Page 1

QUEST JUICE

2 and 4 Flavor

Training Manual

Release Date: April 12, 2004

Publication Number: TP00968

Revision Date: November 23, 2004

Revision: C

Visit the IMI Cornelius web site at www.cornelius.com for all your Literature needs.

Page 2

Quest Juice Training Manual

The products, technical information, and instructions contained in this manual are subject

to change without notice. These instructions are not intended to cover all details or variations of the equipment, nor to provide for every possible contingency in the installation,

operation or maintenance of this equipment. This manual assumes that the person(s)

working on the equipment have been trained and are skilled in working with electrical,

plumbing, pneumatic, and mechanical equipment. It is assumed that appropriate safety

precautions are taken and that all local safety and construction requirements are being

met, in addition to the information contained in this manual.

To inquire about current revisions of this and other documentation or for assistance with

any Cornelius product contact:

IMI Cornelius Inc.

Phone: 800-238-3600

Internet: www.cornelius.com

Trademarks and copyrights:

Aurora, Cornelius, Decade, Hydro Boost, Sitco, Spirit, UF-1, Vanguard, Venture, and Vista

are registered trademarks of IMI Cornelius Inc.

Optifill trademark is pending.

This document contains proprietary information and it may not be reproduced in any way

without permission from Cornelius.

Printed in U.S.A.

Copyright © 2004, All Rights Reserved, IMI Cornelius Inc.

Page 3

Quest Juice Training Manual

TABLE OF CONTENTS

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Product Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Dimensions & Capacities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Quest . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Quest, Two Flavor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Quest, Four Flavor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

IPD Times . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Ice Bath Capacity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

System Details . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Water . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Water Quality . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Water Flow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Adjusting Flow Rates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Concentrate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Setting the Brix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Preview Questions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Key Things To Know / Do . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Counter Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Filling the Ice Bath . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Connecting Water Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Priming/Flushing Water System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Concentrate Handling & Loading . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Loading Concentrate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Changing Concentrate Containers: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Supplies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Checking/Adjusting the Brix Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Programming the Portion Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Cancel/Pour Button . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Planned Maintenance Schedule . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Daily . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Flush System: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Clean Splash Zones & Dispense Nozzles: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Weekly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Sanitize the Juice Dispenser: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Semi-Annual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Clean Water Inlet Strainer: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Clean Chassis Interior: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Check and Top-Off Water Ice Bath: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Annually . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Replace Pump Tubing: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Removing Pump Platform(s): . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Replacing Pump Tubing: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Mechanical Section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

© 2004, IMI Cornelius Inc. - i - Publication Number: TP00968

Page 4

Quest Juice Training Manual

Removal of Merchandiser . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Removal of the Switch Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Removal of the Pump Platforms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Removal of the Cooling Fan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Removal of Panels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Removal of Electrical Box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Removal of the VRB Boards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Removal of the Ice Bank Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Removal of Nozzle Guide Gasket . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Removal of the Cooling Cabinet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

Removal of the Agitator Motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

Removal of the Refrigeration Chassis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

Removal of the Ice Control Probe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

Major Component Review . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

Electrical Box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

Pump Speed Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

Ice Bank Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

Operational Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

Validating Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

Transformer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

Water Inlet Solenoid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

Door Switch - 72 B Serial Number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

Door Switch - 72 E Serial Number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

Platform Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

Water Valve/Flow Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

Bottle Adaptor - O-rings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

Bottle Adaptor - Sold Out Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

Bottle Adaptor - Tray Grommets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Bottle Adaptor - Flush Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

Static Mixers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

Troubleshooting Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

Publication Number: TP00968 - ii - © 2004, IMI Cornelius Inc.

Page 5

PRODUCT DESCRIPTION

Quest Juice Training Manual

OVERVIEW

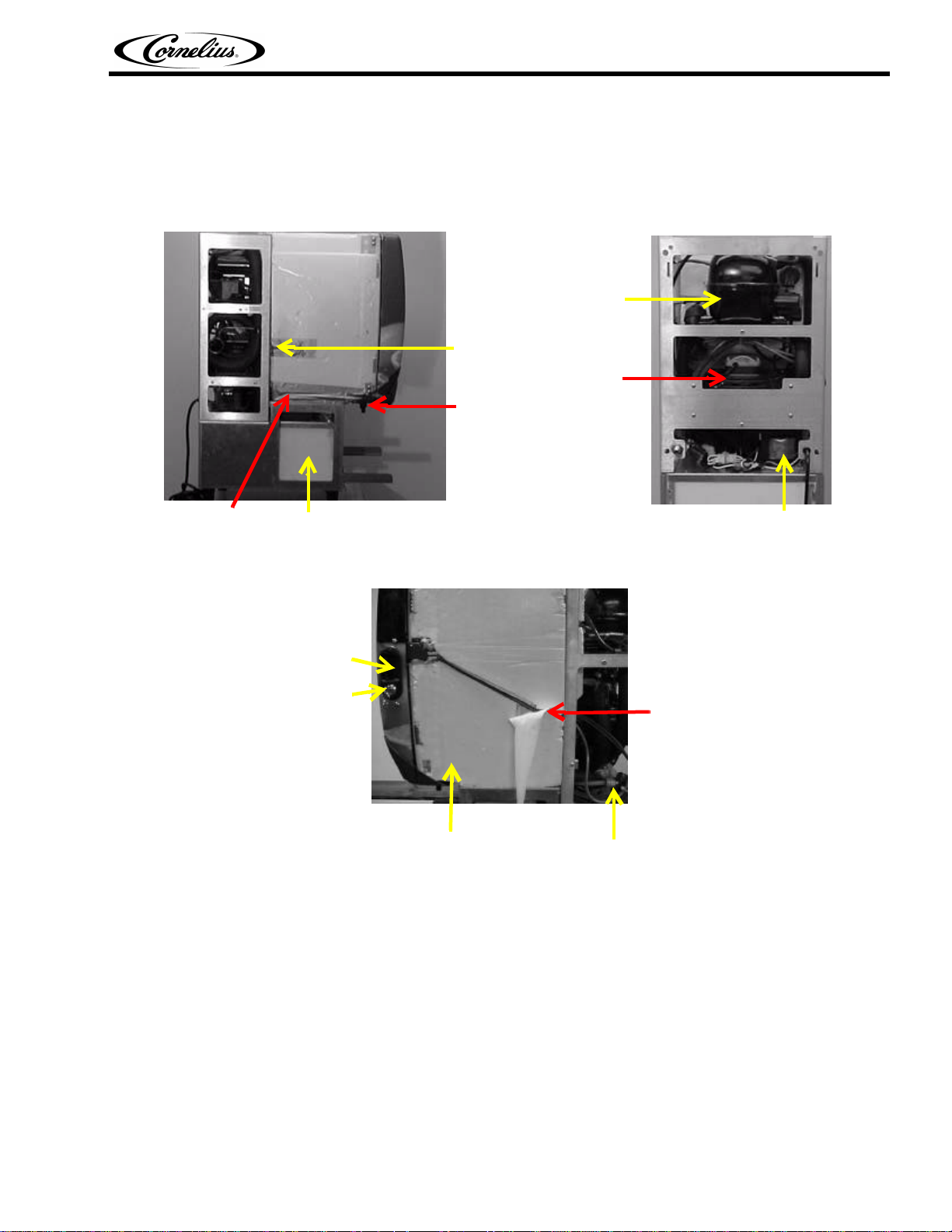

Left Side

Ice bathDoor harness

Door latch

Pump deck

harness

1 and 2

Dispensing

nozzles

Right Side

Rear

Compressor

Condenser

fan motor

and bracket

Transformer

Key lock

Concentrate

cooling cabinet

Water solenoid

and strainer

Pump deck

harness

3 and 4

The Quest Juice Dispenser uses an ice/water bath system to cool both the potable water supply and the

concentrate cabinet.

To achieve cooling capabilities we use an agitator/recalculating pump and motor. This cools the stainless

steel water coils and circulates the cold water through a heat exchanger to cool the cabinet. This gives us

colder drinks for longer periods of time and eliminates the need to have to defrost the cooling cabinet.

A lighted merchandiser is standard.

© 2004, IMI Cornelius Inc. - 1 - Publication Number: TP00968

Page 6

Quest Juice Training Manual

DIMENSIONS & CAPACITIES

Quest

Dispense Rate ........................................1.0 – 2.2 oz./sec.

Electrical rating .......................................115 VAC, 60 Hz, 15 amp dedicated circuit

................................................................220 VAC, 50Hz

Dimensions .............................................29.3” H, 24.3” D

Condenser clearance ..............................4” back, 12” top

Water Connection ...................................3/8” SAE male flare

Water Pressure.......................................80 psi max. static, 20 psi min. dynamic

For best results it should be regulated to 45 to 50 psi

Quest, Two Flavor

Dimensions .............................................10.4” W

Operating weight .....................................120 lbs.

Quest, Four Flavor

Dimensions .............................................15” W

Operating weight .....................................160 lbs.

IPD Times

Quest 4...................................................4.5 hours +

Quest 2...................................................3 hours

Ice Bath Capacity

Quest 4...................................................3.6 gallons; 15-16 lbs of ice IPD

Quest 2...................................................1.8 gallons; 8-9 lbs of ice IPD

Publication Number: TP00968 - 2 - © 2004, IMI Cornelius Inc.

