Page 1

BS Controller for AC SERVO PRESS

BS Controller for AC SERVO PRESS Instruction Manual

Introduction

Request

Instruction Manual Ver1 .08

BS-M3A-1B

Thank you very much for purchasing our Servo press.

This manual describes the hardware scheme, installation procedures, connections,

running, operations, communication, status display and daily inspections.

Make sure to thoroughly understand the contents and use the product properly.

We have taken all possible measures to ensure the contents of this instruction

manual, however, please contact us if you have any questions or find any errors.

The product names, etc. are generally registered trademarks of various companies.

* To secure safety and quality, never fail to refer to this manual.

- 1 -

Page 2

BS Controller for AC SERVO PRESS

1. For safe use ................................................................................................................. 7

2. Before use .................................................................................................................. 11

3. Specifications .............................................................................................................13

4. Construction ..............................................................................................................16

5. Installation ................................................................................................................18

Instruction Manual Ver1 .08

BS-M3A-1B

Table of contents

1.1. Regarding symbols .................................................................................................. 7

1.2. Observe the following for safety ............................................................................. 7

1.3. Caution on attachment and use. .......................................................................... 8

1.4. Make sure to observe for sequencer circuit ........................................................... 9

1.5. EMC directive .......................................................................................................... 9

1.6. Others ....................................................................................................................... 9

1.7. The relation with the Mitsubishi Electric servo system ..................................... 10

2.1. Characteristics of Servo press ............................................................................... 11

2.1.1. Possible to record program execution result ................................................. 11

2.1.2. Programmable action possible ....................................................................... 11

2.1.3. Display of load and stroke during program execution and Graph display . 11

2.2. The suiting tool ....................................................................................................... 11

2.3. Accompanying items .............................................................................................. 11

2.4. About the model name and the version ............................................................... 12

2.4.1. Anybus option ................................................................................................. 12

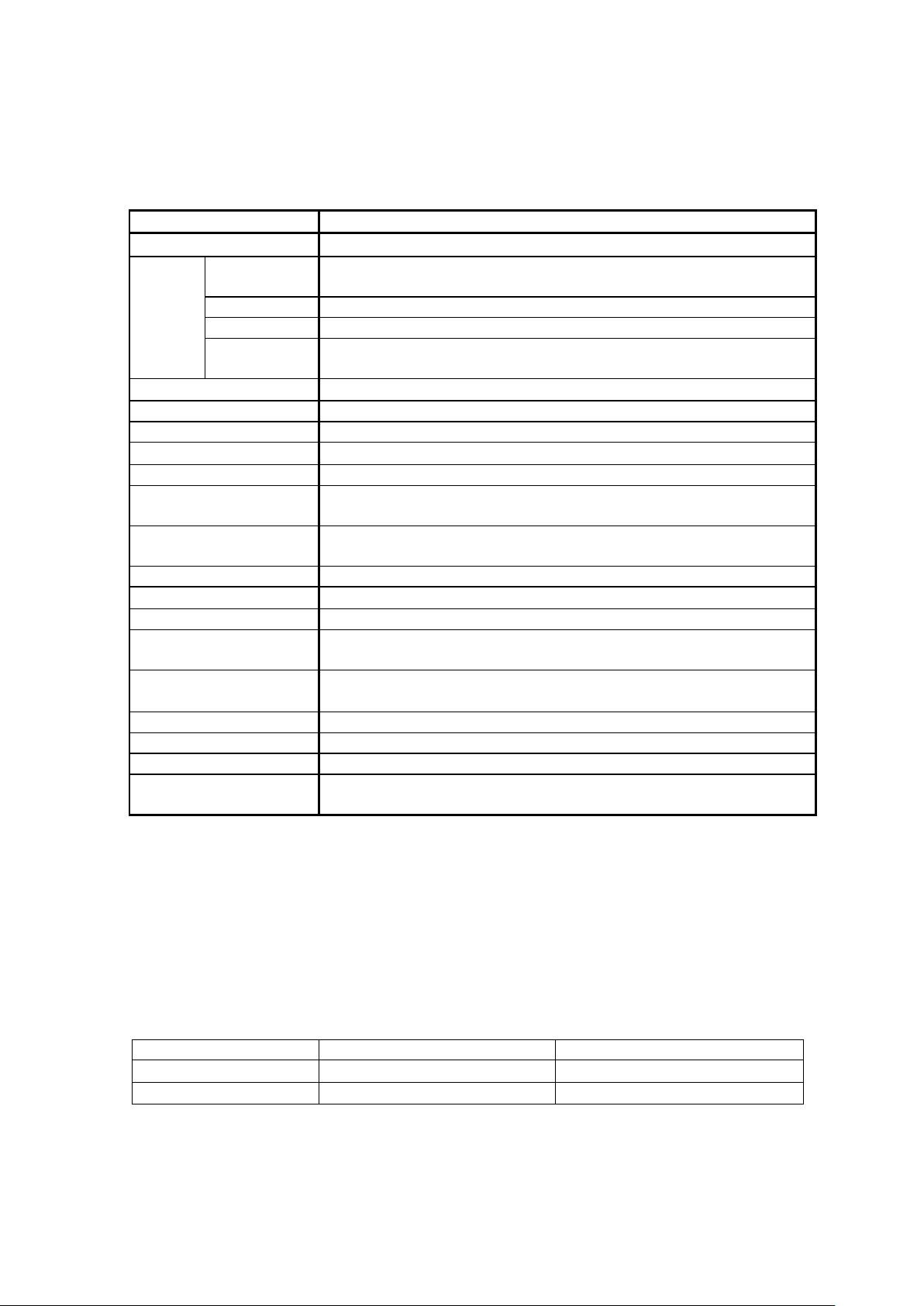

3.1. Specifications of BS-M3A-1B ................................................................................ 13

3.2. Specifications fo brake .......................................................................................... 13

3.3. Common specification of MR-J3A ........................................................................ 14

3.4. Specification peculiar to the tool type .................................................................. 14

3.4.1. BS100 series ................................................................................................... 14

3.4.2. BS200 series ................................................................................................... 15

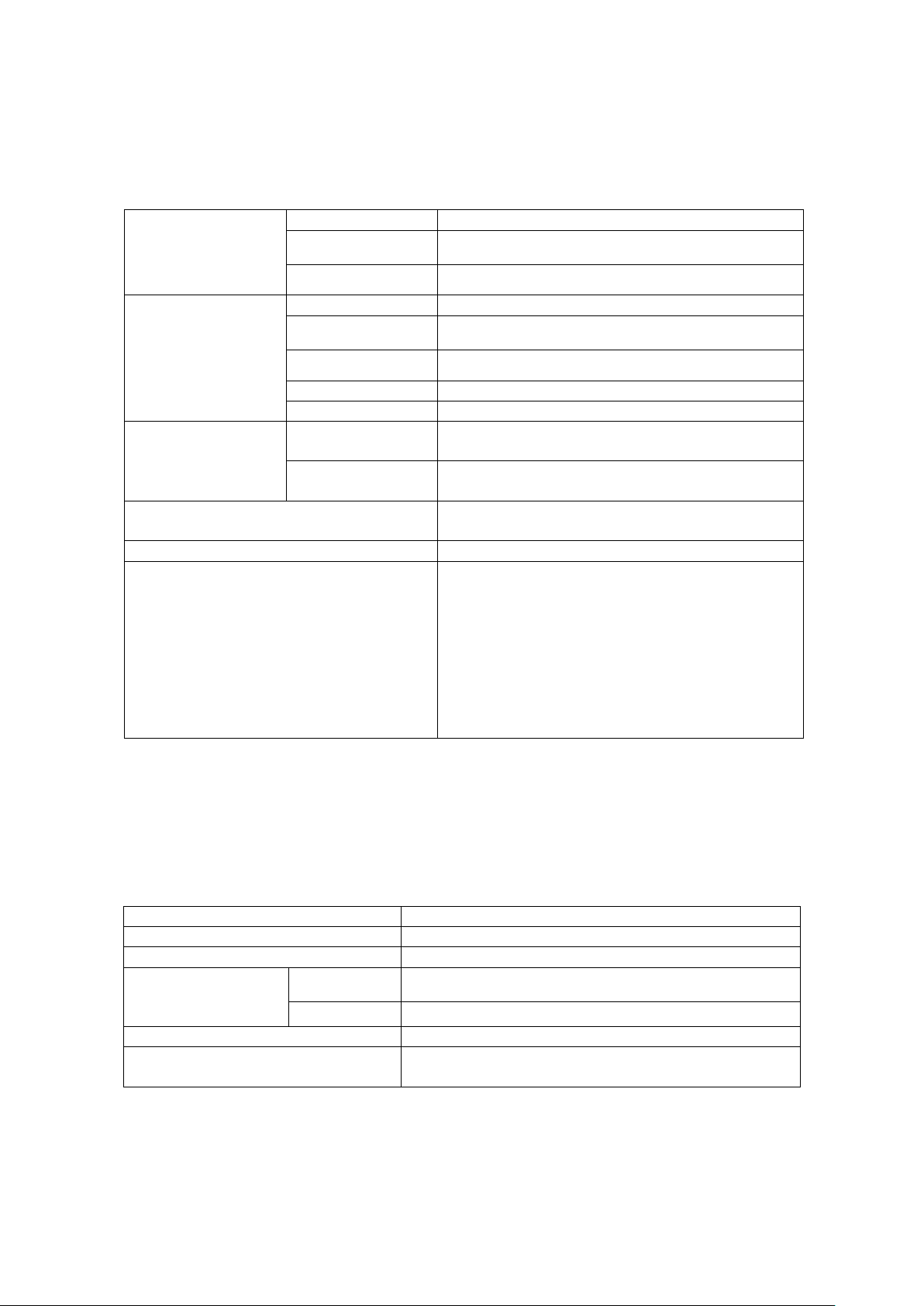

4.1. Name of each part of the controller ...................................................................... 16

4.2. Outline .................................................................................................................... 17

