Page 1

ORIGINAL INSTRUCTIONS IE101K

Installation, Operation

& Maintenance Manual

Plain Style Compressors for Liquid

Transfer-Vapor Recovery

Warning: (1) Periodic inspection and maintenance of Corken products is essential. (2) Inspection, maintenance and installation of

Corken products must be made only by experienced, trained and qualified personnel. (3) Maintenance, use and installation of Corken

products must comply with Corken instructions, applicable laws and safety standards. (4) Transfer of toxic, dangerous, flammable or

explosive substances using Corken products is at user’s risk and equipment should be operated only by qualified personnel according

to applicable laws and safety standards.

Mo de l 4 91-107

Solutions beyond products...

Page 2

Warning

Install, use and maintain this equipment according to Corken’s instructions and all applicable federal, state, local laws

and codes. Periodic inspection and maintenance is essential.

Corken One Year Warranty

CORKEN, INC. warrants that its products will be free from defects in material and workmanship for a period of

one year from date of installation, provided that the warranty shall not extend beyond twenty-four (24) months from

the date of shipment from CORKEN. If a warranty dispute occurs, the DISTRIBUTOR may be required to provide

CORKEN with proof of date of sale. The minimum requirement would be a copy of the DISTRIBUTOR’S invoice to

the customer.

CORKEN products which fail within the warrant period due to defects in material or workmanship will be repaired or

replaced at CORKEN’s option, when returned, freight prepaid to CORKEN, INC., 3805 N.W. 36th St., Oklahoma City,

Oklahoma 73112.

Parts subject to wear or abuse, such as mechanical seals, blades, piston rings, valves and packing, and other parts

showing signs of abuse, neglect or failure to be properly maintained are not covered by this limited warranty. Also,

equipment, parts and accessories not manufactured by CORKEN but furnished with CORKEN products are not

covered by this limited warranty and the purchaser must look to the original manufacturer’s warranty, if any. This

limited warranty is void if the CORKEN product has been altered or repaired without the consent of CORKEN.

All implied warranties, including any implied warranty of merchantability or fitness for a particular purpose, are

expressly negated to the extent permitted by law and shall in no event extend beyond the expressed warranty period.

CORKEN DISCLAIMS ANY LIABILITY FOR CONSEQUENTIAL DAMAGES DUE TO BREACH OF ANY WRITTEN OR

IMPLIED WARRANTY ON CORKEN PRODUCTS. Transfer of toxic, dangerous, flammable or explosive substances

using CORKEN products is at the user’s risk. Experienced, trained personnel in compliance with governmental and

industrial safety standards should handle such substances.

Important notes relating to the European Union (EU) Machinery Directive

Pumps delivered without electric motors are not considered as machines in the EU Machinery Directive. These

pumps will be delivered with a Declaration of Incorporation. The fabricator of the machinery must assure and declare

full compliance with this Directive before the machine in which the pump will be incorporated, or of which it is a part,

is put into service.

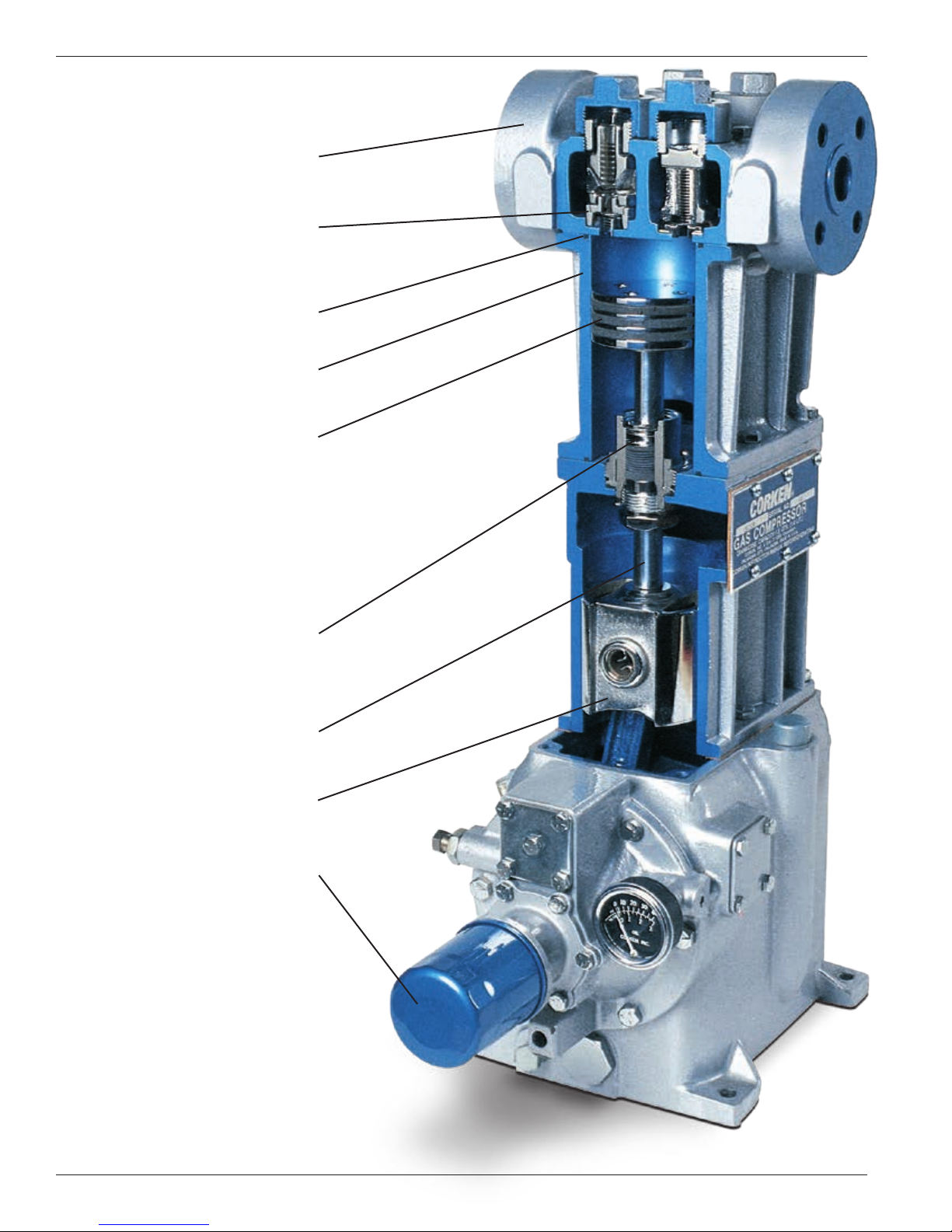

Contacting the Factory

Before you contact the factory, note the model number and serial number of your pump. The serial number directs

us to a file containing all information on material specifications and test data applying to your specific pump. When

ordering parts, the Corken service manual or Operations, Installation and Maintenance (IOM) manual should be

consulted for the proper part numbers. ALWAYS INCLUDE THE MODEL NUMBER AND SERIAL NUMBER WHEN

ORDERING PARTS.

The model and serial numbers are shown on the nameplate of the unit. Record this information for future reference.

Model No.

Serial No.

Date Purchased

Date Installed

Purchased From

Installed By

2

Page 3

Table of Contents

Chapter 1—Introduction ........................................................................4

1.1 Liquid Transfer By Vapor Differential Pressure ...................................................5

1.2 Residual Vapor Recovery ....................................................................5

1.3 Compressor Construction Features ...........................................................6

Chapter 2—Installing Your Corken Compressor ....................................................8

2.1 Location .................................................................................8

2.2 Foundation ...............................................................................8

2.3 Piping ...................................................................................8

2.4 Liquid Traps .............................................................................11

2.5 Driver Installation / Flywheels ...............................................................12

2.6. Crankcase Lubrication ....................................................................12

2.7 Relief Valves .............................................................................14

2.8 Truck Mounted Compressors ...............................................................15

2.9 Shutdown/Alarm Devices ...................................................................15

Chapter 3—Starting Up Your Corken Compressor .................................................16

3.1 Inspection After Extended Storage ...........................................................16

3.2 Flywheel and V-belt Alignment ..............................................................16

3.3 Crankcase Oil Pressure Adjustment ..........................................................16

3.4 Startup Check List ........................................................................17

Chapter 4—Routine Maintenance Chart .........................................................18

Chapter 5—Routine Service and Repair Procedures ...............................................18

5.1 V alve s ..................................................................................18

5.2 Heads ..................................................................................20

5.3 Piston Rings and Piston Ring Expanders ......................................................20

5.4 Pistons .................................................................................21

5.5 Piston Rod Packing Adjustment .............................................................22

5.6 Cylinder and Packing Replacement ..........................................................22

5.7 Bearing Replacement for Crankcase and Connecting Rod ........................................25

5.7.1 Wrist Pin Bushing Replacement ..........................................................25

5.7.2 Replacing Connecting Rod Bearings ......................................................25

5.7.3 Replacing Crankcase Roller Bearings .....................................................25

5.8 Oil Pump Inspection ......................................................................26

Chapter 6—Extended Storage Procedures .......................................................27

6.1 Repair Kits ..............................................................................27

6.2 Gasket Sets .............................................................................28

Appendices

A. Model Number Identification Code and Available Options ..........................................30

B. Specifications ............................................................................32

C. Compressor Selection ......................................................................38

D. Outline Dimensions ........................................................................42

E. Parts Details .............................................................................58

Model 91 and F91 .........................................................................58

Model 291 and F291 .......................................................................66

Model 491 and F491 .......................................................................74

Model 691 and F691 .......................................................................82

Model D891 and FD891 ....................................................................90

F. Troubleshooting ...........................................................................98

3

Page 4

Chapter 1—Introduction

Connections:

Available in threaded NPT or Class 300

RF flanges.

High-efficiency valves:

Valves are quiet and highly durable. Special

suction valves tolerating small amounts of

condensate are available.

O-ring seals:

Easy to install O-ring seals head and cylinder.

Ductile iron construction:

Cylinder and head are made of ductile iron

for maximum thermal shock endurance.

Self-lubricating PTFE piston rings:

State-of-the-art piston ring designs to

provide the most cost-effective operation

of compressors for non-lube service. The

step-cut design provides higher efficiencies

during the entire life of the piston ring.

Positively locked piston:

Simple piston design allows end clearance

to be precisely set to provide maximum

efficiency and long life.

Piston rod seals:

Seals constructed of PTFE incorporating

special fillers to maximize leakage control.

Spring loaded seal design self adjusts to

compensate for normal wear.

Nitrotec ®1 coated piston rods:

Impregnated nitride coating provides

superior corrosion and wear resistance.

Cast-iron crosshead:

Durable cast-iron crossheads provide

superior resistance to corrosion and galling.

Pressure-lubricated crankcase with filter:

Self-reversing oil pump ensures proper

lubrication regardless of directional rotation to

main and connecting rod bearings. Standard

10-micron filter ensures long-lasting bearing

life (not available on Model 91).

1

Registered trademark of TTI Group Ltd.

Construction Details—Model F291 Compressor

4

Page 5

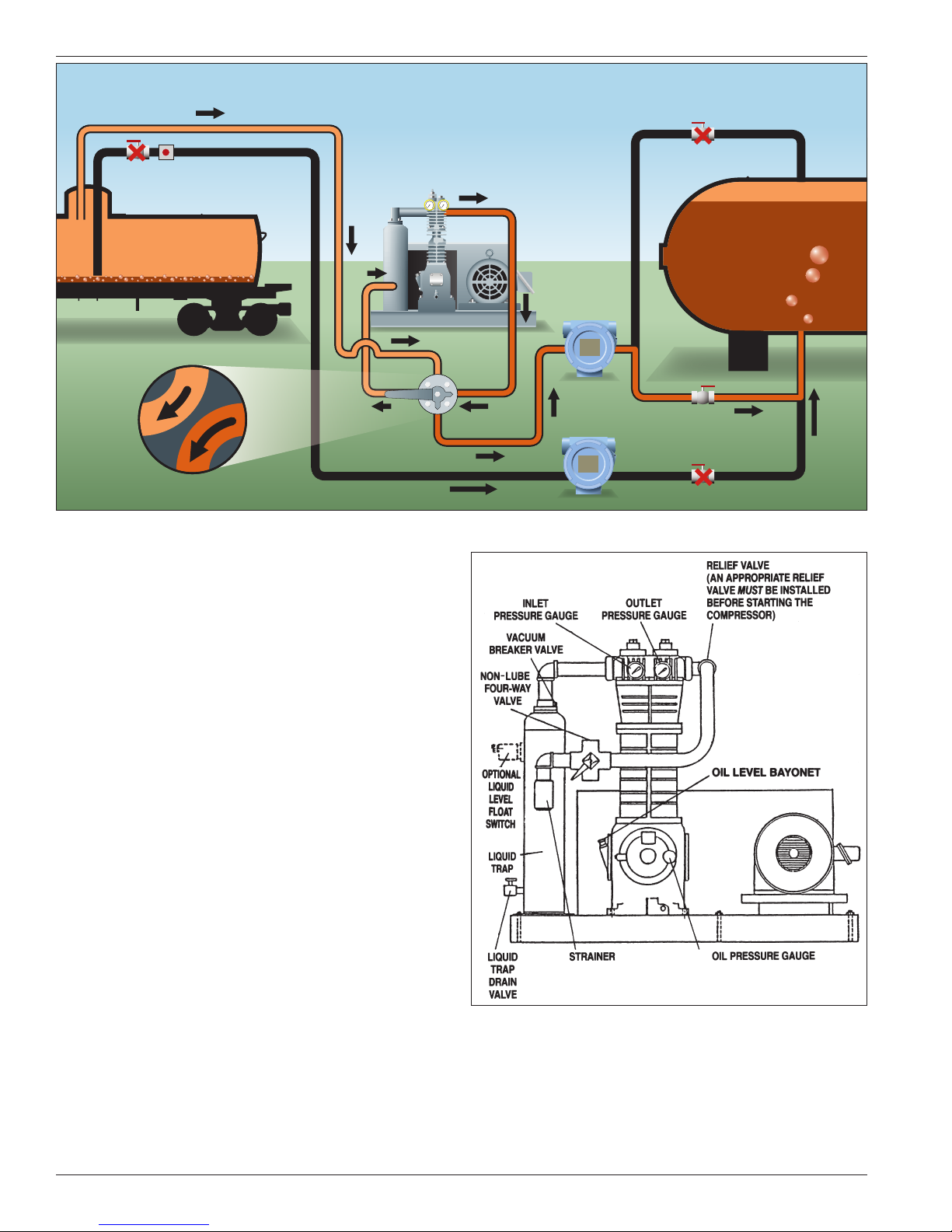

1.1 Liquid Transfer By Vapor

Differential Pressure

Corken LPG/NH3 compressors are designed to transfer

liquefied gases such as butane/propane mixtures

(liquefied petroleum gas or LPG) and Anhydrous Ammonia

(NH3) from one tank to another. Liquefied gases such as

LPG and NH3 are stored in closed containers where both

the liquid and vapor phases are present.

Figure 1.1A: Typical nameplate

(also serves as the packing adjusting screw cover)

There is a piping connection between the vapor

sections of the storage tank and the tank being

unloaded, and there is a similar connection between

the liquid sections of the two tanks. If the connections

are opened, the liquid will seek its own level and

then flow will stop; however, by creating a pressure

in the tank being unloaded which is high enough

to overcome pipe friction and any static elevation

difference between the tanks, all the liquid will be

forced into the storage tank (see figure 1.1B). The

gas compressor accomplishes this by withdrawing

vapors from the storage tank, compressing them

and then discharging into the tank being unloaded.

This procedure slightly decreases the storage tank

pressure and increases the pressure in the other tank,

thereby causing the liquid to flow.

The process of compressing the gas also increases the

temperature, which aids in increasing the pressure in the

tank being unloaded.

1.2 Residual Vapor Recovery

The principle of residual vapor recovery is just the

opposite of liquid transfer. After the liquid has been

transferred, the four-way control valve (or alternate

valve manifolding) is reversed so that the vapors are

drawn from the tank just unloaded and discharged into

the receiving tank. Always discharge the recovered

vapors into the liquid section of the receiving tank.

This will allow the hot, compressed vapors to condense,

preventing an undesirable increase in tank pressure (see

figure 1.2A).

Residual vapor recovery is an essential part of the value

of a compressor. There is an economical limit to the

amount of vapors that should be recovered, however.

When the cost of operation equals the price of the

product being recovered, the operation should be

stopped. For most cases in LP-Gas and Anhydrous

Ammonia services, this point is reached in the summer

when the compressor inlet pressure is 40 to 50 psig

Compressor increases

pressure in tank car by

adding vapor

Pressure difference between

tanks causes liquid to flow out of

the tank car into the storage tank

Four Way Valve Position 1

Vapor Line

Vapor Line

Compressor reduces

pressure in storage tank

by removing vapor

Liquid Line

Figure 1.1B: Liquid transfer by vapor differential pressure.