Page 7

WATER

Water Quality

Water quality has an affect on juice dispensing systems.

• odor

• taste

• clarity/foaming

Water filtration is recommended to assure the best beverage taste.

Water Flow

Inlet water pressure should be regulated to 45 to 50 psi max. (3.1 bar) to prevent damage to pump tubing. Minimum flowing pressure must be 20psi.

Flow Rates

Adequate water flow is necessary and must be at least 3.0 ounces per second (89ml) at the inlet to the

unit.

Quest Juice Training Manual

SYSTEM DETAILS

CONCENTRATE

• Concentrate should be stored frozen and put into a cooler 72 hours before use. Rapid cooling, such

as in a sink of hot water, adversely affects flavor and leads to service calls.

• Proper loading of concentrate is important. Improper loading is a major source of service calls.

Left and Right Pump Platforms

• Concentrates vary in viscosity and mixing valves must be adjusted accordingly.

• When changing concentrate, be sure to check the concentrate container O-ring for damage. It should

be clean and wet with concentrate or a food grade lubricant.

• Shake or stir pulp based concentrates.

• When changing flavors, be sure to flush the system and reset the pump.

• Nozzles should be cleaned daily. Remove the nozzles and wash in warm soap solution. Rinse with

clean water, lubricate the O-ring, and replace nozzle.

• Flushing daily and sanitizing weekly is recommended.

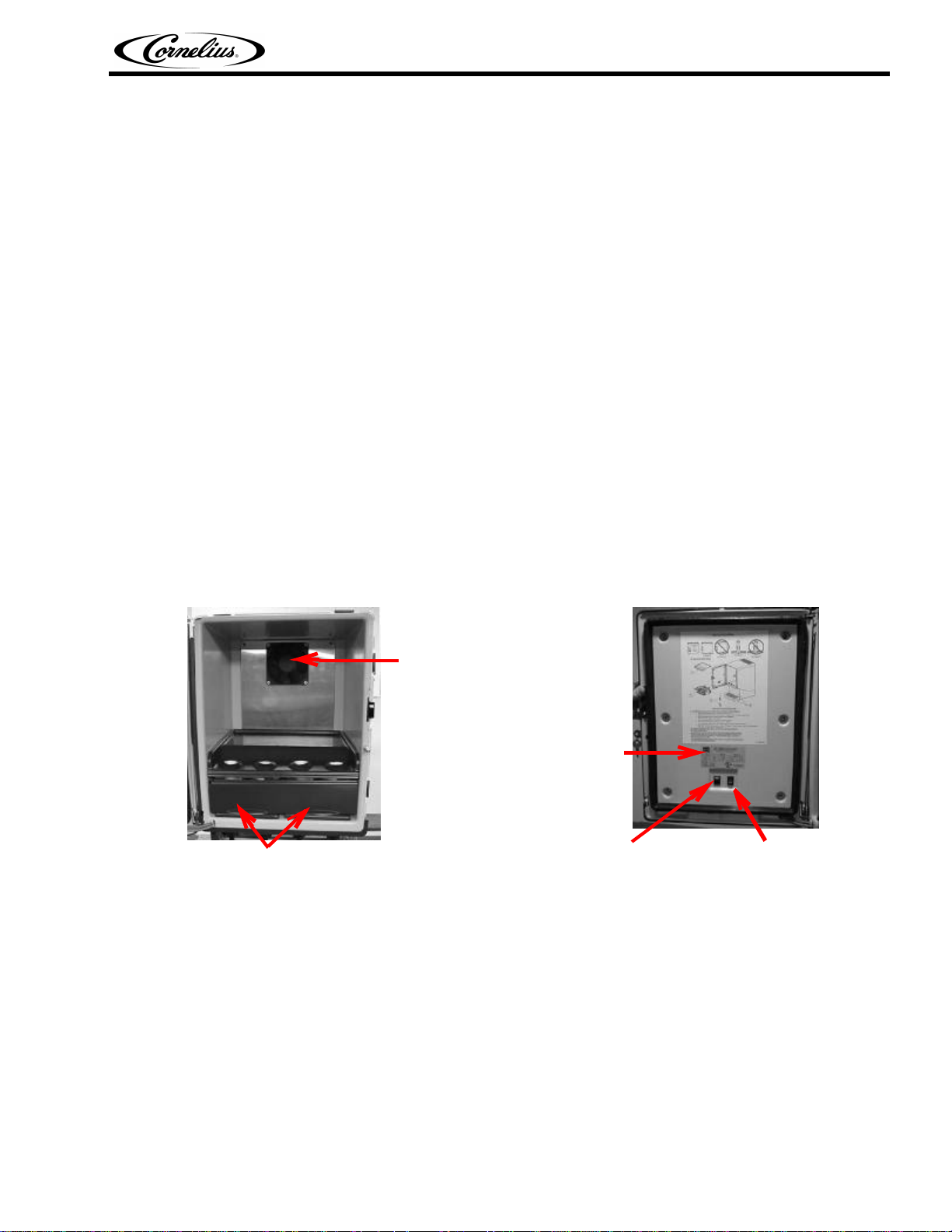

Cabinet

Cooling Fan

Serial Decal

Lighted Merchandiser

ON/OFF

Platform Pump

ON/OFF

SETTING THE BRIX

• A refractometer must be used to measure the post-mix brix.

• Ratio adjustment can be set with a concentrate separator and ratio cup, see Brixing Procedure.

• Ratios are sometimes set by taste but this is not recommended.

© 2004, IMI Cornelius Inc. - 3 - Publication Number: TP00968

Page 8

Quest Juice Training Manual

INTRODUCTION

PREVIEW QUESTIONS

Check your current knowledge by taking a few minutes to answer the following questions:

1.The ice bank control is adjustable?_____ True_____ False

2.The transformer does NOT control the cooling system?_____ True_____ False

3.Condenser airflow passes over the compressor first?_____ True_____ False

4.”Ratio” refers to the amount of water required to dilute one part of concentrate?

_____ True_____ False

5.O-rings may be installed dry (lubrication is not recommended)?

_____ True_____ False

KEY THINGS TO K NOW / DO

• Work Safely! Always unplug/disconnect the power to the dispenser before servicing, and get help lift-

ing the unit if it must be removed from the counter.

• Make certain that the water line has adequate pressure at all times!

• Learn to use a good quality volt-ohm meter. Proper electrical trouble shooting is impossible without it!

• 40-50 PSI dynamic water pressure measured at the dispenser inlet with 3.0 ounces a second. Water

pressure must not exceed 80 lbs static with a minimum flowing pressure of 30 PSI.

• Never leave the Dispense/Flush lever in the Flush position, it can cause the pump tubing to burst.

Publication Number: TP00968 - 4 - © 2004, IMI Cornelius Inc.

Page 9

INSTALLATION

COUNTER LOCATION

The minimum airflow clearance is: 4” (10.16 cm) in back and 12” (30.48 cm) on top and open to the front.

IMPORTANT: Condenser air is drawn in from the bottom of the rear panel and discharged out the top of

the rear panel. Failure to maintain clearance space will reduce capacity of the unit and cause premature

compressor failure.

FILLING THE ICE B ATH

The fill tube is located behind the splash panel. Use the water supply line to fill the ice bath before connecting it to the unit.

Remove the 3/8” cap from the fill tube/sight glass to begin filling the ice bath. Replace the cap when finished filling the ice bath. Lock it in place with its holder.

Full Water

Level

IMPORTANT: Fill the water bath slowly until it runs out

the overflow. Failure to do so can cause back pressure and improper water level. ALWAYS FILL WITH

THE UNIT UNPLUGGED.

Quest Juice Training Manual

Cabinet

drain outlet

Water bath

overflow

Replace the cap TIGHTLY when finished filling the water bath. Lock it in place with its holder.

CONNECTING WATER SUPPLY

The QST series Juice Dispenser is designed to dispense juice at a high flow rate. It is very important that

the incoming water line be dedicated for use by the dispenser only and does not have other machines

connected which could cause a water surge, (i.e., a dishwasher, coffee maker, etc.).

IMPORTANT: The water supply should be consistent with proper water quality standards (neutral pH of

7.0 to 8.0), and should not be connected to a water softener. It is the installers responsibility to ensure

that all water connections to the dispenser are sized, installed, and maintained according to Federal,

State, and Local Laws.

Secure the 3/8” (0.95 cm) swivel nut on the flexible supply tubing to the water inlet

located at the rear of the dispenser. Make sure that the flared gasket is used (tubing and

flared gasket are included with the installation kit).

IMPORTANT: When securing flare nut, use a backup wrench on the male side of the inlet fitting (unit

side) to prevent twisting of the copper tube inside the unit and/or possible damage to the water strainer/

solenoid. A water shut off outside the unit is recommended.

