Corally RDX Phi Instruction Manual

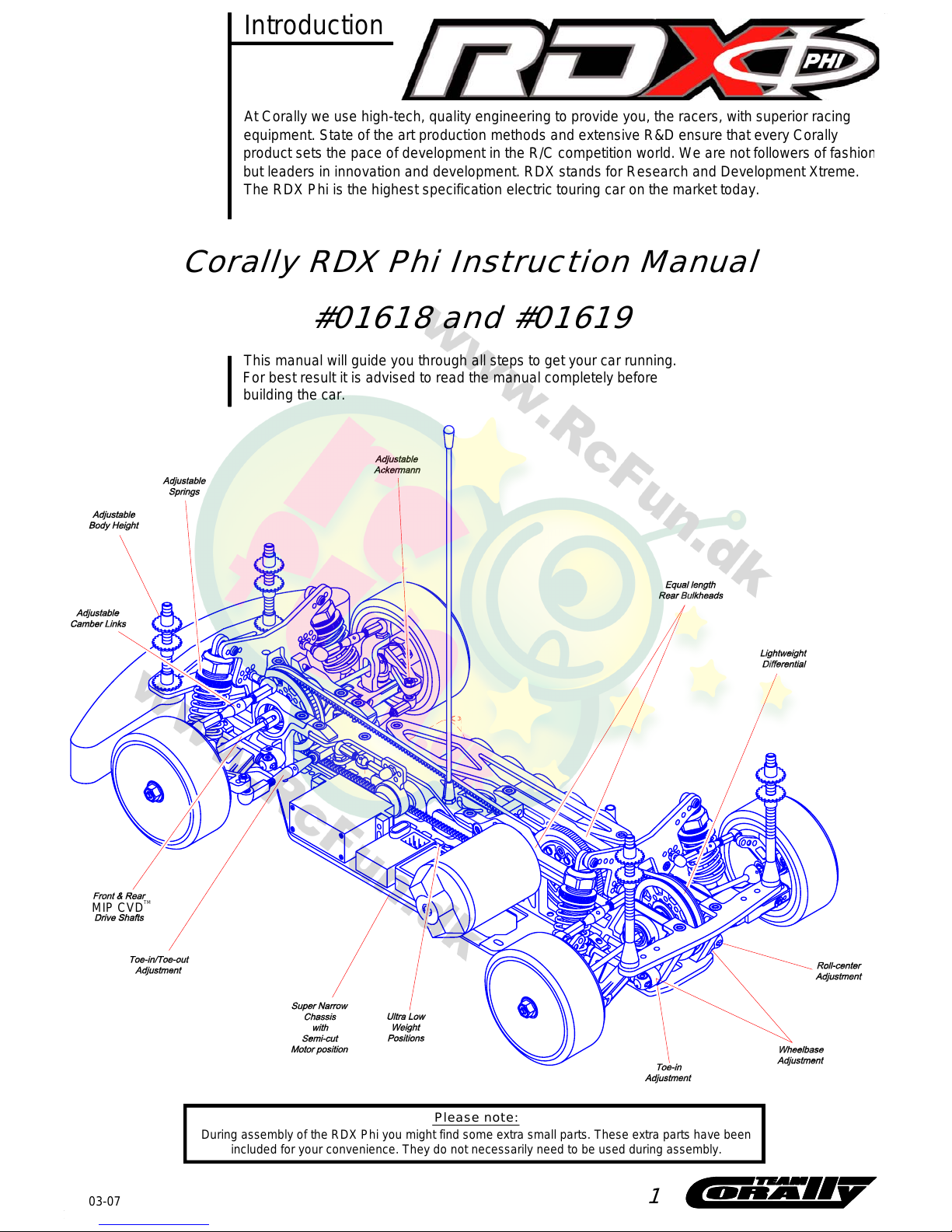

Introduction

TM

MIP CVD

At Corally we use high-tech, quality engineering to provide you, the racers, with superior racing

equipment. State of the art production methods and extensive R&D ensure that every Corally

product sets the pace of development in the R/C competition world. We are not followers of fashio

n

but leaders in innovation and development. RDX stands for Research and Development Xtreme.

The RDX Phi is the highest specification electric touring car on the market today.

This manual will guide you through all steps to get your car running.

For best result it is advised to read the manual completely before

building the car.

1

-

During assembly of the RDX Phi you might find som e ex tra sm al l pa rts. These extra parts have been

included for your convenience. They do no t necessarily need to be used during assembly.

Please note:

#01618 and #01619

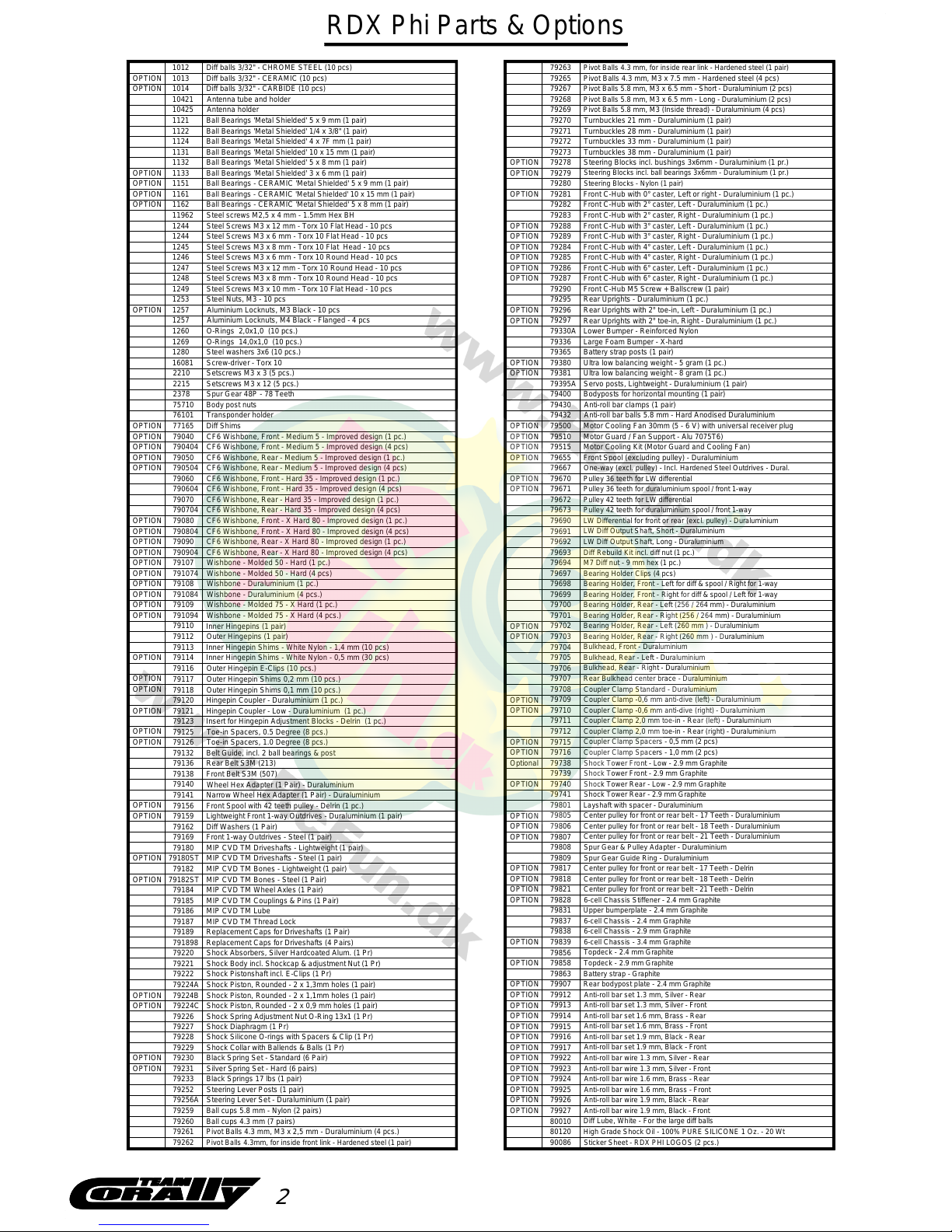

RDX Phi Parts & Options

1012

1013

1121

1131

1133

1132

1151

1161

1244

1280

16081

2378

2215

2210

1269

1249

1253

1248

1247

1246

1245

79121

79120

79116

79123

79138

79140

79136

79132

79126

79125

75710

791094

79110

79112

791084

79107

791074

77165

76101

79180

79184

79182

79162

79159

Toe-in Spacers, 1.0 Degree (8 pcs.)

MIP CVD TM Wheel Axles (1 Pair)

Diff Washers (1 Pair)

Wheel Hex Adapter (1 Pair) - Duraluminium

Lightweight Front 1-way Outdrives - Duraluminium (1 pair)

MIP CVD TM Driveshafts - Lightweight (1 pair)

MIP CVD TM Bones - Lightweight (1 pair)

Front Belt S3M (507)

Rear Belt S3M (213)

Belt Guide, incl. 2 ball bearings & post

Steel Screws M3 x 8 mm - Torx 10 Round Head - 10 pcs

Wishbone - Molded 50 - Hard (4 pcs)

Wishbone - Molded 50 - Hard (1 pc.)

Wishbone - Duraluminium (1 pc.)

Wishbone - Molded 75 - X Hard (4 pcs.)

Wishbone - Molded 75 - X Hard (1 pc.)

Wishbone - Duraluminium (4 pcs.)

Hingepin Coupl er - Low - Duraluminiu m (1 pc. )

Insert for Hingepin Adjustment Blocks - Delrin (1 pc.)

Toe-in Spacers, 0.5 Degree (8 pcs.)

Hingepin Coupler - Duraluminium (1 pc.)

Outer Hingepins (1 pair)

Outer Hingepin E-Clips (10 pcs.)

Inner Hingepins (1 pair)

Transponder holder

Diff Shims

Body post nuts

Steel Nuts, M3 - 10 pcs

Steel Screws M3 x 10 mm - Torx 10 Flat Head - 10 pcs

O-Rings 14,0x1,0 (10 pcs.)

Setscrews M3 x 3 (5 pcs.)

Setscrews M3 x 12 (5 pcs.)

Spur Gear 48P - 78 Teeth

Screw-driver - Torx 10

Steel washers 3x6 (10 pcs .)

Diff balls 3/32" - CHROME STEEL (10 pcs)

Diff balls 3/32" - CERAMIC (10 pcs)

Steel Screws M3 x 8 mm - Torx 10 Flat Head - 10 pcs

Steel Screws M3 x 6 mm - Torx 10 Round Head - 10 pcs

Steel Screws M3 x 12 mm - Torx 10 Round Head - 10 pcs

Steel Screws M3 x 6 mm - Torx 10 Flat Head - 10 pcs

Ball Bearings - CERAMIC 'Metal Shielded' 10 x 15 mm (1 pair)

Ball Bearings - CERAMIC 'Metal Shielded' 5 x 9 mm (1 pair)

Ball Bearings 'Metal Shielded' 5 x 8 mm (1 pair)

Ball Bearings 'Metal Shielded' 3 x 6 mm (1 pair)

Ball Bearings 'Metal Shielded' 10 x 15 mm (1 pair)

Ball Bearings 'Metal Shielded' 5 x 9 mm (1 pair)

Antenna holder

79109

79108

79230

MIP CVD TM Couplings & Pins (1 Pair)

79185

79229

79228

79227

79226

79224A

79222

79220

79189

79187

MIP CVD TM Lube

Shock Spring Adjustment Nut O-Ring 13x1 (1 Pr)

Shock Diaphragm (1 Pr)

Shock Silicone O-rings with Spacers & Clip (1 Pr)

Shock Piston, Rounded - 2 x 1,3mm holes (1 pair)

Shock Absorbers, Silver Hardco ated Alum. (1 Pr)

Shock Pistonshaft incl. E-Clips (1 Pr)

Shock Body incl. Shockcap & adjustment Nut (1 Pr)

Replacement Caps for Driveshafts (1 Pair)

MIP CVD TM Thread Lock

79186

79380

79430

79400

79395A

79381

79283

79297

79365

79330A

79296

79295

79290

79287

79286

79285

79284

79282

79281

79279

79273

79272

79271

79270

79265

79260

79256A

79252

79233

79231

79263

79221

Servo posts, Lightweight - Duraluminium (1 pair)

Bodyposts for horizontal mounting (1 pair)

Anti-roll bar clamps (1 pair)

Ultra low balancing weight - 8 gram (1 pc.)

