series 65 80

Minitransporter

CORMIDI

srl

This manual should always be readily available so that the machine operator may

consult it immediately, and it must be saved for the entire duration of the machine’s life.

© 2010 - The entire or partial reproduction and/or divulging of this document is prohibited in any form without the written consent of the manufacturing company. The

editing of the text, the illustrations, and the paginations were realized by “Cormidi s.r.l.” The information and technical data were furnished, checked and validated by

the Cormidi Technical Office. The illustrations and technical data included in this manual are non binding: the manufacturer reserves the right to carry out

eventual modifications to its product without notice.

Ed. 1

USER’S MANUAL AND MAINTENANCE

leadinginnovation

Via Fonte, 342

84069 Roccadaspide (SA)

0828 943689 Fax 0828 943963

www.cormidi.com info@cormidi.com

Series 65-80

INTRODUCTION

Dear Customer,

We would like to take this opportunity to thank you

for your confidence in us shown by purchasing a

CORMIDI Minitransporter. This product was designed

and constructed for longevity and to be used with

maximum reliability.

It is, however, absolutely necessary to read this

manual carefully in which the procedure for optimum

use of the equipment is described: improper use may

provoke harm to oneself and cause injury to persons

and/or to one’s health.

Therefore, always keep this manual within easy

reach so that it may be consulted at any time, before,

during, and after use. If the machine is resold, do not

forget to give it to the new owner in that inside there

is the EC compliance certificate.

We would like to remind you that the illustrations

contained in the manual correspond for the most part

to the base model and that our models are regularly

improved and perfected with the goal of allowing our

customers to enjoy the maximum benefits of

innovations in technology: for this reason the

characteristics and the information contained in the

present manual may have been varied recently. We ask

you to contact us in case you should encounter

difficulty.

Remember for supplementary information you can

always contact your sales representative/dealer, or you

can contact us directly by telephone or by email at

info@cormidi.com

. If there is any doubt, it is better to

ask rather than proceed on your own.

We leave you to your perusal of the manual and

enjoyment of your machine!

Staff CORMIDI Srl

1. GENERAL INFORMATION

1.1. W

ARRANTY

Your machine is guaranteed for 12 months from the

date of its delivery and includes the substitution of

anything in particular that has resulted as, in the opinion of

our Technical Office, affected by construction defects.

Any part in particular that was not constructed by the

manufacturer, parts used in/on terrain surfaces, and

breakdowns caused by incompetence or carelessness,

including fuelling, are excluded from the guarantee.

The motor, instead, is covered under the manufacturer

of the motor’s own warranty according to the foreseen

conditions and terms.

The guarantee immediately expires if the machine is

utilized for uses different from those foreseen by the

Manufacturer, if it is damaged by the use of unauthorized

accessories or if it is repaired using unsuitable parts.

With the machine a Certificate of Warranty was

supplied which outlines the norms which regulate the

service of assistance under warranty. We highly

recommend reading the warranty form to fully

General Information

understand the various rights and responsibilities.

Collaborate with your sales representative when filling out

the form and make sure it is filled out correctly, in that the

text and the other formalities (shipment within the time

limit, etc.) represent the legal base for the warranty on the

machine.

1.2. G

OAL OF THE MANUAL

This manual has been drawn up by the

manufacturer and is an integral part of the machine: it

was written in Italian, the native language of the

manufacturer (1.7.4 - 2006/42/CE).

The information contained here within is addressed

to expert operators, equipped with specific knowledge

and competence in the sector of use. The manual

defines the objectives for which the machine was

designed and constructed.

To avoid incorrect manoeuvres that risk accident, it

is important to read this manual particularly before the

first use to familiarize oneself with the principal

commands and their functions.

A constant observance of the information

1

Series 65-80

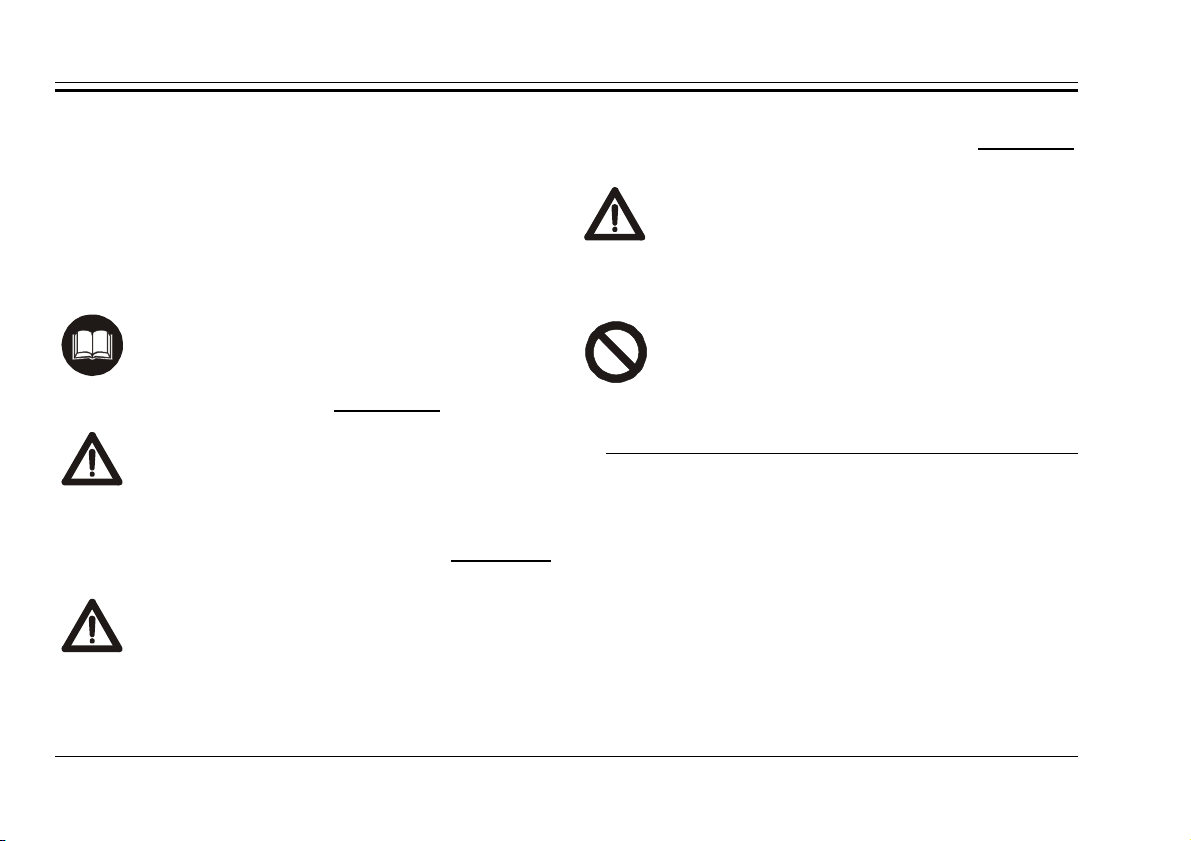

READ CAREFULLY: economy of use, and a

dangerous

voke serious injury or

On the machine potential dangers have

been indicated with a sticker characterized by

potentially

that can provoke

serious injury or death if the instructions are

On the machine the warnings are indicated

orange band

tuation that can provoke injury

or damage to the machine if the instructions

s

yellow band with black text.

IBITED: prohibitions that must be

observed by all persons who interact directly

and/or indirectly with the machine so that

guarantees safety, economy of use, and a longer

functional duration of the machine.

To give a higher prominence to the sections of the text

which must not be ignored, they have been highlighted in

bold and preceded with symbols illustrated and defined

following here:

longer functional duration of the machine.

DANGER: indicates imminently

situations that can pro

death if the instructions are not followed.

a red band with white text.

WARNING: indicates a

dangerous situation

not followed.

with stickers characterized by an

with black text.

CAUTION: indicates a potentially

dangerous si

are not followed.

On the machine situations requiring

caution are indicated by sticker

characterized by a

PROH

risks may be limited.

1.3. M

ACHINE DESCRIPTION

The Series 65-80 machines are compact autounloading tracked vehicles that are equipped with a

body and sometimes with other auto-loading

equipment, designed and manufactured for the

exclusive use of transporting inert materials.

To satisfy the various requirements of the market,

the machine may be equipped with motors that have

similar power but that have different brand names and

characteristics.

2

General Information

READ CAREFULLY: Determine the type of

motor that has been installed in your

read its manual to

READ CAREFULLY: The information

contained here is essential for your safety and

e operated

PROHIBITED: It is strictly prohibited to use

this machine for the transport of persons

PROHIBITED: It is strictly prohibited to use

to tow other machines, vehicles,

and/or devices, not even temporarily or in an

REQUIRED: Always wear suitable work

clothes and above all suitable work shoes

Always use protective hearing

away

et

substitute missing or illegible ones. Respect all

regulations contained in these.

machine accurately, and

familiarize yourself with it.

1.4. S

AFETY INFORMATION

for that of your co-workers!

During the production of this machine, every possible

measure was taken to make your work safer. Simple

prudence, however, is essential: there is no better rule to

prevent accidents.

WARNING: The tool must always b

by a competent and well-trained operator.

Carefully read the information before using the

machine or before performing maintenance and/or

repairs.

A few minutes of your time spent reading this manual

will save you time and effort later on.

Carefully read the warnings and information written

on the signs on the machine and immediately

The machine was made exclusively for the

transportation of inert materials. Any other use is

prohibited.

and/or animals.

this machine

emergency situation.

The machine constitutes a work instrument: always

respect the national regulations, especially those

relative to safety at the place of work.

diligently.

devices.

WARNING: Never wear large or flyclothes (scarves, ties) that could easily g

caught in the moving parts.

It is always advisable to have a first aid kit close at

3

Series 65-80

DANGER: Never use the machine inside

enclosed areas because the gasses emitted

REQUIRED: Carry out the disposal of oils,

minerals, and harmful products with respect

ccordance with

icle when the

motor is on or hot, in the proximity of flames

or while smoking. Always keep the machine

cleaned of lubricant and/or combustible

PROHIBITED: It is strictly prohibited to

remove protection and safety devices with

DANGER: While working always be sure that

the terrain has the required consistency and

avoid working on the edge of embankments,

ditches, or ravines or on excessively steep or

CAUTION: Never leave the machine

unattended while the motor is on, not even

temporarily: when you leave the area, turn off

e and put on the

DANGER: Never let children play with the

hand.

Before turning on the motor, always be sure that

there are not any people, animals, or things that

could be an obstacle in the work area.

by the exhaust are lethal.

for the environment and in a

the current norms.

which the machine is equipped

Avoid working under unsuitable physical conditions

or when you are very tired: in these cases interrupt

your work.

uneven terrain.

Every intervention for cleaning, tuning, and/or

maintenance must be done under good

environmental conditions and with adequate light,

and always with the motor turned off.

DANGER: Never refuel the veh

residues.

Pay careful attention to not come into contact with

the overheated parts of the motor.

4

When putting away the machine take all precautions

so that it might not be moved or turned on by

incompetent or incapable persons.

the motor of the machin

parking brake!

machine, not even if it is turned off!

1.5. M

PROHIBITED: it is strictly prohibited to use

the machine with its safety devices and

protection removed, blocked, or in any way

WARNING: Before beginning work, verify the

working order of the safety devices and

out and/or broken parts

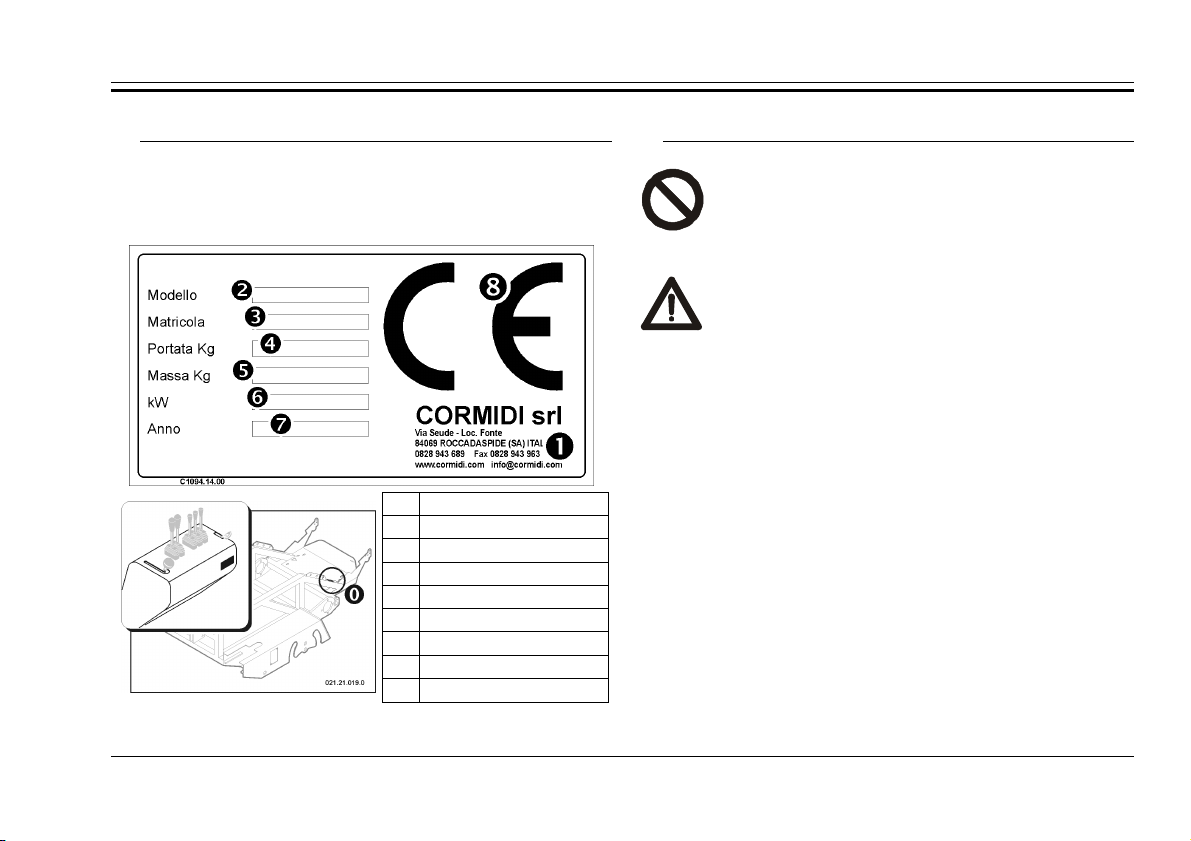

ACHINE AND MANUFACTURER IDENTIFICATION

The data which identifies the machine and the

manufacturer are listed on the aluminium plate that is

affixed on the dashboard of the machine. The frame

number is stamped on the left of back side (see fig. 1).

1.6. S

AFETY DEVICES

made non functional.

substitute any wornimmediately.

