Page 1

FREE STANDING OVEN

Instruction Manual

Cocına De Gas-Eléctrıco Instruccıones De Uso

GB

ESP

Page 2

GB

Dear User,

Our objective is to make this product provide you with the best output

which is manufactured in our modern facilities in a careful working

environment, in compliance with total quality concept.

Therefore, we suggest you to read the user manual carefully before using the

product and, keep it permanently at your disposal.

NOTE:

This user manual is prepared for more than one model. Some of the

features specified in the Manual may not be available in your appliance.

All our appliances are only for domestic use, not for commercial use.

“THIS APPLIANCE SHALL BE INSTALLED IN ACCORDANCE WITH THE

REGULATIONS IN FORCE AND ONLY USED IN A WELL VENTILATED SPACE. READ

THE INSTRUCTIONS BEFORE INSTALLING OR USING THIS APPLIANCE”

CONTENTS:

Important warnings

Technical features of your oven

Installation of your oven

If the appliance does not operate

Description of oven & control panel

Using cooker section

Using oven section

Using grill deflector

Maintenance and cleaning

Usage of Coffeepot support

1 1

Page 3

IMPORTANT WARNINGS

Electrical Connection and Security:

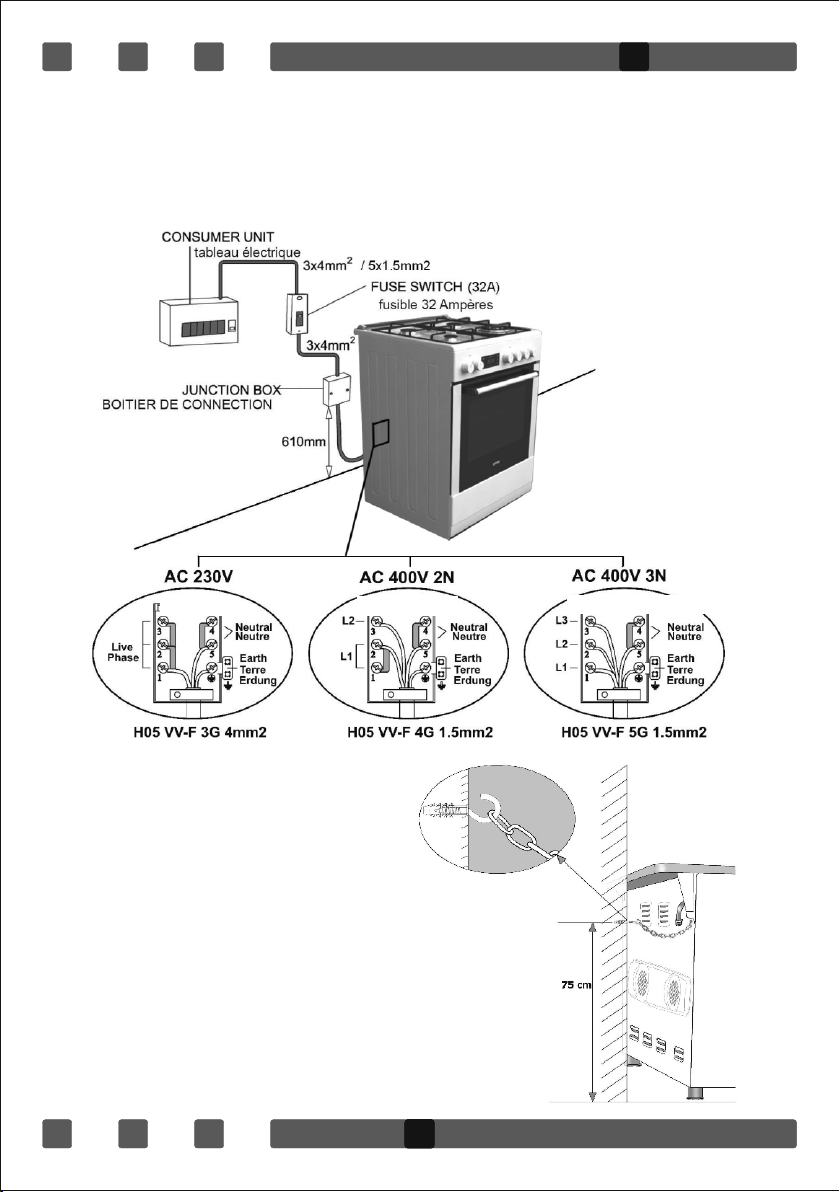

1.Your oven requires 16 or 32 Ampere fuse according to the appliance's

power. If necessary, installation by a qualified electrician is recommended.

2.Your oven is adjusted in compliance with 230V~50-60Hz. (or

230V/400V~50-60Hz.) electric supply. If the mains are different from this

specified value, contact your authorized service.

3.Electrical connection of the oven should only be made by the sockets with

earth system installed in compliance with the regulations. If there is no

proper socket with earth system in the place where the oven will be placed,

immediately contact a qualified electrician. Manufacturer shall never be

responsible from the damages that will arise because of the sockets

connected to the appliance with no earth system. If the ends of the electrical

connection cable are open, according to the appliance type, make a proper

switch installed in the mains by which all ends can be disconnected in case

of connecting / disconnecting from / to the mains.

4.If your electric supply cable gets defective, it should definitely be replaced

by the authorized service or qualified electricians in order to avoid from the

dangers.

5.Electrical cable should not touch the hot parts of the appliance.

6.Please operate your oven in dry atmosphere.

Gas Connection and Security:

Please operate your oven in dry atmosphere.

1.Fit the clamp to the hose. Push one of the hose until it goes to the end of

the pipe.

2.For the sealing control; ensure that the buttons in the control panel are

closed, but the gas cylinder is open. Apply some soap bubbles to the

connection. If there is gas leakage, there will be foaming in the soaped area.

3.The oven should be using a well ventilation place and should be install on

flat ground.

4.Re-inspect the gas connection.

5.When placing your oven to its location, ensure that it is at the counter

level. Bring it to the counter level by adjusting the feet if necessary.

6.Do not make gas hose and electrical cable of your oven go through the

heated areas, especially through the rear side of the oven. Do not move gas

connected oven. Since the forcing shall loosen the hose, gas leakage may

occur.

2

Page 4

GB

7.Before using the appliance, in order to ensure safe use, be sure to fix the

appliance to the wall using the chain and hooked screw supplied. Ensure that

the hook is screwed into the wall securely.