Ultra low balancing weight - 5 gram (1 pc.)

Battery strap posts (1 pair)

Front C-Hub with 0° caster, Left or right - Duraluminium (1 pc.)

Front C-Hub with 6° caster, Left - Duraluminium (1 pc.)

Front C-Hub with 6° caster, Right - Duraluminium (1 pc.)

Front C-Hub M5 Screw + Ballscrew (1 pair)

Front C-Hub with 4° caster, Right - Duraluminium (1 pc.)

Front C-Hub with 4° caster, Left - Duraluminium (1 pc.)

Front C-Hub with 2° caster, Right - Duraluminium (1 pc.)

Front C-Hub with 2° caster, Left - Duraluminium (1 pc.)

Rear Uprights - Duraluminium (1 pc.)

Rear Uprights with 2° toe-in, Right - Duraluminium (1 pc.)

Rear Uprights with 2° toe-in, Left - Duraluminium (1 pc.)

Lower Bumper - Reinforced Nylon

Pivot Balls 4.3 mm, M3 x 7.5 mm - Hardened steel (4 pcs)

Turnbuckles 21 mm - Duraluminium (1 pair)

Turnbuckles 28 mm - Duraluminium (1 pair)

Turnbuckles 33 mm - Duraluminium (1 pair)

Steering Blocks incl. ball bearings 3x6mm - Duraluminium (1 pr.)

Turnbuckles 38 mm - Duraluminium (1 pair)

Silver Spring Set - Hard (6 pairs)

Black Spring S et - Standard (6 Pair)

Shock Collar with Ballends & Balls (1 Pr)

Black Springs 17 lbs (1 pair)

Ball cups 4.3 mm (7 pairs)

Pivot Balls 4.3 mm, for in side rear link - Hardened steel (1 pair)

Steering Lever Set - Duraluminium (1 pair)

Steering Lever Posts (1 pair)

OPTION

OPTION

OPTION

OPTION

OPTION

OPTION

OPTION

OPTION

OPTION

OPTION

OPTION

OPTION

OPTION

OPTION

OPTION

OPTION

OPTION

1122

Ball Bearings 'Metal Shielded' 1/4 x 3/8" (1 pair)

OPTION

791898

Replacement Caps for Driveshafts (4 Pairs)

OPTION

1162

Ball Bearings - CERAMIC 'Metal Shielded' 5 x 8 mm (1 pair)

Diff balls 3/32" - CARBIDE (10 pcs)1014

1257 Aluminium Locknuts, M4 Black - Flanged - 4 pcs

Narrow Wheel Hex Adapter (1 Pair) - Duraluminium

79141

2

MIP CVD TM Bones - Steel (1 Pair)79182STOPTION

Large Foam Bumper - X-hard79336

10425

OPTION

OPTION

OPTION

OPTION

790704

790604

79040

790504

79050

790404

CF6 Wishbone, Front - Medium 5 - Improved design (4 pcs)

CF6 Wishbone, Rear - Medium 5 - Improved design (1 pc.)

CF6 Wishbone, Rear - Medium 5 - Improved design (4 pcs)

CF6 Wishbone, Front - Medium 5 - Improved design (1 pc.)

CF6 Wishbone, Front - Hard 35 - Improved design (1 pc.)

CF6 Wishbone, Rear - Hard 35 - Improved design (4 pcs)

CF6 Wishbone, Rear - Hard 35 - Improved design (1 pc.)

CF6 Wishbone, Front - Hard 35 - Improved design (4 pcs)

79070

79060

790804

79080 CF6 Wishbone, Front - X Hard 80 - Improved design (1 pc.)

CF6 Wishbone, Front - X Hard 80 - Improved design (4 pcs)

79090

790904

CF6 Wishbone, Rear - X Hard 80 - Improved design (4 pcs)

CF6 Wishbone, Rear - X Hard 80 - Improved design (1 pc.)

Outer Hingepin Shims 0,2 mm (10 pcs.)

79117

Outer Hingepin Shims 0,1 mm (10 pcs.)79118

Front Spool with 42 teeth pulley - Delrin (1 pc.)

79156

Front 1-way Outdrives - Steel ( 1 pair)79169

79180ST

OPTION

MIP CVD TM Driveshafts - Steel (1 pair)

79224B Shock Piston, Rounded - 2 x 1,1mm holes (1 pair)

Shock Piston, Rounded - 2 x 0,9 mm holes (1 pair)79224C

Ball cups 5.8 mm - Nylon (2 pairs)

79259

Pivot Balls 4.3 mm, M3 x 2,5 mm - Duraluminium (4 pcs.)79261

Pivot Balls 4.3mm, for in side front link - Hardened steel (1 pair)

79262

Steering Blocks incl. bushings 3x6mm - Duraluminium (1 pr.)

79278

79280

Steering Blocks - Nylon (1 pair)

79289

79288 Front C-Hub with 3° caster, Left - Duraluminium (1 pc.)

Front C-Hub with 3° caster, Right - Duraluminium (1 pc.)

OPTION

OPTION

Anti-roll bar balls 5.8 mm - Hard Anodised Duraluminium79432

Motor Cooling Fan 30mm (5 - 6 V) with universal receiver plug

79500

Motor Guard / Fan Support - Alu 7075T6)

79510

Motor Cooling Kit (Motor Guard and Cooling Fan)

79515

79655

Front Spool (excluding pulley) - Duraluminium

One-way (excl. pulley) - I n cl. Hardened Steel Outdrives - Dural.

79667

Pulley 36 teeth for LW differential

79670

79671

Pulley 36 tee th for duraluminium spool / front 1-way

Pulley 42 teeth for LW differential

79672

Pulley 42 tee th for duraluminium spool / front 1-way

79673

LW Differential for front or rear (excl. pulley) - Duraluminium

79690

LW Diff Output Shaft, Short - Duraluminium

79691

LW Diff Output Shaft, Long - Duraluminium

79692

Diff Rebuild Kit incl. diff nut (1 pc.)

79693

M7 Diff nut - 9 mm hex (1 pc.)

79694

Bearing Holder Clips (4 pcs)

79697

79698

Bearing Holder, Front - Left fo r d iff & spool / Right for 1-way

Bearing Holder, Front - Right for diff & spool / Left for 1-way

79699

Bearing Holder, Rear - Right (256 / 264 mm) - Duraluminium

Bearing Holder, Rear - Left (256 / 264 mm) - Duraluminium

79700

79701

79702

Bearing Holder, Rear - Left (260 mm ) - Duraluminium

Bearing Holder, Rear - Right (260 mm ) - Duraluminium

79703

79705

79704

Bulkhead, Front - Duraluminium

Bulkhead, Rear - Left - Duraluminium

Bulkhead, Rear - Right - Duraluminium

79706

79707

Rear Bulkhead center brace - Duraluminium

79708

Coupler Clamp Standard - Duraluminium

Coupler Clamp -0,6 mm anti-dive (left) - Duraluminium

79709

Coupler Clamp -0,6 mm anti-dive (right) - Duraluminium

79710

Coupler Clamp 2,0 mm toe-in - Rear (right) - Duraluminium

Coupler Clamp 2,0 mm toe-in - Rear (left) - Duraluminium

79711

79712

79716

79715

Coupler Clamp Spacers - 0,5 mm (2 pcs)

Coupler Clamp Spacers - 1,0 mm (2 pcs)

Shock Tower Front - 2.9 mm Graphite

Shock Tower Front - Low - 2.9 mm Graphite

79738

79739

79741

Shock Tower R ear - 2.9 mm Graphite

Shock Tower Rear - Low - 2.9 mm Graphite

79740

Center pulley for front or rear belt - 18 Teeth - Duraluminium

79806

Center pulley for front or rear belt - 21 Teeth - Duraluminium

79807

Center pulley for front or rear belt - 17 Teeth - Duraluminium

79805

79801

Layshaft with spacer - Duraluminium

Spur Gear & Pulley Adapter - Duraluminium

79808

6-cell Chassis Stiffener - 2.4 mm Graphite

79828

Center pulley for front or rear belt - 18 Teeth - Delrin

Center pulley for front or rear belt - 21 Teeth - Delrin

79821

79818

Center pulley for front or rear belt - 17 Teeth - Delrin

79817

Spur Gear Guide Ring - Duraluminium

79809

79914

Anti-roll bar set 1.6 mm, Brass - Rear

Anti-roll bar set 1.9 mm, Black - Front

79915

Anti-roll bar set 1.6 mm, Brass - Front

79916

Anti-roll bar set 1.9 mm, Black - Rear

79917

Topdeck - 2.4 mm Graphite

Topdeck - 2.9 mm Graphite

79839

79856

79838

6-cell Chassis - 3.4 mm Graphite

6-cell Chassis - 2.9 mm Graphite

6-cell Chassis - 2.4 mm Graphite

79837

Upper bumperplate - 2.4 mm Graphite

79858

79863

79907

Battery strap - Graphite

Rear bodypost plate - 2.4 mm Graphite

Anti-roll bar set 1.3 mm, Silver - Rear

79912

79913

Anti-roll bar set 1.3 mm, Silver - Front

79831

79924

79927

79926

79925

79922

Anti-roll bar wire 1.3 mm, Silver - Front

Anti-roll bar wire 1.9 mm, Black - Front

Anti-roll bar wire 1.9 mm, Black - Rear

Anti-roll bar wire 1.6 mm, Brass - Front

Anti-roll bar wire 1.3 mm, Silver - Rear

79923

Anti-roll bar wire 1.6 mm, Brass - Rear

1124

Ball Bearings 'Metal Shielded' 4 x 7F mm (1 pair)

Steel Screws M3 x 12 mm - Torx 10 Flat Head - 10 pcs1244

Aluminium Locknuts, M3 Black - 10 pcs1257

OPTION

Steel screws M2,5 x 4 mm - 1.5mm Hex BH11962

Inner Hingepin Shims - White Nylon - 0,5 mm (30 pcs)

79113

Inner Hingepin Shims - White Nylon - 1,4 mm (10 pcs)

79114

79267

Pivot Balls 5.8 mm, M3 x 6.5 mm - Short - Duraluminium (2 pcs)

Pivot Ball s 5.8 mm, M3 x 6. 5 mm - Long - Duraluminium (2 pcs)

Pivot Balls 5.8 mm, M3 (Inside thread) - Duraluminium (4 pcs)

79269

79268

OPTION

OPTION

OPTION

OPTION

OPTION

Optional

OPTION

OPTION

OPTION

OPTION

OPTION

OPTION

OPTION

OPTION

OPTION

OPTION

OPTION

OPTION

OPTION

OPTION

OPTION

OPTION

OPTION

OPTION

OPTION

OPTION

OPTION

OPTION

OPTION

OPTION

OPTION

OPTION

OPTION

OPTION

OPTION

OPTION

OPTION

OPTION

OPTION

OPTION

OPTION

OPTION

OPTION

OPTION

OPTION

OPTION

OPTION

OPTION

90086

Sticker Sheet - RDX PHI LOGOS (2 pcs.)

