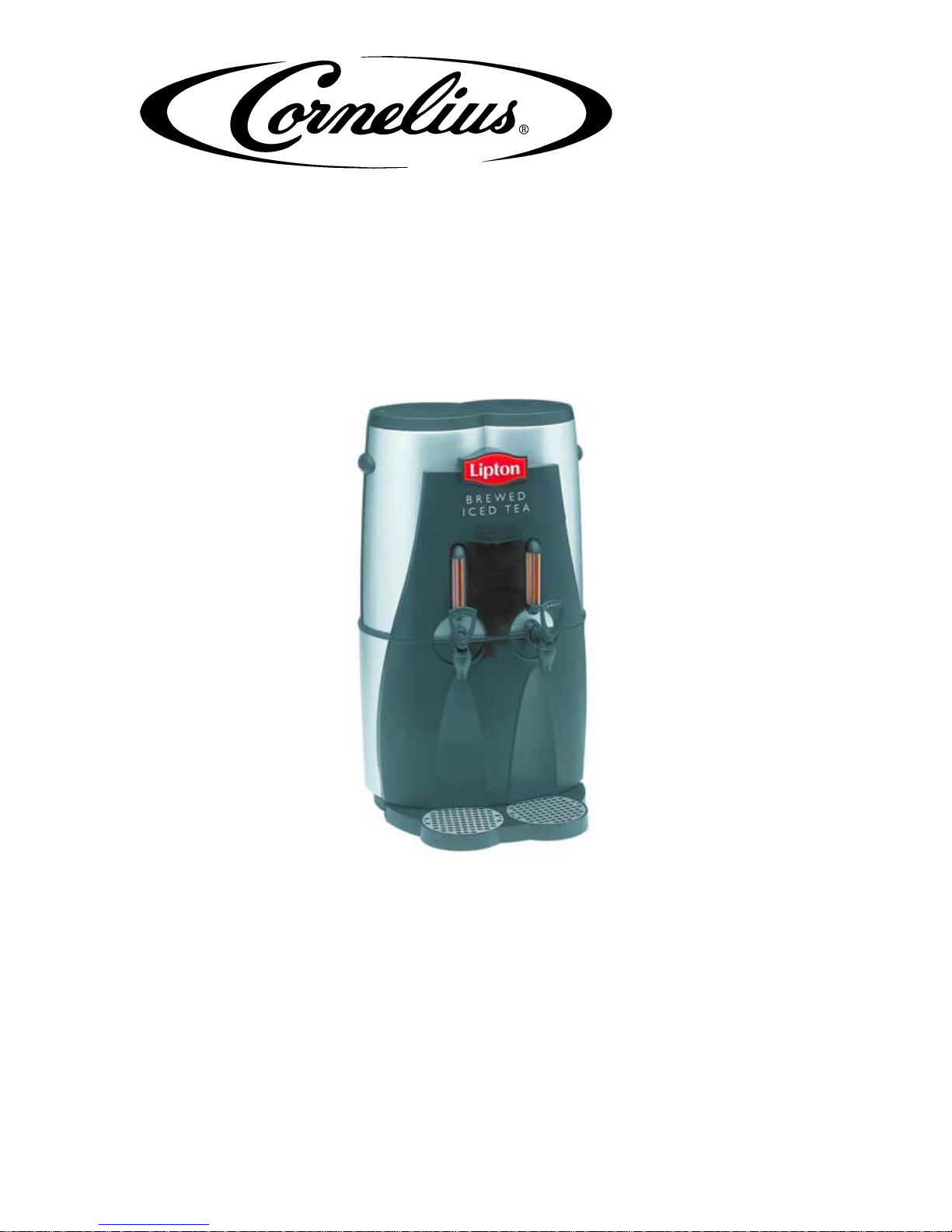

Cornelius Brewed Iced Tea, Lipton Brewed Iced Tea Double Valve Dispenser Installation & Service Manual

Page 1

Lipton Brewed Iced Tea

Double Valve Dispenser

Training, Installation, & Service Manual

Part No. 630460171 May 7, 2002

©2001-2002, IMI Cornelius, Inc. Revision B

Safety & Specifications

Installation

Service

Training

Page 2

Lipton Brewed Iced Tea Training, Installation, & Service Manual

630460171 ii May 7, 2002

Page 3

Lipton Brewed Iced Tea Training, Installation, & Service Manual

Lipton Iced Tea Brewer

Training, Installation, & Service Manual

The products, technical information, and instructions contained in this manual are subject

to change without notice. These instructions are neither intended to cover all details or

variations of the equipment, nor to provide for every possible contingency in the installation, operation, or maintenance of this equipment. This manual supposes that the person(s)

working on the equipment are trained and skilled in working with electrical, plumbing,

pneumatic, and mechanical equipment. In addition to the information this manual provides, Cornelius expects proper installation that includes taking appropriate safety precautions as well as adhering and meeting all local safety and construction requirements.

To inquire about current revisions of this and other documentation, or for assistance please contact:

NGB.

505 Cleveland Street

Blairsville, GA.

30512

U.S.A.

Trademarks and copyrights:

Aurora, Cornelius, Decade, Hydro Boost, Sitco, Spirit, UF-1, Vanguard, Venture, and Vista are registered

trademarks of IMI Cornelius.

Optifill trademark is pending.

LITB Dispenser US and Foreign Patents pending

Fresh Brewed Service:

------------ 1-866-LiptonT

------------1-866-547-8668

Email:

liptontea@ngbservice.com

This document contains proprietary information and it may not be

reproduced in any way without permission from Cornelius.

Printed in U.S.A.

Copyright © 2001-02, All Rights Reserved, IMI Cornelius Inc.

May 7, 2002 iii 630460171

Page 4

Lipton Brewed Iced Tea Training, Installation, & Service Manual

630460171 iv May 7, 2002

Page 5

Lipton Brewed Iced Tea Training, Installation, & Service Manual

TABLE OF CONTENTS

SAFETY- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1

Safety Instructions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -1

Read and follow all safety instructions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1

Recognize safety alerts - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -1

Different types of alerts - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -1

Safety Tips - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2

Authorized Service Personnel - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2

Hot Water Warning - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2

CO2 (Carbon Dioxide) Warning - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3

Shipping And Storage - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -4

Key Things To Know - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -4

Cleaning and Sanitation Practices - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -5

SYSTEM OVERVIEW - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7

Theory of Operation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -7

Function Keys - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -7

Language key - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -7

Menu key - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -7

Stop key - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -7

Rinse key - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -8

Run key - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -8

Menus and Modes of Operation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -8

DATA VIEW mode - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -8

SET TIME mode - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -9

SETTING THE TIME AND DATE - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 9

Setting the RINSE TIME - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -9

ADJUST STRENGTH mode - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 9

SERVICE mode - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -9

Display Errors - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 10

Tea Pump state - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 10

Sweetener valve state - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 10

Hot Brew water valve state - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 10

Rinse Water Valve State - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 10

Cold water valve state - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 10

Tea Bag Sold out state - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 11

Sweetener Sold out state - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 11

Hot water temperature - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 11

Heater relay state - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 11

Motor Volts - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 11

630460171 - v May 7, 2002

Page 6

Lipton Brewed Iced Tea Training, Installation, & Service Manual

Normal Pour - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 11

SET-UP mode - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 11

Tank Status - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 12

System Type - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 12

Set-Up Tea Syrup - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 12

Set-Up Sweetener - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 12

Set-up Cold Water - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 13

Set-Up Hot Brew Water - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 13

Timed Pour - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 13

Control Board Inputs: - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 15

Control Board Outputs: - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 15

Capacities - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 16

Environmental Specifications - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 16

INSTALLATION - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 17

Installation Requirements - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 17

Electrical Requirements - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 17

Environmental Requirements - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 18

Initial Installation Procedure - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 18

Delivery Inspection and Unpacking - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 18

Inspection - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 18

Installation Procedure - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 19

LBIT Installation and set up sequence - - - - - - - - - - - - - - - - - - - - - - - - - - - - 19

Filling the Water Tank - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 20

Set-up Tea Extract - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 21

Set-up Sweetener - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 22

Set-up Cold Water - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 22

Set-up Hot Brew Water - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 22

Set-up the Clock and Rinse Times - - - - - - - - - - - - - - - - - - - - - - - - - - - - 23

Initial Rinse Cycle/Final Adjustments - - - - - - - - - - - - - - - - - - - - - - - - - - 23

Rinse Cycle Procedure (General) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 24

Diagrams - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 26

Sweetener BIB Installation (General) - - - - - - - - - - - - - - - - - - - - - - - - - - - - 28

Maintenance - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 28

SERVICE - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 31

Scheduled Maintenance - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 31

Daily Cleaning - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 31

Daily System Flush (Hot Water Rinse) Procedure - - - - - - - - - - - - - - - - - - - - 32

Rinse Cycle Program - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 33

Monthly Sanitizing Procedure - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 34

Preventative Maintenance - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 35

Annual Pump Tubing Replacement Procedure - - - - - - - - - - - - - - - - - - - - - - 36

May 7, 2002 - vi 630460171

Page 7

Lipton Brewed Iced Tea Training, Installation, & Service Manual

Replacing Pump Tubing - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 36

Troubleshooting - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 39

Service Advisory - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 46

WARRANTY- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 47

630460171 - vii May 7, 2002

Page 8

Page 9

Lipton Brewed Iced Tea Training, Installation, & Service Manual

SAFETY

SAFETY INSTRUCTIONS

Read and follow all safety instructions

Read and follow all safety instructions in this manual and on the machine (decals,

labels, and laminated cards).

