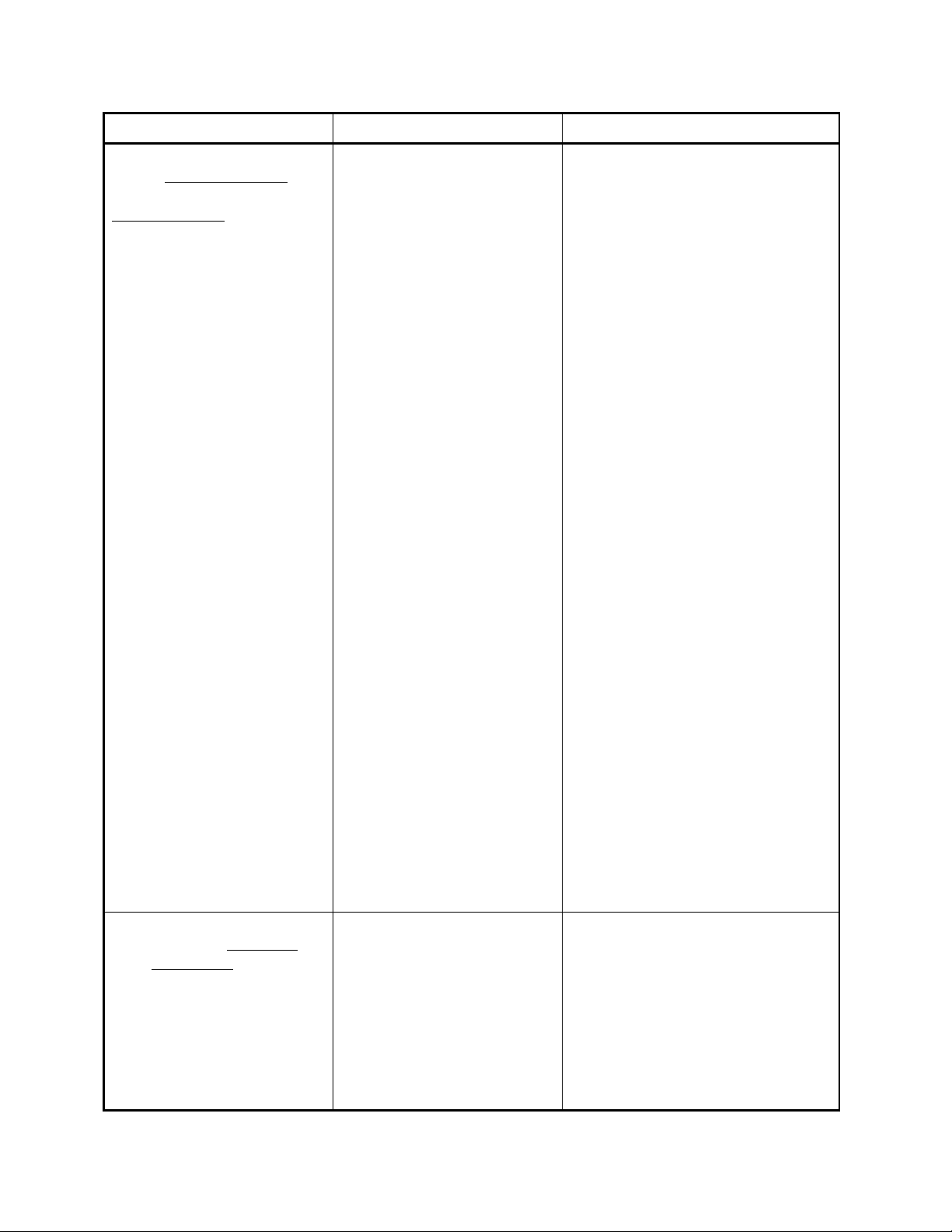

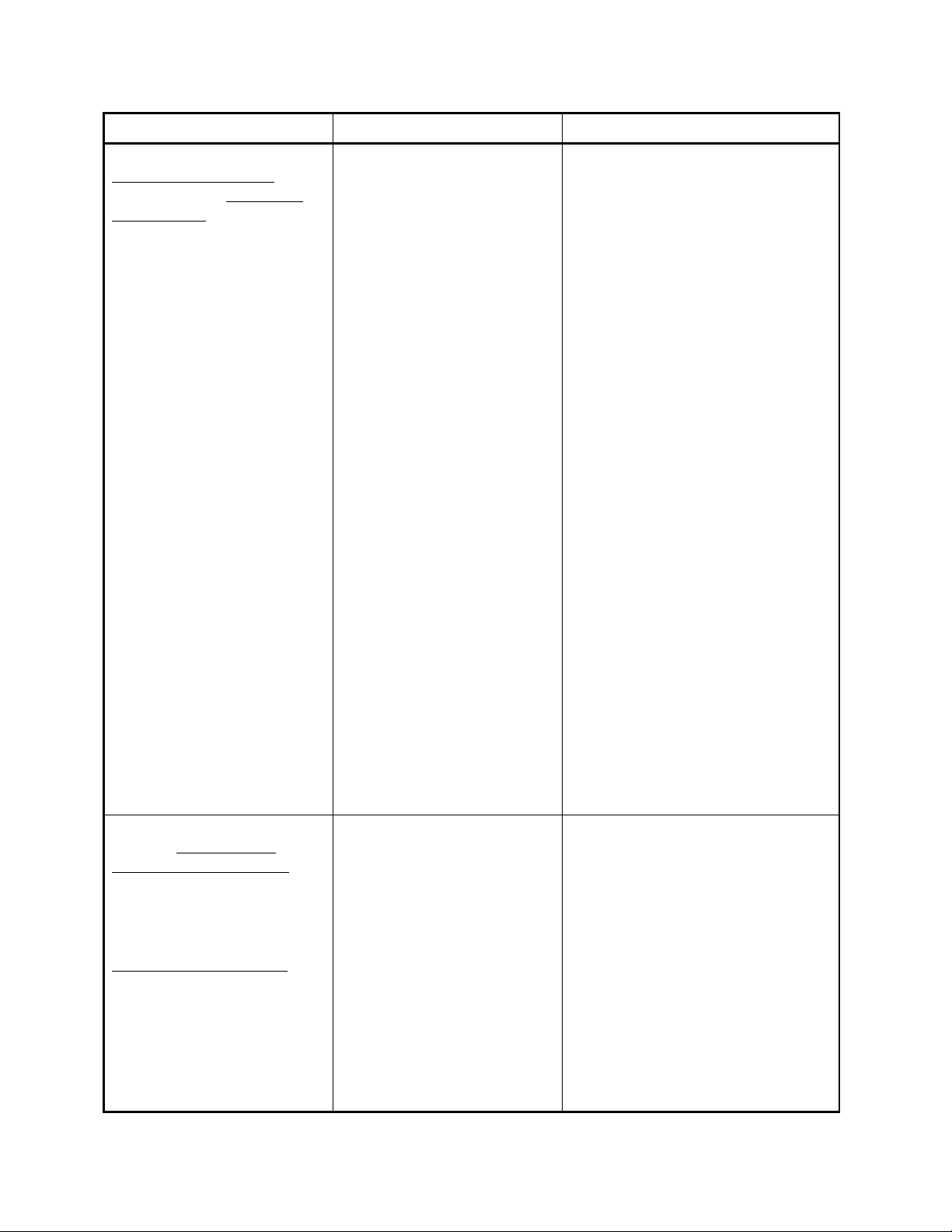

Page 14

Troubleshooting Guide

Problem Probable Cause Remedy

DISPENSER IS BRIXING

OUT TOO HIGH. (Cont.)

