Page 1

USER

MANUAL

MN4000 & MN4100

SERIES THERMAL

IMAGING CAMERAS

RUGGED AUTHORITY

1.888.610.7664

www.ShopThermography.com

Page 2

CONTENTS

Introduction 8

Quick Start Guide 10

Mechanical Installation 12

Important Network Information & Parameters 13

Camera web server 14

CorDEX MONITIR software 15

MODBUS & HTML 15

IP Addressing 17

Factory Reset 17

CE Declaration of Conformity 17

Shop for Thermal Imaging products online at:

1.888.610.7664

www.ShopThermography.com

Page 3

REGISTER

YOUR

PRODUCT.

RUGGED AUTHORITY

Register your product now

at http://www.cord-ex.com/

register-your-product/ and

receive a 12 month extended

warranty.

Terms & Conditions apply.

OVERVIEW

The CorDEX Instruments, MN4xxx series

of continuous monitoring cameras offer an

affordable and accurate means of continuously

monitoring temperature either as a standalone

unit, or as part of a larger control system/

strategy.

The CorDEX MN4xxx camera platforms are

designed primarily with Industry Control &

Monitoring in mind and as such, are provided

with the industry standard communication

ability, MODBUS/TCP for communicating

with devices such as Programmable Logic

Controllers (PLCs).

The CorDEX MN4xxx may be installed in a

standalone or multi camera mode, with each

camera incorporating a built in web server for

basic setup purposes which is accessible via

a standard web browser using Ethernet/IP,

additional CorDEX PC Setup Software is also

available for download.

CorDEX MNxxx cameras are also supplied

with PLC Function Blocks for popular brands.

These prewritten code blocks are designed

to dramatically reduce the amount of time

required to integrate and MN4xxx into a PLC

programme by enabling programmers to

simply select a block and drop the code into

the PLC ladder logic. Function Blocks are

continuously added to the CorDEX MN4xxx

website and include; Communications, Analysis

and Alarming blocks.

RUGGED AUTHORITY

1.888.610.7664

www.ShopThermography.com

Page 4

REGISTER

YOUR

PRODUCT.

RUGGED AUTHORITY

Register your product now

at http://www.cord-ex.com/

register-your-product/ and

receive a 12 month extended

warranty.

Terms & Conditions apply.

Shop for Thermal Imaging products online at:

1.888.610.7664

www.ShopThermography.com

Page 5

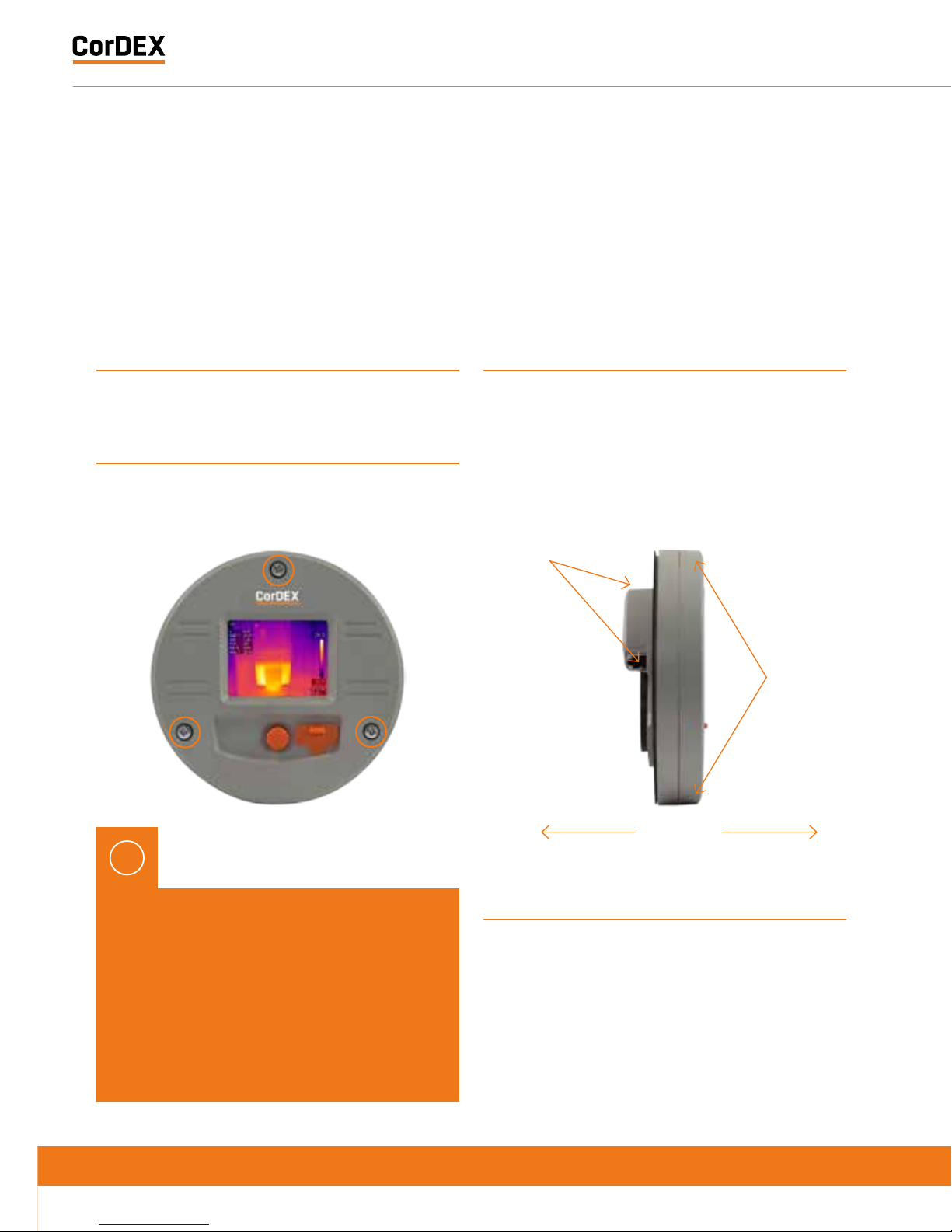

1

Install the camera.

2

Download the CorDEX MONITIR PC Application from

www.cord-ex.com/products/monitir-software/

3

Connect power via the standard screwed terminal

block provided (11-20VDC).

MN4000 MN4100

4

Connect the camera to your PC using a USB

cable.

Connect the camera to your PLC using an Ethernet

cable.

5

Start the CorDEX MONITIR PC App.

6

Select Direct Connect USB icon. Select Direct Connect Ethernet icon.

7

You have now accessed the CorDEX MN4000

series camera. From this screen you can setup

and provide basic control commands to the

camera.

