THE HOTTEST MACHINES ON ICEt

Installation Instructions

“I” Series Flaker/Nugget Ice Machines

Model Number Description

IAF1000 / IAF650 Flaker/Nugget Modular Head Ice Maker Air Cooled

IWF1000 / IWF650 Flaker/Nugget Modular Head Ice Maker Water Cooled

IRF1000 / IRF650 Flaker/Nugget Modular Head Ice Maker Remote Cooled

Part No. 630460004

3/31/97

Revised 4/11/97

THIS DOCUMENT CONTAINS IMPORTANT INFORMATION

This Manual must be read and understood before installing or operating this equipment

IMI CORNELIUS INC; January 1997

PRINTED IN U.S.A

TABLE OF CONTENTS

INTRODUCTION 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

INSTALLATION INSTRUCTIONS 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

WATER AND ICE CIRCUIT 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

“I” SERIES FLAKER CLEANING

AND SANITIZING PROCEDURE 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

WATER TREATMENT 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

WINTER STORAGE 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CLEANING THE CONDENSER (AIR COOLED) 7. . . . . . . . . . . . . . . . . . . . . . . . . . .

INSTALLATION INSTRUCTIONS REMOTE CONDENSERS 14. . . . . . . . . . . . . . . .

REMOTE CONDENSER LOCATION 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

HEAD PRESSURE CONTROL [HEADMASTER] 19. . . . . . . . . . . . . . . . . . . . .

REMOTE SYSTEM EVACUATION/RE-CHARGE 20. . . . . . . . . . . . . . . . . . . . .

FIGURE AND INSTALLATIONS

FIGURE 1. Bin Thermostat Installation 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FIGURE 2. Service Connections 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FIGURE 3. instructions for converting flaked ice to nugget ice. 4. . . . . . . . . . . . . . . . . . .

FIGURE 4. water level 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FIGURE 5. wiring diagram iaf1000 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FIGURE 6. wiring diagram iwf1000 and irf1000 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FIGURE 7. wiring diagram iaf650 and iwf650 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

i

6304600003

FIGURE 1. Bin Thermostat Installation 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FIGURE 2. Service Connections 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FIGURE 3. instructions for converting flaked ice to nugget ice. 4. . . . . . . . . . . . . . . . . . .

FIGURE 4. water level 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FIGURE 5. wiring diagram iaf1000 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FIGURE 6. wiring diagram iwf1000 and irf1000 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FIGURE 7. wiring diagram iaf650 and iwf650 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6304600003

ii

INTRODUCTION

We have strived to produce a quality product. The design has been kept simple thus insuring trouble–free

operation.

This manual has been prepared to assist the Installer.

If you encounter a problem which is not covered in this manual, please feel free to write or call. We will be

happy to assist you in any way we can.

When writing, please state the model and serial number of the machine.

Address all correspondence to:

A Product of IMI Cornelius Inc.

One Cornelius Place

Anoka, MN 55303–1592

Phone 800–554–3526

FAX 612–422–3232

PRINTED IN USA

1 630460004

INSTALLATION INSTRUCTIONS

You will get better service from the ice machine, longer life and greater convenience if you choose its location

with care. Select a location as close as possible to where the highest volume of ice will used.

Here are a few points to consider:

1. Select a location as close as possible to where you are going to use the most ice.

2. Allow a minimum of 6” space at sides and rear of machine for ventilation.

3. A kitchen installation is not desirable as a rule. If a kitchen installation is necessary, locate the machine as

far away from the cooking area as possible. Grease laden air will form a greasy deposit on the condenser.

This reduces the ice making efficiency and necessitates thorough cleaning quite often.

4. If you install the unit in a storeroom, be sure the room is well ventilated.

NOTE: Do not install where the ambient and incoming water temperature will drop below 50° F or rise

to over 100° F.

WARNING: If water pressure exceeds 50 pounds, a water pressure regulator should be

installed in water inlet line between water shut–off valve and strainer. Minimum incoming

water pressure required is 22 pounds.

5. Uncrate the unit by cutting the lower band on the carton and lift the carton off the unit.

6. All “I” series flakers are supplied with bin sealing gasket material. Install the gasket around the bottom

outside edge of the unit by removing the protective paper and pressing in place.

7. Uncrate the ice storage bin and set in place. Connect a drain hose to the bin and level the bin. Install any

required bin adapter(s) at this time.

