Page 1

VFCB Operator’s Manual

VFCB

(Visual Frozen Carbonated

Beverage)

Post-Mix and Pre-Mix

Operator’s Manual

Release Date: 20/04/10

Publication Number:

Revision: 8

Pag. : 1/59

Page 2

VFCB Operator’s Manual

VFCB POST-MIX AND PRE-MIX

OPERATOR’S MANUAL

The products, technical information, and instructions contained in this manual are subject

to change without notice. These instructions are not intended to cover all details or variations

of the equipment, nor to provide for every possible contingency in the installation,

operation or maintenance of this equipment. This manual assumes that the person(s)

working on the equipment have been trained and are skilled in working with electrical,

plumbing, pneumatic, and mechanical equipment. It is assumed that appropriate safety

precautions are taken and that all local safety and construction requirements are being

met, in addition to the information contained in this manual.

To inquire about current revisions of this and other documentation or for assistance with

any Cornelius product contact:

www.cornelius.com

1-800-238-3600

This document contains proprietary information and it may not be

reproduced in any way without permission from Cornelius.

Printed in ITALY.

Copyright © 2006, All Rights Reserved, IMI Cornelius Inc.

Release Date: 20/04/10

Publication Number:

Revision: 8

Pag. : 2/59

Page 3

VFCB Operator’s Manual

TABLE OF CONTENTS

IMPORTANT WARNINGS AND ADVICE ..................................................................................4

TECHNICAL DATA ..........................................................................................................................4

TRANSPORTATION INDICATIONS...........................................................................................4

INSTALLATION................................................................................................................................5

CONNECTING THE ELECTRICITY MAINS ..............................................................................6

CONNECTION DIAGRAMS ..........................................................................................................7

BOWL LOADING OPERATIONS .................................................................................................9

PROGRAMMING ELECTRONIC TOUCH PAD .......................................................................12

CONSISTENCY ADJUSTMENT..................................................................................................20

SIX MONTHLY CLEANING AND SANITATION....................................................................21

SPECIAL MAINTENANCE ...........................................................................................................25

ELECTRONIC MONITORING.....................................................................................................28

WIRING DIAGRAM.......................................................................................................................36

TROUBLESHOOTING...................................................................................................................41

PARTS DIAGRAMS.......................................................................................................................45

Release Date: 20/04/10

Publication Number:

Revision: 8

Pag. : 3/59

Page 4

VFCB Operator’s Manual

IMPORTANT WARNINGS AND ADVICE

This instruction manual represents an integral part of the equipment and must be kept readily

available for use. Read the warnings contained herein carefully before installing and using this

equipment. In addition to offering information concerning routine maintenance for the ice slush

drinks machine and technical back-up for troubleshooting, this manual aims to help the user

make the most of the machine’s potential, adapting it to suit the specific needs of the various

countries it will be used in. Modifications or attempts to modify the equipment will not only

result in the forfeiture of the guarantee, but are also extremely dangerous.

The maintenance operations must be carried out by qualified professionals. Never attempt to

repair the machine yourselves as the intervention of non-qualified persons, as well as being

hazardous, could also lead to serious damage to the machine.

ATTENTION: Before starting up the machine it’s necessary to perform all the cleaning

and sanitation procedures.

TECHNICAL DATA

PLATE DATA

The voltage and the frequency are indicated on the serial number plate, located behind the

drip tray and the right hand side near the controls.

Machine Bowl n° Volt Hertz Ampere

230 50 7.3 VFCB POST MIX 2

115 60 13.8

230 50 7.3 VFCB PRE MIX 2

115 60 13.8

VFCB POST MIX 3 115 60 21.5

IMPORTANT: This machine is intended for use at a maximum ambient temperature of

32°C (90°F).

TRANSPORTATION INDICATIONS

To prevent the oil contained in the compressor from flowing out into the cooling circuit, the

equipment must be transported, stored, and handled in a vertical position, as per the

indications given on the packing. The wooden pallet, equipped with housing for the lifting

forks, allows the packed equipment to be moved using normal handling and hoisting means.

Release Date: 20/04/10

Publication Number:

Revision: 8

Pag. : 4/59

Page 5

VFCB Operator’s Manual

INSTALLATION

1. Release the equipment from the packing, then slide it off

upwards (see Fig. 1). The machine has to be installed in level

with horizontal plane;

2. Checking the machine identification after removing the

packing, you must check that the equipment you have

received is exactly as you ordered, making sure the

specifications indicated on the invoice or the delivery note

are identical to those on the data plate.

Fig. 1

3. Equipment accessories

On opening the packing you will find the following accessories inside the bowls:

• this instruction manual;

• 1 tube of Vaseline to be used for the maintenance machine the requires;

• 2 bags, each one containing a drip tray

• 2 evaporator frontal seals

4. Positioning - make sure the machine’s bodywork is well ventilated (20cm (8”) all around at

least ) and do not install it near heat sources.

We recommend you keep the room temperature at between 59°F (15°C) and 90°F (32°C).

IMPORTANT: All the pieces of packing must be kept out of reach of children as they

represent potential hazards.

Release Date: 20/04/10

Publication Number:

Revision: 8

Pag. : 5/59

Page 6

VFCB Operator’s Manual

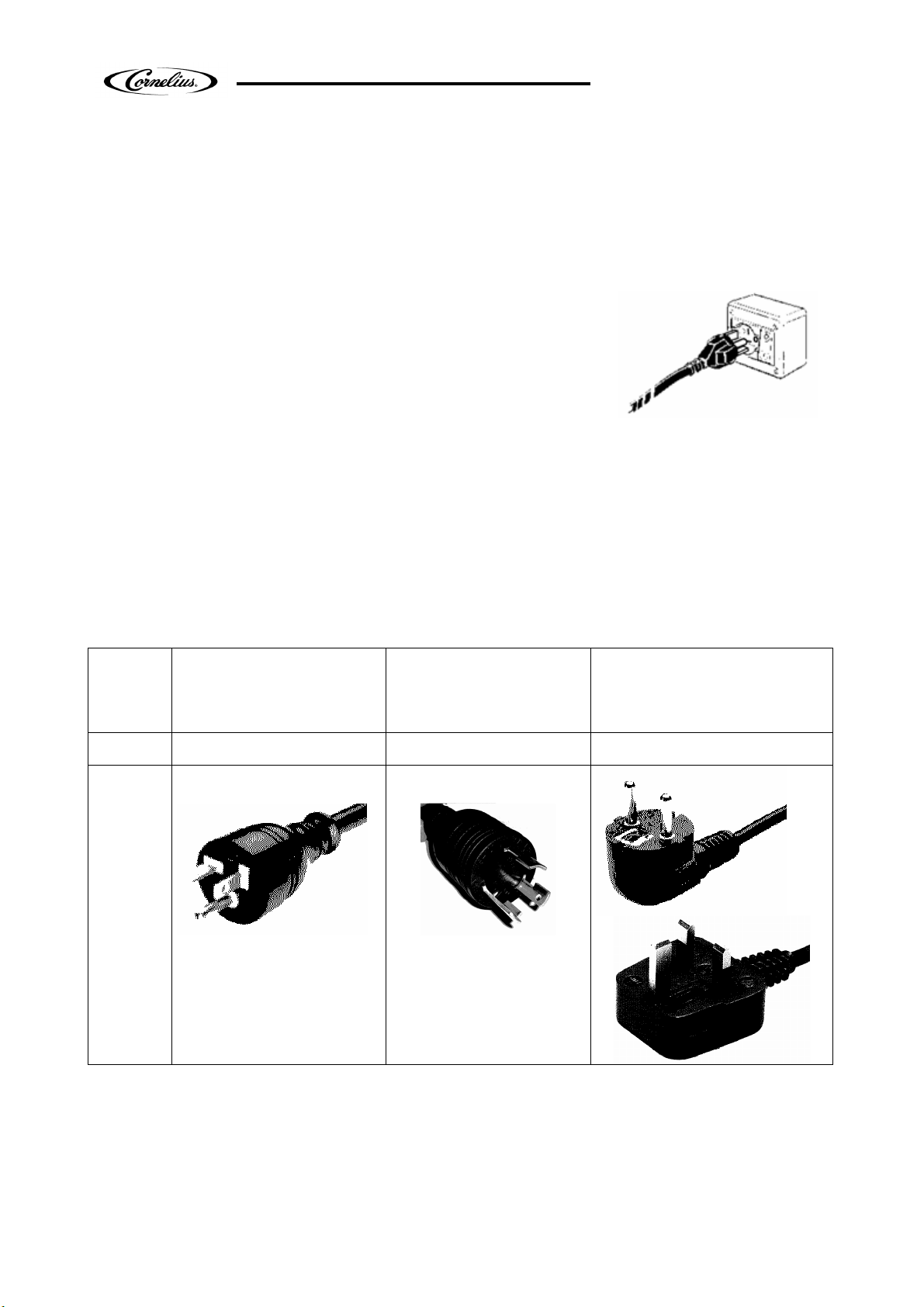

CONNECTING THE ELECTRICITY MAINS

Before inserting the plug into the mains socket for your own safety you must take careful note

of the following precautions.

• The machine’s electrical system can only be considered

safe when it is connected correctly to an earthing system, as

provided for by the national safety regulations. The manufacturer

cannot be held responsible for any damages that may be caused

by failure to earth the system.

• For the system to be installed correctly and safely, it is

essential to provide a suitable socket which complies with the

national safety standards in force (see Fig. 2).

• Check the length of the power supply cable to make sure it is not being crushed, do not use

extension cables and, to remove the plug, first turn off the switch, then hold the plug tightly

and pull gently.

• Do not obstruct the ventilation and the heat dissipation grids as bad airing, in addition to

reducing the output and causing bad functioning, could also lead to serious damage to the

equipment.

• Plug:

Machine VFCB post mix 115-60

2 bowl

VFCB pre mix 230-50

2 bowl

Fig. 2

VFCB post mix 115-60

3 bowl

VFCB post mix 230-50

2 bowl

VFCB pre mix 230-50

2 bowl

Plug Nema 5-20 Nema L5-30 cs-sd or cs-sa

IMPORTANT: If the power supply cable is damaged, it must be replaced by qualified

persons only, to prevent any possible risks.

Release Date: 20/04/10

Publication Number:

Revision: 8

Pag. : 6/59

Page 7

VFCB Operator’s Manual

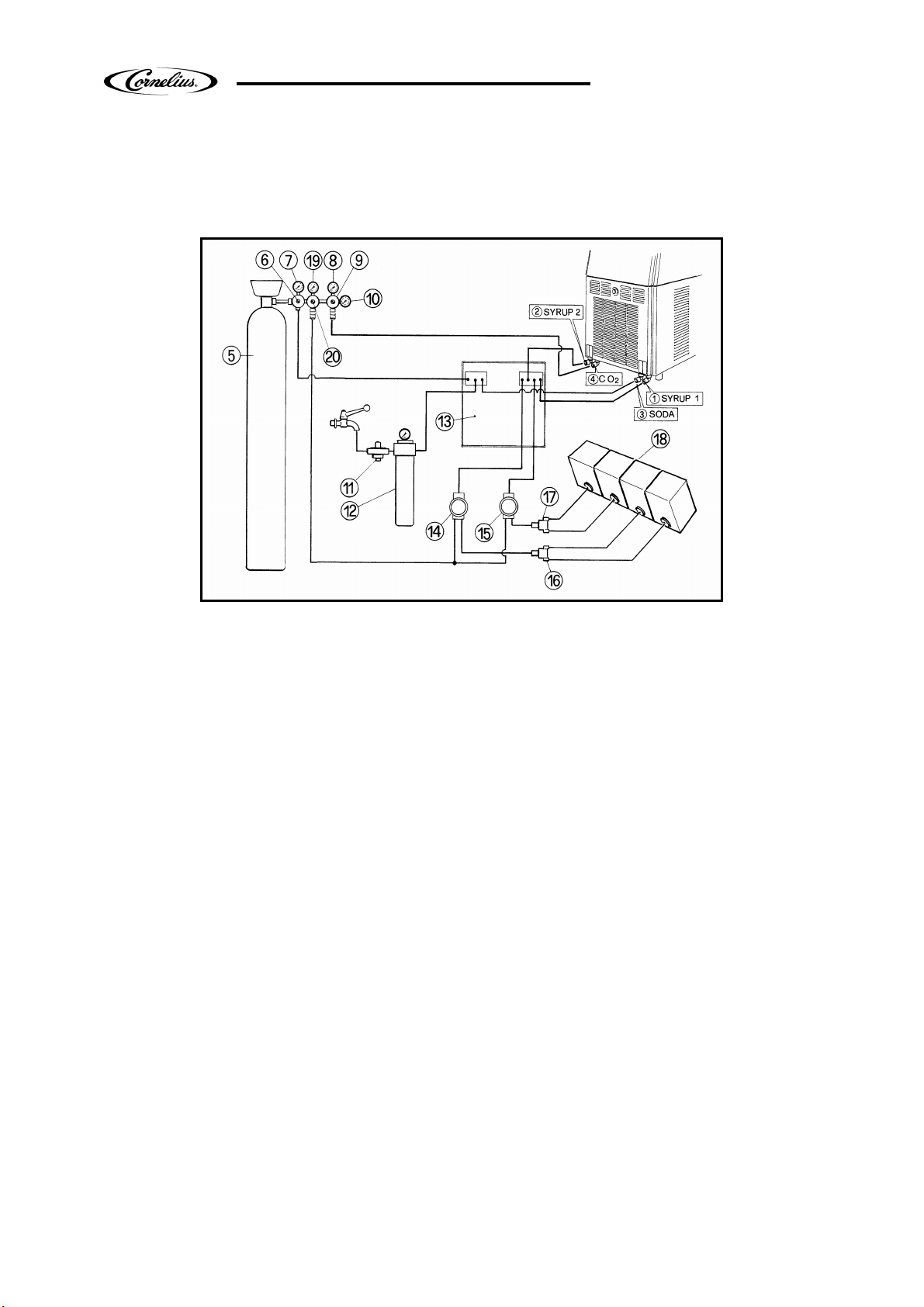

CONNECTION DIAGRAMS

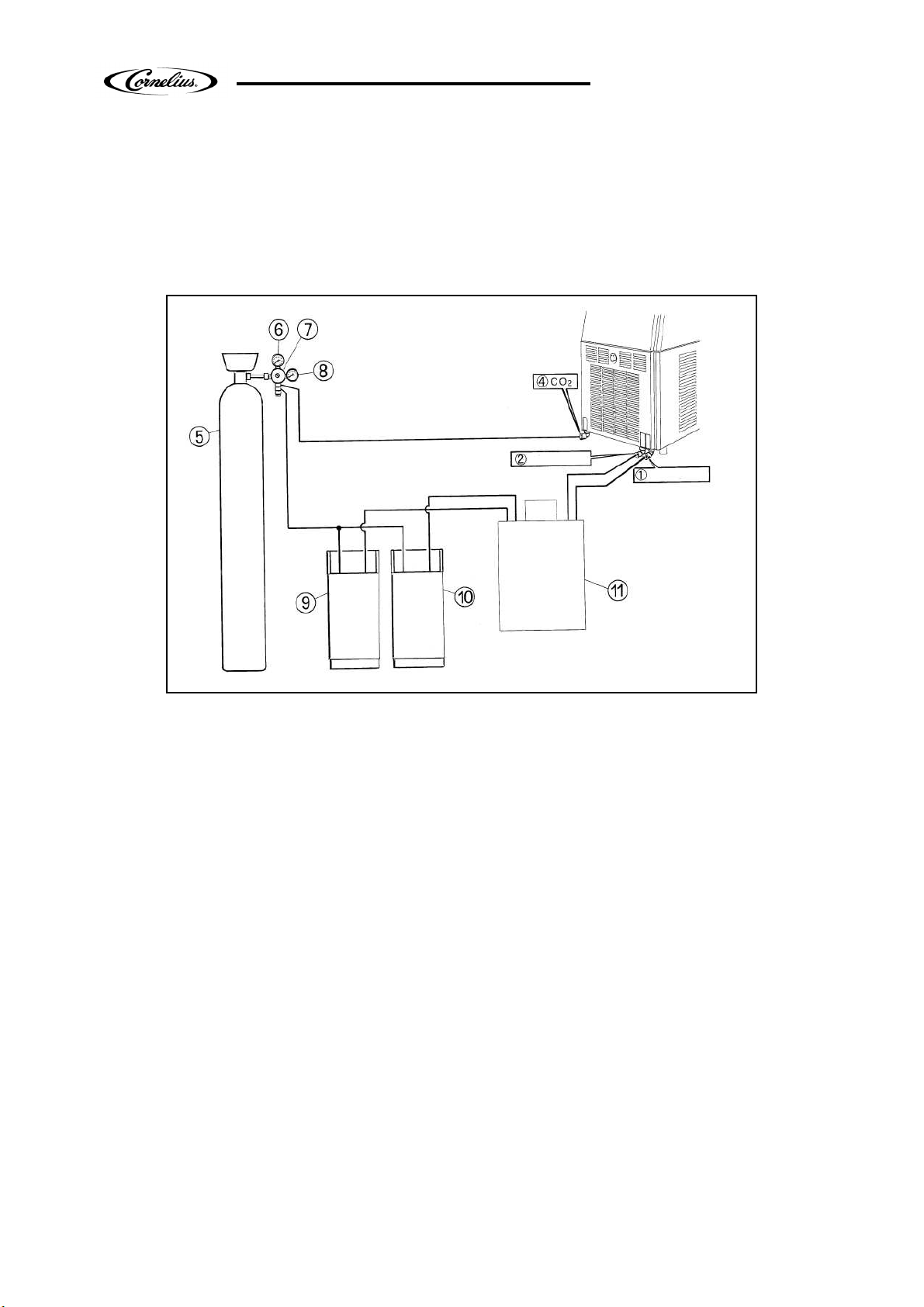

VFCB (PRE-MIX)

The diagram shows the sequence for the connection between the VFCB PRE-MIX to an existing

pre-mix system.

Fig. 3

Description:

(1)Pre-mix product 1 inlet

(2)Pre-mix product 2 inlet

(4)Inlet for CO2 (recommended pressure 21-22 PSI - 1.5 Bar)

(5)CO2 gas cylinder

(6)Operating pressure gauge

(7)CO2 pressure reducing valve

(8)Gas cylinder pressure gauge

(9)Pre-mix product 1 container

(10)Pre-mix product 2 container

(11)Cooling unit

Connection:

Proceed by connecting the points 1, 2, and 4 on the machine to the existing pre-mix system

using quick couplings.

Release Date: 20/04/10

Publication Number:

Revision: 8

Pag. : 7/59

Page 8

VFCB Operator’s Manual

VFCB (POST-MIX)

The diagram shows the sequence for the connection between the VFCB POST-MIX to an

existing post-mix system.

Fig. 4

Description:

(1)Syrup 1 inlet

(2)Syrup 2 inlet

(3)Soda water inlet

(4)Inlet for CO2 (recommended pressure 21-22 PSI - 1.5 Bar)

(5)CO2 gas cylinder

(6)Operating pressure reducing valve for carbonation unit

(7)Carbonation unit operating pressure gauge

(8)Unit Operating pressure gauges

(9)Pressure reducing valve

(10)Gas cylinder operating pressure gauge

(11)Water pressure reducing valve

(12)Filter

(13)Carbonation unit and optional pre-cooling unit

(14)Syrup 1 pump

(15)Syrup 2 pump

(16)Bag-in-box exchanger

(17)Bag-in-box exchanger

(18)Bag-in-box

(19)BIB Operating pressure gauges

(20)Pressure reducing valve

Connection:

Proceed by connecting the points 1, 2, 3, and 4 on the machine to the existing post-mix

system using quick couplings.

Release Date: 20/04/10

Publication Number:

Revision: 8

Pag. : 8/59

Page 9

VFCB Operator’s Manual

BOWL LOADING OPERATIONS

VFCB (PRE-MIX)

• Switch on the machine’s main switch.

• Put the switch (A) into position 1 – Fig. 5 - (switch

A controls the flow of the product in the bowls).

• The machine’s bowls will now fill up until the

maximum level is reached.

• Proceed to start up operations.

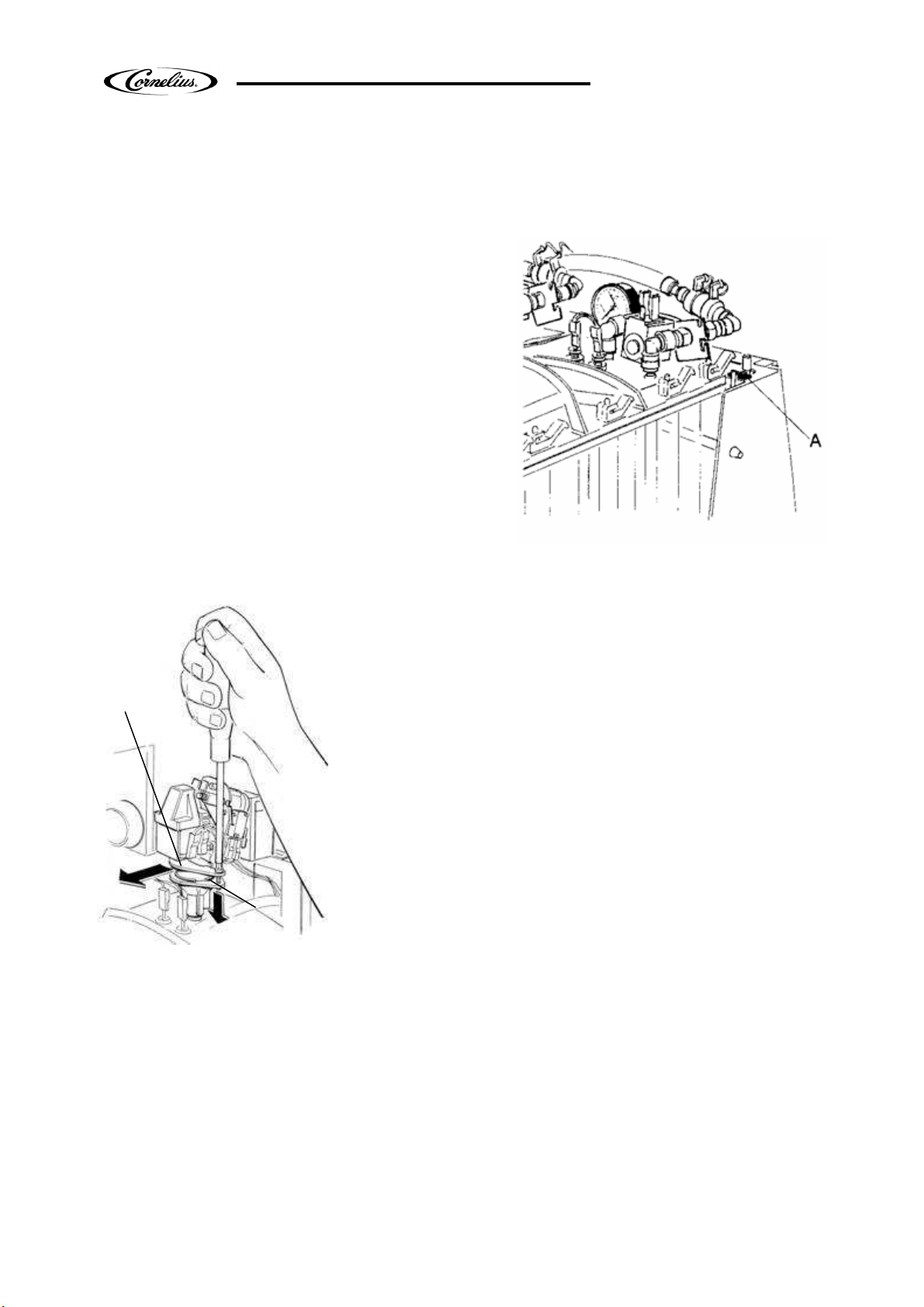

VFCB (POST-MIX)

C1

D1

Fig. 5A

Fig. 5

• Loosen the valve flanges screws as indicated in the fig.5A

without disconnecting them from the inferior flange;

• Remove the superior flange (C1) as indicated by the arrow in

the fig.5A;

• Leave the inferior flange (D1) on the bowl surface, it will be

easier to reassemble it after the brixing procedures.