8.Please use flexible hose for gas connection.

230V~ 50-60Hz

230~/ 400V 2N~ 50-60Hz

Before using the appliance, in

order to ensure safe use, be sure

to fix the appliance to the wall

using the chain and hooked screw

supplied. Ensure that the hook is

screwed into the wall securely.

3

230~ / 400V 3N ~ 50-60Hz

1

Page 5

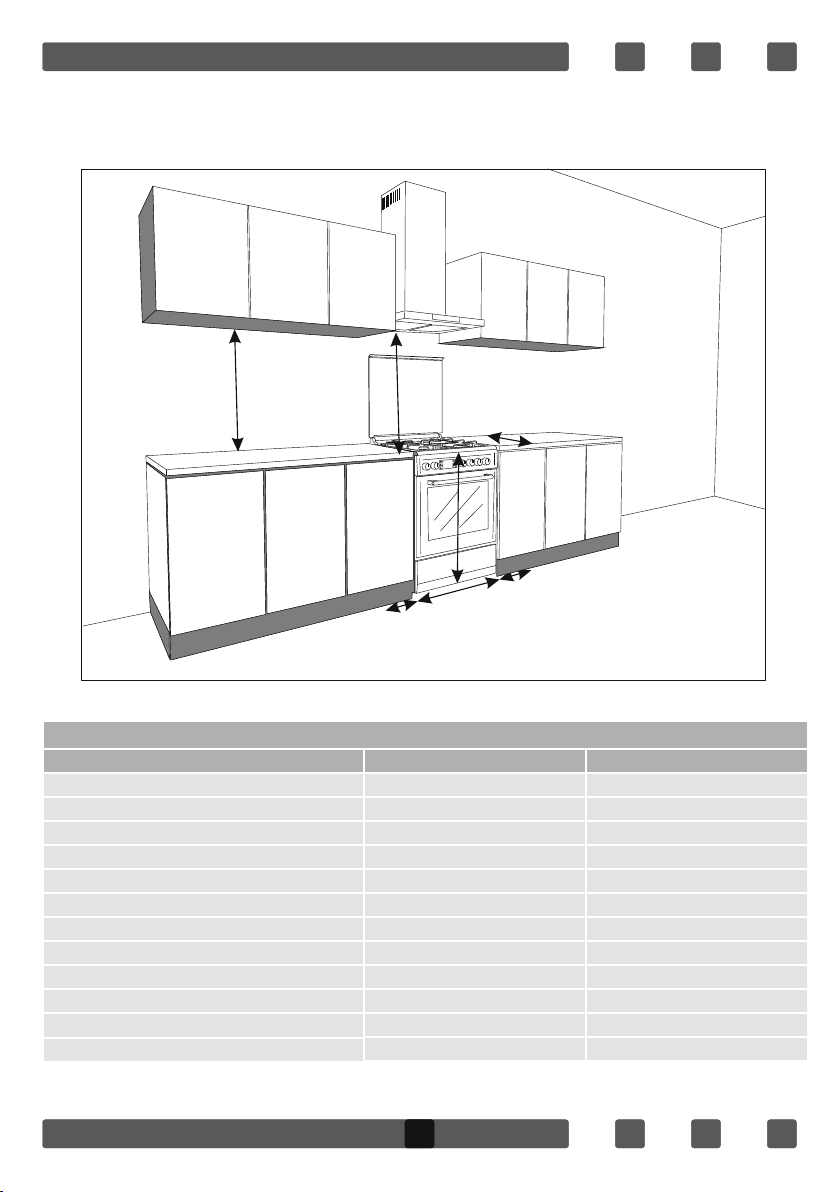

INSTALLATION OF YOUR OVEN

TECHNICAL FEATURES OF YOUR OVEN

SPECIFICATIONS

Outer width

Outer depth

Outer height

Inner width

Inner depth

Inner height

Inner Volume

Lamp power

Bottom heating element

Top heating element

Turbo heating element

Grill heating element

Min:570mm

Min:650mm

640mm

850mm

20mm

*Min:500-600mm

20mm

50x60 60x60

500 mm 600 mm

630 mm 630 mm

855 mm 855 mm

360 mm 460 mm

400 mm 400 mm

330 mm 330 mm

48 lt

15 W 15 W

1000 W 1200 W

800 W 1000 W

1800 W 2200 W

1500 W 2000 W

61 lt

4

Page 6

Supply Voltage

220V-240V AC,50-60Hz (Or 230V400V

AC,50-60 Hz)