Before operating the machine, read and understand all applicable OSHA (Occupation

Safety and Health Administration) safety regulations available from the safety coordinator or supervisor.

Recognize safety alerts

This is the safety alert symbol used in this manual or on the machine. The

safety alert symbol is used to alert personnel to the potential of personal

injury, or damage to the machine.

Different types of alerts

There are three types of safety alerts:

DANGER: Indicates an immediate hazardous situation

which if not avoided WILL result in serious injury,

death, or equipment damage.

WARNING: Indicates a potentially hazardous situation

which, if not avoided, COULD result in serious injury,

death, or equipment damage.

CAUTION: Indicates a potentially hazardous situation

which, if not avoided, MAY result in minor or moderate

injury or equipment damage.

May 7, 2002 - 1 630460171

Page 10

Lipton Brewed Iced Tea Training, Installation, & Service Manual

SAFETY TIPS

• Carefully read all safety messages in this manual and safety signs on the

machine.

• Keep safety signs in good condition and replace missing or damaged safety signs.

• Learn how to operate the machine and how to use the controls properly.

• Do not let anyone operate the machine without proper training.

• Keep the machine in proper working condition.

• Do not allow unauthorized modifications to the machine.

• The brewer can dispense hot water. During the rinse operation water temperature

can exceed 205°F. Certain flow tubes in the brewer carry hot water. Use Caution.

• The heater tank contains no replaceable parts. The entire heater tank must be

replaced if service is required.

• Be certain that the dispenser nozzle is snugly threaded onto the spigot assembly.

AUTHORIZED SERVICE PERSONNEL

CAUTION: Only trained and certified electrical,

plumbing, and refrigeration technicians should

service this unit. ALL WIRING AND PLUMBING MUST

CONFORM TO NATIONAL AND LOCAL CODES.

HOT WATER WARNING

WARNING: This unit dispenses HOT water (160° F

(71°C) - 205° F (96°C) during the rinse cycle.

630460171 - 2 May 7, 2002

Page 11

Lipton Brewed Iced Tea Training, Installation, & Service Manual

CO2 (CARBON DIOXIDE) WARNING

WARNING: CO2 Displaces Oxygen. Strict Attention

must be observed in the prev ent ion of CO2 gas leaks

in the entire CO2 and system. If a CO2 gas leak is

suspected, particularly in a small area, immediately

ventilate the contaminated area before attempting to

repair the leak. Personnel exposed to high

concentration of CO2 gas will experience tremors

which are followed rapidly by loss of consciousness

and death.

CAUTION: PRECAUTIONS TO BE TAKEN IN

STORAGE: Store and use with adequate ventilation.

Firmly secure cylinders upright to keep from falling or

being knocked over. Screw valve protection cap firmly

in place by hand. Store only where temperature will

not exceed 52°C (125°F). Store full and empty

cylinders separately. Use a first-in, first-out inventory

system to prevent storing full cylinders for long

periods.

630460171 - 3 May 7, 2002

Page 12

Lipton Brewed Iced Tea Training, Installation, & Service Manual

CAUTION: PRECAUTIONS TO BE TAKEN IN

HANDLING: Protect cylinders from damage. Use a

suitable hand truck to move cylinders; do not drag,

roll, slide, or drop cylinders. Never attempt to lift a

cylinder by its cap; the cap is intended solely to

protect the valve. Never in sert an objec t (e.g. wrench,

screwdriver, pry bar) into cap openings; doing so may

damage the valve and cause a leak. Use an adjustable

strap wrench to remove over-tight or rusted caps.

Open valve slowly. If valve is hard to open,

discontinue use and contact your supplier. Never

apply flame or localized heat directly to any part of the

cylinder. High temperatures may damage the cylinder

and could cause the pressure relief device to fail

prematurely and venting the cylinder contents. Never

strike an arc on a compressed gas cyl inder or make a

cylinder part of an electrical circuit. For additional

information on storage and handling, refer to

Compressed Gas Association (CGA) pamphlet P-1,

“Safe Handling of Compressed Gases in Contai ners,”

available from the CGA.

Shipping And Storage

CAUTION: Before shipping, storing, or relocating the

unit, product extract systems must be sanitized;

completion requires purging all sanitizing solution

from the systems. In addition, all liquids, after

sanitizing, must be purged from the unit. A freezing

ambient environment causes residual sanitizing

solution or water remaining inside the unit to freeze

resulting in damage to the internal components.

K

EY THINGS TO KNOW

• Always unplug/disconnect the power to the dispenser before servicing.

• Verify adequate water line pressures and volumes.

• Verify water quality, optimum dispense taste may require water treatment.

• Rinse water is very hot (160°- 205° F (71°- 82°C)).

630460171 - 4 May 7, 2002

Page 13

Lipton Brewed Iced Tea Training, Installation, & Service Manual

• Do not activate the heater until the water tank is full.

• Rinse must be performed at least once every 24 hours or the brewer will lock out

and will not dispense product.

• The heater tank contains no replaceable parts. The entire heater tank must be

replaced if service is required.

• Warning Battery Life: Disconnecting the power supply or turning the power

switch off for longer than 48 hours will result in a service call to reprogram the

dispenser. The battery will recharge itself when the power is restored to the

board.

CLEANING AND SANITATION PRACTICES

It is imperative that the daily cleaning procedures, hot water flush, and monthly sanitizing

procedures be followed as outlined in chapter 4.

WARNING: Failure to follow the scheduled cleaning

and sanitizing procedures shown in chapter 4 may

result in the growth of potentially harmful bacteria in

the dispensed tea product.

May 7, 2002 - 5 630460171

Page 14

Lipton Brewed Iced Tea Training, Installation, & Service Manual

630460171 - 6 May 7, 2002

Page 15

Lipton Brewed Iced Tea Training, Installation, & Service Manual

SYSTEM OVERVIEW

The Lipton Iced Tea Brewer (LBIT) looks and operates like a leaf tea brewer. The LBIT

instantaneously mixes and dispenses tea extract, hot water, cold water, and liquid sweetener to provide a finished tea product. Unlike leaf tea brewers, the LBIT does not have

high maintenance and operational costs, and it is not as susceptible to the bacterial growth

inherent to leaf tea brewers.

The following descriptions provide basic information of:

• Theory of Operation

• Function Keys

• Menus and Modes of Operation

• Capacities.

THEORY OF OPERATION

The fresh brewed process involves the mixing of concentrated (100:1) tea extract with hot

water in order to brew the tea. A residence time of about 0.50 seconds ensures that the tea

mixture is adequately dispersed and increases clarity.

A metered quantity of cold water is added to the brewed tea mixture to produce finished

tea. The cold water reduces the temperature of the final product to approximately 90° F

(32° C). This temperature is similar to iced tea product dispensed from leaf tea brewers.

FUNCTION KEYS

The LBIT controller is a specific purpose circuit board residing within the brewer. The

controller monitors inputs, controls outputs, and provides service and display functions.

Keys providing the basic operations within the controller are labeled Language (-), Menu

(+), Stop (#), Rinse (<), and Run (>). The base operations of the keys are as follows.

Language key

Pressing this key will toggle the display between English and Spanish.

Menu key

Pressing this key will advance the display to the beginning of the next menu item.

There are five menu functions that may be selected: Data View, Set - Time, Strength,

Service, and Set-up.

Stop key

Pressing this key will put the brewer in stop mode. In this mode all normal functions

occur except that tea will not be dispensed when the spigot handle is pulled.