Input the camera fixed static IP address

192.168.1.100 into the box and click Connect.

8

Click Submit. The camera will now restart with

desired settings.

You have now accessed the CorDEX MN4100 series

camera. From this screen you can setup and provide

basic control commands to the camera.

9

- Click Submit. The camera will now restart with

desired settings.

QUICK START GUIDE MECHANICAL INSTALLATION

MN4000

The CorDEX MN4000 panel mounted thermal

imager is intended for permanent installation

into electrical panels. Installation is achieved

in two stages.

Once the chassis has been installed, the

camera package can be removed and

replaced without shutting down or interrupting

the panel.

IMPORTANT NOTICE, MN4100

CAMERAS ARE SHIPPED WITH A

PREFIXED STATIC IP ADDRESS OF

192.168.1.100. This can be altered

using the CorDEX MONITIR PC App

(recommended).

1

Install the Chassis into the panel.

!

RUGGED AUTHORITY

1.888.610.7664

www.ShopThermography.com

Page 6

MN4000

The CorDEX MN4000 panel mounted thermal

imager is intended for permanent installation

into electrical panels. Installation is achieved

in two stages.

Once the chassis has been installed, the

camera package can be removed and

replaced without shutting down or interrupting

the panel.

1

Install the Chassis into the panel.

2

Attach the Camera Package to the chassis.

MONITIR Series Thermal Imaging Cameras – User Manual

7

Document Reference MONITIRSERIESUM Rev. A

Shop for Thermal Imaging products online at:

1.888.610.7664

www.ShopThermography.com

Page 7

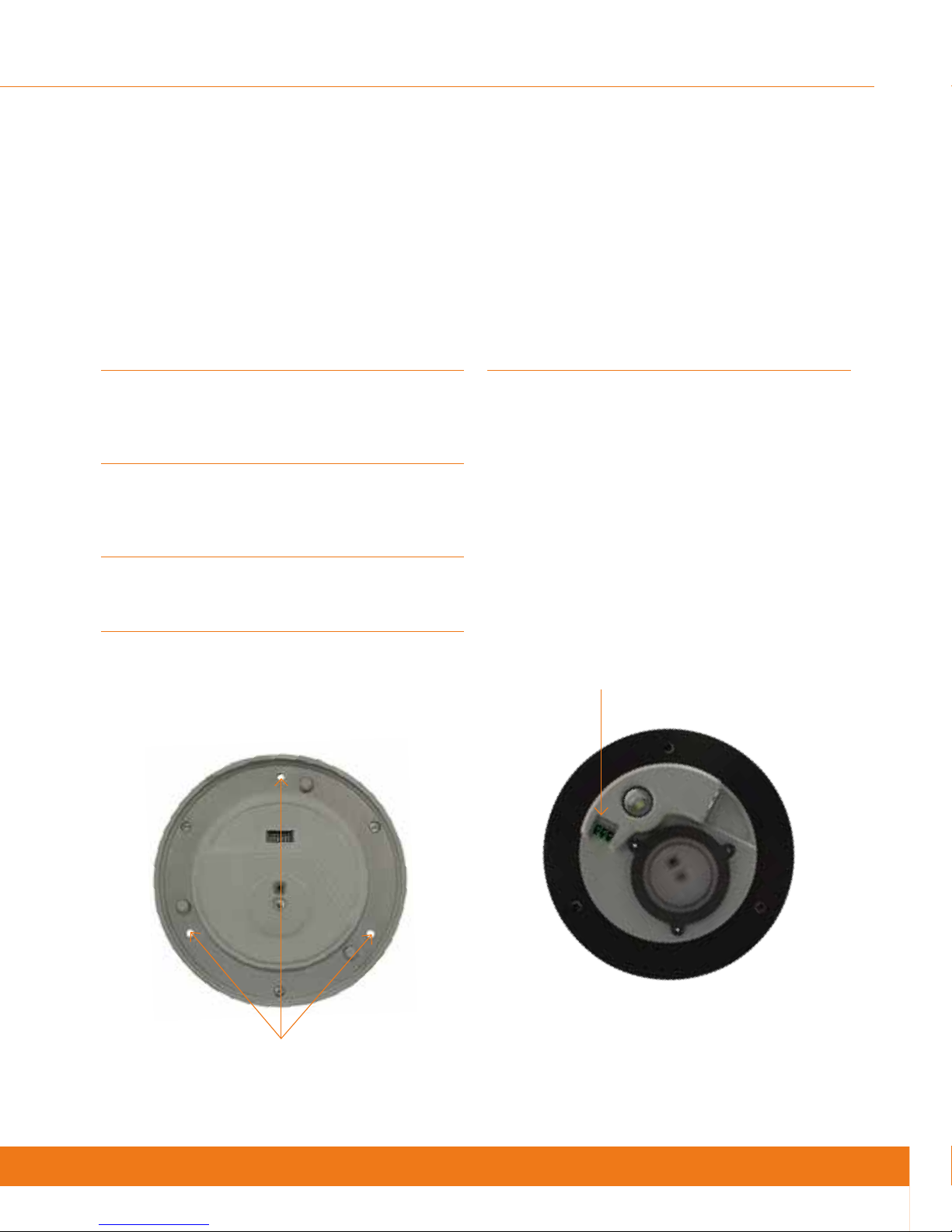

Installation of MN4000 Chassis

WARNING: Working on electrical equipment

presents significant risk and should only be

undertaken by suitably qualified personnel

in accordance with local applicable codes,

standards and corresponding Personal

Protective Equipment (PPE). This installation

procedure assumes a panel has been safely

removed and transported to a suitable location.

!

1

Remove the MN4000 from its packaging and place on

a flat surface, taking care not to scratch the lens.

2

Remove the three screws securing the Camera

Package to the Chassis.

3

Separate the Camera Package from the Chassis by

holding the Chassis communication bulge in one hand

and the Camera Package edge in the other hand then

gently but firmly pull apart.

4

Place the self-adhesive drilling template provided

into the desired location. Care should be taken to

ensure the rear of the panel is clear of ribs or other

obstructions prior to drilling.

5

Using the drill bit specified on the template (xxx), drill

the three fixing holes located around the perimeter.

6

Using an appropriate holes saw or punch, drill the

large (95mm/3¾”) centre hole.

7

Debur all rough edges and treat with rust inhibitor.

8

Align Chassis with mounting holes and attach using

three self-tapping screws provided, making sure to

advance the screws evenly.

Separate

Grip here

Grip here

RUGGED AUTHORITY

1.888.610.7664

www.ShopThermography.com

Page 8

5

Using the drill bit specified on the template (xxx), drill

the three fixing holes located around the perimeter.

