Page 1

Thermostat Reset Upgrade Kit Installation Instructions

INSTALLATION INSTRUCTIONS

FCB Pinnacle 2 Flavor Emerson Units

THERMOSTAT RESET UPGRADE KIT P/N 629088480

IMPORTANT: This procedure is intended for use by a Qualified Service Technician.

IMPORTANT: This kit is intended to be a direct replacement of the existing safety circuit. If the

unit does not have a reset box on the back, call IMI Cornelius Service at 800-238-3600.

NOTE: Open the Cornelius web site www.cornelius.com, search for 629088480INS, and print the

instructions off in color.

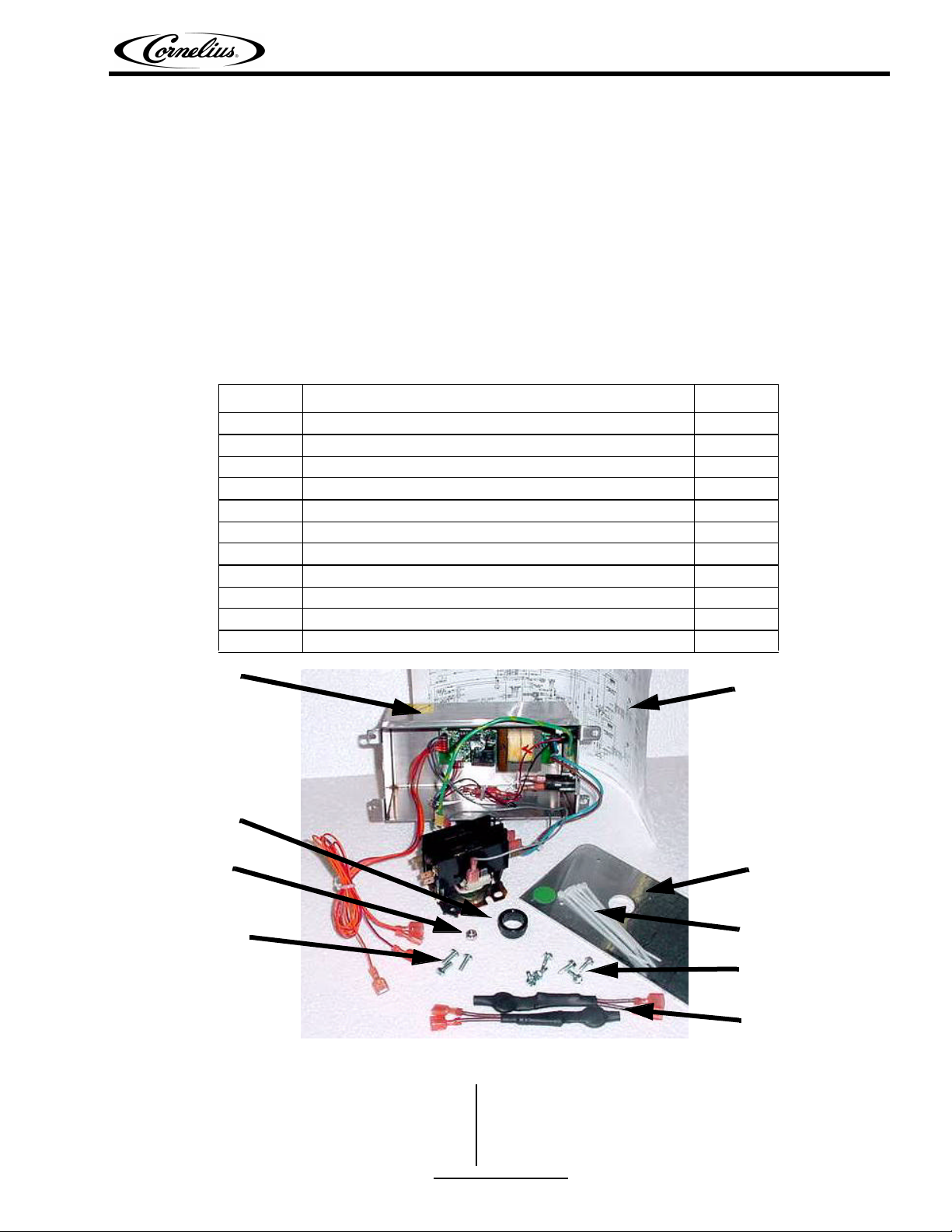

Parts List

Item Description Qty

1 Retro-Kit Enclosure Box (with wiring inside) 1

2 Hole Template 1

3 Short Thread-Cutting Screws (if needed) 6

4 Set of wire ties 1

5 Screws, 1 spare 3

6 Wiring Diagram – 620920907 1

7 7/8” Bushing (if needed) 1

8 Hex Nut 1

9 Harness, In-Rush Protection 2

10 Label, Hot Gas Error (not shown) 1

11 Brass Screws and S.S. Lock-washers (not shown) 4

Retro-Kit

Enclosure Box

Bushing

Hex Nut

Screws

Wire Diagram

Hole Template

Set of Wire Ties

Short Thread

Cutting Screws

In-Rush Protection

Harnesses

Tool List

Multi-Use Screwdriver Wire Stripper/Crimper

1/4” Nut Driver Needle Nose Pliers

Multi-meter Set of Mixed Terminals (red male and female

Release Date: June 30, 2005 www.cornelius.com Revision: C

© 2005, IMI Cornelius Inc. - 1 - Publication Number: 629088480INS

AMP fastons, fully insulated)

Page 2

Thermostat Reset Upgrade Kit Installation Instructions

Installation Instructions

1. Pull Pinnacle away from wall. DISCONNECT POWER FROM THE UNIT. Remove lower back

panel.