General Information

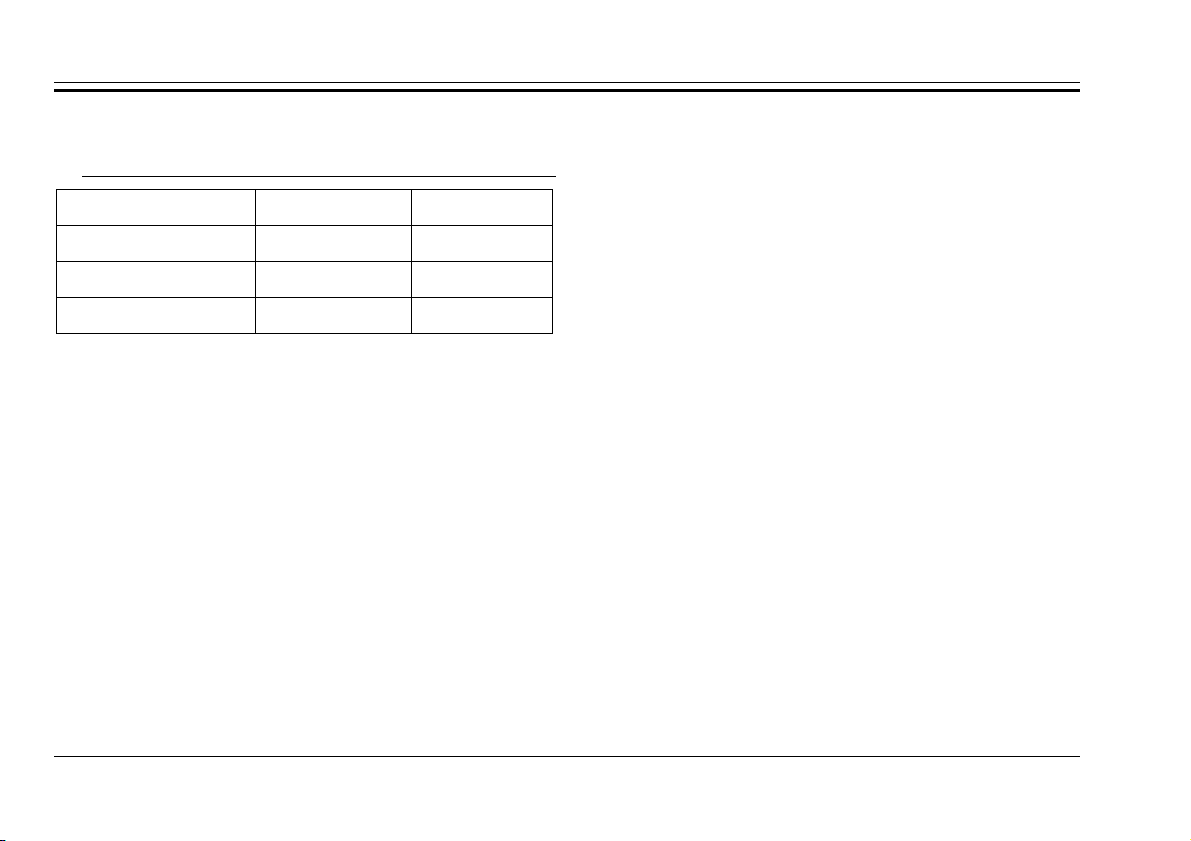

1 Manufacturer

2 Machine Type

3 Serial Numero

4 Load Capacity KG

5 Machine Mass KG

6 Motor Power KW

7 Fabrication Year

8 EC Brand

0 Frame Number

fig. 1 – Identification Plate (cod. C1094.14.00)

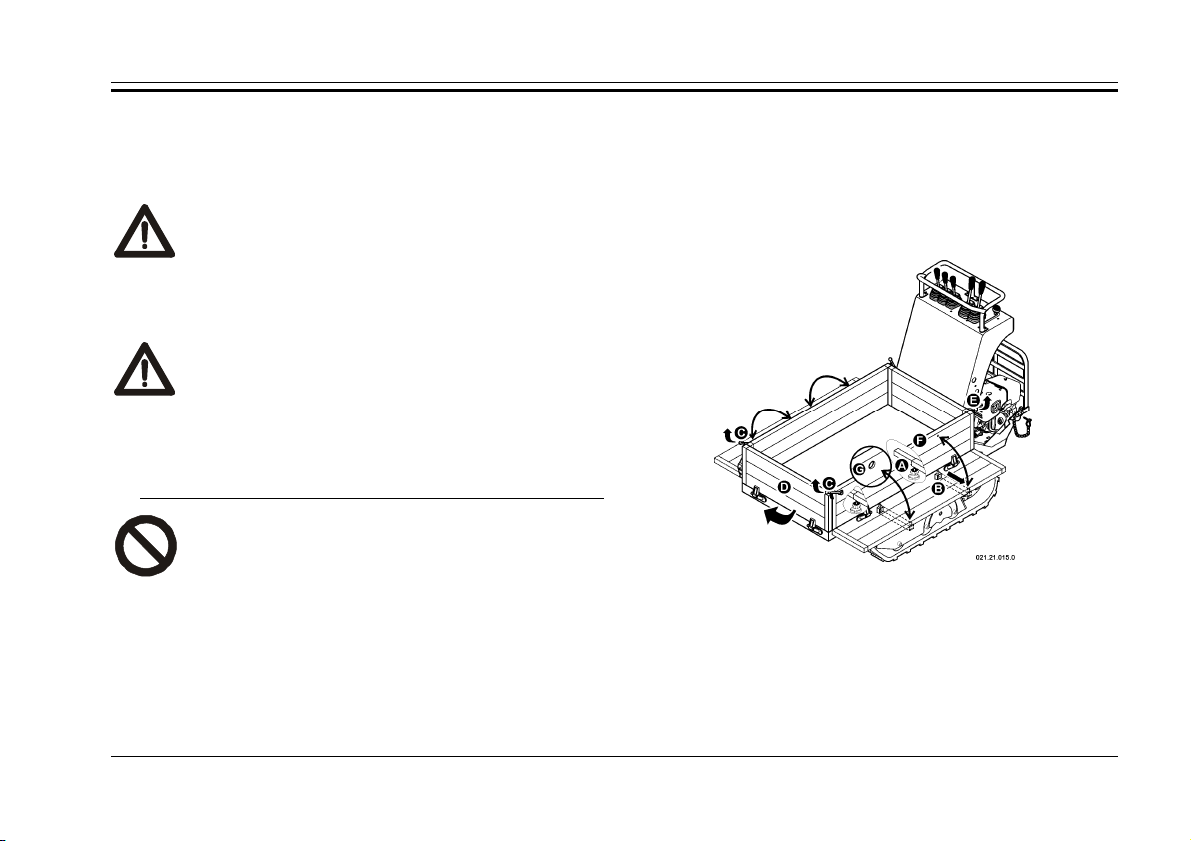

1.6.1. B

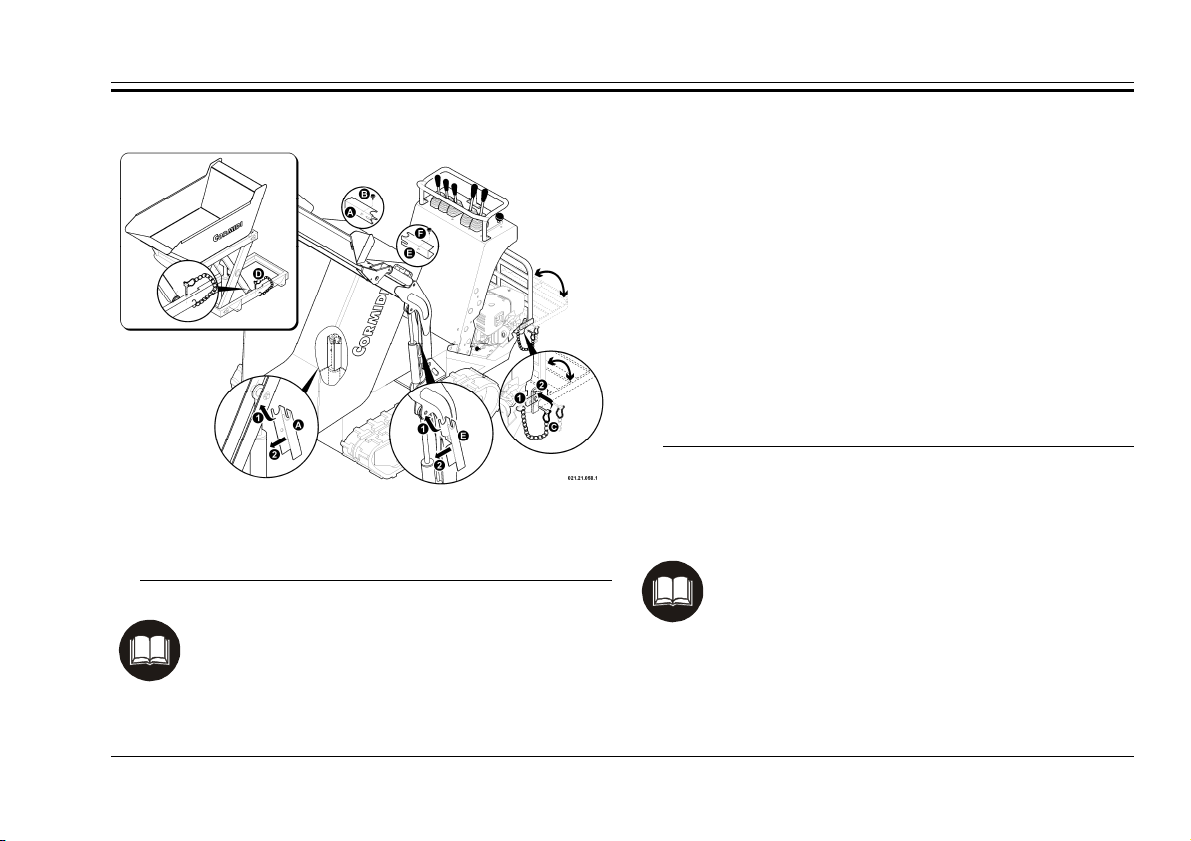

LOCKING THE BODY

The machine is equipped with a device to block the

body in the raised position and to prevent it from lowering

accidentally.

Before carrying out any repair maintenance work with

the body raised, always block the piston following this

procedure (see fig. 2):

• raise the body;

• turn off the motor;

• remove device “A” from its slot, down on the right side

of the body, by unscrewing wheel “B”;

• insert the hole of the bar on the piston of the hydraulic

jack;

• Turn the bar and position it so that it is parallel to the

5

Series 65-80

CAUTION: Always use the drive footrest

in open position during the work, to

Close the drive footrest

piston;

• slowly lower the unit with the motor off until the

correct fit of the device is obtained.

Afterwards remove the device and put it back in its slot.

1.6.2. B

LOCKING THE ARM

If necessary, the machine is equipped with a device

used to block the down-loading arm in the raised

position and prevents accidental lowering, as needed

can be placed on the piston on the left or right in a

similar manner.

Follow these steps (see fig. 2):

• Raise your arm of self-loading;

• Lift the body;

• Turn off the engine;

• Remove the safety device “E”, on the left side of the

container from the housing by loosening the knob “F”;

• Enter the slots of the bar near one of the two pistons of

hydraulic cylinders of the arm;

• Turn the bar and placed it parallel to the piston;

• Pull down slowly, with the engine off, the arm until the

frame of the device.

After the operations, remove the device and place it

back into place.

1.6.3. B

LOCKING THE FOOTREST

The drive footrest must always be blocked in open

position, during the work, to prevent its accidental

movement, by using the safety pin “C” (see fig.2).

Introduce pin “C” into hole “1” to block the footrest in the

raised position;

Introduce pin “C” in hole “2” to block the footrest in the

lowered position;

prevent risks.

only after use.

1.6.4. B

LOCKING THE LIFT

(“HI-TIP”)

The raising device for the body for high

unloading (Hi-Tip) can be blocked in a raised

position to impede accidental movement, by using

the safety pin “D” (see fig. 2).

Introduce the pin in the hole to block the mechanism in

the raised position.

6

General Information

Read the instructions

and the mode of use for the accessories that

have been installed on your machine carefully.

l that was

READ CAREFULLY: During the design phase

everything possible was done to prevent

eventual risks: where it was technically

pictograms were resorted

eventual potential and

e tags were made with

signals and descriptions associated with

pictograms to give a higher importance to

possible dangers, in accordance with

fig. 2 – Safety Devices

1.7. A

CCESSORIES

READ CAREFULLY:

Refer to the instruction manua

provided with them.

The machine is furnished with equippment to make it

possible to carry out normal maintenance operations.

It is also equipped with a hydraulic force instrument: in

the manual the instructions for its use have been

furnished.

Also, the machine the may also be equipped upon

request with particular tools including:

• Cement mixer for mixing concrete;

• Auto-loading tools;

• Excavator;

• Demolition hammer.

1.8. S

AFETY TAGS

impossible, specific

to in order to highlight

imminent risks.

Specific adhesiv

government norms UNI 9244-95 (E).

7

Series 65-80

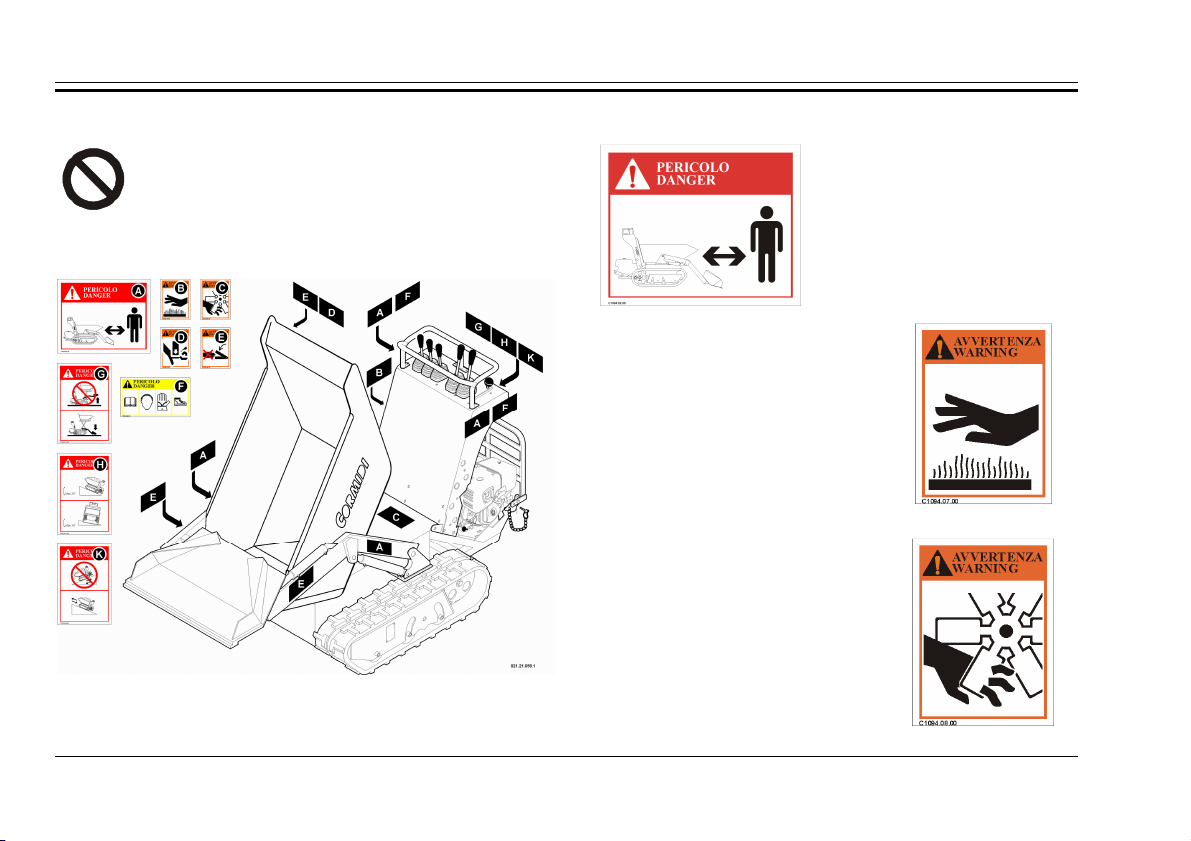

PROHIBITED: it is strictly prohibited to

ove the stickers and the safety plates

which the machine is equipped with:

immediately substitute deteriorated and/or

8

rem

illegible ones.

fig. 3 – Position of the SafetyTags

1.8.1. S

AFETY DISTANCE

Tag which alerts the

serious danger of coming

near and standing within the

field of action of the

machine in that there is an

imminent risk of danger.

fig. 4

(cod. C1094.02.00)

1.8.2. H

OT SURFACE

Invites caution in that there is a

risk of burning because of the

nearness to the hot surface.

1.8.3. FAN

Indicates a potential risk of

danger in that there is a possibility of

coming into contact with moving

mechanical parts that can cause

serious injury.

fig. 5

(cod. C1094.07.00)

fig. 6

(cod. C1094.08.00)

General Information

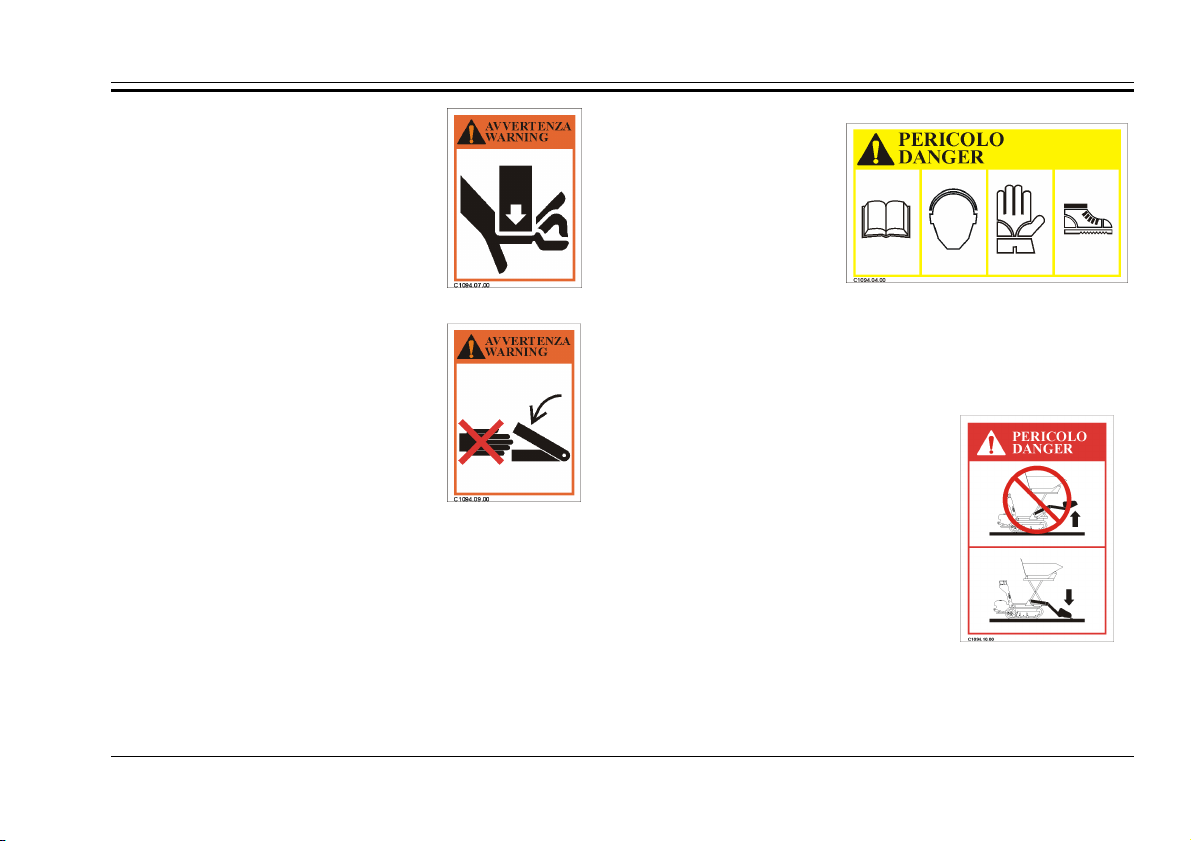

1.8.4. C

RUSHING

Tags which indicate a potential

risk of crushing that may cause very

serious injury or death.

