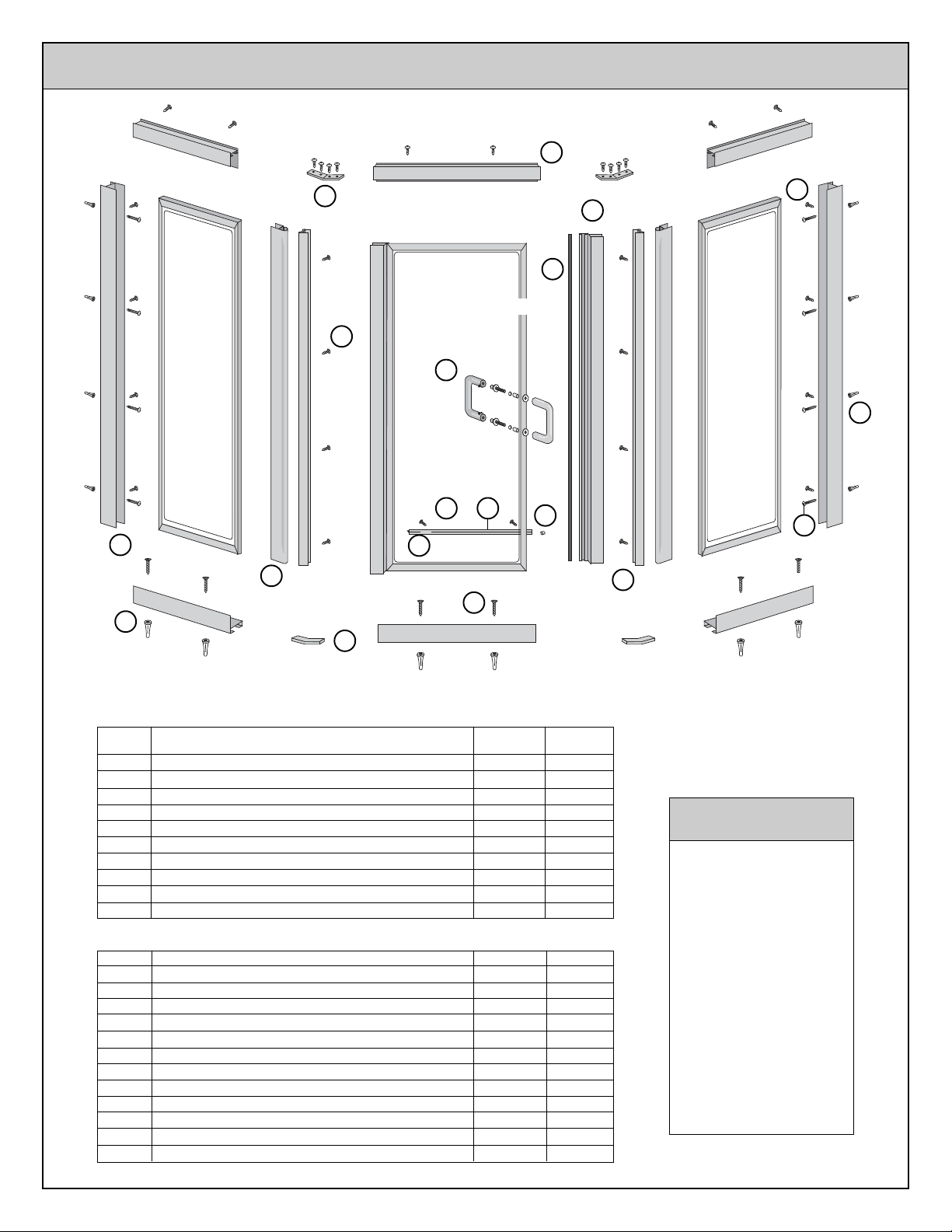

Coral Industries 846J User Manual

O

AG45

ALUMINUM

GUSSET

846J

MAGNETIC DOOR

A688

HEADER

C

A681

STOP

H470

TRUSS HEAD

SCREW

L

G

A682

B

JAMB

A689

A

SILL

FRAME PACKAGE

H470

TRUSS

HEAD

SCREW

L

A686

E

CORNER

POST

N

HG45

PLASTIC GUSSET

MAGNETIC

STRIP

M

PULL

HANDLE

KIT

HT52

A710

DRIP

DRIP

RAIL

RAIL

TAPE

Q

D

VS91 DRIP

R

RAIL SWEEP

H810

FLAT HEAD

J

SCREW

OUTSIDE OF SHOWER

H

H170

HA28

DRIP

RAIL

PLUG

S

F

A687

CORNER

POST

K

H479

PAN HEAD

SCREW

I

H002

ANCHOR

KEY DESCRIPTION PART QTY

A SILL A689 3

B JAMB A682 2

C HEADER A688 3

E ADJUSTABLE CORNER POST(MALE) A686 2

F ADJUSTABLE CORNER POST(FEMALE) A687 2

G MAGNETIC DOOR STOP A681 1

H MAGNETIC STRIP H170 1

D DRIP RAIL A710 1

Q DRIP RAIL TAPE

*

HT52 1

R DRIP RAIL SWEEP VS91 1

HARDWARE BAG PARTS

S DRIP RAIL PLUG HA28 1

I ANCHOR H002 14

J 8A X 1 1/4 FLAT HEAD SCREW H810 6

K 8A X 1 PAN HEAD SCREW H479 8

L 8A X 3/8 TRUSS HEAD SCREW H470 47

M TUBULAR PUSH/PULL HANDLE KIT HTSB 1

ROUND BUSHING 2

PLASTIC WASHER 4

PULL HANDLE 2

HANDLE CONECTOR SCREW 2

N PLASTIC GUSSET HG45 2

O ALUMINIUM GUSSET AG45 2

P 3/32 ALLEN WRENCH H635 1

* Pre-Installed

TOOLS NEEDED

1/8" Drill Bit

3/16" Drill Bit

(3/16" Masonry Bit for

Ceramic Tile)

Measuring Tape

Phillips Screw Driver

File

Drill

Level

China Marker

Caulking Compound

846J 10/02

INSTALLATION INSTRUCTIONS

If installation of this enclosure is planned in conjunction with a base and wall surround, make certain

that all installation steps for the base and walls have been completed before installing this enclosure.

Before starting installation of your new enclosure, carefully read all instructions

and lay out parts to become familiar with their identity. Installation is a manageable task for an

experienced "Do-It-Yourselfer" and a helper.

Do not try to cut the mirrors or glass used in this enclosure.

Tempered glass and mirrors will disintegrate if cut.

USE OF ANCHORS

Anchors are furnished with every enclosure. However, the use of anchors is not recommended when attaching your enclosure to a fiberglass

unit or wall surrounds with board reinforced mounting areas. Mounting holes in this case should be drilled with a 1/8" drill bit.

Mounting of this unit on tile requires the use of anchors. Special care must be taken not to crack the tile. Before drilling holes in the tile, lightly

chip glazed surface of tile at the desired locations. Drill holes using a 3/16" masonry drill bit. Insert anchors into the holes making certain that

ring on large end of anchor meets the surface of the tile.

CLEANING

Cleaning and care of your enclosure is important to its lasting beauty. We suggest using a nonabrasive liquid cleaner.

Never use scouring powder or pads.

