Page 1

IMI CORNELIUS INC One Cornelius Place Anoka, MN 55303-6234

Telephone (800) 238-3600 Facsimile (800) 535-4231

OPERATORS MANUAL – ICE COOLED DISPENSERS

This instruction applies to all models of Drop-In and Free-Standing Ice Cooled

dispensers.

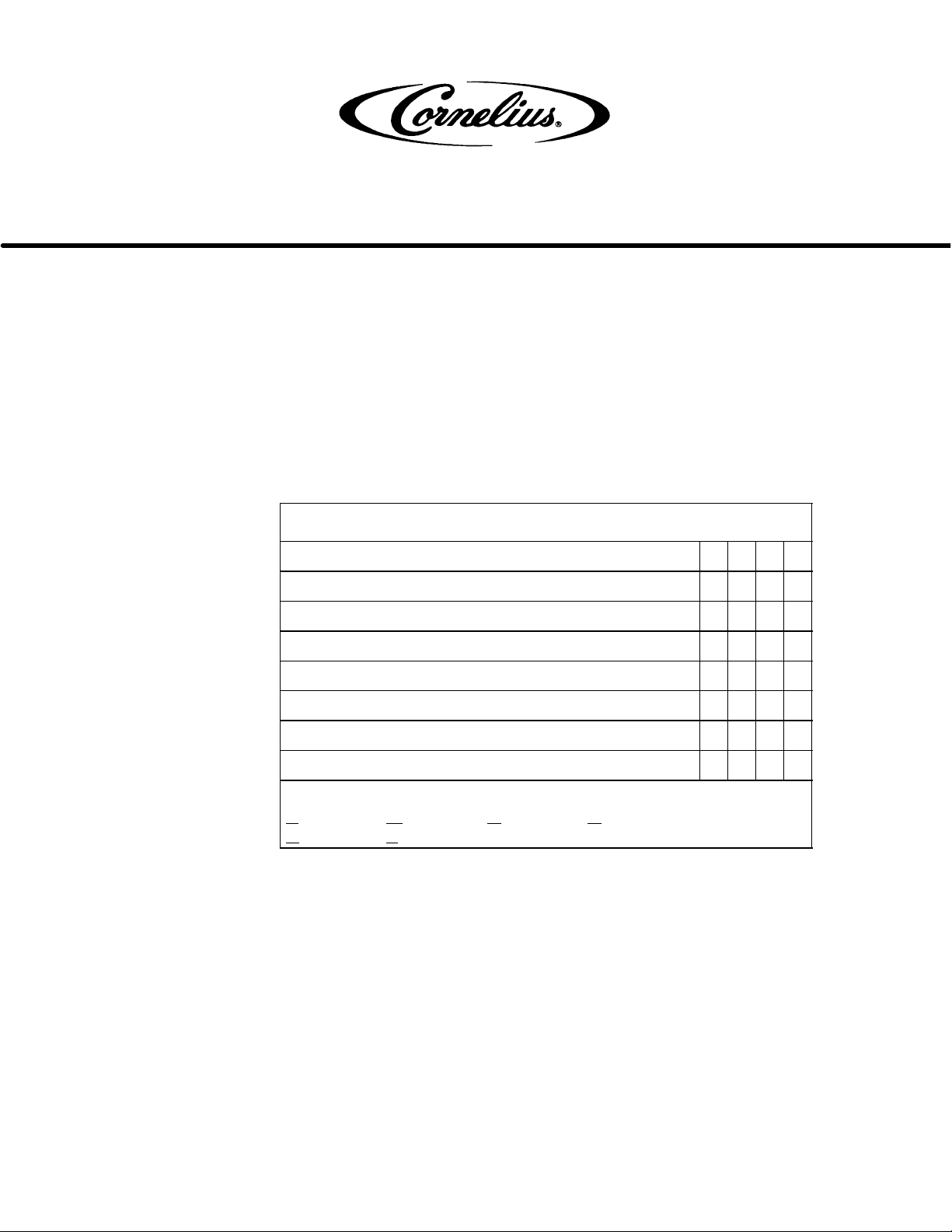

RECOMMENDED MAINTENANCE

Details of each task are listed immediately below the chart. Refer to the details by task number.

