Corken HG601 Series, THG601 Series, HG602 Series, THG602 Series Installation, Operation & Maintenance Manual

ORIGINAL INSTRUCTIONS IJ100D

Installation, Operation

& Maintenance Manual

Plain & T-Style Double-Acting Gas Compressors

Models HG601, HG602, THG601 & THG602 Series

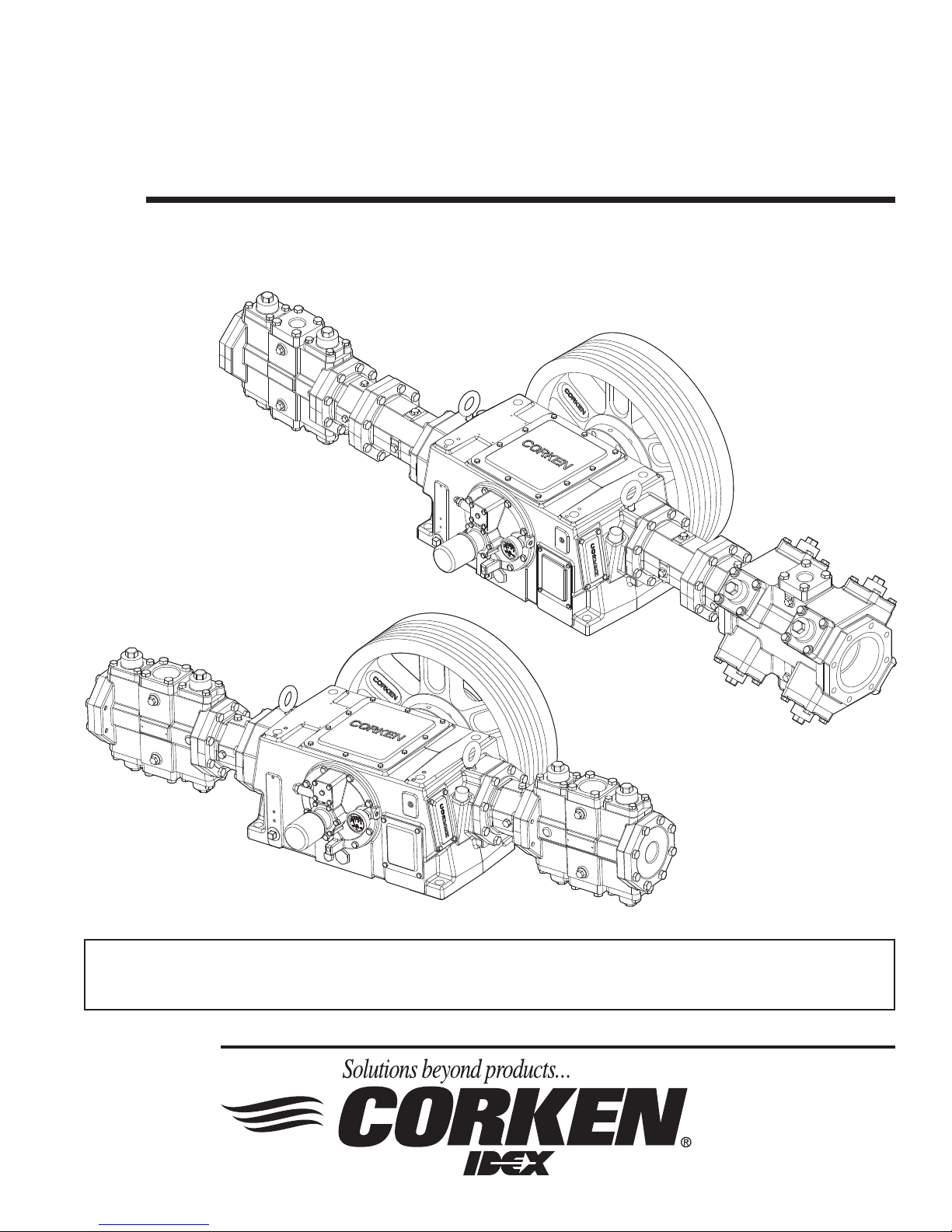

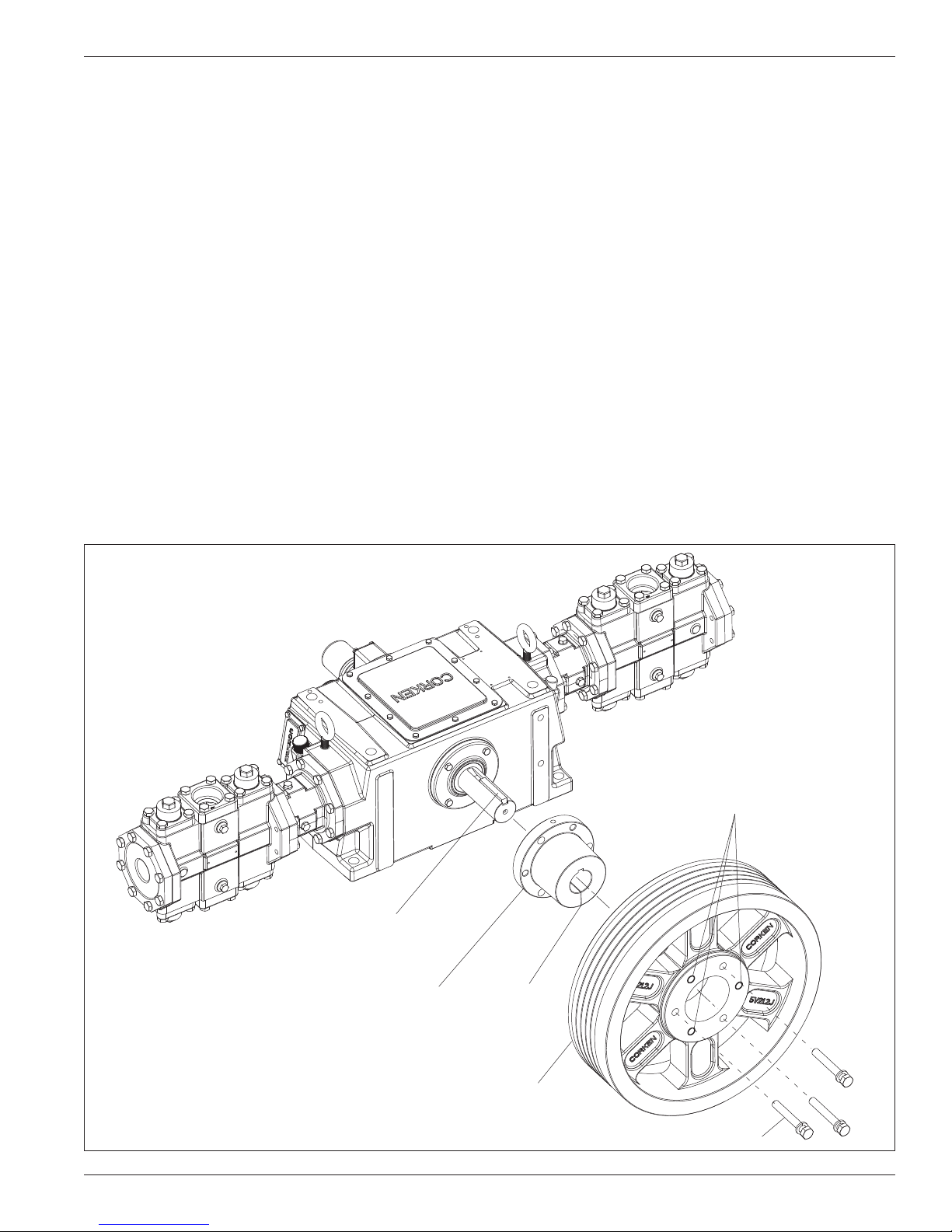

Model THG602BE

(T-style )

Model HG601EE

(Plain style)

Warning: (1) Periodic inspection and maintenance of Corken products is essential. (2) Inspection, maintenance and installation of Corken products must be made

only by experienced, trained and qualified personnel. (3) Maintenance, use and installation of Corken products must comply with Corken instructions, applicable laws

and safety standards (such as NFPA Pamphlet 58 for LP-Gas and ANSI K61.1-1972 for Anhydrous Ammonia). (4) Transfer of toxic, dangerous, flammable or explosive

substances using Corken products is at user’s risk and equipment should be operated only by qualified personnel according to applicable laws and safety standards.

Warning

Install, use and maintain this equipment according to Corken, Inc. instructions and all applicable federal, state, local

laws and codes, and NFPA Pamphlet 58 for LP-Gas or ANSI K61.1-1989 for Anhydrous Ammonia. Periodic inspection

and maintenance is essential.

Corken One Year Limited Warranty

Corken, Inc. warrants that its products will be free from defects in material and workmanship for a period of one

year from date of installation, provided that the warranty shall not extend beyond twenty-four (24) months from the

date of shipment from Corken. Corken products which fail within the warranty period due to defects in material or

workmanship will be repaired or replaced at Corken’s option, when returned freight prepaid to: Corken, Inc., 3805

N.W. 36th Street, Oklahoma City, Oklahoma 73112.

Parts subject to wear or abuse, such as mechanical seals, blades, piston rings, valves, and packing, and other

parts showing signs of abuse are not covered by this limited warranty. Also, equipment, parts and accessories not

manufactured by Corken but furnished with Corken products are not covered by this limited warranty and purchaser

must look to the original manufacturer’s warranty, if any. This limited warranty is void if the Corken product has been

altered or repaired without the consent of Corken.

ALL IMPLIED WARRANTIES, INCLUDING ANY IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS

FOR A PARTICULAR PURPOSE, ARE EXPRESSLY NEGATED TO THE EXTENT PERMITTED BY LAW AND

SHALL IN NO EVENT EXTEND BEYOND THE EXPRESSED WARRANTY PERIOD.

Corken disclaims any liability for consequential damages due to breach of any written or implied warranty on Corken

products. Transfer of toxic, dangerous, flammable or explosive substances using Corken products is at the user’s

risk. Such substances should be handled by experienced, trained personnel in compliance with governmental

and industrial safety standards.

Contacting The Factory

For your convenience, the model number and serial number are given on the compressor nameplate. Space is

provided below for you to keep a written record of this information.

Always include the model number and serial number when ordering parts.

Model No.

Serial No.