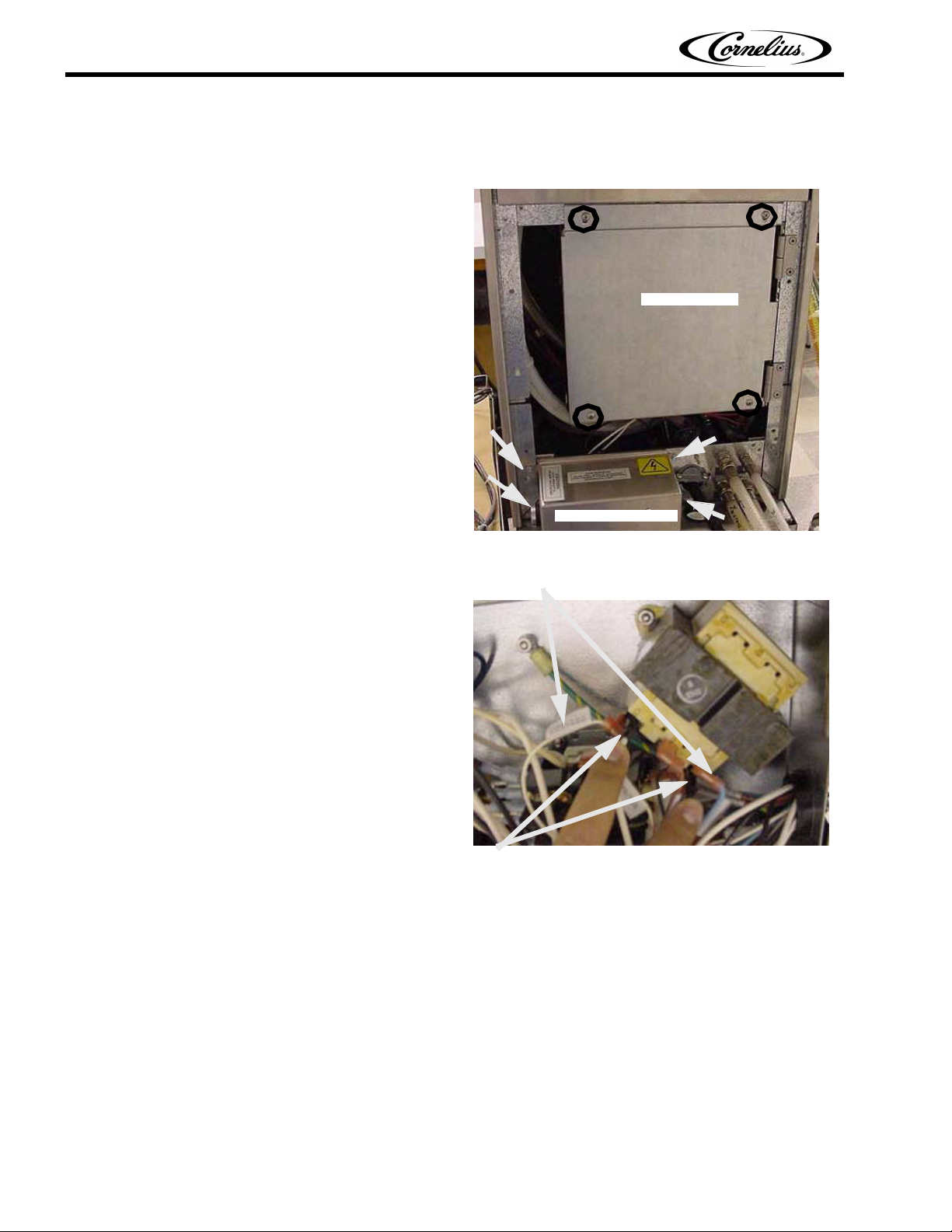

2. Remove the 4 screws holding contactor

box cover (bottom rear of unit). The box

will now pivot on hinges. Also remove the

4 screws holding the original safety circuit

box on the back of the lower frame.

Contactor Box

3. Remove leads LD1 and LD2 from

transformer 1, located in contactor box.

These are the piggybacked connections.

Remove the labeled terminals from the

piggybacks and replace in their original

positions.

Original Safety Box

Place TX1-LD1 and TX1-LD2 back on transformers.

Use same location from placement.

Remove piggybacked wires and leads from transformer.

Publication Number: 629088480INS - 2 - © 2005, IMI Cornelius Inc.

Page 3

Thermostat Reset Upgrade Kit Installation Instructions

4. Remove thermostat wires from their

connections. Feed the wires out of the

contactor box. Discard the black jumper

wire.

5. Feed the white wires that originate from

the safety circuit box out of the contactor

box.

Disconnect white

contactor wire from

thermostat wire.

Disconnect black

jumper from thermostat

wire and discard.

Remove the two white wires

and black thermostat wires

from contactor box.

6. Pull out safety circuit box and remove the ground screw. Disconnect the main power and contactor

harness leads for the contactor.