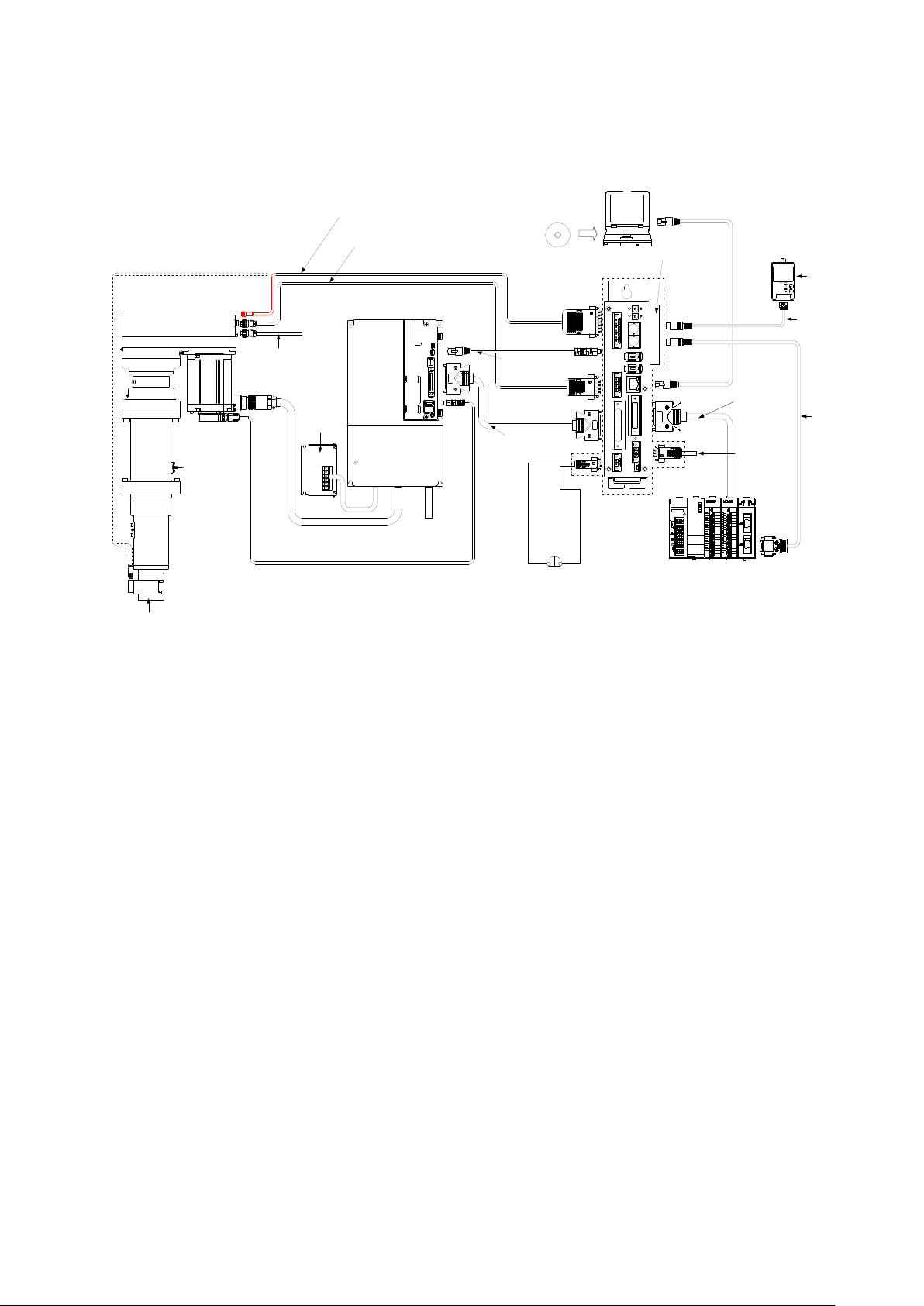

4.3. Connection figure (include options) ..................................................................... 18

5.1. Procedures for installing to control panel ............................................................ 20

5.1.1. Designing conditions for control box ............................................................. 20

5.1.2. Cautions when installing BS ......................................................................... 20

- 2 -

Page 3

BS Controller for AC SERVO PRESS

6. Installing lines ...........................................................................................................21

7. Timing Chart .............................................................................................................31

8. Concept of stroke .......................................................................................................36

Instruction Manual Ver1 .08

BS-M3A-1B

5.1.3. The interval with MR-J3A ............................................................................. 20

5.1.4. Noise Filter of MR-J3A .................................................................................. 20

6.1. Load cell i/f(CN31) ................................................................................................. 21

6.2. Origin sensor i/f(CN32) ......................................................................................... 21

6.3. MR-J3A parallel i/f(CN33) .................................................................................... 21

6.4. Emergency stop(CN34) ......................................................................................... 21

6.5. RS-232C(CN4) ....................................................................................................... 22

6.6. RS-232C(CN5) ....................................................................................................... 22

6.7. RS-485(CN6,7) ....................................................................................................... 22

6.8. Ethernet(CN8) ....................................................................................................... 23

6.9. Parallel I/O (CN9) .................................................................................................. 23

6.9.1. Bit assignment ............................................................................................... 24

6.9.2. PIO connector pin assignment ...................................................................... 27

6.9.3. Wiring by the side of input ............................................................................ 27

6.9.4. Wiring by the side of output .......................................................................... 28

6.10. Control power supply (CN10) ........................................................................... 28

6.11. Backup battery(CN11) ...................................................................................... 28

6.12. Anybus .................................................................................................................... 28

6.13. Brake ...................................................................................................................... 29

6.14. Motor cable ............................................................................................................. 30

6.15. Encoder Cable ........................................................................................................ 30

7.1. Power supply injection .......................................................................................... 31

7.2. Alarm reset ............................................................................................................ 31

7.3. Origin ..................................................................................................................... 31

7.4. JOG ......................................................................................................................... 32

7.5. Program execution ................................................................................................. 32

7.6. Program execution using Post Judge ................................................................... 33

7.7. Writing of a product name and a serial number ................................................. 34

7.8. Post Judge .............................................................................................................. 35

8.1. Semi closed loop ..................................................................................................... 36

8.2. Direction ................................................................................................................. 36

- 3 -

Page 4

BS Controller for AC SERVO PRESS

9. Connection with Personal Computer ........................................................................38

10. Starting ..................................................................................................................44

Instruction Manual Ver1 .08

BS-M3A-1B

8.3. System home position ........................................................................................... 36

8.4. User home position ................................................................................................ 36

8.5. System stroke limit ............................................................................................... 36

8.6. User stroke limit .................................................................................................... 36

8.7. If the stroke limit is exceeded ............................................................................... 37

8.8. A motion of the ram at the time of servo off ........................................................ 37

9.1. Spindle number setup ........................................................................................... 38

9.2. IP address setup of BS controller ......................................................................... 38

9.3. IP address setup of a personal computer ............................................................. 38

9.4. LAN cable ............................................................................................................... 39

9.5. Communicative check ........................................................................................... 39

9.5.1. Setup of operational authoority .................................................................... 39

9.5.2. Setup of receive filter ..................................................................................... 40

9.5.3. Collection setup .............................................................................................. 40

9.5.4. Check of status ............................................................................................... 40

9.6. Starting of two Configurators ............................................................................... 41

9.7. Use of two or more network interface cards ........................................................ 42

9.8. Arbitrary IP address setup ................................................................................... 42

9.8.1. Notes ............................................................................................................... 42

9.8.2. The communication method with an IP address unknown controller ....... 43

10.1. Starting procedure of BS controller ..................................................................... 44

10.1.1. Attachment to equipment .............................................................................. 44

10.1.2. Wiring .............................................................................................................. 44

10.1.3. Control power supply injection ..................................................................... 44

10.1.4. Attachment of a backup battery ................................................................... 44

10.1.5. Parameter setup of MR-J3A .......................................................................... 44

10.1.6. Parameter setup of BS ................................................................................... 44

10.1.7. Re-starting of a power supply ....................................................................... 44

10.1.8. Check of a brake ............................................................................................. 44

10.1.9. Check of an emergency stop .......................................................................... 44

10.1.10. Origin .......................................................................................................... 44

10.1.11. Build a program. ......................................................................................... 44

10.1.12. Execution of a program .............................................................................. 45

- 4 -

Page 5

BS Controller for AC SERVO PRESS

11. Troubleshooting .....................................................................................................53

12. Regeneration ..........................................................................................................61

13. Absolute encoder system ........................................................................................62

14. Load-Sensor-less System .......................................................................................63

15. Tool Type Discernment ..........................................................................................64

16. Stole .......................................................................................................................65

17. Others ....................................................................................................................66

18. Article of Consumption ..........................................................................................67

Instruction Manual Ver1 .08

BS-M3A-1B

10.2. Parameter setup of MR-J3A ................................................................................. 45

10.3. Parameter setup of BS controller ......................................................................... 49

10.4. Re-injection of a control power supply ................................................................. 50

10.5. Check of the brake ................................................................................................. 50

10.6. Check of emergency stop ....................................................................................... 51

10.7. Origin ..................................................................................................................... 51

10.8. Program creation ................................................................................................... 51

10.9. Execution of a program ......................................................................................... 52

11.1. The state display by LED ..................................................................................... 53

11.2. Alarm code table .................................................................................................... 54

12.1. Lowering regeneration frequency ........................................................................ 61

12.2. Regeneration option .............................................................................................. 61

13.1. Setup....................................................................................................................... 62

13.1.1. Setup to BS controller .................................................................................... 62

13.1.2. Setup to MR-J3A ............................................................................................ 62

13.1.3. Wearing of a backup battery ......................................................................... 62

13.2. The alarm release method .................................................................................... 62

17.1. The options of the servo press .............................................................................. 66

18.1. Battery ................................................................................................................... 67

18.1.1. The detection method ..................................................................................... 67

18.1.2. The exchange method .................................................................................... 67

18.1.3. Management ................................................................................................... 67

18.1.4. Clock setup ..................................................................................................... 67

- 5 -

Page 6

BS Controller for AC SERVO PRESS

19. Maintenance of Tool ...............................................................................................68

20. Cautions on abandonment .....................................................................................68

Instruction Manual Ver1 .08

BS-M3A-1B

18.2. Parts having service lives of MR-J3A .................................................................. 67

- 6 -

Page 7

BS Controller for AC SERVO PRESS

1. For safe use

1.1. Regarding symbols

1.2.

Observe the following for safety

This symbol assumes the possibility that accidental

death or serious injury may occur immediately to the

user, if the symbol is neglected and the product is

incorrectly handled.

The power source is as high as 200V. Look out for electric shock.

This symbol assumes that there is a potential for

personal death or injury if this expression is ignored

and this product is mishandled.

In a case where the product is used in an application in which an accident resulting in

as installing a fail-safe device.