1.8.5. C

UTTING

Tags which indicate a potential

fig. 7

(cod. C1094.09.00)

risk of cutting that may cause very

serious injury or death.

1.8.6. P

ROCEDURE FOR CAUTION

fig. 8

(cod. C1094.09.00)

This adhesive which invites caution reminds one to

adopt all anti-injury precau-tions, above all regarding the

use of protective devices and individual prevention. The

meaning of the pictograms is the following:

• Read the manual before turning the machine on for the

first time, each time an operator is changed, and in any

case in which doubt is raised as to how the machine

functions;

• Wear a headset

which protects

hearing or

another device of

this type;

• Wear protective

gloves of the

fig. 9

(cod. C1094.04.00)

prescribed type;

• Wear injury-preventive shoes of the prescribed type.

1.8.7. O

VERTURNING

Indicates an imminent risk of

overturning with serious

consequences during use of the

high unloading.

The correct procedure to carry

out high unloading includes the

necessity to rest the shovel of the

auto-loading on the ground in a

way that stabilizes the machine

before raising the body and

fig. 10

(cod. C1094.10.00)

unloading.

Instead the upper part of the tag indicates the incorrect

procedure which must be avoided absolutely, while the

9

Series 65-80

lower part shows the correct position to carry out the

unloading safely.

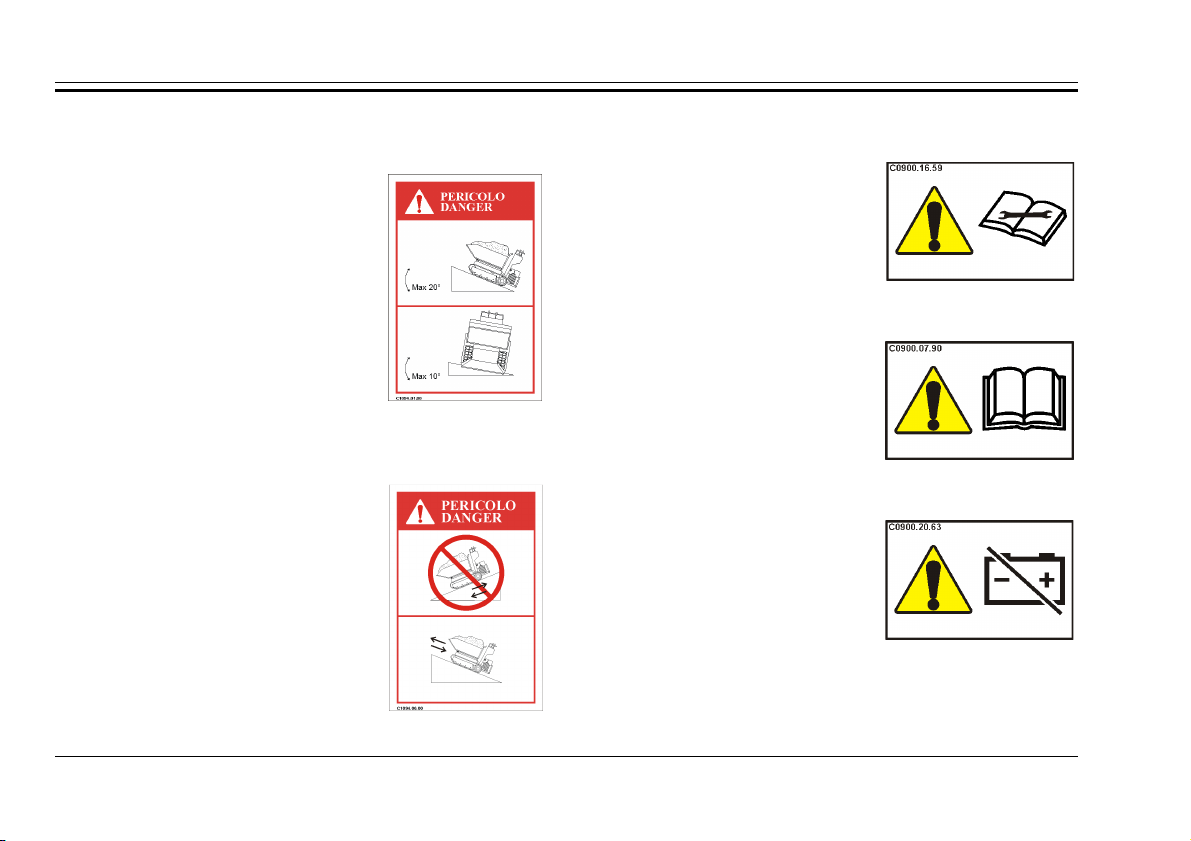

1.8.8. M

AXIMUM SLOPES

Completely avoid working on

terrains that have latitudinal slopes

of more than 10° and longitudinal

slopes of more than 20° to avoid the

possibility of overturning with

serious consequences for the safety

of the operator. In every case, but

especially in the case of slopes, it is

important that the terrain is solid

fig. 11

(cod. C1094.01.00)

and stable.

1.8.9. P

ROCEDURE FOR ADDRESSING SLOPES

Sign which indicates in what way

one must address the downhill and

uphill slopes to avoid serious

consequences for the operator and

for the machine in that there is the

potential danger of overturning.

fig. 12

(cod. C1094.06.00)

1.8.10. O

THER TAGS

The label on the side (fig.

12-a) indicates that it is

necessary to read the

documentation before any

intervention, to avoid technical

problems (ex. Manual attached

to the engine).

The label on the side (fig.

12-b) indicates that you should

read the owner's manual before

using the devices next to this

label, to avoid problems.

The label on the side (fig.

12-c) indicate the possibility of

disconnection of the battery

from the electrical circuit of

the machine; near the label

you can find the cut off

battery device (see cap. 2).

fig. 12-a

fig. 12-b

fig. 12-c

(cod. C0900.16.59)

(cod. C0900.07.90)

(cod. C0900.20.63)

10

A

DANGER: Always avoid working on terrain

with slopes that are greater than those

prescribed to avoid the possibility of

overturning with possible serious

DMISSIBLE SLOPES

General Information

1.9. D

IMENSIONS

Normal Auto-loading Hi-Tip

Length 1940 mm 2530 mm 2530 mm

Width 800 mm 850 mm 850 mm

Wheel Track 610 mm 610 mm 610 mm

Height

Min 1140 mm 1140 mm 1250 mm

Max 1400 mm 1900 mm 2720 mm

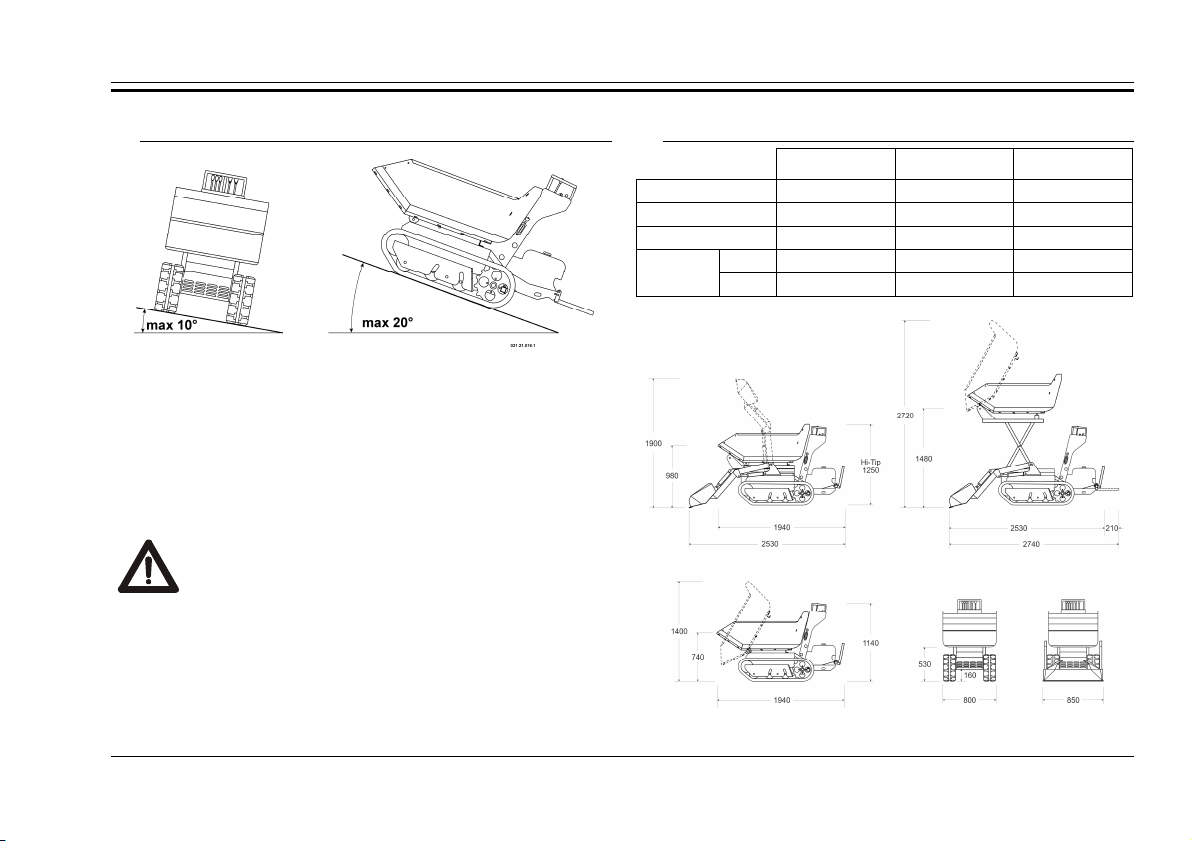

fig. 13 – Maximum admissible slopes

In figure 13 the maximum values for the latitudinal and

longitudinal slopes of the terrain are shown on which it is

possible to work. These conditions must never be

surpassed to avoid the risk of overturning.

consequences for the safety of the operator.

In every case, but especially when working on slopes,

it is important that the terrain is solid and stable.

fig. 14 – Dimensions

11

Series 65-80

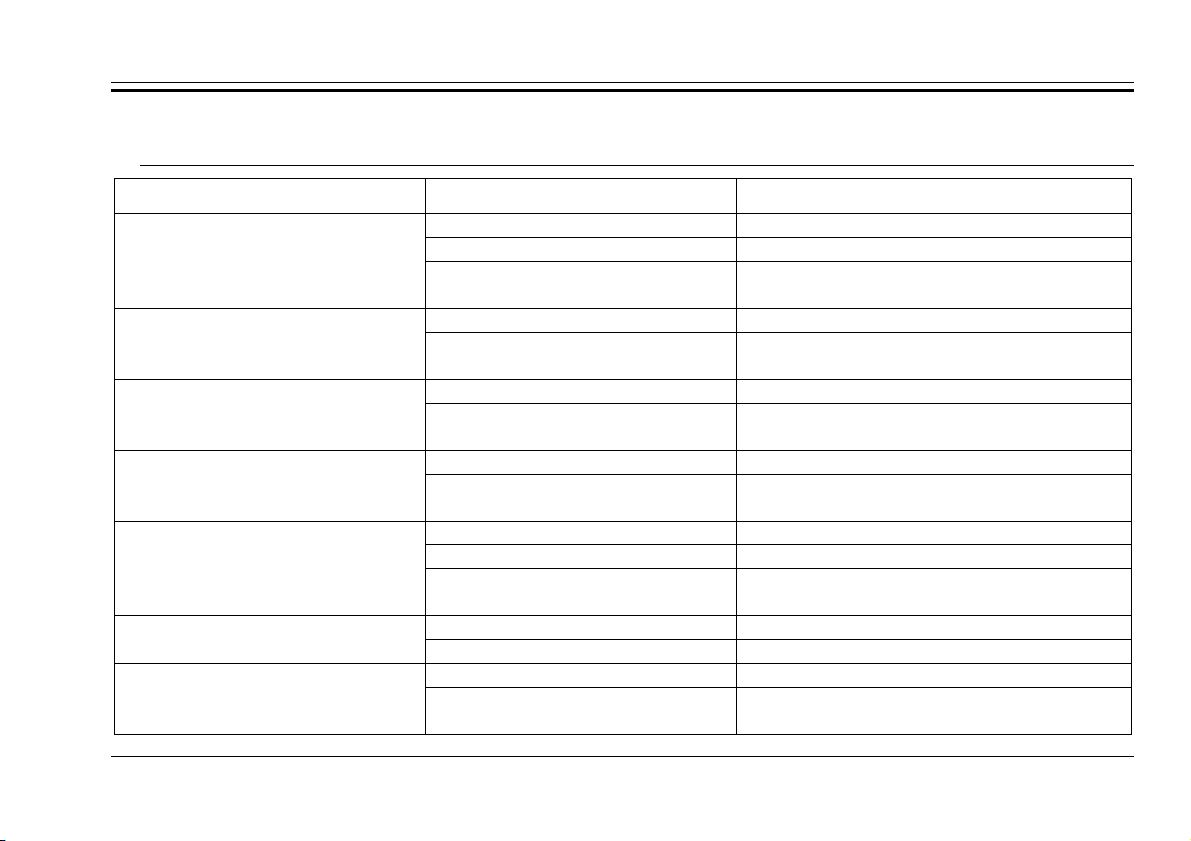

1.10. T

Model

Type

Mass [kg]

Engine

Power [kW]

Max Speed [km/h] - (m/s)

Load Capacity [kg]

Start-up

Accelerator

Trasmission

Parking Brake

Battery

Continuous Equivalent Pondered Acoustic Power Level A LpA =

Continuous Equivalent Pondered Acoustic

Power Level A (assured)

Vibrations Level m/s²

ECHNICAL DATA

Dumper Auto-loading Hi-Tip

9.65 10.80 13.80 9.65 10.80 13.80 9.65 10.80 13.80

430 500 450 500 580 520 630 670 650

petrol diesel petrol petrol diesel petrol petrol diesel petrol

6,7 (9,1) 7,2 (9,8) 9,3 (12,6) 6,7 (9,1) 7,2 (9,8) 9,3 (12,6) 6,7 (9,1) 7,2 (9,8) 9,3 (12,6)

4,6 (1,27) 6,5 (1,8) 4,6 (1,27) 6,5 (1,8) 4,6 (1,27) 6,5 (1,8)

650 800 650 800 650 800

Pull-start or Electric (depending on the type)

12V - 30Ah with negative at mass – petrol engine

12V - 45Ah with negative at mass – diesel engine

Type

LwA =

Manual command lever

Hydrostatic

Mechanical

9.65 10.80 13.80

99 dB(A) 100 dB(A) 100 dB(A)