5

Page 6

Vapor Line

Liquid line is valved closed

during vapor recovery.

Removing vapor from

tank causes liquid heel

to boil into vapor

Four Way Valve Position 2

Liquid Line

Figure 1.2A: Residual vapor recovery.

(3.8 to 4.5 bars). A good rule of thumb is not to operate

beyond the point at which the inlet pressure is onefourth the discharge pressure. Some liquids are so

expensive that further recovery may be profitable, but

care should be taken that the ratio of absolute discharge

pressure to absolute inlet pressure never exceeds 7 to

1. Further excavation of very high value products would

require a Corken two-stage gas compressor.

Vapor Line

Vapor is

bubbled

through liquid

to help cool and

recondense it

Invariably, there is some liquid remaining in the tank

after the liquid transfer operation. This liquid “heel”

must be vaporized before it can be recovered, so

do not expect the pressure to drop immediately.

Actually, more vapor will be recovered during the first

few minutes while this liquid is being vaporized than

during the same period of time later in the operation.

Remember that more than half of the economically

recoverable product is usually recovered during the

first hour of operation on properly sized equipment.

1.3 Compressor

Construction Features

The Corken liquid transfer-vapor recovery compressor

is a vertical single-stage, single-acting reciprocating

compressor designed to handle flammable gases

like LPG and toxic gases such as ammonia. Corken

compressors can handle these potentially dangerous

gases because the LPG/NH3 is confined in the

compression chamber and isolated from the crankcase

and the atmosphere. A typical liquid transfer-vapor

recovery compressor package is shown in figure 1.3A.

Figure 1.3A: 107-style compressor mounting.

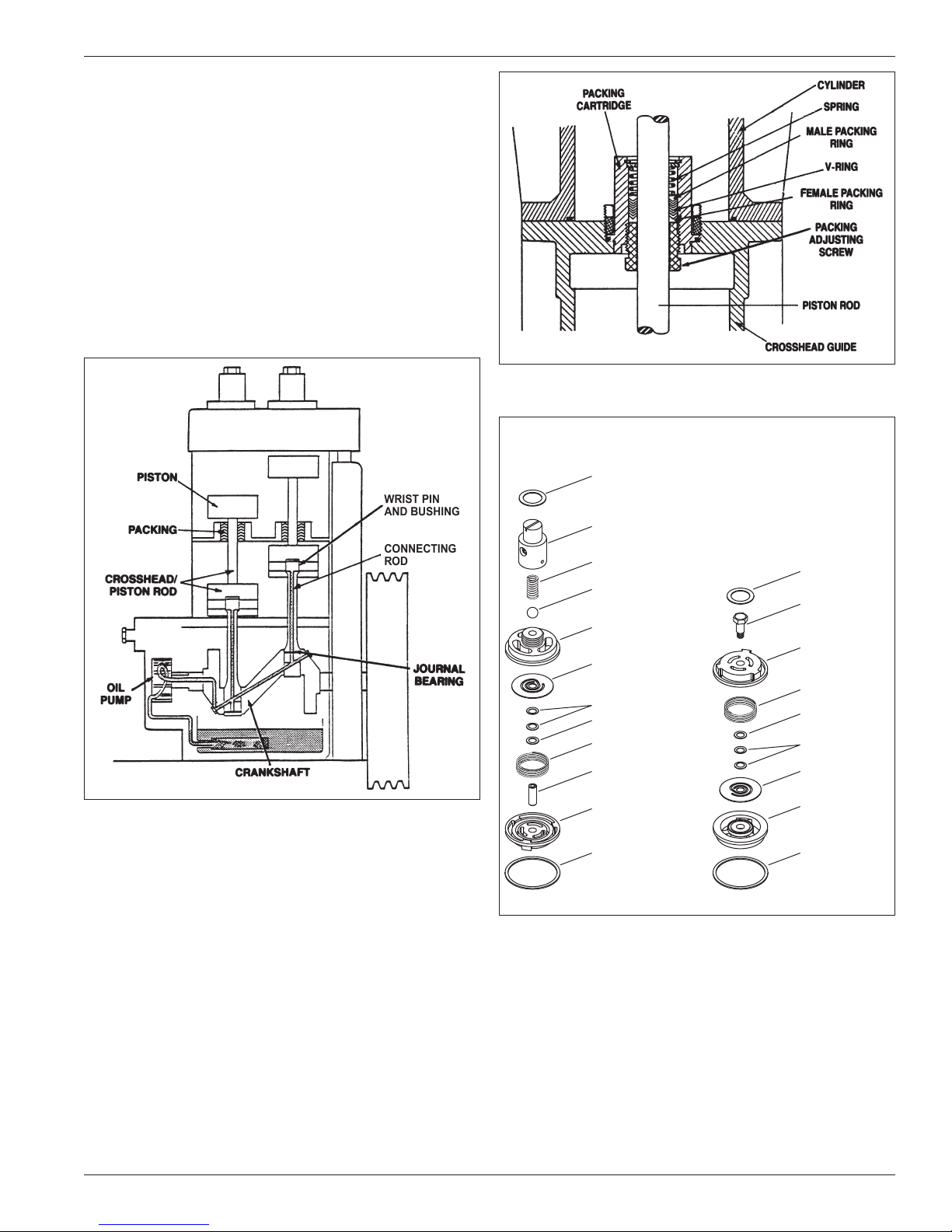

Corken gas compressors are mounted on oil lubricated

crankcases remaining at atmospheric pressure. Crankshafts

are supported by heavy-duty roller bearings and the

connecting rods ride the crankshaft on journal bearings.

With the exception of the small size model 91 compressor,

all compressor crankcases are lubricated by an automotive

type oil pressure system. An automatically reversible gear

6

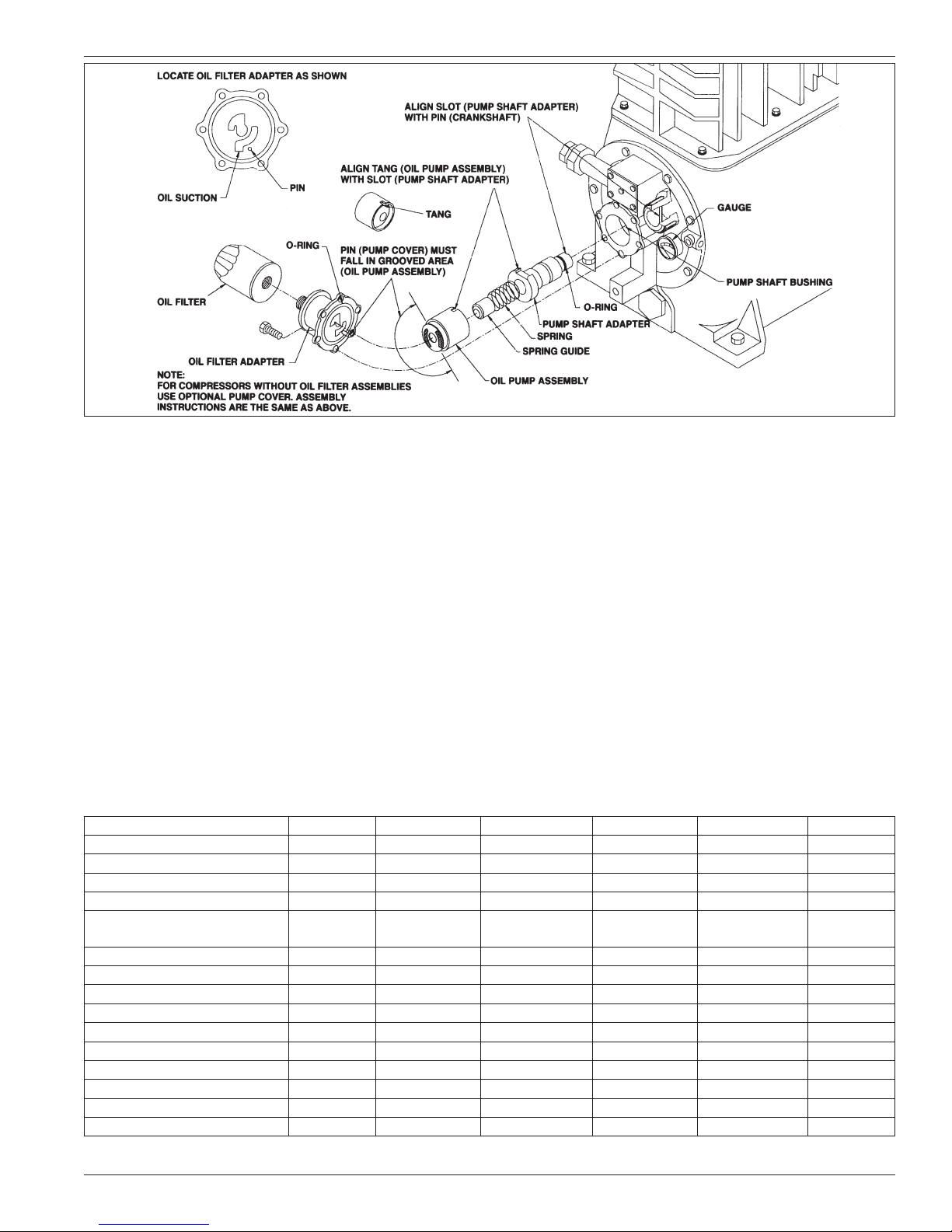

Page 7

type oil pump circulates oil through passages in the

crankshaft and connection rod to lubricate the journal

bearings and wrist pins (see figure 1.3B). Sturdy iron

crossheads transmit reciprocating motion to the piston.

Corken’s automatically reversible oil pump design

allows the machine to function smoothly in either

direction of rotation.

Corken compressors use iron pistons locked to the piston

rod. The standard piston ring material is a glass-filled

PTFE polymer specially formulated for non-lubricated

services. Piston ring expanders are placed behind the

rings to ensure that the piston rings seal tightly against

the cylinder wall.

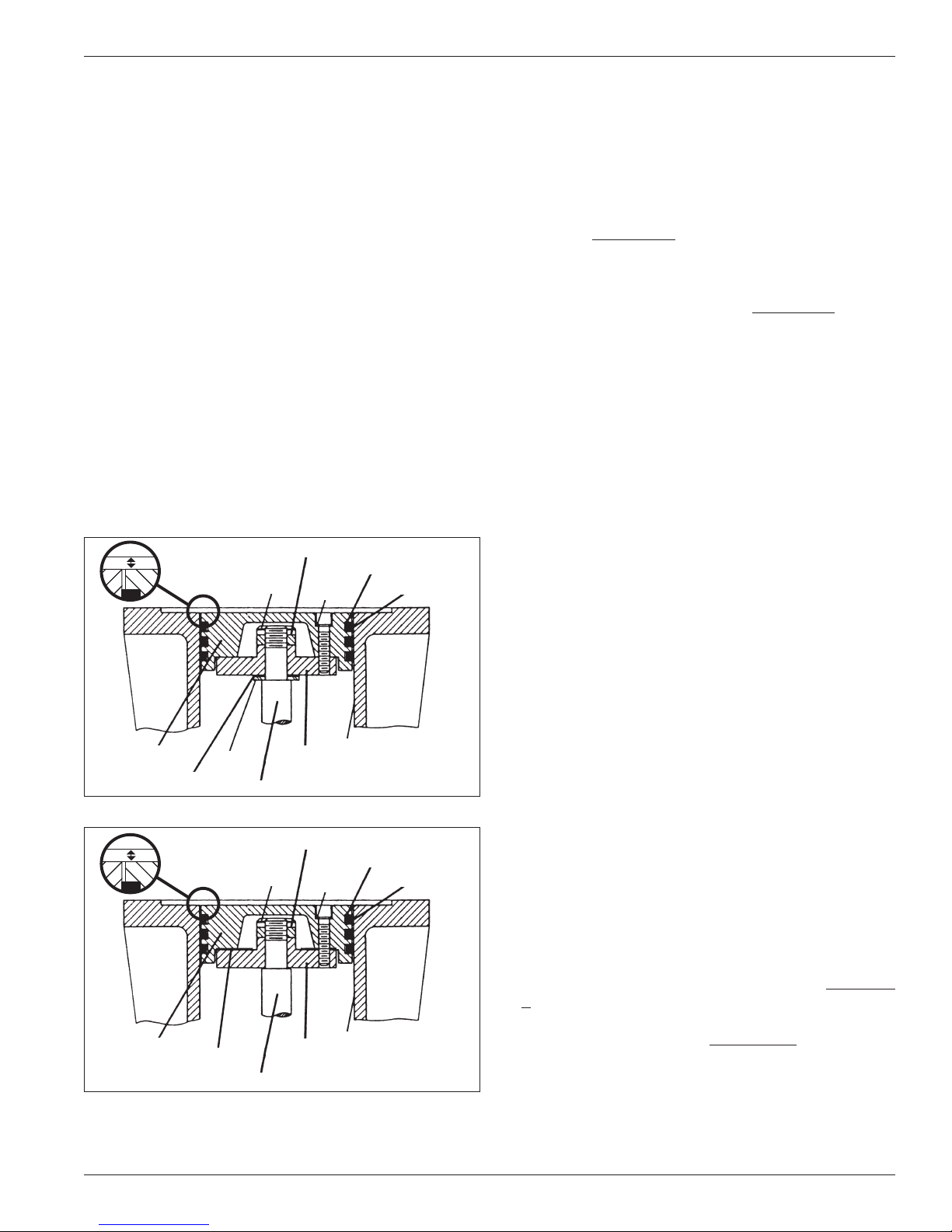

Figure 1.3C: Compressor sealing system

Suction Valve

Spec 3

Gasket

Figure 1.3B: Pressure lubrication system (not available on Model 91).

Piston rod packing is used to seal the gas in the

compression chamber and prevent crankcase oil from

entering the compressor cylinder. The packing consists

of several PTFE V-rings sandwiched between a male and

female packing ring and held in place by a spring (see

figure 1.3C).

The typical Corken compressor valve consists of a seat,

bumper, one or more spring/s and one or more valve/s

discs or plates as shown in figure 1.3D. Special heattreated alloys are utilized to prolong life of the valve in

punishing non-lubricated services. The valve opens

whenever the pressure on the seat side exceeds the

pressure on the spring side.

Adjusting

screw

Relief ball spring

Relief ball

Suction valve

seat

Valve plate

Spacers

Washer

Valve spring

Suction valve

post

Suction valve

bumper

Valve gasket

Figure 1.3D: Compressor sealing system

Discharge Valve

All Specs

Gasket

Bolt

Discharge valve

bumper

Valve spring

Washer

Spacers

Valve plate

Discharge valve

seat

Valve gasket

7

Page 8

Chapter 2—Installing Your Corken

Compressor

2.1 Location

NOTE: Compressor must be installed in a well

ventilated area.

Corken compressors are designed and manufactured

for outdoor duty. For applications where the compressor

will be subjected to extreme conditions for extended

periods such as corrosive environments, arctic

conditions, etc., consult Corken. Check local safety

regulations and building codes to assure installation will

meet local safety standards.

Corken compressors handling toxic or flammable

gases such as LPG/NH3 should be located outdoors. A

minimum of 18 inches (457.2 mm) clearance between the

compressor and the nearest wall is advised to make it

accessible from all sides and to provide unrestricted air

flow for adequate cooling.

NOISE. Corken vertical compressors sizes model 91

through 891 should not exceed an 85 DBA noise level at

a distance of one meter (3.3 ft.) when properly installed.