7. Feed the white wires out through the hole and remove the box.

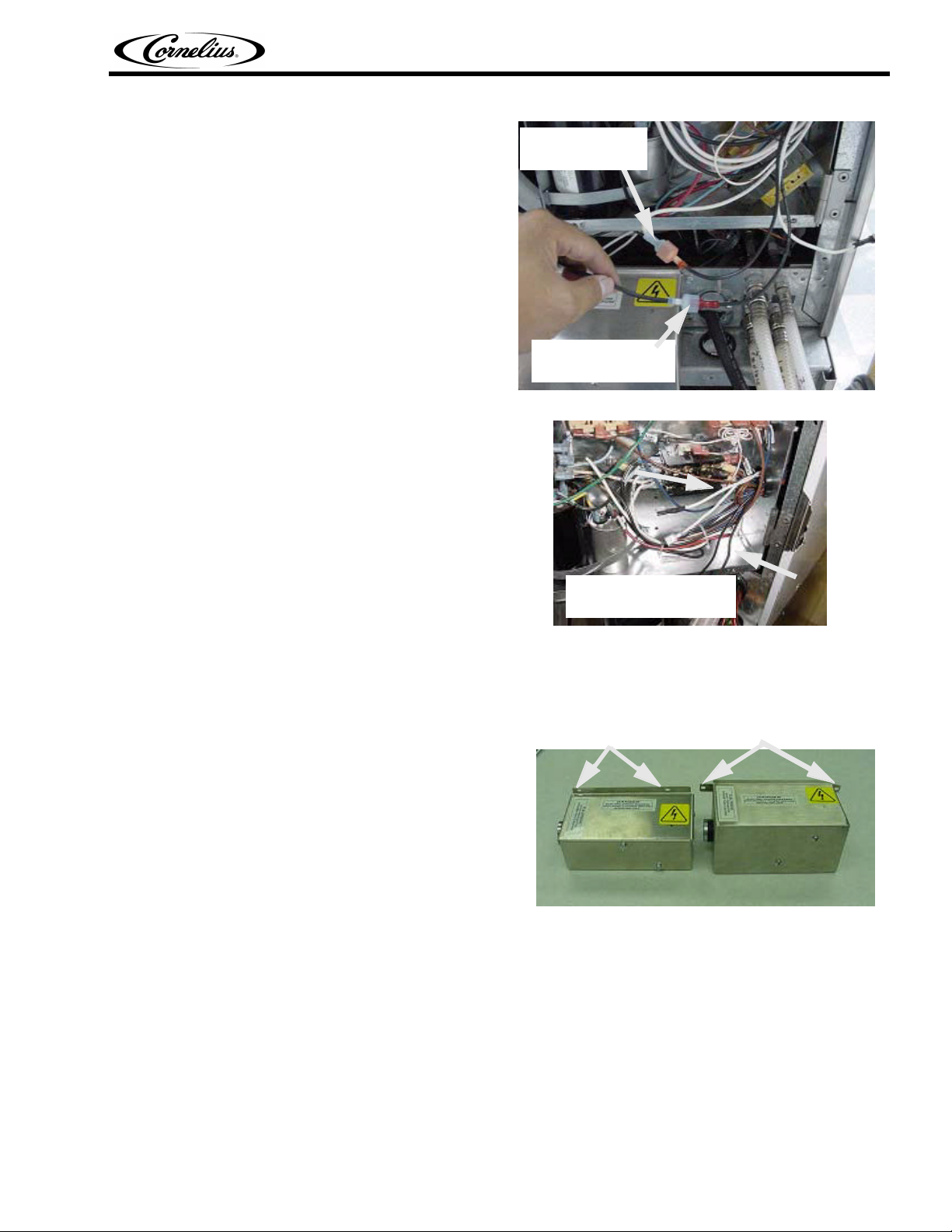

NOTE: Note the mounting hole locations on

the original box. If the mounting holes are on

Box with mounting holes on

top and bottom. Drill new.

Box with mounting holes on

sides. Use existing.

the side of the box, proceed to step 14.

If the mounting locations are on the top and

bottom, remove all wires and bushing and

proceed to the next step to drill new

mounting holes.

© 2005, IMI Cornelius Inc. - 3 - Publication Number: 629088480INS

Page 4

Thermostat Reset Upgrade Kit Installation Instructions

8. Place hole template at lower left of back of frame. The dot sticker should be at the lower left of

template. Line up edge of hole template to edge of frame, as shown, and clamp in place.

Template

Dot sticker in

lower left.

Clamp in place.

Start Holes

9. Start 4 smaller holes with the drill using the 1/8” bit through template and into frame. DO

NOT DRILL THE ENTIRE HOLE, ONLY START HOLE TO MARK LOCATION! If preferred, use a

center punch to mark hole locations.

10. Unclamp the template and place just

inside frame, as shown. The template

MUST BE between the frame and hoses to

prevent hose puncture. Be sure that large

hole in template is in position well above

the holes being drilled

Place template, as shown,

between frame and hoses.

11. Drill the two small holes near the left side. Move the template, as shown, when finished drilling