6

Using an appropriate holes saw or punch, drill the

large (95mm/3¾”) centre hole.

7

Debur all rough edges and treat with rust inhibitor.

8

Align Chassis with mounting holes and attach using

three self-tapping screws provided, making sure to

advance the screws evenly.

9

Connect 11-30VDC to the green power connector

(provided) and attached to Chassis. There are three

connections.

Top: 0V

Centre: Supplemental GND*

Bottom: +ve

*GND is a supplemental Ground connection. MN4000 Primary

Ground is via the RJ45 socket and communications line. If no

communications are installed, the Supplemental GND may

be connected in accordance with local Electrical Codes /

Regulatory Requirements.

Chassis mounting holes

Power connections here

MONITIR Series Thermal Imaging Cameras – User Manual

9

Document Reference MONITIRSERIESUM Rev. A

Shop for Thermal Imaging products online at:

1.888.610.7664

www.ShopThermography.com

Page 9

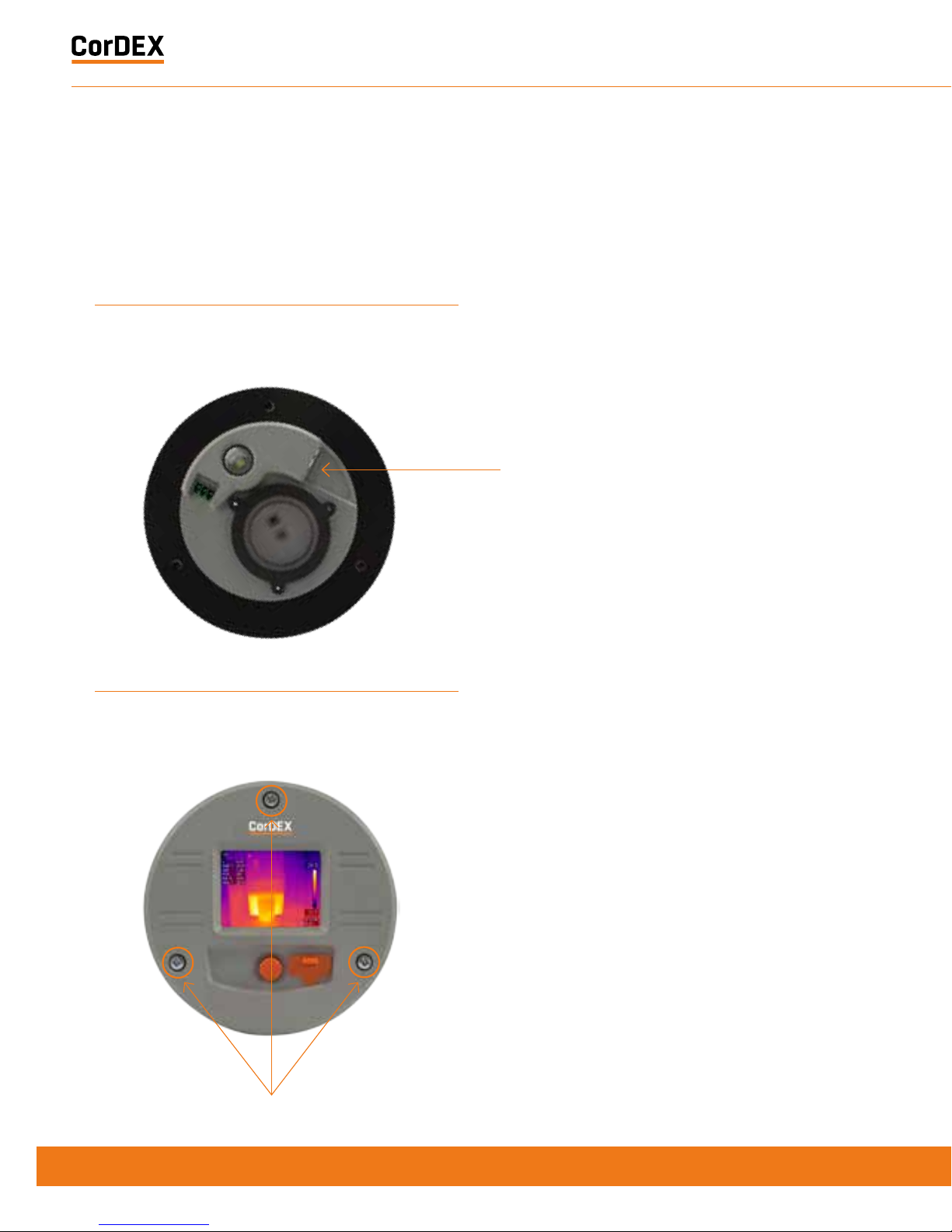

11

Replace the panel and secure before aligning the

Camera Package with the Chassis and fasten into

place with three fixing screws provided.

MN4100 attached to CDX8900-470

mounting arm.

Ethernet connection here

MN4100

The CorDEX MN4100 industrial automation

thermal imager is intended for permanent

installation into fixed locations for industrial

automation, control and safety monitoring

purposes. Installation is via an M6x4 threaded

boss located on the base of the camera

and optional mounting arm, part number

CDX8900-470 is also available.

10

If communications are to be used, connect an

Ethernet cable with RJ45 plug to Chassis.

Chassis mounting screws

RUGGED AUTHORITY

1.888.610.7664

www.ShopThermography.com

Page 10

MN4100 attached to CDX8900-470

mounting arm.

MN4100 Base showing M6x4 mounting

boss and two compression glands.

MN4100

The CorDEX MN4100 industrial automation

thermal imager is intended for permanent

installation into fixed locations for industrial

automation, control and safety monitoring

purposes. Installation is via an M6x4 threaded

boss located on the base of the camera

and optional mounting arm, part number

CDX8900-470 is also available.

MONITIR Series Thermal Imaging Cameras – User Manual

11

Document Reference MONITIRSERIESUM Rev. A

Shop for Thermal Imaging products online at:

1.888.610.7664

www.ShopThermography.com

Page 11

Installation of MN4100

This installation procedure assumes that

mechanical mounting and positioning has

already occurred, for specific mounting

instructions relating to CDX8900-470, please

view the MN4100 Mounting Arm Installation

Manual.

A typical industrial installation will comprise

of armoured cable for both power and

communications, terminating in a junction box

adjacent to the camera. Unarmoured power

and communications cables are run from the

junction box to the camera via the two M16

compression gland entries located in the

camera base.

Typical camera installation diagram

1

Remove rear weather cap from camera to expose

Ethernet socket and power terminals.