Maintenance Schedule

Task D W M Q

1. Clean all exterior surfaces O

2. Clean dispensing valves, Post-Mix O

3. Clean dispensing valves, Pre-Mix O

4. Clean & sanitize ice bin O

5. Sanitize tank systems, post-mix and pre-mix S

6. Sanitize syrup lines, B-I-B systems S

7. Sanitize Bin Drain & Drip Tray Drain O

Legend:

aily Weekly Monthly Quarterly

D

perator Serviceperson

O

DETAILS OF MAINTENANCE TASKS

1. Clean All Exterior Surfaces

Cleaning The Tower

IMPORTANT: DO NOT USE ABRASIVE CLEANERS

A. Remove the cup rest from the drip tray.

B. Wash the drip tray with warm soapy water. Rinse the drip tray, allowing the rinse water to run down

the drain hose.

C. Wipe entire exterior of the tower with a damp cloth. Dry the tower with a clean cloth (see caution be-

low).

IMI Cornelius Inc; 1994–2003

1

Rev 10/8/03

166239002

166239002

Rev. Level 1

Page 2

CAUTION: To minimize the possibility of damaging the surface of the painted tower care

must be taken when choosing a cloth. The cloth must be of clean cotton with a deep nap,

or equivalent. If a damp cloth is instructed to use, it must be rinsed out in clean water, the

damp or the dry cloth must be manually fluffed to a softened consistency before using to wipe or

polish the painted tower.

D. For the painted tower, (rather than a stainless steel tower) the painted surface may be cleaned using

mild detergents or most house hold cleaners like “ Fantastik or Mr. Clean”. After cleaning, wipe entire

exterior of the tower with a damp cloth. (Do not use strong soaps, abrasive cleaners or any

cleaner that contains Alcohol) Dry the tower with a clean cloth.

E. The painted tower surface may be waxed after cleaning using “Simoniz” paste wax, Aero Wax or Glo-

Coat. After applying wax, buff the surface with a clean dry cloth to a high luster finish.

2. Clean Dispensing Valves, Post-Mix

A. Remove the valve cover(s) and wash in plain water.

B. Remove the nozzle and the syrup diffuser and wash the parts in plain water.

IMPORTANT: When washing the dispensing valve, care must be taken not to get water on the electrical solenoid.

C. Hold an appropriate container under the dispensing valve. Being very careful not to get water on the

electrical solenoid, slowly pour plain water over the dispensing valve.

D. Install the nozzle and syrup diffuser on the valve.

E. Install the valve cover(s).

3. Clean Dispensing Valves, Pre-Mix

A. Pour clean water over the valve to rinse away any

sticky residue.

B. Using a small round nylon bristle brush, clean the valve spout with plain water.

C. Dry the valve with a clean dry cloth.

4. Clean and Sanitize Ice Bin, Drains and Drip Tray

IMPORTANT: Only trained and qualified persons should perform these cleaning and sanitizing

procedures.

Sanitizing Solution - Household liquid bleech that contains 5.25% sodium hypochlorit concentration, (such as

Hi-Lex or Chlorox).

Prepare the sanitizing solution by mixing 0.5-ounces of household bleech to one gallion of potable water. This

mixture must not exceed 200 PPM of chorine, allowable by the FDA. Use this mixture for all sanitizing procedures.

A. Remove all ice from the ice bin and melt any remaining ice with hot water.

B. Remove ice bin drain strainer by lifting straight up.

C. Prepare a mild detergent solution in 120 F potable water.

DO NOT use water hotter than 120F

D. Using a nylon bristle brush (Do Not use a wire brush), clean the cold plate and the interior of the ice

bin with the detergent solution.

E. Pour the remainder of the detergent solution down the drip tray and bin drains. Observe that the solu-

tion flows freely. If not, determine the cause. It may be necessary to replace the drain tubing.