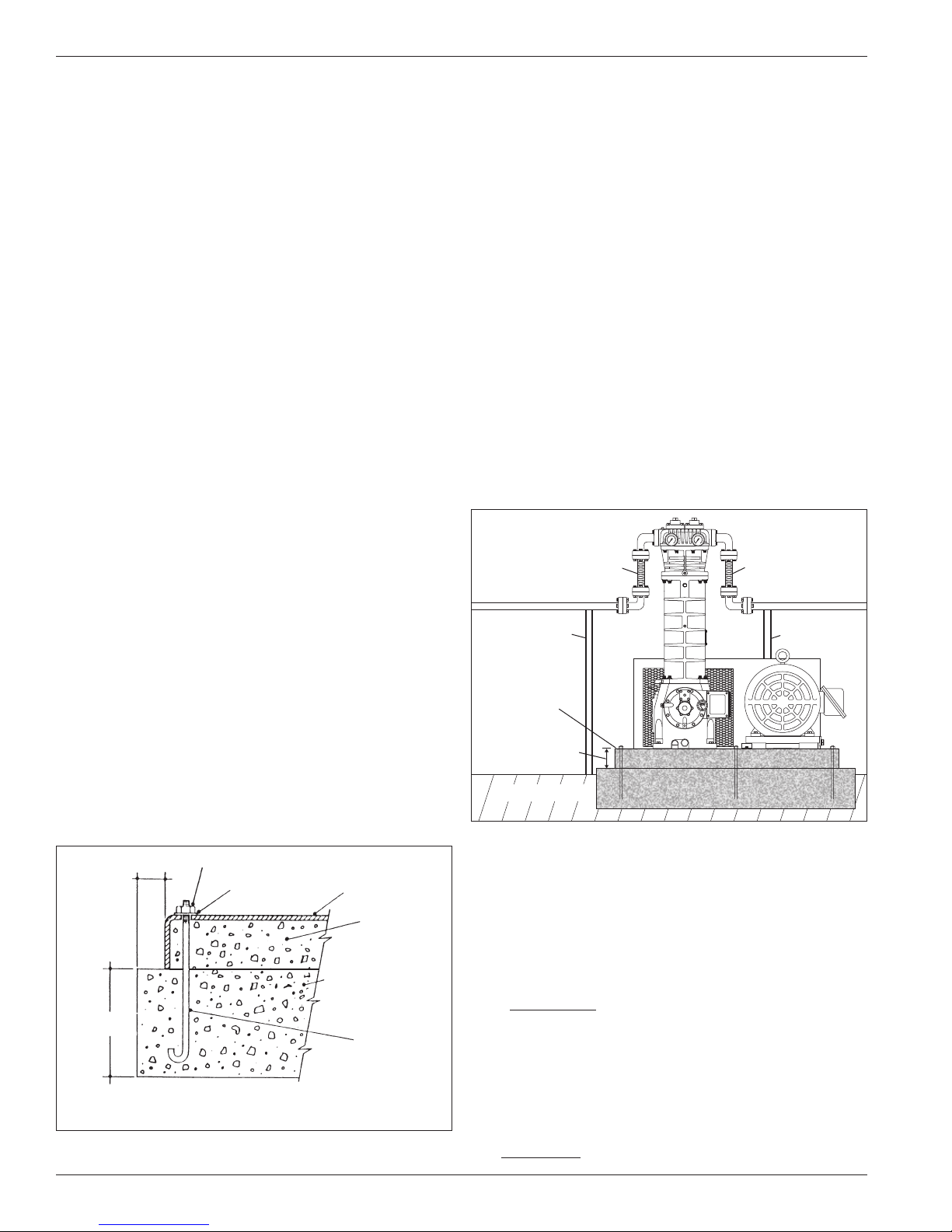

After leveling and bolting down baseplate and/or skid,

the volume beneath the channel iron baseplate must

be grouted to prevent flexing of the top portion of the

baseplate and the “J” bolt that extends beyond the

foundation. The grout also improves the dampening

capabilities of the foundation by creating a solid interface

between the compressor and foundation.

See ED410: Compressor Foundation Design for more

information.

2.3 Piping

Proper piping design and installation is as important as

the foundation is to smooth operation of the compressor.

Improper piping installation will result in undesirable

transmission of compressor vibration to the piping.

DO NOT SUPPORT PIPING WITH THE COMPRESSOR.

Unsupported piping is the most frequent cause of

vibration of the pipe. The best method to minimize

transmission of vibration from the compressor to the

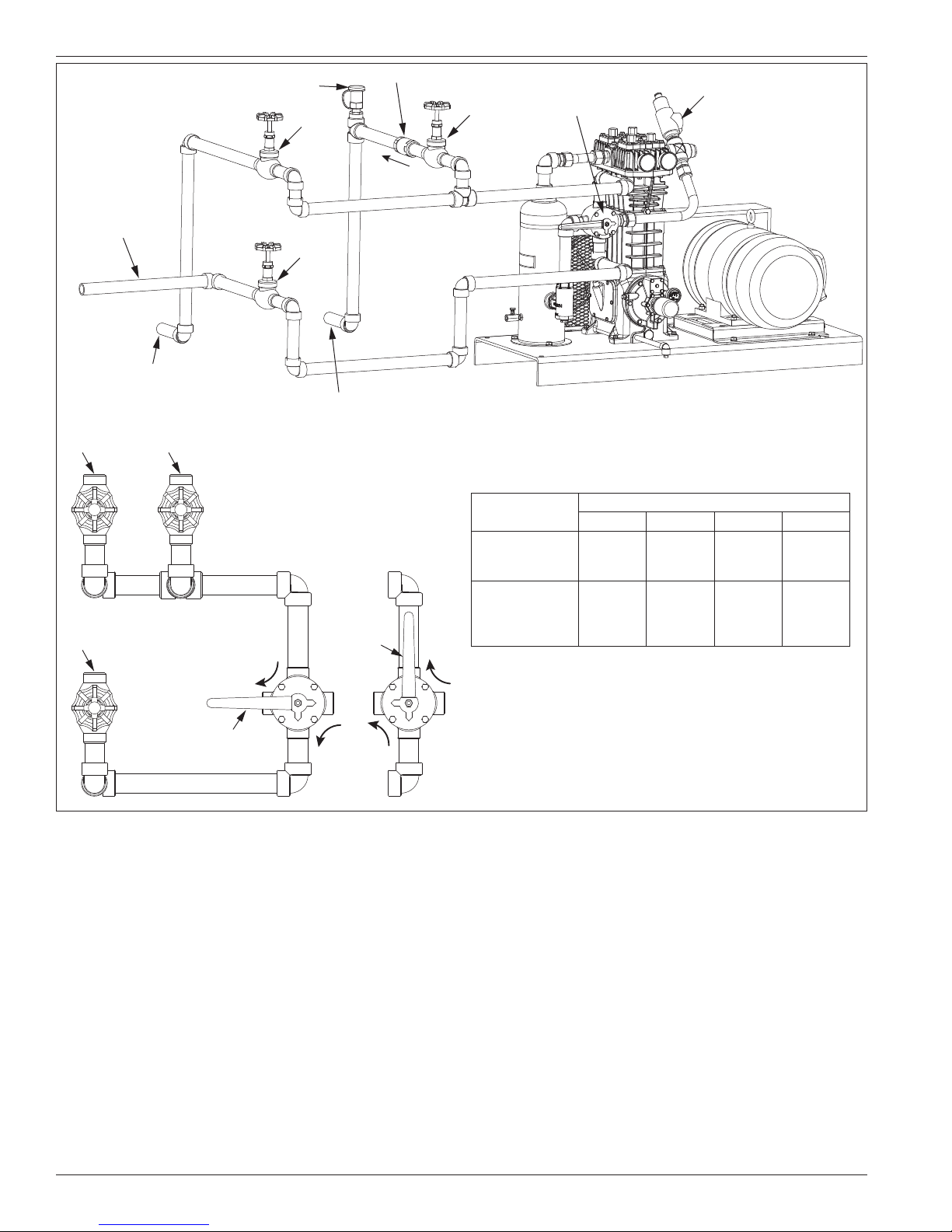

piping is to use flexible connectors (see figure 2.3A).

Flexible

connections

Flexible

connections

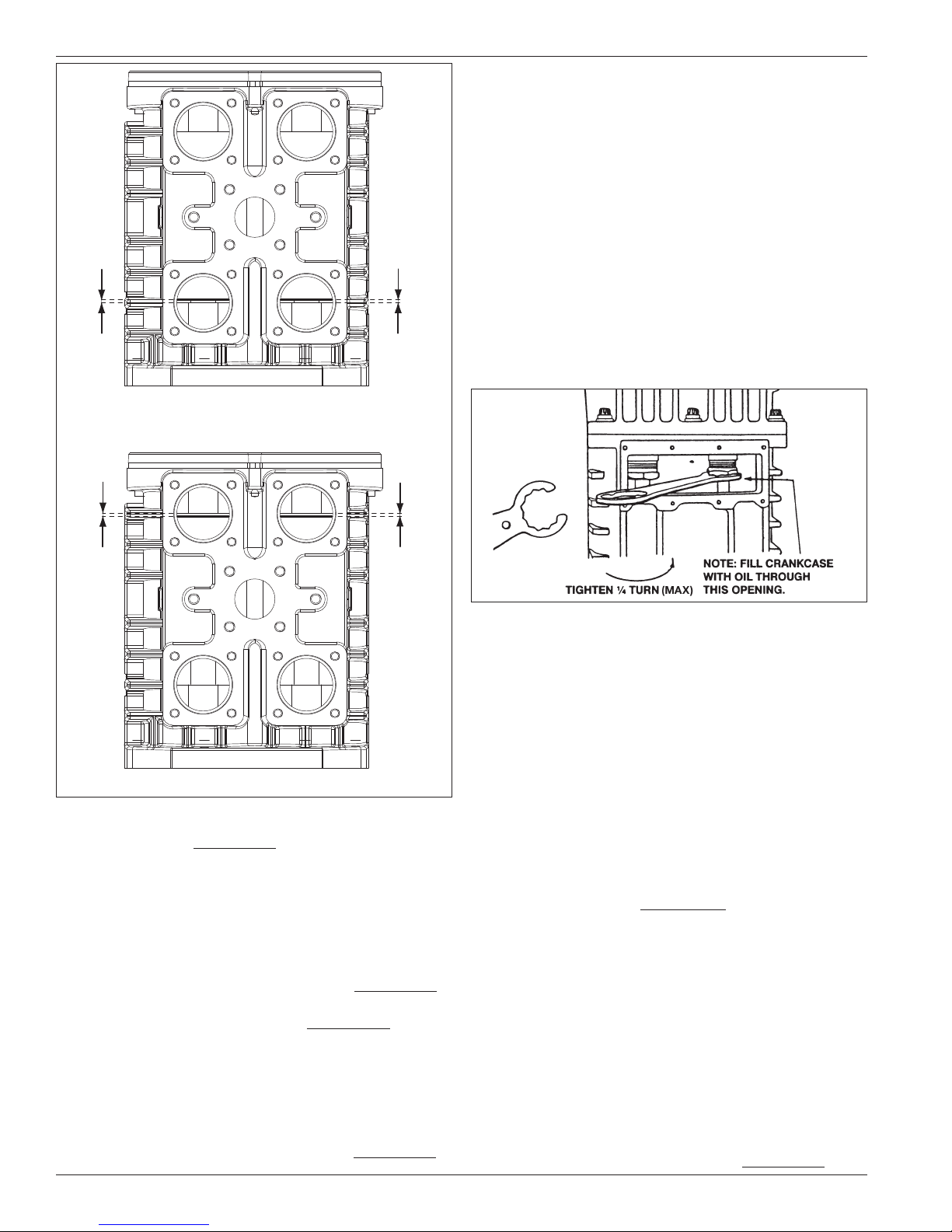

2.2 Foundation

Proper foundations are essential for a smooth running

compression system. The concrete slab should be

at least 8 inches thick with a 2 inch skirt around the

circumference of the baseplate. The total mass of the

foundation should be approximately twice the weight of

the compressor system (compressor, baseplate, motor,

etc.). For Models 91, 291, 491, and 691, the baseplate

should be secured to the foundation using 1/2" diameter

x 12" long “J” bolts. Use 3/4" x 12" anchor bolts for 891.

NOTE: Be sure to use all anchor holes.

Hex nut

2" minimum

all sides

8" minimum

NOTE: Locate “J” bolts per compressor outline

dimension drawings.

Figure 2.2A: Recommended foundation details for Corken

Washer

compressors 91–691.

Compressor

baseplate

Grout beneath

base

Concrete foundation

with reinforcements

should be used on

all models

1/2" “J” bolts

12" long

Pipe

support

Grouted

baseplate

Baseplate should

be a maximum

of 4" high

Ground level

Figure 2.3A: On –107 mountings, the flexible connectors should be

located near the four way valve.

Concrete

foundation

Pipe

support

Pipe must be adequately sized to prevent excessive

pressure drop between the suction source and the

compressor as well as between the compressor and the

final discharge point. In most cases, piping should be

at least the same diameter as the suction nozzle on the

compressor. Typically, LPG/NH3 liquid transfer systems

should be designed to limit pressure drops to 20 psi (1.4

bar). Appendix C shows recommended pipe sizes for

each compressor for typical LPG/NH3 installations.

Care must be taken if a restrictive device such as a valve,

pressure regulator, or back-check valve is to be installed

in the compressor’s suction line. The suction line volume

between the restrictive device and the compressor suction

nozzle must be at least ten times the swept cylinder volume.

See Appendix B for details on cylinder and stroke.

8

Page 9

Vapor line to

D A C

rail car

(inbound bulk

transport)

Hydrostatic relief valve

D

B

A

Back check valve

C

Relief valve

4-Way valve

Bury or

insulate in

cold climate

areas

Vapor line to truck

trailer or tank

(local transport)