2

Insert power and communications cables into camera

via 2xM16 compression glands provided. NOTE, these

glands will accept cables with outside diameters from

3mm – 7mm.

3

Connect 11-30VDC to the green power connector

(provided) and attached to Chassis. There are three

connections

Top: 0V

Centre: Supplemental GND*

Bottom: +ve

*GND is a supplemental Ground connection. MN4000 Primary

Ground is via the RJ45 socket and communications line. If no

communications are installed, the Supplemental GND may

be connected in accordance with local Electrical Codes /

Regulatory Requirements.

4

Attached an RJ45 plug to the communications cable.

DO NOT PLUG INTO THE CAMERA AT THIS STAGE.

RUGGED AUTHORITY

1.888.610.7664

www.ShopThermography.com

Page 12

1

Remove rear weather cap from camera to expose

Ethernet socket and power terminals.

2

Insert power and communications cables into camera

via 2xM16 compression glands provided. NOTE, these

glands will accept cables with outside diameters from

3mm – 7mm.

3

Connect 11-30VDC to the green power connector

(provided) and attached to Chassis. There are three

connections

Top: 0V

Centre: Supplemental GND*

Bottom: +ve

*GND is a supplemental Ground connection. MN4000 Primary

Ground is via the RJ45 socket and communications line. If no

communications are installed, the Supplemental GND may

be connected in accordance with local Electrical Codes /

Regulatory Requirements.

4

Attached an RJ45 plug to the communications cable.

DO NOT PLUG INTO THE CAMERA AT THIS STAGE.

Power connector

RJ45 Socket

Compression glands

MONITIR Series Thermal Imaging Cameras – User Manual

13

Document Reference MONITIRSERIESUM Rev. A

Shop for Thermal Imaging products online at:

1.888.610.7664

www.ShopThermography.com

Page 13

5

Connect camera to a PC running CorDEX MONITIR

software, select Direct Connection, Ethernet and

use the default address 192.168.1.100. You can now

configure the camera for your network, for more

information on CorDEX MONITIR Application, please

refer to the specific software user manual.

6

Once the camera has been locally configured for your

network, attach the RJ45 connector and replace the

weather cover.

7

The camera is now ready for use.

NETWORK INFORMATION

AND PARAMETERS

RUGGED AUTHORITY

1.888.610.7664

www.ShopThermography.com

Page 14

NETWORK INFORMATION

AND PARAMETERS

IMPORTANT NOTICE

CorDEX MN4000 cameras are shipped as DHCP enabled as setup configuration is via the

USB port located on the front of the camera.

CorDEX MN4100 cameras are shipped with a STATIC IP ADDRESS of 192.168.1.100 This is

the default address the CorDEX MONITIR PC Application uses in Direct Ethernet Connect

mode when communicating with the camera during initial setup.

Please refer to your Network Administrator and obtain the correct parameters before

connecting MN4xxx cameras to your network.

MONITIR Series Thermal Imaging Cameras – User Manual

15

Document Reference MONITIRSERIESUM Rev. A

Shop for Thermal Imaging products online at:

1.888.610.7664

www.ShopThermography.com

Page 15

CAMERA WEB

SERVER INTERFACE

EACH CORDEX MN4XXX CAMERA IS SUPPLIED WITH AN ONBOARD WEB INTERFACE.

Accessing the web interface

To access the web interface, open your

internet browser and in the address bar type

the IP Address of the camera you wish to

communicate with.

The speed of the network connection will

determine the rate at which the camera

responds.

The image shown is a snapshot and not a live

feed, to reload an image, click Refresh Image.

Thermal data is captured and made available

for machine vision/automation at a frequency

of 9Hz.

Home tab

The Home tab is the default tab after logging

into the camera. Under the Home tab, it is

possible to change the image type, image

colourisation, set rising and falling isotherms

and to toggle the onboard LED.

IP Address

Image type Example image

Highlight

Combines v isual and thermal images into one with the

hottest areas bleeding through the visual.

Visible only

The visible image captured by the 640x480 onboard

digital camera.

Selecting the correct Image Type

The camera captures both visual and thermal

images simultaneously, your choice of Image

Type determines which of four options are

displayed on the screen.

RUGGED AUTHORITY

1.888.610.7664

www.ShopThermography.com

Page 16

Image type Example image

Highlight

Combines v isual and thermal images into one with the

hottest areas bleeding through the visual.

Visible only

The visible image captured by the 640x480 onboard

digital camera.

Selecting the correct Image Type

The camera captures both visual and thermal

images simultaneously, your choice of Image

Type determines which of four options are

displayed on the screen.

MONITIR Series Thermal Imaging Cameras – User Manual

17

Document Reference MONITIRSERIESUM Rev. A

Shop for Thermal Imaging products online at:

1.888.610.7664

www.ShopThermography.com

Page 17

Thermal only

The thermal image captured by the 80x60 infrared

camera. Due to the resolution of the infrared camera

alone, this mode is not recommended for scenes with a

low dynamic temperature range.

Isotherm overlay

When a rising and/or falling isotherm is configured and

Isotherm overlay selected, the areas w hich fall into

the Isotherm alarm condition are coloured and shown

on the image. This example has both rising and falling

isother ms configured. T he rising isotherm is show n in

red/orange, the falling isotherm is show in purple.

To select an Image Type, click the drop down

box and select the desired option, then click

the Send to Camera button. The command will

be transmitted to the camera and the image

refreshed after a few moments with your new

settings applied.

Setting Rising/Falling Isotherms

An Isotherm is an alarm condition where a

temperature level which is above (rising) or

below (falling) the Isotherm setpoint causes

the image in that set location to be highlighted

on the visual image by means of a colour.

To Set a Rising Isotherm, click the OFF/ON

toggle switch to the ON position (green) and

insert the alarm value in the box adjacent to

the button.

Click “Send to Camera”.

Any temperature in the cameras Field of View

(FOV) above this temperature will be coloured.

To Set a Falling Isotherm, click the OFF/ON

toggle switch to the ON position (green) and

insert the alarm value in the box adjacent to

the button.

Click “Send to Camera”.

Any temperature in the cameras Field of View

(FOV) below this temperature will be coloured.

It is possible to set both Rising and

Falling Isotherms on the same camera

simultaneously.

RUGGED AUTHORITY

1.888.610.7664

www.ShopThermography.com

Page 18

Setting Rising/Falling Isotherms

An Isotherm is an alarm condition where a

temperature level which is above (rising) or

below (falling) the Isotherm setpoint causes

the image in that set location to be highlighted

on the visual image by means of a colour.

