Corken B166, T166 Installation, Operation & Maintenance Manual

ORIGINAL INSTRUCTIONS IH100G

Installation, Operation

& Maintenance Manual

Models B166 and T166 External Automatic

Bypass Valves

Model B166 External

Automatic Bypass Valve

Warning: (1) Periodic inspection and maintenance of Corken products is essential. (2) Inspection, maintenance and installation of Corken products

must be made only by experienced, trained and qualied personnel. (3) Maintenance, use and installation of Corken products must comply with

Corken instructions, applicable laws and safety standards (such as NFPA Pamphlet 58 for LP-Gas and ANSI K61.1-1972 for Anhydrous Ammonia).

(4) Transfer of toxic, dangerous, ammable or explosive substances using Corken products is at user’s risk and equipment should be operated

only by qualied personnel according to applicable laws and safety standards.

Model T166 External

Automatic Bypass Valve

Solutions beyond products...

Warning

Install, use and maintain this equipment according to Corken’s instructions and all applicable federal, state, local laws

and codes. Periodic inspection and maintenance is essential.

Corken One Year Warranty

CORKEN, INC. warrants that its products will be free from defects in material and workmanship for a period of one

year from date of installation, provided that the warranty shall not extend beyond twenty-four (24) months from the date

of shipment from CORKEN. If a warranty dispute occurs, the DISTRIBUTOR may be required to provide CORKEN

with proof of date of sale. The minimum requirement would be a copy of the DISTRIBUTOR’S invoice to the customer.

CORKEN products which fail within the warrant period due to defects in material or workmanship will be repaired or

replaced at CORKEN’s option, when returned, freight prepaid to CORKEN, INC., 3805 N.W. 36th St., Oklahoma City,

Ok l a h o m a 73112 .

Parts subject to wear or abuse, such as mechanical seals, blades, piston rings, valves and packing, and other parts

showing signs of abuse, neglect or failure to be properly maintained are not covered by this limited warranty. Also,

equipment, parts and accessories not manufactured by CORKEN but furnished with CORKEN products are not

covered by this limited warranty and the purchaser must look to the original manufacturer’s warranty, if any. This limited

warranty is void if the CORKEN product has been altered or repaired without the consent of CORKEN.

All implied warranties, including any implied warranty of merchantability or fitness for a particular purpose, are

expressly negated to the extent permitted by law and shall in no event extend beyond the expressed warrantee period.

CORKEN DISCLAIMS ANY LIABILITY FOR CONSEQUENTIAL DAMAGES DUE TO BREACH OF ANY WRITTEN OR

IMPLIED WARRANTY ON CORKEN PRODUCTS. Transfer of toxic, dangerous, flammable or explosive substances

using CORKEN products is at the user’s risk. Experienced, trained personnel in compliance with governmental and

industrial safety standards should handle such substances.

Important notes relating to the European Union (EU) Machinery Directive

Pumps delivered without electric motors are not considered as machines in the EU Machinery Directive. These pumps

will be delivered with a Declaration of Incorporation. The fabricator of the machinery must assure and declare full

compliance with this Directive before the machine in which the pump will be incorporated, or of which it is a part, is

put into service.

Contacting the Factory

Before you contact the factory, note the model number and serial number of your pump. The serial number directs

us to a file containing all information on material specifications and test data applying to your specific pump. When

ordering parts, the Corken service manual or Operations, Installation and Maintenance (IOM) manual should be

consulted for the proper part numbers. ALWAYS INCLUDE THE MODEL NUMBER AND SERIAL NUMBER WHEN

ORDERING PARTS.

The model and serial numbers are shown on the nameplate of the unit. Record this information for future reference.

Model No.

Serial No.

Date Purchased

Date Installed

Purchased From

Installed By

2

Table of Contents

APPLICABLE NOTICES FOR ATEX 2014/34/EU CONFORMITY ........................................4

FEATURES OF THE B166 EXTERNAL AUTOMATIC BYPASS VALVE ...................................5

CHAPTER 1—INSTALLATION OF THE B166 EXTERNAL AUTOMATIC BYPASS VALVE ...................5

1.1 Operation of the B166 External Automatic Bypass Valve ............................................5

FEATURES OF THE T166 AUTOMATIC EXTERNAL BYPASS VALVE ...................................7

CHAPTER 2—INSTALLATION OF THE T166 AUTOMATIC EXTERNAL BYPASS VALVE ...................7

2.1 Operation of the T166 Automatic External Bypass Valve ............................................7

APPENDICES

A. Model Number Identification Code and Available Options ...........................................9

B. Specifications ............................................................................10

C. Performance .............................................................................10

D. Outline Dimensions ........................................................................11

E. Parts Details .............................................................................13

3

Applicable Notices for ATEX

2014/34/EU Conformity

Product Type:

Corken Liquid Transfer Bypass Valves

Training Instructions:

Instructions for the safe application and use of this product

are provided in this manual. Read this manual completely

prior to installation and use of this product. Only qualified

and properly trained personnel should be allowed to install,

operate, and maintain this equipment.