Vapor line to gas phase

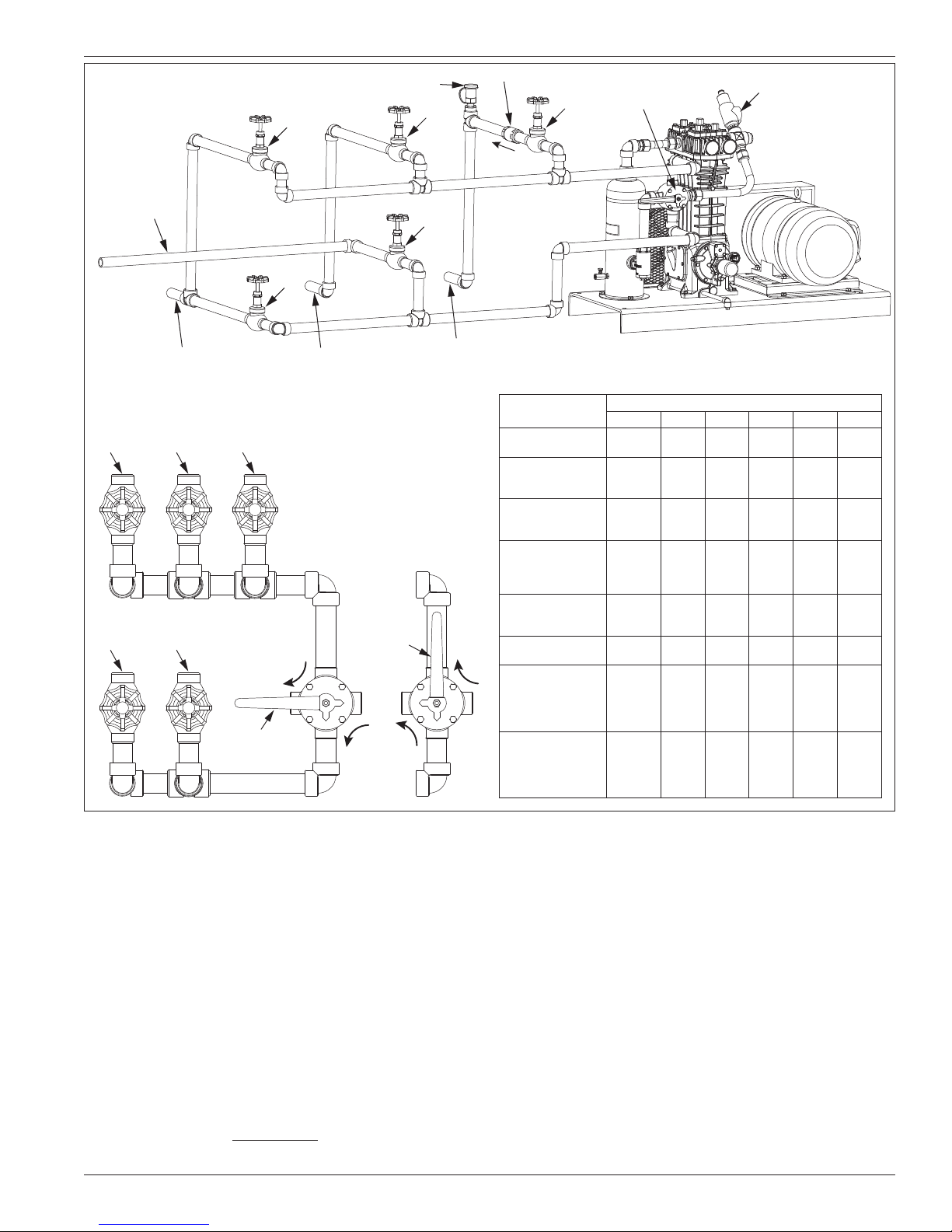

4-way Valve Operation

E B

4-Way Valve

Position 1

E

in storage tank

4-Way Valve

Position 2

Vapor line to liquid phase

in storage tank

Service to Perform

1. Unload tank car

into storage tank

2. Recover vapors

from tank car into

storage tank

3. Unload transport

or truck into

storage tank

4. Recover vapors

from transport or

truck into storage

tank

5. Load truck or

field tank from

storage tank

6. Load truck or field

tank from tank car

7. Equalize between

tank car and

storage tank

without using

vapor pump

8. Equalize between

truck or field tank

and storage tank

without using

vapor pump

Valve Position

4-way A B C D E

Position

Position

Position

Position

Position

Position

Open Open Close Close Close

One

Close Open Open Close Close

Two

Open Close Close Close Open

One

Close Close Open Close Open

Two

Open Close Close Close Open

Two

Close Open Close Open Close

One

— Open Open Close Open Open

— Open Close Close Open Close

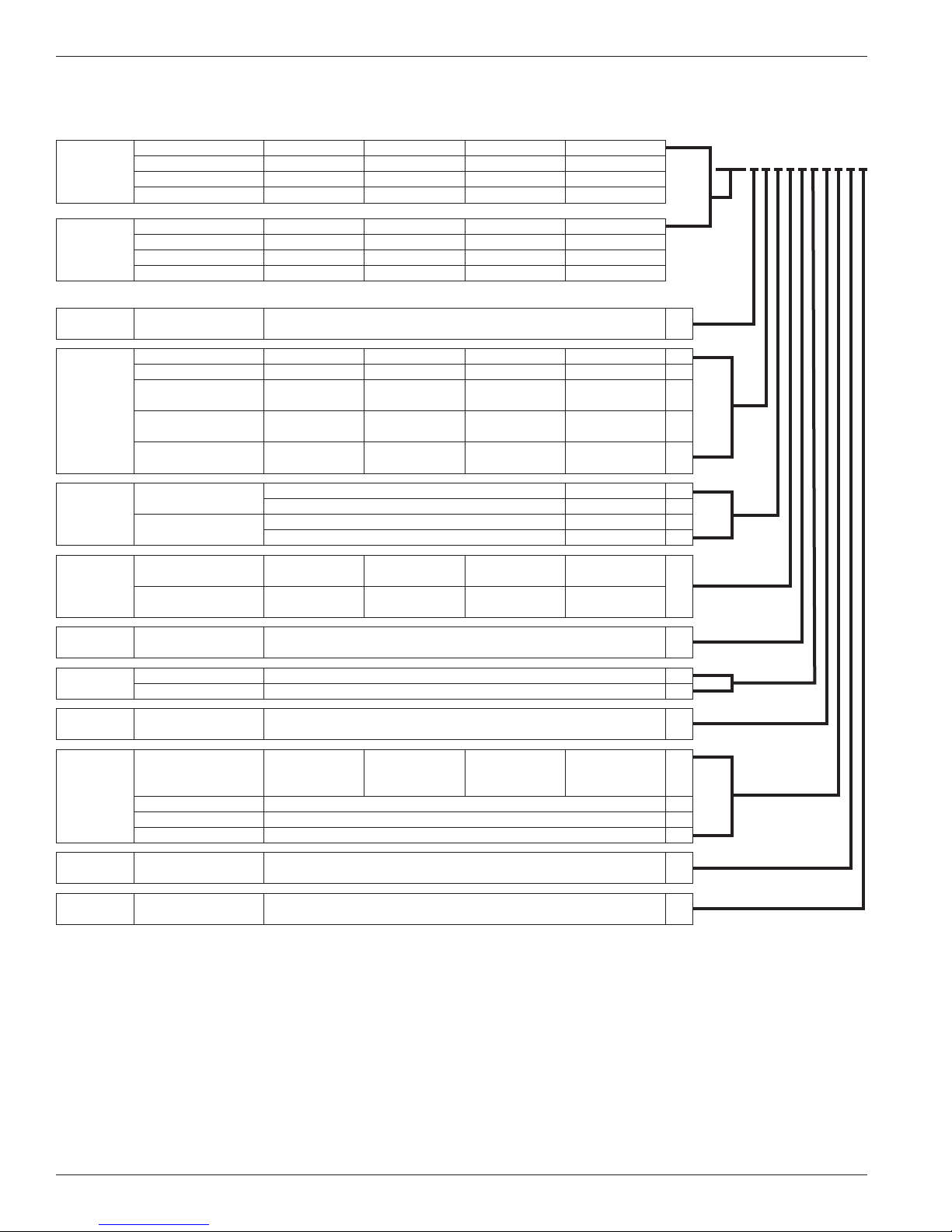

107 style compressors are usually connected using a fivevalve (figure 2.3B) or three-valve manifold (figure 2.3C).

The five-valve manifold allows the storage tank to be

both loaded and unloaded. The three-valve manifold only

allows the storage tank to be loaded. Adequate sizing of

the liquid and vapor lines is essential to limit the pressure

drop in the system to a reasonable level (20 psi or less).

The line size helps determine the plant capacity almost

as much as the size of the compressor, and liquid line

sizes are a bigger factor than vapor lines. If the pressure

gauges on the head indicate more than a 15 to 20 psi

(1.0 to 1.4 bars) differential between the inlet and outlet

pressures, the line sizes may be too small or there is too

much piping restriction. The less restriction in the piping,

the better the flow. Appendix C shows recommended

pipe sizes for typical LPG/NH3 compressor installation.

Figure 2.3B: Five valve manifold piping system.

A tank car unloading riser should have two liquid hoses

connected to the car liquid valves. If only one liquid

hose is used, the transfer rate will be slower and there

is a good possibility that the car’s excess flow valve

may close.

Since the heat of compression plays an important part in

rapid liquid transfer, the vapor line from the compressor to

the tank car or other unloading container should be buried

or insulated to prevent the loss of heat and the compressor

should be located as near as possible to the tank being

emptied. In extremely cold climates, if the line from the

storage tank to the compressor is over 15 feet (4.6 meters)

long, it should be insulated to lessen the possibility of

vapors condensing as they flow to the compressor. The

vapor recovery discharge line should not be insulated.

Placing the compressor as close as possible to the tank

9

Page 10

Hydrostatic releif valve

A C

Vapor line rail car

(in-bound

bulk transfer)

Bury or insulate in

cold climate areas

Vapor line to gas

phase in storage

4-way Valve Operation

Back check valve

A

B

Vapor line to liquid

phase in storage

C

4-Way valve

Relief valve

B

being unloaded will minimize heat loss from the discharge

line for the best liquid transfer rate.

Unloading stationary tanks with a compressor is quite

practical. Delivery trucks and other large containers can

be filled rapidly if the vapor system of the tank to be

filled will permit fast vapor withdrawal, and if the liquid

piping system is large enough. Many older trucks (and

some new ones) are not originally equipped with vapor

excess flow valves large enough to do a good job and

these should be replaced by a suitable size valve. The

liquid discharge should be connected to the tank truck

pump inlet line rather than the often oversized filler valve

connection in the tank head.

4-Way Valve

Position 1

Service to

Perform

1. Unload

tank car into

storage tank

2. Recover

vapors from

4-Way Valve

Position 2

Figure 2.3C: Three valve manifold piping system.

tank car into

storage tank

(see section 2.4). It is of equal importance to protect the

discharge of the compressor from liquid. This may be

done by installing a check valve on the discharge and

designing the piping so liquid cannot gravity-drain back

into the compressor. Make sure to install a check valve

on vapor lines discharging to the liquid space of the tank.

All piping must be in accordance with the laws and codes

governing the service. In the United States, the following

codes apply:

For LP-Gas — The National Fire Protection Association

Pamphlet No. 58, Standard for the Storage and Handling

of Liquefied Petroleum Gases.

Valve Position

4-way A B C

Position

One

Position

Two

Open Open Close

Close Open Open

It is of extreme importance to prevent the entry of

liquid into the compressor. The inlet of the compressor

should be protected from liquid entry by a liquid trap

For Ammonia — The American National Standards

Institute, Inc., K61.1-1999, Storage and Handling of

Anhydrous Ammonia.

10

Page 11

Install, use and maintain this equipment according to

Corken instructions and all applicable federal, state, and

local laws and previously mentioned codes.

2.4 Liquid Traps

Compressors are designed to pressurize gas, not to pump

liquids. The entry of even a small amount of liquid into the

compressor will result in serious damage to the compressor.

On liquefied gas applications, a liquid trap must be used

to prevent the entry of liquid into the compressor.

109 and 107 compressor mountings (see Appendix D for

details on standard Corken compressor mountings).

When the compressor will not be under more-or-less

constant observation an automatic trap is recommended.

The automatic trap replaces the float with electrical float

switches. If the liquid level should rise too high, the level

switch will open and disconnect the power to the motor

starter, stopping the compressor. This design ensures

the machine will be protected even when it is not under

close observation and is standard in the 109A and 107A

mounting configurations.

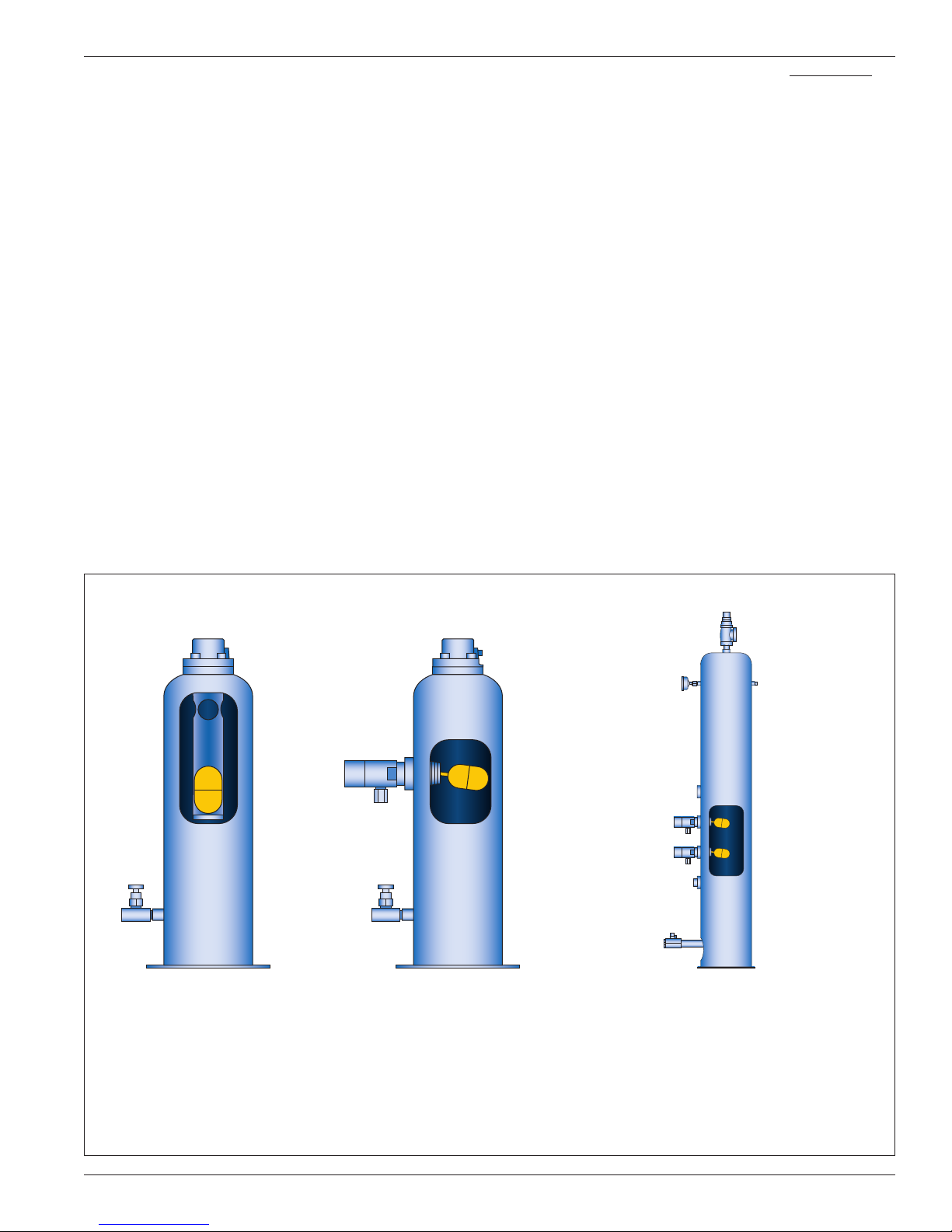

Corken offers three types of liquid traps for removal of

liquids in the gas stream (see figure 2.4A). The simplest is

a mechanical float trap. As the liquid enters the trap the

gas velocity is greatly reduced, which allows the liquid

to drop out. If the liquid level rises above the inlet, the

float will plug the compressor suction. The compressor

creates a vacuum in the inlet piping and continues to

operate until the operator manually shuts it down. The

trap must be drained and the vacuum-breaker valve

opened before restarting the compressor, to allow the

float to drop back. This type of trap is only appropriate

for use where the operator keeps the compressor under

fairly close observation. This trap is provided with the

Corken’s most sophisticated trap provides the most

thorough liquid separation. This trap is larger and is

ASME code stamped. It contains two level switches, one

for alarm and one for shutdown. In some cases the alarm

switch is used to activate a dump valve (not included

with trap) or sound an alarm for the trap to be manually

drained by the operator. This trap also contains a mist

pad. A mist pad is a mesh of interwoven wire to catch fine

liquid mists. The ASME code trap is standard in the 109B

and 107B mounting configurations.

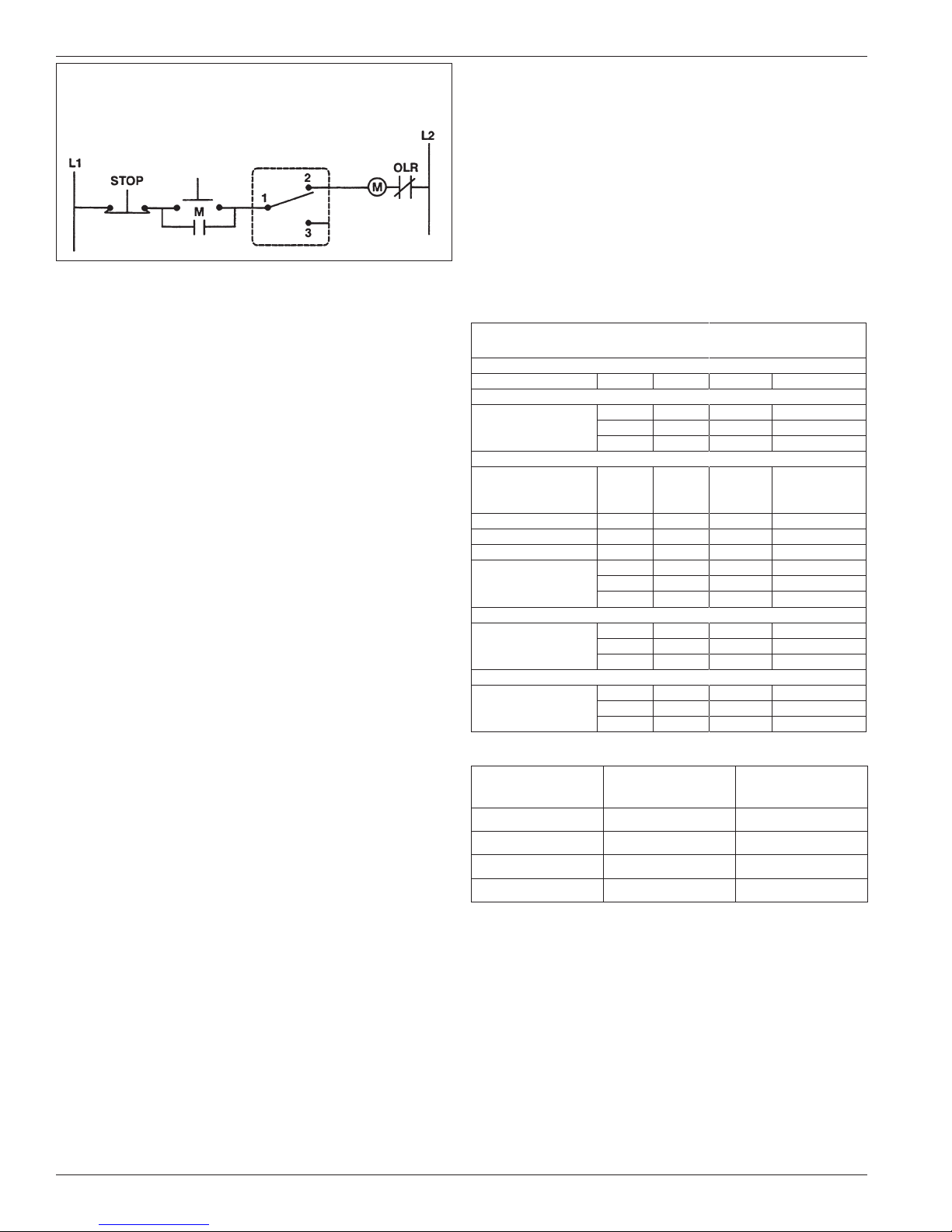

A typical wiring diagram for the liquid level switch is

shown in figure 2.4B.