1000 WHot Plate 145 mm

Hot Plate 180 mm

Hot Plate rapid 145 mm

Hot Plate rapid 180 mm

BURNER INJECTOR VALUES ACCORDING TO THE GAS

TYPE

Injector Ø mm

Wok Burner

Rapid Burner

Semi Rapid Burner

Auxiliary Burner

Oven Burner

Grill Burner

Power kW

Consuption Gr/h,m³/h

Injector Ø mm

Power kW

Consuption Gr/h,m³/h

Injector Ø mm

Power kW

Consuption Gr/h,m³/h

Injector Ø mm

Power kW

Consuption Gr/h,m³/h

Injector Ø mm

Power kW

Consuption Gr/h,m³/h

Injector Ø mm

Power kW

Consuption Gr/h,m³/h

LPG G30/28-

30mbar

0,96 1,30 1,40

3,60 3,35 3,66

284 0,3 0,365

0,85 1,15 1,20

3,00 2,77 3,00

286 0,253 0,326

0,65 0,97 0,95

1,78 1,78 1,61

140 0,167 0,174

0,50 0,72 0,70

0,88 0,99 0,88

70 0,092 0,094

0,70 0,97 0,95

2,16/2,22 1,83/2,00 1,72/1,70

170/175 0,178/0,179 0,183/0,178

0,60/0,65 0,95 0,92/0,95

1,50/1,72 1,78/1,85 1,50/1,60

118/135 0,162/0,169 0,162/0,173

1500 W

1500 W

2000 W

NG

G20/20mbar

NG

G25/25mbar

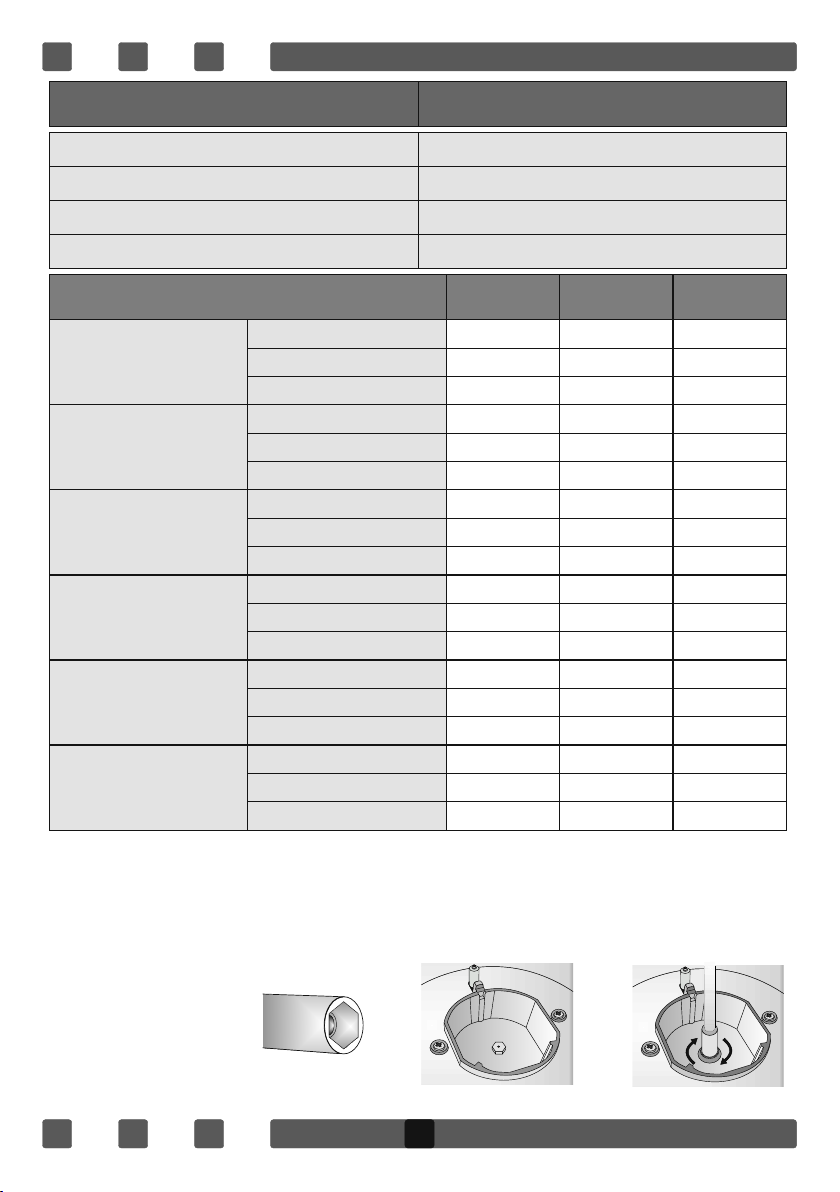

Nozzle change operation:

1. Please use driver with special head for removed and install nozzle as

figure-1

2. Please remove nozzle (Figure -2) from burner with special nozzle driver

and install new nozzle (Figure -3)

Fgure-1 Fgure-2 Fgure-3

5

Page 7

From LPG to NG

From NG to LPG

Rapid Burner

3 Turns Counterclockwise

3 Turns Clockwise

Semi-Rapid Burner

2.5 Turns Counterclockwise

2.5 Turns Clockwise

Auxiliary Burner

2 Turns Counterclockwise

2 Turns Clockwise

WOK Burner

4 Turns Counterclockwise

4 Turns Clockwise

Oven Burner

4,5 Turns Counterclockwise

4,5 Turns Clockwise

Grill Burner

4 Turns Counterclockwise

4 Turns Clockwise

GB

Reduced Flame Gas Cock Adjustment:

In order to adjust your oven to the gas type, make the adjustment for

reduced flame carefully by turning with a small screwdriver as shown below

on the screw in the middle of the gas cocks as well as nozzle changes.