Date Purchased

Date Installed

Purchased From

Installed By

2

Table of Contents

FEATURES AND BENEFITS .....................................................................4

CHAPTER 1—INSTALLATION OF YOUR COMPRESSOR .............................................6

1.1 Location .................................................................................6

1.2 Foundation ...............................................................................6

1.3 Piping ...................................................................................6

1.4 Liquid Trap ...............................................................................7

1.5 Driver Installation and Flywheels ..............................................................8

1.6 Crankcase Lubrication ......................................................................9

1.7 Crankcase Oil Pressure Adjustment ...........................................................9

1.8 Relief Valves .............................................................................10

1.9 Shutdown/Alarm Devices ...................................................................10

CHAPTER 2—STARTING UP YOUR CORKEN COMPRESSOR .......................................11

2.1 Inspection After Extended Storage ...........................................................11

2.2 Flywheel and V-belt Alignment ..............................................................11

2.3 Compressor Speed and Rotation Direction ....................................................12

2.4 Compressor Cooling ......................................................................12

2.5 Force Feed Cylinder Lubrication (Lubed models only) ............................................12

2.6 Variable Clearance Heads (VCH) .............................................................13

2.7 Startup Check List ........................................................................14

CHAPTER 3—ROUTINE MAINTENANCE CHART ..................................................15

CHAPTER 4—ROUTINE SERVICE AND REPAIR PROCEDURES ......................................15

4.1 Compressor Valves .......................................................................15

4.2 Heads ..................................................................................16

4.3 Piston Rings and Piston Ring Expander Replacement ............................................17

4.4 Pistons .................................................................................17

4.5 Cylinder Replacement .....................................................................18

4.6 Packing Replacement Instructions ...........................................................18

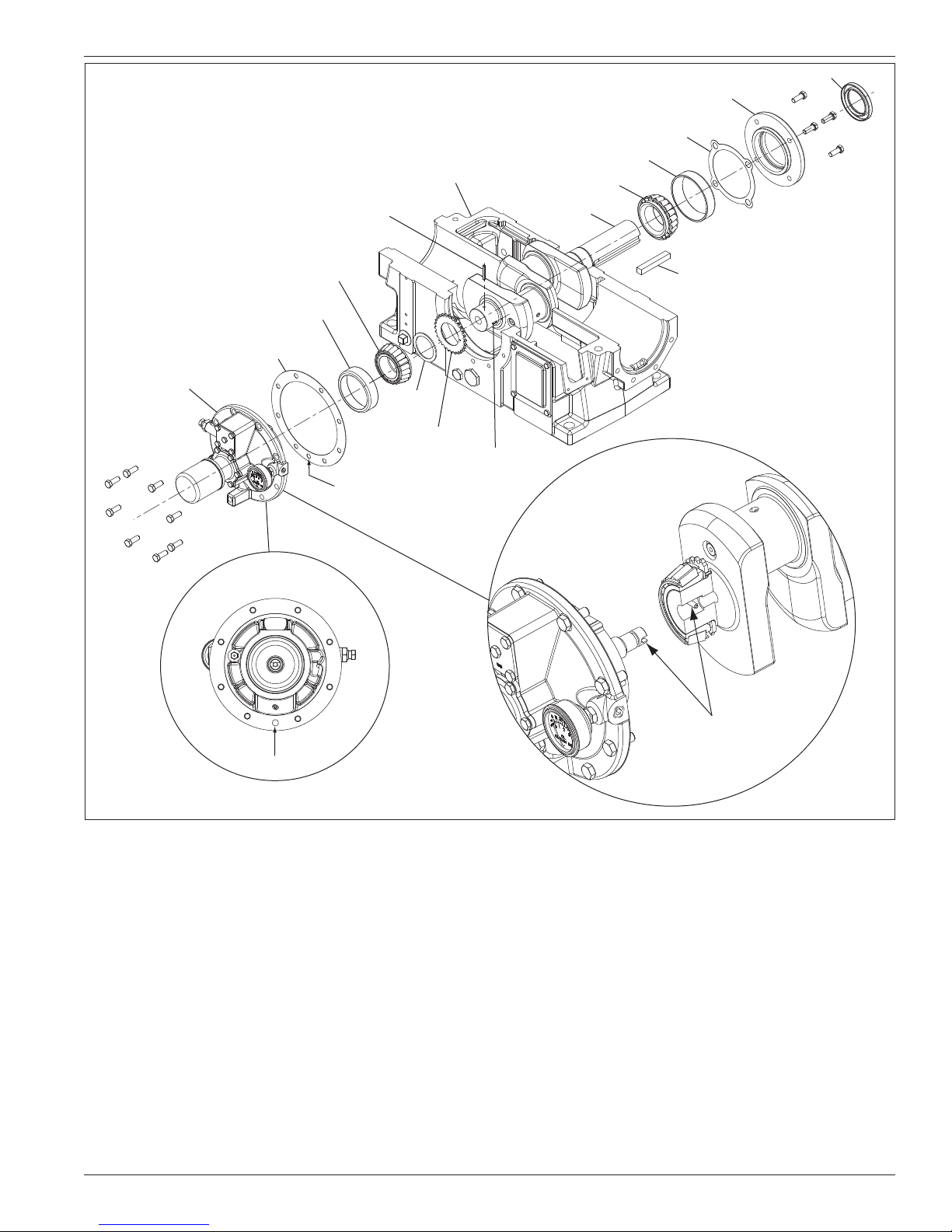

4.7 Bearing Replacement for Crankcase and Connecting Rod ........................................24

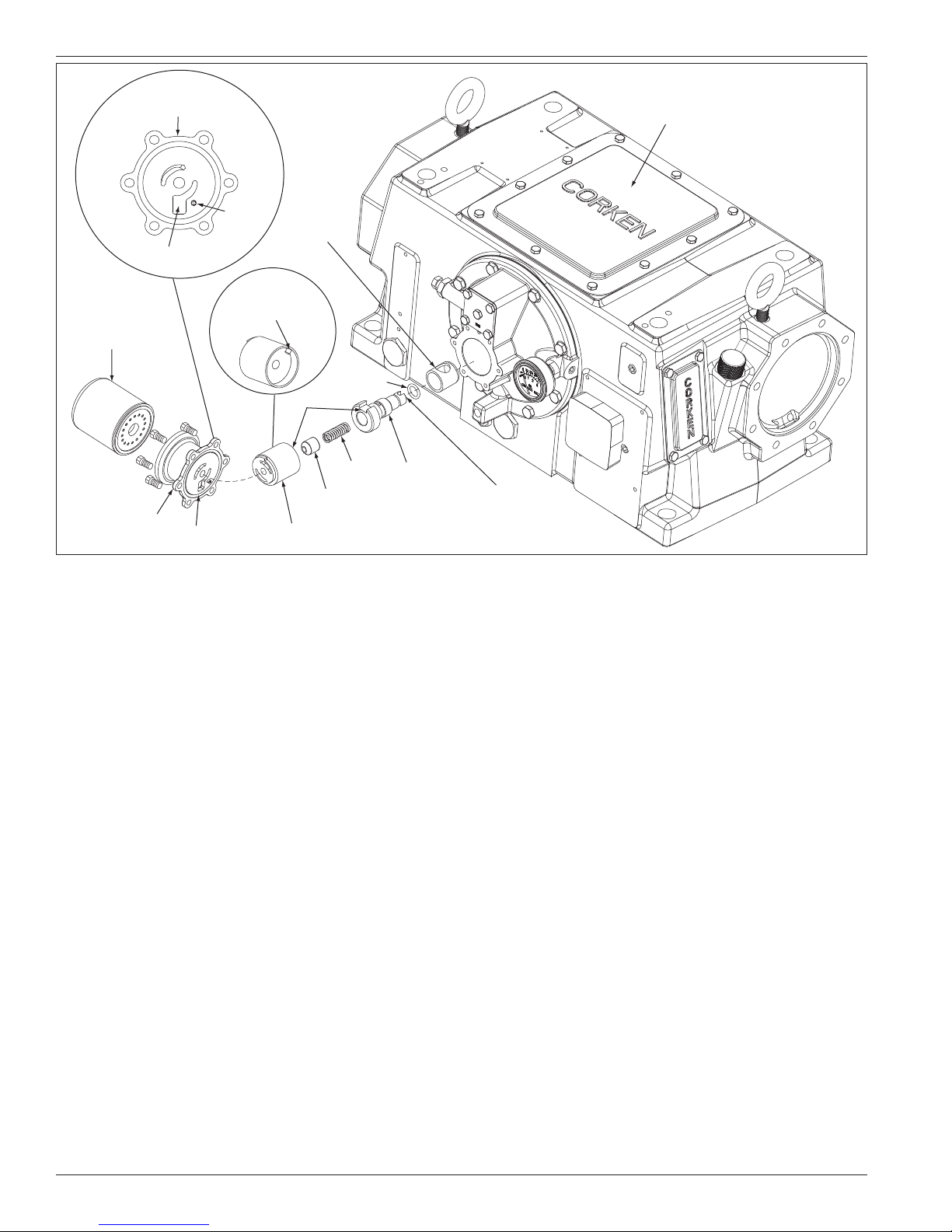

4.8 Oil Pump Inspection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

CHAPTER 5—EXTENDED STORAGE PROCEDURES ...............................................27

Compressor Troubleshooting ..................................................................28

Gasket Sets and Repair Kits ...................................................................29

Crankcase and Cylinder Kit Options .............................................................29

APPENDICES

A. Model Number Identification Code ............................................................30

B. Operating Specifications ....................................................................36

C. Outline Dimensions ........................................................................41

D. Assembly Details ..........................................................................45

3

Features and Benefits

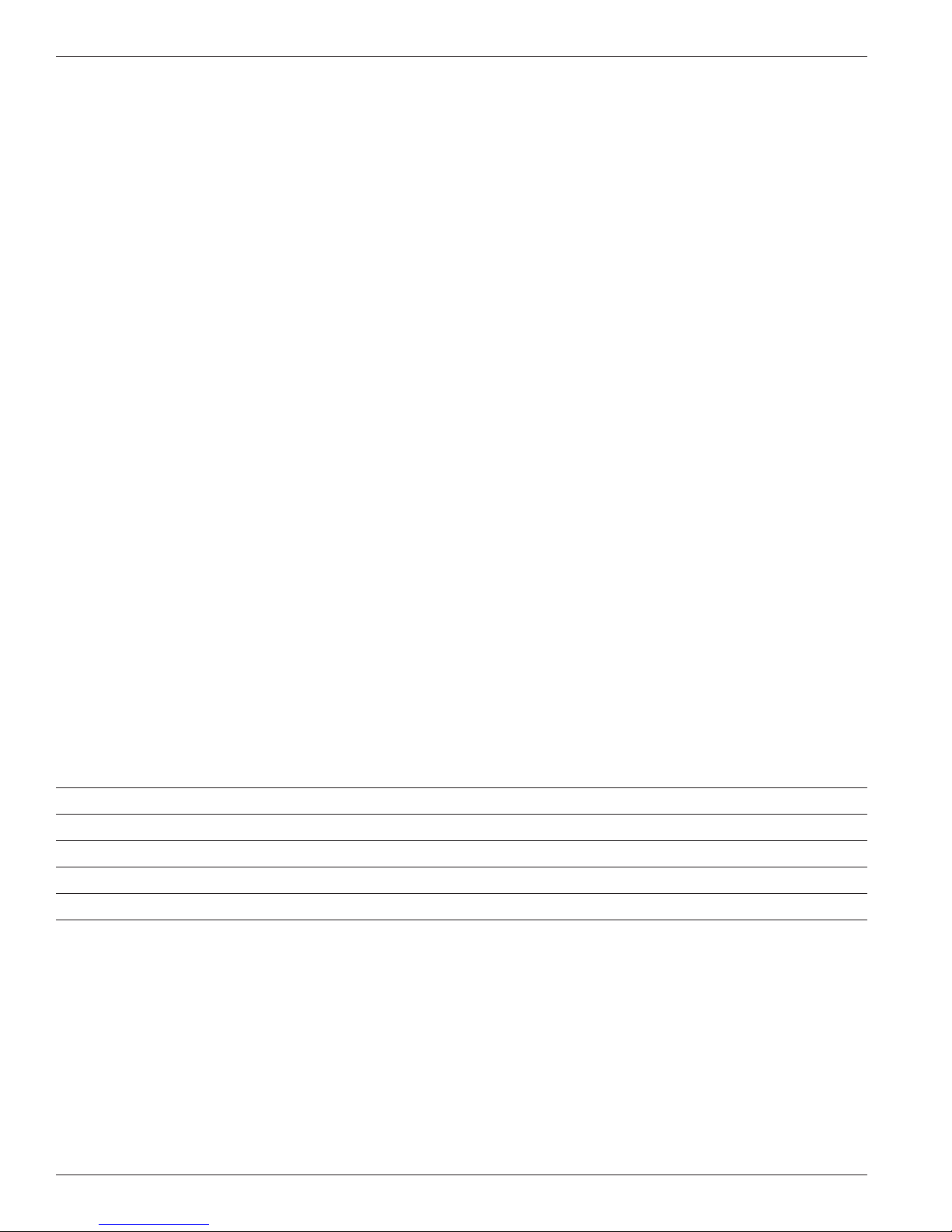

Self-lubricating piston and rider rings:

Made of PTFE to ensure extended service life

Cylinder

nameplate

Adapter

Packing cartridge body:

Holds the outer and

middle sets of packing.

Packing cartridge adaptor:

Holds the inner oil wiper

ring set and inner packing

Lifting eye

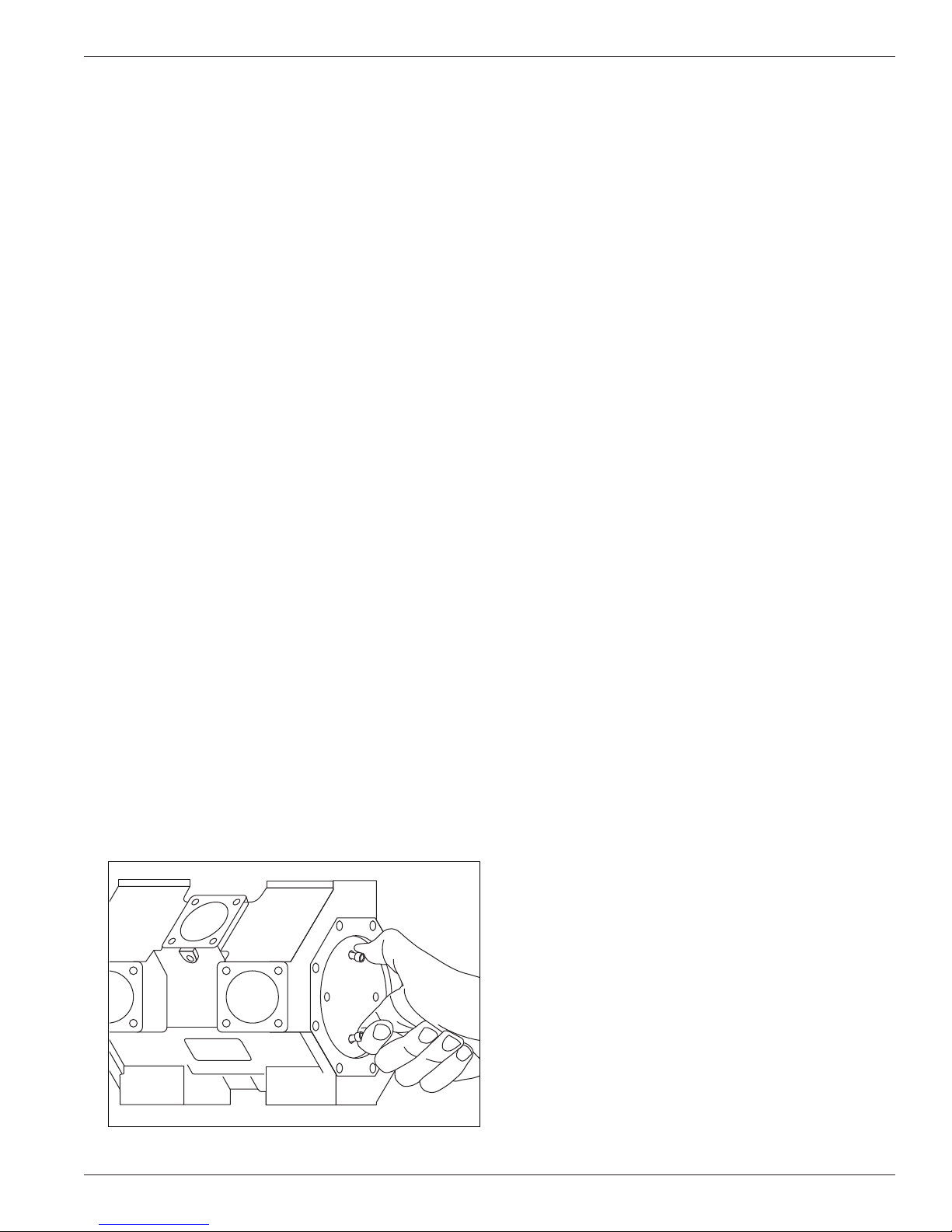

Crankcase inspection plate

Crankcase

nameplate

Placement of valves:

Make inspection and maintenance simple.

(Optional) Thermostatically controlled crankcase heater:

Assures proper oil viscosity throughout all weather conditions.

Why Corken Compressors

are Special

1/4" Pipe plug

Distance piece:

Ensures greater leakage control

(Optional)

Oil divider valve assembly:

Ensures each cylinder has the

same amount of lubrication.

Oil lter

(Optional) Force-feed lubricator:

Assures proper lubrication of

cylinders and packing when required

Figure 1.1 (THG600 shown)

the crankcase. To further seal the compression chamber,

a crosshead/piston rod design with seals around the

piston rod is required.

Corken industrial gas compressors are unique among

compressors their size. Unlike ordinary lubricated gas

compressors, Corken compressors completely isolate

the pressurized gas in the compression chamber from

the crankcase. While piston rings seal the piston tightly

enough for it to do compression work, they do not provide

enough sealing to isolate the compression chamber from

By utilizing specialized piston-rod sealing systems,

Corken compressors can compress pressurized,

flammable and toxic gases. They can also be used to

compress harmless gases where oil-free compression

or elevated suction pressures are required. With a large

selection of design options available, Corken offers the

most versatile line of small gas compressors in the world.