DISPENSER IS BRIXING

OUT TOO LOW.

Low viscosity or highly

concentrated concentrate.

Example 11 to 1 ratio.

Supply water pressure is too

high.

Defective or improperly

regulating flow control .

Locate the pump switches grouped

behind the front splash panel. They

are marked SPEED SWITCH with

the corresponding valve number.

Placing the switch in the low position

slows down the concentrate pumping

rate requiring less water to brix.

Water pressure has a high limit of

100 psi/ 7 bar or over. Place regulator

in supply line to bring pressure down

to 4 bar/ 50 psi flowing.

High water pressure will cause the

flow control not to regulate properly.

If the problem exists after the

pressure has been reduced to 50 psig/

4 bar, the flow control maybe

defective.. Disassemble and check the

spool and sleeve function and the

compensating spring . Replace parts

as required.

Speed switch in the low

position.

Air leak in the concentrate

suction line.

Worn concentrate pump

tubing.

Defective poppet valve and or

spring.

Pump speed switch is in the low

position. Move switch to high

increasing the pumping rate of the

concentrate.

Check that the concentrate line

connection is secured tightly to the

dispenser with the proper gaskets.

Check the connector at the

concentrate source to be sure it is

properly attached.

Remove the front half of the

concentrate pump and inspect the

tubing . Worn or stretched tubing will

decrease the amount of concentrate

pumped. After 1 year tubing should

be replaced.

Disassemble the right side of the

valve which contains the syrup

poppet assembly. Be sure the valve is

not binding, free of debris, return

spring is actuating and the diaphragm

is not torn or punctured.

13

Page 15

Troubleshooting Guide

Problem Probable Cause Remedy

WATER LEAKS FROM

BOTTOM OF DISPENSING

VALVE.

WATER CONTINUOUSLY

DRIPS FROM NOZZLE.

UNIT CONTINUES TO

DISPENSE AFTER BUTTON

HAS BEEN RELEASED.

Nozzle pieces improperly

assembled.

Water solenoid valve not

shutting off tightly.

Inoperative or defective push

button switch, or portion

control board.

Relay on voltage regulator

board hangs up or is stuck

open.

Static mixer inserted in nozzle body

upside down. Cone shaped end must

be visible when remounting the

nozzle assembly to the dispenser.

Disassemble water solenoid located

at the valve and check for foreign

material in the valve seat. Check the

armature for binding, check the

plunger and the seat for defects.

Replace parts as needed.

Check the operation of the push

button for sticking. Check continuity

of switch. Replace as needed.

CAUTION: Access to this panel

requires removal of the bonnet while

the dispenser is plugged in and

operational. *Voltage regulator board

is found in the electrical box mounted

to the refrigeration deck. There is one

board for each valve. Gently tap the

relay. If dispensing stops, relay was

hung up . If tapping the relay solves

the problem, it should be noted that if

a relay sticks once , it will probably

stick again. Replace as needed.

TWO OR MORE PUMPS

OPERATE WHEN ONLY

ONE BUTTON IS PUSHED.

Defective Voltage Regulator

(VRB) Board.

Insulator pad missing or not

properly positioned between

the transistor on VRB board

and mounting bracket.

14

Pull the connector marked DOOR ,

lower right hand connector on the

VRB board. If the unit still continues

to dispense the VRB board is

defective and needs to be replaced.

On the valve that is dispensing in

error, check the insulator pad

between the transistor on the top of

the VRB board and the mounting

bracket. If this pad is missing or

improperly aligned, the VRB board

will make contact with the bracket.

Current will run through the bracket

and set off the valve. Refer to

drawing found in this manual.

Page 16

Troubleshooting Guide

Problem Probable Cause Remedy

TWO OR MORE PUMPS

OPERATE WHEN ONLY

ONE BUTTON IS PUSHED.

(Cont.)

WITH POWER PRESENT

DISPENSER WILL NOT

COOL

Drink temperature should be

35-45°F

2-7°C

VRB Board mounting screw

insulator is missing or

improperly installed.

Refrigeration shut off switch

is in the off position.

Depleted ice bank (not

applicable after period of

heavy usage.)

Check the corresponding VRB board

to the valve that is dispensing in

error. Where the screw mounts the

transistor to the bracket, be sure that

the spacer bushing is present and the

screw is not over tightened. Screw

contact with the bracket will cause a

short and the firing of the valve when

other valves are energized.

Refrigeration shut off switch is

located on the top of the dispenser.

This switch will disable the

compressor and condenser fan motor.

Be sure the switch is in the on

position.

Remove rear bonnet covering the

refrigeration deck. CAUTION should

be observed when working in this

area as the dispenser is energized and

operational. Check to see if the

compressor is running . If so allow

the system to recover (approximately

1 hour).

WITH POWER PRESENT

COMPRESSOR WILL NOT

RUN.

(Compressor shell is cold to

touch.)

COMPRESSOR RUNS BUT

NO COOLING IS TAKING

PLACE.

Loose or broken wire

connections.

Defective compressor start

component.

Ice bank control not connected

or defective.

Low refrigerant charge.

Refrigerant restriction.

Check the wire connections at the

compressor. Be sure they are tightly

secured.

Check the compressor start relay.

Replace as required.

Check the ice bank control

connections. To test, place jumper

between the 2 leads. If the

compressor starts ,the ice bank

control is defective.

Contact a refrigeration service

technician. They will check for leaks

(sign of oil at joints and fitting) and

will recharge if necessary.

Refrigeration technician will examine

the system for, kinks in lines,

restrictions, etc. Heat exchanger may

need to be replaced.

15

Page 17

Troubleshooting Guide

Problem Probable Cause Remedy

COMPRESSOR RUNS BUT

NO COOLING. TRIPPING

OVERLOAD.

(Compressor shell is hot to

touch).

Condenser fan not running.

Inadequate air flow through

the dispenser.

Blocked condenser fins.

Ambient air over 100°F 38°C.

Check that the condenser fan is

running. If the fan is binding or

turning slowly, an overload condition

will occur.

Air flow is top front in, exhaust out

the rear. NEVER PLACE

ANYTHING ON TOP OF THE

DISPENSER. This will block the

airflow over heating the compressor

and causing it to trip the overload.

Remove the rear bonnet and check

the condenser fins. If unit is run in a

dusty environment, condenser fins

can become clogged, stopping the air

flow.

