Cornelius IDC 255 PROGATE DRIVE THRU UNIT Installation Manual

IDC 255 PROGATE DRIVE THRU UNIT

Installation Manual

Release Date: June 27, 2006

Publication Number: 621057419INS

Revision Date: February 19, 2014

Revision: F

Visit the Cornelius web site at

www.cornelius.com for all your Literature needs.

The products, technical information, and instructions contained in this manual are subject to change without notice.

These instructions are not intended to cover all details or variations of the equipment, nor to provide for every possi

ble contingency in the installation, operation or maintenance of this equipment. This manual assumes that the person(s) working on the equipment have been trained and are skilled in working with electrical, plumbing, pneumatic,

and mechanical equipment. It is assumed that appropriate safety precautions are taken and that all local safety and

construction requirements are being met, in addition to the information contained in this manual.

This Product is warranted only as provided in Cornelius Commercial Warrant applicable to this Product and is subject to all of the restrictions and limitations contained in the Commercial Warranty.

Cornelius will not be responsible for any repair, replacement or other service required by or loss or damage resulting

from any of the following occurrences, including but not limited to, (1) other than normal and proper use and normal

service conditions with respect to the Product, (2) improper voltage, (3) inadequate wiring, (4) abuse, (5) accident,

(6) alteration, (7) misuse, (8) neglect, (9) unauthorized repair or the failure to utilize suitably qualified and trained per

sons to perform service and/or repair of the Product, (10) improper cleaning, (11) failure to follow installation, operating, cleaning or maintenance instructions, (12) use of non-authorized parts (i.e., parts that are not 100%

compatible with the Product) which use voids the entire warranty, (13) Product parts in contact with water or the

product dispensed which are adversely impacted by changes in liquid scale or chemical composition.

Contact Information:

To inquire about current revisions of this and other documentation or for assistance with any Cornelius product contact:

www.cornelius-usa.com

800-238-3600

-

-

Trademarks and Copyrights:

This document contains proprietary information and it may not be reproduced in any way without permission from

Cornelius.

This document contains the original instructions for the unit described.

CORNELIUS INC

101 Regency Drive

Glendale Heights, IL

Tel: + 1 800-238-3600

Printed in U.S.A.

TABLE OF CONTENTS

Safety Instructions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Read and Follow ALL Safety Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Safety Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Recognition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Different Types of Alerts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Safety Tips . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Qualified Service Personnel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Safety Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Shipping And Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

CO2 (Carbon Dioxide) Warning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Mounting in or on a Counter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Unit Specification. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Valve Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Specification. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Progate 2 Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Progate Portion Ice Control Features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Lid Dispenser . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Straw Holder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Lid Holder Compatibility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Small Lid Template . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Medium Lid Template. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Large Lid Template . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Mounting and Placement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Adjust Carbonator CO2 Regulator and Turn Water Inlet Supply Line ON . . . . . . . . . . . . . . . . . . . . 10

CO2 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Power Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Water Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

To access cold plate water inlets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Operation Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Lid Dispenser Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Unit Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Loading of Lid Dispenser . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Plastic Wrapped lids. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Individual lids . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Lid Dispenser Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Progate 2 Control Box Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Portion Control Box Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Programming (Changing) the Ice Portion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Agitation Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Programming (Changing) the Agitation Time. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Ice Portion Bar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Diagrams. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Cold Plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

7 Intelli Valves and 1 variety Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

5 Intelli Valves and 3 Variety Valves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

8 Intelli Valves or 8 UFB-1 Valves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

E-Board off Cycle Agitation Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Electrical Schematic. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Main Electrical Box Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Interconnect Schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Power Light Off . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

No Ice Dispense in Manual Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

No Ice Dispense in Automatic Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Beverage Not Dispensing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Flat Drinks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

No Carbonated Water . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

IDC 255 Progate Drive Thru Installation Manual

!

DANGER:

!

WARNING:

CAUTION:

!

!

WARNING:

!

SAFETY INSTRUCTIONS

READ AND FOLLOW ALL SAFETY INSTRUCTIONS

Safety Overview

Read and follow ALL SAFETY INSTRUCTIONS in this manual and any warning/caution labels on the unit

(decals, labels or laminated cards).