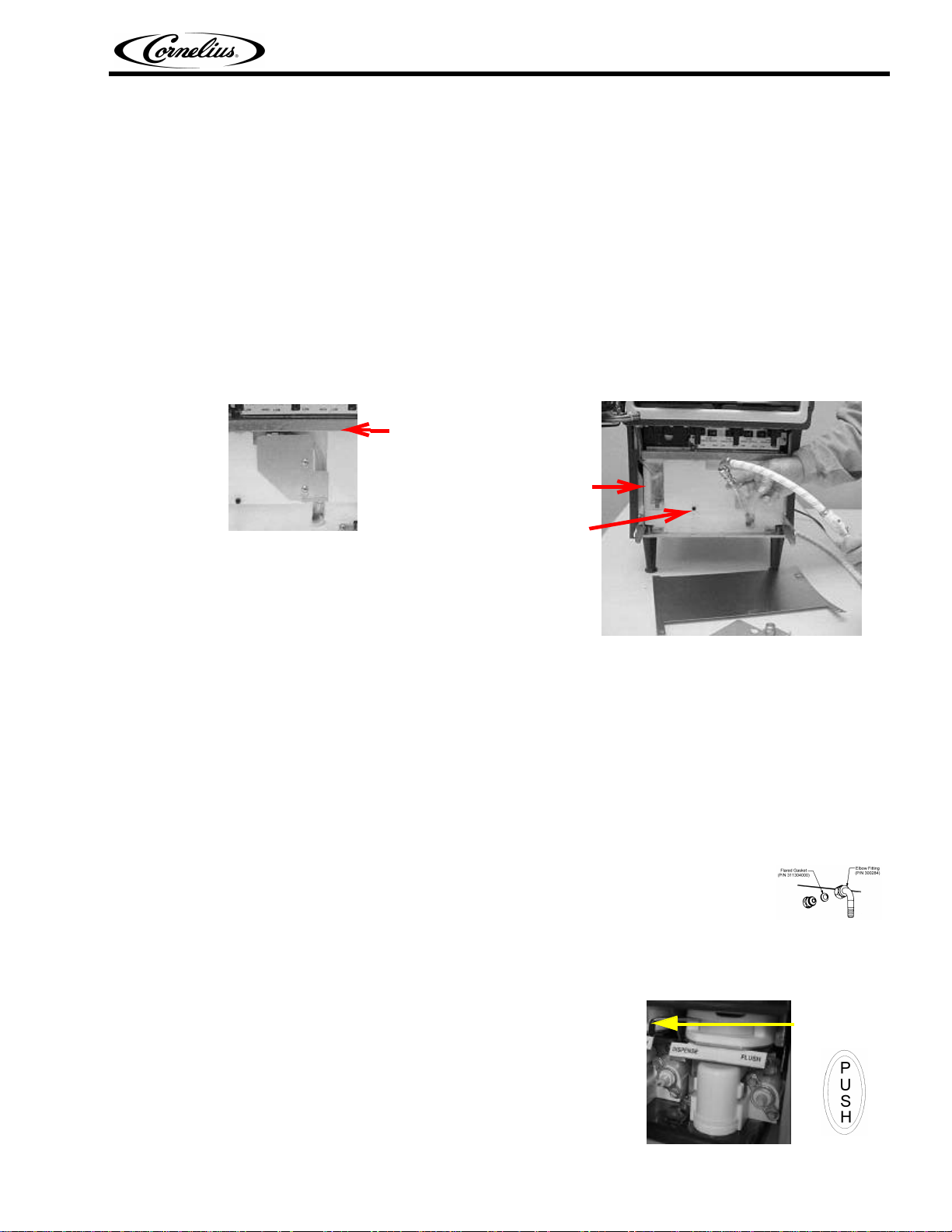

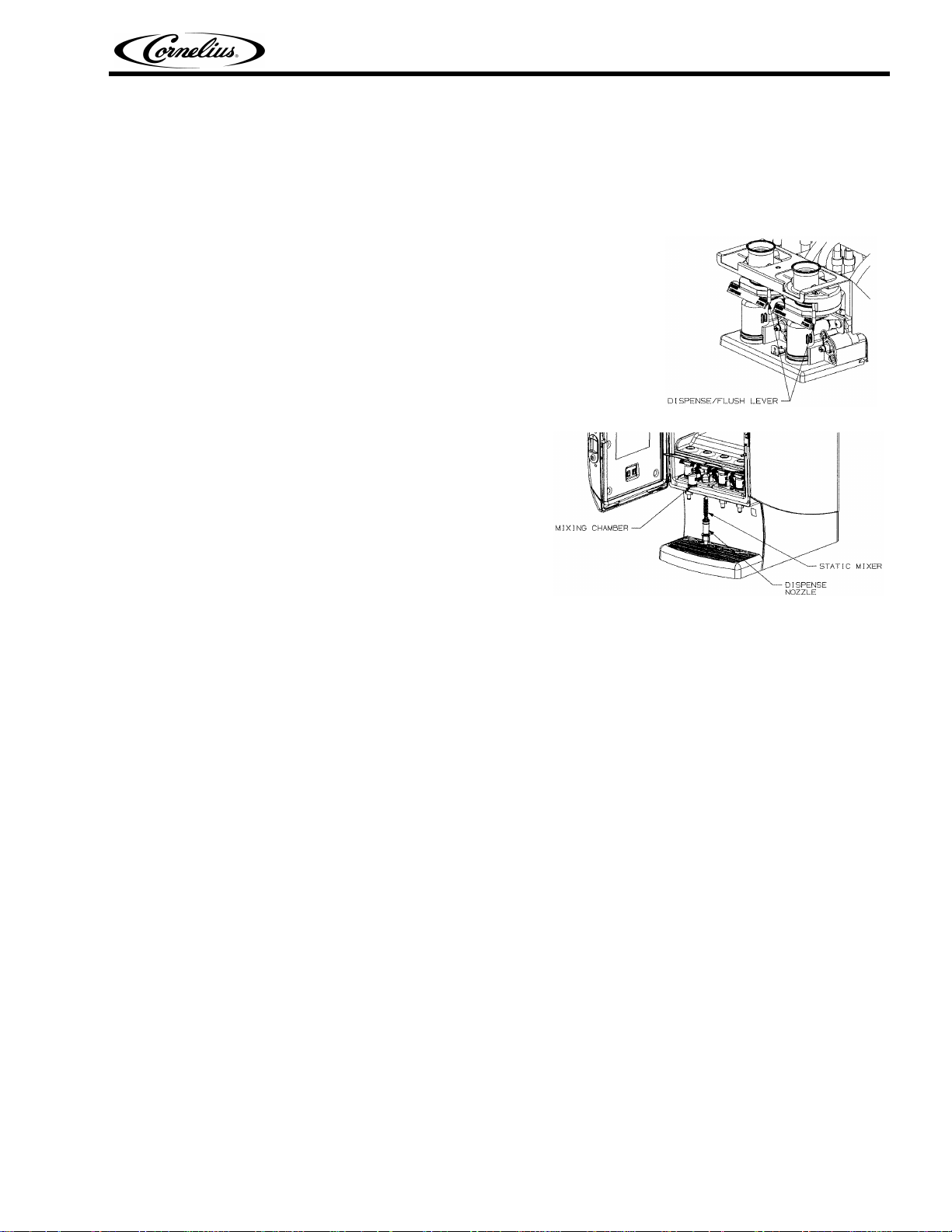

PRIMING/FLUSHING WATER SYSTEM

To properly prime the unit with water and remove air pockets in the

system, open the cabinet door and make sure that all the valve

levers are in the “Dispense” position.

Close the door and press the dispense button for a few seconds.

Repeat until a steady flow of water is observed flowing from all dispense valves.

NOTE: Water splashing may occur during this purge cycle.

Dispense/

Flush Lever

© 2004, IMI Cornelius Inc. - 5 - Publication Number: TP00968

Page 10

Quest Juice Training Manual

CONCENTRATE HANDLING & LOADING

It is recommended that the concentrate be thawed in a refrigerated 35°F-40°F (1.6°C-4.4°C) compart-

ment for a minimum of 48 hours prior to loading into the Quest Juice Dispenser.

WARNING: Concentrate must be completely thawed and within the temperature range of 35°F-

40°F (1.6°C-4.4°C) prior to loading. Failing to supply concentrate inside the recommended tem-

perature range, especially below 35°F (1.6°C), will cause an out of brix drink (refer to the Brixing

Procedure section for details).

LOADING CONCENTRATE

The Quest Juice Dispenser is designed to use either disposable juice concentrate

containers or the optional Cornelius generic refillable container sold separately.

1.Thoroughly shake thawed concentrate prior to use.

2.Place concentrate containers on the dispensing platform shelf inside the refriger-

ated cabinet.

3.Engage the concentrate container by pressing it downward into the bottle adapter

opening on the dispensing platform.

NOTE: Be sure to lubricate the o-ring seal on the container nozzle. This will ensure a good seal

and allow the pumps to draw concentrated from the containers more easily. Failure to create a

good seal at this connection may result in weak drinks and/or seepage of concentrate.

4.Prime each pump by closing the cabinet door and press each dispense button until concentrate flows

from the dispense nozzles.

CHANGING CONCENTRATE CONTAINERS:

1.Open the cabinet door and move the valve handle from “Dispense” to “Flush”

2.Close the door. Depress and hold the dispense button until clear water flows from the dispense noz-

zle.

3.Open the cabinet door and return the handle to “Dispense”.