101 dB(A) 101 dB(A) 101 dB(A)

on arms: ≤ 2,5 m/s²

on body: ≤ 1,1 m/s²

12

2. COMMANDS

STABLE POSIZIONE

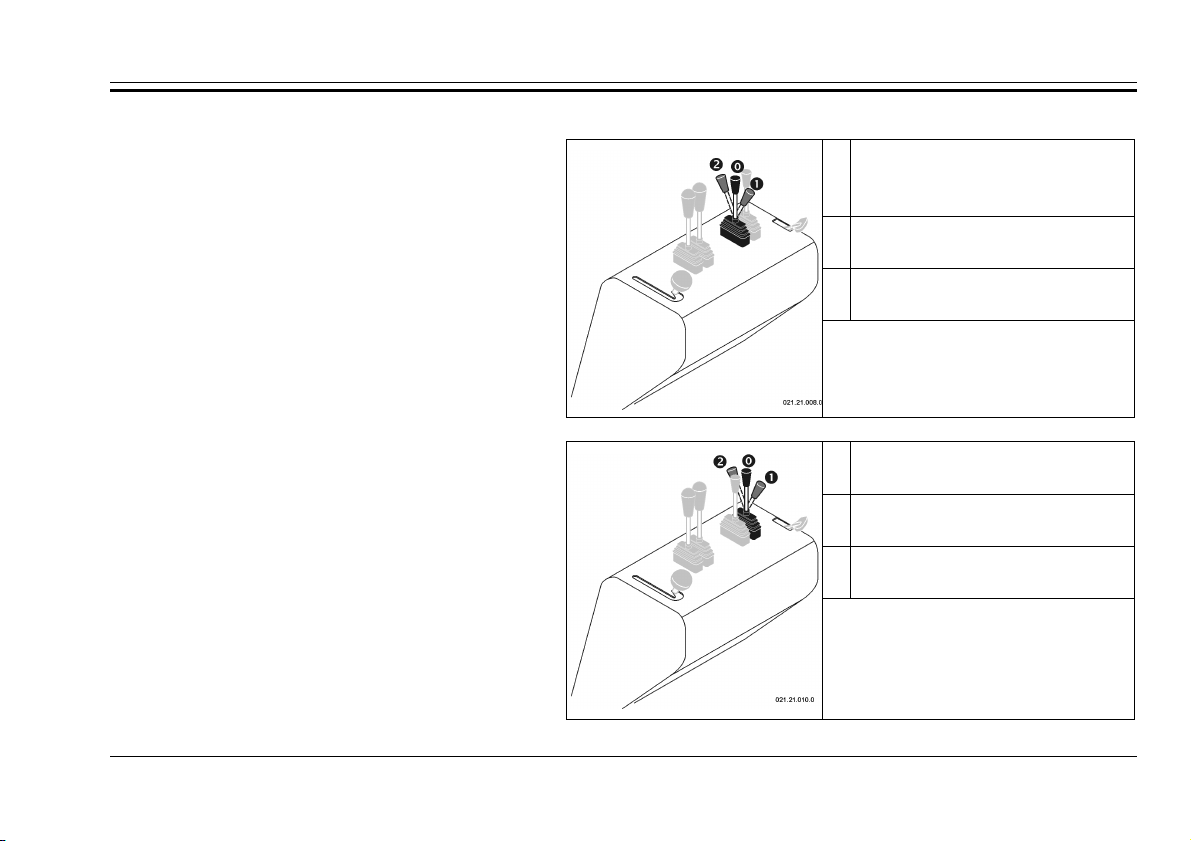

2.1. H

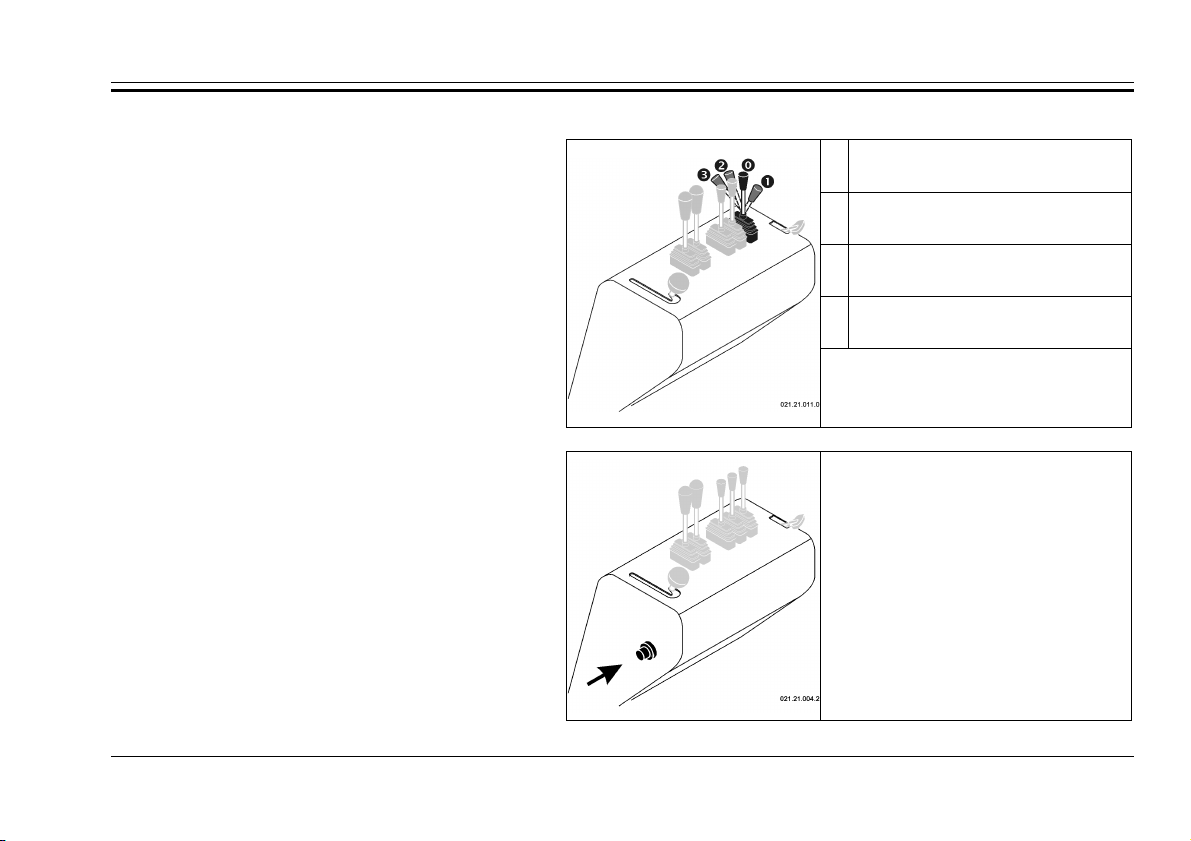

YDRAULIC OVERTURNING VERSION

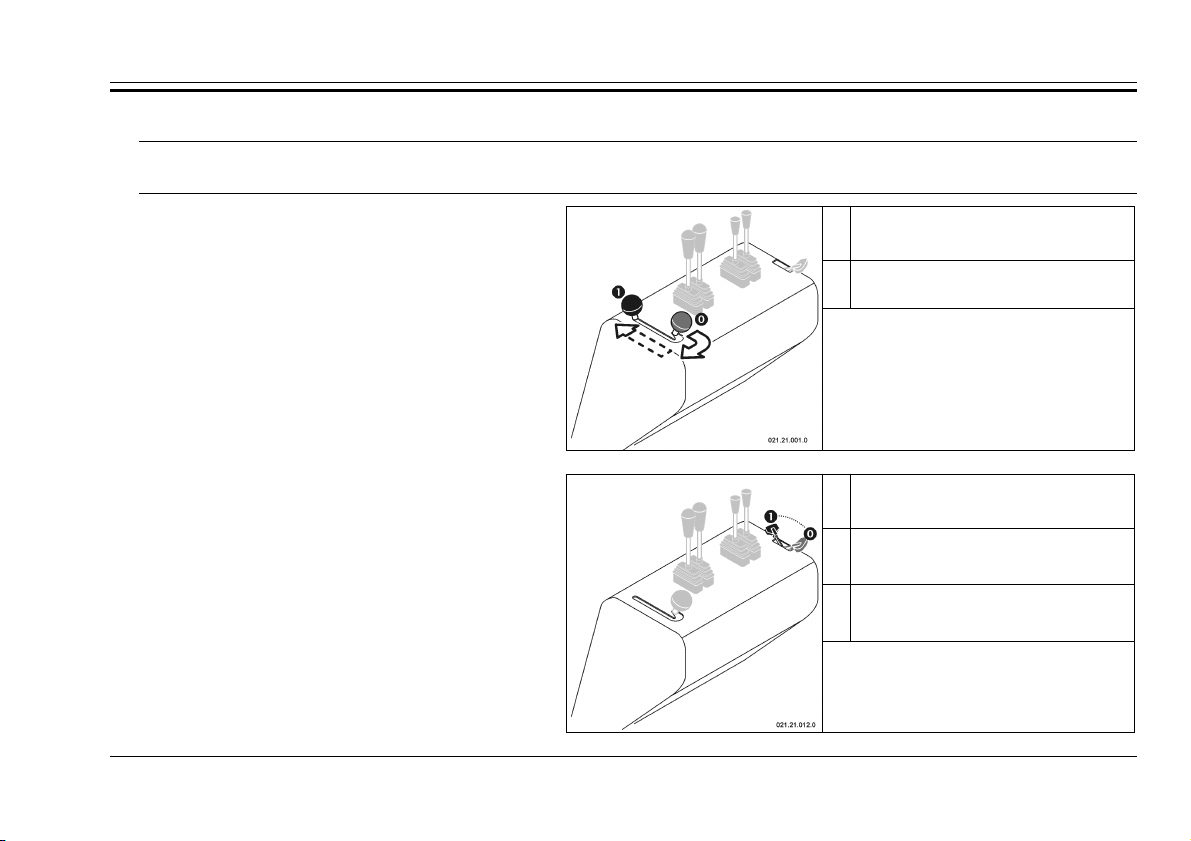

Parking Brake Command

Commands

STABLE POSITION

Deactivated Brake

serves as an emergency brake, allows you to

insert or deactivate the brake.

Accelerator Command

so that you may obtain the required power.

The parking brake command, which also

Allows you to vary the motor rotation regimen,

Activated Brake

fig. 15

Command lever for the parking brake

STABLE POSITION

Minimum regimen

STABLE POSITION

…

Intermediate regimens

STABLE POSITION

Maximum regimen

fig. 16

Accelerator Command

13

Series 65-80

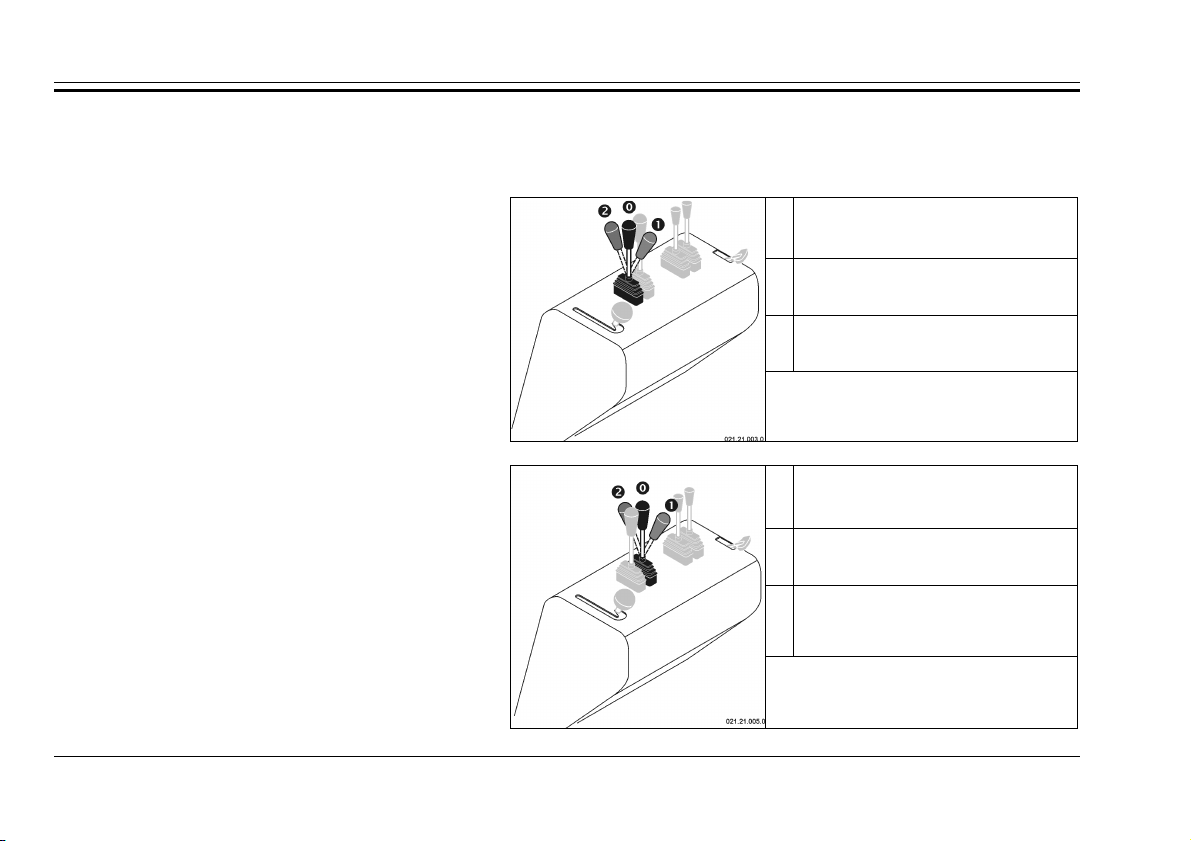

UNSTABLE POSITION

Drive Levers

The command levers control the rotation of the tracks through a hydraulic feed of the hydraulic motors.

The command levers are active only when the motor is turned on.

UNSTABLE POSITION

The left Drive Lever

The left track rotates forward

The left-hand drive lever controls the left track.

The right Drive Lever

The right-hand drive lever controls the right

track.

14

STABLE POSITION

Resting position

UNSTABLE POSITION

The left track rotates backwards

fig. 17

Command lever for the left track

UNSTABLE POSITION

The right track rotates forward

STABLE POSITION

Resting position

The right track rotates

backwards

fig. 18

Command lever for the right track

Command Lever for the Hydraulic Take-off

Command lever for the hydraulic force

Instrument

The hydraulic take-off instrument is composed

of two openings with rapid transmission of standard

type, indicated by the letters “A” and “B”, situated

on the right side of the dashboard.

Commands

UNSTABLE POSITION

Hydraulic pressure on “A”

STABLE POSITION

Resting position

POSIZIONE INSTABILE

Hydraulic pressure on “B”

The auxiliary command lever allows you to put

hydraulic oil pressure on the openings (cap. 3.11).

Command Lever for the Body

The command lever for the body activates the

hydraulic jack that activates the tipping of the body.

This position can only be used with the motor

turned on, while this position can also be used

when the motor is turned off.

fig. 19

instrument

UNSTABLE POSITION

The body overturns

STABLE POSITION

Resting position

UNSTABLE POSITION

Resting position

fig. 20

Command lever for the body

15

Series 65-80

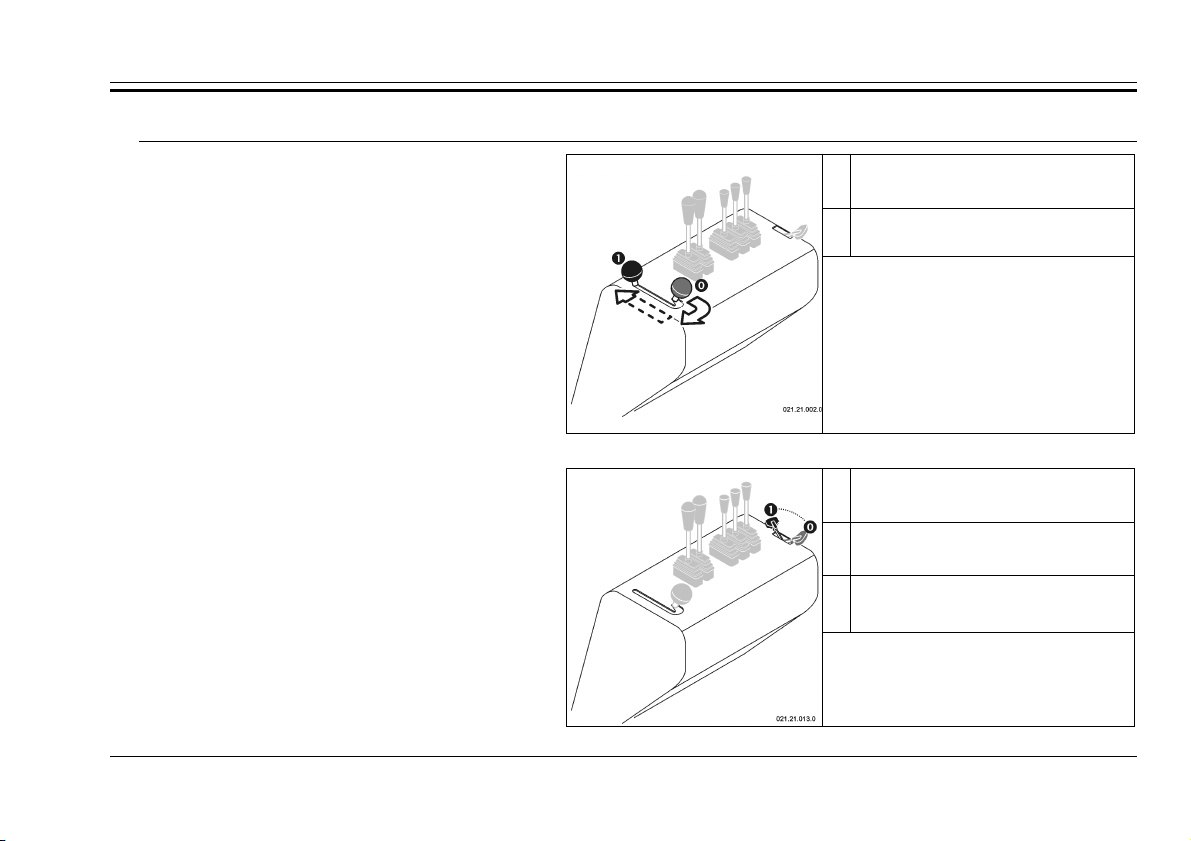

Horn Command

The horn button is on the left side of the

instrument panel. To sound the horn, push the

button. Only intermittent mode horn operation is

enabled. Continuous mode is not enabled.

The command works only with the engine

running.