Release Date: 20/04/10

Publication Number:

Revision: 8

Pag. : 9/59

Page 10

VFCB Operator’s Manual

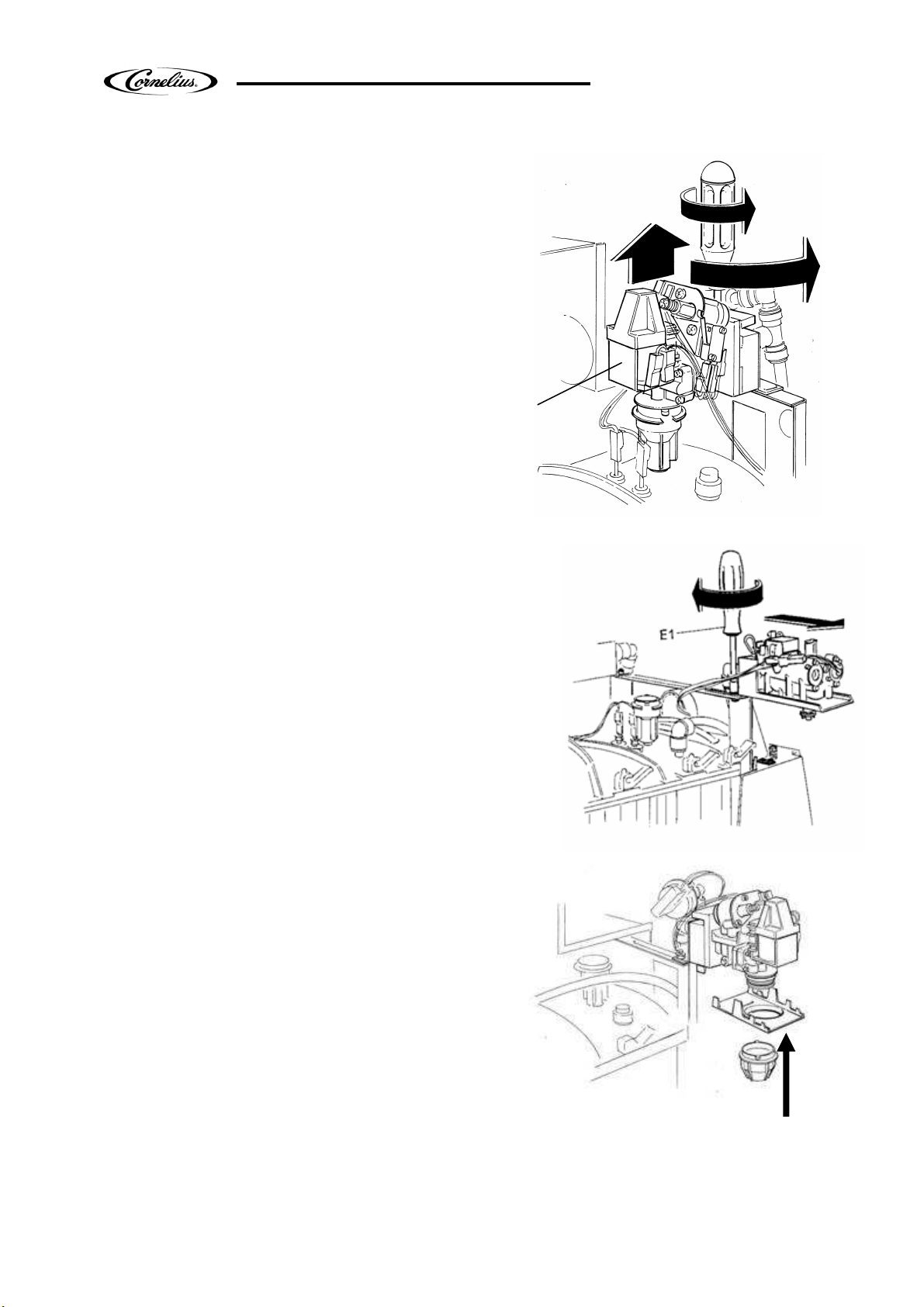

• Switch the machine’s main power switch to the

ON position.

• Make sure the switch (L1) is in the OFF position

(0) – Fig. 6. (Switch L1, A in fig.5, controls the

flow of the products in the bowls)

• Turn mixing motors OFF immediately. Do not

run units with bowls empty

• Using an 8 mm socket wrench (E1), loosen the

nut that holds the post-mix valve (D1).

• Lift the post mix valve (D1) up slightly and turn

it towards the outside. Leaving nozzle (F1) and

coupling attached to the bowl.

D1

• Now rotate the valve assembly 90 degrees and slide to

the outside of the machine. Tighten the 8mm nut using a

socket wrench (E1) – Fig. 7;

• Assemble the valve plate (A1) and the black knob

(B1) (you can find them inside the machine package)

as indicate in the fig.8;

• If you need to do the brixing procedures using the

calibrator/separator you have to assemble it instead

the black knob;

• Checking and adjusting the water flow is most easily

done by first disconnecting the syrup bib.

Fig. 6

E1

L1

F1

Fig. 7

A1

B1

Fig. 8

Release Date: 20/04/10

Publication Number:

Revision: 8

Pag. : 10/59

Page 11

VFCB Operator’s Manual

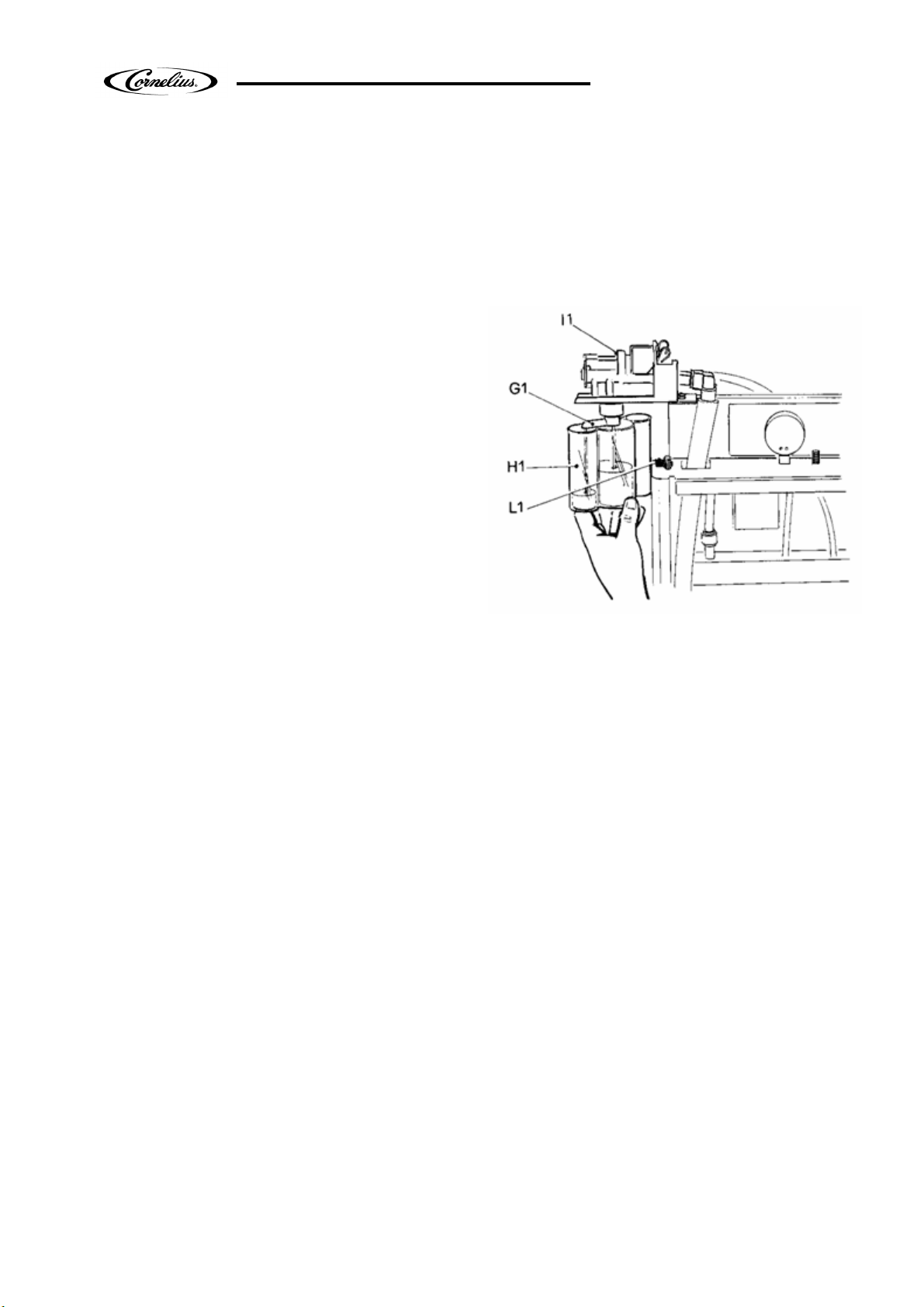

•

If necessary apply the calibrator/separator relative measuring cup (H1) and push the button

(or the micro switch) on the valve (l 1) until both the soda water and the syrup run into the

measuring cup separately (Fig. 9).

•

Adjust the water flow to the minimum level in order to reduce the inlet pressure. Turn the

water adjustment screw on the flow control counter clockwise until the minimum position to

decrease water flow (clockwise to increase it).

•

Reconnect the syrup.

•

Dispense product into a cup or into the

measuring cup by depressing the micro switch

on the valve. Check brix using a refractometer or

the measuring cup. The brix should be set to

13% ± 1%. To increase the brix adjust the syrup

adjustment screw on the valve clockwise to

increase syrup flow or counter clockwise to

decrease syrup flow.

CAUTION: Do not turn the syrup flow

control counter clockwise to far .

•

When the brix has been set to specification,

reposition the valve to its original setting &

tighten retaining nuts.

•

Repeat the operation for the second bowl.

•

Once the adjustments have been completed for each bowl, place the switch (L1) in the “ON”

position.

•

Both bowls will fill until the level sensor is activated.

•

Turn mixing motors “ON” (switch located on the control panel). The dispenser has built in

delays for compressor & bowl fill switch.

•

NOTE: During initial filling it is normal for some foaming to take place. The bowl level

management will adjust as the product freezes & the foam will dissipate.

Fig. 9

Release Date: 20/04/10

Publication Number:

Revision: 8

Pag. : 11/59

Page 12

VFCB Operator’s Manual

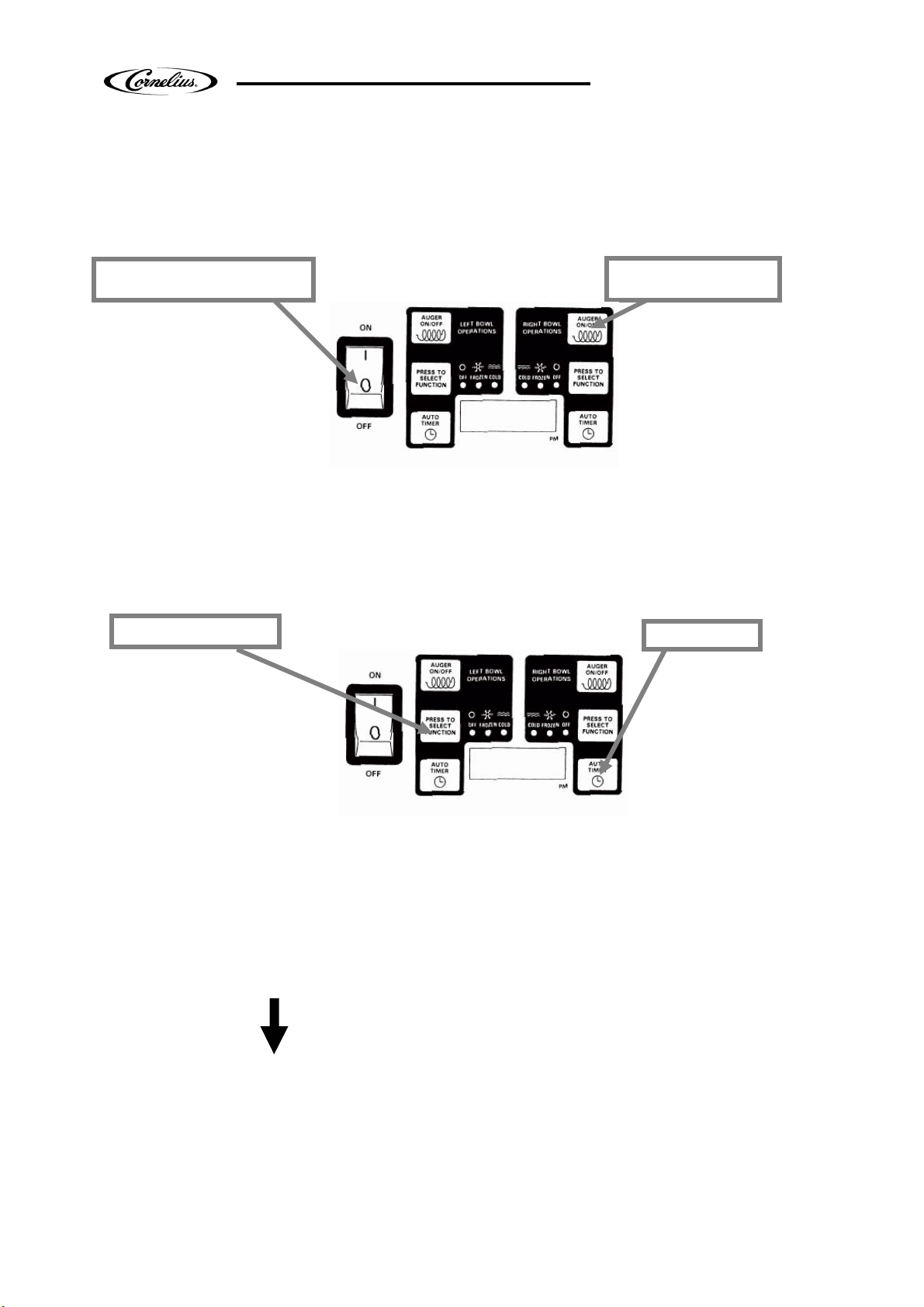

Main Power Switch

Auger ON/OFF

Select Function

Auto Timer

•

PROGRAMMING ELECTRONIC TOUCH PAD

2 bowls 2 compressors

•

Turns unit ON.