May 7, 2002 - 7 630460171

Page 16

Lipton Brewed Iced Tea Training, Installation, & Service Manual

Rinse key

WARNING: This unit dispenses HOT water (160° F. 205° F. (71°C - 96°C) during the rinse cycle.

Pressing this key will place the brewer in the rinse cycle mode. In this mode the

brewer will require user intervention to initiate each flush of hot water through the

system. This is done by opening the spigot when prompted to do so on the display.

After the rinse is completed, the brewer automatically returns to run mode.

Run key

Pressing this key will return the brewer to run mode. This is the only mode where a

normal dispense is available.

NOTE: While in run mode, if an alarm occurs (over temp, sold out,

etc.) the brewer will display the current er rors being de tected. Pressing the LANGUAGE key will step through the current errors being detected.

MENUS AND MODES OF OPERATION

Pressing the MENU key will scroll through five basic modes in a round robin fashion. The

menus and their order are: DATA VIEW, SET TIME, STRENGTH, SERVICE, and SETUP.

To enter a selected mode, the STOP (#) key may be pressed. Once a particular mode is

entered, the keypad keys are referenced as (-), (+), (#), (<), and (>). Display screen

prompts will tell the operator what to do. In general the keys will have the following function: Scroll forward or backward press (>) or (<), change a value press (+) or (-), to exit or

enter a mode or sub-mode (#).

DATA VIEW mode

Scroll to the Data View Mode using the menu key. Press the (#) key to enter. Press the

(>) to advance. The Data View sub modes include: Time of Day, Water Temperature,

Gallons of tea poured in the last 30 days, Total Gallons of tea poured over the life of

the brewer, Number of tea sold outs recorded (bags used), Number of sweetener sold

outs recorded (bags used), and the Number of days the brewer has been in operation.

630460171 - 8 May 7, 2002

Page 17

Lipton Brewed Iced Tea Training, Installation, & Service Manual

SET TIME mode

SETTING THE TIME AND DATE

1. Press MENU until ENTER SET TIME? is displayed.

2. Press (#) key to enter SET TIME and press (>) to advance.

3. Press the (#) key to en ter SET CLOCK?. Read the flash screens.

Press (>) or (<) key to move the cursor. Press (+ ) or (-) keys to

change settings. Press (#) key twice to save new settings.

Setting the RINSE TIME

Contact the manager or the “decision maker” of the restaurant. Request a

time of the day when the brewer will be cleaned. Recommend a time when

they open the restaurant in the morning. This time should be when they normally clean their dispensing equipment, or when there are no customers at

the restaurant, or a slow time of the day.

1. Press the (#) key to enter SET RINSE TIME?. Read the flash

screens. Press (>) or (<) key to move the cursor. Press (+) or (-)

keys to change settings. Press (#) key twice t o save new settings.

2. Press (#) twice to save the rinse time.

3. Press the (#) key to exit SET TIME.

ADJUST STRENGTH mode

1. Press MENU until ENTER STRENGTH? is displayed.

2. Press (#) to enter and (>) to advance.

3. Read the flash screens. Press (+) or (-) key to change strength settings.

Press (+) or (-) keys to change set tings. The allowed adjustment range in

this screen is +/-5% of the installed strength. Ea ch p ress o f th e (+) or (-)

keys will change the tea strength by 1% until the 5% maximum change is

reached.

4. Press (>) to advance and (#) to exit.

SERVICE mode

1. Press MENU until ENTER SERVICE? is displayed.

2. To enter Press and hold the STOP key and then press the RUN key.

3. Press (>) to advance to the following sub-modes.

May 7, 2002 - 9 630460171

Page 18

Lipton Brewed Iced Tea Training, Installation, & Service Manual

4. Press (#) to enter or exit the sub-modes and follow the display instructions.

DISPLAY ERRORS

Displays most recent error first Press (>) to advance through all errors.

TEA PUMP STATE

This screen displays the current state of the Tea pump (ON/OFF). Pull the

dispense lever to start the flow of tea. Release the dispense lever to stop the

flow of tea.

SWEETENER VALVE STATE

This screen displays the current state of the Sweetener valve drive (ON/OFF

or DISABLED). Pull the dispense lever to start the flow of sweetener.

Release the dispense lever to stop the flow of sweetener.

NOTE: If the brewe r is instal led as unsweete ned, the val ve is overridden and locked out, and the controller skips over this function in Service mode.

HOT BREW WATER VALVE STATE

This screen displays the current state of the Hot water valve drive (ON/

OFF). Pull the dispense lever to start the flow of hot water. Release the dispense lever to stop the flow of hot water.

Note: The Hot water valve drive operates both the input and output

Hot water valves at the same time.

RINSE WATER VALVE STATE

This screen displays the current state of the Rinse water valve drive (ON/

OFF). Pull the dispense lever to start the flow of hot water. Release the dispense lever to stop the flow of hot water.

COLD WATER VALVE STATE

This screen displays the current state of the Cold water valve drive (ON/

OFF). Pull the dispense lever to start the flow of cold water. Release the dispense lever to stop the flow of cold water.

630460171 - 10 May 7, 2002

Page 19

Lipton Brewed Iced Tea Training, Installation, & Service Manual

TEA BAG SOLD OUT STATE

This screen displays the current state of the Tea Extract Bag (Sold Out or

OK).

SWEETENER SOLD OUT STATE

This screen displays the current state of the Sweetener (Sold Out or OK).

This screen is skipped if unit is installed as unsweetened.

HOT WATER TEMPERATURE

This screen displays the current hot water heater tank temperature. Pressing

the (+) or (-) key will toggle the display between degrees Fahrenheit and

degrees Celsius.

HEATER RELAY STATE

This screen displays the current state of the hot water heater safety relay

(ON/OFF). Pressing the LANGUAGE key will toggle the state between ON

and OFF. When leaving this screen the safety relay will toggle to ON, unless

an overriding error is present.

MOTOR VOLTS

This screen displays the DC voltage available to drive the tea pump.

NOTE: 30 to 40 Volts DC range. Usually, approximately 37 Volts will

be displayed.

NORMAL POUR

Pull the dispense lever to dispense finished product.

SET-UP mode

1. Press menu until Enter SET-UP is displayed.

2. Press and hold the STOP key and then press the RINSE key

3. Press (>) to advance to the following sub-modes.

May 7, 2002 - 11 630460171

Page 20

Lipton Brewed Iced Tea Training, Installation, & Service Manual

4. Press (#) to enter or exit the sub-modes and follow the displayed instructions.

CAUTION: Ensure there is water in the heater before

the heater relay is turned ON. Otherwise the heater will

fail and it will have to be replaced.

TANK STATUS

The heater tank may be filled with water in this sub-mode. Once water flows

from the spigot nozzle then change the tank status to FULL.

SYSTEM TYPE

The system configuration is displays a double or single spigot.

SET-UP TEA SYRUP

Follow the display instructions to prime the tea extract lines, adjust strength

and dispense a 10 second calibration pour. This is used to calibrate the

amount of tea to be dispensed during a normal pour sequence (approximately 1 gram per second).

NOTE: Tea extract may accumulate in the mix chamber. Several dispenses may be required for tea extract to start flowing from the nozzle.

The allowed strength accustomed range is +/- 20%. Each press of the (+) or

(-) keys will change the tea strength by 1% until the 20% maximum change

is reached.

SET-UP SWEETENER

Pressing the (+) or (-) keys will toggle the sweetener valve from OFF (disabled)) and ON. If OFF is selected, the next step is skipped.

Follow the display instruction to prime the sweetener line and to dispense a

10 second calibration pour. This is used to calibrate the amount of sweetener

to be dispensed during a normal pour sequence.

630460171 - 12 May 7, 2002

Page 21

Lipton Brewed Iced Tea Training, Installation, & Service Manual

SET-UP COLD WATER

Holding the spigot open during this step will cause the brewer to do a 10 second cold water only pour. This is used to calibrate the amount of cold water

to be dispensed during a normal pour sequence.

WARNING: This unit dispenses HOT water (160° F. 205° F.(71°C - 96°C)) during the rinse cycle.

SET-UP HOT BREW WATER

Holding the spigot open during this step will cause the brewer to do a 10 second hot water only pour. This is used to calibrate the amount of hot water to

be dispensed during a normal pour sequence.

TIMED POUR

Holding the spigot open during this step will cause the brewer to do a 10 second finished product pour. This is used to calibrate the total amount of product dispensed during a normal pour sequence.