Read and understand ALL applicable OSHA (Occupational Safety and Health Administration) safety regulations

before operating this unit.

Recognition

RReeccooggnniizzee SSaaffeettyy AAlleerrttss

TThhiiss iiss tthhee ssaaffeettyy aalleerrtt ssyymmbbooll.. WWhheenn yyoouu sseeee iitt iinn tthhiiss mmaannuuaall oorr oonn tthhee uunniitt,,

bbee aalleerrtt ttoo tthhee ppootteennttiiaall ooff ppeerrssoonnaall iinnjjuurryy oorr ddaammaaggee ttoo tthhee uunniitt..

DIFFERENT TYPES OF ALERTS

Indicates an immediate hazardous situation which if not avoided WILL result in serious injury, death or equipment

damage.

Indicates a potentially hazardous situation which, if not avoided, COULD result in serious injury, death, or equipment

damage.

Indicates a potentially hazardous situation which, if not avoided, MAY result in minor or moderate injury or equipment

damage.

SAFETY TIPS

Carefully read and follow all safety messages in this manual and safety signs on the unit.

Keep safety signs in good condition and replace missing or damaged items.

Learn how to operate the unit and how to use the controls properly.

DDoo nnoott let anyone operate the unit without proper training. This appliance is nnoott intended for use by very young children or

infirm persons without supervision. Young children should be supervised to ensure that they do not play with the appliance.

Keep your unit in proper working condition and do not allow unauthorized modifications to the unit.

QUALIFIED SERVICE PERSONNEL

Only trained and certified electrical, plumbing and refrigeration technicians should service this unit. ALL WIRING

AND PLUMBING MUST CONFORM TO NATIONAL AND LOCAL CODES. FAILURE TO COMPLY COULD

RESULT IN SERIOUS INJURY, DEATH OR EQUIPMENT DAMAGE.

© 2006-2014, Cornelius Inc. - 1 - Publication Number: 621057419INS

IDC 255 Progate Drive Thru Installation Manual

!

WARNING:

CAUTION:

!

CAUTION:

!

!

DANGER:

!

WARNING:

SAFETY PRECAUTIONS

This unit has been specifically designed to provide protection against personal injury. To ensure continued protection

observe the following:

Disconnect power to the unit before servicing following all lock out/tag out procedures established by the user. Verify

all of the power is off to the unit before any work is performed.

Failure to disconnect the power could result in serious injury, death or equipment damage.

Always be sure to keep area around the unit clean and free of clutter. Failure to keep this area clean may result in

injury or equipment damage.

SHIPPING AND STORAGE

Before shipping, storing, or relocating the unit, the unit must be sanitized and all sanitizing solution must be drained

from the system. A freezing ambient environment will cause residual sanitizing solution or water remaining inside the

unit to freeze resulting in damage to internal components.

CO2 (CARBON DIOXIDE) WARNING

CO2 displaces oxygen. Strict attention MUST be observed in the prevention of CO2 gas leaks in the entire CO2 and

soft drink system. If a CO

contaminated area before attempting to repair the leak. Personnel exposed to high concentrations of CO

experience tremors which are followed rapidly by loss of consciousness and DEATH.

2 gas leak is suspected, particularly in a small area, IMMEDIATELY ventilate the

2 gas

MOUNTING IN OR ON A COUNTER

When installing the unit in or on a counter top, the counter must be able to support a weight in excess of 661155 llbbss. to

insure adequate support for the unit.

OR EQUIPMENT DAMAGE.

NOTE: Many units incorporate the use of additional equipment such as icemakers. When any addition equipment is used you must check with the equipment manufacturer to determine the additional weight the counter will need to support to ensure a safe installation.

FAILURE TO COMPLY COULD RESULT IN SERIOUS INJURY, DEATH

Publication Number: 621057419INS - 2 - © 2006-2014, Cornelius Inc.