Do not use around combustible gas. If disregarded, it may lead to an explosion.

In a case of handling cables and connectors, etc., cut off the power temporarily without fail.

If disregarded, it may lead to an electric shock.

Do not remove the cover, disassemble, repair or modify the product. If disregarded, it may

lead to an electric shock.

Make sure to connect the protection conductor terminal to ground.

Electric shock might be caused.

Do not touch the power supply terminal in this equipment within five seconds after the

power is turned off. It could cause the electric shock.

Do not forcibly twist, pull or scratch the power cord or cord of the AC plug.

DANGER

WARNING

Instruction Manual Ver1 .08

BS-M3A-1B

Symbols are used to provide warnings in this instruction manual and for indication for

proper product use and to prevent danger to the user or other people and damage to

property from occurring. Understand the indication meanings before reading this

manual.

death or injury or a serious expansion of damage is predictable, take safety measures such

- 7 -

Page 8

BS Controller for AC SERVO PRESS

This symbol assumes that there is a potential for

personal death or injury if this expression is ignored

and this product is mishandled.

Please use this product under the environment of overvoltage category II specified in IEC

60664-1.

Please use this product under the environment of Pollution Degree II specified in IEC

60664-1.

For the operation, stop, and emergency stop shall be done in the final machinery into which

this equipment is incorporated.

This product will surely be in a servo off state, when it is in an alarm state. However,

battery alarm is excepted.

Set up the emergency stop and interlock circuit with the external circuit.

This allows to prevent expansion of damage.

Use the input voltage, frequency and output voltage, and current within the standard. If

disregarded, it may lead to an accident or electric shock.

Do not use the product at over the specified ambient temperature. If disregarded, it may

lead to fire or electric shock.

Use in an environment without condensation due to water or moisture. If disregarded, it

may lead to an electric shock.

When output cannot be obtained, or any other abnormality is found during operation, stop

the product or our company’s sales office without fail.

1.3.

Caution on attachment and use.

This symbol assumes that there is a potential for

personal death or injury if this expression is ignored

and this product is mishandled.

Installation, connection, driving and operation, check and failure diagnosis shall be done by

a qualified technician.

Do not move, install, connect and check this equipment while the power is on. Please make

sure the power is turned off for conducting these works.

For installation requirements of this equipment, protection against electric shock is class

sure this equipment is grounded when installed. (PE should be marked at the protective

earthing terminal.)

This equipment shall be stored in a dustproof and drip-proof controlled box. (IP54 class) If

proof is not strong enough, dielectric strength shall

be decreased, and the potential of dielectric breakdown shall be increased.

The cross-sectional area of the protective bonding conductor shall be the same size as the

input power wire for this equipment.

Do not tighten the Servo press control cable excessively with binding band. Malfunction

might be caused.

The electric shock protection from the power supply terminal block of this equipment to

final machinery shall be provided in the final machinery.

For 24 VDC power supply, use SELV power supply which comply with IEC standard.

A breaker that comply with IEC Standard shall be installed in the final machinery into

which this equipment is incorporated,for the short-circuit protection of this equipment.

The methods of the ground fault protection of this equipment are as follows:

b) For the TN grounded system: Use an over current breaker generally. (The fault loop

CAUTION

WARNING

Instruction Manual Ver1 .08

BS-M3A-1B

use immediately. It may lead to electric shock. Contact the distributor where you purchased

Ⅰ,and equipment mobility is a stationery equipment for indoor installation. Please make

the performance of dustproof and drip-

a) For the TT grounded system: Use an earth leakage breaker (Type A or B shall be used)

- 8 -

Page 9

BS Controller for AC SERVO PRESS

impedance in the final equipment shall satisfy the overcurrent characteristics of the

This symbol assumes that there is a potential for

personal death or injury if this expression is ignored

and this product is mishandled.

When attaching the CPS body, allow a space of 25 mm or more for the right and left

directions and 80 mm or more for up and down directions for cooling.

Do not apply more load on the Servo press tool than allowed.

The life might be considerably shortened.

For connection to the protective earthing terminal, one wire should be provided for each

terminal.

The insulation’s color of the protective earthing conductor shall be green-and-yellow.

Design the sequencer circuit under consideration of safety measure such as emergency stop.

1.4.

Make sure to observe for sequencer circuit

This symbol assumes that there is a potential for

personal death or injury if this expression is ignored

and this product is mishandled.

Insert or pull off the connector only after turning off the power.

Otherwise, controller might fail.

Improper understanding of stroke might cause serious accident. Please understand the

Section 8 in this manual to handle.

1.5.

EMC directive

1.6.

Others

WARNING

CAUTION

Instruction Manual Ver1 .08

BS-M3A-1B

breaker so that the breaker shall be interrupted within 0.4s or less when earth fault is

occurred.)

Safety measure

The EMC directive applies not to the servo units alone but to servo-incorporated

machines and equipment.

This requires the EMC filters to be used with the servo-incorporated machines and

equipment to comply with the EMC directive.

Please ask a concrete solution to our office.

This equipment is classified into the partly completed equipment according to

Machinery Directive (2006/42/EC). Therefore, after this equipment is incorporated into

the final machinery, conformity with Machinery Directive (2006/42/EC) shall be needed

in the final machinery.

- 9 -

Page 10

BS Controller for AC SERVO PRESS

1.7. The relation with the Mitsubishi Electric servo system

Instruction Manual Ver1 .08

BS-M3A-1B

CE marking based on Machinery Directive is not done to the partly completed

machinery. Therefore, for the case that circulates by the partly completed machinery

until this equipment is incorporater into the final machinery in Europe. It is necessary

for the declaration of incorporation and the manual of this equipment to be appended to

this equipment

BS controller works as a higher rank controller of Mitsubishi Electric servo system

MR-J3A.

Please refer to the manual of the Mitsubishi Electric issue about the details of a

MR-J3A system.

- 10 -

Page 11

BS Controller for AC SERVO PRESS

2. Before use

2.1. Characteristics of Servo press

2.1.1. Possible to record program execution result

2.1.2. Programmable action possible

2.1.3. Display of load and stroke during program execution and Graph display

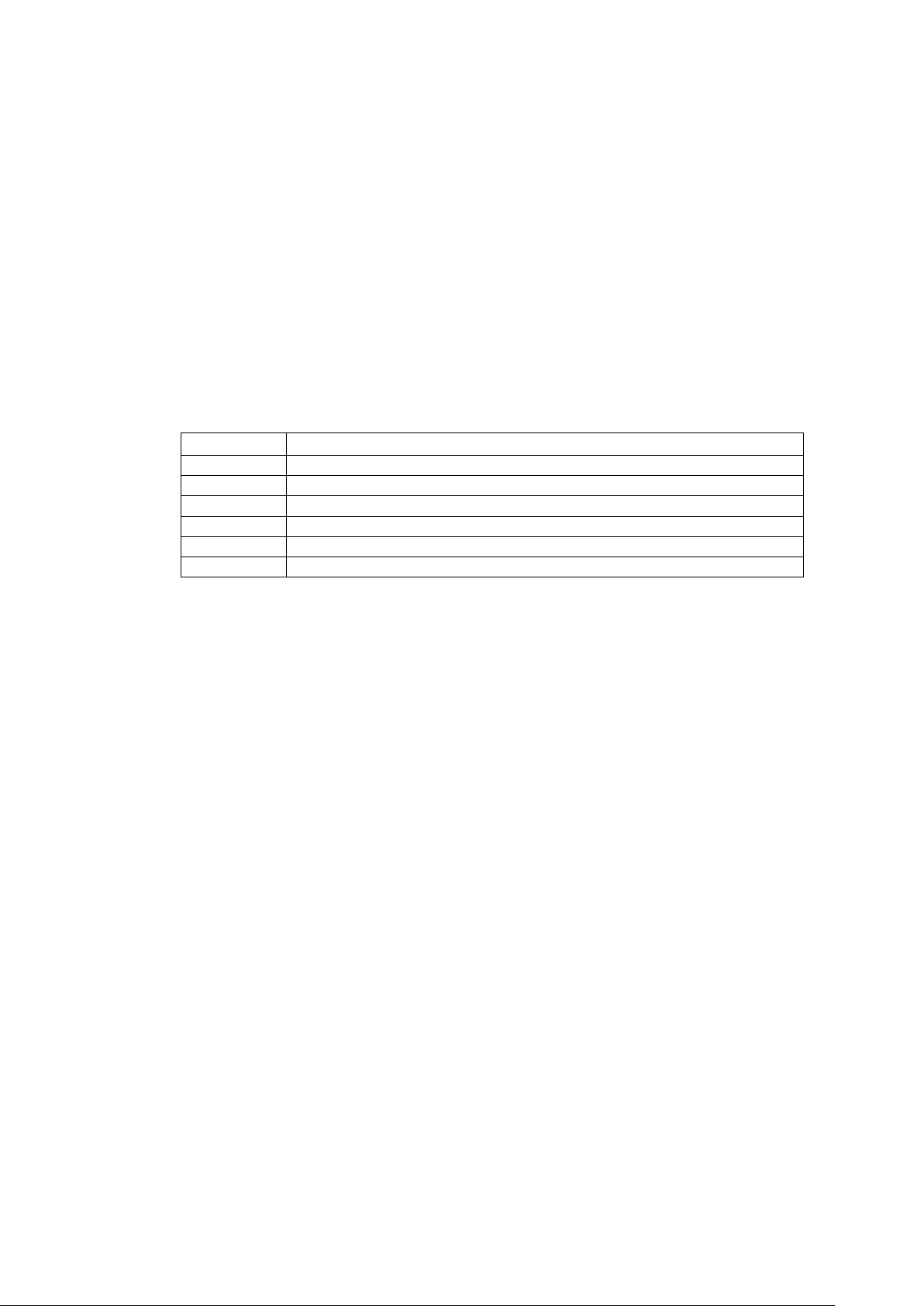

2.2. The suiting tool

Tool type

Adaptation load

(kN)

Servo amplifier

Motor

BS100 series

100

MR-J3-500A

HC-RP503(B)K

BS200 series

200

MR-J3-700A

HF-SP702(B)K

2.3. Accompanying items

Instruction Manual Ver1 .08

BS-M3A-1B

The Servo press provides new production controls, press methods and other actions

by programmable operations, controls and monitoring of the load and stroke

amount. The characteristics are given below.

Up to 2700 pieces of data of press results can be recorded inside the BS

Controller.