To Set a Rising Isotherm, click the OFF/ON

toggle switch to the ON position (green) and

insert the alarm value in the box adjacent to

the button.

Click “Send to Camera”.

Any temperature in the cameras Field of View

(FOV) above this temperature will be coloured.

To Set a Falling Isotherm, click the OFF/ON

toggle switch to the ON position (green) and

insert the alarm value in the box adjacent to

the button.

Click “Send to Camera”.

Any temperature in the cameras Field of View

(FOV) below this temperature will be coloured.

It is possible to set both Rising and

Falling Isotherms on the same camera

simultaneously.

Toggling the onboard LED illuminator

The camera is equipped with an onboard LED

illuminator for extremely low light situations.

To toggle the LED illuminator, click the LED

OFF/ON button and then click the Send to

Camera button.

Spot temperatures

The camera has three spot temperature

points; Hot, Cold and Dynamic.

The Hot temperature identifier puts a red

cross on the hottest part of the image.

The Cold temperature identifier puts a blue

cross on the coldest par t of the image.

The Dynamic temperature measurement

shows the temperature of the cursor in the

Spot Temperature box.

MODBUS Registers & Coordinates

When Configuring Programmable Logic

Controllers (PLCs) to perform actions based

upon MN4xxx measurements, it is necessary

to be able to define either the MODBUS

Register of a particular point in the image

and/or its x,y coordinates.

To do this, hover the mouse over the point

on the image you are interested in and the

MODBUS Reg will be shown in the Modbus

Reg field, in brackets, the x,y coordinates for

the same MODBUS Register are shown.

MONITIR Series Thermal Imaging Cameras – User Manual

19

Document Reference MONITIRSERIESUM Rev. A

Shop for Thermal Imaging products online at:

1.888.610.7664

www.ShopThermography.com

Page 19

Alarm Tab

The Alarm tab opens the grid alarm page of

the MN4xxx webserver. Each MN4xxx camera

can accommodate a 5x5 grid square with a

configurable rising alarm in each square.

When a grid squares maximum temperature

exceeds its alarm threshold the alarm bell

notification on the home page activates and

a specific register in the MODBUS table is

toggled.

Setting a grid alarm

To set a grid alarm, click the grid square of

interest and the alarm setup box will appear.

Select ON from the Alarm OFF/ON toggle and

enter the Rising Isotherm alarm value. Then

click Update, followed by Submit.

The grid square alarm is now active and can

be monitored using a PLC to check for the

MODBUS Register bit associated with that

specific grid. For more information, see page

26, MODBUS & HTML.

Settings

The Settings tab allows users to configure

the camera Location Name, the units of

measurement and network setup information.

The Location Name is a unique identifier input

by the installer which pinpoints the camera

location, once set, this should not be changed

unless the camera duty is altered.

The unit of measure can be selected from

three potential options; Celcius, Fahrenheit

and Kelvin.

DHCP Server enable, Ip Address, Subnet Mask

and Gateway can all be manually configured in

the Settings tab.

Once complete, click Apply and the settings

will be transmitted to the camera.

RUGGED AUTHORITY

1.888.610.7664

www.ShopThermography.com

Page 20

Settings

The Settings tab allows users to configure

the camera Location Name, the units of

measurement and network setup information.

The Location Name is a unique identifier input

by the installer which pinpoints the camera

location, once set, this should not be changed

unless the camera duty is altered.

The unit of measure can be selected from

three potential options; Celcius, Fahrenheit

and Kelvin.

DHCP Server enable, Ip Address, Subnet Mask

and Gateway can all be manually configured in

the Settings tab.

Once complete, click Apply and the settings

will be transmitted to the camera.

CorDEX MONITIR Software

The CorDEX MN4xxx series cameras are

intended for installations of all sizes; from a

single camera, to hundreds. For large scale

installations, determining one camera from

another on a network becomes problematic

To overcome this CorDEX have developed

CorDEX MONITIR PC Application.

MONITIR is an expandable application, initially

used to setup one or more cameras as part

of the installation process. Once installation

is complete, MONITIR can then be used

to access every camera on the network

remotely.

To download the CorDEX MONITIR Software,

please visit www.cord-ex.com/products/

monitir-software/

MONITIR Series Thermal Imaging Cameras – User Manual

21

Document Reference MONITIRSERIESUM Rev. A

Shop for Thermal Imaging products online at:

1.888.610.7664

www.ShopThermography.com

Page 21

Homepage

The CorDEX MONITIR PC Application is

intended for setup purposes both of a

standalone camera and also to aid PLC

Integration.

The Application is broken down into two

main methods of communication; Network

Discovery and Direct Connect.

Network

Discovery

Settings

Direct Connect

(USB)

Direct Connect

(Ethernet)

Network Discovery

Net work Discover is intended to identif y

all CorDEX MN4xxx cameras located on a

net work. This is achieved by broadcasting a

message across the net work, to which each

camera responds providing;

1. Instrument Type – This refers to camera

type (Factory set)

2. Location – This is a description,

uploaded to the camera during initial

installation/setup, that provides a

means of identifying where the camera

is located in a particular facilit y. (User

configurable)

3. Ip Address – The IP Address of the

camera (User configurable)

4. Mac Address – The Mac Address of the

camera (Factor y set)

5. Serial Number – The Serial Number of

the camera (Factory set)

RUGGED AUTHORITY

1.888.610.7664

www.ShopThermography.com

Page 22

Network Discovery

Net work Discover is intended to identif y

all CorDEX MN4xxx cameras located on a

net work. This is achieved by broadcasting a

message across the net work, to which each

camera responds providing;

1. Instrument Type – This refers to camera

type (Factory set)

2. Location – This is a description,

uploaded to the camera during initial

installation/setup, that provides a

means of identifying where the camera

is located in a particular facilit y. (User

configurable)

3. Ip Address – The IP Address of the

camera (User configurable)

4. Mac Address – The Mac Address of the

camera (Factor y set)

5. Serial Number – The Serial Number of

the camera (Factory set)

To deploy Network Discover y from the

homepage, ensure the PC running MONITIR

is connected to the same network as the

MN4xxx cameras and click the Network

Discovery icon, the Network Discover y page

will appear and the user prompted to begin

the Discovery process.

Once complete, the window will be populated

with all the cameras which have responded to

the Network Discovery broadcast message.

Double clicking on a particular camera will

open the corresponding setup page, this is the

same page as Direct Connect Ethernet.

MONITIR Series Thermal Imaging Cameras – User Manual

23

Document Reference MONITIRSERIESUM Rev. A

Shop for Thermal Imaging products online at:

1.888.610.7664

www.ShopThermography.com

Page 23

Direct Connect (USB)

MN4000 Cameras can be configured via the

chassis in Direct Connect Ethernet mode or

when installed and in use, via Direct Connect

USB mode, this is the recommended mode of

communication for initial setup.