Figure-4 Figure-5

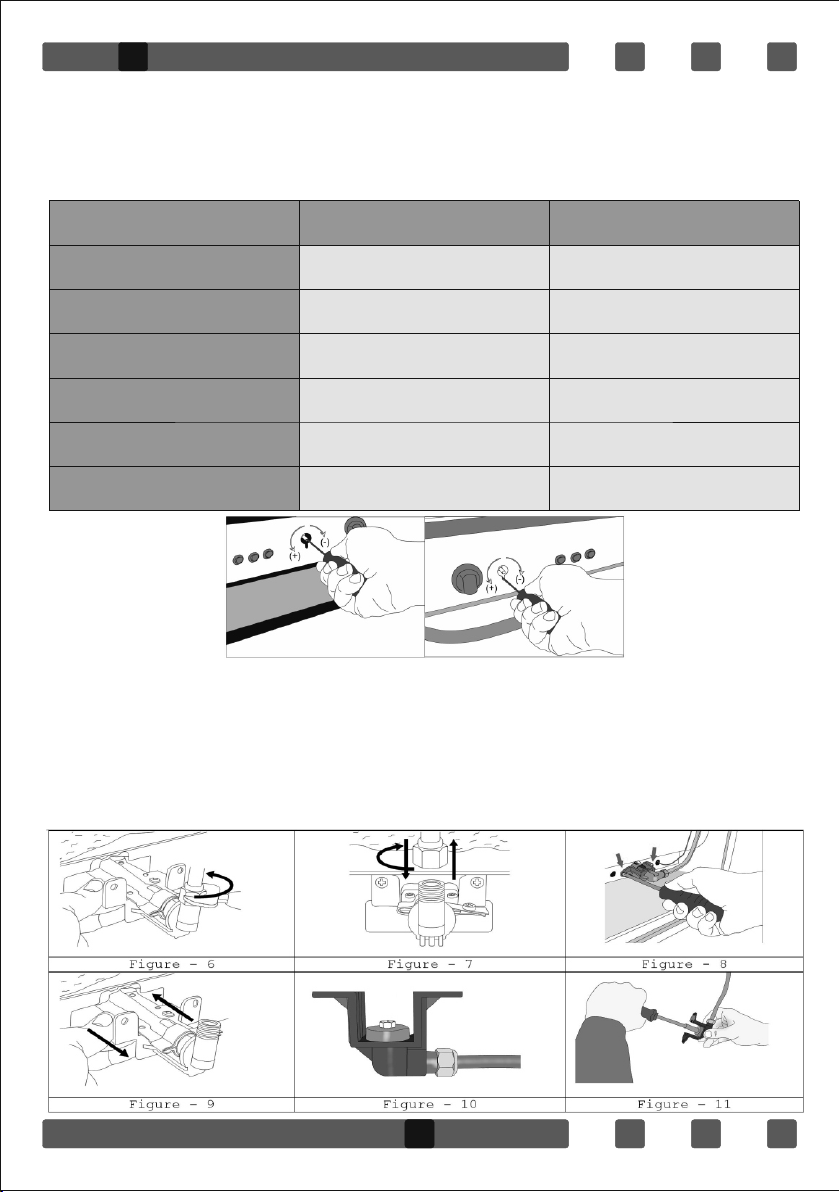

For oven burners:

1.Please remove nut from on nozzle body with nutdriver and disconnect

gas pipe from body as Figure-6 and 7.

2.Please remove nozzle body and burner from cavity as Figure -8/9 and

remove nozzle from injector body (Figure-10/11) and change. Than reinstall nozzle body and burner on cavity by screws.

6

Page 8

If your oven has another type of oven burner, oven burner nozzle replacement

will be:

IMPORTANT WARNINGS:

1.Pay attention to minimum health and safety requirements.

2.The cooker is supplied setup according to the conditions shown on the

rating label which is stuck to the rear of the appliance. From this sticker you

can learn for which gas type (LPG or NG) this appliance is configured when

supplied.

3.Keep the electrical cable of your oven away from the hot areas.

4.If the supply cord is damaged, it must be replaced by the manufacturer its

services agent or similar qualified persons in order to avoid hazard.

5.Ensure that the appliance is switches off before replacing the lamp to avoid

the possibility of electric shock.

6.In case of power failure, readjust your timer definitely. Otherwise, the oven

will not operate (Digital Timer).

7.Your oven can be having different output pressure according your countries

gas and pressure specifications. Be sure that the cooker is configured

correctly for local requirements (for example, the jets must be suitable for local

gas type and gas pressure).

8.Connect your oven to LPG in shortest way and without any leakage. Min. 40

cm Max. 125 cm.

9.When making gas leakage check, never use any flame type like those of

lighter, matches, cigarette fire or similar ones.

10.Usage of your appliance creates moisture and heath in the room it is

placed, make sure that your kitchen is ventilated well. Maintain the natural

ventilation ducts properly.

7

Page 9

GB

11.CAUTION! Do not touch hot parts with bare hands and keep children

well supervised

12.When the oven is hot never touch the oven glass by hand.

13.Before starting to use your appliance, keep curtain, tulle, paper or

inflammable things away from your appliance. Do not keep combustible or

inflammable things in or on the appliance.

14.This appliance is for cooking purposes only. It must not be used for

other purposes, for example room heating. All our appliances are only for

domestic use, not for commercial use.

15.For disconnection from the supply mains having a contact separation in

all poles that provide full disconnection, must be incorporated in fixed

wiring in accordance with the wiring rules.

16.Some models are supplied without a plug-an-lead set. In this case

please use a flexible cable to suitable for connection to mono phase: H05

VV-F 3 G 4 mm2 or for 3 phase: H05 VV-F 5 G 1.5 mm2

17.This appliance is produced in accordance with the safety regulations.

Incorrect use will harm people and appliance.

18.Children should be supervised to ensure that they do not play with the

appliance. Never let them play with the appliance.

19.Unattended cooking on a hob with fat or oil can be dangerous and may

result in fire.NEVER try to extinguish a fire with water, but switch off the

appliance and then cover flame e.g. with a lid or a fire blanket.

20.Danger of fire: do not store items on the cooking surfaces

19.This appliance is not intended for use by persons (including children)

with reduced physical, sensory and mental capabilities or lack of

experience and knowledge, unless they have been given supervision or

instruction concerning the use of the appliance by a person responsible for

their safety.

20.“Caution: Accessible parts may be hot when the grill is in use. Young

children should be kept away”

IF THE APPLIANCE DOES NOT OPERATE

1.Please check the plug of power supply cord has a well connection with

wall socket or not.

2.Please check the electric network.

3.Please check the fuse.

8

Page 10

4.Please check power supply cord for any damage problems.

5.If you can not solve the problem, get in contact with manufacturer-

supplier service agent or similar qualified persons.

DESCRIPTION OF OVEN and CONTROL PANELS

Turnspt Fan

Top + Bottom heatng element Turbo heatng + Fan

Lamp Bottom + Top heatng elements + Fan

Bottom heatng element + Fan Grill heating element+fan

Grill heating e Grill burner / grill heating element

Grill heating element+lamp Top heating element

Electrical timer Oven burner / Bottom heating element

Flame Ignition lighter

THERMOSTAT KNOB; In order to operate the oven, thermostat must be

adjusted to desired temperature. Your thermostat has a feature of

adjustment to 50 - 280 degree.

MECHANIC TIMER KNOB (Optional); In order to operate the oven, timer

switch should be adjusted to desired time from 0-90 minute. You can use

cooking time table.

DESCRIPTION OF THE OVEN and CONTROL PANELS

7

1-Rapid burner

2-Semi-rapid burner

2

1

3

66

4

5

8

9

3-Auxiliary burner

4-Command panel

5-Oven handle

6-Top plate

7-Top lid (glass or metal)

8-Oven door

9-Dish warmer Drawer

9

Page 11

WOK Burner

24-28cm

Big Burner

22-26cm

Normal Burner

18-22cm

Small Burner

12-18cm

GB

USING COOKER SECTION

Using Gas Burners:

Closed

Fully open

Half open

1.In order to obtain maximum output, be careful that the saucepan which

will be used should be flat bottomed, and use the saucepans with

dimensions given herein above.

2.The valves controlling the gas cookers have special security mechanism.

In order to light the cooker;

Always press on the switch forward and bring it to flame symbol by turning

counterclockwise. All of the lighters shall operate and the cooker you

controlled shall light only. Keep the switch pressed until ignition is

performed. Press on the lighter button and turn the knob counter

clockwise.