By using communications software, infinite data can be recorded.

Among factors such as speed, load stroke, time and communications with

external I/O, the programmable factor is what primarily concerns the

customer.

(Refer to the BS Configurator Instruction Manual)

By using special communications software, the values of load and stroke can

be monitored. The electric current can also be monitored by selecting the

details screen. A graph can be displayed after actions and detailed

information can be obtained.

Big-sized servo press controller BS-M3A works as a higher rank controller of

Mitsubishi Electric servo amplifier MR-J3A. The combination of servo amplifier

and a motor is decided according to the adaptation load of a tool.

BS-M3A-1B main body

A set of plug for CN34 (EMERGENCY)

Maker:Phoenix contact Model:MC1.5/2-STF-3.81

A set of plug for CN10 (DC power supply)

- 11 -

Page 12

BS Controller for AC SERVO PRESS

2.4.

About the model name and the version

2.4.1. Anybus option

Code

None

No Anybus option,PIO

CC

CC-Link

DV

DeviceNet

PF

Profibus DP

EI

EtherNet/IP

PN

PROFINET I/O

Instruction Manual Ver1 .08

BS-M3A-1B

Maker:Phoenix contact Model:MC1.5/3-STF-3.81

Backup battery(CR2032WK13)

Operating manual(CD-R)

MR-J3A

The characters which follow the basic model name are explained. At

BS-M3A-1B-zz, zz expresses Anybus option.

説明

- 12 -

Page 13

BS Controller for AC SERVO PRESS

3. Specifications

3.1. Specifications of BS-M3A-1B

Items

Contents

Outline

Refer to outline diagram on the Appendix(Section 4

Environ

ment

Temperature

0~50℃

Humidity

85% or less (No condensation)

Altitude

Altitude 1000 m or lower

Installing

location

Harmful places with corrosive gas, cutting oil, metal powder, oil

etc., are not allowed.

Power for control

DC24V±10%

Power consumption [W]

6 *1

Installing procedures

Installing on back panel

Vibration proof

0.5G(10~50Hz)

Shock proof

5G

Serial communications

RS-485

115.2kbps occupied by MR-J3A

Serial communications

RS-232C

19.2~76.8kbps dedicated protocol

Ethernet

UDP/IP Fixed IP address

Load cell accuracy

1.5%@Tool rating (in a state without an overhang load)

Load sensor resolution

12Bit

Input signals

Start,Reset,P-No. Select,User in etc.

Capacity of photo coupler 24V, 4.8mA, Filter time constant 50ms

Output signals

Ready,Run,Judge,Alarm,User out etc.

Capacity of photo coupler 24V、30mA

Status indicator

LEDs(Charge,Status,Code,OK,NG,DC Power,Ethernet)

Cable length

Maximum 30 m

Executing program

31 points

Executing result storing

function

For 2700 times

3.2. Specifications fo brake

Tool type

Power consumption

Maintenance force [kN]

Instruction Manual Ver1 .08

BS-M3A-1B

)

±

*1 It is only BS-M3A-1B. MR-J3A is not included.

A tool can be equipped with the brake for position maintenance as an option.

The brake is released by electric current at DC24V after 0.2 second from

turning on it. Control of a brake is not performed by BS controller. Please

control by PLC side.

BS100 24V/7W 2.5

BS200 24V/19.4W 23.4

- 13 -

Page 14

BS Controller for AC SERVO PRESS

3.3. Common specification of MR-J3A

Power supply

Voltage/frequency

3-phase 200 to 230VAC, 50/60Hz

Permissible voltage

fluctuation

AC170~253V

Permissible frequency

fluctuation

Within 5%

Control circuit

Voltage, frequency

1-phase 200 to 230VAC, 50/60Hz

Permissible voltage

fluctuation

AC170~253V

Permissible frequency

fluctuation

Within 5%

Input

45W

Inrush current

30A (Attenuated to approx. 0A in 3ms)

Interface power

Voltage,

frequency

DC24V±10%

Power supply

capacity

300mA

Control System

Sine-wave PWM control, current control

system

Dynamic brake

Built-in

Protective functions

Over current shut-off, regenerative over

protection

MR-J3- A

3.4. Specification peculiar to the tool type

3.4.1. BS100 series

Servo motor

HC-RP503(B)K

Servo amplifier

MR-J3-500A

Power supply capacity

7.5kVA

Servo

heat[W]

At rated

torque

195W

With servo off

25W

Area required for heat dissipation

3.9m2

Power supply Inrush Currents

(A0-p)

44A (Attenuated to approx. 20A in 20ms)

Instruction Manual Ver1 .08

BS-M3A-1B

Specification common to MR-J3-500A and MR-J3-700A is indicated. *1

power supply

supply

voltage shut-off, overload shut-off (electronic

thermal relay), servo motor overheat

protection, encoder error protection,

regenerative error protection,

under voltage, instantaneous power failure

protection, over speed protection, excessive

error

*1 It is posting from the data of Mitsubishi Electric. Please refer to the

SERVO AMPLIFIER INSTRUCTION MANUAL for details.

amplifier-generated

- 14 -

Page 15

BS Controller for AC SERVO PRESS

3.4.2. BS200 series

Servo motor

HF-SP702(B)K

Servo amplifier

MR-J3-700A

Power supply capacity

10.0kVA

Servo

heat[W]

At rated

torque

300W

With servo off

25W

Area required for heat dissipation

6.0m2

Power supply Inrush Currents

(A0-p)

88A (Attenuated to approx. 20A in 20ms)

Instruction Manual Ver1 .08

BS-M3A-1B

amplifier-generated

- 15 -

Page 16

BS Controller for AC SERVO PRESS

4. Construction

4.1. Name of each part of the controller

OK/NG LED

ID SW

CN6,7 RS-485

CN9 Ethernet

CN10 PI/O

CN10 Control power

CN34

CN33 MR-J3A Parallel

CN32 Origin sensor

CN31 Load cell

Status LED

Instruction Manual Ver1 .08

BS-M3A-1B

Code LED

Extended bus(Anybus)

CN4 RS-232C CH1

CN5 RS-232C CH2

Emergency stop

Control

Power LED

CN11 Backup battery

- 16 -

Page 17

BS Controller for AC SERVO PRESS

4.2. Outline

Instruction Manual Ver1 .08

BS-M3A-1B

- 17 -

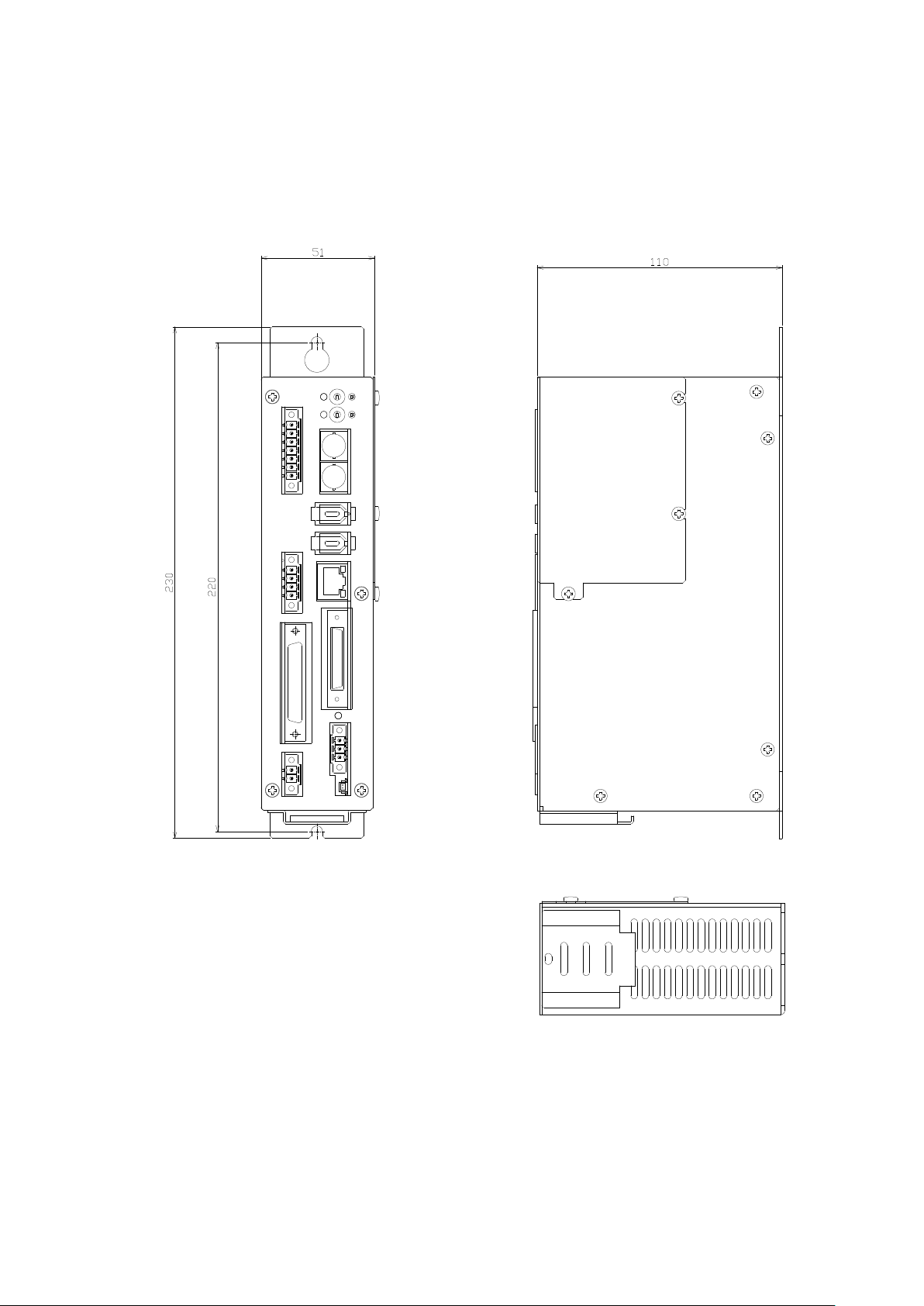

Page 18

BS Controller for AC SERVO PRESS

AC Power *10

AC200V 3φ

PLC

DC Power *10

DC24V

Emergency Stop *11

Servo Amp.