4.Depress and hold the dispense button for 1-2 seconds. This will relieve water pressure from the con-

centrate pump system.

5.Load concentrate container (see Loading Concentrate ).

Publication Number: TP00968 - 6 - © 2004, IMI Cornelius Inc.

Page 11

NOTE: If concentrate is not properly thawed, it will adversely affect the amount of concentrate

dispensed. Thawed product should be between 35 °F/1.6°C to 40°F/4.4°C.

NOTE: You can not dispense drinks with the door open.

SUPPLIES

• 1-Small 12 oz. cup (354.8 ml)

• 1-Large 21 oz. cup (621.1 ml)

• 1-Straw

• Paper Towel

• 1-Thermometer

• 1-Refractometer

• Concentrate Separator (720601323)

Your will also need a flat blade screwdriver to turn a screw if brix adjustments are required.

Quest Juice Training Manual

BRIXING PROCEDURE

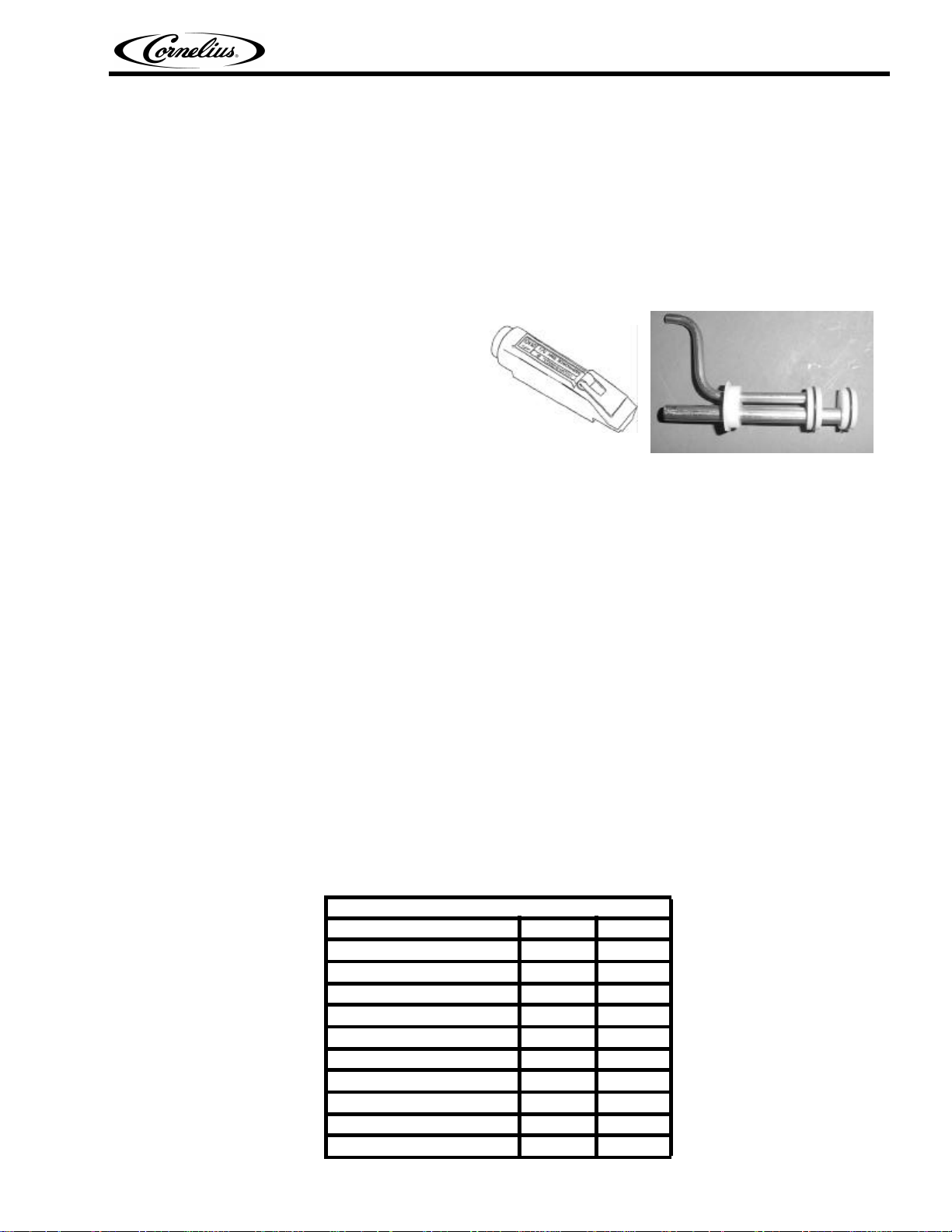

NOTE: The refractometer shown above, P/N 511004000, is available through your local Cornelius

Distributor.

CHECKING/ADJUSTING THE B RIX SETTING

The following instructions are for use with a refractometer.

1.Dispense approximately 8 oz. (236 ml) of drink and discard. Now draw a second 8 oz. drink.

2.Check drink temperature with a reliable thermometer (target is 35-45°F, or 1.6-7.2°C). Discard

this drink after checking temperature.

NOTE: If drink temperature is not within the target range, refer to the basic troubleshooting section. When setting up the unit with warm concentrate and hot water (90 °F) it will take longer to

get the 35-45 °F finished drink.

3.Dispense a 12 oz (354.8 ml) drink sample into a clean, dry cup. Thoroughly stir the sample using a

straw. (Adjustments should be made in 1/8 to 1/4 turn increments).

4.Using a straw, transfer a small sample of finished drink to the refractometer lens (refer to operating

instructions supplied with your refractometer). Check the brix reading against the brix chart below.

NOTE: The following brix chart is generic and intended for reference use only. Contact your frozen concentrate supplier for specific brix readings.

Brix Reference Chart

Flavor Ratio Brix

Orange Juice 4+1 11.8

Grapefruit Juice 5+1 10.6

Cranberry Cocktail 4+1 13.5

Apple Juice 5+1 12.0

Grape 5+1 13.0

Lemonade 5+1 10.5

Tropical Punch 5+1 11.8

Sweetened Iced Tea 7+1 6.0

Pineapple Juice 4+1 12.8

Prune Juice 2+1 16.0

© 2004, IMI Cornelius Inc. - 7 - Publication Number: TP00968

Page 12

Quest Juice Training Manual

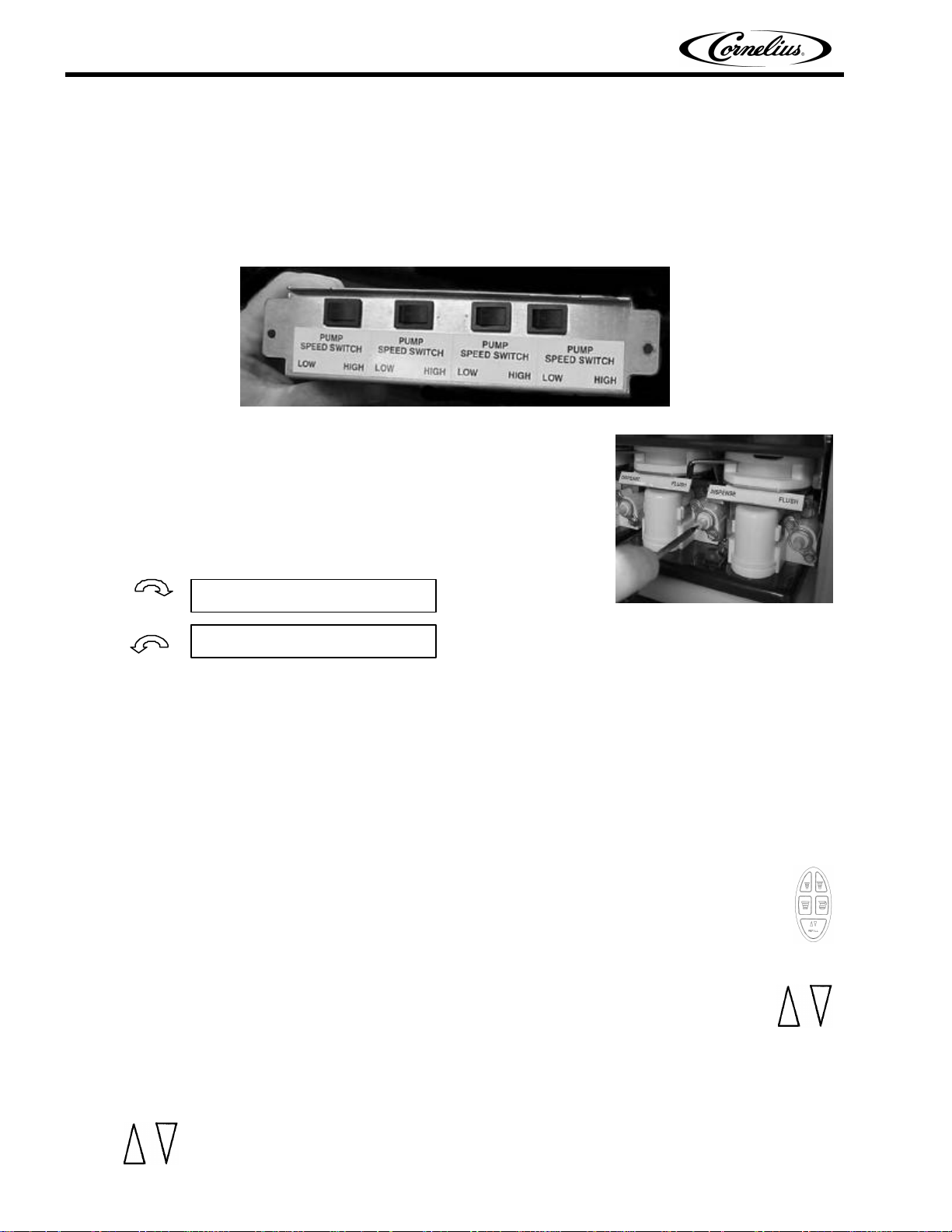

Pump Speed Switch

The pump speed switch has two settings, low and high. For most dispensing situations high speed will be

the preferred speed. Most concentrates use this setting. Low speed is only used when the water pressure is at the low end of the range (25 PSI or less) and the concentrate is a very thin viscosity such as

apple or cranberry. Low speed cuts the output voltage to 18VDC.