•

Selects 12/24 time or

F°/C° temperature display

when turned ON while

simultaneously pressing

the auger button (left one).

•

Sets current time when turned ON

while simultaneously pressing the

“Select function" button.

Fig. 10

•

Must be ON to activate the “Select

function" button to select manual "OFF",

"FREEZE", or "COOLING" functions.

•

Turns auger ON

and OFF when main

power switch is ON.

•

Must be ON to

permit defrost time

to be reset.

•

•

Used to manually select

"OFF", FREEZE", or

"COOLING" functions when

auger is turned ON.

•

Accesses defrost timer

reset mode when pressed

for an extended period

•

when auger is turned ON.

Does not function when light on "Auto Timer".

•

Locks in hours, minutes and final time

settings after they are reset using the

"Auto Timer" button.

•

Reset:

Press and hold the “Auto timer” button on the left. Turn the main switch ON and wait

until “PreS” appears on the display.

Used to adjust the hours and

minutes settings when

readjusting current time or auto

defrost timer.

Turns auto defrost

mode ON or OFF

(light on switch

indicates when

auto defrost mode

is activated).

Release Date: 20/04/10

Publication Number:

Revision: 8

Pag. : 12/59

Page 13

VFCB Operator’s Manual

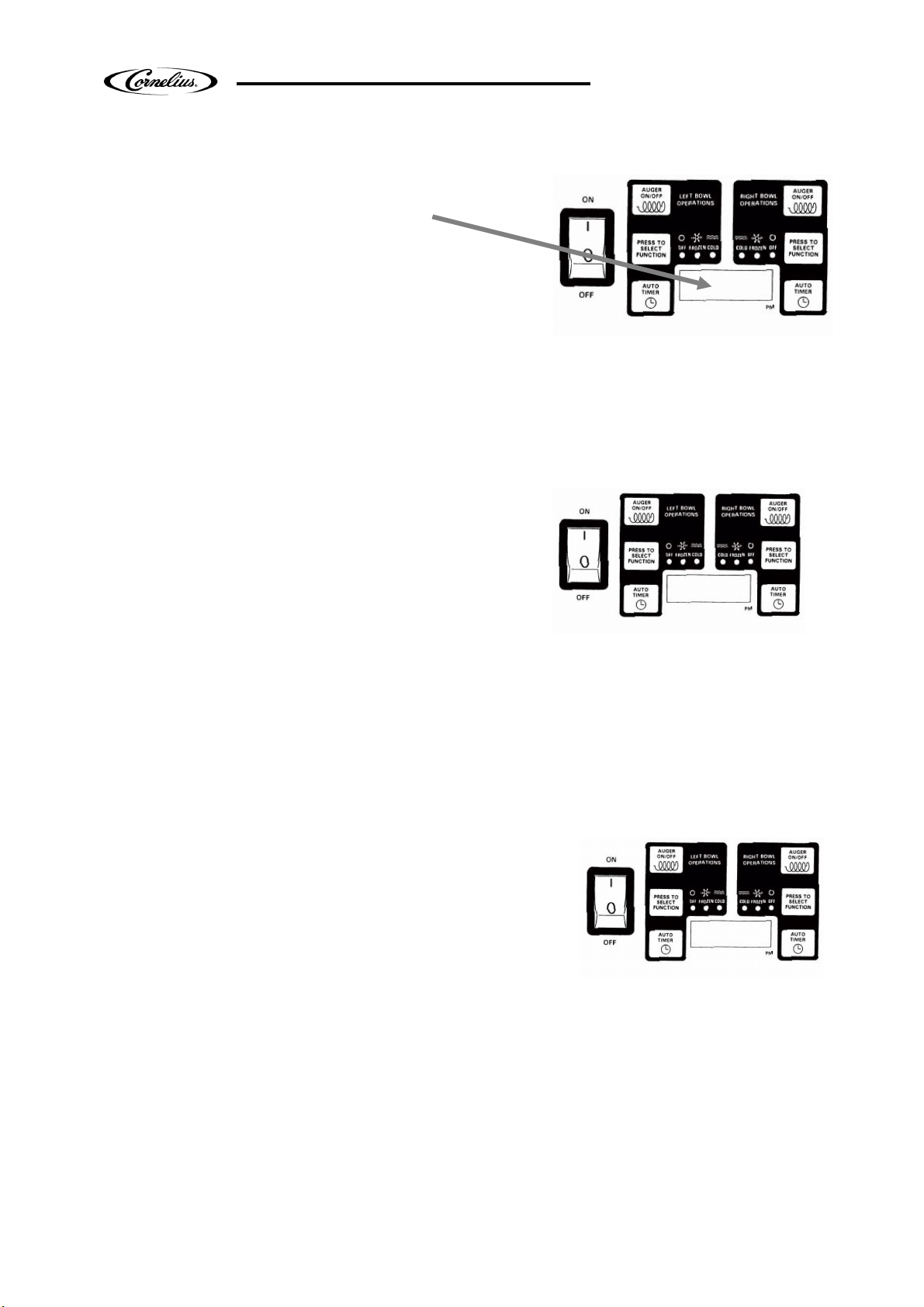

Setting Defrost Timer (Night Setting)

•

t the time you want the machine to turn to freezing mode by following steps above.

NOTE: Once the settings have been saved, the unit will keep the settings

.

Enter Time Programming on Initial Installation or in the Event of a Time Change

hour clock the time is P.M when the dot at the bottom

LEFT BOWL

•

Turn the power switch OFF.

•

Press and hold the left “Select function"

button and turn ON the power switch.

Release the “Select Function" button

when the hour digits start blinking.

•

Set the hour by pressing the "Auto

Timer" clock button until the appropriate

hour is shown.

NOTE: When using a 12

right corner of the LED display is lit; A.M. when dot is not lit.

•

Press the left “Select function" button to set the minutes, then press the "Auto Timer“

clock button until the appropriate minutes are set.

•

Press the “Select function" button one more time to save your settings.

Turn the power switch ON. Make sure the "Auto Timer" is OFF.

•

Press the left "Auger ON/OFF" button ON.

•

Press and hold the “Select function" button until you hear a long beep and the LED,

"Cold" and the "Auto Timer" clock light begins to blink.

•

Press the "Auto Timer" clock button to set the hour you want it to turn to refrigeration

mode, (defrost mode) and then press the “Select function" button to save the hour

setting.

•

Press the "Auto Timer" clock button to set the minutes to complete time setting that

you want it to turn to refrigeration mode (defrost mode). Then press the “Select

function" button to save the minute setting. The "Cold" light will turn off and the

"Freeze" light and "Auto Time" light will begin blinking.

•

Se

Then press the “Select function" button to save the time settings for freeze mode.

NOTE: When the light on the "Auto Timer" clock button is "ON", the defrost timer

is activated. To turn OFF the defrost timer, press the "Auto Timer" clock button

(s) until the light (s) on the clock button (s) turns off.

Release Date: 20/04/10

Publication Number:

Revision: 8

Pag. : 13/59

Page 14

VFCB Operator’s Manual

Setting the 12 or 24 Hour Display

•

Operate in Automatic Mode (with Defrost Timer Activated)

Operate in Manual Mode (without Defrost Timer Activated)

product

•

Turn power switch ON and wait for LED

display to light up.

•

Press the left hand "Auger ON/OFF" button ON.

•

To operate in defrost mode press the "Auto Timer"

button until it is illuminated.

•

When setting automatic times, please keep in mind it will take time for the frozen

product to become liquid or vice versa.

NOTE: As regard the RIGTH BOWL repeat the same operations using the buttons

on the right side of the touch pad.

•

Turn the power switch ON and wait for

LED display to light up.

•

Make sure the clock button is OFF (LED

light on clock button should not be lit up).

•

First turn auger on by pressing the "Auger ON/OFF"

button until it beeps.

NOTE: The auger must be on before the unit will allow the cooling or freezing

mode to be activated.

•

Then select refrigeration or freezing mode by pressing the “Select function"

button until the light under the selection you desire is lit up.

NOTE: In the cooling mode, the LED will read the actual temperature of the

(the temperature setting is preset to NSF standards and is not adjustable). In the

"Freeze" or "Off" mode the LED will read the current time.

•

Turn the power switch OFF.

•

Press and hold the left "Auger On/Off" button and turn

the power switch ON. Release the "Auger On/Off" button

when either "12" or "24" are shown (indicates the current

hour view).

Press the "Auto Timer" button until the desired hour display type is shown (12 to 24).

•

Press the "Select Function" button until the desired temperature display type is

shown (°F or °C).

•

Press the "Select Function" button until the current time is displayed to store the

changes. The unit is now ready for use.

Release Date: 20/04/10

Publication Number:

Revision: 8

Pag. : 14/59

Page 15

VFCB Operator’s Manual

Setting the °F or °C Temperature Display

•

•

Viewing the Bowl Temperature

"Auger On/ Off" button).

•

Turn the power switch OFF.

•

Press and hold the left "Auger On/Off" button and turn ON the power switch. Release the

"Auger On/Off" button when either "12" or "24" are shown (indicates the current hour

view).

Press the "Select Function" button until either °F or °C is shown on the display.

Press the "Auto Timer" button until the desired temperature display type is shown.

•

Store the change by pressing the "Select Function" button until the current time

is displayed. The unit is now ready for use.

•

Press the "Select Function" button until the "Cold" LED is lit. The display will now

show the current bowl temperature in either °F or °C depending on which was

selected in the Setting the °F or °C Temperature Display section.

•

Turn On the auger on the side that you want to display the bowl temperature (press the

“FILTER CLEANING” Alarm

A filter cleaning alarm will activate when the unit is running hot due to insufficient internal air

circulation. When this occurs a “Filt” message will appear on the touch pad LED display readout

and an intermittent audible tone will also sound to alert the operator of this condition.

The “Filt” message will appear when the alarm activates (a beeping sound every 4-5 seconds).

To determine the condition that caused the alarm, see list of conditions below:

• Condition: The filter is dirty and needs to be cleaned.

Corrective Action: Clean and replace filter following instructions(Removing and Cleaning Filter).

• Condition: The unit is positioned too close to a wall or other object restricting air flow and

causing the machine to run at a higher temperature.

Corrective Action: Reposition unit to maximize ventilation space (Installation Instructions).

• Condition: The filter is not properly installed.

Corrective Action: Properly install filter (Removing and cleaning filter).

• Condition: The unit has been installed near a heat source, such as a coffee machine, ice

maker or cold beverage machine which expels hot air from its vents, causing the machine to

run at a high temperature (installation near a heat source should be avoided)

Corrective Action: Reposition unit to maximize ventilation space.

“SYSTEM OVER TEMPERATURE” Alarm

A system over temperature alarm will activate as a safety precaution when the unit has

overheated to protect the compressor.

• The system automatically goes to “OFF” status where the compressor’s operations is

stopped, while augers will keep working to avoid forming ice blocks.

• When this occurs an “Err” message will appear on the touch pad LED readout accompanied

by a continuous buzzer sound to alert the operator of this condition.

