Page 1

MODULAR FLAKED ICE MAKER

MODELS: SERIES 750 (R404a),

Service Manual

SERIES 1100 (R22),

SERIES 2400 (R404a)

Part No. 166240009

OCTOBER 1994

Revised October, 1996

THIS DOCUMENT CONTAINS IMPORTANT INFORMATION

This Manual must be read and understood before installing or operating this equipment

IMI CORNELIUS INC; 10/94 - 10/95

PRINTED IN U.S.A

Page 2

TABLE OF CONTENTS

INTRODUCTION 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SPECIFICATIONS 750 AND 1100 SERIES 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SPECIFICATIONS 2400 SERIES 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

INSTALLATION INSTRUCTIONS 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

REMOTE CONDENSER 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

STACKING INSTRUCTIONS FOR STACKING KIT 29757 8. . . . . . . . . . . . . . . . . . .

TYPICAL WATER CIRCUIT 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TYPICAL REFRIGERANT CIRCUIT 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ELECTRICAL CIRCUIT 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CIRCUIT DESCRIPTION 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

COMPONENT DESCRIPTION 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

BIN THERMOSTAT 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

GEARMOTOR START RELAY 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

POWER RELAY / CONTACTOR 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

GEARMOTOR DELAY THERMOSTAT 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ON–OFF SWITCH / CIRCUIT BREAKER 11. . . . . . . . . . . . . . . . . . . . . . . . . . . .

FAN CYCLING SWITCH (R404A UNITS) 11. . . . . . . . . . . . . . . . . . . . . . . . . . . .

HIGH PRESSURE CONTROL 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

COMPRESSOR START RELAY 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

POTENTIAL RELAYS 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CAPACITORS – GENERAL 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

MAINTENANCE 20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page

SANITIZING AND CLEANING PROCEDURE 21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

WATER TREATMENT 22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

WINTER STORAGE 22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CLEANING THE CONDENSER (AIR COOLED) 22. . . . . . . . . . . . . . . . . . . . . . . . . . .

TROUBLESHOOTING 23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

UNIT WILL NOT RUN 23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

COMPRESSOR CYCLES INTERMITTENTLY. 23. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

MAKING WET ICE. 24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

UNIT RUNS BUT MAKES NO ICE. 24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

WATER LEAKS. 24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

WATER LEAKS. (CONT’D) 24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

EXCESSIVE NOISE OR CHATTERING. 24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

MACHINE RUNS WITH FULL BIN OF ICE. 24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

UNIT OFF OR TRIPS CIRCUIT BREAKER. 25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

UNIT GOES OFF OR TRIPS CIRCUIT BREAKER. (CONT’D) 26. . . . . . . . . . . . . . .

PARTS LIST FOR 750 AND 1100 SERIES 27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PARTS LIST 2400 SERIES 30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

WARRANTY 32. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

i

166240009

Page 3

TABLE OF CONTENTS (cont’d)

LIST OF FIGURES

FIGURE 1. 750 AND 1100 SERIES SPECIFICATIONS 2. . . . . . . . . . . . . . . . . . . . .

FIGURE 2. SPECIFICATIONS FOR 2400 SERIES 4. . . . . . . . . . . . . . . . . . . . . . . . .

FIGURE 3. WATER LEVEL 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FIGURE 4. TYPICAL WATER CIRCUIT 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FIGURE 5. TYPICAL REFRIGERANT CIRCUIT 10. . . . . . . . . . . . . . . . . . . . . . . . . . .

FIGURE 6. WIRING DIAGRAM AF/WF–750–MH-R 13. . . . . . . . . . . . . . . . . . . . . . . .

FIGURE 7. WIRING DIAGRAM AF–750–PMH-50R 14. . . . . . . . . . . . . . . . . . . . . . . . .

FIGURE 8. WIRING DIAGRAM AF/WF–1100–MH 15. . . . . . . . . . . . . . . . . . . . . . . . . .

FIGURE 9. WIRING DIAGRAM RF–1100–MH 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FIGURE 10. WIRING DIAGRAM AF/WF–1100–MH–317. . . . . . . . . . . . . . . . . . . . . .

FIGURE 11. WIRING DIAGRAM AF/WF–1100–MH–50 18. . . . . . . . . . . . . . . . . . . . .

FIGURE 12. WIRING DIAGRAM 2400 SERIES 19. . . . . . . . . . . . . . . . . . . . . . . . . . . .

FIGURE 13. ILLUSTRATED PARTS BREAKDOWN SERIES 750 – 1100 28. . . . . .

FIGURE 14. REMOTE CONDENSER ILLUSTRATED PARTS BREAKDOWN

FOR 1100 SERIES 29. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FIGURE 15. ILLUSTRATED PARTS BREAKDOWN SERIES 2400 31. . . . . . . . . . .

Page

LIST OF TABLES

AF-750-P-MHR PRODUCTION CHART 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

AF-750-P-MH50R PRODUCTION CHART 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

WF-750-P-MHR PRODUCTION CHART 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

AF-1100-P-MH PRODUCTION CHART 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

WF-1100-P-MH PRODUCTION CHART 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

RF-1100-P-MH PRODUCTION CHART 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

AF-2400-P-MHR PRODUCTION CHART 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

166240009

ii

Page 4

INTRODUCTION

We have strived to produce a quality product. The design has been kept simple thus insuring trouble–free

operation.

This manual has been prepared to assist servicemen and users with information concerning installation,

construction and maintenance of the ice making equipment. The problems of the serviceman and user have

been given special attention in the development and engineering of our ice makers.

If you encounter a problem which is not covered in this manual, please feel free to write or call. We will be

happy to assist you in any way we can.

When writing, please state the model and serial number of the machine.

Address all correspondence to:

A Product of IMI Cornelius Inc.

One Cornelius Place

Anoka, MN 55303–1592

Phone 800–554–3526

FAX 612–422–3232

PRINTED IN USA

1 166240009

Page 5

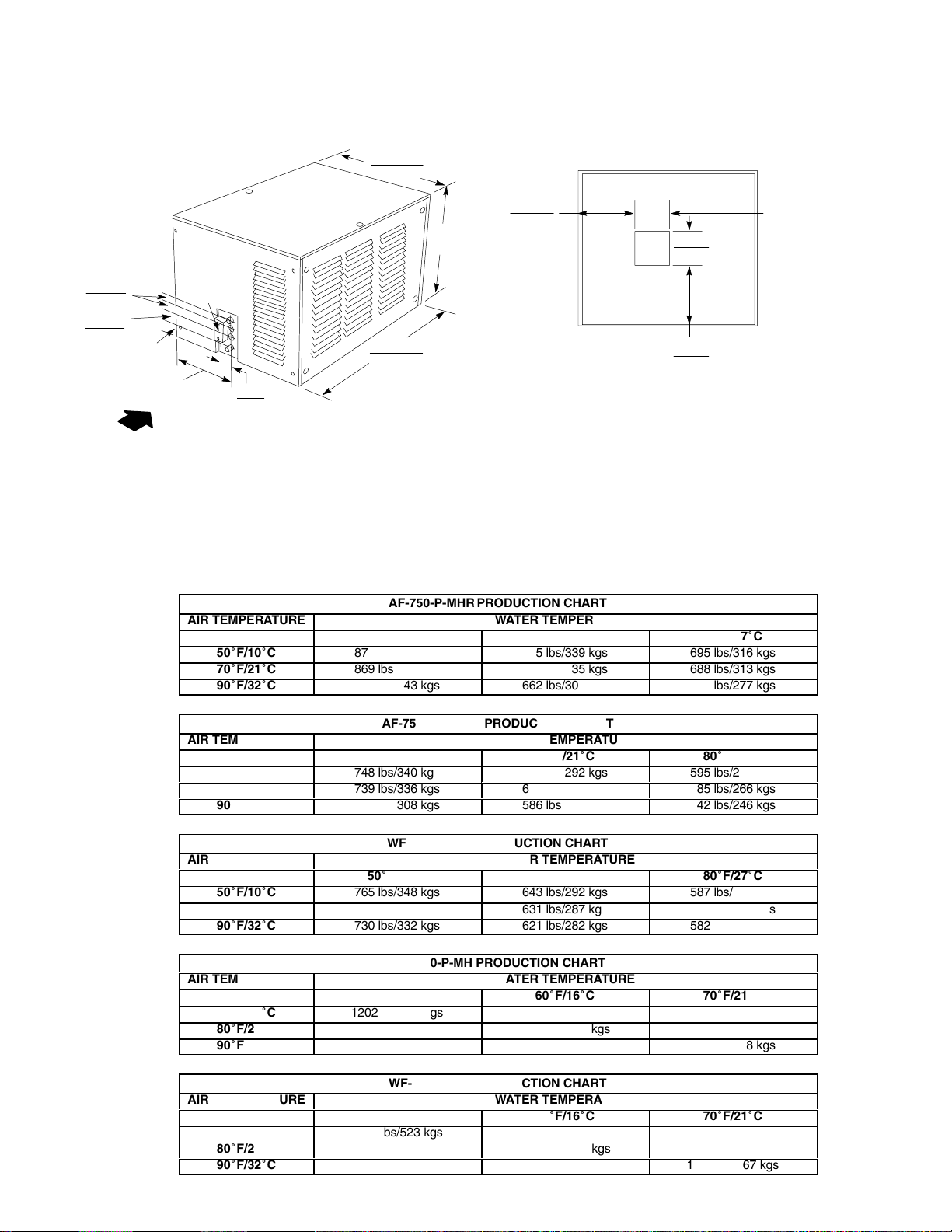

SPECIFICATIONS 750 AND 1100 SERIES

1 1/2-IN.

4-CM

1 3/4-IN.

4-CM

1 1/2-IN.

REAR

VIEW

4-CM

11 1/2-IN.

29-CM

A

B

C

D

E

2-IN.