80120

High Grade Shock Oil - 100% PURE S ILICONE 1 Oz. - 20 Wt

80010

Diff Lube, White - For the large diff balls

OPTION

OPTION

OPTION

O-Rings 2,0x1,0 (10 pcs.)

1260

OPTION

OPTION

OPTION

OPTION

OPTION

OPTION

10421

Antenna tube and holder

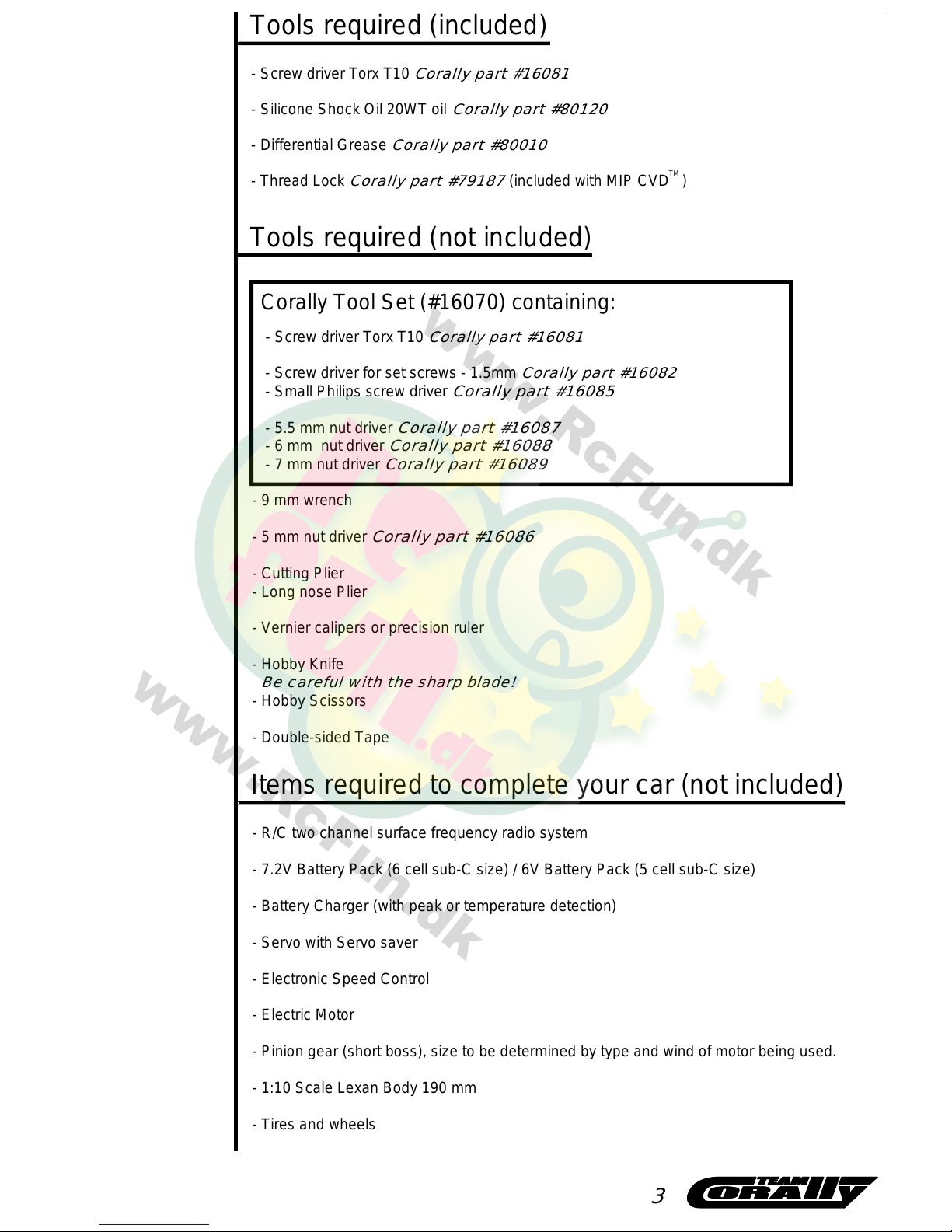

Tools required (not included)

- Screw driver Torx T10

Corally part #16081

- Screw driver for set screws - 1.5mm

Corally part #16082

- Small Philips screw driver

Corally part #16085

- 5.5 mm nut driver

Corally part #16087

- 6 mm nut driver

Corally part #16088

- 7 mm nut driver

Corally part #16089

- 9 mm wrench

- 5 mm nut driver

Corally part #16086

- Cutting Plier

- Long nose Plier

- Vernier calipers or precision ruler

- Hobby Knife

Be careful with the sharp blade!

- Hobby Scissors

- Double-sided Tape

Items required to complete your car (not included)

- R/C two channel surface frequency radio system

- 7.2V Battery Pack (6 cell sub-C size) / 6V Battery Pack (5 cell sub-C size)

- Battery Charger (with peak or temperature detection)

- Servo with Servo saver

- Electronic Speed Control

- Electric Motor

- Pinion gear (short boss), size to be determined by type and wind of motor being used.

- 1:10 Scale Lexan Body 190 mm

- Tires and wheels

- Screw driver Torx T10

Corally part #16081

- Silicone Shock Oil 20WT oil

Corally part #80120

- Differential Grease

Corally part #80010

- Thread Lock

Corally part #79187

(included with MIP CVD )

Tools required (included)

TM

Corally Tool Set (#16070) containing:

3

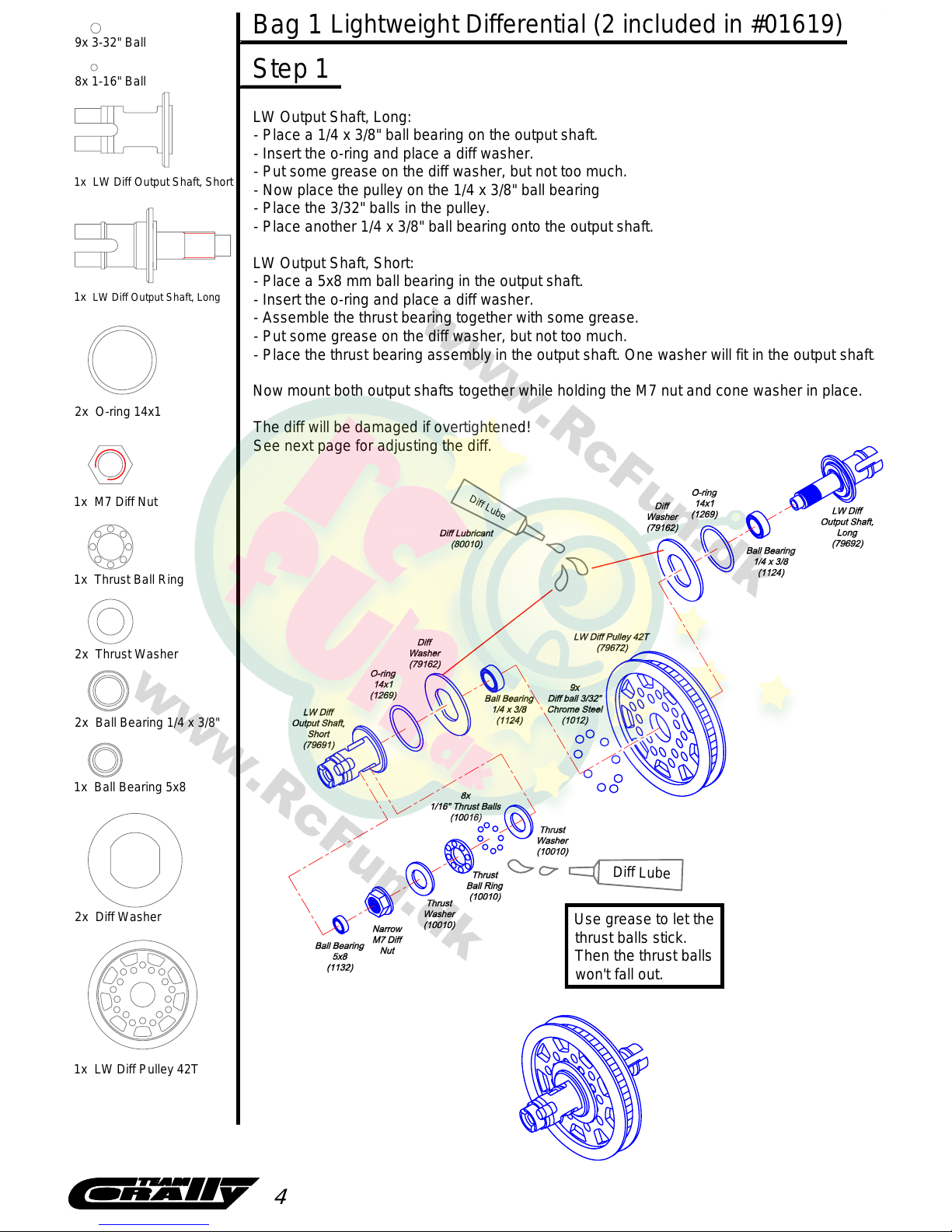

1x LW Diff Pulley 42T

4

2x Diff Washer

1x Ball Bearing 5x8

2x Ball Bearing 1/4 x 3/8"

Use grease to let the

thrust balls stick.

Then the thrust balls

won't fall out.

D

i

f

f

L

u

b

e

LW Output Shaft, Long:

- Place a 1/4 x 3/8" ball bearing on the output shaft.

- Insert the o-ring and place a diff washer.

- Put some grease on the diff washer, but not too much.

- Now place the pulley on the 1/4 x 3/8" ball bearing

- Place the 3/32" balls in the pulley.

- Place another 1/4 x 3/8" ball bearing onto the output shaft.

LW Output Shaft, Short:

- Place a 5x8 mm ball bearing in the output shaft.

- Insert the o-ring and place a diff washer.

- Assemble the thrust bearing together with some grease.

- Put some grease on the diff washer, but not too much.

- Place the thrust bearing assembly in the output shaft. One washer will fit in the output shaft

.

Now mount both output shafts together while holding the M7 nut and cone washer in place.

The diff will be damaged if overtightened!

See next page for adjusting the diff.

1x M7 Diff Nut

1x Thrust Ball Ring

2x Thrust Washer

2x O-ring 14x1

D

i

f

f

L

u

b

e

1x LW Diff Output Shaft, Short

1x LW Diff Output Shaft, Long

9x 3-32" Ball

8x 1-16" Ball

Lightweight Differential (2 included in #01619)

Step 1

Bag 1

Step 2

Differential adjustment.

The differential should be carefully adjusted by holding the M7 nut using

a 9 mm wrench. Overtightening the M7 nut might damage the bearings,

balls and washers in the differential! To test for the correct adjustment,

hold both output shafts and try to spin the pulley. If the pulley slips without

using extreme force, it means the diff is too loose and needs to be

tightened some more by turning the M7 nut.

The differential should function smoothly.