• When this alarm activates, turn off all switches. Then determine the condition. (See “Filter

Cleaning” Alarm Section for Conditions and Corrective Actions)

Release Date: 20/04/10

Publication Number:

Revision: 8

Pag. : 15/59

Page 16

VFCB Operator’s Manual

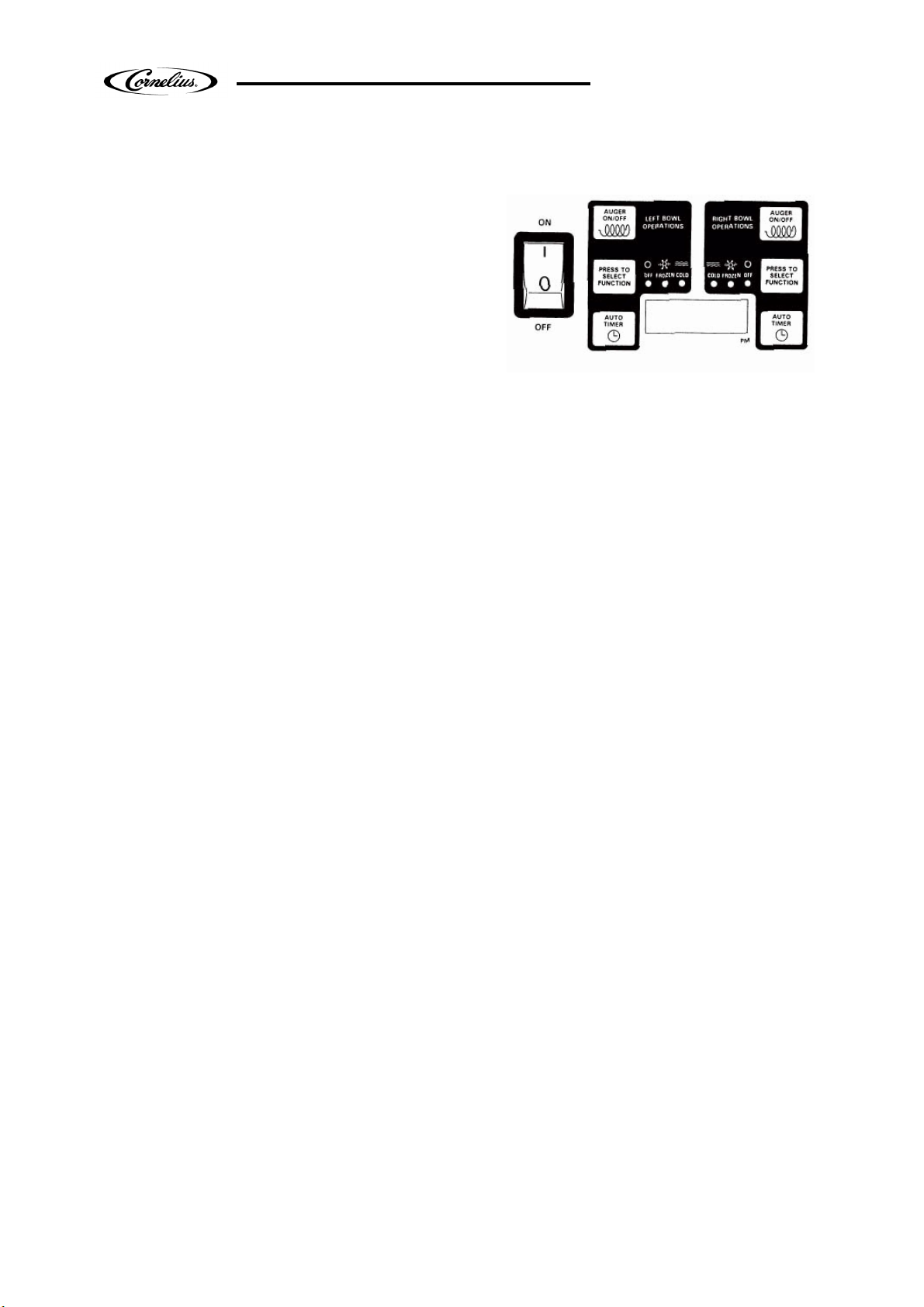

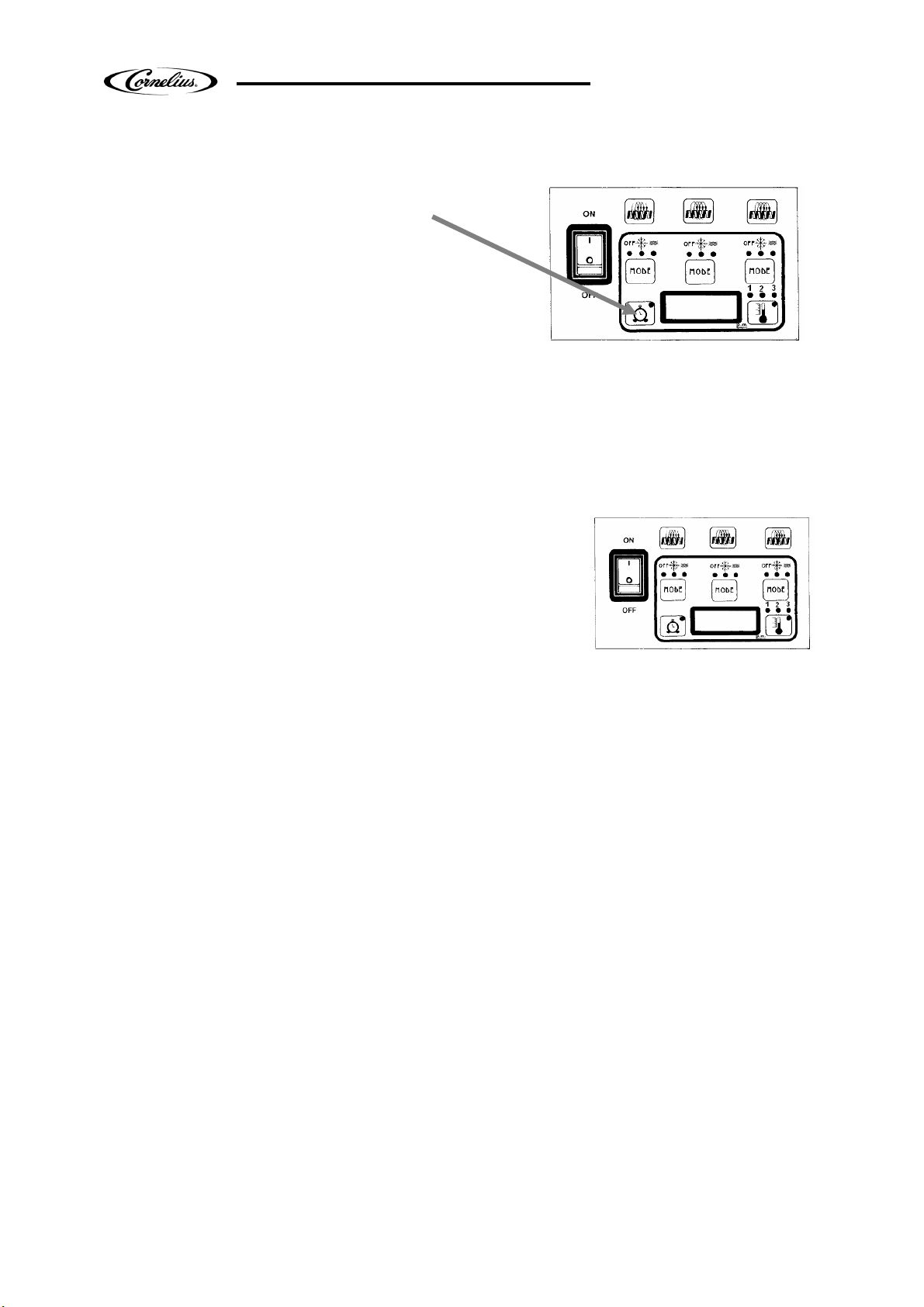

Main Power Switch

Auger ON/OFF

MODE

•

Bowl temperature

product temperature inside the bowl.

3 bowls 3 compressors

•

Turns unit ON.

•

Selects 12/24 time

when turned ON while

simultaneously pressing

the auger button (left one).

•

Sets current time when turned ON

while simultaneously pressing the left

“MODE” button.

•

Turns auger ON

and OFF when main

power switch is ON.

•

Must be ON to

permit defrost time

to be reset.

Fig. 11

•

Must be ON to activate the “MODE”

button to select manual “OFF”,”FREEZE”,

or “COOLING” functions.

Auto Timer

•

•

Used to manually select

“OFF”, “FREEZE”, or

“COOLING” functions when

auger is turned ON .

•

Accesses defrost timer

reset mode when pressed

for an extended period

when auger is turned ON.

Does not function when light on “Auto Timer”.

•

Locks in hours, minutes and final time

settings after they are reset using the

“Auto Timer” button.

•

In defrost condition used to show the

•

Reset:

Press and hold the “Auto timer” button. Turn the main switch ON and wait until “PreS”

appears on the display.

Turns auto defrost

mode ON or OFF

(light on switch

indicates when

auto defrost mode

is activated).

•

Used to adjust the

hours and minutes

settings when

readjusting current

time or auto defrost

timer.

Release Date: 20/04/10

Publication Number:

Revision: 8

Pag. : 16/59

Page 17

VFCB Operator’s Manual

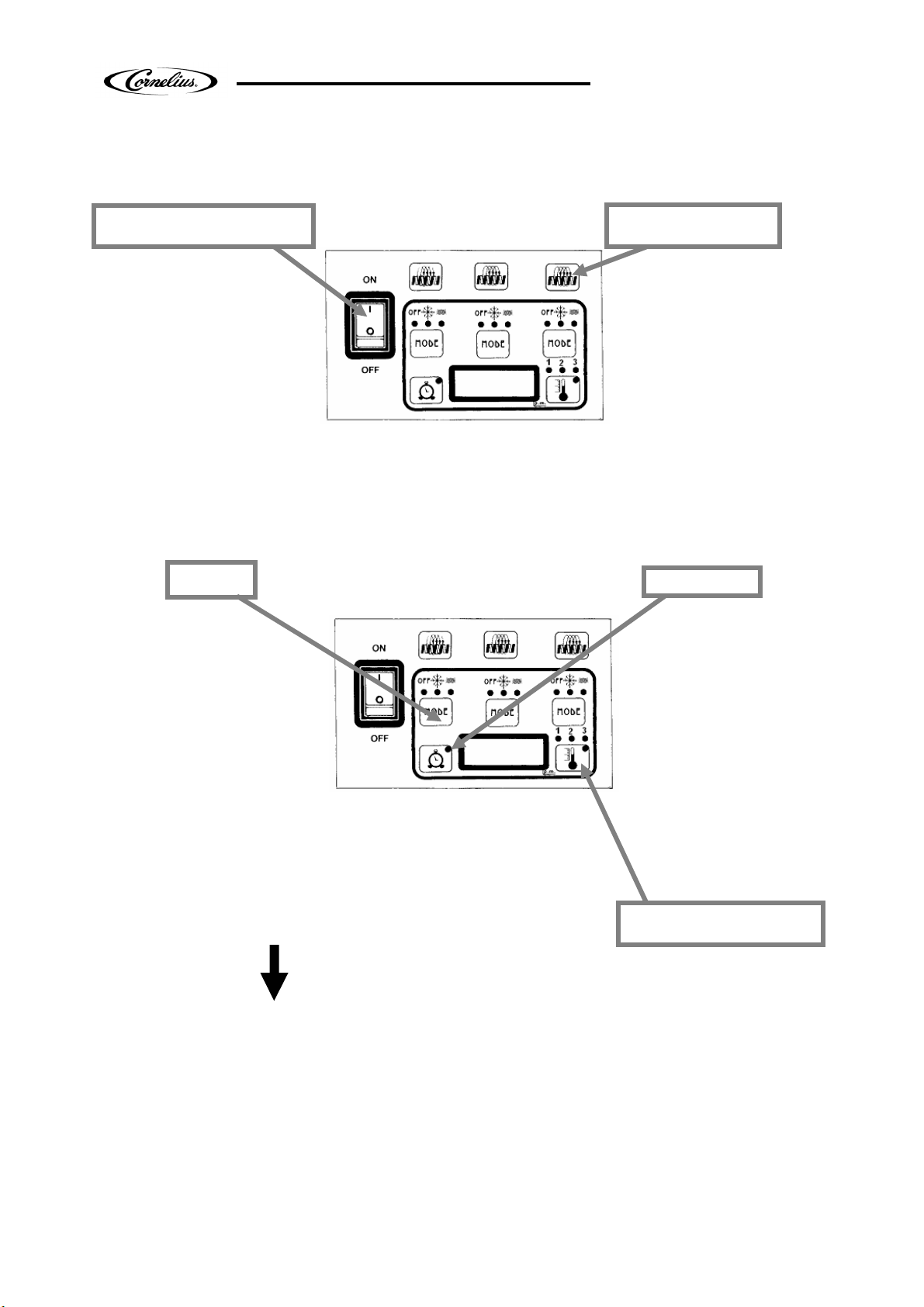

Setting Defrost Timer (Night Setting)

•

NOTE: Once the settings have been saved, the unit will keep the settings

.