making sure it is between the frame and hoses, with the large template hole away from the right

side holes. Drill the 2 smaller holes on the right.

Place template in this

position when drilling

large hole.

12. File down any burrs on all 4 holes, carefully clean up all metal shavings.

13. Place Snap Bushing in the 7/8” hole. Feed the main power and contactor harnesses through the

hole.

Publication Number: 629088480INS - 4 - © 2005, IMI Cornelius Inc.

Page 5

Thermostat Reset Upgrade Kit Installation Instructions

Main power lead

harness.

Harness from

contactor box.

Snap bushing inserted.

14. Remove contactor from box and connect main power and contactor harnesses, as shown.

IMPORTANT – Main power MUST be on same side as flag terminals already attached to contactor

(see photo). Remount contactor in box.

Main power

harness

here.

Contactor

harness

here.

15. Feed the remaining 4 wires (2 red, 2

orange) through hole.

Remount contactor in the box by

locating this screw than turn the

contactor to locate the other screw.

Feed these wires through the hole.

© 2005, IMI Cornelius Inc. - 5 - Publication Number: 629088480INS

Page 6

Thermostat Reset Upgrade Kit Installation Instructions

16. Disconnect terminals bridging the two

thermostats (see photo). Remove wire tie,

if present.

17. Take the wires from the safety circuit and connect them to the thermostats.

IMPORTANT: Make sure that you connect the two red wires to one thermostat and the orange

wires to the other thermostat. Zip tie the bundles together.