Hold the M7 nut in

the output shaft with

a 9 mm wrench.

Differential Adjustment

The differential is an important component

of your car. So build and adjust it very carefully.

The RDX Phi (#01618) has a rear differential and front one-way.

The RDX Phi US Carpet Spec (#01619) comes with

two differentials.

5

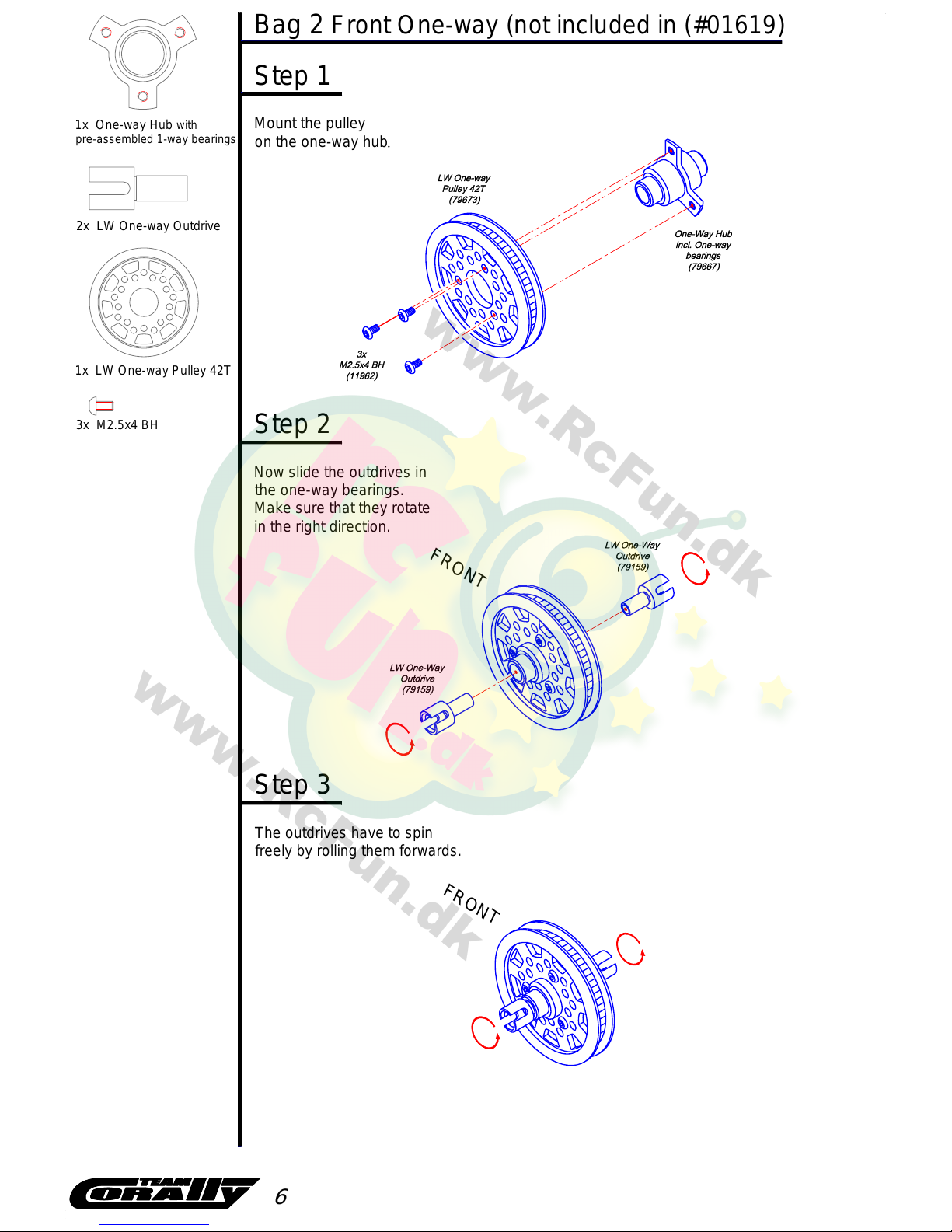

Bag 2

1x One-way Hub with

pre-assembled 1-way bearings

Front One-way (not included in (#01619)

Step 1

Mount the pulley

on the one-way hub

The outdrives have to spin

freely by rolling them forwards.

Now slide the outdrives in

the one-way bearings.

Make sure that they rotate

in the right direction.

Step 3

1x LW One-way Pulley 42T

3x M2.5x4 BH

Step 2

F

R

O

N

T

6

F

R

O

N

T

2x LW One-way Outdrive

Step 1

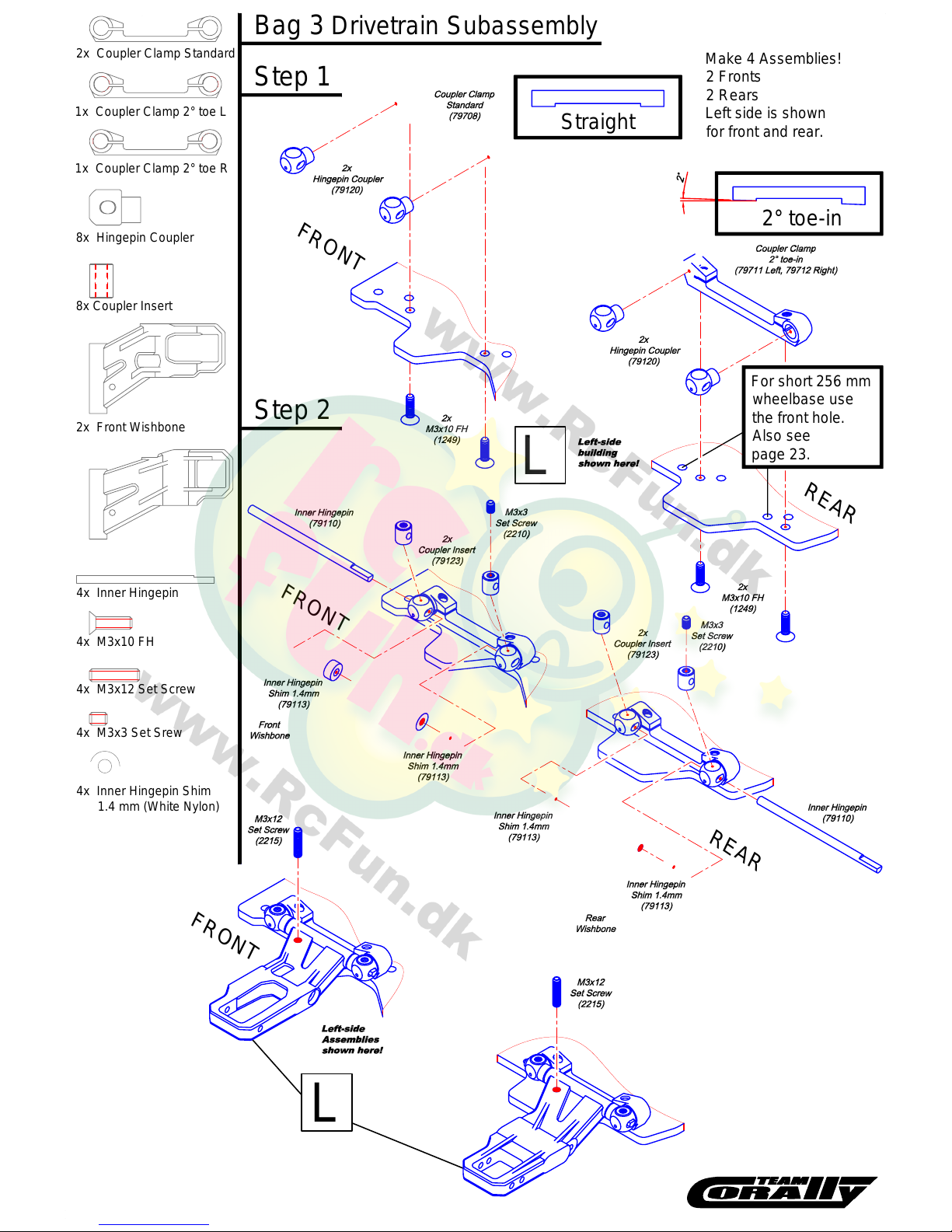

Step 2

Make 4 Assemblies!

2 Fronts

2 Rears

Left side is shown

for front and rear.

L

L

R

E

AR

F

R

O

N

T

8x Hingepin Coup le r

2x Coupler Clamp Standard

1x Coupler Clamp 2° toe R

4x Inner Hingepin

8x Coupler Insert

4x Inner Hingep in Shim

1.4 mm (White Nylon)

4x M3x12 Set Screw

Drivetrain SubassemblyBag 3

4x M3x3 Set Srew

2x Front Wishbone

1x Coupler Clamp 2° toe L

F

R

O

N

T

R

E

AR

F

R

O

N

T

4x M3x10 FH

Straight

2° toe-in

For short 256 mm

wheelbase use

the front hole.

Also see

page 23.

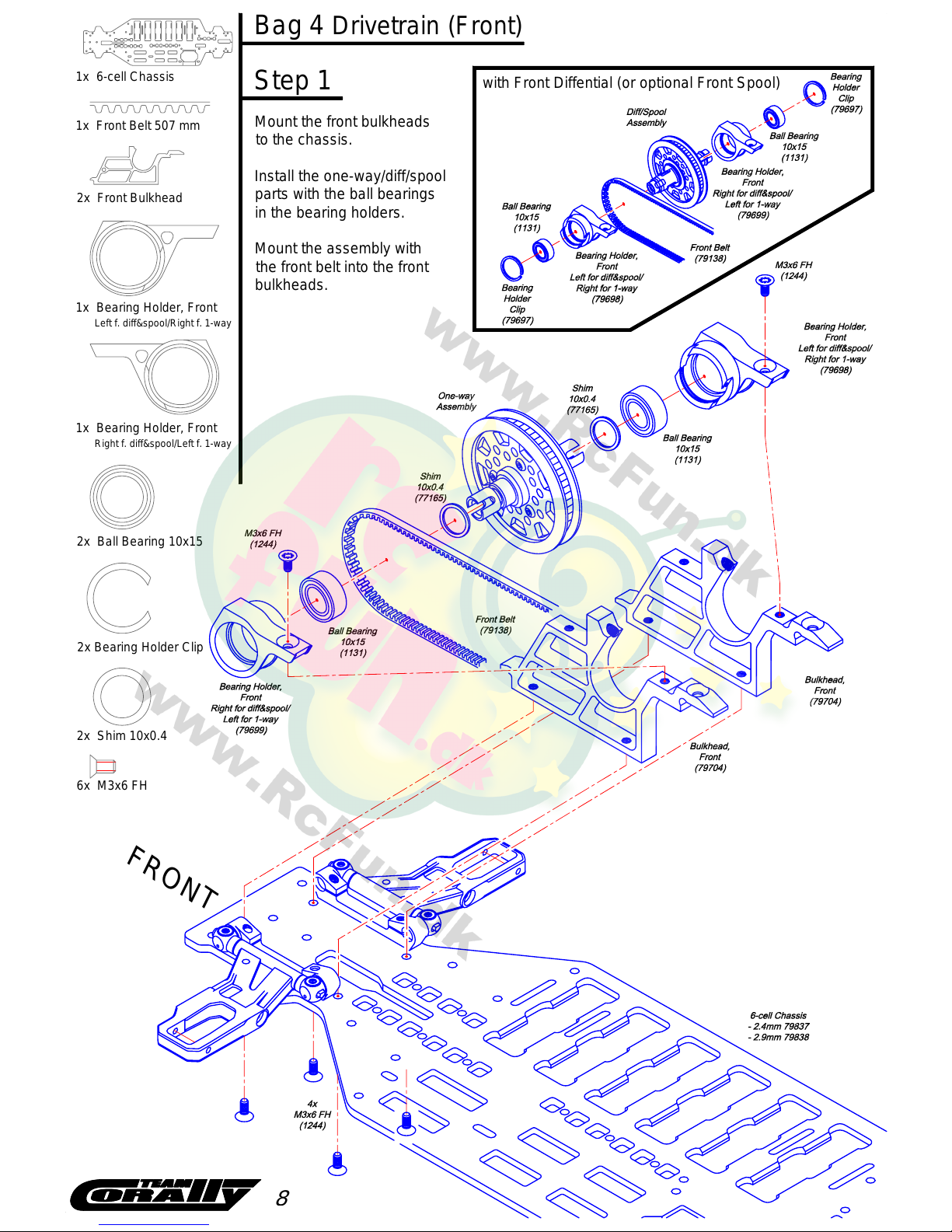

Mount the front bulkheads

to the chassis.