IMI Cornelius Inc; 1994–2003

2

Rev 10/8/03

166239002

166239002

Rev. Level 1

Page 3

F. Prepare two or more gallons of sanitizing solution. Pour half of the solution down the bin and drip tray

drains. After the has completely drained, pour the remaining solution down the drains.

G. Replace the drain strainer.

H. Using a mechanical spray bottle, prepare sanitizing solution and spray the entire interior bin surfaces.

Allow to air dry.

5. Sanitize Tank Systems, Post-Mix and Pre-Mix

A. Remove all ice from the ice bin and melt any remaining ice with hot water.

B. Remove all the quick disconnects from all the tanks.

C. Prepare a mild detergent soap solution in 100 F potable water in a suitable pail or bucket.

D. Submerge all disconnects (gas and liquid) in the soap solution and then clean them using a nylon

bristle brush (Do Not use a wire brush). Rinse with clean water.

E. Prepare sanitizing solution and using a mechanical spray bottle, spray the disconnects. Allow to air

dry.

F. Using a clean, empty tank, prepare five gallons of sanitizing solution. Rinse the tank disconnects with

approximately 9 oz. of the sanitizing solution. Close the tank.

G. Connect a gas disconnect to the tank and then apply one of the product tubes to the tank of sanitizing

solution. Operate the appropriate valve until the sanitizing solution is flowing from the valve.

H. Repeat the step above, applying a different product tube each time until all tubes are filled with the

sanitizing solution.

I. For post-mix valves, remove the nozzle and syrup diffuser and clean them in a mild detergent soap

solution. Rinse with clean water and reassemble the nozzle and syrup diffuser to

the valve.

J. For pre-mix valves, disconnect all product tubes from the tank of sanitizing solution and then open the

valves to allow the pressure to be relieved. Remove the valves from the dispenser, disassemble and

wash thoroughly in a mild detergent soap solution.

K. Rinse the parts in clean water, reassemble the valve and reconnect it to the dispenser.

L. Allow the sanitizing solution to remain in the tubes for the manufacturer’s recommended exposure

time.

M. Discard the tank of sanitizing solution and connect the disconnects to a tank of potable water. Operate

the valves until all sanitizer has been flushed from the system and only water

is flowing.

N. Connect the disconnects to the appropriate product tanks and operate each valve until all water is

purged from the tubing.

6. Sanitize Syrup Lines, B-I-B Systems

A. Remove all ice from the ice bin and melt any remaining ice with hot water.

B. Remove all the quick disconnects from all the B-I-B

containers.

C. Prepare a mild detergent soap solution in 100 F potable water in a suitable pail or bucket.

D. Submerge all disconnects in the soap solution, then clean them using a nylon bristle brush (Do Not

use a wire brush). Rinse with clean water.

E. Using a plastic pail, prepare approximately five gallons of sanitizing solution.

IMI Cornelius Inc; 1994–2003

3

Rev 10/8/03

166239002

166239002

Rev. Level 1

Page 4

F. Rinse the B-I-B disconnects in the sanitizing solution.

G. Sanitizing fittings must be attached to each B-I-B disconnect. If these fittings are not available, the

fittings from empty B-I-B bags can be cut from the bags and used. These fittings open the disconnect

so the sanitizing solution can be drawn through the disconnect.

H. Place all the B-I-B disconnects into the pail of sanitizing solution. Operate all the valves until the sani-

tizing solution is flowing from the valve.

I. Remove the nozzle and syrup diffuser from the valve and clean them in a mild detergent soap solu-

tion. Rinse with clean potable water and reassemble the nozzle and syrup diffuser to the valve.

J. Allow the sanitizing solution to remain in the tubes for the manufacturer’s recommended exposure

time.

K. Remove the sanitizing fittings from the B-I-B disconnects and place them in a container of potable wa-

ter. Operate the valves until all the sanitizing solution has been purged from the tubing.

L. Connect the disconnects to the appropriate B-I-B container. Operate the valves until all water has

been flushed from the system and syrup is flowing freely.

CO2 SETTINGS

IMPORTANT: The settings shown below are nominal settings and they may not satisfy your system.