May 7, 2002 - 13 630460171

Page 22

Lipton Brewed Iced Tea Training, Installation, & Service Manual

PUSH KEY Quick Reference

Push Key

LANGUAGE Toggles between English and Spanish

MENU Scrolls to main menu functions of DATA, SET TIME, ADJUST STRENGTH, AND SERVICE

RINSE Initiates RINSE function

STOP Will stop and prevent further dispensing action (heater stays on)

RUN Initiates normal dispense and operational functions.

Push Key Function

MENU Quick Reference

MENU Option

DATA Selected operational data may be viewed.

SET TIME Clock and Rinse times may be set.

ADJUST STRENGTH Tea strength may be adjusted to a range of +/- 5 percent of as-installed strength.

SERVICE Various service screens (as noted below) may be viewed.

SET-UP Various set-up screens (as noted below) may be viewed.

MENU Option Function

Service Mode is entered by pressing and HOLDING Stop Key and then pressing Run Key.

Set-Up Mode is entere d by pressing and HOLDING Stop Ke y an d th en pres si ng R ins e Key.

SERVICE Quick Reference

SERVICE Screens

Display Errors Error displays may be scrolled by pressing (>) or (<) Keys.

Tea Pump State Tea extract flow may be initiated by pulling spigot handle.

Sweetener Valve State Sweetener flow may be initiated by pull ing spig ot hand le.

Hot Brew Valve(s) State Hot brew water flow may be initiated by pulling spigot handle.

Rinse Valve State Rinse water flow may be initiated by pulling spigot handle.

Cold Water Valve State Cold water flow may be initiated by pulling spigot handle.

Tea Bag Status OK or Soldout

Sweetener Status OK or Soldout

Hot Water Temp In degrees C or F, press (+) or (-) Key To Flip.

Heater Relay Status On or Off press (+) or (-) Key To Flip.

Motor Volts Volts DC

Normal Pour Dispensed drink flow may be initiated by pulling spigot handle

SERVICE Screen Function

SET-UP Quick Reference

SET-UP Screens

Tank Status Operator is able to fill the tank and set the tank status of empty or full.

System Type Single or double spigot configuration is displayed.

Set-Up Tea Extract Operator may prime the tea extract lines and run a 10 seconds calibration pour.

Set-Up Sweetener Operator may set sweetened or unsweetened operation, prime the sweetener lines, and

INSTALL Screen Function

Tea strength may be adjusted to a range of +/- 20 percent of factory set pump speed.

run a 10 second calibration pour.

630460171 - 14 May 7, 2002

Page 23

Lipton Brewed Iced Tea Training, Installation, & Service Manual

Set-Up Cold Water Operator may run a 10 second calibration pour.

Set-Up Hot Brew Operator may run a 10 second calibration pour.

Set-Up Timed Pour Operator may run a 10 second calibration pour.

Error Light Functions

No Light No errors present/dispense ready

Red/Blinking Light Error is present/may not dispense

Possib le errors - out of tea ex tract, ou t of s weetener, rinse required, high water temperature

and low water temperature.

Control Board Inputs:

• Tea Extract Sold Out Sensor

• Based on electrical continuity to detect the presence of tea extract.

• An electrode assembly is inserted into the sold out chamber located

between the pump and the tea bag.

• Sweetener Sold Out Sensor

• This is a pressure based sensor. A sold out condition exists when

there is a loss of BIB pump pressure.

• Water Temperature Sensor

• A temperature sensor is affixed to the water tank to sense hot water

temperature. A HIGH temperature errors will occur when water

temperature is above 215° F. A low temperature error will occur

when the sensed temperature is under 40°F.

• Dispense Switch

• A microswitch is closed when the dispense lever is pulled forward

• This action initiates the dispense function through the control

board.

• Main Power Switch

• A manual power switch at rear of unit activates power to the dis-

penser.

Control Board Outputs:

• Tea Pump

• A peristalic pump is activated to pump tea extract.

• Heater Relay

• The heater relay for the hot water heater operates the heater to

maintain tank temperature between 178°F and 183°F.

• The relay opens to stop heating when there is a high water tempera-

ture error.

May 7, 2002 - 15 630460171

Page 24

Lipton Brewed Iced Tea Training, Installation, & Service Manual

• The bimetallic thermostat mounted on the heater tank acts as a

redundant shut-off control in the event of a malfunction of the

heater relay.

• Wate r Valv e s

• Inlet and outlet water valves to the hot water tank are activated

simultaneously to initiate flow of hot water.

• Sweetener Valve

• The sweetener valve is activated to initiate flow of sweetener

(unless deactivated during installation).

• Error Light

• Flashing red LED is activated in the event of an error.

CAPACITIES

Environmental Specifications

This brewer is intended for indoor installation only

Operating Temperature Range 60° F. to 110° F. (10°C - 38°C)

Storage Temperature Range 40° F. to 130° F (4°C - 54°C)

Electrical Requirement 15 amp

Water Inlet Size 3/8-inch (0.95 cm)

Water Flow Rate 2.5-ounce/second (74 ml/sec) one spigot open

5.0-ounce/second (148 ml/sec) two spigots open

Water Pressure Flowing 35psi (2.41 bar) (minimum) - 80 psi (5.52 bar) (maximum)

Note: If water filter is installed, the 35psi flowing pressure must be

maintained on the outlet side of the filter.

TABLE 1.

Dimensions and Weight Double Spigot

Counter must be level and capable of supporting

brewer weights

Height above counter 27.75 inches (70.5 cm)

Width 16.25 inches (41.3 cm)

Depth 15.00 inches (38 cm)

Shipping weight (approx) 64 lbs.

630460171 - 16 May 7, 2002

Page 25

Lipton Brewed Iced Tea Training, Installation, & Service Manual

INSTALLATION

CAUTION: Only trained and certified electrical, plumbing

and refrigeration technicians should service this unit. ALL

WIRING AND PLUMBING MUST CONFORM TO

NATIONAL AND LOCAL CODES.

INSTALLATION REQUIREMENTS

Electrical Requirements

Before connecting electrical power to the brewer refer to nameplate to determine the

power requirements.

WARNING: To avoid possible electrical shock make sure

the brewer is properly grounded by connecting the earth

ground cable in the power cord to any connection in the

machine marked with a ground symbol.

CAUTION: The wiring must be properly grounded and

connected through a 15-amp disconnect switch (slow–blow

fuse or equivalent HVAC/R circuit breaker). ALL WIRING

MUST CONFORM TO NATIONAL AND LOCAL

CODES.

CAUTION: Only trained and certified electrical, plumbing

and refrigeration technicians should service this unit. ALL

WIRING AND PLUMBING MUST CONFORM TO

NATIONAL AND LOCAL CODES.

May 7, 2002 - 17 630460171

Page 26

Lipton Brewed Iced Tea Training, Installation, & Service Manual

Environmental Requirements

CAUTION: This unit is designed for indoor installation

only, in a non-harsh environment, and out of direct sunlight.

CAUTION: If the unit is exposed to freezing temperature

water in the unit will freeze and may damage the unit.

NITIAL INSTALLATION PROCEDURE

I

Delivery Inspection and Unpacking

INSPECTION

Upon delivery inspect the brewer for damage or irregularities and immediately report problems to the delivering carrier and file a claim with that carrier.

1. Open loose parts packages and inspect parts.

2. Make sure all items are present.

LOOSE PARTS: LBIT Double

Name Part Number Quantity

Urn Filling Tube 560005292 1

3/4” X 1/2” Barb Fitting 560005289 1

Install Instructions - English 630460160 1

Install Instructions - Spanish 630460161 1

Quick Reference Guide - English 630406152 1

Quick Reference Guide - Spanish 630460153 1

Sanitizing Instructions - English 630460165 1

Sanitizing Instructions - Spanish 630460175 1

Drip Tray 560005866 1

Cup Rest 560005867 2

1/2” Union Fitting 560005721 1

Rinse Pitcher 560005277 2

630460171 - 18 May 7, 2002

Page 27

Lipton Brewed Iced Tea Training, Installation, & Service Manual

3. Drip Tray Plumbing Procedure:

• Permanent Drain Connection: It is highly recommended that

the drip tray be connected to a permanent drain tube. The

drain hole in the rear of the drip tray must first be drilled out

with a 5/16” (0.79 cm) drill bit. A plastic drain tube .50” (1.27

cm) outside diameter (not provided) should then be pushed into

the open end of the coupling. The drain tube must be routed

through the lower, rear opening of the housing. The exterior

drain plumbing must comply with local codes. A coupling is

provided to connect the permanent drain tube. The coupling

should be pushed over the 1/2” port on the drip tray.