Brush out and clean with vacuum.

If the dispenser is working in an

environment over 100° ambient or is

drawing in discharged air, during a

heavy period, the unit may trip the

overload.

UNIT IS DISPENSING

CONCENTRATE ONLY

REFRIGERATION SYSTEM

HAS BEEN RUNNING FOR

EXTENDED PERIOD

WITHOUT SHUTTING OFF

FROZEN WATER COIL.

Defective overload.

Defective compressor.

Insufficient water level in the

water bath.

Agitator motor not operating.

Improperly located ice bank

control sensor.

Overload works on shell temperature

and amperage draw and can be

defective. Replace as needed.

Refrigeration technician will verify if

the compressor is defective and needs

to be replaced.

See the Start-up and Operation

Section of this manual. Be sure the

water bath is filled to fill line.

Check the agitator motor located on

the refrigeration deck. Be sure it is

plugged in and receiving power.

Check that the impeller is not

obstructed. Replace if needed.

Melt the ice bank and check the

location of the sensing bulb. Be sure

it is all the way down to the bottom

of the tube.

16

Page 18

Troubleshooting Guide

Problem Probable Cause Remedy

UNIT IS DISPENSING

CONCENTRATE ONLY

REFRIGERATION SYSTEM

HAS BEEN RUNNING FOR

EXTENDED PERIOD

WITHOUT SHUTTING OFF

FROZEN WATER COIL.

Compressor not cycling off. Check the ice bank control. Be sure

that the control has not overheated

and fused the contacts together.

Replace as required.

17

Page 19

Millennium 4 Valve Schematic

18

Page 20

Final Assembly

ITEM PART NO. DESCRIPTION QTY

1 50222 Merchandiser 1

2 720203000 Lens “Refreshing Drinks” 1

3 60064003 Fluorescent Bulb, F15T80 (All Voltages) 1

‡ 350001 Ballast 115v/60hz 1

‡ 60419006 Ballast 230v/50hz 1

‡ 60420001 Starter 115v/60hz 1

‡ 60419004 Ballast 220v/6hz 1

‡ 350164 Socket, Starter 1

4 350061 Lamp Holder 2

5 231050 Reflector 1

6 231051 Wrapper, Stainless Steel 1

7 261142 Bonnet Assembly w/Screen 1

8 400325 Screw 2

9 720200500 Valve Adjustment Cover 1

10 720200400 Valve Enclosure 1

11 84353001 Push Button Switch Assembly 1

12 550088 Condenser 1

13 230509 Shroud 1

14 710160063 Handle 1

15 186074001 Ice Bank Control – All Voltages 1

16 350017 Condenser Fan Motor Blade 1

‡ 350095 Condenser Fan Motor 115v/60hz 1

‡ 350096 Condenser Fan Motor 220v, 230v/50hz, 60hz 1

17 40-0323 Screw 2

18 230040 Bracket, Agitator Motor 2

19 230303 Heat Sink, Agitator Motor 2

20 350078 Agitator Motor w/out Blade 115/60 1

‡ 350079 Agitator Motor w/out Blade, 220v, 230v/50hz, 60hz 1

21 350012 Blade, Agitator 1

‡ 36118 Spring Pin 1

23 400262 Plug Cap (Water Fill Hole) 1

24 260970* Compressor 1/3 Hp R-134a 115v/60hz 1

‡ 550001 Accumulator/Dryer 1

‡ 350148 Compressor Start Relay 1/3 Hp 115v/60hz 1

‡ 350108 Compressor Overload 1/3Hp 115v/60hz 1

‡ 260968* Compressor 1/3 Hp R-134a 230v/50hz 1

‡ 350106 Compressor Overload 1/3 Hp 230v/50hz 1

‡ 350151 Compressor Start Relay 1/3 Hp 230v/50hz 1

‡ 260972* Compressor 1/3 Hp R-134a 220v/60hz 1

‡ 350146 Compressor Overload 1/3 Hp 220v/60 Hz 1

‡ 350152 Compressor Relay 1/3 Hp 220v/60hz 1

*-Compressor includes Relay, Overload, Grommets and Sleeves. Start Capacitor is required for 220V

Compressors only and is supplied with the Compressor.

‡ -Indicates item not shown.

19

Page 21

Final Assembly

ITEM PART NO. DESCRIPTION QTY

‡ Compressor Start Capacitor 220v/60hz 1

25 350115 Hitch Pin 4

26 400407 Washer 4

27 350055 Grommet 4

28 350158 Sleeve 4

‡ 350182 Power Switch, Refrigeration Deck 1

29 720202200 Transformer Assembly 115v/60hz 1

‡ 720202201 Transformer Assembly 220v, 230v/50hz, 60 Hz 1

30 720201400 Electrical Box Assembly (All Voltages) 1

31 720201403 Cover, Electrical Box 1

32 710160156 Refr. Deck Assembly 115v/60hz (w/out Ele. Box & Transformer) 1

‡ 710160159 Refr. Deck Assembly 230v/50hz (w/out Ele. Box & Transformer) 1

‡ 710160157 Refr. Deck Assembly 220v/60hz (w/out Ele. Box & Transformer) 1

33 350130 Power Strip 1

34 260061 Bulb Holder 1

‡ 230983 Bracket, Bulb Holder 1

35 261135 Cabinet Assembly (Includes Items 47 & 48) 1

36 350174 Clip 2

37 350131 Main Power Cord 1

‡ 350112 Main Power Cord 1

38 400501 Elbow 25 MPTX.5B Nylon 1

39 650094 Vinyl Tubing 1/2” ID Overflow

40 720200700 Splash Panel 1

41 720200300 Dispensing Assembly 1

42 720200200 Enclosure Assembly (with Speed Switch Mtg Plate) 1

43 27615 Key Switch with Keys 1

‡ 19578 Key, Double Sided #2009 2

44 720200600 Cup Rest 1

45 720200100 Drain Pan 1

46 89043 Vinyl Tubing 6 Ft

47 231049 Front Panel, Base Riser 1

48 261136 Base Riser Assembly 1

50 261137 Water Coil Assembly 1

51 230208 Bracket 1

52 400193 Flare Nut 1

53 48033002 Nylon Washer 1

54 400135 Coupler 1

‡ 261139 Water Manifold Assembly 4 Valve 1

‡ 400113 Fitting El-Barb 3/8 x 1/4 MPT 1

‡ 400263 Dead Head Plug 1

‡ 650089 Drain Hose 3 Ft

*-Compressor includes Relay, Overload, Grommets and Sleeves. Start Capacitor is required for 220V

Compressors only and is supplied with the Compressor.

‡ -Indicates item not shown

20

Page 22

Final Assembly

.