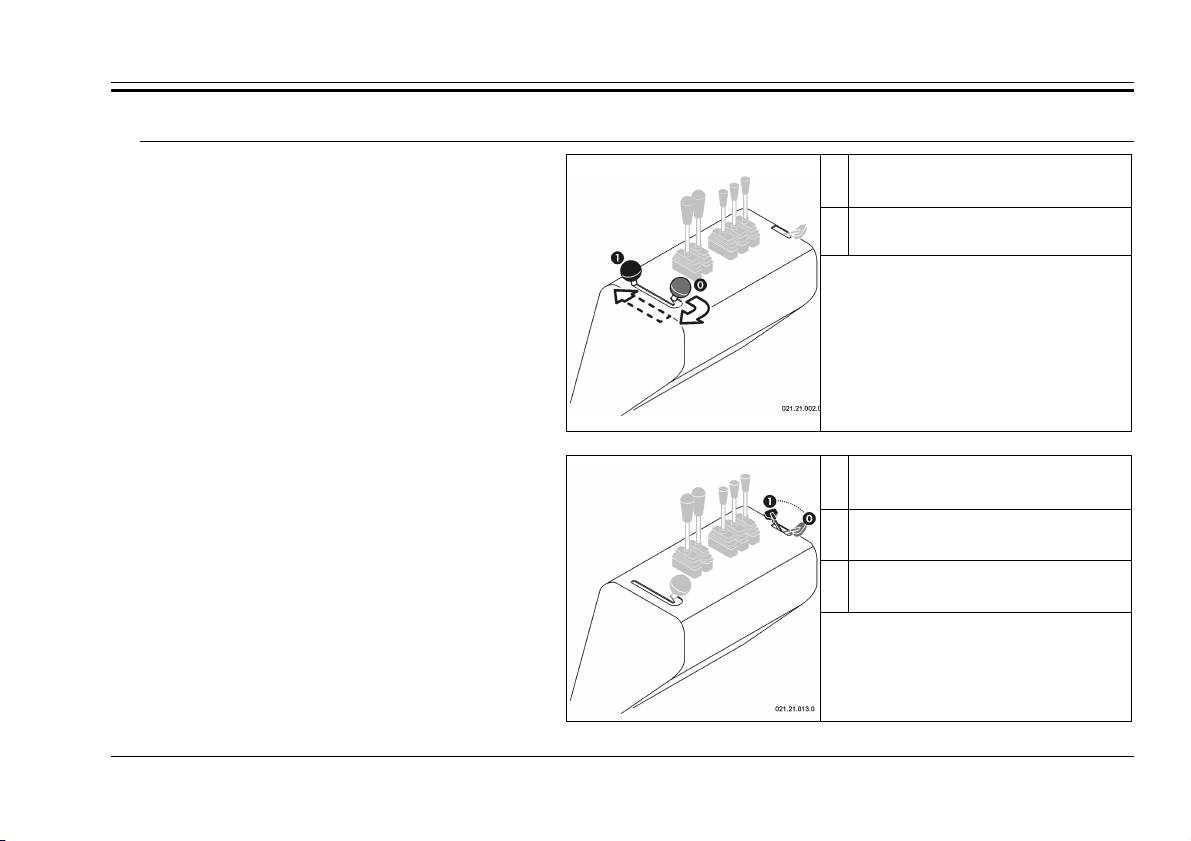

Cut Off Battery Command

The device lever on the left side of the

dashboard controls the disconnection of the battery

from the electrical circuit of the machine.

Use the cut off battery to disconnect power from

the electrical circuit, particularly if the machine stop

to work, for a long period of time, can be removed

the lever to prevent the discharge of the battery.

fig. 21

Horn Command

STABLE POSITION

Battery connected

STABLE POSITION

Battery unplugged

STABLE POSITION

Battery unplugged,

it’s possible remove the lever

fig. 22

Cut Off Battery Command

16

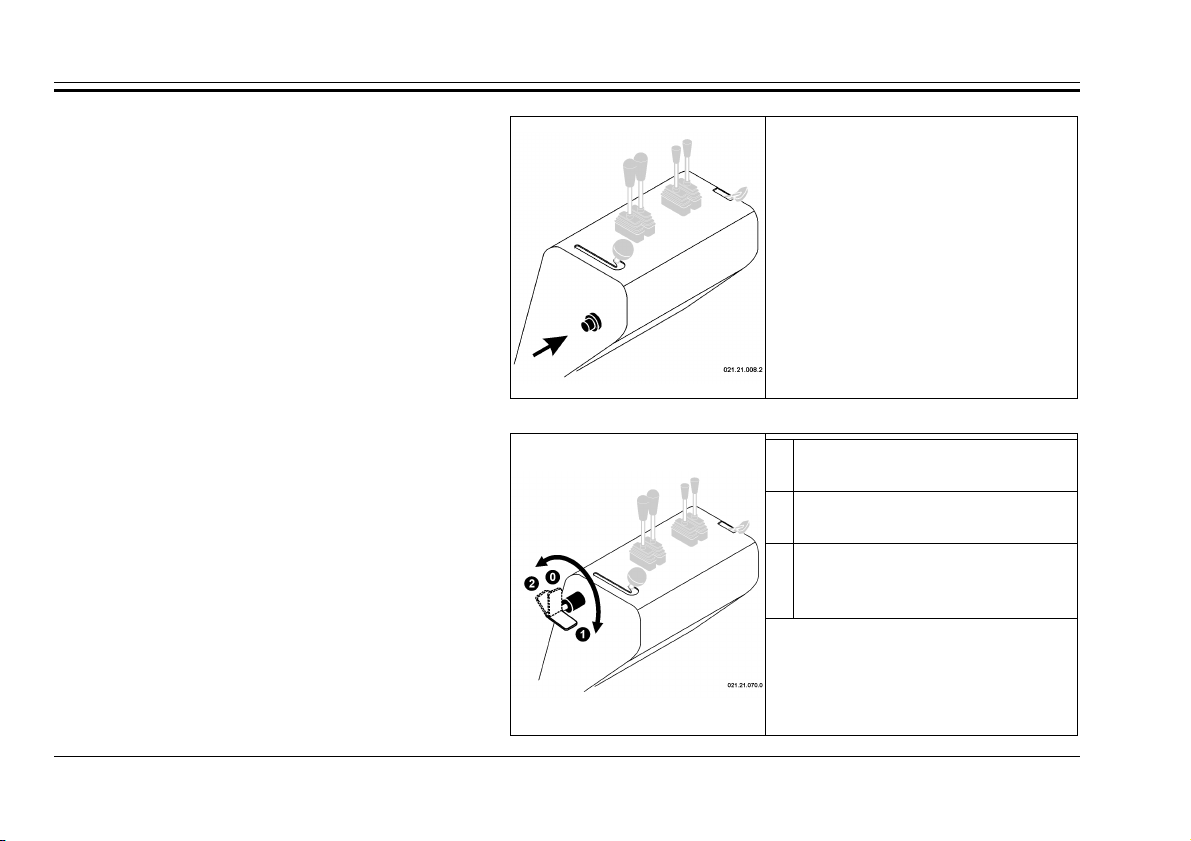

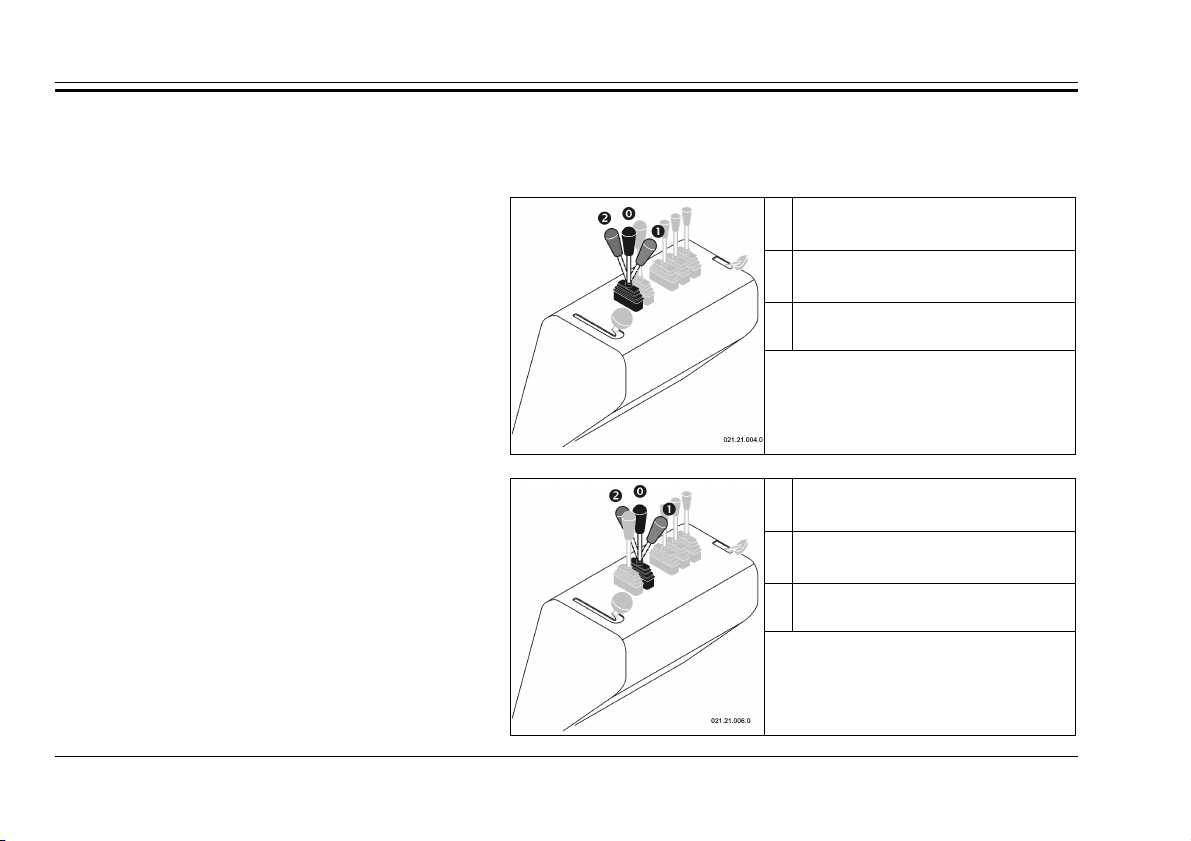

2.2. A

STABLE POSITION

UTOLOADING VERSION

Parking Brake Command

Commands

STABLE POSITION

Deactivated brake

The command for the parking break, which

also serves as an emergency brake, allows one

to activate or deactivate the brake.

Accelerator Command

The command lever for the accelerator acts

upon the motor and allows one to vary the rotation

regimen in order to obtain the required power.

Activated brake

fig. 23

Command lever for the parking brake

POSIZIONE STABILE

Minimum regimen

POSIZIONE STABILE

…

Intermediate regimen

POSIZIONE STABILE

Maximum regimen

fig. 24

Accelerator Command

17

Series 65-80

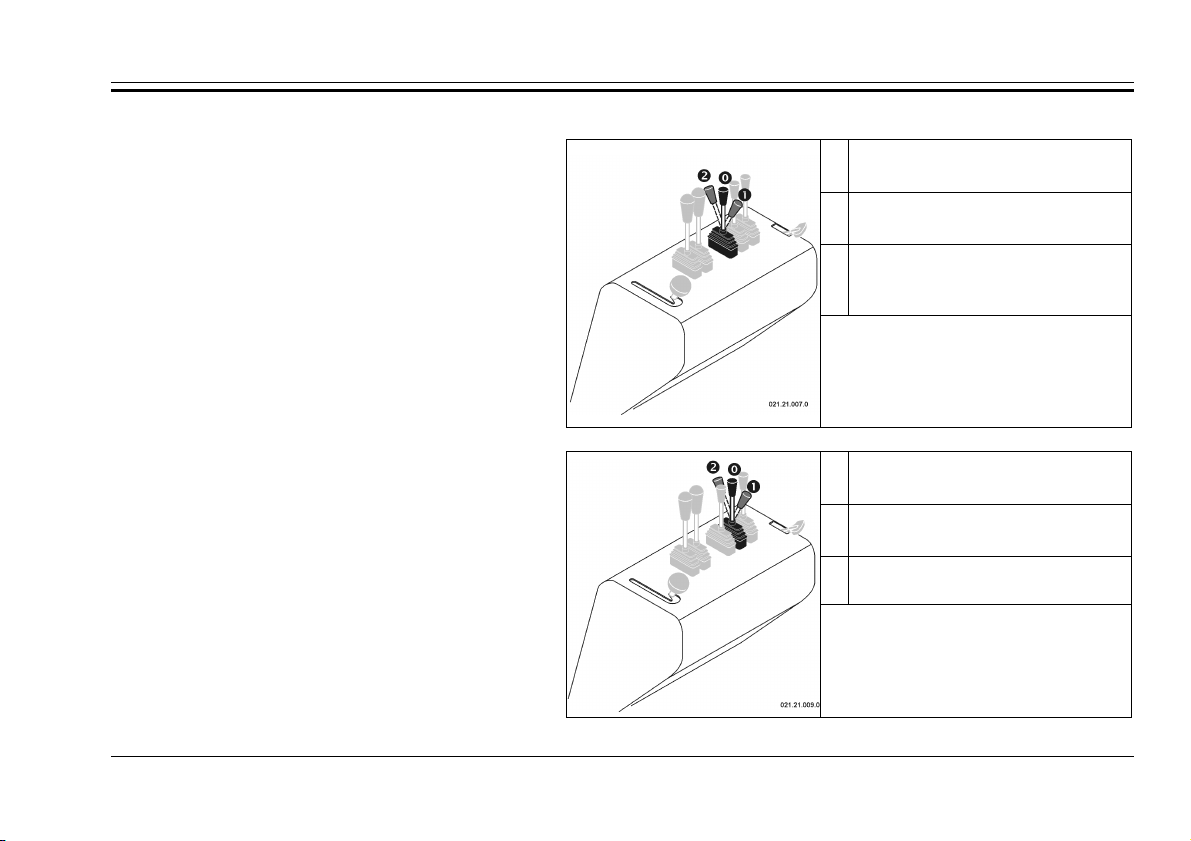

Drive Levers

The drive levers control the rotation of the tracks through a hydraulic feed to the hydraulic motors.

The levers are active only when the motor is turned on.

UNSTABLE POSITION

Left Drive Lever

The left lever controls the left track.

The left track rotates forward

STABLEPOSITION

Resting position

UNSTABLE POSITION

The left track rotates backward

fig. 25

Left track command lever

UNSTABLE POSITION

Right drive lever

The right lever controls the right track.

The right track rotates forward

STABLE POSITION

Resting position

UNSTABLE POSITION

The left track rotates backward

fig. 26

Right track command lever

18

Command Lever for the Hydraulic Take-off

UNSTABLE POSITION

Instrument

The hydraulic take-off instrument is composed

of two openings with rapid transmission of standard

type, indicated by the letters “A” and “B”, situated

on the right side of the dashboard.

The auxiliary command lever allows you to

apply hydraulic oil pressure on the openings

(cap. 3.11).

Command Lever for the Body

The command lever for the body activates the

hydraulic jack that activates the tipping of the body.

Commands

UNSTABLE POSITION

Hydraulic pressure on “A”

STABLE POSITION

Resting position

UNSTABLE POSITION

Hydraulic pressure on “B”

fig. 27

Command lever for the hydraulic

take-off openings

UNSTABLE POSITION

The body overturns

STABLE POSITION

Resting position

turned on, while this position can also be used

when the motor is turned off.

This position can only be used with the motor

The body lowers

fig. 28

Command lever for the body

19

Series 65-80

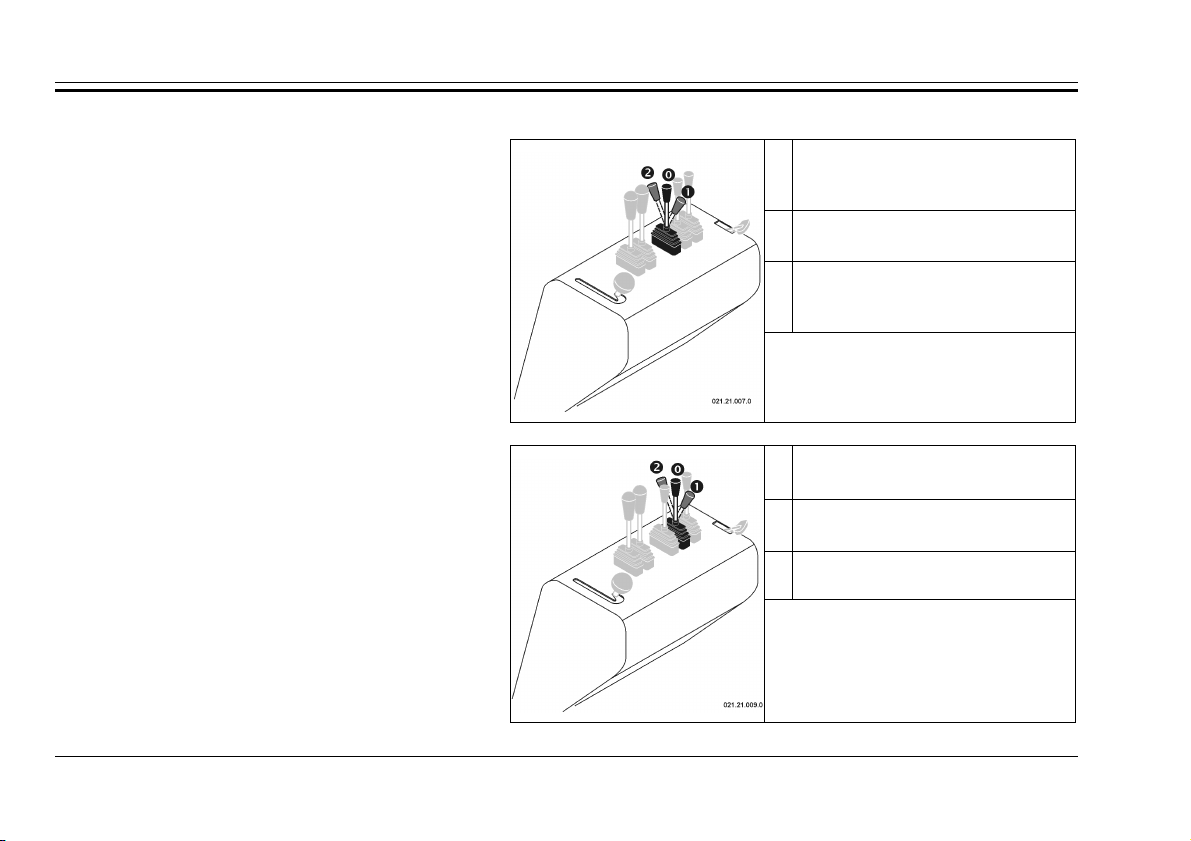

Auto-loading Command Lever

The command lever for the auto-loading tool

works the hydraulic levers that provoke the raising

of the auto-loading bucket.