• No Drain Connection: Optionally, the drip tray may be

installed without connecting to a permanent drain tube. In such

case the drip tray will need to be emptied manually, and the

water heater over flow tube must not be emptied into the drip

tray. The overflow tube must first be disconnected from the

vertical nozzle hidden behind the center support of the lower

housing (must remove lower door to expose). Then the overflow

tube must be lengthened with a barbed splicer and a tube

extension not supplied with the dispenser. The lengthened overflow tube must then be routed through the lower, rear opening

of the housing. The exterior drain plumbing must comply with

local codes.

WARNING: Failure to route the overflow tube away from

the drip tray could result in overflow of hot water from the

drip tray and cause personal injury.

WARNING: Battery Life

Disconnecting the power supply or turning the power switch

off for longer than 48 hours will result in a service call to

reprogram the dispenser. The battery will recharge itself

when the power is restored to the board.

INSTALLATION PROCEDURE

LBIT Installation and set up sequence

NOTE: Read all of these directions before starting installation.

NOTE: The LBIT must be installed with adequate backflow protection to

comply with applicable federal, state, and local codes.

May 7, 2002 - 19 630460171

Page 28

Lipton Brewed Iced Tea Training, Installation, & Service Manual

FIGURE 1 Installation Procedure

The following sections include the brewer’s installation and set up procedures.

FILLING THE WATER TANK

1. Install the Water Filter supplied between the incoming water line and the

brewer.

2. A Water Booster Kit should be added if the water pressure to the unit is

below 40-psi static pressure or 35-psi flowing pressure. A Water Pressure Regulator should be added if the static pressure is above 70-psi.

3. Connect the 3/8-inch water filter outlet to the water inlet fitting on the

back of the brewer. Connect sweetener BIB to the 1/4-inch sweetener inlet tube.

4. Connect the Power Cord to a dedicated 115-volt, 15-amp circuit. Turn

the ON/OFF power switch located on the back of the unit to the ON position.

5. Slide open the top front access door and press the (-) key for 5 seconds

to unlock the key pad.

6. Press Menu key until Enter SET-UP? is displayed.

7. Press and hold the STOP key and then press the RINSE key to enter

SET-UP.

8. Press (>) and then the (#) key to enter TANK STATUS and then read

the flash screen. The Hot Water Tank screen will be displayed. It will

read Is Set To EMPTY.

630460171 - 20 May 7, 2002

Page 29

9. Press (>) key to advance to the FILL WATER TANK screen.

10. Place one of the pitchers that were supplied under the right nozzle.

11. Pull the Right Lever to fill the Hot Water Tank. Release Lever when water begins to pour from the Nozzles. It should take approximately 2 minutes to fill the tank.

12. Press (>) key twice until the Hot Water Tank screen is displayed.

13. Press (+) key to change the Hot Water Tank status to Is Set To FULL.

This will start the tank heater. The heater relay will be turned ON. It will

take approximately 15 to 20 minutes for the temperature of the water in

the tank to reach the desired brewing temperature 160°F minimum to

180°F maximum.

14. Press (<) key and then the (#) key to exit the TANK STATUS.

SET-UP TEA EXTRACT

Lipton Brewed Iced Tea Training, Installation, & Service Manual

1. Press (>) key twice and then the (#) key to enter SETUP TEA SYRUP?.

2. Remove tea extract bag from cardboard box. Handle with care. Unplug

Cap from bag. Hook the blue/white connector in the brewer to the bag.

Ensure that the connector is snapped twice and tight. Hang the bag with

the two holes in the end of the bag to the two red pegs in the brewer, with

the connector facing inside of the unit.

3. Place both pitchers that were supplied - one under each nozzle.

4. Pull both levers to prime the Tea Pumps. Release levers when Tea Syrup

runs from both Nozzles.

5. Press (<) key and then the (#) key to exit SETUP TEA SYRUP?.

May 7, 2002 - 21 630460171

Page 30

Lipton Brewed Iced Tea Training, Installation, & Service Manual

SET-UP SWEETENER

1. Press the (#) key to enter SETUP SWEETENER. Read the flash screen.

2. Verify that the Unit is set for Sweet, if not press (+) key to set the unit

for sweet.

3. Press (>) key to advance to the PRIME SWEET LINE screen.

4. Pull the Right Lever to fill the sweetener lines. Release lever when

sweetener pours from the Right Nozzle.

5. Press (>) key to advance to the TEST SWEETENER screen.

6. Pull the Right Lever to dispense sweetener. The unit will dispense

sweetener for 10 seconds. A normal setting is 115 ml in a 10-second

pour (approx. 10 brix). Turn far right sweetener flow control all the way

counter-clockwise as a starting point (approx. 5 brix). Turn the knob

clockwise to increase sweetness. Do not turn knob more than 2 full turns

clockwise to at which point maximum sweetness (approx. 15 brix) is

reached.

7. Press (>) and then the (#) key to exit SETUP SWEETENER?.

SET-UP COLD WATER

1. Press the (#) key to enter SETUP COLD WATER.

2. Pull a Lever to dispense cold water. The unit will dispense for 10 seconds. Measure volume of cold water dispensed in the measuring pitcher.

It should be 587 ml of cold water for the unsweetened tea spigot, and

472 ml cold water for the sweetened tea spigot. Turn the valve adjusting

screws clockwise to increase flow, and counter-clockwise to decrease

flow.

3. Press (>) key and then (#) key to exit SETUP COLD WATER.

SET-UP HOT BREW WATER

1. Press (#) key to enter SETUP HOT BREW.

2. Pull a Lever to dispense brew water. The unit will dispense for 10 seconds. Measure volume of brew water dispensed in the measuring pitcher. It should be 147 ml of water for each spigot. Turn the valve adjusting

screws clockwise to increase flow, and counter-clockwise to decrease

flow.

3. Press (>) and then the (#) key to exit SETUP HOT BREW.

630460171 - 22 May 7, 2002

Page 31

Lipton Brewed Iced Tea Training, Installation, & Service Manual

4. Press (>) and then the (#) key to exit SETUP.

NOTE: It is necessary to have the power connected and the ON/OFF switch

in the ON position for at least 20 minutes before setting the Clock and Rinse

Times.

This is necessary to insure the battery has sufficient power to retain the settings.

SET-UP THE CLOCK AND RINSE TIMES

1. Press MENU until ENTER SET TIME? is displayed.

2. Press (#) key to enter SET TIME.

3. Press (>) and then the (#) key to enter SET CLOCK?. Read the flash

screens. Press (>) or (<) key to move the cursor. Press (+) or (-) key to

change settings. Press (#) key twice to save new setting.

4. Contact manager or the “Decision Maker” of the restaurant. Request a

Time of the day when the brewer will be cleaned. Recommend a time

when they open the restaurant in the morning. This time should be when

they normally clean their dispensing equipment, or when there are no

customers at the restaurant, or a slow time of the day.

5. Press (#) key to enter SET RINSE TIME?. Read the flash screens. Set

the rinse time according to the procedure in step 37.

6. Press (#) key twice to save the rinse time.

7. Press (#) key to exit SET TIME.

INITIAL RINSE CYCLE/FINAL ADJUSTMENTS

1. Press MENU until ENTER DATA VIEW? is displayed.

2. Press (#) key and then the (>) key 2 times until Hot Water (F) Temperature is displayed. Read the flash screen.

3. Wait for the display to indicate a steady temperature of at least 170°F.

4. Press (<) key 2 times and then the (#) key to exit DATA VIEW.

5. Press RINSE key and then the (+) key 3 times to start a RINSE CYCLE.

Follow instructions displayed on the screen and perform the RINSE operation. The 5th flush will prime the system and will display Run Ready

to serve.

May 7, 2002 - 23 630460171

Page 32

Lipton Brewed Iced Tea Training, Installation, & Service Manual

6. Pour glass of tea over ice and serve the Restaurant Manager to taste.

7. If strength of tea requires an adjustment, press MENU key until ENTER

SETUP? is displayed. Press and hold the STOP key and then press the

RINSE key to enter the SETUP screens.

8. Press (>) key 3 times until SETUP TEA SYRUP is displayed, and then

press (#) key to enter SETUP TEA SYRUP. Press (>) key twice to advance to STRENGTH - Right Spigot. Press (+) or (-) keys to adjust tea

strength as desired. The total sample of adjustment for the installer is

from -20% to +20%.

9. Press (>) twice and repeat above strength adjustment procedure for left

spigot.

Note:The operator can make additional Tea Strength adjustments by using

the menu key to scroll to the ADJUST STRENGTH mode and following the

instructions on the display. Range +/-5%. Explain this procedure to the store

manager.