21

Page 23

Platform Assembly

P/N 720200800

ITEM PART NO. DESCRIPTION QTY

1 720200804 Tube Fittings/Bracket Assembly 1

2 720200801 Base, Pump 1

3 720200802 Bracket, Pump Support 1

4 48432 Pump & Bracket Assembly Millennium 4

5 720201600 Harness Assembly, Pumps to Plug 1

6 48195006 Clamp-Hose, .470”-.XXX” I.D. 8

7 48309 Tube Assembly, Pump Inlet 4

8 48310 Tube Assembly, Valve Inlet 4

9 89078 Tubing-Beverage, 3/8 I.D. Redline 2.3’

10 48114004 Clamp-Ear, 105 (.413/.346) 4

11 48114003 Clamp-Ear, 145 (.571/.472) 2

12 0734801 Rivet, Pop 4

13 0704001 Screw, #8-32 Type “F” BD HD, 3/8” LG 10

14 0733903 Bushing-Snap 2

15 55145 TY-Wrap 5 1/2” Long 2

22

Page 24

Pump & Bracket Assembly

P/N 48432

ITEM PART NO. DESCRIPTION QTY

1 0704105 Screw, 8-32 x 1/2” 4

2 45185 Pump & Motor Assembly 1

3 45283 Rubber Bushing With Nut Insert 4

4 48420 Pump Bracket 1

23

Page 25

Pump Motor Assembly

P/N 48405

ITEM PART NO. DESCRIPTION QTY

1 45016001 Pump Motor with Boot (Item #7) 1

2 45078 Pump Complete, 3-Roller 1

3 45050 Block Assembly, Pump & Motor 1

4 45017001 Thumbscrew 4

5 0702905 Screw, 8-32 x 3/4” 1

6 45098 Tubing Kit (1 Pre-Cut Tube and 2 Clamps) 4

7 45074 Boot-Pump Motor 1

24

Page 26

Dispensing Assembly

P/N 720200300

ITEM PART NO. DESCRIPTION QTY

1 0704107 Screw, *8-32 THMS, 5/8” LG 8

2 45027001 Bushing-Nozzle, SL Juice Dispense 4

3 07033901 Bushing-Snap 2

4 48415 Valve Block/Bracket Assembly 4

5 720200301 Support, Valve Block 1

‡ 45123 Static Mixer 4

‡ 31525-057 O-Ring Mixing Nozzle 13/16 O.D. x .676 I.D. 4

‡ 48808-001 Mixing Nozzle with O-Ring 4

‡ -Indicates item not shown

25

Page 27

Valve Block Assembly

P/N 45045

ITEM PART NO. DESCRIPTION QTY

1 45177 Holder, Poppet Seal 1

2

3 0720406 Nut, #10-32 KEPS 1

4 15321 Ring-Retain, .242 ID 1

5 15323 Armature-EL VLV 1

6 18070001 Gasket-Rubber 1.055 DIA 1

7 18367 Spring-Coil, SS 1

8 19695001 Guide-AS Small ELVL 1

9 31525021 O-Ring, 1-1/4 OD x 1.114 ID 1

10 18071 Seat-Armature Water, FFV 1

11 48258005 Spring-Syrup, FFV 1

12 45192 Valve Body, Mixing 1

13 45193 Valve Block-Water, SL Juice 1

14 45029 Plate-Coil Retainer 1

15 47011 Diaphragm W/Hole-Valve, MDJ 1

16 45180 Spring Actuator-SLJ1000 1

17 45189 Armature Tip 1

18

19 47048 Support-Diaphragm, MDJ 1

20 45195 Valve Block, Front Plate 1

21 45186 Spring - .360 OD x .032 Wire 1

22 31525060 O-ring, .539” x .459” x .875” OD 1

23 48520001 Coil Assembly, -24 V DC 1

24 48978 Flow Control/Bonnet Assembly, -FFV 1

25 60280002 Piston-Water, Ceramic, FFV 1

26 07032001 Screw, #8-18 x 7/16 Type “25” HHWF SS 13

27 60281001 Sleeve-Syrup, Ceramic, FFV 1

28 16779003 Frame – “C” Solenoid 1

29 27408 Petro-Gel 1

30 49612 Valve Port – Water 1

31 31525020 O-Ring, 5/16” OD x .176” ID 1

32 22081 Washer-Holddown EVLV 2

26

Page 28

Valve Block Assembly

P/N 45045

27

Page 29

Electrical Box Assembly

P/N 720201400

ITEM PART NO. DESCRIPTION QTY

1 45238 Voltage Regulator Assembly, SLJ1000-2 2

2 720201401 Enclosure, Electrical 1

3 720201403 Cover, Electrical Box 1

4 0734801 Rivet, Pop 1

5 0704001 Screw, #8-32 Type “F” BD HD, 3/8” LG 7

6 59328001 Fuse – 6.25 Amp, 250 V, SL Juice Dispenser 1

7 45059 Fuse Holder 1

8 720201701 Wiring, Assembly Pumps to E-Box 1

9 720201702 Harness Assembly, Speed Switches E-Box 4 FL 1

10 720201703 Harness Assembly PB Switches E-Box 4 Flavor 1

11 720201704 Harness Assembly Power E-Box 4 Flavor Millennium 1

‡ 720202000 Harness Assembly Pump to E-Box 1

‡ 0733909 Bushing Snap 1/4” I.D. x 3/8” O.D. 1

‡ Items not shown

28

Page 30

Voltage Regulator Assembly, SLJ1000-2

P/N 45238

ITEM PART NO. DESCRIPTION QTY

1 45162 Bracket-Voltage Regulator, SLJ1000-1 1

2 45056 Support-PC Board, SL Juice 8

3 45012002 Board-Voltage Regulator, SLJ 2

4 45613 Fastener, Plastic-VRB Mtg 2

5 45004001 Insulator-Voltage Regulator 2

29

Page 31

PORTION CONTROL ASSEMBLY

30

Page 32

PORTION CONTROL ELECTRICAL DIAGRAM

P/N 720201800

31

Page 33

Millennium Model MJ30-4

Recommended Spare Parts List

(For 10 Dispensers)