4

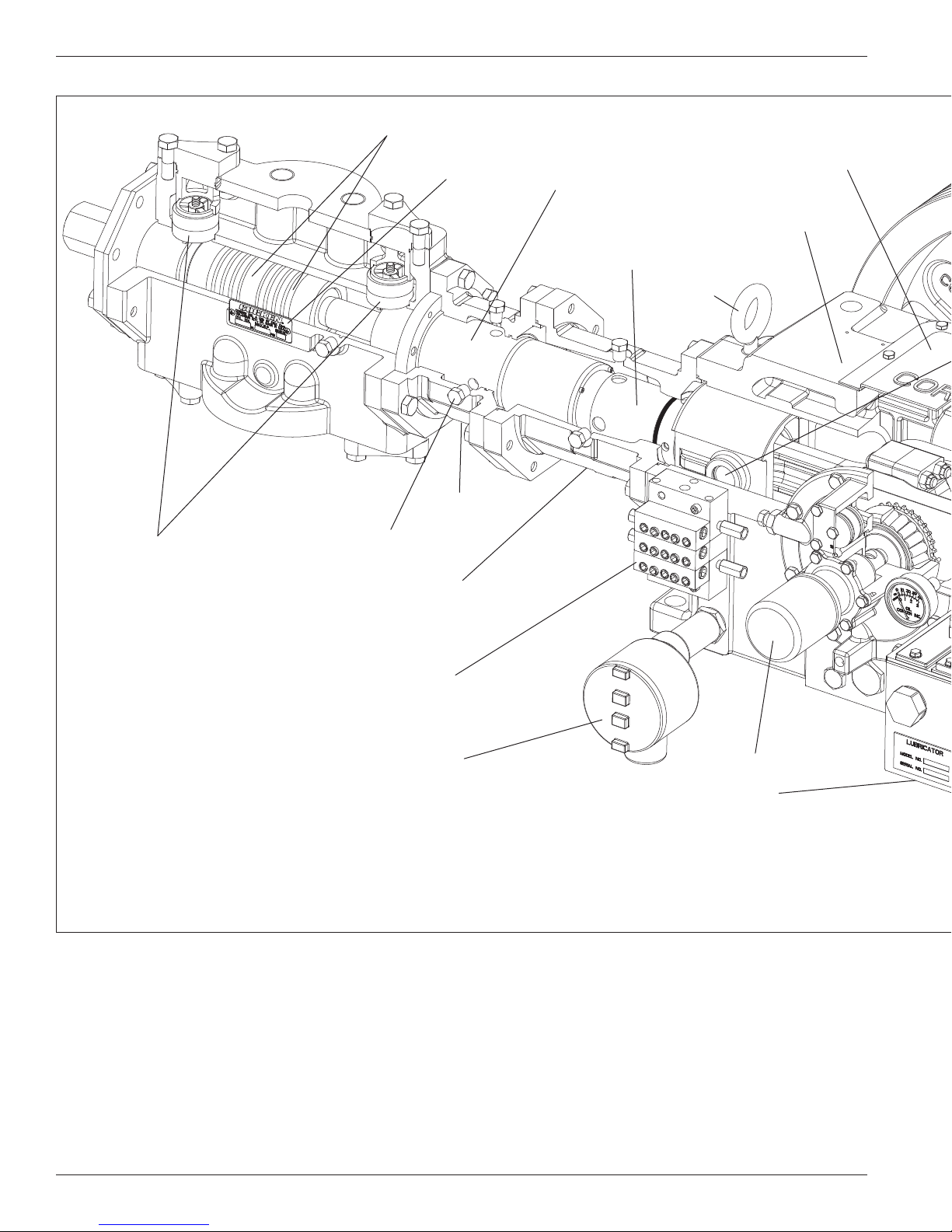

Crankshaft journal, connecting rod

bearings, wrist pins, and crossheads:

Pressure lubricated by an oil pump with oil

ltered by a 10-micron spin on lter.

Heavy-duty cylinder design:

Each cylinder is hydrostatically tested to 1-1/2

times the rated working pressure for maximum

Flywheel

strength. A corrosion resistant coating (MC1002)

is available for all cylinder sizes. MC1002 extends

the life of the cylinder and piston rings.

Inner distance piece

(Barrier 1)

Outer distance piece

(Barrier 2)

Inner oil wiper ring set

Inner packing set

Oil deector ring

Middle packing set

Outer packing set

Variable clearance head:

Enables you to change

the capacity and

BHP requirements.

Heavy-duty crankcase:

A rugged, internally ribbed design,

incorporating heavy-duty main bearings

and four-bolt connecting rods

Corken Horizontal

Gas Compressors

Your new Corken horizontal compressor is a double-acting

reciprocating compressor; however, when an optional blank

valve is used, the compressor is single acting. Corken

horizontal compressors have a large number of configurations

to fit your individual requirements. They are manufactured as

single stage- or two-stage units. For more information on the

various configurations, refer to Appendix A.

5

Chapter 1—Installation Of Your Compressor

1.1 Location

NOTE: Corken compressors are designed to handle

toxic or flammable gases and should be located

outdoors in a well ventilated area.

Proper installation of your compressor is essential for

peak performance and reliable service. The installation

area should be clean, well ventilated and have ample

space to install and maintain your compressor. A

double-acting compressor generates more heat than

a typical single-acting compressor. As a result your

compressor should be located in an area where good

air flow and ventilation can be provided. In extreme

cases, external cooling fans can be used to provide

additional air flow across the cylinders. A minimum of

18 inches clearance between the unit and the nearest

wall is advisable. This space will allow access from all

sides and provide unrestricted air flow for adequate

cooling of the motor and compressor. The unit should

be firmly bolted to a solid, level base.

Corken compressors are designed and manufactured

for outdoor duty. For applications where the compressor

will be subjected to extreme conditions such as corrosive

environments or arctic conditions for extended periods

of time, consult Corken.

Check local safety regulations and building codes to

assure installation will meet local safety standards.

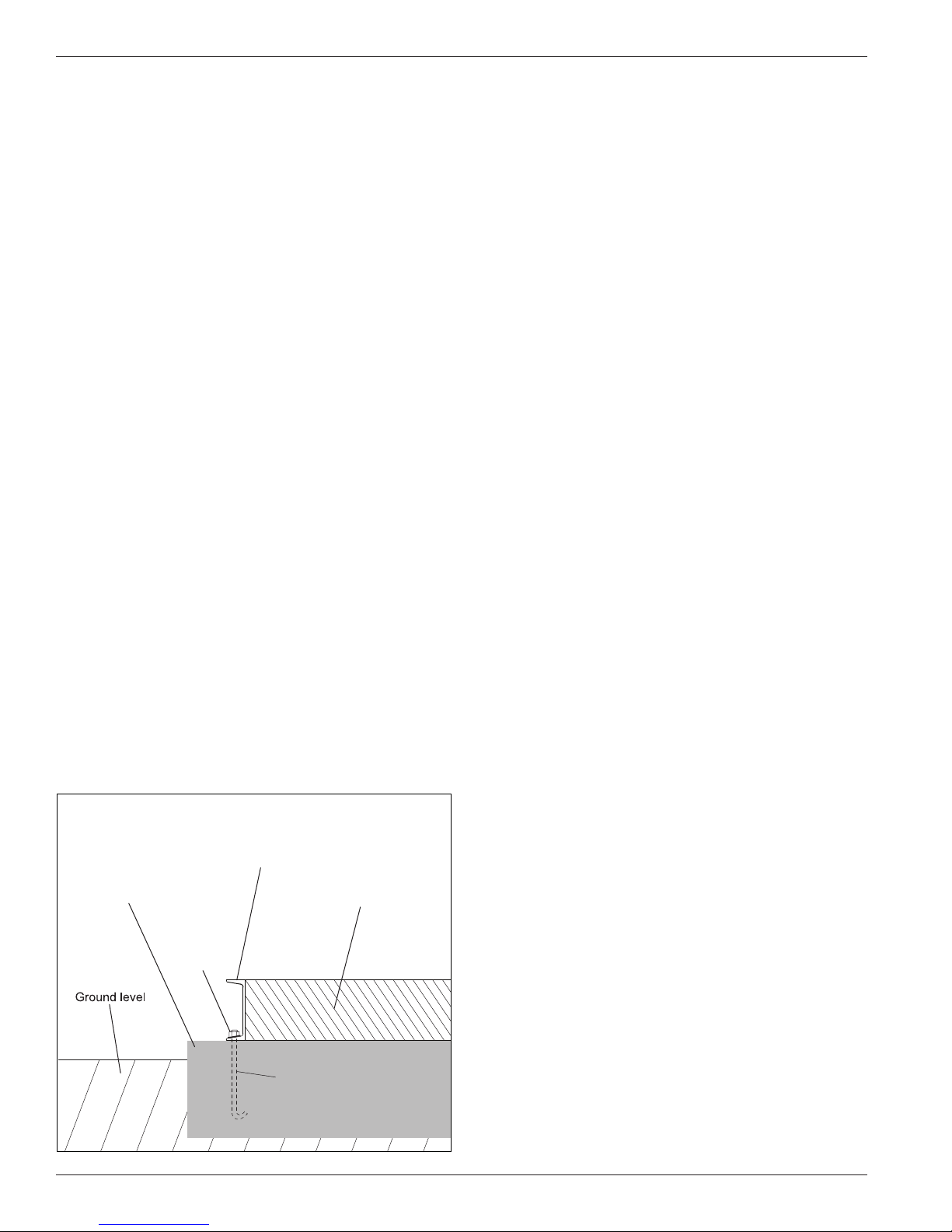

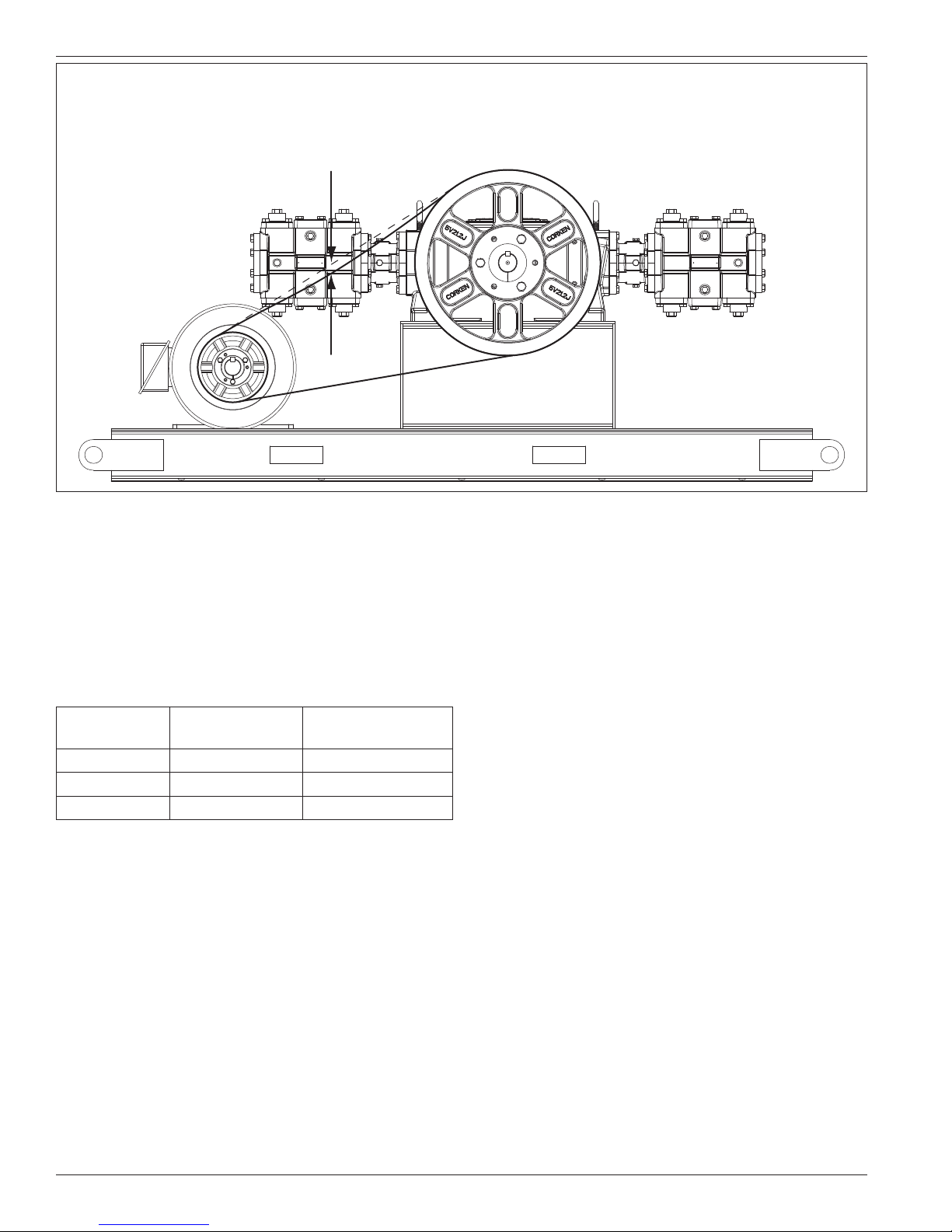

1.2 Foundation

Proper foundations are essential for a smooth running

compression system. The compressor should be

attached to a concrete slab a minimum of 8 inches

thick with a 2 inch skirt around the circumference of

the steel structural skid. The steel structural skid should

be securely anchored into the foundation by 3/4 inch

diameter “J” bolts that are 8 inches long. The total mass

of the concrete foundation should be approximately

twice the weight of the compressor system (i.e. steel

structural skid, compressor, motor, etc.). See figure 1.2

for details.

1.3 Piping

Proper piping design and installation is as important as a

proper foundation is to a smooth operating compressor.

Improper piping installation will result in undesirable

transmission of compressor vibration to the piping. The

compressor piping should be designed for the rate of

flow anticipated and for minimum pressure drop; in no

case should the piping be smaller than the compressor

nozzle to which it connects. If the length of the line must

exceed 100 ft., the next larger size pipe should be used.

Install a strainer at the compressor inlet. Never install

a shut-off valve in the discharge piping unless a safety

relief valve is placed in the line between the shut-off

valve and the compressor. Remember to consider future

expansion in your pipe sizing and layout.

Noise:

Corken horizontal compressors should not exceed an 85

DBA noise level when properly installed.

Note: The depth of the concrete foundation will

vary based on local soil conditions.

Main beam (C-Beam)

Concrete foundation

Hex nut

&

washer

Figur e 1.2

Cross beam (H-Beam)

3/4″ diameter “J” bolt

DO NOT SUPPORT PIPING WITH THE COMPRESSOR.

Unsupported piping is the most frequent cause of vibration

of the pipe. The best method to minimize transmission of

vibration from the compressor to the piping is to use

flexible connectors (see figure 1.3 for details).

Pipe must be adequately sized to prevent excessive

pressure drop between the suction source and the

compressor as well as between the compressor and the

final discharge point. In most cases, piping should be

at least the same diameter as the suction nozzle on the

compressor.

If a restrictive device such as a valve, pressure regulator,

or back-check valve is to be installed in the compressor’s

suction line, care must be taken. The suction line volume

between the restrictive device and the compressor

suction nozzle must be at least ten times the swept

cylinder volume.

On liquefied gas applications such as LPG, it is of

extreme importance to prevent the entry of liquid into

the compressor. Installing a liquid trap on the inlet side

will prevent liquid from entering the compressor (see

se ction 1.4).

6

Figure 1.3

Inlet flange

Discharge

flange

Flexible piping

connection

Flexible

piping

connection

Inlet manifold

Discharge manifold

Mounting base

Packing drain tank

It is of equal importance to protect the discharge side

of the compressor from liquid entry. This may be done

by installing a check valve on the discharge side of the

compressor and using a piping design that does not

allow liquid to gravity drain into the compressor.

For vapor recovery applications, be certain to install

a check valve on vapor lines discharging to the liquid

space of the tank.

All piping must be in accordance with the laws and codes

governing the service. In the United States, the following

codes apply:

For LP Gas—The National Fire Protection Association

Pamphlet No. 58, Standard for the Storage and Handling

of Liquefied Petroleum Gases.

For Ammonia—The American National Standards

Institute, Inc., K61.1-1989, Storage and Handling of

Anhydrous Ammonia.