5-CM

FIGURE 1. 750 AND 1100 SERIES SPECIFICATIONS

ICE PRODUCTION CAPACITY (approximate)

AIR TEMPERATURE

50°F/10°C

70°F/21°C

90°F/32°C

23 1/8-IN.

59-CM

8 1/4-IN.

23-IN.

58-CM

26 1/4-IN.

67-CM

A = POWER INLET

B = WATER INLET

C = CONDENSER (WATER IN)

(WC ONLY)

D = CONDENSER (WATER OUT)

(WC ONLY)

E = CHASSIS DRAIN

AF-750-P-MHR PRODUCTION CHART

50°F/10°C

873 lbs/397 kgs

869 lbs/395 kgs

755 lbs/343 kgs

21-CM

WATER TEMPERATURE

745 lbs/339 kgs

738 lbs/335 kgs

662 lbs/301 kgs

FRONT

70°F/21°C

CHUTE OPENING

5 1/16-IN.

13-CM

5-IN.

13-CM

BOTTOM

VIEW

9-IN.

23-CM

80°F/27°C

695 lbs/316 kgs

688 lbs/313 kgs

609 lbs/277 kgs

AIR TEMPERATURE

50°F/10°C

70°F/21°C

90°F/32°C

AIR TEMPERATURE

50°F/10°C

70°F/21°C

90°F/32°C

AIR TEMPERATURE

70°F/21°C

80°F/27°C

90°F/32°C

AIR TEMPERATURE

70°F/21°C

80°F/27°C

90°F/32°C

AF-750-P-MH50R PRODUCTION CHART

WATER TEMPERATURE

50°F/10°C

748 lbs/340 kgs

739 lbs/336 kgs

678 lbs/308 kgs

WF-750-P-MHR PRODUCTION CHART

50°F/10°C

765 lbs/348 kgs

748 lbs/340 kgs

730 lbs/332 kgs

AF-1100-P-MH PRODUCTION CHART

50°F/10°C

1202 lbs/545 kgs

WF-1100-P-MH PRODUCTION CHART

50°F/10°C

1151 lbs/523 kgs

70°F/21°C

643 lbs/292 kgs

635 lbs/289 kgs

586 lbs/266 kgs

WATER TEMPERATURE

70°F/21°C

643 lbs/292 kgs

631 lbs/287 kgs

621 lbs/282 kgs

WATER TEMPERATURE

60°F/16°C

1119 lbs/508 kgs

WATER TEMPERATURE

60°F/16°C

1123 lbs/509 kgs

2166240009

80°F/27°C

595 lbs/279 kgs

585 lbs/266 kgs

542 lbs/246 kgs

80°F/27°C

587 lbs/267 kgs

585 lbs/266 kgs

582 lbs/265 kgs

70°F/21°C

988 lbs/448 kgs

70°F/21°C

1060 lbs/467 kgs

Page 6

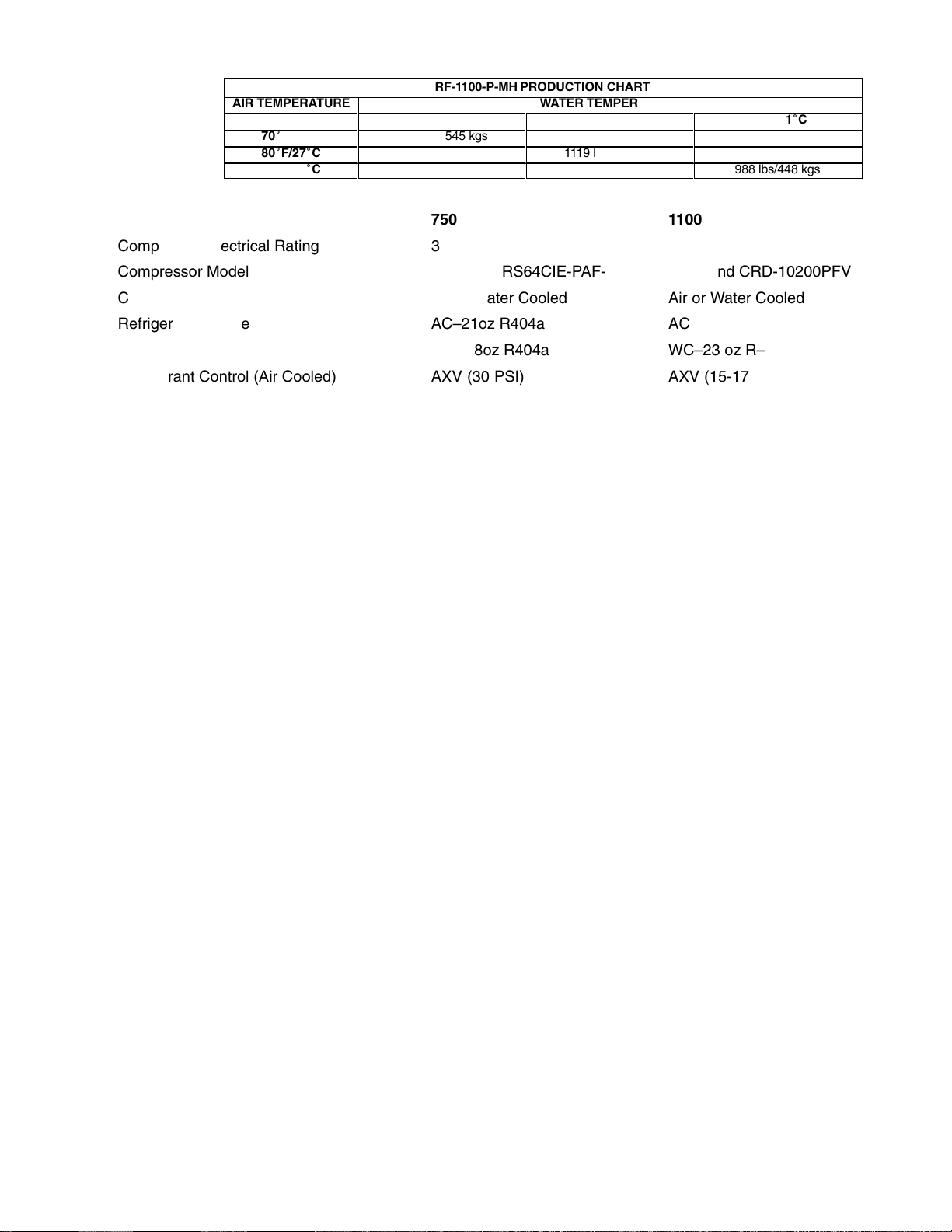

ICE PRODUCTION CAPACITY (approximate)

ББББББББ

ББББББББ

ББББББББ

ББББББББ

RF-1100-P-MH PRODUCTION CHART

AIR TEMPERATURE

50°F/10°C

70°F/21°C

80°F/27°C

90°F/32°C

1202 lbs/545 kgs

750 1100

Compressor Electrical Rating 3/4 hp 2 hp

Compressor Model Copeland RS64CIE-PAF-214 Copeland CRD-10200PFV

Condenser Air or Water Cooled Air or Water Cooled

Refrigerant Charge AC–21oz R404a AC–25 oz R–22

WC–18oz R404a WC–23 oz R–22

Refrigerant Control (Air Cooled) AXV (30 PSI) AXV (15-17 PSI)

Refrigerant Control (Water Cooled) AXV (28 PSI) AXV (15-17 PSI)