10. Press (>) key and then (#) key to exit SETUP TEA SYRUP.

11. Press (>) 4 times, and then press (#) key to exit SETUP.

12. Press the RUN key to advance to normal operation.

13. If Sweetener adjustment is required, turn the knob IN (Clockwise) for a

higher sweetener flow rate. Turn the knob OUT (counter clockwise) for

a lower sweetener flow rate. Reference step 22.

RINSE CYCLE PROCEDURE (GENERAL)

WARNING: This unit dispenses HOT water (160° F. - 205°

F. (71°C. - 96°C.)) during the rinse cycle.

1. If the display says “Rinse Required Go to Rinse Mode” a rinse must be performed before the unit will operate.

2. Place the 1000 ml capacity pitcher provided with the dispenser under the spout.

During the rinse procedure, hot water will be dispensed: Caution must be tak-

en.

CAUTION: Use the pitcher provided with the dispenser to avoid possibility

of overfilling and tipping. Otherwise, use a pitcher with the following specifications:

630460171 - 24 May 7, 2002

Page 33

Lipton Brewed Iced Tea Training, Installation, & Service Manual

• Minimum Fill Capacity: 34 oz (1.0 liter)

• Diameter: 4.0 to 5.0 in. (10 cm. to 12.7 cm.)

• Maximum Height: 8.0 in. (20 cm.)

• Temperature Rating: 210°F (99°C.)

Note: If the rinse procedure is not completed with in 1 hour after starting, it

will be canceled and the entire Rinse Cycle will need to be run again.

3. Press the RINSE key and follow the instructions on the display

4. Place the pitcher provided with the brewer under the spout or follow pitcher

specifications provided above to select a pitcher to collect the HOT rinse water

5. Pull the handle down to start the flow of HOT water. 1 of 5 will be displayed.

6. When water stops flowing, return the handle to the up position.

7. The rinse cycle consists of 5 separate HOT water pours plus 1 normal product

pour for a total dispense of 18 ounces (532 ml.). The operator will be prompted

by the display screen to dispense a pour every 80 seconds and the pours will be

displayed 1 of 5, 2 of 5 etc. until the rinse procedure is complete. The complete

rinse cycle will take about 7 minutes.

8. At the end of the 5 HOT water pours and 1 product pour pull up the lever and

press the RUN key to return to normal operation.

Note: A rinse cannot be performed if the water temperature is less than

160°F.

CAUTION: The heater tank contains no replaceable parts.

The entire heater tank must be replaced if service is

required.

May 7, 2002 - 25 630460171

Page 34

Lipton Brewed Iced Tea Training, Installation, & Service Manual

DIAGRAMS

630460171 - 26 May 7, 2002

FIGURE 2 Plumbing Diagram

Page 35

Lipton Brewed Iced Tea Training, Installation, & Service Manual

May 7, 2002 - 27 630460171

FIGURE 3 Wiring Diagram

Page 36

Lipton Brewed Iced Tea Training, Installation, & Service Manual

SWEETENER BIB Installation (General)

WARNING: To avoid personal injury and/or property

damage, always secure CO2 cylinder in upright position

with a safety chain to prevent it from falling over. Should

valve become accidentally damaged or broken off, CO2

cylinder can cause serious personal injury.

1. Adjust sweetener pump CO2 regulator with 100-psi gage to between 45 and 65psi (80-psi maximum).

2. Connect Bag-in-Box into the Sweetener system.

3. In the electronic display, scroll to “SET-UP MODE” by using the MENU key.

Open the service menu by pressing and holding the STOP key while pressing the

RINSE key at the same time.

4. Scroll to “SET-UP SWEETENER” then press (#) to enter.

5. Scroll to “UNIT IS SET FOR” screen by pressing (>) key. Toggle the sweetener

valve from OFF (disabled) to ON by pressing the (+) key.

6. Press the (>) key twice to “TEST SWEETENER” screen. Hold the spigot open

do a 10 second sweetener pour. This is used to calibrate the amount of sweetener

to be dispensed during a normal pour sequence.

7. Press the Run key to return to normal operation.

Maintenance

WARNING: CO2 displaces oxygen. Strict attention must be

observed in the prevention of CO2 (carbon dioxide) gas

leaks in the entire CO2 and soft drink system. If a CO2 gas

leak is suspected, particularly in a small area, immediately

ventilate the contaminated area before attempting to repair

the leak. Personnel exposed to high concentration of CO2

gas will experience tremors which are followed rapidly by

loss of consciousness and suffocation.

1. Make sure CO2 and syrup supplies are maintained at all times.

2. Remove syrup accumulation form the Bag-in-Box connectors by immersing and

washing them in warm water.

630460171 - 28 May 7, 2002

Page 37

Lipton Brewed Iced Tea Training, Installation, & Service Manual

3. To replenish the sweetener supply, disconnect sweetener line connector form the

empty Bag-in-Box, then connect sweetener line connector to a full box.

FIGURE 4 Bag-In-Box Sweetener System Diagram

FIGURE 5 Sweetener Line & Soldout Switch Inside the Unit

Required Tubing Size:

Standard System Distance -

tanks to dispenser

1 - 50 ft 1/4 inch

16

15

Plug

Tubing Size (i.d.)

51 - 250 ft 3/8 inch

250 ft 1/2 inch

May 7, 2002 - 29 630460171

Page 38

Lipton Brewed Iced Tea Training, Installation, & Service Manual

630460171 - 30 May 7, 2002

Page 39

Lipton Brewed Iced Tea Training, Installation, & Service Manual

SERVICE

Service consists of:

• Scheduled Maintenance

• Preventative Maintenance

• Troubleshooting

SCHEDULED MAINTENANCE

Scheduled maintenance consists of:

• Daily cleaning

• Daily system flush (hot water rinse) procedure

• Monthly sanitizing procedure

Daily Cleaning

1. Prepare the following in four clean buckets.

• Rinse bucket − fill with clean tap water.

• Detergent bucket: mix a solution of mild detergent and warm water.

• Hot rinse pitcher: fill with clean hot water from either the dispenser or from

the tap.

• Empty catch pitcher: empty pitcher to catch the hot water.

2. Remove cup rest and drip tray, submerge them in the detergent bucket and clean

them with a brush or cloth.

3. Remove each part and submerge them into the rinse bucket to remove the detergent.

4. Place the empty catch pitcher under the nozzle(s). Press the STOP key. Pull the

lever and leave in the down position. Slowly pour the hot water from the pitcher

over the area where the lever attaches to the spigot. Return the lever to the upright position. Press the RUN key.

5. Remove nozzle from valve, clean in detergent, rinse in clean water.

6. Place each part on a clean counter to air dry or dry with clean dishtowel.

7. With a clean soft damp cloth wipe off the entire exterior of the brewer. Clean any

product or stains from the area surrounding the brewer.

Note: Hot water rinse must be performed once daily as programmed.

Failure to comply will result in electronic lock-out and the brewer will not

dispense product.

May 7, 2002 - 31 630460171

Page 40

Lipton Brewed Iced Tea Training, Installation, & Service Manual

Note: If the urn filler tube is being used it will need to be cleaned per these

instructions.

Daily System Flush (Hot Water Rinse) Procedure

WARNING: This unit dispenses HOT water (160° F. - 205°

F. (71°C. - 96°C.)) during the rinse cycle.

Press the RINSE key to place the brewer in the rinse cycle mode. In this mode the

brewer will require user intervention to initiate each flush of hot water through the

system. This is done by opening the spigot when prompted to do so on the display.

After the rinse is completed, the brewer automatically returns to run mode.

630460171 - 32 May 7, 2002

Page 41

Lipton Brewed Iced Tea Training, Installation, & Service Manual

Rinse Cycle Program

Rinse

Cycle

Is water

temperature

above 160

degrees F

and disp valve

open?

No

Is water

temperature

above 160

degrees F

and disp valve

open?

No

Yes

Blink LED & warning,

flash backlight for 2 sec onds,

flush deadlegs for 10 seconds

Wait 90 seconds

Is water

temperature

above 160

degrees F

and disp valve

open?

Yes

Blink LED & warning,

flash backlight for 2 sec onds,

flush deadlegs for 10 seconds

Wait 80 seconds

Is water

temperature

above 160

degrees F

and disp valve

open?

Yes

Yes

Blink LED & warning,

flash backlight for 2 sec onds,

flush deadlegs for 10 seconds

Wait 80 seconds

No

Is water

temperature

above 160

degrees F

and disp valve

open?

Yes

Blink LED & warning,

flash backlight for 2 sec onds,

flush deadlegs for 10 seconds

Is dispense

valve open?