Using a water booster system to increase the flowing pressure to the recommended pressure is a

better solution.

5.To change the brix setting, simply readjust the water flow rate.

Located on each of the valve assemblies inside the refrigerated

compartment are the adjusting screws for the water flow rate (one

per valve).

If the brix reading is too high or low, rotate the appropriate water flow

control according to the diagram below. Repeat steps 1-5 until the brix

setting is achieved.

Lowers Brix by increasing water

Raises Brix by reducing water

IMPORTANT: When making changes to the water flow control, do not rotate more than 1/4 turn

per adjustment. Additionally, prior to taking your next brix reading, “tap” the corresponding dispense button several times prior to drawing a sample. This will clear remnant drink from the dispense nozzle AND help move the flow control to its new setting.

PROGRAMMING THE PORTION CONTROL

If your dispenser has optional portion controls, they have been pre-programmed from the factory to pour

7, 12, and 16 ounce drinks. The “extra large” (pitcher icon) size has also been pre-programmed to pour

16 ounces. To change the pour sizes, please follow the instructions below:

1.Simultaneously, press and hold “small” and “extra large” push button switches on the Portion

Control Module until the “Refill” light starts blinking. Release the switches. The blinking Refill

light indicates the programming mode is active.

2.Place the cup under the dispense nozzle and push the selected size button (small, medium,

large, or extra large). Hold the button in until the cup fills to the desired portion, then release

the button. Repeat the above procedure for the remaining sizes.

3.After programming all the drink sizes, press and release the “cancel/pour” switch to return

the Portion Control to the operational mode. The blinking REFILL light will go out.

4.If at a future date it is decided to change the portion size of the drinks, the individual sizes

can be adjusted by the above procedure. It is not necessary to reprogram every size. Additionally the

portion control has full memory retention in case of a power failure.

Cancel/Pour Button

To pour a drink without using a pre-programmed portion control size, simply push and hold the

Cancel/Pour button. Release when the glass is full.

Publication Number: TP00968 - 8 - © 2004, IMI Cornelius Inc.

Page 13

PLANNED MAINTENANCE SCHEDULE

DAILY

Flush System:

1. Move Dispense/Flush levers located on the platform assembly in

the refrigerated cabinet to the “Flush” position. Place an empty

cup on the drip tray below each dispense nozzle.

2. Close the door and depress each dispense button for 2-3 seconds or until clear water flows from each dispense nozzle.

3. Return the Dispense/Flush levers to the “Dispense” position.

4. Press each dispense button for 1-2 seconds to release the water

pressure present in the concentrate pump system.

Clean Splash Zones & Dispense Nozzles:

1. On a daily basis, clean the external cabinet and

splash areas using a clean damp cloth. Remove

and wash the cup rest and drip tray using a mild

dish soap.

2. Remove the dispense nozzles and static mixers

by rotating each 90° and pulling down. Remove

the mixing chambers by pulling straight forward.

Wash using a mild dish soap.

Quest Juice Training Manual

IMPORTANT: DO NOT wash nozzles, static mixers, or mixing chambers in a dish washer. This

will distort the plastic and damage the o-rings. Additionally, do not soak them in sanitizing solution longer than 2 minutes.

WEEKLY

Check concentrate to water brix ratio (refer to the Brixing Procedure in this manual).

Sanitize the Juice Dispenser:

Step 1 - Rinse With Hot Water

1. Prepare two 2 oz. packets of Stera-Sheen Green Label sanitizing solution (or similar brand) by dissolving each packet in 1 gallon (3.8L) of potable water to insure 200 ppm of available chlorine.

IMPORTANT: Use potable water at 80°F-100°F (26.7°C-37.8°C). Water above this range will breakdown the chlorine count and minimize sanitation.

2. Remove the juice concentrate containers and place them in separate refrigerated compartment.

3. “Flush” the system by following the instructions in the Daily Section.

4. Fill a clean empty concentrate container with one quart of extremely hot tap water, approximately

140°F (60°C) and place into unit. Dispense all of the hot water into a large container. Repeat for the

remaining dispense valves.

5. Remove the mixing chambers, nozzles, and static mixers. Rinse in hot water to remove excess pulp

and concentrate.

6. Place the mixing chambers, nozzles, and static mixers in a separate container of sanitizing solution

and agitate vigorously. Allow the parts to soak for two minutes. Rinse thoroughly with fresh tap

water.

7. Reinstall the static mixer, nozzles, and mixing chambers.

© 2004, IMI Cornelius Inc. - 9 - Publication Number: TP00968

Page 14

Quest Juice Training Manual

Step 2 - Sanitize Pump System

1. Fill a clean concentrate container with 2 quarts (1.9L) of fresh sanitizing solution.

2. Place handles in the “dispense” position and close the door.

3. Press and hold the dispense button for 90 seconds then stop. Allow sanitizing solution to remain in

the lines for 5 minutes.

4. After 5 minutes, dispense the remaining sanitizing solution.

Step 3 - Prepare Dispenser for Use

1. Replace sanitizing solution container with a concentrate container and close the door.

2. Press and hold the dispense button until juice appears from the nozzle. Next dispense and discard

at least two 8 oz. (236.6ML) cups of juice in order to prime the system and prepare it for operation.

SEMI-ANNUAL

CAUTION: The following procedures require removal of the dispenser side panel(s). Disconnect

the power cord from the receptacle prior to proceeding.

Clean Water Inlet Strainer:

1. Remove the right side panel from the dispenser.

2. Turn off the water supply to the dispenser.

3. Remove the access port from the “Y” shaped water inlet solenoid

located on the right side of the dispenser.

4. Clean and reinstall the stainless steel water strainer.

Clean Chassis Interior:

1. Clean the condenser cooling fins.

2. Clean the air inlet grilles located on the rear and top panels of the dispenser.

3. Clean the interior base.

4. Wipe the fan blade clean.

5. Reinstall the right side panel, turn on the water supply, and plug the dispenser into the power receptacle.

Check and Top-Off Water Ice Bath:

1. Remove the drip tray and lower splash panel.

2. If the Ice bath level is below the “Full” indicator, top it off with water. Refer to the Filling the Ice Bath

procedure in the Installation section of this manual.

Publication Number: TP00968 - 10 - © 2004, IMI Cornelius Inc.

Page 15

ANNUALLY

Replace Pump Tubing:

A replacement pump tubing kit, part#45098,

is available. The kit consists of one pre-cut

length of pump tubing, two white plastic

hose clamps, and instructions.

Removing Pump Platform(s):

1. Remove the concentrate containers

from the dispenser and place them in a

refrigerator.

2. Remove the cabinet shelf that the concentrate containers sit on.

3. Flush the system prior to removing the

pump platform (refer to the Daily section located at the beginning of the

Planned Maintenance Schedule).

Remove the dispense nozzles and

static mixers.

4. Unplug the water line quick disconnect

by pressing the gray button (see Fig.

1&2).

5. Slide the locking latch forward. Lift the

platform slightly and pull forward to

gain access to the electrical connector

(see Fig.1).

6. Unplug the electrical connector by squeezing the locking tabs on either side and pulling out the connector. Lift and remove the pump platform (see Fig.1).

Quest Juice Training Manual

Replacing Pump Tubing:

1. Remove pump platform (refer to the Removing Pump Platform(s)

procedure located earlier in this section).

2. Remove the two white plastic hose clamps from the pump tube connections (see Fig. 1&2). Remove the concentrate delivery tubes

from the hose ends.

3. Loosen and remove the four screws from the pump body (see fig 3).

4. Remove the rear pump body half only to reveal the pump tube and

rollers.

5. Remove the old pump tube from the pump body. If the roller assembly comes out with the tubing, place it back into the pump housing

being sure to align the roller assembly shaft keyway to the motor

shaft so that the two interlock.

6. Firmly press the new hose into the pump body around the

roller assembly, being sure to keep the protruding ends even

with each other.

7. Once the tubing is in place, hold the tubing with one hand, capture the lower part of the tubing with the outer housing, then

proceed to capture the shaft of the roller assembly and push

the rear pump housing into place. Make sure to capture the

tubing within the body and not pinch it between the halves. Do

not use any tool other than your finger tips to manipulate the

tubing into the housing or you may damage the tube.