Voltage 115V 208/230V 60HZ 1PH

Total Amp. Draw 16 AMPS 12 AMPS

Gearmotor Amp. Draw 1.6 AMPS .7 AMPS

Gearmotor Electrical Rating 1/8 hp 1/7 hp

Maximum Fuse Size 20 AMPS 15 amps

WATER TEMPERATURE

60°F/16°C

1119 lbs/508 kgs

70°F/21°C

988 lbs/448 kgs

3 166240009

Page 7

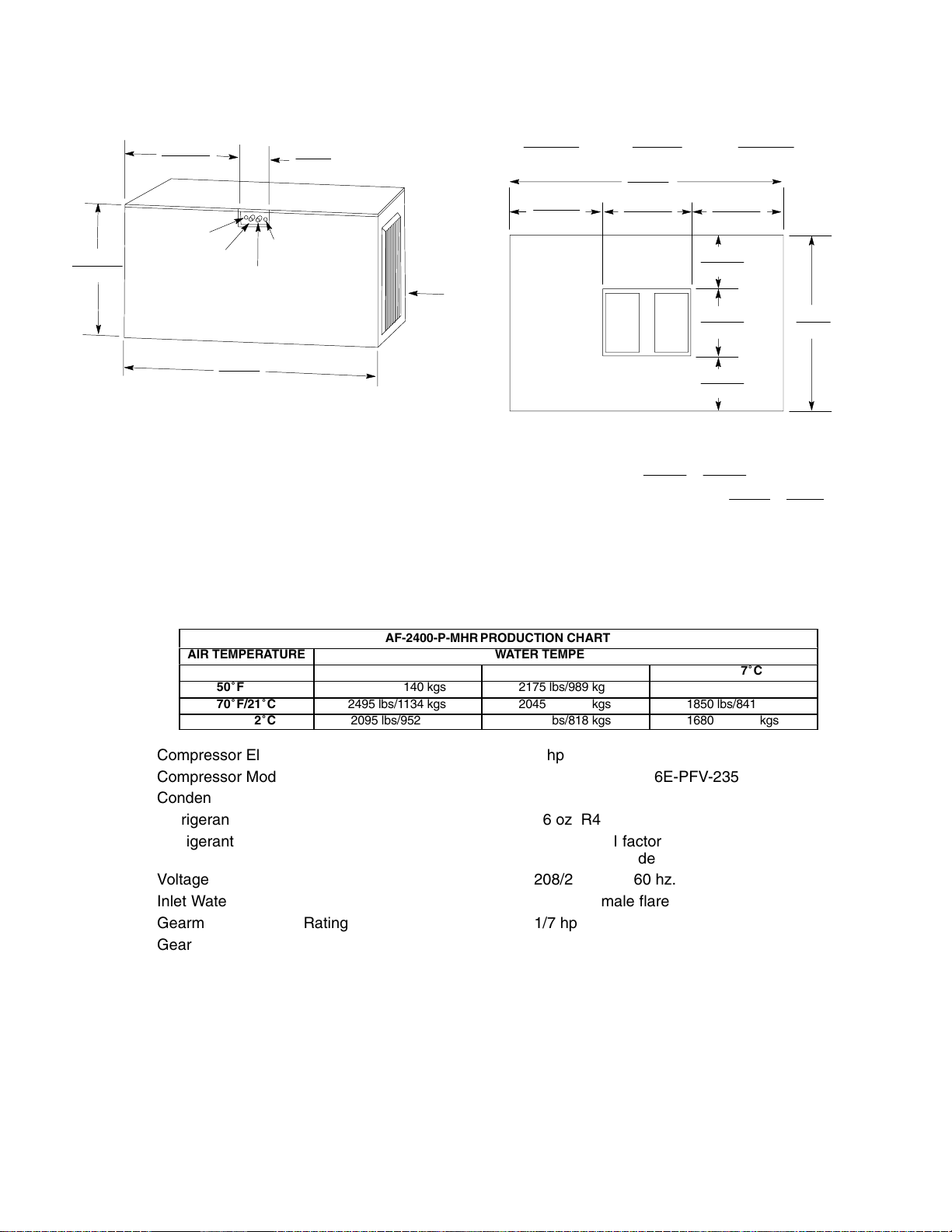

SPECIFICATIONS 2400 SERIES

23 1/2-IN.

60-CM

17 1/2-IN.

44-CM

ELECTRICAL

WATER INLET

WATER OUT (W/C)

44-IN.

112-CM

NOTE: AIR IS EXHAUSTED OUT

BACK AND SIDE OPPOSITE

CONDENSER

8-IN.

20-CM

WATER IN (W/C)

FIGURE 2. SPECIFICATIONS FOR 2400 SERIES

23-9/16-IN. HIGH x 45-1/8-IN. WIDE x 27-5/16-IN. DEEP

60-CM 115-CM 69-CM

15 1/8-IN.

38-CM

AIR IN

CONDENSER SIDE

”A”- ALTERNATE ICE DROP AREA FOR TOP UNIT WHEN TWO ARE STACKED.

”B”-ICE DROP AREA FOR BASIC UNIT.

INDIVIDUAL ”A” & ”B” DIMENSIONS ARE 5-5/32-IN. x 8-9/32-IN.

RECOMMENDED BIN TOP CUT OUT AS SHOWN ABOVE 14-1/4-IN. x 8-3/4-IN.

OVERALL DIMENSIONS

44-IN.

112-CM

14 1/4-IN.

36-CM

AB

13-CM 21-CM

15 1/8-IN.

38-CM

9 1/8-IN.

23-CM

8 3/4-IN.

22-CM

9 1/8-IN.

23-CM

36-CM

27-IN.

69-CM

22-CM

ICE PRODUCTION CAPACITY (approximate)

AF-2400-P-MHR PRODUCTION CHART

AIR TEMPERATURE

50°F/10°C

50°F/10°C

70°F/21°C

90°F/32°C

2507 lbs/1140 kgs

2495 lbs/1134 kgs

2095 lbs/952 kgs

Compressor Electrical Rating 2 hp

Compressor Model Copeland CS14K6E-PFV-235

Condenser Air Cooled

Refrigerant Charge 26 oz R404a/each side

Refrigerant Control AXV 26-PSI factory

Voltage 208/230 1 ph. 60 hz.

Inlet Water Supply 3/8” SAE male flare

Gearmotor Electrical Rating 1/7 hp

Gearmotor Amp Draw .7 amps at 230V

Mamimum Fuse Size 40 amps

Total Amp Draw 30 amps

Refer to serial plate for maximum circuit ampacity and minimum time delay fuse size.

WATER TEMPERATURE

70°F/21°C

2175 lbs/989 kgs

2045 lbs/930 kgs

1800 lbs/818 kgs

setting/Each Side

80°F/27°C

2008 lbs/913 kgs

1850 lbs/841 kgs

1680 lbs/764 kgs

4166240009

Page 8

INSTALLATION INSTRUCTIONS

You will get better service from the ice machine, longer life and greater convenience if you choose its location

with care.

Here are a few points to consider:

1. Select a location as close as possible to where you are going to use the ice.

2. Allow a minimum of 6” space at sides and rear of machine for ventilation.

3. A kitchen installation is not desirable as a rule. If a kitchen installation is necessary, locate the machine as

far away from the cooking area as possible. Grease laden air will form a greasy deposit on the condenser.

This reduces the ice making efficiency and necessitates thorough cleaning quite often.

4. If you install the unit in a storeroom, be sure the room is well ventilated.

NOTE: Do not install where the ambient and incoming water temperature will drop below 50° F rise to

over 100° F.

WARNING: If water pressure exceeds 50 pounds, a water pressure regulator should be

installed in water inlet line between water shut–off valve and strainer. Minimum incoming

water pressure required is 22 pounds.

5. Uncrate the unit by removing the staples or nails from the bottom of the carton and lift off.

6. Remove the bolts holding the skid to the machine.

7. For units supplied with a bin sealing gasket, cement the gasket to the bottom outside edge of the machine

before it is set on the bin. NOTE: This is an N.S.F. requirement and must be done by the installer.

8. Make sure the correct bin adapter has been supplied when used. Then mount the unit on the bin and level

both properly.

9. For units not supplied with bin sealing gasket, seal the machine to bin with an N.S.F. approved sealant

such as Dow R.T.V. #732, 734, or G.E. #102, 108. This is an N.S.F. requirement and is the responsibility

of the installer.

10. The incoming water for the ice making section requires a 3/8” copper line. Connect this water line to the

3/8” male flare fitting on the back of the unit.

NOTE: For water cooled units, a separate 3/8” copper water line is required to be connected to the flare

fitting on the back of the unit marked condenser water in. A 3/8” flare connected line will have

to be provided from the fitting marked condenser water out to the drain.

A water regulating valve installed at the factory was set to maintain 270 to 310 PSI head pressure for R–404a

units and 210 to 225 PSI for R–22 units (Approx. 105_ to 110_F). Check temperatures at condenser outlet and

adjust if necessary.

11. Connect a drain hose to the condensate drain stub tube.

NOTE: All plumbing must be done in accordance with national and local codes.

12. Bring the electrical supply into the unit through a handy box located on the back of unit and make

connections.

NOTE: NOTE: Make sure the proper voltage and number of wires are provided. See serial plate and

make connections.

NOTE: All wiring must conform to national and local codes.

13. Turn on water supply and observe water level in evaporator sections. Water level is to be maintained at

the top of the evaporator. (See adjustment procedure)

5 166240009

Page 9

14. Turn machine on and check for proper voltage and amp draw on the entire unit as well as components

such as the gearmotor and fan motor.

15. Check refrigerant circuit and all plumbing connections for leaks, etc.

16. Check bin thermostat or mechanical shut–off for proper operations. In the mid–range the bin thermostat

will open at 42° and has a 6° differential.

REMOTE CONDENSER

Remote condensers should be installed above the ice machine and in a level configuration. They are connected

to the ice making unit by copper tubing and line valves. The female half of the line valve is mounted on the ice

making unit and the remote condenser. The male half is soldered on the tube ends when tubing kits are

provided with the machine. If tubing kits are not provided, the male half of the line valves will be provided in a

valve kit and the installer will mount them on the tubing he provides.

NOTE: WHEN VERTICAL LINES ARE INVOLVED IN THE INSTALLATION, FOLLOW STANDARD

REFRIGERATION PRACTICES FOR VERTICAL LINES TO ASSURE POSITIVE OIL RETURN TO

THE COMPRESSOR. VERTICAL LIFT TO BE NO MORE THAN 15 FEET.

NOTE: WE DO NOT RECOMMEND TUBING RUNS OF MORE THAN 40 FEET..

NOTE: The seals for the line valves will be found in an envelope on the remote condenser. Make sure

they are used.

NOTE: REMOVE CAP PLUGS FROM ALL LINE VALVES BEFORE MAKING VALVE CONNECTIONS WITH

THE SEAL.

NOTE: A LOW VOLTAGE ELECTRICAL CONTROL CIRCUIT MUST BE FIELD WIRED BETWEEN THE

ICE MACHINE AND THE REMOTE CONDENSER RELAY. THOSE WIRES SHOULD BE RUN WITH

THE TUBING DURING INSTALLATION. REFER TO APPLICABLE WIRING DIAGRAMS.

NOTE: When the line valves are connected to each other the refrigerant circuit is complete. Each valve

half has its own shut-off which must be fully opened to allow the refrigerant to flow though the

system before it is started.

The ice making unit utilizing a remote condenser is shipped from the factory with the receiver holding the

refrigerant charge. Additional refrigerant may be required upon installation depending upon the ambient

conditions the remote condenser is operating under, the condenser and line sizing.

A three way head pressure control valve is used to maintain a relatively consistent head pressure between 175

and 185 PSI for R22 in the receiver in cold ambient conditions. Because of this valve some liquid refrigerant will

be held in the condenser.

NOTE: THE HEAD PRESSURE CONTROL VALVE WILL NOT OPERATE CORRECTLY WHEN A TOTAL

PRESSURE DROP OF 14 POUNDS OR MORE IS CREATED BETWEEN THE ICE MAKING UNIT,

THROUGH THE TUBING TO THE REMOTE CONDENSER, THE CONDENSER AND THE RETURN

TUBING TO THE ICE MAKING UNIT.