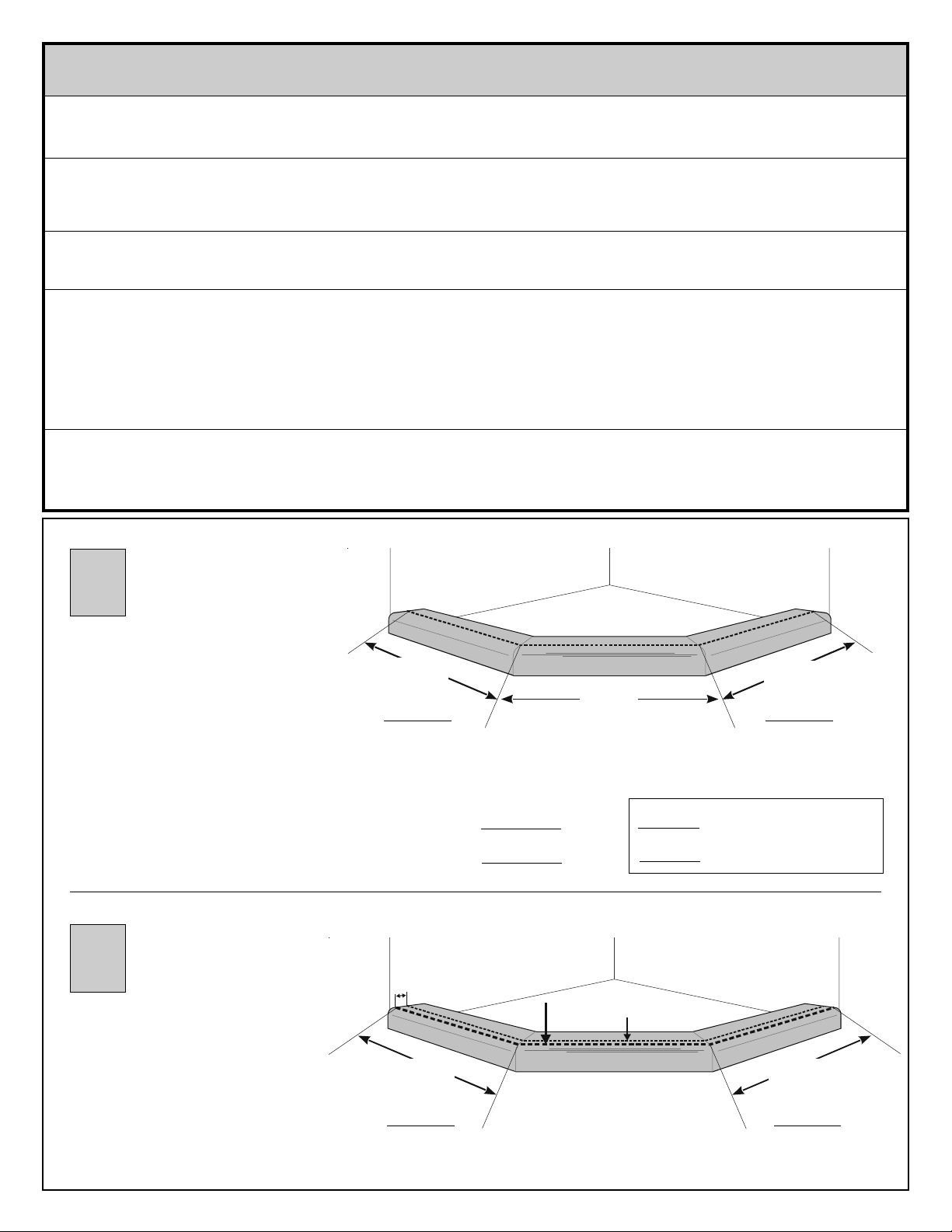

1

Measure and mark a centerline on the top

surface of your base curb using a china

marker. The measurement from the wall

to the intersection of the door and side

centerline is called the wing centerline.

Measure and record each wing centerline.

To determine that this enclosure will fit

your base, measure width of your side

panel. For this enclosure to fit your base,

your wing centerline must be at least

equal to the side panel width plus 1/2";

and at the most side panel width plus

1 3/8".

2

Measure 7/16" from the centerline drawn

in Step 1 toward outside of shower and

draw a Sill Placement Line.

The measurement from the wall to the

intersection of the door and side sill

placement lines will be the wing sill cut

lengths. Measure and record each wing

sill cut length.

Left Wing

Centerline

Door

Door

Centerline

Centerline

OUTSIDE OF SHOWER

Side Panel Width + 1/2" =

Side Panel Width + 1 3/8" =

7/16"

Sill

Placement

Line

Left Wing Sill

Cut Length

OUTSIDE OF SHOWER

Right Wing

Centerline

Compare with actual measurements:

Minimum Wing Centerline

Maximum Wing Centerline

Centerline

Right Wing Sill

Cut Length

846J 10/02

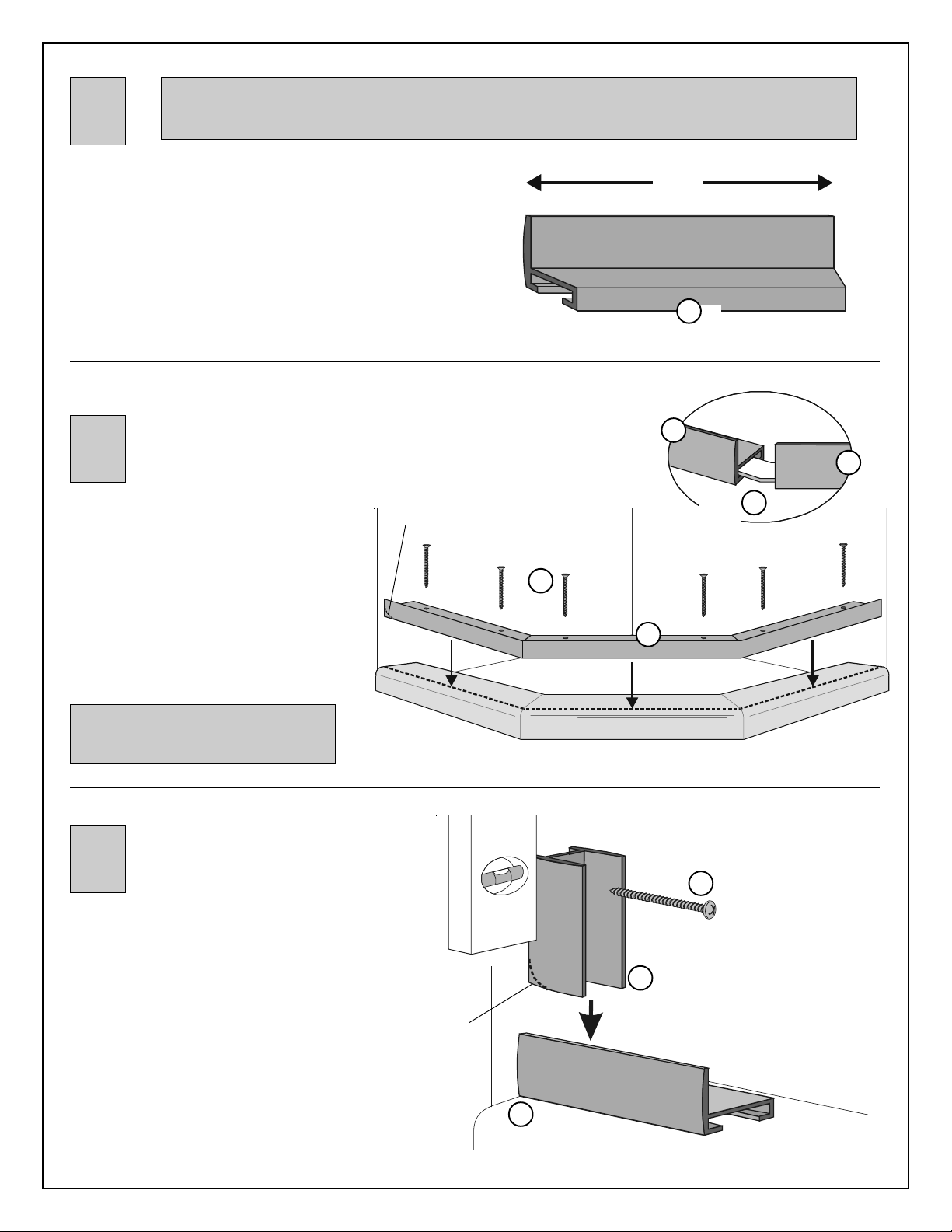

3

Due to the manufacturing process, there may be rack marks present at one end of your sill and

header. All sills and headers must be trimmed to fit individual openings. When cutting sill and header,

make certain to trim off end with rack marks.

There are three parts that make up the sill (A) -- a door sill

with two mitered (pointed) ends, and two wing sills, each

with one mitered end and one butt cut (straight) end.

The door sill is sized to fit your door and is not to be altered.

The wing sills are extra long and must be cut to match your

sill cut lenghs recorded in Step 2. Measure each sill, from

the mitered end toward the butt cut end, to the correct length

and cut. (Cut from butt cut end only.)

Join sill parts together at

mitered ends using plastic

4

Place sill on base curb, sliding sill toward

corner until butt cut ends meet walls. If

necessary for a good fit, file sharp corners of

sill to fit contour of walls.

Mark threshold through pre-punched holes in

sill. Remove sill and drill where marked

using 1/8" drill bit.

Reposition sill on base curb and secure

using 8A x 1 1/4" flat head screws (J).

gussets (N). Make certain that

ends meet tightly.

File to fit

contour of

your unit.

Mitered End

(pointed end)

8A x 1 1/4"

Flat Head

Screw

J

Wing

Sill

A

Measure

Sill

A

A

Sill

Plastic

Gusset

N

Butt Cut End

(square end)

A

Door

Sill

If anchors are used, mounting

holes should be drilled with a 3/16"

drill bit.

5

Place jamb (B) against wall with bottom

resting on sill and short legs against wall.

Align jamb vertically using level and mark

wall through pre-punched holes. If

necessary, file back edge (short legs) of

jambs to fit contour of your unit. Repeat for

remaining jamb on opposite side.

Remove jambs and drill where marked using

1/8" drill bit.

Reposition jambs and secure using 8A x 1"

pan head screws (K).

File to fit

contour your

unit.

Level

Sill

OUTSIDE OF SHOWER

A

OUTSIDE OF SHOWER

B

Jamb

K

8A x 1 "

Pan Head

Screw

846J 10/02

Loading...

Loading...