Enter Time Programming on Initial Installatio

n or in the Event of a Time Change

NOTE: When using a 12 hour clock the time is P.M when the dot at the bottom

•

Turn the power switch OFF.

•

Press and hold the left “MODE” button and

turn the power switch ON.

Release the “MODE” button when the hour

digits start blinking.

•

Set the hour by pressing the “Auto

Timer” clock button until the appropriate

hour is shown.

right corner of the LED display is lit; A.M. when dot is not lit.

•

Press the left “MODE” button to set the minutes, then press the “Auto Timer” clock

button until the appropriate minutes are set.

•

Press the left “MODE” button one more time to save your settings.

Turn the power switch ON. Make sure the “Auto Timer” is OFF.

•

Press the “Auger ON/OFF” button ON (one at least) .

•

Press and hold the left “MODE” button until you hear a long beep and the LED,

"Cold" and the "Auto Timer" clock light begins to blink.

•

Press the “Auto Timer” clock button to set the hour you want it to turn to refrigeration

mode (defrost mode) and then press the “MODE” button to save the hour setting.

•

Press the “Auto Timer” clock button to set the minutes to complete time setting that

you want it to turn to refrigeration mode (defrost mode). Then press the left “MODE”

button to save the minute setting. The “Cold” light will turn off and the "Freeze" light

and “Auto Time” light will begin blinking.

•

Set the time you want the machine to turn to freezing mode by following steps above.

Then press the left “MODE” button to save the time settings for freeze mode.

NOTE: When the light on the “Auto Timer” clock button is “ON”, the defrost timer

is activated. To turn OFF the defrost timer, press the "Auto Timer" clock button

until the light on the clock button turns off.

Release Date: 20/04/10

Publication Number:

Revision: 8

Pag. : 17/59

Page 18

VFCB Operator’s Manual

Operate in Automatic Mode (with Defrost Timer Activated)

Operate in Manual Mode (without Defrost Timer Activated)

and is not adjustable).

•

Turn power switch ON and wait for LED

display to light up.

•

Press "Auger ON/OFF" buttons ON.

•

To operate in defrost mode press the “Auto Timer”

button until it is illuminated.

•

When setting automatic times, please keep in mind it will take time for the frozen

product to become liquid or vice versa.

NOTE: The defrost timer is the same for all the bowls.

The defrost mode can be activated only if one auger button at least is on.

•

Turn the power switch ON and wait for

LED display to light up.

•

Make sure the clock button is OFF (LED

light on clock button should not be lit up).

•

First turn auger on by pressing the “Auger ON/OFF”

button until it beeps.

NOTE: The auger must be on before the unit will allow the cooling or freezing

mode to be activated.

•

Then select refrigeration or freezing mode by pressing the “MODE” button until the light

under the selection you desire is lit up.

NOTE: In the cooling mode, the LED display will read the actual temperature of the

product (the temperature setting is preset to NSF standards

Pushing the thermometer button it is possible to see the temperature into the left

bowl (led 1 light up) or into the right one (led 2 light up).

In the “Freeze” or “Off” mode the LED will read the current time.

Release Date: 20/04/10

Publication Number:

Revision: 8

Pag. : 18/59

Page 19

Setting the 12 or 24 Hour Display

•

Viewing the Bowl Temperature

VFCB Operator’s Manual

•

Turn the power switch OFF.

•

Press and hold the left "Auger On/Off" button and

turn the power switch ON. Release the "Auger On/Off"

button when either “12” or “24” are shown (indicates

the current hour view).

Press the “Auto Timer” button until the desired hour display type is shown (12 to 24).

•

Press the left “MODE” button on the left until the desired temperature display type is

shown (°F or °C).

•

Press the left “MODE” button on the left until the current time is displayed to store the

changes. The unit is now ready for use.

•

Press the left “MODE” button until the “Cold” LED is lit, than press the “bowl

Temperature “ button choosing the bowl. The display will now show the current bowl

temperature in either °F or °C depending on which was selected in the Setting the

°F or °C Temperature Display section. Turn On the auger on the side that you want

to display the bowl temperature (press the “Auger On/ Off” button).

“FILTER CLEANING” Alarm

A filter cleaning alarm will activate when the unit is running hot due to insufficient internal air

circulation. When this occurs a “Filt” message will appear on the touch pad LED display readout

and an intermittent audible tone will also sound to alert the operator of this condition.

The “Filt” message will appear when the alarm activates (a beeping sound every 4-5 seconds).

To determine the condition that caused the alarm, see list of conditions below:

• Condition: The filter is dirty and needs to be cleaned.

Corrective Action: Clean and replace filter following instructions(Removing and Cleaning Filter).

• Condition: The unit is positioned too close to a wall or other object restricting air flow and

causing the machine to run at a higher temperature.

Corrective Action: Reposition unit to maximize ventilation space (Installation Instructions).

• Condition: The filter is not properly installed.

Corrective Action: Properly install filter (Removing and cleaning filter).

• Condition: The unit has been installed near a heat source, such as a coffee machine, ice

maker or cold beverage machine which expels hot air from its vents, causing the

machine to run at a high temperature (installation near a heat source should be

avoided)

Corrective Action: Reposition unit to maximize ventilation space.

“SYSTEM OVER TEMPERATURE” Alarm

A system over temperature alarm will activate as a safety precaution when the unit has

overheated to protect the compressor.

• The system automatically goes to “OFF” status where the compressor’s operations is

stopped, while augers will keep working to avoid forming ice blocks.

• When this occurs an “Err” message will appear on the touch pad LED readout accompanied

by a continuous buzzer sound to alert the operator of this condition.

• When this alarm activates, turn off all switches. Then determine the condition. (See “Filter

Cleaning” Alarm Section for Conditions and Corrective Actions)

Release Date: 20/04/10

Publication Number:

Revision: 8

Pag. : 19/59

Page 20

VFCB Operator’s Manual

CONSISTENCY ADJUSTMENT

1. To dispense the product, place the cup

beneath the tap (Q) and lower the lever (R)

very gently (Fig.12).

2. Adjusting the consistency:

To vary the consistency of the ice slush, turn

the knob (S) as shown in Fig. 13. Turning the

knob counter-clockwise will increase viscosity

(make the product denser). Turning the knob

clockwise will decrease viscosity (make the

product less dense).

ATTENTION: This device only changes the

consistency of the ice slush

dispensed, it does not effect the

cooling temperature.

ATTENTION: When the level of the ice slush

inside the bowl is below the

minimum, to stop the product

becoming too dense you must

switch off the cooling system

(OFF position), or top up the

bowl,

An indicator gauge for reference is located on the

back of the unit approximately 6 inches below the

adjustment knob.

Fig. 12

Fig. 13

Release Date: 20/04/10

Publication Number:

Revision: 8

Pag. : 20/59

Page 21

VFCB Operator’s Manual

SIX MONTHLY CLEANING AND SANITATION

OPERATIONS:

ATTENTION: The cleaning operations must be

performed with the machine

disconnected from the power supply.

1. Empty the bowl of any remaining product and switch

off the main switch.

2. Remove the cover (B) – Fig. 14.

3. Extract the quick couplings (C2) / (F2) - (Fig.

15, 16, and 17).

4. Disconnect the probe fastenings (D2) / (E2) - (Fig. 15 and 16).

Fig. 14

Fig. 15

Release Date: 20/04/10

Publication Number:

Revision: 8

Pag. : 21/59

Fig. 17

Fig. 16

Page 22

VFCB Operator’s Manual

5. Pull the lock pin/safety pin (Y) upwards, if the machine version is

without pin, unscrew one of the two locking knobs (Y1) – Fig.18.

Y1

Fig. 18

6. Slide the locking bar (Z) – Fig. 19 - outwards so that the bowls are

fully released. Unlock relief valve on the bowl lid cap and remove it

(Fig. 20).

Fig. 19

7. Lift the bowl lid cap lever (Fig. 20), remove the cap, unscrew the

knobs (A1) so the bowls can be lowered slightly, open the tap to

remove any remaining liquids and then extract the bowl from its

seating, pulling it outwards (Fig. 20).

Fig. 20

8. Remove the tap from its seating, pressing the two clamping wings at

the same time (Fig. 21) and pushing upwards.

Fig. 21

9. Dismount the tap, holding the body (R) pressed downwards, then

slide the lever (L) out of its seating (Fig. 22). Wash all the parts

thoroughly with hot water and washing-up liquid, rinse them well, and

proceed to remount them.

10. Separate the bowl from its cover, releasing the fastening (D1)

by pulling them upwards as shown in Fig.23.

Release Date: 20/04/10

Publication Number:

Revision: 8

Pag. : 22/59

Fig. 22

Fig. 23

Page 23

VFCB Operator’s Manual

11. Wash the bowl lid cap (Fig. 20), the bowl and its cover

carefully with water and washing-up liquid, rinse them well, and

proceed to remount them, making sure the sealing strip (E1) is

positioned correctly between the cover and the bowl. To

guarantee the seal, the rounded part of the said sealing strip (as

shown in Fig. 24) must be facing the cover.

12. Unscrew the fastening knob (F1) clockwise as the

direction indicated by the arrow (threading to the left) and

proceed by extracting the spiral scraper (G1) and the seals (H1)

and (I1). Clean the individual parts thoroughly (Fig. 25).

13. Clean the drip tray (J1) and the evaporator (K1) well (Fig. 26).

CAUTION: Do not wash any components in a dishwasher.

14. Proceed to remount the mixing unit as follows:

• dampen the sealing strip (l1) and insert it into its seating in

the correct position (Fig. 26A);

• apply a copious amount of Vaseline (supplied with the

machine) to the suction cup seal (H1) (on the part that comes

into contact with the evaporator K1) and insert it in its spiral

seating (Fig. 25 , Fig. 26);

• remount the spiral scraper (G1) (Fig.25);

• fasten all the components in place by screwing the knob F1

counter-clockwise (Fig.25).

15. Remount the bowl by pushing it into its seating (Fig. 27).

16. Proceed to fasten the bowl in place by tightening the

knobs (A1) – Fig. 26 and the locking bar (Z) – Fig. 19.

Fig. 24

Fig. 25

Fig. 26

Fig. 26A

Fig. 27

17. Remount the tap, remembering to smear both is seating in the bowl

and the seals (J) with Vaseline (Figure 28).

Release Date: 20/04/10

Publication Number:

Revision: 8

Pag. : 23/59

Fig. 28

Page 24

VFCB Operator’s Manual

18. Dismount the drip tray (L1) by rotating it slightly and pulling

it outwards (Fig. 29). Wash all the parts carefully and

proceed to reassemble it by following the aforesaid

operations, remembering to reinsert the condensation

discharge pipe (M1) in its seating.

Fig. 29

19.If the drip tray is outfitted with coupling T0(Fig. 30) it is

possible to discharge the water in the drip tray without

removing it. In order to do that proceed as follow:

• remove the tap T1 (Fig. 30);

• connect a tube with the coupling T0 (Fig. 30).

NOTE:

“Six monthly” cleaning procedure is the standard time and it is suitable for the most of the

products, but the cleaning procedure depends on the kind of product used. If the product used

is a made of milk or 100% fruit plus sugar, for example, “Three monthly” cleaning procedure is

request. In case of doubt please contact the assistance or do the “Three monthly” cleaning

procedure.

Fig. 30

Release Date: 20/04/10

Publication Number:

Revision: 8

Pag. : 24/59

Page 25

VFCB Operator’s Manual

SPECIAL MAINTENANCE

MANIFOLD AND BACK RELIEF VALVES CLEANING

ATTENTION: To guarantee the good functioning of the safety system, the cleaning of

the manifold and of the back relief valve is essential.

It’s essential to perform the manifold draining procedures

once a month proceeding as follows:

• disconnect the machine from the power supply;

• dismount the cover (B) – Fig.32;

• disconnect the plug (D) – Fig.33;

• un-thread the back (E) – Fig.33, pulling it high.

• extract the draining tube (R) by unrolling it – Fig.30A;

• drain the product inside a manifold opening the tap (S) -

Fig.30A.

• close the tap ed restore the tube in the initial position.

It’s essential to perform the back relief valves cleaning procedures every three months

proceeding as follows:

• disconnect the machine from the power supply;

• dismount the cover (B) – Fig.32;

• disconnect the plug (D) – Fig.33;

• un-thread the back (E) – Fig.33, pulling it high.

• disconnect the fast-on connections from the

valve;

• disassemble the relief valve coil Z by

unscrewing its fixing nut N with a N°15 monkey

spanner– Fig.30B;

• disassemble the relief valve body V by

unscrewing it with a N°18 monkey spanner–

Fig.30B;

• once disassembled, carefully wash the body V,

the conical spring T and the piston U in order to

clean them from product residuals - Fig.30B.

