Cornelius IACS227 Installation Manual

THE HOTTEST MACHINES ON ICET

“I” Series

227

Ice Cube Machine

INSTALLATION INSTRUCTIONS

Part No. 630460042INS

Release Date: October 27, 2003

Revision Date: January 30, 2007

Revision: B

THIS DOCUMENT CONTAINS IMPORTANT INFORMATION

This Manual must be read and understood before installing or operating this equipment

IMI CORNELIUS INC; 2003–2007©

PRINTED IN U.S.A

TABLE OF CONTENTS

GENERAL 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FREIGHT DAMAGE CLAIMS PROCEDURE 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SPECIFICATIONS, ICE CUBER 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

INSTALLATION INSTRUCTIONS 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

LOCATION OF EQUIPMENT 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PLUMBING CONNECTIONS 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ELECTRICAL 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

INSTALLATION CHECK POINTS 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

START-UP AND CHECK OUT 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

OWNER - OPERATOR 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CLEANING PROCEDURES 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PREP – CLEANING 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CLEANING THE WATER SYSTEM & EVAPORATOR 6. . . . . . . . . . . . . . . . . . . . . . .

SANITIZING PROCEDURES 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DUMP CYCLE 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ADJUSTING BRIDGE THICKNESS 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TOTAL ICE CAPACITY 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

GENERAL

FREIGHT DAMAGE CLAIMS PROCEDURE

The deliverer of your equipment (freight company, distributor or dealer) is responsible for loss or damage

of your shipment. All claims must be filed with the deliverer of your equipment. Please follow the steps

below to determine if your shipment is satisfactory or if a claim must be filed:

1. Check the number of products delivered against the number of products listed on the delivery receipt. Should the totals not match, have the driver note all errors on both copies and both you and

the driver sign and date said notation.

2. Inspect all cartons for visible damage. Open and inspect as required before the driver leaves and

have him or her note any damage on the receipts. All damaged claims must be inspected within 15

days of delivery. Notify your carrier immediately if concealed damage is found after delivery.

3. Should concealed damage be found when product is unpacked, retain the packing material and the

product and request an inspection from the deliverer.

4. All claims for loss or damage should be filed at once. Delays in filing will reduce the chance of

achieving a satisfactory resolution to the claim.