MR-J3-500A

BS Controller *3

BS-M3A-1B

BS100 Tool

Sequence cable

CCKSQ-3M *4

Parallel I/F cable *2

CBSPIF-**M

Serial Com. cable *2

CBS422-**M

Origin Sensor cable *1

CBSGS-**M

Load Cell cable *1

CBSLC-**M

Encoder cable *1 *8

MR-J3ENSCBL**M-L

Motor cable *1 *7

CBSMT10-**M

Brake cable

CBSBK-**M *1 *11

LAN cable(cross) *5

CCKLANC-5M

RS-232C cable

CCK232-3M *9

FA Network

Board

Application software

Regen. Reg. *12

MR-RB31

MR-RB51

PC

LED Display

LDS-24

LED Display cable

CCKDSP-**M *6

4.3. Connection figure (include options)

4.3.1. BS100

Instruction Manual Ver1 .08

BS-M3A-1B

Fig.4-3-1 BS100 Series

*1 The length of a cable is selectable from 5,10 and 20m. The junction cable is not

prepared.

*2 The length of a cable is selectable from 0.5 and 1m.

*3 The connectors in a dashed line are included to the controller set.

*4 This is unnecessary when using a FA Network Board.

*5 The type of LAN cable may not be crossing when using a HUB.

*6 The length of a LED Display cable is selectable from 5 and 10m.

*7 The model name of movable cable is CBSMT10R-**M.

*8 The model name of movable cable is MR-J3ENSCBL**M-H.

*9 Detail of the model name is different for each PLC type.

*10 A customer prepares cables.

*11 A customer controls this line.

*12 A external regeneration resister is an option.

- 18 -

Page 19

BS Controller for AC SERVO PRESS

AC Power *

11

AC200V

3φ

PLC

DC Power *11

DC24V

Emergency Stop *12

Servo Amp.

MR-J3-700A

BS Controller *3

BS

-

M3

A-

1

B

BS200 Tool

Sequence cable

CCKSQ-3M *4

Parallel I

/F cable

*

2

CBSPIF-

**M

Serial Com. cable *2

CBS422-**M

Origin Sensor cable *1

CBSGS-

**M

Load Cell cable *

1

*14

CBSLC-**M

Encoder cable *1 *8

MR

-J3

ENSCBL**M-L

Motor cable *1 *7

CBSMT

10-**

M

Brake cable

CBSBK

-

**M

*1

*

12

LAN cable(cross) *5

CCKLANC-5M

RS-

232

C cable

CCK232

-

3M

*10

FA Network

Board

Application

Software

Regen.Reg. *13

MR-RB31

MR-RB51

PC

LED Display

LDS-24

LED Display cable

CCKDSP-**M *6

Load Cell *9

4.3.2. BS200

Instruction Manual Ver1 .08

BS-M3A-1B

Fig.4-3-2 BS200 Series

*1 The length of a cable is selectable from 5,10 and 20m. The junction cable is not

prepared.

*2 The length of a cable is selectable from 0.5 and 1m.

*3 The connectors in a dashed line are included to the controller set.

*4 This is unnecessary when using a FA Network Board.

*5 The type of LAN cable may not be crossing when using a HUB.

*6 The length of a LED Display cable is selectable from 5 and 10m.

*7 The model name of movable cable is CBSMT20R-**M.

*8 The model name of movable cable is MR-J3ENSCBL**M-H.

*9 The load cell is an option.

*10 Detail of the model name is different for each PLC type.

*11 A customer prepares cables.

*12 A customer controls this line.

*13 A external regeneration resister is an option.

*14 A model without a load cell needs a load cell cable to recognize a tool type.

- 19 -

Page 20

BS Controller for AC SERVO PRESS

5. Installation

5.1. Procedures for installing to control panel

5.1.1. Designing conditions for control box

5.1.2. Cautions when installing BS

5.1.3. The interval with MR-J3A

5.1.4. Noise Filter of MR-J3A

Instruction Manual Ver1 .08

BS-M3A-1B

Please be advised that the control box meets the general safety specifications.

Take the following into consideration.

1. The control box to house the BS should be a dustproof and drip-proof

structure.

2. Temperature in the control box should be from 0 to 50°C.

Heat generating amount of the BS depends on the operating status of

the Servo press. Install a fan, heat exchanger and heat radiation fin

according to the heat generating amount in the control panel.

3. Make sure to apply sealing to the cable outlet and window portion.

4. Consider mounting of the BS so that maintenance such as inspection and

removal is easily carried out.

When installing the main body of the BS, secure space of more than 25 mm (for

cooling) on both sides and more than 80 mm (for removal) above and under the

main body. Moreover, space 100mm or more is required for a front side because

of connectors.

Please make BS controller and MR-J3A adjoin. A connection cable should give

50cm or less as a standard.

Please be sure to insert a line noise filter in AC power supply of MR-J3A.

- 20 -

Page 21

BS Controller for AC SERVO PRESS

6. Installing lines

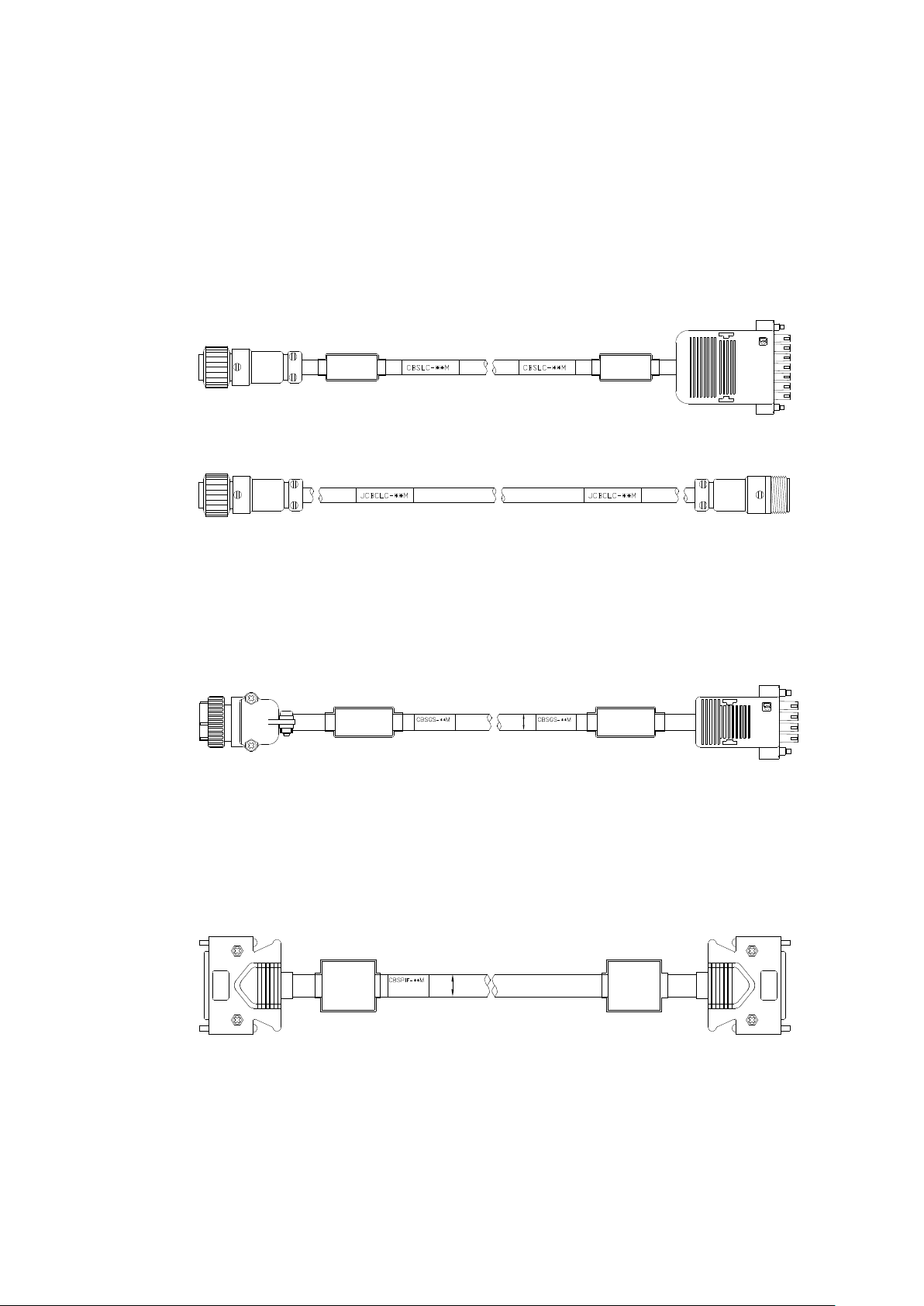

6.1. Load cell i/f(CN31)

6.2. Origin sensor i/f(CN32)

6.3. MR-J3A parallel i/f(CN33)

6.4. Emergency stop(CN34)

Instruction Manual Ver1 .08

BS-M3A-1B

It is used for the communication with strain gauge amplifier. The signal level

is an equivalent for RS-422. There is no necessity for connection in the system

without a load cell.

Cable type:CBSLC-**M(Basic Cable)

Cable type:JCBSLC-**M(Joint Cable)

An origin sensor is connected. Although, as for this system, absolute encoder

specification is also prepared, all tools are equipped with the origin sensor for

the initial position setup.

Cable type:CBSGS-**M

It connects with CN1 of MR-J3A. The position detection pulse of a motor and

the position instruction pulse to MR-J3A are contained. In order to avoid the

influence of a noise, short wiring is recommended as much as possible.

Cable type:CBSPIF-**M

An emergency stop SW is connected. The logic is normally closed. If it is made

opened, an emergency stop will be output to MR-J3A.

- 21 -

Page 22

BS Controller for AC SERVO PRESS

6.5. RS-232C(CN4)

Pin

number

Signal

name

Contents

1

Rxd

2

Txd

3

RTS

4

CTS

5

S-GND

Signal GND

6

7

P-

Power GND

8

24V

Power

6.6. RS-232C(CN5)

Pin

number

Signal

name

Contents

1

Rxd

2

Txd

3

4

5

S-GND

Signal GND

6

7

P-

Power GND

8

24V

Power

6.7. RS-485(CN6,7)

MI-232C**M

Instruction Manual Ver1 .08

BS-M3A-1B

It is a general-purpose serial communication port. Since DC24V power supply

is assigned, it is dangerous if it connects except an exclusive cable here. A

setup of a protocol and a baud rate is performed from CPS SP Configurator.