IDC 255 Progate Drive Thru Installation Manual

UNIT SPECIFICATION

DESCRIPTION

The Ice Drink Cornelius (IDC) series of dispensers solves your ice and beverage service needs in a sanitary, space

saving, economical way. Designed to be manually filled with ice from any remote icemaking source, these

dispensers will dispense cubes (up to 11/4 inch in size), cubelets, and compressed (not flaked). In addition, the units

include beverage faucets, a cold plate, an internal carbonator tank and an external pump for the carbonator, and are

designed to be supplied direct from syrup tanks with no additional cooling required.

VALVE CONFIGURATIONS

IDC 255 Progate Drive Thru Unit with 7 Intelli Valves and 1 Variety Valve

IDC 255 Progate Drive Thru Unit with 5 Intelli Valves and 3 Variety Valves

IDC 255 Progate Drive Thru Unit with 8 Intelli Valves

IDC 255 Progate Drive Thru Unit with 8 UFB-1 Valves

SPECIFICATION

IDC 255

B=Beverage

Model Descriptions

Unit Weight 368 Pounds

Ice Storage 255 Pounds

Maximum Number of Faucets 10

Built in Cold Plate Yes

Electrical

Dimensions

CO

2 Operating Pressure 75-psig (max)

Water

C=Coldplate

H=Internal Carb

P=Progate

Z=No Drip Tray

120/1/60

9.3 Amps of Total Unit Draw

OR

220/1/50

4.7 Amps of Total Unit Draw

Width 29.90 inch (.76 m)

Height 39.75 inch (1.0 m)

Depth 36.90 inch (.94 m)

100 psi (7 bar) maximum static pressure.

40 psi (2.8 bar) minimum dynamic pressure.

3/8 minimum water line recommended.

