Page 1

The Corbin

R Corbin type -S Bullet Swage Dies (1-inch body, 5/8-24 shank). Die

fits the ram, punch used in floating punch holder. Self-ejection.

R Corbin type -M Bullet Swage Dies (7/8-inch body, 5/8-24 shank).

Die fits the ram, punch used in floating punch holder. Self-ejection.

R Corbin type -R Bullet Swage Dies (7/8-14 threads, button/T-slot

punch). Die fits press head, punch fits reloading adapter.

R Corbin type -R Draw Dies (7/8-14 threads, botton/T-slot punch).

Die fits press head directly, punch fits reloading adapter.

R Corbin type -S or -M Draw Dies (7/8-14 threads, 5/8-24 tpi punch).

Die fits press head directly, punch screws into ram.

R RCBS-type reloading dies (7/8-14 threads, button/T-slot shell

holder). Dies fit press head directly, punch fits reloading adapter in

the ram

R All other Corbin dies whose catalog number ends in -S will work in

the

ejection pin for all other punches)

Bullet swage dies have both an internal and an external punch. The internal

punch stays inside the swage die during operation. The external punch is used

to push components into the die and apply pressure to them. The FPH-1-S

floating punch holder is used to position the external punch for different weights

and lengths of bullets with the same set of dies.

S-P

S-PRESS

RESS

(use the short stop pin with slotted punches, long

works with these dies:

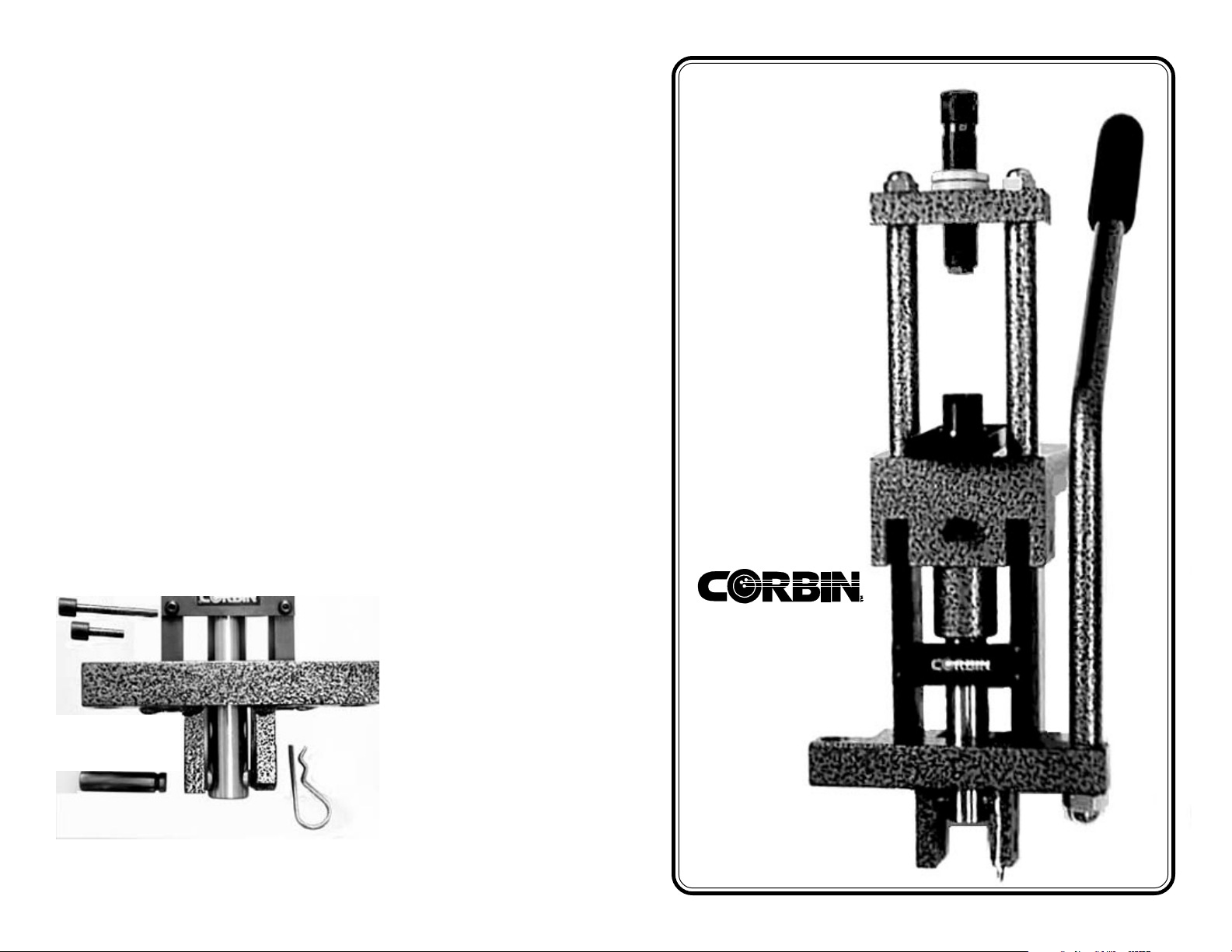

The NEW

S-P

RESS

All-Steel

High pressure

Roller bearing

Bullet

Swaging

and

Reloading

Press

The stop pin, in the front of the press, passes through the ram and stops the

downward movement of the internal punch causing automatic ejection. Point

forming dies have a long internal punch head pinned through a hole, so that the

punch does not move with the ram.

