Page 1

1

1

4. Finish the draw. If you have a .224 jacket maker, the punch is one straight

1

1

1

1

piece and will go through the die. If you have a .243 jacket maker, the punch

is made with two diameters, and will NOT go through the die. To finish a .224

jacket, you must push it all the way through the die and out the top. To do this,

lower the ram and see if the jacket comes of in the die, or stays with the

punch. If the jacket stays with the punch, it will be ejected by the tube and

disk assembly on the down stroke, and you can push it through later with a

second operation. If it stays in the die, you can put the push rod into the

jacket, and shove on the end of this short (1-inch) rod to push the jacket all

the way through the ring die insert. It may not come out the top yet, but it is

drawn. The next jackets will lift it out. Catch the push rod so it doesnt drop on

the floor when you lower the ram. If you have a .243 set, you can use the

knock out rod and a small mallet or block of wood to tap the jacket back out

of the die (or, it may come back with the punch and be ejected automatically).

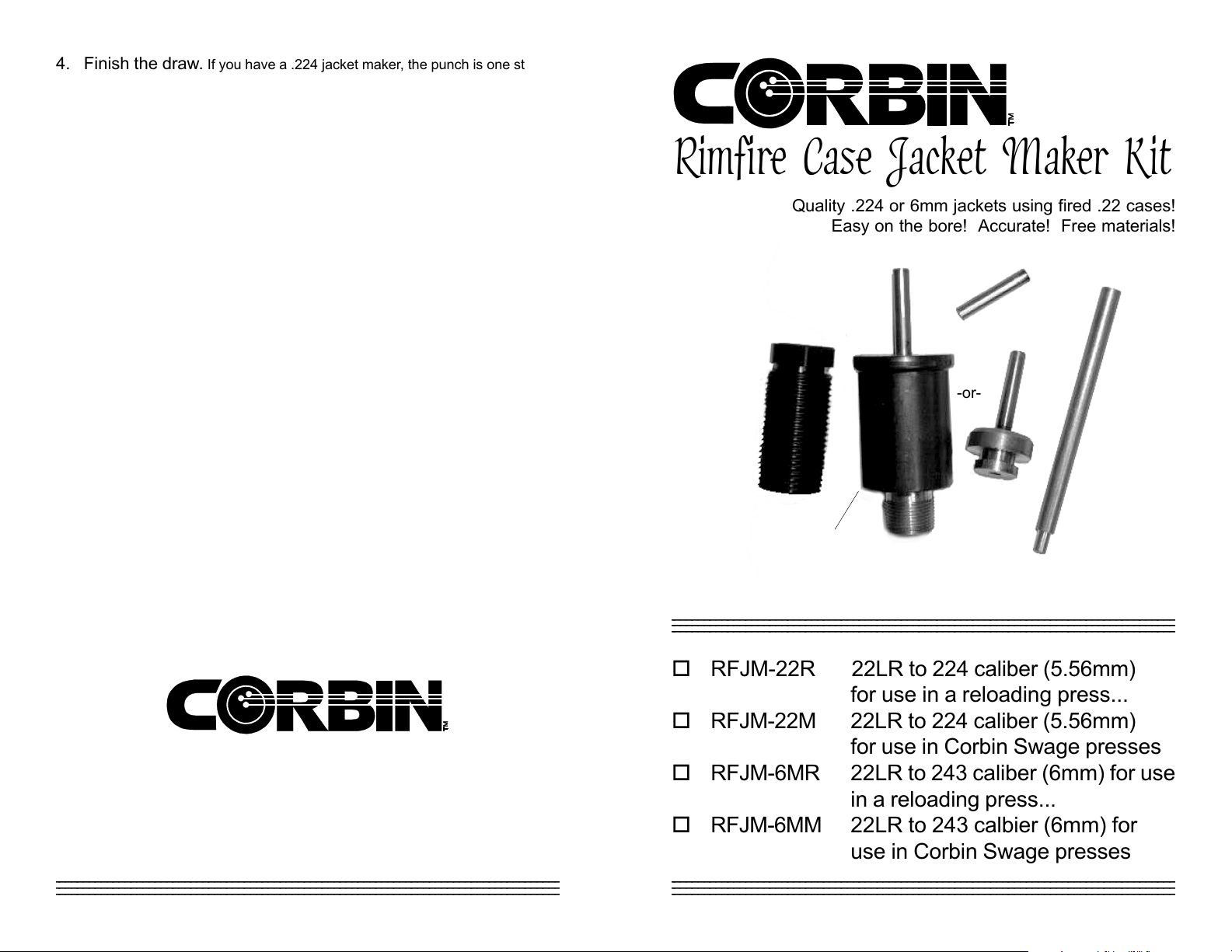

Rimfire Case Jacket Maker Kit

Quality .224 or 6mm jackets using fired .22 cases!

Easy on the bore! Accurate! Free materials!

The .243 jackets are actually a kind of pre-form jacket. They are not brought to

.243 caliber in this operation. The mouth is flared by pressing over the punch

angle joining the two punch diameters, so that it will seal the bore of the core

seating die and hold the lead pressure during core seating, which will expand the

entire jacket to the correct diameter (just like blowing up a balloon, but with thousands of pounds of pressure). Corbin Swage Lube is recommended to increase

die and punch life and lower the force required to draw the jackets.

Discard any cases which are bulged from oversized chambers, which have bad

firing pin cuts or split mouths, or have bad corrosion. Sort your jackets to that your

groups are fired using the same headstamps, and you will probably find the accuracy is improved! The thin rimfire cases require a slightly larger core seating punch

than a commercial jacket. They are very explosive and make excellent varmint

bullets. Accuracy is best if the velocity is kept under about 3,200 fps with most

rifles. Because the jackets are very thin, they dont like being fired at higher speeds!