Install the one-way/diff/spool

parts with the ball bearings

in the bearing holders.

Mount the assembly with

the front belt into the front

bulkheads.

Step 1

FRO

N

T

2x Ball Bearing 10x15

1x Bearing Holder, Front

Left f. diff&spool/Right f. 1-way

1x Front Belt 507 mm

6x M3x6 FH

1x 6-cell Chassis

Bag 4 Drivetrain (Front)

with Front Diffential (or optional Front Spool)

1x Bearing Holder, Front

Right f. diff&spool/Left f. 1-way

2x Front Bulkhead

2x Shim 10x0.4

2x Bearing Ho lder Clip

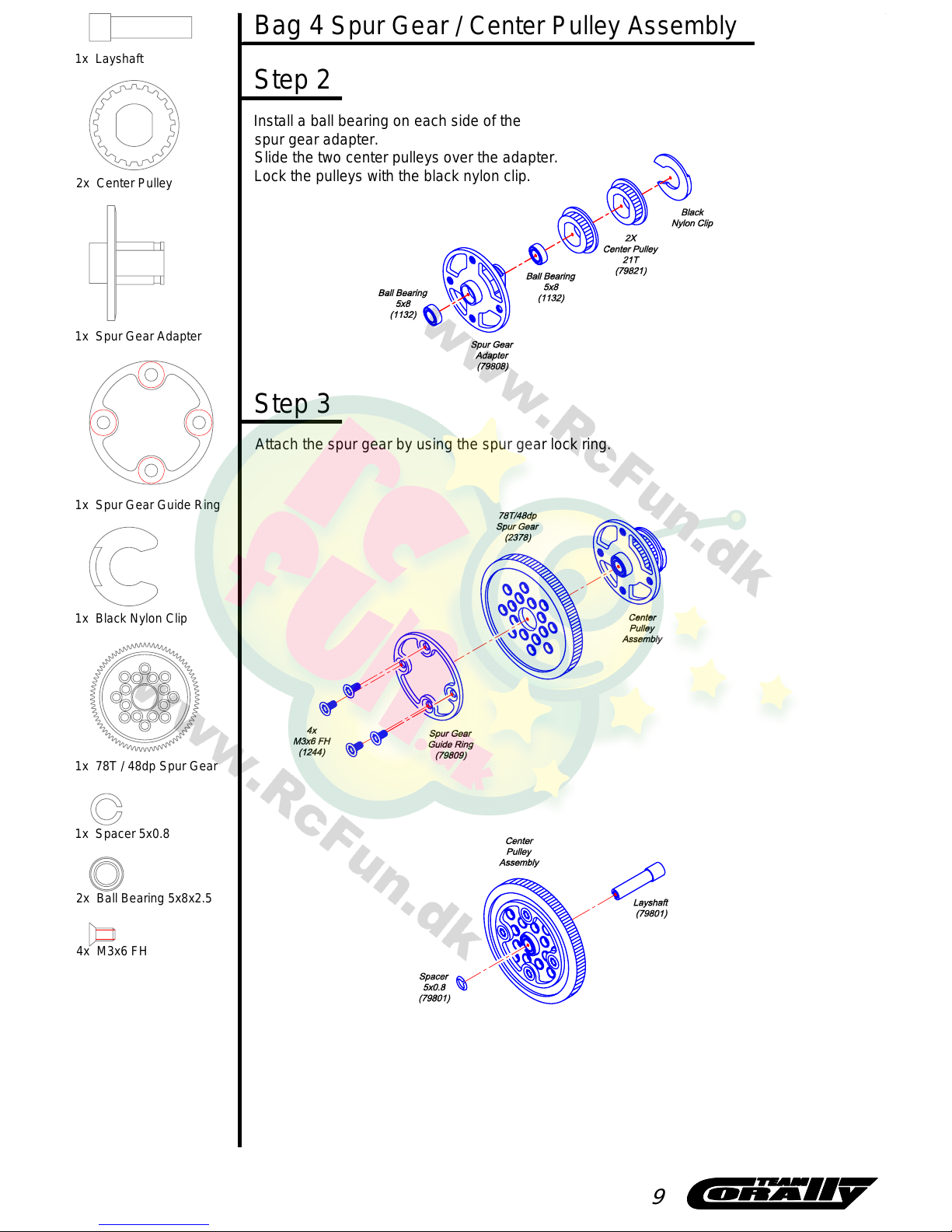

Spur Gear / Center Pulley AssemblyBag 4

1x Spur Gear Adapter

1x Layshaft

1x Spur Gear Guide Ring

2x Center Pulley

Step 2

Install a ball bearing on each side of the

spur gear adapter.

Slide the two center pulleys over the adapter.

Lock the pulleys with the black nylon clip.

4x M3x6 FH

2x Ball Bearing 5x8x2.5

Attach the spur gear by using the spur gear lock ring.

Step 3

1x 78T / 48dp Spur Gear

9

1x Spacer 5x0.8

1x Black Nylon Clip

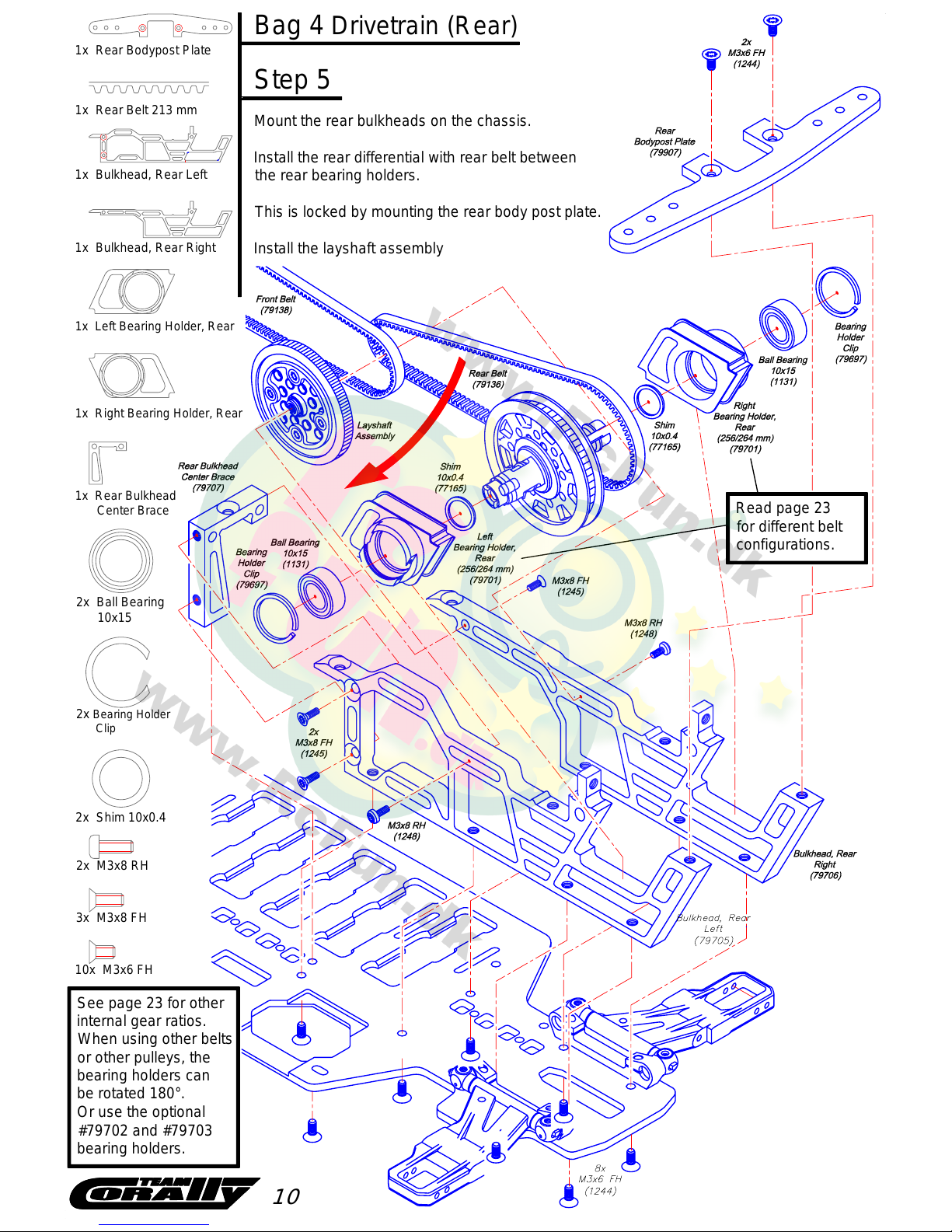

Step 5

Mount the rear bulkheads on the chassis.

Install the rear differential with rear belt between

the rear bearing holders.

This is locked by mounting the rear body post plate.

Install the layshaft assembly

1x Rear Bodypost Plate

2x Ball Bearing

10x15

10x M3x6 FH

2x M3x8 RH

Drivetrain (Rear)Bag 4

1

0

1x Rear Belt 213 mm

1x Bulkhead, Rear Left

1x Bulkhead, Rear Right

1x Left Bearing Holder, Rear

1x Right Bearing Holder, Rear

2x Bearing Holder

Clip

3x M3x8 FH

2x Shim 10x0.4

See page 23 for other

internal gear ratios.

When using other belts

or other pulleys, the

bearing holders can

be rotated 180°.

Or use the optional

#79702 and #79703

bearing holders.

1x Rear Bulkhead

Center Brace

Read page 23

for different belt

configurations.

Bag 5

Steering Lever

Chassis

1x Antenna Holder

7x M3x6 FH

2x Ball Bearing 5x8

4x Pivot Ball 4.3 mm

M3x2.5 mm

1x Steering Lever

1x Steering Lever Post

1x Topdeck

11

Screw the pivot balls on

the steering lever.

Build 3 turnbuckles as shown.

Snap them on the pivot balls.

After assembling the parts to the topdeck,

mount the topdeck under the bulkheads.

6x Ballcup

Turnbuckle long 38mm

(79273)

Turnbuckle short 21mm

(79270)

2x Turnbuckle 38 mm

1x Turnbuckle 21 mm

2x

1x

Step 1

Mount the pivot balls

for the camber links

to the shock tower.

Mount the front bumper.

Slide it between the

bulkheads and the

chassis plate.