PART NO. DESCRIPTION QTY

45003100 Nozzle & O-Ring Assembly 4

45123 Static Mixer (inside disp. nozzle) 4

31525037 O-Ring, Dispensing Nozzle 4

45189 Poppet, Rubber, Valve Mixing Block 4

45177 Poppet Seal Holder 4

47011 Diaphragm with Hole, Valve Mixing Block 4

45180 Spring Actuator, Valve Mixing Block 4

45186 Spring, Valve Mixing Block 4

45179 Diaphragm, Support, Valve Mixing Block 4

18070001 Gasket, Rubber, Water Solenoid 4

15323 Armature Water Solenoid 4

18071 Armature Seat 4

18367 Spring, Coil, S/S, Water Solenoid 4

15321 Ring, Retaining, Water Solenoid 4

31525020 O-Ring, Water Solenoid Valve 4

31525021 O-Ring, Valve Mixing Block 4

48520001 Coil, Water Solenoid, 24 VDC 2

60280002 Piston, Ceramic, Brix Control 3

60281001 Sleeve, Ceramic, Brix Control 3

31525060 O-Ring, Ceramic Sleeve 3

48258005 Spring, Brix Control 3

48978 Flower Control, Bonnet Assembly 3

84353001 Push Button, Dispense 4

45012102 Circuit Board, Voltage Regulator 2

48448 Transformer Assembly 115V/60Hz 1

45432 Switch, Rocker, Speed Adjustment 2

59328001 Fuse, 6.25 Amp, 220 VAC 2

45016001 Pump Gear Motor 1

45098 Pump Tubing Kit (pre-cut tube with clamps) 3

186074001 Ice Bank Control 1

350095 Motor, Condenser, 115V/60Hz 1

350078 Agitator Motor Assembly, 115V/60Hz (w/blade) 1

350148 Relay, Compressor, 115V/60Hz 1

350108 Overload, Compressor, 115V/60Hz 1

60064003 Bulb, Fluorescent 1

350001 Ballast 115v/60Hz 1

350164 Starter 115V/60Hz 1

720200100 Drain Pan Assembly 1

720200600 Cup Rest 1

32

Page 34

Millennium Model MJ30-4

Optional Accessories

The following options are available for the Millennium Dispenser. For more information, please contact

our customer service department at 1-800-238-3600 Monday-Friday between the hours of 8:00 a.m. and

4:30 p.m. CST.

Part No. Description

721900000 Optional Leg Kit Standard (set of 4 steel legs and 2 support braces

721900001 NSU Kit (secures unit for use on ships)

721900002 Kit Leg Adjustable

48350007 Single, 2 Button Bar Gun Kit

48350008 Dual 2 Button Bar Gun Kit

721910000 Portion Control Conversion Kit

33

Page 35

IMI CORNELIUS INC.

Certificate of Warranty

ONE YEAR LIMITED PARTS EQUIPMENT WARRANTY

IMI Cornelius Inc. warrants to the original commercial purchaser/user, that any commercial product of its manufacture bearing

the name “Wilshire” will be free from defect in material and/or factory workmanship, and that if properly installed, maintained,

and serviced in accordance with the Service Manual furnished with the product, it will perform adequately under normal use.

This product warranty shall be effective for a period of one year from the date of original installation or 15 months from the date

of original shipment by IMI Cornelius, whichever period elapses first.

IMI Cornelius Inc.’s obligation, upon return of the part or parts to its factory, transportation charges prepaid, is limited strictly to

replacing or to repairing without charge any part or parts IMI Cornelius finds to be defective in material and/or factory

workmanship during the warranty period. The serial and model numbers and date of original installation of the product must be

given. No part or assembly which has been subject to accident, alteration or misuse or which is not installed, maintained, or

serviced in accordance with the Service Manual furnished with the product, or which is from a machine on which the serial

number has been removed, shall be covered by this warranty. This warranty does not provide for service calls from factory

representatives or from any other agencies and shall not include charges of any nature.

IMI Cornelius Inc. will accept a part, parts, or equipment freight prepaid and return same freight collect to the sender within the

continental U.S. or port of export within the continental limits of the U.S. IMI Cornelius Inc. is not responsible for international

freight, customs fees or duties at country of destination.

ADDITIONAL FOUR YEAR LIMITED WARRANTY ON COMPRESSOR

This warranty shall be effective for a period of four (4) years from the expiration of the above warranty.

The hermetically sealed refrigeration compressor is covered by the above one year limited warranty. In addition to that warranty,

if the compressor fails because of a defect in materials or workmanship during the second through fifth year from the date of

installation, IMI Cornelius Inc. will repair or, at its option, replace the compressor. Labor charges and the cost of relays,

overloads and capacitors are not included.

THIS WARRANTY DOES NOT COVER DAMAGE CAUSED BY LACK OF PREVENTATIVE MAINTENANCE,

IMPROPER INSTALLATION, ACCIDENT, MISUSE, NEGLIGENCE, ALTERATION, FIRE, FLOOD, OR ACTS OF GOD.

In those jurisdictions where liability for damages cannot be disclaimed, original purchasers recovery shall not exceed the cost of

the warranted product.

IMI CORNELIUS INC. ASSUMES NO LIABILITY FOR INCIDENTAL OR CONSEQUENTIAL DAMAGES OF ANY

KIND, INCLUDING, BUT NOT LIMITED TO, SPOILED PRODUCT, LOST PROFITS, OR DAMAGE TO OTHER

PROPERTY.

THIS WARRANTY IS EXCLUSIVE AND IN LIEU OF ALL OTHER WARRANTIES, WHETHER WRITTEN, ORAL, OR

IMPLIED, INCLUDING ANY WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE,

AND SUPERSEDES AND EXCLUDES ANY ORAL WARRANTIES OR REPRESENTATIONS OR WRITTEN

LANGUAGE IN ANY MANUAL, LITERATURE, ADVERTISING BROCHURE OR OTHER MATERIALS NOT

EXPRESSLY DESIGNATED IN WRITING AS A “WARRANTY”.

IMI Cornelius, Inc.

One Cornelius Place

Anoka, Minnesota 55303

612-421-6120 / 800-238-3600

612-422-3255

34

Page 36

ILLUSTRATED PARTS LIST

MILLENNIUM II 4000

IMI CORNELIUS INC.

One Cornelius Place

Anoka, MN 55303-6234

Telephone 1-800-238-3600

Facsimile 1-800-258-0255

www.cornelius.com

Millennium II 4000 1 of 22 Manual Part No.: 620919547IPL

Rev.: B July 7, 2003

© IMI Cornelius Inc., 2003

Page 37

IMI CORNELIUS INC.

ILLUSTRATED PARTS LIST

One Cornelius Place

Anoka, MN 55303-6234

Telephone 1-800-238-3600

Facsimile 1-800-258-0255

www.cornelius.com

5

5

11 10 6

11 10 6

3 7

37

489

4 8 9

12

12

1

2

2

1

CABINETRY

Item

No.

Part No. Name

Item

No.

Part No. Name

1 620050654 Splash Panel 7 172265000 O-Ring (Drip Tray)

2 620708527 Cup Rest 8 620710207 Stainless Steel Insert - R

3 620517118 Drip Tray 9 620048120 Inner (Bracket) - R

4 620048118 Right Side Panel 10 620710208 Stainless Steel Insert - L

5 620048121 Back Panel 11 620048119 Inner (Bracket) - L

6 620048117 Left Side Panel 12 37958 Leg, 4 inch

Manual Part No.: 620919547IPL 2 of 22 Millennium II 4000

Rev.: B July 7, 2003

© IMI Cornelius Inc., 2003

Page 38

TO VALVES

12

To Va lv es

13

ILLUSTRATED PARTS LIST

12 PIN

RED

BLK

BLK

ORG

18

BLK

ORG

ORG

B

O

B

O

L

R

L

R

K

G

K

G

12

BLK

ORG

O

B

R

L

G

K

3

OUT BASE TO B.1.B.

Out Base to B.I.B.