3.Do not continuously operate the igniter for more than 15 seconds. If the

burner does not ignite, wait minimum one minute before try again. If the

burner is extinguished because of any reason, close the gas control valve

and wait minimum one minute before try again.

4.In models with Gas Security System, when flame of the cooker is

extinguished, control valve cuts off the gas automatically. For operate the

burners with gas security system you must press the knob and turn

counter-clock-wise. After the ignition you must wait nearly 5-10 second for

gas security systems activation. If the burner is extinguished for of the any

reason, close the gas control valve and wait a minimum of one minute

before trying again.

Using Hot Plates:

145 mm

180 mm

145 mm rapd

180 mm rapd

LEVEL 1

95 W

115 W

135 W

175 W 220 W

LEVEL 2

155 W

175 W

165 W

LEVEL 3

250 W

250 W

250 W

300 W

LEVEL 4

400 W

600 W

500 W

850 W

LEVEL 5

750 W

850 W

750 W

1150 W

LEVEL 6

1000 W

1500 W

1500 W

2000 W

10

Page 12

1.Electric hotplates have standard of 6 temperature levels (as described

herein above)

2.When using first time, operate your electric hotplate in position 6 for 5

minutes. This will make the agent on your hotplate which is sensitive to heat

get hardened by burning.

3.Use flat bottomed saucepans which fully contact with the heat as much as

you can, so that you can use the energy more productively.

Before operating your hob please make sure that the burner caps are well

positioned. The right placement of the burner caps are shown as below.

USING OVEN SECTION

Using oven burners:

1.If your oven equipped with burners that operates with gas, appropriate

knob should be used in order to ignite the burners. Some models have

automatic ignition from the knob; it is easy to ignite the burner by turning

the knob. Also, burners can be ignited by pressing the ignition button or

they can be ignited with a match.

2.Do not continuously operate the igniter for more than 15 seconds. If the

burner does not ignite, wait minimum one minute before trying again. If the

burner is extinguished for of the any reason, close the gas control valve and

wait a minimum of one minute before trying again.

11

Page 13

GB

Using oven heating elements:

1.When your oven is operated first time, an odor will be spread out which will

be sourced from using the heating elements. In order to get rid of this,

operate it at 250 °C for 45-60 minutes while it is empty.

2.Oven control knob should be positioned to desired value; otherwise oven

does not operate.

3.Kinds of meals, cooking times and thermostat positions are given in

cooking table. The values given in the cooking table are characteristic values

and were obtained as a result of the tests performed in our laboratory. You

can find different flavors suitable for your taste depending on your cooking

and using habits.

4.You can make chicken revolving in your oven by means of the accessories.

5.Cooking times: The results may change according to the area voltage and

material having different quality, amount and temperatures.

6.During the time when cooking is being performed in the oven, the lid of the

oven should not be opened frequently. Otherwise circulation of the heat may

be imbalanced and the results may change.

7.Using cake forms while cooking cake gives better result.

8.5 - 10 min. preliminary heating should be done prior cooking.

Cooking Time Table:

Meals

Creamed cake

Pastry

Biscuit

Cookie

Cake

Braided cookie

Filo Pastry

Savory pastry

Lamb meat

Veal

Mutton

Chicken (pieced)

Fish

Temperature (°C)

150-170

200-220

160-170

160-170

160-180

200-220

180-220

160-180

210-230

210-230

210-230

210-230

190-210

12

Rack position

2

2

3

3

2

2

2

2

1

1

1

1

3

Cooking time (min.)

30-35

35-45

20-25

20-35

25-35

30-40

35-45

20-30

90-120

90-120

90-120

75-100

40-50

Page 14

MAINTENANCE and CLEANING

1.Disconnect the plug supplying electricity for the oven from the socket.

2.While oven is operating or shortly after it starts operating, it is extremely hot.

You must avoid touching from heating elements.

3.Never clean the interior part, panel, lid, trays and all other parts of the oven

by the tools like hard brush, cleaning mesh or knife. Do not use abrasive,

scratching agents and detergents.

4.After cleaning the interior parts of the oven with a soapy cloth, rinse it and

then dry thoroughly with a soft cloth.

5.Clean the glass surfaces with special glass cleaning agents.

6.Do not clean your oven with steam cleaners.

7.Before opening the upper lid of the oven, clean spilled liquid off the lid. Also,

before closing the lid, ensure that the cooker table is cooled enough.

8.Never use inflammable agents like acid, thinner and gasoline when

cleaning your oven.

9.Do not wash any part of your oven in dishwasher.

10.In order to clean the front glass lid of the oven; remove the fixing screws

fixing the handle by means of a screwdriver and remove the oven door. Than

clean and rinse it thoroughly. After drying, place the oven glass properly and

re-install the handle.

2

1

3

1

2

4

13

Page 15

CLEANING AND MAINTENANCE OF THE OVEN'S FRONT DOOR GLASS

Remove the profile by pressing the plastic latches on both left and right sides

as shown in Figure 1 and pulling the profile towards yourself as shown in

Figure 2. Then remove the inner-glass as shown in Figure 3. If required,

middle glass can be removed in the same way. After cleaning and

maintenance are done, remount the glasses and the profile in reverse order.

Make sure the profile is properly seated in its place.

Figure 2Figure 1

Figure 3

USAGE OF COFFEEPOT SUPPORT:

Coffeepot support is to use small diameter pots with your cooker. Place

the support part on the grid centerly and then put the pot on it to start

using.

15

14

Page 16

ESP

ESP

Muy estimado cliente,

Estas instrucciones de uso contienen indicaciones importantes

acerca de la seguridad, la instalación / montaje, el empleo y el

cuidado del equipo.

Por este motivo le recomendamos leerlas cuidadosamente antes

de empezar a utilizar el producto y guardarlas para poderlas

volver a consultar en caso de necesidad.

Observación:

Estas instrucciones de uso han sido creadas para varios

modelos. Algunas de las propiedades indicadas en estas

instrucciones pueden diferir de las del equipo que usted ha

adquirido.

Atención: Todos nuestros aparatos son sólo para el uso

doméstico, no para el uso comercial

ESTE EQUIPO SE HA DE INSTALAR EN CONFORMIDAD CON LA NORMATIVA

VIGENTE Y SOLO PUEDE SER UTILIZADO EN LUGARES BIEN VENTILADOS. LEA

LAS INSTRUCCIONES ANTES DE INSTALARLO O EMPEZAR A UTILIZARLO.