Most other swage dies use a punch that

travels with the ram, and simply rests on

Stop pins

Ram pin

CORBIN PO Box 2659, White City, OR 97503 USA

www.Corbins.com sales@corbins.com 541-826-5211 9am-5pm Mon-Thur.

the stop pin during the last part of the

down stroke (to eject). The

internal point form punch

was previously made with

a slot in the head. The new

stronger style uses a hole through the

punch head. When using the older

style punches (with a slot), use the

short stop pin. All other times, use

the long stop pin.

from

Hand built

by

American

Machinists

in the

USA

Catalog No. CSP-1

Page 2

Specifications

R Swages from .123 to .458-inch diameter bullets (-S dies)

R Swages up to 1.3-inch long bullets

R Dual stroke design: switch from 2-inch to 4-inch with one pin

R Provides over 200% more leverage than a reloading press

R Hardened, ground alloy steel ram, steel frame

R Up to 500% stronger than cast frame reloading presses

R Standard 7/8-14 thread accepts all conventional reloading dies

R Corbin -S dies screw directly into the ram (5/8-24 thread)

R Approximately 22 pounds (48.4kg) shipping weight

Features

R Four sets of precision roller bearings in the steel link arms

R Half the effort, 300% faster compared to reloading press

R Ram travels within two solid bearings in precision honed bore

R Silky smooth operation: all moving joints use bearings

R No pot metal, grey iron, aluminum or zinc castings are used

R Hand-assembled for benchrest precision reloading and swaging

R Free reloading adapter to accept button-type shell holders

R Spring-loaded ball-bearing detent in the shell holder adapter

R Primer and lead extrusion catcher tray travels with the ram

R Comfortable neoprene foam grip, left or right side handle mount

Options

R CSP-A Arbor-press type screw-in anvil set (top and bottom), use

your press with arbor-press type dies, or as a bearing or sight press

R CSP-B Steel bench stand with storage shelf (12-inch height), puts

the die mouth at eye level where you can see the alignment

R CSP-C Handle retainer clip (kit), holds the handle securely in the

up position so that bumping the press or bench won't cause it to fall

R CSP-S Self-supporting floor stand with comfortable deck, for easy

operation without a bench: in an apartment, den or trade-show.

R FPH-1-QC Quick-change T-slotted punch holder, lets you slip the

external punch out to load longer than usual parts quickly

R FPH-1-S Spare floating punch holder for pre-set repeatable

adjustments to weight, style, or tip opening of the bullet

Dual Stroke Operation

Reloading and jacket drawing often require a longer stroke, with less power

then bullet swaging. The

can have either more stroke, or more power, whichever is required for the job.

If you don't use the right position of the toggle-to-ram pin, the position of the ram will

be wrong for the operation, and the operation may not work.

Moving the toggle-to-ram pin:

Short

stroke

position

Long stroke

position

S-PRESS

features a dual-stroke operation, so you

R Short Stroke: In all swaging operations, the ram should be in the

short stroke mode (ram pin should be in the set of holes which

travels in the smaller arc). If the ram does not go high enough (in

drawing or reloading), check the pin that joins the ram with the

toggle arms...it is probably in the wrong set of holes! Move it to the

long stroke set.

R Long Stroke: In nearly all reloading and drawing operations

(unless otherwise instructed) the ram must be in the long stroke

mode (ram pin should be in the set of toggle holes that travels in

the wider arc). If the ram won't go all the way to the top, or the

handle travel seems to be blocked before it reaches either end of

the stroke (during swaging), you probably have the pin that joins

the ram to the toggle arms in the wrong set of holes! Move it to the

short stroke set.

Look at the lower part of the press ram and find the single steel pin that

connects it to the two toggle arms on either side of it. Notice that

the toggle arm on the right side has a heavy "grenade pin" retainer

projecting from the end. This link retainer pin passes close by a

groove in the ram pin, and keeps it from sliding out

sideways.

èGrasp and pull the "grenade pin" out of the

press entirely.

èMove the ram so you can access the ends of the

ram pin, and gently push the ram pin to the left,

until the ram is free (the stop pin will keep the ram

from falling completely out of the press).

èMove the ram and the toggle until you

can easily push the pin, by hand, back into

the other set of holes in the toggle arms.

èReplace the "grenade pin" retainer to

keep the ram pin in position (failure to do so

may result in the pin working out and

damaging the press links)

"Grenade" pin

Loading...

Loading...