© 2006-2014, Cornelius Inc. - 3 - Publication Number: 621057419INS

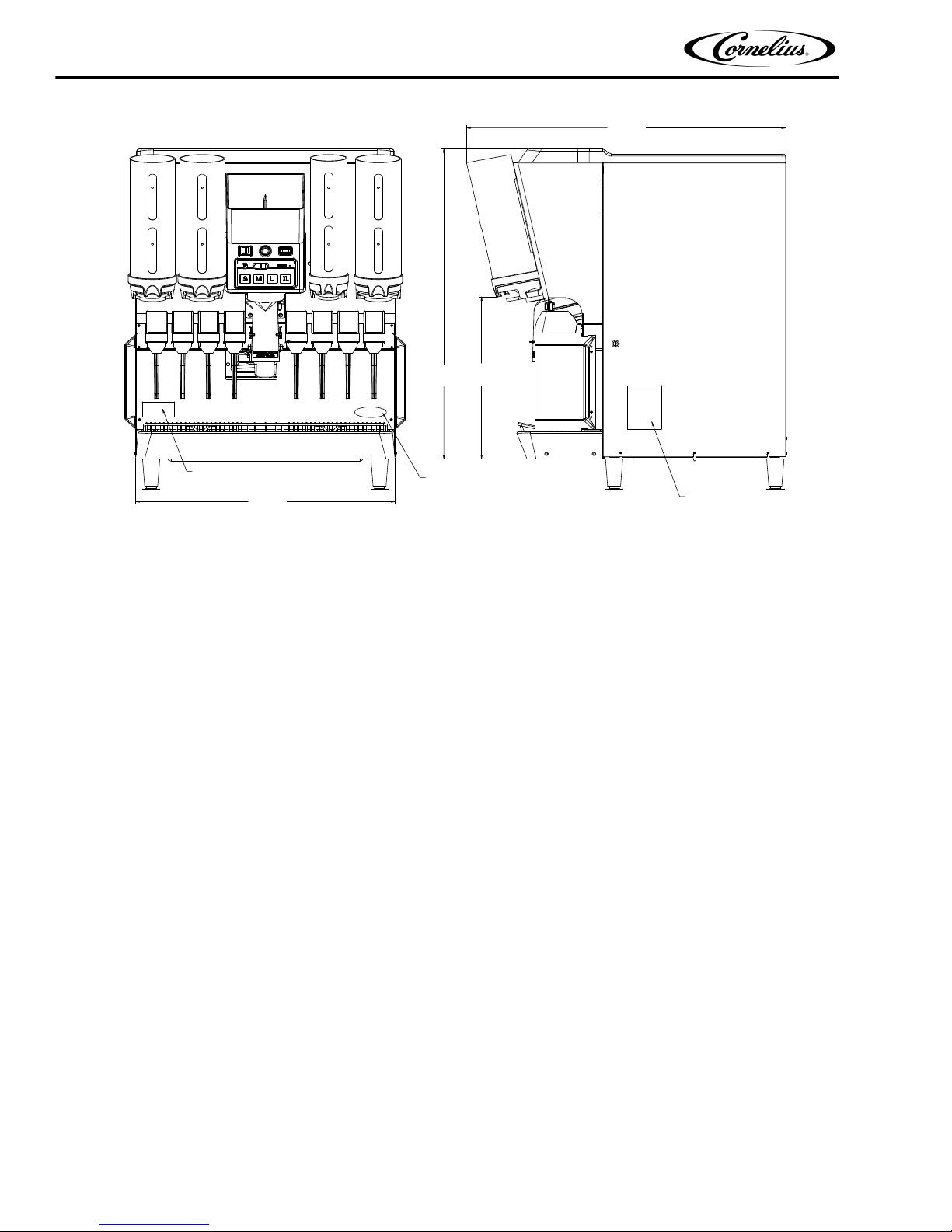

20.756

39.750

36.901

30.000

PCX OUT OF RATIO LABEL

CORNELIUS

LOGO

UNIT

SERIAL NUMBER

IDC 255 Progate Drive Thru Installation Manual

Figure 1.

Electrical Connections: 6 ft long power cord with 3-prong plug attached to dispenser.

Power Requirements:: 9.3

Water Supply Requirements:: 100 psi

amps at 120 volts dedicated power supply.

(7 bar) maximum static pressure 40 psi (28 bar) minimum dynamic pressure.

3/8 minimum water line recommended.

2 Requirements: 100 psi max to unit regulated to 35 psi (2.4 bar) to Progate 2 ice gate system, 75 psi (5.2 bar)

CO

carbonator.

Progate 2 Features

Progate Portion Ice Control Features

4 Programmable ice dispense sizes

Automatic/Manual Ice Dispense Modes

Unit Power On/Off Switch

Programmable Agitation Time

Lid Dispenser

4 lid dispenser locations on the unit

3 Separate removable lid dispensers for small/medium, large, and extra large lids

Straw Holder

Holds up to 140 regular sleeved straws

Publication Number: 621057419INS - 4 - © 2006-2014, Cornelius Inc.