ÍNDICE DE CONTENIDOS

Pagina

Indicaciones de instalación y seguridad

Información técnica

Si la cocina de gas deja de funcionar

A continuación se explica el significado de los símbolos

utilizados en el marco de manejo

Descripción del equipo

Manejo de los fogones

Manejo del horno

Limpieza y cuidados

15

15

Page 17

Indicaciones de instalación y seguridad

CONEXIÓN ELÉCTRICA

1.Esta cocina de gas necesita fusibles de 16 amperios. El enchufe del

equipo solo puede conectarse a una toma de corriente que esté

debidamente conectada a tierra.

2.Este equipo está diseñado para una alimentación de tensión de 230 V,

50 Hz. Si la red eléctrica principal del lugar donde se va a conectar el

equipo no cumple este requisito, diríjase a un punto de servicio autorizado.

3.Proporcione una buena ventilación al lugar (sin corrientes de aire). Este

equipo solo puede ser instalado en espacios que cumplan las normativas

aplicables. Efectúe los trabajos de limpieza y conservación de los

conductos de aire de forma regular.

4.En caso de resultar dañada la línea de alimentación, ésta deberá ser

reemplazada por un técnico de servicio o un técnico electricista autorizado

para evitar posibles peligros.

5.Durante la conexión y el manejo del equipo, preste atención a que la

línea de alimentación no entre en contacto con otras superficies calientes

CONEXIÓN DE GAS

Antes de instalar o cambiar un equipo de gas se ha de informar a la empresa

suministradora de gas local.

1.La instalación y la conexión del equipo solo puede ser efectuada a través

de una empresa registrada en la lista de instaladores o de un servicio de

asistencia técnica bajo contrato.

2.La conexión o el cambio a otro tipo de gas se ha de efectuar conforme a

las normas de conexión aplicables:

3.Gas natural: Normas técnicas para instalaciones de gas (TRGI)

4.Gas licuado de petróleo: Normas técnicas para gas licuado de petróleo

(TRF)

5.Tenga en cuenta las prescripciones aplicables al empleo de equipos de

gas.

6.Encontrará las especificaciones de la cocina de gas y su equipamiento

en la ficha de características que hay en la parte posterior de la misma

(GLP o gas natural –GN-).

7.En caso de utilizar gas natural la conexión se ha de efectuar con una

manguera de seguridad para gas y una toma de gas con un dispositivo de

cierre térmico (TAE).

16

Page 18

ESP

8.En caso de utilizar gas licuado de petróleo se ha de conectar una

pequeña instalación de gas con TAE.

9.No permita que las líneas de alimentación (eléctricas y de gas) entren en

contacto con las piezas calientes.

10.En caso de producirse daños en las líneas de alimentación, un técnico

deberá reemplazarlas por las líneas correspondientes para evitar posibles

peligros.

11.ATENCIÓN: A fin de evitar descargas eléctricas, compruebe que el

equipo está desconectado de la red antes de cambiar la lámpara del

horno.

12. ATENCIÓN: ¡La presencia de fugas solo puede ser comprobada por

un técnico!

13.Durante la búsqueda de fugas no encienda encendedores, cerillas,

cigarrillos ni materiales inflamables.

14.Durante el funcionamiento del horno se calientan varias piezas

descubiertas tales como los mandos, el marco de manejo y la plancha

exterior del horno; mantenga a los niños alejados de estas piezas.

15.No utilice el equipo como una estufa.

16.Cuando el equipo de gas esté en funcionamiento, mantenga alejados

todos los materiales inflamables tales como cortinas, tules, papeles y otros.

No coloque materiales inflamables o combustibles en el interior ni encima

del aparato. En el carro solo se pueden colocar: vajilla o bandejas para

hornos y otros materiales no inflamables.

En caso de producirse un escape de gas:

- cierre la válvula de la instalación o la bombona de gas

- apague todos los quemadores y otras fuentes de encendido.

- ventile la habitación; abra las ventanas y las puertas

- no conecte ningún aparato eléctrico (tampoco la luz)

- informe de la fuga de gas al servicio técnico autorizado inmediatamente

Atención: La conexión incorrecta o realizada por terceros invalidará todas

las responsabilidades y el derecho a garantía.

15

17

Page 19

Antes de usar el artefacto, y a fin de lograr un uso

seguro, no olvide sujetar el artefacto al muro utilizando

la cadena y el tornillo en gancho provisto. Verifique

que el gancho esté atornillado en el muro firmemente

Min:570mm

Min:650mm

640mm

850mm

*Min:500-600mm

20mm

18

20mm

Page 20

ESP

Información técnica

PROPIEDADES

ANCHURA EXTERIOR

PROFUNDIDAD EXTERIOR

ALTURA EXTERIOR

ANCHURA HORNO

PROFUNDIDAD HORNO

ALTURA HORNO

Potencia Lámparas *

Termostato

Calefacción botón

Elemento de calentamiento

Elemento de calentamiento

turbo *

Elemento calefactor

parrilla *

TENSIÓN DE ALIMENTACIÓN

calefacción

calefacción

calefacción

calefacción

Modelo de tubo según tipo de

Quemador Wok

Quemador de gas

grande

Calent.

Calent.

Quemador de gas

mediano

Quemador de gas

pequeño

Superior horno

inferior horno

de la

ø140*

ø180*

ø140*rapid

ø180*rapid

gas

Tubo

Línea

Tubo

Línea

Tubo

Línea

Tubo

Línea

Tubo

Línea

Tubo

Línea

50 x 55

500 mm

550 mm

855 mm

360 mm

400 mm

350 mm

1000 W

800 W

--

1500 W

220 -240 V AC, 50 - 60 Hz ( 230V/400V AC, 50 - 60 Hz.)