8. Carefully place the flaker on the bin. Be careful not to damage the flaker gasket material.

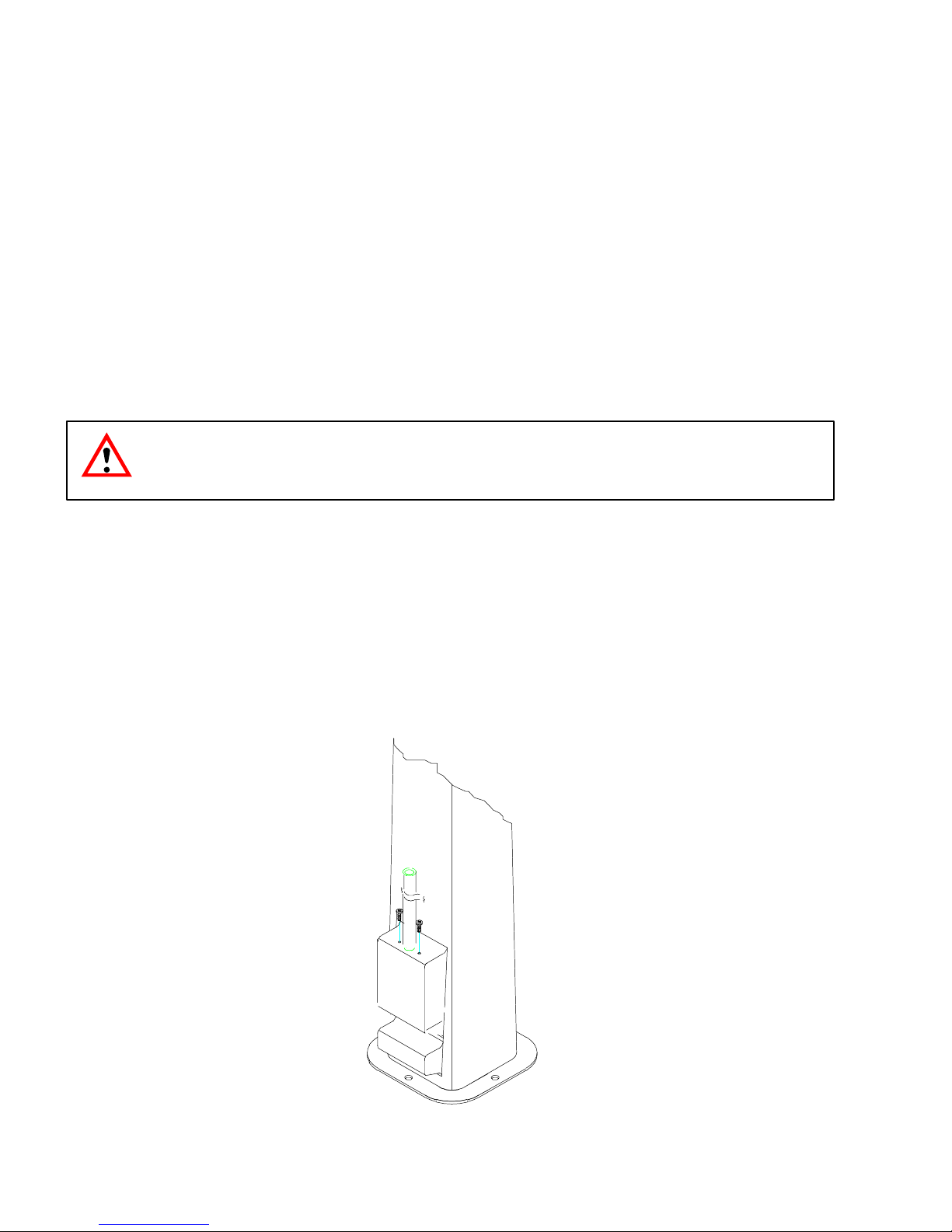

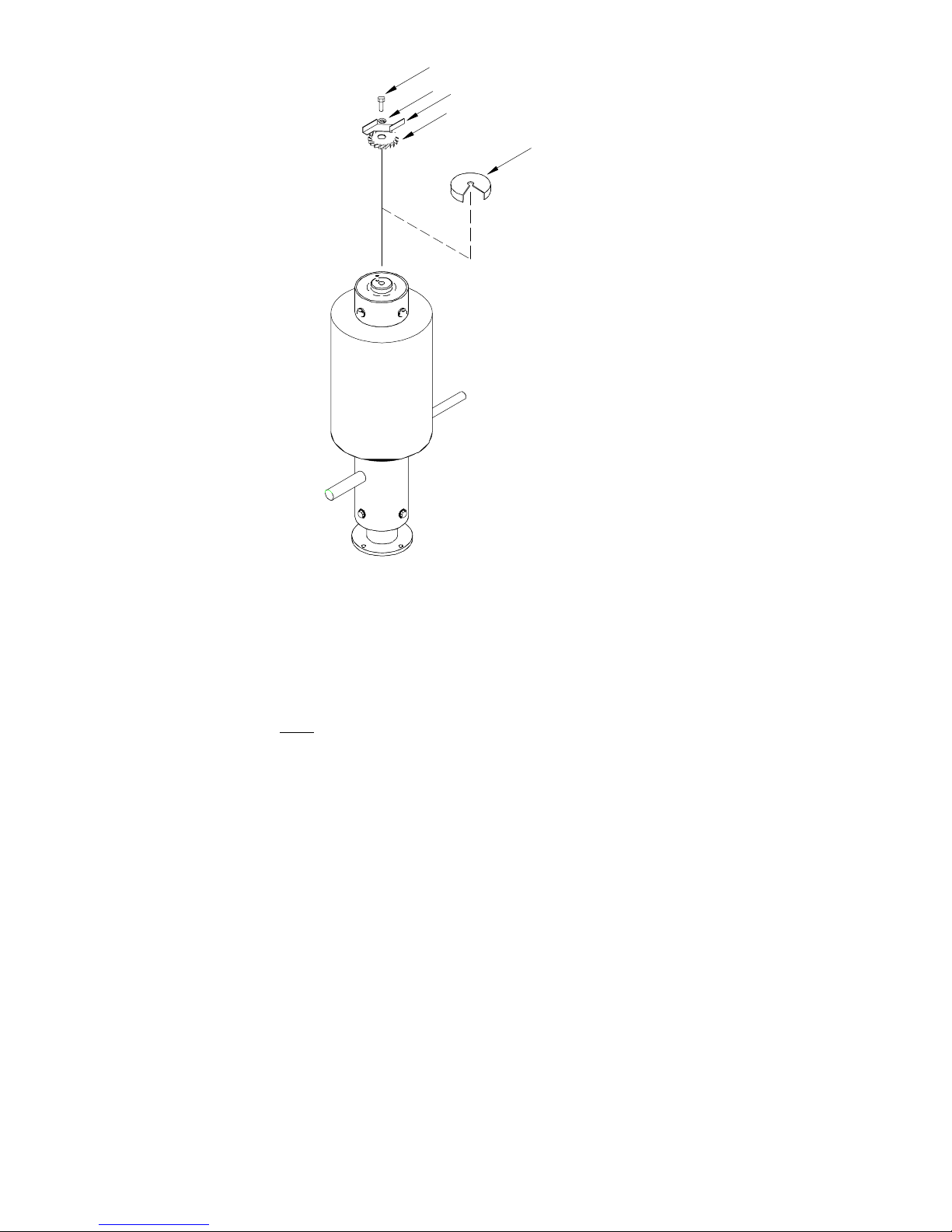

9. Remove the flaker front panel. Position the bin thermostat in place and install the hold down screws as

shown in Figure 1.