IDC 255 Progate Drive Thru Installation Manual

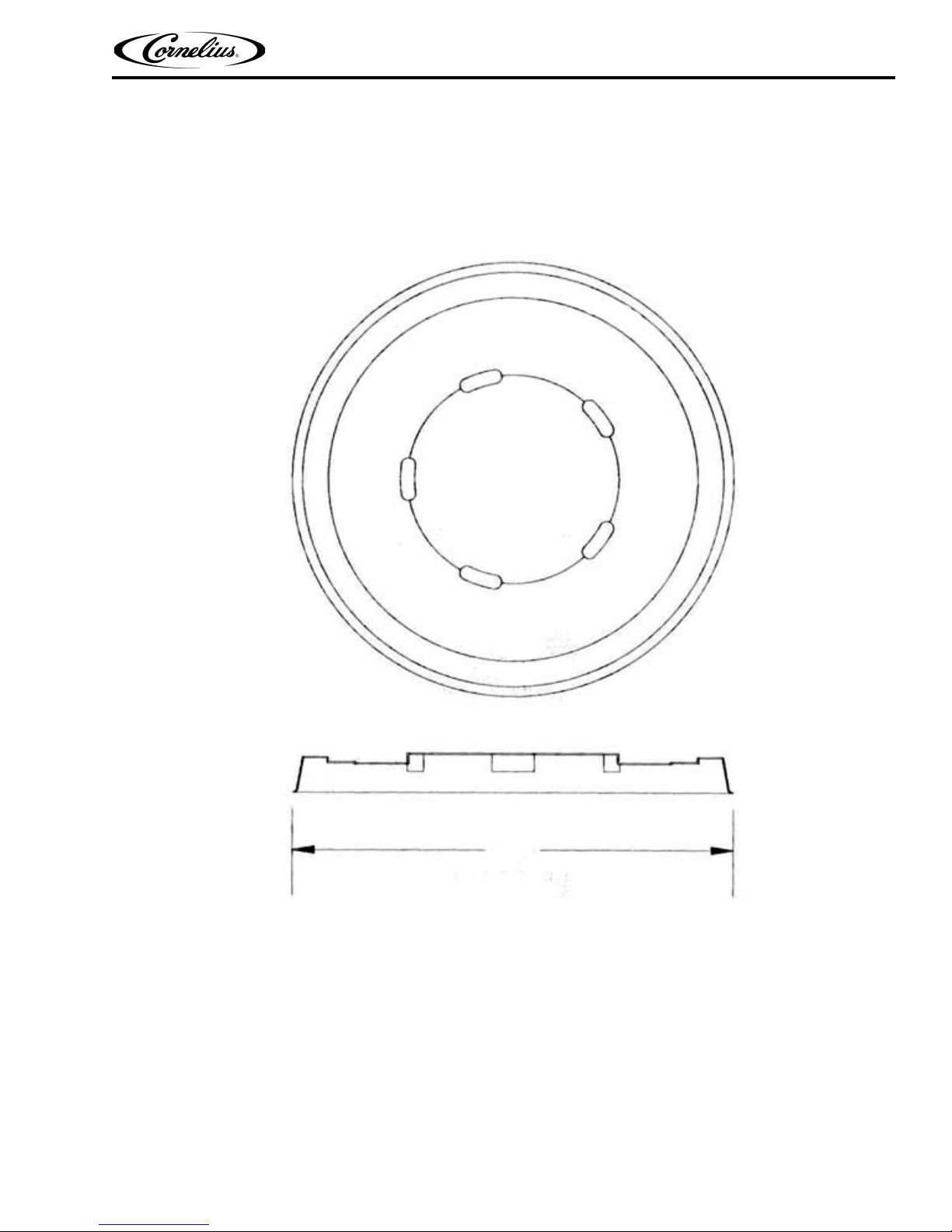

3.750

LID HOLDER COMPATIBILITY

The following template is a guide to validate the compatibility of the cup lids that are used with the Cornelius Lid

Dispensers supplied with the IDC255 Progate Ice Drink Dispenser. The lid dispensers accommodate small lids 3.75"

in Dia. ± .032" in the large lid dispensers. The templates below are to scale to check the lids or compatibility.

Small Lid Template

© 2006-2014, Cornelius Inc. - 5 - Publication Number: 621057419INS

Figure 2.