Disconnect wires here.

Remove wire tie, if present.

Red

Power Leads

18. Change out the screws in the back of the

thermostat with the supplied brass and

stainless steel lockwashers.

NOTE: Only remove one screw at a time. Do

not remove both screws at the same time or

the thermostat can fall and be damaged.

19. Using hand tools remove one screw.

Wire tie bundles

together.

Orange

Publication Number: 629088480INS - 6 - © 2005, IMI Cornelius Inc.

Page 7

Thermostat Reset Upgrade Kit Installation Instructions

20. Place the stainless steel lock-washer over

the brass screw and thread it in (a “screw

starter” screwdriver makes this much

easier).

NOTE:

• Make sure both screws are in place and

secure.

• Do not use power tools to drive screws.

• Use caution not to overtighten the

screw.

21. Insure screw is flush and sealed against lock washer, as shown.

22. Repeat procedure for second screw.

23. Repeat steps 18-20 for all barrels.

If the existing screws do not come out or they break during this change, call IMI Cornelius Service at 800238-3600.

24. After screw replacements, insure thermostat is flush against brass retaining nut, by grasping the

body of the thermostat with your finger and gently trying to wiggle it. No movement should be

detected. If movement is detected, tighten screws and recheck.

Check

Correct

Incorrect

WARNING: If thermostat is loose, it will not correctly detect an over temperature condition. This

could allow product to overheat without being detected.

© 2005, IMI Cornelius Inc. - 7 - Publication Number: 629088480INS

Page 8

Thermostat Reset Upgrade Kit Installation Instructions

25. Set three ground wires (1 from contactor

box, 1 from main power, and 1 from safety

box) in place and tighten screw (see

photo).

26. Before connecting power check the following:

A. Verify that all connections are placed properly per the instructions.

B. Verify that all connections are firmly attached.

C. Verify that the ground connection does not touch a terminal on the contactor in the safety circuit

enclosure.

D. Verify that incoming power L1 and L2 are on the side of the contactor with the existing wires.

E. Verify that the unit power leads T1 and T2 are on the side of the contactor without the existing

wires.

27. After verifying that the unit is wired correctly, connect power to unit and verify. If the unit does not

power up and the red LED is illuminated, call IMI Cornelius Service at 800-238-3600. If the unit

powers up normally, disconnect power and complete the install.

28. Feed remaining extra wire back through

the hole.

Set ground leads

with screw and

tighten nut on

inside of frame.

Route extra

wire back into

unit.

Publication Number: 629088480INS - 8 - © 2005, IMI Cornelius Inc.

Page 9

29. Make sure all wires are in the safety circuit

box, hold box in place against the frame,

and drive 4 short thread-cutting screws

(included in kit) through safety circuit box

into frame.

30. Swing Contactor Box “closed” and place

cover over box. Drive the 4 screws that

were removed to hold cover and box in

place on unit.

Thermostat Reset Upgrade Kit Installation Instructions

31. Replace lower back panel of unit. Move

unit back into place for operation. Open

the front control box to add the in-rush

protection harnesses.

In-Rush

Protection

Harness

© 2005, IMI Cornelius Inc. - 9 - Publication Number: 629088480INS

Page 10

Thermostat Reset Upgrade Kit Installation Instructions

32. Pull the Brown wire labeled “P4” from its

location on the Emerson Inverter Board

33. Place the female terminal of the In-Rush

Protection harness on the terminal that

you just removed the brown wire from.

MAKE SURE THIS IS THE BOARD

TERMINAL LABELED “P4”.

P4 Brown Wire

P4 Board Terminal

Harness

Location for the In-Rush

Protection Harnesses

34. Mate the male terminal of the In-Rush Protection Harness with the Brown wire “P4” terminal that

you pulled from the board.

35. Position the In-Rush Protection Harness into the control box so that it does not contact the control

box or door when closed. Zip tie to the main harness as needed.

36. Repeat steps 25 - 28 on each inverter board on the unit (1 board per barrel).

37. Close front control box.

38. Attach new wiring diagram directly over

the existing one. Place Hot Gas Error

Warning label directly next to the display

panel on the front of the unit.

39. Reconnect power to the unit. Installation is complete and unit is ready for normal operation.

Publication Number: 629088480INS - 10 - © 2005, IMI Cornelius Inc.

Loading...

Loading...