FIGURE 1. BIN THERMOSTAT INSTALLATION

630460004

2

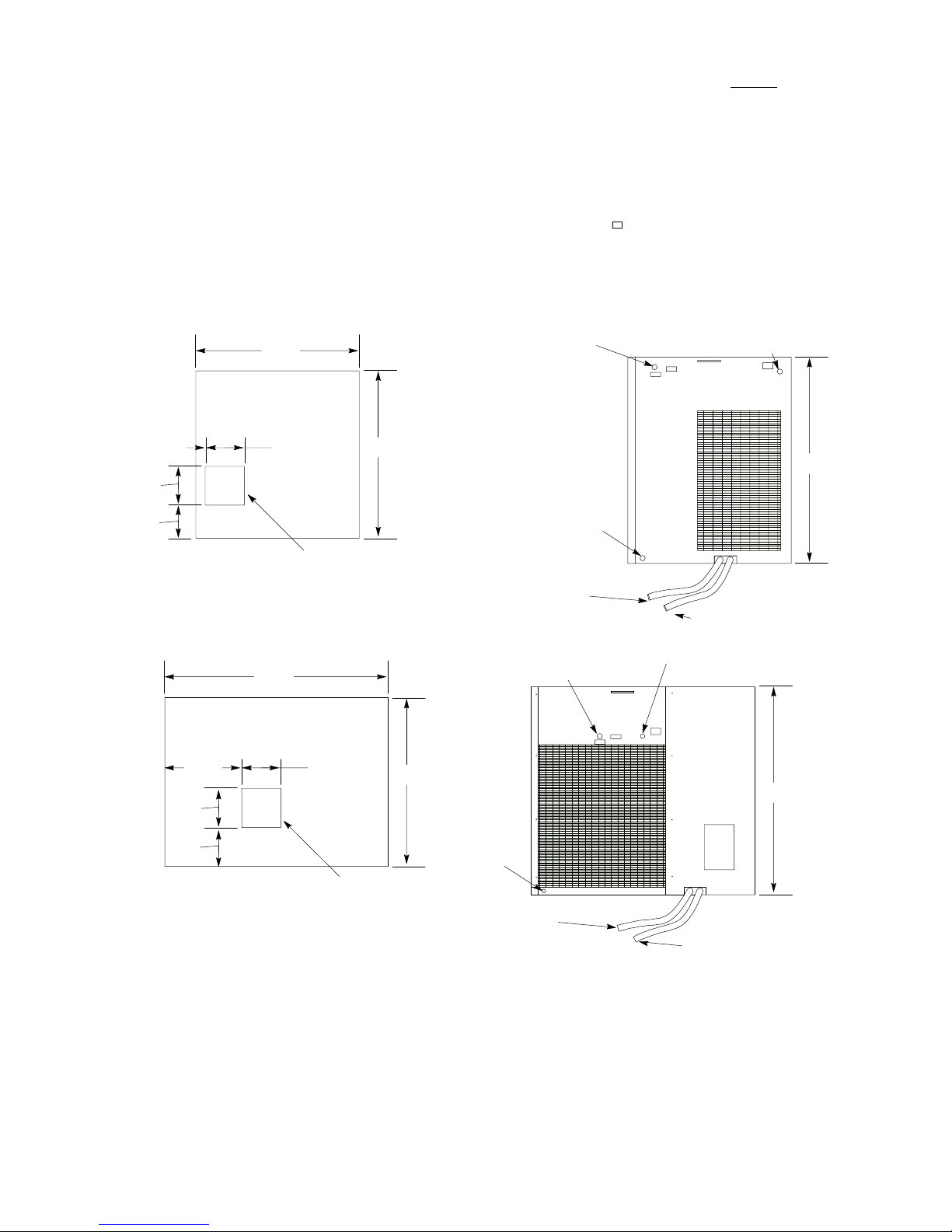

10. The incoming water for the ice making section requires a 3/8” copper tube. Connect this water tube to the

3/8” male flare fitting on the back of the unit. Make all drain connections. Drain tubes cannot

be teed

together. See Figure 2 for location of all plumbing connections.

NOTE: For water cooled units, a separate 3/8” copper water line is required to be connected to the flare

fitting on the back of the unit marked condenser water in. A 3/8” flare connected line will have

to be provided from the fitting marked condenser water out to the drain.

A water regulating valve installed at the factory was set to maintain 290 to 310 PSI head pressure for R–404a

units. After 10 minutes of operation check the water temperature at condenser outlet and adjust to 100_F,

ill371

105_F if necessary.

11. Connect a drain hose to the condensate drain stub tube.

NOTE: All plumbing must be done in accordance with national and local codes.

5.25

4.50

1.25

FRONT SIDE

BOTTOM VIEW

30.00

10.31 5.25

5.25

22.00

5.25

ICE DROP

OPENING

ELECTRICAL SERVICE

OPENING(7/8-IN. DIA. HOLE)

22.60

DUMP VALVE DRAIN HOSE

(9/16-IN. I.D. BY 3/4-IN. O.D.)

IAF 650

ELECTRICAL SERVICE

OPENING(7/8-IN. DIA. HOLE)

22.63

POTABLE WATER INLET

(3/8-IN. MALE FLARE)

27.83

CONDENSER

DRAIN

REAR VIEW

GEABOX/WTRPN DRAIN HOSE

(9/16-IN. I.D. BY 3/4-IN. O.D.)

POTABLE WATER INLET

(3/8-IN. MALE FLARE)

27.83

5.20

FRONT SIDE

BOTTOM VIEW

12. Bring the electrical supply (20 Amp.) into the unit at the rear of the cabinet and enters the unit control box.

The power and ground connections are completed to the leads in the control box. Strain relief connections

must be made at the cabinet and at the control box.

NOTE: Make sure the proper voltage and number of wires are provided. See serial plate for proper

configuration.

NOTE: All wiring must conform to national and local codes.

CONDENSER

DRAIN

ICE DROP

OPENING

DUMP VALVE DRAIN HOSE

(9/16-IN. I.D. BY 3/4-IN. O.D.)

IAF 1000

FIGURE 2. SERVICE CONNECTIONS

3 630460004

REAR VIEW

GEABOX/WTRPN DRAIN HOSE

(9/16-IN. I.D. BY 3/4-IN. O.D.)