If your installer or serviceperson has indicated other pressure settings to you, please adhere to those

settings. If your system is not performing to your satisfaction, call your serviceperson. DO NOT

make adjustments without consulting with a qualified

serviceperson.

The CO2 regulators should be set as indicated in the following chart:

Regulator Pressure Setting

Primary (Carbonator) 90 – 120 PSI

Secondary, Sugared Syrup Tank 55 PSI

Secondary, Diet Syrup Tank 8 – 12 PSI

Secondary, B–I–B 60 PSI

Basic Pressure 47 PSI

For each 10 ft. of horizontal tubing

between tank and dispenser

For each 2 ft. of elevation Add 1 PSI

For each tank per flavor over

3 tanks

Basic pressure shown is based on ambient temperature of 72F. Use a

Cornelius Pre-Mix slide rule for exact calculations.

Post-Mix

Pre-Mix

Add 1 PSI

Add 1 PSI

IMI Cornelius Inc; 1994–2003

4

Rev 10/8/03

166239002

166239002

Rev. Level 1

Page 5

DRINK DISPENSER VALVES

IMI CORNELIUS INC.

MASON CITY IA.

DRINK DISPENSERS

VALVE TYPE

MANUFACTURER

PORTION CONTROL MAXIMUM OPERATING PRESSURE

CORNELIUS 130 psi

LANCER 100psi

FLOWMATIC 100psi

McCANN 130psi

PUSH BUTTON

CORNELIUS 130psi

LANCER 100psi

FLOWMATIC 100psi

McCANN 130psi

LEVER TYPE

CORNELIUS 130psi

LANCER 100psi

FLOWMATIC 100psi

McCANN 130psi

AUTOFILL LEVER

CORNELIUS 130psi

LANCER 100psi

FLOWMATIC 100psi

McCANN 130psi

NON–ELECTRIC

CORNELIUS 130psi

LANCER 100psi

PREMIX TYPE

CORNELIUS 130psi

IMI Cornelius Inc; 1994–2003

5

Rev 10/8/03

166239002

166239002

Rev. Level 1

Page 6

TROUBLESHOOTING

Trouble Probable Cause Remedy

TROUBLESHOOTING

WATER-TO-SYRUP ‘‘RATIO’’

TOO LOW OR TOO HIGH

ADJUSTMENT OF

DISPENSING VALVE SYRUP

FLOW REGULATOR DOES

NOT INCREASE TO DESIRED

WATER-TO-SYRUP ‘‘RATIO’’

A. Dispensing valve syrup flow

regulator not properly

A. Adjust Water-to-Syrup ‘‘Ratio’’ of

dispensed drink as instructed.

adjusted.

B. CO2 gas pressure to syrup

tanks insufficient to push syrup

B. Adjust syrup tanks secondary

CO2 regulator as instructed.

out of tank or to pump from the

B-I-B container.

A. Dispensing valve syrup flow

regulator, syrup tank quick

A. Sanitize syrup system as

instructed.

disconnect, or syrup line

restricted.

B. Syrup tank quick disconnects

B. Secure quick disconnects.

not secure.

C. Syrup tanks secondary CO

regulator out of adjustment.

C. Adjust syrup tanks secondary

2

CO2 regulator as instructed.

D. No syrup supply. D. Replenish syrup supply.

E. Improper syrup Baume. E. Replace syrup supply.

F. Dirty or inoperative piston or

spring in dispensing valve

syrup flow regulator.

F. Disassemble and clean

dispensing valve syrup flow

regulator.

ADJUSTMENT OF

DISPENSING VALVE SYRUP

FLOW REGULATOR DOES

NOT DECREASE TO

DESIRED WATER-TO-SYRUP

‘‘RATIO’’

G. Tapered nylon washer inside

tube swivel nut connector

distorted from being

overtightened.

A. Dirty or inoperative piston or

spring in dispensing valve

syrup flow regulator.

G. Replace nylon washer and make

sure it seats properly.

A. Disassemble and clean

dispensing valve syrup flow

regulator.