7

7

O

B

R

L

G

K

4

TO VALVES

To Val v e s

IMI CORNELIUS INC.

One Cornelius Place

Anoka, MN 55303-6234

Telephone 1-800-238-3600

Facsimile 1-800-258-0255

www.cornelius.com

Out Base

to B.I.B.

11

10

5

4

4

3

3

OUT BASE TO B.1.B.

5

9

8

10

9

11

12

17

6

6

2

2

1

1

Pump Platform Assembly

P/N 620048605

Item

No.

Part No. Name

Item

No.

Part No. Name

1 620048604 Pump Platform 4V 8 41232 Fitting, 1/4 Barb

2 620049104 Bracket, Tubing Back Pump 9 620709025 Fitting, Pump Inlet Front

3 200498003 Nut, Hex 8-32 10 620709026 Fitting, Pump Inlet Rear

4 45185 Pump & Motor Assembly 11 48195-003 Clamp, Hose

5 45283 Bushing, Rubber w/Nut Insert 12 48114004 Clamp #10.5

6 70178 Screw 8-32 13 720201600 Harness, Pump

7 48456 Tubing

Millennium II 4000 3 of 22 Manual Part No.: 620919547IPL

Rev.: B July 7, 2003

© IMI Cornelius Inc., 2003

Page 39

IMI CORNELIUS INC.

ILLUSTRATED PARTS LIST

2

2

3

3

22

22

26

26

One Cornelius Place

Anoka, MN 55303-6234

Telephone 1-800-238-3600

Facsimile 1-800-258-0255

www.cornelius.com

1

1

9

9

8

8

4

4

5

5

6

6

7

7

10

10

11

11

20

25

20

25

24

24

21

21

22

22

23

23

Lower Housing Assembly

P/N 620516502

Item

No.

Part No. Name

1 750100133 Waterbath Assembly 14 18689009 Label Label SYR #2

Item

No.

Part No. Name

(Not Shown)

2 750500001 Insulation, Gasket Slit 15 18689010 Label Label SYR #3 (Not Shown)

3 70959 Nut, 8-32 Hex Nutsert 16 18689011 Label Label SYR #4 (Not Shown)

4 620045743 Pump Base 4V 17 18689112 Label DRAIN (Not Shown)

5 620045430 Support, Pump Base 18 313457000 Label, Electric Shock Hazard

6 71822024 Screw 8-18 19 620919365 Label, Slack (Not Shown)

(Not Shown)

7 620517902 Extension, Leg 20 50386 Tubing, 1/2 ID

8 620047602 Channel, Pump Platform 21 1971 Fitting, L-Barb

9 200498003 Nut Hex 8-32 22 40705 Clamp

10 50459 Bushing, 7/8” 23 50249 Tubing, Insulation 1/2 ID

11 0733903 Bushing, 1-5/16ID X 1/609OD 24 50326 Insulation Tape

(Not Shown)

12 18689004 Label WATER (Not Shown) 25 31699004 Cap-Plug

13 18689008 Label Label SYR #1

(Not Shown) 26 60446 Tubing, 1/4 ID

Manual Part No.: 620919547IPL 4 of 22 Millennium II 4000

Rev.: B July 7, 2003

© IMI Cornelius Inc., 2003

Page 40

ILLUSTRATED PARTS LIST

38

39

IMI CORNELIUS INC.

One Cornelius Place

Anoka, MN 55303-6234

Telephone 1-800-238-3600

Facsimile 1-800-258-0255

www.cornelius.com

40

40

35

35

29

29

41

LABEL TO IDENTIFY RED LEADS

38

REFRIGERANT 134A

39

2

2

28

15

15

41

43

43

32

32

31

31

30

30

11

11

44

44

17

17

28

13

13

18

18

24

24

18

18

3

3

19

19

14

14

26

26

4

4

25

25

27

27

9

9

7

7

12

10

10

20

20

1

1

21

8

12

21

8

LABEL TO BE PLACED ON TOP OF E-BOX ( PART# 620046045)

16

16

5

5

CONNECT ICE BANK PROBE TO BRACKET

42

42

36

37

23

23

22

22

36

37

WITH PROBE RETAINING CLIP

6

6

33

33

Refrigeration Deck Assembly

P/N 620048607

Millennium II 4000 5 of 22 Manual Part No.: 620919547IPL

Rev.: B July 7, 2003

© IMI Cornelius Inc., 2003

Page 41

IMI CORNELIUS INC.

ILLUSTRATED PARTS LIST

One Cornelius Place

Anoka, MN 55303-6234

Telephone 1-800-238-3600

Facsimile 1-800-258-0255

www.cornelius.com

Item

No.

Part No. Name

Item

No.

Part No. Name

1 620045999 Refrigeration Platform 4V 23 750100402 Bracket Probe GIBC .875

2 750300227 Screw SM #8 HXWS 12 STZI 24 750100097 Filter Dryer Assembly

3 750300083 Handle Ref Deck 25 52200 Refrigeration Deck

4 71091 5/16-18 Nylon Insert Locknut 26 620042708

620042709

5 620711604 Insulation Refrigeration Deck

27 313456000 Label Hazard Caution Cover

Agitator Motor Assembly 115V

Agitator Motor Assembly 230V

4V

6 750100004 Refrigeration Evaporator

Assembly 4V

7 2129

2519

620607906

Compressor 1/3 HP 120/60

Compressor 1/3 HP 230/50

Compressor 1/3 HP 230/60

28 60536002 Label Warning Danger Moving

Parts

29 70051 Washer FT 187 437 STZI

8 20223010 Washer FT 489 922 065 STZI 30 750300243 Tab Grounding Oly

9 750300240 Lead-Ground Assembly 31 750900819 Label 24VAC

10 34877001 Screw MA 8-32 HXWS 12 STZI 32 620710702

620710709

Transformer 115V-26V/24V

Transformer 230V-26V/24V

11 1450580001 Label Ground Earthing 33 620313342 Harness Power Millennium

12 90751 Label Notice Rfg Test 34 750300401 Guard 1/32” Fishpaper Trans-

former

13 398034400 Pin Hitch 080D 1.562 STZI 35 50335 Insulation Armaflex 1-3/8 x 3/8

14 70226 Screw SM 10 TB PAPH 24 STZI 36 20322 Rod #6 Phoson Brazing 1/16

Dia

15 560003701

Condenser Coil & Fan 07W

37 20354 Solder 1/16 Dia #35 Silver

120/60 .36

560003702

Condenser Coil & Fan 230 50/

60

16 750100024 Tube Discharge Comp Oly 38 50326 Insulation Tape

17 750100079 Line Suction Compressor Oly 39 50163-1 Insulation Tube

18 750300025 Tube Process Oly 1/3 HP Disp 40 50705 Tie Cable

19 31738003 Accumulator D80+ & 134A 41 750100241 Baffle Air Deck

20 750300232 Line Accumulator Inlet Tube L & M42 750500002 Wrap Social

21 560003860 Probe Ice Bank GCC 43 620049120 Transformer Bracket

22 440000906 Clip Retaining Probe Plastic

44 750100096 Condenser Platform

Black

Manual Part No.: 620919547IPL 6 of 22 Millennium II 4000

Rev.: B July 7, 2003

© IMI Cornelius Inc., 2003

Page 42

ILLUSTRATED PARTS LIST

5

2

4

IMI CORNELIUS INC.