1

2

3

4

5

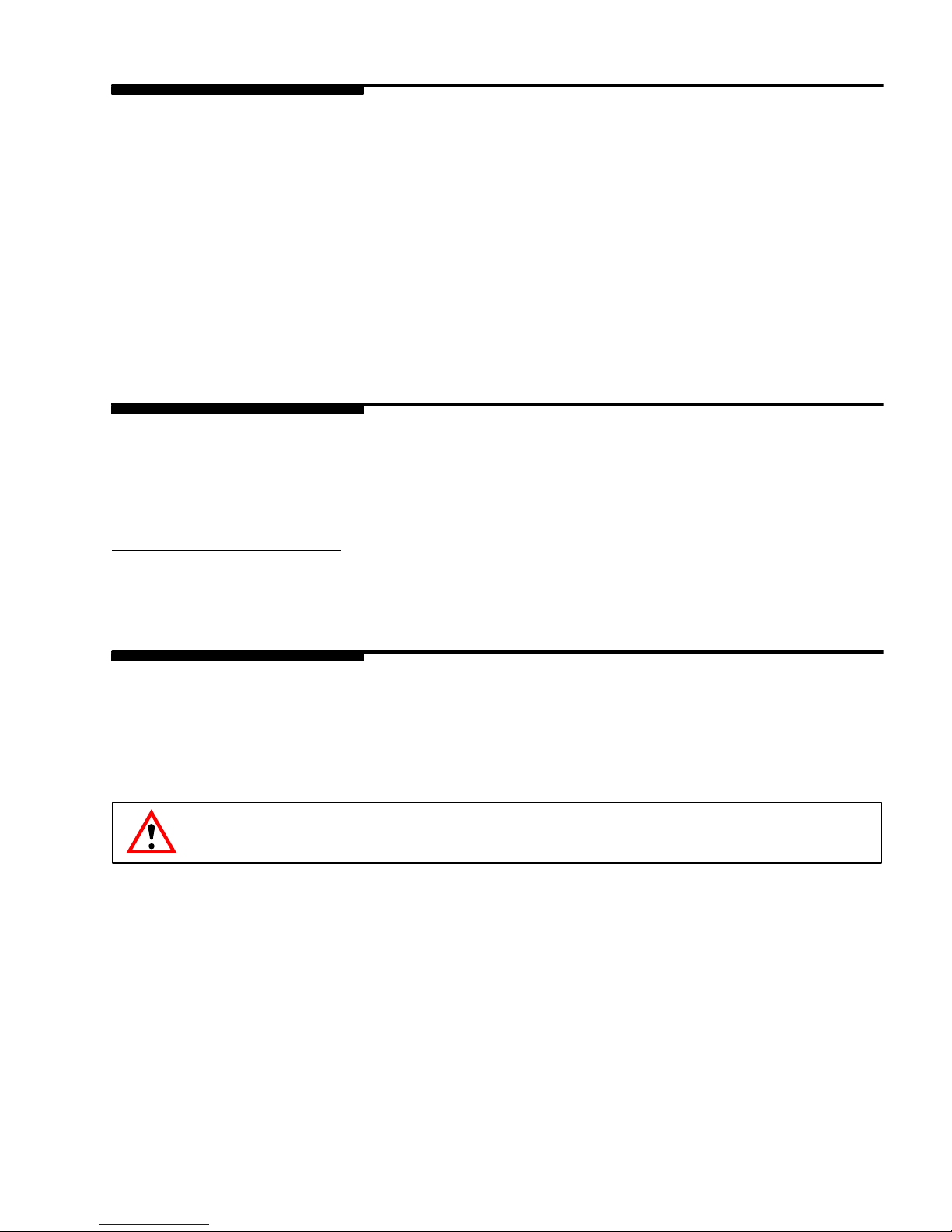

1. Remove the chute from the evaporator assembly

2. Remove item 1, .50-20 x 1.25 bolt; item 2, .50 lockwasher; item 3, ice paddle, and item 4,

flaker cutter head.

3. Install item 5, nugget ice cutter head, and re-install items 1, 2, & 3

4. Re-install chute. (RTV must be used around the base of the chute.)

FIGURE 3. INSTRUCTIONS FOR CONVERTING FLAKED ICE TO NUGGET ICE.