Copies of these are available from NFPA, 60 Baterymarch

Street, Boston, Mass, 02110 and ANSI, 1430 Broadway, New

York, N.Y., 10018. Install, use and maintain this equipment

according to Corken instructions and all applicable federal,

state, and local laws and previously mentioned codes. Other

laws may apply in different industries and applications.

1.4 Liquid Trap

Compressors are designed to pressurize gas and not pump

liquids. The entry of even a small amount of liquid into the

compressor will result in serious damage to the compressor.

A liquid trap (scrubber) must be installed in the suction

piping - and discharge line if condensate can drain back to

the compressor - when handling any but the driest of gases.

If your compressor is equipped with a liquid trap not

manufactured by Corken, make sure it is adequately

sized; otherwise, it may not be able to remove the liquid

entrained in the suction stream.

Corken’s liquid trap provides the most thorough liquid

separation (see figure 1.4) and is American Society of

Mechanical Engineers (ASME) code stamped. It contains

two level switches: one for alarm and one for shutdown.

In some cases the alarm switch is used to activate a

dump valve (not included with trap) or sound an alarm so

the operator can drain the trap using the manual drain

valve at the bottom of the trap. The manual drain valve is

supplied with this trap. NOTE: The liquid level switches

MUST be removed from the trap before grounding

any welding devices to the trap or associated piping.

Failure to do so will damage the switch contacts!

This trap also contains a mist pad. A mist pad is a mesh

of interwoven wire designed to remove fine liquid mists.

7

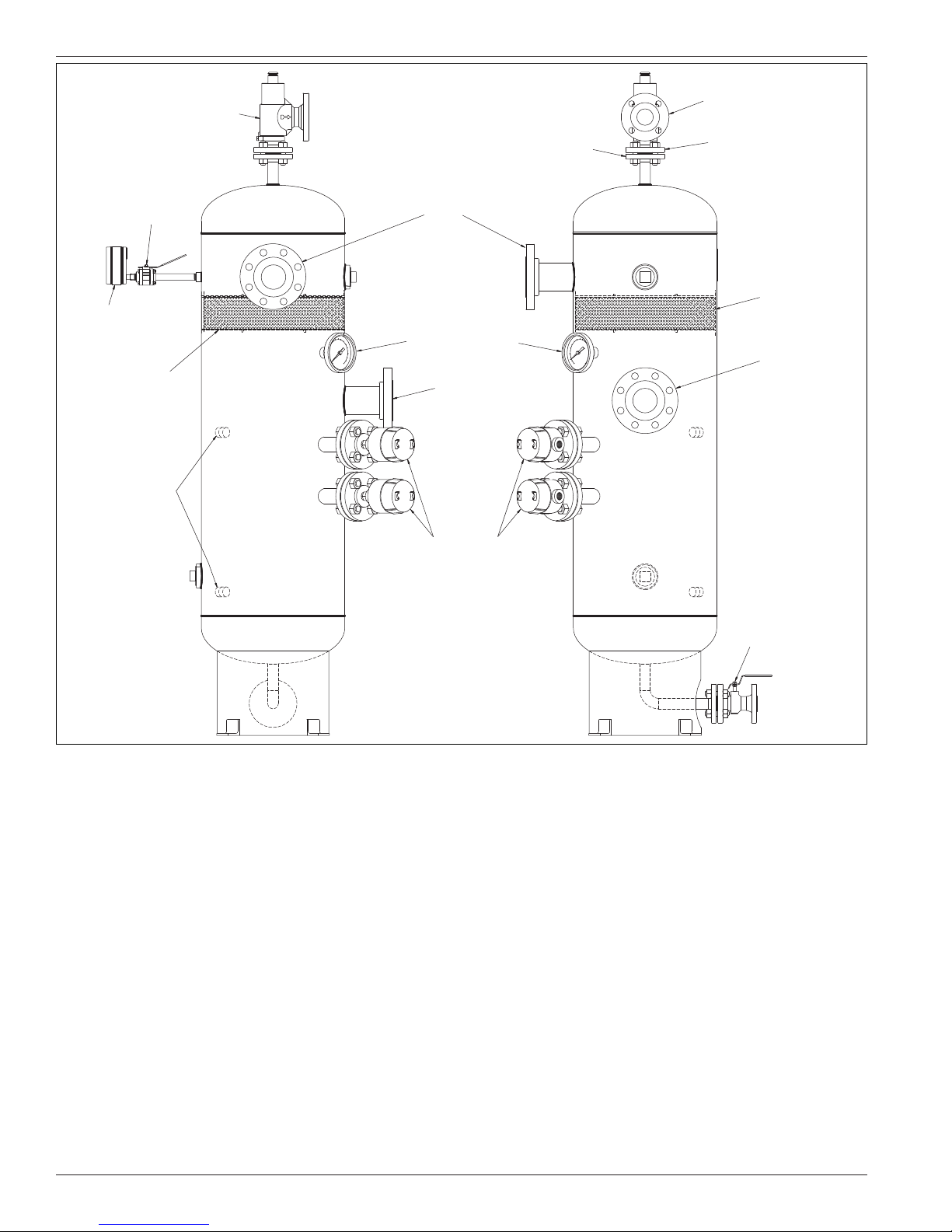

Relief valve

Outlet

2″ 150 lb

Ball valve

Pressure guage

(0–500 PSI)

Stainless steel

demister pad

1/2″ NPT openings

for sight glass

Outlet

3″ 300 lb

Temperature gauge

(0–250 PSI)

Inlet

3″ 300 lb

Liquid level switches

ANSI flange

1″ 300 lb

Inlet

1″ 300 lb

Stainless steel

demister pad

Inlet

3″ 300 lb

Figur e 1.4

1.5 Driver Installation and Flywheels

Corken compressors may be driven by either electric

motors or internal combustion engines (e.g. gasoline,

diesel, natural gas, etc.). The wiring of an electric

motor is extremely important and must be done by a

competent electrician. Low voltage or improper wiring

of the motor will result in expensive consequences. If

you suspect that you have a low voltage problem, call

your power company.

Humid climates can cause problems with explosion

proof motors. The normal breathing of the motor and

alternating between being warm when running and cool

when stopped can cause moist air to accumulate in

the motor. The moist air inside the motor will condense

and if enough water accumulates, the motor will fail. To

prevent this, make a practice of running the motor at

least once a week on a bright, dry day for an hour or so

without the V-belts. During this period of time, the motor

will heat up and vaporize the condensed moisture.

Manual drain valve

NOTE: No motor manufacturer will guarantee their

explosion proof or totally enclosed (TEFC) motor against

damage from moisture.

Drivers should be selected so the compressor operates

between 400 and 1200 RPM. The unit must not

be operated without the flywheel or severe torsional

imbalances will result that could cause vibration and

a high horsepower requirement. The flywheel should

never be replaced by another pulley unless it has a

higher wk2 value than the flywheel.

NOTE: Never operate a reciprocating compressor

without a flywheel.

For installation with engine drivers, thoroughly review

instructions from the engine manufacturer to assure the

unit is properly installed.

8

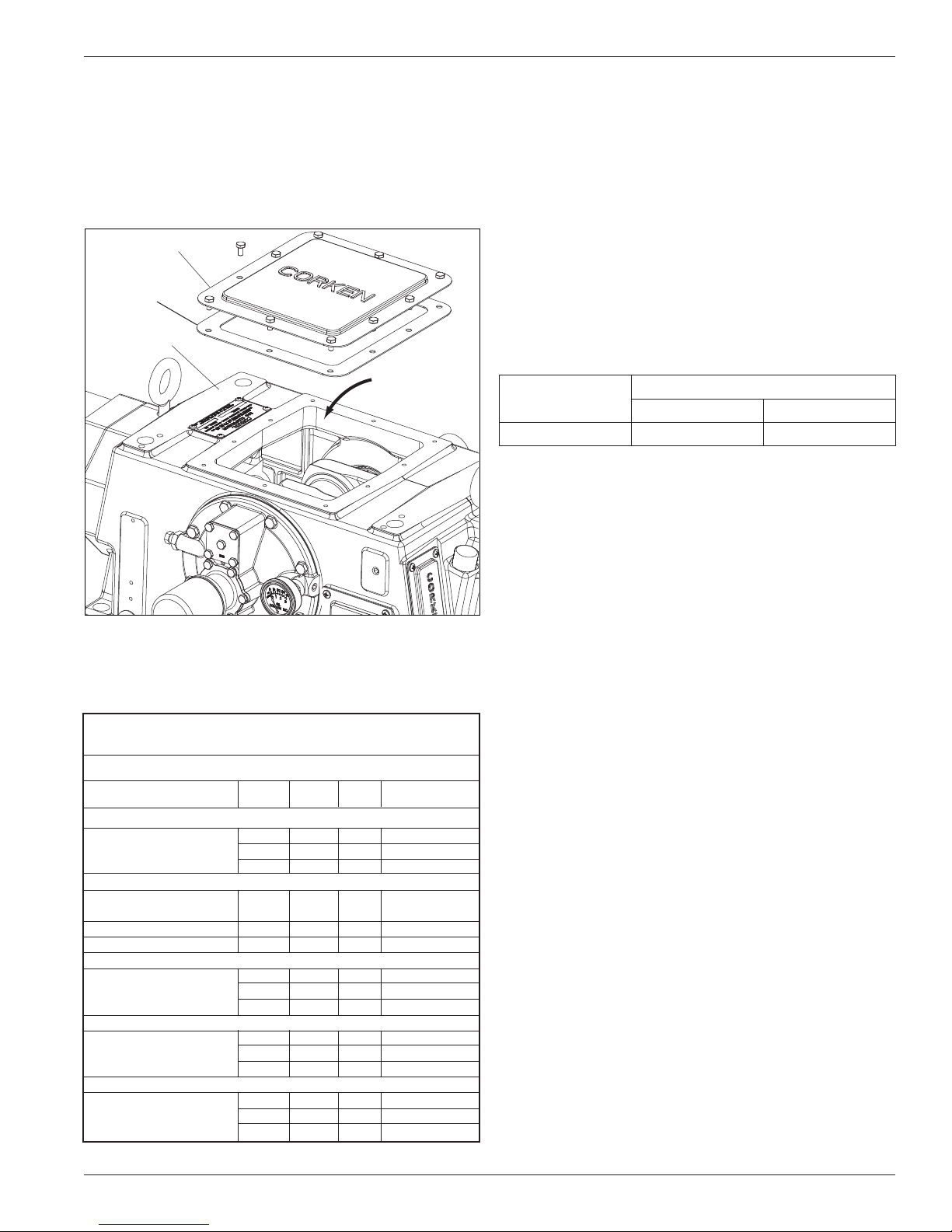

1.6 Crankcase Lubrication

The crankcase of your compressor was drained before

shipment. Before starting the machine, be sure to fill the

crankcase to the full mark on the oil bayonet and not above.

To ensure proper lubrication of the crankcase parts, the

crankcase should be filled through the crankcase inspection

plate (see Fig. 1.6A for the proper oil filling location).

Inspection plate

Inspection plate

gasket

Crankcase

Non-detergent oil is recommended for Corken horizontal

compressors. Detergent oils tend to keep wear particles

and debris suspended in the oil, whereas non-detergent

oils let them settle in the bottom of the crankcase. When

non-detergent oils are not available, detergent oils may

usually be successfully substituted, although compressors

handling ammonia, amine, or imine gases are notable

exceptions. These gases react with the detergent and cause

the crankcase oil to become corrosive and contaminated.

Figure 1.6C shows the recommended oil capacity for the

crankcase. Ensure oil is compatible with the product

being compressed.

Synthetic lubricants are generally not necessary. Please

consult your lubricant supplier if you are considering the

use of synthetic oil.

Fill crankcase

through this opening

Figur e 1.6 A

Use heavy-duty, non-detergent motor oil with rust and

oxidation inhibitors. For viscosity requirements, see

figure 1.6B.

Acceptable Crankcase Oil Products for Corken

Compressors

Constant Weight - Non-Detergent - R&O Inhibited

Oil product ISO VI SAE Ambient Temp.

Exxon®

TERESSTIC 100 95 30 65° - 100° F

68 95 20+ 45° - 70° F

46 95 20 35° - 50° F

Mobil®

RARUS 427 Reciprocating 100 95 30 65° - 100° F

Compressor Oil

DTE Oil Heavy Medium 64 95 20+ 45° - 100° F

Dectol R&O Oil 44 95 20 35° - 50° F

Conoco®

Dectol R&O Oil 100 98 30 65° - 100° F

68 97 20+ 45° - 70° F

46 99 20 35° - 50° F

Texaco®

Regal R&O Oil 100 92 30 65° - 100° F

68 97 20+ 45° - 70° F

46 102 20 35° - 50° F

Sun®

SunVis 900 Oil 100 100 30 65° - 100° F

68 100 20+ 45° - 70° F

46 100 20 35° - 50° F

Figure 1.6B: Oil Selection Chart

Compressor

Model

Approximate Capacity

Quarts Liters

HG/THG600 7 6.6

Figure 1.6C

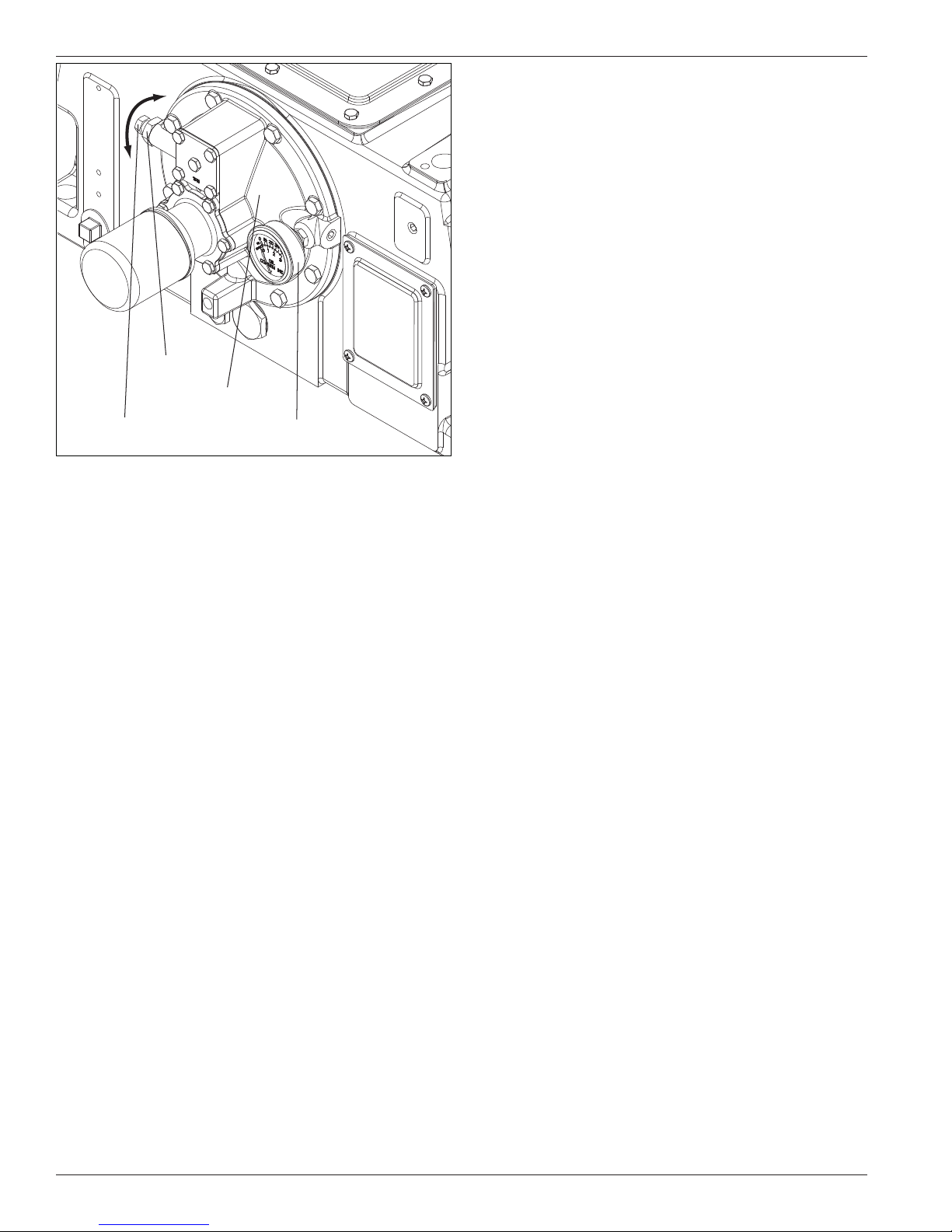

1.7 Crankcase Oil Pressure

Adjustment

Your Corken compressor is equipped with an

automatically reversible gear type oil pump. It is

essential to ensure the pumping system is primed and

the oil pressure is properly adjusted in order to assure

smooth operation.