mm

KW

mm

KW

mm

KW

mm

KW

mm

KW

mm

KW

G 30 - 30

2.16 / 2.22

0.60 / 0.65

2.22 / 1.72

LPG

0.96

3.60

0.85

3.00

0.65

1.78

0.50

0.88

0.70

50 x 60

500 mm

630 mm

855 mm

360 mm

400 mm

350 mm

1000 W

800 W

1800 W

1500 W

50 – 280 °C

1000 W

1500 W

1500 W

2000 W

Gás Natural

G 20 - 20

1.30

3.35

1.15

2.77

0.97

1.78

0.72

0.99

0.97

1.83 / 2.00

0.95

1.78 / 1.85

15 W

60 x 58

600

580 mm

855 mm

460 mm

400 mm

350 mm

mm

60 x 60

600 mm

630 mm

855 mm

460 mm

400 mm

350 mm

1200 W

1000 W

2200 W

2000 W

1200 W

1000 W

2200 W

2000 W

Gás Natural

G 25 - 25

1.40

3.66

1.20

3.00

0.95

1.61

0.70

0.88

0.95

1.72 / 1.70

0.92 / 0.95

1.50 / 1.60

FUEGO PEQUEÑO - Ajuste

Al cambiar el tipo o la presión del

gas se ha de prestar atención a lo

siguiente:

Para ajustar el horno de acuerdo

con el tipo y la presión del gas,

además de cambiar los tubos también

es necesario ajustar la cantidad

del caudal de gas para cada fogón

(tornillo de ajuste junto al

regulador; accesible al desmontar

el mando).

Figura - 1 Figura - 2 Figura - 3

Quemador

grande

Quemador

mediano

Quemador

pequeño

15

19

De GLP a gas natural

3 vueltas en sentido

contrario a las

agujas del reloj

2,5 vueltas en

sen tido contrario a

las agujas del reloj

2 vueltas en sentido

contrario a las

agujas del reloj

De gas natural a

GLP

3 vueltas en

sentido de las

agujas del reloj

2,5 vueltas en

sentido de las

agujas del reloj

2 vueltas en

sentido de las

agujas del reloj

Page 21

Si la cocina de gas deja de funcionar

1.Compruebe si está abierta la válvula de gas principal.

2.Compruebe si la manguera de gas está conectada correctamente a la

cocina.

3.Compruebe si sale gas por los fogones después de abrir la válvula.

4.Si el horno sigue sin funcionar después de efectuar estos controles,

póngase en contacto con un técnico o con el punto de servicio técnico más

cercano.

20

Page 22

ESP

A continuación se explica el significado de los símbolos utilizados en el

marco de manejo

Asado (pollo cocinado)

Cocinar por la única es la parte superior del

horno

Luz

Cocinar por la única y funcionamiento del

ventlador

Cocinar con la parrilla+ Asado (pollo

cocinado)

Cocinar con la parrilla+ Luz

Temporizador

llama

Descripción del equipo

3

Operación de cocción ventilador

Operación de cocción ventilador turbo

Convección, el ventilador está funcionando

Cocinar con la parrilla+ ventilador

Cocinar con la parrilla

Cocinar con la parte superior

Cocinar por la única

PULSADOR DE ENCENDIDO

1. Quemador Grande

7

2

1

66

4

5

8

9

2. Quemador médo

3. Quemador pequeno

4. Marco de manejo

5. Empuñadura de la

6. Espaco de cocna

7. Tapa abatble

8. la puerta del horno

9. plato calente

repartr el c a jón

10.

11. Chapa de calor (solo con

calentador

Manejo de los fogones

Prestar atención a los fogones:

Utilice utensilios de cocina adecuados para cada quemador.

Todos los quemadores están equipados con válvulas de seguridad

especiales. Para encender los fogones tenga en cuenta lo siguiente:

15

21

Page 23

Quemador grande

Quemador medano

Quemador pequeño

Ollas de 24

Ollas de 18 – 22 cm

Ollas de 12 – 18 cm

1. Presione el mando (conmutador) respectivo hacia dentro y gírelo en

–

28 cm

CERRADO

TOTALMENTE

ABIERTO

SEMIABIER-TO

sentido contrario a las agujas del reloj hasta que esté seleccionado el

símbolo de llama al máximo.

2. Presione el pulsador de encendido. Se activan todos los quemadores

pero solo se puede encender el fogón seleccionado.

Importante: Cuando la llama se apaga el sistema de seguridad del gas

desconecta automáticamente la alimentación de gas mediante una válvula

de mando

Todos los fogones de la cocina y del horno funcionan independientemente.

Para encender un fogón es necesario apretar el mando correspondiente y

esperar durante 5 – 10 segundos aproximadamente.

TABLA DE HORNEADO Y ASADO

ALIMENTOS

PASTELES DE NATA

GALLETAS RELLENAS

VOLOVÁN DE HOJALDRE

PASTELES

BIZCOCHOS

GALLETAS

PASTELES

PASTAS DULCES

CORDERO

TERNERA

POLLO (PIEZA)

PESCADO

OVEJA

TEMPERATURA

150 - 170

200 - 220

160 - 170

160 - 170

160 - 180

200 - 220

180 - 220

160 - 180

200 - 230

200 - 230

210 - 230

210- 230

190- 210

POSICIÓN

2

2

3

3

2

2

2

2

1

1

1

1

2

TIEMPO DE HORNEADO O

ASADO (mnutos)

30 - 35

35 - 45

20 - 25

20 - 35

25 - 35

30 - 40

35 - 45

20 - 30

90- 120

90- 120

90- 120

75- 100

40- 50

Observación: Los valores indicados en la tabla son promedios calculados

que pueden no corresponderse con sus necesidades personales. Antes de

hornear o asar, caliente el horno durante 5 – 10 minutos.

A continuación podrá encender el gas electrónicamente presionando el

pulsador de encendido o manualmente con una cerilla. Después de

encender el fuego mantenga el mando del gas presionado durante unos

segundos y luego suéltelo.

22

Page 24

ESP

Para encender los quemadores del horno deje la puerta abierta. Ciérrela

aproximadamente 3 segundos después de que la llama se haya encendido

y de comprobar que quema correctamente.

Manejo del horno

1. La primera vez que utilice el horno es posible que oiga un ruido

molesto. Preste atención a que la habitación esté suficientemente

ventilada y caliente el horno vacío durante aproximadamente 30 minutos

a 250 ºC.

2.Encienda el horno (véase „Manejo de los fogones“).

3.En la tabla de horneado y asado se indican los tipos de alimentos, los

tiempos de horneado y asado y la posición correcta del termostato para

cada uno de ellos.

4.Los valores de la tabla son promedios que han sido obtenidos en los

ensayos realizados en nuestros laboratorios.