The remote condenser requires a separate power supply from the ice making unit. Refer to the remote

condenser wiring diagram.

6166240009

Page 10

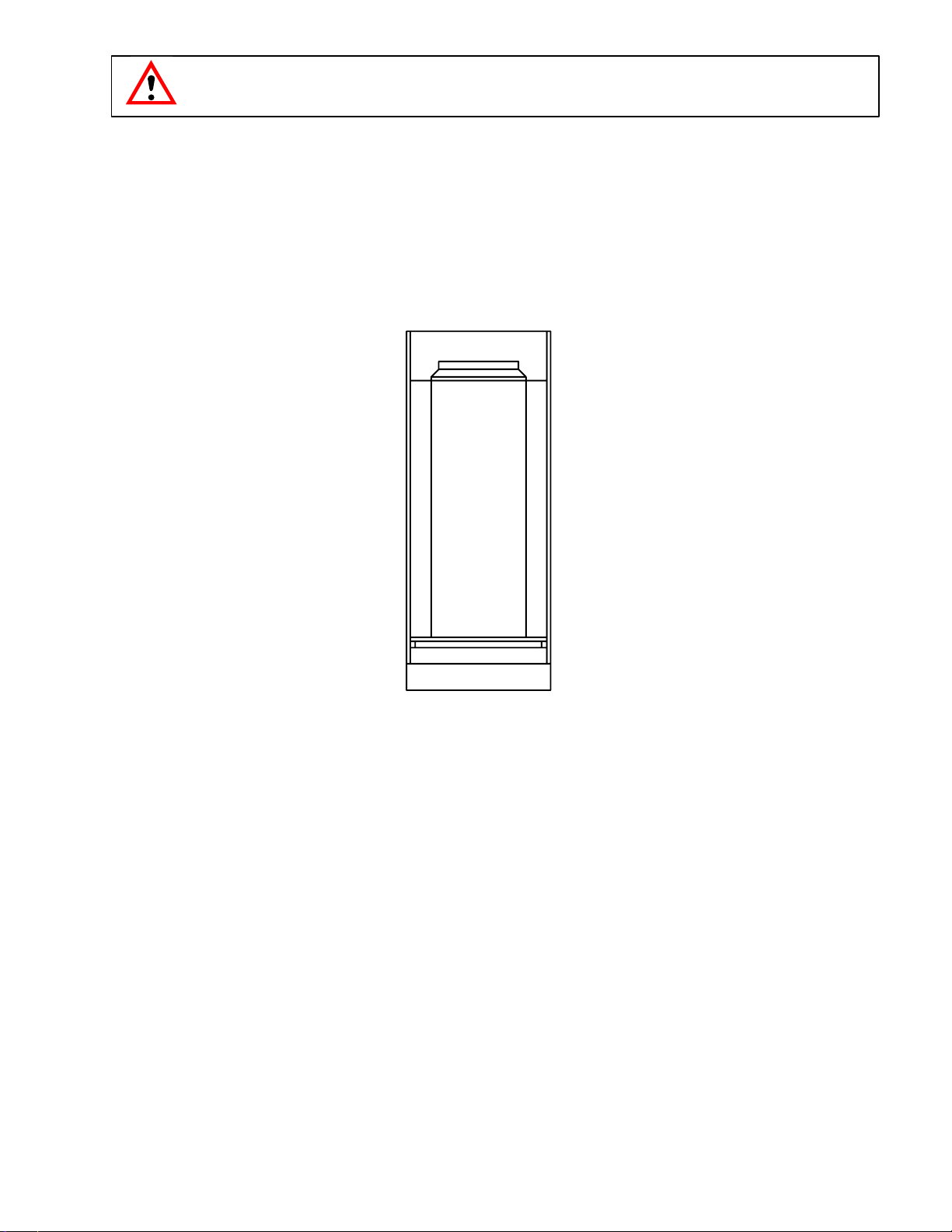

WARNING: WATER LEVEL MUST BE MAINTAINED AT THE TOP OF THE EVAPORATOR.

WATER LEVEL

ill224

FIGURE 3. WATER LEVEL

1. Remove gearmotor and auger.

2. Adjust float valve to get water level to top seam of the evaporator.

3. Re–install auger. WATER LEVEL WILL RISE WHEN AUGER IS INSERTED BUT WHEN THE MACHINE

IS TURNED BACK ON AND ICE STARTS BEING MADE, THE WATER LEVEL WILL GO BACK TO THE

ORIGINAL SETTING.

4. Re–install gearmotor assembly and start machine.

7 166240009

Page 11

STACKING INSTRUCTIONS FOR STACKING KIT 29757

The Kit consists of:

1 – #26102 Sealer

2 – #261 1/4-20x5/8 screw

2 – #256 1/4” flat washer

2 – #239 1/4” Lock Washer

1 – #29758 Stacking Chute Extension

1. After uncrating machine to be stacked, remove front and rear panels.

2. Remove top and front panels of bottom machine.

3. Remove alternate chute opening cover from bottom machine.

4. Insert vertical chute extension from kit into alternate chute opening of bottom unit and seal it to the base

with sealer provided in the kit.

5. Carefully mount stacking unit reversed 180° with the compressor and condenser opposite those of the

bottom unit.

NOTE: When mounting, make sure stacking unit vertical chute aligns and inserts correctly with chute

extension installed in alternate chute opening of bottom unit. Raise chute bracket to cover

opening and tighten bracket screws.

6. Secure both machines together as shown in the illustration utilizing screws and washers provided in the kit.

7. After stacking unit, hook up electrical and water.

NOTE: The two units must operate independently of each other.

8. Connect drain line from tee under the stacked unit to run out of the back of the unit.

9. Replace panels of stacked unit front to front and back to back as the machine is mounted. Replace front

panel of bottom unit.

8166240009

Page 12

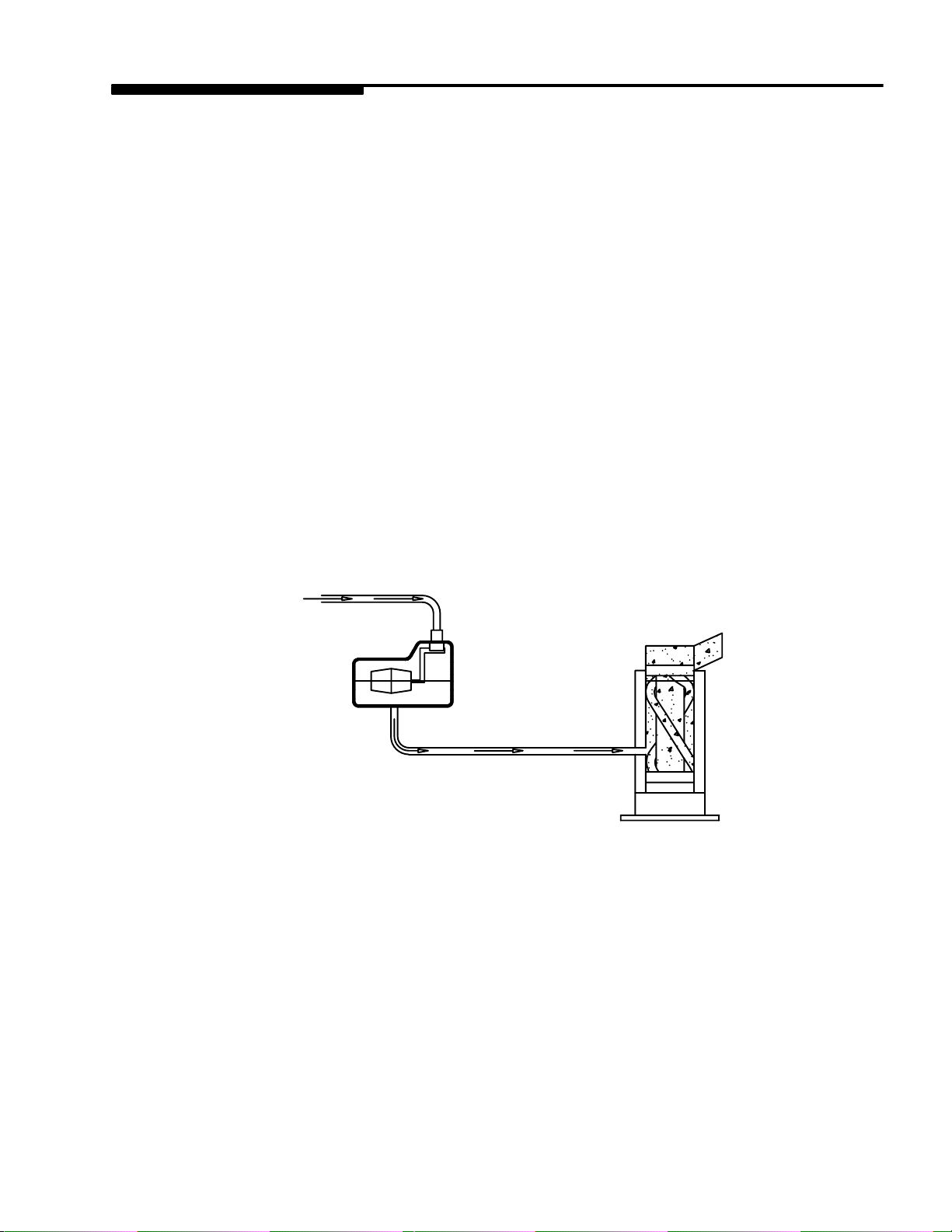

TYPICAL WATER CIRCUIT

The supply water enters the float chamber through a small orifice. The water level rises and lifts the buoyant

float with it. The float attached to the float arm seats a valve to shut off any further water supply. As water

leaves the float chamber, the level drops along with the float and arm, causing the valve to open and admit

more water. Thus the water level is maintained automatically as the machine operates.

Water now flows through a hose connected to the float chamber and enters the opening of the evaporator shell.