630460004

4

W ATER AND ICE CIRCUIT

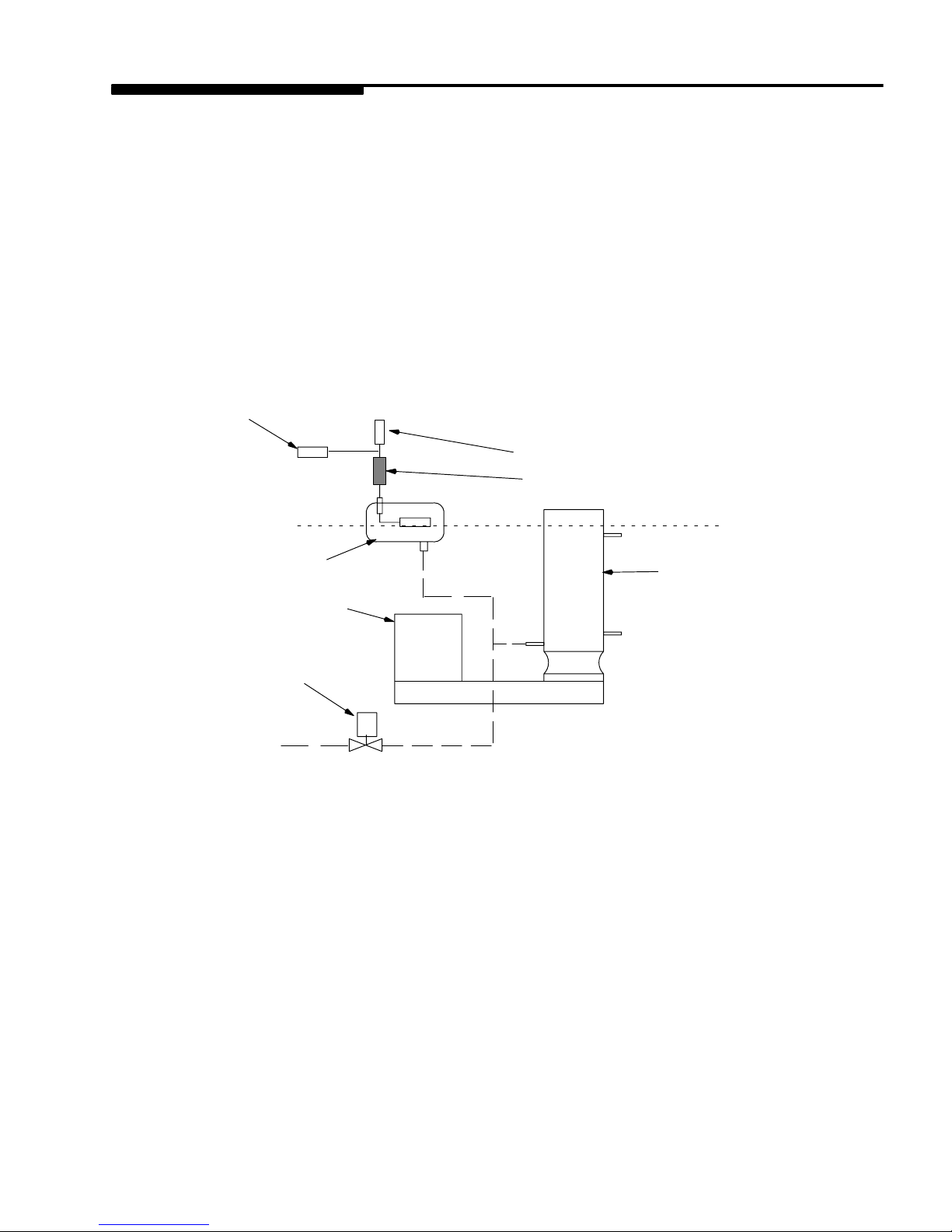

The supply water enters the float chamber through a small orifice. The water level rises and lifts the float arm on

the float valve and seats the valve, shutting off the water supply when the water is at the desired level. As the

water leaves the float chamber, filling the evaporator, the float drops and allows additional water to enter refilling

the float chamber. Thus the water level is maintained automatically as the unit operates.

The water level in the evaporator shell will rise to the same level as the water in the float chamber. The water in

direct contact with the evaporator wall freezes and forms ice on the evaporator wall. As the freezing continues

the ice becomes thicker and exceeds the space between the evaporator wall and the auger. The auger rotating

at 8 RPM then chips off the ice and moves it to the surface of the shell. When the ice reaches the top surface of

the water in the shell it is pushed upward through the extruder opening into the cutter heads. From the cutter

head the ice enters the drop chute and falls into the storage bin. This action continues until the ice comes in

contact with the bin thermostat and the unit is shut down. The unit will remain off until the ice drops from the bin

thermostat through consumption or melting, at which time the unit will restart.

Water Inlet Fitting

Water Pressure Switch

Strainer

Float Valve

Gear Motor

Water Dump Valve

Water Level

Evaporator

FIGURE 4. WATER LEVEL

5 630460004

“I” SERIES FLAKER CLEANING

AND SANITIZING PROCEDURE

1. To eliminate water from entering the reservoir, block up the float located inside the reservoir, activate the

dump switch to the “ON” position and turn the power switch to “ON”. Allow the evaporator to drain. Turn the

power switch to the “OFF” position.

2. Remove the ice chute by removing the hold-down nuts at the base and the self-clamping bolt at the top. Lift

the chute clear of the evaporator assembly.

3. Return the float to it’s normal position. As the float chamber refills with water and fills the evaporator, add 3

oz. of Calgon Nickel-Safe ice machine cleaner to the float chamber. (Gravity will feed the cleaner to the

evaporator.)

NOTE: Do not remove the auger, extruder head, or other parts from the evaporator assembly.

4. Allow the cleaning solution to stand in the evaporator for 20 - 30 minutes. Block up the float and drain the

evaporator as in step 1.

5. Rinse/flush by carefully filling with warm water (100_F) and drain by following step 1 again. Repeat at least

3 times. During the final rinse/flush cycle, add 1 tablespoon of regular Baking Soda and allow it to stand for

10 - 15 minutes.

6. Drain the evaporator and rinse/flush one more time.

7. Install the ice chute and panels. (RTV must be used around the base of the chute.)

CAUTION: Should sanitizing be required, DO NOT use a mixture of household bleach and

water Chlorine will attack stainless steel. Use only a commercial ice machine sanitizer such

as Calgon Sanitizer for ice machines, following the directions on the container.

NOTE: When cleaning and/or sanitizing is complete return the machine back to an ice making cycle.

Discard the first 30 minutes of ice production. DO NOT allow any ice that has been in contact

with sanitizer to ever be used.

630460004

6

WATER TREA TMENT

During the freezing process, as water passes over the evaporator, the impurities in the water have a tendency

to be rejected and the plate will freeze only the pure water.

However, the more dissolved solids in the water, the more troublesome the freezing operation will be. Bicarbonates in the water are the most troublesome of the impurities. These impurities will cause scaling on the evaporator, clogging of the float valve mechanism and other parts in the water system. If the concentration of impurities is high, mushy ice may be the result.

Parts of the Flaker, that are in contact with the water or ice, may corrode if the water is high in acidity. In some

areas, water may have to be treated in order to overcome some of the problems that arise because of the mineral content.

IMI Cornelius has water filter/treatment systems available to control impurities found in most water supplies.

Contact your local dealer for more information.

WINTER STORAGE

If the unit is to be stored in an area where the temperature will drop below freezing, it is most important that all

water lines be drained to prevent them from freezing and possible rupture.

To blow out the water line, disconnect the water supply at the cabinet inlet and use air pressure to force the water into the water reservoir pan, it can then be removed from the water pan.