One Cornelius Place

Anoka, MN 55303-6234

Telephone 1-800-238-3600

Facsimile 1-800-258-0255

www.cornelius.com

1

3

6

Water Coil Assembly

P/N 750100071

Item

No.

Part No. Name

Item

No.

Part No. Name

1 70320 Rivet 5 750100066 Coil, Upper

2 750100042 Flow Baffle 6 750100082 Bracket, Coil

3 750300064 Bracket, Flow Baffle 7 750500101 Spacer (Not Shown)

4 750100065 Coil, Lower

Millennium II 4000 7 of 22 Manual Part No.: 620919547IPL

Rev.: B July 7, 2003

© IMI Cornelius Inc., 2003

Page 43

IMI CORNELIUS INC.

ILLUSTRATED PARTS LIST

8

8

5

5

3

3

2

2

One Cornelius Place

Anoka, MN 55303-6234

Telephone 1-800-238-3600

Facsimile 1-800-258-0255

www.cornelius.com

a4a

4

7

7

1

1

Pump & Motor Assembly

P/N 45185

Item

No.

Part No. Name

Item

No.

Part No. Name

1 45016001 Pump Motor with Boot (item 7) 6 45098 Tubing Kit (1 Pre-cut Tube & 2

Clamps) (Not Shown)

2 45078 Pump Complete, 3-Roller 7 45074 Boot, Pump Motor (Not Shown)

3 45050 Block Assembly, Pump & Motor 8 45078 Roller

4a 45017001 Thumbscrew 46 720701407 Machine Screw, Phillips Pan

Head (Not Shown)

5 0702905 Screw, 8-32 x 3/4”

Manual Part No.: 620919547IPL 8 of 22 Millennium II 4000

Rev.: B July 7, 2003

© IMI Cornelius Inc., 2003

Page 44

13

13

ILLUSTRATED PARTS LIST

12

12

IMI CORNELIUS INC.

Anoka, MN 55303-6234

Telephone 1-800-238-3600

Facsimile 1-800-258-0255

10

10

11

11

One Cornelius Place

www.cornelius.com

2

2

4

4

3

1

1

6

6

7

7

8

8

3

5

5

Valve Panel Assembly

9

Item

No.

Part No. Name

Item

No.

9

Part No. Name

P/N 620407478

1 620045438 Beverage Valve Support 4V 8 31525037 O-Ring

2 45508200 Valve Block Assembly 9 48808001 Mixing Nozzle

3 07032001 Screw 8-18 10 620049103 Touch Panel Bracket 6V

4 720500033 Mixing Chamber 11 70171 Screw 8-32

5 45027001 Nozzle Bushing 12 45586 Washer, Hold Down

6 0704107 Screw 8-32 13 70152 Screw 6-32

7 45123 Static Mixer

Millennium II 4000 9 of 22 Manual Part No.: 620919547IPL

Rev.: B July 7, 2003

© IMI Cornelius Inc., 2003

Page 45

IMI CORNELIUS INC.

6

ILLUSTRATED PARTS LIST

10

10

6

4

4

3

8

3

16

16

8

1

1

5

5

12

12

2

2

One Cornelius Place

Anoka, MN 55303-6234

Telephone 1-800-238-3600

Facsimile 1-800-258-0255

www.cornelius.com

14

14

15

15

11

11

13

13

12

12

9

9

7

7

20

20

19

19

17

18

18

17

12

23

23

12

Valve Block Assembly

P/N 45508200

Item

No.

Part No. Name

Item

No.

Part No. Name

1 45506100 Valve Block 12 07032001 Screw, 8-18

2 45586 Hold Down Washer 13 16779003 “C” Frame Solenoid

3 49612 Valve Port, Water 14 48520001 Coil, 24VDC

4 18071 Armature Seat, Water, FFV 15 0720406 Nut, 10-32

5 7215323 Armature, Solenoid Valve 16 60281001 Ceramic Sleeve, Syrup, FFV

6 71815321 Retaining Ring, .242 ID 17 60280002 Ceramic Piston, Water FFV

7 18367 Coil Spring, SS 18 31525060 O-Ring .539 x .459 x .875 OD

8 31525020 O-Ring, 5/16 OD x .176 ID * 48979103 Spool & Sleeve Assembly

(Items 16, 17, 18)

9 19695001 Guide 19 7245699 Flow Control/Bonnet Assembly

10 620710107 Rubber Gasket, Valve Block 20 48258005 Spring, Syrup, FFV

11 45518 Bracket, Valve Block 23 45587 Hold Down Washer

Manual Part No.: 620919547IPL 10 of 22 Millennium II 4000

Rev.: B July 7, 2003

© IMI Cornelius Inc., 2003

Page 46

ILLUSTRATED PARTS LIST

7

7

8

Harness Push Button Switch #1

HARNESS PUSH BUTTON SWITCH #1

HARNESS PUSH BUTTON SWITCH #2

Harness Push Button Switch #2

8

9

9

Harness Push Button Switch #3

HARNESS PUSH BUTTON SWITCH #3

10

10

HARNESS PUSH BUTTON SWITCH #4

Harness Push Button Switch #4

5

5

IMI CORNELIUS INC.

One Cornelius Place

Anoka, MN 55303-6234

Telephone 1-800-238-3600

Facsimile 1-800-258-0255

www.cornelius.com

11

6

6

11

4

4

12

1

1

2

2

3

3

12

Touch Panel Assembly PB

P/N 620048129

Item

No.

Part No. Name

Item

No.

Part No. Name

1 620517818 Touch Panel 4V 7 620313326 Harness Push Button Switch #1

2 720508502 Bezel, Push Button 8 620313327 Harness Push Button Switch #2

3 720508601 Overlay “Push” 9 620313328 Harness Push Button Switch #3

4 720508801 Board, Push Button 10 620313329 Harness Push Button Switch #4

5 07301029 Flat Washer Nylon .312

OD X .125 ID

11 620045999 Bracket, Switch Protection 4V

(Deleted on some models)

6 0712901 Screw #4 Type B BH 12 70747 Screw MA 8-32 TRPH 16 ST BLK

Millennium II 4000 11 of 22 Manual Part No.: 620919547IPL

Rev.: B July 7, 2003

© IMI Cornelius Inc., 2003

Page 47

IMI CORNELIUS INC.