The water level in the shell will rise to the same level that is maintained in the float chamber. The water that is

in immediate contact with the center post evaporator will be reduced in temperature. As a result, freezing

occurs and ice forms on the surface of the evaporator.

As more water is frozen, the thickness of the ice increases until it exceeds the distance allowed between the

evaporator and auger. The auger rotates at a slow speed to wipe off the accumulated ice as well as help it to

the surface. After the ice reaches the surface it is discharged through the top opening in the shell. An ice chute

attached to the shell conveys the ice to the storage bin where it accumulates in the insulated bin until it is used.

The ice will pile up to a point where the bin thermostat tubing is located. When the ice touches this brass

tubing, the unit will shut–off and remain off until enough ice is used or melted to reduce the pile. Any ice that

melts will pass through the drain and drain hose to an open drain.

WATER IN

FLOAT

CHAMBER

ICE

OUT

EVAPORATOR

CHAMBER

FIGURE 4. TYPICAL WATER CIRCUIT

9 166240009

Page 13

TYPICAL REFRIGERANT CIRCUIT

Heat always flows from hot to cold and therefore, the ”heat load” supplied to the evaporator section by water

gives up its heat to the refrigerant which is at a temperature below the freezing point of water. This refrigerant

now passes through the heat exchanger back to the compressor, as a low pressure vapor.

This low pressure vapor is compressed in the compressor, as it leaves the compressor at a high pressure in

vapor form it enters the top of the condenser. The condenser has a rapid flow of cool air across it which

removes much of the heat from the hot refrigerant vapor.

As the vapor, passing through the condenser, loses heat it condenses back to a liquid since it is still under high

pressure and cooler than when it entered the condenser. The liquid refrigerant then passes through the

drier/filter still under pressure and goes through the heat exchanger where further cooling takes place. As the

refrigerant leaves the automatic expansion valve, the pressure has dropped, causing the refrigerant to vaporize

and boil off as it picks up heat in the evaporator and since the pressure is low, the refrigerant will be cold.

EVAPORATOR

CONDENSER

AXV

HEAT

EXCHANGER

COMPRESSOR

DRIER/FILTER

FIGURE 5. TYPICAL REFRIGERANT CIRCUIT

10166240009

Page 14

ELECTRICAL CIRCUIT

CIRCUIT DESCRIPTION

As the manual on–off–circuit breaker switch is pushed to ”on”, an electrical circuit is completed to the

gearmotor via the circuit breaker gearmotor overload, power relay / contactor, gearmotor delay thermostat and

the bin thermostat. After the previous circuit has been completed the condenser fan motor will start as will the

compressor (via the high pressure control and the compressor starting relay).

COMPONENT DESCRIPTION

BIN THERMOSTAT

This is electrically in ”series” with the ice making system. when the bin is full, the contact opens, terminating

power to the machine.

GEARMOTOR START RELAY

This is a current type relay which means as the gearmotor run winding comes ”on” the line, the current draw

initially is relatively heavy through the relay coil (coil is in series with run winding). It then acts like a normal

relay and the N.O. start contact ”makes”, completing a circuit through the start capacitor to the start winding.

As the gearmotor picks up speed, the amp draw through the relay coil drops off allowing the armature to return

to its normal position (start contact ”opens”). This action removes the start winding from the circuit.

POWER RELAY / CONTACTOR

This relay controls the compressor power only.

GEARMOTOR DELAY THERMOSTAT

This thermostat keeps the gearmotor running until the suction line temperature reaches 45_ after the full bin

switch terminates power to the power relay / contactor.

ON–OFF SWITCH / CIRCUIT BREAKER

This switch interrupts power to the entire unit. The switch has a circuit breaker incorporated into its’ design.

This circuit breaker will trip out in the event the gearmotor draws to high of amps In such an event the power is

interrupted to the unit. To reset the circuit breaker and reestablish power to the unit, push the switch to the ”off”

position and then back to the ”on” position.

FAN CYCLING SWITCH (R404a Units)

The function of this switch is to maintain condensing pressures at a satisfactory level during–low ambient

conditions. The switch breaks the circuit to the condenser fan motor at 205 PSI and makes the circuit at 275

PSI.

HIGH PRESSURE CONTROL

The high pressure cut out is electrically in series with the power relay. As the head pressure rises to 450 PSIG

for R404a charged units and 400 PSIG for R 22 charged units, a preset level, the contact opens thus breaking

the circuit to the compressor via the power relay contactor. This control must be reset manually on R404a units.

11 166240009

Page 15

COMPRESSOR START RELAY

This is a current type relay and contains a N.O. contact which is connected in series with the start winding of the

compressor. The relay coil is electrically in series with the run winding. When power is applied, the compressor

draws high current which sets up a magnetic field around the magnet coil which causes the relay to operate,

closing the relay contact. As the compressor approaches operating speed, the current flowing through the coil

decreases, permitting the relay contact to open, thereby opening the starting circuit.

POTENTIAL RELAYS

The potential relay is used as a compressor starting relay, The contact in the potential relay is N.C.. The

magnet coil is connected across (parallel) the start winding and is affected by induced voltage, generated by the

start winding. As the compressor comes up to design speed, the voltage across the relay coil increases and at

running speed is sometimes as much as 2 1/2 times the supply voltage. This voltage sets up a magnetic field

which causes the relay to operate. The starting relay is calibrated to remove the start capacitor (open the

starting circuit) at approximately 85% of the motor design speed.

NOTE: BOTH TYPES OF RELAYS ARE DESIGNED TO OPERATE WITHIN VERY NARROW LIMITS OF

VOLTAGE AND CURRENT DICTATED BY MOTOR DESIGN, THEREFORE, WHEN MAKING A

REPLACEMENT OF A RELAY ALWAYS PROVIDE AN EXACT REPLACEMENT, RECOMMENDED

BY THE COMPRESSOR MANUFACTURER.

CAPACITORS – GENERAL

An electrical capacitor is a device which stores up electrical energy. Capacitors are used with single phase

motors to provide starting torque and improve running characteristics; by feeding this energy to the start winding

in step with the run winding.

Any capacitor has three (3) essential parts, two (2) of which are usually foil plates separated and insulated by

the third part called the dielectric.

Two general types of capacitors are used with electric motors. The electrolytic starting capacitor usually uses a

very thin film of oxide on the metallic plate as the dielectric. The running capacitor usually is of the liquid filled

type.

12166240009

Page 16

OUTLET

BOX

GR

YL

BL

BL

YLBL

ON-OFF SWITCH

CIRCUIT BREAKER

RATED 2.0 AMPS

BK

BL

WH

WH

BL

YL

RD

BIN

THERMOSTAT

BL

CONTROL

HIGH PRESSURE

BL

BL

THERMOSTAT

RD

CONTACTOR

DELAY

WH

BL

BK

GEAR MOTOR

START RELAY

BK

LOW AMBIENT

SWITCH

COMPRESSOR

OVERLOAD

BK

BL

3

2

(A/C ONLY)

1

GEAR MOTOR

START CAPACITOR

4 64-77 MFD 165 VAC

RD RD

BK

COMPRESSOR

C

BK

MOTOR

FAN MOTOR

M

R

S

YL YL

COMPRESSOR

RUN CAPACITOR

30 MFD 440 VAC

GEAR

M

YL

WH

BK

COMPRESSOR

START CAPACITOR

72-86 MFD 330 VAC

RD

1

2

5

COMPRESSOR

START RELAY

WH

WH

OR

WH

AF/WF-750-MH-R

115 VOLTS 60 Hz

FIGURE 6. WIRING DIAGRAM AF/WF–750–MH-R

13 166240009

Page 17

OUTLET

BOX

LB

YL

GN/Y

BL

BL

ON-OFF SWITCH

CIRCUIT BREAKER

RATED 1.5 AMPS

RD

BK

BR

RD

BK

YL

RD

BR

BIN

THERMOSTAT

BL

HIGH PRESSURE

BL

LB

BL

RD

CONTROL

CONTACTOR

DELAY

THERMOSTAT

BK

RD

GEAR MOTOR

START RELAY

3

2

FAN SWITCH

COMPRESSOR

OVERLOAD

BK

RD

BL

4

RD RD

COMPRESSOR

1

BL

GEAR MOTOR

START

CAPACITOR

WIRE NUT

R

C

S

GN/Y

COMPRESSOR

START RELAY

RD

YL

GEAR

MOTOR

M

GN/Y

RD

FAN MOTOR

BL

YL

M

S

BKBKBK

GN/Y

COMPRESSOR

START CAPACITOR

88-106 MFD 220 V

L

M

RD

YL

AF750PMH-50-R

220 VOLTS 50 Hz

FIGURE 7. WIRING DIAGRAM AF–750–PMH-50R

14166240009

Page 18

OUTLET

BOX

GR

YL

BL

ON-OFF SWITCH

CIRCUIT BREAKER

RATED 1.5 AMPS

BL

RD

BK

RD

RD

BK

BK

RD

BK

YL

RD

BIN

THERMOSTAT

RD

HIGH PRESSURE

BK

POWER RELAY

BL

RD

CONTROL

(W/C ONLY)