Controller side connector typr:HR12-10R-8SDL(HIROSE)

GND

Cable type:CCK232-**M(General)

:CCK232M-**M(Only for Mitsubishi Electric PLCs)

Usage:Connection with RS-232C unit of PLC etc.

It is a general-purpose serial communication port. Since DC24V power supply

is assigned, it is dangerous if it connects except an exclusive cable here. A

setup of a protocol and a baud rate is performed from CPS SP Configurator.

Controller side connector type:HR12-10R-8SDL(HIROSE)

GND

It connects with CN3 of MR-J3A. Although two connectors are prepared for

cascade connection, it cannot be used by 1:1. Please connect either of CNs 6

- 22 -

Page 23

BS Controller for AC SERVO PRESS

Pin

number

Signal

name

Contents

1

RD+

2 RD- 3

TD+ 4

TD- 5

S-GND

Signal GND

6

S-GND

Signal GND

6.8. Ethernet(CN8)

6.9. Parallel I/O (CN9)

CBS422-**M

CBS422-**M

Instruction Manual Ver1 .08

BS-M3A-1B

and 7.

The potential difference of GND for signals is permissible to 7V. When

communication is not stabilized, please turn on GND for signals of the pin

numbers 5 and 6 . If the metal cover of a right-hand side is removed toward BS

controller and 3 and 4 of the dip switch SW4 on the substrate are turned on

(above), GND for signals will become effective.

Cable type:

Controller side connector type:53462(Molex)

Cable type:CBS422-**M

It connects with a personal computer and exclusive application BS

Configurator performs a setup of BS controller etc. The protocol is UDP/IP.

They are 10 / 100M automatic change. It is necessary to make LAN setup of a

personal computer into a fixed IP address.

The example of a setting IP address 192:168:1:1

Subnet mask 255:255:0:0

Please use a cross cable, when you connect a personal computer and CPS

controller directly. Please use a straight cable, when you connect via a HUB.

It connects with a sequencer etc. and BS is controlled.

Cable type:CCKSQ-**M

(Refer to the wiring diagram for CPS<=>PLC connection.)

Connector:54306-3611(MOLEX)

- 23 -

One side is cut.

Page 24

BS Controller for AC SERVO PRESS

6.9.1. Bit assignment

Bit

number

Signal name

Contents

0

STOP

Program execution is interrupted, then a scram is carried

in a servo off state.

1

RESET

Alarm release and judgment output reset.

2

ORIGIN

Origin is started. Original position information

disappears by start of origin.

3

START

Program execution is started.

4

USER_SEL

User output selection.

5

JOG_SPD1/U_IN0

Bit 0 of JOG speed specification binaries/user input 0,

When JOG_ENA is ON, JOG speed is

JOG_ENA is off, it becomes the user input 0.

6

JOG_SPD2/U_IN1

Bit 1 of JOG speed specification binaries/user input 1,

are superposed.

7

JOG_ENA

JOG operation is permitted. Moreover, the output bit 3 is

changed to BAT.ALARM.

8

PNO1/JOG+

The bit 0 of the binary value which specifies an execution

JOG_ENA is ON, JOG operation is carried out in the

direction of +.

9

PNO2/JOG-

The bit 1 of the binary value which specifies an execution

. When

JOG_ENA is ON, JOG operation is carried out in the

direction of -.

10

PNO4

The bit 2 of the binary value which specifies an execution

program number.

11

PNO8

The bit 3 of the binary value which specifies an execution

program number.

12

PNO16

The bit 4 of the binary value which specifies an execution

program number.

13

SERVO_ON

Servo-on is directed to MR-J3A. In operation by PI/O,

at all.*1

14

U_IN2

User input 2.

15

U_IN3

User input 3.

Instruction Manual Ver1 .08

BS-M3A-1B

Input

out. After performing speed zero for 0.2 seconds, it will be

are superposed.

specified in four stages with the input bit 6. When

program number/+ Direction JOG are superposed. When

program number/- Direction JOG are superposed

unless it is in a servo-on state, a system does not operate

*1 On the tool operation screen and a program execution screen of BS Configurator,

SERVO_ON signal are ignored.

- 24 -

Page 25

BS Controller for AC SERVO PRESS

Bit

number

Signal name

Contents

0

ALARM(N.C)

Alarm. It is normaly closing. It turns off in the

state of alarm.

1

ALM_MR(N.C)

The alarm state of MR-J3A is shown. It is normal

closing.

2

READY

The completion of operation preparation.

3

IN_ORIGIN/BAT.ALARM

In origin mode/Battery alarm are superposed.

BAT.ALARM is chosen when JOG_ENA is ON.

4

RUN

It turns on during program execution.

5

OK

O.K. judging output. The output timing of

program.

6

NG

NG judging output.

7

IN_JOG/AREA1

Under JOG operation/Area signal1 are

ON.

8

P_ANS1/U_OUT0

The response of the bit 0 of binary value which

when USER_SEL is ON. It is the same to the bit

12.

9

P_ANS2/U_OUT1

The response of the bit 0 of binary value which

output 1 are superposed.

10

P_ANS4/U_OUT2

The response of the bit 1 of binary value which

output 2 are superposed.

11

P_ANS8/U_OUT3

The response of the bit 2 of binary value which

output 3 are superposed.

12

P_ANS16/U_OUT4

The response of the bit 3 of binary value which

output 4 are superposed.

13

U_OUT5

User output 5.

14

U_OUT6

User output 6.

15

USER_SEL_ANS

The response of USER_SEL.

16

BAT.ALARM

It is an output only for battery alarms. *1

17

ORIGIN_END

It turns on, when origin is completed. It turns off,

when origin is required. *1

18

PJ _WA IT

When using a post judgment, it turns on in the

state of waiting a judgement from a PC.

19

AREA2

Area signal 2.

20

AREA3

Area signal 3.

21

AREA4

Area signal 4.

22-31

RESERVED

Instruction Manual Ver1 .08

BS-M3A-1B

Output

y

O.K./NG is a time of executing jdg command in a

superposed. IN_JOG is chosen when JOG_ENA is

specifies an execution program number/User

output 0 are superposed. User outputs are chosen

specifies an execution program number/User

specifies an execution program number/User

specifies an execution program number/User

specifies an execution program number/User

* Above bit16 can be used only when Anybus option is chosen. It is that PI/O (CN9)

- 25 -

Page 26

BS Controller for AC SERVO PRESS

Instruction Manual Ver1 .08

BS-M3A-1B

suits from bit0 to bit15.

BS controller of version 1.02.23 or more is needed to use bit16 to bit18.

BS controller of version 1.02.31 or more is needed to use bit19 to bit21.

- 26 -

Page 27

BS Controller for AC SERVO PRESS

6.9.2. PIO connector pin assignment

PIN

No.

Bit

Color

Signal name

PIN

No.

Bit

Color

Signal name

1

I0

Gn

STOP

19

O0

LB/W

ALARM

2

I1

Br

RESET

20

O1

R/Bk

ALARM_MR

3

I2

Bl

ORIGIN

21

O2

Gn/Bk

READY

4

I3

Gy

START

22

O3

Br/Bk

IN_ORIGIN/BAT.ALA

RM

5

I4

Or

USER_SEL

23

O4

Bl/Bk

RUN

6

I5

Pr

JOG_SPD1/U_IN0

24

O5

Gy/Bk

OK 7 I6

Pn

JOG_SPD2/U_IN1

25

O6

Or/Bk

NG

8

I7

LB

JOG_ENA

26

O7

Pn/Bk

IN_JOG/AREA

9

I8 W PNO1/JOG+

27

O8

LB/Bk

P_ANS1/U_OUT0

10

I9

Gn/W

PNO2/JOG-

28

O9

W/Bk

P_ANS2/U_OUT1

11

I10

Bw/W

PNO4

29

O10

Gn/R

P_ANS4/U_OUT2

12

I11

Bl/W

PNO8

30

O11

Br/R

P_ANS8/U_OUT3

13

I12

Gy/W

PNO16/U_IN4

31

O12

Bl/R

P_ANS16/U_OUT4

14

I13

Or/W

SERVO_ON

32

O13

Gy/R

U_OUT5

15

I14

Pr/W

U_IN2

33

O14

Or/R

U_OUT6

16

I15

Pn/W

U_IN3

34

O15

Pn/R

USER_SEL_ANS

17 R

+24V

35 Bk

0V

18 R/W

+24V

36 Bk/W

0V

6.9.3. Wiring by the side of input

BS

17,18

DC24V

IN

IN

IN

Instruction Manual Ver1 .08

BS-M3A-1B

A pin number, the wiring color of PIO cable, and a signal name are shown.

The shield line of a cable is connected to the connector shell by the side of a

controller.

Connector(MOLEX:54306-3611)

Connector shell(MOLEX:54331-0361)

Cable(SUN LIGHTSX 0.2×18P)

- 27 -

Common voltage is DC24V and serves as a photo-coupler input.(Current is

about 5mA / 1 circuit.)

Page 28

BS Controller for AC SERVO PRESS

6.9.4. Wiring by the side of output

6.10. Control power supply (CN10)

6.11. Backup battery(CN11)

Please attach for a red lead to upside.

6.12. Anybus

BS

DC24V

L

L

L

OUT

OUT

OUT

17,18

35,36

Instruction Manual Ver1 .08

BS-M3A-1B

Open collector output (30mA / 1 circuit)

Control power supply 24V are connected.

The exclusive battery for SRAM backup is connected. Please connect a backup

battery in the state of control power supply ON. Although the life of a battery

is about five years, it changes a lot according to a use state and environment. If

battery voltage is less than 2.1V, BAT.ALARM (parallel output 3) turns on.

Even in such a case, inside information is held unless a control power supply is

turned off.

If the metal cover of the right side is removed toward CPS controller, the

- 28 -

Page 29

BS Controller for AC SERVO PRESS

6.13. Brake

RED(+24V)

WHITE(0V)

Instruction Manual Ver1 .08

BS-M3A-1B

connector for Anybus will appear. If it equips with Anybus card which HMS

offers, control equivalent to PI/O will be attained by networks, such as

CC-Link.

Although a tool with a brake can be chosen as an option, brake control is not

performed by BS controller. Please control a brake by the user system side. A

brake will be released if current is passed between a No. 1 pin and a No. 2 pin.

The brake is completely released in 0.2 seconds after turning on the current.