IDC 255 Progate Drive Thru Installation Manual

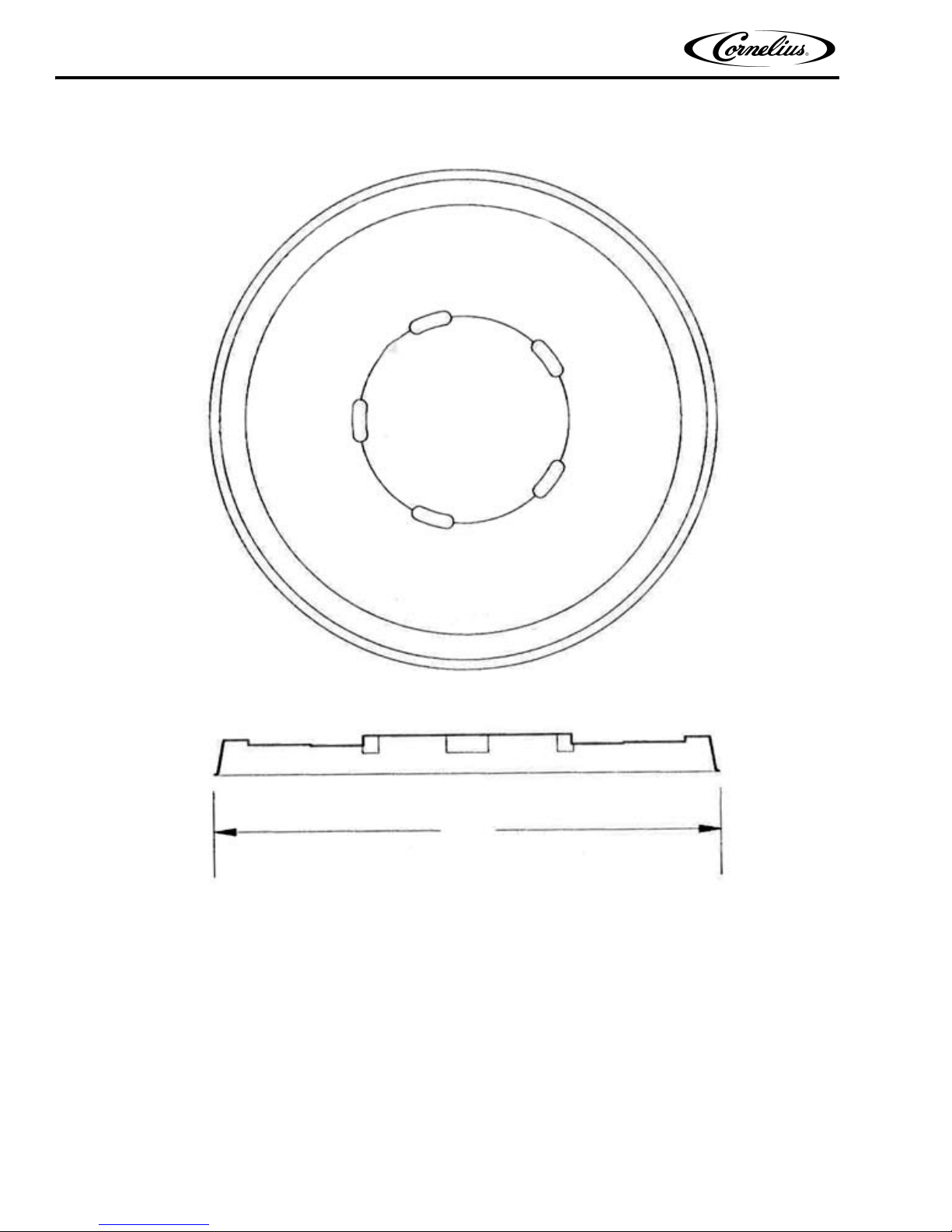

4.350

Medium Lid Template

Publication Number: 621057419INS - 6 - © 2006-2014, Cornelius Inc.

Figure 3.