Before starting your compressor, check and fill the

crankcase with the proper amount of lubricating oil

(see figure 1.6A for details).

When the compressor is first started, observe the

crankcase oil pressure gauge. If the gauge fails to

indicate pressure within 30 seconds, stop the machine.

Loosen the oil filter and remove the pressure gauge.

Restart the compressor and run it until oil comes out

of the pressure gauge opening or around the filter.

Tighten the filter and reinstall the gauge.

The oil pressure should be about 20 psi (1.4 bars)

minimum for normal service. If the discharge pressure

of the compressor is above 200 psi (14.8 bars), the

oil pressure must be maintained at 25–30 psi (1.7–2.1

bars). A spring-loaded relief valve mounted on the

bearing carrier opposite the flywheel regulates the oil

pressure. As shown in figure 1.7, turn the adjusting

screw clockwise to increase the oil pressure and

counterclockwise to lower it. Be sure to loosen the

adjusting screw locknut before trying to turn the screw

and re-tighten it after making any adjustment (see

figure 1.7 for details).

9

Locknut

the maximum design temperature for the compressor

of 350°F (176°C).

3. Low Suction Pressure Switch: Shuts down the

unit if inlet pressure is not within the preset limit (set

point). In some cases, it is important not to pull a

vacuum because of the potential of pulling oil from the

crankcase into the gas stream.

4. High Discharge Pressure Switch: Shuts down the

unit if the outlet pressure reaches a preset limit (set

point). Both the switch and the compressor have an

operating range. The set point of the pressure switch

should be as follows:

Greater than the normal operating pressure for the

compressor.

Bearing carrier

Oil pressure relief valve

adjustment screw

Oil pressure guage

Figur e 1.7

1.8 Relief Valves

An appropriate relief valve must be installed on

the discharge side of the compressor. On Corken

107C-style mounted units, a relief valve should be

fitted in the piping between the compressor discharge

and the four-way valve. Relief valves should be made of

a material compatible with the gas being compressed.

Local codes and regulations should be checked for

specific relief valve requirements. Also, relief valves

may be required at other points in the compressor’s

system piping.

1.9 Shutdown/Alarm Devices

For many applications, shutdown/alarm switches will

provide worthwhile protection that may prevent serious

damage to your compressor system. All electronic

devices should be selected to meet local code

requirements. Shutdown/alarm devices typically used on

Corken compressors are as follows:

Less than 90% of the relief valve set point pressure.

Less than the maximum operating pressure of the

compressor.

Midpoint of the pressure switch range.

5. Vibration Switch: Shuts down the unit if vibration

becomes excessive. Recommended for units mounted

to a portable skid.

1. Low Oil Pressure Switch: Shuts down the unit if

crankcase oil pressure falls below 12 psi due to oil

pump failure or low oil level in crankcase. The switch

or the compressor controller must have a 30 second

delay on startup which allows the compressor to build

oil pressure in the crankcase.

2. High Discharge Temperature Switch: This switch

is strongly recommended for all applications. Both

the High Discharge Temperature switch (HDT) and

compressor have an operating pressure range. It is

preferable that the switch set point be 30°F (-1°C)

above the normal discharge temperature, but below

10

Chapter 2—Starting Up Your Corken Compressor

The initial operation of your compressor is the most critical

time it will ever face. READ ALL OF CHAPTER TWO BEFORE

YOU PROCEED WITH THE STARTUP CHECKLIST.

2.1 Inspection After Extended

Storage

If your compressor has been out of service for a long

period of time, you should verify that the cylinder bore

and valve areas are free of rust and other debris. For

valve and/or cylinder head removal instructions, refer to

chapter 4 of this IOM manual.

Drain the oil from the crankcase and remove the

crankcase inspection plate. Inspect the running gear for

signs of rust and clean or replace parts as necessary.

Fill crankcase with the appropriate lubricant through the

crankcase inspection plate opening. Squirt oil on the

crossheads and rotate the crankshaft by hand to ensure

that all bearing surfaces are coated with oil.

Rotate unit manually to ensure running gear functions

properly. Replace the crankcase inspection plate and

proceed with startup.

2.2 Flywheel and V-belt Alignment

Before working on the drive assembly, make sure the

electrical power is turned off. Always make sure the

driver and compressor are close enough together to

avoid forcing the belts over the flywheel and sheave.

Tighten the belts so that they are taut, but not extremely

tight. Consult your V Belt supplier for specific tension

recommendations. Belts that are too loose will cause

excessive vibration while those that are too tight may

cause premature bearing failure (refer to figure 2.2C).

Improper belt tension and sheave alignment can cause

vibration, excessive belt wear and premature bearing

failures. Before operating your compressor, check

alignment of the V-grooves of the compressor flywheel

and driver sheave. Visual inspection often will indicate if

the belts are properly aligned, but use of a straight edge

tool or string is the best method.

Crankshaft key

Align hub with crankshaft key.

Flywheel removal holes

(threaded openings)

Split

Flywheel

Tighten flywheel bolts in an even and progressive manner.

Figure 2.2A (model HG601EE (plain style) shown)

11

NOTE:

1) If you are using five individual V-belts, 1/4 to 3/8 inches (6.4 to 9.5 mm) of movement is normal.

2) If you are using five banded V-belts, movement will be much less due to the stiffness of the banded V-belt design.

Figure 2.2C

The flywheel is mounted on the shaft via a split, tapered

hub and three bolts (see figure 2.2A). These bolts should

be tightened in an even and progressive manner to

the specified torque values listed in figure 2.2B. There

must be a gap between the hub and the flywheel when

installation is complete. Failure to do so will cause the

flywheel to be misaligned. Always check the flywheel run

out before startup and readjust if it exceeds the value

listed in Appendix B.

Hub Size

SF 4.625 (11.7) 12–18 (2.5)

E 6.0 (15. 2) 30–36 (4.9)

J 7.25 (18.4) 75–81 (11.1)

Diameter

in. (cm)

Bolt Torque

Ft·lb (kg·meter)

cooling fans can be used to provide additional air flow

across the cylinders.

WATER COOLED: If your unit has water cooled cylinders

(optional), be sure that the cooling system has been

inspected for leaks and proper circulation. Purge air

from the cooling jackets to eliminate air pockets in the

cooling system. If chilled water systems are used be sure

that water shut-off valves are installed to stop water flow

when compressor stops. Monitor system for any signs of

internal sweating. If internal moisture is detected, water

temperatures and flow rates should be checked. Normal

flow rate for cylinders is approximately 1 - 2 gpm.

2.5 Force Feed Cylinder

Figure 2.2B

2.3 Compressor Speed and

Rotation Direction

The lubrication system of the Corken horizontal

compressor is designed to operate at a minimum of 400

RPM. If lower speeds are necessary, consult the factory.

The maximum speed is 1200 RPM. The crankshaft may

be rotated in either direction.

2.4 Compressor Cooling

AIR COOLED: Double acting units generate a lot of

heat around the valve area. It is very important that

the compressor be located where good air flow and

ventilation can be provided. In extreme cases external

Lubrication (Lubed models only)

An external lubricator is bolted directly to the crankcase

and is driven by a chain inside the crankcase at 80%

of crankshaft speed. To ensure each cylinder receives

the same volume of lubrication, an oil divider valve

assembly is also mounted to the opposite end of

the crankcase (see lubricator assembly details in

Appendix D). Since lubricators supplied with Corken

compressors are made by a number of different

manufacturers, refer to the manufacturer’s instructions

provided with the lubricator for specific details on

priming, adjusting and maintaining your lubricator.

Basic operating instructions and flow rate adjustments

are also listed on the side of the lubricator reservoir.

At the initial setup of your compressor, the lubricator

flow should be set to maximum capacity. After the first

hour, reduce the flow to normal operating levels. Normal

12

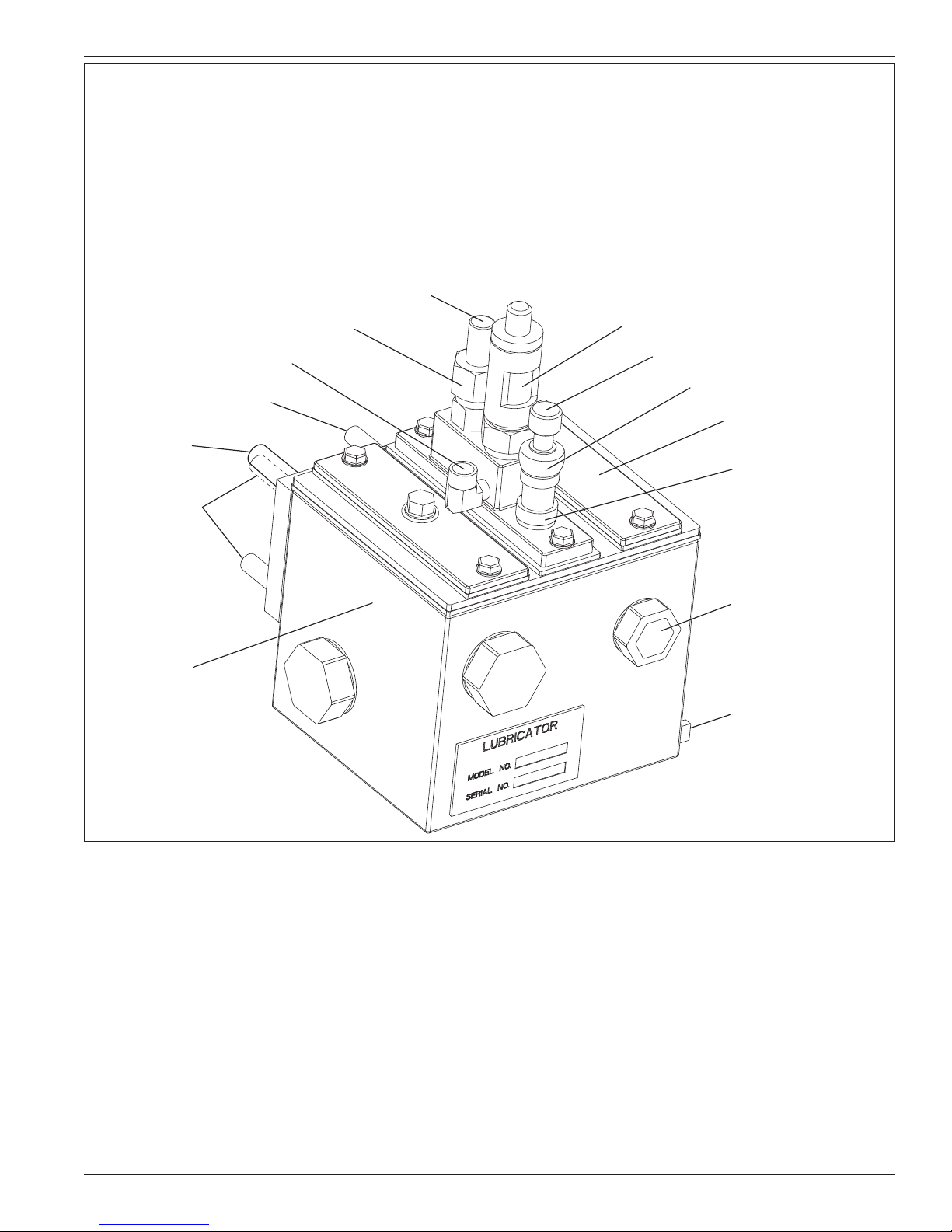

NOTE:

1) Since Corken uses more than one vendor when purchasing lubricators, the lubricator shown below and

respective operational instructions may vary from the one used on your compressor.

2) Operational instructions can be found on the side of the lubricator reservoir.

3) Oil used in the reservoir is for lubricating the internal parts of the lubricator only and not the compressor.

4) Depending on the cylinder size, the oil flow rate for the drip tube site glass is three to six drops per minute

during normal operations.

Oil outlet (1/8″)

Mounting stud

Drive shaft

Mounting studs

Reservoir

Oil inlet (1/8″)

Union nut

Drip tube sight glass

Priming button

Flushing unit

Oil ll opening

Lock nut

Reservoir sight glass

Drain plug

Premier lubricator model number P-55U with pump no. 91490 shown above.

operating levels range from three to six drops per minute

depending upon the cylinder size.

NOTE: The lubricator supplied on your CORKEN

compressor must be supplied with oil from an external

supply tank and NOT from the compressor crankcase or

lubricator reservoir.

Oil types: Refer to section 1.6 (crankcase lubrication).

2.6 Variable Clearance Heads (VCH)

Variable clearance head (VCH) assemblies (outboard)

allow adjustment of the compressor when operating

conditions change. By turning the clearance volume

adjusting cup, you can easily change the capacity

and bhp requirements of the cylinder. Normally, the

packager will have already provided at least a preliminary

adjustment of the VCH. If not, you may wish to adjust

the heads for maximum clearance before startup. After

startup, adjust the heads inward to increase the capacity

and bhp of the cylinder to the desired levels.

To adjust the variable clearance heads, follow the steps

below.

1) Remove the VCH adjusting screw nut. Adjustment can

be made while the unit running.

2) Turn the end of the adjusting cup to adjust the cylinder

head end clearance.

13

3) Turning the end of the adjusting cup inward (clockwise)

reduces cylinder head end clearance.