Model Covered:

T16 6 O NLY

Intended Application:

The bypass valve models covered by this manual conform to

the European Union ATEX 2014/34/EU Directive for explosive

gas atmospheres and transfer of liquefied gases such as

Liquefied Petroleum Gas, anhydrous ammonia, freons, etc.

Possible Misuse Warning:

The designated bypass valve models must only be

installed in systems designed for its intended use, similar

to the examples presented in this manual.

ATEX Classification:

Group II; Category 2; G; Temperature Class T4 – T5

These products are classified under the ATEX directive

as Equipment – Group II – Category 2 – equipment is

intended for use in areas where explosive atmospheres

caused by gases or vapors (G) may be present. The

surface Temperature Class rating is a range between T4

275°F (135°C) and T5 212°F (100°C).

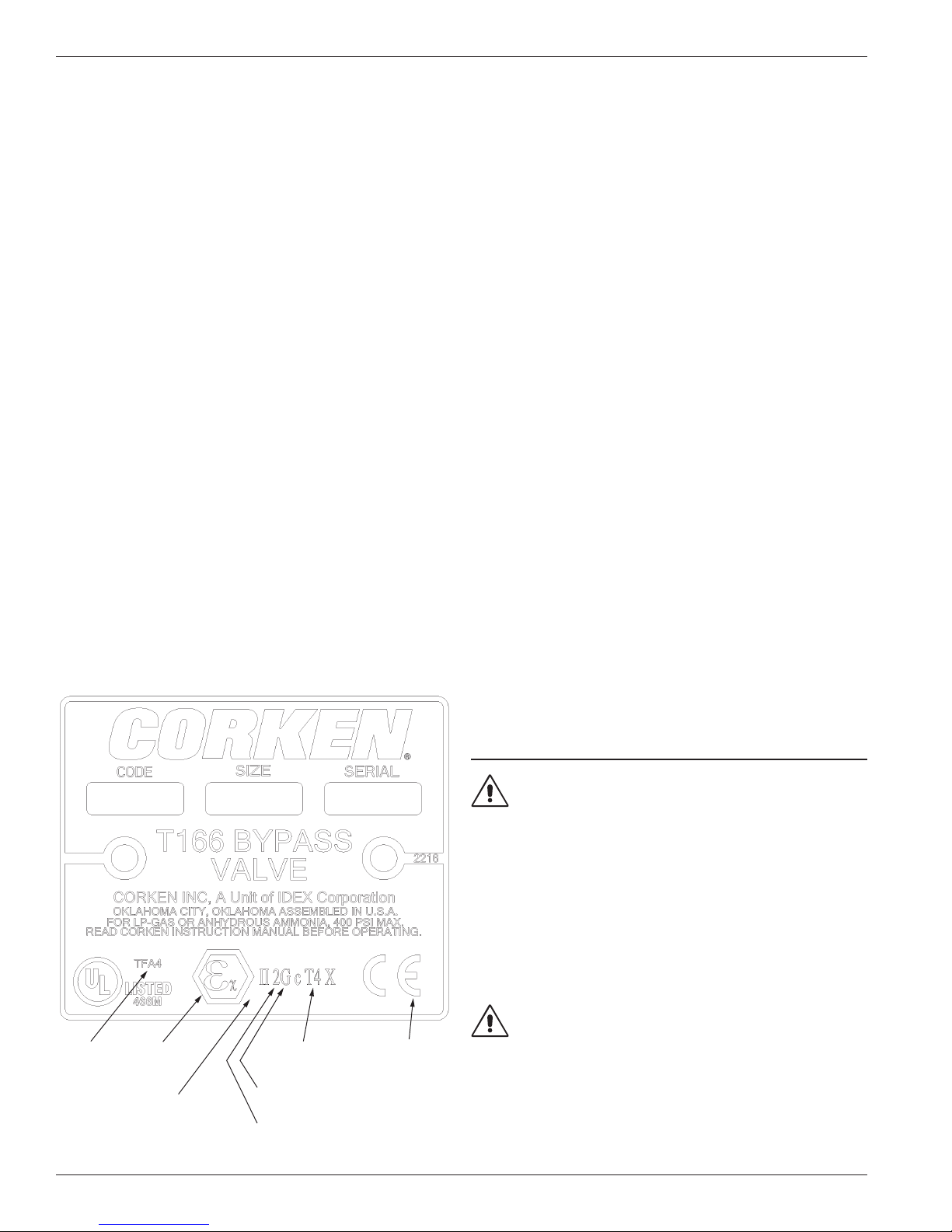

Nameplate:

Mechanical Ignition Sources:

The bypass valve is installed as part of an assembly including

the pump and the entire system must be grounded to prevent

possible electrostatic discharge. Installation and adjustment

guidelines are provided in this manual and are to be followed

for the proper operation and performance of the valve.

Sound Levels:

These products are reactionary devices used in pumping

systems. Sound levels are highly dependent upon the

application, product being pumped, and installation. When

operating in the system the valves should have a noise

level no higher than 80 dBA.

Piping Forces and Moments:

Maximum Allowable Nozzle Forces and Moments

Note: Piping systems should be designed according to

standard engineering practice and applicable national

and local codes. NO piping induced forces or moments

are recommended for Corken T166 bypass valves.

X—Horizontal (perpendicular to valve discharge port)

Y—Vertical

Z—Horizontal (parallel to valve discharge port)

Fx = Fy = Fz = 42 lb (19 kg)

Mx = My = Mz = 70 ft•lb (10 kg•m)

File number

Explosion

protection

ATEX Directive

2014/34/EU marking

Surface temperature

ran g e T4

(135°C) 275°F

Explosion gas

atmosphere high level

Equipment classified

as Group II—Catagory 2

ATE X an d

machinery

directive

Notice!

Corken bypass valves should only be installed in LPG

& NH3 systems that have been designed by qualified

engineering personnel and operated and maintained

by qualified technicians. The system must conform to

all applicable local and national regulations and safety

standards (specifically, LPG systems must conform to

NFPA 58). This manual must be kept with the bypass

valves and be reviewed before installing, operating or

performing any maintenance work.

Warning!

Do not attempt to open the pump or bypass valve until you

have bled off the pressure. High pressure in the system

can cause personal injury and/or property damage.

Please note: if the system contains a meter, the differential

valve will keep liquid under pressure in the pump, meter

and piping even after the hose has been emptied.

4

Features of the B166 External

Automatic Bypass Valve

The CORKEN B166 external bypass valve is a patented,

dual purpose, automatic priming and differential valve

designed for high-pressure volatile liquid service. This valve

may be used with stable liquids as well.

The B166 external bypass valve was also designed to work

in conjunction with CORKEN’s Coro-Flo® regenerative

turbine pumps but may be used with centrifugal pumps and

others as well.

To ensure optimum performance of the external bypass

valve and the entire pumping system, follow the instructions

in this manual.