Please do not move the ram until the brake is released.

An option brake is an object for position maintenance to the last, and is not

applicable to dynamic braking.

If a jig weight added to the ram exceeds several percent of the tool maximum

thrust, the ram may fall naturally. In such a case, please use the brake for

position keeping.

MR-J3A builds in the dynamic brake. A sudden stop is possible if an emergency

stop (CN34) is opened.

Cable type:CBSBK-**M

- 29 -

Page 30

BS Controller for AC SERVO PRESS

6.14. Motor cable

6.15. Encoder Cable

Sield

Sield

Sield

Sield

Instruction Manual Ver1 .08

BS-M3A-1B

Please fully perform measure against a noise about the motor cable of MR-J3A.

Noise filters, such as a ferrite core, need to be attached.

The cables for BS100 series

Cable type:CBSMT10-**M

Cable type:CBSMT10R-**M (Cable for movable)

Cable type:CBSMT10L-**M

The cables for BS200 series

Cable type:CBSMT20-**M

Cable type:CBSMT20R-**M (Cable for movable)

Cable type:CBSMT20L-**M

Cable type:MR-J3ENSCBL**M-L

Cable type:MR-J3ENSCBL**M-H (Cable for movable)

- 30 -

Page 31

BS Controller for AC SERVO PRESS

Timing Chart

7.1. Power supply injection

7.2. Alarm reset

Alarm may not be canceled unless it outputs RESET twice.

7.3. Origin

O READY

O ALARM

I RESET

MR-J3A CTRL PW

0.5s

MR-J3A AC PW

BS CTRL PW 0.2s

O

READY

I

SERVO_ON

I ORIGIN

I STOP

I JOG_ENA

O IN_ORIGIN

/BAT.ALARM

O SERVO_ON

O ORIGIN_END

Origin is interrupted by STOP.

Orign normal end

Instruction Manual Ver1 .08

BS-M3A-1B

7.

The timing chart of fundamental operation is shown.

- 31 -

Page 32

BS Controller for AC SERVO PRESS

O READY_RUN

I START

I PRG.NO

O RUN

O ANS

O OK/NG

I RESET

7

7

55 4 4 8

8

7.4. JOG

7.5. Program execution

I SERVO_ON

I

JOG_ENA

I PNO1/JOG+

I PNO2/JOG-

I JOG_SPD1/U_IN0

I JOG_SPD2/U_IN1

O

IN_JOG/AREA

Instruction Manual Ver1 .08

BS-M3A-1B

When you turns on JOG_ENA, it is required for PNO1/JOG+, and PNO2/JOG-

to be in the state of off. It will become alarm if JOG_ENA is turned ON when

either of those signals is ON.

- 32 -

Page 33

BS Controller for AC SERVO PRESS

7.6.

Program execution using Post Judge

O READY_RUN

I START

Anybus

Setting Post Judge No.

I PRG.NO

O RUN

O PJ_WAIT

Collecting Waveform data

Judgement of PC

Ethernet

O ANS

O OK/NG

I RESET

5

4

5

4

Instruction Manual Ver1 .08

BS-M3A-1B

"Post Judge" is the function to take in waveform data to PC, to perform a

special analysis in PC, and to return judgment to BS controller. This function

can perform judgment processing which cannot be realized only by the

real-time operation within BS controller. Please refer to a BS_Configurator

handling description for details.

- 33 -

Page 34

BS Controller for AC SERVO PRESS

7.7.

Writing of a product name and a serial number

PLC

BS

PC

A product name, a serial

number, etc. are set to

each spindles via

AnyBus I/f.

Start each

spindles

The status sense to each

spindles.

A numerical and waveform

data are collected from the

ended spindles.

Data is saved.

Instruction Manual Ver1 .08

BS-M3A-1B

The flow chart in the case of recording a product name, a serial number, etc.

to numerical data using Anybus i/f is shown

- 34 -

Page 35

BS Controller for AC SERVO PRESS

7.8.

Post Judge

PLC

CPS

PC

PLC

BS

PC

A post judg

number is set up

vis AnyBus I/f.

Start each

spindles

The status sense to each

spindles.

A numerical and waveform

data are collected from the

ended spindles.

When using Post Judge,

waveform analysis is

performed according to the

specified judgment number.

A result is returned to BS.

O.K./NG is outputted

considering the

judgment from PC,

and an internal

judgment.

Instruction Manual Ver1 .08

BS-M3A-1B

"Post Judge" is the function to take in waveform data to PC, to perform special

analysis in PC, and to return a judgment to BS controller. This function can

perform judgment processing which cannot be realized only by the real-time

operation within BS controller. Please refer to a BS_Configurator handling

description for details.

- 35 -

Page 36

BS Controller for AC SERVO PRESS

8. Concept of stroke

8.1. Semi closed loop

8.2. Direction

8.3. System home position

8.4. User home position

8.5. System stroke limit

8.6. User stroke limit

Instruction Manual Ver1 .08

BS-M3A-1B

When using the Servo press, an incorrect setting of stroke will cause a

serious accident.Please be sure to understand concept of stroke well before

using the servo press. then design user programs, sequence, and system

after that.

The stroke value of a servo press is calculated from the encoder pulse of a

motor, and may not show the exact position of the ram always.

The right stroke value cannot be outputted before an origin return.

In proportion to load, a tool is distorted slightly. It is about 0.3mm at the

maximum load

When the mechanism of a timing belt or others breaks down, the actual

position and stroke value of the ram are-less correlating.

When the position of the ram has serious influence for operation of a system ,

we recommend you to form the sensor which detects the position of the ram

uniquely.

The direction where ram is extended is the direction of +.

It is used when adjusting offset of the whole system. It is set as a controller

using BS Configurator. When tools are exchanged, adjustment of an

attachment position can be easily performed by change of a system home

position.

It is the offset which can be arbitrarily set up in a user program. It specifies

using a home position table. It is set up on the basis of a system home position.

The stroke value of 32 pieces is prepared for the home position table. The

contents of a home position table can be changed by BS Configurator.

The stroke value treated in a user program starts from a user home position.

It is the maximum stroke value set to the tool table.*1 A setup can be

arbitrarily changed in the range exceeding it. The stroke value starts from an

origin sensor.

It is the stroke limit which can be described in a user program. The stroke

- 36 -

Page 37

BS Controller for AC SERVO PRESS

8.7. If the stroke limit is exceeded

8.8. A motion of the ram at the time of servo off

Instruction Manual Ver1 .08

BS-M3A-1B

value starts from a user home position.

If one of stroke limits is exceeded, a controller turns off READY and will be in

a servo off state. Please input RESET, in order to restore. If ON of READY is

checked, please move ram into a stroke limit by manual operation.

At the moment of servo-off, a ram may shift from various factors slightly. The

amount of shift is 1mm or less. In order to prevent the shift, please stop

servo-off or use the brake for position keeping.

*1 A tool table is the file various setting value about a tool is indicated to be. It

exists under the installation folder of BS Configurator. If a tool type is chosen

on a tool selection screen, the contents of a tool table will be displayed.

- 37 -

Page 38

BS Controller for AC SERVO PRESS

9. Connection with Personal Computer

9.1. Spindle number setup

The spindle number setting method

BS front

In the left figure, the spindle number

indle number in one

Please set up the number between

31.In the other setup, it becomes

an error.

9.2. IP address setup of BS controller

9.3. IP address setup of a personal computer

0

5

1

4

2

3

6

9

87

0

5

1

4

2 3

6

9

87

IDx10

IDx1

Instruction Manual Ver1 .08

BS-M3A-1B

In order to set up BS controller, exclusive application BS Configurator is

started, and it is necessary to connect with a personal computer. The procedure

is explained.

BS controller is connectable with the same communication system to 31 sets.

In this case, in order to discriminate each controller, it is necessary to set up a

spindle number.

is set as 5.

ID x 10 is 10 digits.

ID x 1 is 1 digit.

Please set up a sp

communication system not to overlap.

Duplication of a spindle number

causes a communication error.

01-

When a spindle number is changed, a spindle new number becomes effective

after a re-injection of a power supply.

The IP address of BS controller is set up like this 192:168: (master number

+14) : (spindle number).

A master number is set up by the SW1 bits 0-3 on CPU board. A master

number adds 1 to the binary value of 4 bits of SW1 low ranks. SW1 is visible if

the cover of an expansion bus is removed. A front panel side is a low rank bit.

The master number is set as 1 at the time of shipment. The controller of a

different master number is not connectable with one communication system.

The default gateway is 192.168.1.1.

In order to communicate with BS controller, it is necessary to set a fixed IP

- 38 -

address for a personal computer in the communication method of Ethernet.

Since the setting methods of a fixed IP address differ for every OS, refer to

Page 39

BS Controller for AC SERVO PRESS

9.4. LAN cable

9.5. Communicative check

9.5.1. Setup of operational authoority

Instruction Manual Ver1 .08

BS-M3A-1B

other data for them.

An example of a setting of an IP address

IP address 192.168.1.1(The default gateway of BS)

Subnet mask 255.255.0.0

Since it is not connectable with the Internet environment in almost all cases,

the personal computer set as the fixed IP address should be careful.

Please use a cross cable, when you link a BS controller and a personal

computer directly. Please use a straight cable, when you go via a hub.

If connection is completed, BS Configurator will be started and communication

will be checked. In the following explanation, the spindle number shall be set

as No. 1.

Operation authority can be set to BS Configurator. All operations are attained

by setting it as "All ". If setup-operation authority is chosen with a pull down

menu, an operation authority screen (Fig. 9-1) will be displayed. The radio

button of “All” is turned ON, a password is inputted, and O.K. button is clicked.

The initial value of a password is "2".

Fig.9-1 Operational authority screen

- 39 -

Page 40

BS Controller for AC SERVO PRESS

9.5.2. Setup of receive filter

9.5.3. Collection setup

9.5.4. Check of status

Instruction Manual Ver1 .08

BS-M3A-1B

If a setup-data collection-receiving filter is chosen with a pull down menu, a

receiving filter screen will be displayed. Please set up, as shown in Fig. 9-3.

Fig.9-3 Receive filter screen

At the pull down menu, check is put into setup-data collection-collection. (refer

to Fig. 9-4.)

Fig.9-4 Collection setup

If the status bar of the screen lower part is displayed as shown in Fig. 9-5,

communication is performed normally. Although various alarms are displayed

when no setup for BS controller is performed, there is no problem. As shown in

- 40 -

Page 41

BS Controller for AC SERVO PRESS

9.6.