IDC 255 Progate Drive Thru Installation Manual

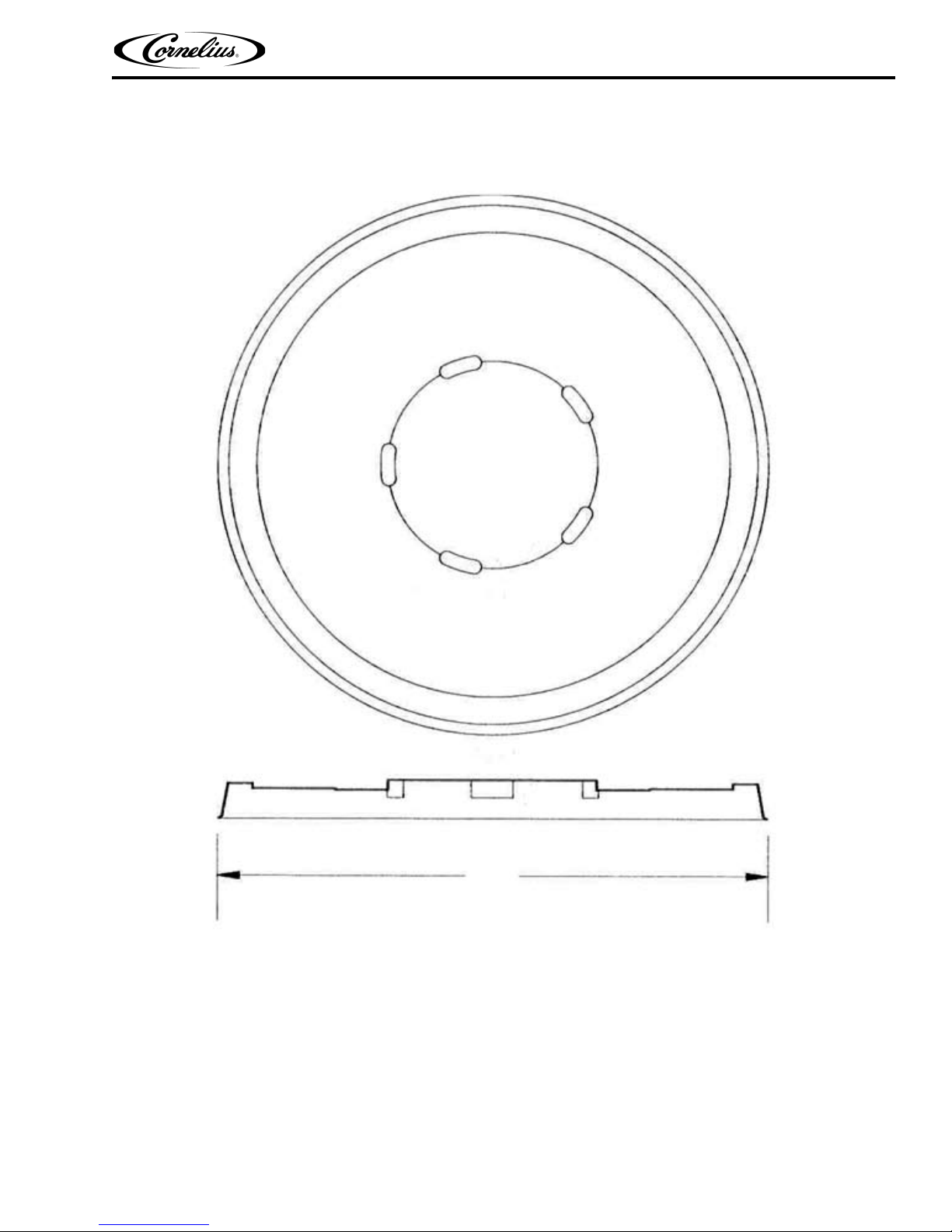

4.700

Large Lid Template

© 2006-2014, Cornelius Inc. - 7 - Publication Number: 621057419INS

Figure 4.

IDC 255 Progate Drive Thru Installation Manual

!

WARNING

:

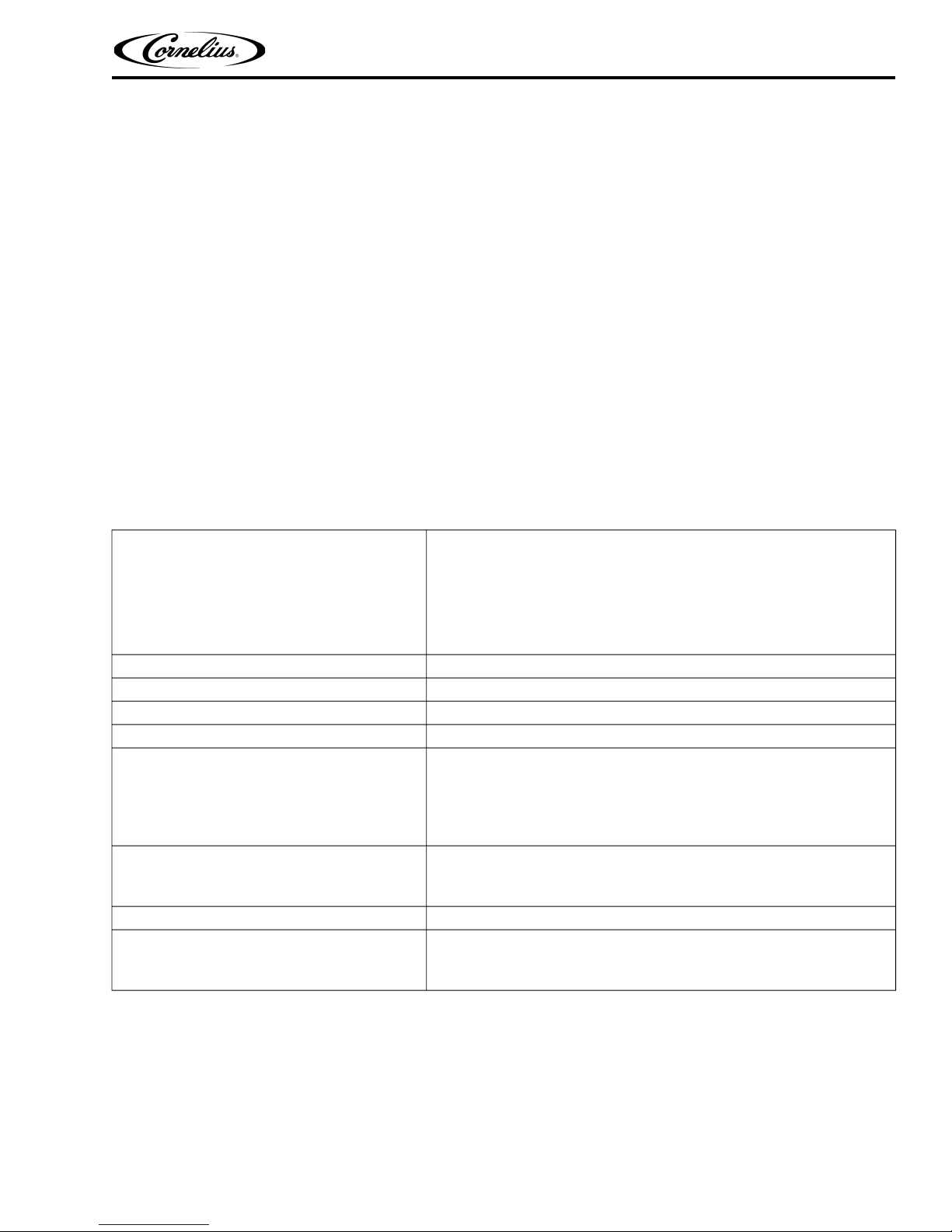

30

26 3/81 13/16

1 5/16

18 5/8

12

9

3 1/2

9 1/2

11

23

21 1/4

30

31 1/2

REMOVABLE SINK

RECOMMENDED COUNTER OPENING SIZE

9 X 12 FOR UTILITIES AND BEVERA GE

TUBING. OPENING CAN B E LOCATED

ANYWHERE WITHIN SHAD ED AREA .

7/16 DIA.

23 1/16

Z Styl e

INSTALLATION

MOUNTING AND PLACEMENT

It is the responsibility of the installer to ensure that the water supply to the dispensing equipment is provided with

protection back flow by an air gap as defined in ANSI A 112.1.2-1979; or an approved vacuum breaker or other such

method as proved effective by test and must comply with all federal, state and local codes.

Failure to comply could result in serious injury, death or damage to the equipment.

Water pipe connections and fixtures directly connected to a potable water supply shall be sized, installed and

maintained according to Federal, State and Local laws.

1. Locate the dispenser indoors on a level counter top.

A. LEG OPTION

Unpack the four (4) legs and install them into the threaded holes provided at the bottom of the unit. The

installer must provide flexibility in the product and utility supply to permit shifting the position of the dispenser sufficiently to clean the area beneath it.

COUNTER MOUNTING

The ice drink dispenser must be sealed to the counter. The template drawing indicates where openings can be cut in

the counter. Locate the desired position for the dispenser, then mark the outline dimensions on the counter using the

template drawings. Cut openings in counter.

Apply a continuous bead of

1/4-inch inside of the unit outline dimensions and around all openings. Then, position the unit on the counter within

the outline dimensions. All excess sealant must be wiped away immediately.

Publication Number: 621057419INS - 8 - © 2006-2014, Cornelius Inc.

NSF International

Figure 5.

(NSF) silastic sealant (Dow 732 or equal) approximately

Loading...

Loading...