This command may only be used when the

motor is turned on.

STABLE POSITION

The bucket is free (floating)

UNSTABLE POSITION

Lowering of the bucket

STABLE POSITION

Resting position

UNSTABLE POSITION

Raising of the bucket

Horn Command

The horn button is on the left side of the

instrument panel. To sound the horn, push the

button. Only intermittent mode horn operation is

enabled. Continuous mode is not enabled.

The command works only with the engine

running.

20

fig. 29

Command lever for the body

fig. 30

Horn Command

Cut Off Battery Command

The device lever on the left side of the

dashboard controls the disconnection of the battery

from the electrical circuit of the machine.

Use the cut off battery to disconnect power from

the electrical circuit, particularly if the machine stop

to work, for a long period of time, can be removed

the lever to prevent the discharge of the battery.

Commands

STABLE POSITION

Battery connected

STABLE POSITION

Battery unplugged

STABLE POSITION

Battery unplugged,

it’s possible remove the lever

fig. 31

Cut Off Battery Command

21

Series 65-80

STABLE POSITION

2.3. A

UTOLOADING VERSION WITH SWIVEL BUCKET

Parking Brake Command

STABLE POSITION

Deactivated brake

The command for the parking break, which

also serves as an emergency brake, allows one

to activate or deactivate the brake.

Accelerator Command

The command lever of the accelerator works on

the motor and allows one to vary the rotation

regimen in order to obtain the required power.

22

Activated brake

fig. 32

Command lever for the parking brake

STABLE POSITION

Minimum regimen

STABLE POSITION

…

Intermediate regimen

STABLE POSITION

Maximum regimen

fig. 33

Accelerator command

Drive Levers

The drive levers control the rotation of the tracks through a hydraulic feed to the hydraulic motors.

The levers are active only when the motor is turned on.

UNSTABLE POSITION

Left Drive Lever

The left lever controls the left track.

The left track rotates forward

STABLE POSITION

Resting position

UNSTABLE POSITION

The left track rotates backward

Left track command lever

UNSTABLE POSITION

Right Drive Lever

The right lever controls the right track.

The right track rotates forward

POSIZIONE STABILE

Resting position

POSIZIONE INSTABILE

The left track rotates backward

Commands

fig. 34

fig. 35

Right track command lever

23

Series 65-80

UNSTABLE POSIT

ION

UNSTABLE POSITION

UNSTABLE POSITION

Command Lever for the Swivel Bucket

The swivel bucket command lever works the

hydraulic jack that provokes the rotation of the

bucket of the auto-loading tool.

The command may only be used when the

motor is on.

The bucket turns towards the

anterior side of the machine

STABLE POSITION

Resting Position

Provokes the rotation of the

bucket towards the operator

Command Lever for the Body

The command lever for the body activates the

hydraulic jack that activates the tipping of the body.

This position can only be used with the motor

turned on, while this position can also be used

when the motor is turned off.

24

Fig. 36

Swivel bucket command lever

UNSTABLE POSITION

The body overturns

STABLE POSITION

Resting position

The body lowers

fig. 37

Command lever for the body

Auto-loading Command Lever

The command lever for the auto-loading tool

works the hydraulic jack that provokes the raising

of the auto-loading bucket.

This command may only be used when the

motor is turned on.

Horn Command

The horn button is on the left side of the

instrument panel. To sound the horn, push the

button. Only intermittent mode horn operation is

enabled. Continuous mode is not enabled.

The command works only with the engine

running.

Commands

STABLE POSITION

The bucket is free (floating)

UNSTABLE POSITION

Lowering of the bucket

POSIZIONE STABILE

Resting position

POSIZIONE INSTABILE

Raising of the bucket

fig. 38

Command lever for the body

fig. 39

Horn Command

25

Series 65-80

Cut Off Battery Command

The device lever on the left side of the

dashboard controls the disconnection of the battery

from the electrical circuit of the machine.

Use the cut off battery to disconnect power from

the electrical circuit, particularly if the machine stop

to work, for a long period of time, can be removed

the lever to prevent the discharge of the battery.

STABLE POSITION

Battery connected

STABLE POSITION

Battery unplugged

STABLE POSITION

Battery unplugged,

it’s possible remove the lever

fig. 40

Cut Off Battery Command

26

Commands

STABLE POSITION

2.4. “HI-TIP” V

ERSION

Parking Brake Command

The command for the parking break, which

also serves as an emergency brake, allows one

to activate or deactivate the brake.

Accelerator Command

The command lever of the accelerator acts

upon the motor and allows one to vary the rotation

regimen in order to obtain the required power.

STABLE POSITION

Deactivated brake

Activated brake

fig. 41

Command lever for the parking brake

STABLE POSITION

Minimum regimen

STABLE POSITION

…

Intermediate regimen

POSIZIONE STABILE

Maximum regimen

fig. 42

Accelerator command

27

Series 65-80

UNSTABLE POSITION

UNSTABLE POSITION

Drive Levers

The drive levers control the rotation of the tracks through a hydraulic feed to the hydraulic motors.

The levers are active only when the motor is turned on.

UNSTABLE POSITION

Left Drive Lever

The left lever controls the left track.

The left track rotates forward

STABLE POSITION

Resting position

The left track rotates backward

fig. 43

Left track command lever

UNSTABLE POSITION

Right Drive Lever

The right lever controls the right track.

The right track rotates forward

STABLE POSITION

Resting position

The left track rotates backward

28

fig. 44

Right track command lever

“Hi-Tip” (High Unloading) Command Lever

UNSTABLE POSITION

UNSTABLE POSITION

The command lever the “Hi-Tip” works the

hydraulic jack that provokes the raising of the

anchoring structure of the body to consent the

unloading in containers or tubs with a high border.

The command may be used only when the

motor is on.

Commands

UNSTABLE POSITION

Allows the body to be raised

STABLE POSITION

Resting position

Provokes the lowering of the

body

Command Lever for the Body

hydraulic jack that activates the tipping of the body.

turned on, while this position can also be used

when the motor is turned off.

The command lever for the body activates the

This position can only be used with the motor

fig. 45

“Hi-Tip” Command Lever

UNSTABLE POSITION

The body overturns

STABLE POSITION

Resting position

The body lowers

fig. 46

Command lever for the body

29

Series 65-80

Auto-loading Command lever

The command lever for the auto-loading tool

works the hydraulic jack that provokes the raising

of the auto-loading bucket.

This command may only be used when the

motor is turned on.

Horn Command

The horn button is on the left side of the

instrument panel. To sound the horn, push the

button. Only intermittent mode horn operation is

enabled. Continuous mode is not enabled.

The command works only with the engine

running.

STABLE POSITION

The bucket is free (floating)

UNSTABLE POSITION

Lowering of the bucket

STABLE POSITION

Resting position

UNSTABLE POSITION

Raising of the bucket

fig. 47

Command lever for the body

fig. 48

Horn Command

30

Cut Off Battery Command

The device lever on the left side of the

dashboard controls the disconnection of the battery

from the electrical circuit of the machine.

Use the cut off battery to disconnect power from

the electrical circuit, particularly if the machine stop

to work, for a long period of time, can be removed

the lever to prevent the discharge of the battery.

Commands

STABLE POSITION

Battery connected

STABLE POSITION

Battery unplugged

STABLE POSITION

Battery unplugged,

it’s possible remove the lever

fig. 49

Cut Off Battery Command

31

Series 65-80

efore using the

machine you must read all of the instructions

in this manual and the user’s and

maintenance manual of the motor installed on

your machine scrupulously. Furthermore,

Read the user’s manual

and the maintenance manual for the motor

installed in your machine carefully and follow

the instructions prescribed for its own break

3. INSTRUCTION FOR USE

3.1. F

IRST USE

READ CAREFULLY: B

always keep it attached to the machine.

fig. 50 – Container

for manuals

32

The owner' s

manual and mai ntenance, together

with th e m anual of

the engine of the

mac hine, must be

al ways easily a vailable and should be

kep t in the dedica ted

co ntaine r fix ed on

the machine (se e the

fi g . 50).

The machine is normally delivered completely

assembled and ready for use with an empty fuel tank.

Fill the fuel tank, open the fuel tap and follow the start-

up procedure described in the appropriate paragraph.

3.2. B

REAKING-IN PERIOD

The technology used during the construction of your

machine does not require a break in period. However,

during the first period of use, it is necessary to use these

precautions:

During the first 50 hours, avoid using the motor at over

70 % of the total power.

READ CAREFULLY:

in period.

After the first 20 hours of operation, check the level of

the hydraulic oil in the tanks.

Instruction for use

WARNING: Before turning on the motor,

always insert the parking brake to avoid

uld

DANGER: Refuelling must always be done

le

refuelling or while handling fuel to avoid the

t up the motor only after

having made certain that there are no traces

During the first period of use, the tracks undergo an

adjustment, for which it is necessary, after the first 50

hours of operation, to carry out the regulation of the

tension of the tracks.

3.3. M

OTOR START-UP

Every time you wish to start up the motor, always

verify the following indications scrupulously:

•

Always start up the motor outside and be certain that

there are no other persons in the vicinity of the

machine and/or other impediments.

•

Check that there is fuel in the tank and, if necessary,

add some.

•

Always insert the parking brake.

eventual movement of the machine that co

present safety issues for the operator.

•

Follow the specific procedure prescribed by the

constructor of the motor shown in the attached

instructions.

When the motor is hot, in petrol operated motors,

avoid inserting the starter.

In diesel engines, can be an automatic valve that

helps to raise the start, it works automatically in the

first seconds of starting the engine.

3.4. R

EFUELLING

with the motor turned off! Do not smoke whi

risk of fire!

Refuelling and /or movement of the fuel from one

container to another must always be done outside,

always from fires or from other heat sources. Always

check that the type of fuel is the correct one, specified for

the motor of your machine.

•

Position the machine on a clean surface.

•

Unscrew the plug slowly.

•

Pour the fuel into the tank slowly.

•

Screw the plug on again tightly. Immediately dry any

fuel leakage.

WARNING: Star

of fuel that have accidentally spilled out!

33

Series 65-80

WARNING: The conservation of the fuel must

always be done with respect for the specific

from sources of

heat, and with clean, well closed suitable

REQUIRED: Avoid the dispersion of fuel

and/or fuel containers in the environment.

Carry out the disposal according to the

ect for the

DANGER: Always avoid overloading the

machine above the prescribed limits: during

movement, an overload could create

variations that were not foreseen

and could provoke the overturning of the

WARNING: Where possible, try to avoid

travelling on rocky or icy terrain, on rails and

may damage

the tracks and reduce their longevity. Also

avoid passing over material that could ruin the

tracks, such as sharp objects, pieces of metal,

etc. that could get caught up in the tracks and

provoke a break.

laws, in suitable places, away

containers!

current laws and with resp

environment.

3.5. D

RIVING THE MACHINE

structural

machine with serious safety consequences.

railway sections because they

At the start-up, regulate the number of rotations of the

engine to the desired level by activating the accelerator

lever, according to the required power (when the machine

is loaded, you must bring the lever above the halfway

mark between the minimum and maximum).

Under some conditions, especially when the machine

is loaded or going uphill, a loss of engine power may

occur because of a motor overload; this may also cause

it to shut down. In this case, slowly release the drive

command lever, regulating the speed to a level that does

not provoke an overload of the propeller.

Your machine is equipped with a hydrostatic

transmission, so, it is not necessary that the

rotations of the engine be at maximum for the

displacement. Leave the engine operating at its

maximum number of rotations does not improve the

functioning of the machine, rather, it certainly (and

uselessly) increases its fuel consumption: it is

advisable, therefore, to increase the rotations of the

engine only where it is absolutely necessary (to

proceed at maximum speed, to address steep slopes

with a full load, etc.).

34

Instruction for use

Never drive with the footrest unblocked:

always verify that the footrest is blocked and that

When you open or close the

you may

DANGER: When the machine is in gear, the

operator must always maintain the prescribed

3.5.1. D

RIVING POSITION

During the driving of the machine and during the work,

is necessary utilize the footrest platform in open position,

always (see fig. 51), to prevent risks.

Close the footrest platform only after use..

To use this footrest

you must position it in the

correct way:

•

Take out the safety

pin which blocks the

footrest;

•

Rotate the footrest to

a horizontal position;

•

Block the footrest

again by positioning

the safety pin again.

fig. 51 –Driving position

DANGER –

the safety pin is positioned correctly.

WARNING –

footrest, be careful with your hands:

cut yourself or crush them.

When the machine is in gear, always grasp the

stronghold handle firmly with one hand and use the other

hand simultaneously to activate both drive levers.

Never release the handle to operate the command

levers with both hands.

driving position.

Never speed when working, rather proceed at a

speed adjusted to your walking speed, in this way you will

maintain a safe control over the commands.

3.5.2. F

ORWARD GEAR

To allow the machine to advance one must activate

both drive levers simultaneously by pushing them

forward.

Avoid addressing downhill slopes in forward gear,

refer to the paragraph: “Travelling on Slopes”.

3.5.3. R

EVERSE GEAR

To allow the machine to back up you must activate

both drive levers, pulling them back simultaneously.

Avoid addressing uphill slopes in reverse gear,

35

Series 65-80

DANGER: While in reverse gear, always

check to see that there are no obstacles

DANGER: Completely avoid working on

terrains that have lateral slopes of more

than 10° and longitudinal slopes of more

than 20° to avoid the possibility of

with serious consequences for

especially with a loaded machine, rather follow the

procedure described in the paragraph: “Travelling on

Slopes” .

and/or persons in the vicinity.

3.5.4. T

RAVELLING ON SLOPES

overturning

the safety of the operator.

fig. 52 – a) going uphill; b) going downhill

When addressing sloped segments, especially when

the machine is loaded, you must use this particular

driving technique (see fig. 52):

Always address the uphill slopes in forward gear;

Always address the downhill slopes in reverse gear.

On high slope ground is necessary to work with high

regimen of motor (as the slope) minimizing the opening of

drive levers (see fig. 44); otherwise could be verify

cavitation problems and missing the “engine-brake” effect

(the hydraulic motors are forced by the slope and they

function like a pump): if the machine increase the speed

“alone”, release the drive levers.

fig. 53 – Motor regimen going downhill

36

Instruction for use

DANGER: if the machine travelling on high

slope with minimum motor regimen and

maximum opening of drive levers, “engine

brake” effect is missing and the machine

out of control with

the possibility of serious consequences for

the safety of operator and the proximity

coud increase the speed

persons.

3.5.5. S

TOPPING MOVEMENT

To stop movement one must release the drive levers

for the tracks simultaneously.

3.5.6. M

OVEMENT IN CURVES

To allow the machine to turn one must release the

lever on the side to which one intends to turn:

To turn to the right, release the right-hand drive lever;

To turn to the left, release the left-hand drive lever.

The steering is determined by the slowing of the

speed of one track with respect to the other.

Consequently the speed and the degree of steering are

proportional to the intensity of the release and to the

pressure with which you apply to each lever

3.5.7. C

OUNTER-ROTATION

It is also possible to make the machine spin round,

carrying out a complete “counter-rotation” around its axis,

in order to carry out manoeuvres in small spaces.

To make a clockwise counter-

rotation (towards the direction

of the clock hands) you must

push the left-hand lever

forward and pull the righthand lever back;

fig. 54 – Clockwise counter-rotation

To make a counter-clockwise

counter-rotation (towards the

opposite direction of clock

hands) you must push the righthand lever forward and pull the

left-hand lever back.

fig. 55 – Counterclockwise counter-

rotation

Using the counter-rotation manoeuvre often reduces

the duration of the rubber tracks, especially if you do it

upon rough surfaces.

37

Series 65-80

WARNING: If you move away from the

machine and leave it unattended, always

ing brake and be sure that no

unauthorized persons may turn it on or move

it. In the models which are equipped with one,

up key and unplug

PROHIBITED: It is strictly prohibited to use

the parking brake while the machine is

moving to arrest movement of the machine

If, when trying to deactivate the

brake, the lever resists noticeably, avoid

forcing the mechanism in that the wheel may

block. Before deactivating the brake, move

l

you have obtained the unblocking of the

3.6. S

TOPPING AND PARKING

activate the park

an emergency stop when the operator may deem

necessary to have an instantaneous block of the machine

during worko.

always take out the startthe battery.