Starting of two Configurators

Instruction Manual Ver1 .08

BS-M3A-1B

Fig. 9-6, when status is displayed, communication is not performed normally.

Please improve a setup from the beginning of Chapter 9.

Fig.9-5 Status bar Alarm state

Fig.9-6 Status bar Communication error state

It is also possible to install two BS Configurators in one PC, and to start

simultaneously. Starting of the 2nd Configurator displays the message "the

port cannot be used." It is because the 1st Configurator has already used the

port number 5008 (default value). Then, at the 2nd Configurator, it is set up so

that the port number except 5008 may be used. In the menu of the 2nd

Configurator,Setup-Data collection-Communication is chosen, and the

communication setting screen is opened.

Please choose 5009 at the list-box of All Port No. button, and click O.K. button.

Please re-start the 2nd Configurator. Two Configurators can be used if the

message about a port is not displayed. If two Configurators are used, data can

be displayed by the station.

Fig. 9-5 Communication Setup screen

- 41 -

Page 42

BS Controller for AC SERVO PRESS

9.7.

Use of two or more network interface cards

9.8.

Arbitrary IP address setup

9.8.1. Notes

Instruction Manual Ver1 .08

BS-M3A-1B

If LAN Interface Card Name in the Communication Setup screen of Fig. 9-5 is

used, the communication route between a PC and controllers can be specified.

Mixture of a network is avoidable if this function is used when using two or

more network interface cards. Moreover, if two Configurators are started and

data collection is performed by the separated network interface card, the time

of data collection can be shortened.

As shown in Fig. 9-5, the network interface card names are displayed in a

floating window by right click of the lower part of LAN Interface Card Name.

A setup will become effective, if LAN Interface Card Name of you wish is

chosen and O.K. button is clicked.

Arbitrary IP addresses can be set up now to the controller of a version 1.02.26

or later. On Fig. 9-5 Communication Setup screen if IP Address button is

clicked, Fig.9-6 IP Address Setup screen will open. The IP address of

Configurator and the IP address of a controller can be arbitrarily set up on this

screen. Address 4 is decided by the

spindle number. A spindle number

is set up with the rotary SWs of the

front upper part of a controller. The

setting range of a spindle number is

Fig.9-6 IP Address Setup screen

from 1 to 31.

Communication is impossible unless Configurator and a controller are the

same IP addresses. Moreover, it is necessary to also change the IP address of

the network interface card used with a personal computer. Please setup

addresses 1 and 2 with the same addresses of a controller.

A setup of a controller becomes effective after a re-injection of a power supply.

- 42 -

Page 43

BS Controller for AC SERVO PRESS

9.8.2. The communication method with an IP address unknown controller

Instruction Manual Ver1 .08

BS-M3A-1B

Please use a default fixed IP address to the controller with an unknown setup

of an IP address. When a spindle number is set as 71 to 99 with the rotary SW

of the upper part in front of a controller, the IP address of the controller is as

follows.

192.168.15.(spindle number - 70)

A new IP address becomes effective by re-injection of a power supply.

- 43 -

Page 44

BS Controller for AC SERVO PRESS

10. Starting

10.1. Starting procedure of BS controller

10.1.1. Attachment to equipment

10.1.2. Wiring

10.1.3. Control power supply injection

10.1.4. Attachment of a backup battery

10.1.5. Parameter setup of MR-J3A

10.1.6. Parameter setup of BS

10.1.7. Re-starting of a power supply

10.1.8. Check of a brake

10.1.9. Check of an emergency stop

10.1.10. Origin

10.1.11. Build a program.

Instruction Manual Ver1 .08

BS-M3A-1B

The outline procedure in the case of actually using BS controller is shown

below. The item which needs details is indicated after [2].

BS controller,MR-J3A and a tool are fixed to equipment.

Please wire with reference to a wiring diagram.

Only a control power supply is switched on. Please refer Section7 Timing Chart

7-1 Power supply injection.

The backup battery for holding the contents of a setting is attached.

The parameter of MR-J3A is set up. (It is required work only when MR-J3A is

purchased alone.)

Tool type selection, a setup of a stroke limit, etc. are performed from exclusive

PC application BS Configurator.

After a setup of a parameter, a power supply is turned off at once and only a

control power supply is switched on again. If alarm has not occurred, AC power

supply is also switched on. When alarm has occurred, please remove a cause

with reference to troubleshooting.

When a mechanical brake is chosen as an option, it checks that a brake is

taken off in the state of operation.

Please perform emergency stop operation and check that an emergency stop

operates.

Large restriction is applied to speed and output load when origin has not been

completed.

Build a program which suited the purpose using BS Configurator, and

transmit to BS controller.

- 44 -

Page 45

BS Controller for AC SERVO PRESS

10.1.12. Execution of a program

10.2. Parameter setup of MR-J3A

Caution 1

Caution 2

Caution 3

Parameter A

No.

Symbol

Name

Setting

Unit

Range

Change

required

PA01

*STY

Control mode

0000

0000-0235h

*

PA02

*REG

Regenerative option

0000

0000-000Ah

*

PA03

*ABS

Absolute position detection system

0000

0000-0004h

*

PA04

*AOP01

Function selection A-1

0000

0000-0011h

PA05

*FBP

Number of command input pulses

per revolution

16384

0/1000-50000

*

PA06

CMX

Electronic gear numerator

(Command pulse multiplying factor

numerator)

1

1-1048576

*

PA07

CDV

Electronic gear denominator

ommand pulse multiplying factor

denominator)

1

1-1048576

*

PA08

ATU

Auto tuning

0001

0000-0003h

PA09

RSP

Auto tuning response

12

1-32

PA10

INP

In-position range

100

pulse

0-10000

PA11

TLP

Forward torque limit

100.0

%

0.0-100.0

PA12

TLN

Reverse torque limit

100.0

%

0.0-100.0

PA13

*PLSS

Command pulse input from

0010

0000-0712h

PA14

*POL

Rotation direction selection

0

0-1 * PA15

*ENR

Encoder output pulses

16384

pulse/rev

1-100000

*

PA16

For manufacturer setting

0000

0000-FFFFh

PA17

*MSR

For manufacturer setting

0000

0000-FFFFh

PA18

*MTY

For manufacturer setting

0000

0000-FFFFh

PA19

*BLK

Parameter write inhibit

000C

0000-FFFFh

*

Instruction Manual Ver1 .08

BS-M3A-1B

If you run a program and there is an inconvenient portion, please add

correction and raise the completeness of a program.

When purchased in lump sum with a tool, the parameter of MR-J3A is already

set up.

About PA05 and PA15, those are setups for SP200 series. It is set

to 8192 in SP100 series. As for the parameter by which a setup is changed into

BS systems, * mark is attached to the Change required item.

About PA02, it is a setup of standard regeneration resistance.

When equipping with regeneration resistance of an option, a setup needs to be

changed.

About PA03, it is a setup of an incremental system. When you use

it by the absolute encoder system, please set it as 2.

- 45 -

(C

Page 46

BS Controller for AC SERVO PRESS

Parameter B

No.

Symbol

Name

Setting

Unit

Range

Change

required

PB01

FI LT

Adaptive tuning mode (Adaptive

filter )

0000

0000-0002h

PB02

VRFT

Vibration suppression control filter

(Advanced vibration suppression

control)

0000

0000-0002h

PB03

PST

Position command

(Position smoothing)

10

ms

0-20000

*

PB04

FFC

Feed forward gain

0 % 0-100

PB05

FFCF

For manufacturer setting

500

rad/s

10-4500

PB06

GD2

Ratio of load inertia moment to

servo motor inertia moment

0.8

times

0.0-300.0

PB07

PG1

Model loop gain

38

rad/s

1-2000

PB08

PG2

Position loop gain

58

rad/s

1-1000

PB09

VG2

Speed loop gain

327

rad/s

20-50000

PB10

VIC

Speed integral compensation

21.5

ms

0.1-1000.0

PB 11

VDC

Speed differential compensation

980

0-1000

PB12

OVA

For manufacturer setting

0 % 0-100

PB13

NH1

Machine resonance suppression

filter 1

4500

Hz

100-4500

PB14

NHQ1

Notch form selection 1

0000

0000-0330h

PB15

NH2

Machine resonance suppression

filter 2

4500

Hz

100-4500

PB16

NHQ2

Notch form selection 2

0000

000-0331h

PB17

NHF

Automatic setting parameter

000E

0000-031Fh

PB18

LPF

Low-pass filter

3141

rad/s

100-18000

PB19

VRF1

Vibration suppression control

vibration frequency setting

100.0

Hz

0.1-100.0

PB20

VRF2

Vibration suppression control

resonance frequency setting

100.0

Hz

0.1-100.0

PB21

VRF3

For manufacturer setting

0.00

0.00-1.00

PB22

VRF4

For manufacturer setting

0.00

0.00-1.00

PB23

VFBF

Low-pass filter selection

0000

0000-0011h

PB24

*MVS

Slight vibration suppression control

selection

0000

0000-0021h

PB25

*BOP1

Function selection B-1

0000

0000-1F12h

PB26

*CDP

Gain changing selection

0000

0000-0014h

PB27

CDL

Gain changing condition

10

0-9999

PB28

CDT

Gain changing time constant

1

ms

0-100

PB29

GD2B

Gain changing ratio of load inertia

moment

7.0

0.0-300.0

PB30

PG2B

Gain changing position loop gain

37

rad/s

1-2000

PB31

VG2B

Gain changing speed loop gain

823

rad/s

20-50000

PB32

VICB

Gain changing speed integral

compensation

33.7

ms

0.1-5000.0

Instruction Manual Ver1 .08

BS-M3A-1B

tuning mode

acceleration/deceleration time

constant

moment to servo motor inertia

倍

- 46 -

Page 47

BS Controller for AC SERVO PRESS

PB33

VRF1B

Gain changing vibration

setting

100.0

Hz

0.1-100.0

PB34

VRF2B

Gain changing vibration

setting

100.0

Hz

0.1-100.0

PB35

VRF3B

For manufacturer setting

0.00

0.00-1.00

PB36

VRF4B

For manufacturer setting

0.00

0.00-1.00

PB37

VP1

For manufacturer setting

100

pulse

0-32767

PB38

TGW1

For manufacturer setting

0.0

0.0-20.0

PB39

TGW2