Loosen the bulkheads

screws a couple of turns

to make it easier.

Then tighten the

screws again.

Step 3

3x M3 Nut

2x M3x6 FH

2x Pivot Ball 4.3mm

Front Camber Link

1x Front Bumper

1x Front Shock Tower

2x 3x6 Washer

Bag 5 Chassis (Front)

1

2

Mount the shock tower

assembly to the front

bulkheads.

Step 2

3x M3x8 FH

Mount the shock tower

assembly to the rear

bulkheads.

Step 1

Mount the pivot balls

for the camber links

to the shock tower.

1x Rear Shock Tower

Step 2

2x M3x6 FH

2x Pivot Ball 4.3mm

Rear Camber Link

2x M3 Nut

Chassis (Rear)Bag 5

2x 3x6 Washer

1

3

4x MIP CVD Axle

4x MIP CVD Bone

4x Driveshaft Cap

4x MIP CVD Coupling

2x C-hub Ball Screw

Step 2

Step 1

MIP CVD Assembly

FRO

N

T

R

E

A

R

L

R

8x Ball Bearing 5x9

1x C-hub 2-L (2° Left)

2x Steering Block

2x Rear Upright, Narrow 0°

Build 2 front steering block and 2 upright assemblies.

2x C-hub Screw

M

I

P

L

u

b

e

TM

TM

MIP CVD

MIP CVD

TM

MIP CVD

TM

TM

MIP CVD

TM

TM

TM

TM

TM

4x MIP CVD Cross Pin

M

I

P

T

h

r

e

a

d

l

o

c

k

(4 pieces)

Apply a little bit

of threadlock

to the setscrew.

Bag 6 Suspension 1 (Subassembly)

1x C-hub 2-R (2° Right)

2x MIP CVD SET

TM

#79180 containing:

#79180

4x MIP CVD M4 Lock Nut

TM

TM

2x MIP CVD Set Screw Driver

1

4

4x MIP CVD Set Screw

2x Pivot Ball 4.3 mm

M3x2.5 mm

Step 1

Mount the front steering block

assemblies to the wishbones

by using the outer hingepins.

Lock the hingepin with a set screw.

The hingepins can also be locked

with the e-clips.

2x M3x3 Set Screw

2x Outer Hingepin

2x Pivot Ball 4.3 mm

M3x7.5 mm

2x M3 Nut

4x E-clip

Suspension 1 (Front)Bag 6

1

5

Mount the rear upright

assemblies to the wishbones

by using the outer hingepins.

Lock the hingepin with a set screw.

The hingepins can also be locked

with the e-clips.

Step 1

2x Outer Hingepin

Suspension 1 (Rear)Bag 6

1

6

4x E-clip

2x M3x3 Set Screw

4x Large Delrin Spacer

4x Small Delrin Spacer

4x Spring Adjustment Nut

4x Spring Collar

4x Spring 17.0 lbs

8x E-clip

4x Spring Clip

4x Ball End

4x Shock Diaphragm

4x 13x1mm O-ring

4x Shock Cap

4x Piston Shaft

8x Silicone O-ring

4x Shock Body

4x Piston

4x Shock Top

Holding the shock straight up, fill

with shock oil to the top of the

body. Then slowly move the

shaft up and down several times

to allow air bubbles to escape

to the top.

Make sure all air bubbles escape

to the top then install shock

diaphragm, shock top and

aluminium shock cap.

Apply a few drops of

shock oil to lubricate

the O-rings.

S

i

l

i

c

o

n

e

S

h

o

c

k

O

i

l

(

8

0

1

2

0

)

S

i

l

i

c

o

n

e

S

h

o

c

k

O

i

l

(

8

0

1

2

0

)

Suspension 2 (Shocks) - PRE-ASSEMBLED

Use plier to hold

shaft, but do not

damage the shaft.

Grip it close to

thread.

Build 4 identical Shock Absorbers (79220).

Build them very carefully.

Bag 7

1

7

NOTE: NO OIL in pre-assembled shocks

Step 1

2x Turnbuckle 33mm

4x Ball Cup

Front Turnbuckle 33mm

(79272)

Snap all links in place with a plier.

Snap the aluminium balls in the shocks and

mount them to the shock tower and wishbones.

2x Pivot Ball 5.8 mm Short

Bag 7 Suspension 2 (Front)

Step 2

1

8

2x

Assemble 2 Turnbuckles as shown.

2x M3x8 RH

2x Pivot Ball 5.8 mm

Step 1

Step 2

Turnbuckle 28mm

(79271)

2x Turnbuckle 28mm

4x Ball Cup

Assemble 2 Turnbuckles as shown.

2x

Snap the rear turnbuckles in place

with a plier.

Snap the aluminium balls in the shocks

and mount them to the shock tower

and wishbones.

2x Pivot Ball 5.8 mm Long

Suspension 2 (Rear)Bag 7

1

9

2x Pivot Ball 5.8 mm

2x M3x8 RH

2x Battery Strap Post

3x M3x8 RH

2x M3x10 FH

4x Body Post

3x M3x6 FH

4x Wheel Hex Adapter

4x Pin Ø9.5x2

4x M2x5

Finals (Wheelhex & Bodyposts)Bag 8

1x O-ring 2x1

1x Belt Guide Post

1x Belt Guide Tower

1x Belt Guide

2x Ball Bearing 4x7x2.5F

NOTE:

Do not screw the M2x5 screws in the hexagons too

tight. They are meant to eliminate play and to keep

the hexagons in place when pulling off the wheels.

Use a medium servo saver (10201)

(not included) to protect your servo.

The servo link length is just an

indication. The servo saver must

stand up straight when all the

settings of the car are in the

neutral position.

- 4x Tires on wheels

- 1x Servo with Servo-Saver

2x M3x8 RH

2x Servo Post

2x Alu Washer Ø3.2x7

1x Foam Bumper

2x Body Post Nut

Not Included:

Finals (Wheels & Foambumper)Bag 8

2x M3x6 FH

1x Bumper Plate

It is recommended to drill

or ream the servo saver

up to Ø4 mm to allow

the use of a M3 insert

Install the electronics and the body post nuts.

Use double-sided tape

for your receiver and

electronic speed

controller.

1x Battery Strap

8x Body Post Nut

2x M3x8 FH

Not Included:

- Electronic Speed Control

- Receiver

- Electric Motor

2x M3x6 FH

2x O-ring 2x1

Finals (Electronics)Bag 8

- Pinion Gear

- Double-sided Tape

Mount the servo with servo saver

to the chassis.

Then snap the turnbuckle 21mm

to the pivot balls on the steering

lever and the servo saver.

- Sub-C Battery-pack (5 or 6-cell)

2x M3x8 RH

Radio adjustments

- Turn the transmitter on.

- Make sure the motor is disconnected.

- Connect your battery pack.

- Turn the power switch on.

- Make sure the wheels move in the right

direction. If you turn the steering control

to the left, the wheels should move to the

left. If you turn the steering control to the

right, the wheels should mo v e to the right.

- Adjust the servo link so your servo saver

is rising upwards.

- Using the two steering turnbuckles, adju s t

the front wheels so they are pointed

straight up.

- Adjust the Electronic Speed Controller

according to your speed control

manual. Turn off the power switch.

- Connect the motor. Be sure that the wheels

do not touch anything. Turn on the power

switch and check the settings of the ESC and

steering. Turn t he power switch off again.

- The transmitter is always the

FIRST TO BE TURNED ON and

THE LAST TO BE TURNED OFF.

Gear Ratio Charts

- Standard 507 mm / 213 mm belts with 42T / 21T pulleys

- Optional 510 mm* / 210 mm* belts with 42T / 21T pulleys

- Optional 507 mm / 186 mm* belts with 42T / 17T pulleys (turn Bearing holders 180° for 256 mm belt configuration)

- Optional 510 mm / 186 mm* belts with 42T / 18T pulleys (turn Bearing holders 180° for 256 mm belt configuration)

- Optional 480 mm / 210 mm* belts with 36T / 17T pulleys

- Optional 507 mm / 186 mm* belts with 36T / 18T pulleys

- Optional 507 mm / 186 mm* belts with 36T / 21T pulleys (use Bearing holders #79702 and #79703 for 260 mm belt configuration)