DELAY

THERMOSTAT

BK RD

BK

RD

RD

BL

4

3

2

GEAR MOTOR

START RELAY

BK

EVAPORATOR HEATER

COMPRESSOR

R

C

S

BK

BK

GEAR MOTOR

START

CAPACITOR

RD

BL

FAN MOTOR

A/C ONLY

M

COMPRESSOR

RUN

CAPACITOR

RD

YL YL

COMPRESSOR

START RELAY

GEAR

MOTOR

M

RD

5

YL

BK

BK

COMPRESSOR

START

CAPACITOR

OR

2

1

RD

RD

RD

AF/WF-1100-MH

208/230 VOLTS 60 Hz

FIGURE 8. WIRING DIAGRAM AF/WF–1100–MH

15 166240009

Page 19

OUTLET

BOX

YL

GW

BL

BL

ON-OFF SWITCH

CIRCUIT BREAKER

RATED 1.5 AMPS

RD

BK

RD

RD

BK

BK

RD

YL

RD

BK

CRANKCASE HEATER

BIN

THERMOSTAT

RD

HIGH PRESSURE

BK

BL

RD

CONTROL

CONTACTOR

DELAY

THERMOSTAT

BK

BK

RD

RD

GEAR MOTOR

START RELAY

3

2

4

24V FIELD

WIRING

230V

REMOTE

CONDENSER

COMPRESSOR

R

C

S

BK

BK

BL

BL

GEAR MOTOR

START

CAPACITOR

RD RD

M

COOLING

FAN MOTOR

POWER

RELAY

COMPRESSOR

RUN

CAPACITOR

RD

YL YL

COMPRESSOR

START RELAY

GEAR

MOTOR

M

BK

TRANSFORMER

M

FAN

MOTOR

COMPRESSOR

RD

1

5

2

YL

CLASS II

START

CAPACITOR

OR

RD

BK

WH

RD

RD

RF-1100-MH

208/230 VOLTS 60 Hz

FIGURE 9. WIRING DIAGRAM RF–1100–MH

16166240009

Page 20

BL

OUTLET

BOX

RD

BK

YL

GR

YL

RD

BL

BL

BIN

THERMOSTAT

RD

BK

RD

BL

THERMOSTAT

RD

ON-OFF SWITCH

CIRCUIT BREAKER

RATED 1.5 AMPS

GEAR MOTOR

DELAY

START RELAY

BK

BL

BL

GEAR

3

2

4

GEAR MOTOR

START

CAPACITOR

RD RD

FAN MOTOR

M

MOTOR

M

RD

BK

YL

RD

BL

RD

BK

RD

BK

BK

AF/WF-1100-MH-3

3 PHASE 208/230 VOLTS 60 Hz

CONTROL

HIGH PRESSURE

(W/C ONLY)

CONTACTOR

RD

RD

BL

BK

COMPRESSOR

M

FIGURE 10. WIRING DIAGRAM AF/WF–1100–MH–3

17 166240009

Page 21

OUTLET

BOX

YL

GW

BL

BL

ON-OFF SWITCH

CIRCUIT BREAKER

RATED 1.5 AMPS

RD

BK

LB

LB

BR

BR

RD

BK

YL

RD

BIN

THERMOSTAT

RD

HIGH PRESSURE

BK

CONTROL

(W/C ONLY)

CONTACTOR

BL

THERMOSTAT

RD

RD

DELAY

GEAR MOTOR

START RELAY

3

BK

2

COMPRESSOR

C

BK

BK

RD

4

RD RD

R

S

BL

BL

GEAR MOTOR

START

CAPACITOR

FAN MOTOR

M

COMPRESSOR

CAPACITOR

RD

YL

COMPRESSOR

START RELAY

RUN

GEAR

MOTOR

M

BK

RD

YL

5

2

YL

RD

COMPRESSOR

START

CAPACITOR

1

RD

OR

RD

AF/WF-1100-MH-50

240 VOLTS 50 Hz

FIGURE 11. WIRING DIAGRAM AF/WF–1100–MH–50

18166240009

Page 22

COMPRESSOR

CAPACITOR

145-174 MFD

19

START

250V

WH

YL

MOTOR

COMPRESSOR

CAPACITOR

RD

YL

2

5

COMPRESSOR

1

START RELAY

GEAR

START

RELAY

3

2

4

GEAR MOTOR

DELAY

THERMOSTAT

RD

RUN

35 MFD

370V

BK

RD

YL

HIGH

PRESSURE

SWITCH

CO 450

GEAR

MOTOR

BL

RD

CAPACITOR

COMPRESSOR

R

C

S

BK

BK

YL

BL

YL

YL

M

RD

GEAR

MOTOR

START

BL

SYSTEM 1

CONTACTOR

BL

ON-OFF SWITCH

CIRCUIT BREAKER

RATED 1.5 AMPS

RD

BK

BL

BK

BK

RD

THERMOSTAT

BL

OR

RD

BK

RD

BK

MAIN

ON-OFF

SWITCH

RD BK

RD

OR

BIN LIMIT

BL

SYSTEM 1

BK

BK

BIN

THERMOSTAT

LOW

WATER

PRESSURE

SWITCH

CO 10CI 20

LOW AMBIENT

PRESSURE

SWITCHES

CI 275

CO 205

BK

BK

SYSTEM 2

GEAR MOTOR

& COMPRESSOR

CONTROL RELAY

4

1

6

3

RD RD

YL YL

M

GW

BK

WH

RD

COND.

FAN

A/C

ONLY

SYSTEM 2

CONTACTOR

BL

ON-OFF SWITCH

CIRCUIT BREAKER

RATED 1.5 AMPS

BK

BL

BK

COMPRESSOR

BK

YL

YL

GEAR

MOTOR

R

C

S

BK

PRESSURE

SWITCH

BL

YL

M

CAPACITOR

RD

BL

RD

COMPRESSOR

CAPACITOR

35 MFD

RD RD

YL YL

COMPRESSOR

START RELAY

HIGH

CO 450

GEAR

MOTOR

START

RD

BL

RUN

370V

5

GEAR

MOTOR

START

RELAY

GEAR MOTOR

DELAY

THERMOSTAT

2

1

4

23

BK

COMPRESSOR

START

CAPACITOR

145-174 MFD

250V

WH

YL

166240009

AF/WF-2400 PMHR DUAL COMPRESSORS

208/230 VOLTS 1 PHASE

FIGURE 12. WIRING DIAGRAM 2400 SERIES

Page 23

MAINTENANCE

THE FOLLOWING MAINTENANCE SHOULD BE PERFORMED AT LEAST EVERY SIX MONTHS ON

FLAKED ICE MACHINES:

1. Check power supply with machine running for proper voltage.

2. Check water level in the float tank reservoir. Water level should be maintained at the top of the evaporator.

Adjust if necessary. (See illustration and adjustment procedure)

3. Clean the air–cooled condenser coil with a stiff brush or vacuum cleaner (See procedure)

CAUTION: CONDENSER COOLING FINS ARE SHARP, USE CARE WHEN CLEANING.

4. Clean the ice storage bin and flush the bin drain at least once a month.

5. If a water conditioner is installed in the inlet water line, change, replace, or clean the filter, strainer or cartridge as required.

6. If heavy mineral deposits on the auger and evaporator shell are encountered due to bad local water conditions, follow sanitizing and cleaning procedure.

7. Loosen hold–down cam locks and remove gearmotor assembly.

8. Check thrust washer; replace if noticeably worn.

9. Lift out auger and examine for wear. The corkscrew auger guide bushing pressed into the drive block

should be checked for wear. Replace if loose or if worn flat with auger drive block. If the Helix auger on

the corkscrew auger round bar becomes flat on the inside more than 1/8 of an inch over a length of two

inches or more it should be replaced.

NOTE: HELIX AUGERS DO HAVE MACHINED FLAT RELIEF SURFACES. DON’T CONFUSE THEM WITH

WORN FLAT AREAS.

Check the insert in the bottom ring of the Helix auger and replace if excessively worn.

10. Check shell vertical strips for wear. Replace the shell if excessive wear is shown.

11. Check O–Ring, replace if worn or cut.

12. Re–assemble, steps 7through 11.

CAUTION: IN RE–ASSEMBLING THE AUGER GEARMOTOR, THE HOLD DOWN CLAMPS

MUST BE RIGHT AND SECURE. IN RE–INSTALLING THE EVAPORATOR SHELL, BE

ABSOLUTELY SURE THAT THE ”O” RING IS NOT PINCHED OFF AS THIS WOULD CAUSE A

WATER LEAK AROUND THE BASE OF THE EVAPORATOR. LUBRICATE THE ”O” RING WITH

FOOD GRADE LUBRICANT BEFORE RE–ASSEMBLING SHELL.

13. Check for alignment of ice chute. Make sure chute gasket is not blocking path of ice flow.

14. Check bin thermostat operation. In the mid–range position the bin thermostat will open at 42_ and has a

6_ differential.

20166240009

Page 24

SANITIZING AND CLEANING PROCEDURE

1. Turn switch to ”OFF” to stop unit.

2. Remove top cabinet panel.

CAUTION: Hazardous moving parts. Do not operate unit with panel removed.

3. Mix sanitizing solution by using 0.5-ounces of household liquid bleach (such as Hi-Lex or Chlorox) to one

gallon of potable water. This mixture must not exceed 200-ppm of chlorine.

4. Turn water ”OFF”. Remove water hose from float chamber and allow all water to drain from the float

chamber and evaporator. Restore hose to float chamber and add sanitizing solution to the float chamber.

Turn water ”ON”.

OR

Remove float chamber cover and while holding float up to prevent water from entering the chamber, remove water hose and allow all water to drain from the float chamber and evaporator. Restore hose to float

chamber and add sanitizing solution to the float chamber.

5. Reinstall float chamber cover.

6. Remove vertical ice chute cover.

7. With a plastic bristle brush and sanitizing solution, scrub the interior of the vertical ice chute, including the

interior and exterior of the evaporator chute that extends into the vertical chute. Also scrub the vertical

chute cover and sensor tube. Allow all parts to air dry.

8. Reinstall the vertical chute cover and cabinet top panel.

9. Turn switch to ”ON” and allow unit to make ice.

10. Remove or melt with warm water, all ice inside of bin.

11. Using the sanitizing solution from step 7 and brush, scrub the interior of the ice bin including the underside

of the ice bin cover. Scrub the outside of the ice chute that protrudes into the ice bin, and the inside and

outside of the ice bin door.