Before stopping the machine, it is preferable to

position yourself on a flat paved surface, or on a flat and

compact ground.

•

Using the accelerator lever, bring the motor down to

its minimum number of rotations.

•

Insert the parking brake.

•

Turn off the engine.

•

Close the gas tap (on the models that are equipped

with one).

3.7. U

SING THE PARKING BRAKE

The machine has a safety device nominated as the

“Parking Brake” which impedes the machine from

moving even if the towing commands are activated. This

device serves to impede the accidental movement of the

machine in the absence of its operator; it also serves as

38

unless in case of emergency.

To activate: Pull the lever lightly towards yourself

and move it to the left making it go out of its slot and then

let it go: the brake will insert itself automatically.

To deactivate: Pull the lever towards yourself

decisively and lightly and move it to the right hooking it

into the special slot to block it: the brake has been

deactivated.

WARNING –

the machine forward and backward a bit unti

device.

Emergency Brake: the parking brake serves also as

a brake in emergency situations. To carry out an

emergency brake, pull the lever towards yourself lightly,

Instruction for use

DANGER: In the case that you may have to

the emergency brake, consider that this

causes the drive mechanism to block

instantaneously and may cause a loss of

WARNING: After the emergency brake

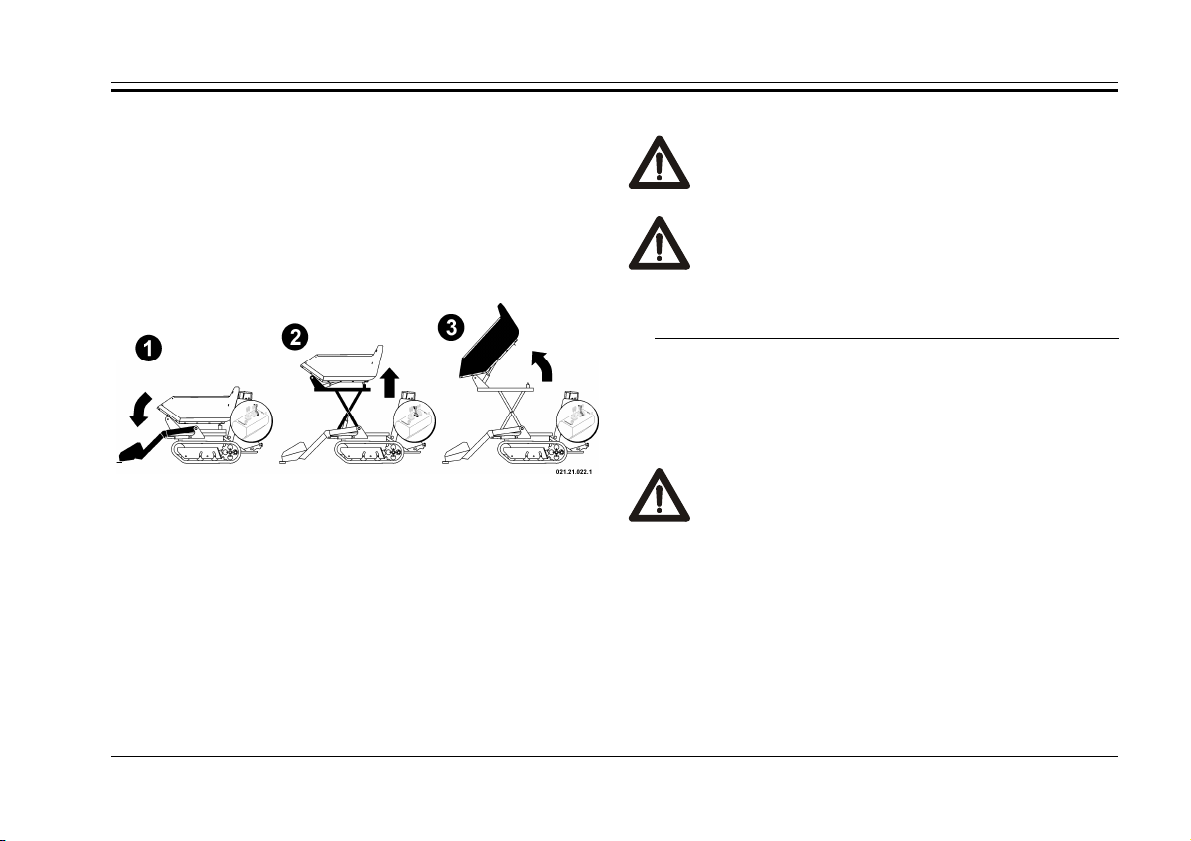

intervention, have the integrity and the

the device verified: a

continued use of the machine with an

inefficient device could be dangerous for your

PROHIBITED: It is strictly prohibited to

city limits indicated in

move it towards the left making it come out of the slot and

let it go: the brake will insert itself automatically.

use

control of the machine.

working order of

own safety and that of others.

3.8. T

RANSPORTING LOADS

surpass the load capa

the table on page 11.

3.8.1. C

ONSTRUCTION BODY (DUMPER)

The machine is equipped with a “dumper” type body

to transport inert and solid materials, suitable mainly to be

used for construction work.

3.8.2. “F

ARMING” TYPE BODY

Upon request, your machine may be fitted, in place of

the “dumper” type body, with a body that has sides that

can be opened, and is suitable to transport farming

materials.

fig. 56 – Farming type body

The opening of the sides allows one to enlarge the

loading surface to be able to transport cumbersome

objects. To obtain a larger loading surface, work with one

side at a time as follows (see fig. 56):

•

Open two anterior hooks “C”, lower the anterior side

39

Series 65-80

Before unloading, be certain that

the terrain is flat, solid and compact. Carry

out the dumping manoeuvre slowly and

rward with the

CAUTION: During the unloading, if the body

hits up against an obstacle, avoid moving the

machine forward: this could damage the

junctions of the body!

strictly prohibited to travel

“D” and take it out;;

•

Loosen the two wheels “A” positioned under the

loading surface;

•

Take out the two supports “B” from their housings;

•

Open the posterior hook “E” and lower the left lateral

side “F” making coincide the notches of the supports

in the holes “G”;

•

Repeat the operation on the other side;

•

Be sure that the sides are blocked and position the

load so that it will not fall: if possible tied it.

3.9. U

3.9.1. O

NLOADING MATERIAL

VERTURNING OF THE BODY

WARNING -

uniformly. Do not move fo

machine during the dumping phase.

Your machine is equipped with a hydraulic dumping

device for the body which allows for the unloading of material.

To carry out the dumping manoeuvre:

•

Position yourself on a level, solid, and compact

surface or terrain;

•

If the machine is equipped with a farming body,

unblock the anterior side;

•

Push the lever forward to provoke the overturning of

the body and the unloading of the material;

•

Pull the lever back until the body has returned to

travelling position, and then release the lever.

PROHIBITED: It is

if the body is not in its resting position.

3.9.2. R

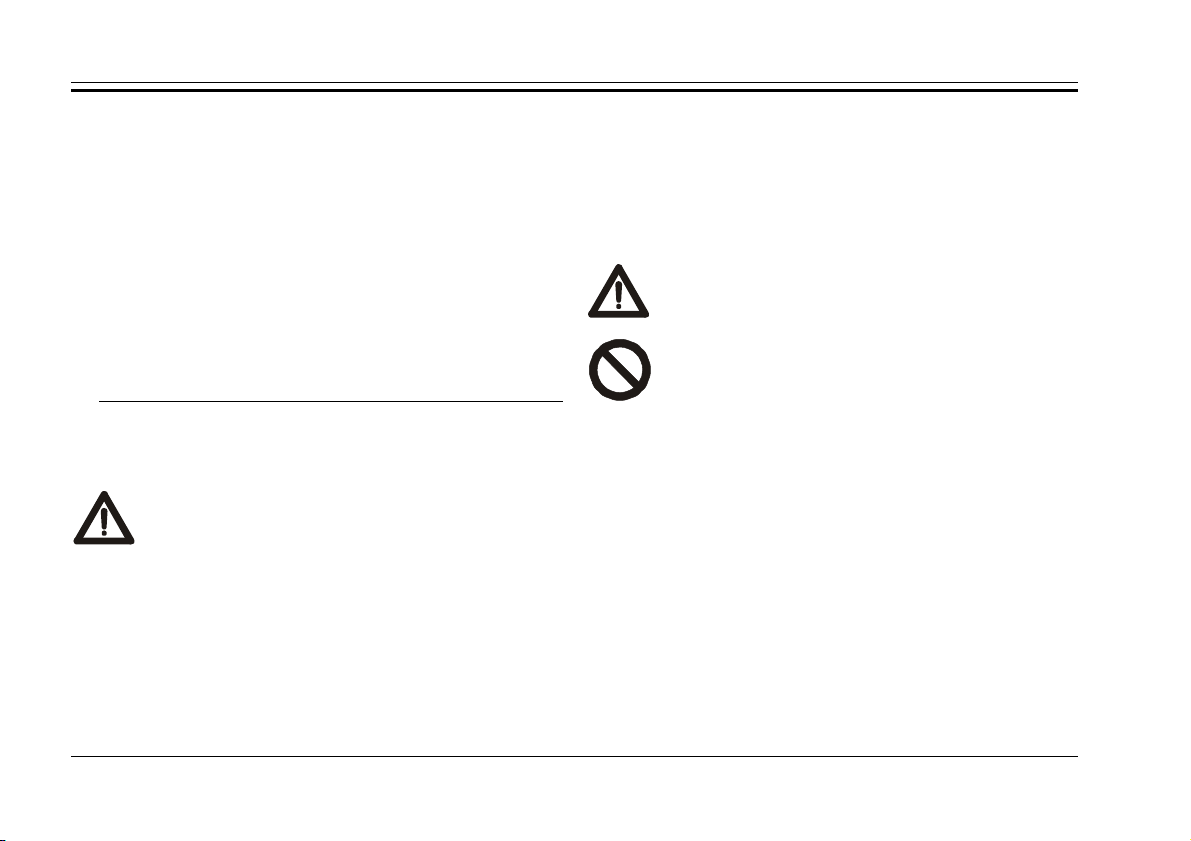

AISING THE BODY

(“HI-TIP”)

On request the machine may be equipped with a

hydraulic device to raise the body during the unloading to

allow for unloading in containers or tubs with high walls,

named “Hi-Tip”.

To unload material normally, use the lever for the

overturning of the body (as indicated in the preceding

paragraph).

To carry out a high unloading, proceed as follows:

•

Position yourself on a level surface or on a level, solid,

and compact terrain;

40

•

DANGER: Never carry out the raising of the

body without first stabilizing the machine with

DANGER: Never, for any reason, activate the

ou could provoke

-

loading device must remain raised above the

surface of the land to avoid collision with the

terrain and must be in a position that does not

Use the lever of the auto-loading device pushing it

forward to place the shovel on the ground in order to

stabilize the machine;

•

Raise the body to the desired height by pushing

forward the lever for raising;

•

Push the overturning lever for the body forward to

allow for the unloading of the material.

Instruction for use

the auto-loading shovel.

raising lever while driving. Y

the overturning of the machine

3.10. U

SE OF THE SELF-LOADING

Your machine may be equipped with an self-loading

mechanism consisting of an anterior bucket that has a

hydraulic command.

fig. 57 – Position for high unloading

To bring the body back to a driving position, proceed

as follows:

•

Pull back the overturning lever and bring the body

back to a horizontal position;

•

Release the command lever for the body

•

Pull the lever for raising the body backward until it has

reached the driving position;

•

Release the raising lever.

CAREFUL: During movement the auto

obstruct visibility.

Loading: To be able to load the body using the auto-

loading tool, you must follow this procedure:

•

advance the machine towards the pile of material

maintaining the benna in a horizontal position;

•

raise the shovel by pulling the lever towards yourself

until you have poured the contents into the body.

Repositioning: Push the lever forwards until the

41

Series 65-80

d movement

loading device must

READ CAREFULLY: Read the user’s

instructions carefully for all accessories

and/or tools that have been installed on

your machine. Always refer to the manual

which was provided with them and always

bucket has lowered to the correct height from the

ground.

Floating (auto-levelling): the auto-loading tool

may also be used to function as an auto-levelling

device, useful, for example for levelling ground. To

block the bucket in the floating position you must

push the auto-loading lever forward past the lowering

position until you have heard a click (the lever

remains in stable position).

CAREFUL: During the driving an

of the machine, the selfnot remain the the floating position.

3.11. S

UPPLEMENTARY HYDRAULIC COMMAND

Some versions may be equipped with a hydraulic

force instrument for the command of auxiliary

equipment.

The hydraulic force instrument is composed of two

openings with rapid transmission of standard type,

indicated by the letters “A” and “B”, situated on the right

side of the dashboard.

To obtain hydraulic oil pressure on the openings you

must work the auxiliary command lever.

To obtain pressure on the “A” opening, push the lever

forward.

To obtain pressure on the “B” opening, pull the lever

backward, toward yourself.

keep it attached to this manual.

3.12. A

Your machin e can

CCESSORIES

be equipped with

some addition a l

devices tha t mak e it

mor e complete.

To the side is

show n th e p o s it ion o f

the 12V DC po wer

out l e t (see fig. 5 8 )

that provi d e s power

fig. 58 - DC- out

for operation of

42

electrical devices with

WARNING: During transport, always position

elly to avoid the spilling of oil

additional features

highl ighted by the close

label (see fig. 59).

The label on the side

(fig. 60) shows the

electrical connection

dedicated to recharge the

electric battery of the

machine.

The electrical

recharging point outlet

is located on the right

side, near the lifting

point of the machine

(see fig. 61).

fig. 59

(cod. C0901.23.02)

fig. 60

(cod. C0902.23.02)

fig. 61

Richarging point

Instruction for use

3.13. T

RANSPORT

the machine lev

or other liquids .

If the machine needs to be transported, one must

proceed correctly to avoid dangers to persons and/or

to the machine, if there is any on the machine, keep

down completely the bucket during the transport.

Because of the weight of the machine, it is not

possible to move it manually. Thus, it is necessary to

use suitable means of lifting to load it onto a means

of transport.

The machine is equipped with 4 hooks for lifting

each one with a capacity of 7.000N (700kg) for a

total of 28.000N (2.800kg).

The position of each hook is

indicated with a label like the one

shown in the fig. 62 (C0900.13.66).

To do this operation safely you

should use, as tools of lifting, 4

ropes with hooks, CE compliant; the

two front ropes are 200cm of length,

and the two rear ropes are 170cm of

Lifting point

fig. 62

43

Series 65-80

WARNING: Raise the machine by hooking

it exclusively to the hooks predisposed for

this purpose: the anchoring of the

machine in other points can cause

ent fall of the

machine and can cause serious harm to

length, in the following way:

•

Disconnect the battery, turning the device to cut

off battery;

•

Empty the fuel tank and close the plug;

•

Fix the lifting hooks exclusively to the anchoring

points that were prescribed by the manufacturer

(fig. 63);

breakage with the consequ

persons.

fig. 63 – Anchoring points to lift the machine

44

Instruction for use

•

Fix it to the surface of the means of transport

pulling down firmly, with CE compliant ropes, and

always connecting to the points as indicated in the

figure 64.

fig. 64 – Anchoring points for transport

3.14. T

OWING

The machine is equipped with tow

hooks, located at the bottom of the

undercarriage, front abd rear (see fig.

66); if you need to tow the machine, to

take care of emptying the body.

Each anchor point for the

towing is evidenced by a label with

fig. 65

Towing point

the symbol shown in figure 65 and

can withstand a pull of 10.000N (1.000kg approx).

fig. 66 – Anchoring points for towing

45

Series 65-80

3.15. S

TORAGE

Whenever the machine must remain inactive for

several months, it is necessary to provide a correct

garaging so that the machine is in perfect working order

when it is used again.

In particular one must carry out storage by following

all of these instructions:

•

Carry out all necessary repairs;

•

Disconnect the battery, turning the device to cut off

battery;

•

Empty the fuel tank completely;

•

Proceed with a careful cleaning and remove all

mud, and/or organic residues carefully;

•

Proceed with all operations regarding the motor that

are described in its own manual;

•

Carry out a greasing of all points listed in the

specific chapter;

•

Place the machine in such a way that it is sheltered

from atmospheric agents under stable conditions

and on a flat surface;

•

If the machine is equipped with batteries, unplug

them and lubricate with the correct grease;

•

Periodically, every two months, recharge the

battery;

•

If the motor is equipped with a start-up key, take it

out and conserve in a safe place.

When putting the machine back into service:

•

carry out all greasing again in all prescribed points

found in the specific chapter;

•

If the machine is equipped with a battery, recharge

it and reconnect it being certain of the correct

polarity of the ends;

•

Insert the cut off battery lever;

•

Proceed with the operations concerning the motor

described in its own manual;

•

Check the oil level and add some if necessary.

46

4. MAINTENANCE

DANGER: always carry out all maintenance

operations with the motor off and with the

Maintenance and Adjustment Table

Maintenance

start up keys not inserted.