Standard Liquid Trap Automatic Liquid Trap ASME Automatic Liquid Trap

Standard liquid trap with

mechanical float assembly

and drain valve.

Sizes: • 1-1/4" x 1-1/4" NPT

• 1-1/4" x 1-1/2" NPT

Automatic liquid trap, with one

NEMA 7 liquid-level switch for

compressor shutdown and

drain valve.

Sizes: • 1-1/4" x 1-1/4" NPT

• 1-1/4" x 1-1/2" NPT

Figure 2.4A: Liquid traps.

11

Class 300 RF flange code-stamped

automatic liquid trap with two NEMA 7 liquidlevel switches for compressor shutdown and

alarm. Equipped with relief valve, pressure

gauge, demister pad, and drain valve.

Sizes: • 1-1/2" x 1-1/2" NPT

• 2" x 2" Class 300 RF flange

Page 12

Typical Float Switch Wiring Diagram

1 = Common, black

2 = Normally closed, blue

3 = Normally open, red

Figure 2.4B: Typical float switch wiring diagram.

NOTE: The level switch MUST be removed from

the trap before grounding any welding devices to

the trap or associated piping! Failure to do so will

damage the switch contacts.

If your compressor is equipped with a liquid trap

of other than Corken manufacture, make sure it is

of adequate size to thoroughly remove any liquid

present in the suction stream.

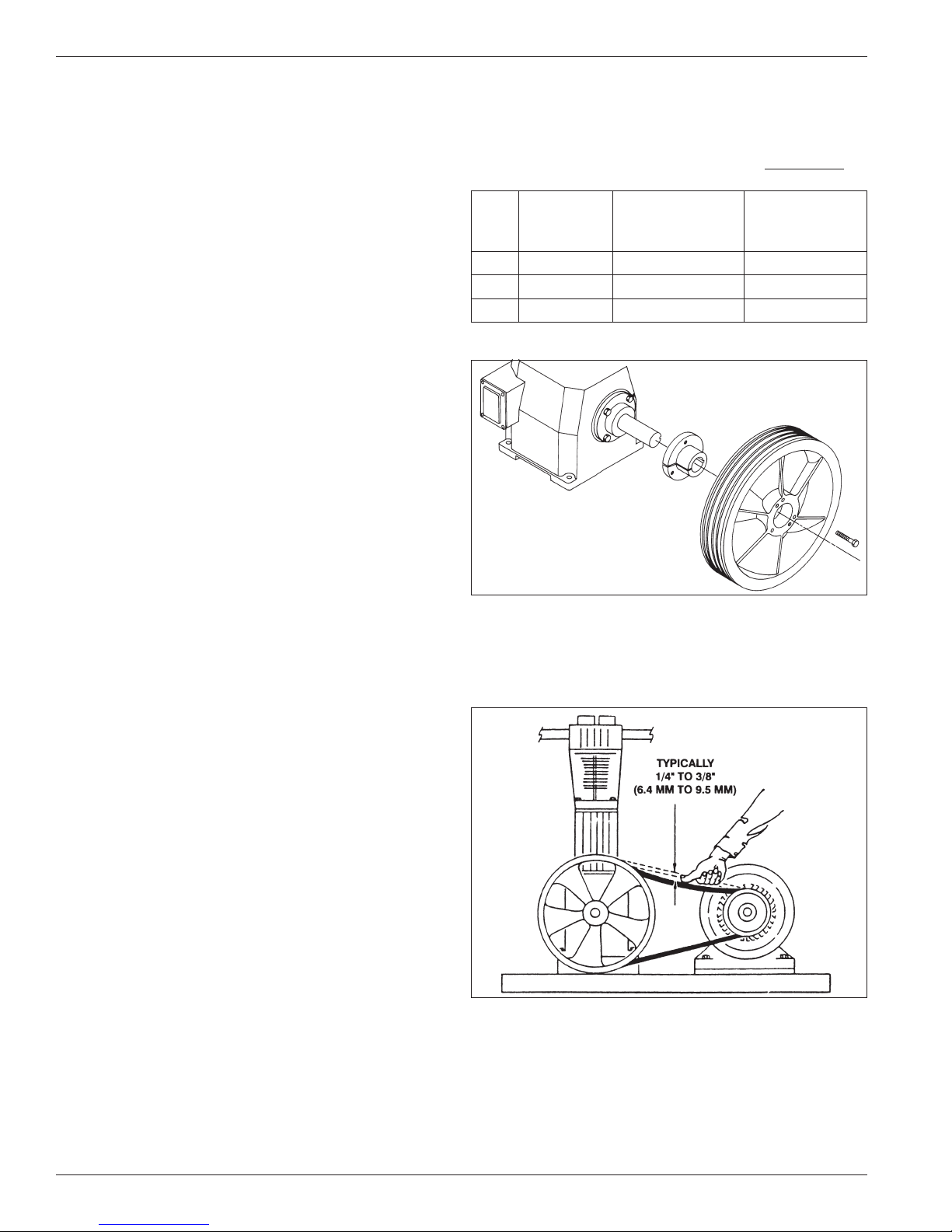

2.5 Driver Installation / Flywheels

Corken vertical compressors may be driven by either

electric motors or combustion engines (gasoline, diesel,

natural gas, etc.). Corken compressors are usually V-belt

driven but they are also suitable for direct drive applications

as well. Direct drive applications require an extended

crankshaft to allow the attachment of a rigid metal coupling.

Note: Flexible couplings are not suitable for reciprocating

compressors. Never operate a reciprocating compressor

without a flywheel.

Drivers should be selected so the compressor operates

between 350 to 825 RPM. The unit must not be operated

without the flywheel or severe torsional imbalances will result

that could cause vibration and high horsepower requirement.

The flywheel should never be replaced by another pulley

unless it has a higher WK 2 value than the flywheel.

A humid climate can cause problems, particularly in

explosion proof motors. The normal breathing of the

motor, and alternating between being warm when running

and being cool when stopped, can cause moist air to be

drawn into the motor. This moist air will condense, and

may eventually add enough water inside the motor to

cause it to fail. To prevent this, make a practice of running

the motor at least once a week on a bright, dry day for an

hour or so without the V-belts. In this period of time the

motor will heat up and vaporize the condensed moisture,

driving it from the motor. No motor manufacturer will

guarantee their explosion proof or totally enclosed

(TEFC) motor against damage from moisture.

For installation with engine drivers, thoroughly review

instructions from the engine manufacturer to assure the

unit is properly installed.

2.6. Crankcase Lubrication

Non-detergent oil is recommended for Corken vertical

compressors. Detergent oils tend to keep wear particles

and debris suspended in the oil, whereas non-detergent

oils let them settle in the bottom of the crankcase.

When non-detergent oils are not available, detergent

oils may usually be successfully substituted, although

compressors handling ammonia, amine, or imine gases

are notable exceptions. These gases react with the

detergent and cause the crankcase oil to become

corrosive and contaminated. Figures 2.6A and 2.6B show

recommended oil viscosities and crankcase capacities.

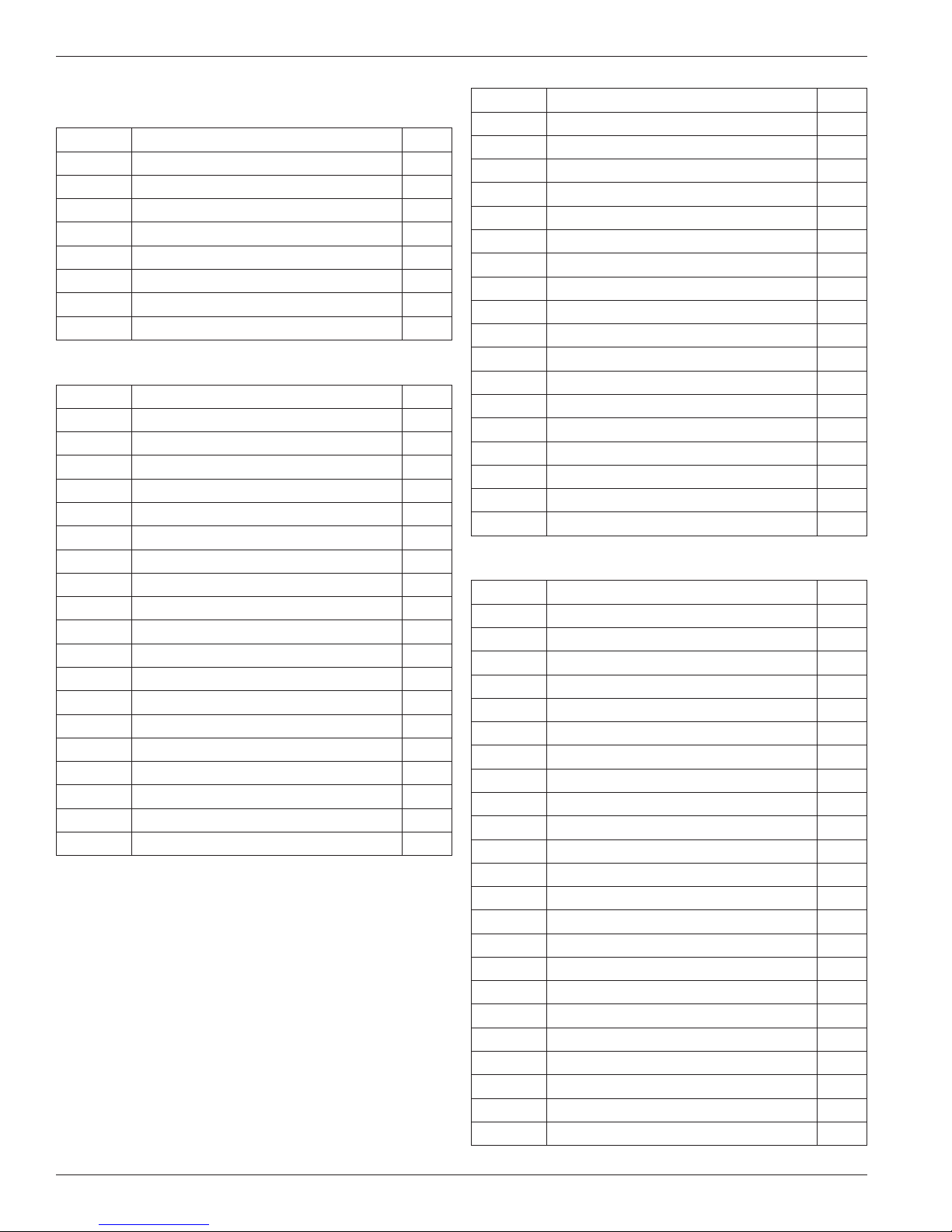

Acceptable Crankcase Oil Products

for Corken Compressors

Constant Weight - Non-Detergent - R&O Inhibited

Oil product ISO VI SAE Ambient Temp.

®

Exxon

100 95 30 65° – 100° F

TERESSTIC

®

Mobil

RARUS 427

Reciprocating

Compressor Oil

DTE Oil Heavy Medium 68 95 20+ 45° – 70° F

Dectol R&O Oil 46 95 20 35° – 50° F

®

Conoco

Dectol R&O Oil

®

Texaco

Regal R&O Oil

®

Sun

SunVis 900 Oil

Compressor

Model

91 0.9 0.8

291 1.5 1.4

491 3.0 2.8

691/891 7.0 6.6

Synthetic lubricants are generally not necessary. Please

consult your lubricate supplier if you are considering the

use of synthetic oil. To add oil, remove the name plate

and pour through the opening.

General Notes on Crankcase Oil

Corken gas compressors are used for a wide variety of

gases in a multitude of operating conditions. They are

used in all areas of the world from hot dusty deserts, to

humid coastal areas, to cold arctic climates. No single

crankcase oil or maintenance schedule is right for every

compressor installation. Availability of brands and grades

68 95 20+ 45° – 70° F

46 95 20 35° – 50° F

100 95 30 65° – 100° F

100 98 30 65° – 100° F

68 97 20+ 45° – 70° F

46 99 20 35° – 50° F

100 92 30 65° – 100° F

68 97 20+ 45° – 70° F

46 102 20 35° – 50° F

100 100 30 65° – 100° F

68 100 20+ 45° – 70° F

46 100 20 35° – 50° F

Figure 2.6A: Oil selection chart.

Approximate

Quarts

Figure 2.6B: Oil capacity chart.

Capacity Liters

12

Page 13

of oil varies from one location to another. These factors

can make it challenging for a Corken compressor user to

select a suitable crankcase oil.

It is safe to say that purchasing a quality crankcase oil,

and changing it regularly, is significantly less costly than

the repair bill and downtime associated with a lubrication

failure in any gas compressor. Given the relatively

small volume of oil used in the crankcase of a Corken

compressor, and the critical nature of the services

where these compressors are typically used, selecting

the appropriate high-quality oil is the most economical

choice. It will help ensure the dependability and longevity

of the compressor.

Oils to Avoid

Selecting a crankcase oil based on low price or easy

availability is seldom the most economic decision.

Following are oils to avoid.

• Do not use engine/motor oil with an API Service SA

through SH.

• Do not use any oil with a viscosity index below 95.

Viscosity Index

Viscosity Index (VI) is a measure of how much the

oil’s viscosity changes as its temperature changes. A

low viscosity index is an indication that the viscosity

changes more as the temperature changes. A high

viscosity reflects a more stable viscosity, and is generally

preferred for Corken compressors.

Oil with a low viscosity index tends to thin out as the oil

temperature increases. This can cause lubrication failure

as well as unstable oil pressure. The minimum Viscosity

Index for oils used in Corken compressors is 95 (VI is

a unit-less number). This is particularly important when

operating at high or low temperature extremes, or at a

variety of ambient temperatures (seasonal changes).

Pour Point

The pour point of an oil is the lowest temperature at

which the oil flows. At temperatures below the pour

point, the oil is very thick and can’t freely flow to the

compressor’s bearings and other wear surfaces, or even

to the compressor’s oil pump.

• Do not use any oil with a pour point less than 15ºF

(8ºC) lower than the anticipated minimum ambient

temperature (unless a crankcase oil heater is used).

See below for additional detail on each of these parameters.

Industrial Oils

Corken recommends using industrial oils (rather than

engine oil or “motor oil”). Industrial oils have additives

specifically selected and blended for specific purposes.

Many are designed specifically for the conditions

inherent in compressor crankcases. Such industrial

oils are required for Corken compressors operating in

continuous duty or heavily loaded applications.

Industrial oils do not receive an API service designation

like an engine oil does.

Critical Oil Characteristics

Viscosity

The viscosity of a crankcase oil is a measure of its

resistance to flow. Viscosity is the most important

physical property of lubricating oil. Oils with higher

viscosity (ISO 100 and ISO 150) are thicker and are

used for higher ambient temperatures. Oils with lower

viscosity (ISO 68, ISO 46, and ISO 32) are thinner and

are used at lower ambient temperatures. However, oils

with a high viscosity index (see below) can be used at

wider ambient temperature range compared to oils with

a lower viscosity index.

In low ambient temperature operation, the oil’s pour point

is critical. An oil should have a pour point at least 15ºF

(8ºC) below the lowest expected ambient temperature.

For example, if the minimum ambient temperature is

expected to be 0ºF (-18ºC), the pour point must be no

higher than -15ºF (-26ºC).

Do not assume the pour point of an oil is low enough.

Consult the oil’s technical data sheet. Many oils have a

pour point around 0 to 10ºF (-18 to -12ºC) which is too

high for low ambient temperatures. Synthetic oils often

have a lower pour point than conventional oils.

Engine Oils (Motor Oils)

Engine oils are formulated for use in internal combustion

engines and contain additives that specifically counter

the contaminants created by the combustion of fuel

(soot, CO2, water, etc.). A gas compressor crankcase

is a different environment than an engine crankcase.

Thus, engine oils are not necessarily the best oils to use

in a gas compressor. They are by far the most readily

available oils.

If a suitable industrial oil is not available, engine oils can be

used in Corken compressors used in intermittent service.

Heavily loaded compressors or those in continuous duty

service should always use high quality industrial oil. If

engine oil is used, it is critical that the engine oil have an

adequate API Service Grade.

13

Page 14

API Service

The American Petroleum Institute (API) grades motor

oils (oils designed for use in engines in cars and trucks)

with a two letter classification. Oils with API grades “SA”

through “SH” are obsolete and should never be used

in modern engines or gas compressors. Unfortunately,

motor oils with an “SA” and “SB” ratings are still readily

available at parts stores, service stations, and other

retail outlets at low prices. These are low quality oils and

should NEVER be used in Corken compressors. If motor

oil is used in a Corken compressor, it should have an

API Service of SJ or better. Multigrade motor oils such

as 10W-40 tend to have a higher viscosity index.