5.En función del estilo de horneado y asado que utilice y de sus propias

costumbres podrá preparar distintos platos.

6.Tiempos de horneado y asado: Éstos tiempos sirven solo como

referencia, ya que los materiales, las cantidades y los alimentos

utilizados pueden dar distintos resultados en función de la temperatura

utilizada

7.No abra la puerta del horno durante las operaciones de horneado y

asado (pérdida de calor).

8.Ello podría perjudicar el resultado del horneado o el asado

9.A fin de obtener mejores resultados cuando haga pasteles,

recomendamos utilizar moldes de horno apropiados

10. No coloque sartenes, ollas ni bandejas sobre el fondo del horno para

asar o mantener la comida caliente.

11. No coloque papel de aluminio ni ningún otro tipo de material sobre el

fondo del horno.

12. Ello podría estropear el esmalte.

13. No deje enfriar la comida dentro del horno (el horno podría oxidarse).

14. Ello invalidará el derecho a garantía.

15

23

Page 25

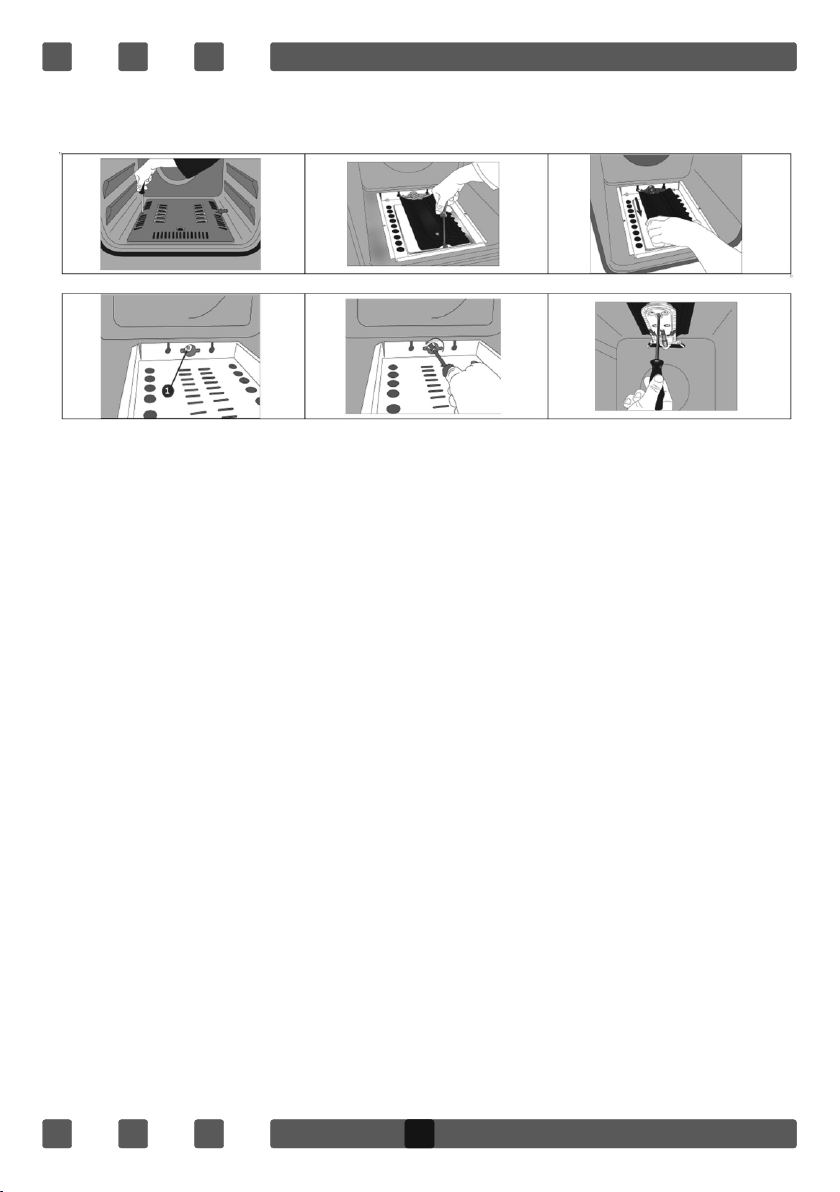

USO DE LA PLACA DE PROTECCIÓN

1. Para proteger el panel de control del horno, una placa fue diseñada.

(Figura 1)

2. Recomendamos el uso de esta pieza de protección para evitar daños

que pueden ser causados p or el calor durante la cocción.

3. Coloque la hoja de protección en el panel de control mediante la

apertura del horno (Figura 2)

4. Asegúrese de que la placa está bien posicionada cerca de su horno

(Figura 3)

5. Es importante mantener la tapa abierta.

6. La placa le asegurara su seguridad y protegerá las partes del panel de

control.

Limpieza y cuidados

1.Cuando efectúe los trabajos de limpieza y cuidado preste atención a lo

siguiente:

2.Antes de empezar la limpieza o el mantenimiento del equipo, asegúrese

de que está desconectado de la red eléctrica y de que está cerrada la

alimentación de gas.

3.Si el equipo todavía está caliente, déjelo enfriar el tiempo suficiente antes

de empezar la limpieza o el mantenimiento.

4.Cuando efectúe los trabajos de limpieza y cuidado preste atención a lo

siguiente:

5.Antes de empezar la limpieza o el mantenimiento del equipo, asegúrese

de que está desconectado de la red eléctrica y de que está cerrada la

alimentación de gas.

6.Si el equipo todavía está caliente, déjelo enfriar el tiempo suficiente antes

de empezar la limpieza o el mantenimiento.

24

Page 26

ESP

1

1

2

LIMPIEZA Y MANTENIMIENTO DEL VIDRIO DE LA PUERTA FRONTAL DEL HORNO

Retire el perfil presionando los enganches plásticos tanto a la derecha como

a la izquierda según se indica en la Figura 1 y traccionando el perfil hacia

usted como se indica en la Figura 2. Luego retire el vidrio interno según se

indica en la Figura 3. Si es necesario, el vidrio del medio puede retirarse del

mismo modo. Una vez realizados la limpieza y el mantenimiento, vuelva a

instalar los vidrios y el perfil en el orden inverso. Asegúrese de que el perfil esté

correctamente asentado en su lugar.

3

2

4

Figura 3

25

Figura 2Figura 1

Loading...

Loading...