Fig.1

Fig. 2

© 2004, IMI Cornelius Inc. - 11 - Publication Number: TP00968

Page 16

Quest Juice Training Manual

8. While holding the pump halves together with your hand, reinsert

the four screws and tighten using a crisscross pattern as shown.

The screws should be tightened about 1/4 turn beyond snug.

9. Insert the two concentrate delivery tubes into the pump tubing

ends and secure them using the new hose clamps supplied in

the kit. Be sure to use pliers to squeeze and tighten the hose

clamps.

Fig. 3

Publication Number: TP00968 - 12 - © 2004, IMI Cornelius Inc.

Page 17

MECHANICAL SECTION

REMOVAL OF MERCHANDISER

Quest Juice Training Manual

1.Remove (6) screws from the top, the front,

and the side of the door (as shown).

NOTE: You now have access to the ballast

and light panel.

NOTE: Remember the door switch is used to

reset the refill light.

NOTE: The pumps can not be operated with

the door in the open position.

1 2

3

4

5

6

Ballast Assembly

NOTE: Trying to bypass the door switch during the Brixing/Ratio procedure will result in

longer pull down times and improper settings.

© 2004, IMI Cornelius Inc. - 13 - Publication Number: TP00968

Page 18

Quest Juice Training Manual

REMOVAL OF THE SWITCH PANEL

1.Remove (2) screws from behind the right and

left flavor tabs and the (2) screws from the

front underside of the switch panel assembly.

NOTE: The switch harness is marked 1-4 and

the connectors are indexed.

2

3

1

4

2.Remove (3) screws to replace a dispensing

switch, if necessary.

NOTE: If a change of dispensing venue is

required (push to portion) Cornelius makes

available a complete lower door assembly to

expedite this change.

Publication Number: TP00968 - 14 - © 2004, IMI Cornelius Inc.

Page 19

REMOVAL OF THE PUMP PLATFORMS

1.Remove the cabinet shelf by lifting it up and pulling it

forward.

2.Pull the front flap out and up.

Quest Juice Training Manual

3.Remove the dispensing nozzles by turning them 1/4

turn clockwise and pulling down.

4.Pull the locking latch forward and lift the platform up

and pull it forward slightly.

© 2004, IMI Cornelius Inc. - 15 - Publication Number: TP00968

Page 20

Quest Juice Training Manual

5.Press the release button on the water connector to

release the platform.

6.Disconnect the platform electrical connector by

squeezing the release tabs on either side of the connector and pulling straight back. The platform can

now be removed from the cabinet.

Publication Number: TP00968 - 16 - © 2004, IMI Cornelius Inc.

Page 21

REMOVAL OF THE COOLING FAN

1.Remove (4) screws from the cabinet rear panel.

2.Turn the panel so the fan is facing you. To do this you will have to pull the wire leads gently through the

back of the cabinet.

3.Disconnect the wire leads and remove the

ground wire (as shown).

4.Remove (4) screws from the fan mounting

bracket.

NOTE: When installing a new fan always

make sure the label is facing the front of the

cabinet.

Quest Juice Training Manual

When reinstalling the panel it will be necessary

to pull back through the wire lead connected to

the fan.

Fan Label

© 2004, IMI Cornelius Inc. - 17 - Publication Number: TP00968

Page 22

Quest Juice Training Manual

REMOVAL OF PANELS

1.Loosen the 2 screws from the top panel.

2.Open the front door.

3.Lift the rear of the top panel and slide forward

and remove.

4.Slide the drip tray forward and remove.

5.Remove the 2 screws on the front panel and

remove the front panel.

6.Slide the panel up and pull out to remove. On

the 2 flavor unit it will be necessary to remove

2 screws from the back panel.

Publication Number: TP00968 - 18 - © 2004, IMI Cornelius Inc.

Page 23

7.Remove the side panels.

A. Right Panel: The 2 screws and switch backing plate must be removed before the right panel can

be removed.

B. Left Panel: The door must be open while removing the left panel.

Once the screws are removed, pull the panel clear off the frame and tip forward. Slide panel forward and

up until it clears the mounting tab (insert). Move the panel down and back. Once it is clear of the door the

panel will release.

REMOVAL OF ELECTRICAL BOX

Quest Juice Training Manual

1.Remove the nozzles.

2.Remove the screw on the right side of the

electrical box.

3.Pull the electrical box forward and straight

out.

© 2004, IMI Cornelius Inc. - 19 - Publication Number: TP00968

Page 24

Quest Juice Training Manual

REMOVAL OF THE VRB BOARDS

1.Remove the cover.

2.Remove the connectors.

3.Loosen and remove the nut and insulation.

4.Turn the box over and locate the standoffs on

the VRB board to be removed. Gently

squeeze with a needle nose pliers. This will

release the standoff and allow it to be pushed

back through the hole in the bracket.

5.The VRB board can now be removed from the

electrical box itself.

6.The standoffs (4) can be removed by gently

squeezing the tip with needle nose pliers and

at the same time pushing through the board.

NOTE: The nut and insulation must be

assembled as illustrated. Failure to assemble

and tighten correctly can result in component

overheating causing the concentrate pump

not to run.

Lock washer

Washer

Insulator pad

Insulator washer

Publication Number: TP00968 - 20 - © 2004, IMI Cornelius Inc.

Page 25

REMOVAL OF THE ICE BANK CONTROL

1.Slide the ice control toward the center of the

deck to release and lift up while gently pulling

forward. The box will come forward only as far

as the cables will allow.

NOTE:The electrical box and nozzles must be

removed to remove the ice bank control.

2.The connectors are very tight. To successfully remove use a crescent wrench to grip the outside of the

connector rocking gently up and down while pulling up to release. The best way to work from right to

left.

Quest Juice Training Manual

REMOVAL OF NOZZLE GUIDE GASKET

1.The nozzle guide gaskets can be removed for

cleaning or replacement by pulling them up

and over the nozzle guides.

© 2004, IMI Cornelius Inc. - 21 - Publication Number: TP00968

Page 26

Quest Juice Training Manual

REMOVAL OF THE COOLING CABINET

1.Remove (4) 7/16” nuts from the under side of

the cabinet frame. Current productions uses

(2) nuts only.

2.Cut the wire tie from the wire bundle in the

rear of the unit, just above the condenser.

3.Disconnect the cooling cabinet wire harness.

4.Remove the insulation from around the inlet

and outlet fittings of the heat exchange.

Remove the locking clips from the inlet and

outlet fittings.

5.Insert the screwdriver blade against the locking ring and pull down on the hose.

Publication Number: TP00968 - 22 - © 2004, IMI Cornelius Inc.

Page 27

6.Remove the inlet water line from the cabinet

manifold.

Quest Juice Training Manual

7.Remove (4) screws that secure the cooling to

the frame.

NOTE: For best results use a screw driver

that has at least an 8” blade.

8.After you lift the cabinet off the frame you can

service the agitator motor.

2

1

3

4

© 2004, IMI Cornelius Inc. - 23 - Publication Number: TP00968

Page 28

Quest Juice Training Manual

REMOVAL OF THE AGITATOR MOTOR

1.Remove the thumbscrew located at the rear

of the motor before removing the agitator

motor.

2.Lift the motor out of the ice bath. Disconnect

the wire lead from the ice bank control.

Note: You will have to feed the water tubes through

the refrigeration frame to completely remove.

REMOVAL OF THE REFRIGERATION CHASSIS

1.With the cabinet removed, remove (2) screws

from the lower front and (2) screws from the

lower rear of the water bath housing.

2.Unsnap the wire harnesses (red and white)

connectors from the bracket mounted to the

water bath cover.

1

1

2

3

4

Publication Number: TP00968 - 24 - © 2004, IMI Cornelius Inc.

Page 29

3.Disconnect the following connectors and

leads:

• Remove the top ground wire from the

post.

• Red/White - from transformer #1

Quest Juice Training Manual

• Blue - from transformer #2

• Lead from inlet solenoid #3.

4.Slide the refrigeration chassis out from the

frame.

Ground Wire/Post

Blue

Red/White

Lead

5.Remove (4) screws from the base of the

refrigeration chassis and lift off of the water

bath.

1

2

3

4

© 2004, IMI Cornelius Inc. - 25 - Publication Number: TP00968

Page 30

Quest Juice Training Manual

BE SURE TO REMEMBER THE WIRE

REMOVAL OF THE ICE CONTROL PROBE

1.Carefully turn the chassis over to gain access

to the probe assembly.

Cut the wire tie holding the probe assembly

only. Push up and slide the probe assembly

off the bracket. DO NOT REMOVE THE

BRACKET.

2.The connector must be disassembled to pass

the wire leads through the water bath cover.

3.Carefully remove the grommet from the water

bath cover.

4.With the wire loose, pass the connectors first

through the grommet and the water bath

cover itself.

ORDER WHEN RE-ASSEMBLING

Current version

GRAY wire

cover

Yellow

Orange

Early version

BLACK wire

cover

Blue

Brown

Publication Number: TP00968 - 26 - © 2004, IMI Cornelius Inc.