WATER COOLED CONDENSER – To remove water from condenser unhook water supply and attach compressed air hose. Start machine. As head pressure reaches the appropriate level opening the water regulating

valve, the compressed air will force the water out. Do not let the machine operate longer than necessary.

CLEANING THE CONDENSER (AIR COOLED)

In order to produce at full capacity, the refrigeration condenser must be kept clean. The frequency of cleaning

will be determined by surrounding condition. A good maintenance plan calls for an inspection at least every two

months.

With a vacuum cleaner, remove all accumulated dust and lint that has adhered to the finned condenser at the

rear of the unit. The use of a stiff bristle brush may be helpful.

CAUTION: CONDENSER COOLING FINS ARE SHARP. USE CARE WHEN CLEANING.

7 630460004

BL

RD

RD

M

RD

YL

CONDENSER

FAN MOTOR

CONTROL

LOW PRESSURE

C.I. 20 PSIG

C.O. 10 PSIG

T/D

3

COMPRESSOR

START

CAPACITOR

145-174MFD 250V35MFD 370V

1

5

2

M

RD

1

WH

OR

RD

GW

BK

BK

RD

BL

BIN

THERMOSTAT

RD

BL

CONTROL

HIGH

BL

BK

RD

PRESSURE

C.O. 450 PSIG

WATER DUMP

SWITCH

2

1 3

BL

CONTACTOR

RD

BK

BL

BK

THERMOSTAT

ON-OFF SWITCH

CIRCUIT BREAKER

RATED 1.5 AMPS

DELAY

BK

WATER DUMP

VALVE

COMPRESSOR

BR

RD

BK

FAN SWITCH

CI 275

CO 205

BL

GEAR MOTOR

START RELAY

GEAR

3

BK

2

RD

R

C

S

BK

RD

YL

YL

4

BK

WH

COMPRESSOR

RUN

CAPACITOR

COMPRESSOR

START RELAY

BKBK

BK

RD

208/230 VOLTS 60 Hz

FIGURE 5. WIRING DIAGRAM IAF1000

630460004

8

Crankcase Heater

(IRF Only)

BK

BL

RD

RD

BK

BK

RD

BK

GW

BL

RD

BL

BL

Bin

Thermostat

RD

Control

High Pressure

CO 450 PSIG

Water Dump

Switch

2

1

3

BL

RD

BK

BL

BK

Contactor

BK

ON-OFF Switch

Circuit Breaker

Rated 1.5 Amps

Delay

Thermostat

BK

Water Dump

Valve

Compressor

RD

BR

BK

Control

Low Pressure

CI 20 PSIG

CO 10 PSIG

BL

Gear Motor

Start Relay

YL

BK

T/D

M

BK

BK

M

Cooling Fan

Motor

RD

Compressor Run

Capacitor

35MFD 370 V

R

C

S

RD RD

YL YL

BK

Compressor

Start Relay

BK

WH

Compressor Start

Capacitor

145-174MFD 250 V

OR

BK

RD

WH

RD

FIGURE 6. WIRING DIAGRAM IWF1000 AND IRF1000

Liquid Line

Solenoid

(IRF Only)

RD

RD

9 630460004

BK

WH

BK

GW

BL

RD

BK

BIN

THERMOSTAT

RD

BK

CONTROL

LOW PRESSURE

C.I. 20 PSIG

C.O. 10 PSIG

BL

BL

DELAY

THERMOSTAT

BK

22i

21

BL

BK

WH

12k

ON–OFF SWITCH

CIRCUIT BREAKER

RATED 2.0 AMPS

11

GEAR MOTOR

START RELAY

3

2

YL

4

BK

GEAR

M

WH

WH

3

T/D

WH

WH

1

BK

BK

BL

CONTROL

HIGH

WATER DUMP

BL

SWITCH

PRESSURE

C.O. 450 PSIG

2

1

3

BL

BK

WH

CONTACTOR

BK

WATER DUMP

VALVE

BL

BR

COOLING

FAN MOTOR

IWF ONLY

WH

WH

LOW AMBIENT

SWITCH (A/C ONLY)

CI275 C0205

R

C

S

COMPRESSOR

BR

RD RD

YL

COMPRESSOR

START RELAY

M

RUN

COMPRESSOR

CAPACITOR CAPACITOR

30MFD 440V

BK

M

CONDENSOR FAN MOTOR

(A/C ONLY)

COMPRESSOR

YL

1

5

2

BKBKBK

START

OR

WH

FIGURE 7. WIRING DIAGRAM IAF650 AND IWF650

630460004

10

“I” Series “Remote”

Ice Machine

Remote Condenser Specifications

Model CR800

Volts 230

Phase 1

Hertz 60

Amps 1.0

Output, HP 1/6

Max, fuse size, Amps (HVAC circuit breaker

required)

20

11 630460004

630460004

12

BK

M

CAPACITOR

2 mfd 440 VAC

RED

COLORED

BAND

BK

HEAT SHRINK

TAPE

GR

FAN CYCLING

SWITCH

CONDENSER

FAN MOTOR

HEAT SHRINK TAPE

BK

HEAT SHRINK TAPE

CR800, CR1200, & CR1400 REMOTE CONDENSERS

RD

GR

208/230 VOLTS 60 HZ

13 630460004

Installation Instructions Remote Condensers

UNIT

LEG

1/4-20 SCREW

LEG

BRACE

1. Follow the standard installation instructions supplied with

flaker. Do not hook flaker into the power source until the remote condenser and line set installation is complete.

2. Assembly of remote condenser (see drawing):

a. Assemble legs to base panel.

Install leg supports on legs.

b. Locate the remote condenser in a well–ventilated area

on the roof away from other refrigeration equipment’s

condenser discharge air flow.

c. Use the mounting holes provided to secure the remote

condenser to the roof. Seal over heads of bolts or fasteners with tar or pitch to prevent entrance of moisture.