4) Turning the end of the adjusting cup outward

(counterclockwise) increases cylinder head end

clearance.

17. Carefully check for any loose connections or bolts.

18. Remove all stray objects (rags, tools, etc.) from

vicinity of the unit.

19. Confirm all valves are open or closed as required.

5) Replace the VCH adjustable screw nut and O-ring.

The approximate clearance volume change per turn of

the adjusting bolt is 3%.

2.7 Startup Check List

Please verify each item on this list below before starting

your compressor! Failure to do so may result in a costly

and/or dangerous mistake.

Before Starting the Compressor

1. Become familiar with the function of all piping

associated with the compressor. Know each line’s use!

2. Make certain actual operating conditions will match

the anticipated conditions.

3. Ensure line pressures are within cylinder pressure

ratings.

4. Clean out all piping.

5. Ensure all adapter and distance piece openings are

tubed or plugged as desired.

6. Check all mounting shims, cylinder and piping supports

to ensure that no twisting forces or other undesired

nozzle forces or torque is applied to the compressor.

7. Make certain strainer elements are in place and clean.

20. Re-check all of the above.

After Starting Compressor

1. Verify and note proper oil pressure. Shut down and

correct any problems immediately.

2. Observe noise and vibration levels. Correct

immediately if excessive.

3. Verify proper compressor speed.

4. Examine entire system for gas or oil leaks.

5. Note rotation direction.

6. Check start-up voltage drop, running amperage

and voltage.

7. Verify proper lubrication rate (lubed units only).

8. Test each shutdown device and record set points.

9. Test or confirm set point on all relief valves. Test all

dump valves, relief valves and unloaders.

10. Check and record all temperatures and pressures

after 30 minutes and 1 hour. Retain records for

future reference.

11. After approximately one hour of running time, tighten

all head bolts, valve holddown bolts, and baseplate

bolts. See Appendix B for torque values.

8. Make certain cylinder bore and valve areas are clean.

9. Check V-belt tension and alignment or drive alignment

on direct drive units.

10. Rotate unit by hand and make certain there is no

wobble or play in the flywheel or sheave.

11. Check crankcase oil level.

12. Drain all liquid traps, separators, etc.

13. Verify proper electrical supply to motor and panel.

14. Check all gauges and confirm a zero level reading.

15. Test piping system for leaks.

16. Purge unit of air before pressurizing with gas. Follow

your company procedures for this operation.

14

Chapter 3—Routine Maintenance Chart

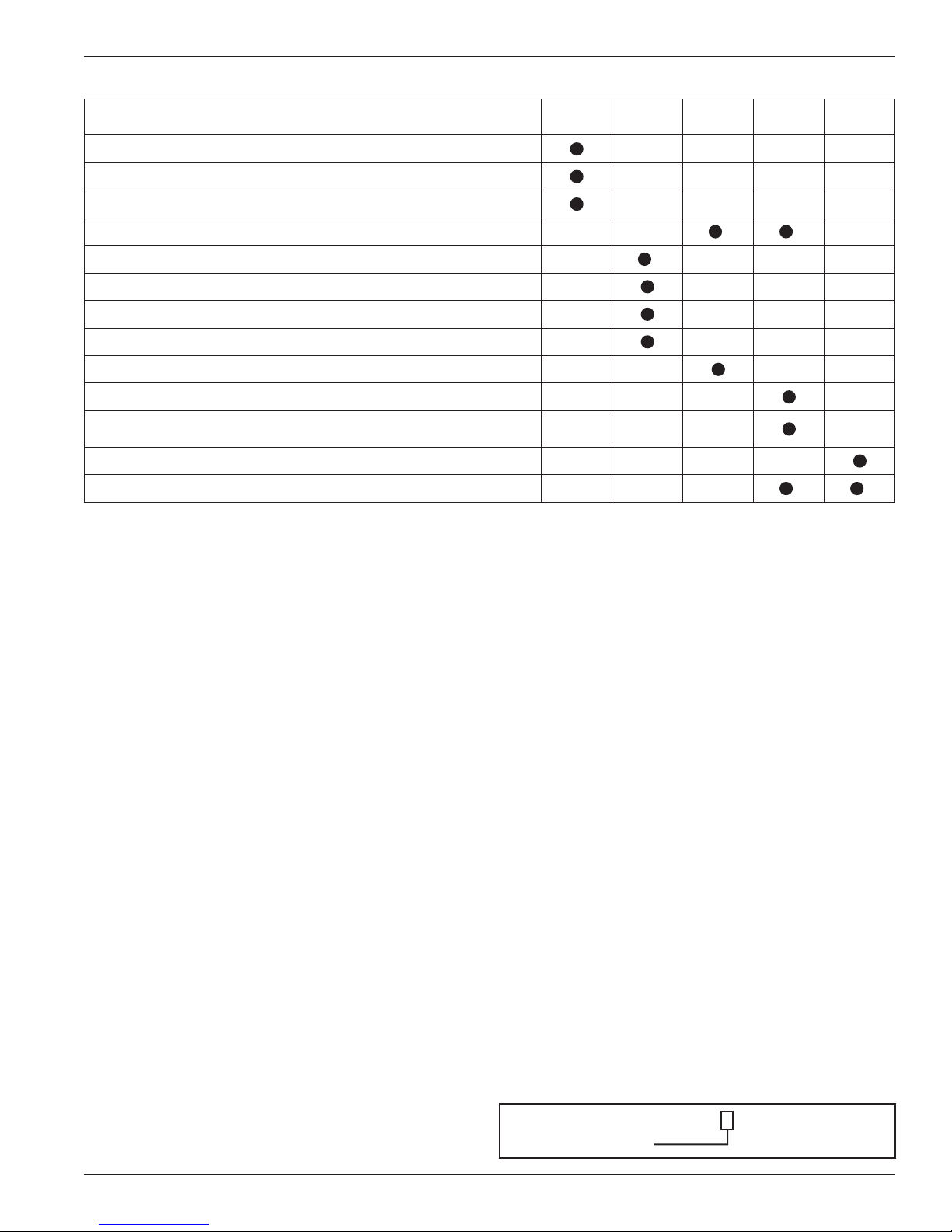

Item to Check Daily Weekly Monthly

Six

Months

Yearly

Crankcase oil pressure

Compressor discharge pressure

Overall visual check

Crankcase oil level

Drain liquid from accumulation points

3

2 2

Drain adapters and distance pieces

Clean cooling surfaces on compressor and intercooler (if any)

Lubricator supply tank level (if any)

Check belts for correct tension

Inspect valve assemblies

Lubricate motor bearings in accordance with manufacturers’

recommendations

Inspect motor starter contact points

Inspect piston rings

1

Piston ring life varies greatly, depending on application, gas and operating pressures. Consult factory for additional recommendations for your

specific application.

2

Change oil ever y 2,200 hours of operation or every 6 months, whichever occurs first. If the oil is unusually dirty, change it as often as needed

to maintain a clean oil condition. Change replacement filter 4225 with every oil change.

3

Liquid traps should be drained prior to star tup.

1

1 1

Chapter 4—Routine Service and Repair Procedures

CAUTION: Always relieve pressure in the unit before

attempting any repairs. After repair, the unit should

be pressure tested and checked for leaks at all joints

and gasket surfaces.

If routine maintenance is performed as listed in chapter

3, repair service on your Corken gas compressor is

generally limited to replacing valves or piston rings.

When it comes time to order replacement parts, be sure

to consult the part details appendix in the back of this

Installation, Operation & Maintenance (IOM) manual for a

complete list of part numbers and descriptions.

4.1 Compressor Valves

Test the compressor valves by closing the inlet piping

valves while the unit is running; however, do not allow

the machine to operate in this way very long. If the inlet

pressure gauge does not drop to zero almost immediately,

one or more of the compressor valves is probably damaged

or dirty. However, it is possible for the pressure gauge itself

to be faulty.

cover plates to each other. If a valve or gasket is leaking,

it will have a higher operating temperature. NOTE: This

method will not be suitable for two stage compressors if

each stage does not have more than one valve.

Each suction and/or discharge valve assembly is easily

removed as a unit for inspection. If any part of the

valve assembly is broken, the valve assembly should be

replaced. See valve assembly parts details in the Appendix

D for a complete list of part numbers and descriptions.

If a compressor valve is leaking due to dirt or any other

foreign material that keeps the valve plate and seat from

sealing, the valve may be cleaned and reused. New gaskets

and/or O-rings should be used to ensure a good seal.

The valve holddown components and valve assemblies

listed in Appendix D show the various specifications

used on horizontal compressors. Since more than one

suction valve arrangement is available for each model of

compressor, it is necessary to know your complete model

number so you can identify the valve type specification

number (see example listed below).

In most cases, if a compressor valve or valve gasket

is leaking, it will create more heat. On a single stage

compressor, you may be able to compare the operating

temperatures of the two suction or discharge valves and

Model number THG601BBGM 4 FBANSNNN

Valve type = spec 4

15

Valve Inspection and/or Replacement

Before removing and inspecting the valves, begin by

depressurizing and purging (if necessary) the unit and

refer to Appendix D.

Disassembly of 2.75" Cylinder Size

1. Remove the valve cover plate and O-ring by removing

each of the three bolts.

replaced. Replacement is usually preferable although

repair parts are available. If valve plates are replaced,

seats should also be lapped until they are perfectly

smooth. If more than .005 of an inch must be removed

to achieve a smooth surface, the valve should be

discarded. If plates are replaced without re-lapping

the seat, rapid wear and leakage may occur.

Assembly of 3.25", 4", 5", 6" and 8" Cylinder Sizes

2. After the cover plate and O-ring have been removed,

the valve assembly and valve gasket can be lifted out.

3. Inspect valves for breakage, corrosion, debris and

scratches on the valve plate. In many cases, valves

may simply be cleaned and reinstalled. If the valves

show any damage, they should be repaired or

replaced. Replacement is usually preferable although

repair parts are available. If valve plates are replaced,

seats should also be lapped until they are perfectly

smooth. If more than .005 of an inch must be removed

to achieve a smooth surface, the valve should be

discarded. If plates are replaced without re-lapping

the seat, rapid wear and leakage may occur.

Assembly of 2.75" Cylinder Size

1. Insert metal valve gasket into the suction and/or

discharge opening of the head. The metal valve

gasket should always be replaced when the valve

is reinstalled.

2. Insert cleaned or new valve assembly. Make sure the

suction and discharge valves are in the proper suction

and discharge opening in the head.

3. Replace the O-ring and valve cover plate. Torque the

bolts to the value listed in Appendix B. CAUTION: Be

sure the holddown screw has been removed. NOTE:

Gaskets and O-rings are not normally reusable.

4. Check bolts after first week of operation. Re-torque if

necessary. See Appendix B for torque values.

Disassembly of 3.25", 4", 5", 6" and 8" Cylinder Sizes

1. Unscrew the valve cap and remove the O-ring.

2. Remove the valve cover plate, O-ring and holddown

screw by removing each of the four bolts. The

holddown screw is easily removed with the special

wrench supplied with your compressor.

3. After the cover plate and O-ring have been removed,

the valve cage, valve assembly and valve gasket can

be lifted out.

4. Inspect valves for breakage, corrosion, debris and

scratches on the valve plate. In many cases, valves

may simply be cleaned and reinstalled. If the valves

show any damage, they should be repaired or

1. Insert metal valve gasket into the suction and/or

discharge opening of the head. The metal valve

gasket should always be replaced when the valve is

reinstalled.

2. Insert cleaned or new valve assembly. Make sure the

suction and discharge valves are in the proper suction

and discharge opening in the head.

3. Insert the valve cage.

4. Replace the O-ring and valve cover plate. Torque the

bolts to the value listed in Appendix B. CAUTION: Be

sure the holddown screw has been removed.

5. To ensure the valve gasket is properly seated, insert

the holddown screw and tighten to the value listed

in Appendix B. NOTE: Gaskets and O-rings are not

normally reusable.

6. Replace the O-ring and valve cap and tighten to the

value listed in Appendix B.

7. Check bolts and valve holddown screws after first

week of operation. Re-torque if necessary. See

Appendix B for torque values.

4.2 Heads

A horizontal compressor cylinder head or adjusting cap

seldom require replacement if the compressor is properly

maintained. The primary cause of damage to a cylinder

head and adjusting cap is corrosion and the entry of

solid debris or liquid into the compression chamber.

Improper storage can also result in corrosion damage to

the cylinder heads and adjusting caps (for proper storage

instructions see chapter 5).

Many compressor repair operations require removal

of the cylinder heads and adjusting caps. While the

compressor is disassembled, special care should be

taken to avoid damage or corrosion. If the compressor

is to be left open for more than a few hours, bare metal

surfaces should be coated with rust preventative.

When reassembling the compressor, make sure the

bolts are re-tightened to the torque values listed in

Appendix B.

16

4.3 Piston Rings and Piston Ring

Expander Replacement

4. Remove the lock nut, washer and shims and pull the

piston off the end of the piston rod. Keep track of which

piston washer and shims came out of each cylinder.

Piston Ring Life - Dry Cylinder Compressor Applicat ions

It is unrealistic to expect the same piston ring life from

a dry cylinder compressor as from a lubricated cylinder

machine because the PTFE rings have greater wear,

particularly under high temperature conditions.

CORKEN uses one of the best PTFE ring formulations

available. The normal life expectancy is approximately

2,200 hours of continuous service within recommended

compression ratios. However, ring life will vary considerably

depending upon piston speed (RPM), ambient temperature,

intermittent service conditions, compression ratio and the

nature of the gas being handled.

The secret to long ring life is operating at a low temperature.

A low ambient temperature and compression ratio along

with better intercooling will provide better ring wear.

Piston Ring Life - Lubricated Cylinder

Compressor Applications

If your compressor is equipped with cylinder lubrication

you can expect considerably longer life from your piston

rings than the dry cylinder units described above.

Piston ring life will vary considerably from application to

application. Ring life will improve dramatically at lower

speeds and temperatures.

Piston and Piston Ring Expander Replacement

1. To replace the piston rings, depressurize the

compressor and purge if necessary.

2. Remove the cylinder cap (if any) and head.

3. Loosen the piston cap screws and remove the piston

cap as shown in figure 4.3 by pinching two loose

screws together.

5. Piston rings and expanders may then be easily

removed and replaced. Corken recommends replacing

expanders whenever rings are replaced. To determine

if rings should be replaced, measure the radial

thickness and compare it to the chart in Appendix B.

4.4 Pistons

As you read the following instructions, refer to

Appendix D for parts details.

1. To replace the pistons, depressurize the compressor

and purge if necessary.

2. Remove the head (or adjusting screw nut, cylinder

cap, adjusting cup and head - applies to adjustable

head configuration only) as shown in Appendix D.

3. Remove the piston cap and shims by loosening and

removing the piston cap screws holding the piston cap

to the piston. Re-insert two loose screws as shown

in figure 4.3. Using your fingers, pinch the screws

together and pull the piston cap out of the cylinder.

4. Remove the lock nut and thrust washer and pull the

piston out of the cylinder. Then, remove the thrust

washer and shims on the end of the piston rod.