Purple

Green/Yellow

Page 31

MAJOR COMPONENT REVIEW

ELECTRICAL BOX

The electrical box houses the Voltage Regulator Boards (VRB) that is used to convert AC voltage from

the transformer to DC voltage that powers the pumping system. It also incorporates the sold out logic.

Each flavor has its own VRB.

WHITE CONNECTOR - INPUT CABLE

Transformer- 26VAC

Sold out from platform push button

Quest Juice Training Manual

RED CONNECTOR - OUTPUT CABLE

Pump motors

Platform solenoid

Water inlet solenoid

6.25 Slo Blo Fuse

BOARD OUTPUT

Platform solenoid and pump motor

Rear water inlet solenoid

(4 -pin connector)

BOARD INPUT

26VAC from Transformer

(2- pin connector)

Sold-out from platform

(2-pin connector)

Touch pad –SWITCH

Refill light

(2-pin connector)

28 VDC

Pump

3

Pump

VRB

Board

Pump

4

Pump

1 2 3 4

2

Pump

1

Speed Switch (4)

Second transistor for slow -speed

operation only. No heat sink required

SPEED SWITCH

(2 -pin connector)

SOLD–OUT

FUNCTION-JUMPER

(3-pin connector)

J5 PIN

Enabled dispense light only

LK PIN

Disabled dispense pump head

stops when light is on.

© 2004, IMI Cornelius Inc. - 27 - Publication Number: TP00968

Page 32

Quest Juice Training Manual

PUMP SPEED SWITCH

The pump speed switch has two settings, low and high. For most dispensing situations high speed will be

the preferred speed. Most concentrates use this setting. Low speed is only used when the water pressure is at the low end of the range (25 PSI or less) and the concentrate is a very thin viscosity such as

apple or cranberry. Low speed cuts the output voltage to 18VDC.

Using a water booster system to increase the flowing pressure to the recommended pressure is a

better solution.

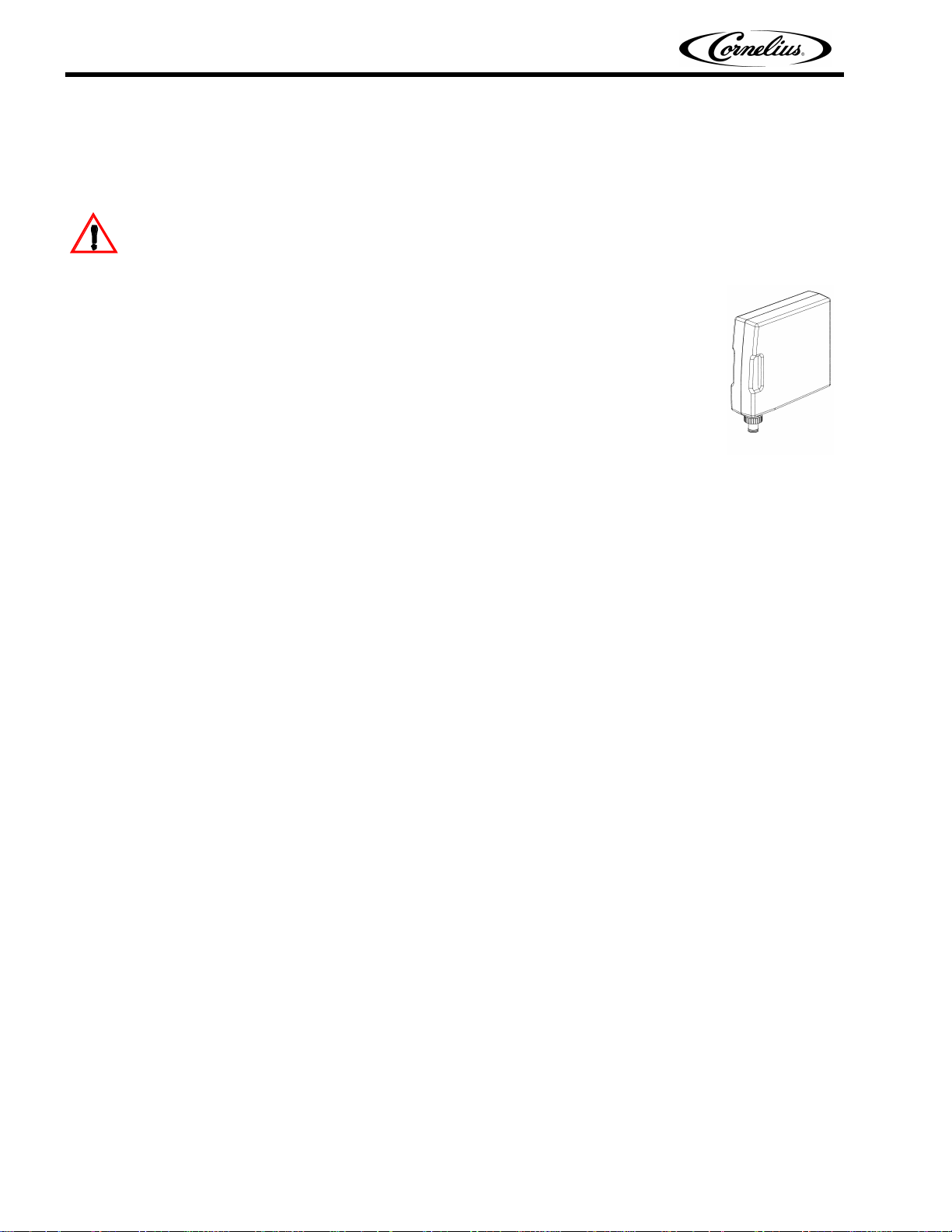

ICE BANK CONTROL

The ice bank control is the only devise used to

control the refrigeration system for both the

cabinet and the water chiller.

Operational Overview

There is no adjustment of any kind to this control. The control will not activate without having

sufficient water in the water bath tank.

(See chapter on installation -water bath filling)

THERE IS A 3 -MINUTE DELAY BUILT INTO EACH CONTROL AS A SAFTEY PRECAUTION.

The default mode is an open circuit. Any break in the continuity i.e. broken wire, and the system reads it

as a no water condition.

Control is powered by line voltage. All connectors are label and keyed for proper installation.

Validating Operation

With box detached from the unit, remove the

ice bank probe connector by gently rocking the

wrench up and down to loosen and pull off to

remove.

As the probe is very low voltage, insert a standard set of pliers into the connector gripping

the middle terminal and allowing the Pliers’

jaws to come in contact with the outside 2.

Wait the 3 minutes and the compressor and

condenser fan should cycle on. Run for 1

minute and remove the pliers.

The compressor will shutdown in 45-60 seconds. If it does not then a sticking relay is a possibility and the

control should be replaced.

Publication Number: TP00968 - 28 - © 2004, IMI Cornelius Inc.

Page 33

TRANSFORMER

This is a dual stage transformer with 2 outputs.

The purpose of the transformer is to step the

line voltage to 26 VAC primary to the electrical

box and the VRB and 24 VAC secondary is to

light the merchandiser.

Current production transformers are equipped

with a thermal overload protection device that

will cut out when high temperature or high

amperage is detected. THE OVERLOAD

RESETS AUTOMATICALLY

WATER INLET SOLENOID

The water inlet solenoid is connected to the

incoming water line and is only activated when

the dispense button is pressed. The water inlet

solenoid prevents backflow and is equipped

with a strainer screen that needs to be

removed and cleaned once a year.

Quest Juice Training Manual

Primary wires are Blue

Secondary are Red

NOTE: THE INLET SOLENOID COIL IS

ACTIVED FROM THE VRB BOARD USING

THE 28VDC.OUTPUT AN AC COIL WILL

NOT WORK IN THIS APPLICATION.

DOOR SWITCH - 72 B SERIAL NUMBER

The door switch on the 72B serial number units

is a combination of a door latch and switch. The

primary function of the door switch is to interrupt the 26 VAC coming into the VRB board

when refilling the concentrate. By cutting this

voltage the refill lights are reset automatically.

NOTE: WHEN THE DOOR IS OPEN THE DISPENSE CIRCUIT IS INOPERABLE DO NOT

ATTEMPT TO DEFEAT THIS WITH ANYTHING. BUT THE CAM-LOCK FOUND ON

THE DOOR. A SPECIAL TOOL IS AVAILABLE FOR THIS PURPOSE.

Switch #720202009

Cam Lock

# 720201439

© 2004, IMI Cornelius Inc. - 29 - Publication Number: TP00968

Page 34

Quest Juice Training Manual

DOOR SWITCH - 72 E SERIAL NUMBER

On or before April 1, 2004 the door switch configuration will be changed to separate the reset

switch from the catch. The serial number for

this will have a prefix of 72 D for Quest 4 flavor

and 72C for Quest 2 flavor.

Kit #720911146 is available to convert field

units to this configuration. The sold-out feature

however will be inoperable with the use of this

kit.

PLATFORM COMPONENTS

Water Valve/Flow Control

The flow control is a ceramic spool and sleeve.

It must move freely to regulate the water flow

and maintain brix.

Be sure the o-ring is in place and sealing properly.