LEG SUPPORT

REMOTE CONDENSER

3. Remote condenser electrical hook-up:

a. Connect remote condenser to a power source

(208/230VAC, 60 HZ) separate from the flaker. An external disconnect switch must be used.

b. Make sure the electrical connections follow all local and

national codes.

c. DO NOT turn condenser on until flaker install and re-

frigerant line connections are complete!

a. Never wire condenser into flaker section. The con-

denser is an independent electrical connection.

b. Fan motor will not start until pressure rises to 205

PSIG [14.07 Bars] closing fan cycling switch.

c. The condenser fan may cycle off during the harvest

cycle – this would be normal.

Note: Installing an IMI Cornelius remote flaker with other

than an IMI Cornelius remote condenser and line set

may be reason to void the warranty.

LEG

630460004

14

LIQUID

REFRIGERANT

LINE

DISCHARGE

LINE

4. Each condenser and flaker is connected with two (2) *precharged lines.

a. The pre-charged lines are ordered separately from the

condenser to suit each individual application.

b. The pre-charged line lengths are 20 feet [6.096 meters],

35 feet [10.66 meters] and 55 feet [16.76 meters].

Note: *(Pre-charged is defined as a vapor holding charge –

not a portion of the system charge.)

5. Installation of line kits (see drawing). Remove the tubing

from the carton. Carefully uncoil the lines so the tubing

doesn’t become kinked, and route lines to flaker and condenser.

6. Keep line-set as short as possible. Place a 3-foot service

loop behind flaker to allow for rear service should it ever be

required.

CORRECT

15 630460004

Remote Condenser Location

1. Physical Line-Set Length: 55 Ft. Maximum [16.764 me-

ters]

The ice machine compressor must have the proper oil return. Line-set rises, drop, or horizontal runs greater than the

maximum distance allowed will exceed the compressor startup and pumping design limits, and will result in poor oil return to the compressor.

NOTE: MAX. LINE-SET

LENGTH FOR IMI CORNELIUS

FLAKERS IS 55 FT.

DO NOT CONFUSE LINE

LENGTH WITH CALCULATED

LINE DISTANCE.

Line-Set Rise: 35 Ft. Maximum [10.66 meters]

Line-Set Drop: 15 Ft. Maximum [4.57 meters]

2. Calculated Line-Set Distance: 100 Ft. [30.48 meters]

To prevent the combination of rises, drops and horizontal

runs exceeding the compressor start-up and pumping design

limit, the following calculations should be made:

B

A

C

B

A - (RISE) CONDENSER HIGHER THAN EVAP.

MAX. 35 FT.

B - LINE LENGTH 15 FT.: EXAMPLE

630460004

B - LINE LENGTH 35 FT.: EXAMPLE

C - (DROP) CONDENSER LOWER THAN EVAP. 15 FT.: MAX.

16

Maximum Line-Set Distance Formula

a. Measured rise x 1.7= Calculated

Rise 35 ft. Max) [10.66 meters]

b. Measured drop x 6.6= Calculated

Drop 15 ft. Max) [4.57 meters]

c. Measured Horizontal Distance = actual measurement.

d. Total Calculated Distance (A+B+C)=Total

Calculated Distance (100 ft. Max.) [30.48 meters]

H

COMBINATION OF

DROP(S)

WITH HORIZONTAL

COMBINATION OF RISE AND

DROP(S)WITH HORIZONTAL

H

H

R

EXAMPLES:

AIR

FLOW

R

a. Insert measured rise (R) into the formula and multiply

it by 1.7 to get a calculated rise.

example: A condenser located 15 ft. [4.572 meters]

above the ice machine has a 25.5 ft. [8.874 meters]

calculated total (15 ft. x 1.7 = 25.5).

b. Insert measured drop (D) into formula and multiply by

6.6 to get a calculated drop.

D

AIR

FLOW

example: A condenser located 8 ft. [2.438 meters]

below the ice machine has a 52.8 ft. [16.093 meters]

calculated total (8 ft. x 6.6 = 52.8 ft.).

c. Insert measured horizontal distance into formula. No

calculation is necessary. (6 ft.) [1.828 meters].

D

AIR

FLOW

d. Add the calculated rise, calculated drop, and hori-

zontal distance together to get the total calculated

distance (25.5 + 52.8 + 6) equals 84.3 ft. [25.694 meters]. If 100 ft. [30.48 meters] total calculated distance is exceeded, the condenser must be moved to

a new location which permits proper equipment operation.

Caution

If a line-set rise is followed by a line-set drop, a second

line-set rise cannot be made.

Or

If a line-set drop is followed by a line-set rise, a second

line-set drop cannot be made.

3. Lengthening or Reducing the Line-Set Lengths

In most cases, by routing the line-set properly, shortening

17 630460004

will not be necessary (refer to illustration). However, when

shortening or lengthening is required, do so before connecting the line-set to the ice machine or the remote condenser.

This prevents the loss of refrigerant from the ice machine or

the condenser.

The quick connect fittings on the line-sets are equipped with

Schrader Valves. Use these valves to recover any vapor

charge from the line-set. When lengthening or shortening

lines, apply good refrigeration practices and insulate new

tubing. Do not change the tube sizes. Evacuate the lines

and place approximately 5 oz. of

vapor refrigerant charge in each line.

SCHRADER

VALVE

PARENT

METAL

SEAL

INTERMEDIATE

SEAL

4. Connection of Line-Set

a. Remove the plastic caps from the line-set, the condens-

er, and the ice machine.

b. Apply refrigeration oil to the threads on the quick connect

couplers before connecting them to the condenser.

c. Carefully thread the female fitting onto the condenser or

ice machine by hand.

d. Using the proper size wrench, tighten the couplings until

they bottom out. Turn an additional 1/4 turn to ensure

proper brass-to-brass seating.

e. Check all fittings for leaks.

5. Final Installation:

a. Remove grill from the right-hand side panel of flaker.

b. Turn service port on receiver tank to open position re-

leasing refrigerant to the balance of the system.

c. Leak check line-set connections at flaker and condenser.

d. Replace grill.

e. Connect flaker to power source.

f. Make sure electrical connections follow all local and na-

tional codes.

Caution

630460004

6. Start Up:

a. Use standard procedures from flaker installation instruc-

tions.

b. After the flaker is running, check the remote condenser

and verify that the condenser fan is running.