IMI Cornelius Inc; 1994–2003

6

Rev 10/8/03

166239002

166239002

Rev. Level 1

Page 7

Trouble RemedyProbable Cause

DISPENSED PRODUCT

CARBONATION TOO LOW

DISPENSED PRODUCT

COMES OUT OF

DISPENSING VALVE CLEAR

BUT FOAMS IN CUP OR

GLASS

A. Carbonator primary CO

regulator out of adjustment for

existing water conditions or

2

A. Adjust carbonator primary CO

regulator (Reference manual

provided with carbonator).

temperature.

B. Air in carbonator tank. B. Vent air out of carbonator tank

through relief valve. Actuate

dispensing valve carbonated

water lever to make carbonator

pump cycle on.

C. Water, oil, or dirt, in CO

supply.

2

C. Remove contaminated CO2.

Clean CO2 system (lines,

regulators, etc.) using a mild

detergent. Install a clean CO

supply.

A. Oil film or soap scum in cup

A. Use clean cup or glass.

or glass.

B. Ice used for finished drink is

sub-cooled.

B. Do not use ice directly from

freezer. Allow ice to become ‘‘wet’’

before using. (Refer to following

NOTE).

2

2

NOTE: Crushed ice in the glass also causes dispensing problems. When finished drink hits sharp

edges of ice, carbonation is released from dispensed drink.

C. Carbonator CO2 regulator

pressure too high for existing

water conditions or

C. Reduce carbonator CO2 regulator

pressure setting. (Reference

manual provided with carbonator).

temperature.

D. Syrup over-carbonated with

CO2 as indicated by bubbles in

inlet syrup lines leading to

unit.

D. Remove syrup tanks quick

disconnects. Relieve tank CO

pressure, shake tank vigorously,

then relieve tank CO2 pressure as

many times as necessary to

remove over-carbonation.

2

IMI Cornelius Inc; 1994–2003

7

Rev 10/8/03

166239002

166239002

Rev. Level 1

Page 8

Trouble Probable Cause Remedy

DISPENSED PRODUCT

PRODUCES FOAM AS IT

A. Dispensing valve restricted

or dirty.

A. Sanitize syrup system as

instructed.

LEAVES DISPENSING VALVE

B. Tapered nylon washer inside

carbonated water line swivel

B. Replace nylon washer. Make sure

it is properly seated.

nut connector distorted

restricting carbonated water

flow.

C. Dirty water supply. C. Check water filter. Replace

cartridge. (see NOTE)

D. Warm Product - No ice in bin,

bridged ice on cold plate or

plugged drain.

D. Replenish ice, break ice up to

eliminate bridging, unplug the

drain.

NOTE: If water supply is dirty, be sure to flush lines and carbonator completely. It may be necessary to

remove lines to carbonator tank, invert tank, and flush tank and all inlet lines to remove any foreign

particles or dirt.

NO PRODUCT DISPENSED

A. Transformer unplugged. A. Plug in the transformer.

FROM ALL DISPENSING

VALVES

B. No electrical power to

B. Check fuse or circuit breaker.

transformer.

C. Disconnected dispensing

valves power cord.

C. Connect dispensing valves

power cord.

NO PRODUCT DISPENSED

FROM ONE DISPENSING

VALVE

D. Disconnected or broken wiring

D. Connect or replace wiring.

to dispensing valves.

E. Inoperative transformer. E. Replace transformer as

instructed.

A. Broken or disconnected wiring. A. Repair or connect wiring.

B. Inoperative dispensing valve

solenoid coil.

C. Inoperative dispensing valve

micro switch.

B. Replace solenoid coil as

instructed.

C. Replace micro switch as

instructed.

IMI Cornelius Inc; 1994–2003

8

Rev 10/8/03

166239002

166239002

Rev. Level 1

Page 9

Trouble Probable Cause Remedy

ONLY CARBONATED WATER

DISPENSED

A. Quick disconnects not secure

on syrup tanks.

B. Out of syrup. B. Replenish syrup supply as

C. B-I-B connectors not properly

connected.

D. Syrup secondary CO

2

regulator not properly

adjusted.