To communicate via Direct Connect USB, first

ensure the MN4000 is powered up and the

PC running MONITIR Application is connected

to the USB port located on the front of the

camera.

Direct Connect (Ethernet)

Both MN4000 and MN4100 have the capability

for a direct, PC to Camera Ethernet connection

using the MONITIR PC Application. Direct

Connect (Ethernet) is the recommended initial

setup mode for MN4100 cameras as they are

shipped with a factory set static IP address.

To communicate with the camera, ensure

the PC running the MONITIR Application is

connected to the camera with an Ethernet

cable, then click the Direct Connect (Ethernet)

icon from the homepage.

Then click the Direct Connect (USB) icon

from the home screen and the Application

will communicate directly with the camera,

displaying returned data in the following

format.

RUGGED AUTHORITY

1.888.610.7664

www.ShopThermography.com

Page 24

Direct Connect (Ethernet)

Both MN4000 and MN4100 have the capability

for a direct, PC to Camera Ethernet connection

using the MONITIR PC Application. Direct

Connect (Ethernet) is the recommended initial

setup mode for MN4100 cameras as they are

shipped with a factory set static IP address.

To communicate with the camera, ensure

the PC running the MONITIR Application is

connected to the camera with an Ethernet

cable, then click the Direct Connect (Ethernet)

icon from the homepage.

If this is a first time setup of an MN4000, type

192.168.1.100 into the Ip address box and click

Connect. If this is not a first time setup, you

must type the Ip address associated with your

specific camera.

MONITIR Series Thermal Imaging Cameras – User Manual

25

Document Reference MONITIRSERIESUM Rev. A

Shop for Thermal Imaging products online at:

1.888.610.7664

www.ShopThermography.com

Page 25

MODBUS & HTML

The MN4000 and MN4100 have Modbus

TCP and HTML access for mage display and

analysis.

MODBUS/TCP

The Modbus protocol used is Modbus TCP/

IP also known as Modbus TCP. http://w ww.

modbus.org/docs/Modbus_Messaging_

Implementation_Guide_V1_0b.pdf

Following Modbus command function codes

are used:

• Function code 3: Read Multiple Registers

• Function code 4: Read Input Registers

• Function code 6: Write Single Registers

• Function code 16: Write Multiple Registers

Modbus TCP/IP connects over TCP/IP

net works using por t 502. A checksum is

not required as a checksum calculation

implemented in the lower layers already

provides checksum protection. The frames do

not include a checksum.

On TCP/IP the Modbus server is addressed

using its IP address. The Modbus Unit

Identifier is set to 0FFh.

Register Access: Code 4

The MN4xxx cameras implement Modbus

TCP command function code 4 “Read Input

Registers” (16 bit), with the addresses as

defined in the following table.

MODBUS Function Code 4 TCP registers

* MODBUS access is big-endian

** To convert to Fahrenheit= (cK*9)/5-45967,

Celcius=(cK-27315)/100

Register Access: code 3, 6, 16

The MN4xxx cameras implement Modbus TCP

command function codes 3, 6 and 16 with the

addresses as defined in the following table.

MODBUS Function code 3, 6, 16 TCP Registers

Address*

Function Code: 4 Comment

0 to 4799

Sensor temperature

array, 80x60

Units: cK

(ccentikelvin**)

Global

constants:

Emissivity =1

0= Top LHS,

4799= Bottom

RHS

4800

AlarmBit [24:16]

for each bit

1: alarmed

0: no alarm

Corresponds

to 25 grid

alarm limits.

Alarm for

any pixel >T

set

4801

AlarmBit [15:0] for

each bit

1: alarmed

0: no alarm

Corresponds

to 25 grid

alarm limits.

Alarm for

any pixel >T

set

Address*

0 to 24

Address*

0 to 24

RUGGED AUTHORITY

1.888.610.7664

www.ShopThermography.com

Page 26

Register Access: code 3, 6, 16

The MN4xxx cameras implement Modbus TCP

command function codes 3, 6 and 16 with the

addresses as defined in the following table.

MODBUS Function code 3, 6, 16 TCP Registers

HTML Browser

A web browser may be used to setup

all aspects of the camera operation, the

recommended browser is Chrome.

HT TP browser access can be used to

access camera data structures by software

integrators as follows:

• http:IP-address/vis.jpg visible image jpeg

• http:IP-address/ir.bmp IR image

• http:IP-address/raw.bin IR temperature

array, 80 x 60 x 16bit

• http:IP-address/lep.bin IR info

• http:IP-address/alarm.bin alarm settings,

5 x 5 x 16bit

• http:IP-address/firmware.html prompts for

binary file then reboots 10s after upload

Address*

Function Code;

3, 6, 16

Comment

0 to 24

Sensor alarm array,

5x5

Units: cK (centikelvin)

0=Top LHS,

14=Bottom RHS

Address*

Function Code;

3, 6, 16

Comment

0 to 24

Sensor alarm array,

5x5

Units: cK (centikelvin)

0=Top LHS,

14=Bottom RHS

MONITIR Series Thermal Imaging Cameras – User Manual

27

Document Reference MONITIRSERIESUM Rev. A

Shop for Thermal Imaging products online at:

1.888.610.7664

www.ShopThermography.com

Page 27

HTML Access (Settings page)

The setting page information is accessed

using a HTTP GET.

The webserver is not capable of Server Side

Includes. Instead all data on the page is

populated from a binary file loaded from the

ser ver using javascript. The offsets within the

binary file are as shown in the javascript.

The form submit has parameters:

• t= as session token

• cfk= as the units

(0:Celcius/1:Farentheit/2:Kelvin)

• loc= as the location text field

• ethIpAddress= as the static IP in decimal

• ethSubnetMask= as the static subnet

mask in decimal

• ethGateway= as the static gateway in

decimal

• dhcp= as the (0:DHCP/1:Static IP)

An example implementation is as follows:

Reading

HT TP GET /lep.bin returns a binary file. In the

javascript this is converted to an unsigned 16

bit array s[].

Where

• cfk is at s[8+2*176+5];

• dhcp is at s[8+2*176+25]; upper 8 bits

• loc is at s[8+2*176+8]; nex t 16 characters

• ethIpAddress is at s[8+2*176+26]; next 4

bytes

• ethSubnetMask is at s[8+2*176+28]; next 4

bytes

• ethGateway is at s[8+2*176+30]; next 4

bytes

• token t is at s[8+2*176+34+4];

Setting

HTTP GET /eth.ccgi?&t=1234&cfk=0&loc=

cordex&dhcp=1ðIpAddress=1234ð

SubnetMask=1234ðGateway=1234

Note on units for web browser access

All temperature values sent to camera are in

the current units format (C, F, K).