A good maintenance is necessary and is the secret to

obtaining low running costs, to lengthening the life of your

machine, and to always maintaining it at its highest

efficiency.

Beyond the normal maintenance operations on the

mechanic and hydraulic parts, it is a good rule to carry out

a periodic washing of the machine and to proceed with a

careful cleaning to take away all mud residues. After

every wash it is necessary to grease all of the parts that

are subject to friction, as specified in the paragraph

“Greasing”.

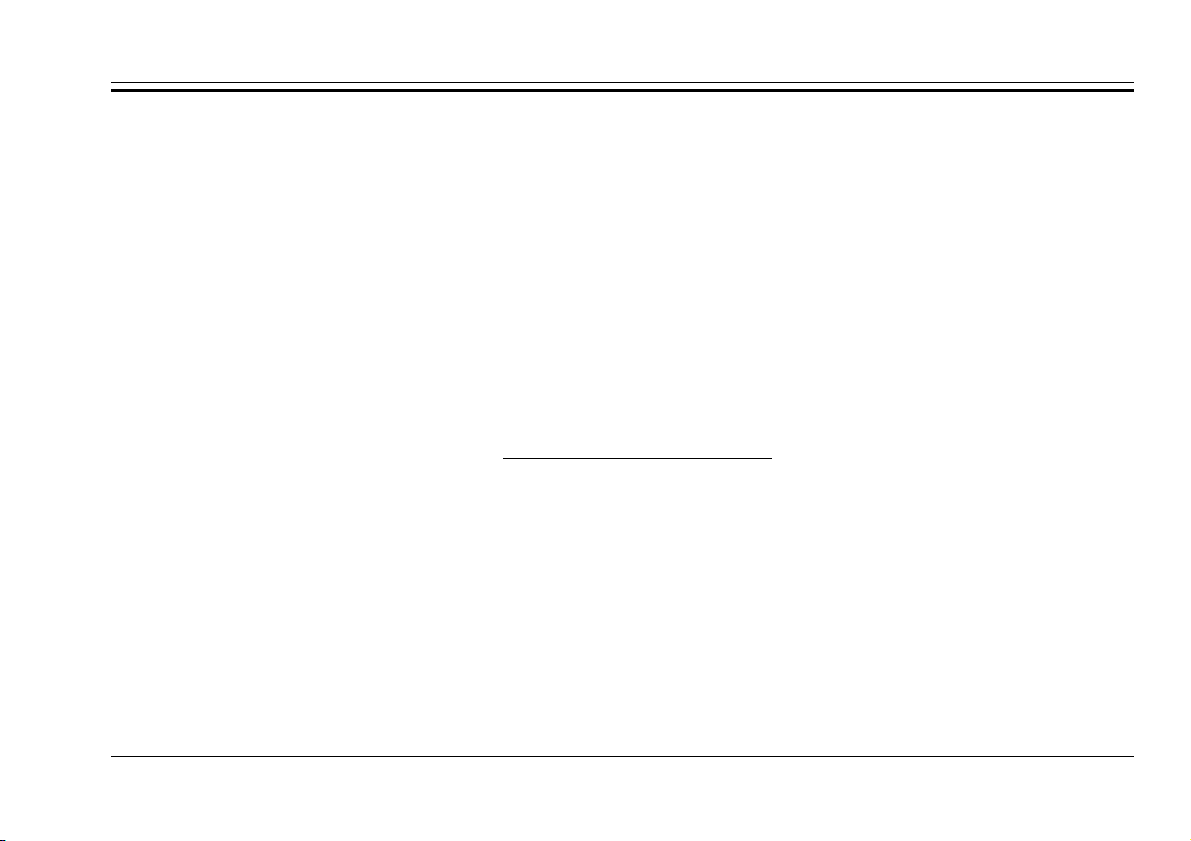

4.1. M

AINTENANCE INTERVALS

To maintain the highest level of efficiency, it is

necessary that the maintenance be carried out at regular

programmed intervals.

In the following table a summary of the maintenance

operations is listed that are to be carried out periodically.

Work

Frequency

Every 8 hours

Every 50

hours

Every 100 h. Parking Brake

Every 200 h. Motor wheel hubs

Every year

or 300 hours

(1)

Check with the attached manual for the motor

(2)

In dusty areas you must increase the frequency

Description

Machine

Drive Levers

Command Levers

Body

Auto-loading

“Hi-Tip” lift

Track rollers

(1)

Motor oil

Tracks

Hydraulic oil

Air filter

Hydraulic oil

Hydraulic services oil filter

Hydraulic drive oil filter

Dry air filters

Motor oil

(1)(2)

(1)

(1) (2)

Verify

Greasing

Cleaning

Adjustment

Substitution

47

Series 65-80

READ CAREFULLY: Carefully read the

instructions and the mode of use for the

REQUIRED: When changing the motor oil,

always use a suitable aspirator to remove old

Avoid the dispersion of oil and filters in the

environment and carry out their disposal with

respect for the environment and the

4.2. M

OTOR

motor found in the attached specific manual.

The machine that was delivered could be equipped at

the origin with different engine types for specific needs

and/or markets.

A correct maintenance is the best way to conserve the

motor of your machine so that it is always working at its

highest efficiency and this allows you to maintain low

operation costs.

For the maintenance of the motor, pay scrupulous

attention to the attached manual that was given to you.

oil.

regulations in force.

4.2.1. PRE-

FILTER AND AIR FILTER IN AN OIL BATH

Your machine can be equipped with a special air filter in

an oil bath, which increases and improves the filtration

capacity.

The maintenance

of pre-filter “P” (see

fig. 67), establish the

cleaning every 100

hours.

Unscrewing the

wing screw (see fig.

68), which blocks the

cover of pre-filter,

remove the section in

clear plastic “T”,

clean using a simple

washing with water

and then replace il.

For the maintenance of the filter in

an oil bath “F”, is

Pre-filter and Air Filter

fig. 67

necessary remove the engine hood.

After removing the hood, the air filter is easily

accessible.

48

Maintenance

Every 15 days, to check the oil level in the filter,

release the bottom cup of the filter (fig. 68), loosening

the hooks “G”.

Remove the cup of the air filter, being careful not

to spill the oil content, verify that oil reaches the

metal tab “L”, and if necessary, add the missing oil.

Replace the filter bowl.

fig. 68 – Pre-filter and Air Filter with oil bath

cartridge “C” and change the oil in the filter bowl cup.

To clean the cartridge is recommended to wash by

immersion in a vassel containing diesel or petrol to

remove the dirth.. To replace oil in the air filter,

remove all the oil in the cup and wash it with diesel or

petrol. Dry the cup and restore the right level of oil

wich reaches the metal tab “L” like described above

(fig. 68).

Verify

Every 15 days Check the level of the oil in the cup.

Substitution

Every 60 days

Substitute the oil in the cup and

clean the filter part.

For the verify and the substitution of the oil in the cup of

the air filter, utilize only synthetic oil 10W – 40W.

DANGER: do not throw the oil in the environment.

Carry out the disposal with respect for the environment

and the regulations in force.

Every 60 days, it is necessary to clean the filter

49

Series 65-80

REQUIRED: Avoid the dispersion of oil in the

environment and carry out the disposal with

respect for the environment and the

DANGER: The hydraulic oil can reach high

temperatures, especially after a day of work:

avoid substituting the oil when it is hot to

LY: The thermometer

installed in the machine is equipped with a

double scale and may be read in centigrade °C

and Farheneit °F according to the conventions

of the different countries. Be reminded that in

Italy measurement in °C is used: refer only to

4.3. H

4.3.1. H

YDRAULIC CIRCUIT

YDRAULIC OIL

regulations in force.

Your machine was provided with a specific

thermometer/signal to verify both the temperature and the

level of the hydraulic oil in the tanks, positioned on the

right side of the dashboard (see fig. 69).

Verifying Temperature

avoid the risk of burning yourself.

READ CAREFUL

this value.

The temperature of the hydraulic oil is verified by

reading the value on thermometer “B” (see fig. 69): the

temperature is considered regular when it does not

surpass 85°C.

Verifying Oil Level

Every 8 hrs

Check the level of hydraulic oil in the

tank.

To verify the correct hydraulic oil level, the

machine will be placed on a flat surface, with the body

closed and self-loading arm lowered to the ground, if

any.

The engine must be started for several minutes

(about 5 min.) So that the

oil has a temperature of

40 ° C.

The correct level is when

the oil reaches the bottom of

the line “D” (see fig. 69 “D”).

Restoring Oil Level

• Unscrew the top “A” on

the upper tank;

• Restore the level by

fig. 69 – Oil level

50

Maintenance

the emptying

when the motor is off and with the body

adding the oil specified into the opening “A”;

• Screw the top “A” back on sealing it properly, and turn

on the motor following the correct procedure;

• Briefly operate the drive levers and the command

levers;

• Stop the motor and check that the level of the oil “C”

reaches the red line “D” and, if necessary, repeat the

operation.

Substitution

Every 300 hrs

To substitute the hydraulic oil, use a suitable aspirator

and work when the oil is cool, verifying its temperature

using the thermometer.

DANGER: Always carry out

blocked with the special bar.

Empty the upper tank first;

• Unscrew the top “A” on the upper tank, removing the

washer “B”, and vacuum the oil using a suitable

Substitute the hydraulic oil in the

tank.

fig. 70 – Substitution of oil and filters

51

Series 65-80

lways carry out the emptying

operation of the lower tank when the motor is

turned off, and with the body blocked by the

DANGER: Always substitute the filters when

blocked

REQUIRED: Carry out the disposal of the oil

and filters with respect for the environment

aspirator.

DANGER: A

appropriate bar.

• Unscrew the top “C” on the lower tank and remove the

washer “D”;

• Move the terminal “E” and remove the top “F” with the

washers;

• Vacuum the oil completely using the suitable aspirator;

• When you have completed the operation, place the top

“F” and terminal “E” back on carefully;

• Screw the top “C” back on with its washer “D”;

• Fill the tank exclusively from the upper tank from the

opening of “A” until the red line is reached;

• Screw the top “A” back on with its washer “B” and turn

on the motor;

• Briefly operate the drive and command levers;

• Turn off the motor and check the level if necessary,

add more;

• After 8 hours of working, check the level again.

4.3.2. H

hydraulic oil circuit, positioned in the lower part of the

YDRAULIC OIL FILTER

Your machine is equipped with two filters on the

frame, under the body. One of the filters, which is an

immersion type, is screwed directly into the tank (see fig.

70 pos “G”), while the other one which is a cartridge type

(see fig. 70 pos “H”) is positioned near to the other.

the motor is shut off and the body is

by the appropriate bar.

and for the regulations in force.

Drive Circuit

Every 300 hrs

The filter in the circuit which feeds from the auxiliary

drive pump is a cartridge type and does not require any

type of cleaning operation, however must be substituted at

the prescribed intervals.

To substitute, carefully follow the described operations

(see fig 70):

• Empty the oil tanks, both the upper one and the

anterior one, by following the procedure in the

preceding paragraph;

• Using the appropriate key, unscrew the old filter “H”;

Replace the hydraulic drive circuit oil

filters.

52

• Lightly lubricate the washer of the new filter;

• Screw the new filter down well, clenching tightly by

hand only;

• Refill the oil level again.

Maintenance

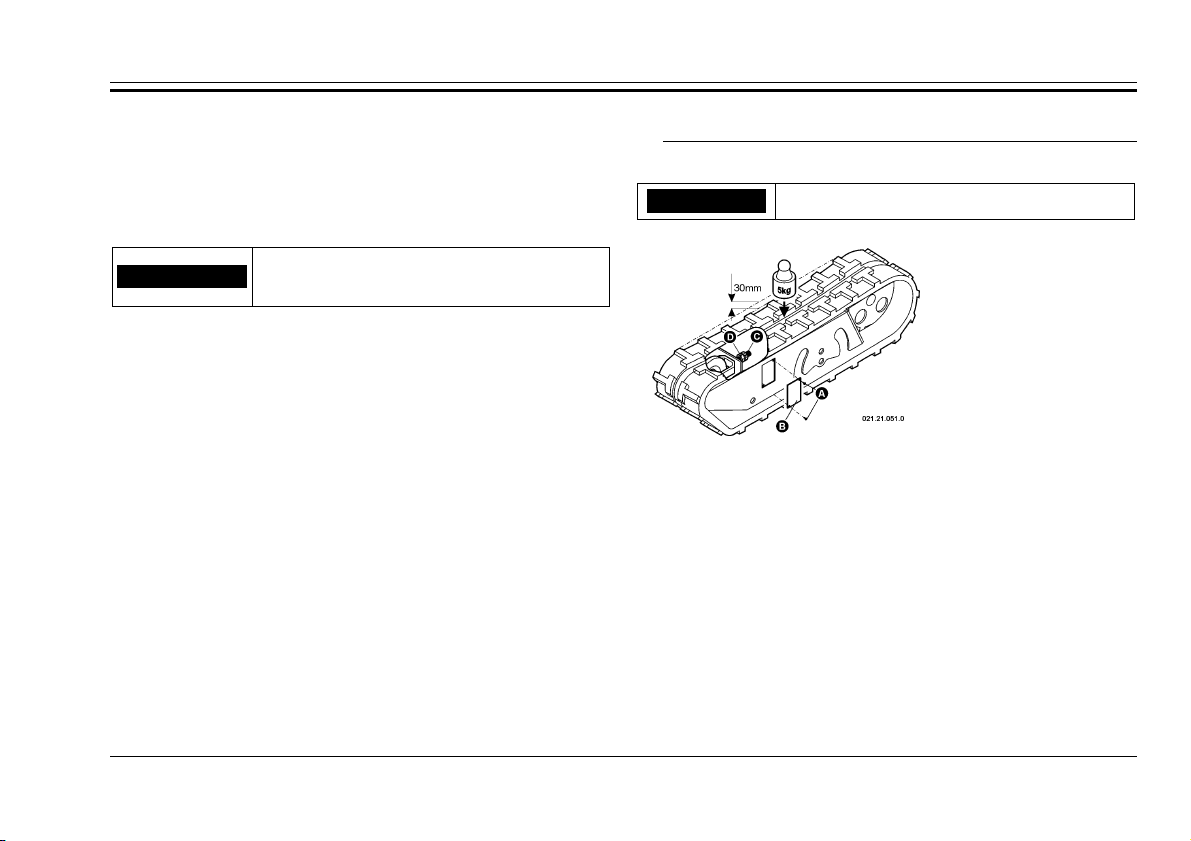

4.4. T

RACKS

Registration

Every 50 hrs Register the tension of the tracks.

Services Circuit

Every 300 hrs

Substitute the oil filter for the

services circuit.

The filter for the circuit feed of the auxiliary service

pump is an immersion type and is screwed directly to the

inferior tank.

Replacement:: to replace the filter, follow these

instructions (see fig. 70):

• Empty the oil tanks, both the upper and anterior ones

by following the correct procedure;

• Unscrew the oil tube “G” by working on the junction;

• Unscrew the filter and take it out of the tank;

• Put the nipple on the new filter always checking the

lining;

• Screw the filter back into the tank;

• Screw the oil tube back on;

• Fill the tanks and check the levels.

The correct tension of the tracks is

important in order to

guarantee their longevity and for your

own safety: to check

it, apply a pressure

of 5 kg on the track

and check that the

fig. 71-Regulation track tension

arrow is at about

30mm.

To carry out the regulation of the tension of the tracks

correctly:

• Take off the cover “B” by unscrewing the two screws “A”;

• Using two wrenches, loosen the counter-nut “C”;

• Regulate the tension by working on nut “D”;

• Check that the arrow is at 30 mm;

• When you have finished regulating, block the counter-

nut;

• Put the cover back on;

• Repeat the same procedure on the other track.

53

Series 65-80

DANGER: Never work with the machine

raised on a jack or suspended, rather always

place it upon suitable trestles that can

maintain the weight of the machine before

Substitution

starting work.

For the substitution

of the tracks, proceed

as follows:

• Raise the side of

the machine on

which you wish to

work using

hydraulic jacks or a

crane;

• Position the

machine on

suitable trestles, and check to see that it is stable;

• Take off the cover “B” by unscrewing the screws “A”;

• Using two wrenches, loosen the counter-nut “C” and

completely unscrew both the counter-nut and nut “D”;

• Take off the track “E” starting from the anterior part;

• Mount the new track lining it up with the teeth in the

drive wheel “F”;

• Fit in the anterior part of the track onto the neutral

fig. 72 – Substitution of tracks

wheel “G”;

• Register the tension by working on nut “D”;

• Check that the arrow is at 30mm;

• When the registering is done, block the counter-nut

“C”;

• Put the cover back on.

4.5. P

ARKING BRAKE

Registering

A correct registering of

the parking brake is

obtained when, the brake is

deactivated with the lever

“A” in position , and the

cursor “E” is 10mm from the

hub wheel “F”.

To register, proceed as

follows:

• Unscrew the nut “B”

from the register “C”;

• Regulate the tension of

the cable “D” by working

on the register “C”;

• Verify the correct posi-

fig. 73 – Regulation

of parking brake

54

Maintenance

tion of the cursor “E”;

• Tighten the nut “B”;

4.6. G

REASING

Every 8 hrs

Refurnish the grease in all

prescribed points.

fig. 74 – Greasing points

Refurnish the grease in all prescribed greasing points,

using a suitable grease.