* optional belts available from mid 2007

19

18

22

23

21

20

24

26

25

27

30

29

28

32

31

23

33

36

37

35

34

32

31

30

29

28

27

26

25

24

39

38

40

48dp 64dp78T 98T 100T 104T

8.67

5.57

5.03

4.88

5.20

5.38

5.78

6.00

6.24

6.50

6.78

7.09

7.42

7.80

8.21

8.52

5.94

4.90

5.03

5.16

5.30

5.44

5.60

5.76

6.13

6.32

6.53

6.76

7.00

7.26

7.74

7.84

8.17

8.70

6.06

5.88

5.71

5.56

5.40

5.26

5.13

5.00

8.33

8.00

7.70

7.41

7.14

6.90

6.67

6.45

6.25

9.04

6.30

5.20

5.33

5.47

5.62

5.78

5.94

6.11

6.50

6.71

6.93

7.17

7.43

7.70

8.00

8.32

8.67

#2378 #24098 #24100 #24104

17

9.18

22

8.91 9.09 9.45

5.85

39

5.97 6.21

5.71

40

5.83 5.98

48dp

24

31

32

28

29

30

27

25

26

23

19

18

22

21

20

17

29

8.368.037.877.57

6.92

6.02

6.17

6.34

6.52

6.72

7.14

7.36

7.61

33

36

37

35

34

32

31

30

38

7.06

6.85

6.66

6.47

6.30

6.13

7.67

7.52

7.28

8.08

7.82

7.57

7.13

6.92

6.73

6.55

6.38

7.25

7.27

6.99

6.73

6.27

6.06

5.68

5.86

6.40

28

10.87

#24104

10.09

9.69

9.32

8.97

8.65

10.53

104T

10.59

#24100

8.32

8.63

8.96

9.32

9.71

10.13

100T

10.37

22

#24098

9.39

9.14

8.78

8.46

8.16

9.93

98T64dp

24

25

26

27

23

78T

10.09

7.90

8.26

8.65

9.09

9.56

#2378

10.69

6.20

39

6.33 6.59

6.42

6.05

40

6.18

11.67

10.70

10.27

9.88

9.51

9.17

11.17

8.56

8.29

8.03

7.55

7.33

7.14

6.94

6.76

7.78

8.86

#24104

104T

24

29

8.528.358.03

31

32

28

29

30

27

25

26

7.33

6.37

6.54

6.72

6.52

7.12

7.56

7.81

8.07

33

36

37

35

34

32

31

30

38

7.49

7.26

7.06

6.86

6.68

6.50

8.23

7.96

7.72

7.71

7.41

6.88

6.64

6.42

5.83

6.21

6.64

48dp

23

19

18

22

21

20

17

28

11.22

#24100

8.82

9.15

9.50

9.88

10.29

10.73

100T

11.00

22

#24098

10.08

9.68

9.31

8.96

8.64

10.52

98T64dp

24

25

26

27

23

78T

10.70

8.37

8.26

9.17

9.63

10.14

#2378

11.33

17 22

7.84

22

7.62 7.77 8.08

17

27

30

29

28

32

31

20

21

22

18

19

23

26

25

24

27 32

4.94 5.565.34

32

5.24

4.76

4.30

4.17

4.45

4.50

5.39

4.68

4.81

4.94

5.08

5.23

4.50

4.62

4.75

4.88

5.34

5.18

38

34

35

37

36

33

4.93

4.79

4.66

4.53

4.41

5.08

4.45

4.27

40

4.19

4.564.38

39

4.29

30

29

28

32

31

38

34

35

37

36

33

40

39

7.02

6.67

6.35

6.06

5.80

7.41

23

27

26

25

24

7.29

5.99

6.20

6.44

6.70

6.98

7.29

6.98

6.70

6.45

6.20

6.11

7.73

6.35

6.59

6.84

7.14

7.41

28

5.13

5.33

5.74

5.93

5.52

5.70

30

31

5.59

5.40

5.56 5.78 5.89 6.13

29

20

21

22

18

19

23

23

27

26

25

24

28

26

25 30

31

24 29

48dp

#2378

78T 64dp 98T

#24098

100T

#24100

104T

#24104 #2378

78T48dp

#24104

64dp 98T

#24098

100T

#24100

104T

17

9.73 9.649.44

22

10.02

27

6.12 6.49

32

6.63 6.89

6.48

6.30

6.12

5.96

5.80

6.68

5.51

5.65

31

32

28

29

30

5.70

5.51

5.17

5.33

5.90 6.32

5.46

5.62

5.77

5.94

6.11

33

36

37

35

34

38

6.42

6.24

6.06

5.89

5.73

5.58

5.19

40

5.30

5.33

39

5.44

9.19

8.82

8.48

8.16

7.87

9.59

7.35

7.11

7.60

23

19

18

22

21

20

9.19

7.19

7.52

7.87

8.27

8.70

28

7.57

7.31

8.15

8.48

8.83

9.22

8.66

8.31

7.99

7.69

7.42

9.03

24

25

26

27

23

25

26

6.61

6.36 6.70

6.93

31

30

7.07

6.84

24

6.89

29

7.317.16

#24104

104T48dp 78T

#2378

100T

#24098

98T64dp

#24100

42T / 21T Pulleys (standard) 42T / 18T Pulleys (optional) 42T / 17T Pulleys (optional)

36T / 21T Pulleys (optional) 36T / 18T Pulleys (optional) 36T / 17T Pulleys (optional)

8.91 9.09 9.45

6.506.256.13

6.30

5.47

5.62

5.78

5.94

6.11

5.26

5.40

5.56

5.71

5.88

6.06

5.76

5.60

5.44

5.30

5.16

5.94

5.205.004.90

5.335.135.03

8.52

7.00

7.26

7.74

7.84

8.17

8.70

8.33

8.00

7.70

7.41

7.14

9.04

7.43

7.70

8.00

8.32

8.67

6.71

6.93

6.45

6.676.53

6.32

6.76 6.90 7.17

9.18

5.78

5.57

5.03

4.88

5.20

5.38

8.21

7.80

7.42

7.09

6.78

8.67

6.00

6.24

6.50

The RDX Phi has several internal ratio options.

- 2,00 : 1

- 2,00 : 1

- 2,47 : 1

- 2,33 : 1

- 2,11 : 1

- 2,00 : 1

- 1,71 : 1

79912 Anti-roll bar set 1.3 mm, Silver - Rear

79913 Anti-roll bar set 1.3 mm, Silver - Front

79914 Anti-roll bar set 1.6 mm, Brass - Rear

79915 Anti-roll bar set 1.6 mm, Brass - Front

79916 Anti-roll bar set 1.9 mm, Black - Rear

79917 Anti-roll bar set 1.9 mm, Black - Front

79922 Anti-roll bar wire 1.3 mm, Silver - Rear

79923 Anti-roll bar wire 1.3 mm, Silver - Front

79924 Anti-roll bar wire 1.6 mm, Brass - Rear

79925 Anti-roll bar wire 1.6 mm, Brass - Front

79926 Anti-roll bar wire 1.9 mm, Black - Rear

79927 Anti-roll bar wire 1.9 mm, Black - Front

Anti-roll bar clamps:

Use the big slot for Black 1.9mm Anti-roll Bar and the

small slot for Silver 1.3mm Anti-roll Bar. When using

the Brass 1.6mm Anti-roll Bar, sand 0.3mm off the

bottom of the clamp so the 1.9mm slot will fit the

1.6mm Anti-roll Bar wire.

Anti-roll bar mounting instructions (option part)

4x M3x12 Set Screw

4x Pivot Ball 5.8mmm

2x M3x15 RH

4x M3x8 FH

1x Anti-roll Bar Rear

4x Anti-roll Bar Clamp

2x Pivot Ball 5.8 mm Short

1x Anti-roll Bar Front

2

4

2x Pivot Ball 5.8 mm

4x M3x3 Set Screw

4x Ball End 5.8mm

Race adjustments:

FRONT

+

+

Toe-out

Toe-in

Toe-in

Toe-out

Toe-out:

Increases turn-in steering a lot.

But can make the car very nervous on the straight.

More than 1° of front toe-out make the front even more

nervous, so it's better not to use more than 1° toe-out.

Toe-in:

Stabilizes the car on the straight, and coming out of

the corners.

It smoothes out the steering response, making the car

easier to drive.

It can make the car turn in a little more in the middle and

exit part of a corner.

Toe-in:

This is one of the most sensitive adjustments! One degree goes

a long way. Stabilizes the car greatly. It makes the rear end

"stick". The more toe-in you use, the more the rear of the car

sticks. This becomes especially apparent going in and coming

out of the corners.

But more toe-in make more difference between sticking and

breaking loose. Large amount of toe-in (2.5°... 3°) scrub off

a little speed on the straights.

Toe-out:

Rear toe-out is never used. It makes the rear of the car very

unstable.

-

-

Toe-in

Toe-out

Toe-in

Toe-out

Your RDX Phi Touring Car comes with many possible geometry adjustments, shock adjustments,

camber changes, etc. The standard setup in this manual is a good starting point to begin

with. For optimising your car's performance, improvements can be made with the following

tuning tips. Always make one step at a time, and see if there are any improvements or the

performance is getting worse. On www.corally.com you can download the latest setup

sheets from Team Corally to help you find a good setup.

Front toe-in / toe-out:

Setting toe-in of the front wishbones in the center of the car will make the suspension work

better on bumpy conditions. Never use toe-out.

Adjust for neutral feeling 0° toe. A slight amount of toe-out will increase the turn-in of the car

but too much of it will make the car difficult to drive.

[min. = -1 / max. = +1]

Rear toe-in:

Toe-in is set standard on 2° in the rear with the coupler clamps. To increase toe-in in the rear,

use the rings of 0.4mm for 0.5° settings and 0.8mm for 1° settings.

[min. 0 / max. 3]

2

5

-

Camber:

Camber is best set when the contact patches of the tires are is always as big as possible. So with a

stiff suspension and firm tires you'll need less camber than with soft suspension or tires with big,

flexible sidewalls. If the tire wear evenly across their contact patches, the camber is about right. Whe

using camber on the front in combination with caster blocks something must be kept in mind. Caster

will cause camber in the front when steering and the front will lift up.

[min. 0 / max. 2]

Camber Link Locations:

The RDX Phi has a couple of camber-link locations. We recommend to start off by mounting the

camber links in 1 of the lower positions on the shocktower. This will give more camber-change

while cornering, thus stability. The longer or higher the link, the more traction and less stability. The

shorter or lower the link, the less traction and greater stability.

Long Link: A long link gives a lot of body roll in turns. It feels as if the body is willing to keep on

rolling until it can't, but the springs prevent it from rolling any further.

The car has more grip in corners, especially in the middle part. But if there already is a lot of traction,

long camber links can slow down in turns.

Short Link: A short link will make the chassis roll less. Its tendency to roll drops as it rolls.

It feels as if the car generates a little less grip.

More Parallel Link: A parallel link gives a little more roll than an angled one. It feels smooth,

and consistant as the body rolls in turns.

Angled Link: An angled link makes the car feel as if it has a tendency to center itself (level, no roll

)

other than through the spring or anti-roll bar. It will give more initial grip, steering into corners.

It makes it very easy to "throw" the car. The body rolls a little less than with parallel links. It's possibl

e

to use softer springs and a softer damping than with parallel links, without destabilising the car.

Always keep an eye on the balance of the car; large differences in roll-center front versus rear will

make the car feel less consistant!

Inner Hingepin Locations:

It is possible to mount the wishbones on different heights to the bulkheads. This will change the

roll-center of the car.

Low mounting: The roll-center becomes lower, which generates more chassis-roll into the

corner.

Higher mounting: The roll-center becomes higher, which generates less chassis-roll.

Car changes quicker from direction, but less grip will be generated. Feels very stable.

REAR

5 Positions6 Positions

FRONT

3 Positions

REARFRONT

2

6

FRONT

Position:

0°

Position:

0.8°

Front Caster:

Caster can be very important to the handling of the car. Adding or removing caster can transform

the steering balance of a car. The total of Caster is degrees Kick-up + degrees Caster C-hub.

More Caster: Will give stability, especially at high speeds. More Caster generally suits large

high-speed open tracks.

Less Caster: Will increase steering drastically. Steering feels more direct, so the car turns tighter

and faster. Small amounts of caster are suitable for tight tracks.

These settings can be arranged with the optional C-hubs and the inner hingepin settings.

[min. 0 / 2 / 4 / max. 6]

Front Kick-up and anti-dive:

Refers to the angle in which the front suspension is mounted in relation to horizontal when looked fro

the side of car. Kick-up and anti-dive are adjusted by changing the angle of the front wishbones,

which can be done by the aluminium hingepin adjustment blocks. The setting of 0° kick-up will have

more aggressive steering feeling but will not absorb bumps well. The setting of 1.6° kick-up will work

better in most conditions, especially in bumpy conditions. The anti-dive setting of 1.6° will give a very

aggressive steering feeling and will improve the front braking traction by entering corners. For less

agressive steering feeling a setting of 0.8° is also possible. It is necessary to use the optional couple

r

clamps (#79709) for the left and (#79710) for the right. When using anti-dive a differential must b

e

used in the front. Use at least 2° caster C-hubs. Anti-dive will not work on bumpy conditions.

Rear anti-squat:

Describes the angle at which the rear suspension is mounted when looked sideways at the car.

Generally more anti-squat make the car more sensitive by throttle input. The car has more steering

while braking (when diff is used), and also a little more powering out of the corners. Less anti-squat

gives more side-bite, on-power and while braking. It feels easier to drive in low-grip situations.

Wheelbase adjustment:

1.6°

high (#79709 and #79710 must be used)low

FRONT

Position: Position:

Position:

high/low

0°

high/low

Position:

FRONT

lowhigh

Adjustment shims Adjustment shims

Kick-up Anti-dive (only use 2°,3°,4° or 6° caster bloc

k

2

7

1.6°

0.8°

1.6°

low high

high

high low (#79709 and #79710 must be used)

low

high/lowhigh/low

NEUTRAL STEERING

Adjust the wheelbase by moving the white inner hingepin shims. A short wheelbase makes the car

feel good in tight turns. Use a short wheelbase on very small and tight tracks. A longer wheelbase

makes the car feel a lot more stable, and better in wide, high-speed turns. Use a longer wheelbase

on wide open tracks. Moving the shims to the front of the front wishbones will shorten the wheelbase

and decrease rear traction and greater stability. Moving the shims to the rear of the front wishbones

will lengthen wheelbase and increase rear traction. Moving the shims to the front of the rear wishbon

e

will lengthen the wheelbase and decrease rear traction and greater stability. Moving the shims to the

rear of the rear wishbones will shorten the wheelbase and increase rear traction.