12. Rinse interior of the ice bin with clean water.

13. Allow machine to make ice for at least 1/2 hour then discard all the ice made. DO NOT ALLOW ICE WITH

SANITIZER IN IT TO BE USED.

21 166240009

Page 25

WATER TREATMENT

During the freezing process, as water passes under the freezing plate, the impurities in the water have a tendency to be rejected and the plate will freeze only the pure water.

However, the more dissolved solids in the water, the more troublesome the freezing operation will be. Bicarbonates in the water are the most troublesome of the impurities. These impurities will cause scaling on the evaporator, clogging of the water distributor head, float valve mechanism and other parts in the water system. If the

concentration of impurities is high, cloudy cubes or mushy ice may be the result.

Parts of the ice maker, that are in contact with the water or ice, may corrode if the water is high in acidity. In

some areas, water may have to be treated in order to overcome some of the problems that arise because of the

mineral content.

IMI Cornelius has water filter/treatment systems available to control impurities found in your water supply. Contact your local dealer for more information.

WINTER STORAGE

If the unit is to be stored in an area where the temperature will drop below freezing, it is most important that all

water lines be drained to prevent them from freezing and possible rupture.

To blow out the water line, disconnect the water supply at the cabinet inlet and use air pressure to force the water into the water reservoir pan. This can then be removed from the water pan.

WATER COOLED CONDENSER – To remove water from condenser unhook water supply and attach compressed air hose. Start machine. As head pressure reaches the appropriate level opening the water regulating

valve, the compressed air will force the water out. Do not let the machine operate longer than necessary.

CLEANING THE CONDENSER (AIR COOLED)

In order to produce at full capacity, the refrigeration condenser must be kept clean. The frequency of cleaning

will be determined by surrounding condition. A good maintenance plan calls for an inspection at least every two

months.

Remove the unit compartment grill at the front. With a vacuum cleaner, remove all accumulated dust and lint

that has adhered to the finned condenser.

CAUTION: CONDENSER COOLING FINS ARE SHARP. USE CARE WHEN CLEANING.

22166240009

Page 26

TROUBLESHOOTING

Trouble Probable Cause Remedy

UNIT WILL NOT RUN A. On–off switch in ”off” position. A. Turn switch to ”on”.

B. Defective on–off switch. B. Check and replace.

C. Blown fuse. C. Replace fuse and check for cause

of blown fuse.

COMPRESSOR CYCLES

INTERMITTENTLY.

D. Thermostat set too warm for

ambient.

E. Power relay contacts

corroded.

F. Defective thermostat. F. Check and replace.

G. Loose electrical connection. G. Check wiring.

H. Gearmotor overload protector

has cut off machine.

A. Low voltage. A. Check line voltage.

B. Dirty condenser. B. Clean condenser.

C. Air circulation restricted. C. Remove restriction.

D. Defective condenser fan

motor.

E. Defective relay, overload

protector or starting capacitor.

F. Loose electrical connection F. Check wiring.

D. Adjust colder.

E. Check and clean.

H. Turn switch to off then to on.

D. Check and replace.

E. Check and replace.

23 166240009

Page 27

Trouble RemedyProbable Cause

MAKING WET ICE. A. Surrounding air temperature

too high.

B. High water level in float

reservoir.

C. Dirty condenser. C. Clean condenser

D. Faulty compressor. D. Check and replace

E. Refrigerant leak. E. Check and repair

F. ”O” ring leaking at bottom of

evaporator shell.

*NOTE: Special care must be used with R404a (HP62) charged systems using (POE) Polyolester oil.

The refrigeration system must not be open longer than 15 min., and the appropriate drier must be used

due to the moisture absorption properties of the POE oil.

UNIT RUNS BUT MAKES NO

ICE.

A. Leak in refrigerant system. A. Check and repair.

B. Moisture in system. B. Check, dehydrate and add drier to

C. No water. C. Check water supply.

D. ”O” ring leaking at bottom of

evaporator shell.

A. Correct or move unit

B. Lower water level, see step 2,

page 5

F. Check and replace

system.

D. Check and replace ”O” ring.

E. Compressor not running. E. Check and replace ”O” ring

WATER LEAKS. A. Worn or bad float valve. A. Check and replace.

B. Float and arm assembly stuck. B. Check and adjust or replace.

EXCESSIVE NOISE OR

CHATTERING.

MACHINE RUNS WITH FULL

BIN OF ICE.

C. ”O” ring leaking at bottom of

evaporator shell.

D. Storage bin drain and tubing. D. Check and repair.

A. Mineral or scale deposits on

inside of evaporator shell.

B. Intermittent water supply . B. Check inlet water line .

C. Water level in float tank too

low.

D. Auger gearmotor end–play or

worn bearings.

E. Air lock in gravity water supply

line from float tank to

evaporator shell.

A. Storage bin thermostat set too

cold.

C. Check and replace.

A. Remove and clean inside

surfaces by immersing evaporator

shell in ice machine cleaner.

C. Check and adjust water level.

D. Repair or replace.

E. Check and adjust warmer.

A. Check and adjust warmer.

B. Bin thermostat thermowell out

of path of ice.

24166240009

B. Adjust thermowell.

Page 28

Trouble RemedyProbable Cause

UNIT OFF OR TRIPS CIRCUIT

BREAKER.

A. Ice jams up in evaporator

shell.

B. Bin thermostat will not shut–off

machine. Set too cold.

C. Auger motor has worn

bearings.

D. Ice chute out of alignment,

restricted ice flow out of

evaporator section.

E. Ice chute center separator

bent restricting ice flow out of

evaporator section .

F. Incoming water temperature

too cold.

G. Bin thermostat does not

shut–off when bin is full of ice.

H. Mineral or scale deposits on

inside of evaporator shell and

evaporator.

I. Strips loose or missing on

inside of evaporator shell.

A. Clean inside surface of

evaporator shell.

B. Check and adjust or replace .

C. Check and replace.

D. Re–align.

E. Replace ice chute .

F. Maintain temperature above 50°F.

G. Replace bin thermostat if

necessary.

H. Inspect and clean.

I. Inspect and replace evaporator

shell if necessary.

J. Low ambient temperature in

room where unit is located.

K. Gearmotor sticking which

causes it to draw excessive

amperage.

J. Maintain temperature above 50°.

K. Check amp draw of gearmotor

with an amprobe (1.6 amps) at

115V, (.7 amps) 230V for normal

loaded amps.

25 166240009

Page 29

Trouble RemedyProbable Cause

UNIT GOES OFF OR TRIPS

CIRCUIT BREAKER. (CONT’D)

L. Plugged expansion valve, or

capillary tube causing low back

pressure.

M. Slight leak, causing low back

pressure.

N. Loose hold–down assy. N. Check and tighten or replace.

O. Auger worn excessively on the

inside surfaces causing thicker

flaked ice to be made.

P. Auger out of line causing

excessive wear on the lower

outside surface where it rubs

against evaporator shell liner

at the bottom.

Q. Broken auger Q. Replace auger.

R. Evaporator surfaces worn or

gouged, causing thicker ice to

be made.

S. Auger guide bushing worn

down.

L. Check back pressure, replace

valve or capillary tube. Evacuate

and re–charge system, replace

drier–strainer.

M. Check back pressure, find gas

leak, repair leak, evacuate

system, add drier and recharge.

O. Replace auger.

P. Replace auger and evaporator

shell.

R. Inspect and replace evaporator if

necessary.

S. Replace auger guide bushing

(corkscrew type augers only).

T. Loose gearmotor mounting

place.

U. Low water level in float tank

reservoir.

V. Worn thrust washer. V. Replace.

W. Gearmotor Delay Thermostat

does not keep gearmotor

running after Bin Thermostat

shuts down.

T. Check and tighten.

U. Adjust float arm to maintain

correct water level.

W. Check operation and / or replace.

26166240009

Page 30

PARTS LIST FOR 750 AND 1100 SERIES

ILL.