No

No

No

Do a 5 second pour

2

to reprime the lines

Save this rinse time to EE

Clear flag indicating "rinse required"

Blink LED & warning,

flash backlight for 2 sec onds,

flush deadlegs for 10 seconds

May 7, 2002 - 33 630460171

Go to run mode

Wait 80 seconds

Page 42

Lipton Brewed Iced Tea Training, Installation, & Service Manual

Monthly Sanitizing Procedure

1. Prepare the following in six clean buckets:

• Two wash buckets − mix a solution (one Tablespoon/gallon) of mild, low-

sudsing, detergent with warm water (refill as necessary).

• Two rinse buckets− fill with warm tap water (refill as necessary).

• Two sanitizing buckets − mix a solution of one Tablespoon unscented house-

hold bleach (5.25% Cl Na O concentration) with two gallons of tap water.

The mixture should provide 100 PPM of available chlorine (Refill as necessary).

2. Unscrew the nozzle from the dispensing valve. Wearing sanitary gloves, gently

clean the nozzle with a soft brush, removing any product from around the screw

threads and place nozzle into the sanitizing bucket. Dip the brush into the sanitizing bucket and insert it into the bottom of the dispensing valve. Gently rotate

brush in the threaded area, removing any product. Remove nozzle from the sanitizer and screw back onto the valve.

3. Place a clean, container (one quart or larger) beneath the nozzle. (Empty as required)

4. Disconnect the Bag-in-Box connectors from the tea and sweetener containers.

5. Remove the end caps located opposite the tubing connections on the bag-in-box

connectors.

6. Disconnect the Tea Sold-Out Chamber from the clip on the back wall of the tea

extract compartment. Disconnect the electrical probe wire harness at the top of

the chamber. Stretch out the tea line assembly so that it is sloped downward towards an empty container. Remove the tea sold out probe, this will allow the sold

out chamber to drain all old tea extract out. Discard old tea extract. Replace

probe and wire harness, keeping the Tea sold out chamber lying on its side during the Sanitizing procedure. Replace chamber in clip as positioned prior to removal once sanitizing is complete.

7. Place the connectors and end caps into a detergent bucket. With a soft cloth or

brush, clean the connectors, and then swirl them in the detergent until clean.

Clean the end caps.

8. Place the tea extract connector into one of the detergent buckets and the sweetener connector into the other detergent bucket prepared in step 1.

9. Open the dispensing valve lever to prime the tea pump. When priming the tea

pump position the Tea sold out chamber such that the tubing is in the up position

and the fitting is down. When the pump is primed, press RUN to pull detergent

through both the tea and sweetener systems.

630460171 - 34 May 7, 2002

Page 43

Lipton Brewed Iced Tea Training, Installation, & Service Manual

10. After all of the detergent solution has been run through the system. Repeat step

6 above to completely empty the Tea Sold-Out Chamber of detergent.

11. Place the connectors and end caps into the two rinse buckets that were prepared

above. Repeat steps 8 and 9 to run the rinse solution through the system.

12. After all of the rinse solution has been run through the system. Repeat step 6

above to completely empty the Tea Sold-Out Chamber of rinse solution.

13. Place the connectors and end caps into the two Sanitizing buckets that were prepared above. Repeat steps 8 and 9 to run the sanitizing solution through the system.

14. After all of the Sanitizing solution has been run through the system, replace the

end caps removed in step 5 and reconnect the Bag in Box Connectors onto their

respective bags.

15. Using the Tea extract and Sweetener, dispense 3 to 4 quarts (2.84 L to 3.79 L) of

finished product to insure that the Sanitizer is purged from the system.

16. Perform manual hot water rinse and push RUN to return to normal operation.

Note: If the urn filler tube is being used it should be cleaned and sanitized per

these instructions.

PREVENTATIVE MAINTENANCE

Preventative maintenance consists of:

• Pump tubing replacement

May 7, 2002 - 35 630460171

Page 44

Lipton Brewed Iced Tea Training, Installation, & Service Manual

Annual Pump Tubing Replacement Procedure

The pump tubing must be replaced annually. A replacement pump tubing kit, part #

631500149, is available. The kit consists of one pre-cut length of pump tubing, two

hose clamps, and instructions.

FIGURE 6 TEA EXTRACT PUMP

REPLACING PUMP TUBING

Replace pump tubing as follows:

1. Remove pump/motor assembly from the metal pump mounting bracket.

2. Remove the hose clamps from the pump tube connections. Remove the

extract delivery tubes from the hose ends.

3. Loosen and remove the four thumb screws from the pump body.

4. Remove the bottom pump body half only

rollers.

to reveal the pump tube and

630460171 - 36 May 7, 2002

Page 45

Lipton Brewed Iced Tea Training, Installation, & Service Manual

FIGURE 7

5. Remove the old pump tube from the pump body. If the roller assembly

comes out with the tubing, place it back into the pump housing being

sure to align the roller assembly shaft keyway to the motor shaft so that

the two interlock.

6. Firmly press the new hose into the pump body around the roller assembly, being sure to keep the protruding ends even with each other.

FIGURE 8

7. Once the tubing is in place, hold the tubing with one hand, capture the

lower part of the tubing with the outer housing, then proceed to capture

the shaft of the roller assembly and push the rear pump housing into

place. Make sure to capture the tubing within the body and not pinch it

between the halves. Do not use any tool other than your finger tips to

manipulate the tubing into the housing or you may damage the tube.

8. While holding the pump halves together with your hand, reinsert the

four thumb screws and tighten using a criss-cross pattern as shown. The

thumb screws should be tightened about ¼ turn beyond snug.

May 7, 2002 - 37 630460171

Page 46

Lipton Brewed Iced Tea Training, Installation, & Service Manual

FIGURE 9

9. Insert the extract delivery tube into the pump tubing ends and secure

them using the new hose clamps supplied in the kit. Be sure to use pliers

to squeeze and tighten the hose clamps.

10. Re-install the pump/motor assembly on the pump mounting bracket.

630460171 - 38 May 7, 2002

Page 47

TROUBLESHOOTING

IMPORTANT: Only qualified Personnel should service

internal components or electrical wiring.

WARNING: If repairs are to be made to a syrup system,

disconnect extract supply from the applicable syrup system,

then relieve the system pressure before proceeding. If

repairs are to be made to the CO

shut off the CO2 supply, then relieve the system pressure

before proceeding. If repairs are to be made to the unit

electrical system, make sure electrical power is disconnected

from the unit before proceeding.

Lipton Brewed Iced Tea Training, Installation, & Service Manual

system, stop dispensing,

2

Should the brewer fail to operate properly, check that there is power to the

brewer. If the brewer does not dispense, check the following chart under the

appropriate symptoms to aid in locating the defect.

Diagnostic Tools Needed: Thermometer (suggested range 150°F to 210°F),

Multimeter & Amp Probe

NOTE: Contact NGB Service for additional information and help troubleshooting the beverage system. FRESH BREWED SERVICE: 1-(866)-LiptonT (547-8668) liptontea@ngbservice.com

May 7, 2002 - 39 630460171

Page 48

Lipton Brewed Iced Tea Training, Installation, & Service Manual

Trouble Probable Cause Troubleshooting & Repair

NO HOT WATER • No power to heater.

• Heater open or shorted.

Procedures

• Check power supply or loose wires.

• Check heater.

• All new production has a manual

reset on the thermostat.

• Tank: When heating will draw

approximately 10 amps draw, measured at the black wire on the harness

to the tank. The tank will heat water

at about 12

• Low Power Mode: Unit will go into a

low power mode when tank tempera-

ture reaches 170°. In low power

mode, the tank will only heat for 20

seconds out of every minute. (40 seconds off/20 seconds on).

• Full power to the tank will resume if

the water tank temperature drops

below 165

• Unit will shut off heater relay if water

temperature exceeds 215

temperature message will appear on

the data mode screen. To turn the

heater relay back on, the tank tem-

perature must drop below 215

• Unit will lock out the RINSE on low

temperature if the tank temperature is

below 160°F., the display will say,

“Heating, please wait”. In RUN

mode, it will still dispense if the

water temp is below 160

• The thermostat on the tank acts as a

redundant temperature control. The

circuit board monitors tank temperature controls power supplied to the

heater.

°F per minute.

°F.

°F. A high

°F.

°F.

630460171 - 40 May 7, 2002

Page 49

Lipton Brewed Iced Tea Training, Installation, & Service Manual

Trouble Probable Cause Troubleshooting & Repair

NO HOT WATER (CONT.) • Heater open or shorted (cont.).

• Defective solid state relay.