Ackermann:

This is a term describing the effect of the inner front wheel turning tighter than the outside front whee

The perfect angle (no slip in theory) between the two front tires is called "the Ackermann angle".

The angle can be varied by adjusting the steering linkages. The Ackermann setup works well in mos

t

conditions and will provide a very smooth, predictable steering.

Shock Springs:

Try to keep your car level during acceleration, deceleration and cornering.

Stiffer springs make the car feel more responsive, more direct. The car reacts faster to driver input.

Stiff springs are suited for tight, high-traction tracks, which aren't too bumpy. Usually, when you stiffe

n

the whole car, you lose a small amount of steering.

Softer springs are better for bumpy and very large and open tracks. They can also make the car feel

as sluggish and slow.

Stiffer Front:

The car has less front traction, and less steering. It's harder to get the car to turn, the turn radius is

bigger and the car has a lot less steering exiting corners. On very high-grip tracks, if the track itself

feels tacky or sticky, very stiff springs are the way to go.

Softer Front:

The car has more steering, especially in the middle part and the exit of the corner.

Front springs that are too soft can make the car hook and spin.

Stiffer Rear:

The car has more steering, in the middle and exit of the turn. This is especially apparent

in long, high-speed corners. But rear traction is reduced.

Softer rear:

The car has generally more rear traction, in turns as well through bumpy sections and

while accelerating.

2

8

L

-

3

0

°

L

-

3

0

°

R

-

21

°

R

-

2

2

°

MORE NEUTRAL STEERING

Damping:

Thicker oil (heavier damping) makes the car more stable, and makes it handle more smoothly.

If damping is too heavy, traction could be lost in bumpy sections. The car will also change direction

slower. Soft damping makes the car react quicker. Damping should always be adapted to the

spring ratio; the suspension should never feel to "springy" or too slow.

Heavier Front or Softer Rear: The turn radius is wider, but smoother. The car doesn't hook up

suddenly. The car is easier to drive, and high-speed steering feels very nice. Easy to drive.

Softer Front or Heavier Rear: The steering reacts quicker. More and better low-speed steering

Shock Pistons:

The assumption is made that if pistons are changed, the viscosity of oil is also adapted, to give the

same static feel. (Same low-speed damping)

Smaller holes (#79223) means more "pack". Pack means the damping gets very stiff, or almost

locks up, over sharp bumps. Small holes are good for smooth tracks.

Bigger holes (#79224) mean less pack. The point at which the damping gets stiff (where the

shock "packs up") occurs a lot later, at higher shock shaft speeds. Big holes are very good for bump

y

tracks. The car is more stable and has more traction in the bumpy sections. It won't be thrown up ov

e

sharp bumps, the suspension will soak them up a lot better.

Ride Height:

This describes the height of the chassis in relation to the surface sitting on. This adjustment must

be made with the chassis ready-to-run but with no body. By turning the spring adjustment nut the

chassis can be raised or lowered. Start with about 6mm clearance between the chassis and ground.

Try using a slightly lower ride height for high traction conditions as carpet racing. Do not use a ride

height lower than 4mm.

Higher: The car feels better in bumpy sections. It can feel tippy, or even flip over in high-grip

conditions.

Lower: The car feels more direct, and it can potentially corner a bit faster. It's also harder

to flip the car over. Lowering one end of the car, or putting the other end higher up, gives a little

more grip at the lowest end, but try to avoid big differences in ride height between the front and the

rear.

Anti-Roll Bars:

Before using anti-roll bars first try to play with the droop settings. Anti-roll bars can be used to stabiliz

a car from excessive roll (which occurs when your car leans through the turns by centrifugal force).

Anti-roll bars are generally used on smooth, high traction track conditions. If the conditions are very

bumpy, then anti-roll bars are probably not necessary. If you are driving on a high traction surface an

d

your car wants to oversteer, then use the optional #79913 (soft), #79915 (medium) anti-roll bar or

#79917 (hard) on the front only. This will decrease the front chassis roll and decrease steering

throughout the corner. This has the feeling of increasing rear traction. If your car is understeering,

then try the optional #79912 (soft), #79914 (medium) anti-roll bar or #79916 (hard) anti-roll bar

on the rear only. The rear anti-roll bar will decrease rear chassis roll and decrease rear traction (this

has the feeling of increasing steering).

Downstops (droop-setting):

When the Wishbones have a lot of droop the chassis is free to roll in turns. The center of gravity

of the car won't change much. Chassis rolls around its roll-center. But if the wishbones almost have

no droop the chassis will be pulled down as it rolls. It cannot roll anymore around its roll-center,

because the chassis will become one-piece with the wishbone as it rolls. Then the center of gravity

will become lower.

2

9

Front:

- Less droop makes the car smoother in the middle of a corner and gives more steering under

acceleration. Sometimes too little droop makes a car difficult to accelerate out from corners.

- More droop gives more steering response in the middle of a corner and makes the car push on

throttle.

Rear:

- Less droop makes the rear more stable to the corner and gives less grip in the middle and out of

the corner.

Less droop will heat up tires more.

- More droop reduces rear grip into the corner, but rear tires stay cooler and the car works more

stable through your heat.

Before using anti-roll bars, the droop-setting is a better option first to play with. The wishbones are

already prepared for using downstops. See the instructions on page 7 for installing the M3x12

set screws which are required for adjusting the droop. The adjustment of left and right should be the

same. But don't use your downstops for lowering your chassis, because this isn't the way to do so.

This must be done by the spring adjustment of your dampers.

Front Drive:

- Ball Differential (#79690) can be adjusted for tightness (and slippage), so it makes them very

versatile. By adjusting the front diff a little tighter, some more understeer will be experienced. But

there will be a little more steering and traction exiting the corner. It feels more stable. When tighten

the rear diff, the rear of the car will become easier to break loose. But adjusting the diffs is not really

a good solution to solve the problem of under/oversteer balance.

- One-way (#79667) contains two one-way bearings; one for each wheel. It acts like a diff in only

the forward direction. The front wheels can only turn faster than the rear wheels, but not slower. Left

and right wheel can rotate independantly from each other, when power off entering a corner. This will

give slightly more steering, so the corner can be taken faster. With a one-way front diff there will be

no front braking, no differential action off power, high cornering speed, and excellent acceleration out

of the corner. On really high-grip, open tracks with smooth, flowing high speed corners it is a one to

have thing. So it comes standard in this kit.

- Spool (#79655) is like a fully locked diff but has no moving parts. It's super-solid with no

adjustments. Because there's no differential action at all, a lot of speed is scrubbed off in corners.

A spool at the front will make the car very hard to turn in. But gives stability under acceleration and

deceleration. A spool at the rear will give a lot of steering.

Shock position:

The RDX Phi allows 3 front and 4 rear top fixing positions for the shock absorbers.

More Inclined: Has a more progressive smoother feel. More lateral grip. Having all shocks incline

d

makes the car very easy to drive, and it feels like the car has more grip, but it's not always fast...

Less Inclined (more vertical): More direct feel. Less lateral grip. (site-bite)

Front more inclined than rear: Ste ering fee ls very smooth. A little more mid -co rner steering.

Mounting the rear shocks very much upright can result in the rear end feeling unpredictable. It also

makes the rear end jitter in turns.

Rear more inclined than front: Feels agressive turning in, but for most of time the car has

a little less steering. The car has a lot of side traction in the rear, and the turn radius isn't very tight.

2 Wishbone Settings 3 Wishbone Settings

FRONT VIEW

Top Settings

REAR VIEW

Top Settings

30

Wishbones:

I

t's possible to use different kind of Wishbones:

Medium 5 : Front (#79040) - Rear (#79050)

Hard 35 : Front (#79060) - Rear (#79070)

X-Hard 80 : Front (#79080) - Short (#79090)

Duraluminium : Front and Rear (#79108)

Softer Wishbones can add a little more grip because they flex a bit more.

Harder Wishbones can be used if there is plenty of traction but suspension setup will be more

important. Suspension setup feels better and more consistent.

Tires & Inserts:

All these possibilities cannot be fully exploited if the car does not run on quality wheels. Tires and

inserts are two of the most influential changes you can make to your car. The Corally RDX Phi kit

comes without tires and wheels. There's a variety of wheels, inserts and tires available. Which one

is the best for you depends on the different weather or track conditions as well as local rules when

competing in championships.

Tire Additives:

Corally tire additives come in a large can (150ml) complete with brush for easy application.

TC-1: Classic formula for use on foam tires on carpet tracks.

TC-2: JACK THE GRIPPER is odorless and EFRA legal. This is the most populair choice for use on

rubber and foam tires on any surface.

TC-3: Formulated for outdoor use.

TC-4: CARPET JACK is upgraded Jack The Gripper specially formulated to provide maximum grip

for rubber tires on carpet tracks - odorless.

- TC-1 (#13788) Formulated for foam tires on carpet

- TC-2 (#13779) Jack the Gripper (Minimum Odor)

- TC-3 (#13789) Unpleasant Smell, Maximum Traction

- TC-4 (#13790) Carpet Jack

Setup Sheet:

There's a setup sheet included in this manual. Set up your RDX Phi with the standard settings at right

then deviate from them in response to your track conditions and driving style, as noted below.

For best result, make only one setup change at a time, testing it before making another change. Mak

e

a copy of the setup sheet included in this manual to help keep track of your changes. Before make

any changes to standard setting, make sure you can get around the track without crashing. None of

your setup changes will work if you cannot stay on the track. Your goal is consistent laptimes.

Inconsistent lap times may indicate poor control. When you have consistent lap times, then make

changes to your car. If the change results in a faster lap, then mark the change in your setup sheet.

If performance is worse, then revert to previous setup and try another change. Fill out your setup

sheet thoroughly when you are satisfied with it and file it away. It can be a practical guide for future

track lay-outs and conditions you encounter. Always keep in mind that your car stays in balance. Too

much difference in front and rear setup can make the car feel unpredictable.

We at Team Corally wish you best luck and see you at the track!

Contact:

http://www.corally.com

e-mail: team@corally.com

Fax: (+31) 78 621 26 89

Corally R/C BV

Ploegstraat 49

3319 LG Dordrecht

Holland

31

T

T /Spur / Pinion

Finish

Race Comments

Traction

Temp.

Main

Track Conditions

Radio

Body

Motor

Surface

Servo

Lead Weights

Wing

Motor setup

g

Qual. Pos.

Weight balance

ESC

Re

a

Oil

Piston

Tires

Others

Rear

Toe-in

Camber

Ride Height

Anti-squat

Anti-roll bar

mm

Downstops

Driver:

Track / City:

Event:

Oil

Piston

Front

Ride Height

Camber

Toe-out

Caster

mm

Anti-roll bar

Downstops

S E T U P S H E E T

WT

Date:

Upright

Front width

Rear width

mm

mm

toe-in

WT

Front

HIGH PERFORMANCE 1:10 ELECTRIC TOURIN G CAR

Spring

Spring

lbs

lbs

Time

Laps

Wishbone

Wheelbase

Wishbone

Front drive

Front pulley

Steering

Shock tower

Steering block

Coupler clamp

Clamp shims

F Coupler

F coupler shims

R Coupler

R coupler shims

Rebound

Wheelbase

Center pulley

Rear pulley

F Coupler

R Coupler

R coupler shims

F coupler shims

Clamp shims

Coupler clamp

Rebound

Shock tower

Tire additive

Notes

T

T

Coupler

clamp

Coupler

clamp

FR

FR

Loading...

Loading...