NO . DESCRIPTION 1100 750 1100–50Hz 750–50Hz

1 Shroud, condenser 27597 161890012 27597 161890012

2 Condenser 26266 161870004 26266 161870004

3 Bracket, fan motor 37977 163183006 37977 163183006

4 Blade, condenser fan 23527 165595003 23527 165595003

5 Motor, condenser fan 35961 161871003 35961 161871003

6 Coil, condenser 22499 22429 22499 N/A

7 Clamp, condenser coil 35987 35987 35987 N/A

8 Bracket, coil mounting 36836 36836 36836 N/A

9 Drier 21850 166184002 21850 166184002

10 Valve, water regulating 01211 164980002 01211 N/A

11 Clip, delay thermostat 25871 25871 25871 25871

12 Thermostat, gearmotor delay 25864 25864 25864 25864

13 Pad 26124 26124 26124 26124

14 Hold–down, evaporator 163277003 163277002 163270003 163270002

15 Evaporator 42597 41100 42597 41100

16 O–Ring 03120 03120 03120 03120

17 Auger 21078 03796 21078 03796

18 Shell 162966001 09182 162966001 09182

19 Valve, automatic expansion 27653 161921004 27653 161921004

20 Thrust washer 21711 08043 21711 08043

21 Gearmotor assembly 164826003 164826001 164826003 164826002

22 Disc, centering 20956 20956 20956 20956

23 Chute, vertical 27599 27598 27599 27599

24 Float tank assembly 21789 21789 21789 21789

25 Float & valve only 21924 21924 21924 21924

26 Screw, wing 00890 00890 00890 00890

27 Gasket, chute 08065 08065 08065 08065

28 Chute, inclined ice 20885 09287 20885 09287

29 Compressor (1PH) 40569 162964013 40569 162964041

Compressor (3PH) 41166 N/A N/A N/A

30 Cover, vertical chute 42316 29299 42316 29299

31 Control, high pressure 07024 165677006 07024 165677006

32 Control, low ambient fan 23838 165677005 23838 165677005

33 Relay, power (1PH) 40713 164884002 40713 40713

Relay, power (3PH) 35547 N/A N/A N/A

34 Compressor cooling fan motor (not shown) 23308 N/A 23308 N/A

35 Thermostat, bin 09570 09570 09570 09570

36 Capacitor, compressor run 27765 161192004 27765 N/A

37 Capacitor, compressor start 40284 161165008 40284 25335

38 Capacitor, gearmotor start 37909 161165000 37909 29519

39 Switch, on–off / Circuit Breaker 166220000 166220001 166220000 166220000

40 Relay, compressor start 40285 161998009 40285 161998012

41 Relay, gearmotor start 161627003 161627001 161627003 161627003

42 Compressor cooling fan blade (not shown) 09355 N/A 09355 N/A

43 Plate, gearmotor mounting 03163 03163 03163 03163

44 Valve, Service N/A 162978003 N/A 162978003

45 Top panel 163652068 163652068 163652068 163652068

Top panel, stainless steel 27654 27654 27654 N/A

46 Front panel 163498068 163498068 163498068 163498068

Front panel, stainless steel 27655 27655 27655 N/A

47 Left side panel 163653068 163653068 163653068 163653068

Left side panel, stainless steel 27657 27657 27657 N/A

48 Right side panel 163654068 163654069 163654068 163654069

Right side panel, stainless steel 27670 27670 27670 N/A

49 Back panel 163499068 163499068 163499068 163499068

Back panel, stainless steel 27656 27656 27656 N/A

50 Switch, Fan Cycling N/A 165677005 N/A 165677005

51 Switch, High Pressure Control N/A 165677006 N/A 165677006

27 166240009

Page 31

45

21

22

47

18

12

43

20

28

27

49

5

25

9

31

35

32

29

30

33

34

23

41

4

3

2

6

1

42

24

11

19

26

16

15

14

13

7

8

39

48

50

46

44

17

36

51

37

38

40

10

FIGURE 13. ILLUSTRATED PARTS BREAKDOWN SERIES 750 – 1100

28166240009

ill227

Page 32

13

1

2

3

4

5

6

7

9

8

14

12

10

11

FIGURE 14. REMOTE CONDENSER ILLUSTRATED PARTS BREAKDOWN FOR 1100 SERIES

ILL. NO. PART NO. DESCRIPTION

1 27334 Condenser

2 27149 Shroud

3 27576 Frame assy

4 27183 Fan blade

5 27185 Motor, fan

6 27384 Bracket, fan motor mounting

7 27181 Relay

8 27379 Cover, electrical box

9 27345 Electrical box assy

10 42145 CNN–Quick, male

11 42624 CNN–Quick, male

12 42202 Bracket, connector

13 42278 Tube Condenser In

14 42277 Tube Condenser Out

29 166240009

Page 33

PARTS LIST 2400 SERIES

ITEM NO DESCRIPTION PART NO.

1 Condenser A/C 161870011

2 Fan mounting bracket 164820021

3 Fan motor 27185

4 Fan blade 27183

5 Drier 166184002

6 Masonite Pad 26124

7 Hold–down 163277003

8 Evaporator 42597

9 Evaporator O–Ring 03120

10 Auger 21078

11 Shell L.H. 162966001

12 Shell R.H. 162966002

13 Automatic expansion valve 161921010

14 Thrust washer 21711

15 Gearmotor 164826003

16 Vertical chute cover 166205001

17 Vertical chute 42328

18 Water reservoir 35225

19 Float & valve 27156

20 Hose 35771

21 Float mounting bracket 35231

22 Compressor 162964029

23 Thermowell end cap 20421

24 Fan Cycling Switch 165677006

25 Delay thermostat 25864

26 Delay thermostat clip 25871

27 Contactor 40713

28 Capacitor, compressor start 40284

29 Gearmotor start relay 161627003

30 Gearmotor–compressor control relay 35548

31 Bin thermostat 09570

32 On–off switch/Circuit breaker 166220000

33 Gearmotor start capacitor 37909

34 Water pressure switch 165677007

35 Compressor run capacitor 27765

36 Gearmotor mounting plate 03163

37 Centering disc 20956

38 Compressor start relay 40285

39 Main power switch 35546

40 Reservoir cover 35230

41 High pressure control switch 165677005

42 Chute 20885

43 Chute gasket 08065

44 Screw, chute mounting 00890

CABINET PARTS NOT ILLUSTRATED 2400 SERIES

Description Part No.

Top cover 163494068

Front panel 163493068

Right side panel 163492068

Left side panel 163491068

Rear panel 163490068

30166240009

Page 34

41

24

43

15

22

10

13

12

36

25

37

26

14

8

7

6

5

23

37

16

17

9

20

14

13

11

10

36

44

34

21

19

18

20

8

6

7

32

39

35

33

28

42

38 38

29 2930 31

32

40

3

45

27

35

33

28

2

1

FIGURE 15. ILLUSTRATED PARTS BREAKDOWN SERIES 2400

31 166240009

Page 35

CORNELIUS LIMITED COMMERCIAL WARRANTY PLAN

TO THE ORIGINAL OWNER OF A CORNELIUS COMMERCIAL FLAKE ICEMAKER

This warranty applies to Icemakers installed within the United States, Canada, Mexico and Puerto Rico

only.

For warranty information outside the U.S., Canada, Mexico and Puerto Rico, contact your nearest IMI Cornelius

Sales Office.

PARTS WARRANTY PERIOD

IMI CORNELIUS INC., hereinafter referred to as CORNELIUS, warrants to the original owner of a new CORNELIUS commercial flake ice

machine (“Machine”) who buys solely for commercial uses, that the Machine shall be free from defects in material and/or factory workmanship if

properly installed, operated and maintained, under normal and proper use and service conditions with competent supervision. The parts

warranty period is two years (24 months) from the date of installation or 27 months from the date of shipment by CORNELIUS whichever time

period elapses first. With respect to compressor and the evaporator, and the evaporator only for refrigeration leaks and restrictions which

would effect the normal operation of the unit, the warranty period will be five years (60 months) from the date of installation or 63 months from

the date of shipment by CORNELIUS whichever time period elapses first. The obligation of CORNELIUS under this warranty is limited to repair

or replacement (at the option of CORNELIUS) FOB factory in Mason City, Iowa of the part (or Parts) of any Machine that is proven defective.

LIMITED LABOR WARRANTY PERIOD

In addition to the parts warranty, CORNELIUS will pay scheduled straight time labor to repair or replace a defective component when failure

occurs within one year (12 months) from the date of installation or 15 months from the date of shipment by CORNELIUS whichever time period

elapses first. With respect to the compressor, evaporator, refrigeration condenser, condenser fan motor, and auger gearmotor, the labor

warranty period will be two years (24 months) from the date of installation or 27 months from the date of shipment by CORNELIUS whichever

time period elapses first. Time and rate schedules for labor compensation will be published periodically by CORNELIUS. Additional expenses

including but not limited to travel time, truck charges, overtime charges, material cost, accessing or removal of the ice machine,

normal prescribed maintenance cleaning, adjustments, and ice purchases are the responsibility of the original owner.

No parts warranty or labor allowance on the motor compressor assembly will apply when the ice machine’s refrigeration system is modified with

a condenser heat reclaim device, or parts and assemblies not provided by CORNELIUS, unless CORNELIUS provides approval, in writing, for

these modifications for specific locations.

The parts warranty shall not apply when destruction or damage is caused by alterations, unauthorized service, using other than factory

authorized replacement parts, risks of transportation, accidents, misuse, damage by fire, flood or acts of God. No components or assembly

from which the serial number or identification number has been altered or removed will be covered. Any defective parts to be repaired or

replaced must be returned to us through a CORNELIUS distributor/dealer, transportation charges prepaid, and they must be properly sealed

and tagged. The serial and model number of the Machine and the date of original installation of such Machine must be given. The warranty of

repaired or replaced parts will not extend beyond the period of the original warranty. The decision of the CORNELIUS Service Department

regarding the warrantability of parts and eligibility for the labor allowance will be final.

No representative, distributor/dealer or any other person is authorized or permitted to make any other warranty or obligate CORNELIUS to

make any other warranty or obligate CORNELIUS to any liability not strictly in accordance with this policy. This warranty is in lieu of all other

warranties expressed or implied and of all other obligations or of liabilities on our parts.

OUR LIABILITIES ARE LIMITED SOLELY AND EXCLUSIVELY TO REPAIR OR REPLACEMENT OF THE DEFECTIVE PRODUCT. WE ARE

NOT LIABLE FOR ANY SPECIAL, INCIDENTAL OR CONSEQUENTIAL DAMAGES OF ANY KIND WHATSOEVER. In those jurisdictions

where liability for damages cannot be disclaimed, original purchaser’s recovery shall not exceed the cost of the warranted product.

Except for descriptions of size, quantity and type, which may appear on CORNELIUS product with specifications of certain industry,

government or professional organizations standards which may appear as product information disclosures in CORNELIUS literature and other

documents from time to time, THIS WARRANTY IS IN LIEU OF AND EXCLUDES ALL OTHER WARRANTIES, EXPRESSED OR IMPLIED,

INCLUDING WARRANTIES OR MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE.

CORNELIUS MAKES NO WRITTEN WARRANTY TO ANY PURCHASER WHO BUYS FOR PERSONAL, FAMILY OR HOUSEHOLD USE.

IMI CORNELIUS INC.

ONE CORNELIUS PLACE

ANOKA, MINNESOTA 55303-6234

166240010 32

P/N 163238002

Effective March. 1, 1996

Starting with Production

Serial

Number Code 9603

Page 36

THIS PAGE LEFT BLANK INTENTIONALLY

166240010 33

Page 37

IMI CORNELIUS INC.

Corporate Headquarters:

Anoka, Minnesota 55303-6234

One Cornelius Place

(763) 421-6120

(800) 238-3600

16624001034

Loading...

Loading...