All temperatures returned from the camera are

in centikelvin. This is due to limitations in the

HTML implementation.

Any writes that change the DHCP, IP address,

Netmask, or Gateway configuration will also

cause a reboot a few seconds later. This is

required as the Ethernet stack needs to be

restarted in this situation.

Applies to both the eth.cgi and the USB.

RUGGED AUTHORITY

1.888.610.7664

www.ShopThermography.com

Page 28

Setting

HTTP GET /eth.ccgi?&t=1234&cfk=0&loc=

cordex&dhcp=1ðIpAddress=1234ð

SubnetMask=1234ðGateway=1234

Note on units for web browser access

All temperature values sent to camera are in

the current units format (C, F, K).

All temperatures returned from the camera are

in centikelvin. This is due to limitations in the

HTML implementation.

Any writes that change the DHCP, IP address,

Netmask, or Gateway configuration will also

cause a reboot a few seconds later. This is

required as the Ethernet stack needs to be

restarted in this situation.

Applies to both the eth.cgi and the USB.

MONITIR Series Thermal Imaging Cameras – User Manual

29

Document Reference MONITIRSERIESUM Rev. A

Shop for Thermal Imaging products online at:

1.888.610.7664

www.ShopThermography.com

Page 29

HTML Access (IR data structure)

The structure for the IR information:

typedef struct lepton_settings_struct

{

__packed uint16_t isotherm_min_enable;

__packed uint16_t isotherm_max_enable;

__packed uint16_t isotherm_min;

__packed uint16_t isotherm_max;

__packed uint16_t palette;

__packed uint16_t units;

__packed uint16_t led;

__packed uint16_t reserved1;

__packed char name[16];

__packed char serial[STRING_LENGTH];

__packed enum View_Mode view_mode;

__packed enum DateFormat date_format;

__packed enum TimeFormat time_format;

__packed enum Dhcp dhcp;

__packed uint32_t static_ip_addr;

__packed uint32_t static_netmask;

__packed uint32_t static_gateway;

__packed uint32_t crc;

} lepton_settings_type;

typedef struct lepton_info_struct

{

__packed uint16_t bin_max;

__packed uint16_t bin_min;

__packed uint16_t max_x;

__packed uint16_t max_y;

__packed uint16_t min_x;

__packed uint16_t min_y;

__packed uint16_t palette_depth;

__packed int16_t ambient;

__packed uint16_t palette_lut[PALETTE_

LARGEST];

__packed uint16_t palette_temp[PALETTE_

LARGEST];

__packed lepton_settings_type settings;

__packed uint32_t firmware;

__packed uint32_t alarm_status;

__packed uint16_t token;

} lepton_info_type;

typedef struct alarm_settings_struct

{

__packed uint16_t alarm[25];

__packed uint32_t alarm_enable;

__packed uint16_t token;

} alarm_settings_type;

enum Palette { GREY_POSITIVE=0, GREY_

NEGATIVE, IRON, HOTMETAL, RAINBOW, AMBER,

SEPIA };

enum View_Mode { ISOTHERM_OVERLAY,

THERMAL_ONLY, VISIBLE_ONLY, HIGHLIGHT,

MAX_VIEW_MODE };

enum Units { CELSIUS, FARENHEIT, KELVIN,

MAX_UNITS };

enum DateFormat { YYYYMMDD, DDMMYYYY,

MMDDYYYY, MAX_DATE_FORMAT };

enum TimeFormat { HH24MMSS, HH12MMSS,

MAX_TIME_FORMAT};

enum Dhcp { DHCP, STATIC_IP, MAX_DHCP};

enum Led { LED_DISABLED, LED_ENABLED,

MAX_LED};

DateFormat and TimeFormat are not used.

palette_lut[PALETTE_LARGEST] is an array of

colors

Colours are RGB565, 16 bit colour.

palette_temp[PALETTE_LARGEST] is an array

of temperatures in cK

The temperatures of each palette colour.

RUGGED AUTHORITY

1.888.610.7664

www.ShopThermography.com

Page 30

enum Palette { GREY_POSITIVE=0, GREY_

NEGATIVE, IRON, HOTMETAL, RAINBOW, AMBER,

SEPIA };

enum View_Mode { ISOTHERM_OVERLAY,

THERMAL_ONLY, VISIBLE_ONLY, HIGHLIGHT,

MAX_VIEW_MODE };

enum Units { CELSIUS, FARENHEIT, KELVIN,

MAX_UNITS };

enum DateFormat { YYYYMMDD, DDMMYYYY,

MMDDYYYY, MAX_DATE_FORMAT };

enum TimeFormat { HH24MMSS, HH12MMSS,

MAX_TIME_FORMAT};

enum Dhcp { DHCP, STATIC_IP, MAX_DHCP};

enum Led { LED_DISABLED, LED_ENABLED,

MAX_LED};

DateFormat and TimeFormat are not used.

palette_lut[PALETTE_LARGEST] is an array of

colors

Colours are RGB565, 16 bit colour.

palette_temp[PALETTE_LARGEST] is an array

of temperatures in cK

The temperatures of each palette colour.

MONITIR Series Thermal Imaging Cameras – User Manual

31

Document Reference MONITIRSERIESUM Rev. A

Shop for Thermal Imaging products online at:

1.888.610.7664

www.ShopThermography.com

Page 31

Window Coordinate Conversions

For user co-ordinates, the top LHS is

considered to be location (x=0, y=0)

Fig 11.5 Pixel x,y coordinates and Modbus registers

USB Commands

The USB commands available to MN4xxx

cameras are as follows:

USB_MAC_ADDRESS, USB_ISOMINEN,

USB_ISOMAXEN, USB_ISOMIN,

USB_ISOMAX, USB_PALETTE, USB_UNITS,

USB_LED, USB_NAME, USB_SERIALNUM,

USB_VIEWMODE, USB_DHCP, USB_IP_ADDRESS,

USB_NETMASK, USB_GATEWAY, USB_ALARM

This command set is sufficient setup a MN4xxx

via USB prior to placing on the IP network.