Service classification

S=gasoline engine

C=diesel engine

API (American

Petroleum Institute)

A

P

V

I

R

C

E

S

I

E

S

Quality rating

N

SAE

• Oil dilution caused by condensation or other liquids in

the gas stream (see below)

• Change in viscosity for any reason (various oil additives

can break down over time)

• Changing ambient temperature may cause the need for

a different viscosity

The oil should be changed as often as necessary

to maintain clean, undiluted oil. Each time the oil is

changed, the oil filter (Corken part number 4225) should

also be changed.

Ammonia Services

Never use a detergent oil in a compressor in ammonia

service. Ammonia will react with the detergent and cause

lubrication failure.

Oils that can be used in ammonia compressors:

• Royal Purple: Uni-Temp

• Phillips 66: Ammonia Compressor Oil

E

Example of API “Donut” symbol used on motor oil.

Oil suppliers post product data sheets on line that

contain various physical properties of the oil , and the

API Service classification. If there is any doubt, do not

use the oil.

Oil Change Intervals

Oil change intervals can vary significantly depending

on local environmental conditions, the gas being

compressed, and the oil being used. Unless there are

factors that shorten the life of the oil, the following

recommendations apply:

Conventional oil: 2200 hours or 6 months – whichever

Synthetic oil: 6000 - 8000 hours* or one year –

*Oil change intervals in this range should be confirmed via oil analysis.

5W-30

N

E

R

G

Y

C

comes first

whichever comes first

O

N

S

E

R

V

G

N

I

• Chevron: Capella P68

Crankcase Oil Heater Option

Corken offers a crankcase oil heater as an option on

all models except the small model 91. This heater is

available in 110V and 220V versions and is rated for Class

1, Division 1 and 2, Group B, C, D service. The heater

includes a thermostat set at 70°F (21.1°C).

If a crankcase heater is desired, it is best to order the

heater with the compressor (crankcase specification

“MH”). The mounting hole for the heater is not drilled

unless the heater is ordered with the compressor. It is

also possible to order the compressor with the hole

drilled (1" NPT), but without the heater (crankcase

specification “MR”). With this option, a customer can

supply their own heater.

2.7 Relief Valves

An appropriate relief valve must be installed at the

compressor discharge. On Corken 107-style mounted

units a relief valve should be fitted in the piping between

the compressor discharge and the four-way valve (see

figure 1.3A). Relief valves should be made of a material

compatible with the gas being compressed. Local codes

and regulations should be checked for specific relief

valve requirements. Also, relief valves may be required at

other points in the compressor’s system piping.

Factors that shorten the life of the oil:

• Dirty or dusty environmental conditions that cause the

oil to become dirty or discolored

14

Page 15

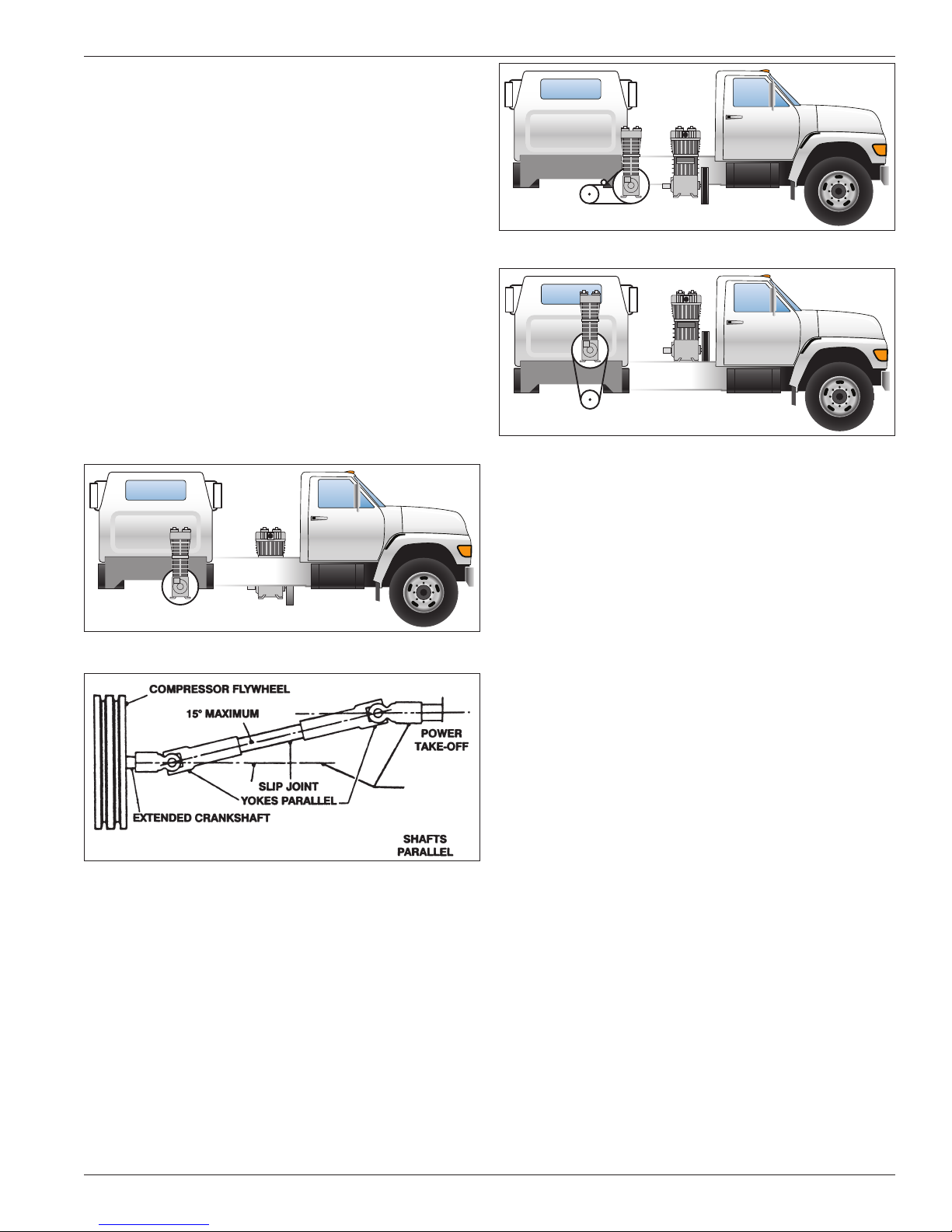

2.8 Truck Mounted Compressors

Corken compressors may be mounted on trucks to perform

liquid transfer operations as described in section 1.1. The

compressor should be mounted so the inspection plate is

accessible for packing adjustment. The compressor must

be protected against liquid as explained in section 2.4

and a relief valve must be installed in the discharge piping

before the first downstream shutoff valve.

Three types of mountings are typically used. The inside

mounting (figure 2.8A) drives the compressor directly off

the PTO shaft. The PTO must be selected to drive the

compressor between 400 and 800 RPM. An extended

compressor crankshaft is required so the U-joint yoke

may connect to the compressor without removing the

flywheel. Do not operate the compressor without a

flywheel. Use a U-joint with a splined joint and make sure

the connections are parallel and in line. The U-joint angle

should be less than 15 degrees (see figure 2.8B). Always

use an even number of U-joints.

Figure 2.8C: Outside transport mounting

Figure 2.8D: Top transport mounting.

2.9 Shutdown/Alarm Devices

For many applications, shutdown/alarm switches will

provide worthwhile protection that may prevent serious

damage to your compressor system. All electronic

devices should be selected to meet local code

requirements. Shutdown/alarm devices typically used on

Corken compressors are as follows:

Figure 2.8A: Inside transport mounting.

Figure 2.8B: U-joint drive for compressor.

Depending on the truck design, the compressor may be

outside or top mounted as shown in figures 2.8C and

2.8D to be V-belt driven. Power is transmitted through

a U-joint drive shaft, jackshaft with two pillow block

bearings, V-belt sheave and V-belts. An idle pulley may

be used under the truck frame.

1. Low Oil Pressure Switch: Shuts down the unit if

crankcase oil pressure falls below 12 psi due to oil

pump failure or low oil level in crankcase. The switch

or the compressor controller must have a 30 second

delay on startup which allows the compressor to

build oil pressure in the crankcase.

2. High Discharge Temperature Switch: This switch

is strongly recommended for all applications. Both

the High Discharge Temperature switch (HDT) and

compressor have an operating pressure range. It is

preferable that the switch set point be midpoint in its

range and 30°F (-1°C) above the normal discharge

temperature, but below the maximum design

temperature for the compressor of 350°F (176.7°C).

3. Low Suction Pressure Switch: Shuts down the

unit if inlet pressure is not within the preset limit (set

point). In some cases, it is important not to pull a

vacuum because of the potential of pulling oil from the

crankcase into the gas stream.

4. High Discharge Pressure Switch: Shuts down the

unit if the outlet pressure reaches a preset limit (set

point). Both the switch and the compressor have an

operating range. The set point of the pressure switch

should be as follows:

15

Page 16

Greater than the normal operating pressure for the

compressor.

Less than 90% of the relief valve set point pressure.

Less than the maximum operating pressure of the

compressor.

Midpoint of the pressure switch range.

5. Vibration Switch: Shuts down the unit if vibration

becomes excessive. Recommended for units mounted

to a portable skid.

Chapter 3—Starting Up Your

Corken Compressor

NOTE: Before initial startup of the compressor be

sure the principal of using a compressor for liquid

transfer by vapor differential pressure is understood

(see section 1.1). Read this entire chapter, then

proceed with the startup checklist.

bushing and three bolts (refer to figure 3.2A). These bolts

should be tightened in an even and progressive manner until

torqued as specified below. There must be a gap between

the bushing flange and the flywheel when installation is

complete. Always check the flywheel runout before startup

and readjust if it exceeds the value listed in Appendix B.

Hub

Size

Diameter

in. (cm)

SF 4.625 (11.7) 12-18 (1.7–2.5) 22 (3.1)

E 6.0 (15.2) 30-36 (4.1–4.9) 22 (3.1)

J 7.25 (18.4) 75-81 (10.3 –11.1) 10 9 (15.1)

Bolt Torque

Ft-lb (kg-meter)

Set Screw

Torque Ft-lb

(kg-meter)

3.1 Inspection After

Extended Storage

If your compressor has been out of service for a long period

of time, you should verify the cylinder bore and valve areas

are free of rust and other debris (see chapter 5 of this IOM

manual for valve and/or cylinder head removal instructions).

Drain the oil from the crankcase and remove the

nameplate and crankcase inspection plate. Inspect the

running gear for signs of rust and clean or replace parts

as necessary. Replace the crankcase inspection plate

and fill crankcase with the appropriate lubricant. Squirt

oil on the crossheads and rotate the crankshaft by hand

to ensure that all bearing surfaces are coated with oil.

Rotate unit manually to ensure running gear functions

properly. Replace nameplate and proceed with startup.

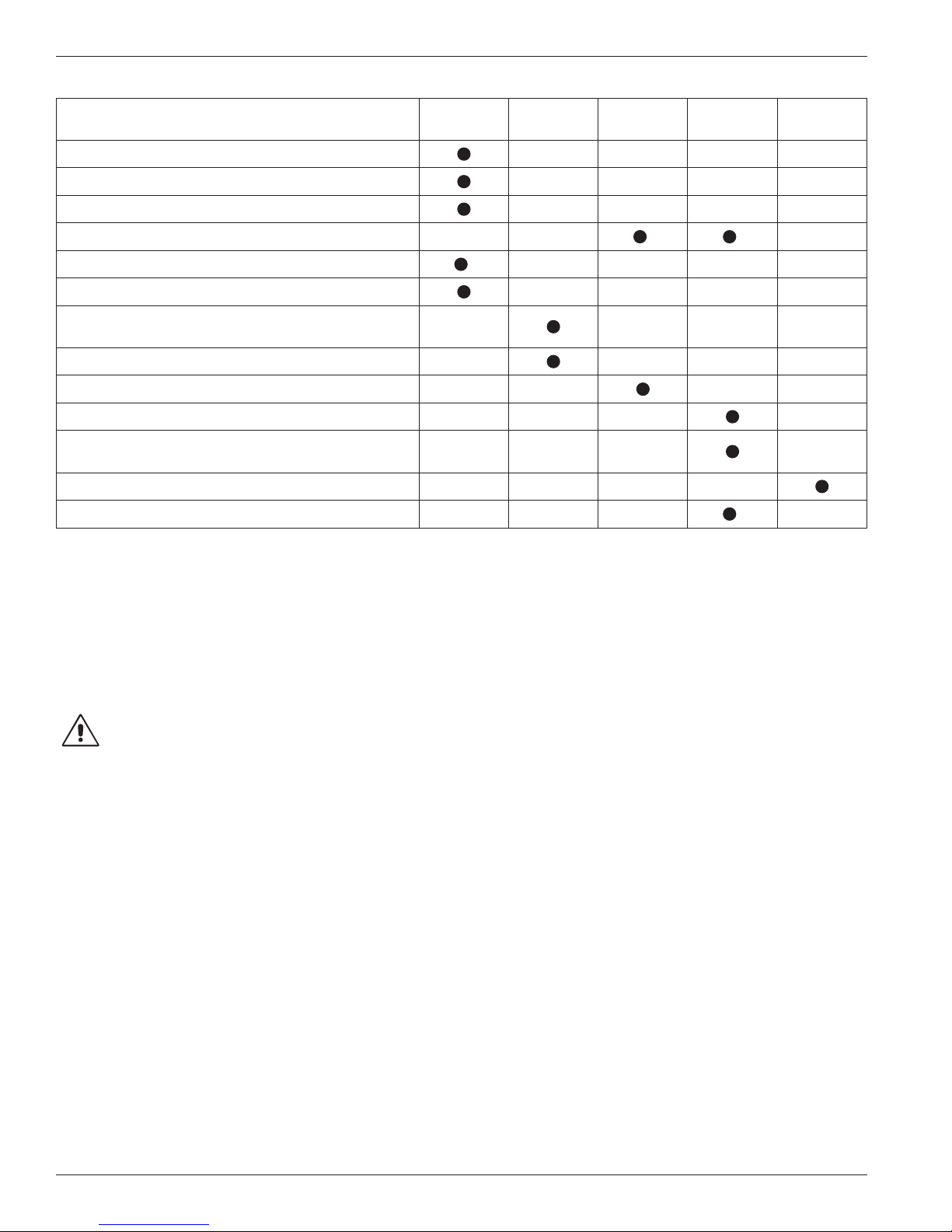

3.2 Flywheel and V-belt Alignment

Before working on the drive assembly, be sure that the

electric power is disconnected. When mounting new

belts, always make sure the driver and compressor are

close enough together to avoid forcing.

Improper belt tension and sheave alignment can cause

vibration, excessive belt wear and premature bearing

failures. Before operating your compressor, check alignment

of the V-grooves of the compressor flywheel and driver

sheave. Visual inspection often will indicate if the belts are

properly aligned, but use of a square is the best method.

The flywheel is mounted on the shaft via a split, tapered

Figure 3.2A: Flywheel installation.

Tighten the belts until they are taut, but not extremely

tight. Consult your V-belt supplier for specific tension

recommendations. Belts that are too tight may cause

premature bearing failure. Refer to figure 3.2B.

Figure 3.2B: Belt tension.