5. Check the thrust washer and shims for damage and

replace if necessary.

6. Measure the thickness of the existing shims.

7. Insert one thrust washer against piston rod shoulder

followed by the same shims (or the same thickness of

shims) as before.

8. Before installing the piston, attach the piston ring

expanders and piston rings to the piston. Then, install

the piston on the piston rod.

Figure 4.3

9. Install a thrust washer and lock nut and tighten the

lock nut to the value listed in Appendix B.

10. Now remove an inboard valve and measure dimension

“Y” on the inboard end of the piston as shown in

Appendix B. If this measurement does not fall within

the tolerances listed in the piston assembly details

(Appendix B), remove the piston and adjust the shims

as necessary. Re-install the piston and tighten the

lock nut to the value listed in Appendix B. Re-measure

the “Y” dimension.

11. After the “Y” dimension is within tolerance, install

the piston cap with the same shim/shims (or same

thickness of shims) as before.

17

12. Torque the piston cap screws to the value listed in

Appendix B.

13. Install the head (or head and adjustable cap applies to adjustable head configuration only) as

show in Appendix D. Torque bolts to the value listed

in Appendix B.

14. Now remove an outboard valve and measure

dimension “X” at the outboard end of the piston as

shown in the Appendix B. If this measurement does

not fall within the tolerances in Appendix B, remove

the head (or head and adjustable cap - applies to

adjustable head configuration only) and piston cap

and adjust the shims as necessary. Re-install the

piston cap and tighten the piston cap screws in an

alternating sequence to the values listed in Appendix

B. Re-install the head (or head and adjustable cap

- applies to adjustable head configuration only) and

torque to the value listed in Appendix B. Re-measure

the “X” dimension again.

15. After the “X” dimension is within tolerance, remove

the adjustable cap and install the adjustable cup

followed by the adjustable cap and adjustable screw

nut as shown in Appendix D.

16. Torque the bolts in an alternating sequence to the

values listed in Appendix B.

17. Replace the previously removed valves. Best results

will be obtained if new valve gaskets are used.

18. Follow standard startup procedures.

1) Keep foreign material out of crosshead bore on

crankcase. Wipe inside of bore with clean rag and

coat bore with oil.

2) Inspect piston rod for cleanliness and coat with oil

before assembly.

3) Before installing adapter and packing cartridge

on piston rod, install packing installation cone

(Corken #3905) over piston rod threads. This

will aid and protect packing during installation.

Failure to use this packing cone could result in

packing damage. Refer to Appendix D for correct

installation of packing.

4) Rotate flywheel/crankshaft by hand several revolutions

to ensure proper fit of all assembled parts.

5) Orient cylinder inlet and outlet to piping installation

to ensure proper valve alignment with system.

Valves must be properly oriented with suction and

discharge piping.

6) For piston installation instructions, see section 4.4.

7) After installing the piston, again, rotate flywheel/

crankshaft by hand several revolutions to ensure

proper fit of all assembled parts.

8) Check crankcase for proper oil level.

9) See start-up procedure in section 2.7. During startup, listen to the compressor for any unusual noises.

If any problems arise during assembly, please

contact the factory.

4.5 Cylinder Replacement

Cylinders very seldom require replacement if the

compressor is properly maintained. The primary cause

of damage to cylinders is corrosion and the entry of solid

debris or liquid into the compression chamber. Improper

storage can also result in corrosion damage to cylinder

(for proper storage instructions see chapter 5). Damage

can also occur if the piston rings are allowed to wear so

much that the ring expander can reach the cylinder wall.

Many compressor repair operations require removal of

the cylinder. While the compressor is disassembled,

special care should be taken to avoid damage or

corrosion to the cylinder. If the compressor is to be left

open for more than a few hours, bare metal surfaces

should be coated with rust preventative.

If the cylinder does become damaged or corroded, use

a hone to smooth the cylinder bore and then polish it

to the value shown in Appendix B. If more than .005 of

an inch must be removed to smooth the bore, replace

the cylinder. Cylinder liners and oversized rings are not

available. OVERBORING THE CYLINDER WILL RESULT

IN GREATLY REDUCED RING LIFE.

When reassembling the compressor, make sure the

bolts are retightened using the torque values listed in

Appendix B.

4.6 Packing Replacement

Instructions

Caution: Before installing the new piston rod packing,

bleed all pressure from the compressor and piping and

purge if necessary. After the new piston rod packing has

been installed, the unit should be pressure tested and

checked for leaks at all joints and gasket surfaces. When

the compressor is being used with toxic, dangerous,

flammable or explosive gases, this pressure and leak

testing should be done with air or a dry, inert gas such

as nitrogen.

For specific construction details and actual part numbers,

consult Appendix D in the back of this Installation,

Operation & Maintenance (IOM) manual. Use instructions

below that apply to the MODEL and SERIAL NUMBER of

your compressor.

18

Cleanliness:

Sealing a reciprocating piston rod is a very difficult task.

In order to create the best seal possible between the

piston rod and the packing, KEEP YOUR HANDS, PARTS

AND TOOLS CLEAN DURING INSTALLATION.

Workmanship:

Your Corken compressor is a precision piece of equipment

with very close tolerances. Treat it as such. Never beat

on it to get parts in or out.

Disassembly of Packing—Plain-style Compressor

Models HG601 and HG602

1. Depressurize and open the compressor before

performing any tasks.

2. Remove the head (along with adjustable head

components, if any), pistons and cylinder.

3. Standard Packing Specification

a. Refer to Appendix D for your particular model of

compressor and note the order in which the parts

are removed.

b. Mark the top of the packing cartridge body to

facilitate later reassembly. Remove the four socket

head bolts that attach the packing cartridge

assembly to the adapter. It is not normally necessar y

to remove the adapter from the crankcase in order

to disassemble or reassemble the packing.

c. Partially insert the bolts in the puller holes in the

outer end of the packing cartridge body and pull

outward to remove the entire packing cartridge

assembly from the adapter and over the piston

rod. If the packing cartridge assembly does not

slide out easily, it may be necessary to alternately

turn the bolts clockwise in the puller holes so

that the bolts engage the adapter and force the

packing cartridge assembly to come out.

d. Remove the outer retainer ring, solid packing breaker

(not included on 6" and 8" cylinders), packing cups,

all packing sets, backup rings, etc. from the cylinder

side of the packing cartridge body.

e. Remove the inner retainer ring, packing washer

and oil wiper ring set from the crankcase side of

the packing cartridge body.

head bolts that attach the packing cartridge cap

to the adapter. It is not normally necessary to

remove the adapter from the crankcase in order to

disassemble or reassemble the packing.

c. Partially insert the bolts in the puller holes in the

outer end of the packing cartridge cap and pull

outward to remove the packing cartridge cap from

the rest of the packing cartridge assembly, adapter

and over the piston rod. If the packing cartridge

cap does not slide out easily, it may be necessary

to alternately turn the bolts clockwise in the puller

holes so that the bolts engage the adapter and

force the packing cartridge cap to come out.

d. Mark the top of the packing cartridge body to

facilitate later reassembly and proper alignment

with the packing cartridge cap. Pull outward to

remove the packing cartridge assembly from the

adapter and piston rod.

i. 2-3/4" and 3-1/4" Cylinders: Using a pair

of flat-bladed screwdrivers or similar tools,

engage the annular groove on the outer end

(cylinder side) of the packing cartridge body

and pry the packing cartridge assembly from

the adapter and over the piston rod.

ii. 4", 5", 6" and 8" Cylinders: Partially insert

the bolts in the puller holes in the outer end of

the packing cartridge body and pull outward

to remove the packing cartridge assembly

from the adapter and over the piston rod. If the

packing cartridge assembly does not slide out

easily, it may be necessary to alternately turn

the bolts clockwise in the puller holes so that

the bolts engage the adapter and force the

packing cartridge assembly to come out.

e. In addition to the packing cartridge cap previously

removed, remove the solid packing breaker (not

included on 6" and 8" cylinders), packing cups,

all packing sets, backup rings, purge packing

cups, cup spacer, packing spacer, oil wiper cup,

oil wiper ring set, etc. from the cylinder side of the

packing cartridge body.

Assembly of Packing—Plain-style Compressor

Models HG601 and HG602

1. Always use new O-rings, packing and oil wiper ring

sets during assembly.

4. Purge Packing Specification

a. Refer to Appendix D for your particular model of

compressor and note the order in which the parts

are removed.

b. Mark the top of the packing cartridge cap to

facilitate later reassembly. Remove the four socket

2. Clean packing cartridge body and parts removed

from it during disassembly process.

3. Standard Packing Specification

a. Refer to Appendix D and note the order in which the

parts are to be installed and their correct orientation.

19

b. Install the oil wiper ring set, packing washer and

inner retainer ring into the crankcase side of the

packing cartridge body.

c. Install the O-ring on the packing spacer, and

install both into the cylinder side of the packing

cartridge body.

d. Install a back-up ring, segmented packing set

(tangent-tangent [TT]) and packing cup with

O-ring into the cylinder side of the packing

cartridge body.

e. Install a back-up ring, a segmented packing set

(radial-tangent [RT]) and packing cup with O-ring

into the cylinder side of the packing cartridge

body. Repeat this process for the remaining RT

packing sets.

f. Install the pressure breaker ring (not included

on 6" and 8" cylinders) and final packing cup

with O-ring into the cylinder side of the packing

cartridge body. Reinstall outer retainer ring.

g. Install a packing installation cone (Part no. 3905)

on threaded end of the piston rod

h. Install a new O-ring inside the adapter.

i. Carefully install the assembled packing cartridge

assembly on the piston rod and insert into the

adapter. Be sure the mark previously made on the

packing cartridge body is oriented up because the

packing cartridge body can only be installed in

one position. Attach the packing cartridge body to

the adapter with the four socket head bolts.

j. Remove the packing installation cone.

k. Replace the cylinder, pistons and cylinder head

(along with adjustable head components, if any).

l. Rotate the unit by hand to insure proper assembly.

4. Purge Packing Specification

a. Refer to Appendix D and note the order in which the

parts are to be installed and their correct orientation.

b. Install oil wiper ring set and oil wiper ring cup into

the cylinder side of the packing cartridge body.

c. Install a biased packing set (tangent-tangent with

springs toward cylinder [TTs]), purge packing

cup with O-ring and cup spacer into the cylinder

side of the packing cartridge body. NOTE: The

6 springs in the biased packing sets are very

small and fit loosely, so extra care is needed to

keep from losing them or having them become

dislodged during assembly.

d. Install a purge packing cup with O-ring and biased

packing set (tangent-tangent with springs toward

crankcase [sTT]) into cylinder side of packing

cartridge body.

e. Install the O-ring on the packing spacer, and

install both into the cylinder side of the packing

cartridge body.

f. Install the back-up ring, segmented packing set

(tangent-tangent [TT]) and packing cup with

the O-ring into the cylinder side of the packing

cartridge body.

g. 2-3/4", 3-1/4" and 4" Cylinders: Each of these

cylinder sizes includes a pressure breaker ring

on the outer end of the packing cartridge

assembly. Also, these cylinder sizes include a

packing cartridge cap into which at least some

of the segmented packing sets (radial-tangent

[RT]) are positioned.

i. Install a back-up ring, segmented packing

set (radial-tangent [RT]) and packing cup with

O-ring into cylinder side of packing cartridge

body. Repeat this process as necessary for

additional RT packing sets until a packing cup

extends partially from the cylinder side of the

packing cartridge body.

ii. Install the pressure breaker ring and packing

cup with O-ring into the packing cartridge cap.

iii. Install a back-up ring, segmented packing

set (radial-tangent [RT]) and packing cup with

O-ring into the packing cartridge cap. Repeat

this process for remaining RT packing sets.

iv. Install the packing cartridge cap on the packing

cartridge body, making sure the previouslymade markings on each are aligned. The

portion of the packing cup extending from the

packing cartridge body should extend into the

packing cartridge cap.

v. Insure that the pin extending from the outer

end of packing box cartridge fits into the

corresponding hole in the packing cartridge

cap. NOTE: Some early models did not have

this pin.

h. 5", 6" and 8" Cylinders: Each of these cylinder sizes

includes a flat packing cartridge cap that fits on the

outer end of the packing cartridge body.

i. Install a back-up ring, segmented packing

set (radial-tangent [RT]) and packing cup with

O-ring into the cylinder side of the packing

cartridge body. Repeat this process for

remaining RT packing sets.

20

ii. Position the packing cartridge cap on the

packing cartridge body, making sure the

previously-made markings on each are aligned.

The holes in the packing cap should be aligned

with the corresponding holes in the packing

cartridge body.

i. Install a packing installation cone (Part no. 3905)

on threaded end of the piston rod

j. Install a new O-ring inside the adapter.

k. Carefully install the assembled packing cartridge

assembly with packing cartridge cap on the piston

rod and insert into the adapter. Be sure the marks

previously marked on the packing cartridge body

and cap are oriented up because most packing

cartridge bodies can only be installed in one

position. Attach the packing cartridge cap to the

adapter with the four socket head bolts.

l. Remove the packing installation cone.

m. Replace the cylinder, pistons and cylinder head

(along with adjustable head components, if any).

cartridge assembly from the adapter and over the

piston rod.

a. 2-3/4" and 3-1/4" Cylinders: Using a pair of flat-

bladed screwdrivers or similar tools, engage the

annular groove on the outer end (cylinder side) of the

packing cartridge body and pry the packing cartridge

assembly from the adapter and piston rod.

b. 4", 5", 6" and 8" Cylinders: Partially insert the

bolts in the puller holes in the outer end of the

packing cartridge body and pull outward to remove

the packing cartridge assembly from the adapter

and over the piston rod. If the packing cartridge

assembly does not slide out easily, it may be

necessary to alternately turn the bolts clockwise

in the puller holes so that the bolts engage the

adapter and force the packing cartridge assembly

to come out.

7. Separate the packing cartridge adapter from the

packing cartridge body by removing the four small

socket head screws. Remove the cup spacer by

sliding it out of the packing cartridge body or packing

cartridge adapter.

n. Rotate the unit by hand to insure proper assembly.

Disassembly of Packing—T-style Compressor

Models THG601 and THG602

1. Depressurize and open the compressor before

performing any tasks.

2. Remove the head (along with adjustable head

components, if any), pistons and cylinder.

3. Refer to Appendix D for your particular model of

compressor and note the order in which the parts

are removed.

4. Mark the top of the packing cartridge cap to facilitate

later reassembly. Remove the four socket head bolts

that attach the packing cartridge cap to the adapter.

It is not normally necessary to remove the adapter

from the distance piece or the distance piece from

the crankcase in order to disassemble or reassemble

the packing.

5. Partially insert the bolts in the puller holes in the outer

end of the packing cartridge cap and pull outward

to remove the packing cartridge cap from the rest of

the packing cartridge assembly, adapter and over the

piston rod. If the packing cartridge cap does not slide

out easily, it may be necessary to alternately turn the

bolts clockwise in the puller holes so that the bolts

engage the adapter and force the packing cartridge

cap to come out.