IP Addressing

IP Address Allocation

This section describes the following:

• IP address allocation and discovery for

MN4100 which doesn’t have a display

(also can be used for MN4000)

• Networks without a DHCP server will

default to an IP address which can then

be set to a static IP address

The Following methods are used for IP address

allocation:

• Auto-Find: IP discovery program returns

the IP address allocated by the DHCP

server to each AW

• Manual configuration of static IP address

• Default static IP address (192.168.1.100)

The cameras will be shipped with following IP

address allocation as default

• MN4000 ship with DHCP Enabled

(non-static address),

• MN4100 Ship with static IP address of

192.168.1.100

Ip Address Discovery (Auto-Find IP)

The units use the network DHCP server to

assign IP addresses. A discovery program is

used to return the local unit IP addresses.

For the case where there is no DHCP server

the unit will default to IP address 169.254.xx.xx,

where xx.xx is a randomly generated number.

The camera verifies this default IP address is

unique in the local network.

The auto-find will return this address.

RUGGED AUTHORITY

1.888.610.7664

www.ShopThermography.com

Page 32

Ip Address Discovery (Auto-Find IP)

The units use the network DHCP server to

assign IP addresses. A discovery program is

used to return the local unit IP addresses.

For the case where there is no DHCP server

the unit will default to IP address 169.254.xx.xx,

where xx.xx is a randomly generated number.

The camera verifies this default IP address is

unique in the local network.

The auto-find will return this address.

Camera Identification (Host Name)

An auto-find is implemented using UDP

broadcast on port 46000 containing “MonitIR?”

The host name field that appears in the router

table is as follows:

• Auto-configured as Monitir_<processorU

ID>. The processorUID is a 64-bit number

• The DHCP client returns a hostname of

“MonitIR-“+(unique serial number)

• This can be used to identify any camera

in the table and will appear in the

broadcast response

• This can also be used with a unicast

address to obtain the same response

Information in the broadcast response is as

follows:

• Serial number: “Monitir”+(unique serial

number)

• MAC address

• Location ID (text)

• Instrument identification

MONITIR Series Thermal Imaging Cameras – User Manual

33

Document Reference MONITIRSERIESUM Rev. A

Shop for Thermal Imaging products online at:

1.888.610.7664

www.ShopThermography.com

Page 33

Auto-Find Example

The example has a button and a list box as

follows:

• When the button is clicked function

button1_Click() is called that sends a UDP

broadcast on port 46000 containing

“MonitIR?”.

• The list box is populated with the replies

contents

This could be rejigged to suit a multithreading

app by using non-blocking calls instead of

using the ReceiveTimeout.

// MonitIRfinder note the changed offsets

within ServerResponseData

using System;

using System.Collections.Generic;

using System.ComponentModel;

using System.Data;

using System.Drawing;

using System.Linq;

using System.Text;

using System.Threading.Tasks;

using System.Windows.Forms;

using System.Net;

using System.Net.Sockets;

namespace MonitIRfind

{

public partial class MonitIRfinder : Form

{

public MonitIRfinder()

{

InitializeComponent();

}

private void button1_Click(object sender,

EventArgs e)

{

var client = new UdpClient();

var RequestData = Encoding.ASCII.

GetBytes(“MonitIR?”);

var ServerEp = new IPEndPoint(IPAddress.

Any, 0);

client.EnableBroadcast = true;

client.Client.ReceiveTimeout = 3000;

listBox1.Items.Clear();

// send data: “MonitIR?”

client.Send(RequestData, RequestData.Length,

new IPEndPoint(IPAddress.Broadcast, 46000));

// then receive data

while (true)

{

try

{

var ServerResponseData = client.

Receive(ref ServerEp);

var ServerResponse = Encoding.ASCII.Get-

String(ServerResponseData).Substring(0, 24);

var ServerVer = “”;

var ServerMac = “”;

var ServerLocation = “”;

if (ServerResponseData.Length > 25)

RUGGED AUTHORITY

1.888.610.7664

www.ShopThermography.com

Page 34

InitializeComponent();

}

private void button1_Click(object sender,

EventArgs e)

{

var client = new UdpClient();

var RequestData = Encoding.ASCII.

GetBytes(“MonitIR?”);

var ServerEp = new IPEndPoint(IPAddress.

Any, 0);

client.EnableBroadcast = true;

client.Client.ReceiveTimeout = 3000;

listBox1.Items.Clear();

// send data: “MonitIR?”

client.Send(RequestData, RequestData.Length,

new IPEndPoint(IPAddress.Broadcast, 46000));

// then receive data

while (true)

{

try

{

var ServerResponseData = client.

Receive(ref ServerEp);

var ServerResponse = Encoding.ASCII.GetString(ServerResponseData).Substring(0, 24);

var ServerVer = “”;

var ServerMac = “”;

var ServerLocation = “”;

if (ServerResponseData.Length > 25)

{

ServerVer = ServerResponseData[25].

ToString();

ServerMac = BitConverter.ToString(ServerRe

sponseData.Skip(26).Take(6).ToArray());

ServerLocation = Encoding.ASCII.GetString(

ServerResponseData).Substring(32, 16);

}

listBox1.BeginUpdate();

listBox1.Items.Add(ServerResponse + “ at “ +

ServerEp.Address.ToString() + “ Ver: “ + ServerVer + “ MAC: “ + ServerMac + “ Location: “ +

ServerLocation);

listBox1.EndUpdate();

}

catch (Exception exc) { break; }

}

client.Close();

}

}

}

Parse the response as follows

Bytes[0..24] = “MonitIR-“+serial_number,

bytes[25] = hardware_version, bytes[26..31] =

mac address, bytes[32..47] = location

Hardware version identifies the units as

MN4000 / MN4100 and reflects hardware

defined signals.

The hardware signals are PB[15:14] copied as

HWVersion[1:0]

MONITIR Series Thermal Imaging Cameras – User Manual

35

Document Reference MONITIRSERIESUM Rev. A

Shop for Thermal Imaging products online at:

1.888.610.7664

www.ShopThermography.com

Page 35

Factory Reset

MN4100 has a Factory Reset function which

erases all user configured settings/data and

returns the unit to it original factor y setup.

MN4000 Factory reset

The MN4000 has no Factory Reset as all

parameters are available locally at the

camera.

MN4100 Factory reset

The MN4100 Factory Reset is achieved by

pressing and holding the Factory Reset button

located at the rear of the camera for one

second.

PB[15:14}

HWVersion[1:0]

PB[15:14} = HWVersion [1:0]

defines unit ID

00 = MN4100 (no LCD)

01= MN4000 (with LCD)

RUGGED AUTHORITY

1.888.610.7664

www.ShopThermography.com

Page 36

RUGGED AUTHORITY

Revision A

MONITIR Series Thermal Imaging Cameras – User Manual

37

Document Reference MONITIRSERIESUM Rev. A

Shop for Thermal Imaging products online at:

1.888.610.7664

www.ShopThermography.com

Loading...

Loading...