E. Inoperable dispensing valve. E. Repair dispensing valve.

F. Dispensing valve syrup flow

regulator not properly

adjusted.

G. Dispensing valve syrup flow

regulator, syrup tank quick

disconnect, or syrup lines

restricted.

ONLY SYRUP DISPENSED A. Plain water inlet supply line

shutoff valve closed.

B. Carbonator power cord

unplugged from electrical

outlet.

A. Secure quick disconnects on

syrup tanks.

instructed.

C. Properly attach the connectors.

D. Adjust syrup tanks secondary

CO2 regulator as instructed.

F. Adjust dispensing valve syrup

flow regulator (Water-to-Syrup

‘‘Ratio’’) as instructed.

G. Sanitize syrup system as

instructed.

A. Open plain water inlet supply line

shutoff valve.

B. Plug carbonator power cord into

electrical outlet.

C. Carbonator primary CO

regulator not properly

adjusted.

2

C. Adjust carbonator primary CO

2

regulator (Reference manual

provided with carbonator).

IMI Cornelius Inc; 1994–2003

9

Rev 10/8/03

166239002

166239002

Rev. Level 1

Page 10

WARRANTY

IMI Cornelius Inc. warrants that all equipment and parts are free from defects in material and workmanship under normal use and service. For a copy of the warranty applicable to your Cornelius product, in your country,

please write, Fax or telephone the IMI Cornelius office nearest you. Please provide the equipment model number and the date of purchase.

IMI Cornelius Offices

AUSTRALIA P. O. 210, RIVERWOOD, NSW 2210, AUSTRALIA (61) 2 533 3122 FAX (61) 2 534 2166

AM LANGEN FELDE 32 A-1222 VIENNA, AUSTRIA (43) 1 233 520 FAX (43) 1-2335-2930

AUSTRIA

BOSKAPELLEI 122 B-2930 BRAASCHAAT, BELGIUM (32) 3 664 0552 FAX (32) 3 665 2307

BELGIUM

RUA ITAOCARA 97 TOMAS COELHO RIO DE JANEIRO, BRAZIL (55) 21 591 7150 FAX (55) 21 593 1829

BRAZIL

TYTHING ROAD ALCESTER WARWICKSHIRE, B49 6 EU, ENGLAND (44) 789 763 101 FAX (44) 789 763 644

ENGLAND

71 ROUTE DE ST. DENIS F-95170 DEUIL LA BARRE PARI S, FRANCE (33) 1 34 28 6200 FAX (33) 1 34 28 6201

FRANCE

GERMANY

GREECE

HONG

ITALY

NEW

SINGAPORE

SPAIN

USA

CARL LEVERKUS STRASSE 15 D-4018 LANGENFELD, WEST GERMANY (49) 2173 7930 FAX (49) 2173 77 438

488 MESSOGION AVENUE AGIA PARA SK EV I 153 42 ATHENS, GREECE (30) 1 600 1073 FAX (30) 1 601 2491

KONG 1104 TAIKOTSUI CENTRE 11-15 KOK CHEUNG ST TAIKOKTSUE, HONG KONG (852) 789 9882 FAX (852) 391 6222

VIA PELLIZZARI 11 1-20059 VIMARCATE, ITALY (39) 39 608 0817 FAX (39) 39 608 0814

ZEALAND 20 LANSFORD CRES. P. O. BOX 19-044 AVONDALE AUCKLAND 7, NEW ZEALAND (64) 9 8200 357 FAX (64) 9 8200 361

16 TUAS STREET SINGAPORE 2263 (65) 862 5542 FAX (65) 862 5604

POLIGONO INDUSTRAIL RIERA DEL FONOLLAR E-08830 SANT BOI DE LLOBREGAT BARCELONA, SPAIN (34) 3 640 2839 FAX (34) 3 654 3379

ONE CORNELIUS PLACE ANOKA, MINNESOTA (612) 421-6120 FAX (612) 422-3255

IMI Cornelius Inc; 1994–2003

10

Rev 10/8/03

166239002

166239002

Rev. Level 1

Loading...

Loading...