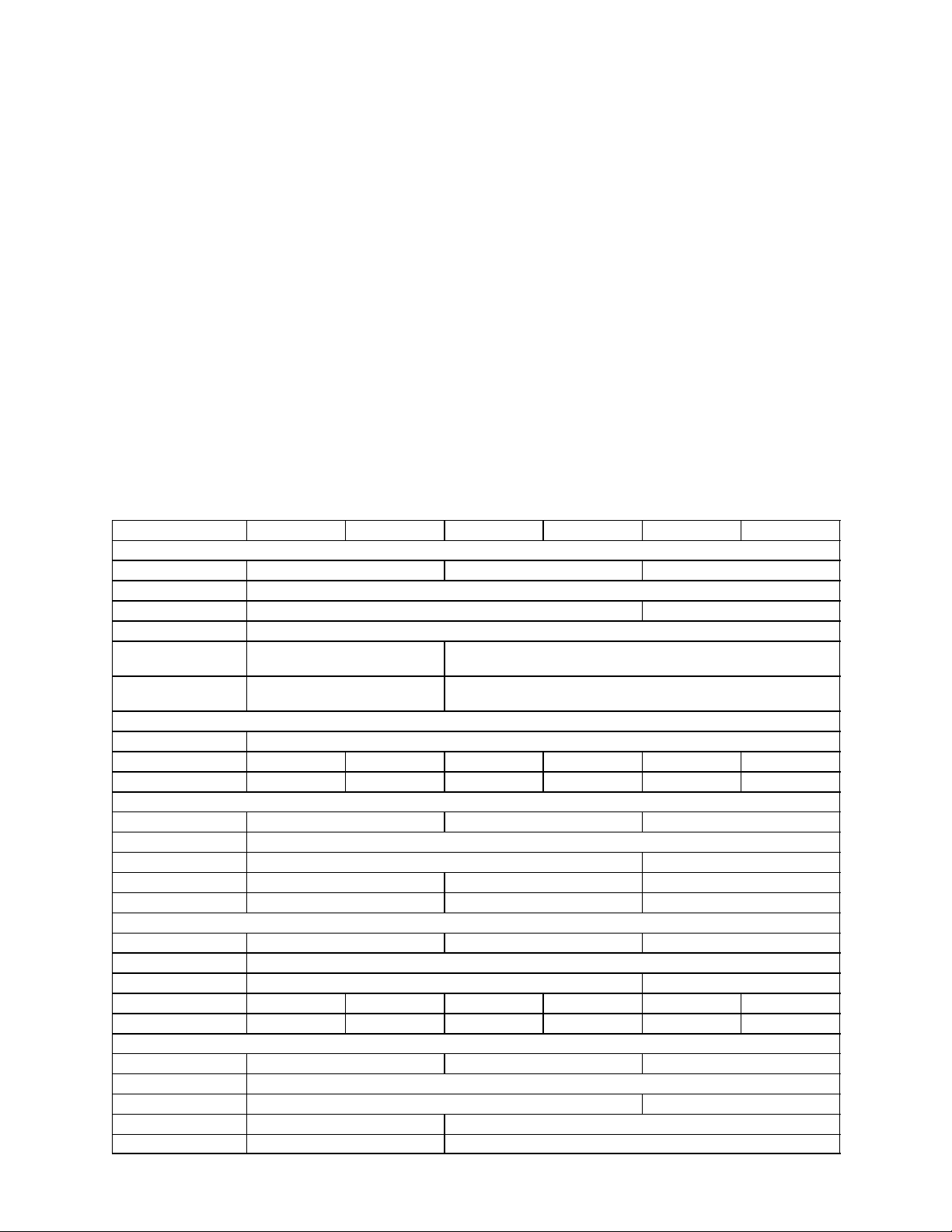

SPECIFICATIONS, ICE CUBER

The following table contains equipment specification information for the Ice Cubers.

Model IACS227 IWCS227 IACS227E60 IWCS227E60 IACS227E50 IWCS227E50

UNIT

Volts 115 230 220

Phase 1

Hertz 60 50

No. Wires 2+Ground

MIN. CIRCUIT

Amps 20 15

MAX. FUSE SIZE

Amps 20 15

REFRIGERANT

Type R404A

Weight (oz) 17 15 17 15 17 15

Weight (g) 482 425 482 425 482 425

COMPRESSOR

Volts 115 230 220

Phase 1

Hertz 60 50

LRA 51 24 26

RLA 11.5 5.7 5.3

CONDENSER FAN MOTOR

Volts 115 230 220

Phase 1

Hertz 60 50

Amps 1.7 NA 1.2 NA 0.75 NA

Watts 50 NA 60 NA 50 NA

WATER PUMP

Volts 115 230 220

Phase 1

Hertz 60 50

Amps 0.88 0.5

Watts 1/40 1/30

Important: All product supply voltage specifications are –5%/+10% for proper component operation.

630460042INS

1

INSTALLATION INSTRUCTIONS

Installation and start-up of the equipment should be performed by the distributor or the dealer’s professional staff.

LOCATION OF EQUIPMENT

For maximum performance the location should be away from heat sources such as ovens, direct sunlight,

hot air discharge, etc.

To reduce cost of maintenance and loss of efficiency, avoid placing air-cooled equipment in areas where

grease, flour and other airborne contaminants are present. Allow clearance at the front for proper air circulation. Restricted air circulation will affect the efficiency and required maintenance of the product.

IMPORTANT: Never operate your equipment in room temperature below 50_F (10_C) or above

100_F (38_C). Should the location of your product ever be exposed to freezing temperatures, it

must be shut down and winterized.

FIGURE 1. INSTALLATION

PLUMBING CONNECTIONS

1. All plumbing lines and connections must conform to local and national plumbing codes.

2. Line shut-off valves must be located in supply water lines for cuber and condenser if product is water-cooled. Water supply to water-cooled condenser must include a stand-pipe to prevent “water

hammer”.

3. Should your local water supply quality require the installation of a water filter system, consult your

local distributor or dealer for proper size required.

4. Water supply pressure must not be lower than 20 PSI (1.37 BAR), nor should it exceed 120 PSI

(8.16 BAR).

Important: Water filters larger then 5 microns do not give proper protection. Water pressures

above 80 PSI (5.44 BAR) will destroy the filter.

Important: Bin and cuber drain lines must never be connected together and must be vented.

2

630460042INS

Loading...

Loading...