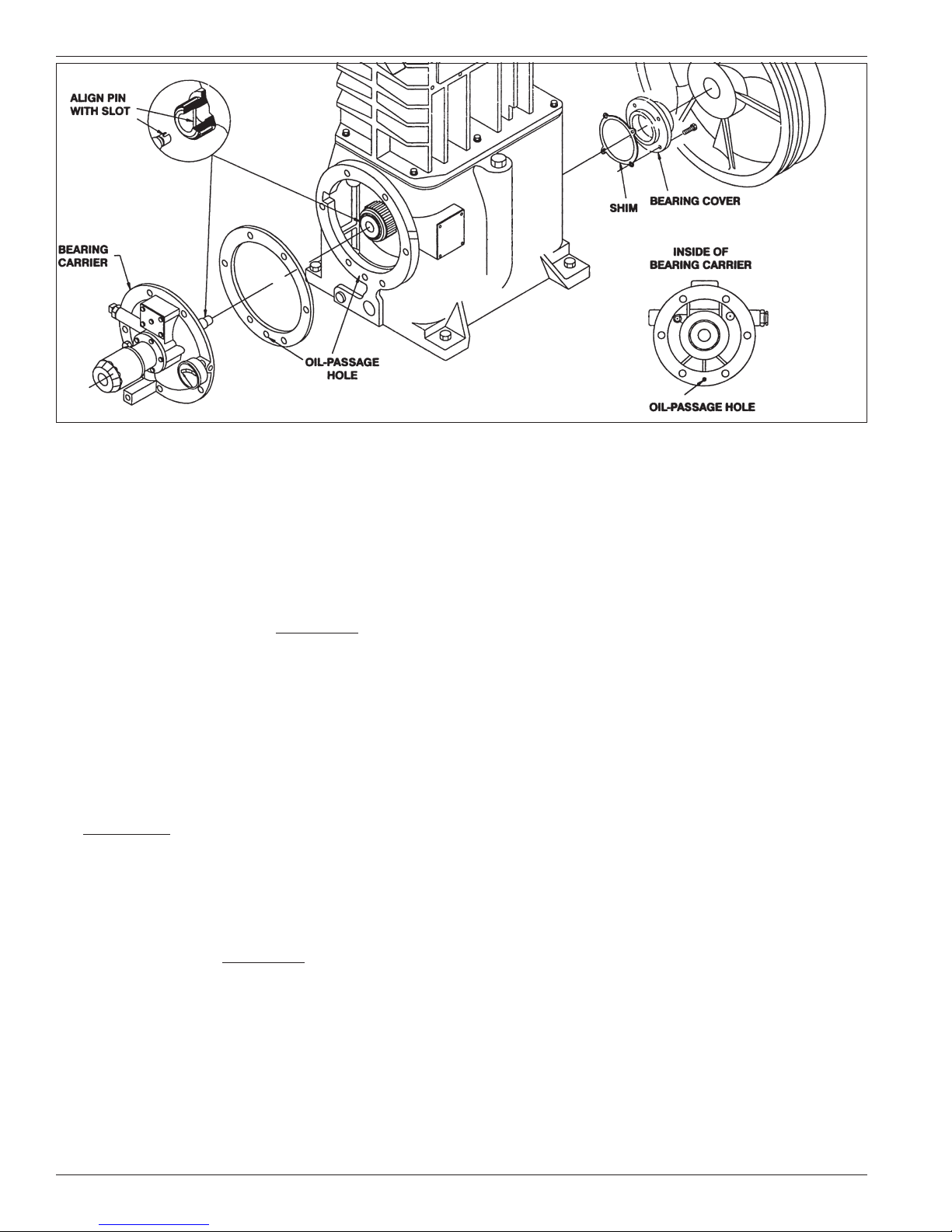

3.3 Crankcase Oil Pressure

Adjustment

Corken compressor models 291 through 891 are

equipped with an automatically reversible gear type oil

pump (if your compressor is the splash lubricated Model

16

Page 17

91, proceed to section 3.4). It is essential to ensure

the pumping system is primed and the oil pressure is

properly adjusted in order to assure smooth operation.

5. Check all mounting shims, cylinder and piping

supports to ensure that no undue twisting forces exist

on the compressor.

Before starting your compressor, check and fill the

crankcase with the proper quantity of lubricating oil.

(Refer to section 2.6)

When the compressor is first started, observe the

crankcase oil pressure gauge. If the gauge fails to

indicate pressure within 30 seconds, stop the machine

and loosen the oil filter. Restart the compressor and run

until oil comes out and tighten the filter.

The oil pressure should be about 20 psi (1.4 bars)

minimum for normal service. If the discharge pressure

is above 200 psi (13.8 bars) the oil pressure must be

maintained at a minimum of 25 psi (1.7 bars). A springloaded relief valve mounted on the bearing housing

opposite the flywheel regulates the oil pressure. As

shown in figure 3.3A, turn the adjusting screw clockwise

to increase the oil pressure and counterclockwise to

lower it. Be sure to loosen the adjusting screw locknut

before trying to turn the screw and tighten it after making

any adjustment.

6. Verify that strainer elements are in place and clean.

7. Verify that cylinder bore and valve areas are clean.

8. Check V-belt tension and alignment. Check drive

alignment on direct drive units.

9. Rotate unit by hand. Check flywheel for wobble or play.

10. Check crankcase oil level.

11. Drain all liquid traps, separators, etc.

12. Verify proper electrical supply to motor and panel.

13. Check that all gauges are at zero level reading.

14. Test piping system for leaks.

15. Purge unit of air before pressurizing with gas.

16. Carefully check for any loose connections or bolts.

17. Remove all stray objects (rags, tools, etc.) from

vicinity of unit.

-

Oil Pressure

Adjusting

Screw

Lock Nut

Oil Pump Cover

+

Oil Level Bayonet

Oil Pressure Gauge

Figure 3.3A: Oil pressure adjustment.

3.4 Startup Check List

Please verify all of the items on this list before

starting your compressor! Failure to do so may result

in a costly (or dangerous) mistake.

Before Starting the Compressor

1. Become familiar with the function of all piping

associated with the compressor. Know each line’s use!

2. Verify that actual operating conditions will match the

anticipated conditions.

18. Verify that all valves are open or closed as required.

19. Double-check all of the above.

After Starting Compressor

1. Verify and note proper oil pressure. Shut down and

correct any problem immediately.

2. Observe noise and vibration levels. Correct

immediately if excessive.

3. Verify proper compressor speed.

4. Examine entire system for gas, oil or water levels.

5. Note rotation direction.

6. Check start-up voltage drop, running amperage and

voltage at motor junction box (not at the starter).

7. Test each shutdown device and record set points.

8. Test all relief valves.

9. Check and record all temperatures, pressures and

volumes after 30 minutes and 1 hour.

3. Ensure that line pressures are within cylinder

pressure ratings.

4. Clean out all piping.

10. After 1 hour running time, tighten all head bolts, valve

holddown bolts, and baseplate bolts. See Appendix B

for torque values.

17

Page 18

Chapter 4—Routine Maintenance Chart

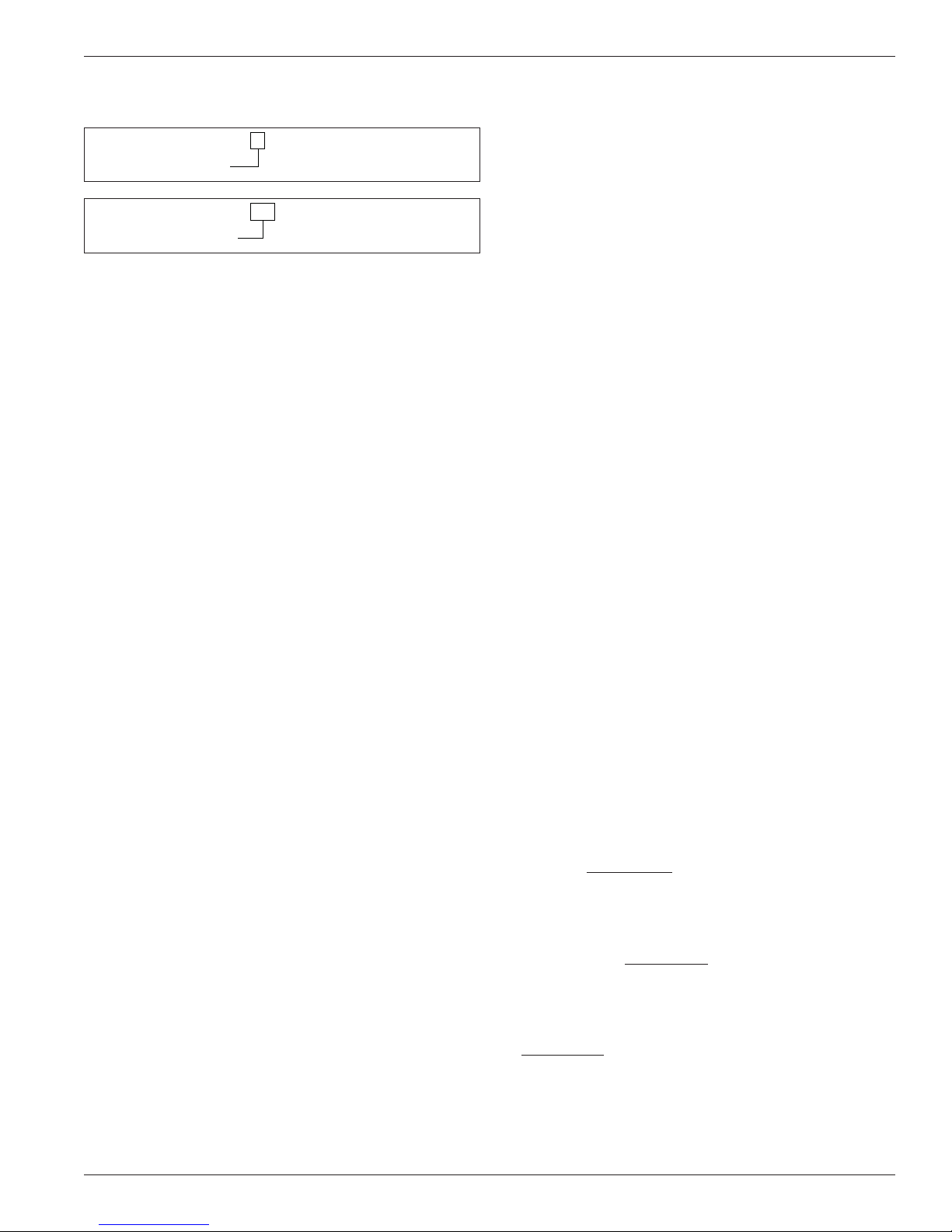

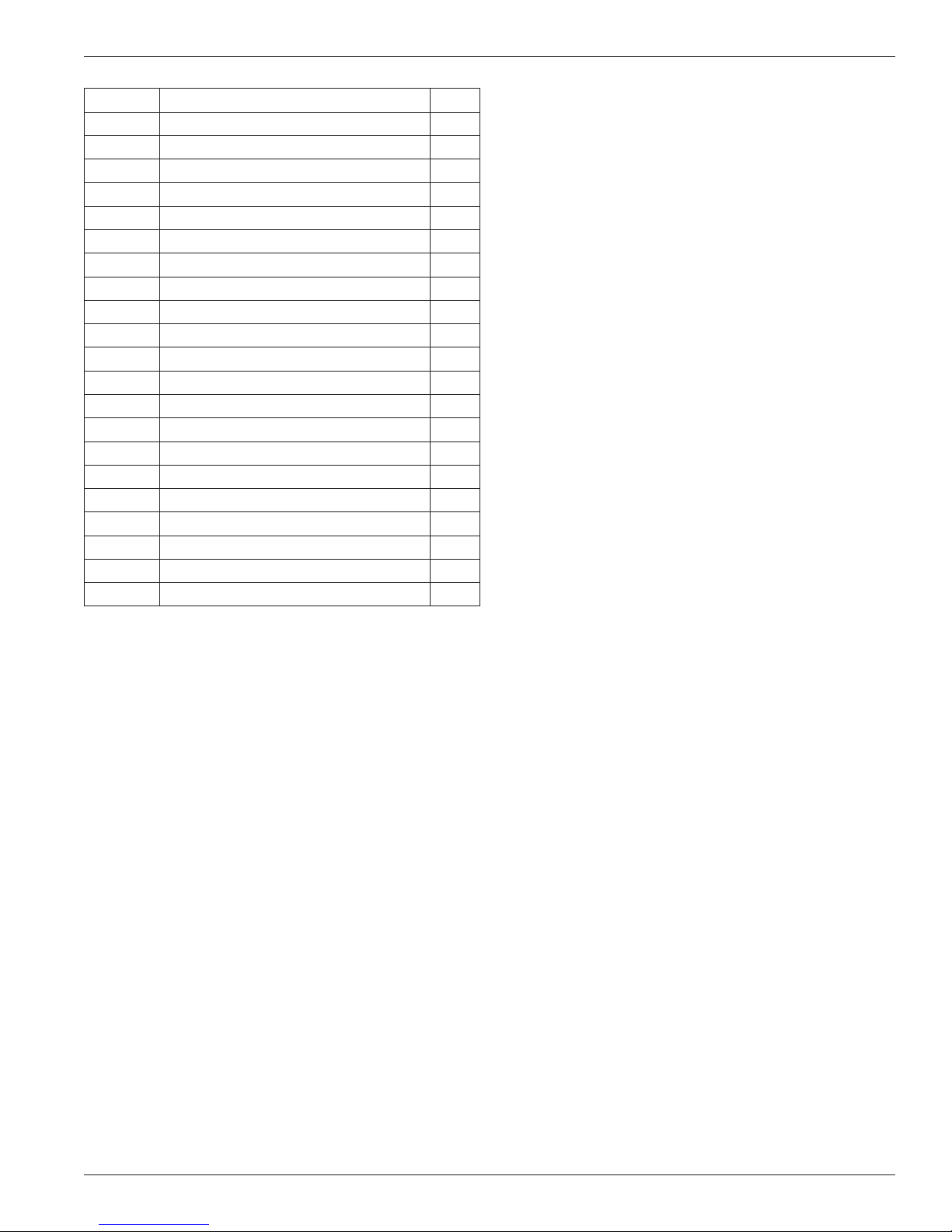

Item to Check Daily Weekly Monthly

Six

Months

Yearly

Crankcase oil pressure

Compressor discharge pressure

Overall visual check

Crankcase oil level

Drain liquid from accumulation points

2

1 1

Drain distance pieces

Clean cooling surfaces on compressor and

intercooler (if any)

Lubricator supply tank level (if any)

Check belts for correct tension

Inspect valve assemblies

Lubricate motor bearings in accordance with

manufacturers’ recommendations

Inspect motor starter contact points

Inspect piston rings

1

Change oil every 2,200 hours of op eration or every 6 months, whichever occurs fir st. If the oil is unusually dirty, change it as often as needed to maintain a

clean oil condition. Change replaceme nt filter 4225 with every oil change.

2

Liquid traps should be drained prior to startup.

3

Piston ring life varie s greatly, depending on application, gas, and operating pre ssures. Consult factory for additional re commendations for your specific

application.

1

3

Chapter 5—Routine Service and

Repair Procedures

CAUTION: Always relieve pressure in the unit

before attempting any repairs. After repair,

the unit should be pressure tested and checked for

leaks at all joints and sealing surfaces.

If routine maintenance is performed as listed in chapter

4, repair service on your Corken gas compressor is

generally limited to replacing valves or piston rings.

When it comes time to order replacement parts, be sure

to consult the part details appendix in the back of this

Installation, Operation & Maintenance (IOM) manual for a

complete list of part numbers and descriptions.

5.1 Valves

Test the compressor valves by closing the inlet piping

valves while the unit is running; however, do not allow

the machine to operate in this way very long. If the

inlet pressure gauge does not drop to zero almost

immediately, one or more of the valves is probably either

damaged or dirty. It is possible, of course, that the

pressure gauge itself is faulty.

Inspect valves for breakage, corrosion, debris, and

scratches on the valve disc. In many cases, valves may

simply be cleaned and reinstalled. If the valves show

any damage, they should be repaired or replaced.

Replacement is usually preferable, although individual

parts are available. If valve discs are replaced, seats

should also be lapped until they are perfectly smooth.

A maximum of .005 inch can be removed during the

lapping process. If more than .005 inch must be removed

to achieve a smooth surface, the valve should be

discarded. If discs are replaced without relapping the

seat, rapid wear and leakage may occur.

Each suction and/or discharge valve assembly is easily

removed as a unit for inspection. If any part of the valve

assembly is broken, the valve assembly should be replaced.

See valve assembly parts details in the appendices for a

complete list of part numbers and descriptions.

If a valve is leaking due to dirt or any other foreign

material that keeps the valve plate and seat from sealing,

the valve may be cleaned and reused. New gaskets and/

or O-rings should be used to assure a good seal.

The valve holddown assemblies and valve assemblies on

the following pages show the various specifications used

on models 91, 291, 491, 691 and 891 compressors. Since

more than one suction valve arrangement is available for

each model of compressor, it is necessary to know your

complete model number so you can identify the valve

18

Page 19

type specification number (see examples listed below).

In most cases for liquid transfer and/or vapor recovery

compressors, the valve type will be spec 3 or 3P.

Model number 491AM 3 FBANSNN

Valve type = spec 3

Model number 691AM 3P FBANSNN

Valve type = spec 3P

Valve Inspection and/or Replacement for Models

91 and 291 Compressors

Before removing and inspecting the valves, begin by

depressurizing and purging (if necessary) the unit.

Disassembly

1. Unscrew the valve cap and remove O-ring.

2. With the special wrench supplied with your compressor

at time of purchase, remove the holddown screw.

Valve Holddown Assemblies: Depending on your model

of compressor, the valve holddown assembly has all or a

combination of the following:

1. Valve cap / cover

2. Valve cap O-ring

3. Holddown screw

4. Valve cover plate

5. Valve cover plate bolts

6. Valve cover plate O-ring

7. Valve spacer (model 491 only)

8. Valve cage

9. Valve assembly

10. Va lve ga sket

Valve Assemblies: Depending on your valve specification,

the valve assembly has all or a combination of the following:

1. G asket

2. Adjusting screw

3. Relief ball spring

4. Relief ball

5. Valve seat

6. Valve plate

7. Spacers

8. Washer

9. Valve spring

10. Suction valve post

3. After the holddown screw has been removed, the

valve assembly and valve gasket can be lifted out.