• carefully dry up all the disassembled parts;

• reassemble the spring on the piston in the right direction as described in picture 30B;

• reassemble all other parts carefully tightening them in order to avoid air leakage during the

functioning.

You are reminded that all the operations described above must be carried out with

the machine switched off and the power cable disconnected.

Fig. 30A

Fig. 30B

Release Date: 20/04/10

Publication Number:

Revision: 8

Pag. : 25/59

Page 26

VFCB Operator’s Manual

CONDENSER FILTER CLEANING

ATTENTION: To guarantee the cooling system a good performance level, the routine

cleaning of the condenser filter is essential.

As explained earlier, an acoustic signal, accompanied by the word

FILT appearing on the control panel display, will warn the operator

when the filter is clogged and so must be cleaned before the

machine comes to an automatic stop.

Proceed as follows:

• disconnect the machine from the power supply;

• remove the filter as showed in Fig. 31 and clean it;

• dismount the cover (B) – Fig. 32;

• disconnect the plug (D) – Fig. 33;

• un-thread the back (E) – Fig. 33, pulling it high.

• clean the condenser with a brush if necessary (Fig.34).

You are reminded that all the operations described above

must be carried out with the machine switched off and the

power cable disconnected.

INSUFFICIENT AIR FLOW ALARM

To protect the entire cooling system, the ice slush drinks

maker is fitted with an electronic system which issues an

acoustic warning signal in the event of insufficient

ventilation or if the condenser filter is clogged with dust. In

addition to this, the words Filt and then Err will appear on the

control panel display.

If the operator does not intervene when the signal is issued,

restoring normal working conditions (i.e. ensuring better

ventilation or cleaning the filter), this electronic system will stop

the machine automatically.

Fig. 31

Fig. 32

Fig. 33

Fig. 34

Release Date: 20/04/10

Publication Number:

Revision: 8

Pag. : 26/59

Page 27

VFCB Operator’s Manual

SEAL MAINTENANCE

SPINDLE BUSHING: replace every 6 to 12 months

depending on conditions of use and level of maintenance.

Replacement should ONLY be done by a qualified service

technician

• Remove the Rulon bushing using a flathead screwdriver as

shown

• Insert the brass guide tool on the drive shaft and slip the

bushing over the guide tool and firmly press into place.

• Using the special tool C and rubber mallet, gently seat the

bushing into place as shown

• Lubricate the bell shaped seal and reassemble onto

evaporator/auger shaft.

BELL SHAPED SEAL: replace every 1 to 6 months depending on conditions of use,

level of maintenance and lubrication. This part should be lubricated during

reassembly after every cleaning

BOWL GASKET: it’s the red gasket located at the rear of the bowl, replace as

necessary depending on conditions of use and level of maintenance; this part should

be lubricated during the re-assembling after every cleaning.

O-RING: the dispense valve o-ring should be replaced every 6 to 12 months or as

necessary when wear is apparent. Lubricate the o-ring each time they are replaced

or the dispense handle is removed for cleaning

Release Date: 20/04/10

Publication Number:

Revision: 8

Pag. : 27/59

Page 28

VFCB Operator’s Manual

ELECTRONIC MONITORING

ELECTRONIC MONITORING AND SAFETY

SYSTEM

GENERAL FEATURES

The diagram shows the electronic pressures and

levels management system:

1. Safety valve

2. Cut out level bowls control board

3. Bowl 1 discharge solenoid valve

4. Bowl 2 discharge solenoid valve

5. CO2 inlet solenoid valve

6. Pressure and levels control board

7. Draining tube

8. Tube to the bowl 1

9.Tube to the pressure and level control board (6)

10.Tube to the operating pressure gauge

11.Tube to the bowl 2

Fig. 35

The diagram shows the pressures and levels management system in the 3 bowls VFCB:

1. Safety valve

2. Cut out level bowls control board

3. Bowl 1 discharge solenoid valve

4. Bowl 2 discharge solenoid valve

5. CO2 inlet solenoid valve

6. Pressure ( bowls 1,2 and 3) and levels

(2 and 3) control board

7. Draining tube

8. Tube to the bowl 1

9.Tube to the pressure and level control

board (6)

10.Tube to the operating pressure gauge

11.Tube to the bowl 2

12. Level control board (bowl 1)

13. Bowl 3 discharge solenoid valve

14. Bowl 3 discharge solenoid valve

Fig. 36

Release Date: 20/04/10

Publication Number:

Revision: 8

Pag. : 28/59

Page 29

VFCB Operator’s Manual

switch

Left Bowl

Right Bowl

VFCB POST MIX

Safety Probes

Level Probes

Sold Out

pressure

Description

Sold out = Pressure switch / product presence

The “sold out” pressure switches ,set on the electro-valves, detect the presence (or not) of

product in the bag in box. The “sold out” pressure switches are not related to ANY control

board. They work INDEPENDENTLY one from the other (left bowl sold out works

independently from right bowl sold out). When the “sold out” pressure switches detect the lack

of product, they stop the mix (product and water) dispensing. In managing bowls level

condition they are active only during a bowl loading phase

Level bowl =Level probes

The “level bowl” probes function is to control and manage the product level in the bowl. They

work INDEPENDENTLY one from the other (left bowl level probes work independently from

right bowl level probes).

Cut out level bowl = overflow probes

The “cut out level bowl” probes are safety probes. Their function is to avoid bowl’s overflow if

the “level bowl” probes are out of function (both of them or just one of them). If they are

active they inhibit the “pressure and level control board”.

Release Date: 20/04/10

Publication Number:

Revision: 8

Pag. : 29/59

Page 30

VFCB Operator’s Manual

If the “level bowl” probes are uncovered ,the mix is introduced in the bowl. If the “sold out”

During the first filling condition it necessary that both “level bowl” probes (the left bowl and

“Sold out” Pressure switch

Active

only

during the

bowl loading phase

“Sold out” Pressure switch

Pressure means product, no pressure means no product

First Filling Condition

First Filling Condition

Each time the unit is turned off and then turned on

Each time the there is a lack of power supply to the unit

First Filling Condition

pressure switch has detected product ,the bowl filling goes on until the “level bowl” probes

are covered (4 minutes max); otherwise the unit begins to buzz after 4 minutes because

the “level bowl” probes are not covered yet and the led (out of product) on the frontal

panel is lit. So that it is necessary to turn the unit off, remove the empty bag in box,

replace it with a new one and turn the unit on. The unit will work as a first filling condition.

the right one) are reached otherwise the unit begins to buzz and it does not work

“Sold out” pressure switch begins to work only if it detects product

4 minutes is the maximum time for filling the bowls

Managing bowl Level

“Level bowl” probes

uncovered

Product introduced in the bowl until the “level bowl”

probes are covered

The “pressure and level control board” INDIRECTLY detects the lack of product because

when the “sold out” pressure switch , set on the electro-valve, has detected the product

missing, it stops the mix dispensing. In this situation the “level bowl” probes will never

be covered, so after 1 minute (set time) the “pressure and level control board” detects

the lack of product and the led (out of product) on the frontal panel is lit.

If the “level bowl” probes are not covered by a minute ( i.e. the unit dispenses the mix

continuously so the mix introduced in the bowl does not counterbalance the mix

dispensed) the bowl loading phase stops and it is necessary to turn the unit off and then

turn the unit on. The unit works as a first filling condition.

Release Date: 20/04/10

Publication Number:

Revision: 8

Pag. : 30/59

Page 31

VFCB Operator’s Manual

it will work as a first filling condition.

the bowl loading phase

the product level in the

Overflow Condition

The overflow condition

only if the “level

bowl” probes are out

of service (both of

them or just one)

The overflow condition

If just one “cut out

level bowl” is reached

it is enough to stop

in both the bowls.

When the product

level in the bowl

reaches the “cut

out level bowl”

probes the unit

interrupts the bowl

loading phase.

Until both “cut out

level bowl” probes are

uncovered the product

can not be introduced

in any bowl ( i.e. until

left bowl is not under

the LT “cut out level

bowl” ,the unit do not

fill the right bowl).

Case Study

Some events that can happen during unit working are following:

1. If a bag in box is empty during the first filling condition, the “sold out” pressure switch,

set on the electro-valve, detects the lack of product and stops mix dispensing. After 4

minutes the “pressure and level control board” turns the frontal led (out of product)

on. So that it is necessary to turn the unit off, remove the empty bag in box , replace it

with a new one and turn the unit on. The un

2. If the unit is switched off and then switched on without removing the empty bag in

box, the unit works as a first filling condition and it happens the same situation

described at point 1.

3. If the “level bowl” probes are covered and the unit is switched off and then switched on,

the unit ignores the first filling condition because the “level bowl” probes are already

covered.

4. If the product inside a bag in box finishes during a managing bowl level, it is necessary

to switch the unit off, remove the empty bag in box and replace it with a new one and

then turn the unit on. The unit works as a first filling condition and, when the “level

bowl” probes are covered, the unit stops the mix dispensing in the bowl.

5. If the product inside a bag in box finishes as soon as the “level bowl” probes are

covered, the unit does not detect the end of product. As soon as the “level bowl” probes

are uncovered the “sold out” pressure switch detects the end of product and stops the

mix dispensing. After 1 minute the “pressure and level control board” lights the relative

led (out of product) on. So that it is necessary to turn the unit off, remove the empty

bag in box , replace it with a new one and turn the unit on. The unit will work as a first

filling condition.

Release Date: 20/04/10

Publication Number:

Revision: 8

Pag. : 31/59

Page 32

VFCB Operator’s Manual

Presence Probes

Electrovalve

Bowl Pressure Managing

The pressure inside the bowls is managed by the “pressure and level control board”.

First filling condition

In first filling condition the pressure inside the bowls is not checked until product reaches the

“level bowl” probes in BOTH the bowls. When the “level bowl” probes are satisfied in BOTH the

bowls the “pressure and level control board” begins to work and maintains the pressure inside

each bowl between 120mbar (on ) e 160mbar (off). After 1 minute and 30 seconds, if the

pressure inside the bowls does not reach 160mbar, there are 2 possibilities:

• there is no more gas in the CO2 external tank; so the “out gas” frontal led is lit and it is

necessary to turn the unit off, remove the empty CO2 tank and replace it with a new

one

• there is a lack of CO2; so the CO2 dispensing is interrupted in order to avoid the CO2

external tank run out. It is important to find out the origin of this lack.

Pressure managing

The pressure inside the bowl (between 120mbar e 160mbar) is managed INDEPENDENTLY

from “level bowl” probes. For example if the “level bowl” probes (in both bowls or just in one)

are uncovered and a bag in box is empty, the led (out of product) on the frontal panel is lit

(after 1 minute) but the pressure inside the bowl remains between 120mbar e 160mbar even if

the bag in box is not removed and replaced with a new one.

VFCB PRE MIX

Safety Probes

Level Probes

Product

Left Bowl Right Bowl

Description

Sold out = Product presence probes

The “sold out” probes detect the presence (or not) of product in the external tank/s.

They work independently one from the other (left bowl sold out works independently from

right bowl sold out). In first filling condition they are working after 30 seconds from the unit

switched on . In managing bowls level condition they are active only during a bowl loading

phase and they are working with an hysteresis of 3 seconds.

Level bowl =Level probes

The “level bowl” probes function is to control and manage the product level in the bowl. They

work independently one from the other (left bowl level probes work independently from right

bowl level probes).

Cut out level bowl = overflow probes

The “cut out level bowl” probes are safety probes. Their function is to avoid bowl’s overflow if

the “level bowl” probes are out of function (both of them or just one of them). If they are

active they inhibit the “pressure and level control board”.

Release Date: 20/04/10

Publication Number:

Revision: 8

Pag. : 32/59

Page 33

VFCB Operator’s Manual

First Filling Condition

First Filling Condition

First Filling Condition

If the “level bowl” probes are uncovered, the product is introduced in the bowl. After

30 seconds if the “sold out” probes have detected product ,the bowl filling goes on

until the “level bowl” probes are covered (4 minutes max); otherwise the unit begins

to buzz because the external tank is empty (or both tanks or just one as showed by

the led on the frontal panel). So that it is necessary to turn the unit off, remove the

empty tank (or the empty tanks) , replace it (them) with a new one/s and turn the

unit on. The unit work as a first filling condition. During the first filling condition it

necessary that both “level bowl” probes (the left bowl and the right one) are reached

otherwise the unit begins to buzz and it does not work.