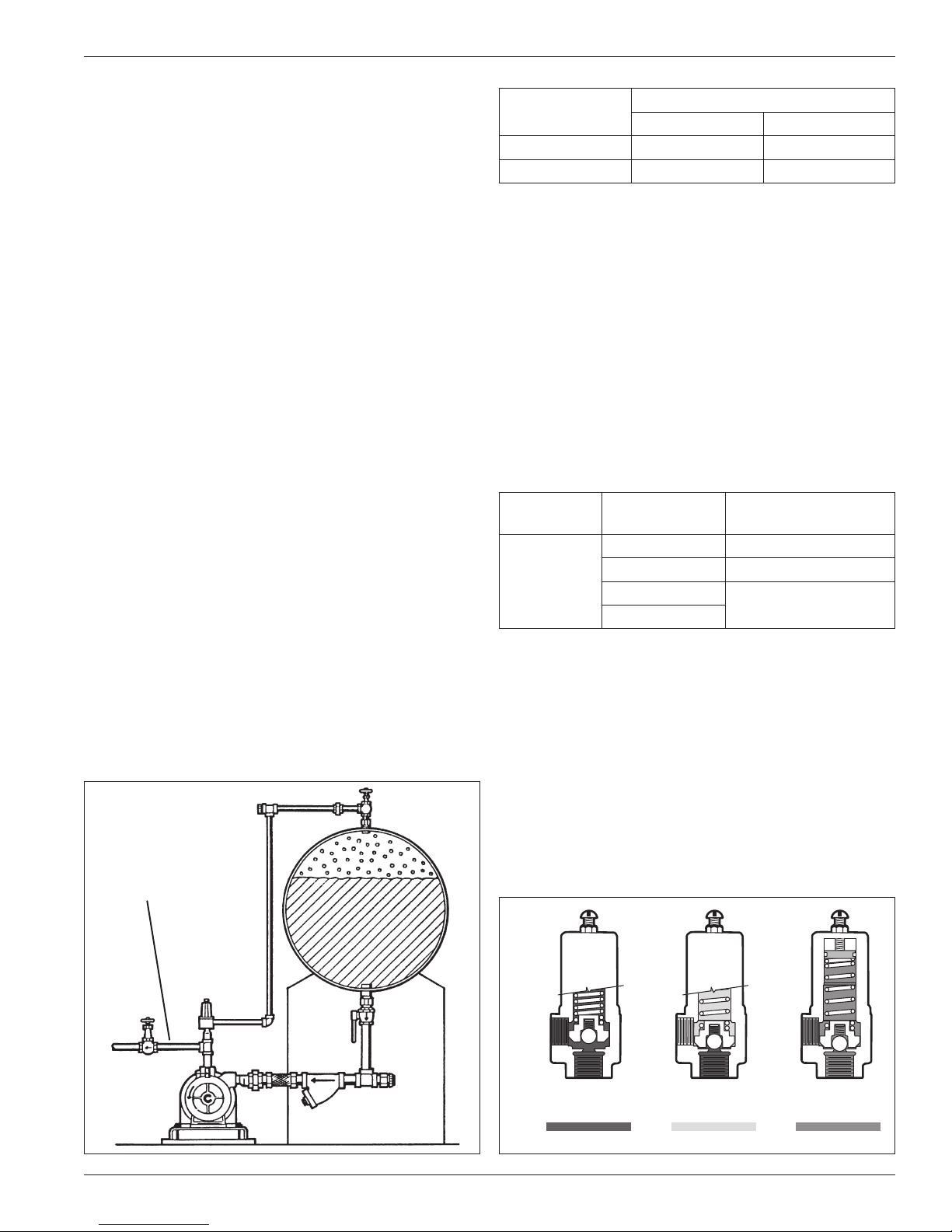

Chapter 1—Installation of the B166

External Automatic Bypass Valve

Proper installation of the CORKEN B166 external bypass

valve ensures optimum performance of the pump and

external bypass valve. Install the B166 external bypass

valve on the discharge side of the pump in either a vertical

or horizontal position. All CORKEN Coro-Flo® turbine

pumps have a 3/4" NPT opening in the discharge nozzle for

piping this valve. When using other pump designs without a

3/4" NPT opening, a tee must be installed in the discharge

line. The discharge piping of the bypass valve should

connect to the vapor section of the supply tank using an

excess flow valve and not a back check valve. Do not

connect the outlet piping of the external bypass valve

to the inlet piping of the pump. A typical installation

is shown in Figure 1.1. The recommended pipe sizes for

discharge lines are given in the table below. For distances

of 50 feet or more, the next larger pipe size should be used.

Pipe Sizes for Discharge Line

Flow Rate

Up to 30 GPM 3/4" —

Up to 40 GPM — 1"

Pipe Size by Model Number

B166 B-.75 B166B -.1

1.1 Operation of the B166 External

Automatic Bypass Valve

Stationary Applications:

The differential pressure setting of the B166 external

bypass valve is adjustable. The range of differential

pressure depends on the size of the spring installed in

the bypass valve. When the bypass valve ships from

the CORKEN factory, a tag identifying the spring size

is attached to the valve bonnet. The table below shows

the part number and differential pressure range for each

spring. All of the springs are interchangeable with each

valve size.

Valve Model Spring Number

113 8 25–60

B166

119 3 50–150

119 3

1313

After the external bypass valve has been installed, it must

be set properly.

1. Install liquid-filled pressure gauges equipped with a

needle valve or snubber in the following locations:

a. Pump discharge gauge port or inlet side of the

bypass valve.

Differential Pressure

(PSIG)

100 –225

Discharge line

Figure 1.1: Typical installation. Figure 1.2: B166 with priming function.

b. Supply tank and/or pump suction.

2. Attach an ammeter to a motor lead of the electric motor.

Delivery line

shut-off or

pressure build

up is so high

that valve

opens and

relieves

capacity back

into supply

tank.

FIG. 1 Relieving Operation

No circulation

- all pump

capacity

going to

delivery.

INLET

OPEN

LIQUID VAPOR VAPOR and/or LIQUID

INLET INLET

FIG. 2 Pumping Operation

CLOSED

Liquid from

supply tank

seeking its

level in pump

and bypass

piping.

OUTLETOUTLETOUTLET

FIG. 3 Priming Operation

OPEN

5

Loading...

Loading...