Once the refrigerant lines are connected, the seal is broken in

the fittings. If the lines are removed or loosened from the flaker

or remote condenser, the refrigerant charge will be discharged

to the atmosphere. DISCHARGING TO THE ATMOSPHERE IS IN

VIOLATION OF THE CLEAN AIR ACT OF JULY, 1992.

18

discharge

Head Pressure Control [Headmaster]

The Cornelius “I” series remote systems use an Alco Head Pressure

Control, normally referred to as a headmaster. This control is

mounted in the remote condenser with a fan cycling control switch.

Using both these controls gives the system positive operation under

a wide range of condensing temperatures.

The cycling control starts the fan at 270 PSI and stops it at 205 PSI

allowing a positive efficient operation at the high temperature operating ranges.

The headmaster controls the operation when the condensing tem-

receiver

condenser

above 70°F

normal

perature drops below 70°F. The “I” series refrigerant charge is HP 62 [R - 404A] and the headmaster dome charge setting is 200 PSI

of nitrogen pressure making it stable under the low temperature operating range down to - 20°F.

The normal flow pattern through the headmaster is from the condenser port to the receiver port. When this flow pattern is unable to

maintain a receiver outlet pressure equal to or above the dome

pressure setting of the valve, the dome pressure will force the valve

portage to change closing the condenser port and opening the bypass port from the compressor discharge line. This allows the high

pressure vapor from the discharge port to “buck” the receiver pressure back up. With the condenser port closed, the refrigerant is

backed up in the condenser, basically reducing the condenser size,

assisting in maintaining the discharge portage flow and increasing

the head pressure.

discharge

condenser

below 70°F by-pass

receiver

Remember, sense of touch to the lines of the headmaster will determine the flow path the headmaster is in, condenser to receive, or

bypass to receiver.

High side gauge installed at the receiver outlet valve will determine

if the headmaster is functioning to maintain the proper operating

pressure.

In the event the control appears to be “stuck in bypass”, the pressure drop across the headmaster must be measured. With a gauge

installed at the receiver outlet valve and the high side service valve,

the pressure difference at these two points must be less than the 15

PSI. The three most common causes of an excessive pressure drop

are shortage of refrigerant, kinked remote lines, and excessive line

length.

Eliminate refrigerant shortage first. Add refrigerant in two-pound increments (not to exceed six pounds) to determine if it corrects the

pressure drop. If pressure drop is not corrected, inspect line set for

sharp bends or kinks and correct as required. If adding refrigerant

does not correct continued (bypass) condition and line set is not

damaged, replace headmaster.

19 630460004

Remote System Evacuation/Re-charge

All field repairs to the sealed system must start with a total discharge of the system following the requirements of the Clean Air Act

of July, 1992.

Proper evacuation of the total remote system will require a three (3)

point hook-up of your manifold and hose set, (see drawing):

Point #1 - flaker receiver outlet valve

Point #2 - flaker high side service valve

Point #3 - flaker low side service valve

Evacuation:

1. With flaker power supply turned “OFF” disconnect and insu-

late all 3 compressor leads at the compressor. Turn power

supply on, place power switch in the “on” position. This will

energize (open) the Liquid Line solenoid allowing evacuation

of the Liquid Line between the solenoid and the expansion

valve(s).

2. Evacuate system to 200/250 microns or less. At this point,

there should be a holding test of five(5) minutes. You may

expect a slight loss of vacuum as normal. A rapid rise to normal atmospheric pressure indicates moisture still present in

the system. On a “wet” system, it will prove beneficial to use

heat lamps to warm the compressor dome and evaporator

surface during evacuation.

3. Turn flaker power switch OFF. Reconnect compressor leads.

630460004

20

OPEN

EVACUATION

MANIFOLD SET

OPEN

1ST STAGE CHARGING

MANIFOLD SET

OPEN

CLOSED

2ND STAGE CHARGING

COMPRESSOR OPERATING

CLOSED

MANIFOLD SET

OPEN

RECEIVER

OPEN

RECEIVER

OUTLET

VALVE

VACUUM

PUMP

OPEN

OPEN

CHARGING

CYLINDER

CLOSED

HIGH SIDE

SERVICE

VALVE

LOW

SIDE

SERVICE

VALVE

CLOSED

ELECTRONIC

SCALE

RECEIVER

OPEN

RECEIVER

OUTLET

VALVE

VACUUM

PUMP

CLOSED

CLOSED

OPEN

CHARGING

CYLINDER

OPEN

ELECTRONIC

HIGH SIDE

SERVICE

VALVE

LOW

SIDE

SERVICE

VALVE

SCALE

RECEIVER

CLOSED

RECEIVER

OUTLET

VALVE

VACUUM

PUMP

CLOSED

CLOSED

HIGH SIDE

SERVICE

VALVE

LOW

SIDE

SERVICE

VALVE

OPEN

CHARGING

CYLINDER

OPEN

ELECTRONIC

SCALE

21 630460004

4. *After proper evacuation hold test has been performed, the

refrigerant charge should be “dumped” into the receiver until

the pressure equalizes, stopping the flow. Do not try to

throttle the refrigerant flow. Doing so will allow system

pressure to balance too soon. The high-side service valve

should be closed and the balance of the charge fed slowly

through the suction side service valve with the compressor

operational. Control the feed rate at no faster than four (4)

ounces [113.g] per minute to ensure the compressor oil does

not become too saturated with refrigerant resulting in a loss

of compressor lubrication.

5. All refrigerant re-charging must be weighed into the system,

utilizing an electronic charging scale. DO NOT attempt to

recharge the system by sight glass, system pressure, amperage, frost line or sweat patterns.

6. Always leak check entire system after recharge.

Caution

Before programming the electronic scales to “dump” the

charge,

de-energize the liquid line solenoid, close the shut-off valve on

vacuum pump and low side of the manifold set.

630460004

22

IMI CORNELIUS INC.

Corporate Headquarters:

Anoka, Minnesota 55303-6234

One Cornelius Place

(612) 421-6120

(800) 238-3600

Loading...

Loading...