Each time the unit is turned off and then turned on

Each time the there is a lack of power supply to the unit

“Sold out” probes begin to work with delay of 30 seconds

from the unit switched on

4 minutes is the maximum time for filling the bowls

Managing bowl Level

“Sold out” probes

Active only during the bowl loading phase

“Sold out” probes

“Level bowl”

probes uncovered

The “sold out” probes detect the product presence (or not) in the external tanks with an

hysteresis of 3 seconds. 3 seconds software hysteresis are introduced to prevent the

probes recognize the tank bowl conduit as empty when there is residual gas in it.

If the “level bowl” probes are not covered by a minute ( i.e. the unit dispenses the mix

continuously so the mix introduced in the bowl does not counterbalance the mix dispensed)

the bowl loading phase stops and it is necessary to turn the unit off and then turn the unit

on. The unit works as a first filling condition.

Release Date: 20/04/10

Publication Number:

Revision: 8

Pag. : 33/59

Detect the lack of product with an hysteresis of 3 second.

Product introduced in the bowl until “level bowl” probes are covered

Page 34

VFCB Operator’s Manual

The overflow condition

pha

se.

Overflow Condition

When the product

level in the bowl

reaches the “cut out

level bowl” probes

only if the “level

bowl” probes are out

of service (both of

them or just one)

The overflow condition

If just one “cut out

level bowl” is reached

it is enough to stop the

bowl loading phase in

both the bowls.

the unit interrupts

the bowl loading

Until both “cut out

level bowl” probes

are uncovered the

product can not be

introduced in any

bowl ( i.e. until the

product level in the

left bowl is not under

the LT “cut out level

bowl” the unit do not

fill the right bowl).

Case Study

It follows some events that can happen during unit working:

1. If external tank (or tanks) is (are) empty during the first filling condition, the “sold

out” probes , after 30 seconds , detect the lack of product and stop the unit. So it is

necessary to switch the unit off, remove the empty tank and replace it with a new

one and then turn the unit on.

2. If the unit is switched off and then switched on without removing the external tank

empty (or tanks), the unit works as a first filling condition and it happens the same

situation described at point 1.

3. If the “level bowl” probes are covered and the unit is switched off and then switched

on, the unit ignores the first filling condition because the “level bowl” probes are

already covered.

4. If the product inside the external tank finishes during a managing bowl level (the

relative led must be lit), it is necessary to switch the unit off, remove the empty

tank and replace it with a new one and then turn the unit on. The unit works as a

first filling condition and, when the “level bowl” probes are covered, the unit stops

the product dispensing in the bowl.

5. If product inside the external tank finishes as soon as the “level bowl” probes are

covered, the unit does not detect the end of product because the monitoring of the

“sold out” probes (covered / uncovered) is active only during the bowl loading

phase. As soon as the “level bowl” probes are uncovered the “sold out” probes

(after 3 second hysteresis ) detect the end of product; so it is necessary to turn the

unit off, remove the empty tank and replace it with a new one and then turn the

unit on.

Release Date: 20/04/10

Publication Number:

Revision: 8

Pag. : 34/59

Page 35

VFCB Operator’s Manual

Bowl Pressure Managing

The pressure inside the bowls is managed by the “pressure and level control board”

First filling condition

In first filling condition the pressure inside the bowls is not checked until product reaches the

“level bowl” probes in BOTH the bowls. When the “level bowl” probes are satisfied in BOTH

the bowls the “pressure and level control board” begins to work and maintains the pressure

inside each bowl between 120mbar (on ) e 160mbar (off). After 1 minute and 30 seconds, if

the pressure inside the bowls does not reach 160mbar, there are 2 possibilities:

• there is no more gas in the CO2 external tank; so the “out gas” frontal led is lit and it is

necessary to turn the unit off, remove the empty CO2 tank and replace it with a new

one

• there is a lack of CO2; so the CO2 dispensing is interrupted in order to avoid the CO2

external tank run out. It is important to find out the origin of this lack.

Pressure managing

The pressure inside the bowl (between 120mbar e 160mbar) is managed INDEPENDENTLY

from “level bowl” probes. For example if the “level bowl” probes (in both bowls or just in one)

are uncovered and the external tank (product tank) is empty, the led is lit in the frontal panel

(after 3 second hysteresis) but the pressure inside the bowl remains between 120mbar e

160mbar even if the external tank is not removed and replaced with new one (product tank).

Release Date: 20/04/10

Publication Number:

Revision: 8

Pag. : 35/59

Page 36

VFCB Operator’s Manual

WIRING DIAGRAM

Release Date: 20/04/10

Publication Number:

Revision: 8

Pag. : 36/59

Page 37

VFCB Operator’s Manual

Release Date: 20/04/10

Publication Number:

Revision: 8

Pag. : 37/59

Page 38

VFCB Operator’s Manual

Release Date: 20/04/10

Publication Number:

Revision: 8

Pag. : 38/59

Page 39

VFCB Operator’s Manual

Release Date: 20/04/10

Publication Number:

Revision: 8

Pag. : 39/59

Page 40

VFCB Operator’s Manual

Release Date: 20/04/10

Publication Number:

Revision: 8

Pag. : 40/59

Page 41

VFCB Operator’s Manual

TROUBLESHOOTING

NOTE: The following procedures must be performed by a qualified service technician.

Problem Possible Cause Solution

“Filt” or “Err” message

appears on the touchpad LED

readout

The machine does not cool, or

cools only partially, but the

compressor/s is/are running

• The filter is dirty and needs

to be cleaned

• The unit is positioned too

close to a wall or other object

restricting air flow and

causing the machine to run at

a higher temperature

• The filter is not properly

installed

• The unit has been installed

near a heat source, such as a

coffee machine, ice maker or

cold beverage machine which

expels hot air from its vents,

causing the machine to run at

a high temperature.

(Installation near a heat

source should be avoid)

• The space around the

machine is inadequate for

ventilation

• Freezer is in defrost

• The condenser fins are

clogged with airborne

particles

• Fan motor is not running

• Refrigerant is leaking

• Clean and replace filter

following instructions

(Removing and Cleaning

Filter)

• Reposition unit to maximize

ventilation space (see

installation figures)

• Properly install filter see

“Removing and cleaning filter”

• Reposition unit to maximize

ventilation space (see

installation figures)

• Allow at least 8” (20cm)

between the machine and

anything next to it; keep

away from heat sources

• Return to freeze mode

• Remove the side panels.

Using a brush or compressed

air clean the condenser

• Check the fan motor’s

electrical connections and, if

disconnected, reconnect. If

still not operating, replace the

motor

• Locate the leak, eliminate it

and recharge the system

Release Date: 20/04/10

Publication Number:

Revision: 8

Pag. : 41/59

Page 42

VFCB Operator’s Manual

The machine over-freezes,

making the auger movement

slow or stopped

The machine is noisy

The main power switch is

“On”. The unit is not running.

• Electrical components of the

compressor(s) are not

functioning

• Some electrical connections

are not complete

• One or more of the

compressors are

malfunctioning

• No current is coming to the

“compressor delay” mother

board

• The product brix is too low

• The screw setting for the

product consistency control

system is set too far toward

the “+” position

• The limit switch arm is bent

away from the gear motor

and prevents contact

• The level of the product in

the bowl is too low

• The compressor PC board

contacts don’t open

• The fan motor blades are

hitting internal components

• The fuse(s) are blown

• The pressure cut-out switch

has activated

• Replace the malfunctioning

components

• Check the contacts and

correct those that are

incomplete

• Replace the compressor(s)

• Check the electrical

connections to the PC board

as well as the transformer

feeding the PC board and

correct

• Check the product brix and

correct

• Reset the screw toward the

“-” position to produce a

thinner consistency product

• Using pliers, straighten the

limit switch arm

• Add more product or turn

the refrigeration “Off”

• Replace the PC board

VFCB Operator’s Manual

• Check and correct

• Replace the fuse(s)

• Clean the condenser or add

ventilation space around the

machine (the cut-out switch

reset is automatic when the

conditions are corrected)

Release Date: 20/04/10

Publication Number:

Revision: 8

Pag. : 42/59

Page 43

VFCB Operator’s Manual

Product is leaking out of the

bowl

Product is leaking from the

dispensing valve

Product is flowing into drain

tray through drainage tube

The auger is not turning

The auger is creating noises

as it rotates

• Some electrical connections

are not complete

• The main power is not

functioning

• One of the bowl seals is not

in place

• The dispensing valve has

been incompletely or

incorrectly replaced in its

position

• The free movement of the

dispensing valve is impeded

• Dispensing valve o-rings are

damaged

• The bell shaped “shaft” seal

between the front of the

cylinder and the auger hub

has not been reinstalled

properly

• The bell shaped “shaft” seal

or the spindle bushing seal is

damaged or worn

• Auger not turned on

• Some electrical connections

are not complete

• The gear motor(s) are

malfunctioning

• The large red bowl seal is

not in position, causing the

gear teeth not to mesh

• Check the contacts and

correct those that are

incomplete

• Replace the switch

• Replace or reposition the

seals

• Reassemble and replace

• Clean and lubricate the

valve and valve cylinder with

the lubricant provided with

the machine

• Replace the damaged/worn

seal and check the condition

of the driveshaft.

• Replace the o-rings

• Find the seal and put it back

in place

• Turn auger on

• Check the contacts and

correct the ones that are

incomplete

• Replace the gear motor(s)

• Check and correct

Release Date: 20/04/10

Publication Number:

Revision: 8

Pag. : 43/59

Page 44

VFCB Operator’s Manual

There is no light in the

merchandising lid or rear

merchandising panel

The cover does not fit

properly on the bowl

Bowl not refilling

CO2 leaking from back of unit

• The product brix is incorrect

• The bell shaped “shaft” seal

has been replaced without

lubrication or is damaged

• The auger has been

incompletely or incorrectly

reassembled (i.e. the auger’s

gear pins are not properly

seated)

• The light bulb is burnt out

• The 5 Amp fuse between

the transformer and the lamp

is blown

• The transformer is blown

• The bowl is incorrectly

positioned (the lower, outside

corner is not over the lower,

outside base piece)

• Out of syrup

• Out of CO2

• Valves are shut off or

blocked

• Foam covering probes

• Fill Switch in off position

• Defective syrup pressure

switch

• Defective CO2 shut off

• Proper function of bowl over

pressure discharge solenoids

• Poor connection

• Check the product brix and

correct

• Replace or Clean and

lubricate with the lubricant

provided with the machine

• Check and correct

• Replace (See “Changing the

light bulb” section in this

manual)

• Replace

• Replace

• Remove bowl and position

properly

• Replace

• Replace

• Open

• Wait

• Turn on

• Replace

• Replace

• If not continuous leak it is

normal operation

• Repair leak

Release Date: 20/04/10

Publication Number:

Revision: 8

Pag. : 44/59

Page 45

VFCB Operator’s Manual

PARTS DIAGRAMS

Release Date: 20/04/10

Publication Number:

Revision: 8

Pag. : 45/59

Page 46

VFCB Operator’s Manual

Release Date: 20/04/10

Publication Number:

Revision: 8

Pag. : 46/59

Page 47

VFCB Operator’s Manual

Release Date: 20/04/10

Publication Number:

Revision: 8

Pag. : 47/59

Page 48

VFCB Operator’s Manual

Release Date: 20/04/10

Publication Number:

Revision: 8

Pag. : 48/59

Page 49

VFCB Operator’s Manual

Release Date: 20/04/10

Publication Number:

Revision: 8

Pag. : 49/59

Page 50

VFCB Operator’s Manual

Release Date: 20/04/10

Publication Number:

Revision: 8

Pag. : 50/59

Page 51

VFCB Operator’s Manual

Release Date: 20/04/10

Publication Number:

Revision: 8

Pag. : 51/59

Page 52

VFCB Operator’s Manual

Release Date: 20/04/10

Publication Number:

Revision: 8

Pag. : 52/59

Page 53

VFCB Operator’s Manual

Release Date: 20/04/10

Publication Number:

Revision: 8

Pag. : 53/59

Page 54

VFCB Operator’s Manual

Release Date: 20/04/10

Publication Number:

Revision: 8

Pag. : 54/59

Page 55

VFCB Operator’s Manual

Release Date: 20/04/10

Publication Number:

Revision: 8

Pag. : 55/59

Page 56

VFCB Operator’s Manual

Release Date: 20/04/10

Publication Number:

Revision: 8

Pag. : 56/59

Page 57

VFCB Operator’s Manual

Release Date: 20/04/10

Publication Number:

Revision: 8

Pag. : 57/59

Page 58

VFCB Operator’s Manual

Release Date: 20/04/10

Publication Number:

Revision: 8

Pag. : 58/59

Page 59

VFCB Operator’s Manual

Release Date: 20/04/10

Publication Number:

Revision: 8

Pag. : 59/59

Loading...

Loading...