Procedures

• Thermostat adjustments should be in

small increments. We are only using

the bottom part of the total adjustment range of the thermostat. Usually the tank is adjusted to one tick

mark above medium.

• Replace tank.

• Relay is solid state. Cannot check its

function off of unit since, it requires a

load on the output side to be able to

check it correctly.

• If it fails, it would tend to fail in the

forward (on) position. If it failed, the

tank would be cycling on the tank

thermostat only, no low power mode

or high temp. lock out would be

available.

• On initial startup, the relay would be

on 100% of the time, until 170

reached. Once 170

reached the relay would begin to

cycle on low power mode. Signal

voltage from the control module

would supply 3.3 VDC to the low

side, terminals #3 (red) and #4

(black) of the relay. The high side of

the relay would handle the AC line

voltage to the tank thermostat.

• Remember, when checking the relay

for function, that under the low

power mode it will only get a signal

voltage from the control module for

20 seconds out of every minute. To

check accurately for signal voltage, a

meter must be monitored on the low

side for at least a minute.

• Check the high side for voltage, terminals #1 and #2. There should be

line voltage all the time between terminal #2 on the relay and neutral, but

there should only be line voltage

between terminal #1 and neutral

when there is signal voltage to #3 and

#4.

° F has been

° F is

May 7, 2002 - 41 630460171

• Low Temperature Lockout Error.

• Low Temp Lockout errors prevent

against an open circuit to the temperature sensor. A Low Temp Lockout

error locks the heater relay off.

• Check that the connection to the temperature sensor is good. Clear the

error by entering the TANK STATUS

mode enter the Set-up menu.

Page 50

Lipton Brewed Iced Tea Training, Installation, & Service Manual

Trouble Probable Cause Troubleshooting & Repair

NO HOT WATER (CONT.) • No water entering tank.

• No power to control board.

Procedures

• Check water supply.

• Plugged water filter.

• See “defective hot water valve”

• Same coil used for Hot, Cold, and

Sweetener Valve.

• Utilizes standard piston and sleeve

flow control.

• The Ohm resistance for the coil is

approximately 6 Ohms.

• Check power supply and 24V transformer.

• Uses two standard (80 VA) beverage

transformers.

• Voltage output should be approximately 27 VAC. with no load. Under

load the output should be between 22

and 25 VAC. No lower than 22 VAC.

• As viewed from the rear. The left

transformer supplies power to the

KIP valves and flow control valves

(power is only switched through the

control module).

• The right transformer supplies power

to the board and for the pump motor.

• Defective Hot water valve.

• Check adjustment.

• Check coil resistance.

• Same coil used for Hot, Cold, and

Sweetener Valve.

• Utilizes standard piston and sleeve

flow control.

• The Ohm resistance for the coil is

approximately 6 Ohms.

• Check for restrictions.

• Check for power to coil.

• As viewed from the rear. The left

transformer supplies power to the

KIP valves and flow control valves

(power is only switched through the

control module).

630460171 - 42 May 7, 2002

Page 51

Lipton Brewed Iced Tea Training, Installation, & Service Manual

Trouble Probable Cause Troubleshooting & Repair

NO HOT WATER (CONT.) • Defective KIP Valve.

Procedures

• Check coil resistance.

• KIP is a brand name valve.

• Two KIP valves are used in the unit.

Both are activated in the rinse cycle.

The top one is activated in the first

rinse and runs hot water through the

cold water and sweetener lines. The

bottom one is activated in the 2nd

through 5th rinses and runs hot water

through the brew tube to clean that

out.

• The Ohm resistance for the KIP valve

coil is approximately 20 Ohms.

• The KIP valve is directional. The

direction of flow for the valve is indicated by a dash (-) line on the outlet

side of the body. Take careful note of

the orientation of the dash (-) line on

the body of the valve. It may be in

one position for Hot flow and in

another position for Cold flow.

• Check for restrictions.

• Check for power to coil.

• As viewed from the rear. The left

transformer supplies power to the

KIP valves and flow control valves

(power is only switched through the

control module).

• Defective Valve Seat.

NO COLD WATER. • No water entering brewer.

No power to control board.

• Defective cold water valve.

• Defective valve seat.

• Replace.

• Check supply.

• Plugged water filter.

• Check power supply and 24 VAC

transformer.

• Voltage output should be approximately 27 VAC. with no load. Under

load the output should be between 22

and 25 VAC. No lower than 22 VAC.

• Check power, coil, 6 Ohms, and for

restrictions.

• Replace.

May 7, 2002 - 43 630460171

Page 52

Lipton Brewed Iced Tea Training, Installation, & Service Manual

Trouble Probable Cause Troubleshooting & Repair

BAD TASTE • No extract.

• No sweetener.

• Poor water quality.

• Ratio setting wrong.

• Extract has exceeded shelf life.

• Not sanitized properly.

• Defective extract pump.

Procedures

• Check extract supply.

• Check supply lines.

• Check pump motor and tubing.

• Check BIB connector.

• Check BIB connector.

• Check sweetener supply.

• Check valve assembly.

• Check for restrictions.

• Check BIB pump and gas supply.

• Add or replace filter.

• Calibrate.

• Check for kinked extract tubing.

• Replace extract.

• Sanitize per procedure.

• Repair or replace pump.

• Pump tubing past P.M. date.

WON’T DISPENSE • Defective valve micro-switch.

•

No power to valve micro-switch.

•

Control board failure.

• Not in the run mode.

WON’T GO INTO RINSE. • Low water temperature. • Heater not working.

• Replace tubing.

• Replace.

• With the wires disconnected, check

function of switch with Ohm meter,

check between the common and normally open terminals while activating switch.

• Replace switch.

• Check the signal voltage from the circuit board. There should be approximately 2.4 VDC signal voltage from

the board.

• Check supply 115V and 24V.

• Check board functions.

• Verify ready to run message.

• Unit will lock out the RINSE procedure on low temperature if the tank

temperature is below 160

play will say, “Heating, please wait”.

In RUN mode, it will still dispense if

the water temp is below 160°F.

• Defective sensor.

• Overdrawn heater capacity.

°F., t h e dis -

630460171 - 44 May 7, 2002

Page 53

Lipton Brewed Iced Tea Training, Installation, & Service Manual

Trouble Probable Cause Troubleshooting & Repair

EXCESSIVE BURPING (CONSTANT DISCHARGE FROM

BURP TUBE)

WATER IN BOTTOM OF

BREWER

WATER UNDER BREWER • Water temperature too high. • Measure and adjust as necessary.

CLOUDY TEA • Air injector not venting.

• Temperature too high. • Re-adjust thermostat (see no Hot

water).

• Examine for leaks.

• Air ejector leaking.

• Repair or replace leaking component.

• Repair or replace.

• Check to see that the ball in the air

ejector is not stuck. If the ball is

stuck, homogeneity problems will

result. One symptom of the ball

being stuck can be air pockets going

out through the dispense nozzle.

• The fitting should be finger tight only.

• Unit will shut off heater relay if water

temperature exceeds 192

temperature message will appear on

the data mode screen. To turn the

heater relay back on (two things are

required), first the tank temperature

must drop below 192°F and then the

operator needs to press Run to put the

unit back into operation (See advisory).

• Repair or replace.

• Check to see that the ball in the air

ejector is not stuck. If the ball is

stuck, homogeneity problems will

result. One symptom of the ball

being stuck can be air pockets going

out through the dispense nozzle.

• The fitting should be finger tight only.

Procedures

°F. A high

May 7, 2002 - 45 630460171

• Low brewing temperature.

• Exceeding capacity of unit.

• See No Hot Water.

Page 54

Lipton Brewed Iced Tea Training, Installation, & Service Manual

SERVICE ADVISORY

PRODUCT: LIPTON BREWED ICED TEA DISPENSER (LBIT)

SUBJECT: “HEATING, PLEASE WAIT” MESSAGE

ADVISORY RELEASE DATE: MARCH 23, 2001

Diagnostic Overview

A “Heating, Please Wait” message may appear during a programmed rinse. This message indicates that the

hot water temperature is less than the minimum temperature of 160 degrees Fahrenheit needed to initiate and

complete the programmed rinse cycle.

SERVICE ADVISORY

There are several possible causes if the message does not go out within 10 minutes-- 1) the thermostat needs

adjustment, 2) the solid state relay has failed, 3) the re-settable thermal fuse on the heater tank has opened, 4)

the heating element is bad, or 5) the displayed temperature is not accurate. If the dispenser has operated

normally for more than several days, then the most likely cause is that the thermostat needs adjustment. This