However, with reasonable velocities, the .22 rimfire case jacket can give you a

virtually unlimited supply of free bulletsjust add scrap lead, swage them into

quality bullets using Corbin swage dies, and you can avoid the cost of commercial

bullets forever!

World Leader in Bullet Swaging Technology Since 1975!

PO Box 2659

600 Industrial Circle

White City, OR 97503 USA

Phone Mon-Thur. 9am-5pm: 541-826-5211

FAX: 24-hr 541-826-8669

E-Mail: corbin@mind.net

Internet web pages: http://www.shooters.com/corbin

23456789012345678901234567890121234567890123456789012345678901212345678901234567890

Helper rod

-or-

Draw Die

(4-part assembly)

Ejector tube

and disk

23456789012345678901234567890121234567890123456789012345678901212345678901234567890

23456789012345678901234567890121234567890123456789012345678901212345678901234567890

23456789012345678901234567890121234567890123456789012345678901212345678901234567890

Draw

Punch (-M)

Draw

Punch (R)

Jacket K.O.

Rod

o RFJM-22R 22LR to 224 caliber (5.56mm)

for use in a reloading press...

o RFJM-22M 22LR to 224 caliber (5.56mm)

for use in Corbin Swage presses

o RFJM-6MR 22LR to 243 caliber (6mm) for use

in a reloading press...

o RFJM-6MM 22LR to 243 calbier (6mm) for

use in Corbin Swage presses

23456789012345678901234567890121234567890123456789012345678901212345678901234567890

23456789012345678901234567890121234567890123456789012345678901212345678901234567890

Page 2

The Corbin RFJM-22M

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

7

7

7

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

7

7

7

12

12

12

12

12

Rimfire Jacket-Maker Die:

K.O. Punch (used to push a jacket out of the die,

when needed to push out a jacket).

Die Assembly, consists of the threaded die holder

body (7/8-14 TPI), which screws into the press

head, the ring die insert which does the actual

drawing, the spacer tube, and the retaining bushing

(hexagon head, screws into the top of the die body

and presses against the spacer tube, which in turn

holds the ring die insert).

Ejection disk and tube assembly (press fit together,

slips over the punch and strips the jackets off the

punch on the down stroke of the press). Your press

ram must fit inside this tube in order to use the die

set on a reloading press.

How to use the jacket maker sets:

1. Clean and sort the cases. Separate them into groups by headstamp for

the best accuracy. Throw away any that are punched through at the firing pin

dent, or have been smashed flat. Boil the cases in hot water with detergent

and a couple of tablespoons of vinegar to remove corrosion and dust. Rinse

them in clean hot water and spread them out on an old towel to dry.

2. Draw the cases. Screw the die into the top of the press (hex nut faces

away from the ram). Bottom of the die should be from flush with the press

frame to about 1/8-inch below it. Insert the punch into the press ram (screws

into Corbin rams, slips sideways into regular loading press rams like a shell

holder). Corbin CSP-1 press must be in the LONG STROKE or reloading

position of the ram and toggle, not the short swaging stroke. With a film of

Corbin Swage Lube on your fingers, touch a small amount of lube on the

punch, and on the O.D. of the case. Put the case over the punch, and push it

into the die about 1/4 inch (the press should run out of stroke at this point).

Adjust the die so that the drawing is done at the END of the press stroke.

Only about 1/4-inch of the case is drawn down in this operation.

3. Anneal the cases. The cases must be brought to a temperature sufficient

to stress relieve and soften the brass, without burning it. Generally, if the

cases are brought to a barely visible red glow in a dimly lit room, they were

hot enough to avoid folding at the tip when you form the ogive later. A selfcleaning oven generally gets hot enough. Spread the cleaned cases out on

an old cookie sheet and bake in the self-clean cycle of your electric range,

or heat the cases by using a propane torch to quickly bring them to a red heat

visible in dim light. Failure to anneal only means that the ogive may fold over

instead of drawing smoothly to a point. Let them cool to room temperature.

Push rod, which can be used to finish pushing the

jacket through the die, after using the punch alone

to unfold the rim at the end of the stroke. The rod

adds about an inch to the travel of the ram, suffi-

cient to push the de-headed case through the ring

die insert. In the 6mm version, the jacket is NOT

pushed all the way through the die: it is ejected

after unfolding the head and used at original

diameter (it expands in the core seating operation).

Punch, used to push the case into the die just far

enough to draw out the rim into a straight section

without folds or creases. This is done at the end of

the press stroke. The push rod is the put into the

case and used to shove the case the rest of the

way through the die (for .224 jackets only).

6mm (.243)

PUNCH-R, and PUNCH-M

234567890

234567890

234567890

234567890

234567890

234567890

234567890

234567890

-R

234567890

234567890

234567890

234567890

234567890

234567890

234567890

234567890

234567890

234567890

You can convert

from .224 to .243

or vice versa just

by obtaining the

-M -M

correct punch to

fit your press

ram! Type -R

punches fit the

reloading press,

type -M fit

Corbin presses.

23456

23456

23456

.224 (5.56mm)

PUNCH-M, and PUNCH-R

234567890

234567890

234567890

234567890

234567890

234567890

234567890

234567890

234567890

234567890

234567890

234567890

234567890

234567890

234567890

234567890

234567890

234567890

23456

23456

23456

-R

Loading...

Loading...