4. Carefully inspect for dirt or broken/damaged parts.

5. Inspect valves for breakage, corrosion, debris and

scratches on the valve disc or plate. In many cases,

valves may simply be cleaned and reinstalled. If the

valves show any damage, they should be repaired or

replaced. Replacement is usually preferable although

repair parts are available. If valve plates are replaced,

seats should also be lapped until they are perfectly

smooth. If more than .005 in. must be removed

to achieve a smooth surface, the valve should be

discarded. If plates are replaced without relapping the

seat, rapid wear and leakage may occur.

Assembly

1. Insert metal valve gasket into the suction and/or

discharge opening of the head. The metal valve

gasket should always be replaced when the valve

is reinstalled.

2. Insert cleaned or new valve assembly. Make sure the

suction and discharge valves are in the proper suction

and discharge opening in the head. NOTE: The spec

3 suction valves for a model 91 and 291 compressor

are pre-set so no adjustments to liquid relief pressure

are necessary.

3. Replace the holddown screw and tighten to the value

listed in Appendix B to ensure the valve gasket is

properly seated. NOTE: Gaskets and O-rings are not

normally reusable.

4. Replace the O-ring and valve cap and tighten to the

value listed in Appendix B. O-rings sealing the valve

caps should be replaced.

11. Valve bumper

12. Valve gasket

See valve holddown and valve assembly part details

in the appendix for a complete list of part numbers

and descriptions.

5. Check bolts and valve holddown screws after first

week of operation. Re-torque if necessary. See

Appendix B for torque values.

Valve Inspection and/or Replacement for Models

491, 691 and 891 Compressors

Before removing and inspecting the valves, begin by

depressurizing and purging (if necessary) the unit.

19

Page 20

Disassembly

1. Unscrew the valve cap/nut and remove the O-ring

from the coverplate.

adjusting screw to set the liquid relief pressure. To set

the liquid relief pressure, the screw bottom must be

tightened to 1.8" from the top of the valve body.

2. Remove the valve cover plate, O-ring and holddown

screw by removing each of the four bolts. NOTE:

Since the holddown screw has been secured with an

impact wrench at the factory, you will probably need

to wait to remove the holddown screw until after the

cover plate has been removed. At this point in time,

the holddown screw can be easily removed from the

cover plate. The holddown screw on model 691 and

891 is most easily removed with the special wrench

supplied with your compressor at time of purchasing.

3. After the cover plate and O-ring have been removed,

the valve spacer (model 491 only), valve cage, valve

assembly and valve gasket can be lifted out.

4. Inspect valves for breakage, corrosion, debris,

and scratches on the valve plate. In many cases,

valves may simply be cleaned and reinstalled. If the

valves show any damage, they should be repaired or

replaced. Replacement is usually preferable although

repair parts are available. If valve plates are replaced,

seats should also be lapped until they are perfectly

smooth. If more than .005 in. must be removed

to achieve a smooth surface, the valve should be

discarded. If plates are replaced without relapping the

seat, rapid wear and leakage may occur.

Assembly

1. Insert metal valve gasket into the suction and/or

discharge opening of the head. The metal valve gasket

should always be replaced when the valve is reinstalled.

2. Insert cleaned or new valve assembly. Make sure the

suction and discharge valves are in the proper suction

and discharge opening in the head.

8. Check bolts and valve holddown screws after first

week of operation. Re-torque if necessary. See

Appendix B for torque values.

5.2 Heads

A compressor head very seldom requires replacement

if the compressor is properly maintained. The primary

cause of damage to a head is corrosion and the entry

of solid debris or liquid into the compression chamber.

Improper storage can also result in corrosion damage to

the head (for proper storage instructions see chapter 6).

Many compressor repair operations require removal of the

head. While the compressor is disassembled, special care

should be taken to avoid damage or corrosion to the head. If

the compressor is to be left open for more than a few hours,

bare metal surfaces should be coated with rust preventative.

When reassembling the compressor, make sure the bolts

are retightened as shown in Appendix B.

5.3 Piston Rings and Piston Ring

Expanders

Piston ring life will vary considerably from application to

application. Ring life will improve dramatically at lower

speeds and temperatures.

1. To replace the piston rings, depressurize the

compressor and purge if necessary.

2. Remove the head to gain access to the compressor

cylinder.

3. Insert the valve cage and valve spacer (NOTE: spacer

applies to model 491 compressor only).

4. Replace the O-ring and valve cover plate. Torque

bolts to the value listed in Appendix B. CAUTION: Be

sure the holddown screw has been removed.

5. Insert the holddown screw and tighten to the value

listed in Appendix B to ensure the valve gasket is

properly seated. NOTE: Gaskets and O-rings are not

normally reusable.

6. Replace the O-ring (or gasket) and valve cap/nut and

tighten to the value listed in Appendix B. O-rings

sealing the valve cap should be replaced if they show

signs of wear or damage. Valve caps sealed by flat

metals gaskets should be reinstalled with new gaskets.

7. NOTE: The Model 491 Spec 3 suction valve has an

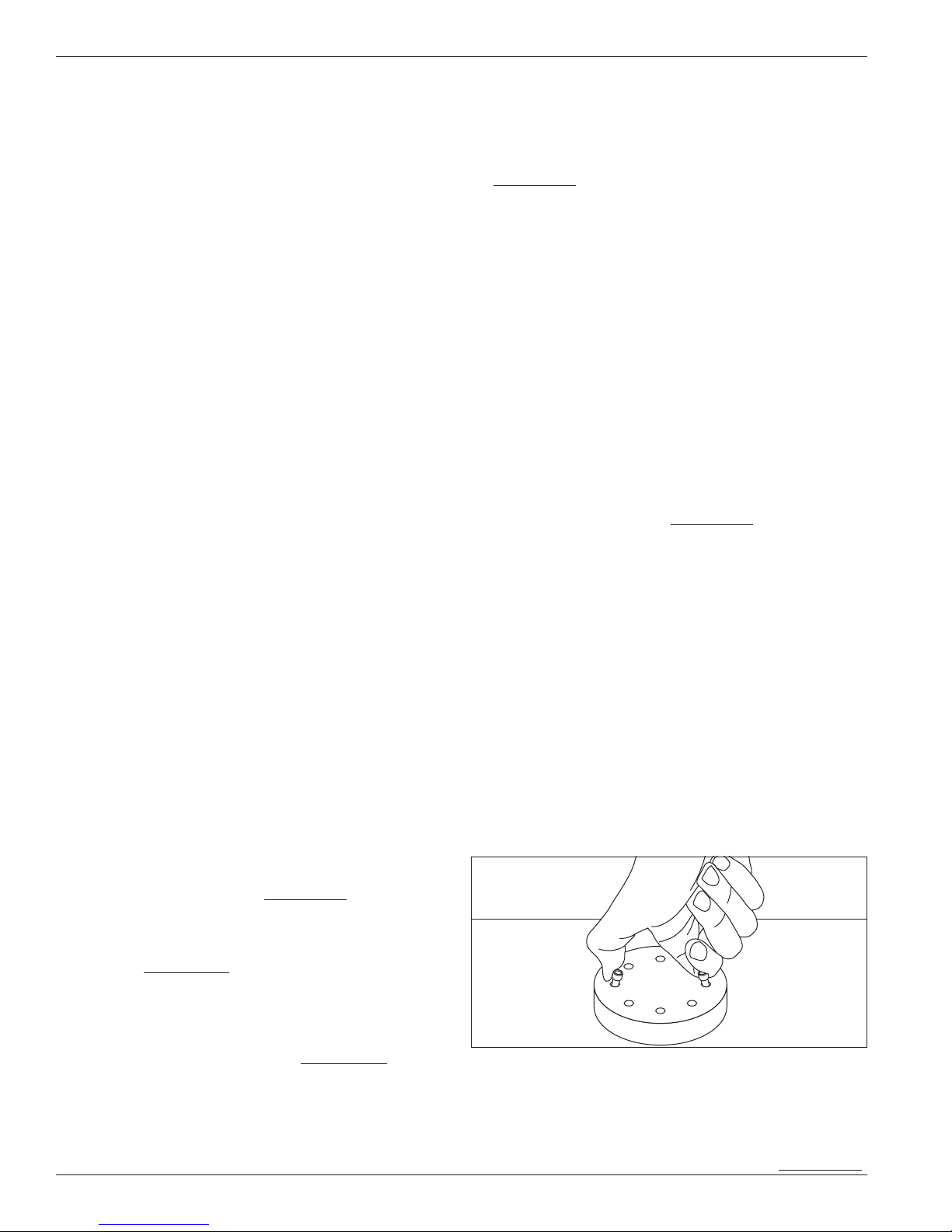

3. Loosen the piston head bolts. Remove the piston as

shown in figure 5.3A by pinching two loose bolts together.

Figure 5.3A: Piston removal

4. Piston rings and expanders may then be easily

removed and replaced. Corken recommends replacing

expanders whenever rings are replaced. To determine

if rings should be replaced, measure the radial

thickness and compare it to the chart in Appendix C.

20

Page 21

5.4 Pistons

Models 91, 291, 491, and 691

1. To replace the pistons, depressurize the compressor

and purge if necessary.

7. Reinstall the piston platform with the same thickness

of shims as before, BUT DO NOT REINSTALL THE

ROLL PIN.

8. Install the cylinder and install the piston heads with

new piston rings and expanders.

2. Remove the compressor cylinder and head (see

section 5.2).

3. Remove the piston head by loosening and removing

the socket head bolts holding the piston head to the

piston platform (see figure 5.3A).

4. Next, remove the lock pin with a pair of needle nose

pliers. The locknut may then be removed and the

piston platform lifted off the end of the piston rod.

5. Check the thrust washer and shims for damage and

replace if necessary.

6. Before installing the new piston, measure the thickness

of the existing shims. For Models 91, 291, and 491, the

shims are placed between the thrust washer and piston

platform. For model 691, the shims are placed between

the platform and piston head (see figures 5.4A and 5.4B).

“X” Piston

Clearance

Piston Locknut

Lock Pin

Piston Ring Expander

Piston

Bolt

Piston Ring

9. Now measure dimension “X” shown in the illustration.

If this measurement does not fall within the tolerances

shown in Appendix B, remove the piston, adjust the

shims as necessary and remeasure the “X” dimension.

10. When the piston is properly shimmed, tighten the lock

nut to the torque value shown in Appendix B.

11. Now install a new lock pin and lock the piston nut

in place.

12. Install the piston head and tighten the socket head

bolts in an alternating sequence.

13. Reinstall the head (see section 5.2) and follow standard

startup procedure. (Note: Some compressors may

have self-locking nuts without roll pins.)

Model 891

1. To replace the pistons, depressurize the compressor

and purge if necessary.

2. Remove the cylinder cap, head and cylinder.

3. Remove the piston cap by loosening and removing

the socket head bolts holding the piston cap to the

piston (see figure 5.3A).

Piston Head

Shims

Figure 5.4A: Piston cross section model sizes 91 through 491

Piston Head

Figure 5.4B: Piston cross section model 691

Thrust

Washer

“X” Piston

Clearance

Shims

Platform

Piston Rod

Piston Locknut

Lock Pin

Platform

Piston Rod

Piston

Piston

Piston

Cylinder

Piston Ring Expander

Bolt

Cylinder

Piston Ring

4. Next, remove the lock nut and lift the piston off the

end of the piston rod.

5. Check the thrust washer and shims for damage and

replace if necessary.

6. Before installing the new piston, measure the thickness

of the existing shims.

7. Replace the cylinder.

8. Install the piston with the same thickness of shims as

before, and with new piston rings and expanders.

9. Now remove a lower valve and measure dimension

“Y” at the bottom of the piston shown in Appendix

E—Piston Assembly Details. If this measurement

does not fall within the tolerances listed in the

piston assembly details (Appendix E), remove the

piston, adjust the shims as necessary and measure

the “Y” dimension.

21

Page 22

(Y) (Y)

Piston

Piston

Piston bottom dead center

(X) (X)

15. Replace the previously removed valves. Best results

will be obtained if new valve gaskets are used.

16. Follow standard startup procedures.

5.5 Piston Rod Packing

Adjustment

Piston rod packing should be adjusted or replaced

whenever leakage becomes noticeable. Typically, it is a

good idea to replace piston rod packing and piston rings

at the same time. For instructions on replacing the piston

rod packing, see section 5.6.

NOTE: Packing that cannot be adjusted should be

replaced.

Piston

Piston

Piston top dead center

10. When the piston is properly shimmed, tighten the lock

nut as shown in Appendix B.

11. Replace the piston cap with the same thickness of

shims as before.

12. Reinstall the piston cap and cylinder head.

13. Now remove an upper valve and measure dimension

“X” at the top of the piston shown in Appendix E—

Piston Assembly Details. If this measurement does

not fall within the tolerances in Appendix E, remove

the cylinder head and piston cap and adjust the shims

as necessary. Repeat the steps and measure the “X”

dimension again.

14. When the piston cap is properly shimmed, tighten the

socket head bolts in an alternating sequence. Torque

socket head bolt to the values listed in Appendix B.

Figure 5.5A: Packing adjusting nuts.

5.6 Cylinder and Packing

Replacement

Cylinders very seldom require replacement if the

compressor is properly maintained. The primary

cause of damage to cylinders is corrosion and the

entry of solid debris or liquid into the compression

chamber. Improper storage can also result in corrosion

damage to cylinder (for proper storage instructions

see chapter 6).

If the cylinder does become damaged or corroded, use

a hone to smooth the cylinder bore and then polish it

to the value shown in Appendix B. If more than .005

in. must be removed to smooth the bore, replace the

cylinder. Cylinder liners and oversized rings are not

available. OVERBORING THE CYLINDER WILL RESULT

IN GREATLY REDUCED RING LIFE.

Many compressor repair operations require removal of

the cylinder. While the compressor is disassembled,

special care should be taken to avoid damage or

corrosion to the cylinder. If the compressor is to be left

open for more than a few hours, bare metal surfaces

should be coated with rust preventative.

When reassembling the compressor, make sure the bolts

are retightened to the valves shown in Appendix B.

22

Page 23

Packing Replacement Instructions

Caution: Bleed all pressure from the compressor and

piping, and purge (if necessary), before starting to install

new piston rod packing. After repair, the unit should be

pressure tested and checked for leaks at all joints and

gasket surfaces. When the compressor is being used

with toxic, dangerous, flammable or explosive gases,

this pressure and leak testing should be done with air or

a dry, inert gas such as nitrogen.

For simplicity, heads, pistons, and inspection plates are

not shown. For specific construction details and actual

part numbers, consult the appendix in the back of this

IOM manual. Use instructions below that apply to the

MODEL and SERIAL NUMBER of your compressor. Be

careful to arrange packing sets in the proper order.

Cleanliness:

Prior to installation, inspect all parts for cleanliness

and visible defects. There should be absolutely no

scratches, dings, porosity, or foreign materials on

bearing surfaces, sealing surfaces, and packing

cartridge inner and outer diameters.

Workmanship:

Your Corken compressor is a precision piece of equipment

with very close tolerances. Treat it as such. Never beat

on it to get parts in or out.

Model 91 Compressor

(Refer to Appendix E for packing assembly details)

Disassembly of Packing

1. Depressurize and open the compressor.

5. Install locking device (part number 1192) into adjusting

screw and cut, leaving 1/8" exposed. Tighten adjusting

screw until plastic locking device engages the first

thread in the crosshead guide.

6. Oil piston rod and install the packing installation cone

(part number 4005) over the threaded end of the

piston rod.

7. Carefully slip the crosshead guide over the piston rod;

otherwise, you may damage the lips of the packing rings.

8. Remove packing installation cone.

9. Install the crosshead guide O-ring, cylinder, piston

and head.

Model 291 Compressor (serial number SS55685

and later)

Model 491 Compressor (serial number XC30633

and later)

(Refer to Appendix E for packing assembly details)

Disassembly of Packing

1. Depressurize and open the compressor.

2. Remove head, pistons and cylinder.

3. Remove cartridge holddown screw with special

wrench supplied with the compressor and packing

box cartridge.

4. Loosen adjusting screw and remove retainer ring,

washers, packing spring and old packing from

packing box cartridge.

2. Remove head, piston, cylinder, inspection plate and

crosshead guide.

3. Loosen adjusting screw and remove retainer ring,

washers, packing spring and old packing from

crosshead guide.

Assembly of Packing

1. Clean, then lightly oil, packing area inside the

crosshead guide.

2. Slightly thread in the adjusting screw into the

crosshead guide.

3. Install packing rings including male and female