Reset Switch in Top of Door

New Door Latch

Configuration

Bottle Adaptor - O-rings

When doing any assembly work on the bottle

adaptor be sure to use a small amount of lubricant on each o ring This should be a food

approved non petroleum based grease.

Sleeve

Spool

Spring

Adjustment Screw

Publication Number: TP00968 - 30 - © 2004, IMI Cornelius Inc.

Page 35

Tip:

When re-assembling the large o-ring may be

pinched if not installed properly. Place the slide

valve into the bottom of the adaptor keeping

straight across. Press evenly to seat the o-ring.

It is not advisable to rotate the valve back and

forth in and attempt to seat the o-ring. Do the

same when installing the top.

When securing the screws do it in the X pattern

tightening the opposites across from each

other. Be sure the are fully tighten to prevent

leaking.

Quest Juice Training Manual

Bottle Adaptor - Sold Out Sensors

The sold-out sensors are located in the bottle

adaptor neck.

The do not get cleaned during normal flushing

procedures. They are cleaned only during sanitizing.

Be sure there is no build up of pulp or concentrate on the pins themselves. The results will be

an erratic operation of the refill lights.

Bottle Adaptor - Tray Grommets

When installing the grommets be sure that

each one is sealed below the lead in taper on

the top of the bottle adaptor.

1

4

Sold Out Contacts

3

2

TIP: Press the entire tray down evenly to seat

Run finger around the edge to seal.

© 2004, IMI Cornelius Inc. - 31 - Publication Number: TP00968

Page 36

Quest Juice Training Manual

Bottle Adaptor - Flush Mode

THE FLUSH MODE IS FOR FLUSHING THE

PUMP SYSTEM OF CONCENTRATE ONLY.

Dispensing water in the flush mode over

long periods can cause the pump tubing to

split at the inlet of the pump.

Static Mixers

The Quest dispenser has static mixer option.

The DN MIXER (part number 720703202) is

used for high viscosity concentrates. It helps

promote proper mixing. The cone top mixer is

the standard. Both are interchangeable with

each other.

All feet must be attached for proper operation.

If all or any are missing the mixer should be

replaced.

Standard

DN Mixer

Publication Number: TP00968 - 32 - © 2004, IMI Cornelius Inc.

Page 37

WIRING DIAGRAM

Quest Juice Training Manual

© 2004, IMI Cornelius Inc. - 33 - Publication Number: TP00968

Page 38

Quest Juice Training Manual

Publication Number: TP00968 - 34 - © 2004, IMI Cornelius Inc.

Page 39

Quest Juice Training Manual

TROUBLESHOOTING GUIDE

The following pages contain troubleshooting information intended to aid an experienced service person

in diagnosing operational problems that may occur. For further assistance, contact the IMI Cornelius

Technical Services department at 1-888-248-5568 (630-539-6850 outside the United States) between

the hours of 7:30A.M. and 5:00P.M. Central Standard Time. You must have the model and serial number

(Located on the right side of the dispenser) prior to calling.

PROBLEM PROBABLE CAUSE REMEDY

Totally Inoperative • No power to dispenser due to

No cooling • Line voltage is not within +/-

No water dispensed,

concentrate only

tripped circuit breaker

• Loose or broken power supply

connection inside dispenser.

10% of nameplate specifications

causing compressor overload to

trip

• No water in water ice bath or

water level extremely low exposing

the ice bank sensing probe

• Defective Ice Bank Control or

sensing probe

• Cabinet fan is inoperative resulting in warm concentrate (water

continues to cool)

• Compressor short cycles on

overload

• Compressor starts but hums

and trips overload

• Defective compressor overload

or start capacitor

• Compressor starts but does not

switch off of start winding

• Refrigerant leak • Repair leak, evacuate and

• No water to dispenser • Restore Water

• Water supply line inside refrigerated cabinet disconnected from

pump platform

• Water solenoid located on pump

platform clogged or defective

• Main water solenoid/strainer

located at the rear of dispenser is

clogged, binding or defective

• Water supply pressure is

greater than 80 psi (5.5 bar) forcing the brix flow control closed

• Reset circuit breaker. Confirm that

breaker is correct size and no other

equipment is operating on the same

circuit. Also confirm that supply voltage is +/- 10% of nameplate specifications.

• Repair connection.

• Contact an electrician

• Fill ice bath to proper water level

• Replace

• Replace

• Excessively high discharge pressure due to restricted condenser or

inoperative condenser fan motor

• Seized or shorted compressor,

replace

• Test and replace

• Relay or compressor is defective.

Test and replace faulty item

recharge system

• Reconnect

• Disassemble and clean solenoid.

Replace if necessary.

• Remove and clean strainer. Confirm 28VDC is present at solenoid

during dispense. Confirm solenoid

coil is not open. Disassemble and

clean solenoid.

• Add external regulator and lower

pressure to 50 psi (3.5 bar)

© 2004, IMI Cornelius Inc. - 35 - Publication Number: TP00968

Page 40

Quest Juice Training Manual

PROBLEM PROBABLE CAUSE REMEDY

• Freeze-up of water coil in ice

bath

• • Refrigeration system may be low

No water and no concentrate, refrigeration

is working

• Black service switch located on

the rear of the cabinet door in OFF

position

• White door switch open • Door switch must be closed in

• 6.25 amp fuse inside front electrical box blown

• No output from Transformer • Confirm transformer output by of

• Defective voltage regulator

board (VRB) located inside front

electrical box

• Defective dispense push button

or portion control board

No concentrate dispensed, water only

• Concentrate container not fully

engaged into receptacle on pump

platform

• Dispense/Flush lever in FLUSH

position

• Concentrate too cold, not properly

thawed

• Defective pump motor • Replace pump motor

Warm Drink • Ambient air around dispenser is

too warm

• Excessive demand on dispenser • Add water pre-cooler or second dis-

• Dirty condenser coil • Clean condenser coil

• Inoperative condenser fan • Replace condenser fan motor

• Defective Ice Bank Control • Test and replace if necessary

• Loss of refrigerant charge due to

leak in system

Water continuously

drips from nozzle

when in OFF mode

Concentrate warm,

• Main water solenoid at base of

unit or water solenoid on pump

platform not shutting off tightly

• Cabinet fan inoperable • Check/replace fan

water cold

• Agitator motor/pump inoperable

or restricted

• Loss of refrigerant charge due to

leak in system

• Unplug dispenser and allow 2-4

hours to thaw. Check operation of

agitator motor and ice bank control.

on charge resulting in a deformed ice

bank and freeze-up of the water coil

in the ice bath.

• Turn on switch

order to dispense. Check switch

operation and replace if necessary.

• Replace with 6.25, 250VAC slow

blow fuse and test

26VAC +/- 2. Replace transformer if

necessary.

• Measure across the VDC output of

the board. There should be 28VDC

present when the dispense button is

pressed. Replaced VRB if necessary.

• Test and replace if necessary

• Refer to Concentrate Loading section of this manual

• Move lever to DISPENSE position

• Concentrate should be 35-40°F

(1.7-4.5°C) prior to loading

• Relocate dispenser

penser

• Repair leak and recharge system

• Clean solenoid(s), replace parts as

necessary (refer to the Planned

Maintenance Section)

• Check/replace agitator motor

• Repair leak and recharge system

Publication Number: TP00968 - 36 - © 2004, IMI Cornelius Inc.

Page 41

Quest Juice Training Manual

PROBLEM PROBABLE CAUSE REMEDY

Brix Problem • Water supply pressure too low,

less than 20 psi (1.4 bar) flowing

water pressure fluctuates sharply

• Water flow control binding or

spring is defective

• Improperly thawed concentrate.

Brix changes as the concentrate

• Correct water supply problem to

ensure a constant 50 psi (3.5 bar)

flowing to the dispenser

• Clean and/or replace parts as necessary

• Concentrate should be 35-40°F

(1.7-4.5°C) prior to loading

temperature changes (concentrate becomes thinner as temperature rises)

Pump Inoperative • Pump motor defective • 28VDC should be present at pump

motor during dispense. If voltage is

present and motor does not start,

replace pump motor

• No power to transformer or no

28VAC output from transformer

• Confirm transformer has line voltage

present on primary side. If no

28VAC output from the secondary

replace transformer

• Defective voltage regulator board

(VRB) located inside front electrical box

• Confirm board produces 28VDC

present when the dispense button is

pressed (refer to the Electrical Box

Wiring Diagram for VDC output location). Replace VRB if necessary

• Defective dispense control board

• Test and replace if necessary

(Push button or portion control)

Machine continues to

dispense after dispense button is

released or dispenses without operator input

• Push button or portion control pad

stuck in on position

• Relay on voltage regulator board

(VRB) stuck on.

• Disconnect the wire harness from

the rear of the portion control and

close the door. If unit does not dispense on its own the dispense control board is bad (stuck on)

• Disconnect the 4-wire harness from

the lower right corner of the VRB. If

the unit continues to dispense on its

own the VRB is defective (relay

stuck on)

© 2004, IMI Cornelius Inc. - 37 - Publication Number: TP00968

Page 42

Quest Juice Training Manual

NOTES

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

_______________________________________________________________________

Publication Number: TP00968 - 38 - © 2004, IMI Cornelius Inc.

Page 43

www.cornelius.com

Loading...

Loading...