6. Mark the top of the packing cartridge body to facilitate

later reassembly. Pull outward to remove the packing

8. Outer Packing

a. In addition to the packing cartridge cap previously

removed, remove solid packing breaker (not

included on 6" and 8" cylinders), packing cups,

packing sets, backup rings, packing spacer and

purge packing cup, etc. from the cylinder side of

the packing cartridge body.

b. If the packing components are not easily removable,

it may be necessary to use Corken Packing Removal

Tool 4789-X. Referring to Figure 4.6A, orient the

packing cartridge body so that the open end

(cylinder side) faces down, and align the tool with

the center opening of the packing cartridge.

c. Insert Tool 4789-X into the packing cartridge body

until the engagement end of the tool is just above

the purge packing cup. See Figure 4.6B.

d. Press the spring-loaded lever inward so that the

engagement end of the lever moves outward. While

still holding the lever in, place the engagement

ends of the tool and lever in contact with the purge

packing cup, and use a hammer or similar device

to drive the outer packing set from the packing

cartridge body.

9. Middle Packing: Remove the packing cups, packing

sets, backup rings, packing spacer and purge packing

cup, etc. from the crankcase side of the packing

cartridge body. If necessary Packing Removal Tool

4789-X may be used to remove the middle packing

set in a manner similar to the outer packing set.

21

Lever

Engagement end of tool

Step 1 Step 2

Packing removal

tool (4789-X)

Engagement end of lever

Packing cartride body

Packing removal

tool (4789-X)

Push lever in to actuate

Purge packing cup

Purge packing cup

Figure 4.6A: Packing disassembly Figure 4.6B: Packing disassembly

10. Inner Packing: Remove the purge packing cup,

segmented packing, oil wiper cup, oil wiper ring set, etc.

from the cylinder side of the packing cartridge adapter.

Assembly of Packing—T-style Compressor Models

THG601 and THG602

1. Always use new O-rings, packing sets and oil wiper

ring sets during assembly.

2. Clean the packing cartridge body and parts removed

from it during disassembly process.

3. Refer to Appendix D and note the order in which the

parts are to be installed and their correct orientation.

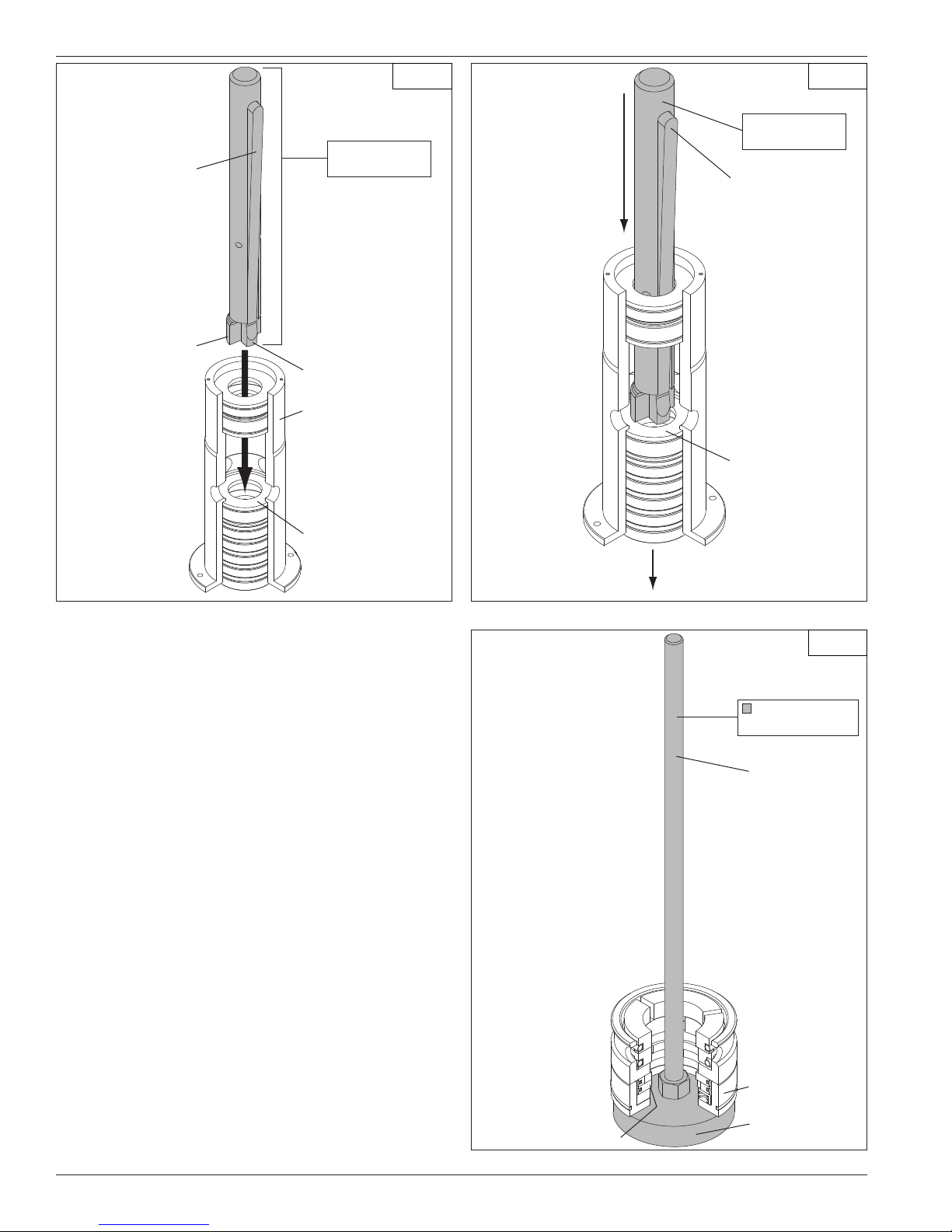

4. Inner Packing: The inner packing set is most easily

assembled using Packing Assembly Tool 4794-X.

a. Set the end plate of the Tool 4794-X on a

horizontal work surface and remove the slotted

clamp of the tool.

Step 1

Packing assembly

tool (4974-X)

Rod

b. Place a purge packing cup and a biased packing

set (TTs) onto the end plate of the tool and over

the rod of the tool. The cylinder side of the packing

should face the end plate of the tool such that the

springs in the biased packing set face toward the

end plate. NOTE: The 6 springs in the biased

packing sets are very small and fit loosely,

Biased packing set (TTs)

22

Purge packing cup

End plate

Figure 4.6C: Packing assembly

Nut

Rod

Step 2 Step 3

Packing assembly

tool (4974-X)

Slotted clamp

Packing cartridge adapter

Packing assembly

tool (4974-X)

Slotted clamp

Wiper ring cup and

inner oil wiper ring set

Purge packing cup and

inner packing set

End plate

Figure 4.6D : Packing assembly

Packing cartridge

body

Step 4

Inner packing set

End plate

Packing cartridge

adapter

Figure 4.6E : Packing assembly

so extra care is needed to keep from losing

them or having them become dislodged during

assembly. Place the oil wiper ring cup and oil

wiper ring set onto the purge packing cup. You

now have a full inner packing set positioned on the

end plate of the tool. See Figure 4.6C.

c. Orient the packing cartridge adapter so that the

open end (cylinder side) faces down. Being careful

not to dislodge the inner packing set previously

placed on the end plate of the tool, position the

packing cartridge adapter over the inner packing

set and end plate of the tool so that the rod of

the tool extends through the packing cartridge

adapter. Place the slotted clamp above the packing

cartridge adapter as shown in Figure 4.6D.

Inner

packing

set

Figure 4.6F : Packing assembly

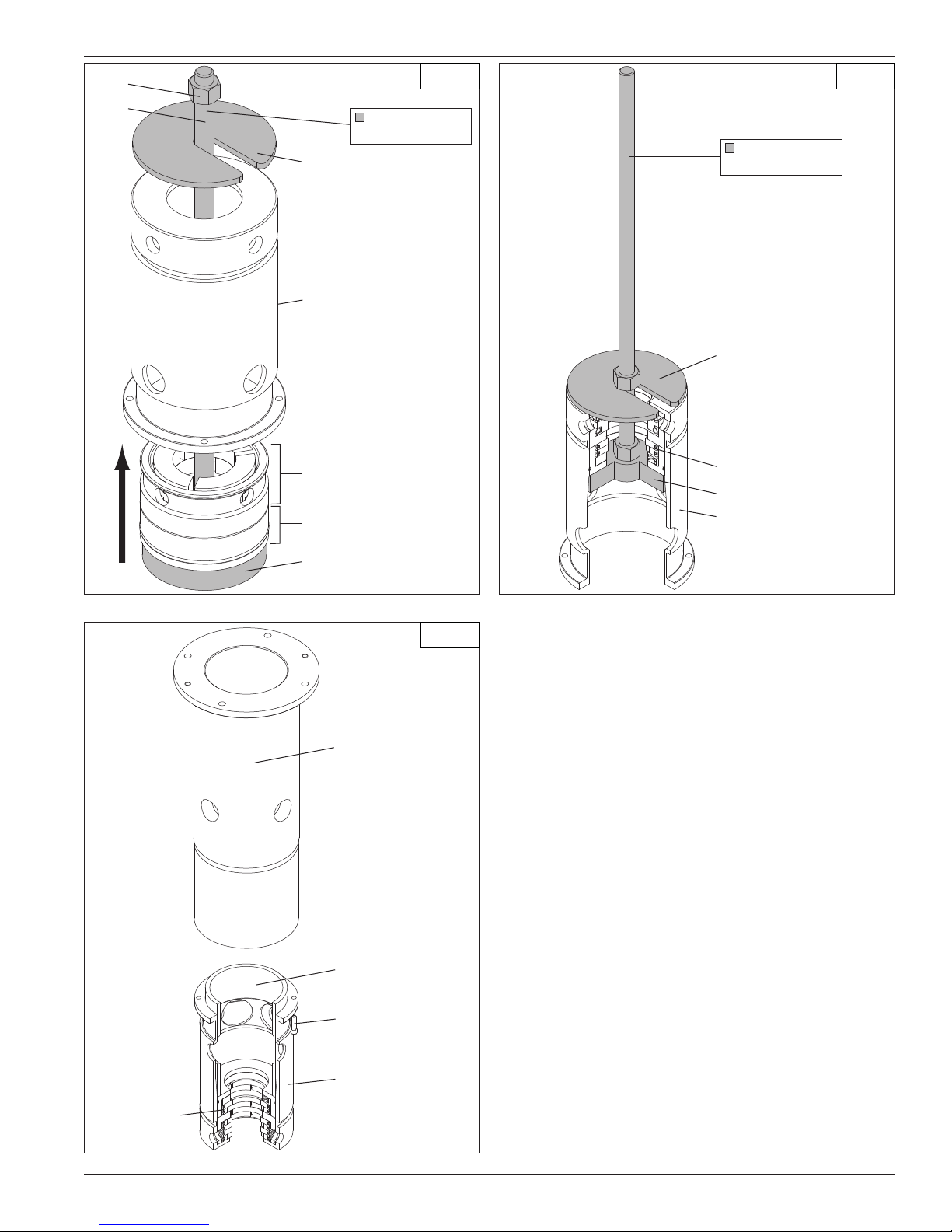

Cup spacer

Socket head

screw

Packing cartridge

adapter

d. Tighten the nut on the rod of the tool until the

inner packing set is fully drawn into the packing

cartridge adapter. See Figure 4.6E.

e. Invert the packing cartridge adapter with the inner

packing set in it, and remove Tool 4794-X. Slide

the cup spacer into the packing cartridge adapter

so that it engages the inner packing set. See

Figure 4.6F.

f. Place an oil deflector ring inside the cup spacer

so that it is generally concentric with the inner

packing set.

23

5. Middle Packing

a. For compressors set up for pad packing

(Specification Code G), install a purge packing

cup with O-ring and a biased packing set (tangenttangent with springs toward cylinder [TTs]) into

the crankcase side of the packing cartridge body.

NOTE: The 6 springs in the biased packing sets

are very small and fit loosely, so extra care is

needed to keep from losing them or having them

become dislodged during assembly.

b. Install an O-ring on a packing spacer and install

both into the crankcase side of the packing

cartridge body.

c. Install a backup ring, segmented packing set (tangent-

tangent [TT]) and packing cup with O-ring into the

crankcase side of the packing cartridge body.

d. For compressors set up for purge packing

(Specification Code H), the middle packing set

components are installed in the opposite order

from Specification Code G, so that the springs

are toward the crankcase side of the packing

cartridge body.

e. For both Specification Codes G and H, install the

packing cartridge adapter onto the crankcase

side of the packing cartridge body such that the

cup spacer slides into the crankcase side of the

packing cartridge adapter and engages the middle

packing set to retain it in the packing cartridge

body. Attach the packing cartridge adapter to the

packing cartridge body with the four small socket

head screws.

f. Install a new O-ring on the outside of the packing

cartridge adapter and inside the adapter

g. Install a packing installation cone (Part no. 3905)

on the threaded end of the piston rod.

h. Carefully install the completed packing cartridge

assembly on the piston rod and insert into the

adapter. Be sure the mark previously made on the

packing cartridge body is oriented up because

most packing cartridge bodies can only be

installed in one position.

i. Install the packing cartridge cap in the adapter.

Be sure the mark previously made on the

packing cartridge cap is oriented up because

the packing cartridge cap can only be installed

in one position. On 2-3/4", 3-1/4" and 4"

Cylinders only, insure that the pin extending

from the outer end of the packing box cartridge

fits into the corresponding hole in the packing

cartridge cap.

j. Attach the packing cartridge cap to the adapter

with the four socket head bolts

k. Remove the packing installation cone.

7. Replace the cylinder, pistons and cylinder head (along

with adjustable head components, if any).

8. Rotate unit by hand to insure proper assembly.

4.7 Bearing Replacement for

Crankcase and Connecting Rod

6. Outer Packing

a. Install a purge packing cup with O-ring and biased

packing set (tangent-tangent with springs toward

crankcase [sTT]) into cylinder side of packing

cartridge body.

b. Install an O-ring on a packing spacer, and install

both into cylinder side of packing cartridge body.

c. Install a back-up ring, segmented packing set

(tangent-tangent [TT]) and packing cup with O-ring

into the cylinder side of packing cartridge body.

d. Install a back-up ring, segmented packing set

(radial-tangent [RT]) and packing cup with O-ring

into the cylinder side of packing cartridge body.

Repeat this process for remaining RT packing sets

e. Install a pressure breaker ring (not included on 6"

and 8" cylinders) and final packing cup with O-ring

into the cylinder side of packing cartridge body

1. To replace the crankcase roller bearings, wrist

pin bushing and connecting rod bearings, begin

by removing the head (or head, adjustable cap

and adjustable cup - applies to adjustable head

configuration only), cylinder, pistons, adapter, distance

piece (THG600 only) and crosshead and connecting

rod assemblies.

2. Drain the crankcase and remove the inspection plates.

3. Choose and mark one connecting rod and the