ILLUSTRATED PARTS LIST

7

7

HARNESS PORTION CONTROL SWITCH #1

Harness Portion Control Switch #1

8

8

HARNESS PORTION CONTROL SWITCH #2

Harness Portion Control Switch #2

HARNESS PORTION CONTROL SWITCH #3

Harness Portion Control Switch #3

One Cornelius Place

Anoka, MN 55303-6234

Telephone 1-800-238-3600

Facsimile 1-800-258-0255

www.cornelius.com

9

9

10

10

Harness Portion Control Switch #4

HARNESS PORTION CONTROL SWITCH #4

11

11

6

6

5

5

4

4

12

12

1

1

2

2

3

3

Touch Panel Assembly PC

P/N 620048131

Item

No.

Part No. Name

Item

No.

Part No. Name

1 620517818 Touch Panel 4V 7 620313332 Harness Portion Control Switch #1

2 720508505 Bezel, Portion Control 8 620313335 Harness Portion Control Switch #2

3 720508602 Overlay Portion Control 9 620313334 Harness Portion Control Switch #3

4 720508802 Board, Portion Control 10 620313333 Harness Portion Control Switch #4

5 07301029 Flat Washer Nylon .312

OD X .125 ID

11 620045999 Bracket, Switch Protection 4V

(Deleted on some models)

6 0712901 Screw #4 Type B BH 12 70747 Screw MA 8-32 TRPH 16 ST BLK

Manual Part No.: 620919547IPL 12 of 22 Millennium II 4000

Rev.: B July 7, 2003

© IMI Cornelius Inc., 2003

Page 48

16

IMI CORNELIUS INC.

One Cornelius Place

Anoka, MN 55303-6234

Telephone 1-800-238-3600

Facsimile 1-800-258-0255

www.cornelius.com

ILLUSTRATED PARTS LIST

1

1

4

4

14

14

5

5

16

3

3

4

4

E-BOX WIRING HARNESS

E-BOX WIRING HARNESS (INTERNAL)

(INTERNAL)

12

13 14 15

12 13 14 15

Electrical Box Assembly

P/N 620314115

Item

No.

Part No. Name

Item

No.

Part No. Name

1 620314116 E-Box 10 720201702 Harness Assembly Speed E-Box Blue

2 720201403 E-Box Cover 11 720201703 Harness Assembly PB Switch E-Box

White

3 07093001 Screw 8 x 3/8” PHSS

12 720201704 Harness Assembly Power E-Box

Self Drill

4 45238 Voltage Regulator

13 0733909 Bushing Snap 1/4 ID x 3/8 OD

Assembly SL

5 0704001 Screw 8 x 3/8 Type F TH 14 31707 Splicer, 1/4 QC

9 720201701 Harness Assembly

Pump E-Box Red

2

2

Millennium II 4000 13 of 22 Manual Part No.: 620919547IPL

Rev.: B July 7, 2003

© IMI Cornelius Inc., 2003

Page 49

IMI CORNELIUS INC.

HARNESS GIBC MAINS

HARNESS GIBC

AGITATOR

HARNESS GIBC

COMPRESSOR/FAN

HARNESS GIBC PROBE

BROWN WIRE: A1

BLUE WIRE: A2

GREEN/YELLOW WIRE: A3

BROWN WIRE: B4

BLUE WIRE: B5

GREEN/YELLOW WIRE: D10

BLUE WIRE: D11

BROWN WIRE: D12

One Cornelius Place

Anoka, MN 55303-6234

Telephone 1-800-238-3600

Facsimile 1-800-258-0255

www.cornelius.com

ILLUSTRATED PARTS LIST

4

4

GREEN/YELLOW WIRE: D10

HARNESS GIBC PROBE

5

5

3

HARNESS GIBC

COMPRESSOR/FAN

HARNESS GIBC

AGITATOR

BLUE WIRE: D11

BROWN WIRE: D12

BROWN WIRE: C7

BROWN WIRE: C7

BLUE WIRE: C8

BLUE WIRE: C8

GREEN/YELLOW WIRE C9

GREEN/YELLOW WIRE C9

BROWN WIRE: B4

BLUE WIRE: B5

1

HARNESS GIBC MAINS

BROWN WIRE: A1

BLUE WIRE: A2

GREEN/YELLOW WIRE: A3

Ice Bank Control Assembly

P/N 620314406

Item

No.

Part No. Name

1 440000902 Global Ice Bank Control-

Item

No.

Part No. Name

4 620313340 Harness GIBC Probe

ler

2 620313338 Harness GIBC Mains 5 620313341 Harness GIBC Compres-

sor/Fan

3 620313339 Harness GIBC Agitator 6 620049107 GIBC Bracket (Not Shown)

Rev.: B July 7, 2003

© IMI Cornelius Inc., 2003

Manual Part No.: 620919547IPL 14 of 22 Millennium II 4000

Page 50

IMI CORNELIUS INC.

One Cornelius Place

Anoka, MN 55303-6234

Telephone 1-800-238-3600

Facsimile 1-800-258-0255

www.cornelius.com

ILLUSTRATED PARTS LIST

4

4

1

1

5

5

2

HARNESS SPEED SWITCH

HARNESS SPEED SWITCH

6

6

7

7

Speed Switch Assembly

P/N 620313207

Item

No.

Part No. Name

Item

No.

Part No. Name

1 620049102 Bracket Speed Switch 4V 5 48457002 Label Notice SPD Switch #2

(Not Shown)

2 45432 Switch Rocker Sealed 6 48457003 Label Notice SPD Switch #3

(Not Shown)

3 720201900 Harness Speed Switch 4V

(Not Shown)

7 48457004 Label Notice SPD Switch #4

(Not Shown)

4 48457001 Label Notice SPD Switch #1

(Not Shown)

Millennium II 4000 15 of 22 Manual Part No.: 620919547IPL

Rev.: B July 7, 2003

© IMI Cornelius Inc., 2003

Page 51

IMI CORNELIUS INC.

7

ILLUSTRATED PARTS LIST

One Cornelius Place

Anoka, MN 55303-6234

Telephone 1-800-238-3600

Facsimile 1-800-258-0255

www.cornelius.com

5

5

3

3

4

4

7

1

1

6

6

8

8

2

2

Top Panel Assembly

P/N 620048134

Item

No.

Part No. Name

Item

No.

Part No. Name

1 620517015 Panel Top 4V Black 5 750300233 Boot Rocker Switch

2 750100265 Baffle Anti-Spill 4V 6 750300304 Harness Rocker Switch

3 750300230 Screw Snap-In Captive 8-32 7 33300 Switch Key

4 39725003 Switch Rocker 8 620313361 Harness Key Switch

Manual Part No.: 620919547IPL 16 of 22 Millennium II 4000

Rev.: B July 7, 2003

© IMI Cornelius Inc., 2003

Page 52

ILLUSTRATED PARTS LIST

13

13

IMI CORNELIUS INC.

One Cornelius Place

Anoka, MN 55303-6234

Telephone 1-800-238-3600

Facsimile 1-800-258-0255

www.cornelius.com

2

2

1

1

9

11

9

8

8

11

5

5

10

10

12

12

6

6

7

7

Merchandiser Assembly

P/N 6200444205

Item

No.